Plant fiber molded product transfer method and plant fiber molded product turning transfer device

A technology for molded products and plant fibers, which is used in conveyor objects, transportation and packaging, textiles and papermaking, etc., can solve problems such as inability to produce high-quality products, affecting product positioning accuracy, and production variety restrictions, achieving structural The effect of compactness, increased variety, and increased turning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

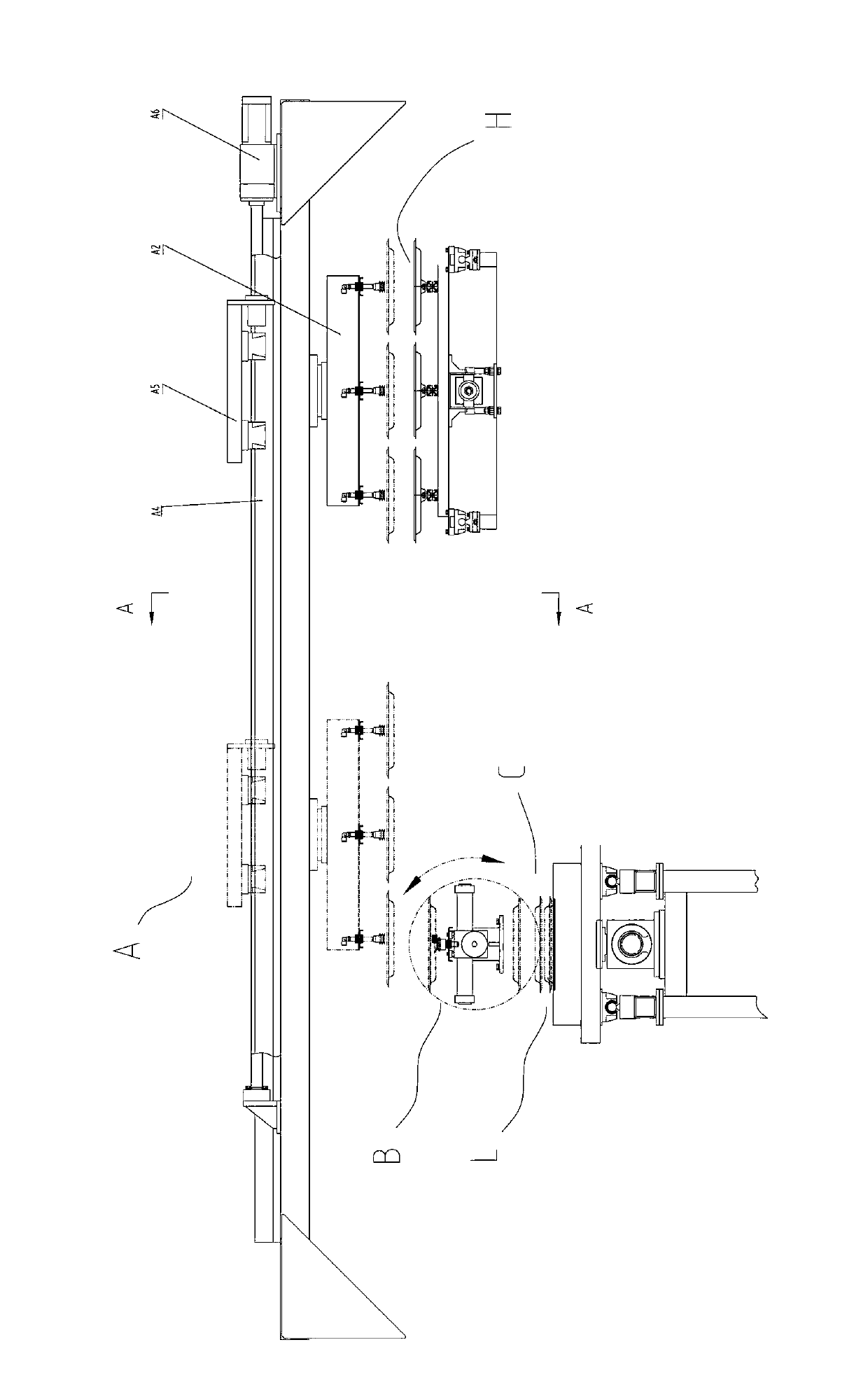

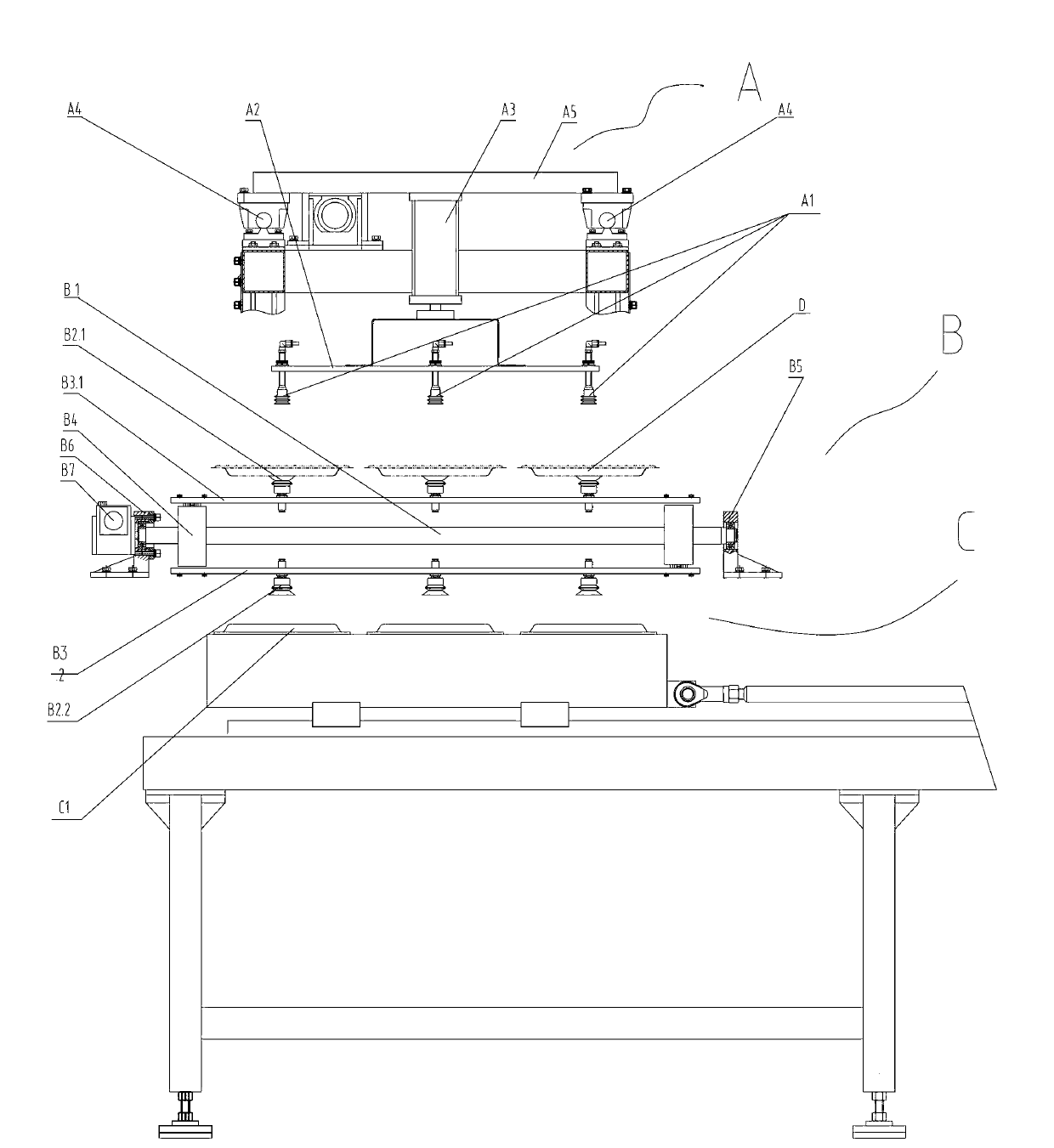

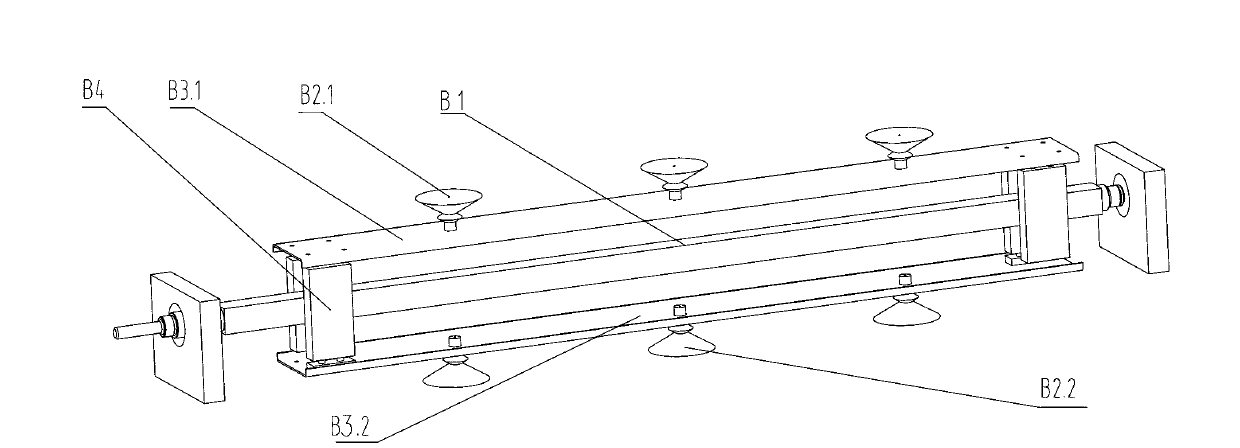

[0042] Such as figure 1 , figure 2 , as shown in Figure 3, the plant fiber molded product turning and transferring device includes a high-level discharge device A and a turner device B. There is generally a product receiving device C below the turning transfer device.

[0043] High-level delivery device A includes: high-level delivery suction cup group A1, delivery suction cup group fixing frame A2, transfer cylinder A3, delivery horizontal track A4, transfer cylinder fixing frame A5, and delivery power transmission mechanism A6;

[0044] The high-level discharge suction cup group A1 is fixed on the discharge suction cup group fixed frame A2, the piston rod of the transfer cylinder A3 is connected with the discharge suction cup group fixed frame A2, and the cylinder body of the transfer cylinder is fixed on the transfer cylinder fixed frame A5. The cylinder can drive the fixed frame of the delivery suction cup group to move up and down, so the high-level delivery suction cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com