Mobile phone screen glass surface defect detection device

A glass surface and defect detection technology, applied in measuring devices, material analysis by optical means, instruments, etc., to achieve the effect of improving the actual detection effect, avoiding adjustment and turning over, and saving operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

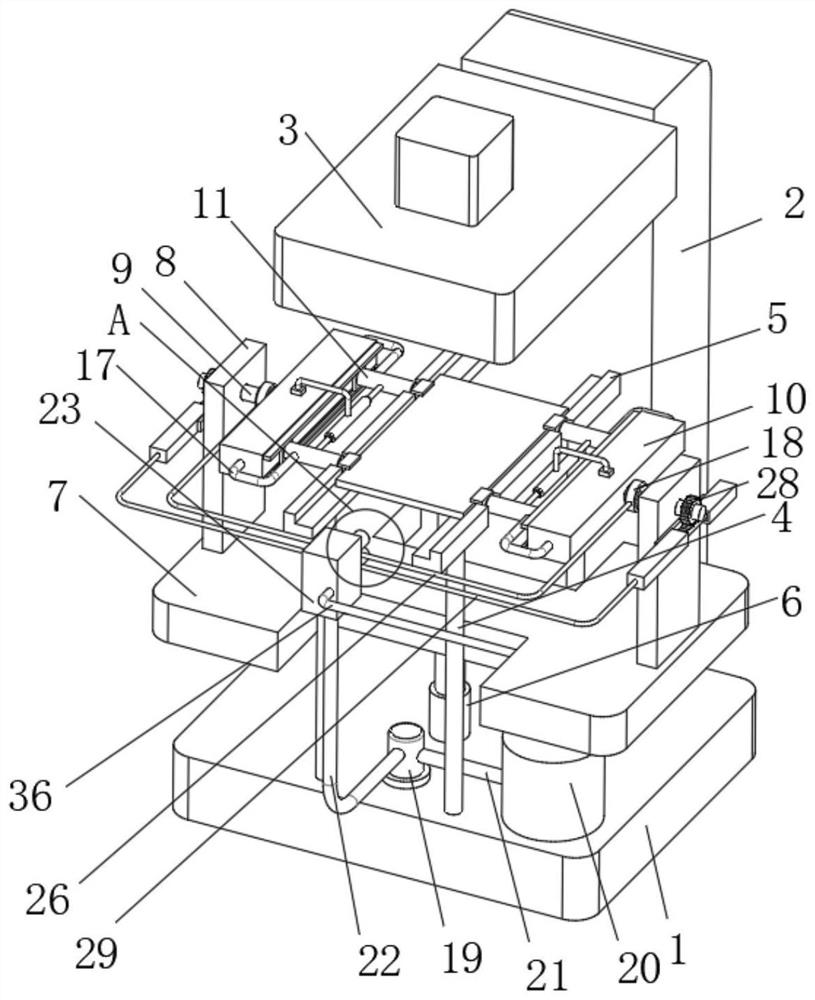

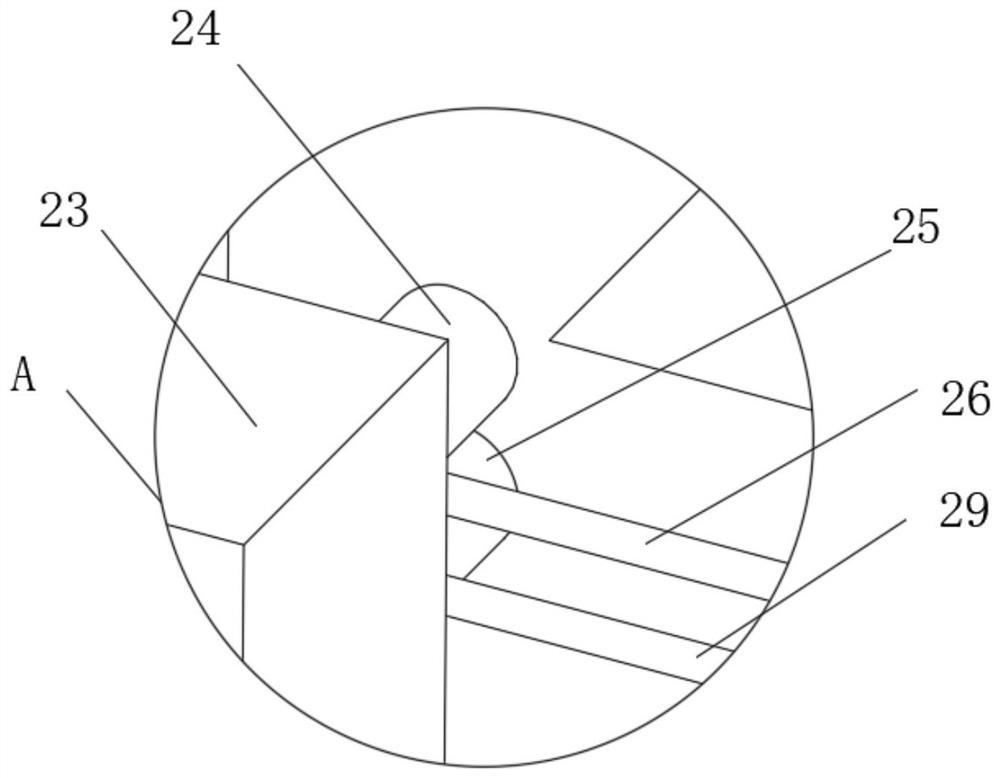

[0037] The first embodiment: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, the screen glass to be tested is placed on the top surface of the positioning plate 5, the control pump 19 is activated, and the control valve 23 is actuated, so that the control pump 19 sends the hydraulic oil in the oil tank 20 to No. 1 through the control valve 23. In the communication sleeve 24, with the feeding of hydraulic oil, the hydraulic oil is sent into the interior of the entry mechanism 18 through the No. 2 pipe 26, and into the distribution box 10 through the inner cavity of the sleeve 9, and into the distribution box. The hydraulic oil in 10 enters into the movable tube 11 through the No. 1 tube 17, and pushes the sealing plug 13 to slide along the inner surface of the movable tube 11, while the No. 1 spring 12 stretches, so that multiple sets of plywood 15 clamp the screen glass at the same time The side of the lift rod 6 drives the mounting plate...

no. 2 example

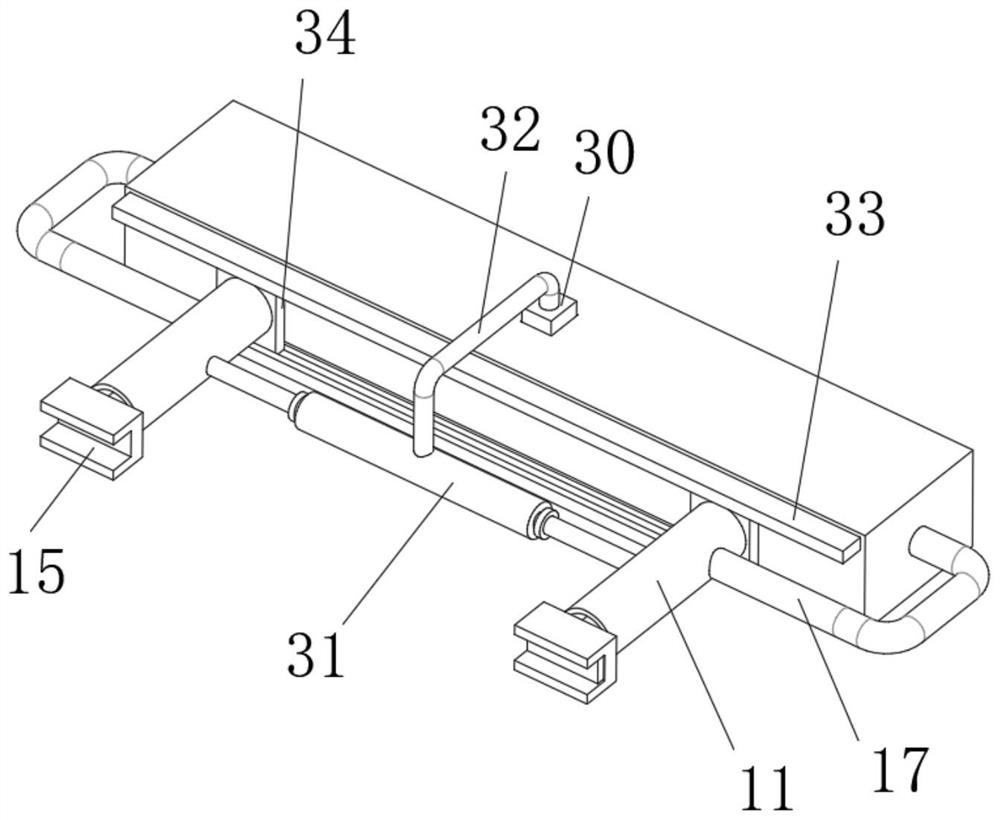

[0047] Second embodiment: as figure 1 , figure 2 , image 3 , Figure 4 and Figure 7As shown, when the screen glass is turned over and detected, the solenoid valve 30 is activated, so that the hydraulic oil entering the distribution box 10 enters the middle sleeve 313 through the fourth pipe 32. With the increase of the hydraulic oil in the middle sleeve 313, the hydraulic pressure The oil pushes the inner circular plates 312 on both sides to move, and at the same time, the No. 3 spring 315 is stretched, and the sleeve rod 311 pushes the movable tube 11 to move laterally along the side plates 33 on the side of the distribution box 10 , thereby making the adjacent plywood 15 away, so that the clamping position changes, the previously blocked clamping position is automatically opened, and the detection seat 3 on the top is used to conduct a comprehensive inspection, and after a comprehensive inspection is performed on one side, the control valve 23 controls the hydraulic oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com