Integrated header for corn ear-picking, conveying and peeling

An integrated header technology, which is applied to headers, harvesters, agricultural machinery and implements, etc., can solve the problems of increasing the length of the header, unfavorable longitudinal stability of the whole machine, and operation controllability, so as to reduce operating links, The effect of improving operation efficiency and reducing impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

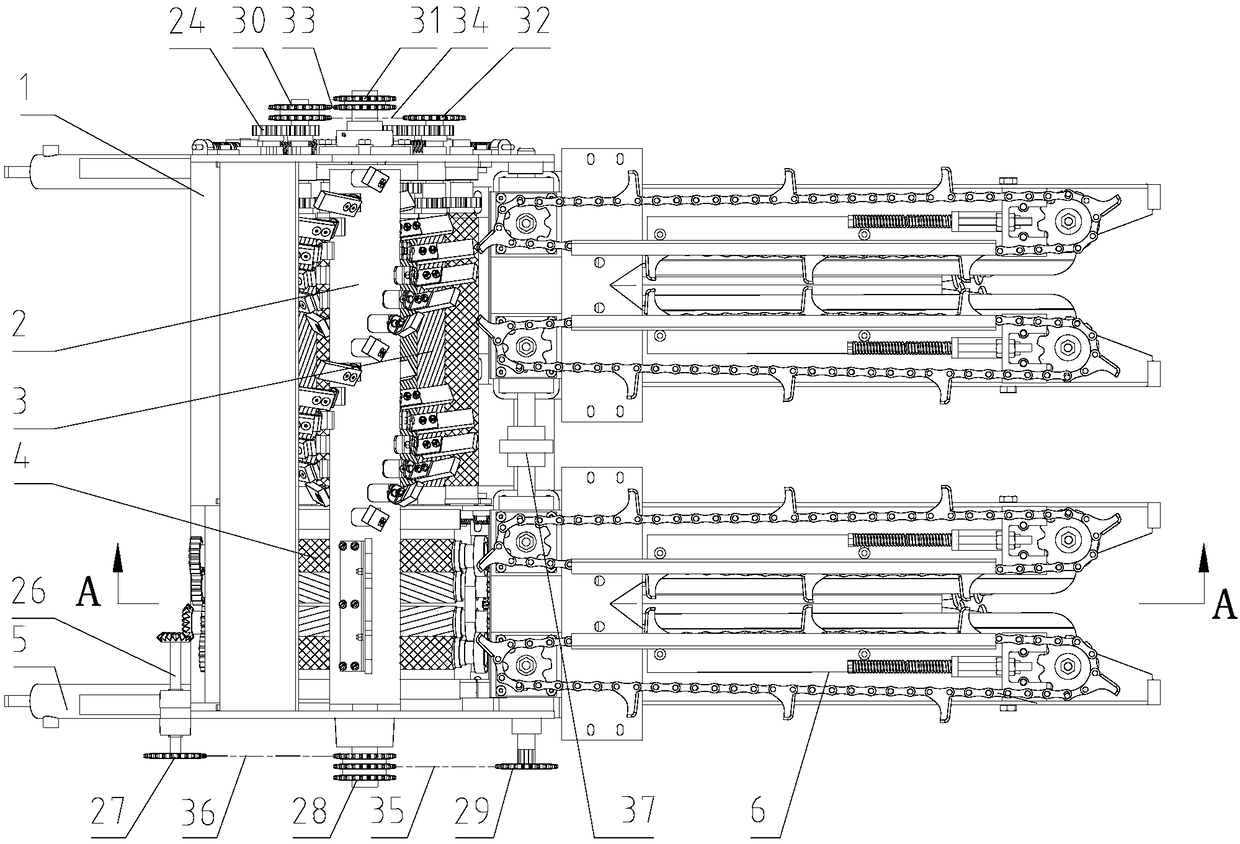

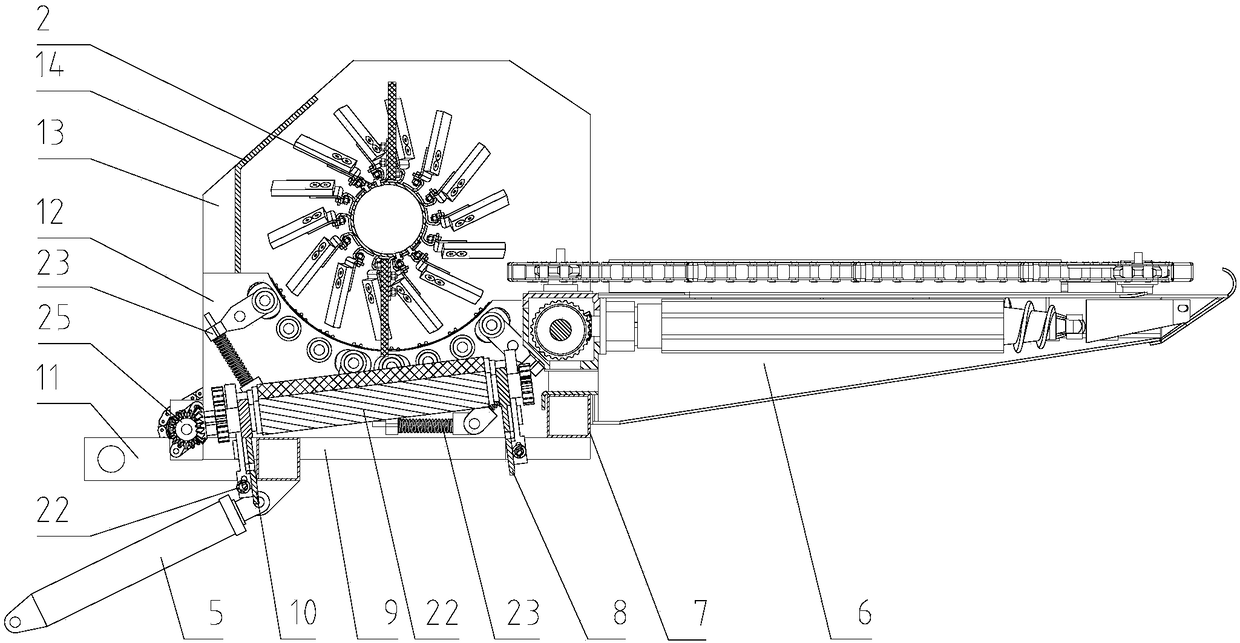

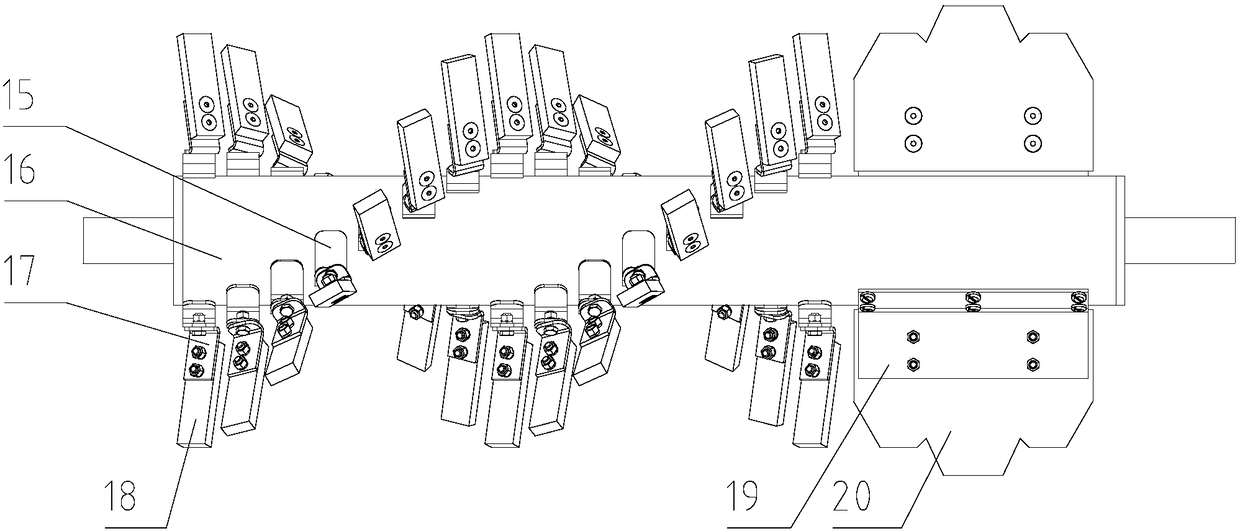

[0021] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, a corn ear picking conveying and peeling integrated header includes a frame 1, a pressure feeding auger 2, a horizontal peeling roller combination 3, a longitudinal peeling roller combination 4, a lifting hydraulic cylinder 5, an ear picking device 6 and a transmission system Etc., it is characterized in that: the frame 1 includes a beam 7, a longitudinal beam 9, an articulated beam 11, an inner plate 12, an outer plate 13, a longitudinal roller front plate 8, a longitudinal roller rear plate 10 and a cover plate 14, etc., and the outer plate 13 Located on the left and right sides of the frame 1, the inner panel 12 is located in the middle of the frame 1, the beam 7, the longitudinal beam 9 and the hitch beam 11 are located at the bottom of the frame 1, the longitudinal roller front plate 8 is located at the front of the frame 1, and the longitudinal roller rear plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com