Ceramic tile flip-over method and ceramic tile flip-over device

A ceramic tile flipping device and ceramic tile technology are applied in the field of ceramic machinery to achieve the effects of simple structure, fast flipping speed and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

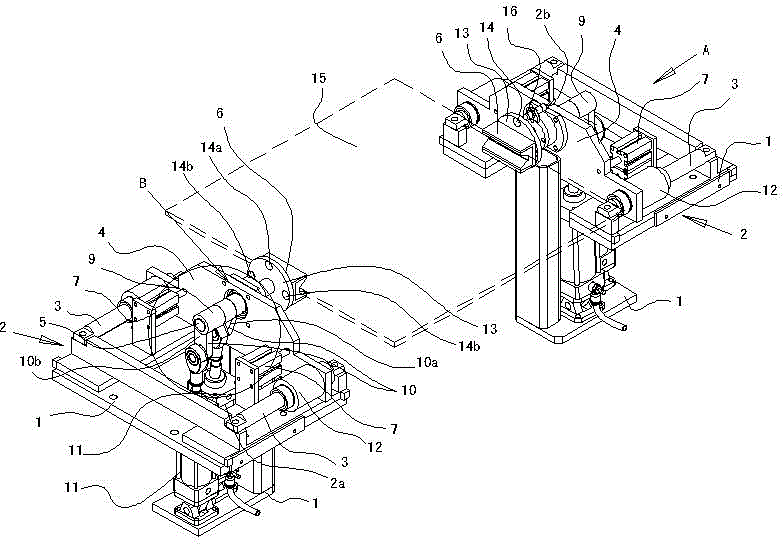

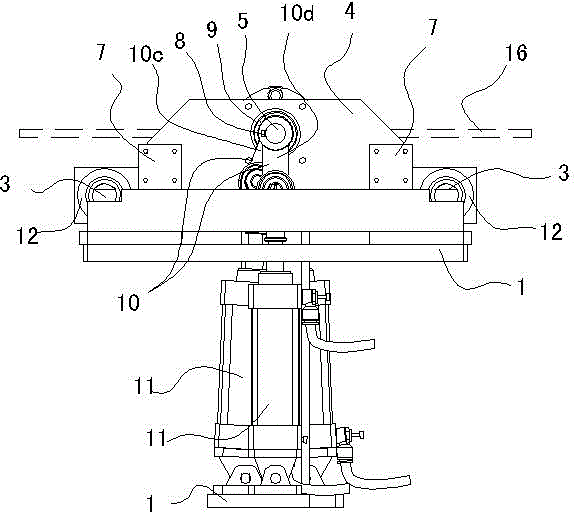

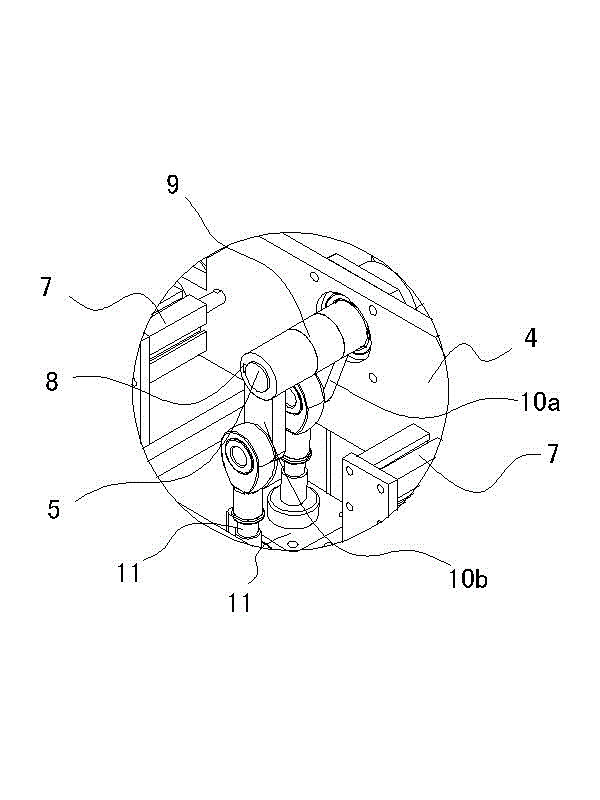

[0014] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0015] The tile overturning method of the present invention is realized in this way, including the tile clamping process and the tile overturning process; The tile flipping process is composed of the clockwise flipping process of the tiles and the counterclockwise flipping process of the tiles in sequence; the clockwise flipping process of the tiles is socketed on the shaft of one of the two bayonets to drive the shaft to rotate The sleeve is connected with two pendulum rods perpendicular to the axis. When the bayonet is at the initial position, one of the pendulum rods is located at the downward and leftward position, and the other pendulum rod is located at the vertical downward position. First, use a One of the swing rods is supported by the cylinder, and the rotating shaft is driven to rotate clockwise by a certain angle through the sleeve, and the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com