Patents

Literature

107results about How to "Flip fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

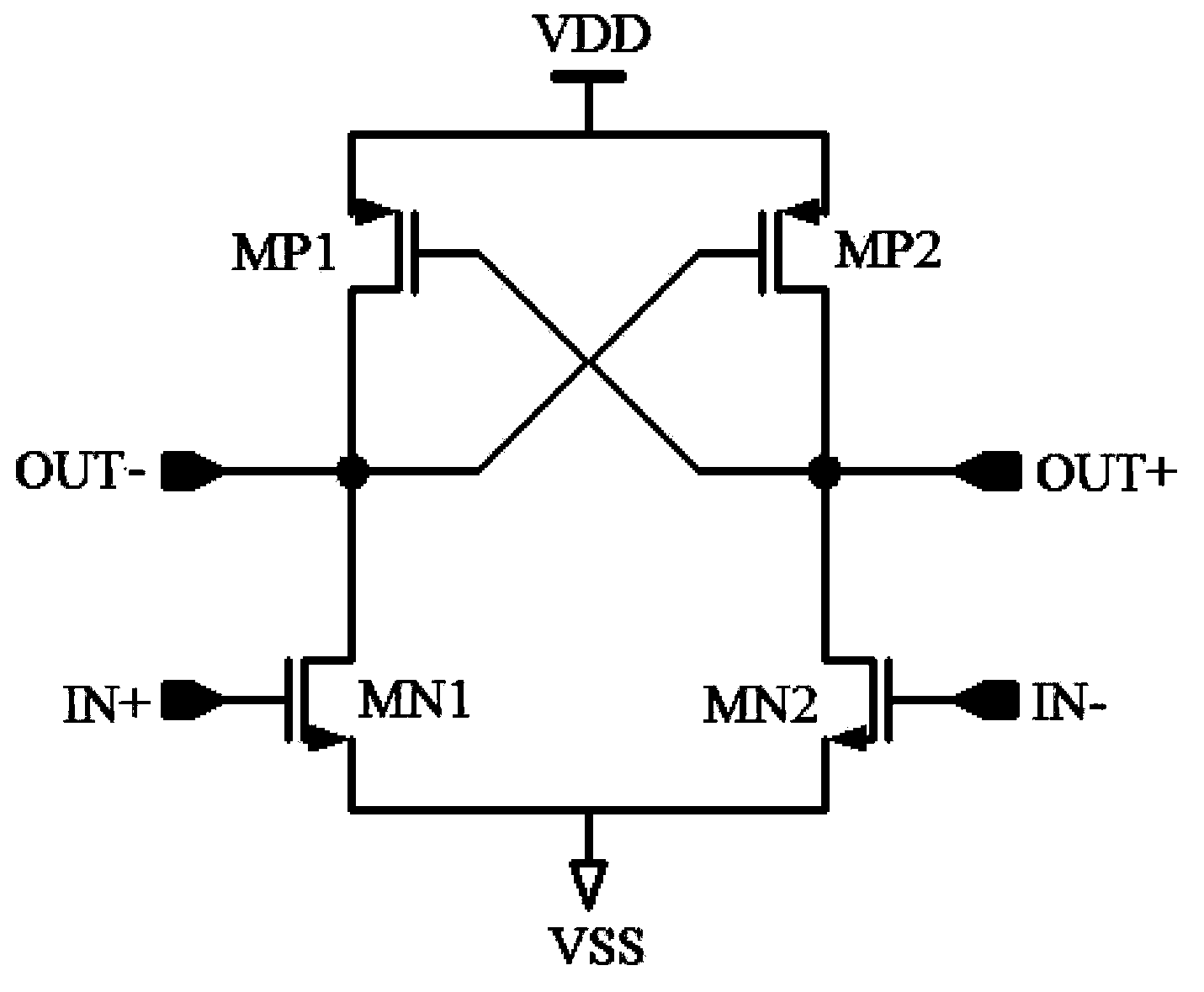

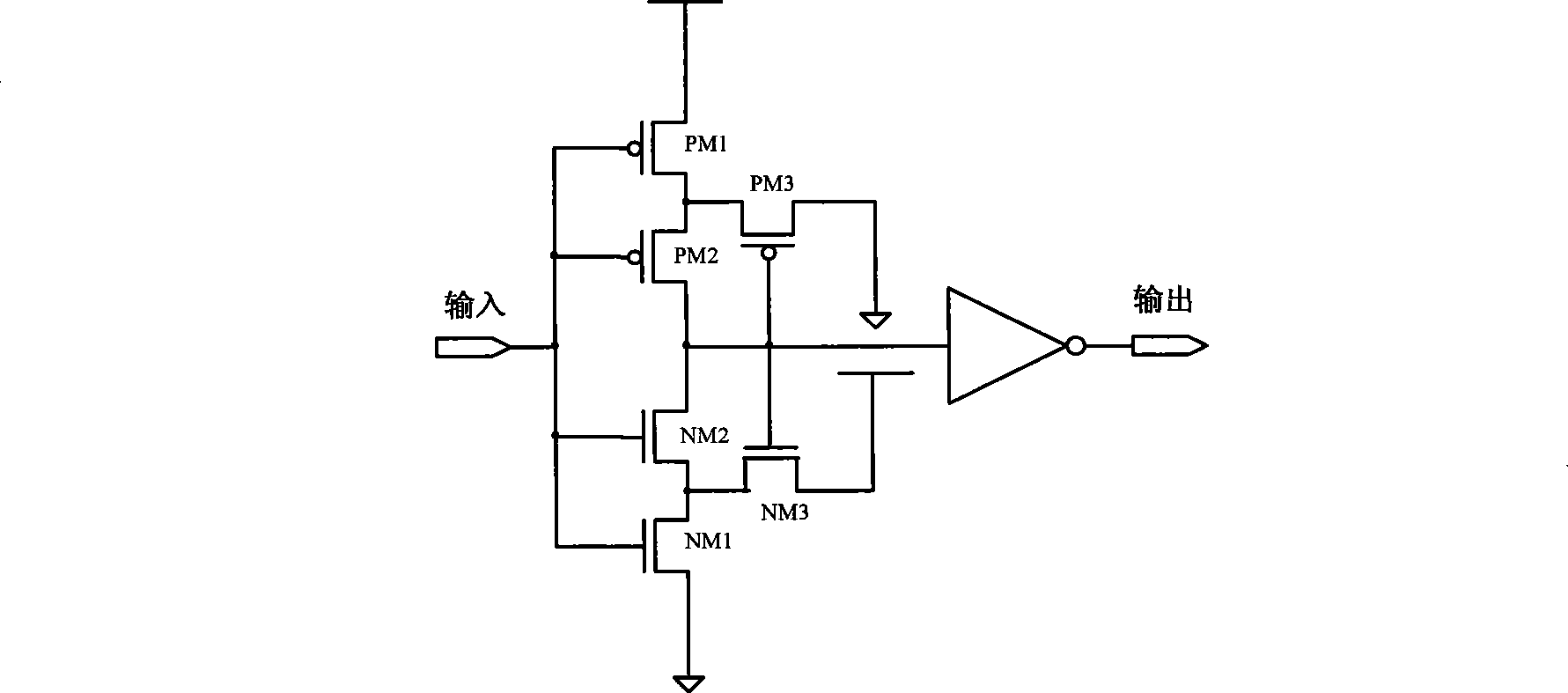

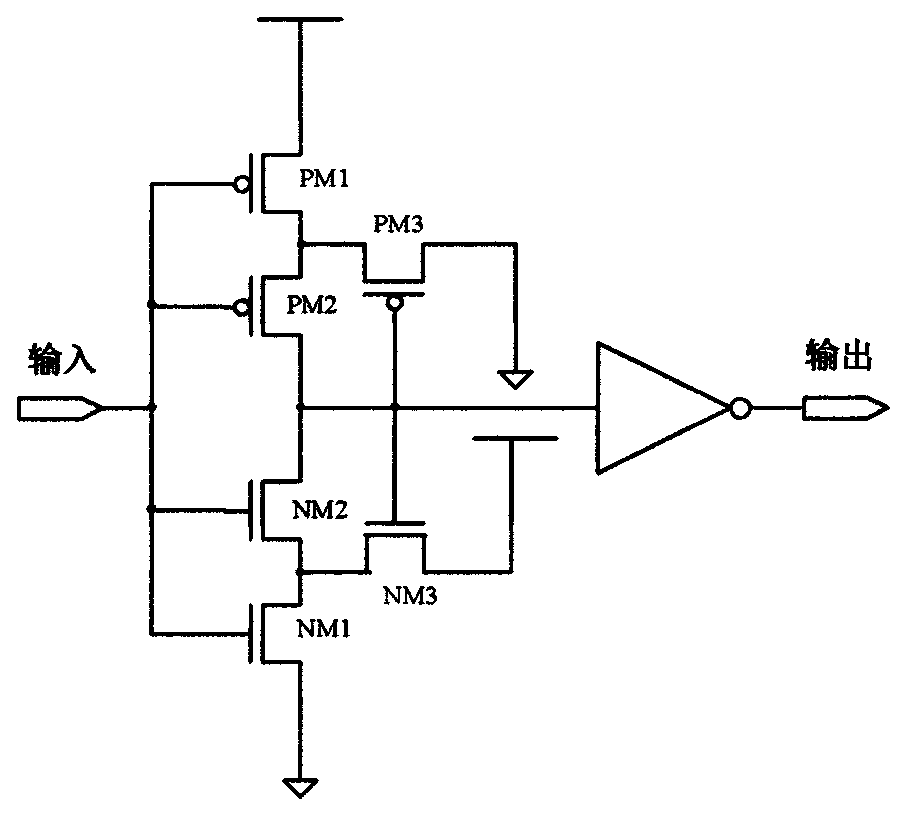

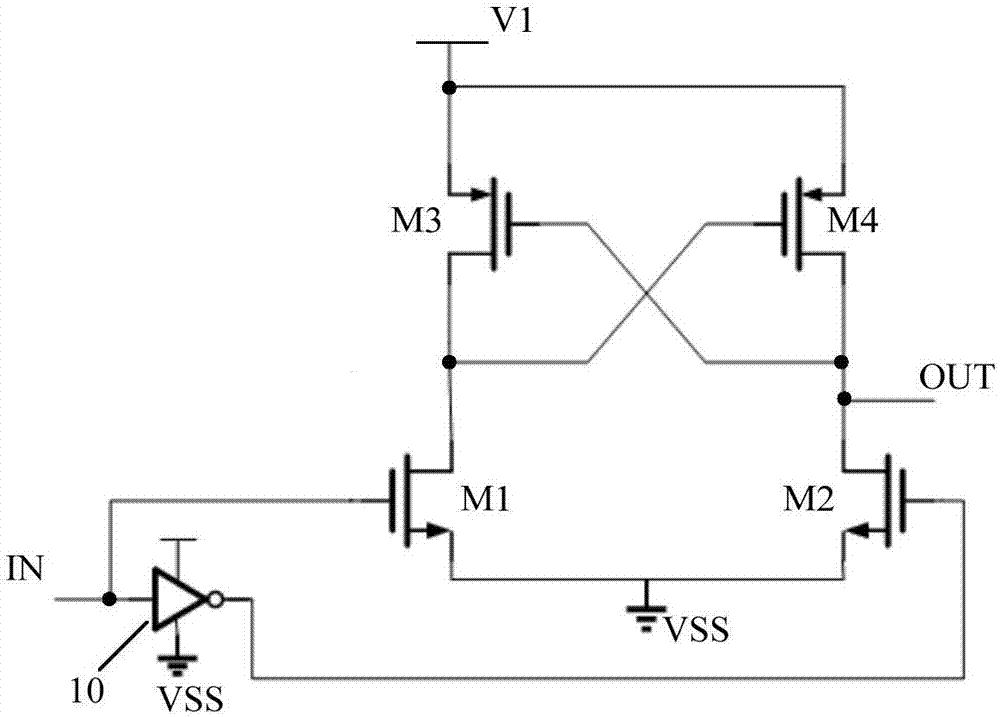

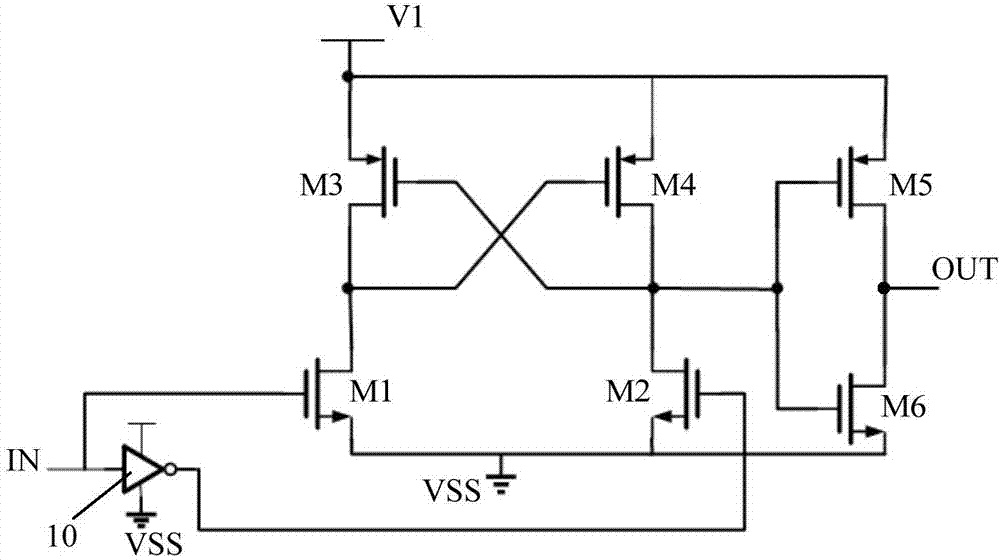

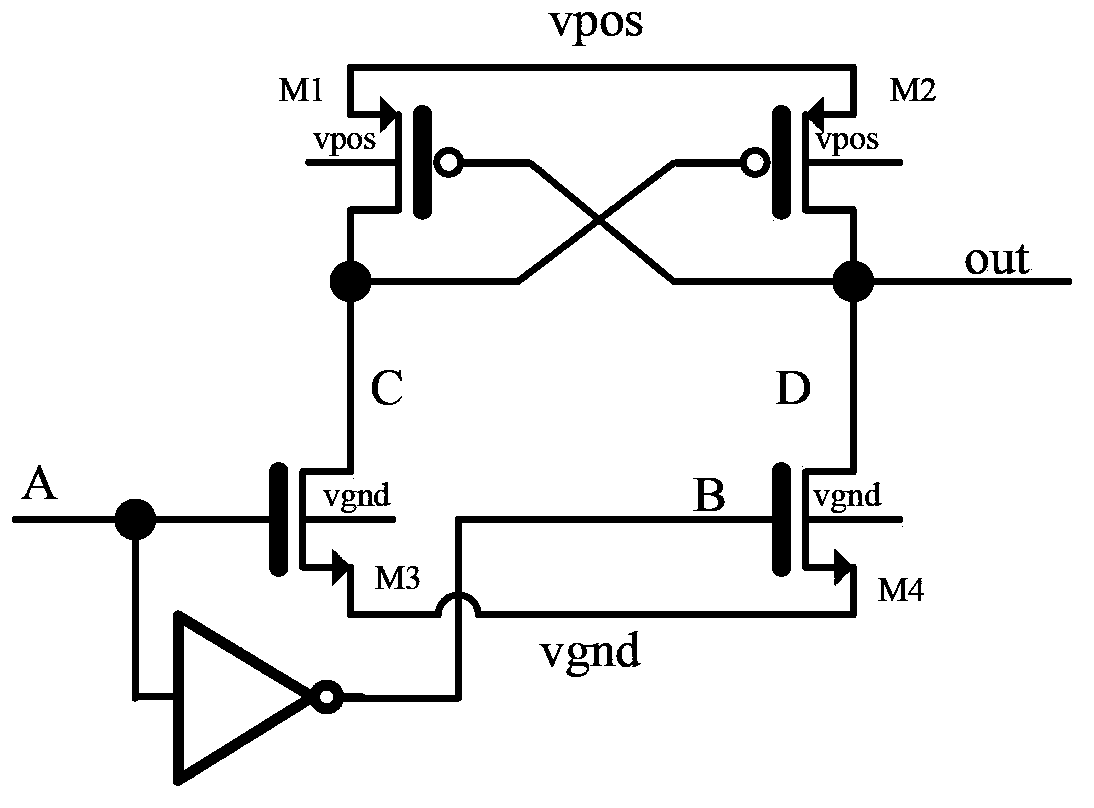

Low-to-high logic level conversion circuit

InactiveCN103856206AEliminate indefinite stateGuaranteed to workLogic circuits coupling/interface using field-effect transistorsElectricityLow voltage

The invention discloses a low-to-high logic level conversion circuit which comprises a latch, an actuator, a phase inverter and a feedback pipe. The input of the latch is a differential pair pipe which is formed by a first NMOS transistor and a second NMOS transistor, and a load of the latch is a cross coupling pair pipe which is formed by a first PMOS transistor and a second PMOS transistor. The actuator is arranged in the latch and helps the latch to be quickly turned over. The phase inverter and the feedback pipe are arranged at the output end of the latch, the feedback pipe enables a circuit output to be in a steady state when a low-voltage area is not powered, and when the low-voltage area is normally powered, normal work of the latch is not affected. By means of the low-to-high logic level conversion circuit, the probability that logic level is in an unsteady state when being converted to power level is avoided, and power consumption is reduced.

Owner:SHANGHAI HUAHONG INTEGRATED CIRCUIT

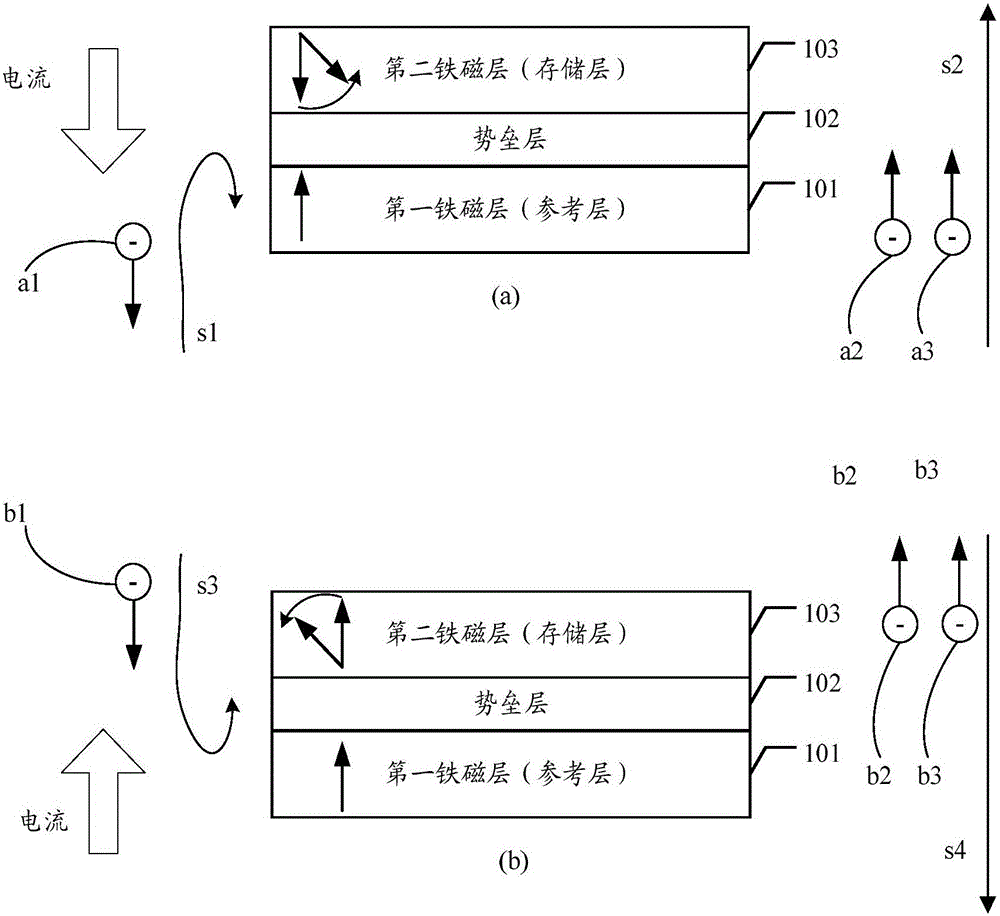

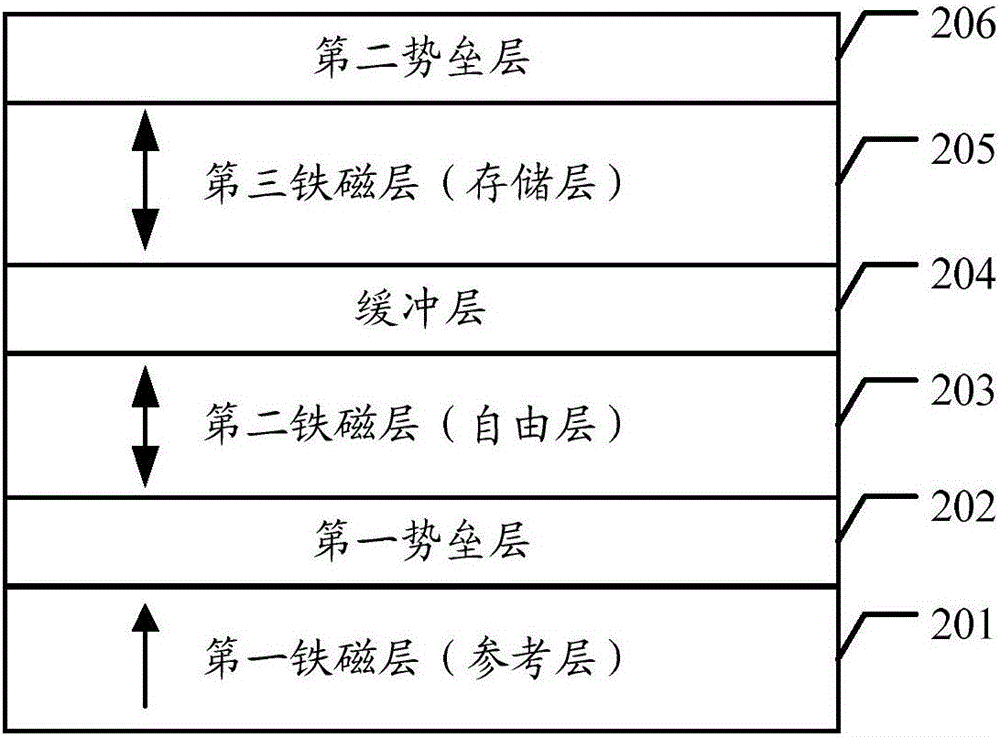

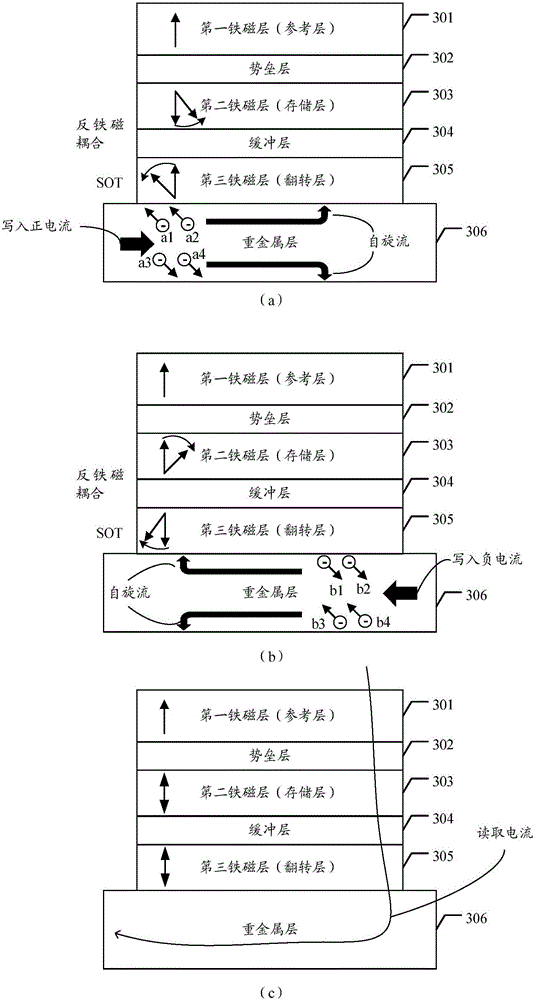

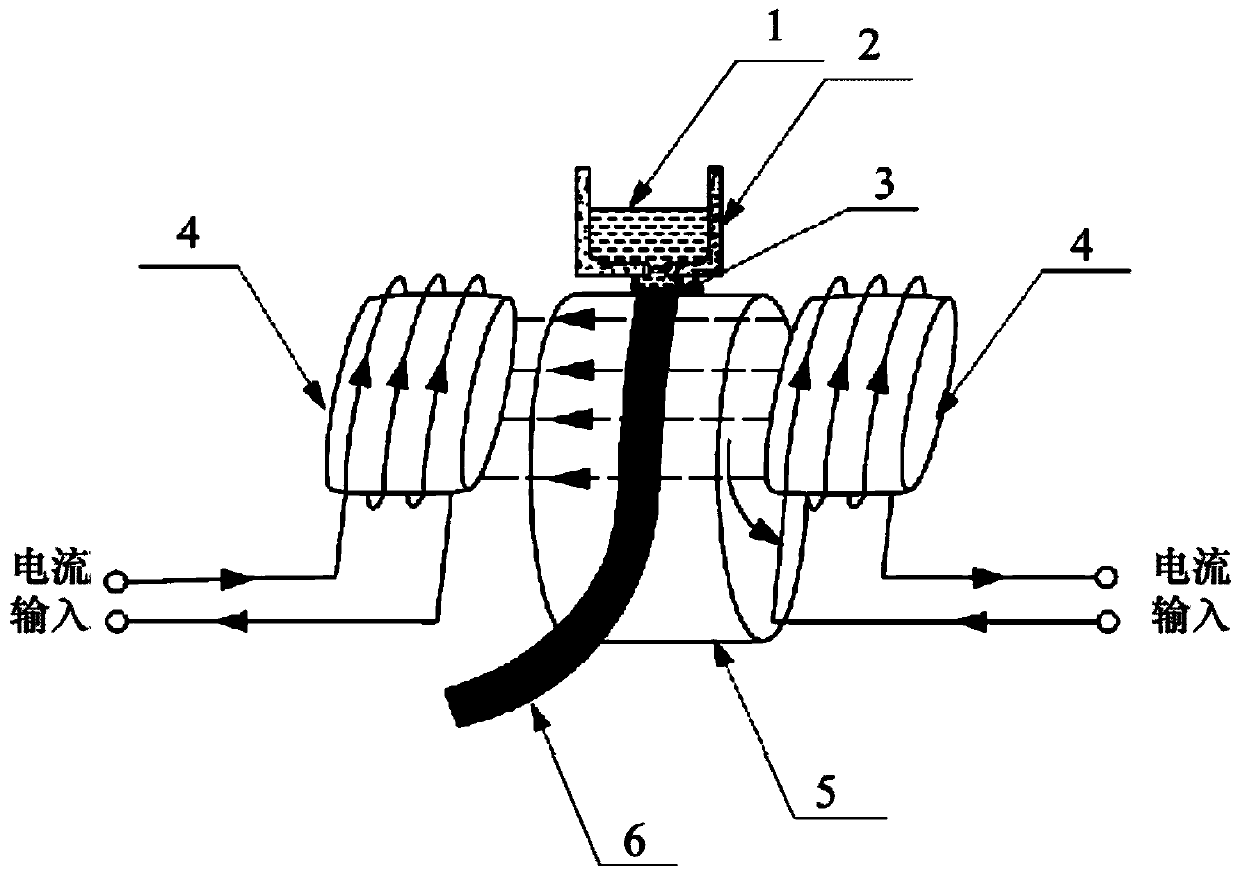

Magnetic tunnel junction and magnetic memory

ActiveCN106025063AFlip fastMagnetic-field-controlled resistorsAntiferromagnetic couplingMagnetic memory

Embodiments of the invention disclose a magnetic tunnel junction (MTJ) and a magnetic memory. The MTJ comprises a first ferromagnetic layer, a barrier layer, a second ferromagnetic layer, a buffer layer, a third ferromagnetic layer and a heavy metal layer from upper to lower in sequence, wherein the first ferromagnetic layer, the second ferromagnetic layer and the third ferromagnetic layer all comprise mixed metal materials; the barrier layer comprises a metal oxide material; the buffer layer comprises a non-ferromagnetic material; the magnetizing direction of the first ferromagnetic layer is a fixed direction; and the second ferromagnetic layer and the third ferromagnetic layer form ferromagnetic coupling or anti-ferromagnetic coupling. By adoption of the embodiments of the invention, the turnover speed of the third ferromagnetic layer in the magnetic tunnel junction in the magnetizing direction can be accelerated, the reliability of the MTJ can be improved, the write current can be reduced, and the power consumption can be lowered consequently.

Owner:HUAWEI TECH CO LTD

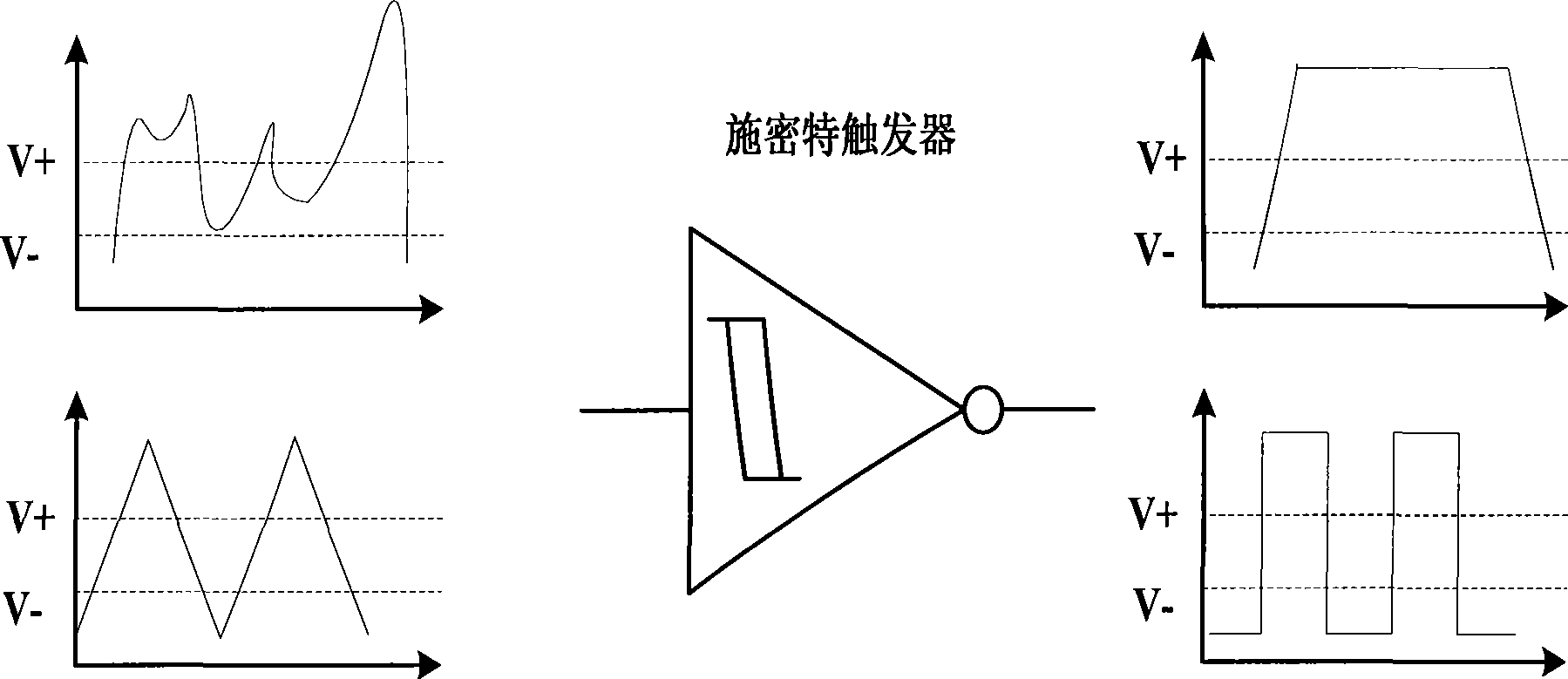

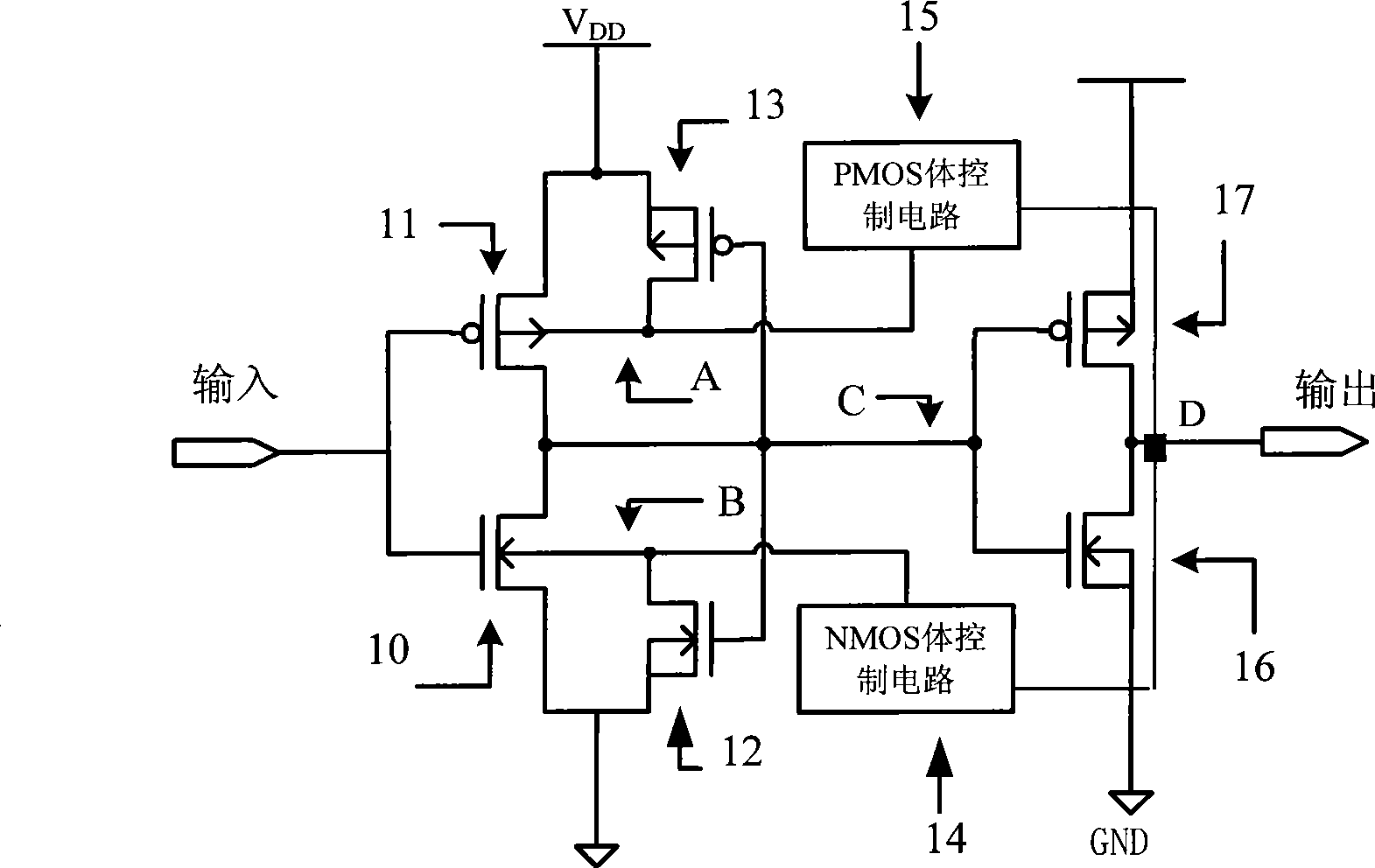

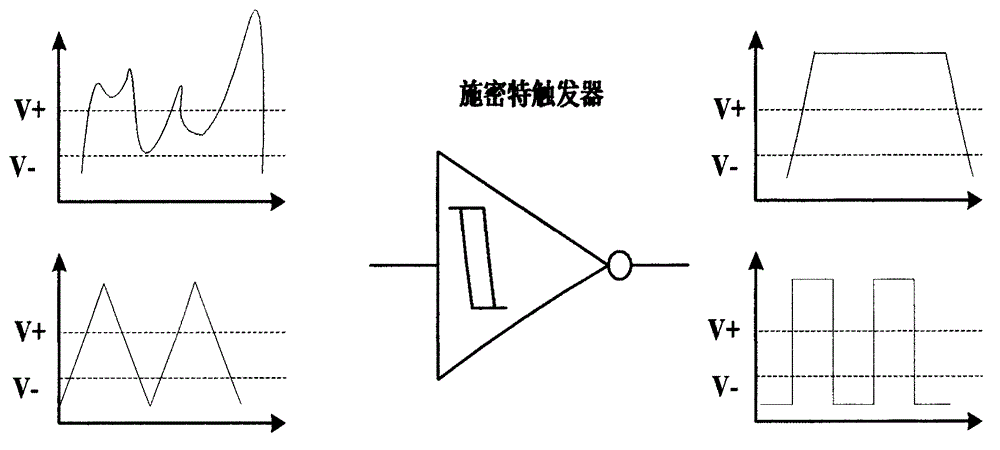

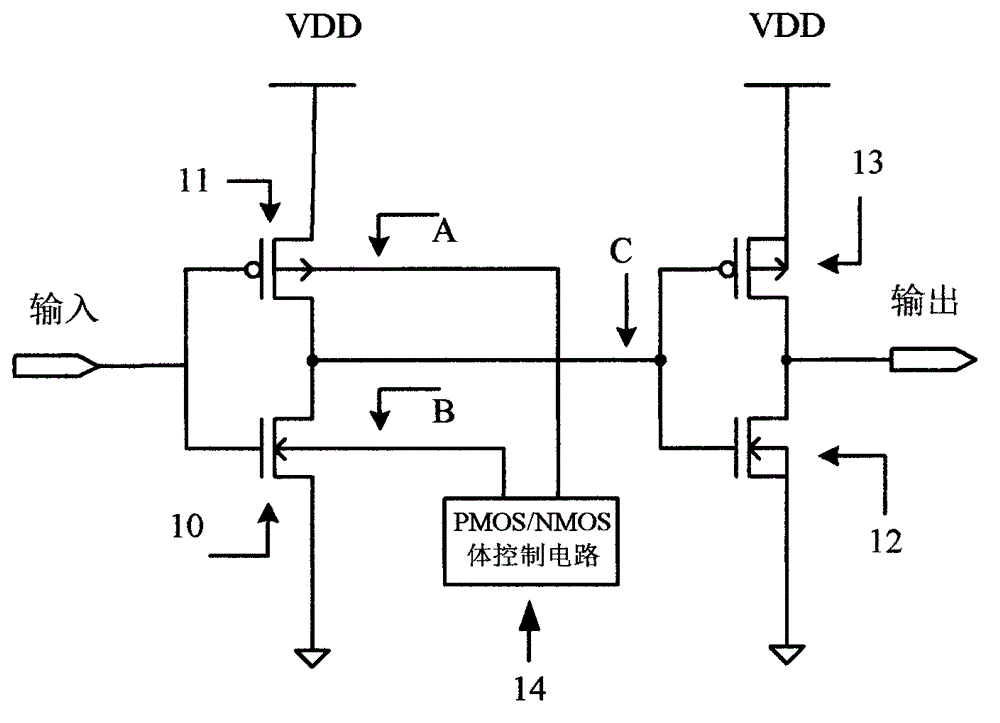

Dynamic body bias Schmitt trigger circuit

The invention discloses a dynamic body-bias Schmitt trigger circuit which utilizes a body-bias technique to control the body-area voltages of a first NMOS transistor (10), a first PMOS transistor (11), change the threshold voltages of the first NMOS transistor (10) and the first PMOS transistor (11) and further form the Schmitt trigger circuit with a double-switching threshold value. When an input signal is a lower electric level, under the action of a second NMOS transistor (12), a second PMOS transistor (13), an NMOS body control circuit (14) and a PMOS (15) control circuit, a Schmitt trigger presents a high switching threshold value V+; and similarly, when an input signal is a higher electric level, under the action of the second NMOS transistor (12), the second PMOS transistor (13), the NMOS body control circuit (14) and the PMOS (15) control circuit, the Schmitt trigger presents a low switching threshold value V-.

Owner:CHINA AEROSPACE TIMES ELECTRONICS CORP NO 771 RES INST

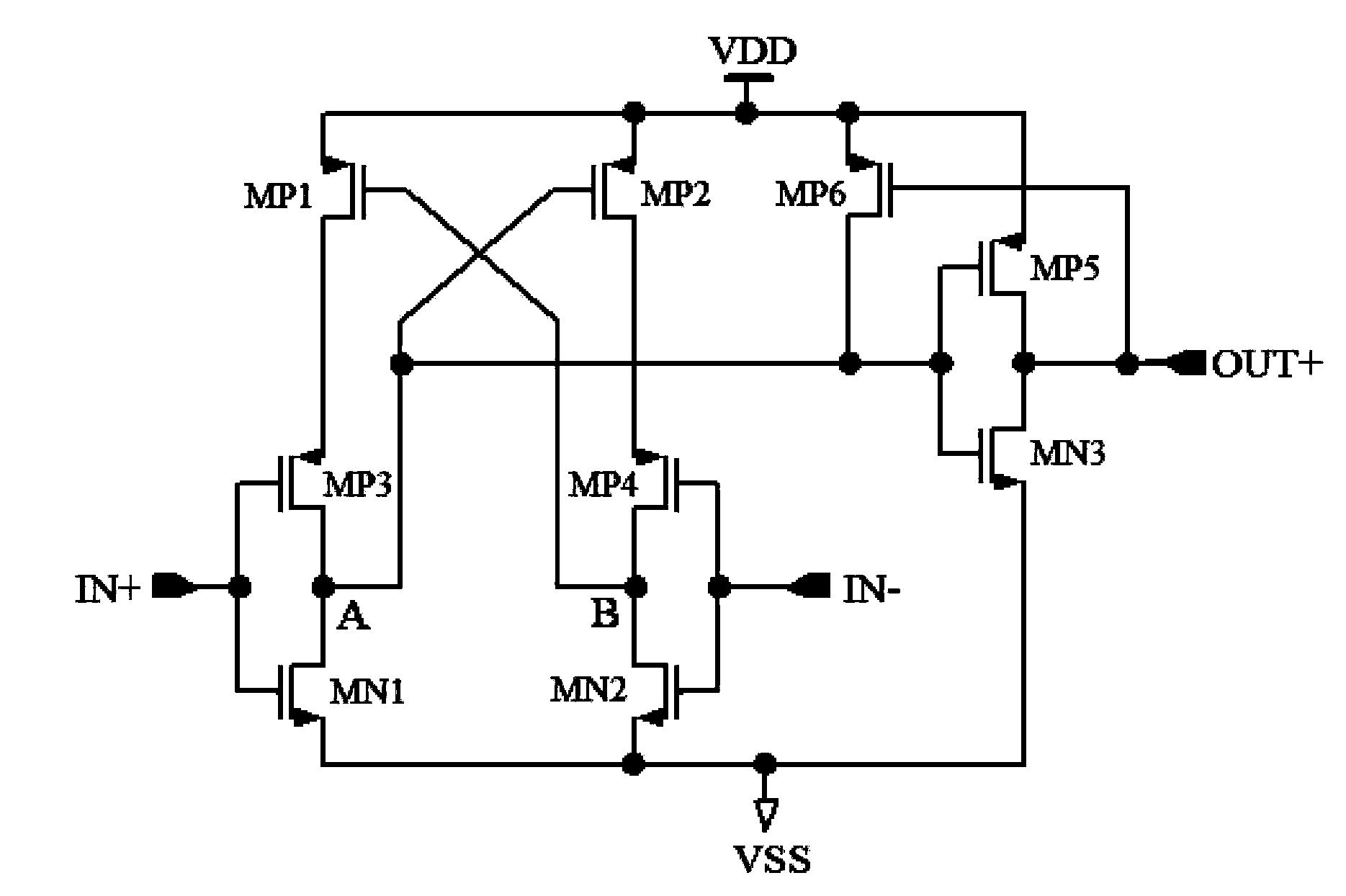

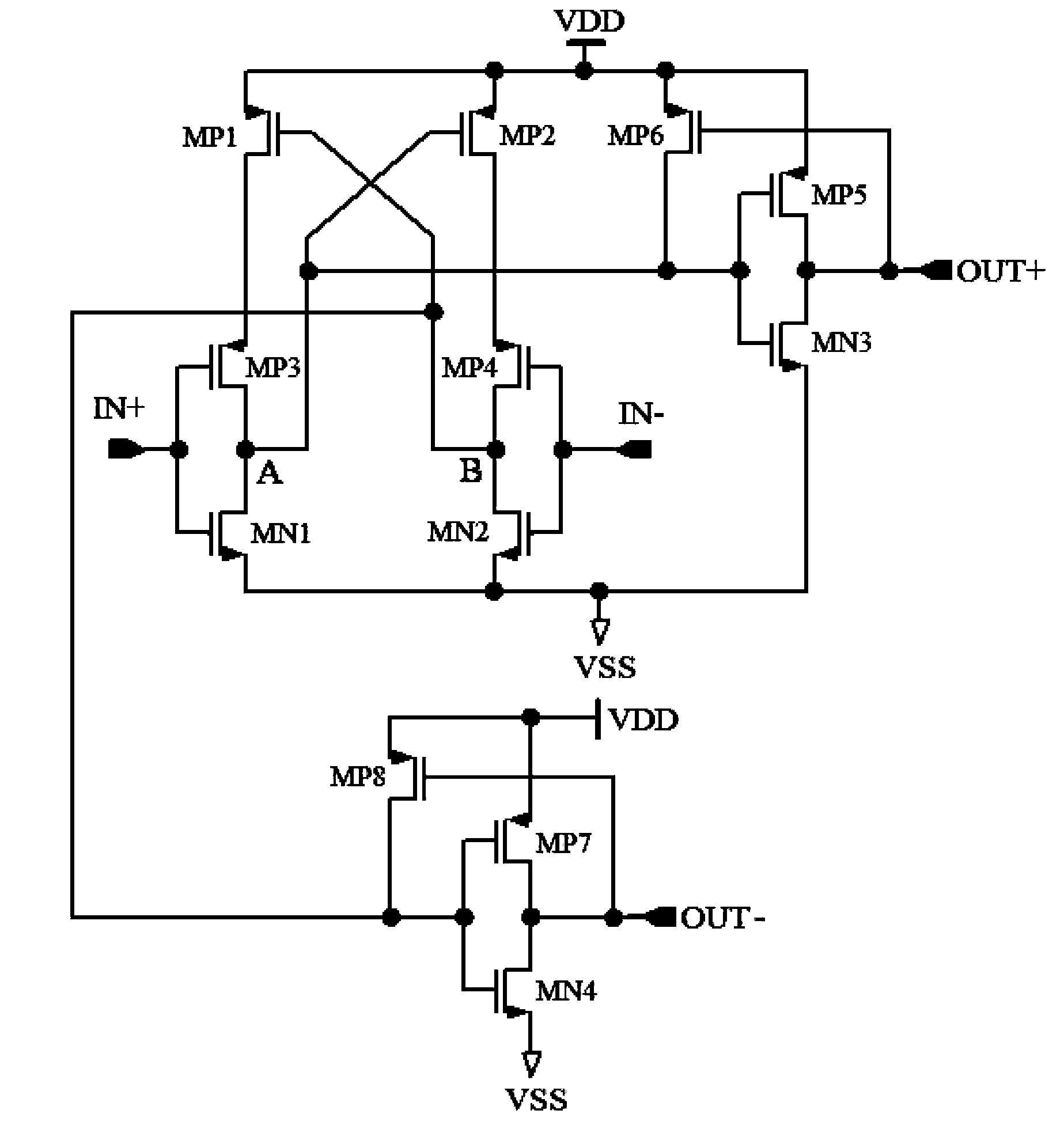

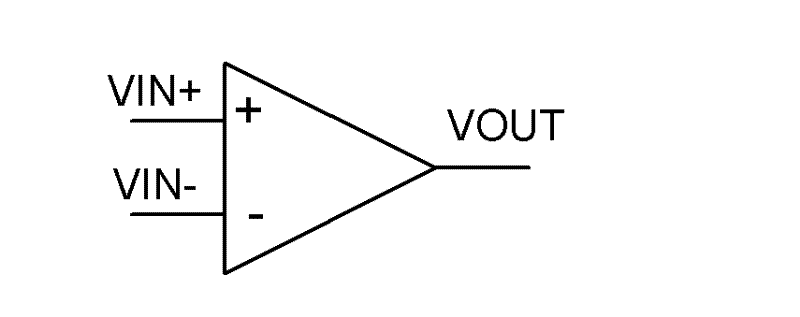

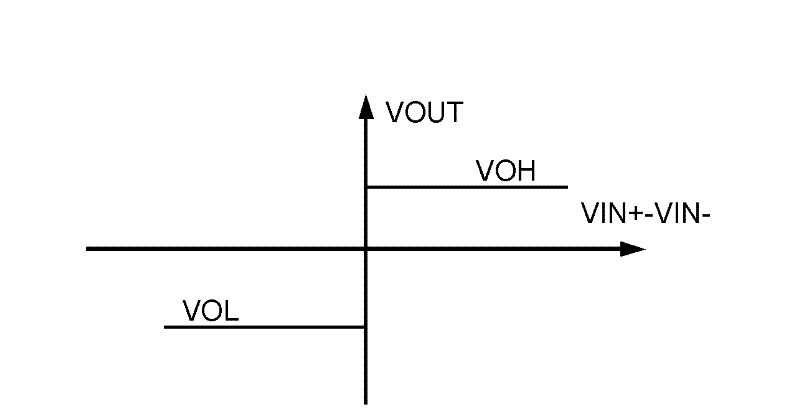

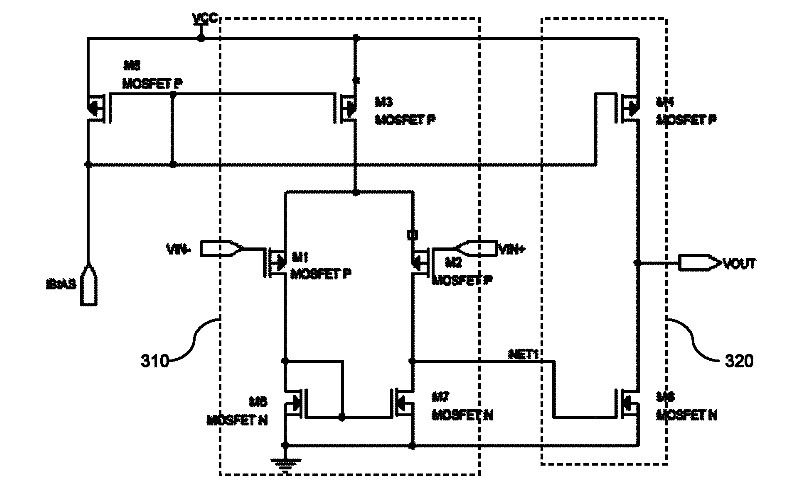

Comparator

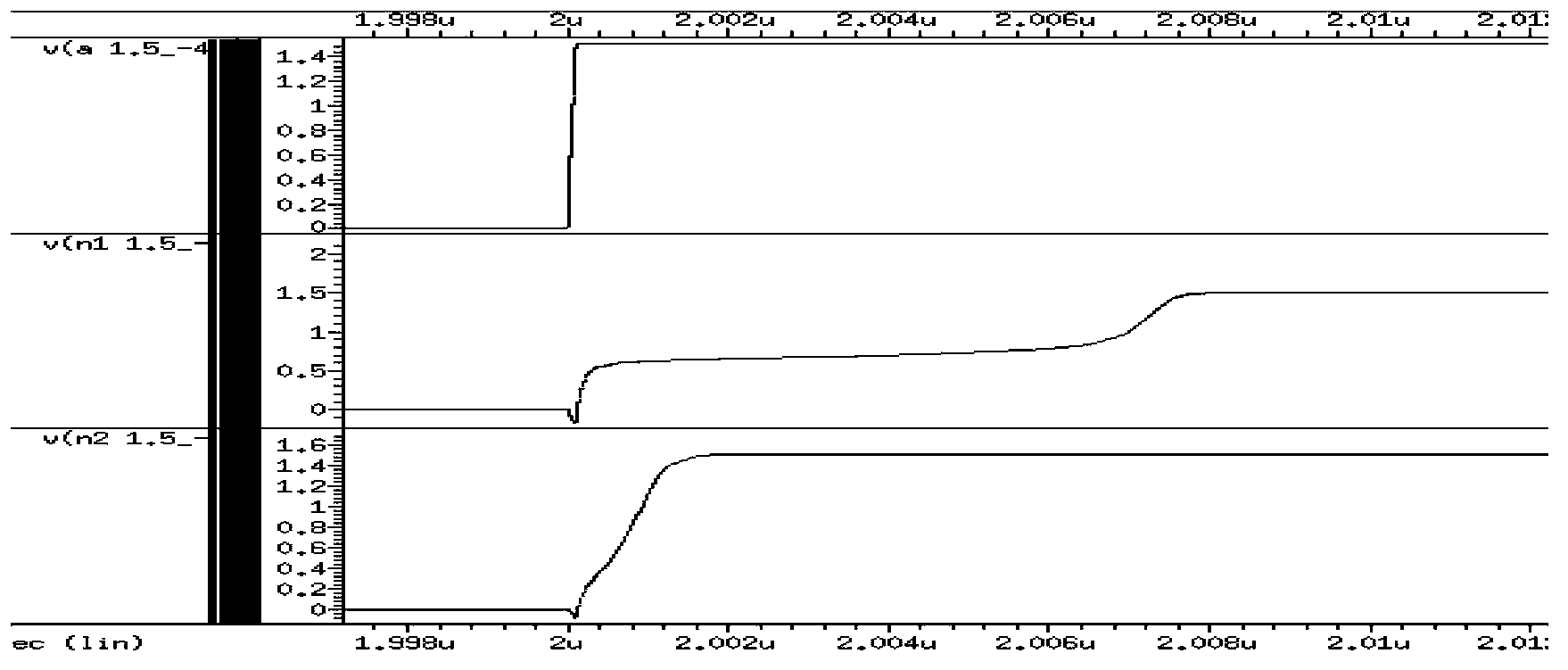

ActiveCN102420594AReduce latencyFlip fastMultiple input and output pulse circuitsEngineeringComparator

The invention provides a comparator. The comparator comprises an input-stage circuit, an output-stage circuit and a clamping circuit, wherein the input-stage circuit comprises a first input end, a second input end and an output end; and when the voltage of the first input end equals to the voltage of the second input end, the voltage at the output end is flipped; the output-stage circuit comprises an input end and an output end, wherein the input end of the output-stage circuit is connected with the output end of the input-stage circuit; when the voltage at the output end of the input-stage circuit is flipped, the voltage at the output end of the output-stage circuit is also flipped; the clamping circuit is connected between the output end of the input-stage circuit and the output end of the output-stage circuit and is used for clamping the lowest value of the voltage of the output end of the input-stage circuit at a first voltage threshold value and clamping the highest value of the voltage of the output end of the input-stage circuit at a second voltage threshold value. By using the comparator, the delay time of the comparator can be shortened, so that the flipping speed of the comparator is improved.

Owner:WUXI ZGMICRO ELECTRONICS CO LTD

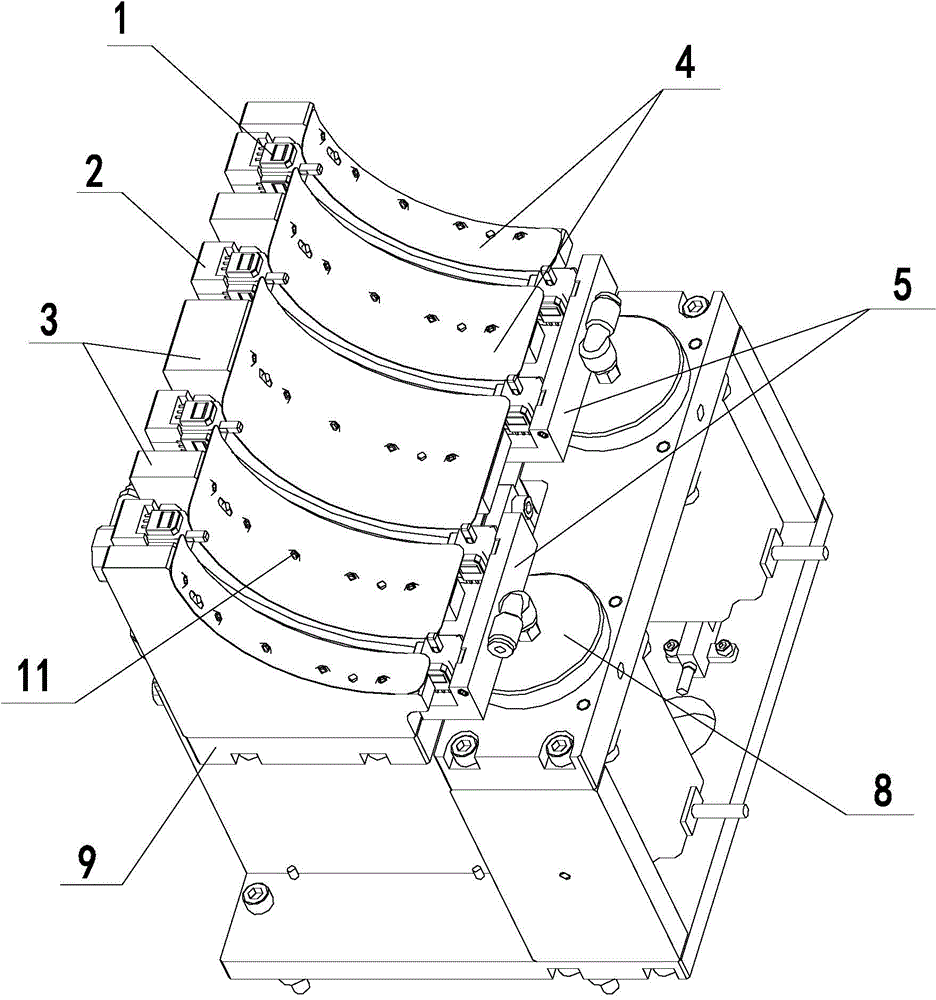

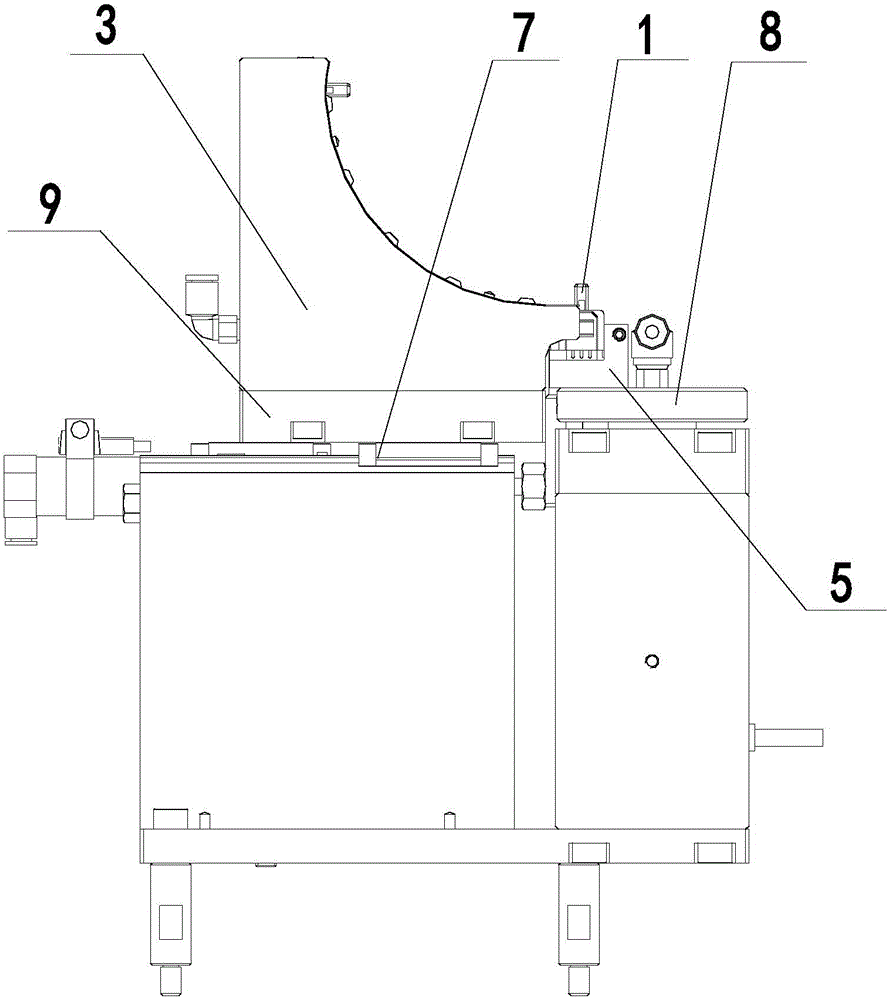

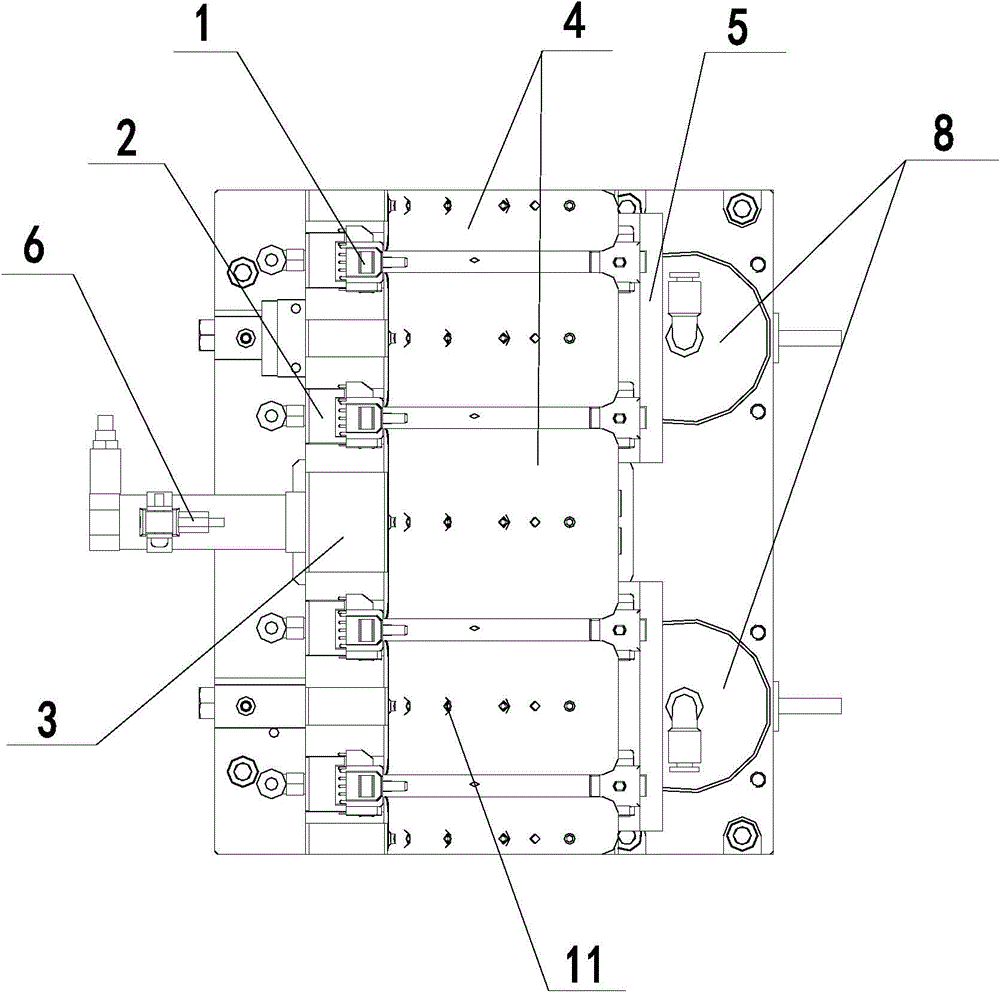

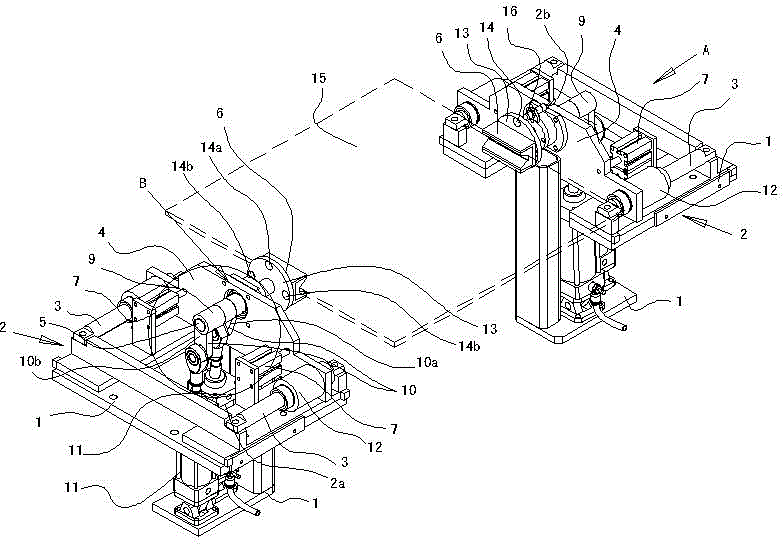

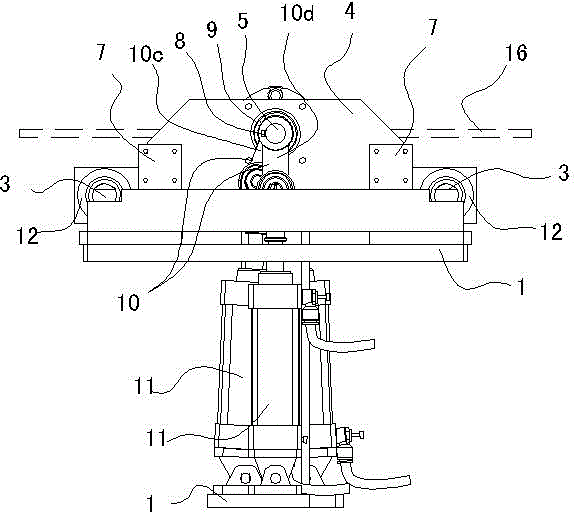

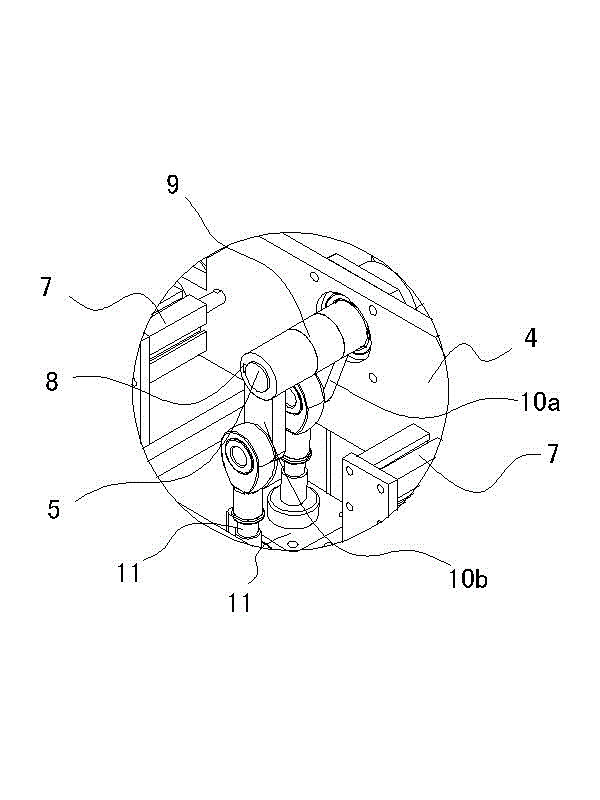

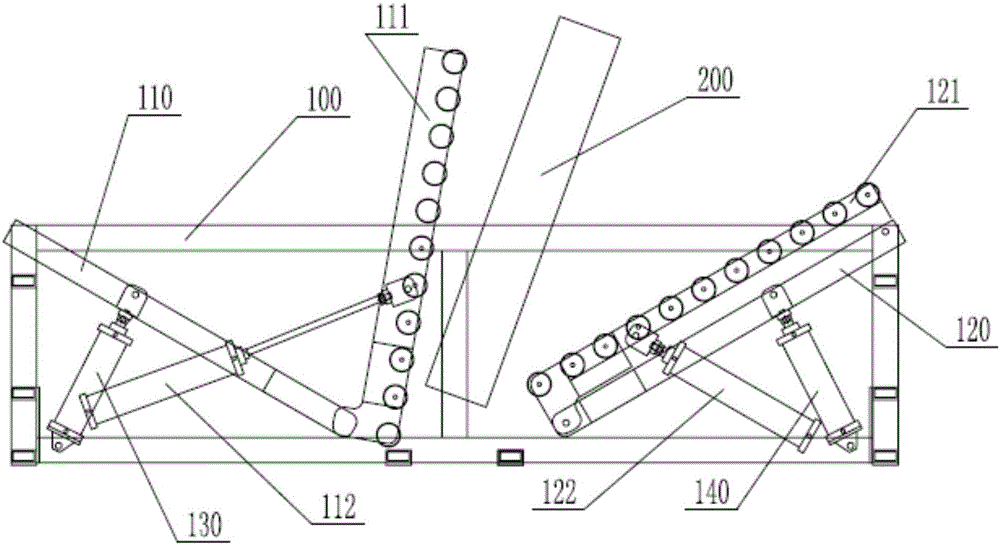

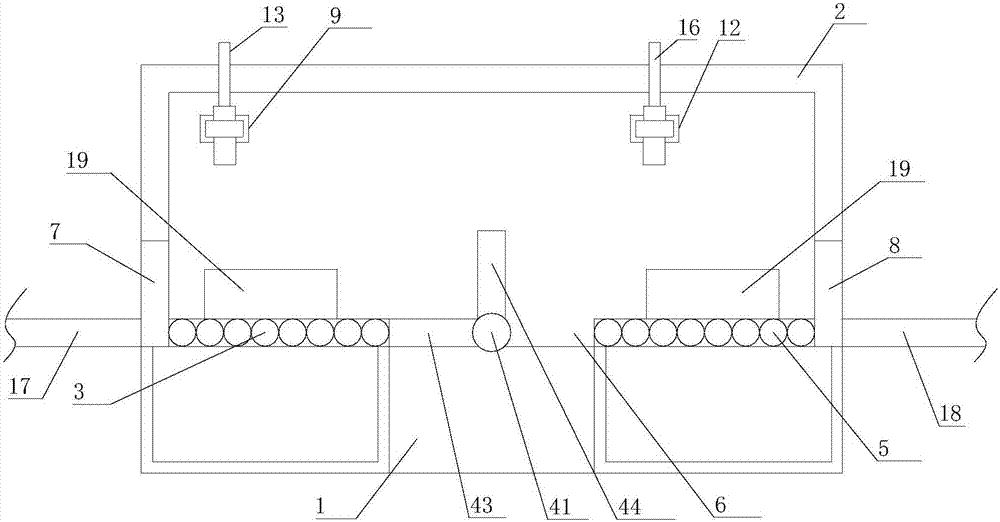

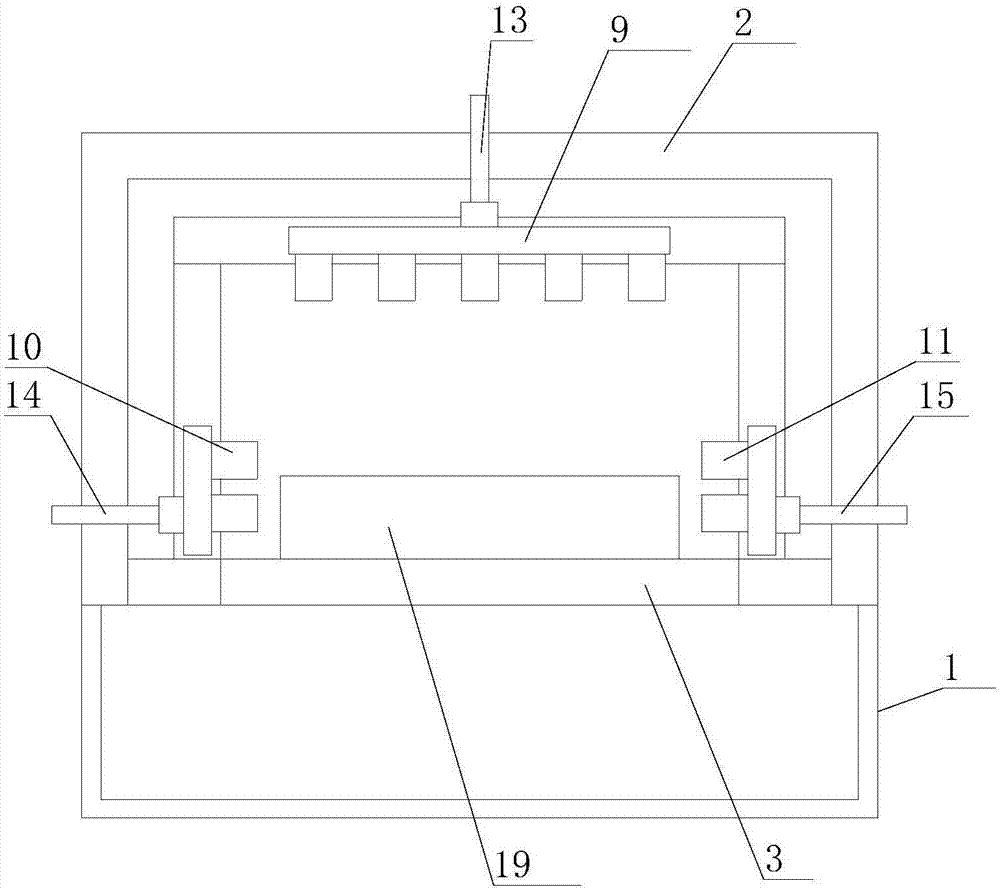

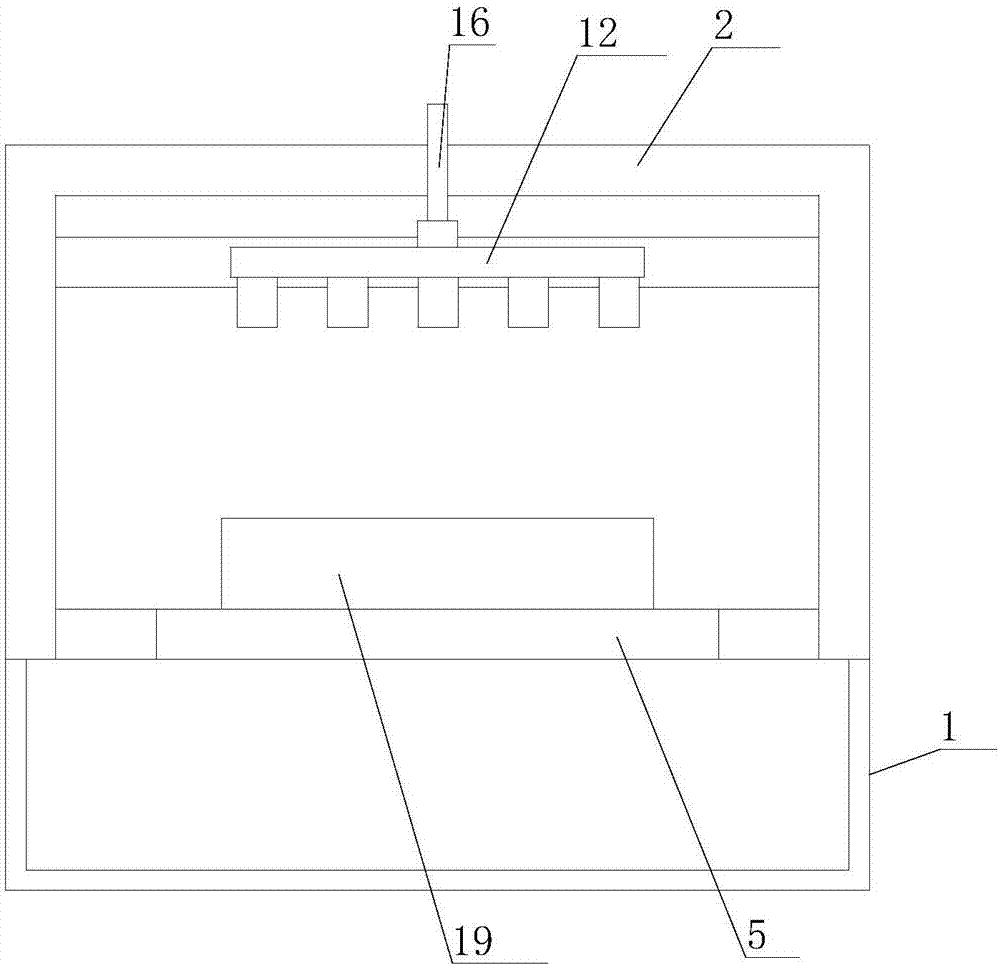

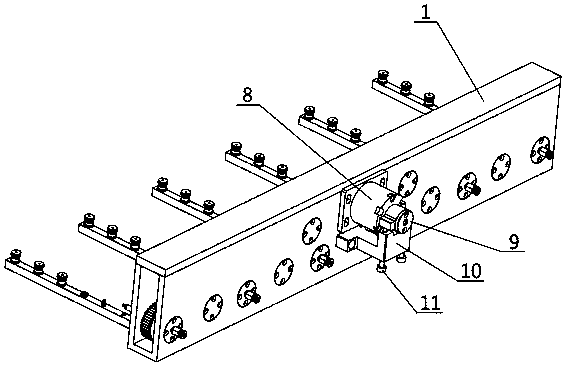

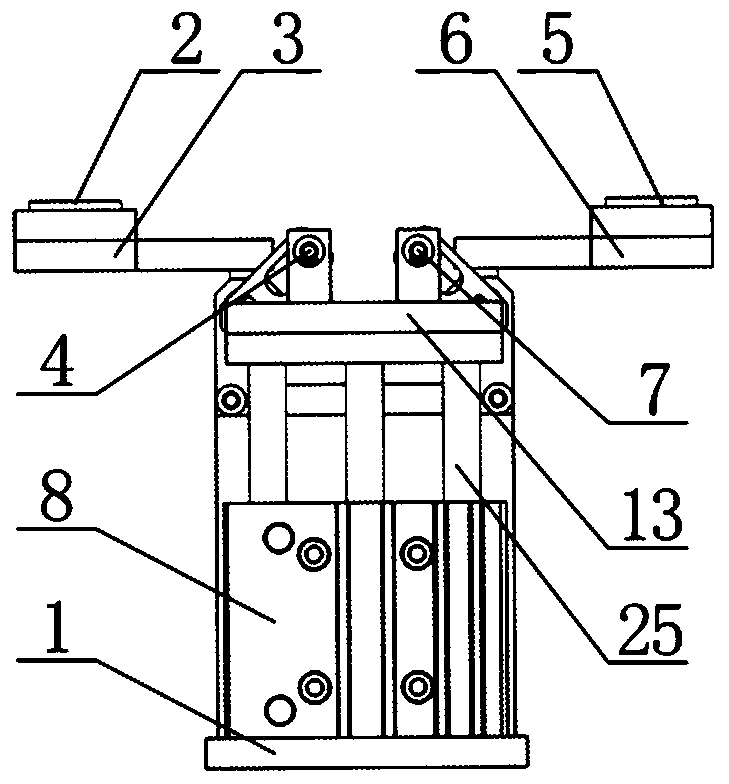

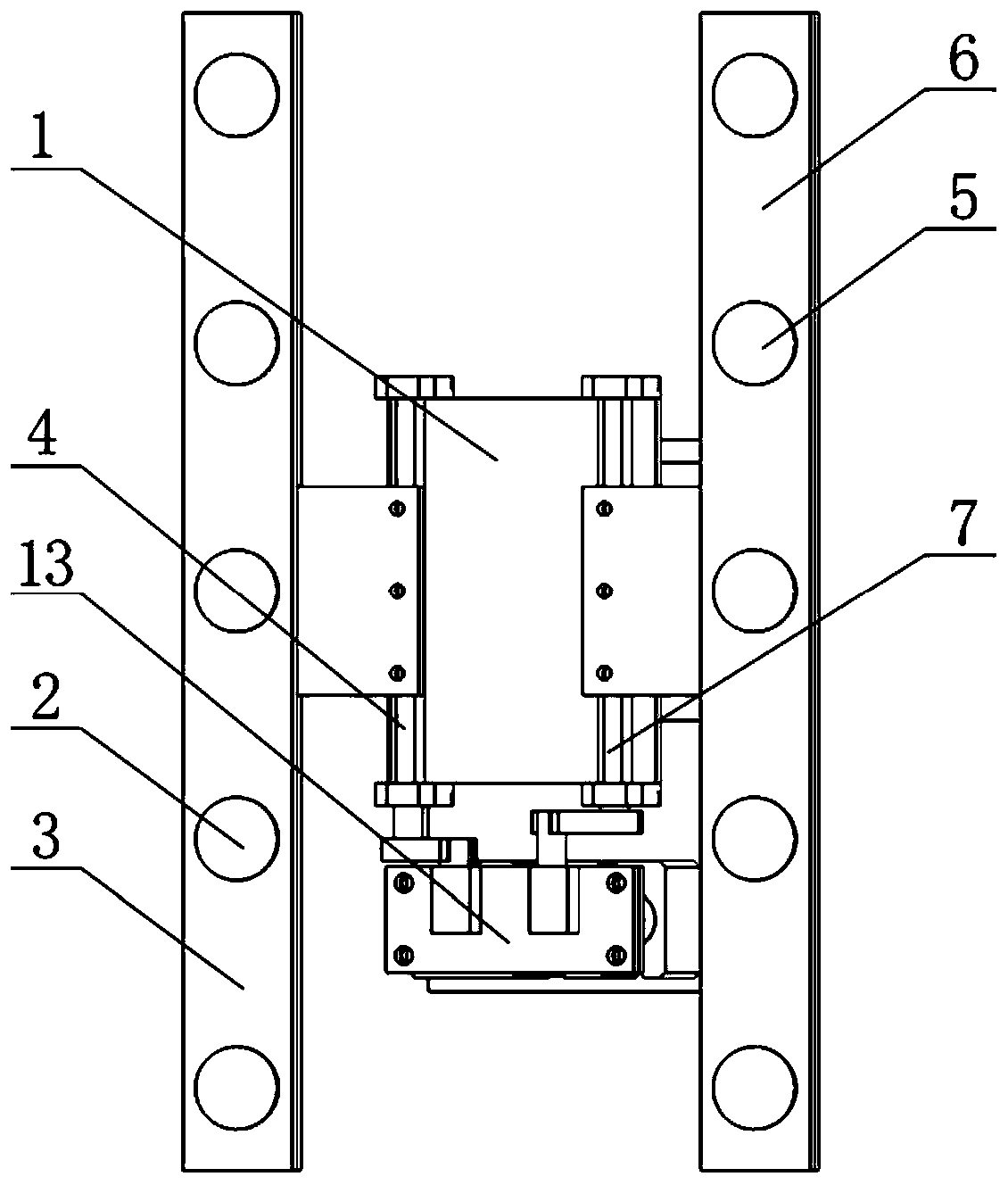

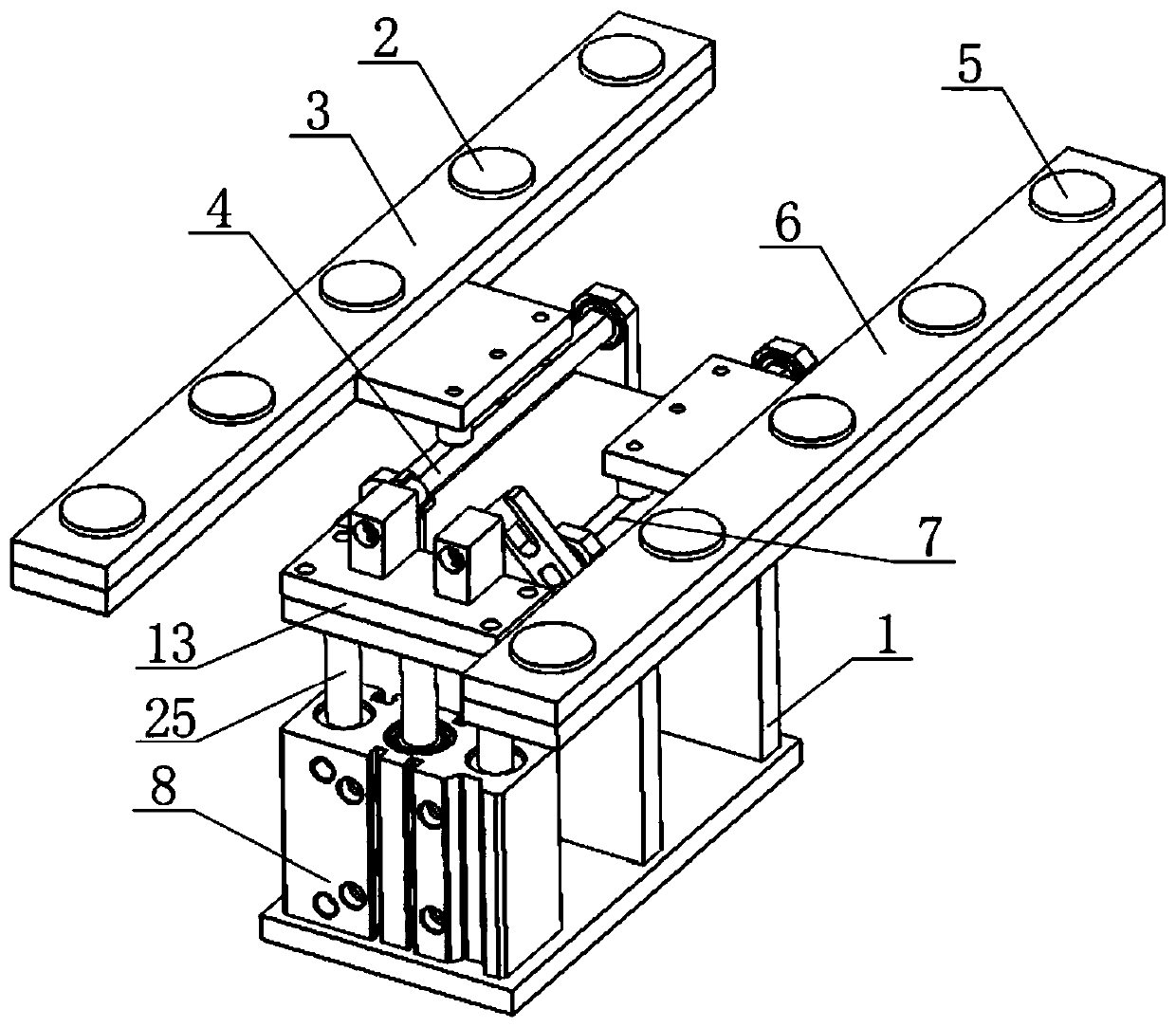

Special-shaped member turnover device and turnover device thereof

ActiveCN104828526ASave installationSave extra spaceConveyor partsEngineeringElectrical and Electronics engineering

The invention provides a special-shaped member turnover device and a turnover device thereof. The special-shaped member turnover device comprises a base, arc guide rails, limitation plates, support plates and positioning blocks. The arc guide rails and the support plates are fixedly arranged on the base; the arc guide rails are of an arc groove structure and are in interval arrangement with the support plates; the limitation plates are fixedly arranged on the support plates and are used for limiting the turnover of special-shaped members; the special-shaped members are arranged on the arc guide rails through the head ends of the arc guide rails, and can slide in arc space formed by the limitation of the limitation plates along the arc guide rails; and the positioning blocks are arranged at the tail ends of the arc guide rails, and are used for positioning the overturned special-shaped members. According to the special-shaped member turnover device and the turnover device thereof, turnover and positioning of the special-shaped members can be realized; the effects of simple structure and flexible operation can be achieved; and external power is not needed.

Owner:GOERTEK INC

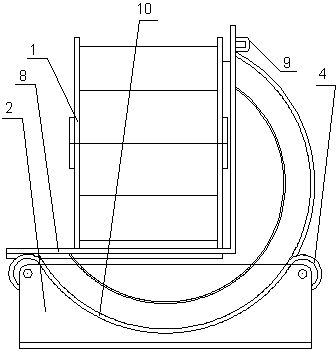

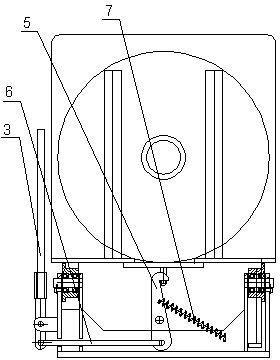

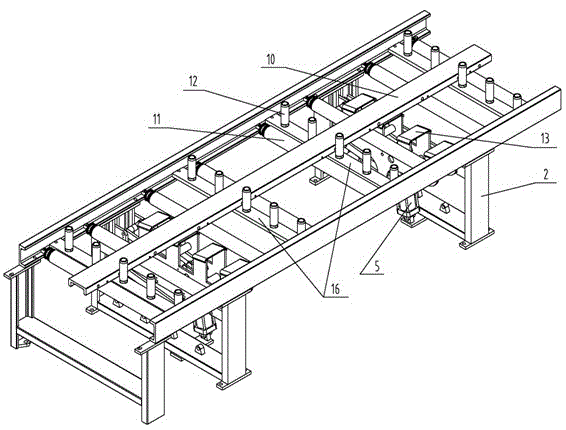

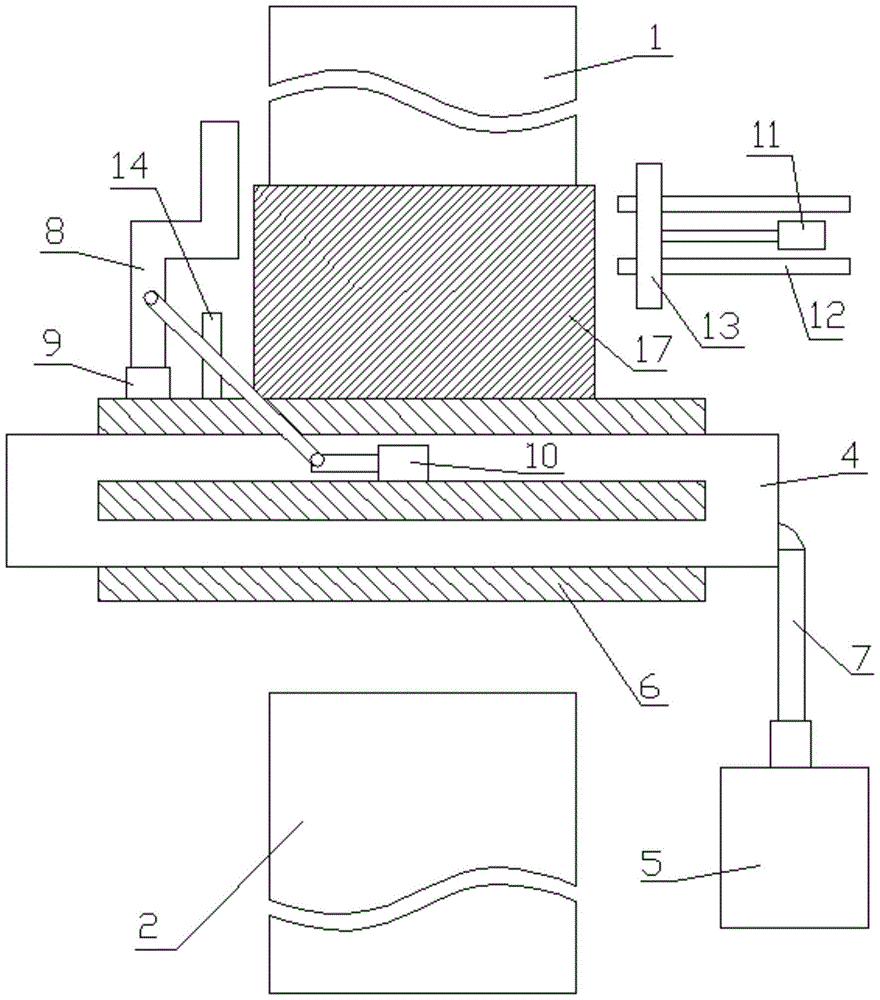

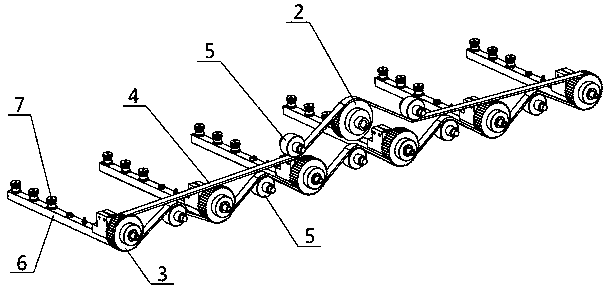

Unpowered rollover machine

InactiveCN103625896AFlip fastSimple structureConveyor partsEngineeringElectrical and Electronics engineering

The invention relates to an unpowered rollover machine which comprises a machine frame, a rollover body and a trip device, wherein the rollover body and the trip device are arranged on the machine frame. Idler wheels are arranged on the machine frame. The rollover body comprises two flat plates used for bearing wire coils and fixed claw hooks connected to the lower surfaces of the flat plates, arc-shaped guide rails are arranged on the lower portions of the flat plates and the idler wheels slide on the guide rails. The trip device is arranged in the machine frame and movably connected with the fixed claw hooks, and the rollover body is controlled to move on the idler wheels. The unpowered rollover machine is simple in structure, convenient to operate, low in production cost, capable of replacing a wire coil rollover machine to be used, high in wire coil rollover speed, safe, reliable, applicable to being used for rolling fully-coiled cables by 90 degrees for furnace entering and annealing, applicable to being used for rolling the fully-coiled cables by 90 degrees for vertical pay-off and applicable to being used for rolling uncoiled / coiled cables for packaging.

Owner:JIANGSU QUNYE ELECTRICAL

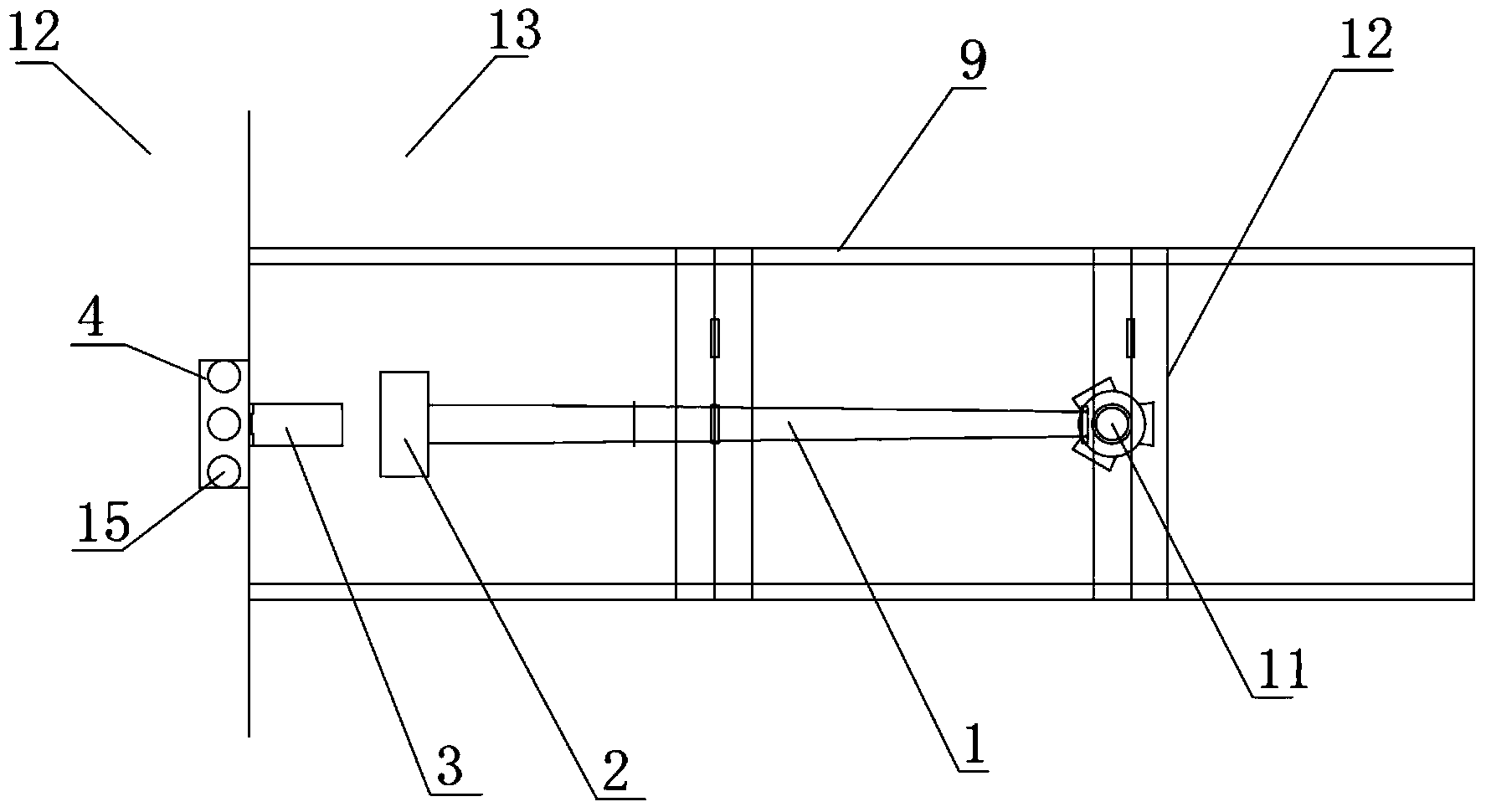

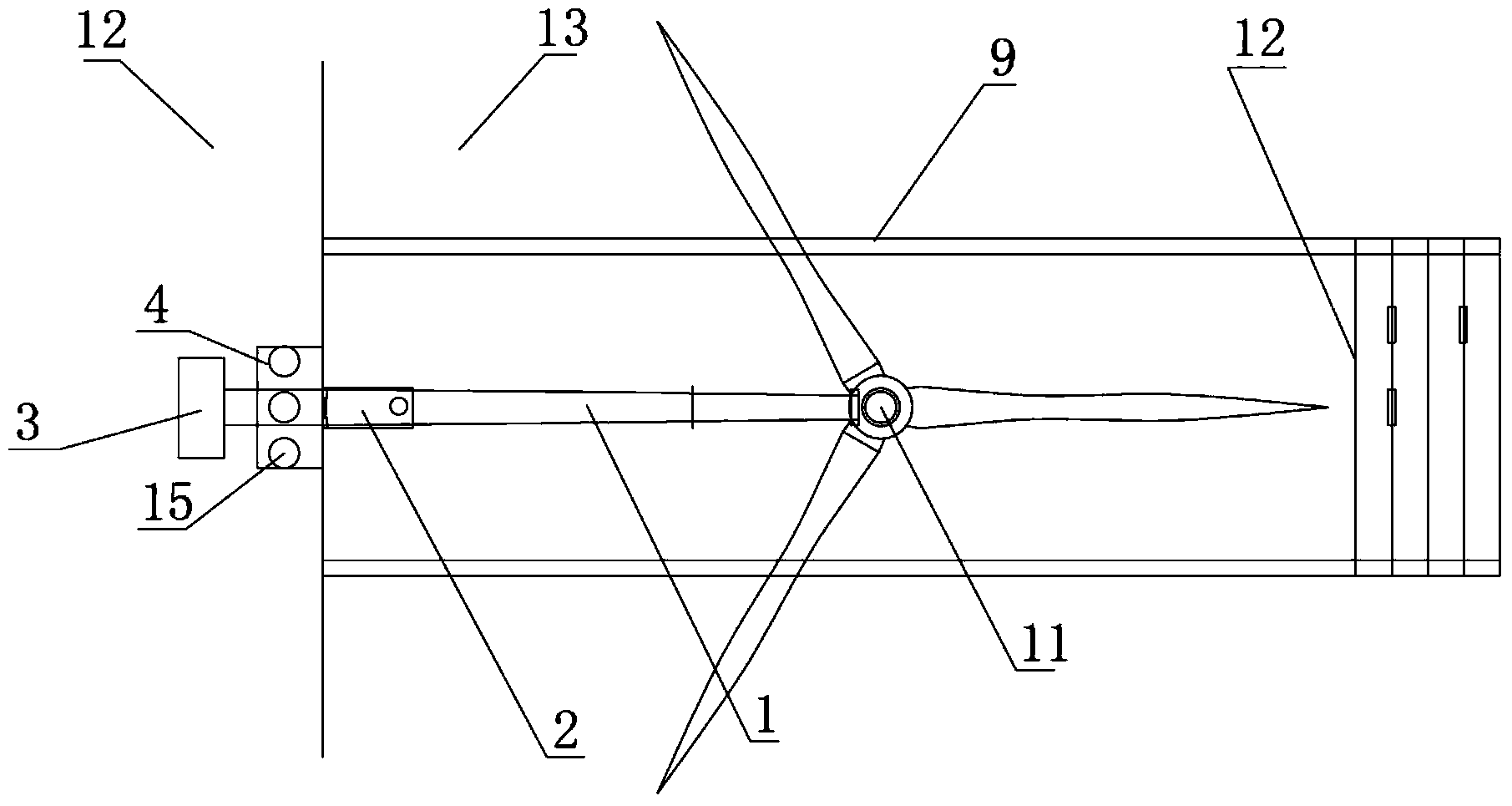

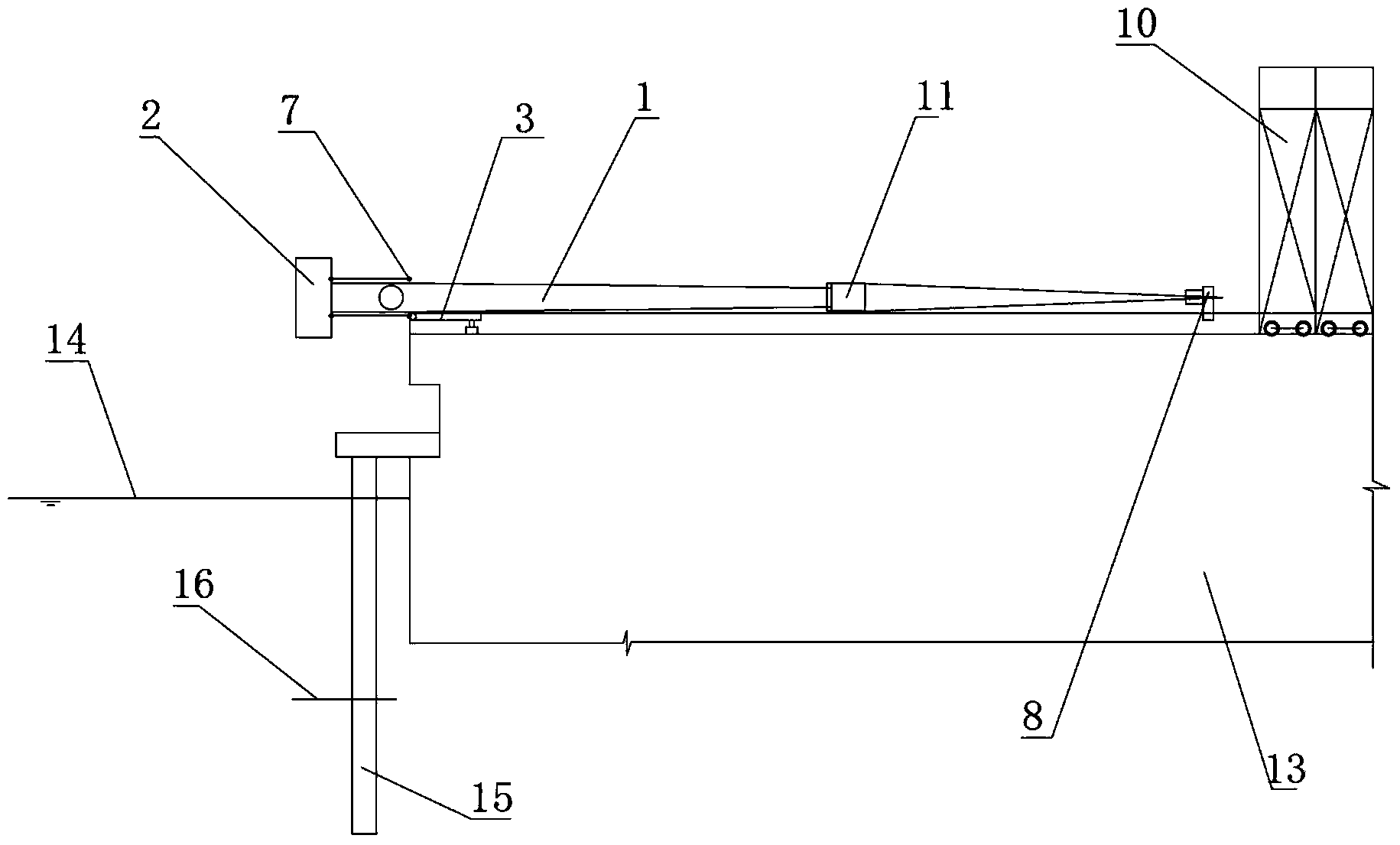

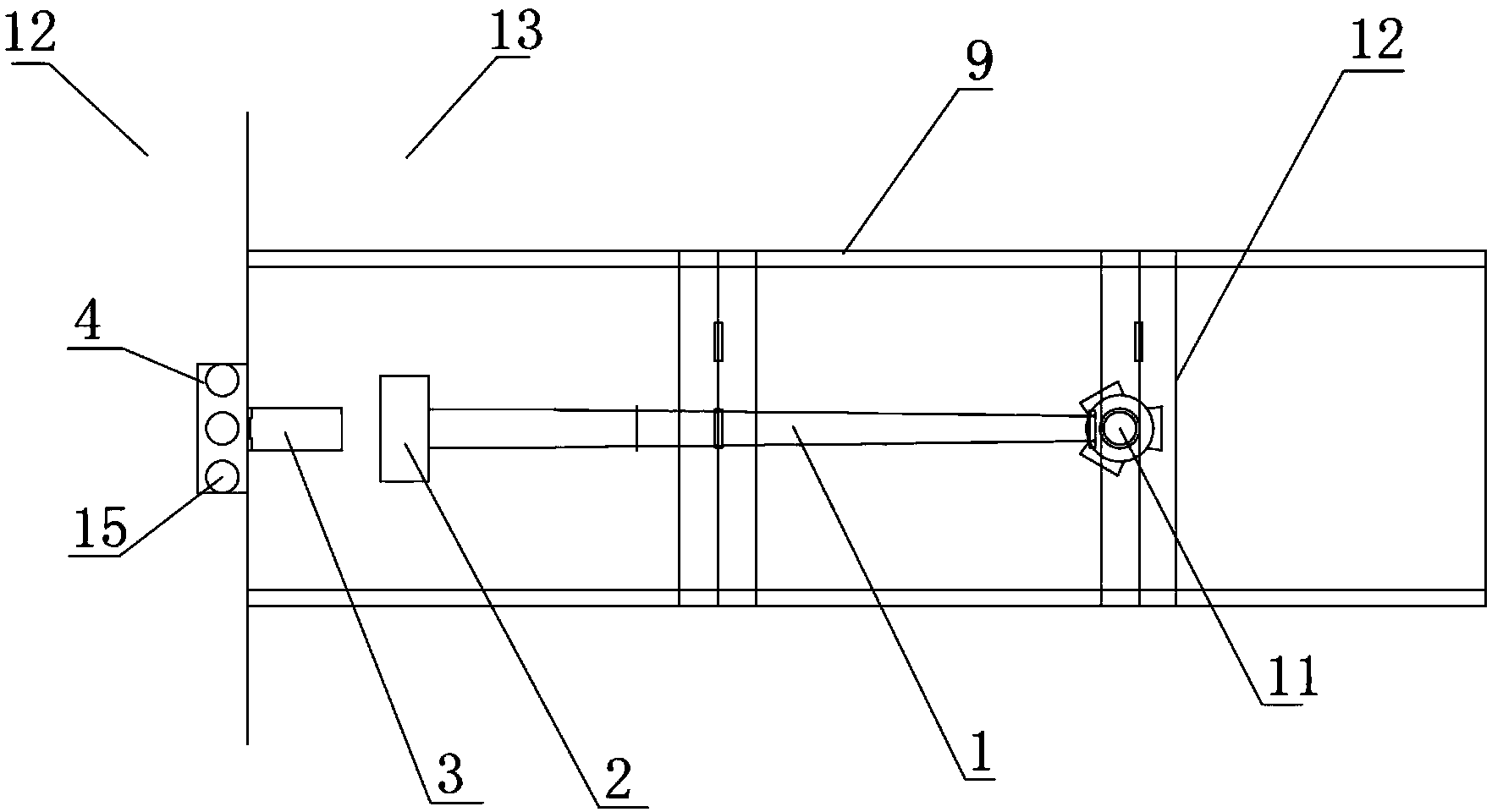

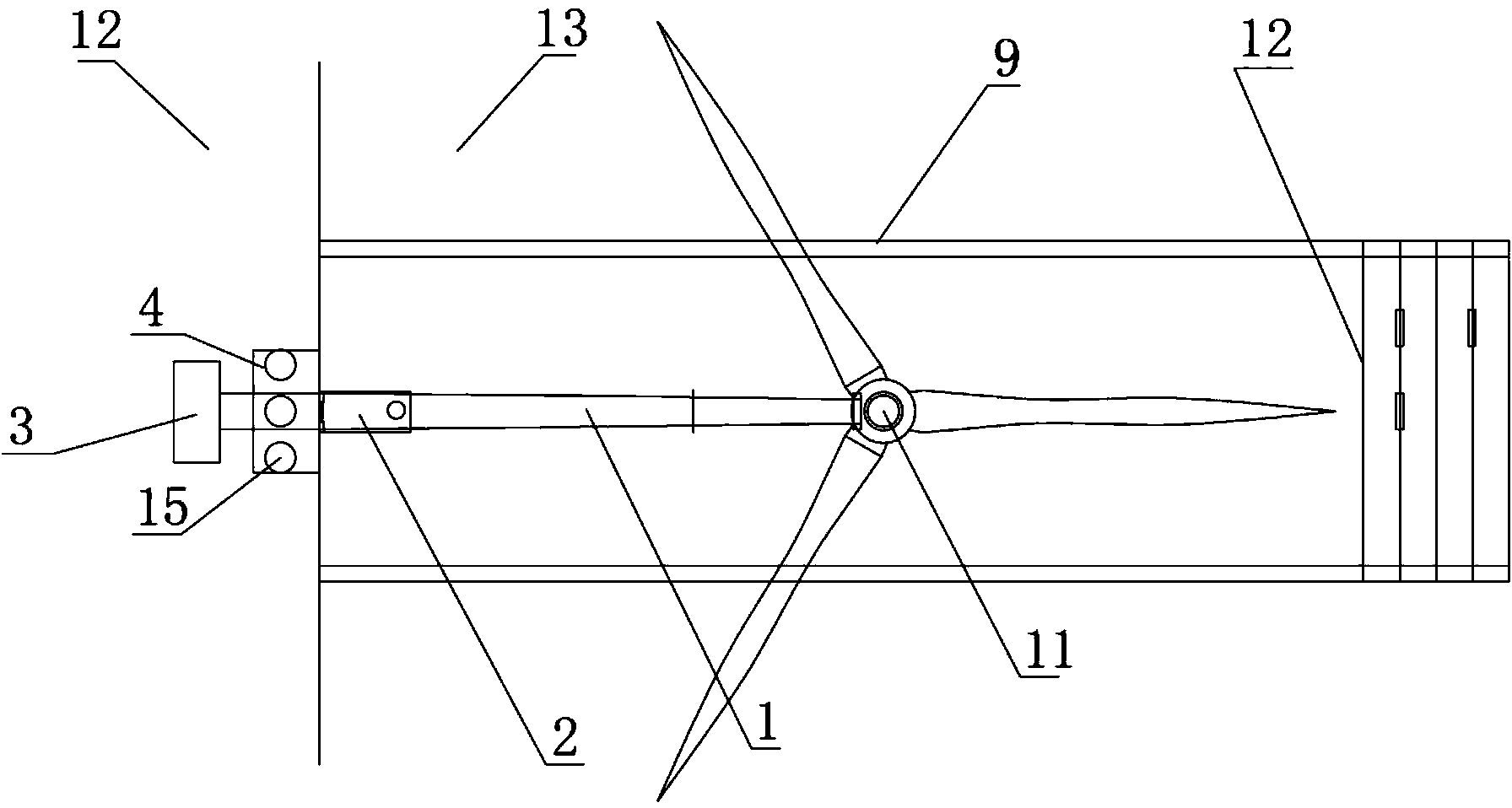

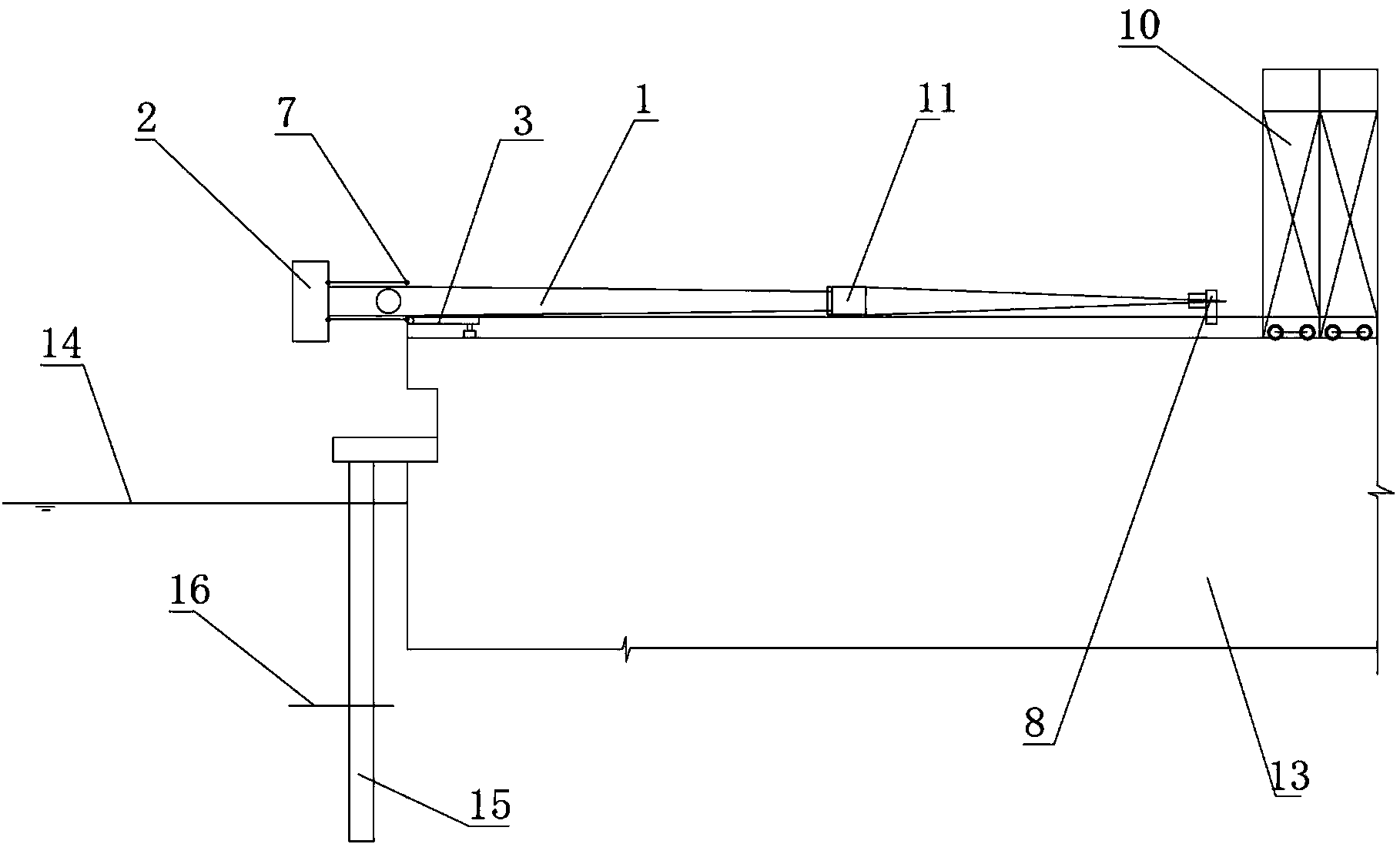

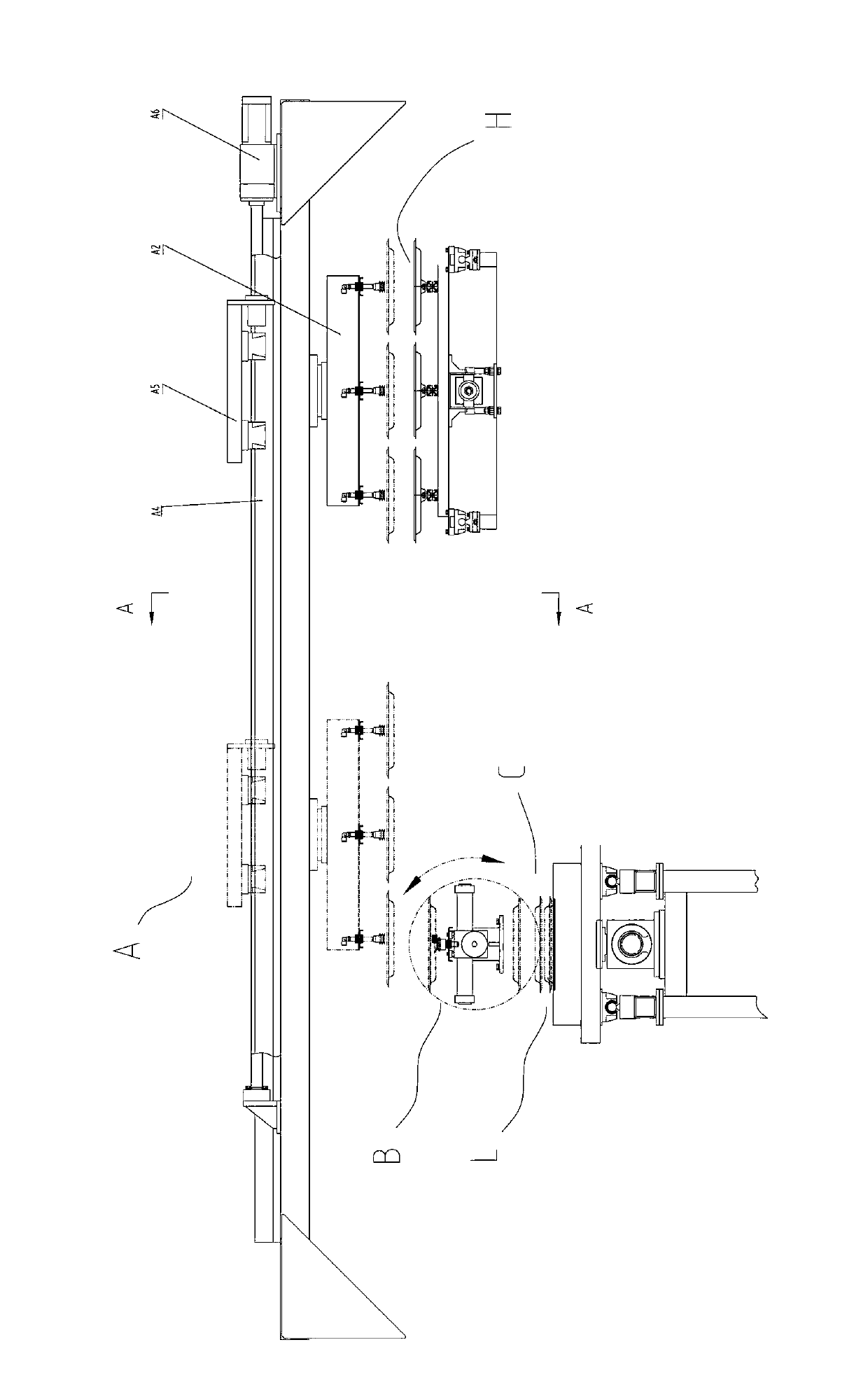

Offshore wind power generation set horizontally-assembling and integrally-overturning-and-erecting device and construction method thereof

ActiveCN103807115AFast assemblyFlip fastArtificial islandsWaterborne vesselsMarine engineeringOffshore wind power

The invention relates to an offshore wind power generation set horizontally-assembling and integrally-overturning-and-erecting device which comprises a ballasting system detachably mounted on the bottom of a fan tower tube, an overturning device arranged beside a wharf, and a supporting platform arranged below the overturning device, wherein the overturning device comprises an overturning supporting plate hinged to the edge of the wharf and a hydraulic oil cylinder with one end hinged to the overturning supporting plate and the other end hinged to the wharf. By the adoption of the structure, fan assembly can be achieved quickly and safely, the influence of natural conditions such as wind and other weather conditions is small, construction is convenient, overturning speed is high, and the tower tube can be both overturned and placed flat. The technology is small in influence on the surrounding environment, safe, and low in engineering construction cost.

Owner:NO 2 ENG CO LTD OF CCCC FIRST HARBOR ENG

Offshore wind power generation set horizontally-assembling and integrally-overturning-and-erecting installation system and method

ActiveCN103807114AFast assemblyFlip fastWind energy generationWind motor componentsEngineeringOffshore wind power

The invention relates to an offshore wind power generation set horizontally-assembling and integrally-overturning-and-erecting installation system which is characterized by comprising a hoisting system, a draught fan, a tower tube and a supporting platform arranged below a wharf, the hoisting system, the draught fan and the tower tube are arranged on the wharf, a draught fan tower tube erecting device is further arranged on the wharf, and the erecting device comprises a ballasting system detachably mounted on the bottom of the draught fan tower tube and an overturning device arranged beside the wharf. The method comprises the steps that the draught fan is horizontally assembled and then moved to a position beside the wharf, the draught fan tower tube is made to be perpendicular to the wharf, and then the draught fan tower tube is erected. By the adoption of the structure, draught fan assembly can be achieved quickly and safely, the influence of natural conditions such as wind and other weather conditions is small, construction is convenient, overturning speed is high, and the tower tube can be both overturned and placed flat. The technology is small in influence on the surrounding environment, safe, and low in engineering construction cost.

Owner:NO 2 ENG CO LTD OF CCCC FIRST HARBOR ENG

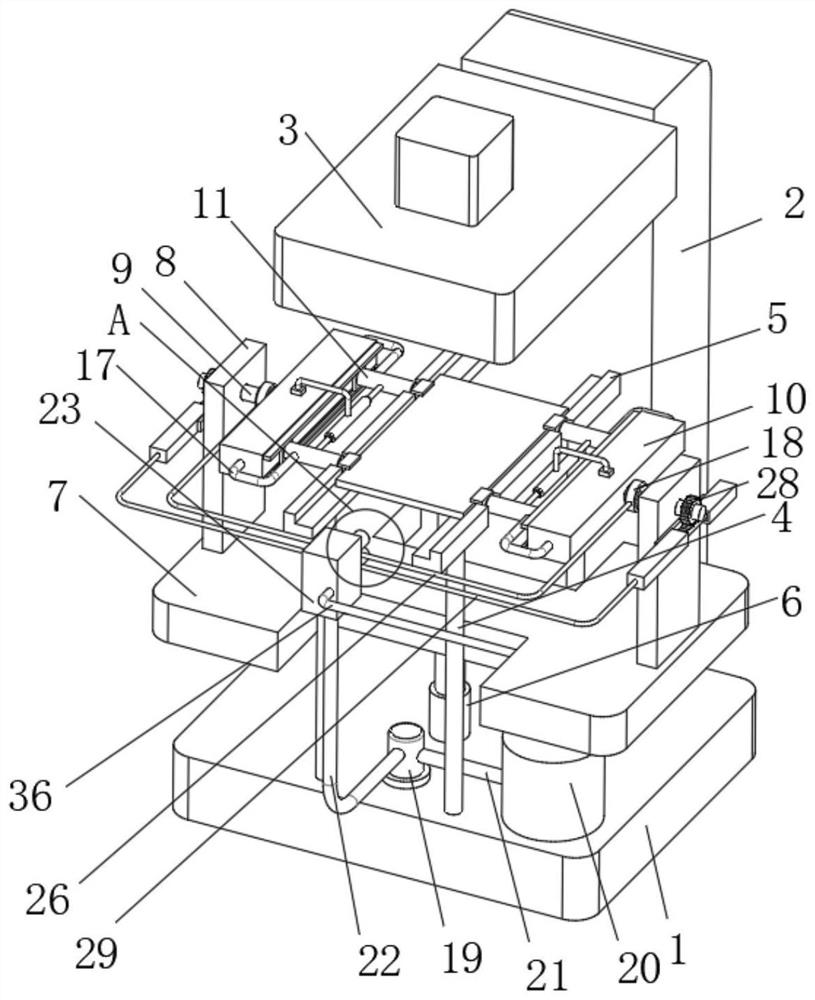

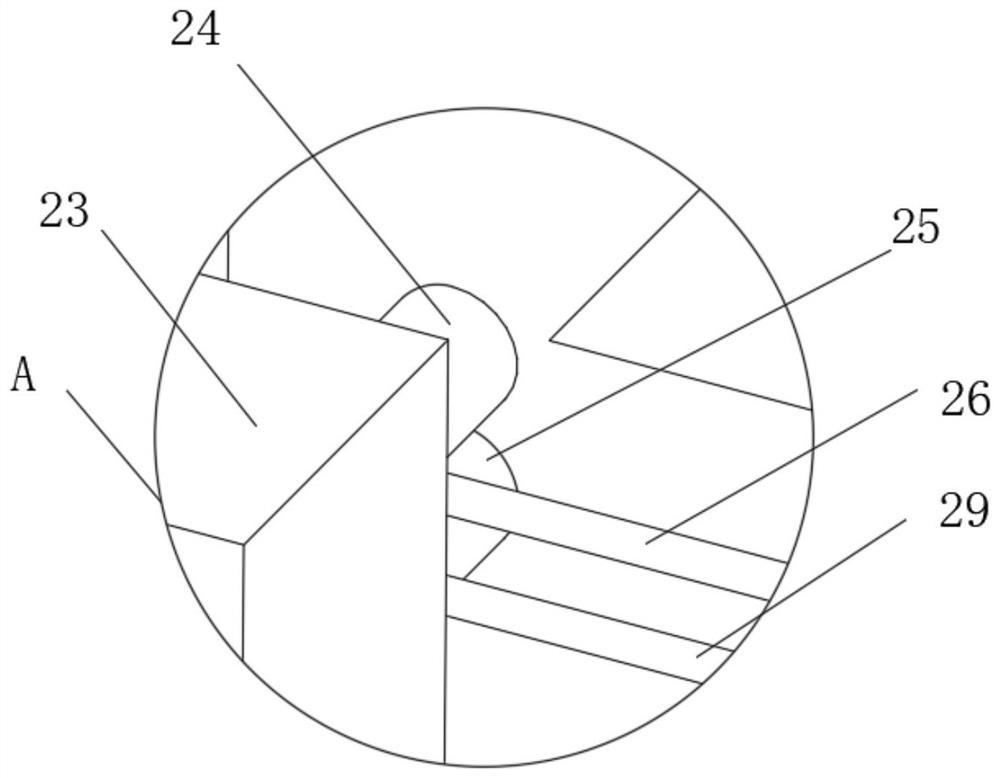

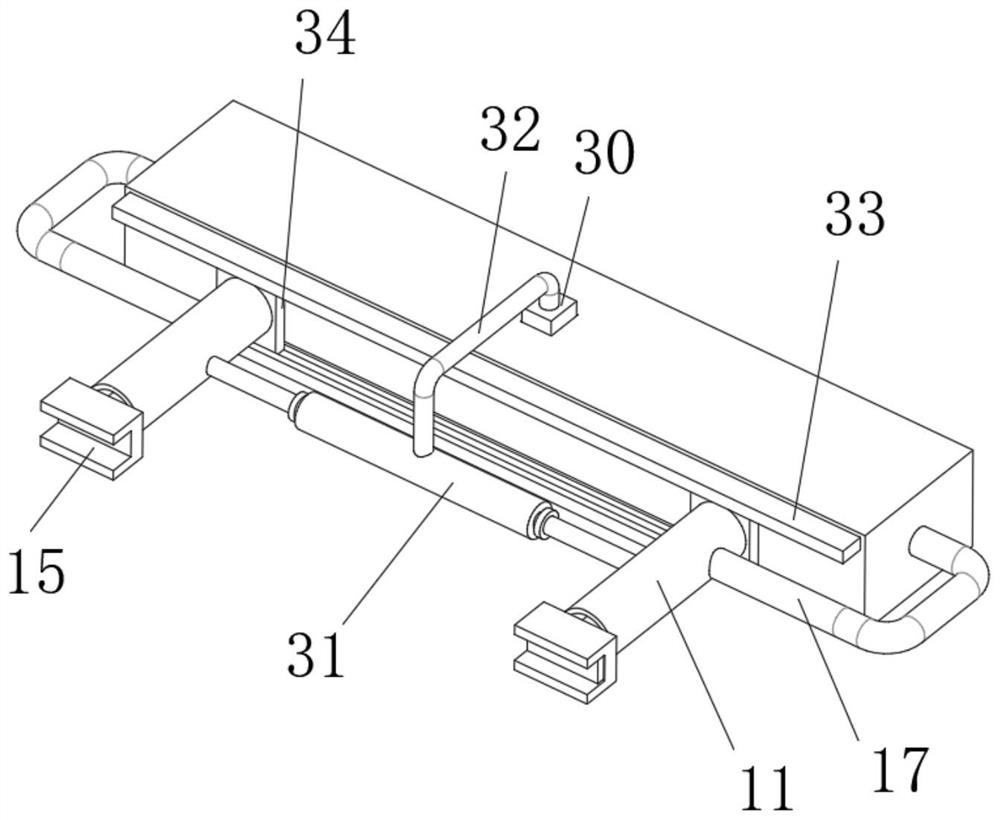

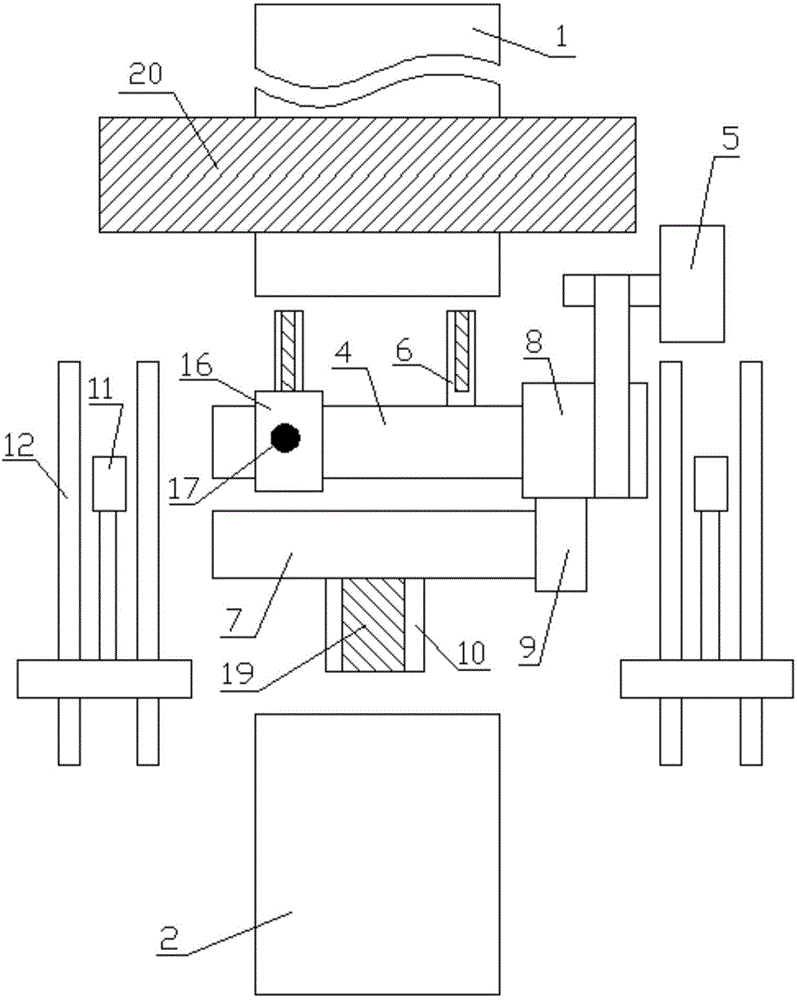

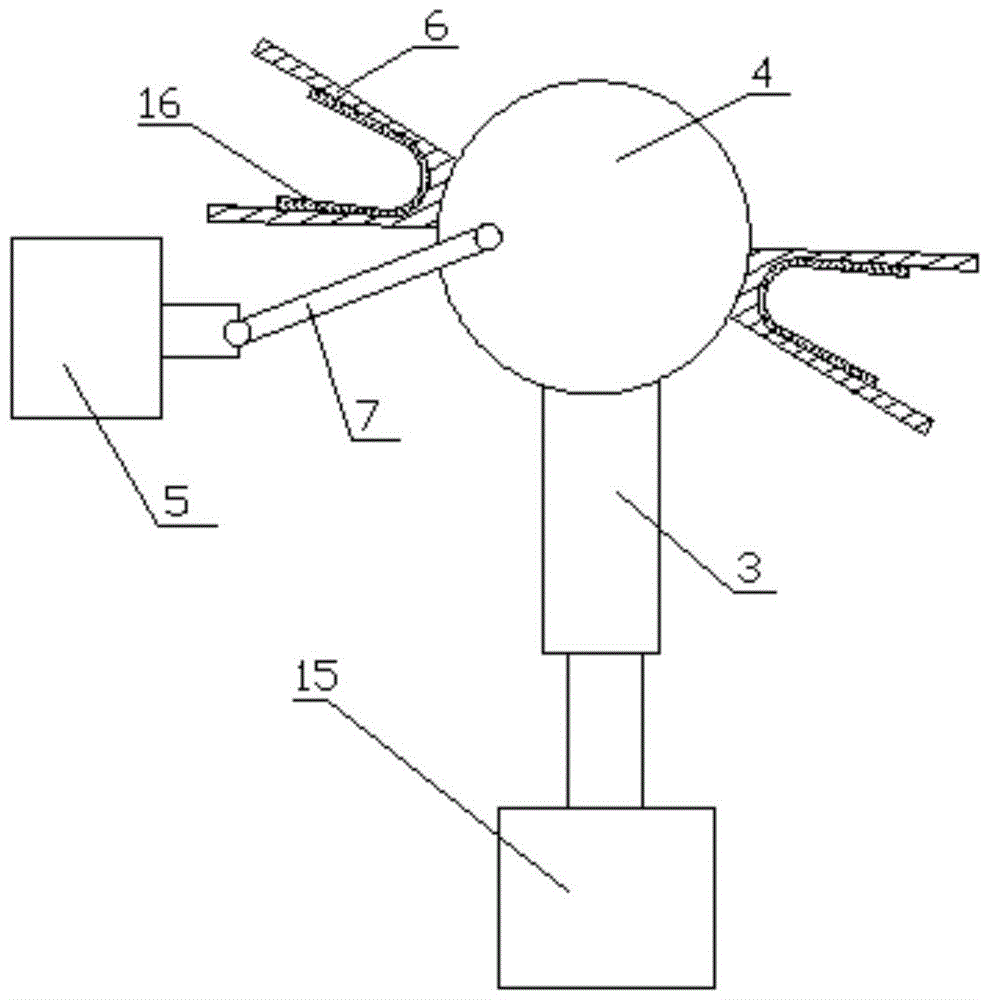

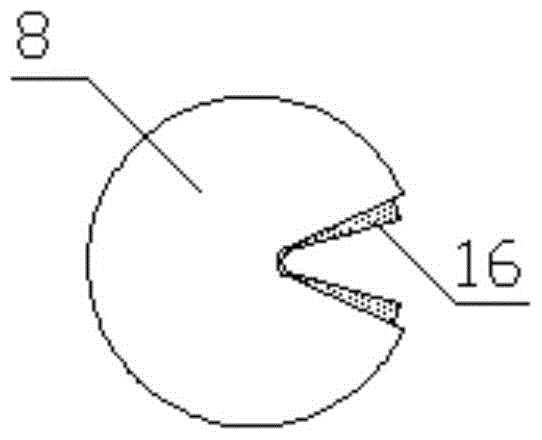

Plant fiber molded product transfer method and plant fiber molded product turning transfer device

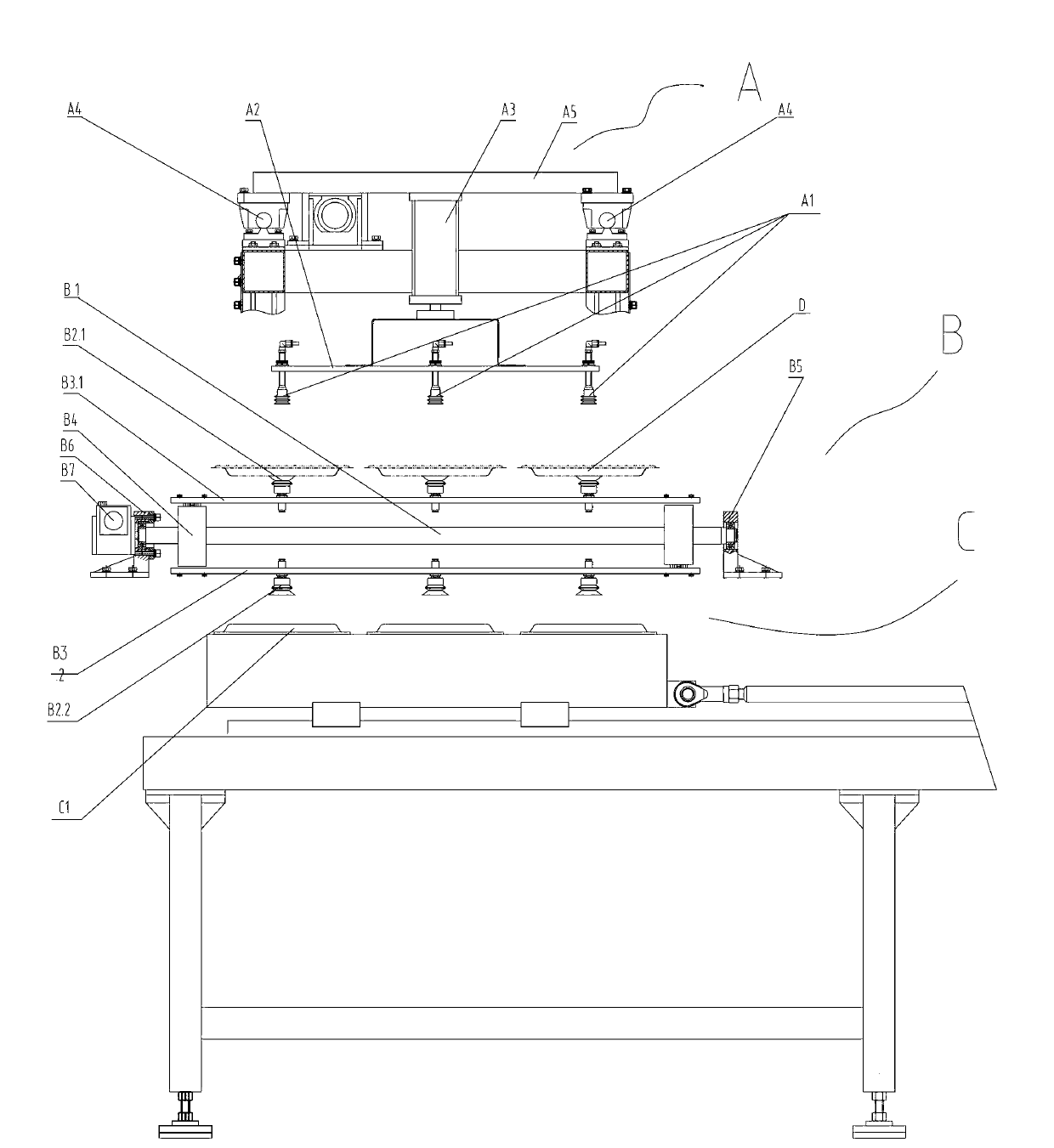

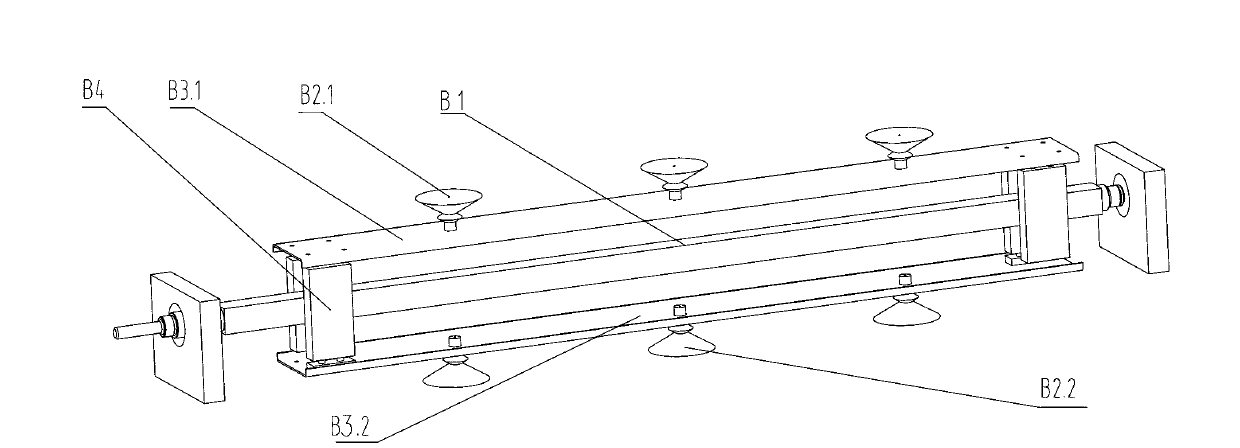

The invention relates to a plant fiber molded product transfer method and a plant fiber molded product turning transfer device, wherein the method and the device have the advantage of being capable of improving product quality and production efficiency. The plant fiber molded product transfer method is characterized in that a turner device B is arranged, a high-position transfer device sucks a product from a high position which the product is to be transferred to and transferring the product horizontally to the turner device B, and the product is transferred to a lower portion from the high position through the turner device B, and turning of the product is achieved at the same time. The plant fiber molded product turning transfer device comprises the high-position transfer device A. The high-position transfer device A comprises a high-position transfer sucking disc group A1, a transfer air cylinder A3, a transfer power transmission mechanism A6 and the like. The plant fiber molded product turning transfer device is characterized by being further provided with the turner device B. The turner device B comprises a turning shaft B1.

Owner:EURASIA LIGHT IND EQUIP MFR

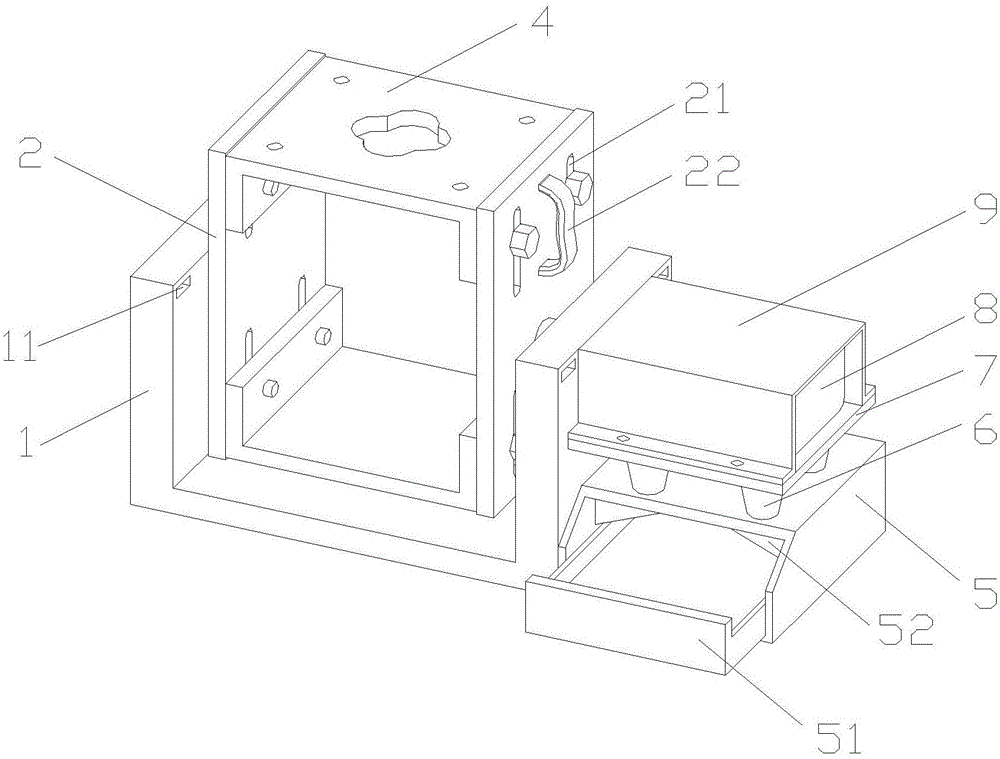

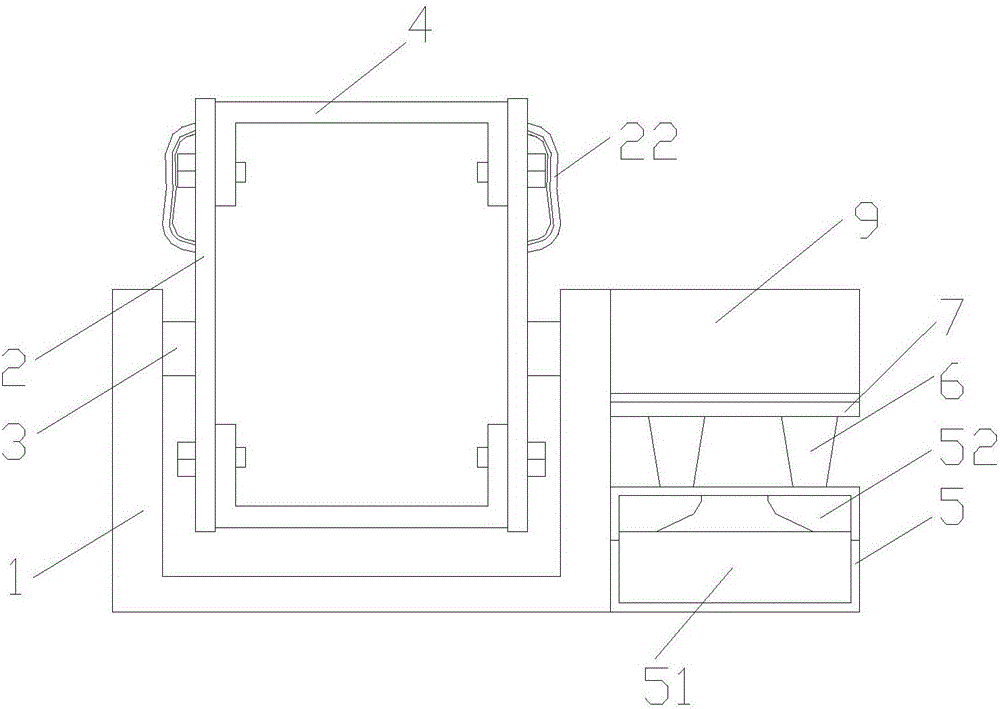

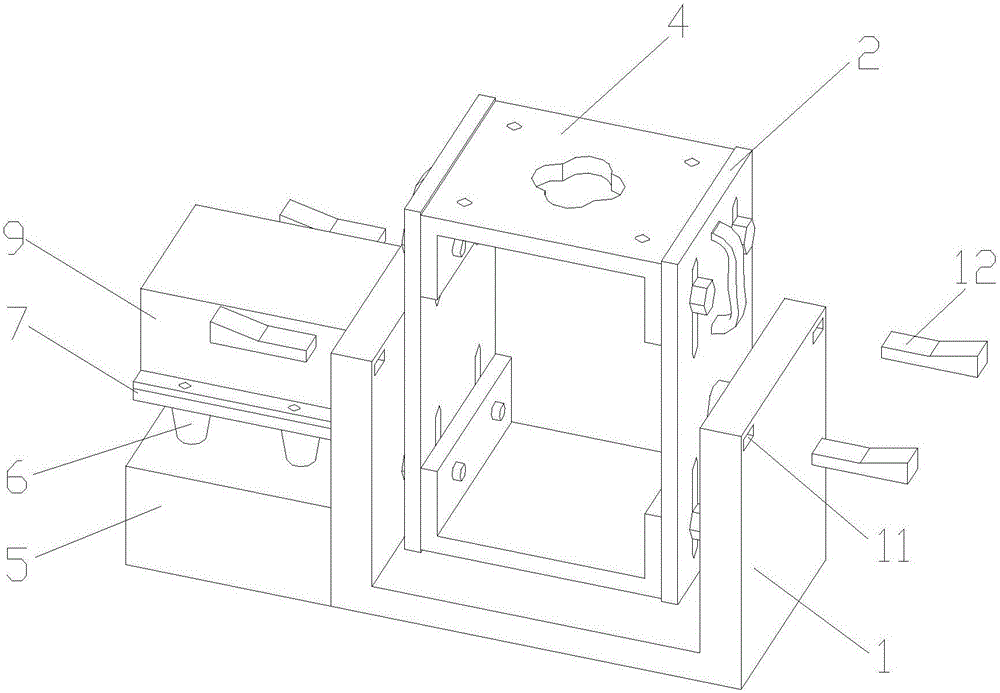

Rotary type 360-degree product burr detecting device

ActiveCN108982509ARealize directional deliveryTransport stableOptically investigating flaws/contaminationPulp and paper industryManipulator

The invention discloses a rotary type 360-degree product burr detecting device. The device comprises a worktable, wherein a discharging port at the left side of a vibrating tray is connected with a vibrating guide rail, a splitting part comprises a splitting block, the front end of the splitting block is connected with the end of the vibrating guide rail, the rear end of the splitting block is connected with a splitting cylinder, a stock moving part comprises a manipulator, the lower side of the manipulator is connected with a product moving fixture, the lower end of a rotary fixture is fixedto an output shaft end of a servomotor, a first observation hole, which is downwards concave inwardly, is formed in the center of the surface of the rotary fixture, the two sides of the first observation hole serve as locating tables, second observation holes penetrate through interior of centers of the locating tables and are vertical to the first observation hole, each product comprises a substrate, and two parts to be detected are symmetrically fixed to the lower surface of each substrate. The device has the effects that the splitting block accurately separates the products, two optical cameras detect burrs in a 360-degree dead-corner-free manner, and the efficiency of detection is high.

Owner:DONGGUAN SHENGXIANG PRECISION METAL

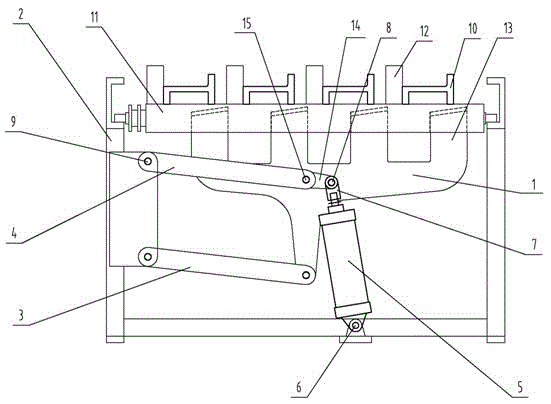

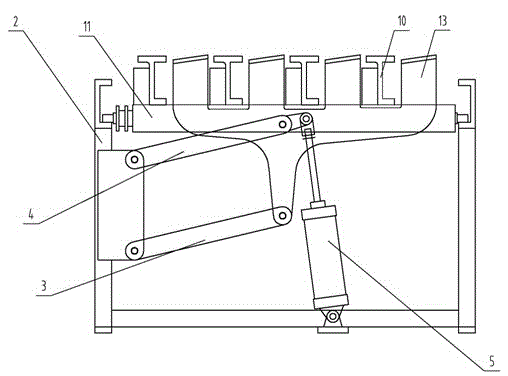

Pneumatic overturning conveying device

The invention discloses a pneumatic overturning conveying device, which comprises a conveying roller way frame, wherein the conveying roller way frame is provided with a carrier roller for conveying articles; a jacking and overturning device is arranged below the conveying roller way frame, and comprises a fixed mount and a power jacking mechanism which is connected to the fixed mount and is used for jacking articles; and the power jacking mechanism comprises an overturning frame and an air cylinder of which one end is connected to a fixed mount base and the other free end is connected with and used for driving the overturning frame to performing jacking actions. The pneumatic overturning conveying device has the advantages of high overturning speed during production and use, high efficiency, low application labor intensity, prevention of equipment from being damaged and easiness in maintaining. According to the pneumatic overturning conveying device, the overturning frame is driven through the stroke of the air cylinder for realizing overturning of articles, the flow of an entire production line is semi-automatic, the production working efficiency is increased, and the production cost is lowered.

Owner:ANHUI HAOYUN MACHINERY

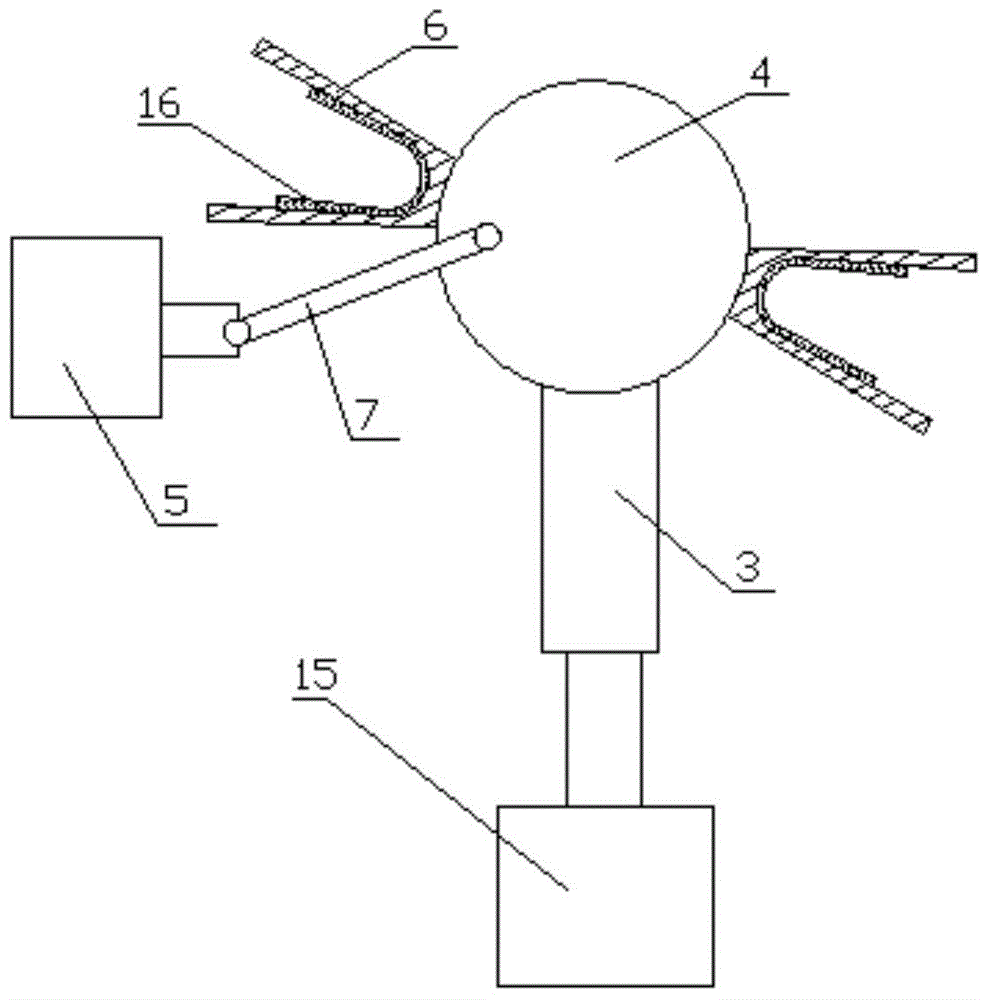

Ceramic tile flip-over method and ceramic tile flip-over device

Disclosed are a ceramic tile flip-over method and a ceramic tile flip-over device. The ceramic tile flip-over method includes a tile clamping process and a tile flipping process. The ceramic tile flipping process includes a tile clockwise-flipping process and a tile anticlockwise-flipping process, performed in cyclic sequence. The tile clock-wise flipping process includes: jacking one swing bar by an air cylinder to allow a rotary shaft of one chuck to rotate at certain angle; and jacking the other swing bar deviating to the left by the other air cylinder to allow a guide bush to drive the rotary shaft to continue rotating clockwise, thereby turning anticlockwise a ceramic tile to be vertical. The tile anticlockwise-flipping process includes: jacking one swing bar by one air cylinder, driving the corresponding rotary shaft to rotate anticlockwise at certain angle by the corresponding guide bush; jacking the other swing bar deviating to the right by the other air cylinder to enable the corresponding guide bush to drive the rotary shaft to continue rotating anticlockwise, thereby turning anticlockwise the ceramic tile to be vertical. Compared with the prior art, the ceramic tile flip-over method and the ceramic tile flip-over device have the advantages that flipping speed is high, structure is simple, reliability is high, maintenance is easy, and heavy ceramic tiles can be flipped continuously.

Owner:KING STRONG MATERIAL ENG LTD

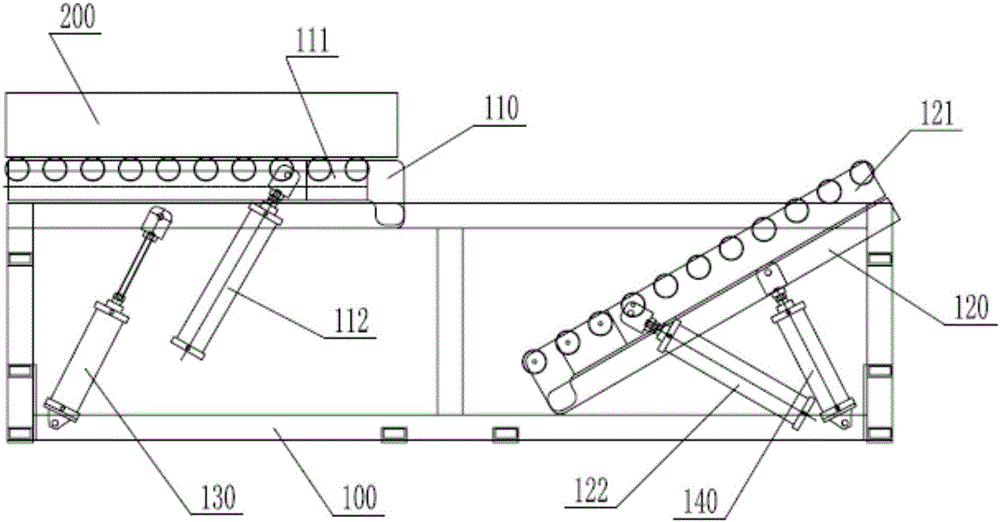

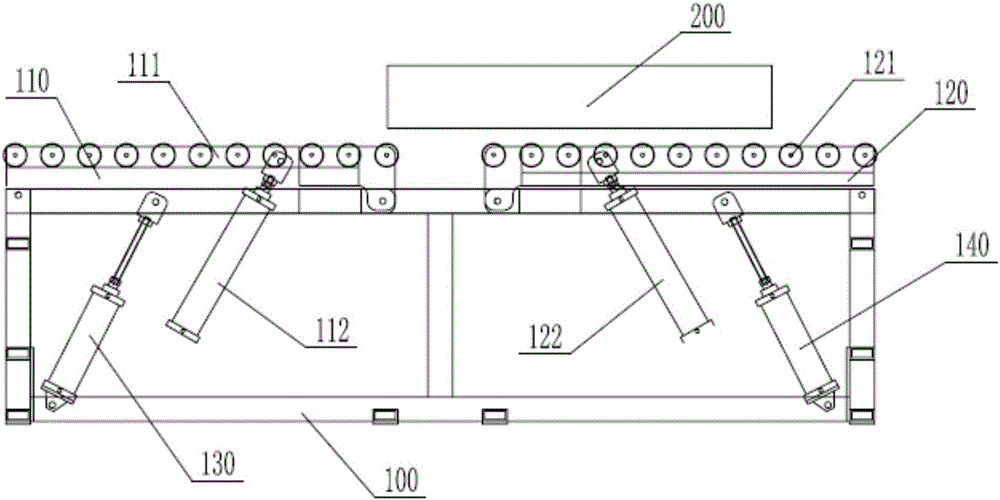

Mattress overturning machine

The invention relates to a mattress production device, in particular to a mattress overturning machine which comprises a bottom frame, a first conveying mechanism and a second conveying mechanism. The first conveying mechanism and the second conveying mechanism are installed on the top face of the bottom frame, and a conveying face of the first conveying mechanism and a conveying face of the second conveying mechanism are locate on the same horizontal plane. The side, close to the second conveying mechanism, of the first conveying mechanism is hinged to the bottom frame. A first roller set air cylinder capable of pushing the first conveying mechanism to overturn upwards and reset along the hinge joint position is installed below the first conveying mechanism. The first conveying mechanism can drive a mattress to overturn, and the conveying face of the first conveying mechanism can be kept horizontal after the mattress is overturned and resets. By means of the mattress overturning machine, due to the combination of reverse rotation of a first overturning frame and a second overturning frame and opposite rotation of the of the first conveying mechanism and the second conveying mechanism, the mattress can be overturned without manual carrying, and the mattress overturning machine has the beneficial effects of being high in automation degree, high in overturning speed and the like.

Owner:SHENZHEN ZHONGSHEN AIDE BEDDING TECH CO LTD

Small-sized and quickly-turning Schmitt trigger circuit used for silicon on insulator technique

The invention discloses a small-sized and quickly-turning Schmitt trigger circuit used for silicon on insulator technique. A p-channel metal oxide semiconductor (PMOS) / n-channel metal oxide semiconductor (NMOS) control circuit is adopted to change threshold voltage, input change from a high level to a low level and input change from the low level to the high level can have different turn thresholds, and therefore a Schmitt trigger function can be achieved. Through adoption of the PMOS / NMOS control circuit, time for ascending and descending is shortened, the amount of transistors on a pull-up path and a pull-down path is decreased at the same time, and compared with a traditional structure, the circuit is fast in turning speed and small in size.

Owner:GUANGZHOU HUIZHI MICROELECTRONICS

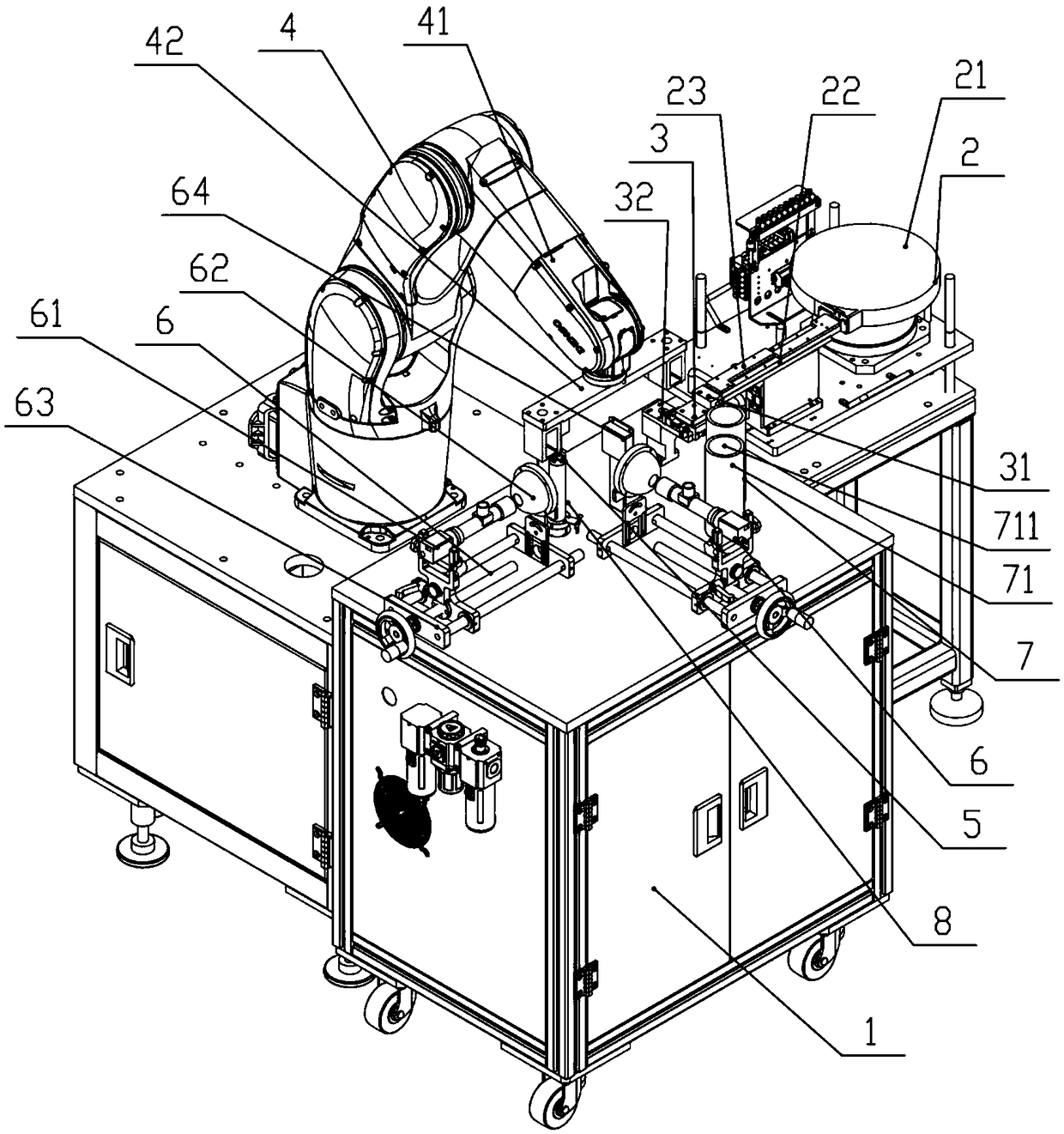

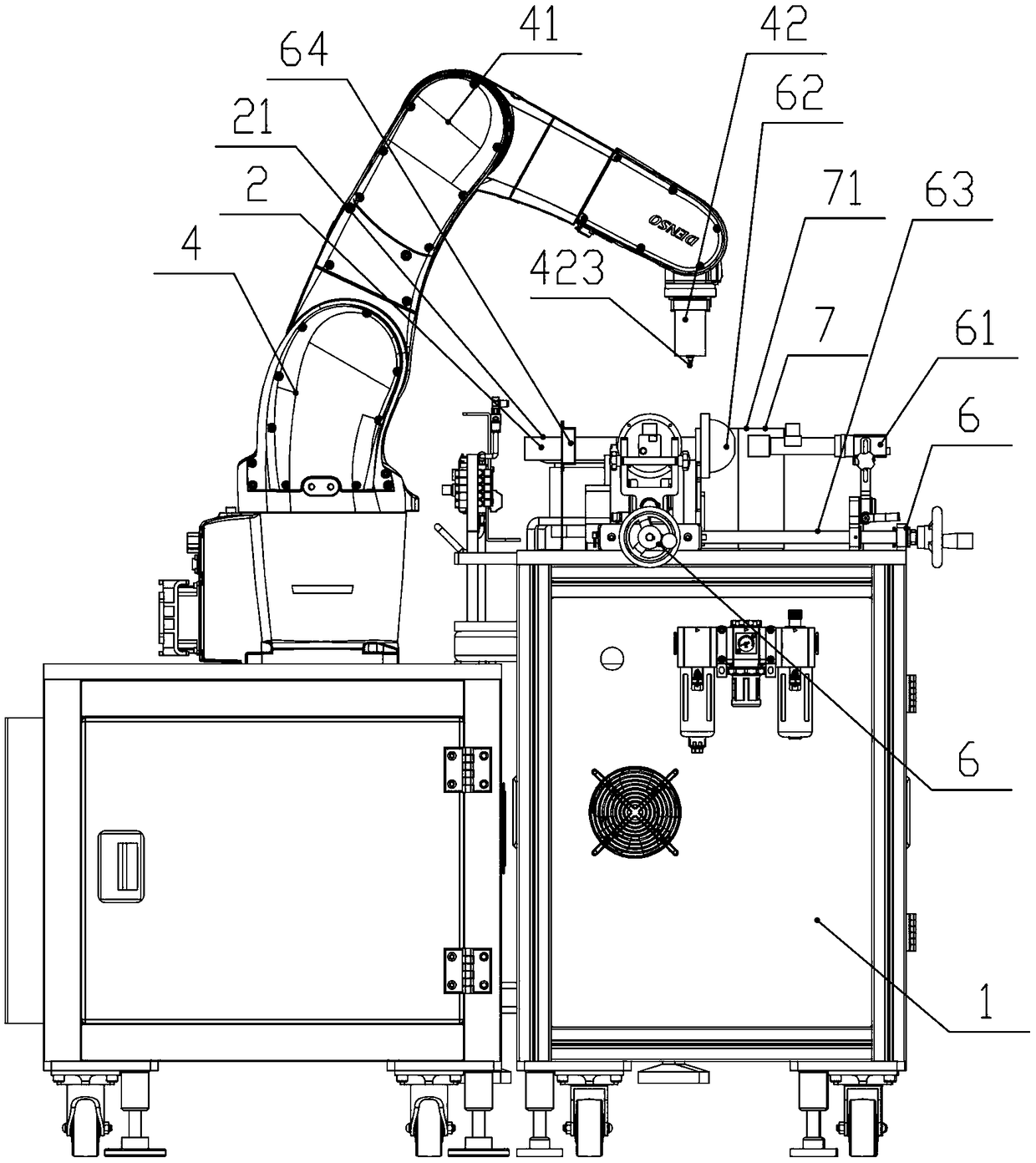

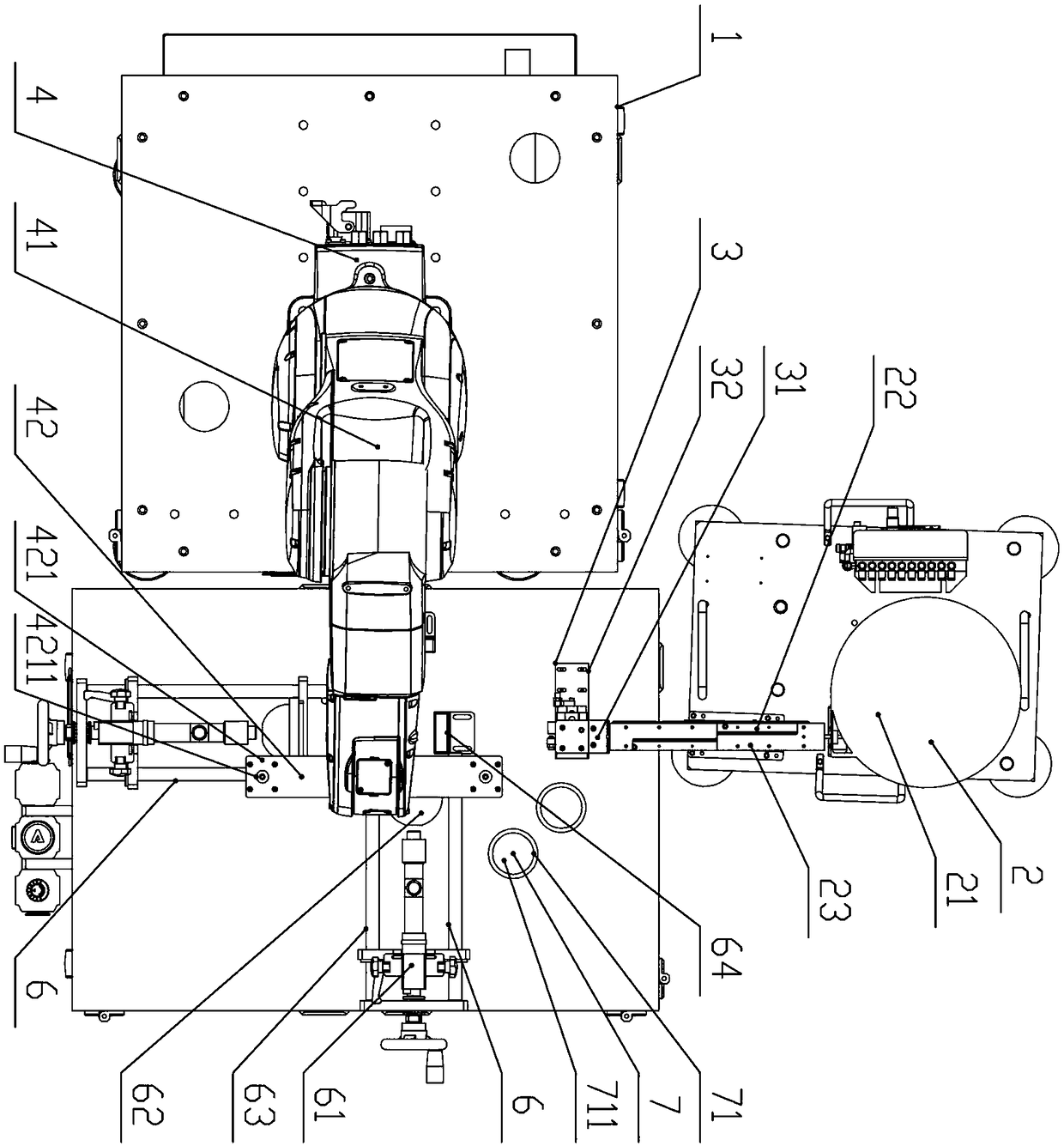

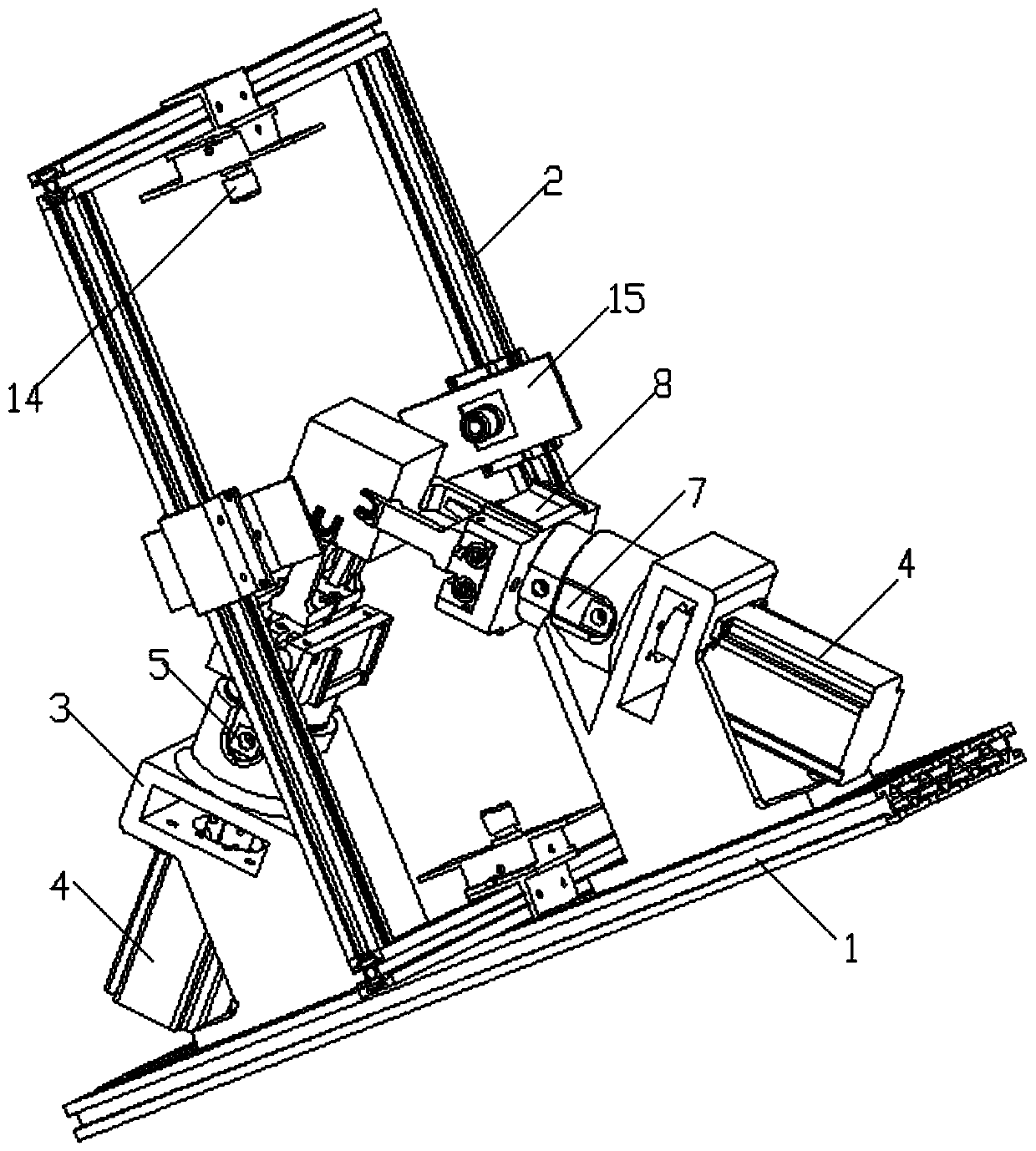

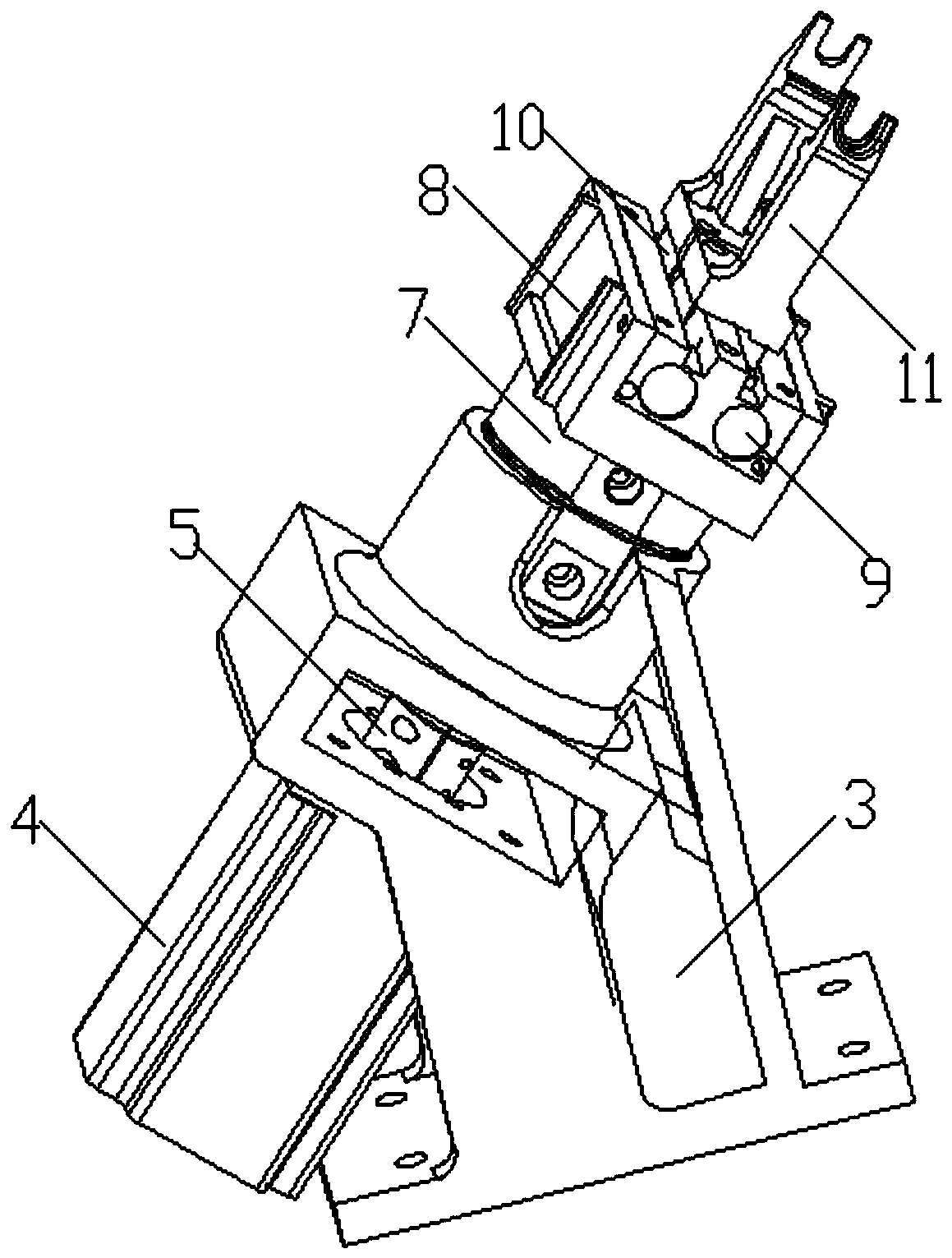

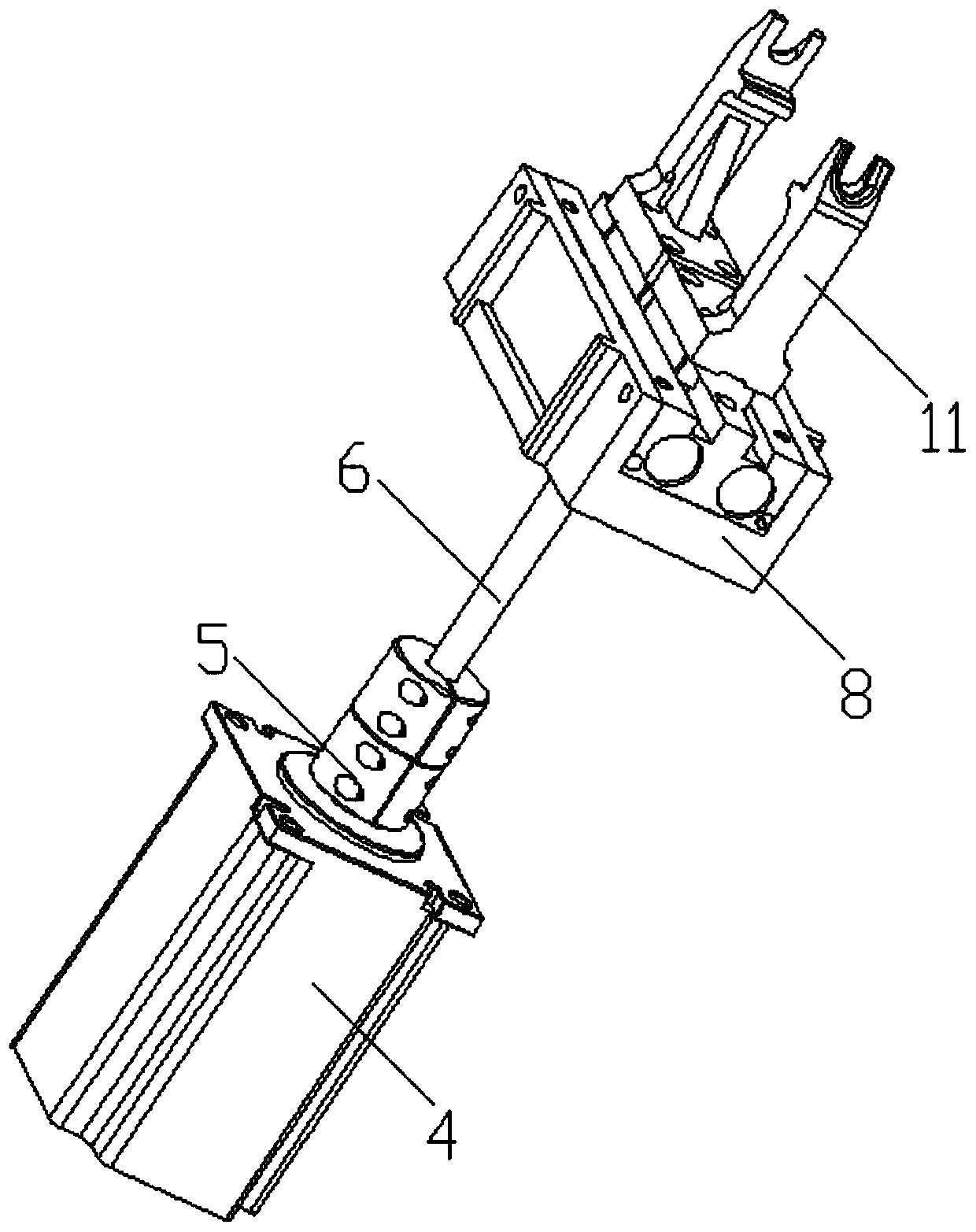

Double-arm magic cube robot

PendingCN110053059AAccurate collectionFast recognitionProgramme-controlled manipulatorGripping headsEngineeringManipulator

The invention relates to a double-arm magic cube robot which comprises a base plate, a frame, two manipulators and an image acquisition system. Each manipulator comprises a manipulator support, a rotating motor and a mechanical claw, wherein the rotating motor is arranged on the base plate through the manipulator support, and the rotating motor is connected with a long screw rod, the long screw rod is connected with the manipulator support through a rotary joint, the other end of the long screw rod extends upwards and is connected with a limiting plate, the mechanical claw is arranged on the limiting plate, the mechanical claw comprises a pair of claws and a driving mechanism used for driving the pair of claws to act, and supporting parts and U-shaped slot holes are arranged on the claws.Through a plurality of cameras, information acquisition is more accurate, and identification speed is faster; due to the fact that the corresponding supporting parts are arranged on the claws, a magiccube can be placed more accurately and conveniently, and meanwhile, the U-shaped slot holes are formed in the claws, so that inaccurate information acquisition caused by the fact that the claws blockthe magic cube is avoided; and each manipulator is provided with one pair of claws, the magic cube is more flexible to turn over, and the turning speed is higher.

Owner:WUYI UNIV

Card overturning mechanism

Owner:SHENZHEN AOMAI XING AUTOMATION EQUIP CO LTD

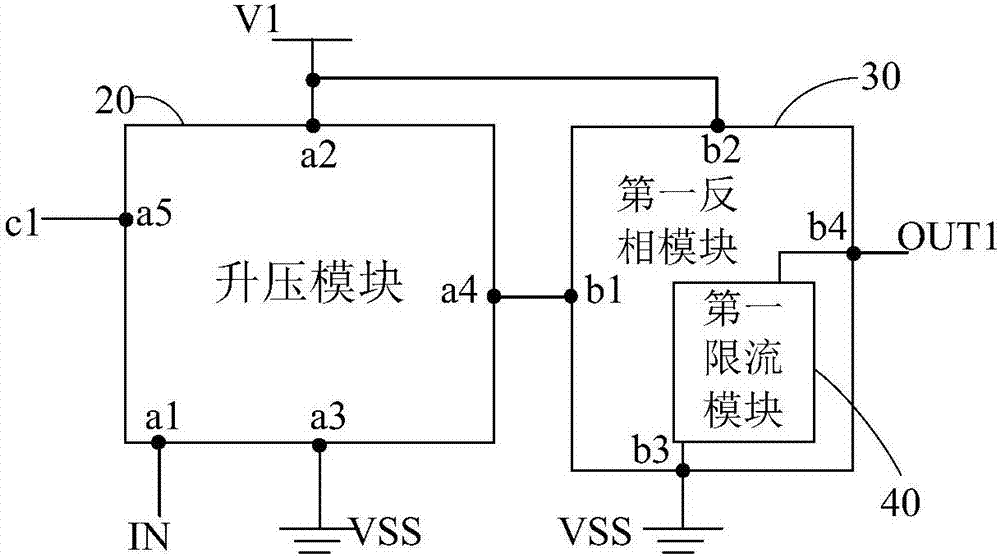

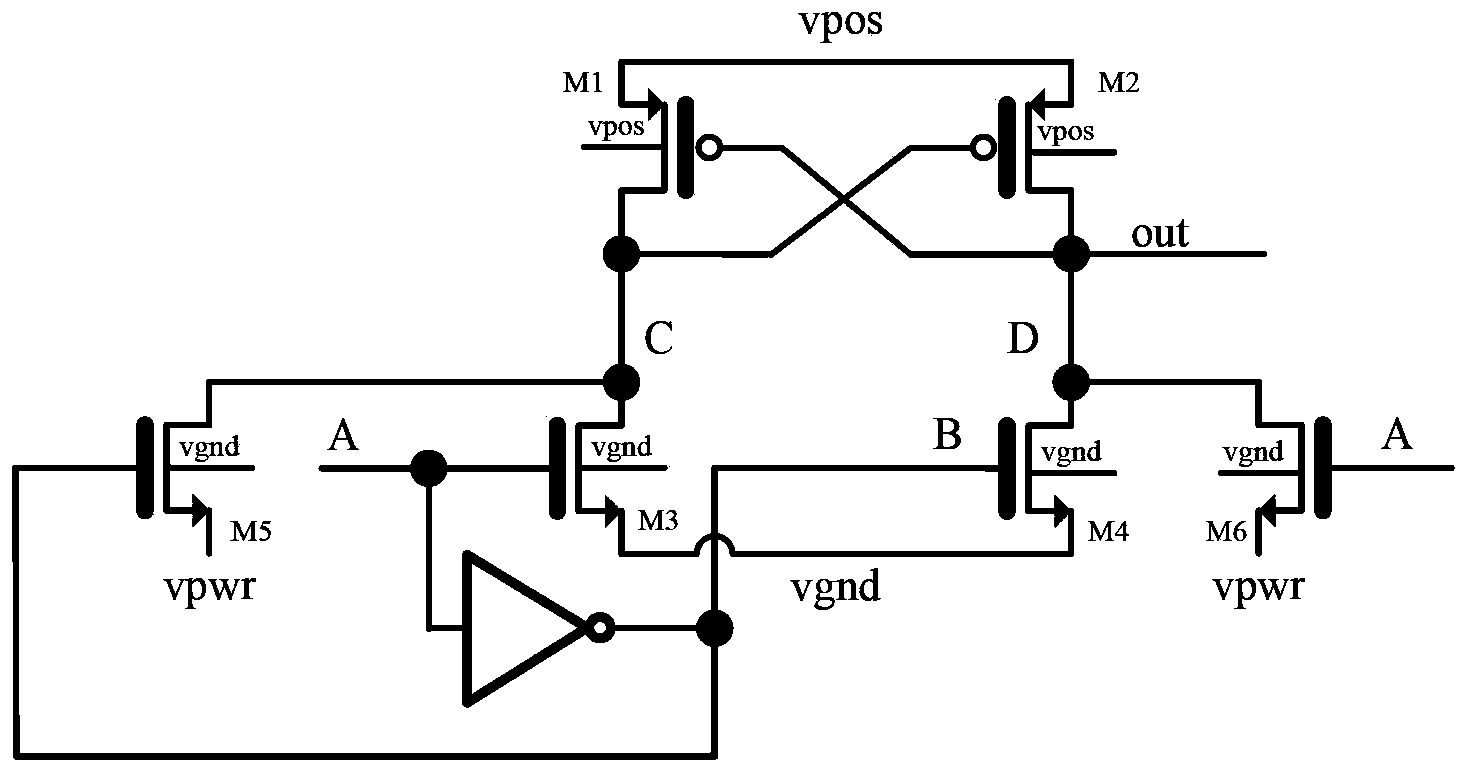

Level shifting circuit

ActiveCN107222198AReduce peak currentFlip fastLogic circuits coupling/interface using field-effect transistorsVoltage/current interference eliminationLevel shiftingCurrent limiting

The invention provides a level shifting circuit. The level shifting circuit comprises a booster module and a first phase reversal module; the first end of the booster module is connected with the input end of the level shifting circuit, the second end of the booster module is connected with a first high level signal end, the third end of the booster module is connected with a low level signal end, and the fourth end of the booster module is connected with the first end of the first phase reversal module; the second end of the first phase reversal module is connected with the first high level signal end, the third end of the first phase reversal module is connected with the low level signal end, and the fourth end of the first phase reversal module is connected with the first output end of the level shifting circuit; the first phase reversal module is used for communicating the third end and the fourth end of the first phase reversal module when the first end receives a high level signal; the first phase reversal module is used for communicating the second end and the fourth end of the first phase reversal module when the first end receives a low level signal; and a first current limiting module is arranged between the second end and the fourth end or between the third end and the fourth end of the first phase reversal module, and the first current limiting module is used for limiting current passing through the current limiting module per se to enable the maximum current value to be not greater than a first preset value. The invention can reduce peak current while improving the driving capability.

Owner:BOE TECH GRP CO LTD

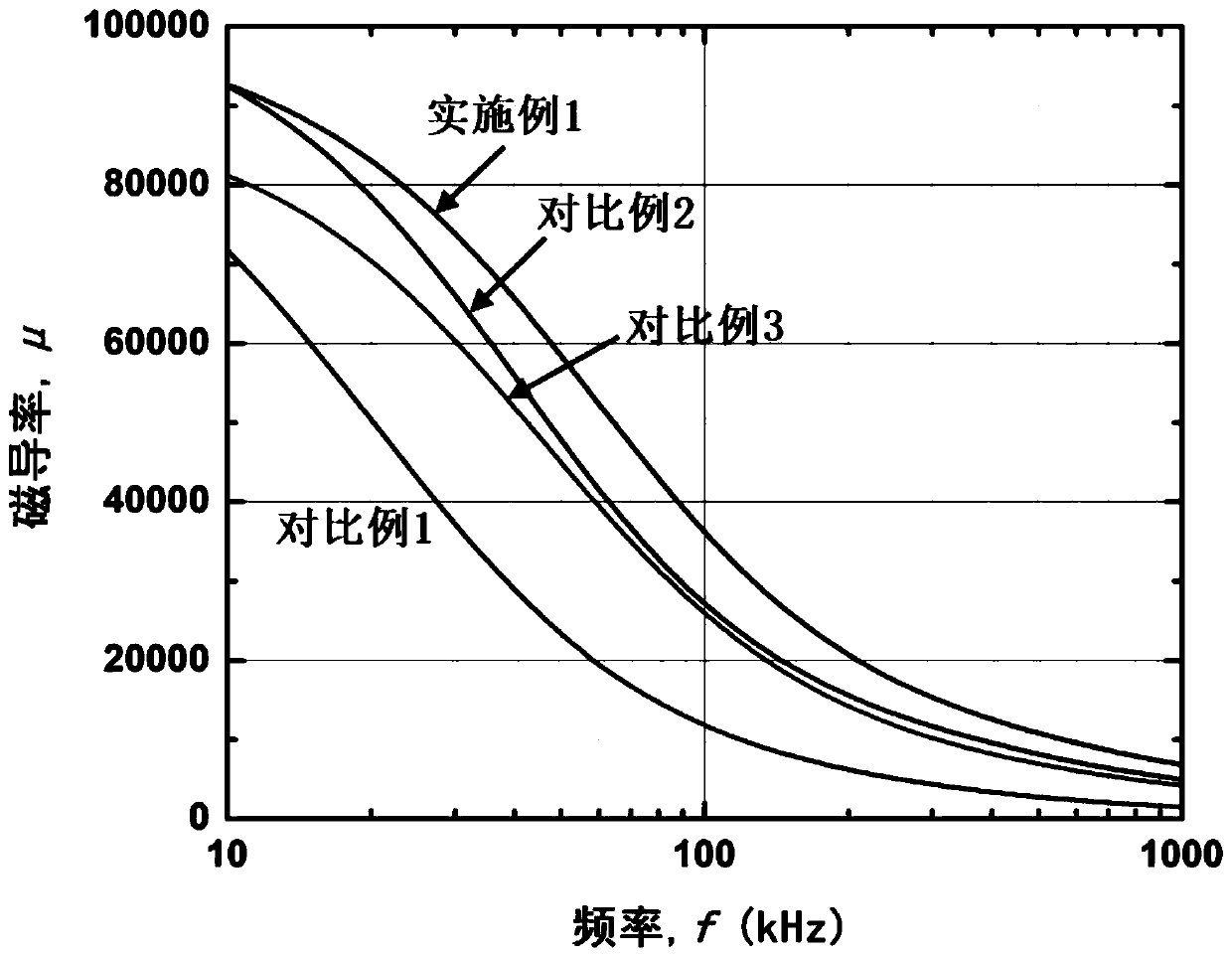

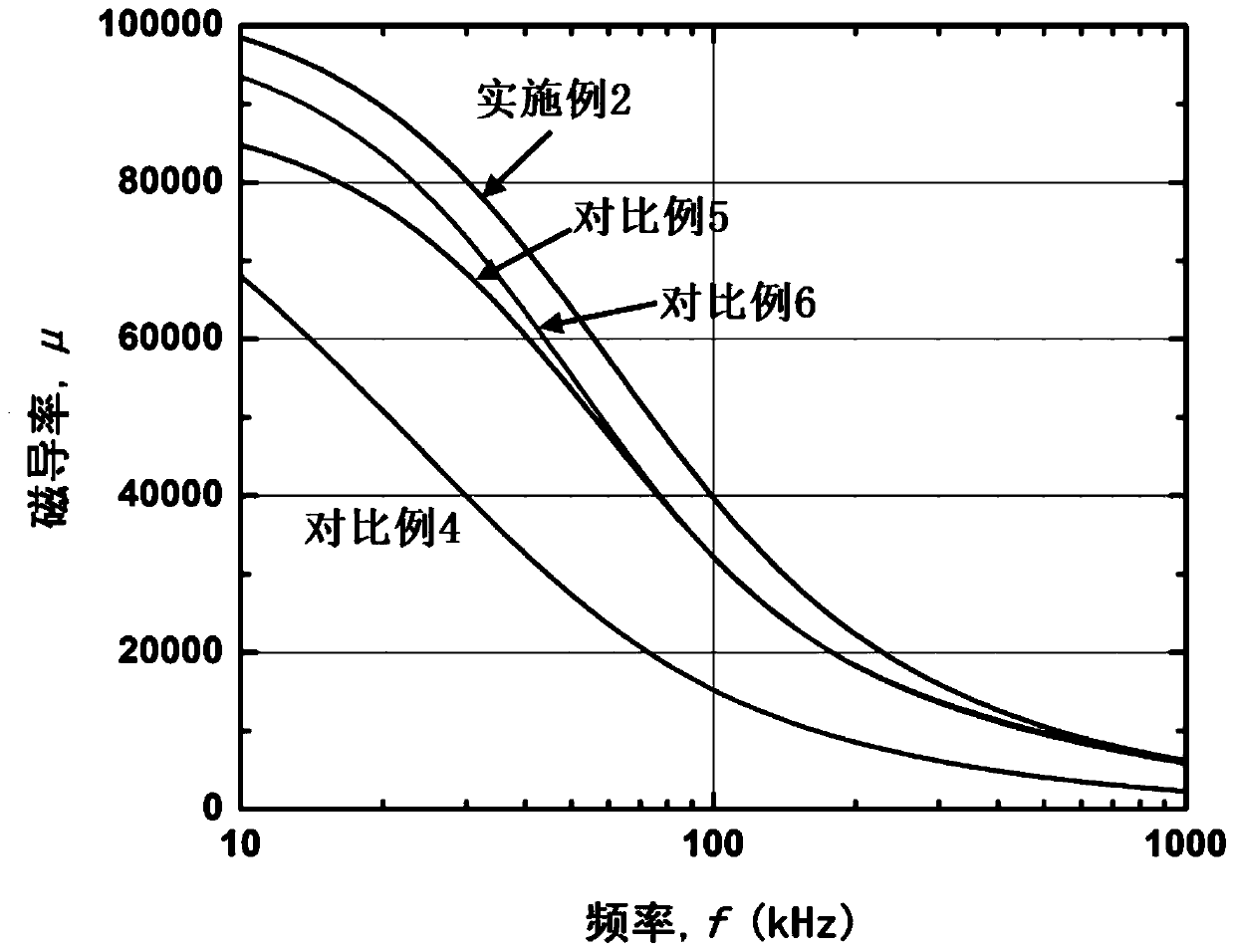

Preparation method of amorphous nanocrystalline alloy with high magnetic permeability

ActiveCN111057970AImprove permeabilityFlip fastMagnetic materialsUltimate tensile strengthMaterials science

The invention discloses a preparation method of an amorphous nanocrystalline alloy with high magnetic permeability. The preparation method comprises the following steps that the weighting is carried out according to the content of the various elements in the amorphous nanocrystalline alloy component expression, the amorphous nanocrystalline alloy component expression is FeaCobSicBdCueMfM'g, wherein M is at least one of V, Ta and Nb, M' is at least one of Ti, Zr, Hf, Ni, Ge, Cr, Mn, W, Zn, Sn, Sb, Mo, Y and Al; a, b, c, d, e, f and g represent the atomic percent content of the corresponding element; a, b, c, d, e, f and g satisfy the conditions that a is less than or equal to 82 and greater than or equal to 74, b is less than or equal to 5 and greater than 0.01, c is less than or equal to 15 and greater than or equal to 5, d is less than or equal to 13 and greater than or equal to 4, e is less than or equal to 1.5 and greater than or equal to 0.2, f is less than or equal to 4 and greater than or equal to 1, and g is less than or equal to 1 and greater than or equal to 0 and a + b + c + d + e + f + g is equal to 100. The mother alloy is smelted, the amorphous alloy strip is prepared,and the amorphous alloy strip is subjected to magnetic field heat treatment to obtain the nanocrystalline alloy material. The nanocrystalline alloy material has an effective permeability of 100 kHz or less and has the effective permeability of 35,000kHz or above, and meanwhile, the nanocrystalline alloy material has a saturation magnetic induction intensity advantage of 1.35 T or above.

Owner:NINGBO ZHONGKE BIPULASI NEW MATERIAL TECH CO LTD

Multifunctional static powder spraying machine

InactiveCN106944277AAvoid scratchesImprove work efficiencyLiquid spraying plantsEngineeringHigh pressure

The invention provides a multifunctional static powder spraying machine which comprises a base, an isolation cover and a static spraying mechanism. A conveying device is arranged between the feeding end and the discharging end of the base and comprises a first conveying mechanism, an overturning mechanism and a second conveying mechanism which are arranged in sequence. The static spraying mechanism comprises a first static sprayer, a second static sprayer, a third static sprayer, a fourth static sprayer, a first powder supply pipe, a second powder supply pipe, a third powder supply pipe, a fourth powder supply pipe, a powder supply device and a high-pressure static device. By means of the multifunctional static powder spraying machine, due to the mutual cooperation of a controller, the first conveying mechanism, the second conveying mechanism, the third conveying mechanism, the fourth conveying mechanism, the first static sprayer, the second static sprayer, the third static sprayer and the fourth static sprayer, automatic static spraying machining can be achieved on a workpiece, the overturning mechanism is arranged for overturning the workpiece, the overturning speed is high, the effect is good, and spraying of the front face, the back face and the side face of the workpiece is achieved.

Owner:TIANCHANG JINLING ELECTRONICS

Mobile phone screen glass surface defect detection device

ActiveCN114646648ARealize secondary detectionImprove detection efficiencyMaterial analysis by optical meansEngineeringControl valves

The invention discloses a mobile phone screen glass surface defect detection device in the technical field of screen detection equipment, and discloses a mobile phone screen glass surface defect detection device which comprises a base, a vertical plate is fixedly mounted on the top surface of the base, a detection seat is arranged on the front surface of the vertical plate, and a mounting plate is arranged above the base. According to the invention, a push rod is driven to move through first oil supply to realize rapid clamping of the side surface of screen glass, and after top surface detection is completed, an oil delivery path is changed through a control valve, so that hydraulic oil is delivered into a moving mechanism through a third pipe, and a toothed plate in the moving mechanism is pushed to drive a gear to rotate by 180 degrees; according to the screen glass detection device, the casing pipe drives the distribution box, the movable pipe and the screen glass to turn over, so that secondary detection of the bottom surface of the screen glass is quickly and conveniently realized, manual operation for adjusting and turning over is avoided, the actual turning-over speed is high, the operation is convenient and fast, the operation time is greatly saved, and the detection efficiency of the screen glass is improved.

Owner:SHENZHEN DEEP HON HAI AUTOMATION EQUIP CO LTD

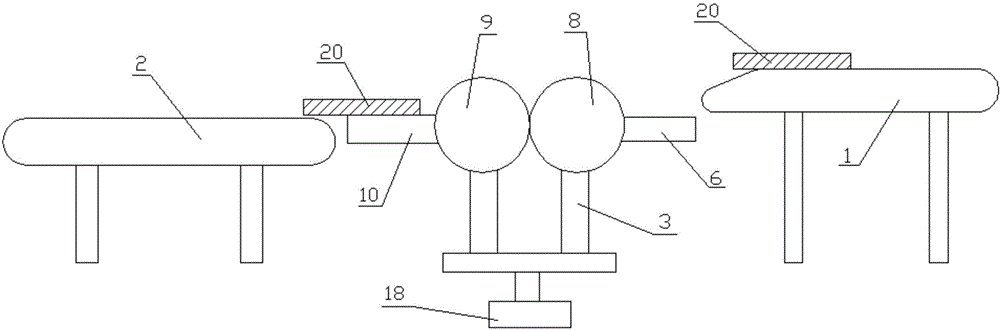

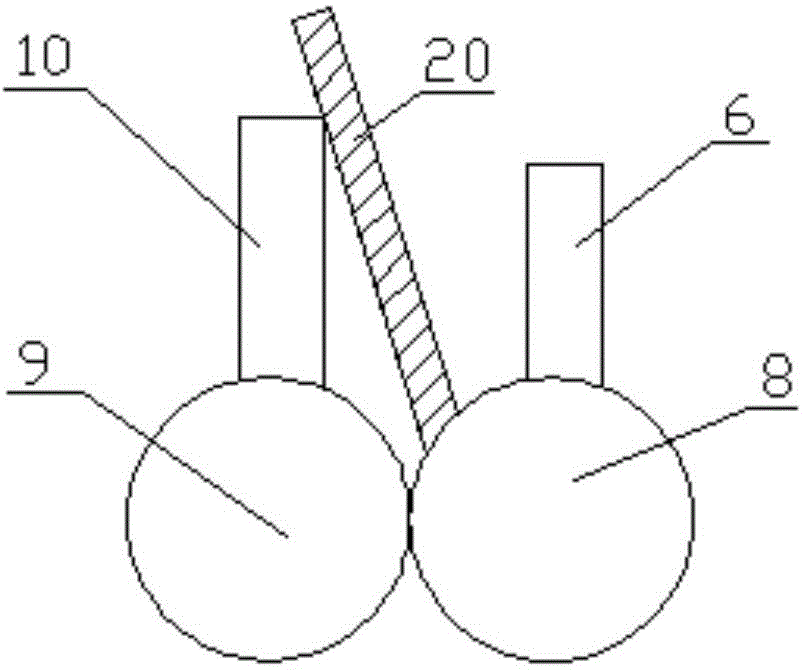

Apparatus for overturning metal plate

The invention discloses an apparatus for overturning a metal plate. The apparatus is composed of a first conveyor belt, a second conveyor belt, a support, a first rotating shaft, and a rotating cylinder. The first rotating shaft is arranged between the first conveyor belt and the second conveyor belt; and the two ends of the first rotating shaft are connected with the support in a transmission mode. The first rotating shaft is in transmission connection with the rotating cylinder; at least one first connecting rod group is arranged at the first rotating shaft along the peripheral direction and at least includes a first connecting rod; one end of the first connecting rod is connected with the first rotating shaft and the other end extends outwardly and approaches the first conveyor belt; and a vertical height of one end, far away from the first rotating shaft, of the first connecting rod above the ground is not larger than that of the first conveyor belt above the ground. Therefore, a phenomenon that the metal plate can not slide to the first connecting rod normally can be avoided. According to the invention, on the basis of mutual cooperation of the first rotation shaft, a second rotating shaft, the first connecting rod and a second connecting rod and the like, the metal plate can be overturned with a fast overturning speed; and the effect is good. The overall apparatus has a simple structure and can be used conveniently.

Owner:WUHU RUNYU PRECISION MACHINERY

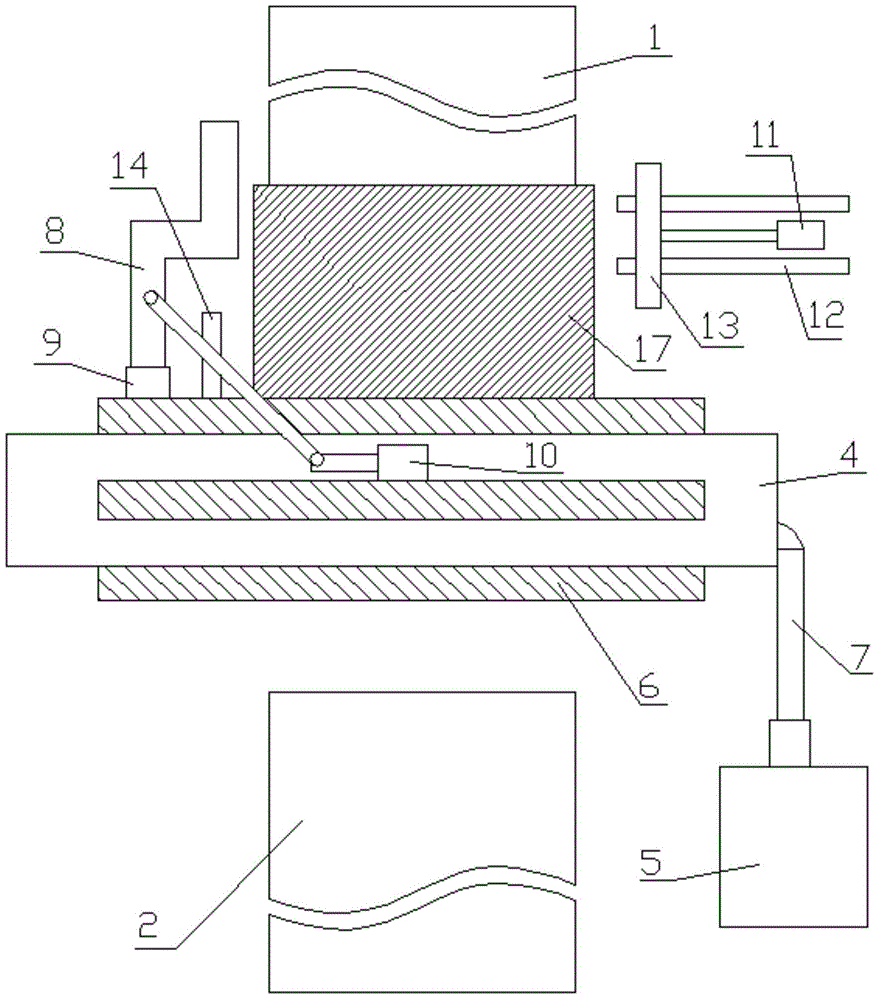

Apparatus for assisting in overturning metal plate

The invention, which belongs to the technical field of the metal work processing, discloses an apparatus for assisting in overturning a metal plate. The apparatus is composed of a first conveyor belt, a second conveyor belt, a bracket, a rotating shaft, and a cylinder. The rotating shaft is arranged between the first conveyor belt and the second conveyor belt and is connected with the bracket in a rotating mode. A plurality of clamping plates for clamping a metal plate are arranged at the rotating shaft along the peripheral direction; the length directions of the clamping plates extend along the axial direction of the rotating shaft; and the extension directions of clamping mouths of the clamping plates are parallel to a moving direction of the metal plate. An output terminal of the cylinder is in transmission connection with the rotating shaft by a connecting rod. According t the invention, on the basis of mutual cooperation of the rotation shaft, the clamping plates, the connecting rod, and a push plate and the like, the metal plate can be overturned with a fast overturning speed; and the effect is good. Moreover, overturning of the metal plate can be realized no matter whether the straight heights of the first conveyor belt and the second conveyor belt over the ground are identical; and with a rubber layer, the metal plate surface can be protected from being scratched. The overall apparatus has a simple structure and can be used conveniently.

Owner:繁昌县陈氏金属制品有限公司

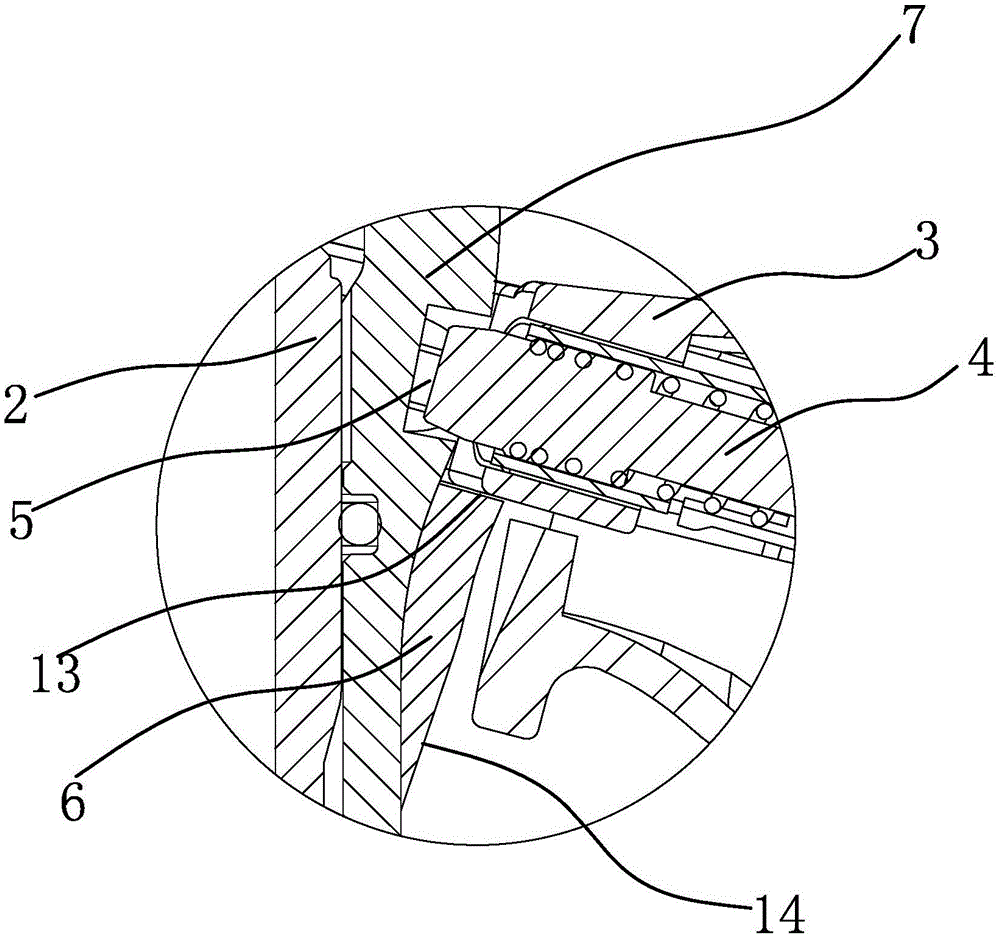

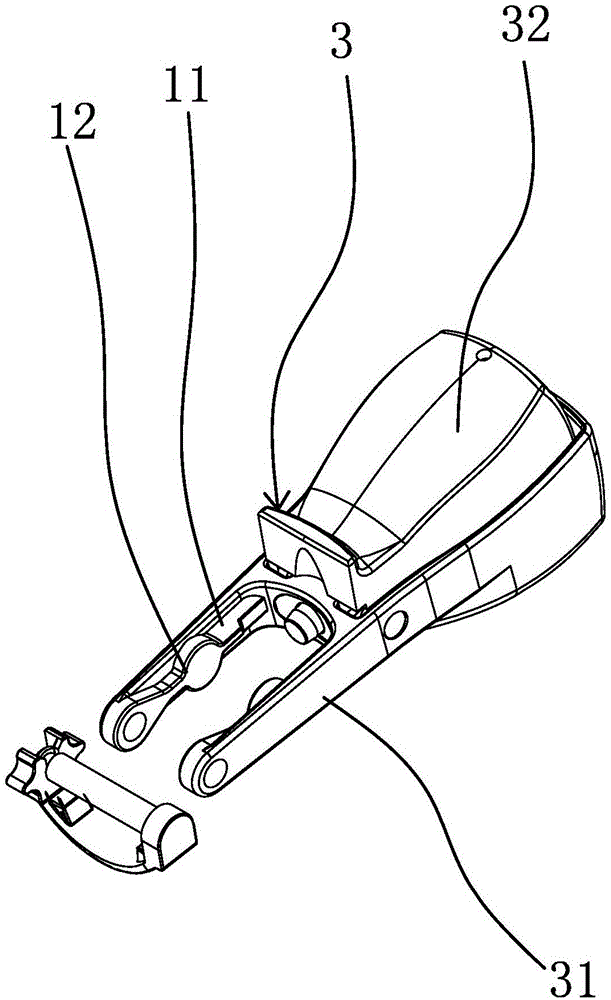

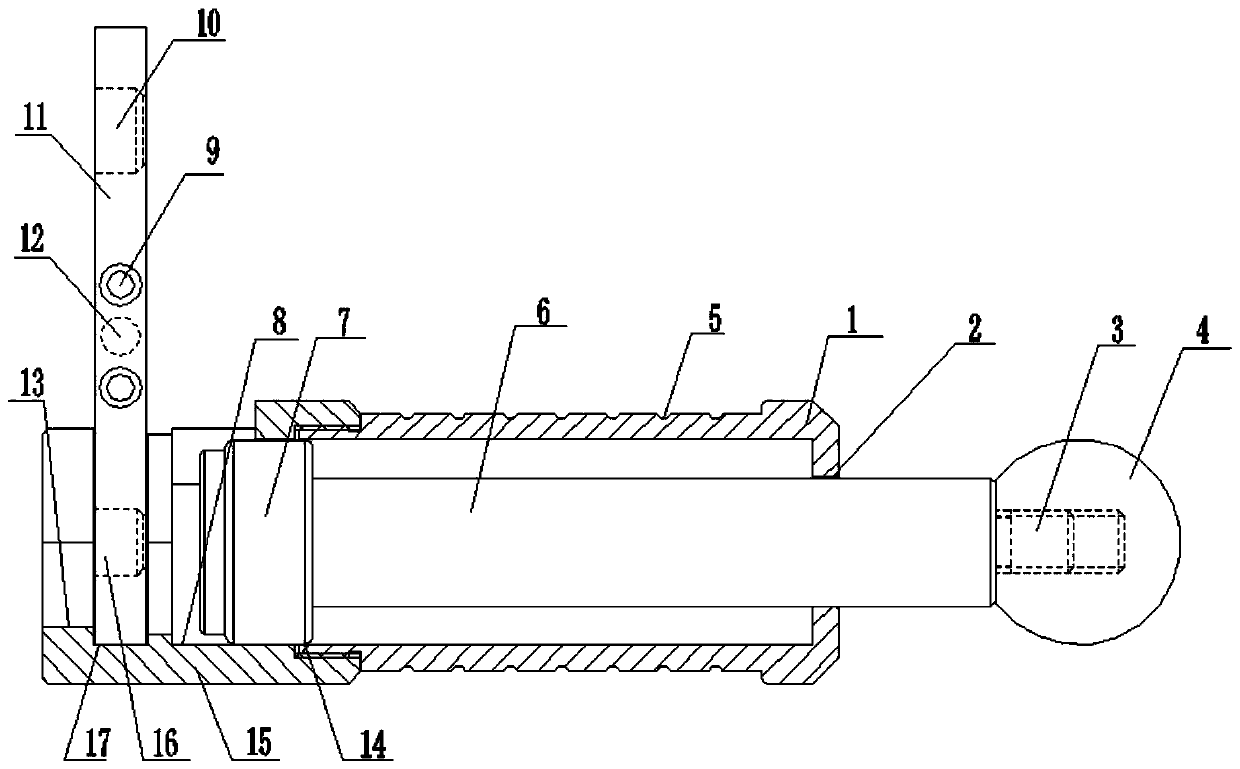

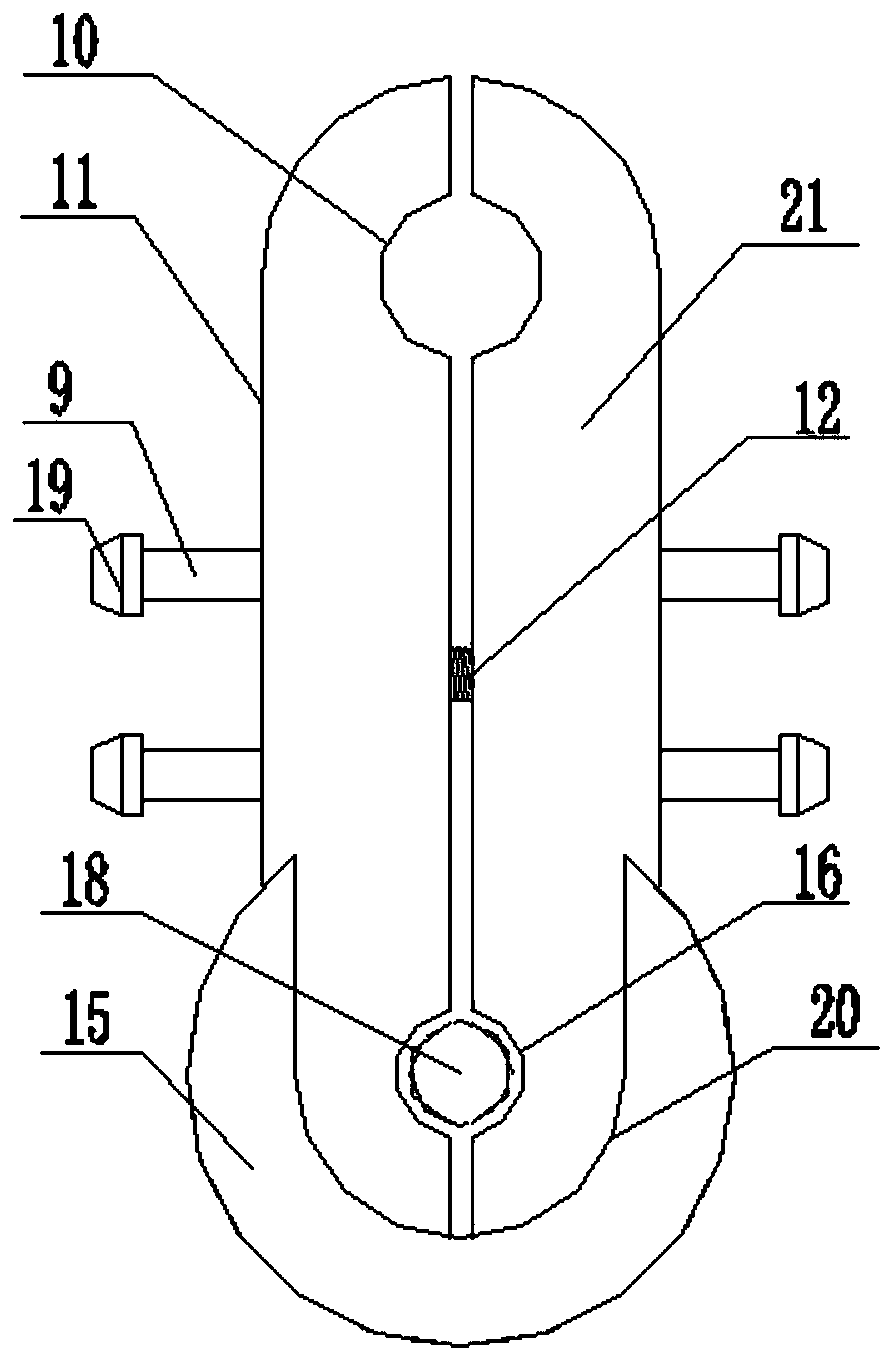

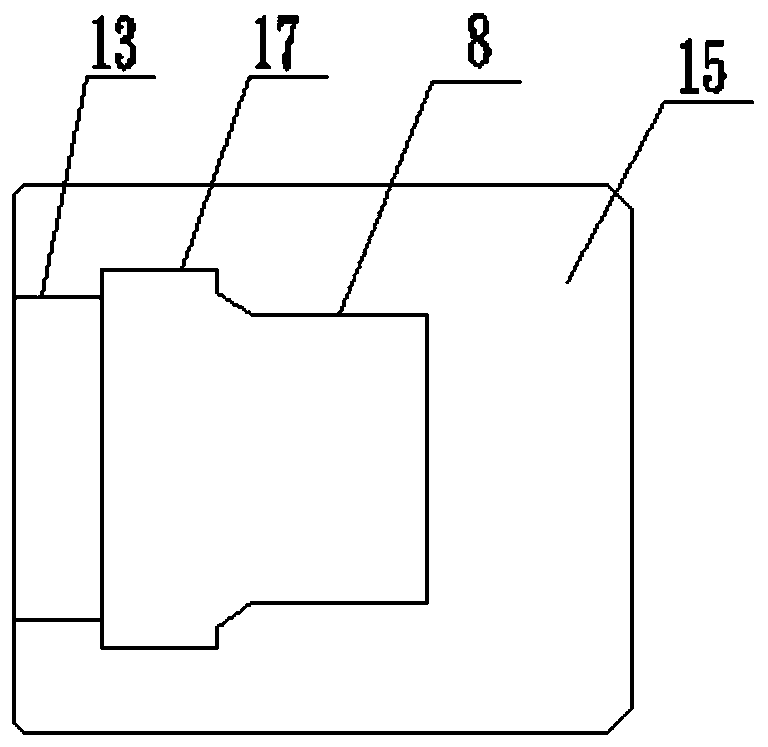

Turnover mechanism for high-voltage circuit breaker, and application method for turnover mechanism

ActiveCN107527761AEasy to operateEasy to observeElectric switchesEngineeringUltimate tensile strength

The invention discloses a turnover mechanism for a high-voltage circuit breaker, and an operating method for the turnover mechanism. The turnover mechanism comprises a turnover substrate, and the center of the turnover substrate is provided with a vertically parallel clamping seat. Hand-operated rocking arms are disposed between waist-shaped holes at the upper sides of the clamping seat. Two sides of the clamping seat are provided with rotating shafts, and a supporting seat is disposed in the clamping seat. One side of the turnover substrate is provided with an installation seat, and the interior of the installation seat is hollow. The upper side of the installation seat is provided with supporting legs which are arranged in an array. The upper sides of the supporting legs are provided with a horizontal turnover motor platform, and the turnover motor platform is provided with a turnover motor, wherein the outer side of the turnover motor is provided with a protection cover. The turnover mechanism has two turnover modes: a manual turnover mode and a mode of turnover through the driving of the turnover motor. The manual turnover mode can be used by an operator when the operator needs to control the turnover angle by himself, and the manual turnover mode brings convenience to the operator for operating and observing structural members at different angles and different positions. The mode of turnover through the driving of the turnover motor can achieve the turnover through the turnover motor, is high in turnover speed, and greatly reduces the work intensity.

Owner:HUAINAN WANTAI RONGBO LIGHTING TECH

A device for assisting the overturning of metal plates

The invention, which belongs to the technical field of the metal work processing, discloses an apparatus for assisting in overturning a metal plate. The apparatus is composed of a first conveyor belt, a second conveyor belt, a bracket, a rotating shaft, and a cylinder. The rotating shaft is arranged between the first conveyor belt and the second conveyor belt and is connected with the bracket in a rotating mode. A plurality of clamping plates for clamping a metal plate are arranged at the rotating shaft along the peripheral direction; the length directions of the clamping plates extend along the axial direction of the rotating shaft; and the extension directions of clamping mouths of the clamping plates are parallel to a moving direction of the metal plate. An output terminal of the cylinder is in transmission connection with the rotating shaft by a connecting rod. According t the invention, on the basis of mutual cooperation of the rotation shaft, the clamping plates, the connecting rod, and a push plate and the like, the metal plate can be overturned with a fast overturning speed; and the effect is good. Moreover, overturning of the metal plate can be realized no matter whether the straight heights of the first conveyor belt and the second conveyor belt over the ground are identical; and with a rubber layer, the metal plate surface can be protected from being scratched. The overall apparatus has a simple structure and can be used conveniently.

Owner:繁昌县陈氏金属制品有限公司

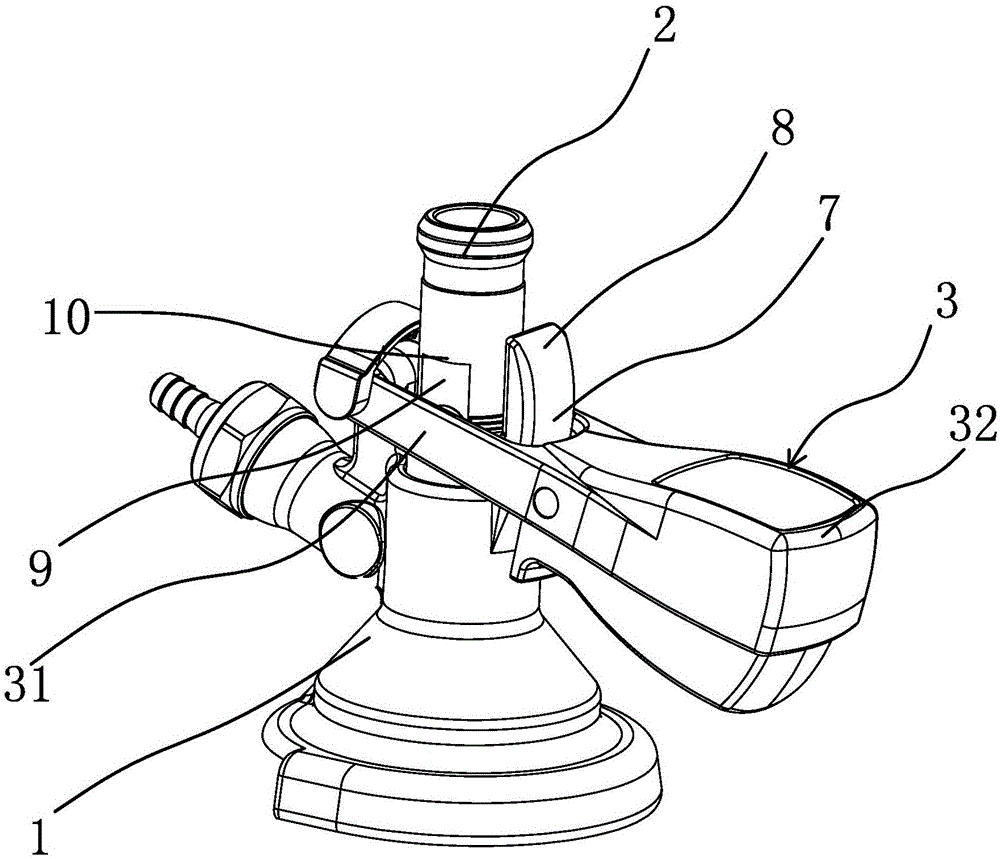

Distributor

ActiveCN105000523AEasy to operateAvoid overdoingDischarging meansBottle emptyingEngineeringDistributor

The invention provides a distributor and belongs to the technical field of wine drinking equipment. The distributor solves the technical problem of existing distributors that using is not convenient enough. The distributor comprises a valve body, a wine outlet pipe and a handle, wherein the wine outlet pipe is inserted in the valve body in a sliding mode, the handle is hinged to the valve body and can drive the wine outlet pipe to slide relative to the valve body, and a telescopic rod is arranged in the handle; a clamping groove connected with the telescopic rod in a clamping mode is formed in the valve body, and a protrusion capable of abutting against the handle is arranged on the valve body and located below the clamping groove. By arranging the protrusion below the clamping groove, when a user pulls the handle downwards to a certain position, the handle abuts against the protrusion to enable the telescopic rod on the handle to directly face the clamping groove so that the handle can be quickly pulled to a predetermined position and the telescopic rod can be clamped in the clamping groove, and operation is quite convenient; meanwhile, damage to the handle caused by excessive operation can be avoided.

Owner:TALOS TECH CORP

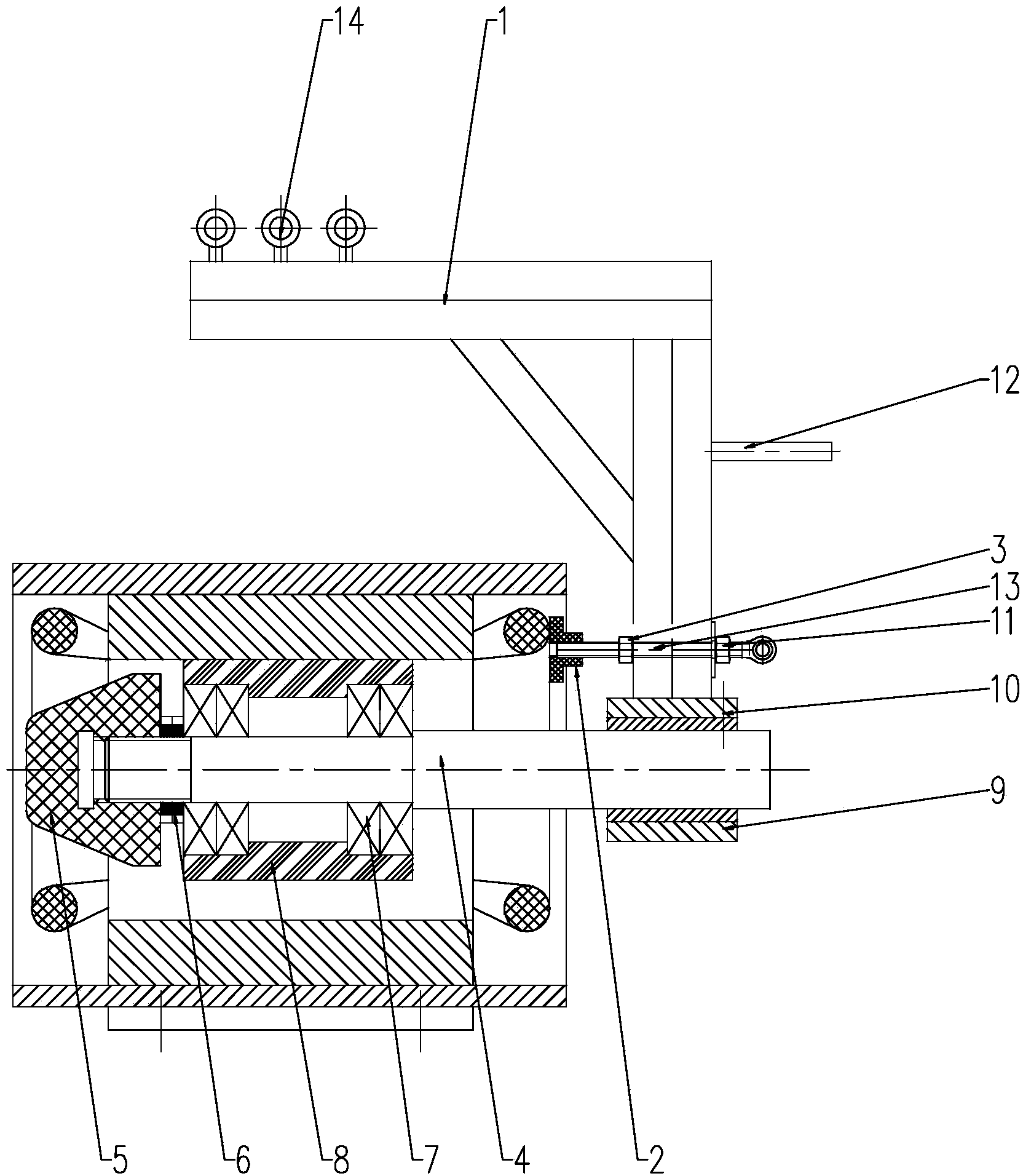

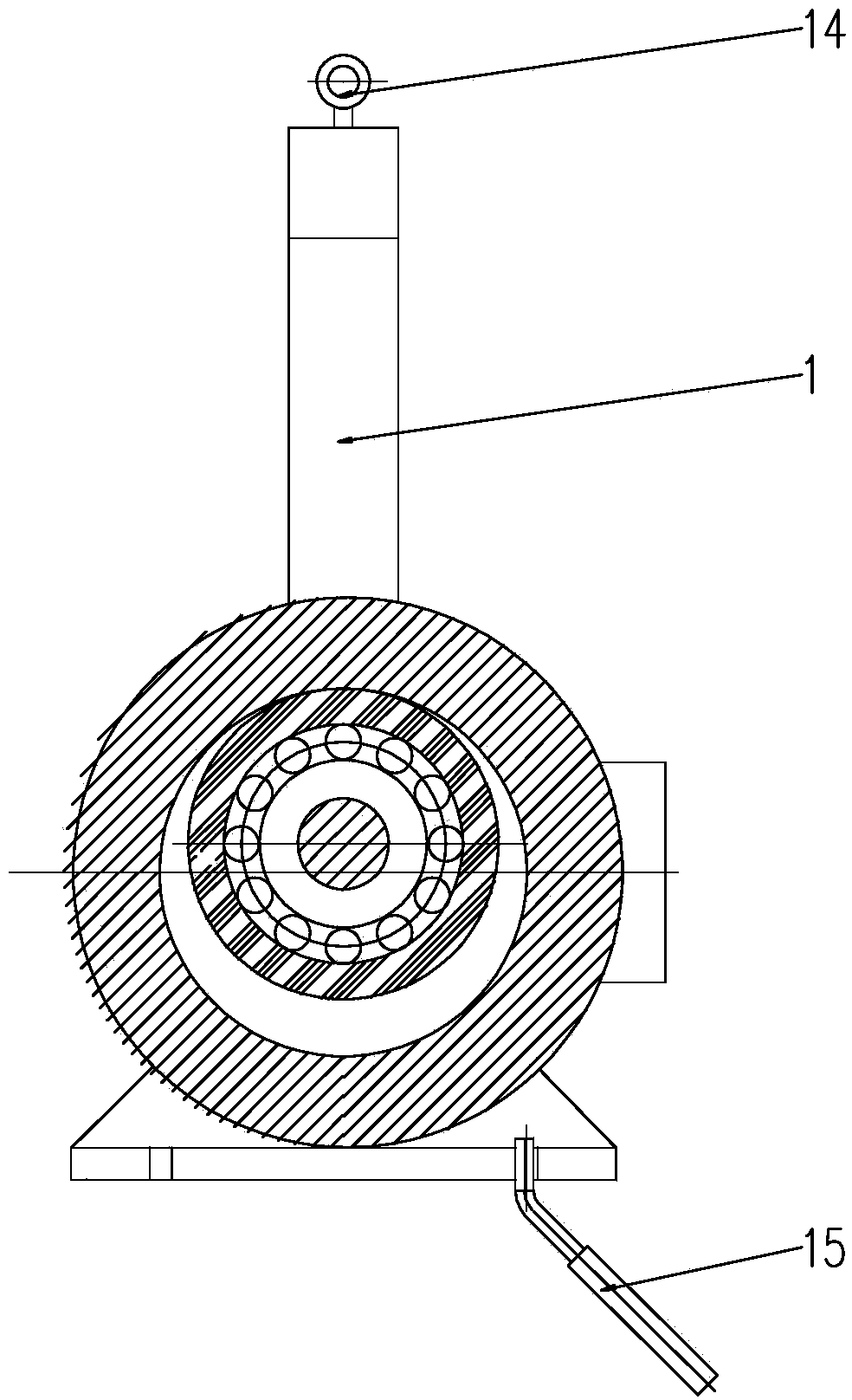

Special frame for turning motor stator frame

ActiveCN104167888AFlip fastImprove securityManufacturing dynamo-electric machinesEngineeringMechanical engineering

The invention relates to a special frame for turning, in particular to a special frame for turning a motor stator frame, and belongs to the technical field of the motor industry. The special frame comprises a hanging frame, the lower end of the hanging frame is provided with a second sleeve, a rotary mandrel is inserted into the second sleeve, the rotary mandrel supports a first sleeve through multiple rolling bearings, one side of each rolling bearing is locked and positioned through a round nut connected with the rotary mandrel, and the other side of each rolling bearing is positioned through a shaft shoulder of the rotary mandrel. The upper end of the hanging frame is provided with lifting bolts. The special frame is convenient to machine and manufacture and easy to use; the turning speed of the motor stator frame is improved, and labor intensity of operations of workers is reduced; turning safety of the motor stator frame is improved, and qualified assembly quality and a favorable guarantee are provided for the motor stator frame to quickly and smoothly enter the next procedure.

Owner:WUXI ZHONGDA MOTORS

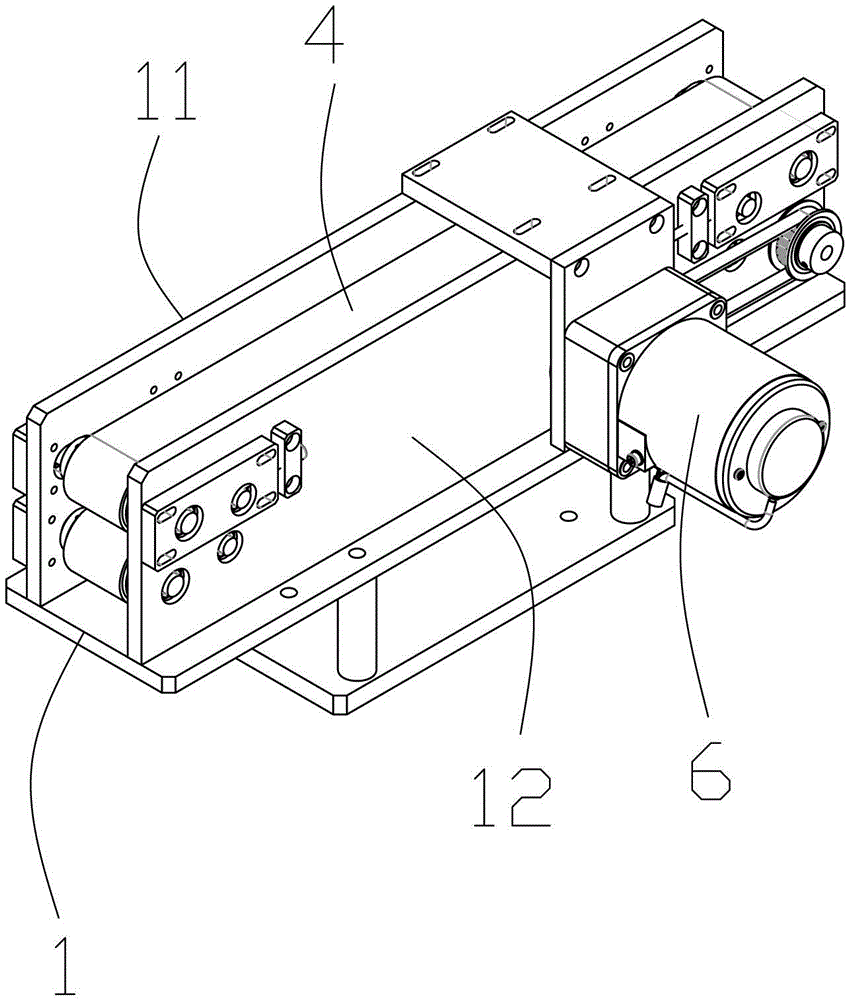

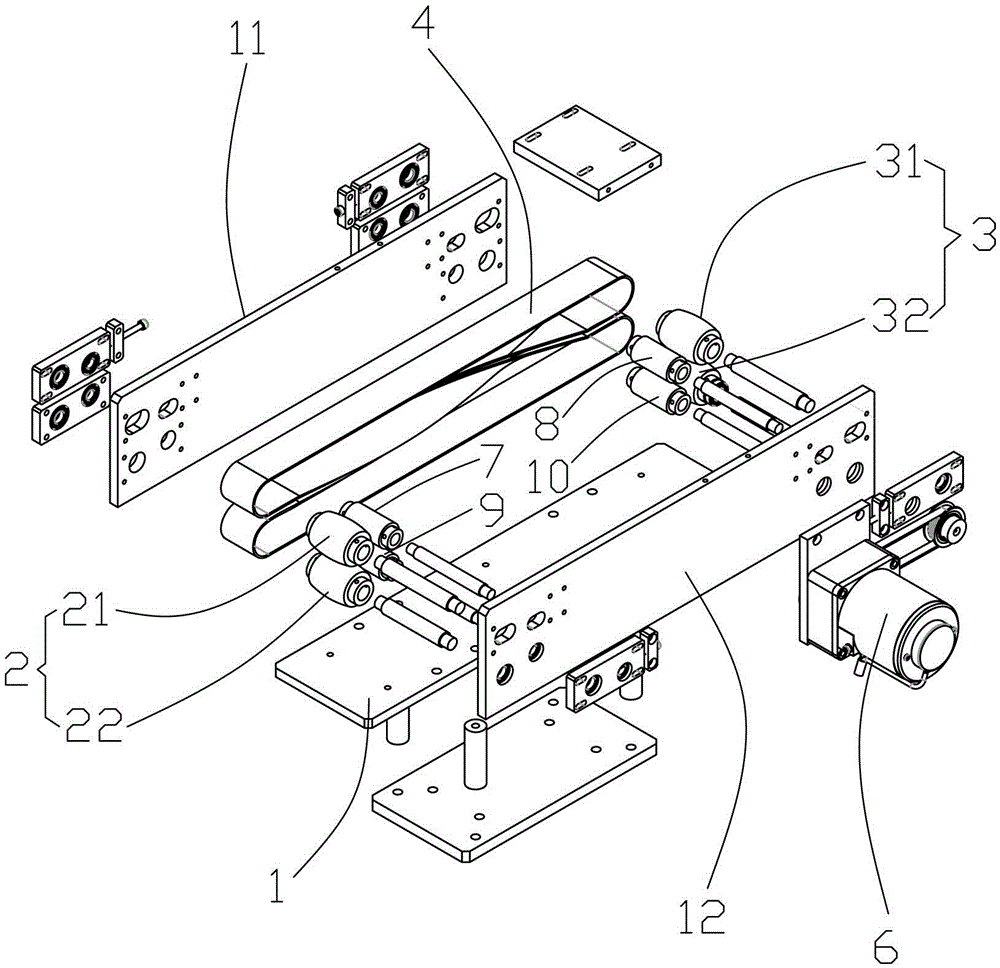

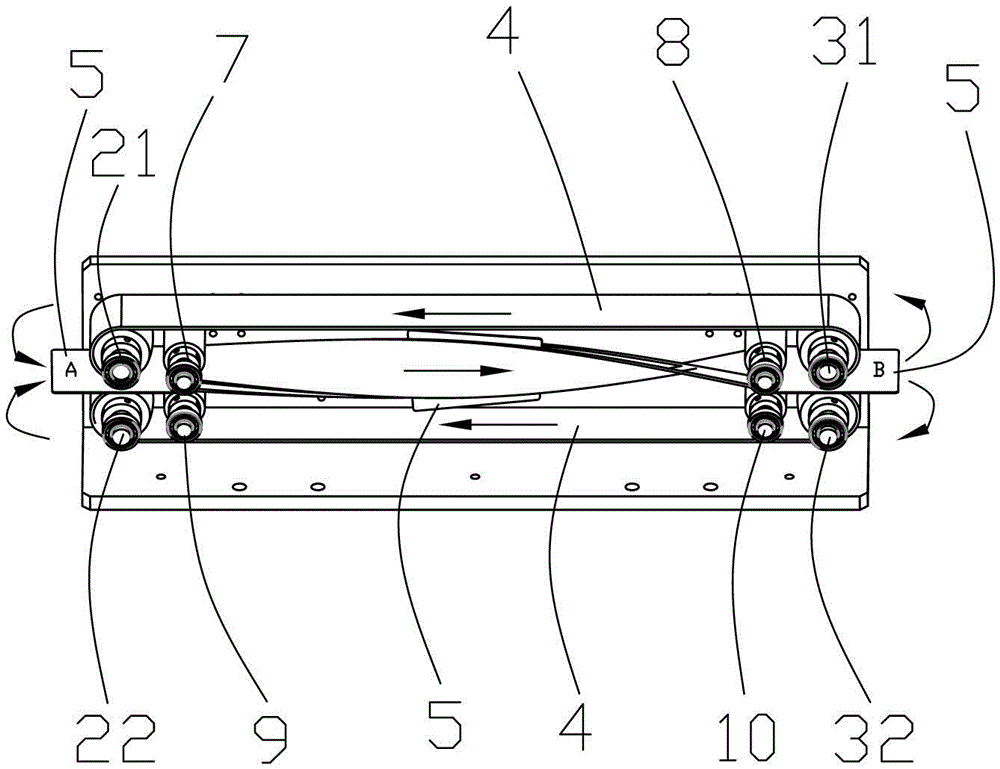

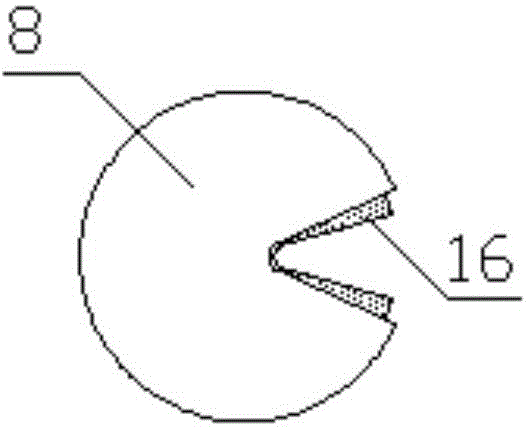

Multi-workpiece synchronous overturning mechanism for laser cutting equipment

PendingCN108555466AHigh consistency of synchronous flip angleFlip fastLaser beam welding apparatusPressure transmissionDrive wheel

The invention discloses a multi-workpiece synchronous overturning mechanism for laser cutting equipment. The multi-workpiece synchronous overturning mechanism comprises a shell, wherein a driving wheel and a plurality of driven wheels are mounted in the machine shell, the driving wheel is driven to rotate by a blade type oscillating cylinder mounted outside the machine shell, the driven wheels arelinearly distributed in an equal interval manner in the machine shell, the driving wheel is located slightly above the middle point of a connecting line of all the driven wheels, the driving wheel and the driven wheels are sleeved with a transmission belt, a tension wheel pressure transmission belt is arranged on each of two sides of the driving wheel and between every two driven wheels, the transmission belt, the driving wheel, and each driven wheel and each tension wheel are arranged in an external tangent manner; and an arm lever is connected to the rear end of each driven wheel, and a suction disc for sucking workpieces is arranged on each arm lever. According to the multi-workpiece synchronous overturning mechanism, the driving wheel drives the driven wheels through the transmissionbelt by virtue of the blade type oscillating cylinder, and the overturning of the arm levers is realized, so that the synchronous overturning of multiple workpieces is realized.

Owner:江苏先河激光技术有限公司

Electric level converter

InactiveCN103856198AFlip fastReduce areaLogic circuit coupling/interface arrangementsHigh pressureLevel converter

This invention discloses an electric level converter. Source electrodes of a first transistor and a second transistor are connected to an external high-voltage power supply; the drain electrode of the first transistor, the grid electrode of the second transistor, the drain electrode of a third transistor and the drain electrode of a fifth transistor are connected, the grid electrode of the first transistor and the drain electrodes of the second transistor, a fourth transistor and the sixth transistor are connected and are used as an output terminal of the circuit, the grid electrodes of the third transistor and the sixth transistor are connected to the input terminal of an inverter, the output terminal of the inverter is connected to the grid electrodes of the fourth transistor and the fifth transistor, the source electrodes of the third transistor and the fourth transistor are connected to the ground, and the source electrodes of the fifth transistor and the sixth transistor are connected and connected to the voltage of the external power supply. The electric level converter not only improves the inverting efficiency of the voltage, but also reduces the area of the circuit board.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Watch lens turning device

PendingCN110817434AQuick flipFulfill the purpose of flippingCharge manipulationConveyor partsEngineeringMechanical engineering

The invention discloses a watch lens turning device. The watch lens turning device comprises a rack, a vacuum suction cup A, a carrying table A, a rotating shaft A, a vacuum suction cup B, a carryingtable B, a rotating shaft B, a transmission mechanism and a driving device, wherein the vacuum suction cup A and the vacuum suction cup B are arranged on the carrying table A and the carrying table Bcorrespondingly and correspond to each other; the vacuum suction cup A and the vacuum suction cup B are connected with a vacuum generator through pipelines correspondingly; the carrying table A and the carrying table B are mounted on the rotating shaft A and the rotating shaft B correspondingly; the rotating shaft A and the rotating shaft B are mounted on the rack in parallel; the driving device drives the rotating shaft A and the rotating shaft B to rotate through the transmission mechanism; the rotating shaft A and the rotating shaft B drive the carrying table A and the carrying table B to rotate correspondingly; the carrying table A and the carrying table B rotate to be in a vertical state from a horizontal state; and a glass sheet adsorbed to the vacuum suction cup A is adsorbed to thevacuum suction cup B. The watch lens turning device has the greatest characteristics of being simple but not simple, few in component, low in cost, high in practicability, high in efficacy and convenient to maintain.

Owner:心鉴智控(深圳)科技有限公司

Manual corrugated pipe edge overturning tool

The invention discloses a manual corrugated pipe edge overturning tool. The manual corrugated pipe edge overturning tool comprises a first sleeve and a second sleeve which are detachably connected; the end, away from the second sleeve, of the first sleeve is provided with a push rod insert-in port; the end, close to the second sleeve, of the first sleeve is provided with a knocking head stretch-out port; a push rod is arranged in the first sleeve in a penetrating manner; a knocking head is integrally formed on the end portion of the end, inserted into the first sleeve, of the push rod and canstretch into the second sleeve through the stretch-out port; the end, away from the first sleeve, of the second sleeve is provided with a corrugated pipe insert-in port in which a corrugated pipe is inserted in; the side wall of the second sleeve is further provided with a caliper gauge insert-in port in which a caliper gauge clamping assembly is inserted and connected; and the corrugated pipe canbe clamped and fixed by the caliper gauge clamping assembly. The manual corrugated pipe edge overturning tool solves the problems that a special convenient and fast manual tool for corrugated pipe end portion extruding and edge overturning is lacking in a current machining tool and equipment, and consequently the edge overturning operation of the corrugated pipe is tedious and wastes time are solved.

Owner:安徽恒达管业有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com