Studding recovery method for reconstructing covering layer through dead zone wastefill and top surrounding rock spallation collaboratively

A recovery method and overburden technology, which is applied in earth square drilling, ground mining, underground mining, etc., can solve the problems of high ore loss rate and large exposed area of goaf, and achieve strong adaptability, flexibility, and layout The effect of flexible mining methods and mining techniques

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

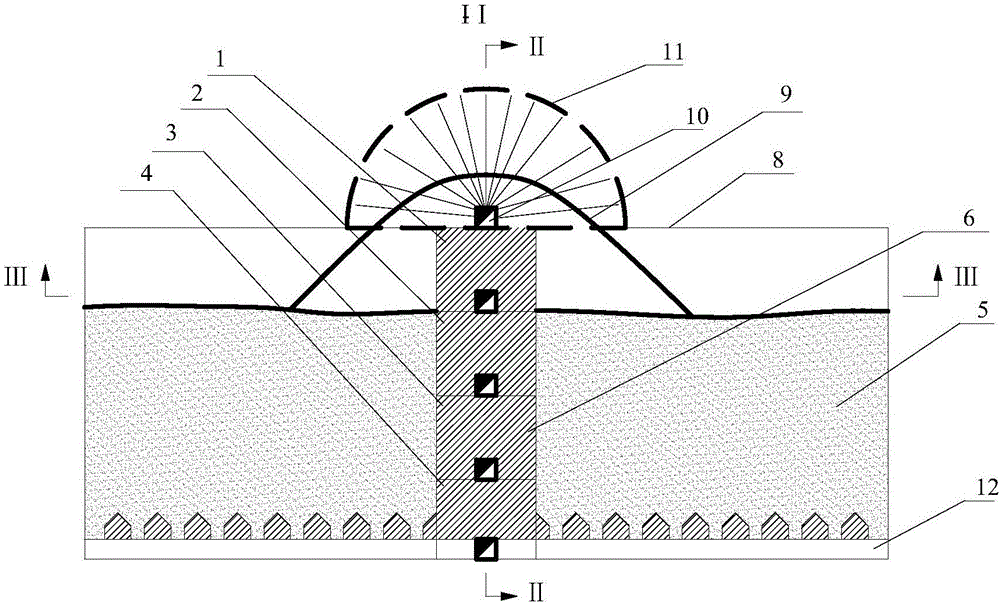

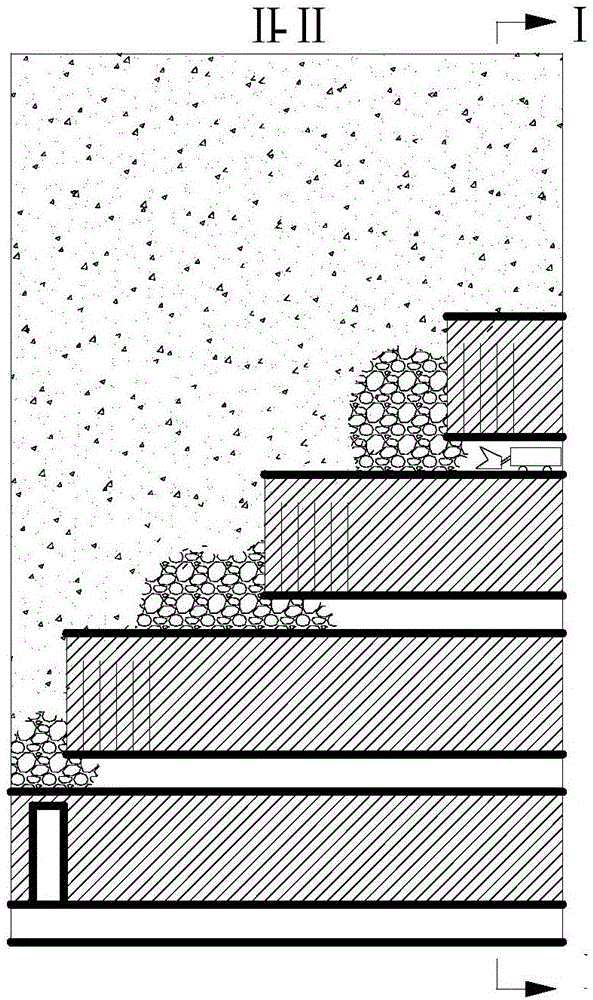

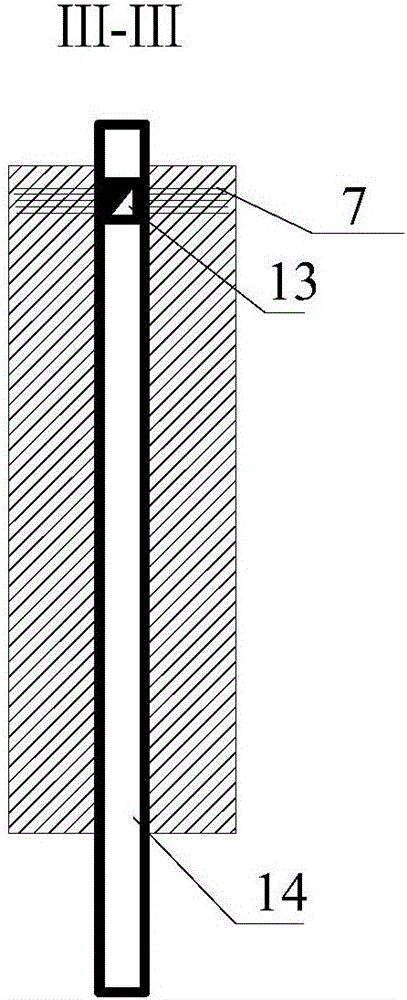

[0029] The technical solutions of the present invention will be further described below through the accompanying drawings and embodiments.

[0030] Such as figure 1 , figure 2 and image 3 As shown, the space column recovery method of the waste rock filling in the empty space and the collapse of the top surrounding rock in cooperation with the reconstruction of the covering layer according to the present invention comprises the following steps:

[0031] (1) Divide the ore bodies with moderately stable surrounding rocks, medium-thick-extremely-thick ore bodies with gentle slopes or steeply-inclined thick-extreme thick ore bodies along the strike, and the ore blocks are divided into ore rooms and pillars, and the mining of the ore rooms is completed Finally, the remaining intercolumns are 50m long, 15m high, and the width is the thickness of the ore body, and the intercolumns are layered according to each layer of 10-15m.

[0032] (2) if figure 1 As shown, after filling the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com