Protease super-concentrated laundry detergent and preparation method thereof

A technology of laundry detergent and protease, applied in the field of daily chemicals, can solve the problems of inability to completely remove the removal effect and poor performance, and achieve the effects of less foam, easy storage, and strong resistance to hard water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

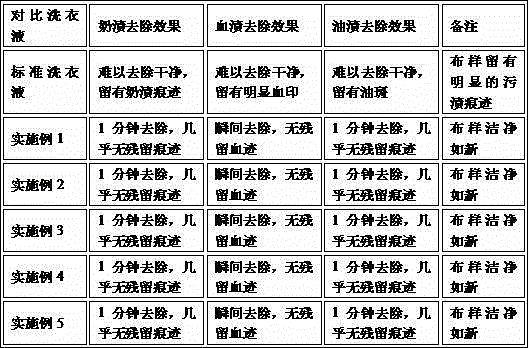

Examples

Embodiment 1

[0028] A protease super-concentrated laundry detergent with an effective active content of 33%, mainly composed of the following raw materials in mass percentages: 22% of nonionic surfactants (including 13% of fatty alcohol polyoxyethylene ether-7, 4% of Fatty alcohol polyoxyethylene ether-9, 5% coconut oil fatty acid diethanolamide), 11% anionic surfactant (including 10% fatty alcohol polyoxyethylene ether sodium sulfate and 1% sodium alpha-olefin sulfonate) , 0.1% highly active biological protease, 1% triethanolamine, 1% sodium citrate, 0.8% refined salt, 63.9% deionized water, 0.2% essence and trace (two parts per million) pigment.

[0029] The preparation method of the protease super-concentrated laundry detergent of the present embodiment may further comprise the steps:

[0030] 1) Heat 450g of deionized water to 45°C and put it into the reaction kettle, add 130g of fatty alcohol polyoxyethylene ether-7, 40g of fatty alcohol polyoxyethylene ether-9, 50g of coconut oil fat...

Embodiment 2

[0035] A protease super-concentrated laundry detergent with an effective active content of 31%, mainly composed of the following raw materials in mass percentages: 19% of nonionic surfactants (including 5% of fatty alcohol polyoxyethylene ether-3, 10% of Fatty alcohol ethoxylates-9, 4% isomeric alcohol ethoxylates), 11% anionic surfactants (including 6% fatty alcohol ethoxylate sodium sulfate and 5% dodecylbenzenesulfonate sodium citrate), 0.1% high-activity biological protease, 0.1% high-activity compound protease, 2% triethanolamine, 0.5% sodium citrate, 1% refined salt, 66.1% deionized water, 0.2% essence and trace (2 parts per million) pigments.

[0036] The preparation method of the protease super-concentrated laundry detergent of the present embodiment may further comprise the steps:

[0037] 1) Heat 495g of deionized water to 45°C and put it into the reactor, add 50g of fatty alcohol polyoxyethylene ether-3, 100g of fatty alcohol polyoxyethylene ether-9, and 40g of iso...

Embodiment 3

[0042] A protease super-concentrated laundry detergent with an effective active content of 34%, mainly composed of the following raw materials in mass percentages: 19% of nonionic surfactants (including 4% of fatty alcohol polyoxyethylene ether-3, 10% of Fatty alcohol ethoxylates-7, 5% alkyl glycosides), 15% anionic surfactants (including 10% sodium alpha-olefin sulfonate and 5% sodium dodecylbenzene sulfonate), 0.1% Highly active compound protease, 1% triethanolamine, 0.8% sodium citrate, 0.8% refined salt, 63% deionized water, 0.3% essence and trace (two parts per million) pigment.

[0043] The preparation method of the protease super-concentrated laundry detergent of the present embodiment may further comprise the steps:

[0044] 1) Heat 500g of deionized water to 45°C and put it into the reactor, add 40g of fatty alcohol polyoxyethylene ether-3, 100g of fatty alcohol polyoxyethylene ether-7, 50g of alkyl glucoside, and 100g of α -sodium olefin sulfonate and 50g of sodium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com