Composition with whitening effect, whitening soluble microneedle patch with high drug loading and preparation method thereof

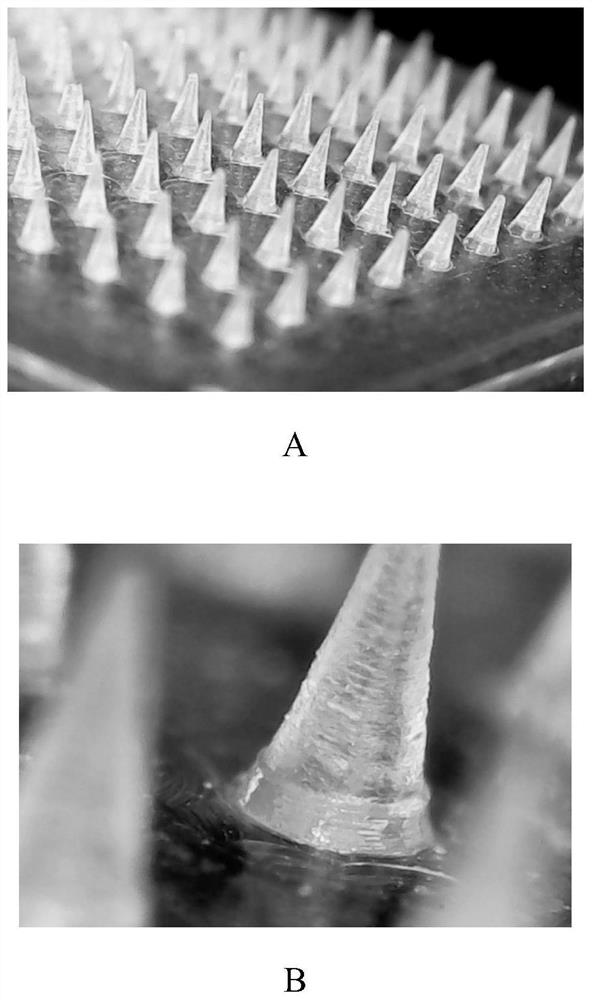

A high drug-loading and soluble technology, applied in the field of microneedles, can solve the problems that microneedles cannot pierce the skin, low microneedle strength, and low drug-loading capacity, so as to reduce treatment costs, improve transdermal absorption rate, and improve efficacy Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The whitening soluble microneedle patch with high drug loading provided in this embodiment is composed of a needle point and a base; the raw materials of the needle point are composed as follows (in parts by weight): 13 parts of arbutin, 15 parts of magnesium ascorbyl phosphate, 7 parts of adenosine, 0.4 parts of sturgeon caviar extract, 106.2 parts of sodium hyaluronate (molecular weight of 280kDa), 6 parts of polyvinylpyrrolidone (molecular weight of 1300kDa), 12 parts of glycerin, 6 parts of hydroxypropyl cellulose; The composition of raw materials is as follows: 1.1 parts of sodium hyaluronate (molecular weight: 280Kda), 0.1 parts of glycerin, and 0.1 parts of hydroxypropyl cellulose.

[0062] The preparation method of the whitening soluble microneedle patch with high drug loading provided in this example is as follows:

[0063] S1: Preparation of needle tips: After uniformly mixing the above-mentioned raw materials for preparing needle tips, add 591.4 parts of dist...

Embodiment 2

[0066] The whitening soluble microneedle patch with high drug loading provided in this embodiment is composed of a needle point and a base; the raw materials of the needle point are composed as follows (in parts by weight): 13 parts of arbutin, 15 parts of magnesium ascorbyl phosphate, 7 parts of adenosine, 0.4 parts of sturgeon caviar extract, 70.8 parts of hyaluronic acid (molecular weight of 280kDa), 6 parts of polyvinylpyrrolidone (molecular weight of 1300kDa), 12 parts of glycerin, 6 parts of hydroxypropyl cellulose; The composition of the raw materials is as follows: 1.1 parts of sodium hyaluronate (molecular weight: 280 kDa), 0.1 parts of glycerin, and 0.1 parts of hydroxypropyl cellulose.

[0067] The preparation method of the whitening soluble microneedle patch with high drug loading provided in this example is as follows:

[0068] S1: Preparation of needle tips: After uniformly mixing the above-mentioned raw materials for preparing needle tips, add 591.4 parts of dis...

Embodiment 3

[0071] The whitening soluble microneedle patch with high drug loading provided in this embodiment is composed of a needle point and a base; the raw materials of the needle point are composed as follows (in parts by weight): 13 parts of arbutin, 15 parts of magnesium ascorbyl phosphate, 7 parts of adenosine, 0.4 parts of sturgeon caviar extract, 35.4 parts of hyaluronic acid (molecular weight: 280kDa), 6 parts of polyvinylpyrrolidone (molecular weight: 1300kDa), 12 parts of glycerin, 6 parts of hydroxypropyl cellulose; the raw materials of the base The composition is as follows: 1.1 parts of sodium hyaluronate (molecular weight: 280 kDa), 0.1 parts of glycerin, and 0.1 parts of hydroxypropyl cellulose.

[0072] The preparation method of the whitening soluble microneedle patch with high drug loading provided in this example is as follows:

[0073] S1: Preparation of needle tips: After uniformly mixing the above-mentioned raw materials for preparing needle tips, add 591.4 parts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com