A device for assisting the overturning of metal plates

A metal plate and rotating shaft technology, applied in the field of metal product processing, can solve the problems of easily damaged steel plates, inconvenient operation, complex structure, etc., and achieve the effects of convenient use, fast turning speed and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described further below:

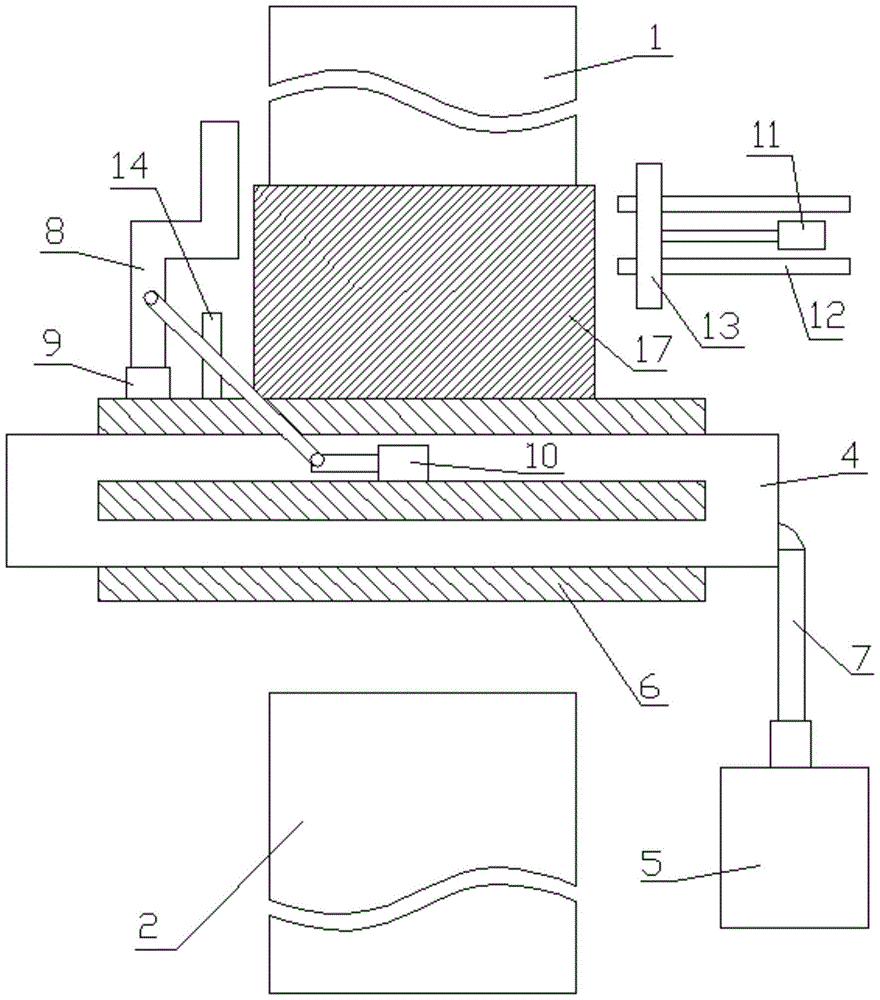

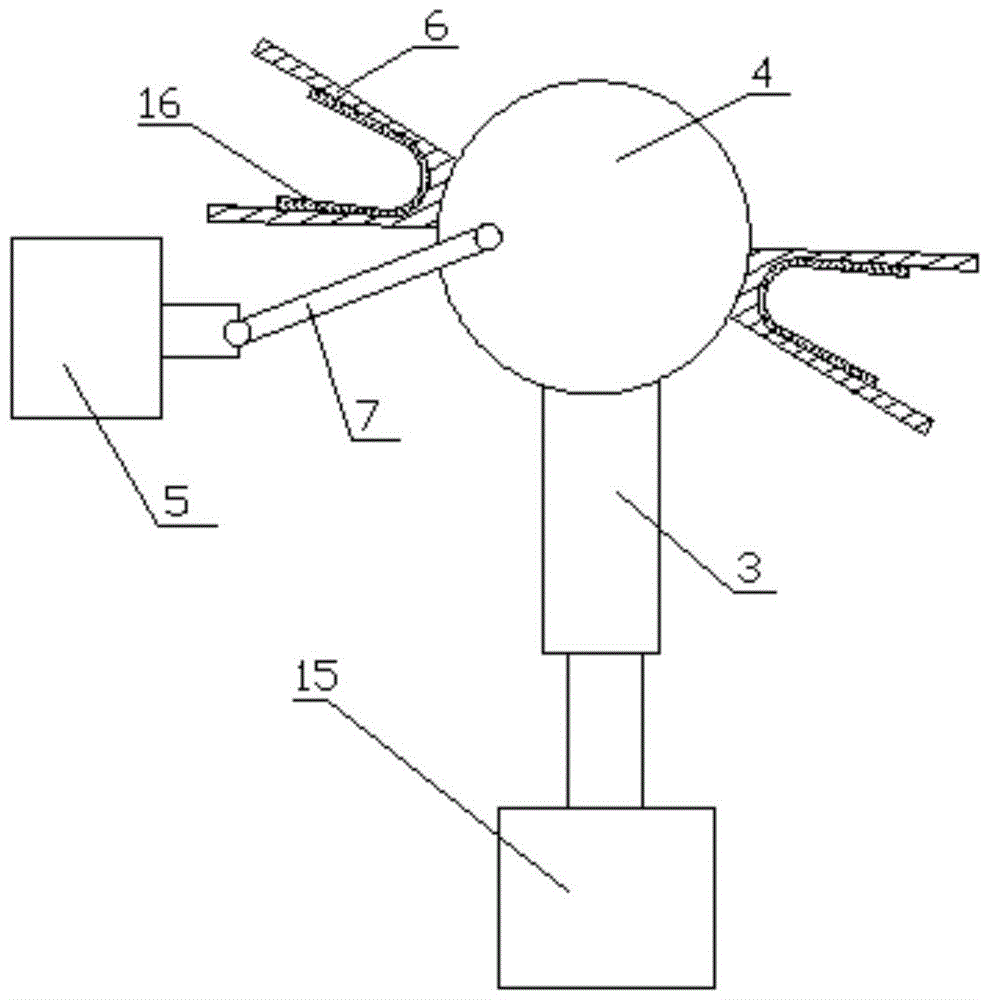

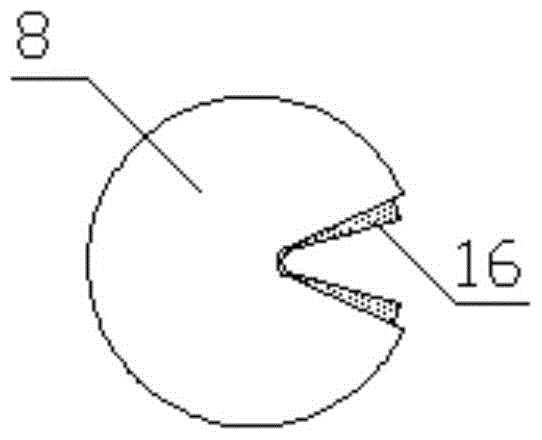

[0028] combine figure 1 , 2 , 3: A device for assisting the flipping of metal plates, including a first conveyor belt 1, a second conveyor belt 2, a bracket 3, a rotating shaft 4, and a cylinder 5. The rotating shaft 4 is placed on the first conveyor belt 1 and the second conveyor belt Between the belts 2, the rotating shaft 4 is rotationally connected with the bracket 3, and the rotating shaft 4 is provided with a plurality of clamping plates 6 for clamping the metal plate along the circumference, and the length direction of the clamping plates 6 extends along the axial direction of the rotating shaft 4. The elongation direction of the clamping opening of the clamping plate 6 is parallel to the moving direction of the metal plate 17;

[0029] The metal plate 17 is placed on the first conveyor belt 1, and the first conveyor belt 1 drives its displacement. When one end of the metal plate 17 contacts the clamping plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com