Special frame for turning motor stator frame

A motor stator and machine base technology, which is applied in the field of special racks for turning over and motor stator bases, can solve the problems of potential safety hazards, high labor intensity, and laborious turning over, so as to reduce the labor intensity of operation and improve safety , The effect of convenient processing and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

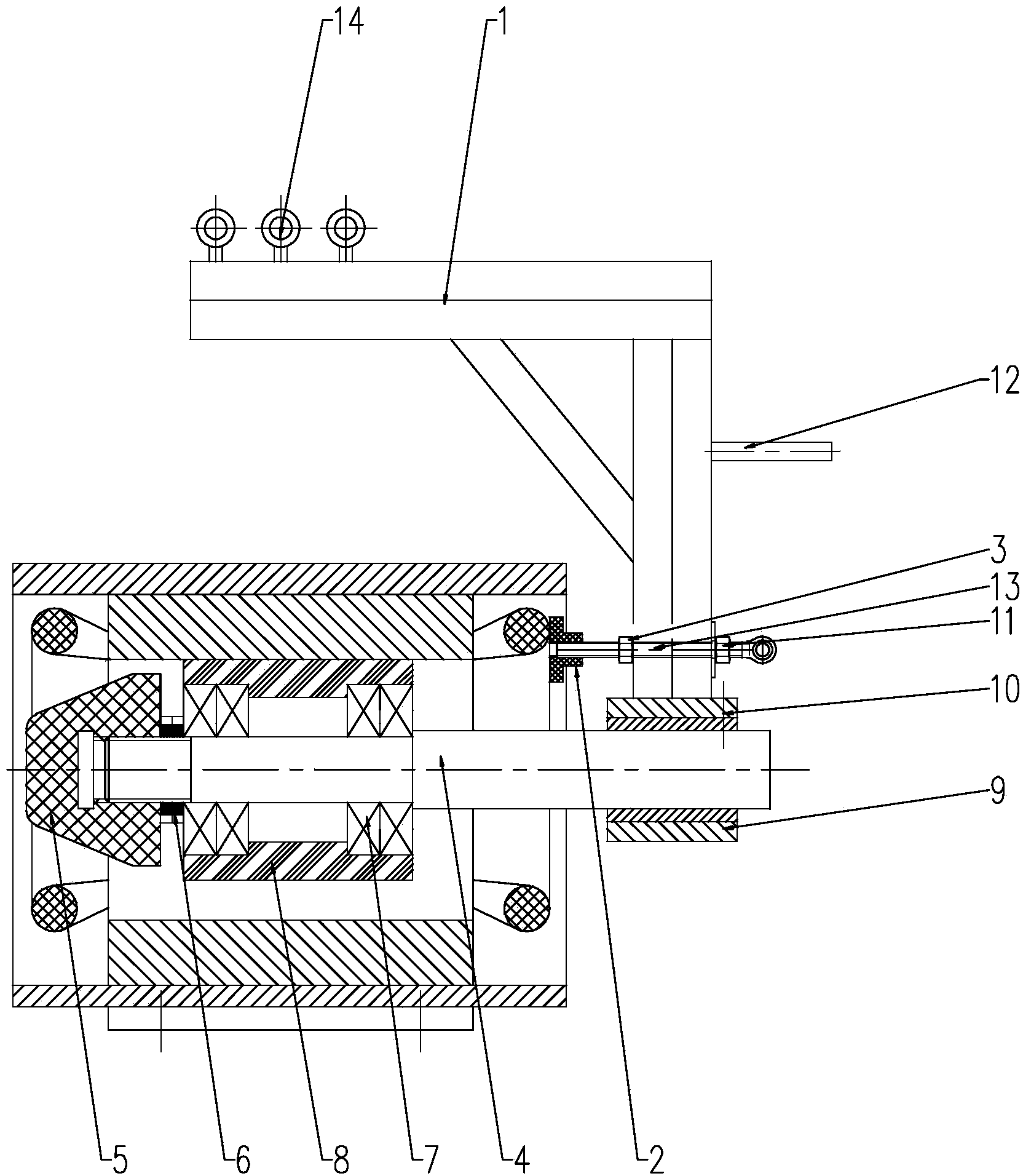

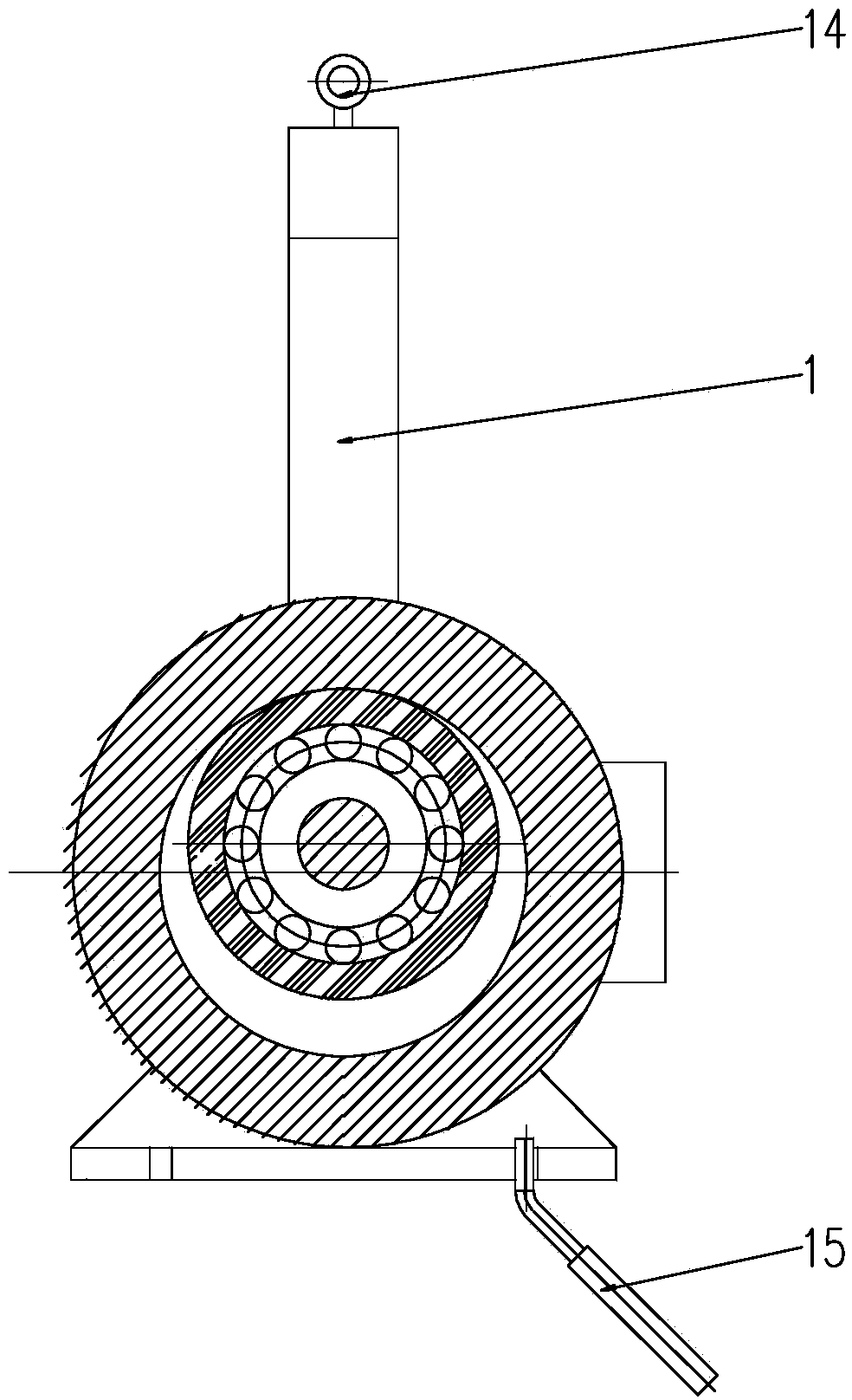

[0016] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

[0017] like Figure 1~2 As shown, the present invention mainly includes a hanger 1, the lower end of the hanger 1 is provided with a second sleeve 9, and the rotary mandrel 4 is inserted into the second sleeve 9. A set screw 10 is connected to the second sleeve 9 , and the set screw 10 is tightened to lock the rotary mandrel 4 in the second sleeve 9 .

[0018] The rotary mandrel 4 supports the first sleeve 8 through a plurality of rolling bearings 7, one side of the rolling bearing 7 is locked and positioned by the round nut 6 connected to the rotary mandrel 4, and the other side of the rolling bearing 7 is passed through the shaft of the rotary mandrel 4. shoulder positioning. The end of the rotary mandrel 4 is connected with a protective taper nut 5 so as to protect the rotary mandrel 4 .

[0019] The hanger 1 is connected with an adjusting bolt 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com