Apparatus for overturning metal plate

The technology of a metal plate and a rotating shaft is applied in the field of the device for turning the metal plate, which can solve the problems of inconvenient operation, easy damage to the steel plate, complicated structure, etc., and achieve the effects of fast turning speed, convenient use and simple device structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described further below:

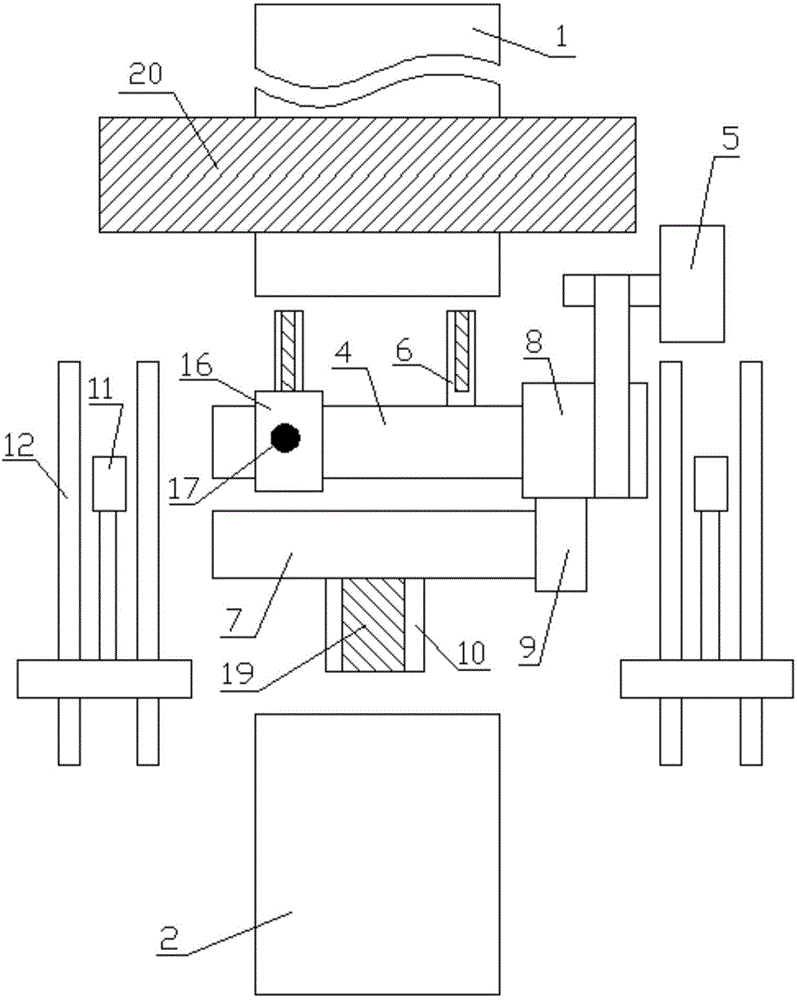

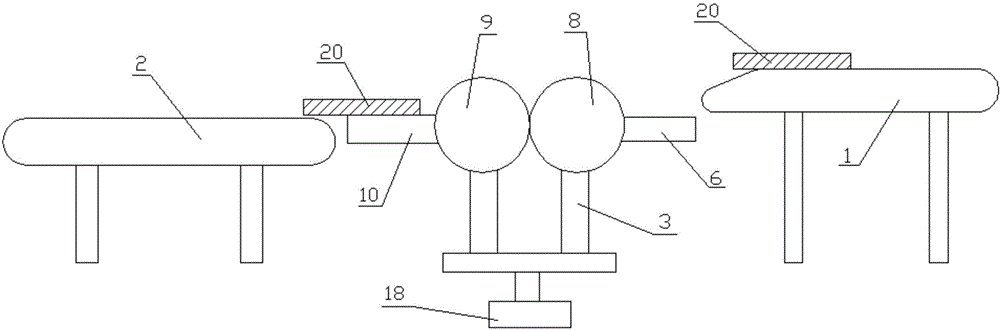

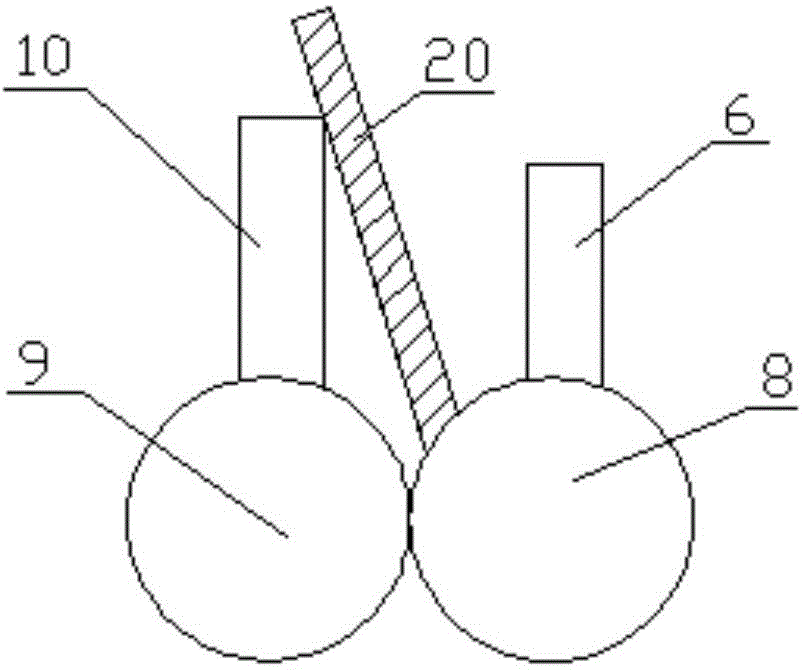

[0034] combine figure 1 : A kind of device that is used for flipping metal plate, comprises first conveyer belt 1, second conveyer belt 2, support 3, first rotating shaft 4, rotary cylinder 5, and this first rotating shaft 4 is placed in first conveyer belt 1, second conveyer belt Between the two conveyor belts 2, both ends of the first rotating shaft 4 are rotationally connected with the support 3, and the first rotating shaft 4 is in transmission connection with the rotating cylinder 5, and the first rotating shaft 4 is provided with at least one first connecting rod along the circumferential direction group, the first connecting rod group includes at least one first connecting rod 6, one end of the first connecting rod 6 is connected to the first rotating shaft 4, and the other end extends outward and is close to the first conveyor belt 1, the first connecting rod 6 The vertical height between the end of the rod 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com