Electric level converter

A level converter and transistor technology, applied in the direction of logic circuit connection/interface layout, etc., can solve the problems of area loss, increase the size of M3 and M4 tubes, etc., and achieve the effect of reducing area and improving flipping speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to enable your examiners to have a further understanding and understanding of the purpose, features and effects of the present invention, the following detailed description is as follows with the accompanying drawings.

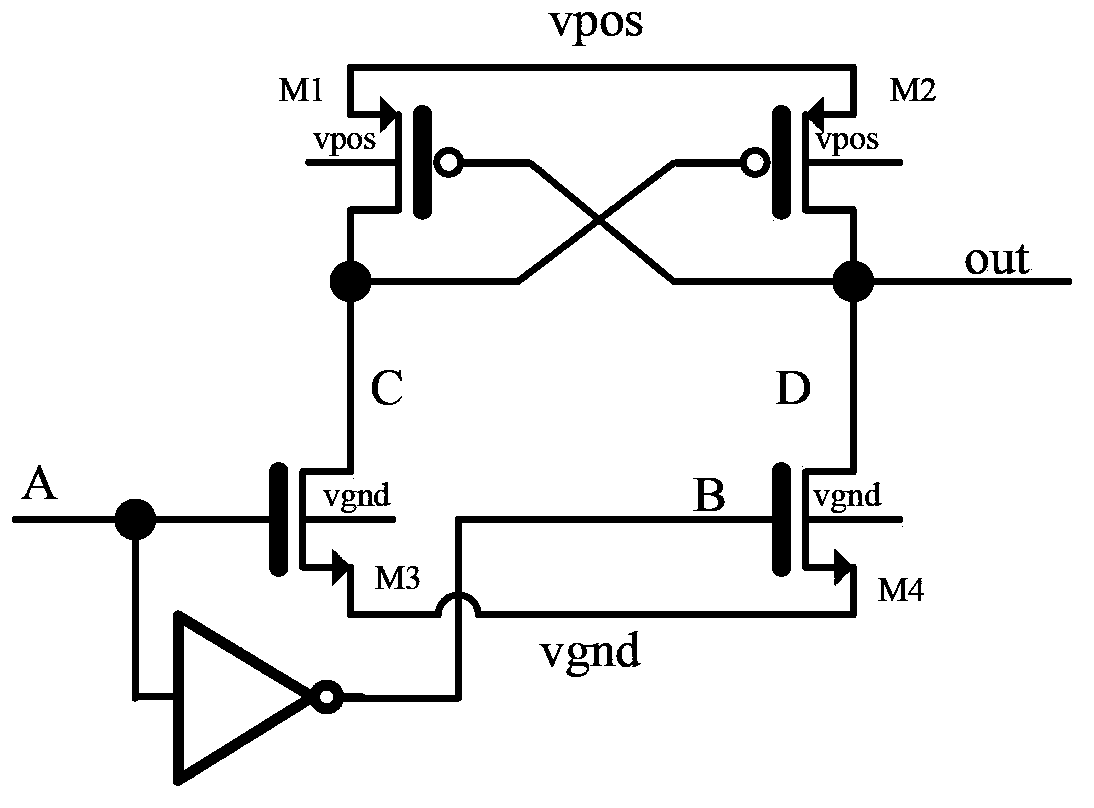

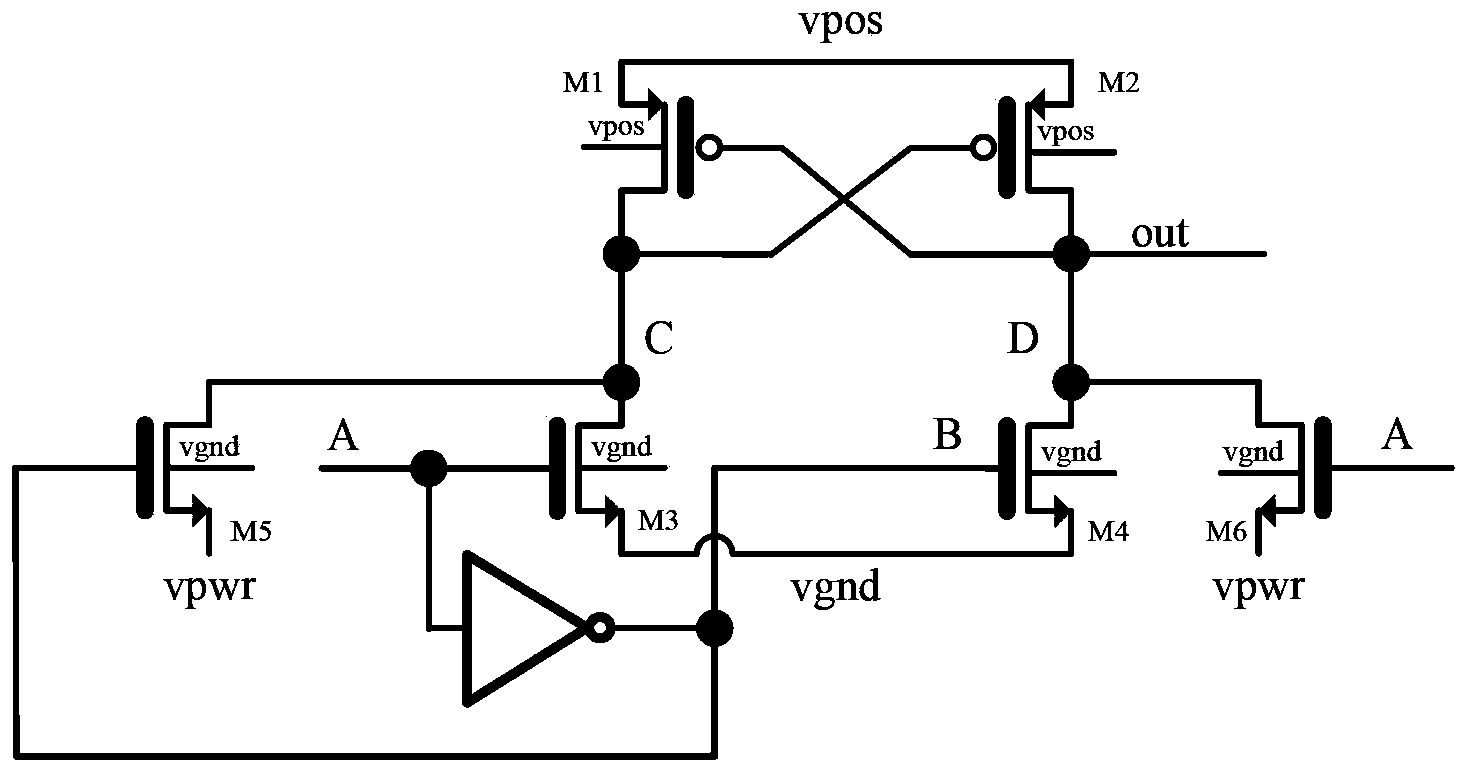

[0016] Such as figure 2 As shown, the source terminals of the first transistor M1 and the second transistor M2 are connected to the external high voltage power supply (vpos), the drain of the first transistor M1, the gate of the second transistor M2, the drain of the third transistor M3 and The drain of the fifth transistor M5 is connected to point C, the gate of the first transistor M1, the drain of the second transistor M2, the drain of the fourth transistor M4 and the drain of the sixth transistor M6 are connected to point D, and serve as The circuit output terminal (out), the gate of the third transistor M3, the gate of the sixth transistor M6 are connected to the input terminal of the inverter at point A, the output terminal of the invert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com