Patents

Literature

33results about How to "Realize directional delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

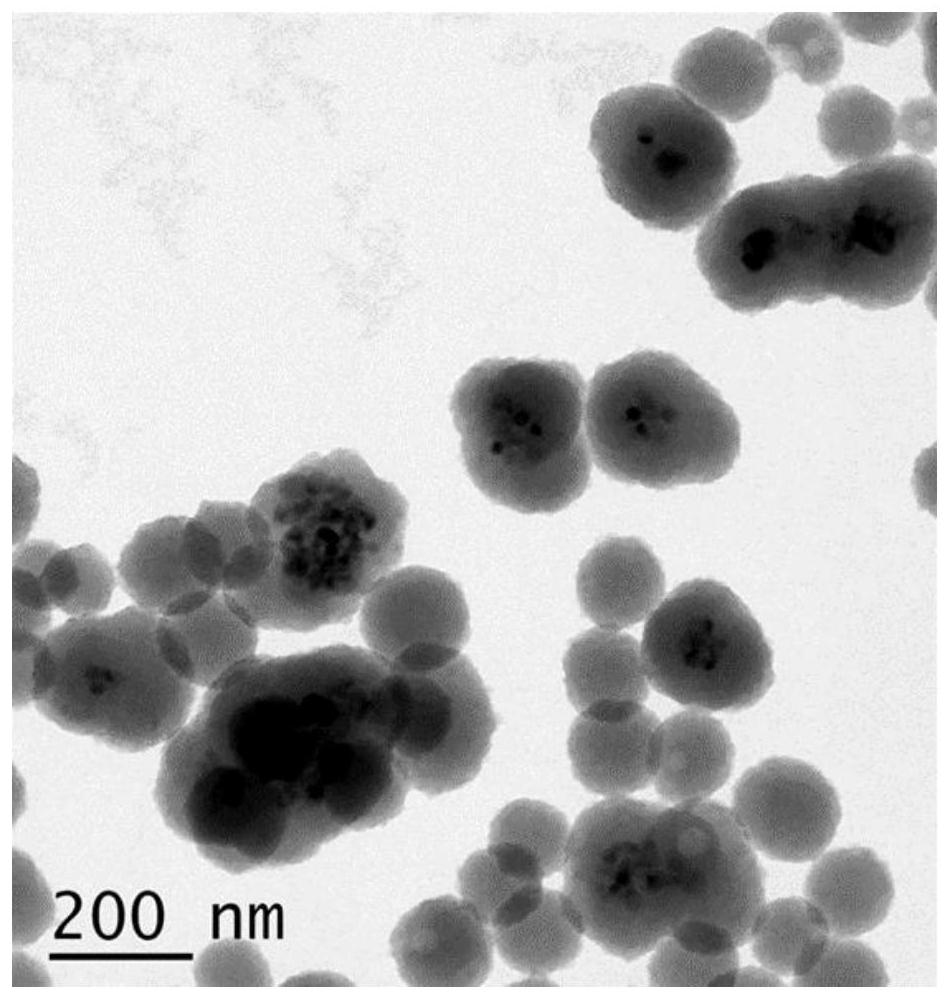

Preparation of super paramagnetic nano particles dispersible in water

InactiveCN1583575AImprove stabilityGood dispersionIron oxides/hydroxidesInorganic material magnetismParamagnetic nanoparticlesSuperparamagnetism

A process for preparing the super-paramagnetic nanoparticles dispersed in water easily includes such steps as mixing the polymer chelating agent with Fe ions, dripping alkali while reacting to generate inn oxide and continuously dripping alkali until pH=9-10.

Owner:SHANGHAI JIAO TONG UNIV

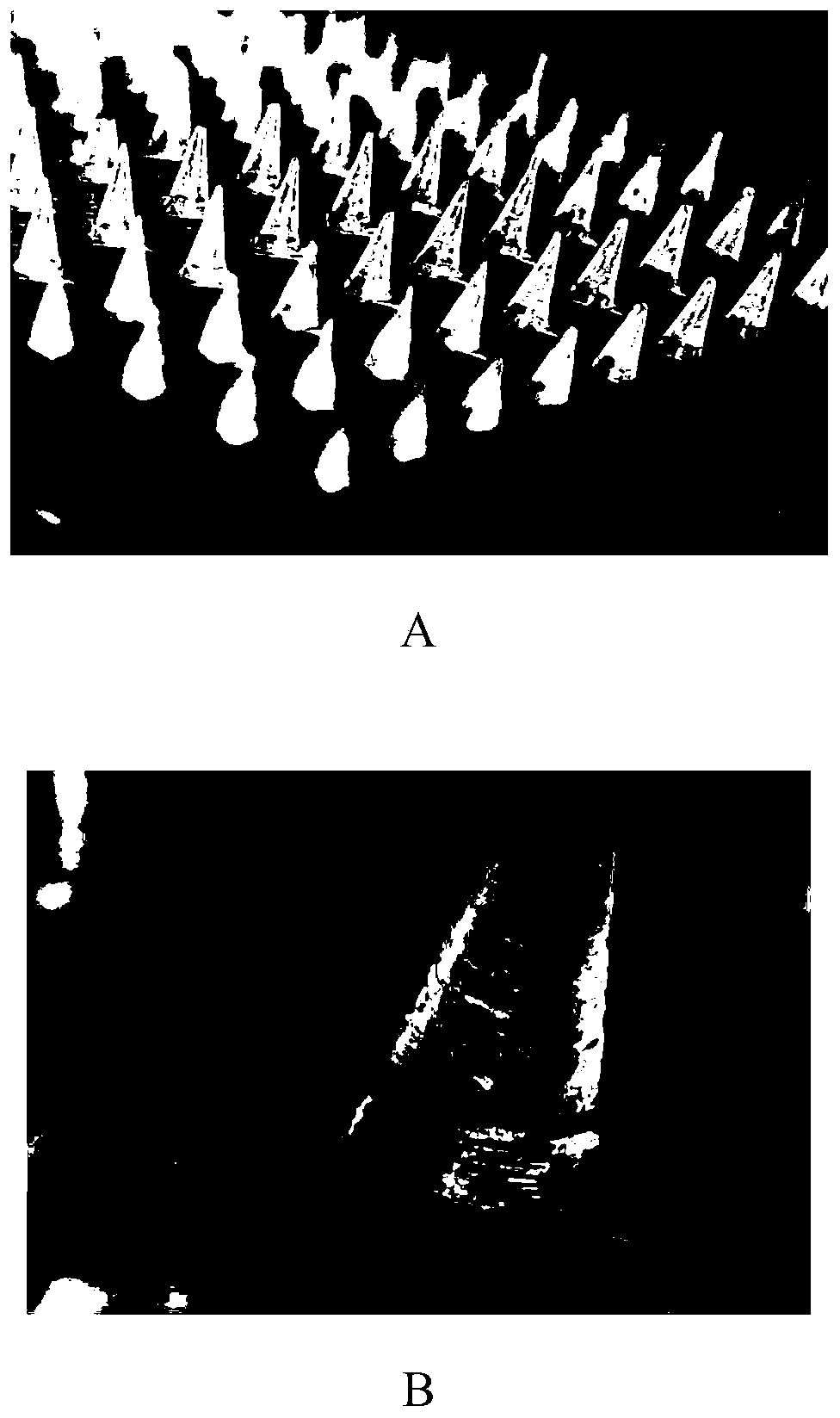

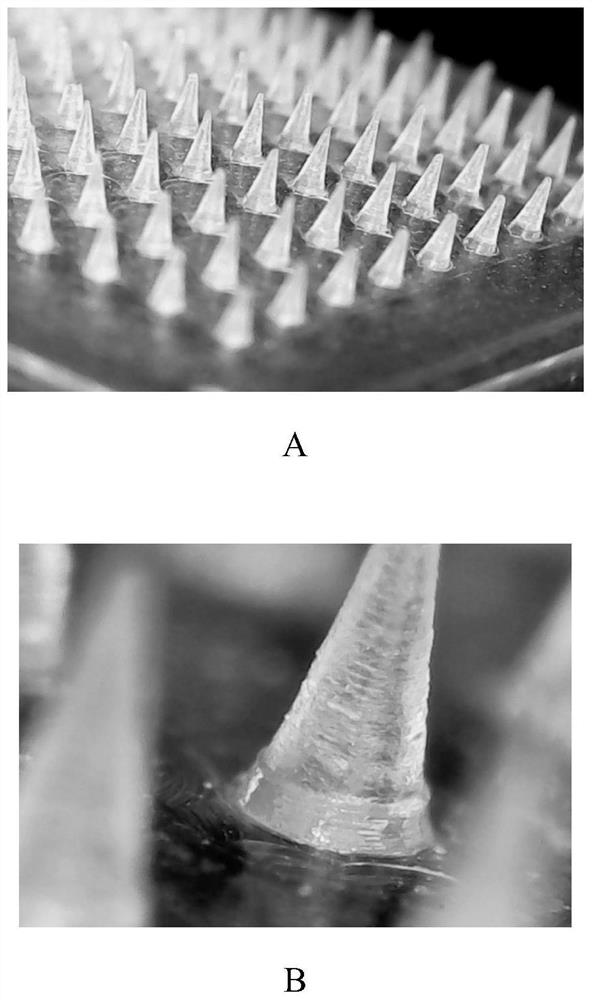

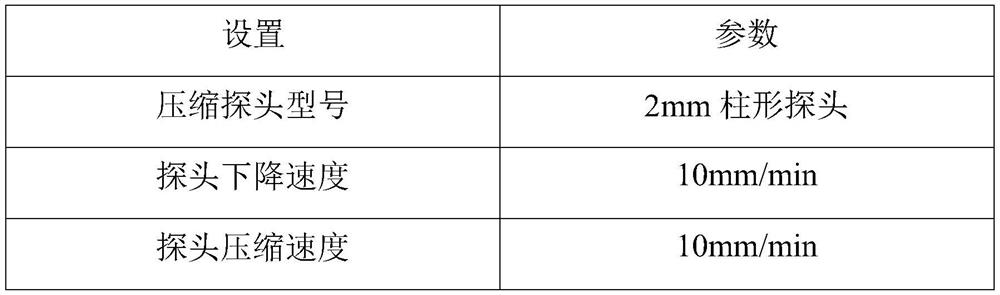

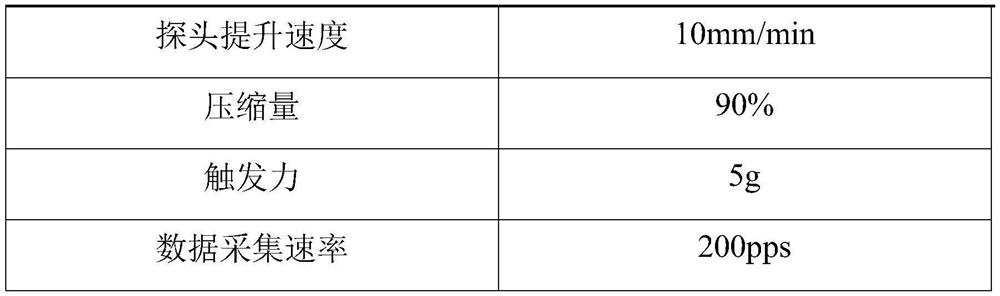

Composition with skin whitening effect, skin-whitening soluble micro-needle patch with high drug loading capacity, and preparation method of skin-whitening soluble micro-needle patch

ActiveCN110664646AAccelerates decomposition and excretionReduce skin pigmentationCosmetic preparationsToilet preparationsSodium hyaluronateSkin whitening

The invention relates to a composition with a skin whitening effect, a skin-whitening soluble micro-needle patch with high drug loading capacity, and a preparation method of the skin-whitening solublemicro-needle patch. The composition with the skin whitening effect comprises, by weight, 10-20 parts of arbutin, 10-20 parts of magnesium ascorbyl phosphate, 5-10 parts of adenosine, and 0.1-0.5 partof a sturgeon caviar. The skin-whitening soluble micro-needle patch comprises a pinpoint and a substrate, and the pinpoint is prepared from the composition with the skin whitening effect, hyaluronicacid or sodium hyaluronate, and a micro-needle auxiliary material, wherein the mass ratio of the composition with the skin whitening effect to hyaluronic acid or sodium hyaluronate to the micro-needleauxiliary material is 1 to 0.1-5 to 0.2-1; and the micro-needle auxiliary material is composed of polyvinylpyrrolidone, glycerol and hydroxypropyl cellulose. The skin-whitening soluble micro-needle patch has the high drug loading capacity, excellent mechanical performance, and good effects of skin whitening, spot fading and moisture preserving.

Owner:广州新济薇娜生物科技有限公司

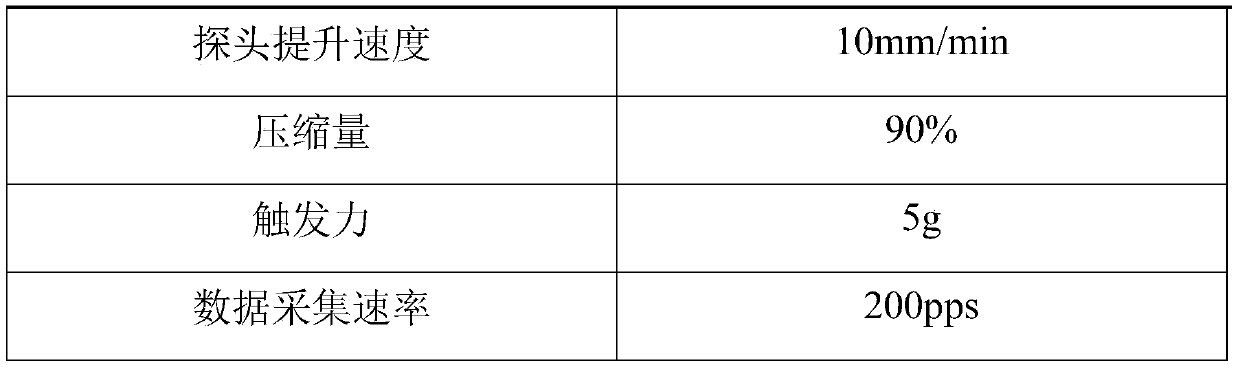

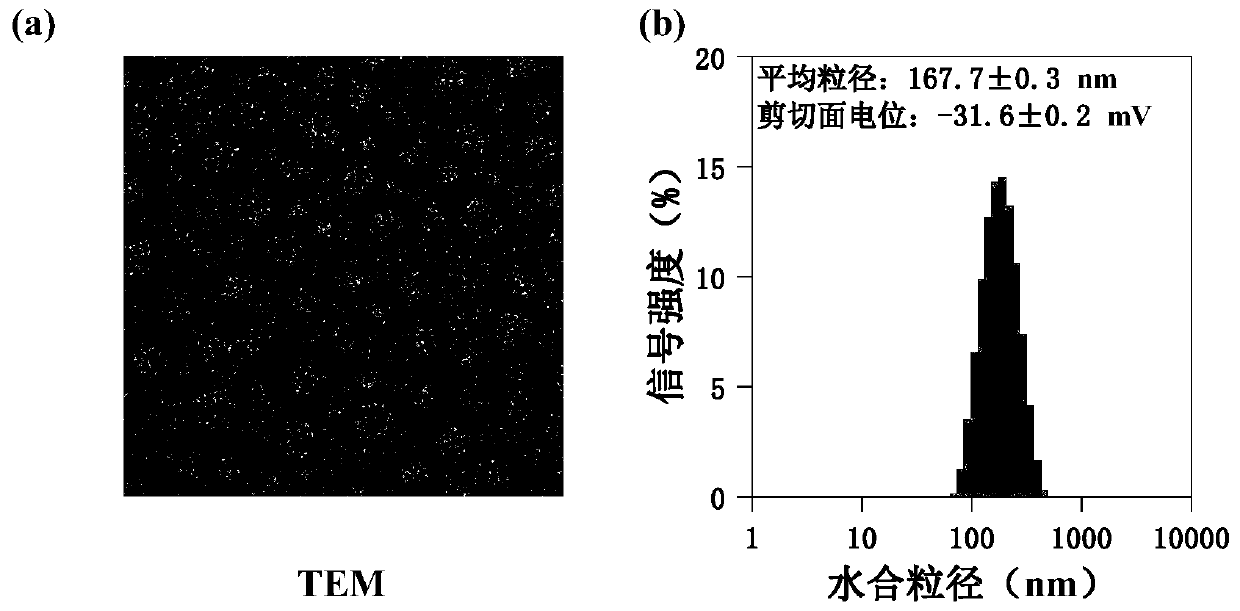

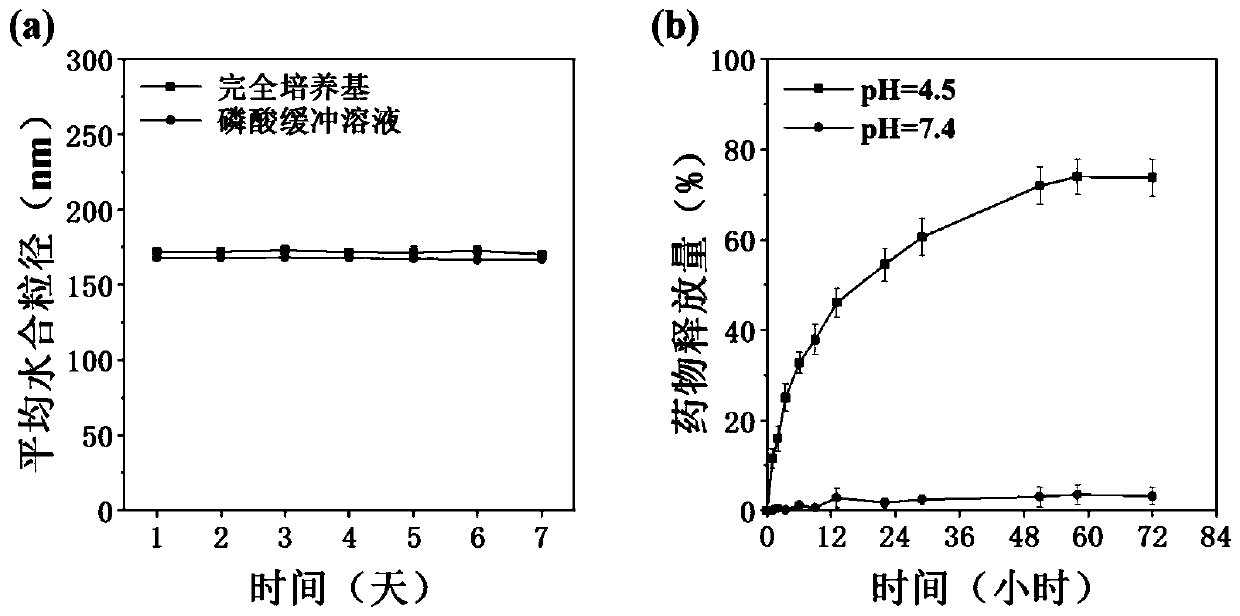

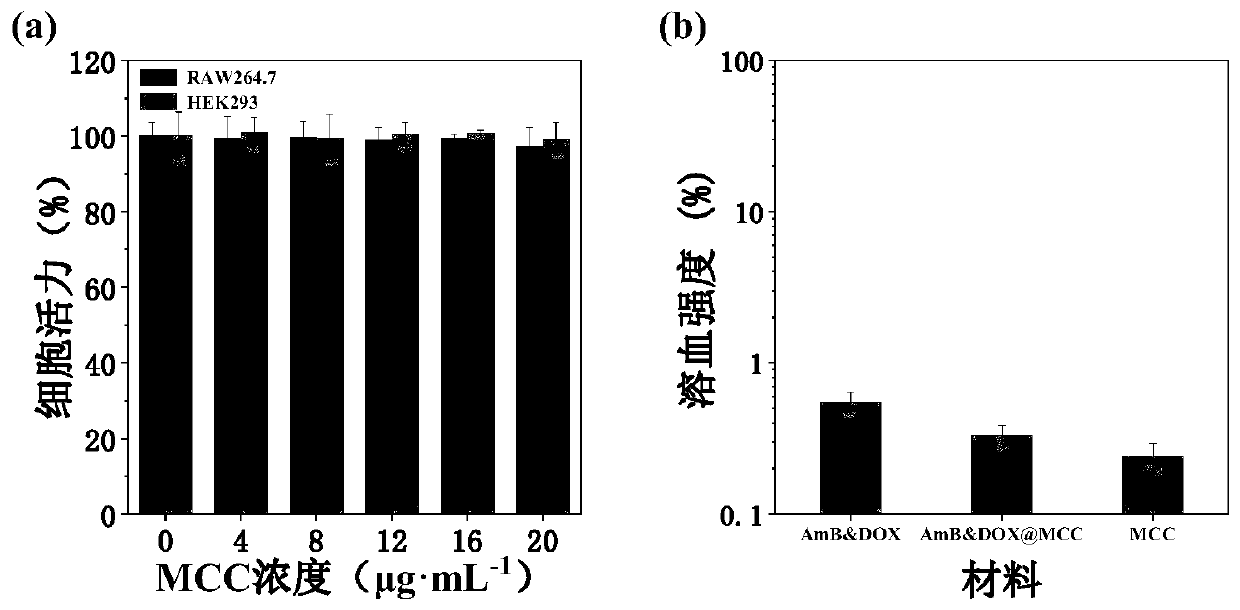

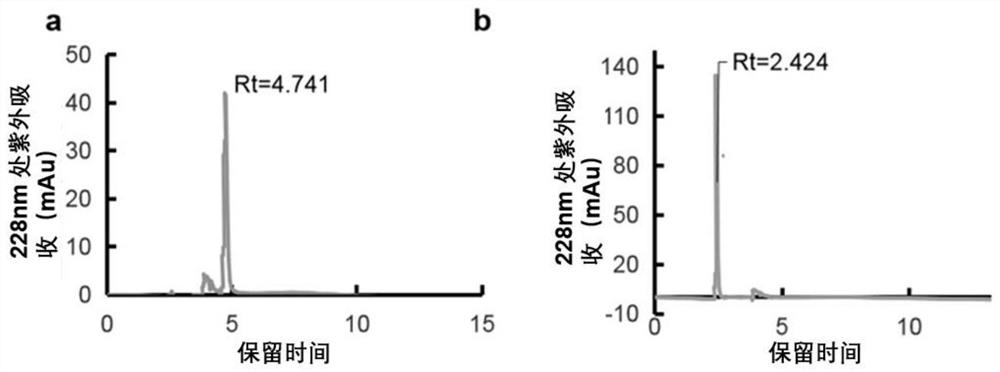

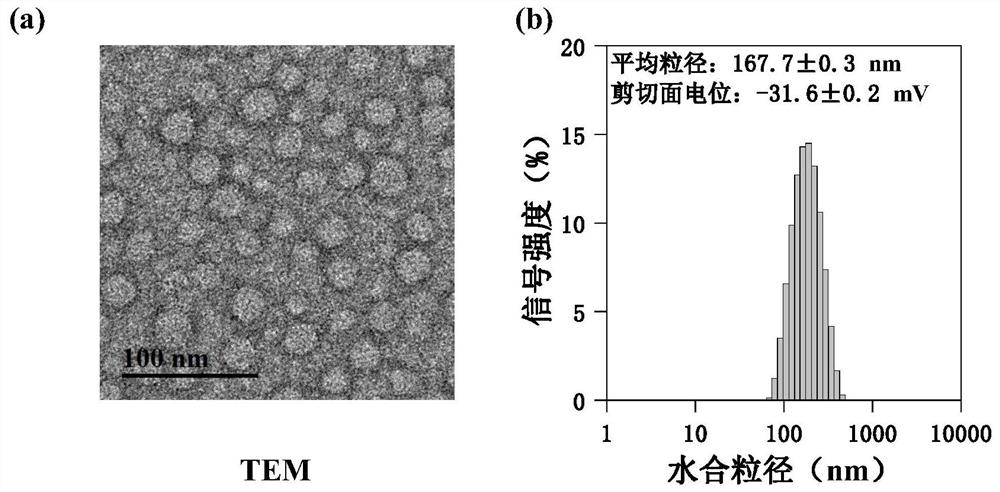

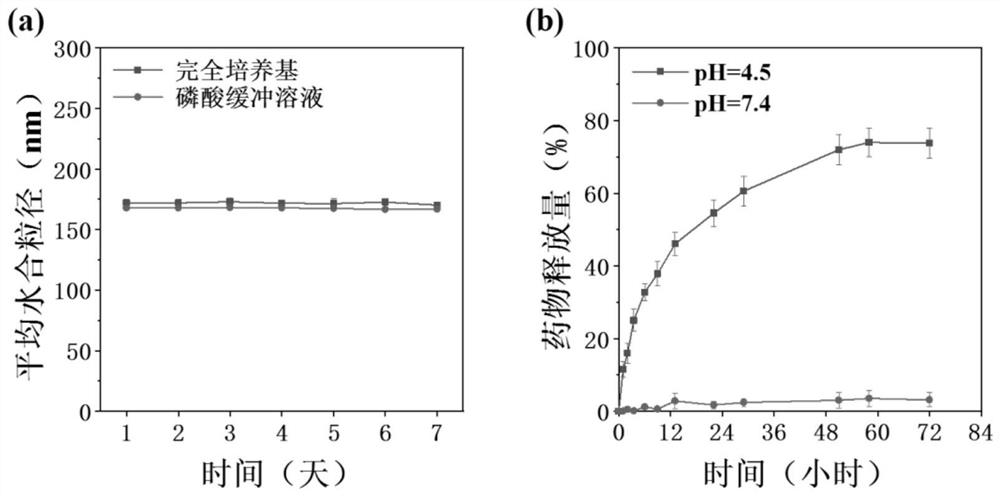

Targeted drug composition for co-loading amphotericin B and adriamycin and application of targeted drug composition

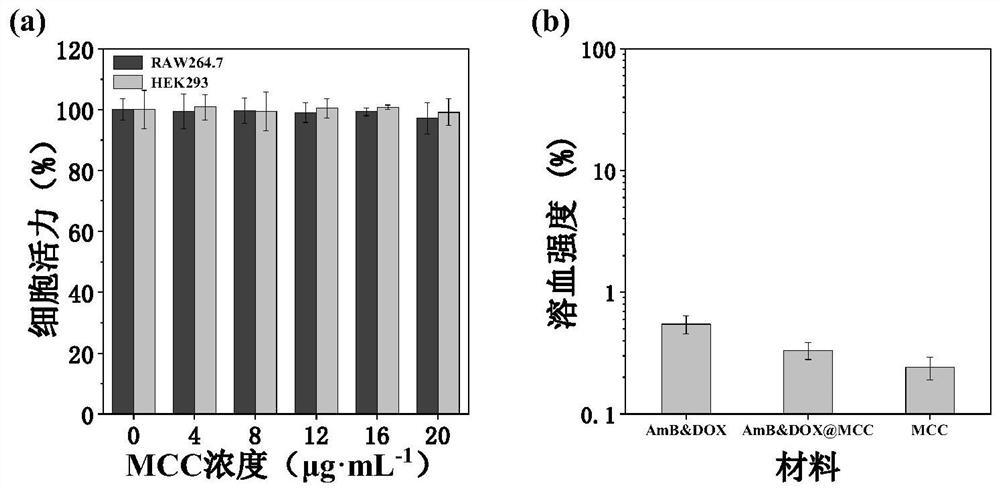

ActiveCN110801433AAchieving Synergistic TherapyImplement fixed-point releaseOrganic active ingredientsAntiparasitic agentsSide effectCyclodextrin

The invention discloses a targeted drug composition for co-loading amphotericin B and adriamycin and an application of the targeted drug composition, and belongs to the fields of medicines and pharmaceutics, and provides a novel medical composition for treating leishmaniasis. Two medicines of amphotericin B and adriamycin having fluorescent tracing properties are used and loaded in a pharmaceutical carrier material which is favorable in biological safety and has pH responsiveness to form the medical composition, wherein the carrier material consists of hydrophilicity mannose residues which actively target macrophages, beta-cyclodextrin and hydrophobic propionyl. The medical composition is good in biological safety (cytotoxicity and hemolytic activity), and the stability, pH response medicine release properties, target capacity, and treatment efficiency are verified in a cell model. Besides, the synergistic reaction of the amphotericin B and the adriamycin is realized, so that the consumption of the medicine is greatly reduced, the side effect is reduced, the economic burden of patients is alleviated, and the targeted drug composition is hopeful to exert great effects on clinical application.

Owner:JIANGNAN UNIV

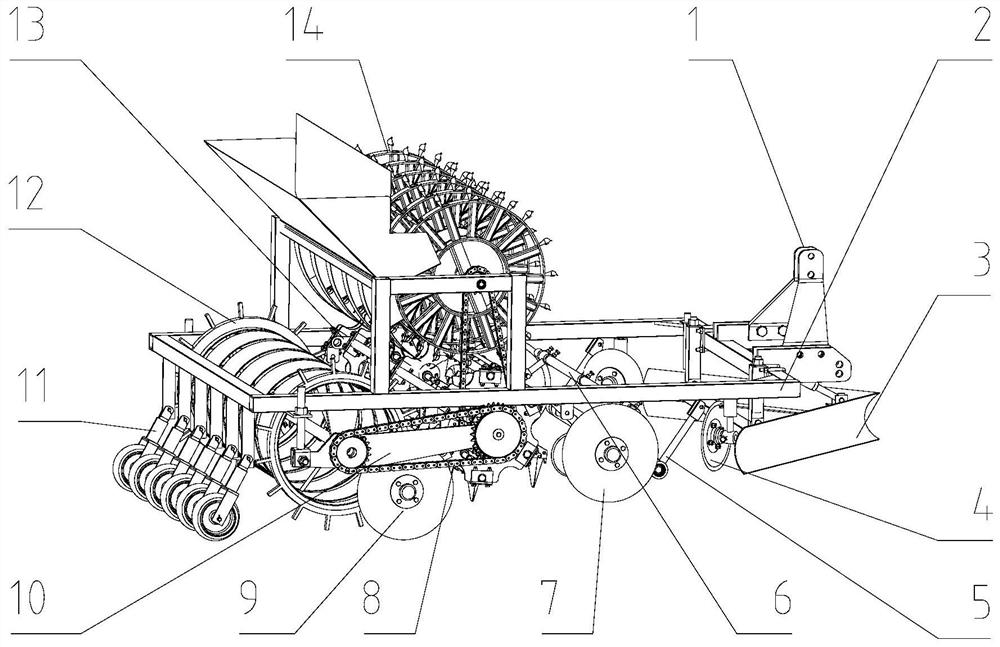

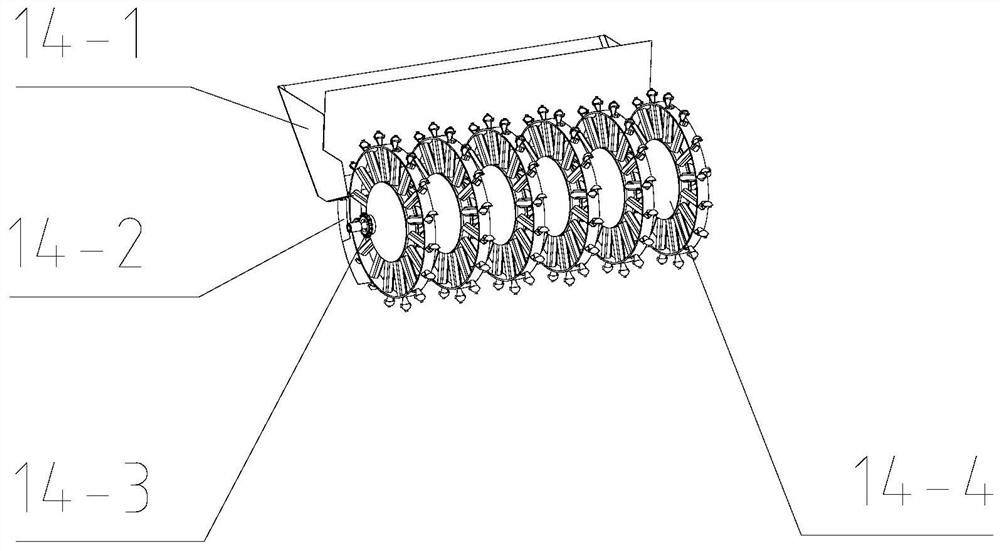

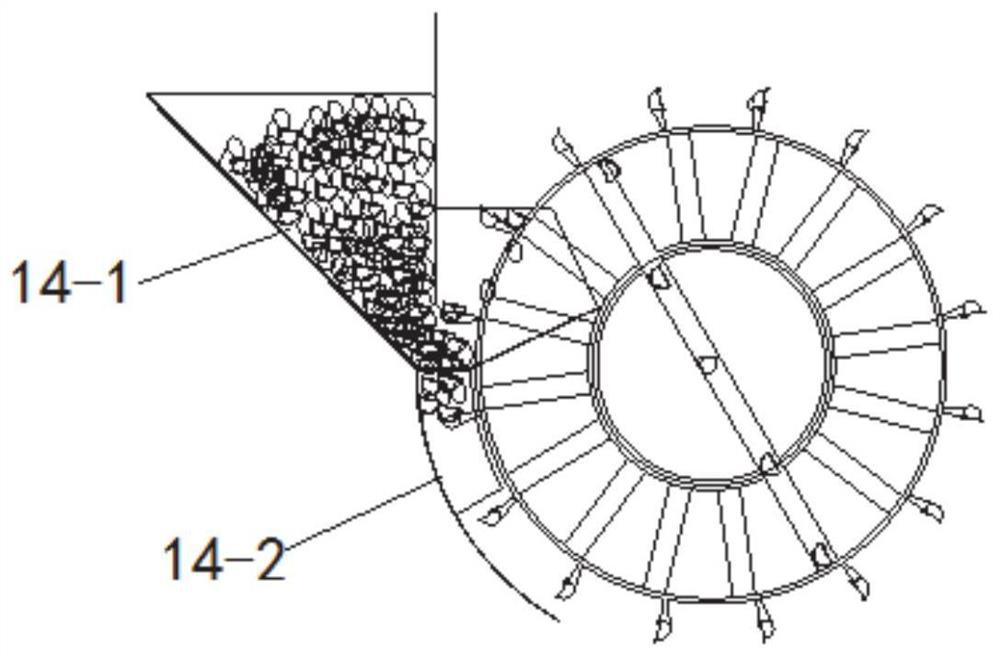

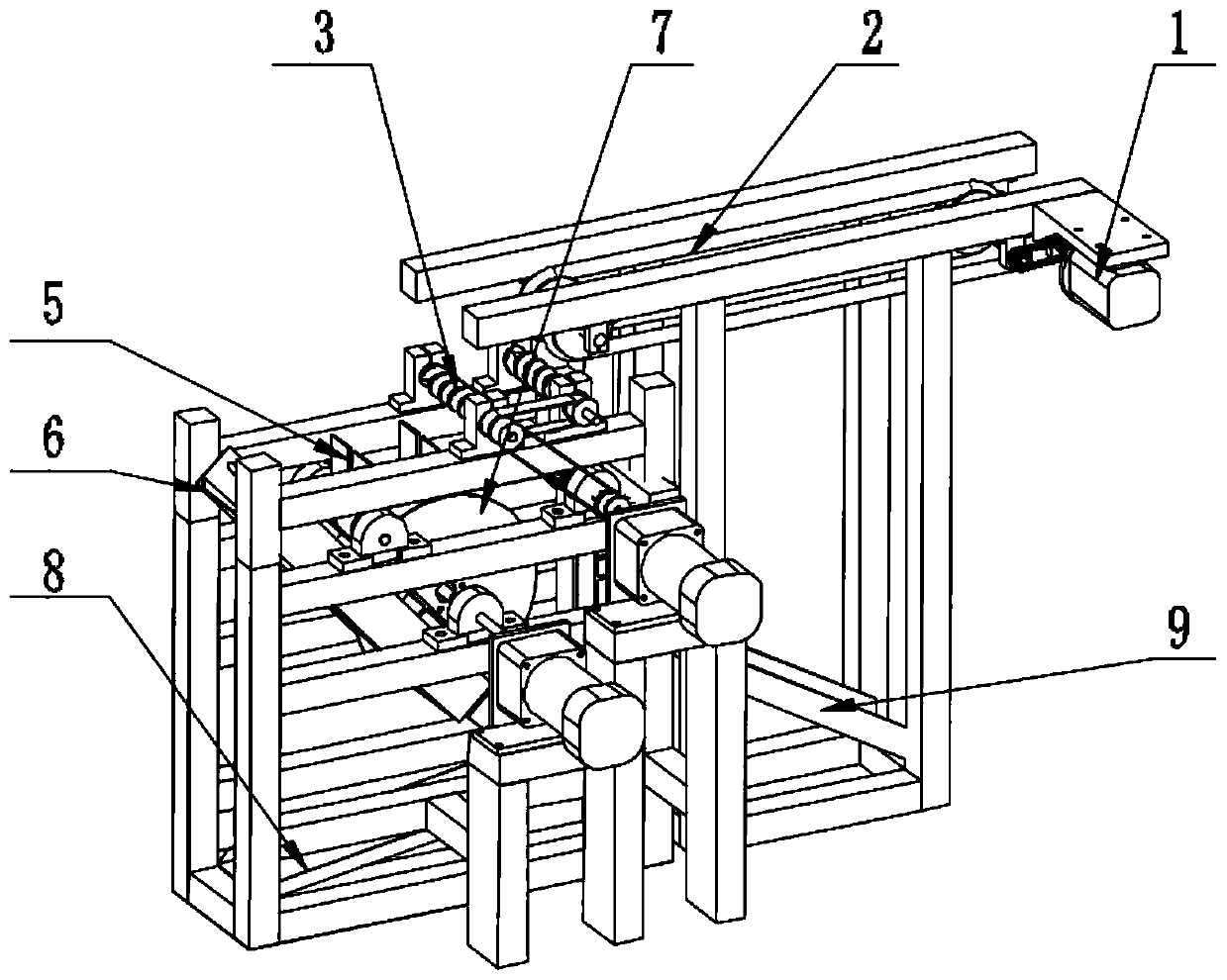

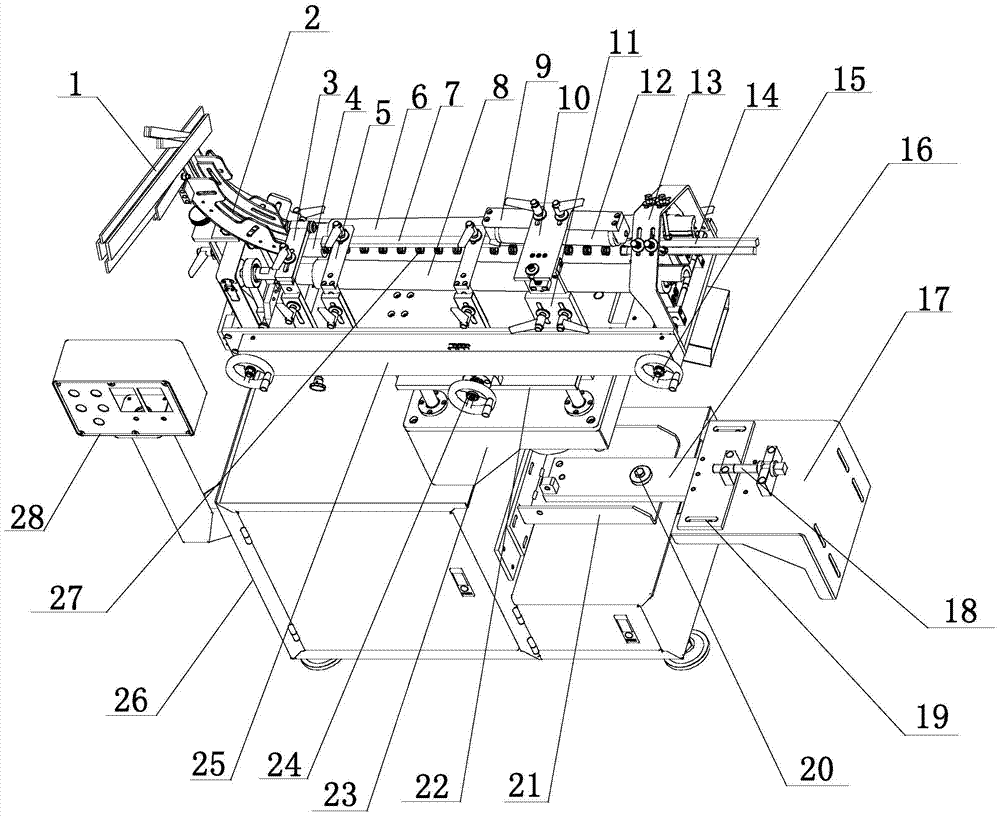

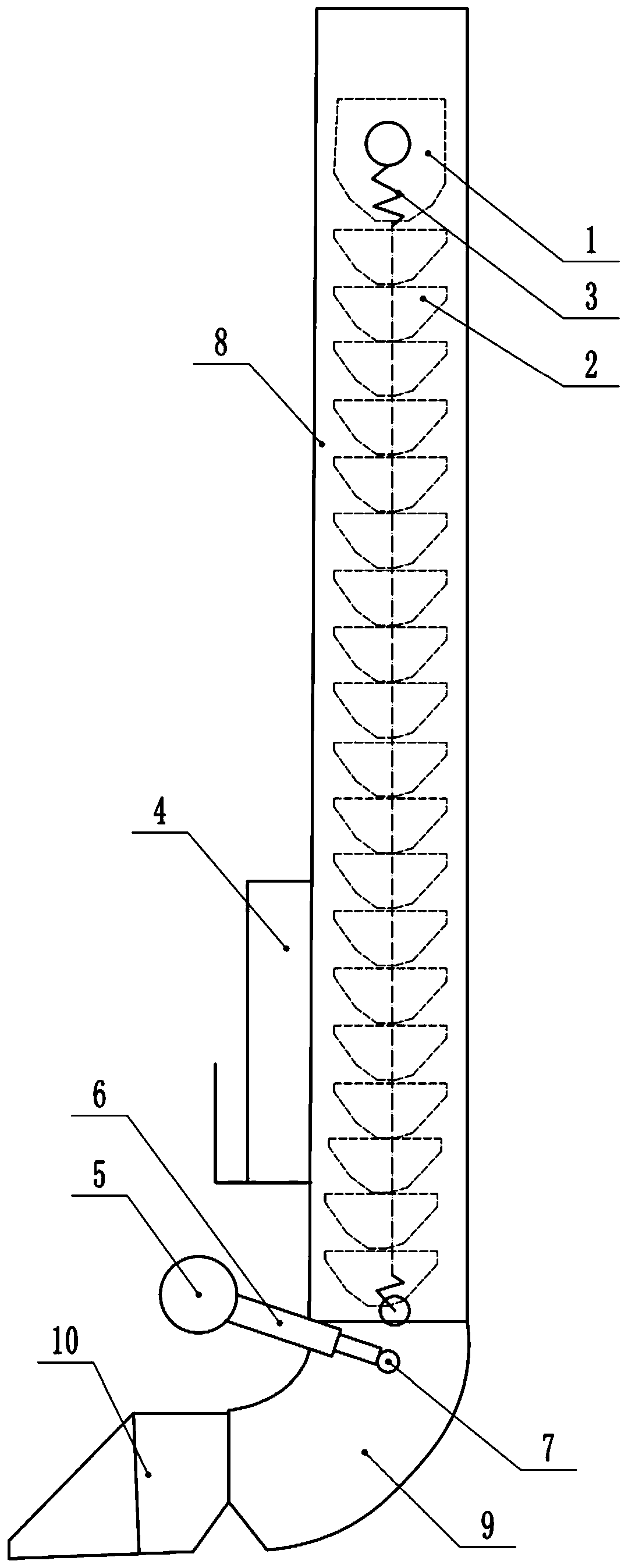

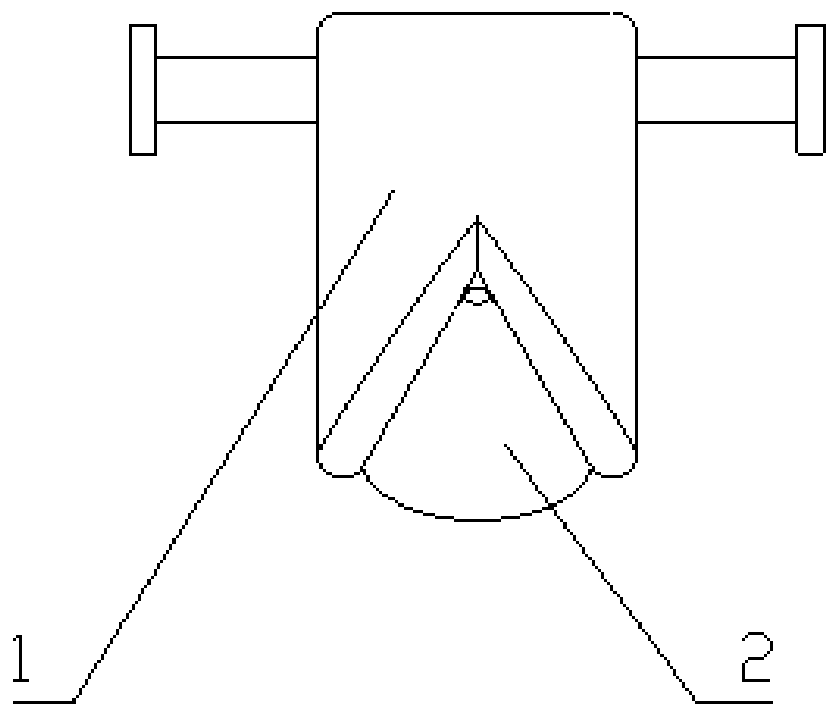

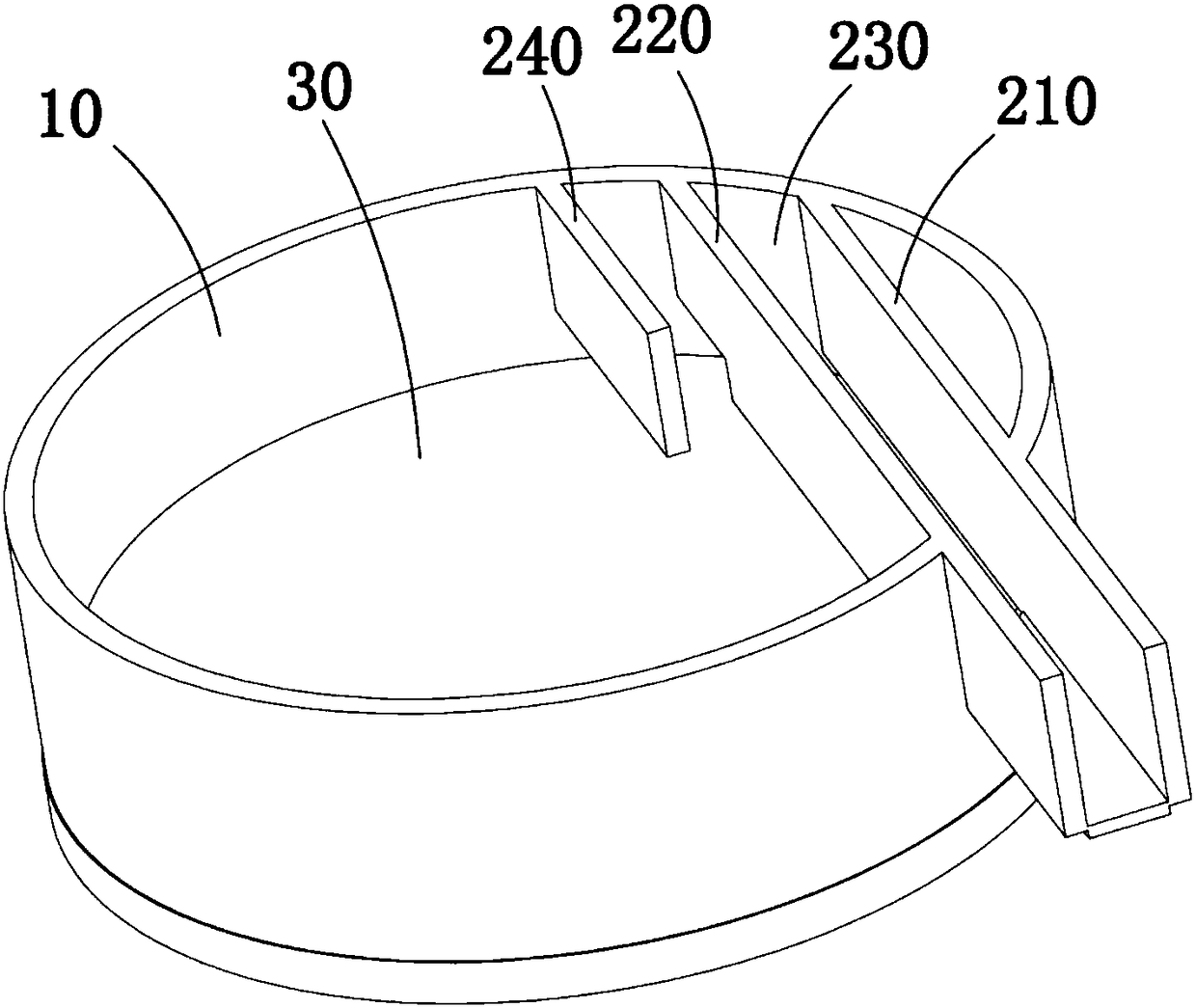

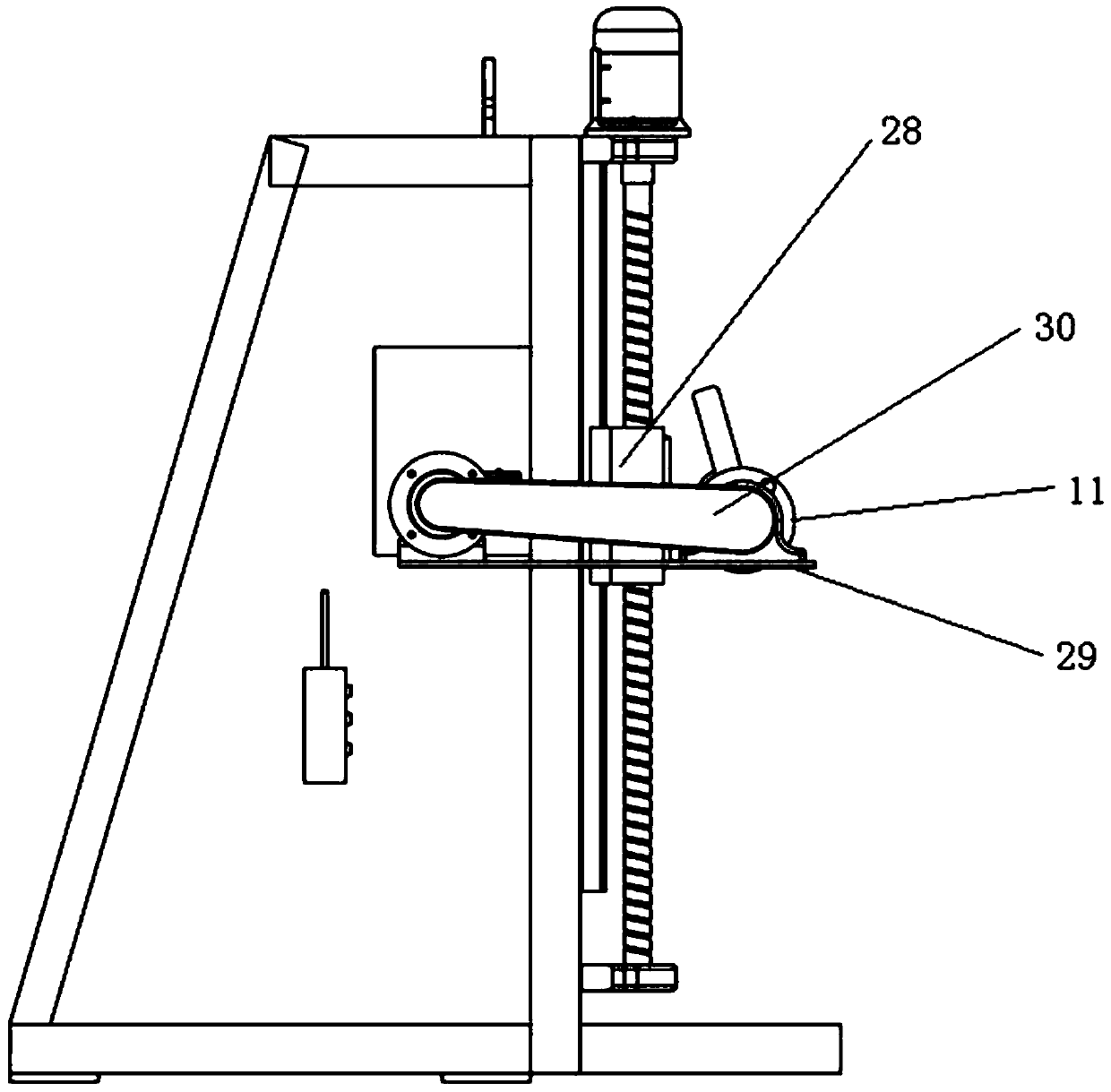

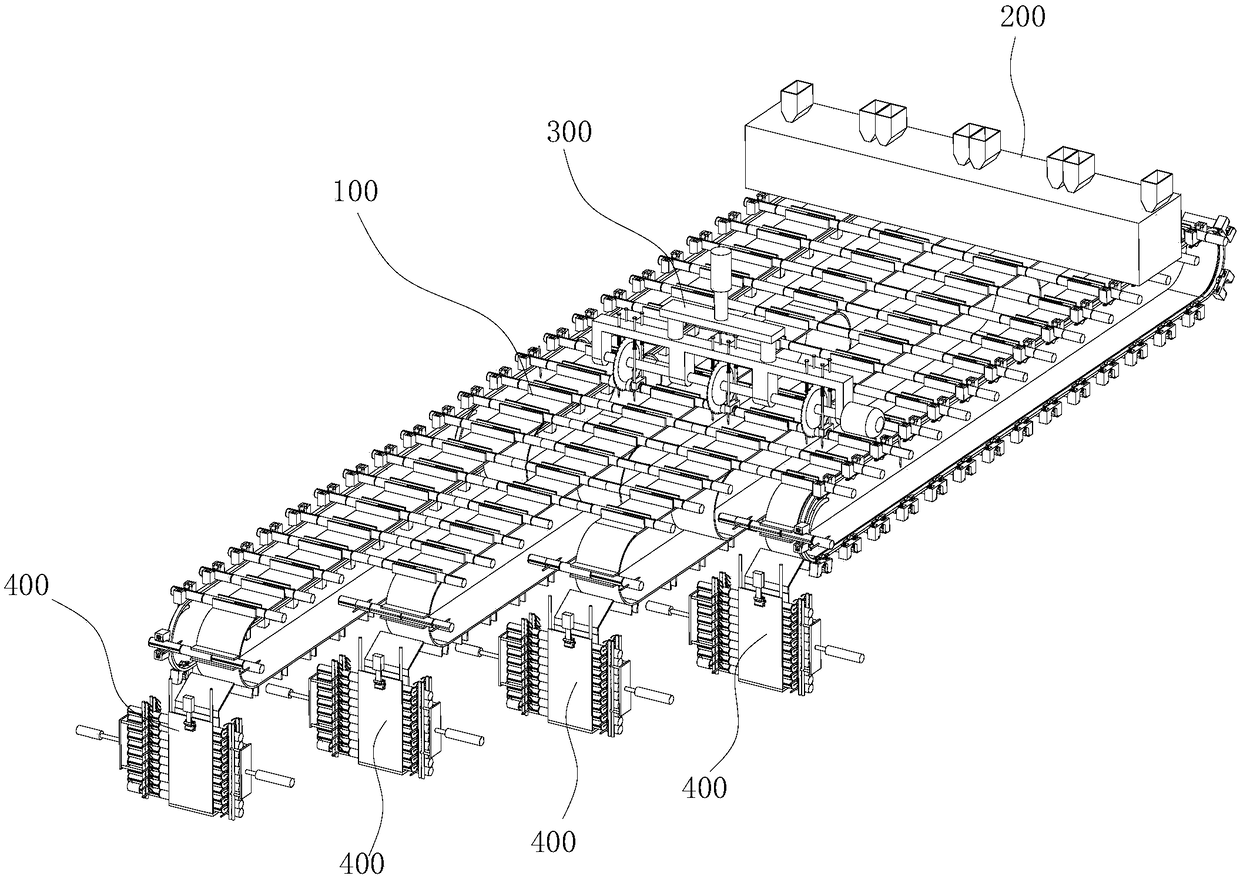

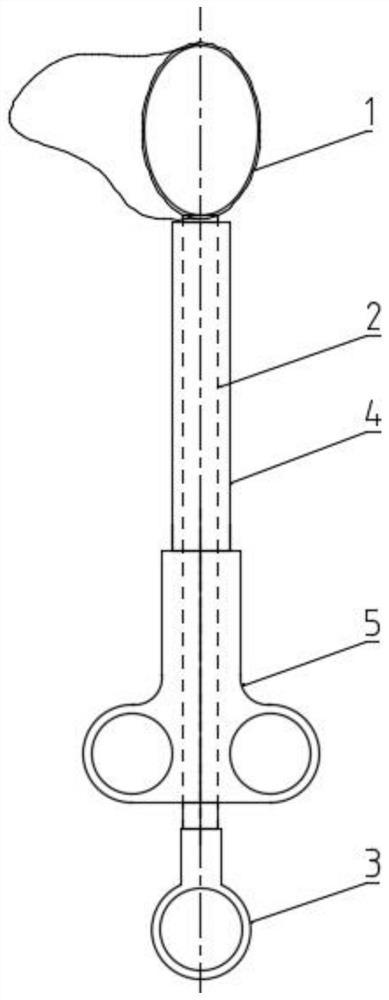

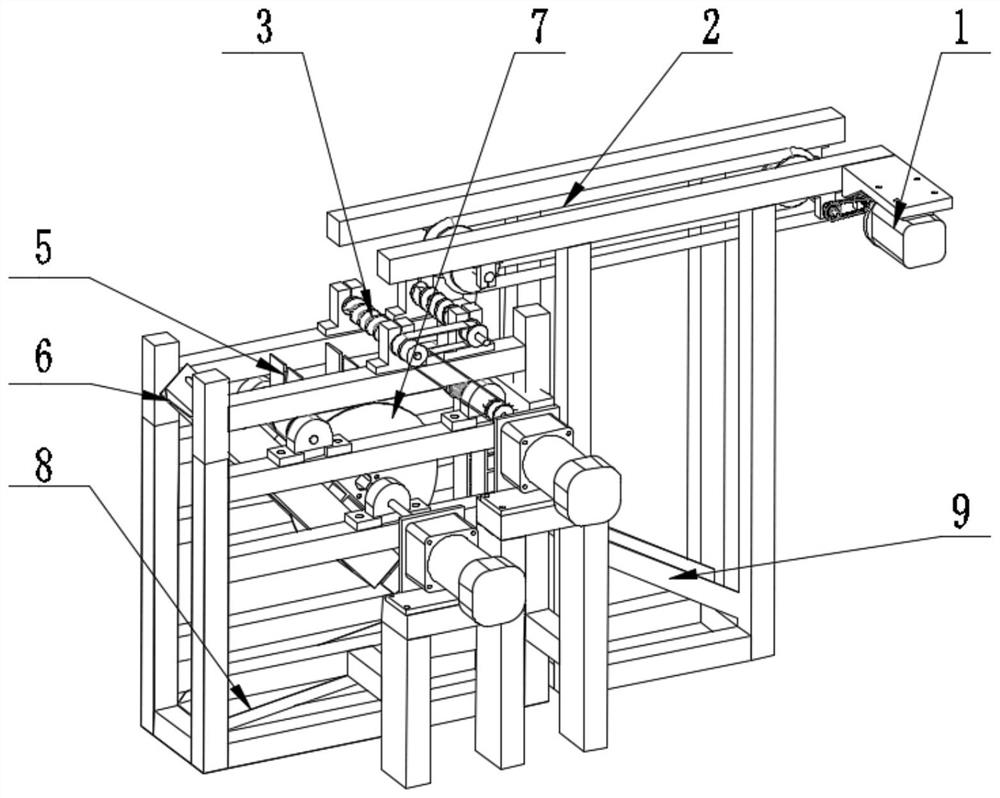

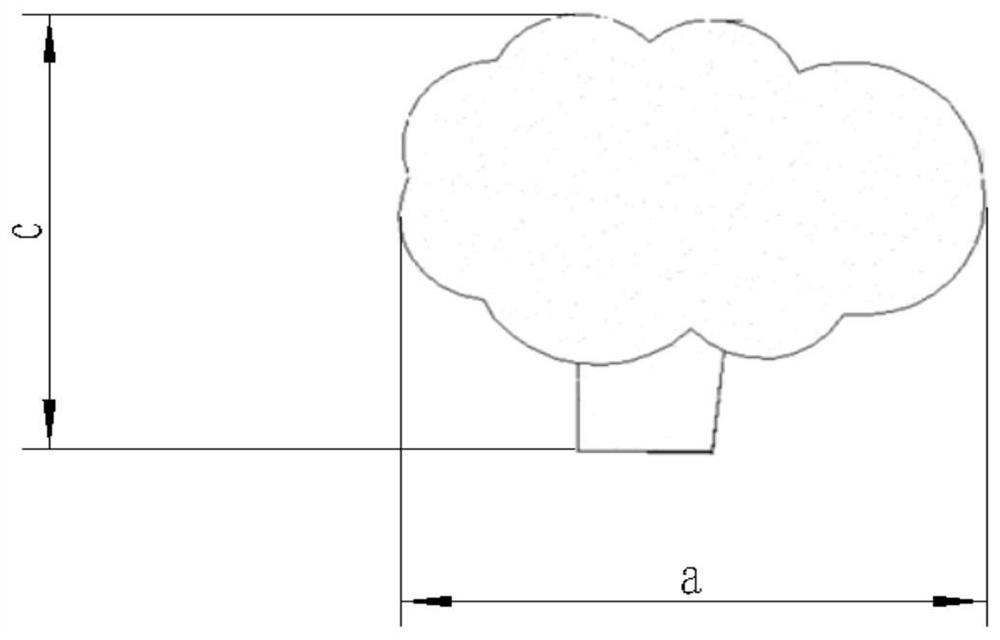

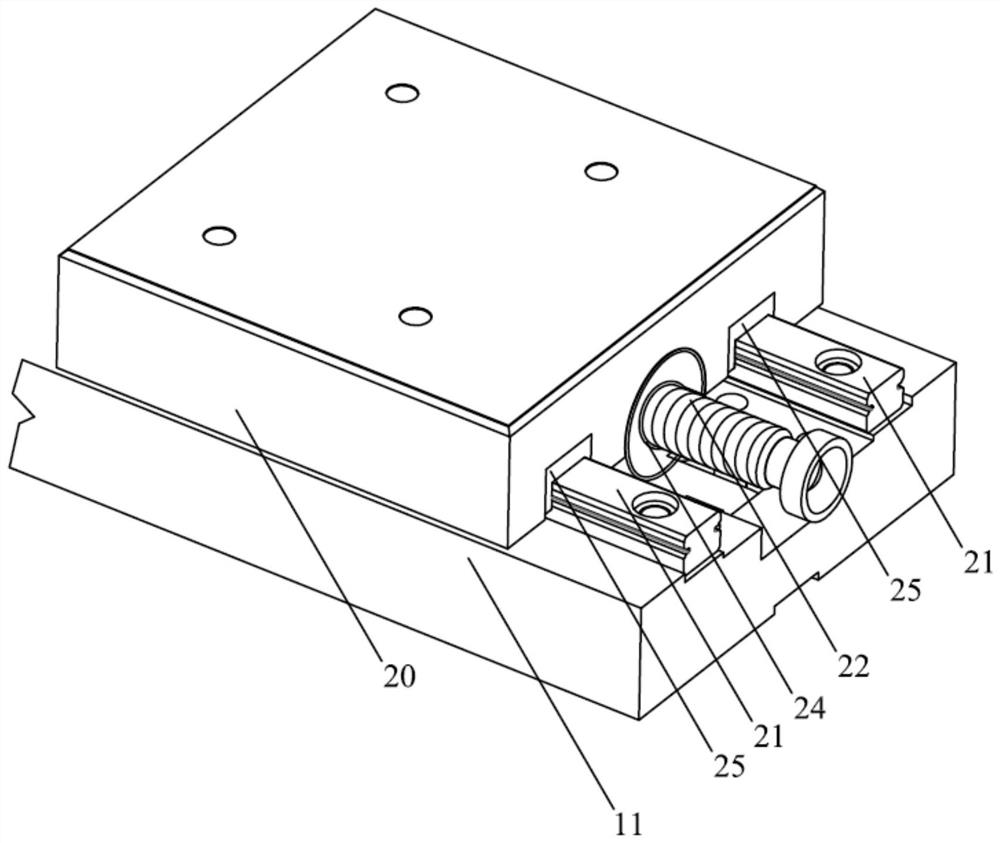

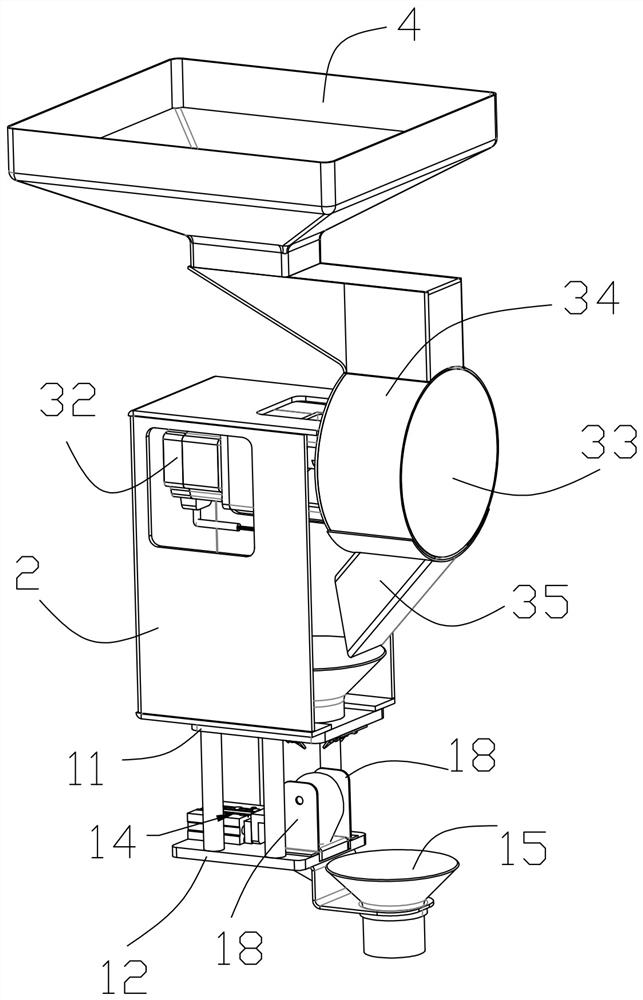

Inner channel type seed taking and direction changing device and on-film garlic planting machine

ActiveCN111919558ARealize continuous operationRealize directional deliveryClimate change adaptationPotato plantersAgricultural engineeringAllium sativum

The invention discloses an inner channel type seed taking and direction changing device and an on-film garlic planting machine, solves the problems that a garlic seed metering device in the prior artis unstable in work and cannot guarantee planting upright degrees of garlic, and has the advantages of achieving directional sowing and improving the planting upright degrees of garlic seeds. The specific scheme is as follows: the inner channel type seed taking and direction changing device comprises a seed box, a garlic groove and at least one seed taking and direction changing unit, wherein thesize of the top of the seed box is larger than that of the bottom of the seed box, the whole garlic groove is arc-shaped, the garlic groove is formed below the seed box, the seed box and the garlic groove are located on one side of the at least one seed taking and direction changing unit, the adjacent seed taking and direction changing units are connected, each seed taking and direction changing unit comprises a rotatable seed taking disc and seed taking spoons arranged in the circumferential direction of the seed taking disc, a plurality of conveying pipes are supported through the seed taking disc, direction turning pipes are fixed to a rack, the size of one side of the transverse section of a garlic seed turning channel in each direction turning pipe is larger than that of the other side, and each direction turning pipe and the conveying pipes on the top end side and the bottom end side of the direction turning pipe can be located on a same straight line.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

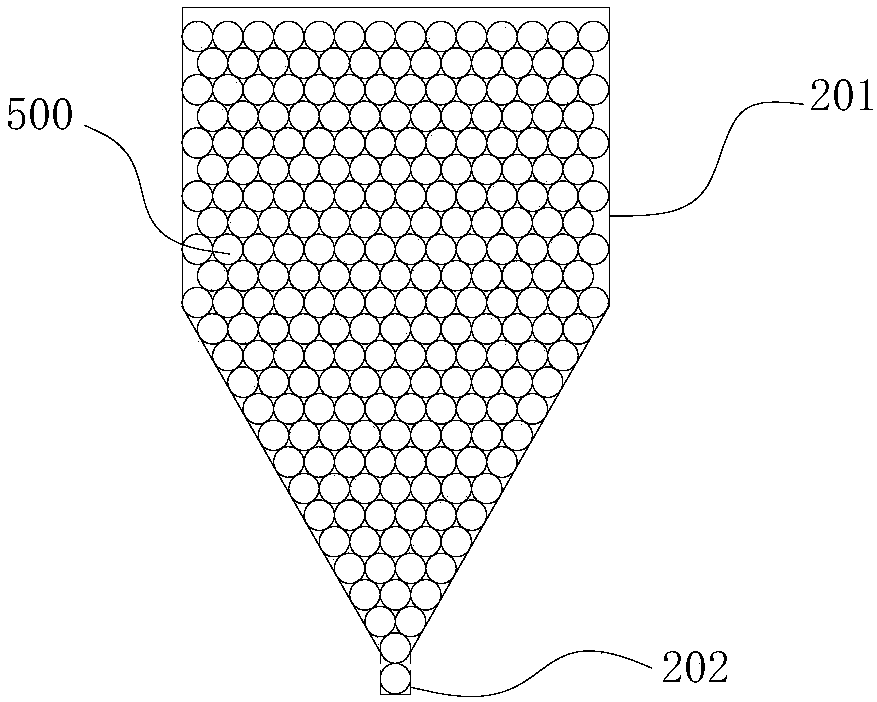

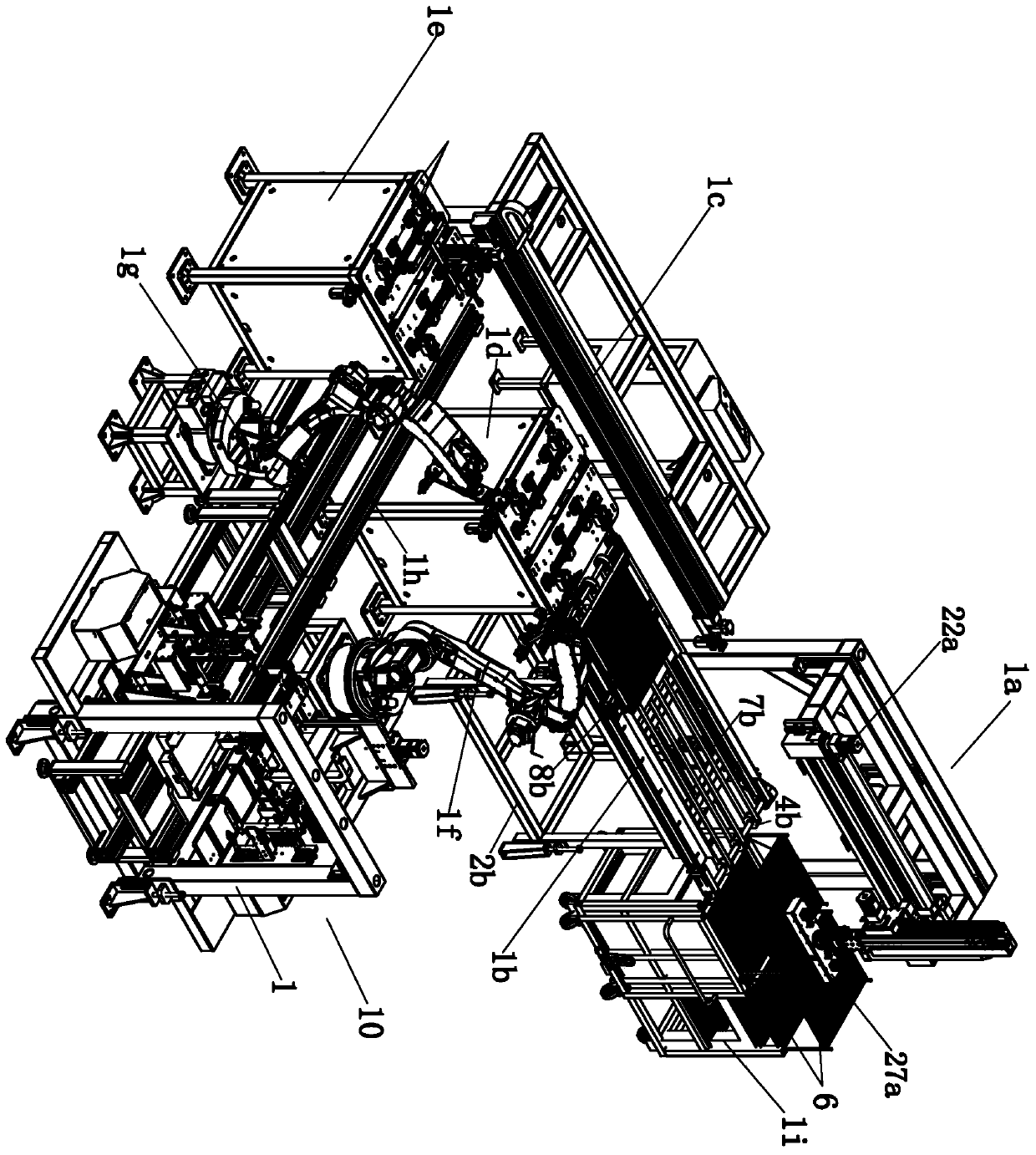

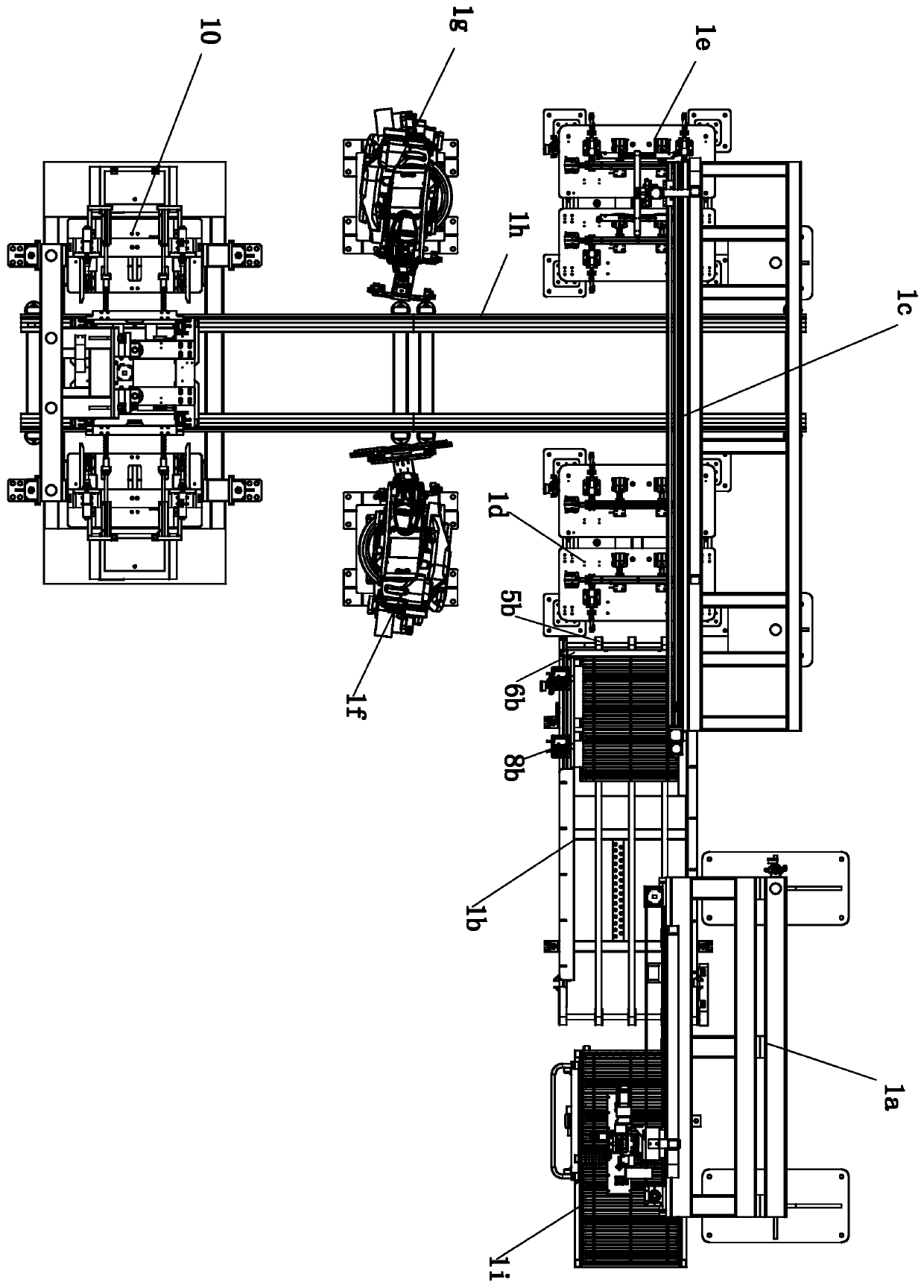

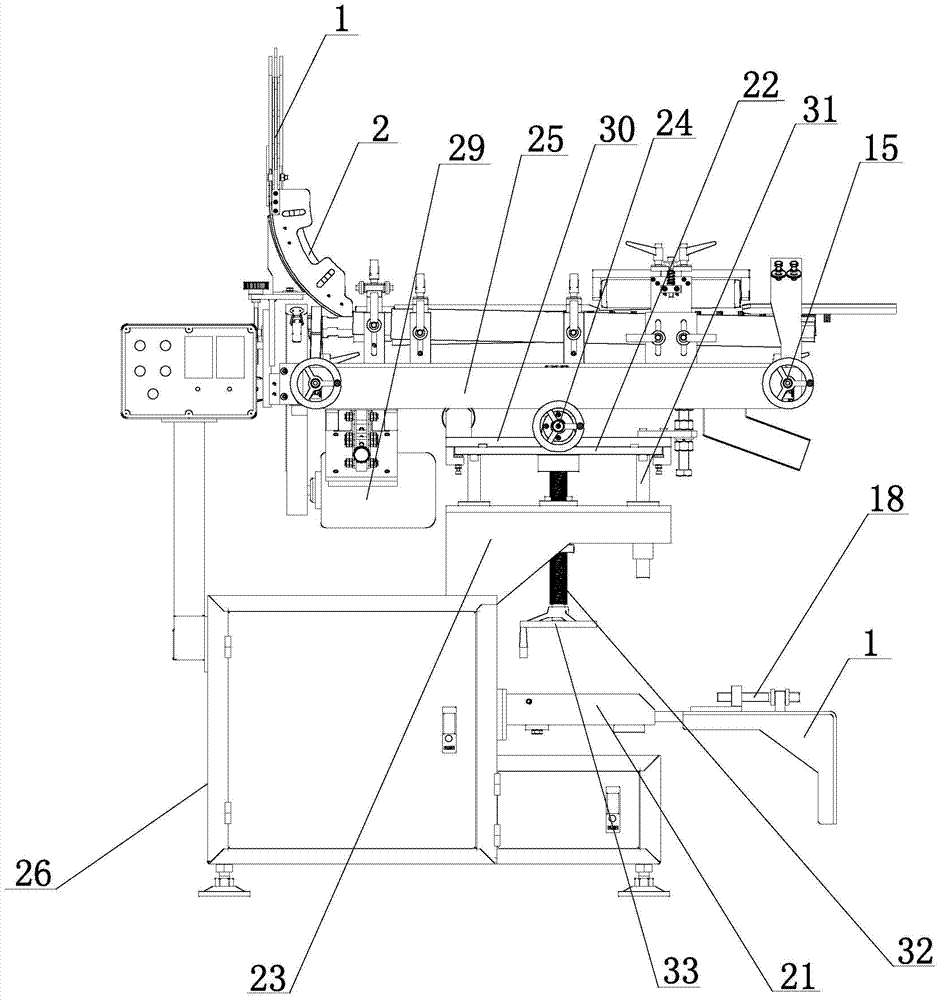

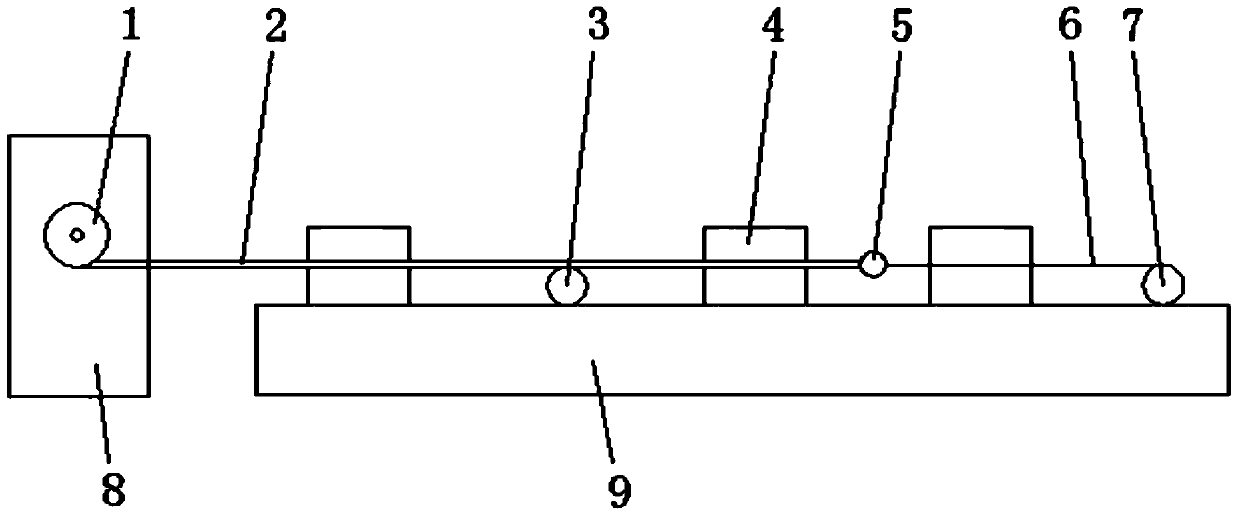

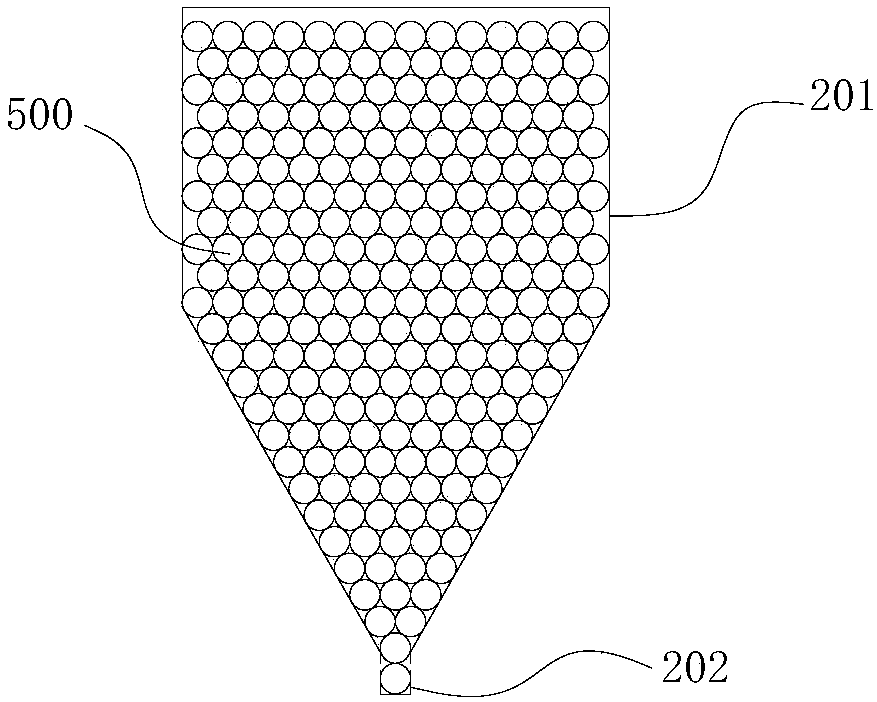

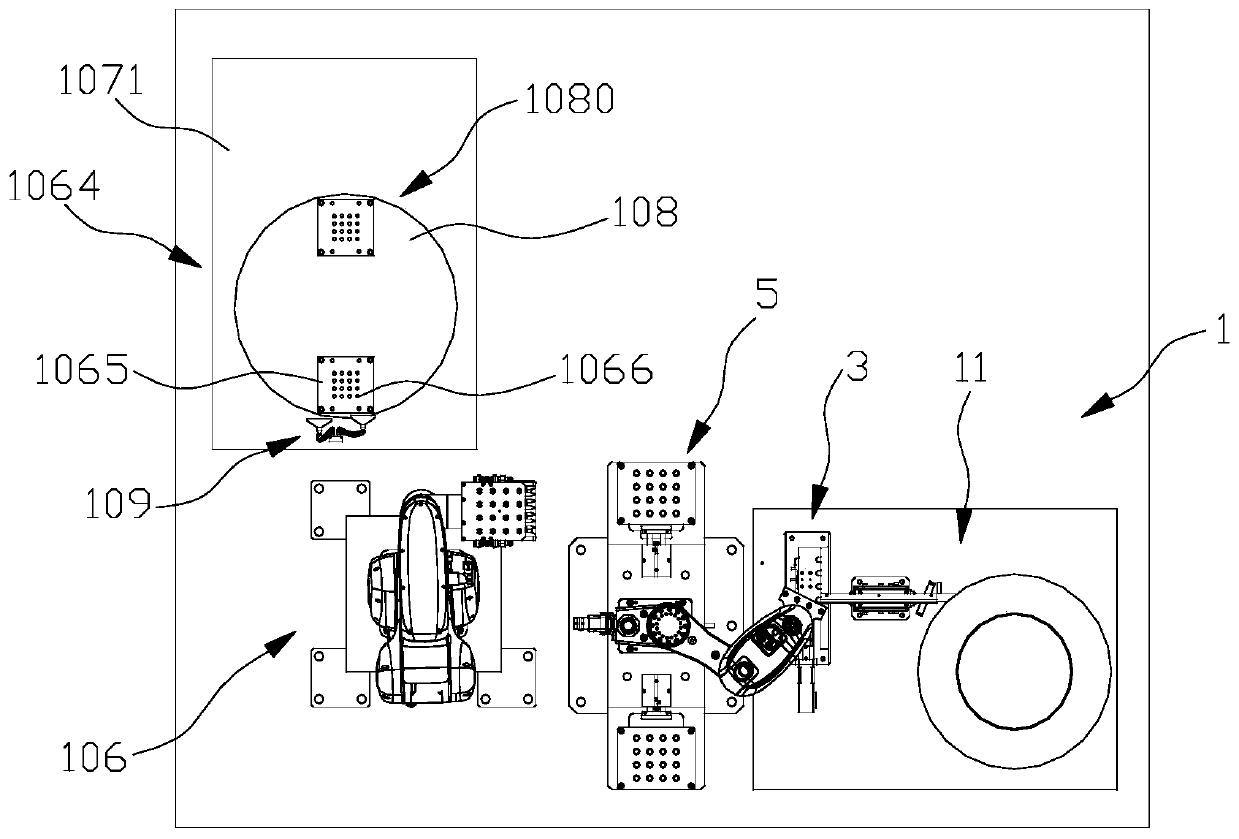

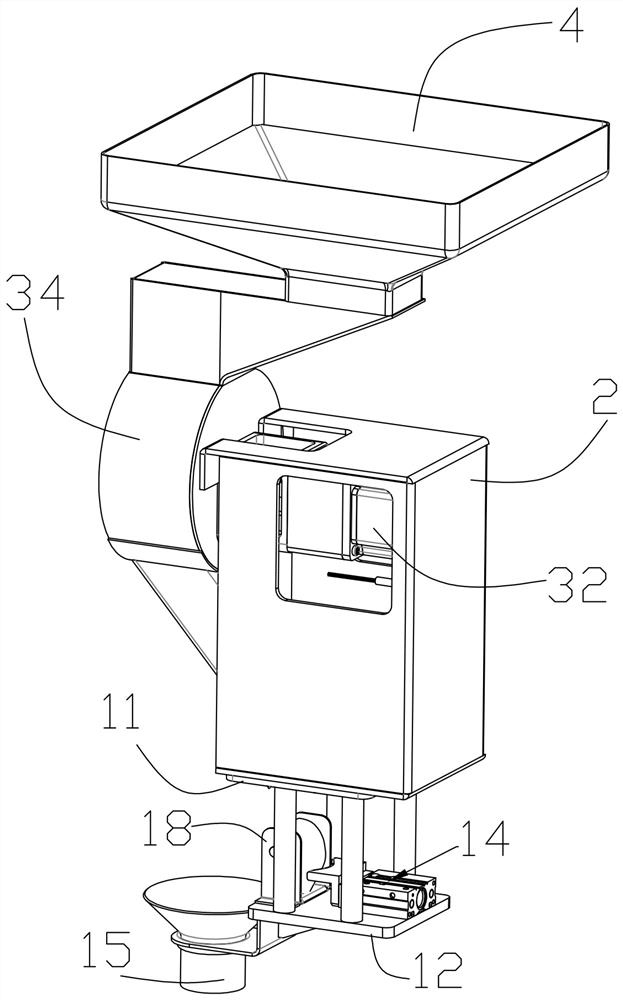

Sugarcane seed steam bud calibration system

The invention belongs to the technical fields of agricultural production planting and agricultural product processing, and particularly relates to a sugarcane seed steam bud calibration system. The system comprises a positioning and conveying device, a calibration object, a marking device, a cutting device and a collecting device; the positioning and conveying device is configured to make the sugarcane stem conveyed in a fixed posture, the marking device and the cutting device are sequentially arranged above the positioning and conveying device, the marking device is used for fixing the calibration object on the sugarcane seed stem, the cutting device is used for cutting the calibrated sugarcane seed stem to form small segments, and the collecting device is arranged at the end of the positioning and conveying device and is used for collecting the processed sugarcane seed stem. The calibration object and the stem buds of the sugarcane seed stem are arranged according to a specific position relationship, and the calibration object can be captured or recognized by a seeder, so the seeder can distinguish the positions of the stem buds on the sugarcane seed stem in order to realize thedirectional transportation and seeding of the sugarcane seed stem.

Owner:ANQING WANCAO QIANMU AGRI TECH

Preparation of gas containing lipid body and composite granule

InactiveCN1582901AEasy to controlEasy particle size and stabilityEmulsion deliveryIn-vivo testing preparationsDrugDrug delivery

Owner:SHANGHAI JIAO TONG UNIV

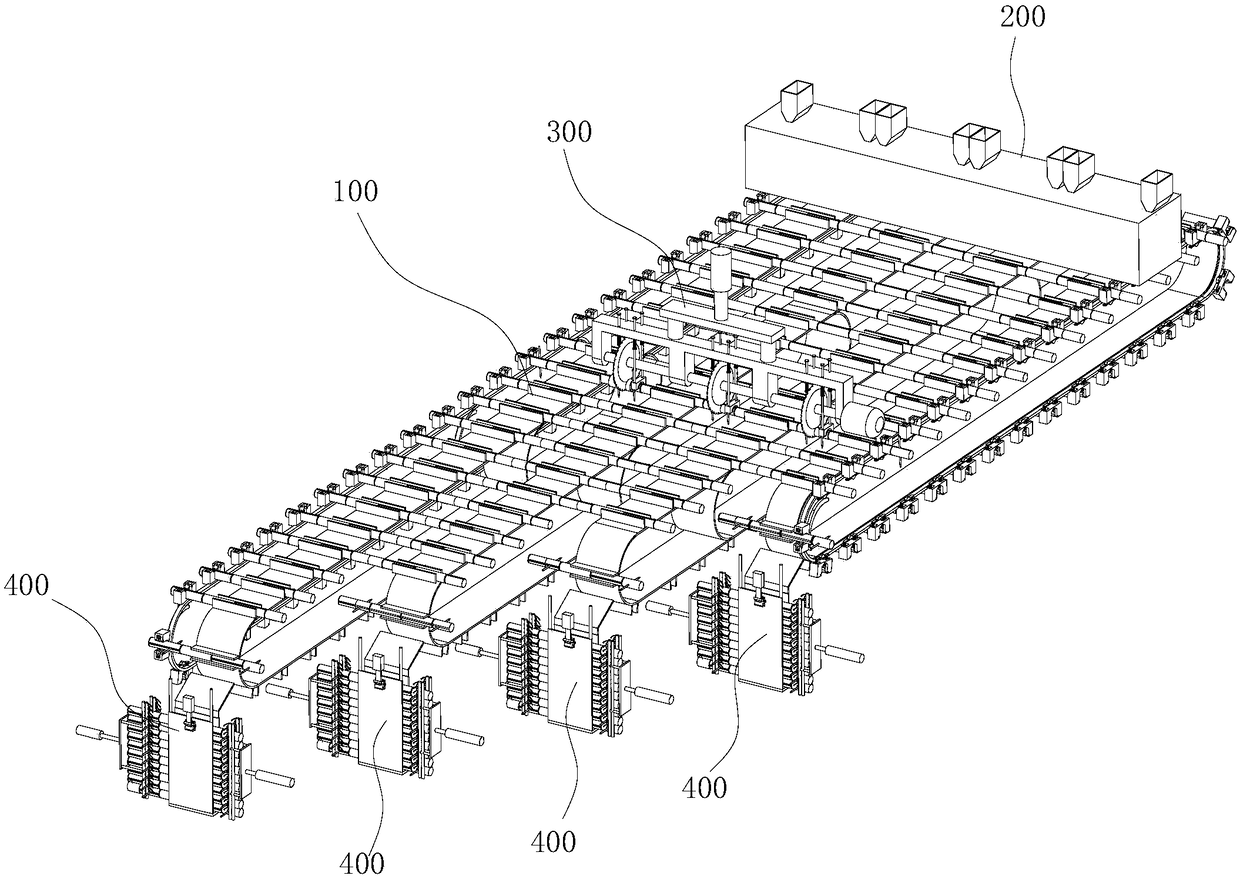

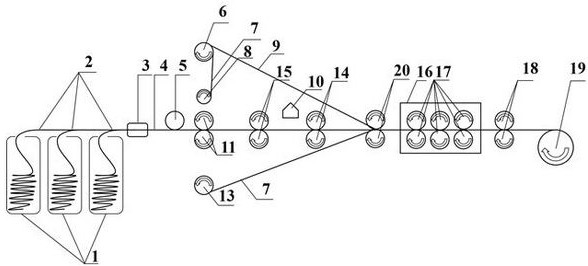

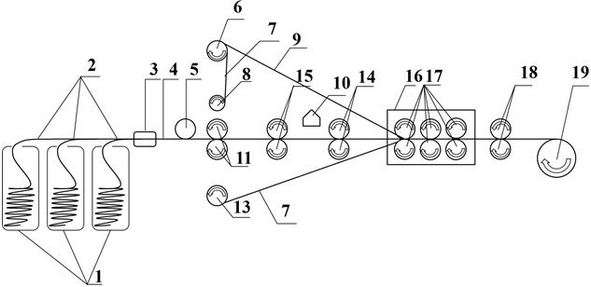

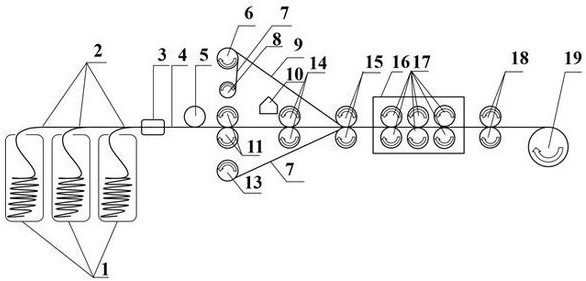

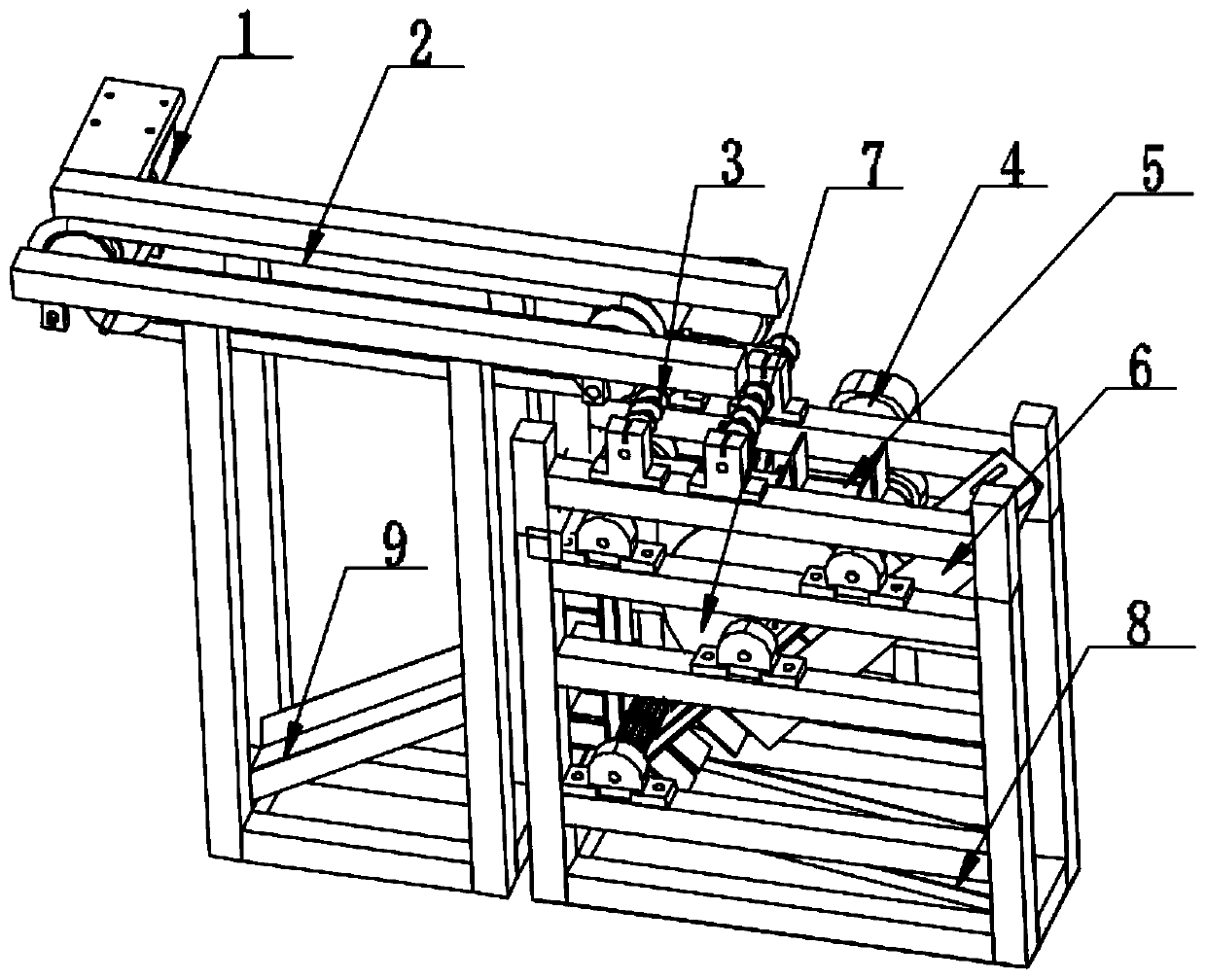

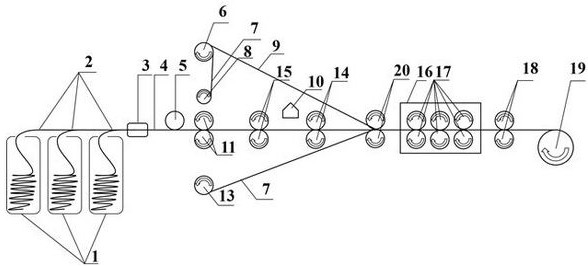

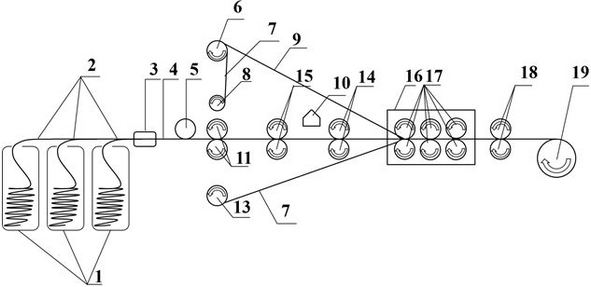

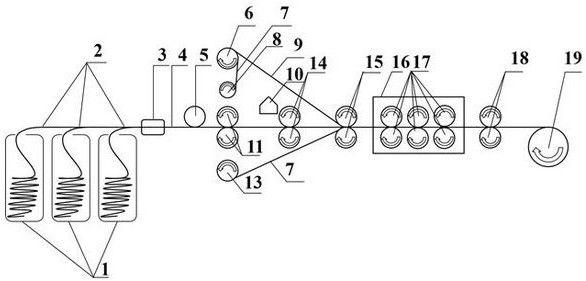

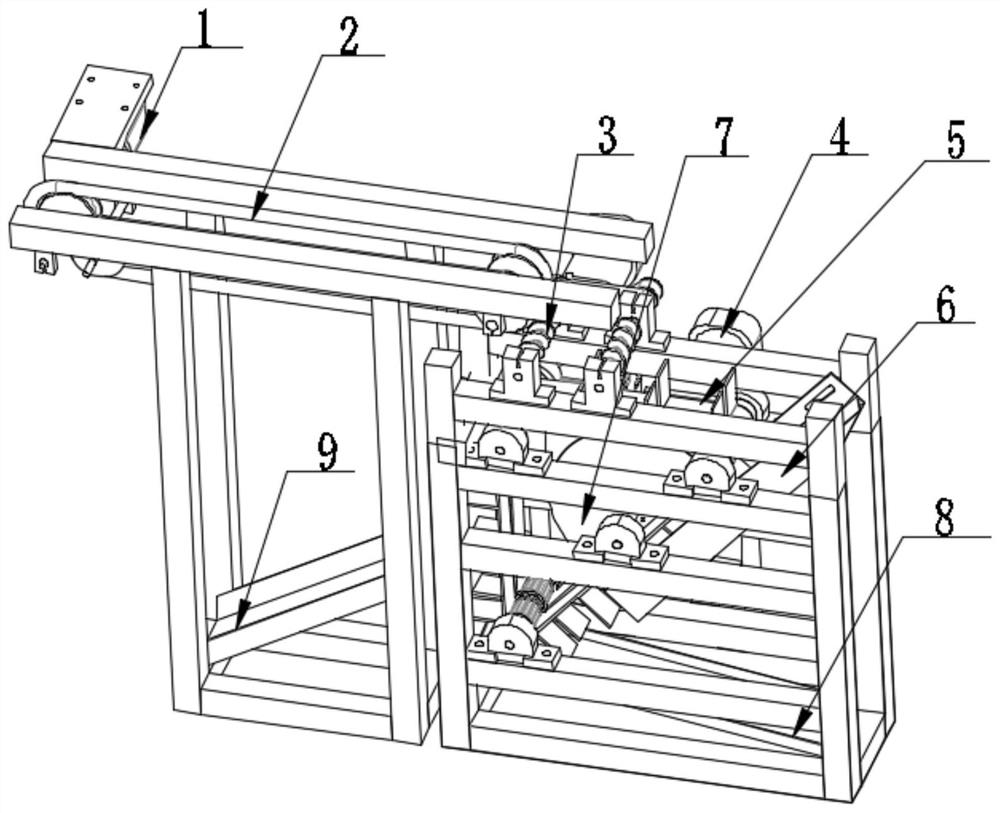

One-way long hemp fiber prepreg production line and production process

ActiveCN113954392AReduce processing difficultyShort processCarding machinesCoatingsProcess engineeringManufacturing line

The invention discloses a one-way long hemp fiber prepreg production line and a production process. The production line is sequentially provided with a feeding device, a fiber spreading device, a drafting station, a shaping station, a film covering station, a hot pressing device and a conveying roller in the fiber conveying direction. The one-way long hemp fiber prepreg production line and the process with the long hemp strips as the raw materials are innovatively researched and developed, the production line and process are simple and easy to implement, due to the fact that the long hemp strips are adopted as the feeding raw materials, the processing difficulty of the long hemp strips is small, the process is short, the speed is high, and the preparation cost of prefabricated reinforcing materials can be remarkably reduced; the output width and thickness are designable, and the arrangement straightness of the long hemp fibers in the long hemp fiber belt and the prepreg is high; and the production line is suitable for continuous production of large-batch one-way long hemp fiber belts and prepregs, and fills the industry blank.

Owner:TIANJIN POLYTECHNIC UNIV

Broccoli differential sorting and secondary uniform stripping and slicing device and method

ActiveCN110682342ARealize directional deliverySecondary slicing worksMetal working apparatusGradingBroccoli raabConveyor belt

The invention discloses a broccoli differential sorting and secondary uniform stripping and slicing device and method. An existing machine is not suitable for secondary stripping and slicing of broccoli. The device comprises a differential circular belt, two screw rods, a partition board conveyor belt, an inclined slideway and a disc cutter, wherein the inclined slideway is positioned below the partition board conveyor belt. The method comprises the following steps that two differential circular belts convey and sort broccolis in a differential manner, after sorting, the longest sides of broccolis falling down between the two screw rods rotate to be parallel with the axes of the screw rods under the rotating action of the two screw rods with opposite spirals, and the broccolis fall down between two transverse partition boards adjacent to the partition board conveyor belt; when being conveyed to a bevel edge position, the broccolis enter the inclined slideway; and the disc cutter carries out secondary stripping and slicing on the broccolis. According to the device, the two differential circular belts are utilized to automatically sort broccolis; the two screw rods are utilized to automatically adjust the orientation of broccolis; the transverse partition board of the partition board conveyor belt keeps the orientation of broccolis; and the inclined slideway with a fillet enablesthe broccolis to be in the middle of the inclined slideway so as to improve the stripping and slicing uniformity.

Owner:ZHEJIANG SCI-TECH UNIV

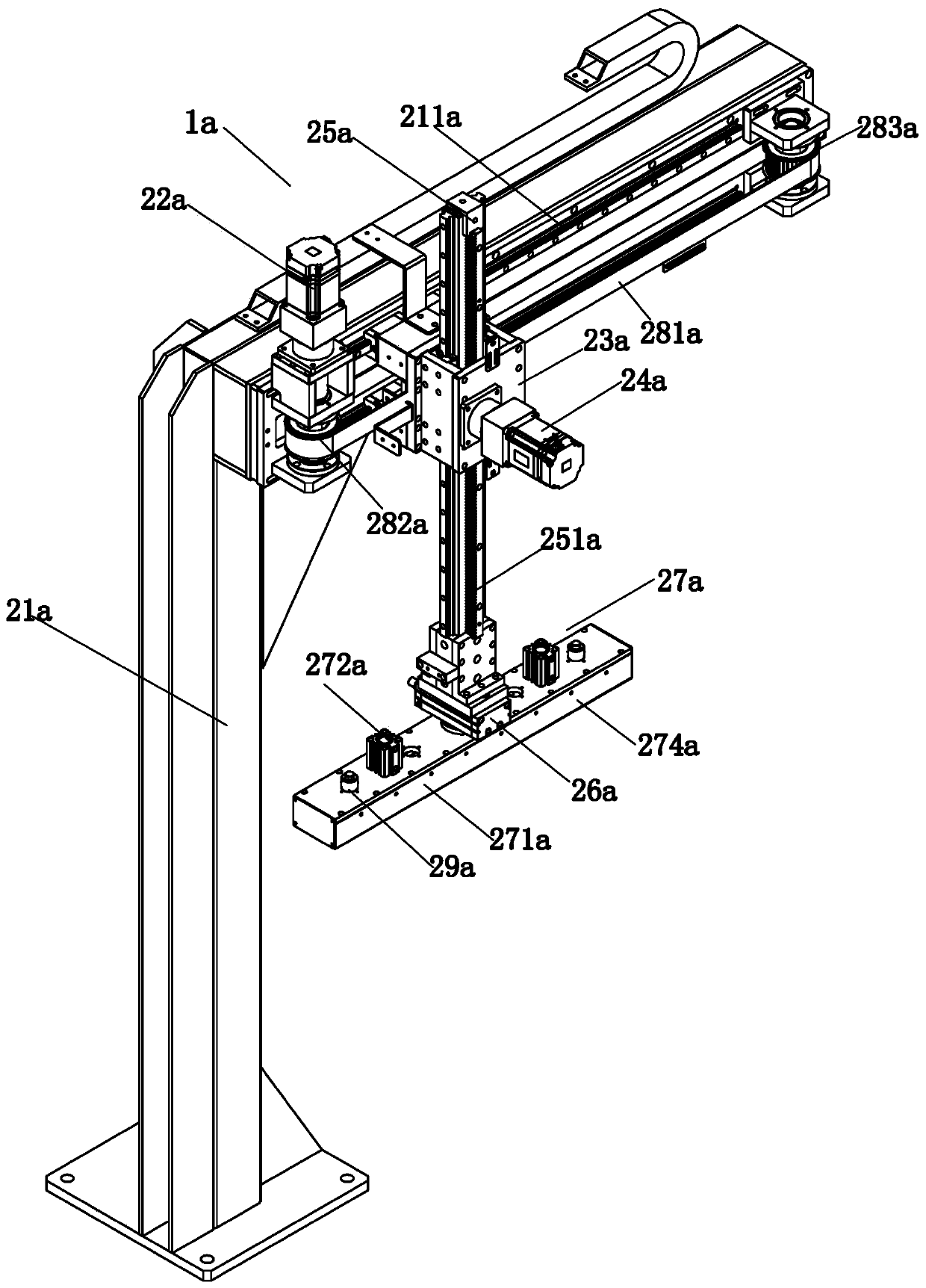

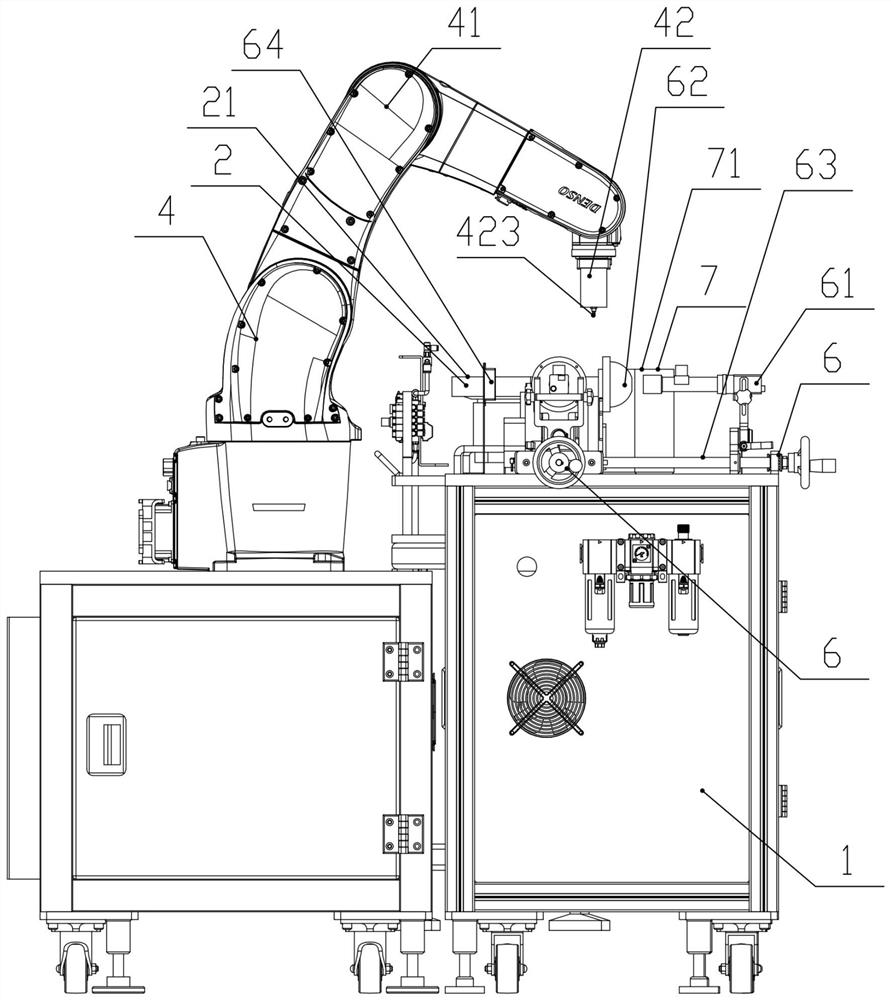

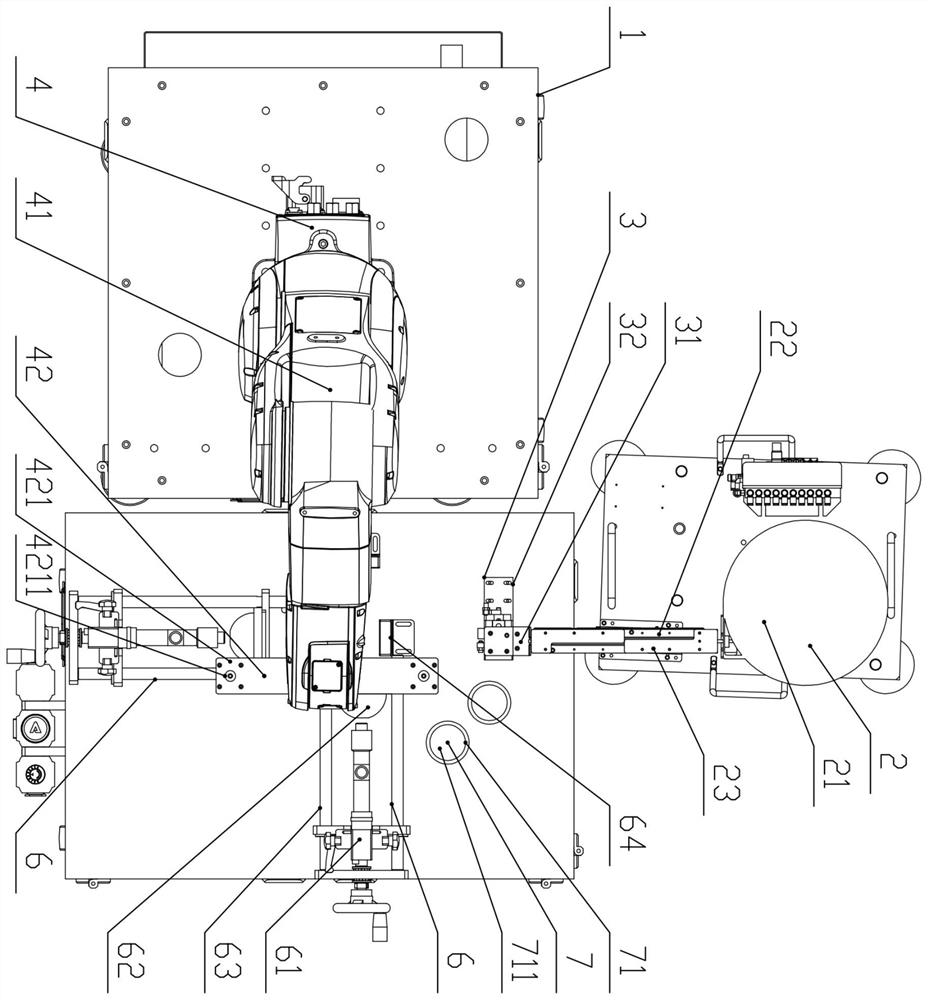

Robot assembling section for box body and cross beam of disinfection cabinet production line

PendingCN111376015AAutomate installationIncrease productivityMetal working apparatusProduction lineRobot hand

The invention relates to a robot assembling section for a box body and a cross beam of a disinfection cabinet production line. The robot assembling section comprises a feeding mechanical hand, a positioning conveying line, a secondary positioning table, a box body assembly line and a cross beam screw driving machine. The positioning conveying line is used for positioning the cross beam grabbed bythe feeding mechanical hand. Multiple first positioning air cylinders are arranged on the top of the secondary positioning table and are used for conducting secondary positioning on the cross beam. The box body assembly line is used for conveying the box body to the cross beam screw driving machine. The cross beam screw driving machine is used for positioning the box body and the cross beam and used for driving screws on the cross beam on the box body so that the cross beam can be fixed on the box body. By means of the robot assembling section for the box body and the cross beam of the disinfection cabinet production line, a cross beam tool vehicle, the feeding mechanical hand, the positioning conveying line, the secondary positioning table, a material sending mechanical hand, a cross beamfeeding robot, the box body assembly line and the cross beam screw driving machine are used for achieving the processes of cross beam feeding, positioning, applying, screw driving and the like, and therefore the cross beam can be automatically installed on the box body of a disinfection cabinet, the production efficiency is greatly improved, an the production cost is reduced.

Owner:FOSHAN SHUNDE KAISHUO PRECISION MOLD AUTOMATION TECH CO LTD

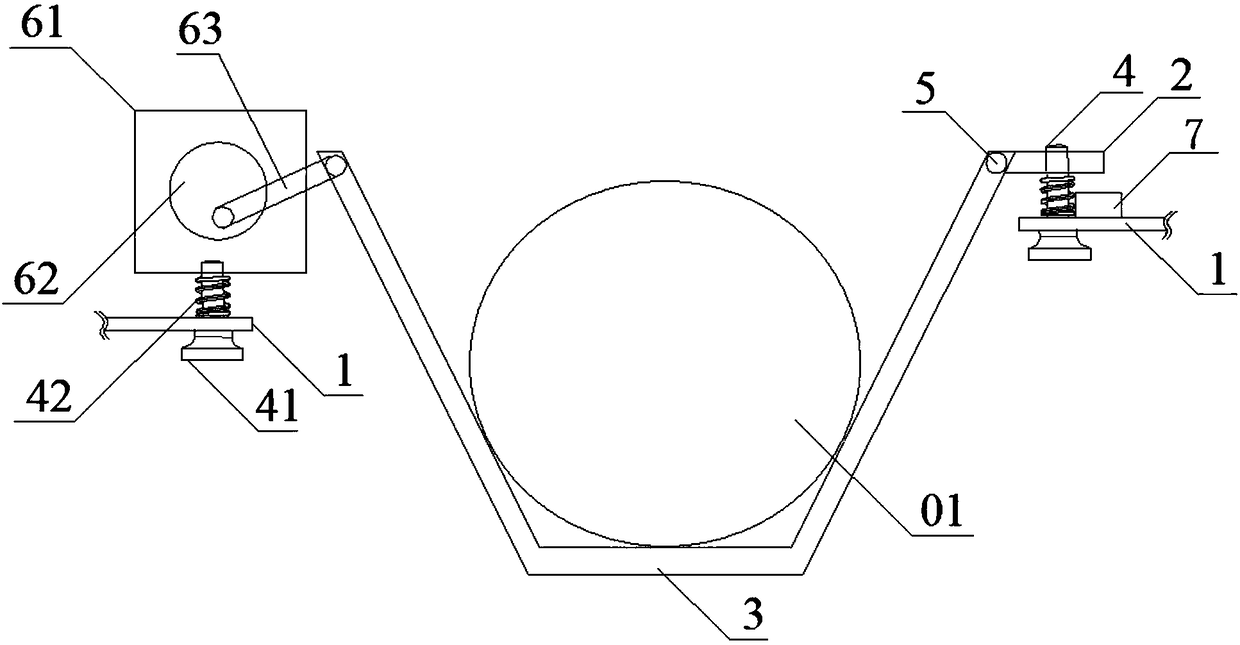

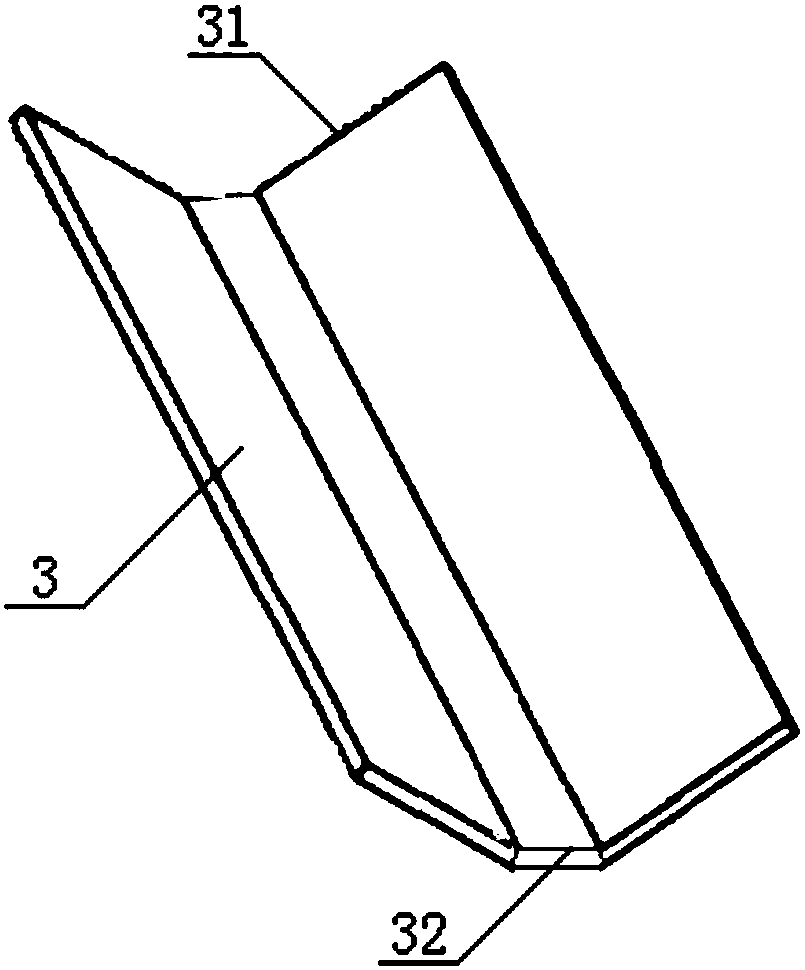

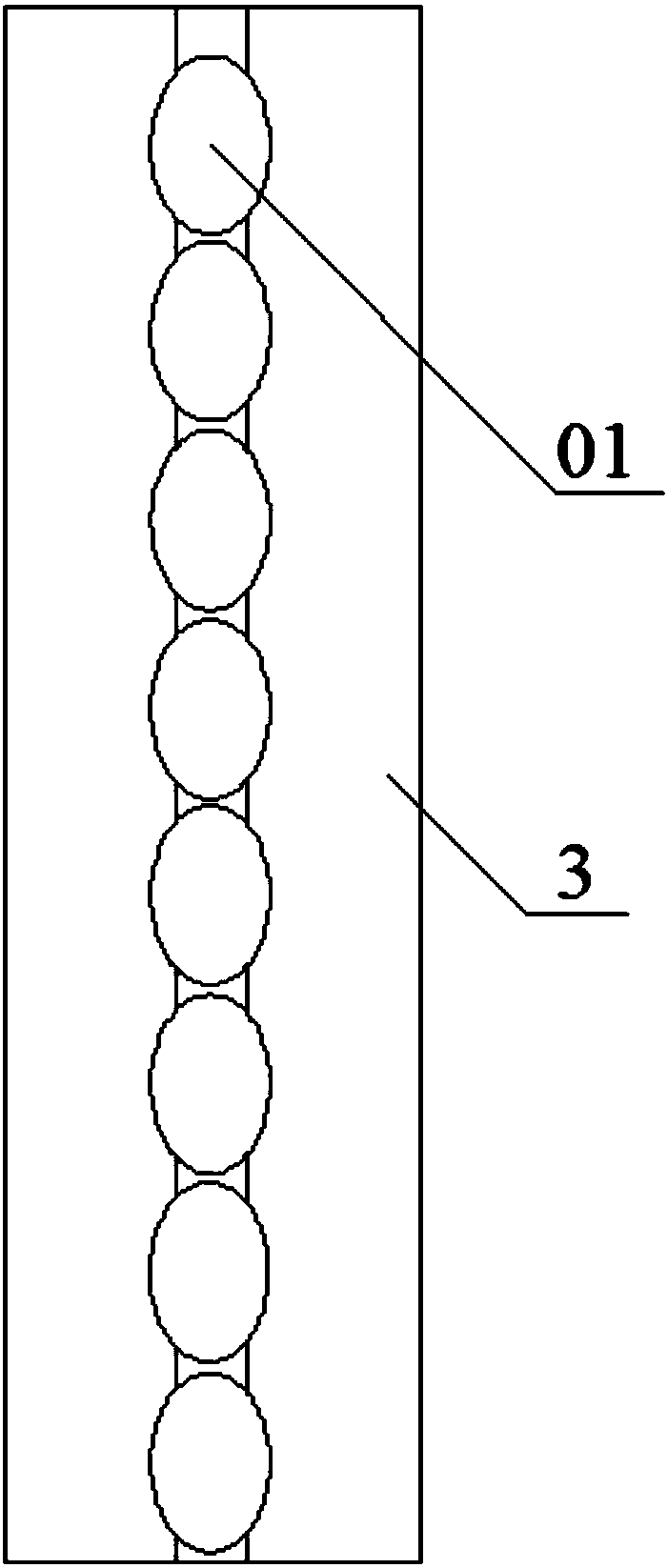

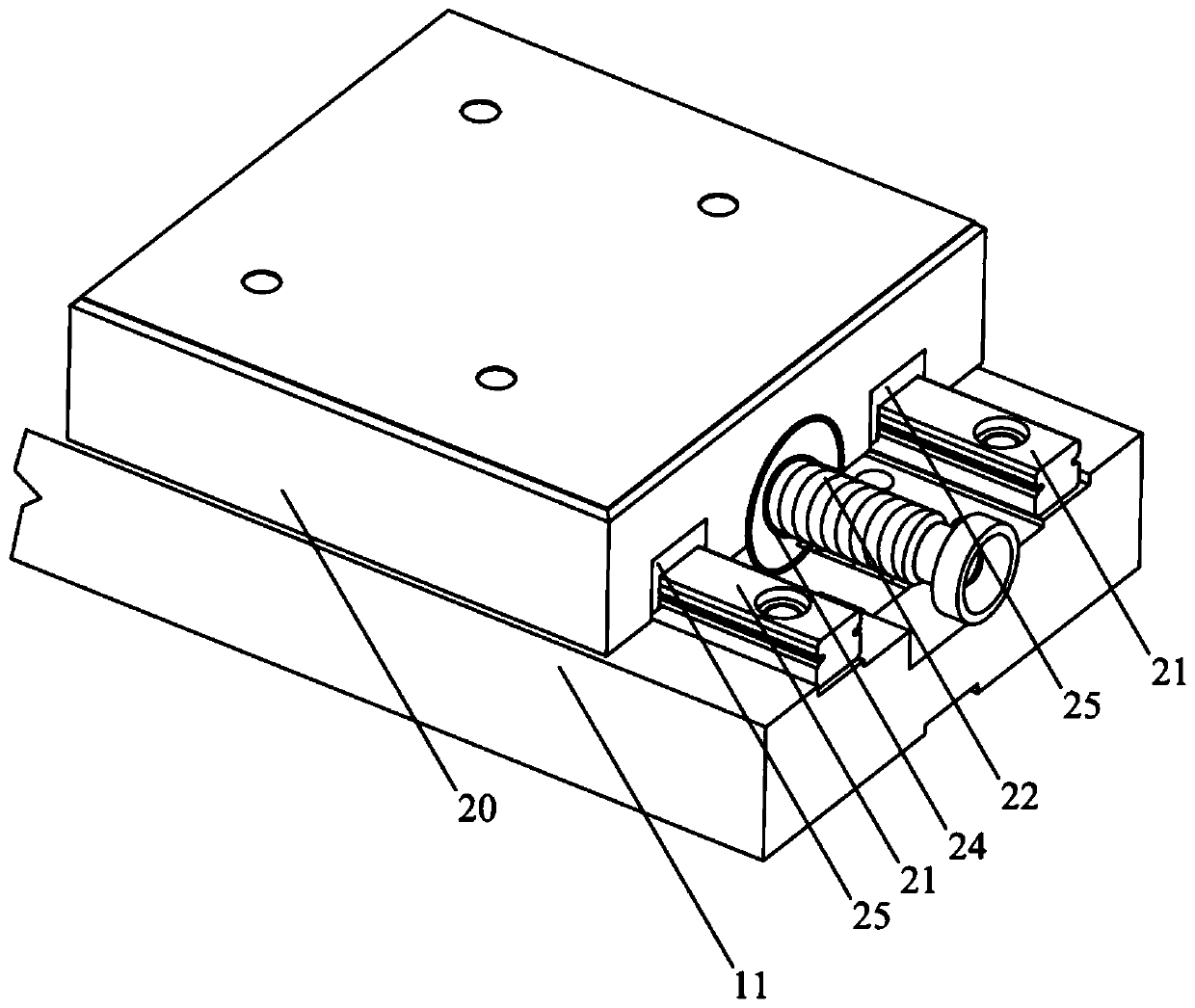

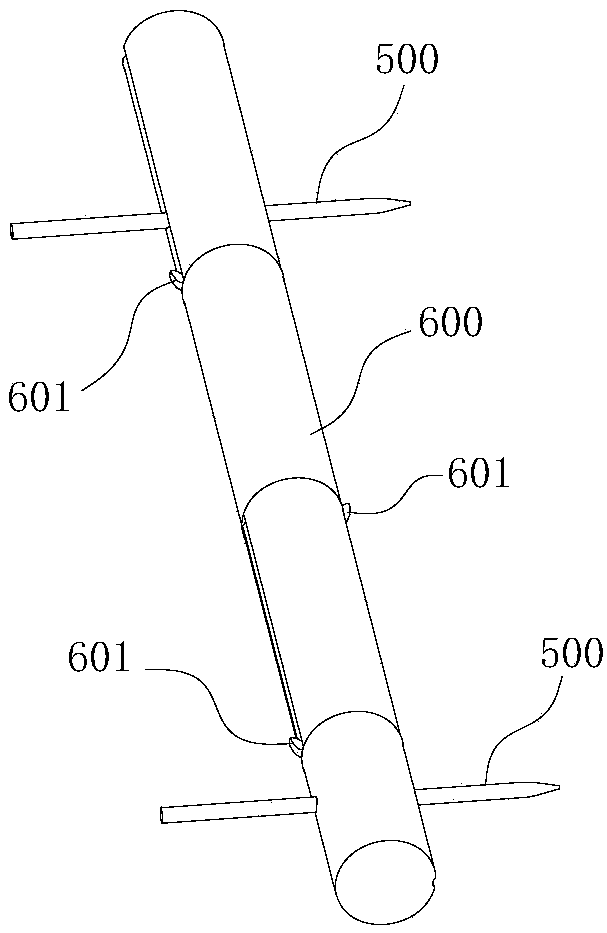

Seismic pendulum type conveying mechanism

PendingCN108275418ASimple structureEasy to operateJigging conveyorsConveyor partsLong axisEngineering

The invention relates to the technical field of food processing equipment, and discloses a seismic pendulum type conveying mechanism, and is used for conveying flat round or approximately pear-shapedarticles. The mechanism comprises racks, a fixed seat, a conveying groove, an elastic connecting mechanism and a driving mechanism used for driving the conveying groove to swing left and right, and avibration device used for driving the elastic connecting mechanism to vibrate; one side of the conveying groove is connected with the fixing base through a rotating shaft, the other side is hinged tothe driving mechanism, and the fixing base and the driving mechanism are connected with the racks through the elastic connecting mechanism; the conveying groove comprises an inlet and an outlet and isinclined from the inlet to the outlet; and the conveying groove and the object size conveyed by the conveying groove have to meet the following conditions that the two sides of the long axis direction of the article are correspondingly abutted against the inner walls of the two sides of the conveying groove, and the bottoms of the long-axis direction of the objects are in contact connection withthe bottom of the conveying groove. The mechanism has the advantages that the structure is simple, the operation is convenient, and the long shaft of the objects located in the mechanism can tend to be parallel in the vibration swinging process according to the length method of the conveying groove, so that directional conveying is achieved.

Owner:广州二十四度橙园智能装备科技有限公司

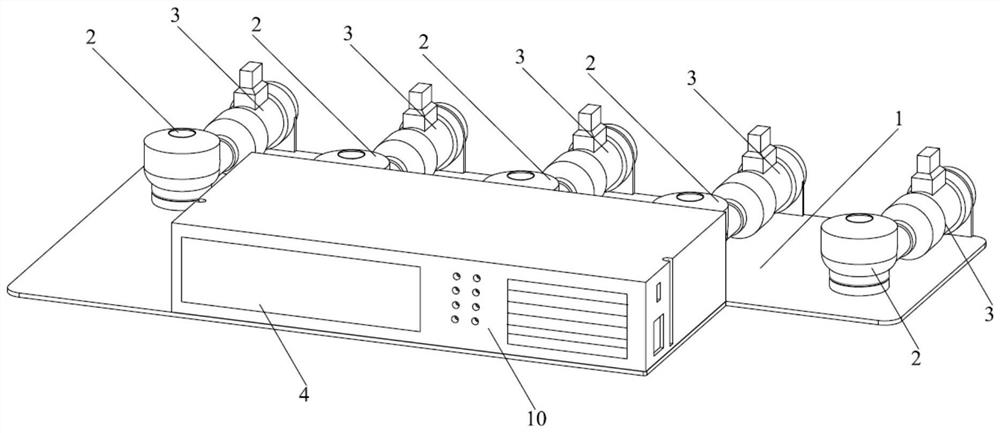

A centerless grinder automatic feeder

ActiveCN105522451BRealize directional deliveryAdjust the angular positionRevolution surface grinding machinesGrinding feedersVertical planeTransverse plane

Owner:新昌县东霸智能科技有限公司

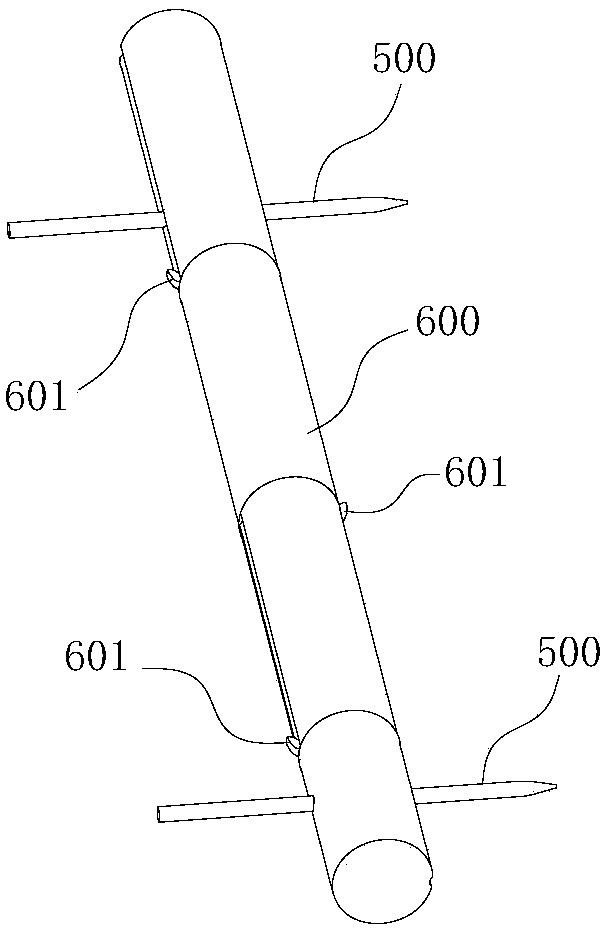

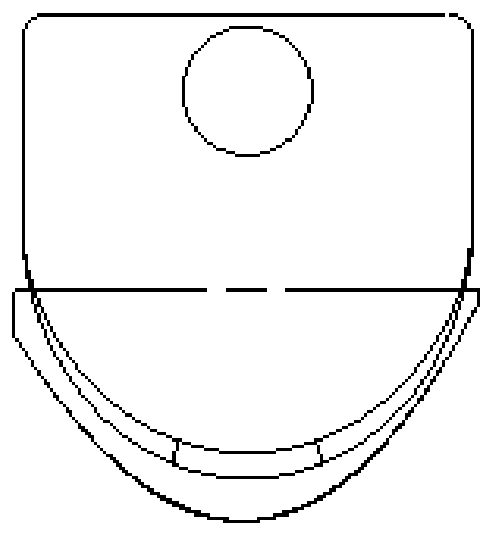

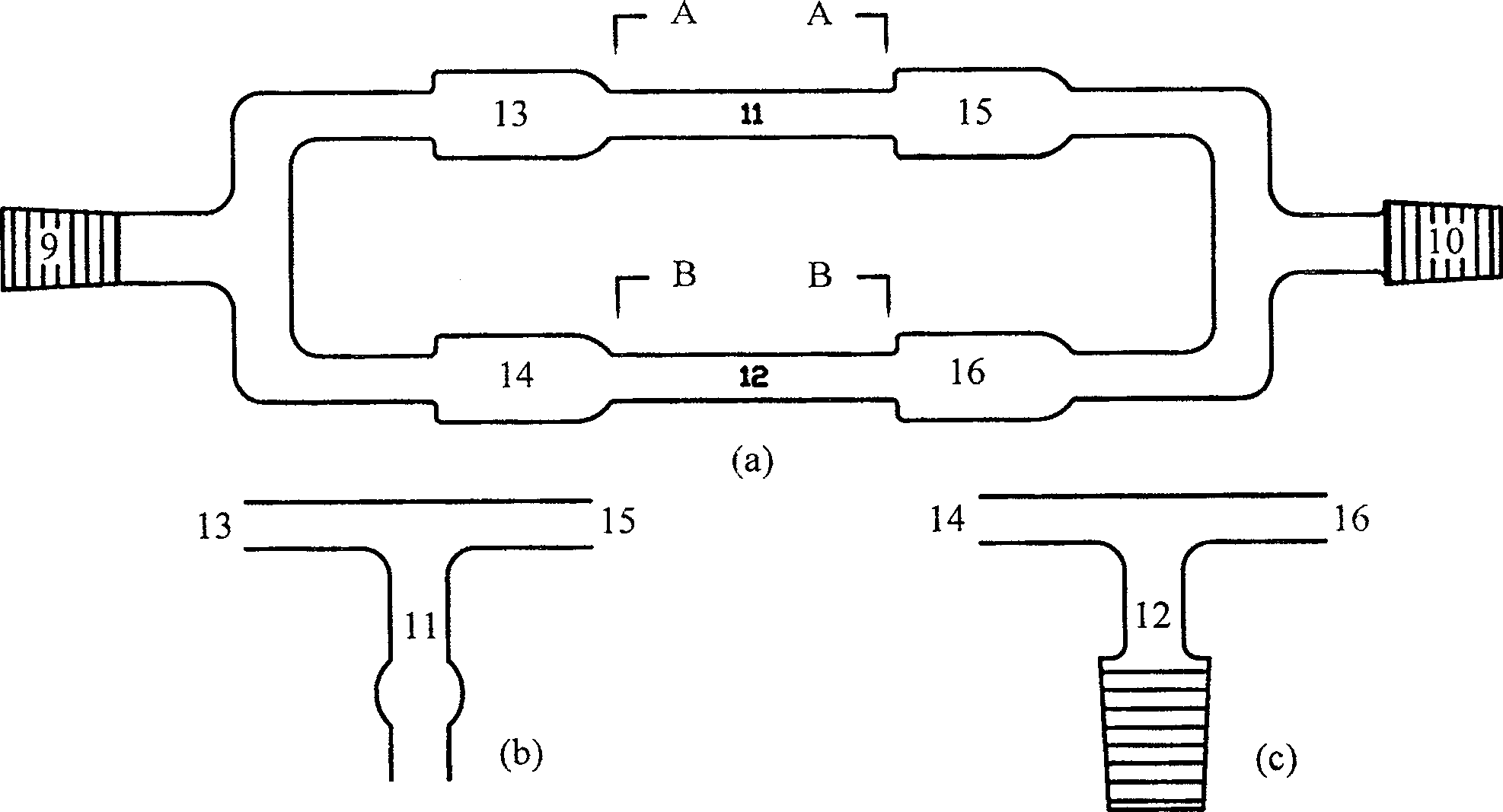

Garlic conveying device and sowing machine

PendingCN110476555AIntegrity guaranteedPromote growthPotato plantersFurrow making/coveringEngineeringUltimate tensile strength

The invention discloses a garlic conveying device and a sowing machine. The garlic conveying device comprises a vertical section, an arc section and a horizontal section which are communicated with one another in sequence, wherein the vertical section comprises a conveying cylinder of which the cross section is oval, and a seed pressing block is cooperatively arranged in the conveying cylinder, cooperatively provided with a tension spring, and used for pushing garlic seeds in the conveying cylinder to the arc section under the effect of the tension spring; a seed putting port is formed in theend, close to the arc section, of the horizontal section, the arc section is cooperatively provided with a seed collecting claw, and the seed collecting claw is used for conveying the garlic seeds inthe conveying cylinder into the seed putting port. Through the arrangement of a pushing device, garlic can be planted in the way that bulbil faces upwards, and the backs have the same orientation. Theproblems in the prior art that garlic is manually planted with a squatting gesture, and therefore, the efficiency is low, and the work intensity is large are solved.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

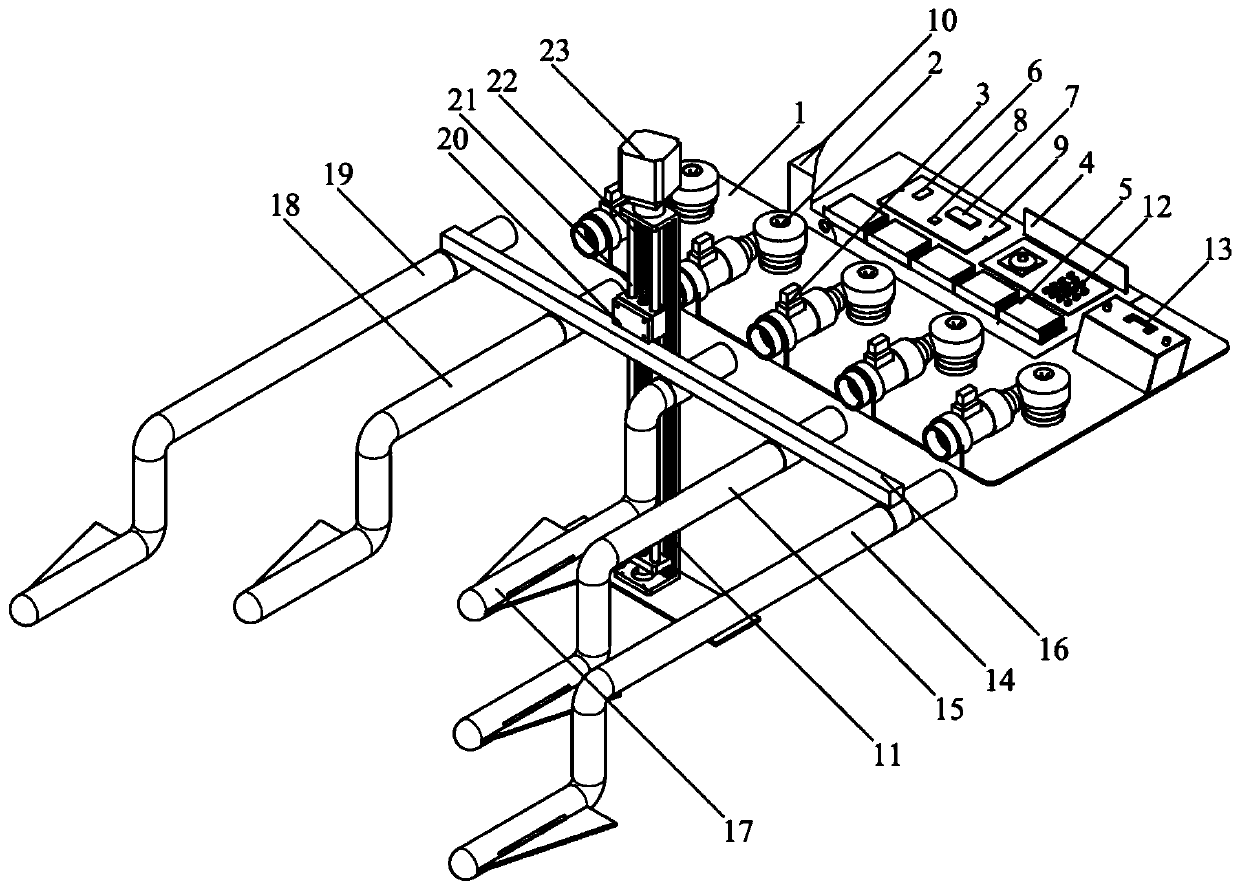

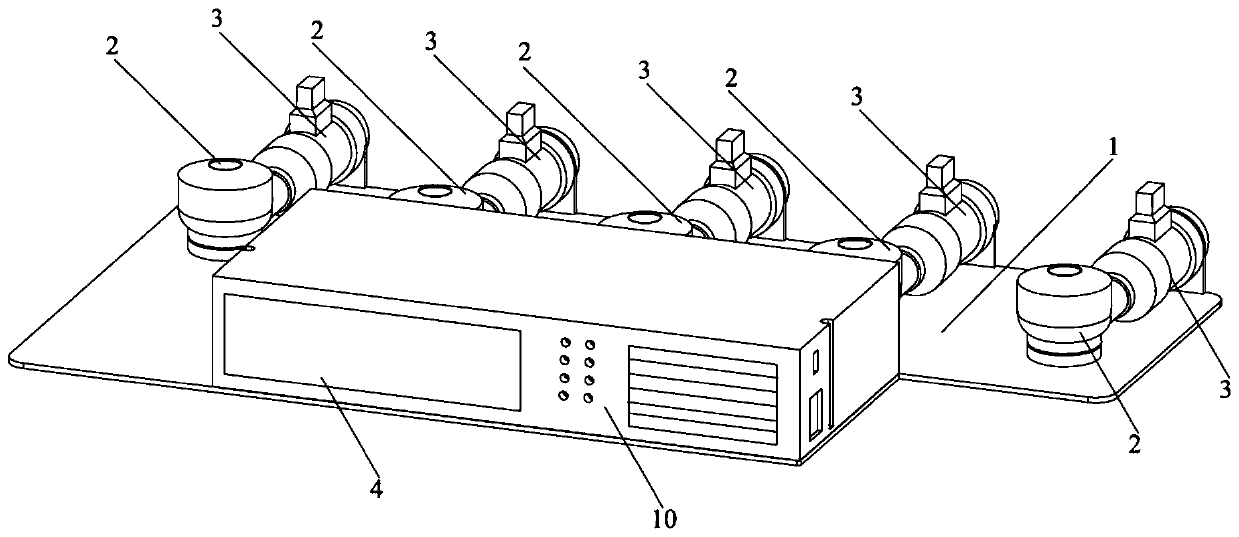

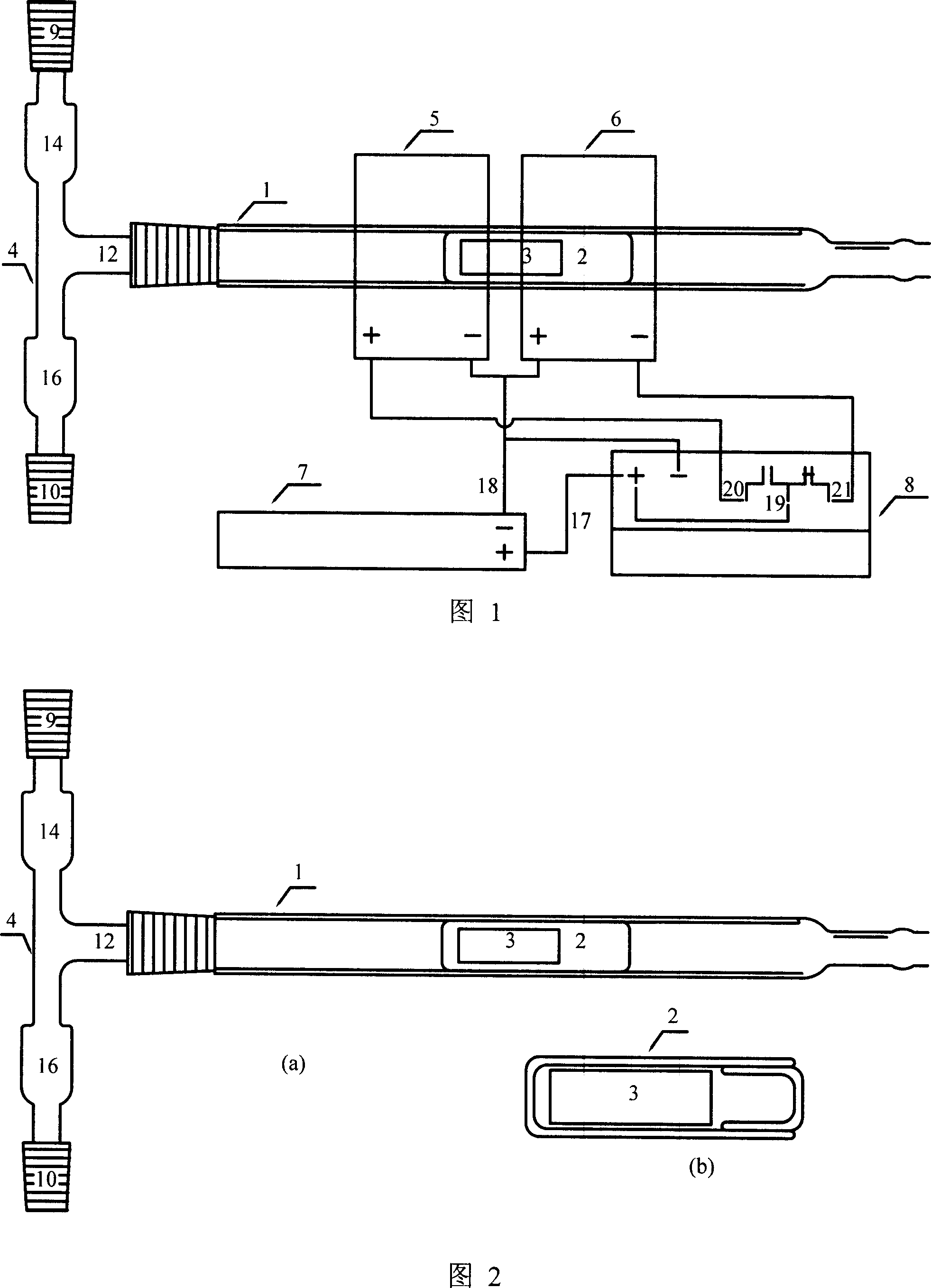

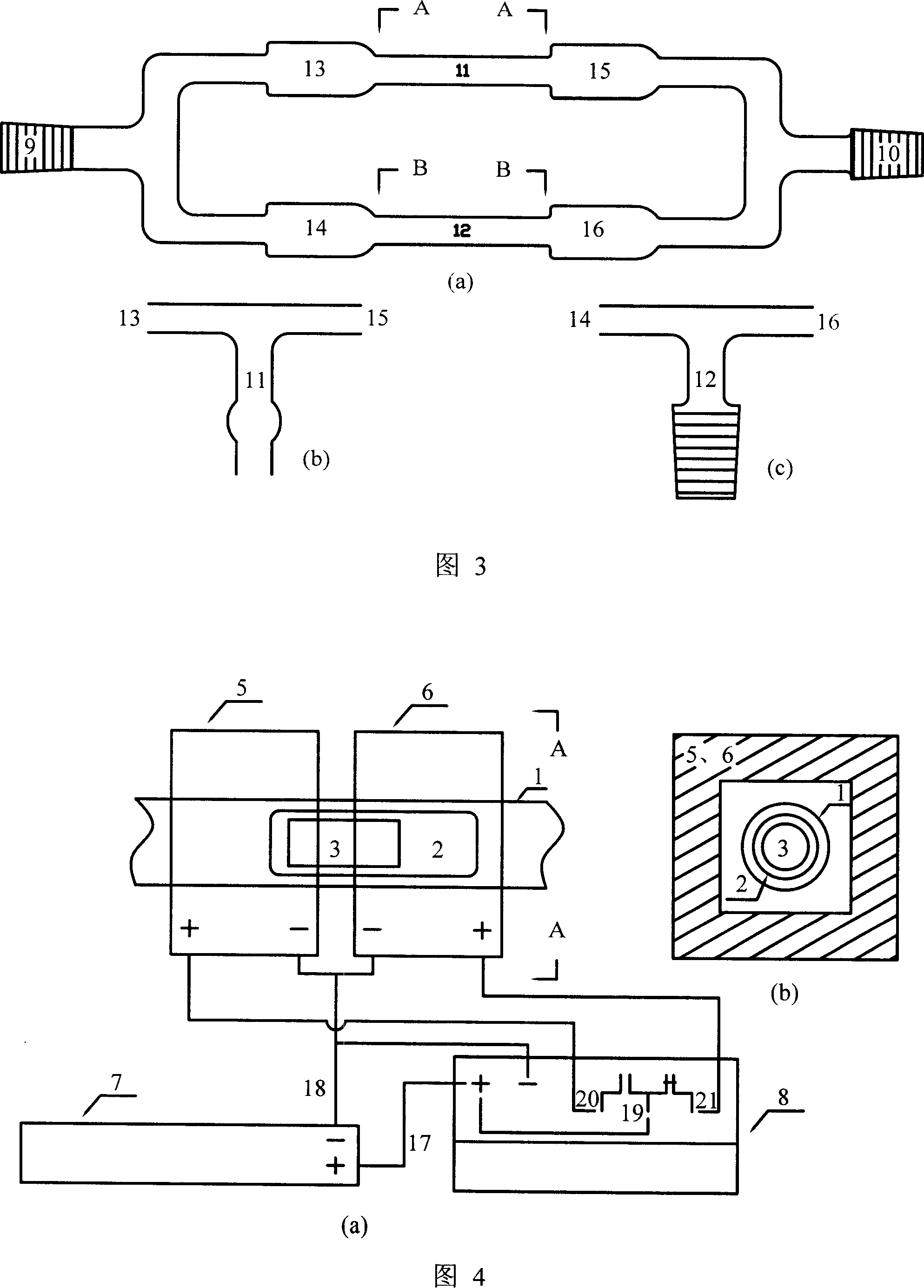

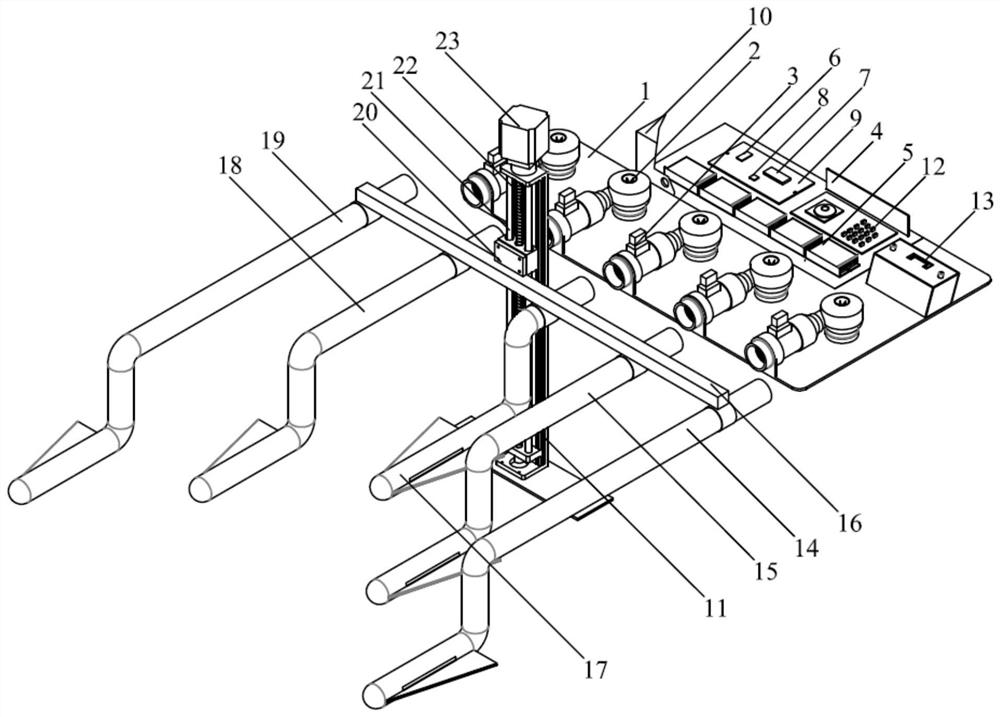

Pneumatic pollination control device and method for seed production of hybrid rice with large ration of male and female parents

ActiveCN111248081AEven and stable pollinationRealize directional deliveryAgriculturePlant genotype modificationLoop controlWireless transmission

The invention discloses a pneumatic pollination control device and method for seed production of hybrid rice with a large ration of male and female parents. The device comprises a bottom plate, fans,a wind speed sensor, an airflow adapter, fan drivers, a processing chip, a wireless transmission module, an electronic compass module, an integrated circuit board, an upper cover and a touch screen, wherein each fan is driven by independent fan driver; the wireless transmission module receives environmental natural wind speed and wind direction information; the electronic compass module determinesthe advancing direction of a pollination machine; after a controller calculates a target output wind speed, the processing chip calculates in real time according to a preset algorithm to obtain a corrected wind speed, so that pollen floats to a target area; the wind speed sensor detects the wind speed of a wind outlet and transmits the wind speed back to the processing chip in real time to form closed-loop control; and the pollination machine can still enable the operating pollen to move in a target state under the condition of the disturbance of external natural wind. The pneumatic pollination control device is simple and compact in overall structure, simple in interaction and high in reliability, and a fan control device with excellent performance is provided for the pneumatic pollination machine of the hybrid rice.

Owner:ZHEJIANG UNIV

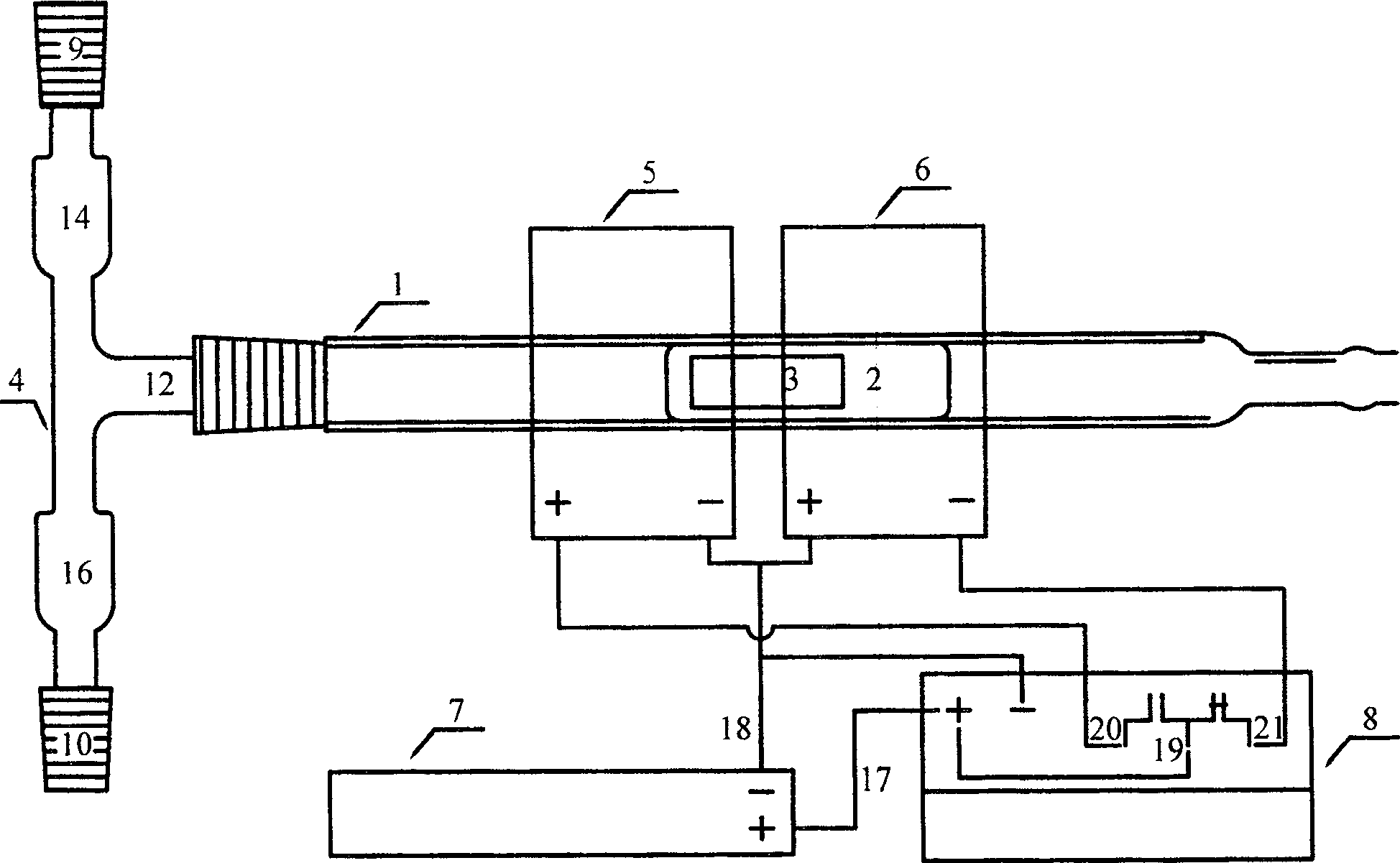

Glass magnetic force piston-type pump

ActiveCN101082330AImprove air tightnessImprove utilization efficiencyPumpsPositive-displacement liquid enginesMagnetic tension forceAir tightness

The invention discloses a glass magnetic piston; it includes glass part and electromagnetic driving part. For glass part, glass piston with fixed magnetic core in it, set in glass pump body. Left end of glass pump connects to the glass grinding port of glass combination unidirectional valve. Right end of glass pump connects to the glass interface of glass combination unidirectional valve. Glass pumps body through the first and second electromagnetic coil. The invention is used in driving gas cycle; it has good air tightness, easy connection with glass device, and can run under high suction pressure.

Owner:陕西中核交大超洁能源技术有限公司

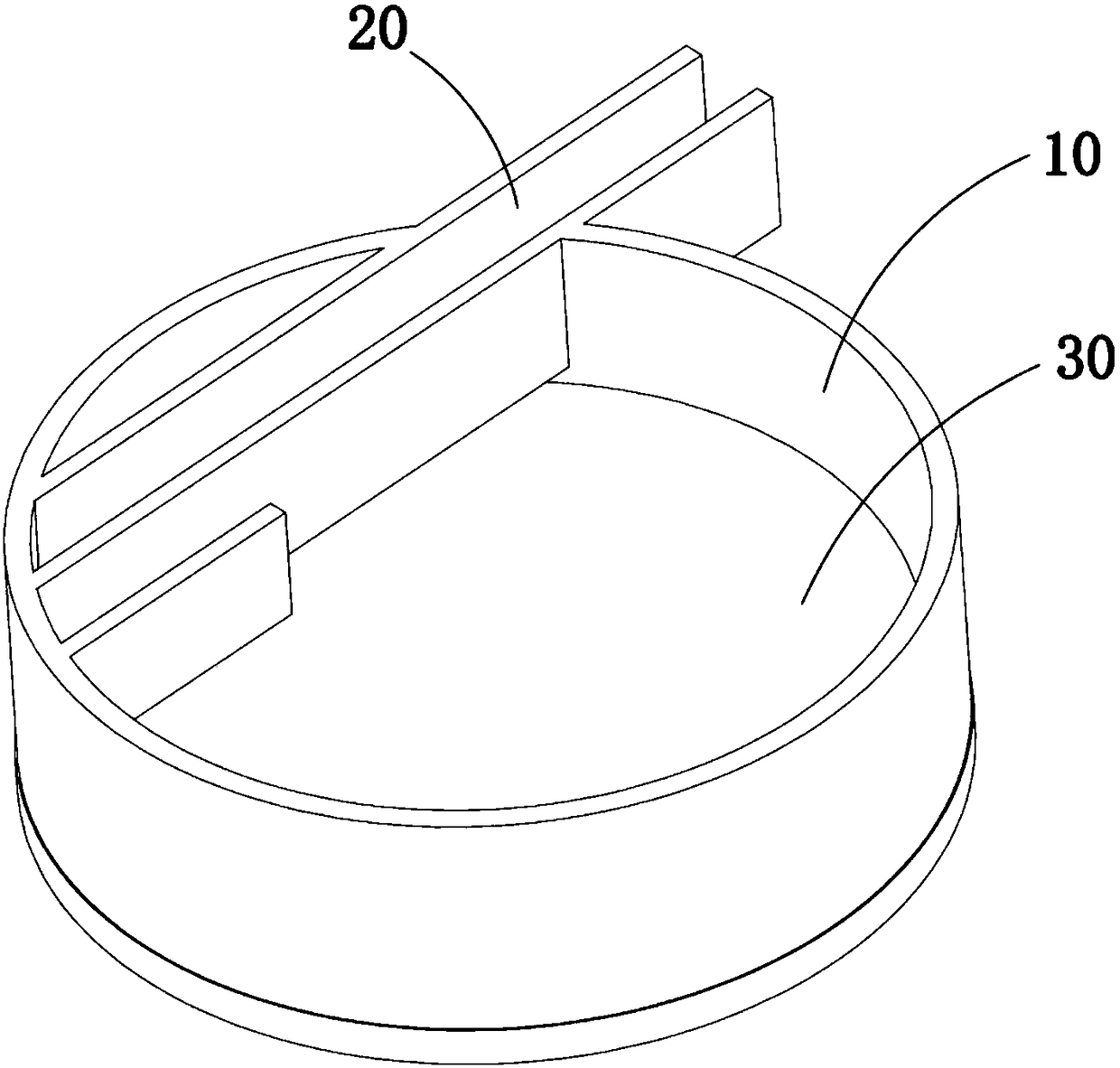

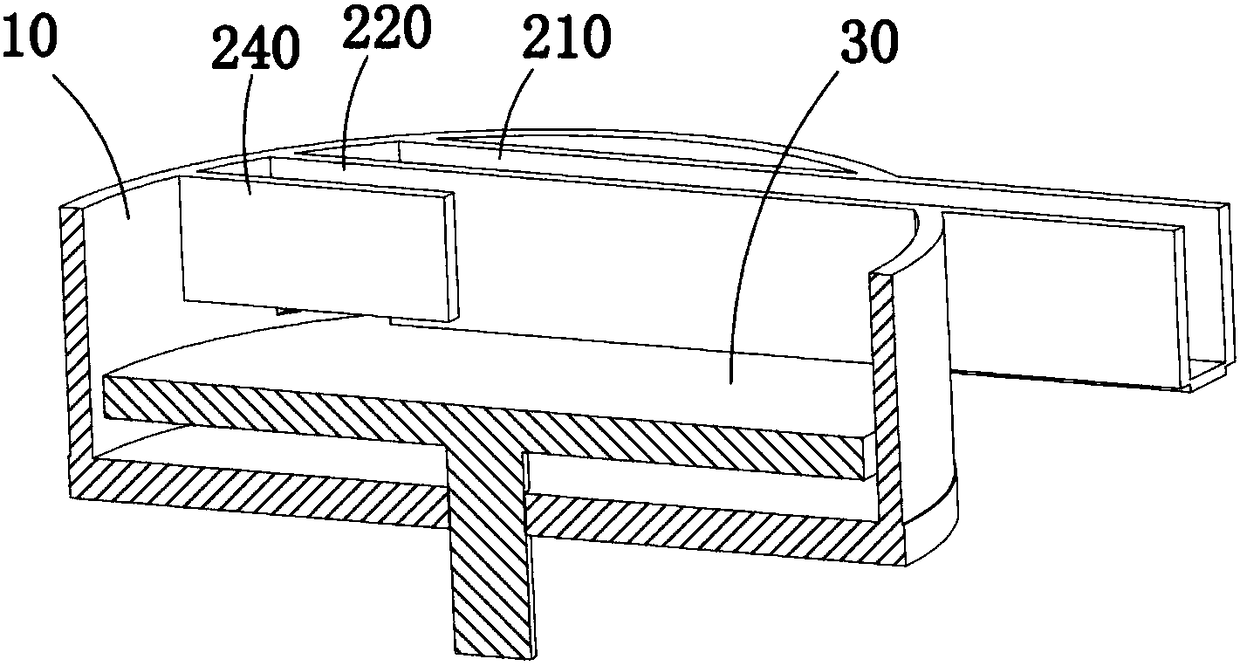

High-precision bearing outer ring orienteering smooth conveying technology

InactiveCN108116862AAchieve levelingRealize directional deliveryConveyorsConveyor partsEngineeringMechanical engineering

The invention discloses a high-precision bearing outer ring orienteering smooth conveying technology. The high-precision bearing outer ring orienteering smooth conveying technology includes the stepsthat a plurality of bearing outer rings are placed in a material-collecting tank, an opening of the material-collecting tank faces upward, the bottom of a groove of the material-collecting tank is provided with a base station which can rotate around a self-axis, and the material-collecting tank is further internally provided with a leveling mechanism which is located above the base station and isused for leveling the bearing outer rings; the leveling mechanism includes a first plate body and a second plate body which are arranged in parallel, the first plate and the second plate body are parallel to the diameter of the base station, and a material-carrying channel is formed by a gap between the first plate body and the second plate body; when the base station rotates around the self-axisand pushes the bearing outer rings toward the direction of the second plate body, the size of a notch limits the movement of the bearing outer rings, only one of the bearing outer rings can pass through the notch at a time, thereby achieving the leveling treatment for the bearing outer rings; and the bearing outer rings located at the material-carrying channel are pushed by the base station to move towards an delivery end of the material-carrying channel in the guide direction of the material-carrying channel.

Owner:安徽徽熳动力机械制造有限公司

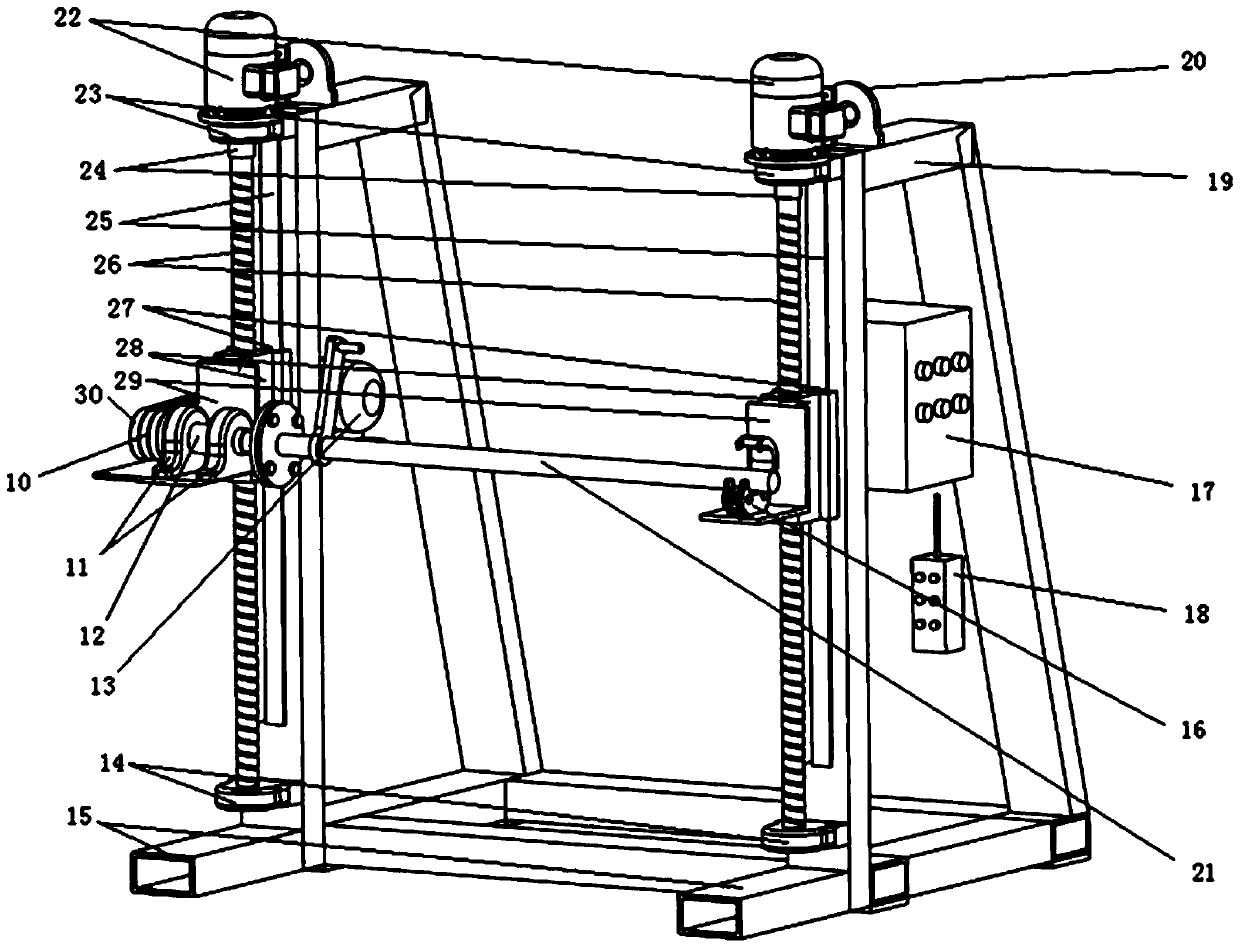

Automatic cable transfer system

ActiveCN105173881BRealize automatic deliveryRealize directional deliveryFilament handlingApparatus for laying cablesCable transmissionTransport system

The invention discloses an automatic cable transmission system, which includes a general controller, a cable reel, an automatic portable cable transmission robot, a metal rope sheath, a steel wire rope, a synchronous positioning traction device, a cable automatic lifting and laying device and a bracket, and the cable is automatically lifted and lowered. A cable reel is installed on the laying device, and a bracket is placed on the side of the automatic cable lifting and laying device, and several automatic portable cable transmission robots and a synchronous positioning traction device are fixed on the bracket in turn. There is a pay-off metal rope cover connected to the top, and the pay-off metal rope cover is connected with the cable wound on the cable reel. The cable automatic lifting and laying device, the automatic portable cable transmission robot, and the synchronous positioning traction device are respectively connected with the master controller. The invention realizes the fully automatic operation of the whole cable laying process, saves time and effort, has extremely high laying efficiency and low cost.

Owner:博锋智能科技(大连)有限公司

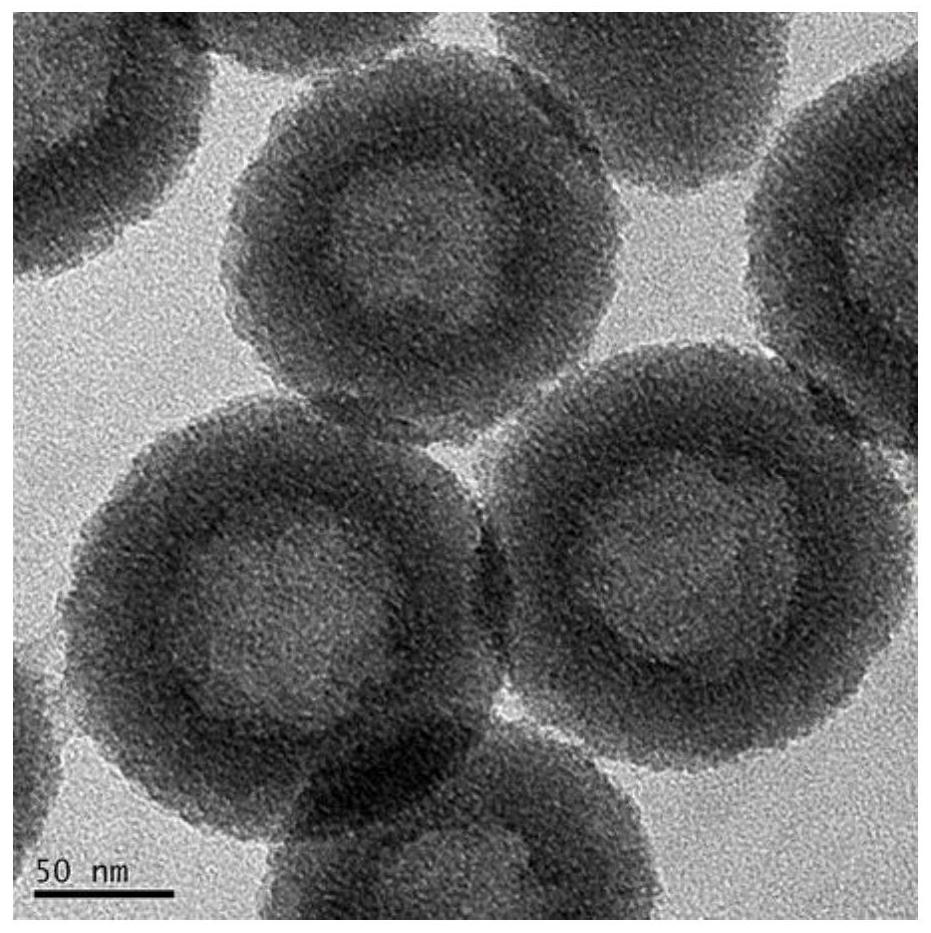

Targeted nano-composite as well as preparation method and application thereof

PendingCN114425087AHas the effect of tumor targeting therapyHigh selectivityMaterial nanotechnologyNanomagnetismRadio isotopesTumor target

The invention discloses a targeted nano-composite and a preparation method and application thereof, and the targeted nano-composite comprises a nano-carrier, biological targeted molecules, radioisotopes and a synergistic treatment functional substance; the biological targeting molecule is in coupling connection with the nano-carrier; the synergistic treatment functional substance is loaded in the nano-carrier; the radioactive isotope is carried on the nano-carrier. The targeted nano compound provided by the invention has a tumor targeted treatment effect, and by modifying an existing anti-cancer nano preparation, the selectivity of a drug to tumor tissues is improved, directional delivery and gradual release of the drug are realized, the metabolic kinetics and physicochemical properties of the drug are improved, and the toxic and side effects of the drug are reduced. Meanwhile, combined treatment of radioisotope treatment and chemotherapy or photothermal treatment or photodynamic treatment or sonodynamic treatment or magnetic thermal treatment can be achieved, and the problem that a good effect is difficult to generate through single chemotherapy is solved.

Owner:CIXI INST OF BIOMEDICAL ENG NINGBO INST OF MATERIALS TECH & ENG CHINESE ACAD OF SCI +1

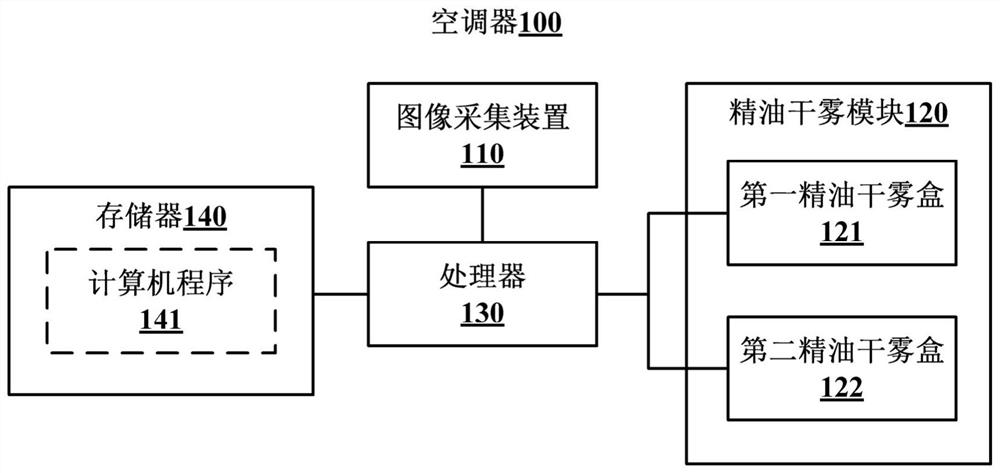

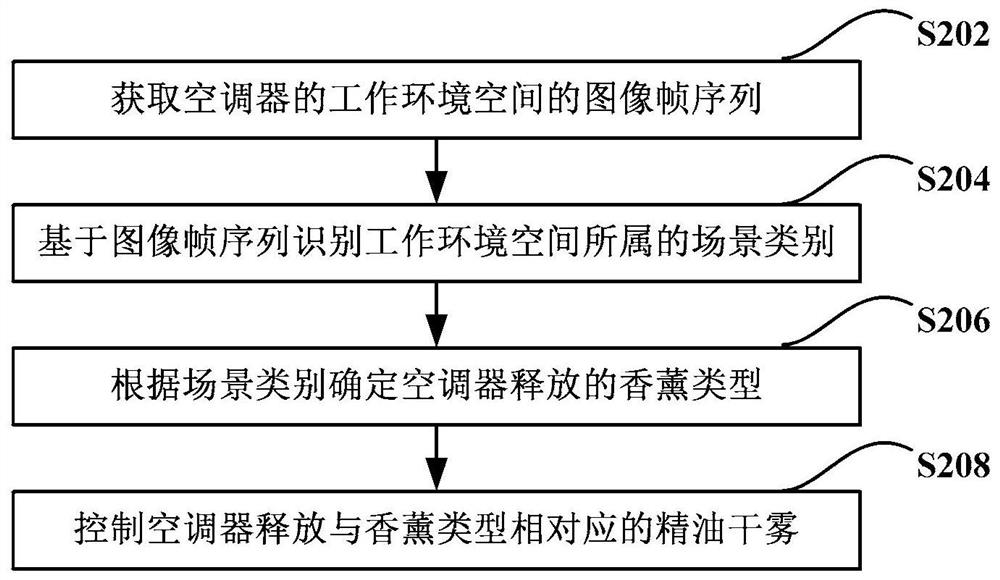

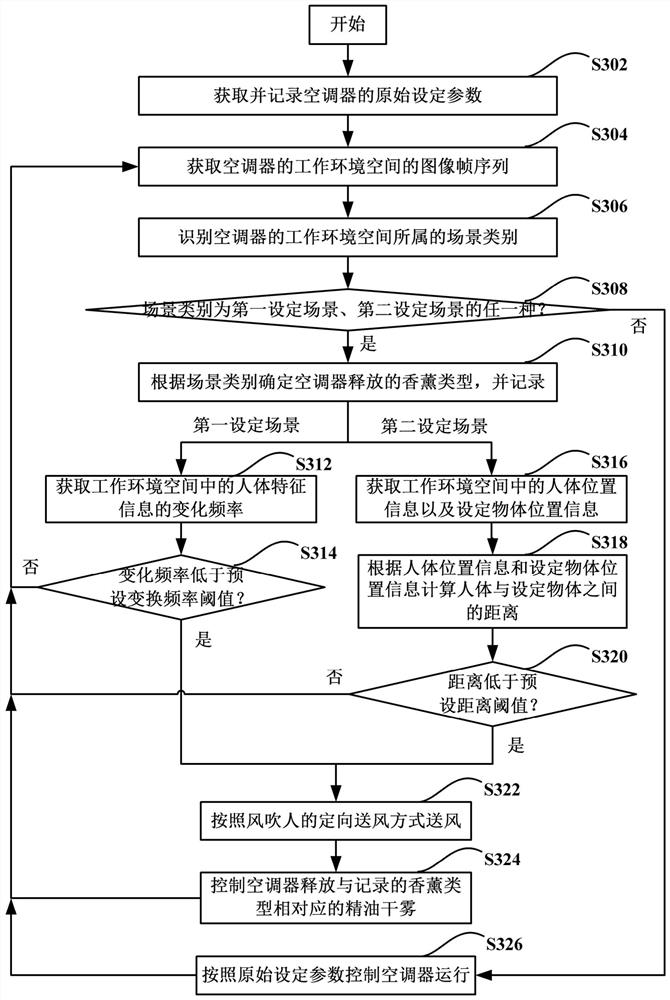

Air conditioner with aromatherapy function and method for adjusting environment

ActiveCN112268354BSatisfy Aromatherapy NeedsImprove user experienceMechanical apparatusLighting and heating apparatusAromatherapyProcess engineering

The invention provides an air conditioner with aromatherapy function and an environment adjustment method. The environment adjustment method includes: acquiring an image frame sequence of a working environment space of an air conditioner; identifying a scene category to which the working environment space belongs based on the image frame sequence; determining the type of aromatherapy released by the air conditioner according to the scene category; The corresponding essential oil dry mist. The solution of the present invention can release the essential oil dry mist suitable for the scene category without any operation performed by the user, so that the aroma of aromatherapy can be effectively controlled, and the level of intelligence is improved while avoiding waste.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +2

Calibration method of sugarcane seed stem buds

The invention belongs to the technical field of agricultural production planting and agriculture product processing, and particularly relates to a calibration method of sugarcane seed stem buds. Calibration objects are added on sugarcane seed stems through a sugarcane seed stem bud calibration system; the calibration objects and the sugarcane seed stem buds are distributed according to a specificposition relation; the calibration objects can be captured or identified through a sower. As the calibration objects and the sugarcane seed stem buds are distributed according to a specific position relation, and the calibration objects can be captured or identified through the sower, sowing equipment can recognize positions of the buds on the sugarcane seed stems, and further realizes the directional conveying and sowing of the sugarcane seed stems.

Owner:ANQING WANCAO QIANMU AGRI TECH

A kind of unidirectional long hemp fiber prepreg production line and production process

ActiveCN113954392BReduce processing difficultyShort processCarding machinesCoatingsProcess engineeringManufacturing line

The invention discloses a unidirectional long hemp fiber prepreg production line and a production process. The production line is equipped with feeding device, fiber spreading device, drafting station, shaping station, laminating station, hot pressing device and conveying roller in sequence according to the fiber conveying direction. The present invention innovatively develops a set of unidirectional long hemp fiber prepreg production line and process using long hemp sliver as raw material, which is simple and easy to implement. Since long hemp sliver is used as feeding raw material, the processing of long hemp sliver is less difficult and the process flow It is short and fast, which can significantly reduce the preparation cost of prefabricated reinforcement materials; the output width and thickness can be designed, and the long hemp fiber tape and the long hemp fiber inside the prepreg have high straightness; suitable for large quantities of unidirectional long hemp fiber The continuous production of tapes and prepregs fills the gap in the industry.

Owner:TIANJIN POLYTECHNIC UNIV

Glass magnetic force piston-type pump

ActiveCN100510393CImprove air tightnessImprove utilization efficiencyPumpsPositive-displacement liquid enginesMagnetic tension forceEngineering

Owner:陕西中核交大超洁能源技术有限公司

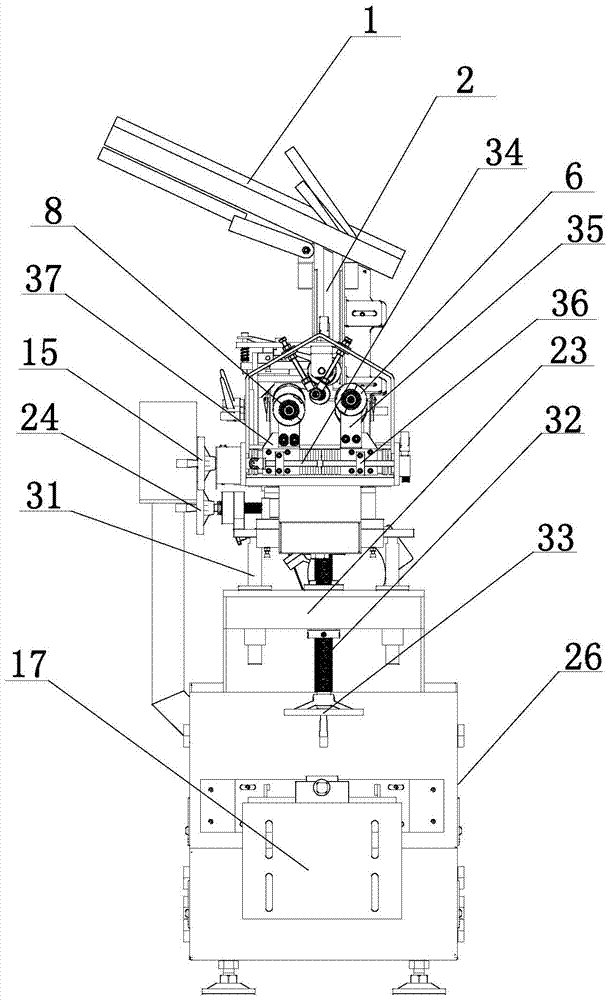

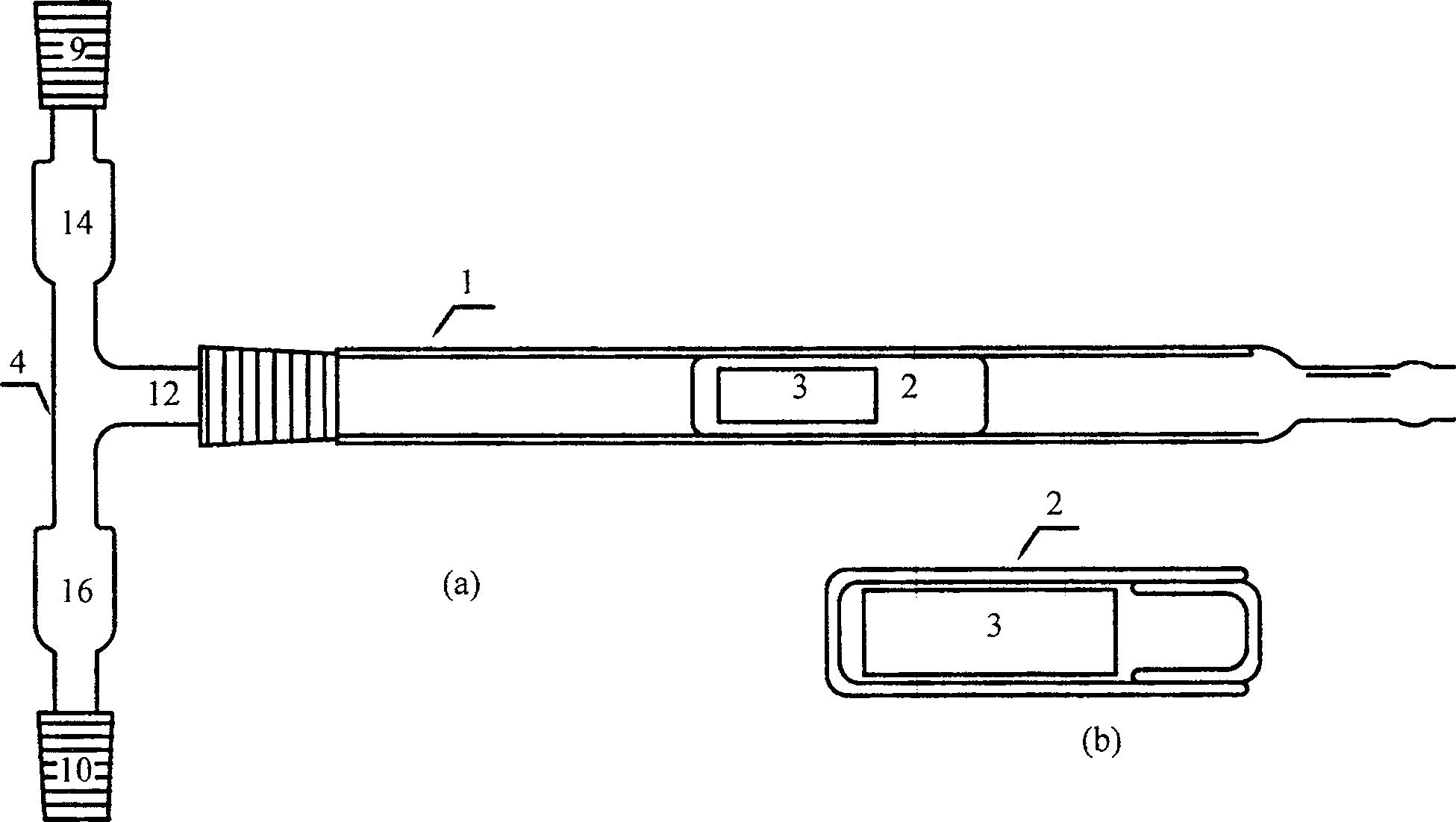

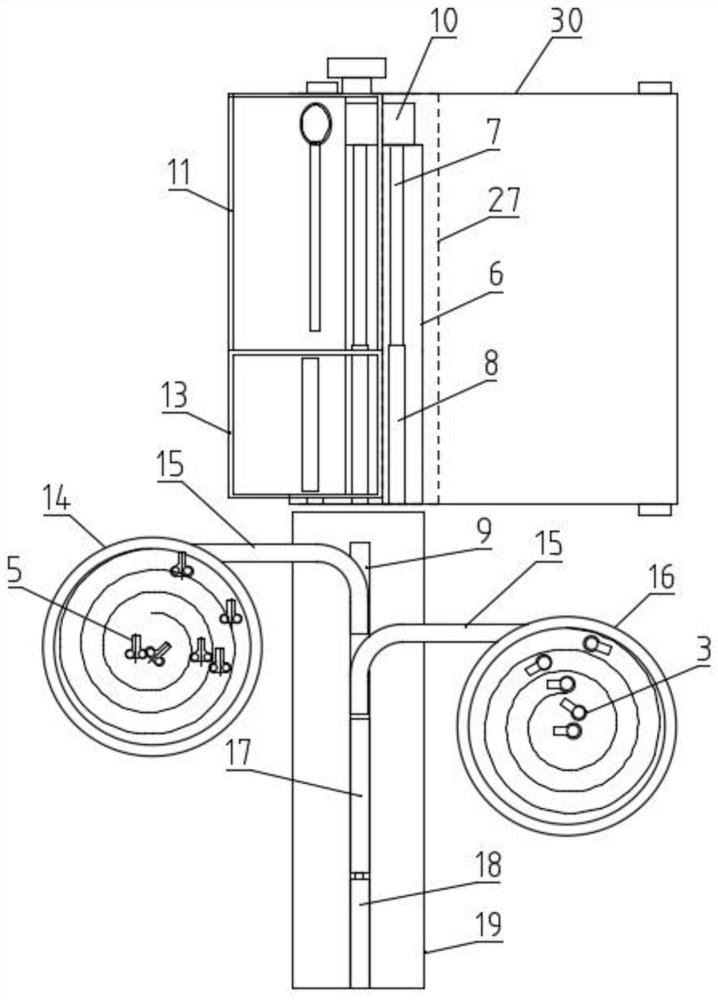

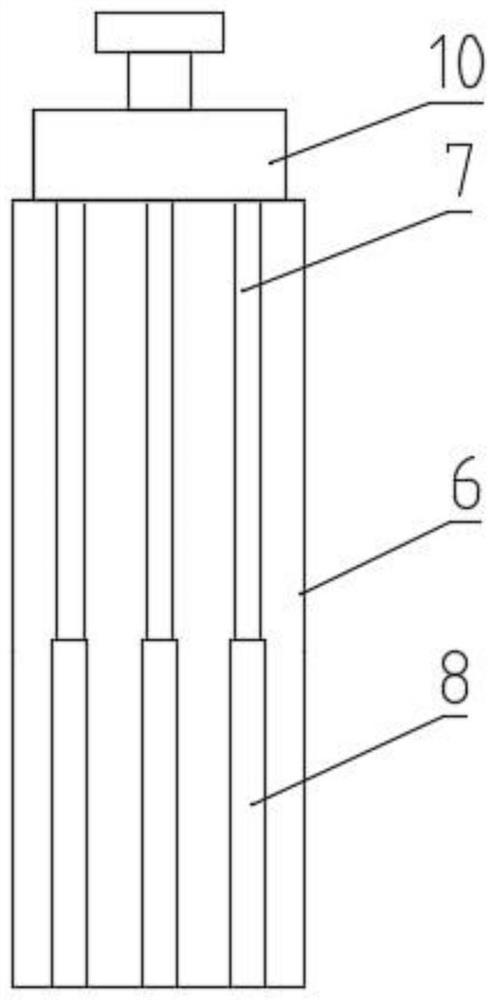

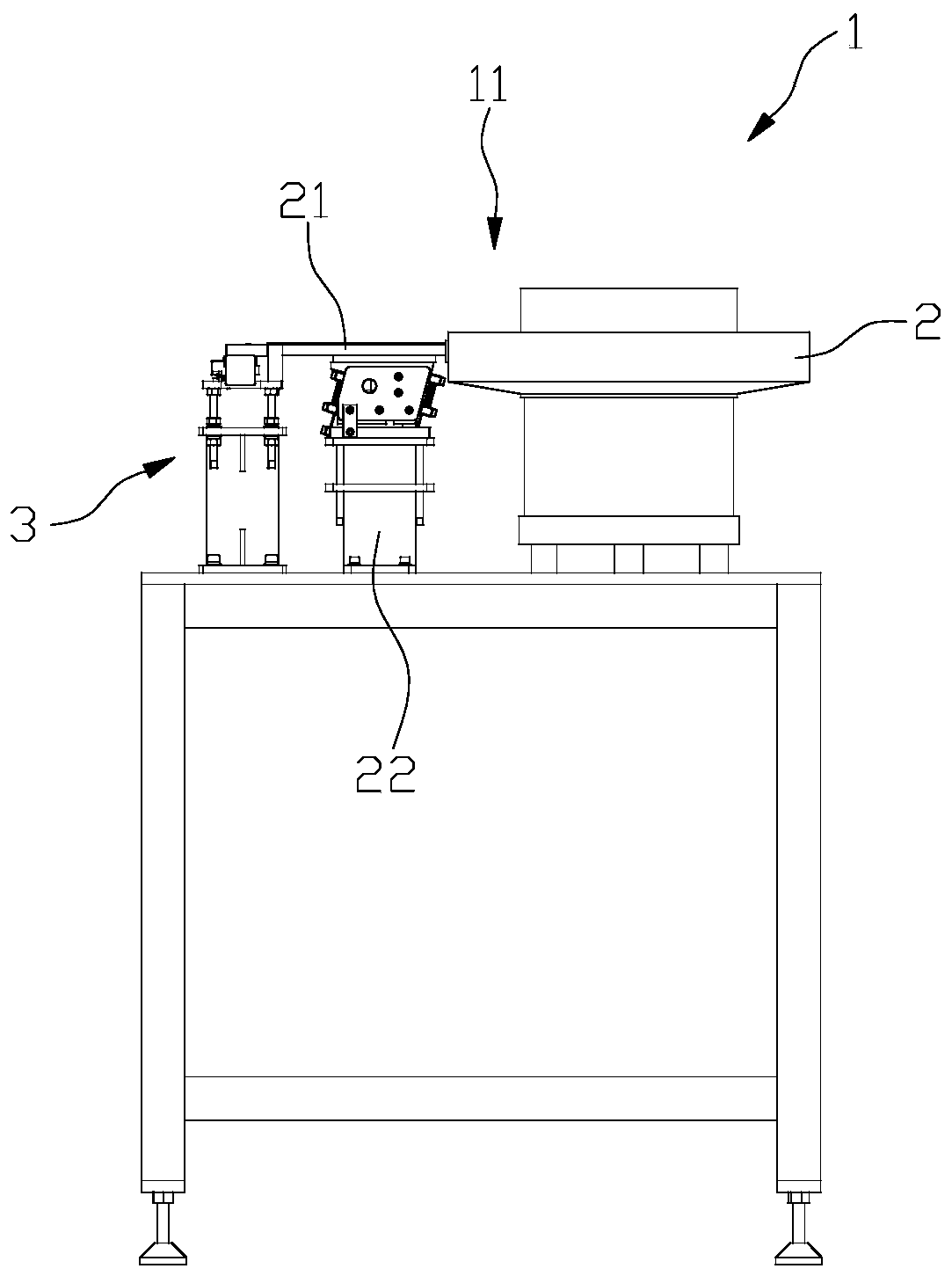

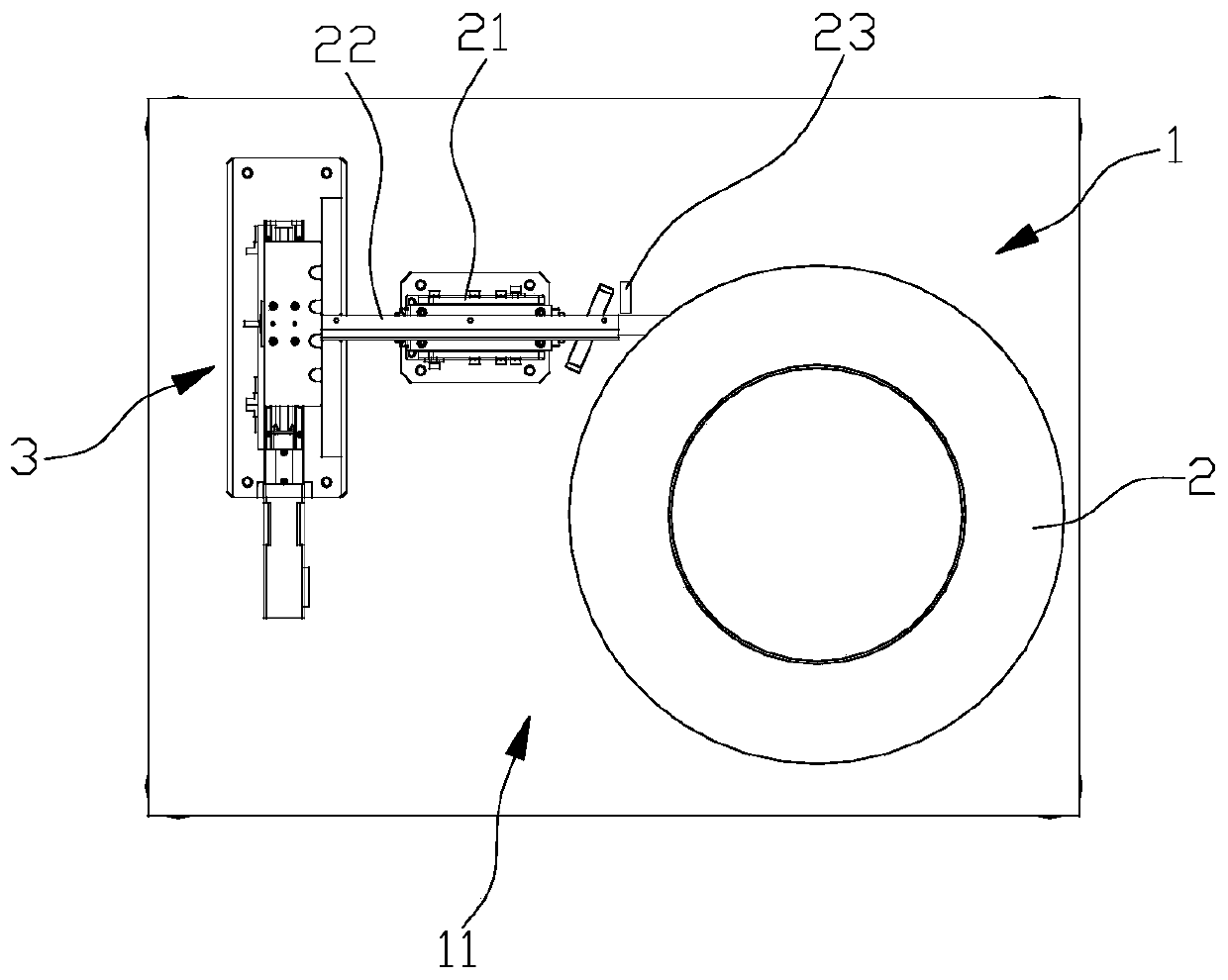

Automatic assembly equipment for disposable fetcher for laparoscopic surgery

ActiveCN114102126ARealize directional deliveryRealize automatic U-turn conveyingAssembly machinesMetal working apparatusApparatus instrumentsConveyor belt

The invention relates to the technical field of medical instruments, in particular to automatic assembly equipment for disposable fetchers for laparoscopic surgery, which comprises a roller, and a first hopper and a second hopper are arranged on the input side of the roller; a first groove and a second groove are formed in the roller; a positioning assembly table is arranged below the roller; a first positioning groove is formed in one end of the positioning assembly table, and a sliding seat is arranged at the other end of the positioning assembly table and provided with a second positioning groove; the positioning assembly table and the sliding seat are arranged in two halves, and the first positioning groove and the second positioning groove are arranged in two halves; the positioning assembly table is connected with a transverse movement driving piece; a discharging conveyor belt is arranged below the positioning assembly table; a butt joint seat is arranged at one end of the positioning assembly table; a pushing groove is formed in the butt joint seat; the pushing groove is connected with the first vibration disc and the second vibration disc; and a pushing block is arranged at the rear end of the pushing groove. According to the automatic assembly device, the problem of automatic assembly of the disposable fetcher is solved, rapid and automatic assembly of the disposable fetcher is achieved, the production efficiency is improved, and the product quality is ensured.

Owner:岳阳职业技术学院

Device and method for differential speed sorting and secondary uniform cutting of broccoli

ActiveCN110682342BRealize directional deliverySecondary slicing worksMetal working apparatusGradingBroccoli raabEngineering

Owner:ZHEJIANG SCI-TECH UNIV

A kind of targeted pharmaceutical composition and application thereof loaded with amphotericin b and doxorubicin

ActiveCN110801433BGood biocompatibilityRealize directional deliveryOrganic active ingredientsAntiparasitic agentsSide effectCyclodextrin

Owner:JIANGNAN UNIV

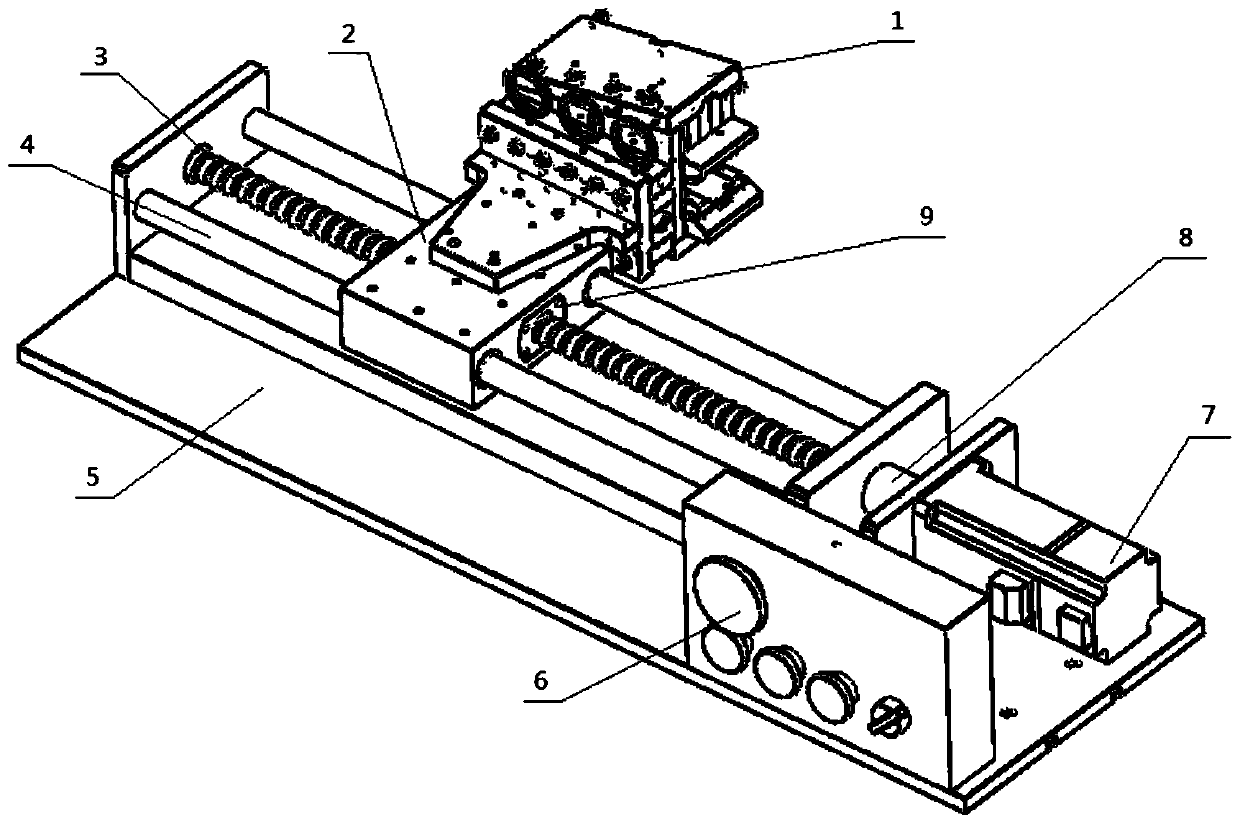

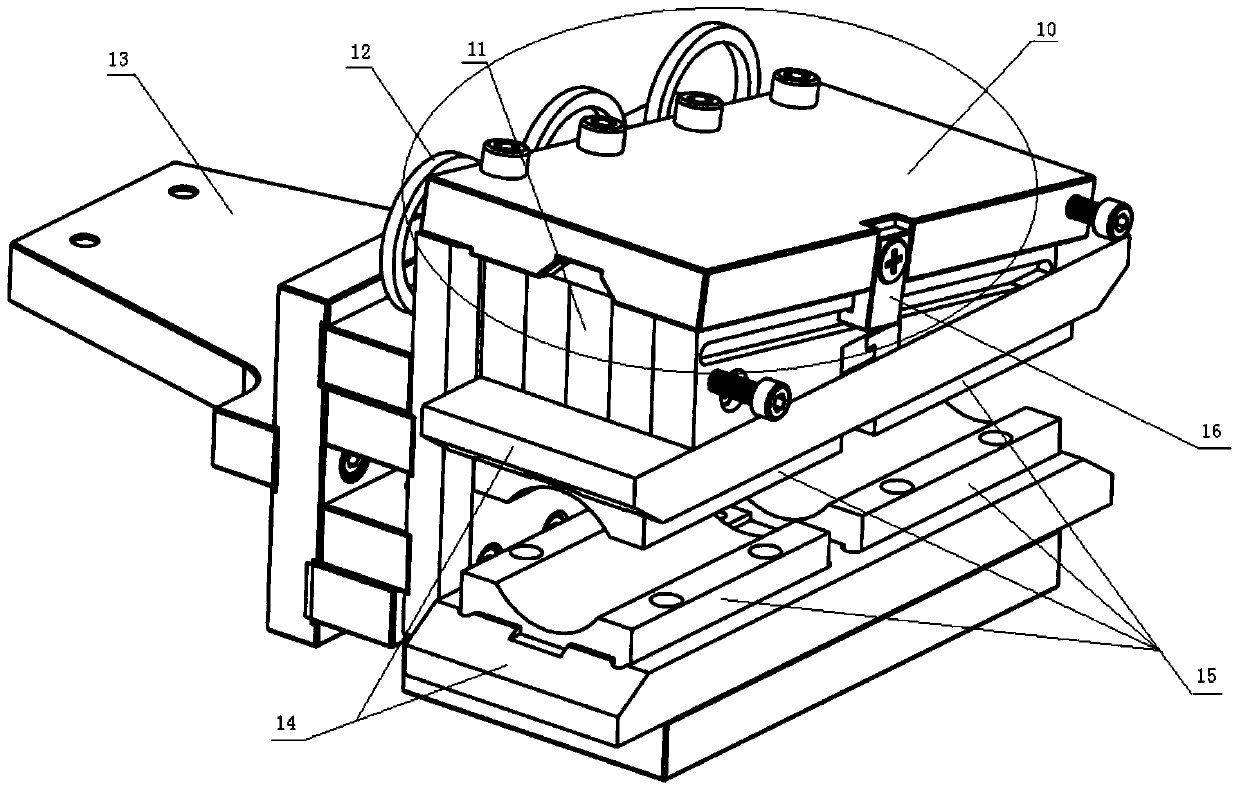

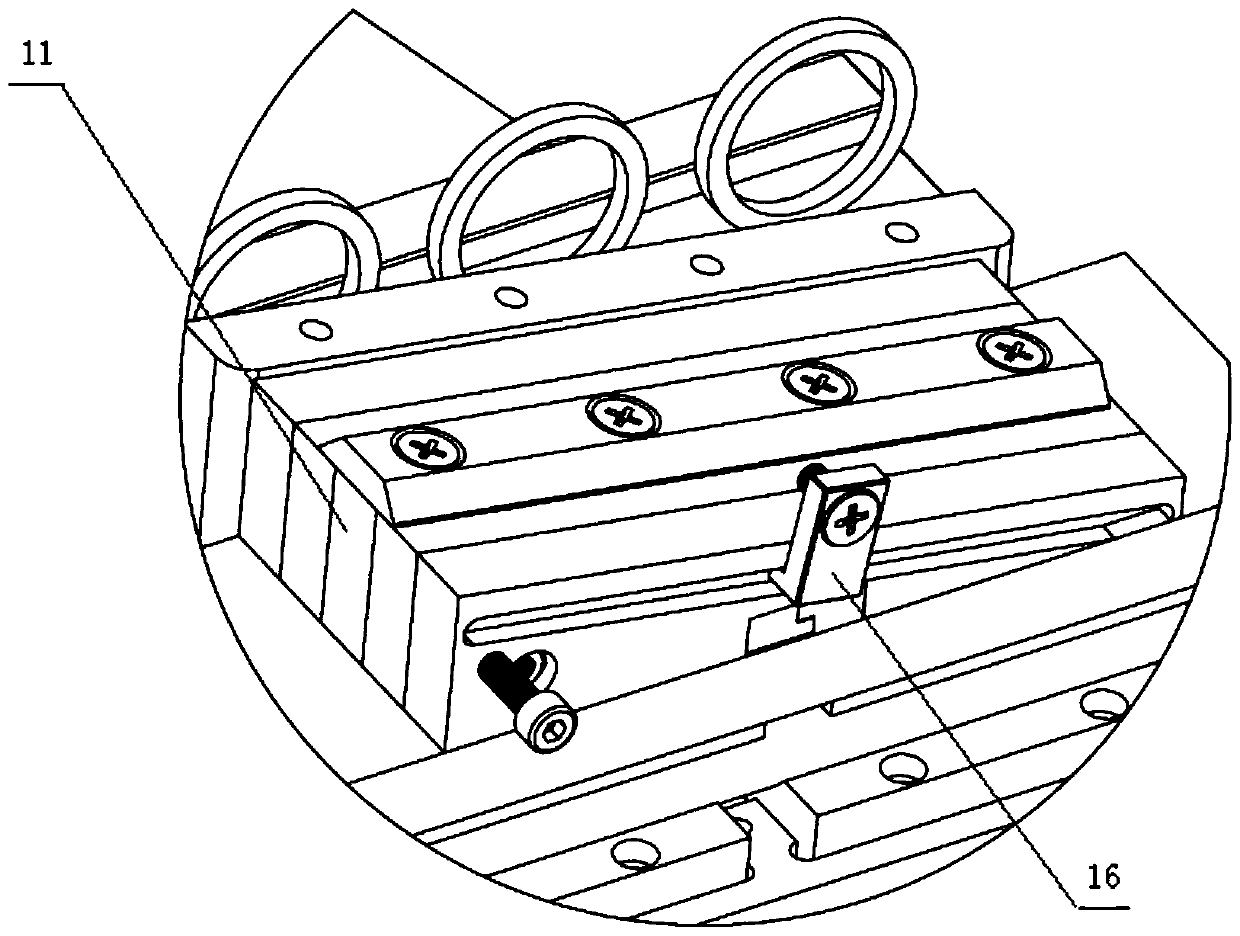

Automatic Portable Cable Delivery Robot

ActiveCN105068517BRealize automatic deliveryRealize directional deliveryProgramme-controlled manipulatorTotal factory controlAutomatic transmissionRemote control

The invention discloses an automatic portable cable transmission robot. A servo motor is connected to one end of a ball screw, and the other end of the ball screw is installed on a base. The ball screw is fitted with a screw nut fixedly mounted on a slide. In the table, the light rods located on both sides of the ball screw pass through the slide table and both ends are installed on the base, and the slide table is equipped with a mechanical arm. The present invention realizes the automatic transmission of the cable by using the servo motor and the ball screw, which greatly reduces the manual use; through the mechanical arm with the one-way transmission function and the self-adapting outer diameter function, the directional transmission of the cable is realized, and the efficiency is improved; Stand-alone control or online coordination of multiple institutions can adapt to different working conditions and freely match according to actual needs; use wired or wireless remote control to coordinate multiple institutions in a unified manner, adjust the number, speed, operation mode and other indicators of institutions, and ensure that each The synchronous action of the mechanism improves the work efficiency.

Owner:博锋智能科技(大连)有限公司

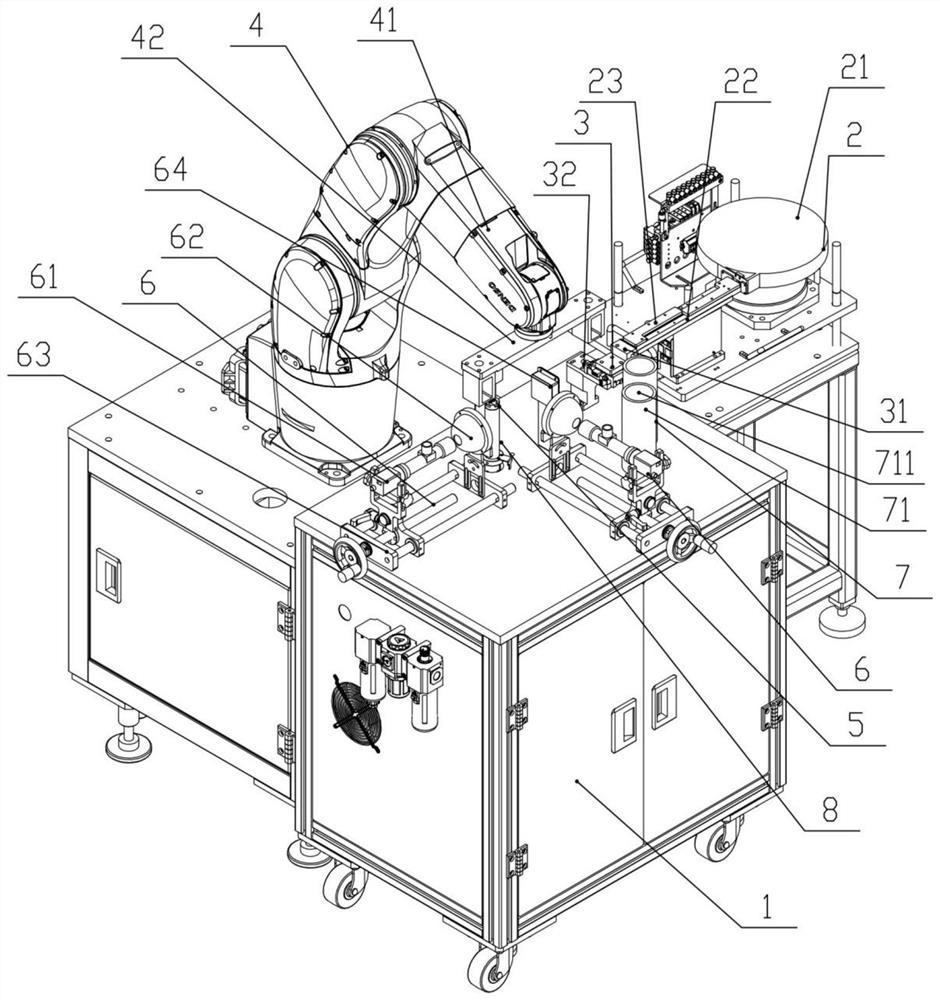

Screwdriver cap over-molding device

PendingCN110126186ARealize directional deliveryAchieve transferDomestic articlesMaterial transferBiomedical engineering

The invention provides a screwdriver cap over-molding device. The screwdriver cap over-molding device comprises a screwdriver cap conveying device, a screwdriver cap arranging and locating device, a material transferring device and an injection molding device. The screwdriver cap conveying device conveys screwdriver caps and quantitatively arranges the screwdriver caps according to one array unit.The screwdriver cap arranging and locating device is used for arranging the multiple workpieces in array. The material transferring device transfers the workpieces arranged in array to the injectionmolding device as a whole. The injection molding device receives the workpieces transferred by the material transferring device and conducts over-molding. Compared with the prior art, the screwdrivercap over-molding device can automatically arrange the multiple screwdriver caps in array and conducts over-molding on the screwdriver caps arranged in array. The screwdriver cap over-molding device has the advantages of being high in automation degree, rapid in production speed and the like.

Owner:广东三扬机器人有限公司 +1

A rotating 360-degree product burr detection device

ActiveCN108982509BFlip fastImprove detection efficiencyOptically investigating flaws/contaminationEngineeringServomotor

The invention discloses a rotary type 360-degree product burr detecting device. The device comprises a worktable, wherein a discharging port at the left side of a vibrating tray is connected with a vibrating guide rail, a splitting part comprises a splitting block, the front end of the splitting block is connected with the end of the vibrating guide rail, the rear end of the splitting block is connected with a splitting cylinder, a stock moving part comprises a manipulator, the lower side of the manipulator is connected with a product moving fixture, the lower end of a rotary fixture is fixedto an output shaft end of a servomotor, a first observation hole, which is downwards concave inwardly, is formed in the center of the surface of the rotary fixture, the two sides of the first observation hole serve as locating tables, second observation holes penetrate through interior of centers of the locating tables and are vertical to the first observation hole, each product comprises a substrate, and two parts to be detected are symmetrically fixed to the lower surface of each substrate. The device has the effects that the splitting block accurately separates the products, two optical cameras detect burrs in a 360-degree dead-corner-free manner, and the efficiency of detection is high.

Owner:DONGGUAN SHENGXIANG PRECISION METAL

Pneumatic pollination control device and method for large row ratio hybrid rice seed production

ActiveCN111248081BEven and stable pollinationRealize directional deliveryAgriculturePlant genotype modificationAgricultural scienceLoop control

The invention discloses a large-row-ratio hybrid rice seed production pneumatic pollination control device and a control method thereof. The device includes a base plate, a fan, a wind speed sensor, an airflow transfer pipe, a fan driver, a processing chip, a wireless transmission module, and an electronic compass module. , integrated circuit board, upper cover, touch screen. Each fan is driven by a separate fan driver, the wireless transmission module receives the environmental natural wind speed and wind direction information, and the electronic compass module determines the direction of the pollinator. After calculating the target output wind speed through the controller, the processing chip calculates in real time according to the preset algorithm The corrected wind speed is obtained, so that the pollen falls to the target area, and the wind speed of the tuyere is detected by the wind speed sensor and sent back to the processing chip in real time to form a closed-loop control; so that the pollinator can still make the pollen to the target even when the pollinator is disturbed by the external natural wind. State movement; the overall structure is simple and compact, the interaction is simple, and the reliability is high, providing a fan control device with excellent performance for the hybrid rice pneumatic pollinator.

Owner:ZHEJIANG UNIV

Composition with whitening effect, whitening soluble microneedle patch with high drug loading and preparation method thereof

ActiveCN110664646BHigh content of active ingredientsImprove mechanical propertiesCosmetic preparationsToilet preparationsCellulosePhosphoric Acid Esters

The invention relates to a composition with whitening effect, a whitening soluble microneedle patch with high drug loading and a preparation method thereof. The composition with whitening effect comprises the following components in parts by weight: 10-20 parts of arbutin, 10-20 parts of magnesium ascorbyl phosphate, 5-10 parts of adenosine, and 0.1-0.5 parts of sturgeon caviar extract. The whitening dissolvable microneedle patch is composed of a needle tip and a base, the needle tip is prepared from the composition with whitening effect, hyaluronic acid or its sodium salt, and microneedle auxiliary materials; the composition with whitening effect , hyaluronic acid or its sodium salt, and the mass ratio of the microneedle auxiliary material are 1:0.1-5:0.2-1; the microneedle auxiliary material is composed of polyvinylpyrrolidone, glycerin and hydroxypropyl cellulose. The whitening soluble microneedle patch has high drug loading and excellent mechanical properties, and has high whitening, blemish-lightening and moisturizing effects.

Owner:GUANGZHOU NEWORLD PHARMA CO LTD

Avocado directional conveying assembly line and avocado directional conveying method

ActiveCN110713026BRealize directional deliveryFacilitate subsequent processingLoading/unloadingConveyor partsAgricultural scienceAgricultural engineering

The invention discloses an avocado directional conveying line and an avocado directional conveying method, including a conveyor belt, and an avocado directional conveying device is arranged at one end of the conveyor belt; the avocado directional conveying device includes a directional mechanism, a main support, a rotary distributor and a hopper, and the directional mechanism It includes a directional top plate, a directional bottom plate, a directional feeding pipe, a material pushing part, a directional discharging pipe, a directional block, a buffer positioning component and two baffles. A photoelectric sensor is fixed on the baffle, and the pushing part is set on the directional bottom plate. The buffer positioning assembly is set on the directional top plate, the main support is fixed on the directional top plate, the hopper is correspondingly set on the rotary feeder, and the rotary feeder is fixed on the main support; the invention can realize the directional transportation of avocado, which is beneficial to the avocado The follow-up processing of avocados does not require manual orientation, which greatly saves labor costs, improves production efficiency, and reduces the processing cost of avocados.

Owner:精海联科(宁波)智能设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com