Pneumatic pollination control device and method for large row ratio hybrid rice seed production

A technology of hybrid rice and control device, which is applied in the fields of botanical equipment and methods, plant genetic improvement, agriculture, etc., can solve the problem that the pollen cannot move in the target state, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific structure and implementation of the present invention will be further described below in conjunction with the accompanying drawings.

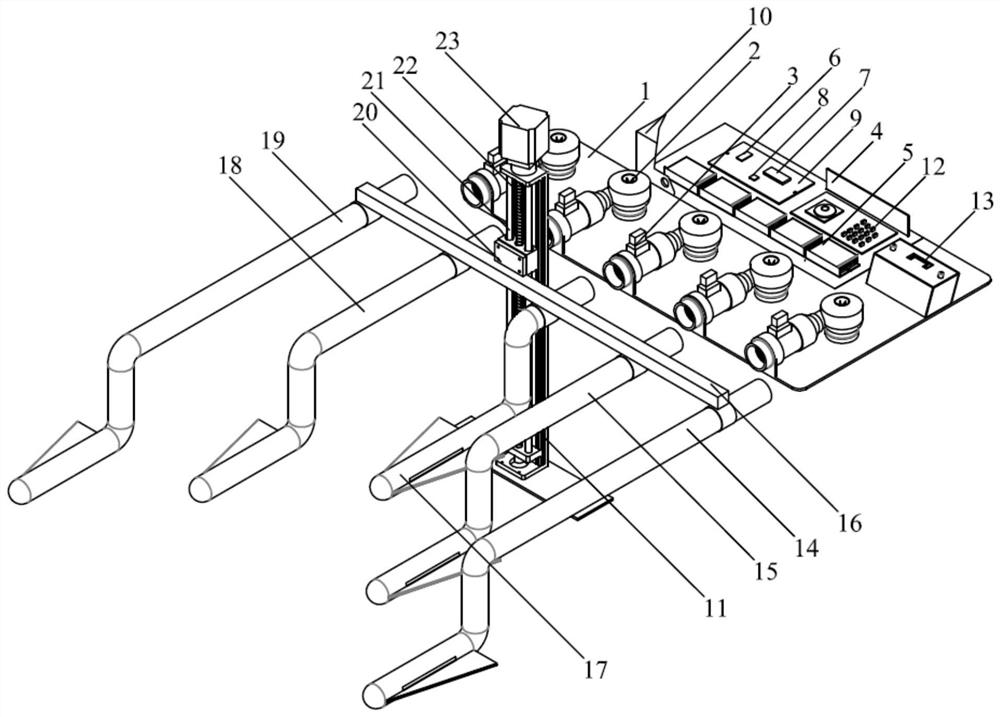

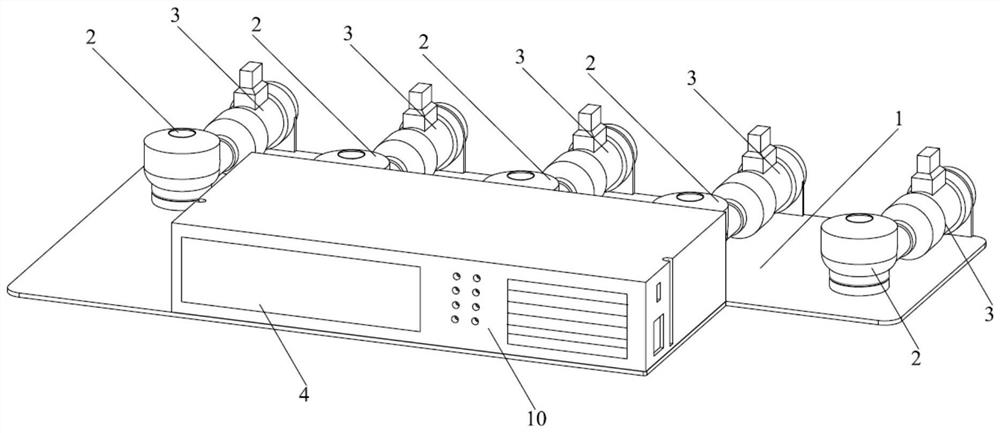

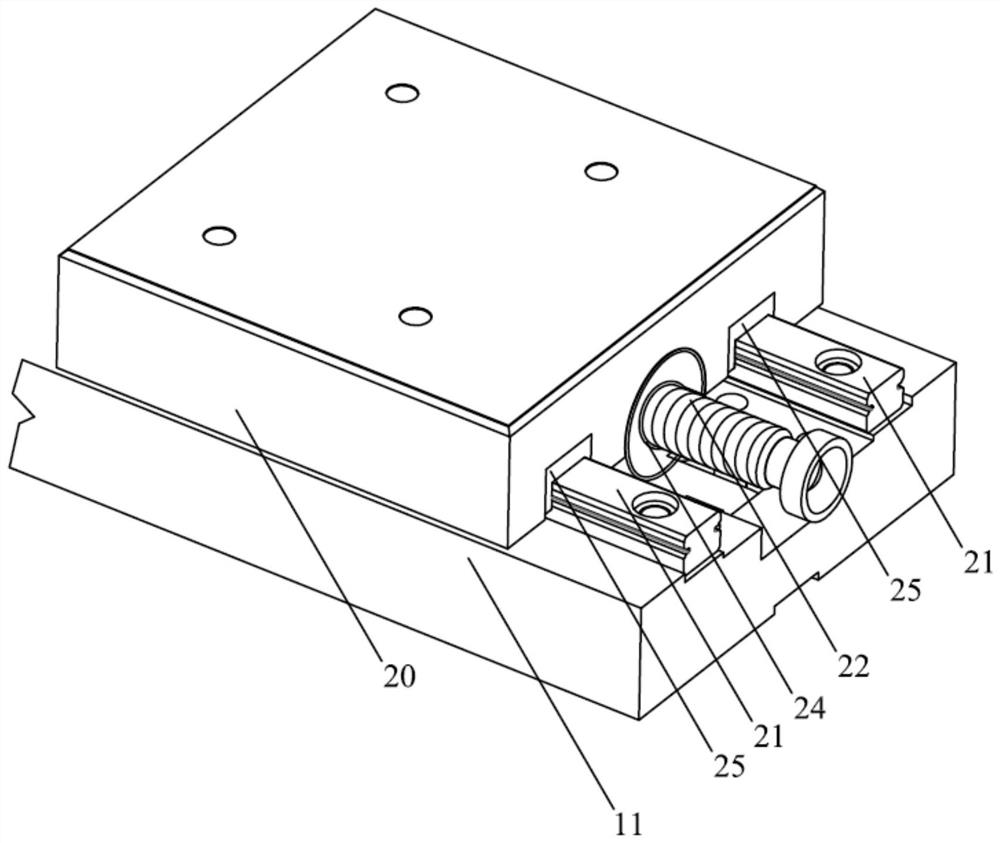

[0036] like Figure 1~4 Shown is a large-row-ratio hybrid rice seed production pneumatic pollination control device of the present invention, whose main components include airflow control assembly, field wind field detection assembly and pneumatic pollination assembly. Wherein, the pollination power chassis of large row ratio hybrid rice seed production can adopt any chassis that can drive the device to advance in the hybrid rice seed production field, and its form is not limited, so the present invention will not repeat it in detail. The airflow control assembly is installed on the pollination power chassis of large row ratio hybrid rice seed production through the bottom plate 1, and is used to control the operation of the pneumatic pollination assembly; and the pneumatic pollination assembly is installed on the large row ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com