Patents

Literature

108results about How to "Not allergic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Skin care composition with moisturizing and wrinkle-resistant effects

InactiveCN105919827ANot allergicGood moisturizing effectCosmetic preparationsToilet preparationsTryptophanTyrosine

The invention discloses a skin care composition with moisturizing and wrinkle-resistant effects. The composition is prepared by using sterile deionized water as a solvent, and the solute comprises amino acids, vitamins and trace elements including glycine, phenylalanine, alanine, proline, glutamine, serine, arginine, threonine, asparagine, tryptophan, aspartic acid, tyrosine, cysteine, valine, cystine, vitamin H, glutamic acid, nicotinamide, histidine, vitamin B6, isoleucine, vitamin B2, leucine, and vitamin B1. The skin care composition has good moisturizing and wrinkle-resistant effects, and has the advantages of safety without side effect, skin nourishing and good skin penetration capacity.

Owner:BEIJING SINOCELL CO LTD

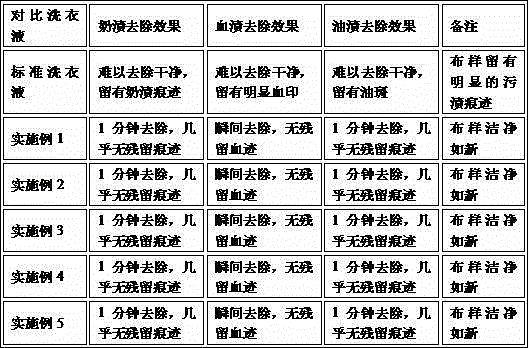

Protease super-concentrated laundry detergent and preparation method thereof

ActiveCN105062703AMild in natureGentle to the touchOrganic detergent compounding agentsNon-ionic surface-active compoundsActive agentBiology

The present invention discloses a protease super-concentrated laundry detergent, which mainly comprises, by mass, 3-38% of a non-ionic surfactant, 1-22% of an anionic surfactant, 0.1-1% of protease, 0.1-2% of triethanolamine, 0.1-2% of sodium citrate, 0.1-2% of refined salt and 60-70% of deionized water, wherein the protease comprises biological protease and compound protease. According to the present invention, the protease super-concentrated laundry detergent product is neutral and has characteristics of mild nature, no stimulation, soft hand-feeling, no alkaline residue after washing, no skin allergy and other symptoms, no damage on fabrics, water solubility, easy use, easy use amount control, easy storage, and easy use; and the process operation of the preparation method is simple, and the method is easily subjected to industrial production.

Owner:DONGGUAN XIANGYU CHEM

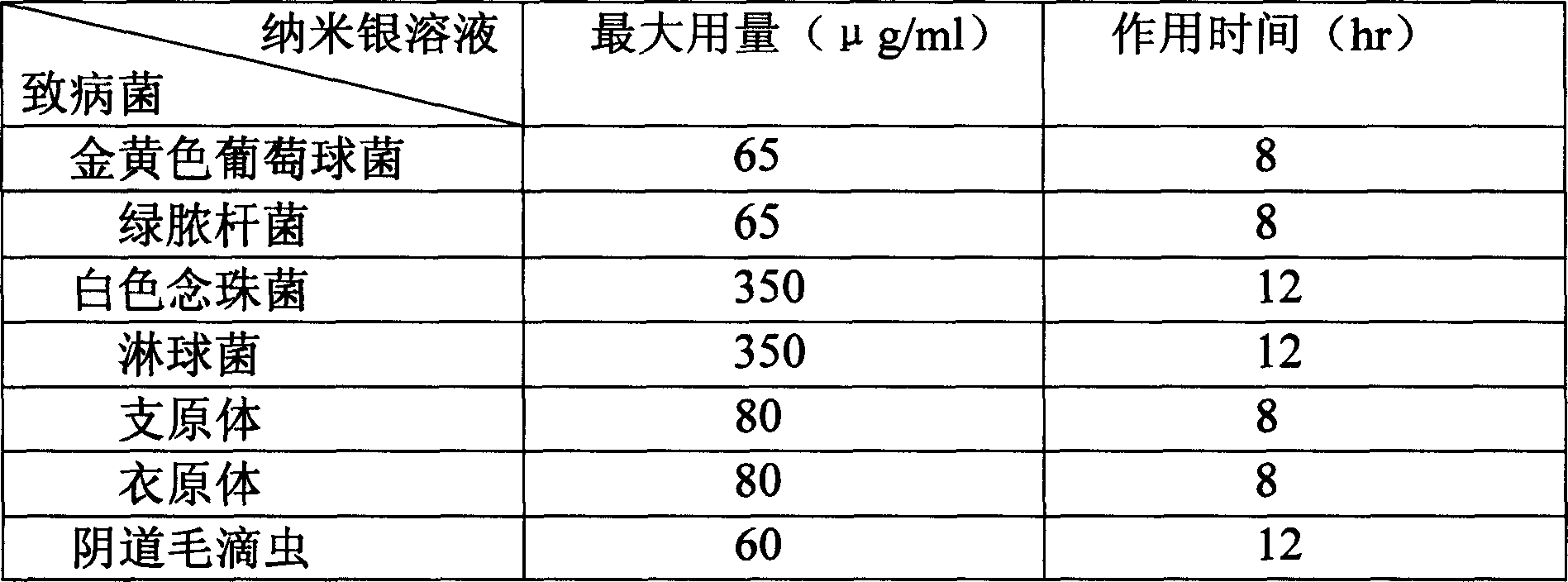

Nano-silver aqueous solution preparation and its preparation method, use and using method

InactiveCN1569366AEasy injectionNo stimulationInorganic active ingredientsMixing methodsReducerInto bladder

The invention relates to a nanometer silver aqueous solution preparation. Its components and weight percentage are: nanometer silver 0.05-1.5, the dispersant 0.5-1.5, the reducer 0.05-0.2, the stabilizer is nanometer silver 0.5-1.5, the dispersant 0.5-1.5, the reducer is 0.05-0.2, the stabilizer is 0.5-10, and the deioned water is 1000. The invention also relates the manufacturing method for above mentioned nanometer silver aqueous solution preparation, and the usage for curing man social disease, and the using method for ejecting the medicine into bladder through urethra. The reducer and stabilizer in the solution accord with the standards of America FDA or china sanitary department.

Owner:杨漓 +1

Papermaking process method utilizing paper mulberry bark as raw material

ActiveCN105544282AFlexibleFine paperMechanical/thermomechanical pulpRaw material divisionPapermakingPrimary screening

The invention provides a papermaking process method utilizing paper mulberry bark as a raw material. The method comprises the following steps of firstly, performing primary screening and soaking on the paper mulberry bark, stewing the paper mulberry bark into a paper steamer, then grinding, adding quick lime, soaking for a period of time, then stewing the obtained paper mulberry bark into the paper steamer at a high temperature, washing off the lime and impurities from the obtained paper mulberry bark, kneading for peeling, cutting the peeled raw material into slices by use of a steel knife, putting the slices into a stone cistern, and mashing to obtain a paper pulp; and finally, pouring the mashed paper pulp into a paper channel full of water, fully stirring so as to ensure that the paper pulp forms uniform suspension flocculent in water, then performing papermaking and paper squeezing, and sweeping, stoving and tearing off wet paper with moisture, wherein the produced paper is not added with chemicals, does not cause damage to health of users, is fine and smooth in quality, flexible and tough, smooth in hand feeling, abrasion-resistant, free of wrinkles, long in preservation life and wide in application range, and has the characteristics of safety, no pollution, economical efficiency and environmental friendliness.

Owner:SHAANXI UNIV OF SCI & TECH

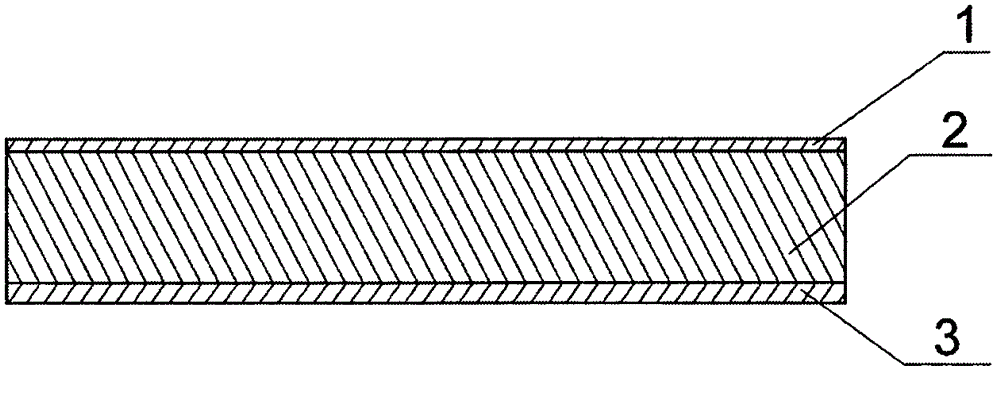

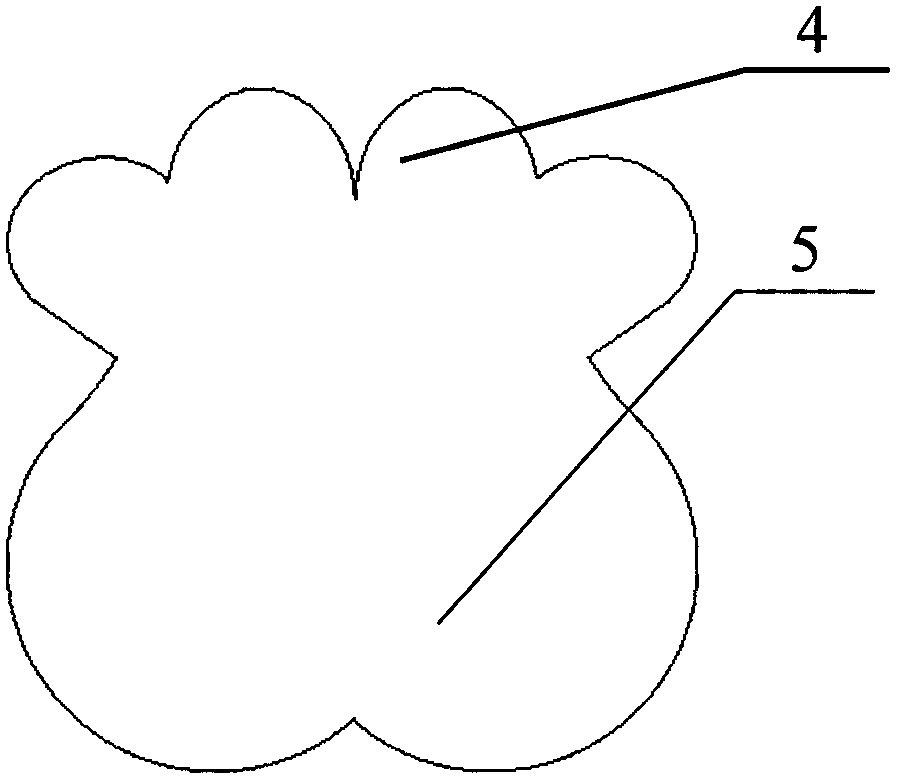

Medical cold compress plaster and preparation process thereof

InactiveCN105878217ASimple production processEase of mass productionAntipyreticAnalgesicsTriclosanVitamin C

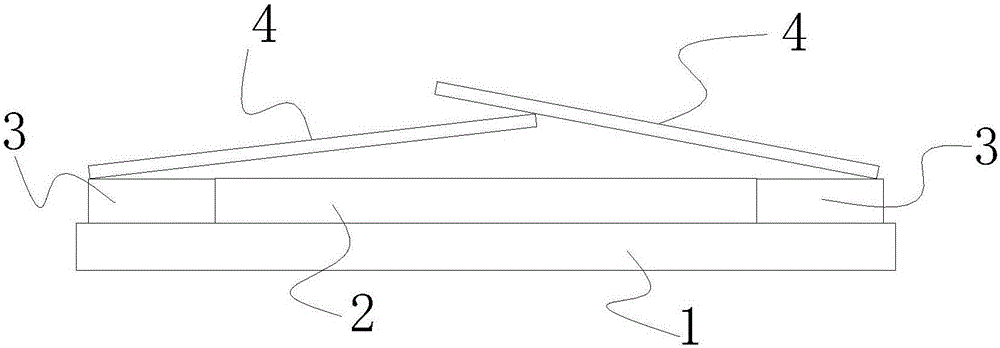

The invention provides a medical cold compress plaster. The medical cold compress plaster is composed of a support layer, a gel layer and an isolating layer, and has the special shape according with the physiological curve of the applied part. An oil phase and a water phase forming the hydrophilic gel layer respectively comprise the following components in percentage by weight: the oil phase: 20-35% of a dispersing agent, 5-7% of macromolecule resin, 0.05-0.15% of dihydroxyaluminium aminoacetate, 0.01-0.15% of ethylene diamine tetraacetic acid, 0.15% of absolute ethyl alcohol, 0.04-0.1% of menthol, 0.1-1% of vitamin E, and 0.05-0.1% of triclosan; the water phase: 0.2-0.8% of tartaric acid, 1.2-2% of carbomer, 0.5-1% of sodium carboxymethylcellulose, 0.01-0.1% of vitamin C, the balance of medical purified water, and the total weight percentage is 100%. A preparation process comprises the following steps: dispersing all the components of the oil phase into the dispersing agent, and uniformly stirring the components; dissolving all the components of the water phase into water, and uniformly stirring the components; mixing the water phase and the oil phase, uniformly stirring the water phase and the oil phase in a vacuum mixing pot, thus obtaining the hydrophilic gel substrate of the medical cold compress plaster, coating the support layer with the hydrophilic gel substrate, meanwhile covering with the isolating layer, and carrying out cutting, solidifying and packaging to obtain the needed medical cold compress plaster product.

Owner:HANGZHOU JIERSI BIOTECH CO LTD

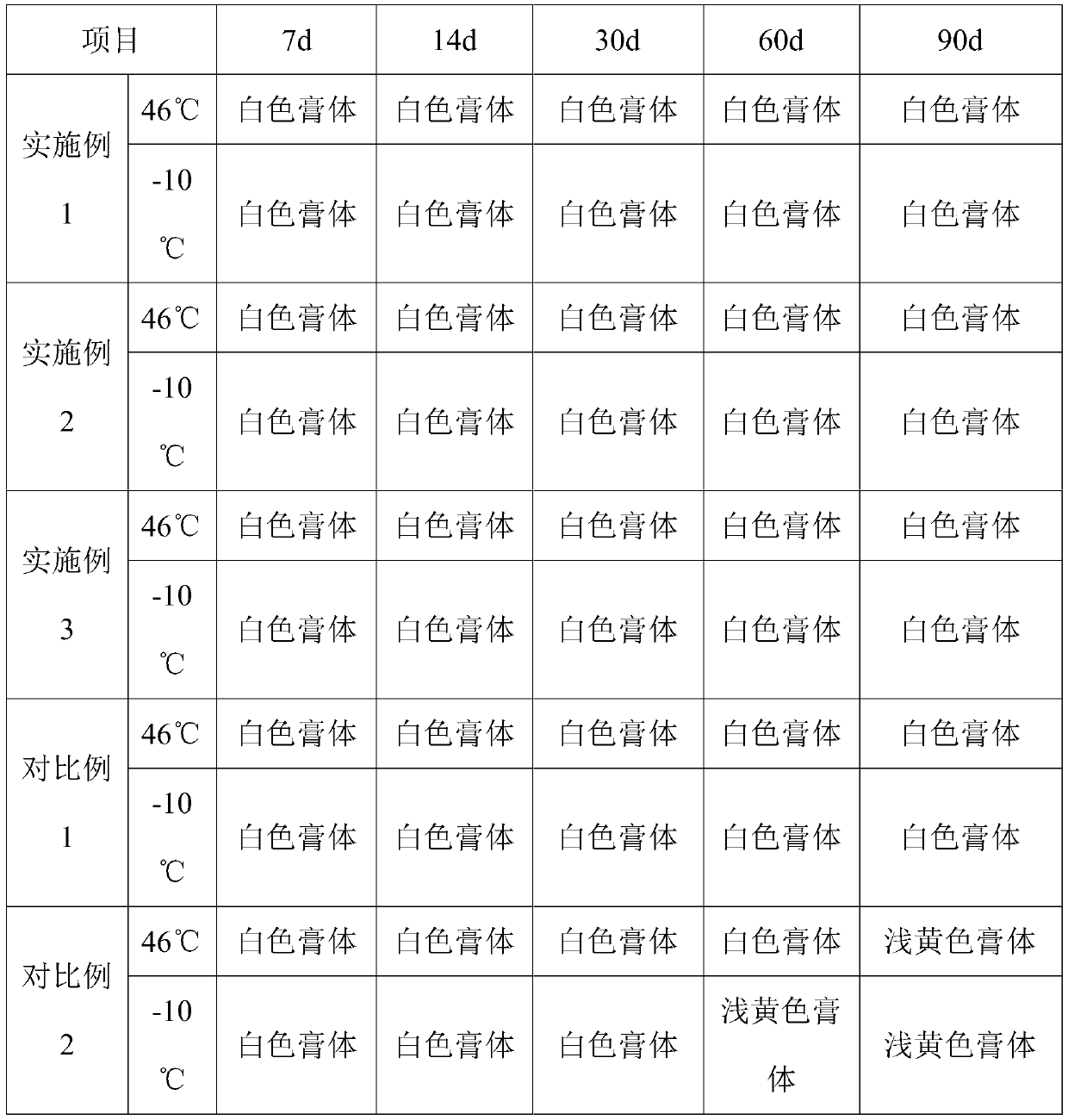

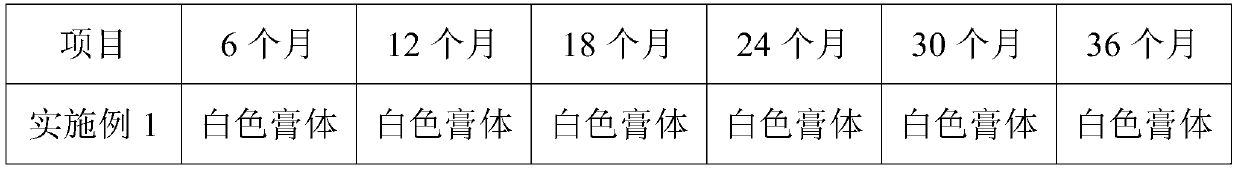

Whitening cream and preparation method thereof

PendingCN110897995AExcellent silky feelIncreased durabilityCosmetic preparationsToilet preparationsAcetophenoneTranexamic acid

The invention discloses a whitening cream and a preparation method thereof. The whitening cream is mainly prepared by compounding three whitening components, namely 1-methyl hydantoin-2-imide, a Bifida Ferment Lysate fermentation product lysate and carnosine, the synergistic whitening effect is achieved; the effects of whitening and removing freckles can be achieved; and sodium hyaluronate, allantoin, p-hydroxyacetophenone, EDTA disodium, nicotinamide, hydrogenated polyisobutene, caprylic / capric triglyceride, avocado butter, polydimethylsiloxane, citric acid, tranexamic acid and tocopheryl acetate are used as auxiliary materials, so that the whitening cream is capable of moisturizing and repairing skin, safe, free of side effects and comprehensive in effect.

Owner:深圳市琉璃光生物科技有限公司

Corn fiber quilt preparation method

A corn fiber quilt preparation method is characterized in that the preparation method adopts corn fiber as the filler of the quilt core and comprises the following steps: sampling shell fabric, clipping and sewing, weighting raw materials, matching and mixing, opening and carding, air-assisted filling, carding and lapping and non-gel shaping, filling and coating, sealing and basting, examine and packaging and warehousing the finished products. The corn fiber is used as the filler of the quilt core, the quilt is loose, comfortable and durable, the quilt can easily recovery after extrusion and is easy to wash, the product appearance can not be changed for a long time and the corn fiber also has the characteristics of good heat preservation and humidity-discharging.

Owner:SHANGHAI SHUIXING HOME TEXTILE

Plant source antibacterial agent and preparation method thereof

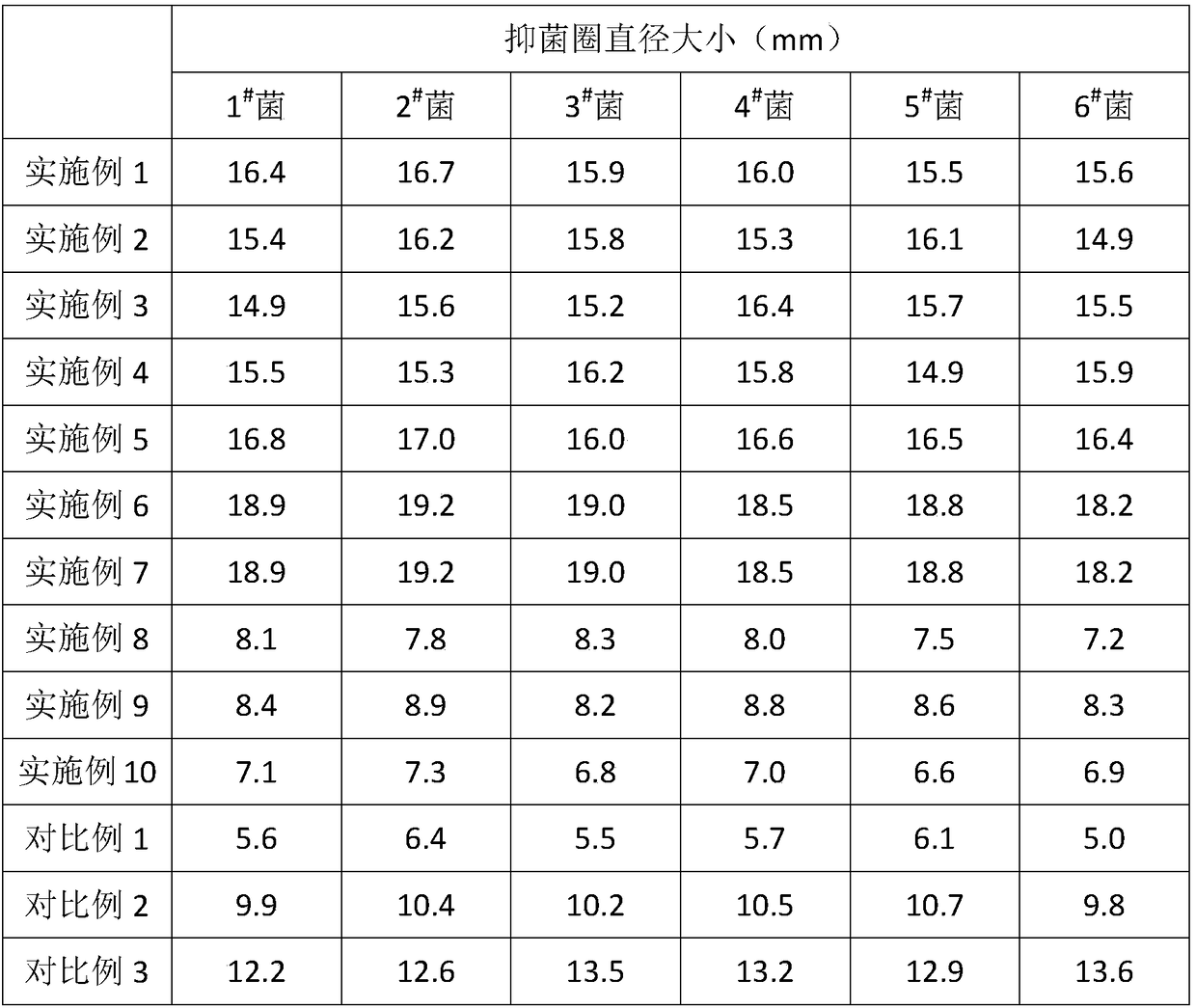

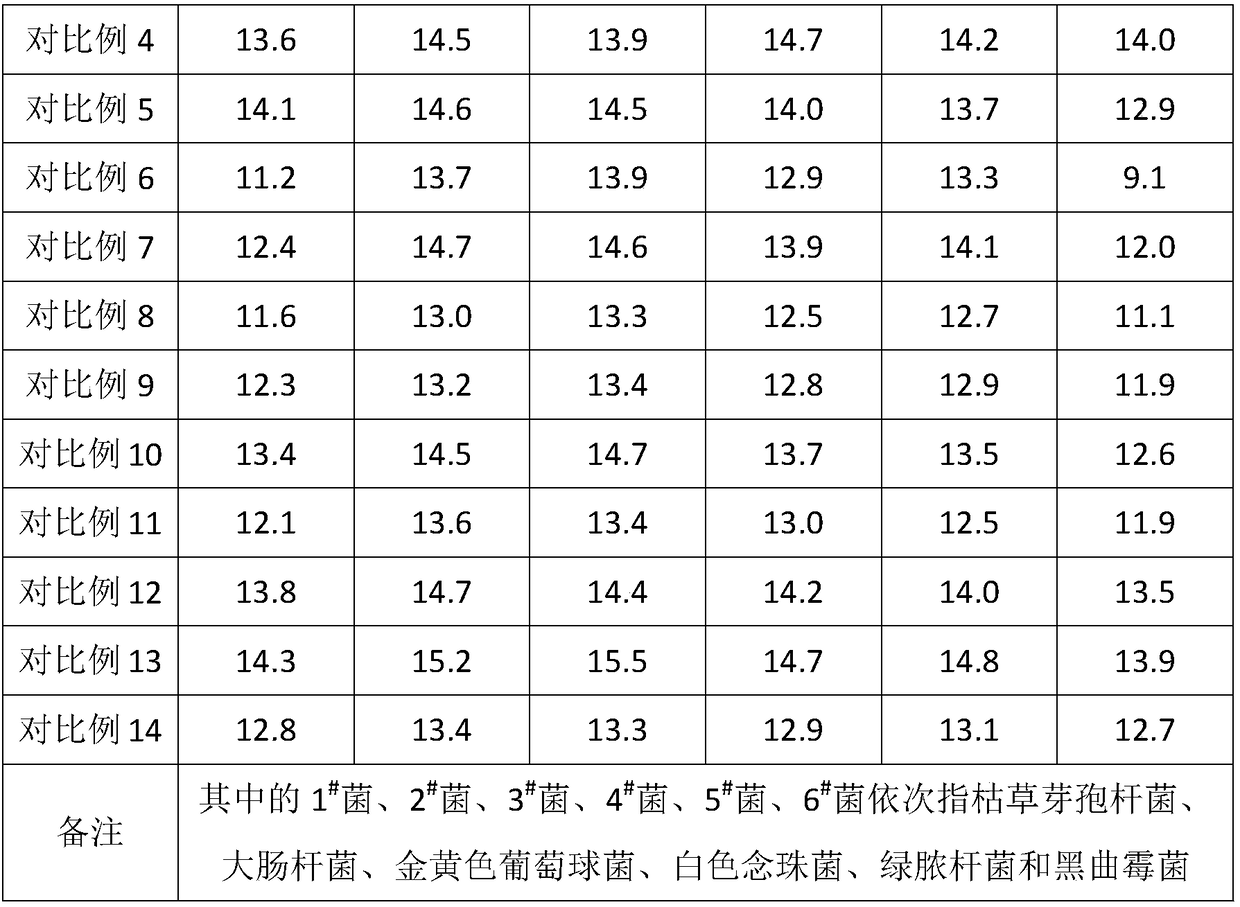

ActiveCN108294060AImprove high temperature stabilityEasy to prepareBiocideCosmetic preparationsEscherichia coliPulsatilla koreana

The invention relates to the field of daily chemical products, in particular to a plant source antibacterial agent and a preparation method thereof. The plant source antibacterial agent comprises thefollowing components in parts by weight: 20-33 parts of a pulsatilla cernua extract, 14-36 parts of a Chinese prickly ash extract and 20-38 parts of a tillandsia usneoides extract. The plant source antibacterial agent provided by the invention has a very high property of inhibiting growth of bacillus subtilis, escherichia coli, staphylococcus aureus, candida albicans, pseudomonas aeruginosa, aspergillus niger and the like, and a preservative property as well, besides, the stability of the agent can be also very well improved at a high temperature. In addition, cosmetics can be kept gentle whenantibacterial effects and high-temperature stability are maintained, and the agent has the characteristics of being non-toxic and non-irritant to human bodies.

Owner:上海科颜生物科技有限公司

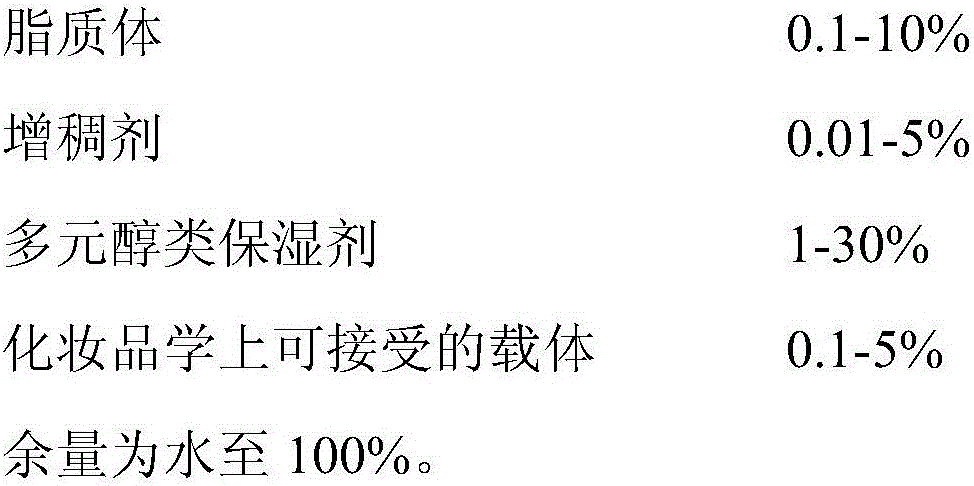

Skin whitening toning lotion containing lipidosome and preparation method thereof

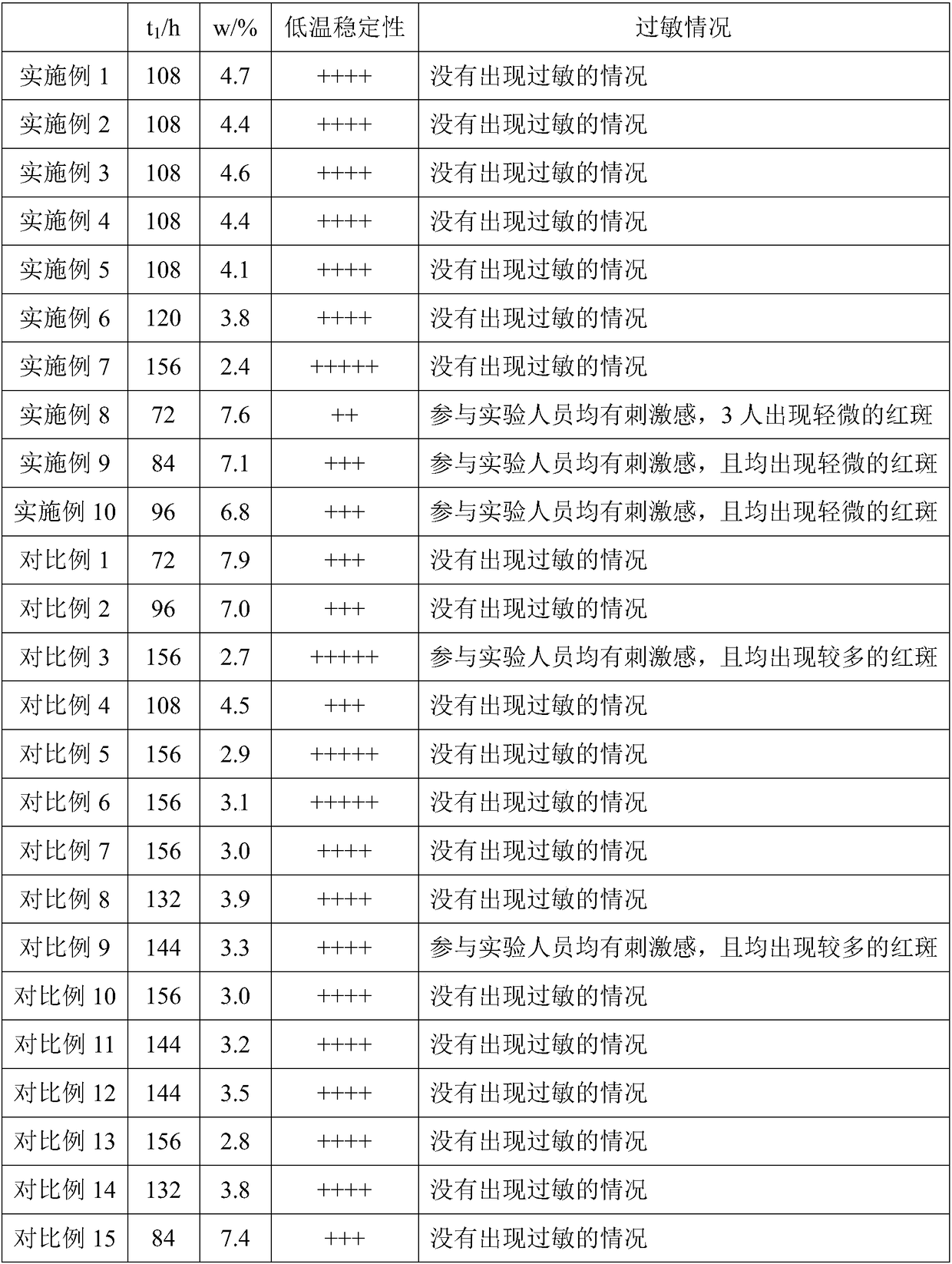

InactiveCN106214511AGood whitening effectNo discolorationCosmetic preparationsToilet preparationsMedicineAdditive ingredient

The invention relates to the field of cosmetics and particularly discloses skin whitening toning lotion containing lipidosome and a preparation method thereof. The skin whitening toning lotion is prepared from, by weight, 0.1-10% of lipidosome, 0.01-5% of thickener, 1-30% of polyalcohol humectant, 0.1-5% of cosmetically-accepted carrier and the balance water. The sum of the weight percentages is 100%. The lipidosome ingredient is added to the toning lotion, the formula is reasonable, the dry environment can be effectively resisted, the elastic and smooth skin can be restored, the skin is moisturized and tender, production of melanin is effectively restrained, the skin is brighter and whiter, the skin whitening toning lotion can deeply penetrate into the bottom layer of the skin, the dry environment is effectively resisted, the elastic and smooth skin is restored, and the skin is moisturized and tender.

Owner:上海乐宝日化股份有限公司

Composite function liquid wound dressing and its use

A multifunctional liquid dressing for cleaning wound, fast haemostasis and filing, preventing infection and promoting healing is a liquid sol composed of the superfine inorganic superfine particles (0.01-20%) and the liquid medium (80-99.9%) consisting of water and disinfectant.

Owner:邢宪生

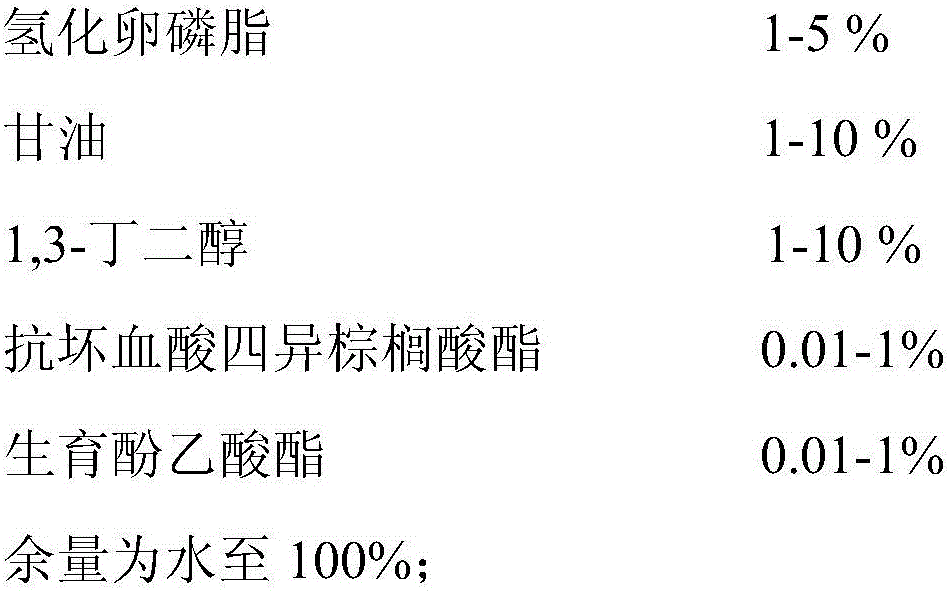

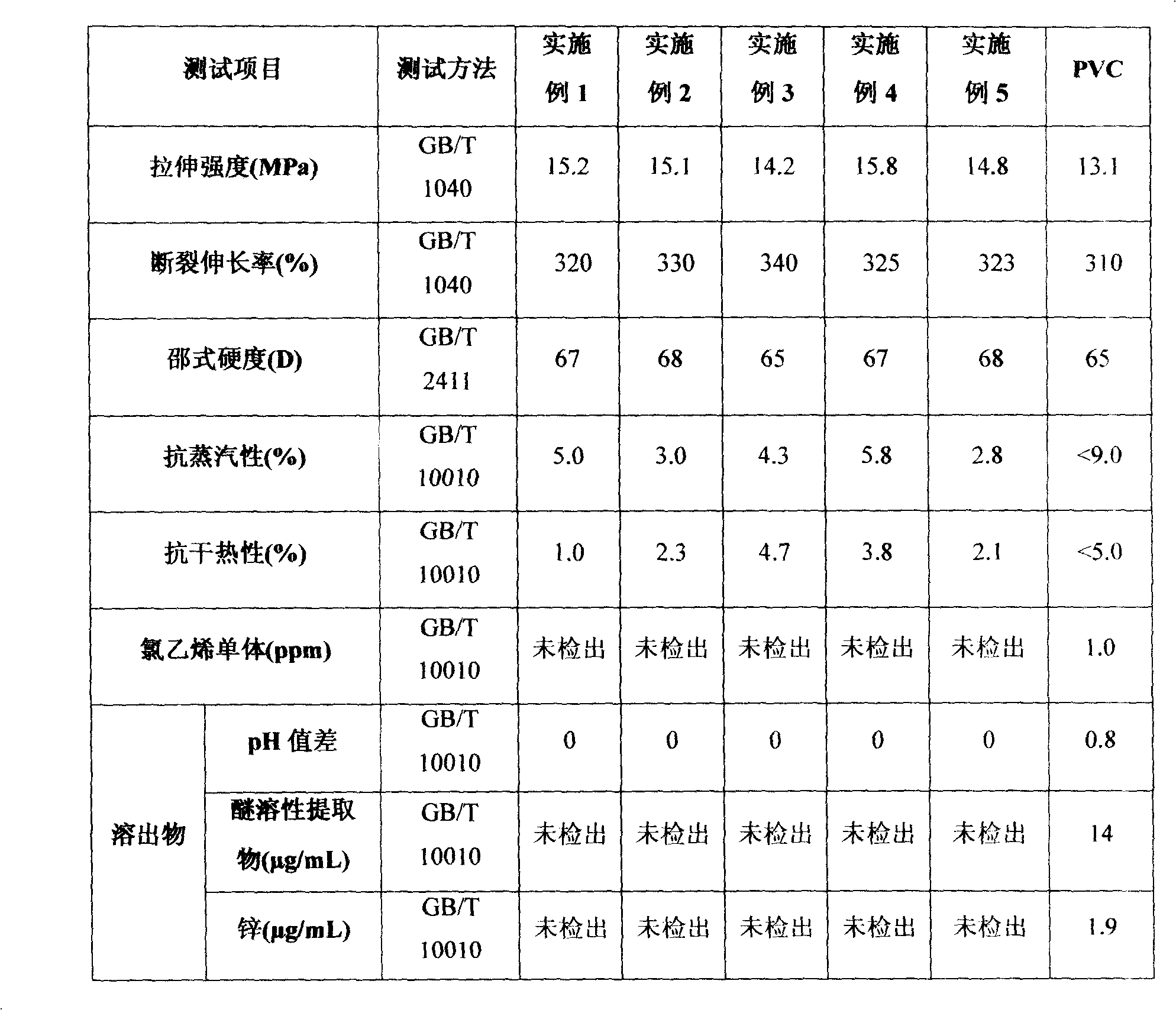

Novel material for totally nontoxic non-polyvinyl chloride medical perfusion tube and method for manufacturing same

The invention provides a novel material for a totally nontoxic non-polyvinyl chloride medical perfusion tube. The novel material is characterized in that the material contains the following materials according to the weight percentages thereof: 100 parts of styrene-hydrogenation dialkene block copolymer which is partially hydrogenated, 5-200 parts of ethylene-propylene copolymer of low molecular weight, and 0.01-10 parts of modified natural oxidation inhibitor vitamin E. The invention further provides a method for manufacturing the novel material. A medical perfusion tube made of the novel material has the advantages of high transparency, high flexibility, steam and dry-heat resistance superior to the PVC medical perfusion tube, and better than the PVC medical perfusion tube in terms of mechanical performance. The medical perfusion tube made of the novel material is totally nontoxic, can not generate allergy, variation and exclusive reaction to human organizations, has the high temperature resistance, aging resistance and uvioresistant performance, can be directly sterilized through high temperature boiling and ultraviolet rays. The novel material of the medical perfusion tube can completely replace PVC and be used for producing medical perfusion tubes of various specifications.

Owner:ZHEJIANG SANPO POLYMER

Lipstick and preparation method thereof

InactiveCN106667874AHas antibacterial propertiesNot perishableCosmetic preparationsMake-upPreservativeJojoba oil

The invention relates to the technical field of cosmetics and especially relates to a lipstick and a preparation method thereof. The preparation method comprises mixing 10 to 20 portions of olive oil, 10 to 20 portions of jojoba oil, 5 to 10 portions of rosehip oil and 3 to 5 portions of natural beeswax, heating the mixture to 35 to 45 DEG C, carrying out uniform stirring, adding 3 to 5 portions of radix astragali extract, 3 to 5 portions of honey extract, 3 to 5 portions of squalane and 1 to 3 portions of a dragon fruit red pigment into the mixture obtained by the step 1, carrying out uniform stirring to obtain a lipstick liquid, putting the lipstick liquid into a mold, and carrying out cooling to -5 to -1 DEG C to obtain the lipstick. The lipstick contains natural moisturizing agents such as olive oil, jojoba oil, rosehip oil and squalane so that the lipstick is mild and has a moisturizing effect. Beeswax has antibacterial properties, is a natural preservative and is not easy to degenerate. Radix astragali has an antioxidant effect. The dragon fruit red pigment is a natural plant pigment, does not contain heavy metals and does not cause skin allergy.

Owner:彭志成

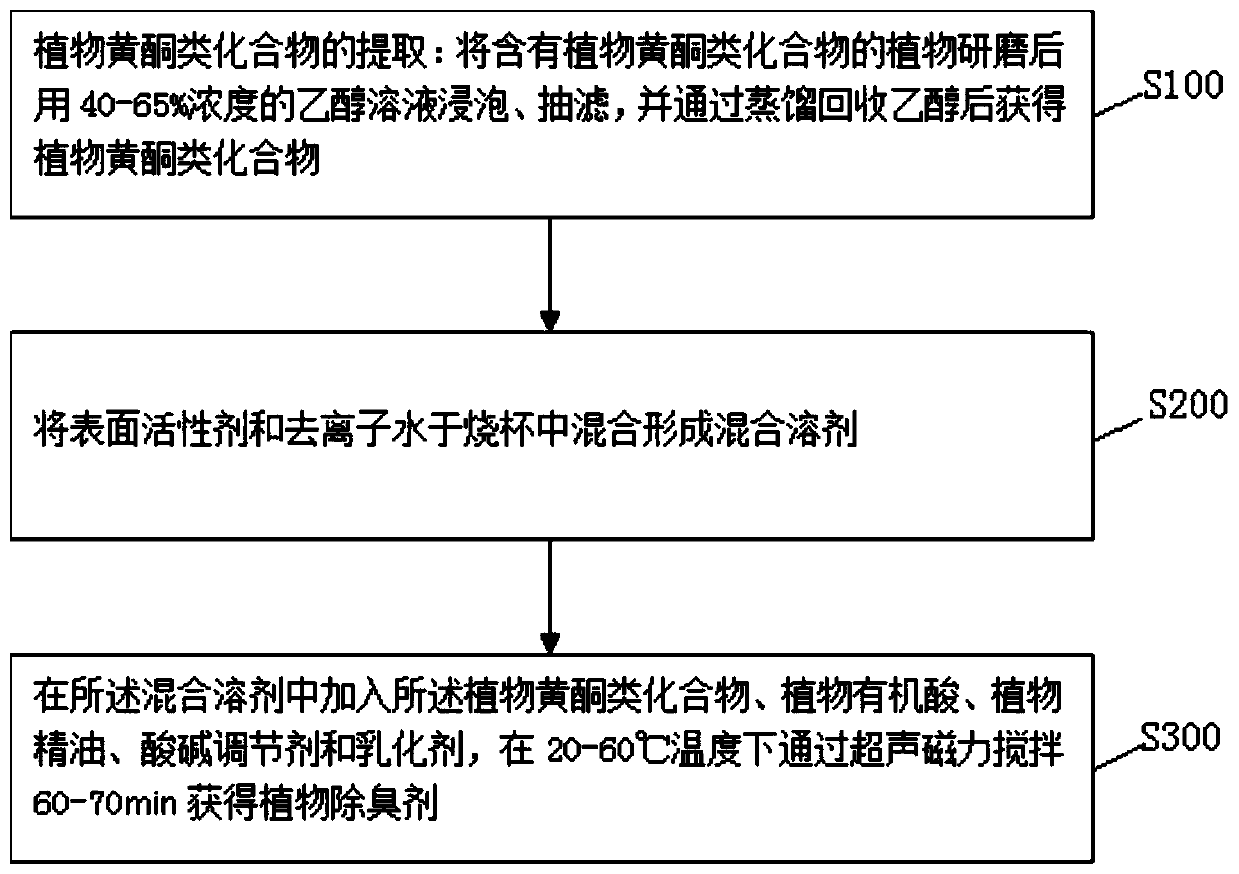

Plant deodorant for treatment of solid waste peculiar smell and preparation method

InactiveCN110420552AGood deodorizing effectEasy to deodorizeGas treatmentDispersed particle separationIonChemistry

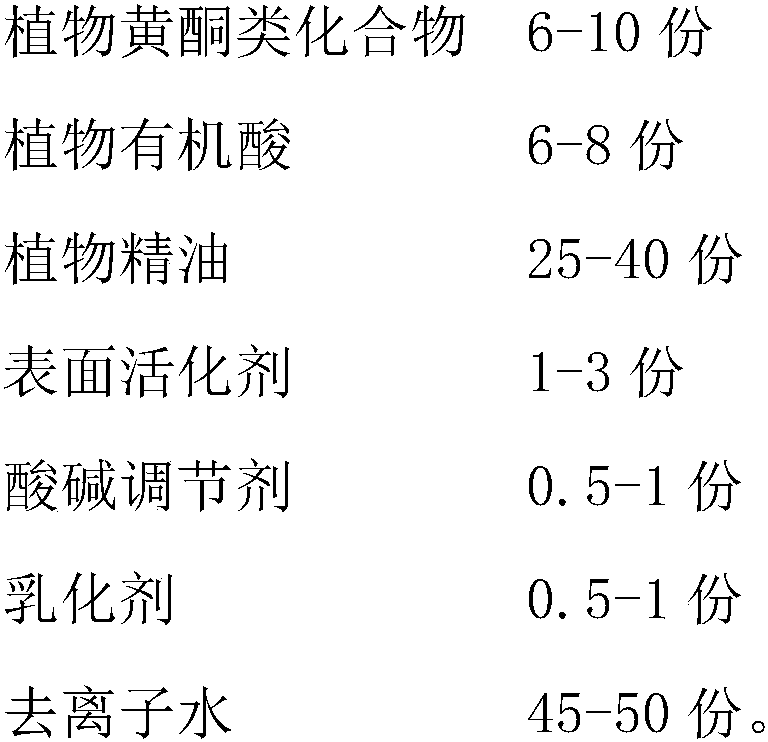

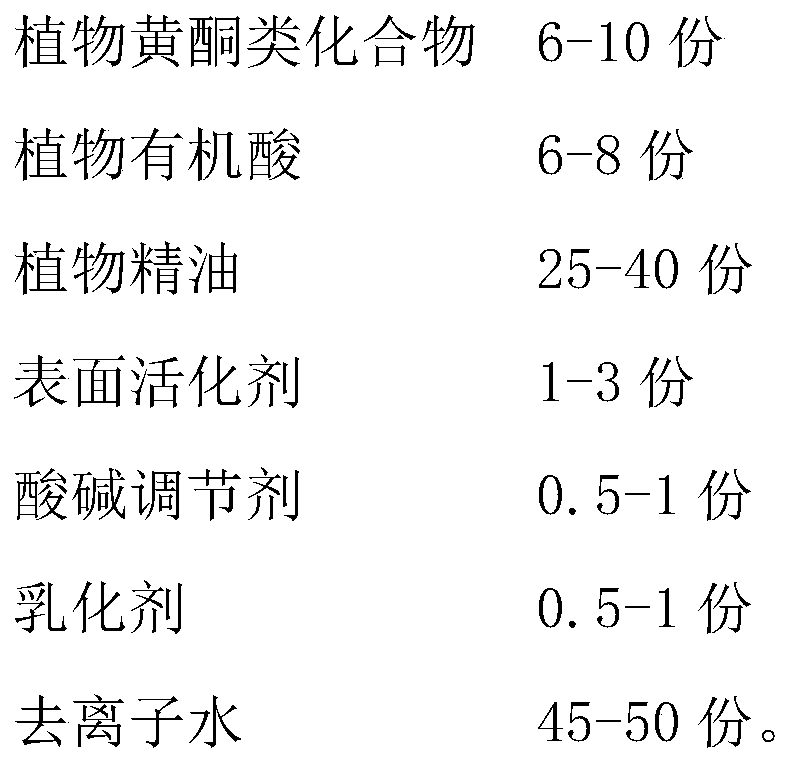

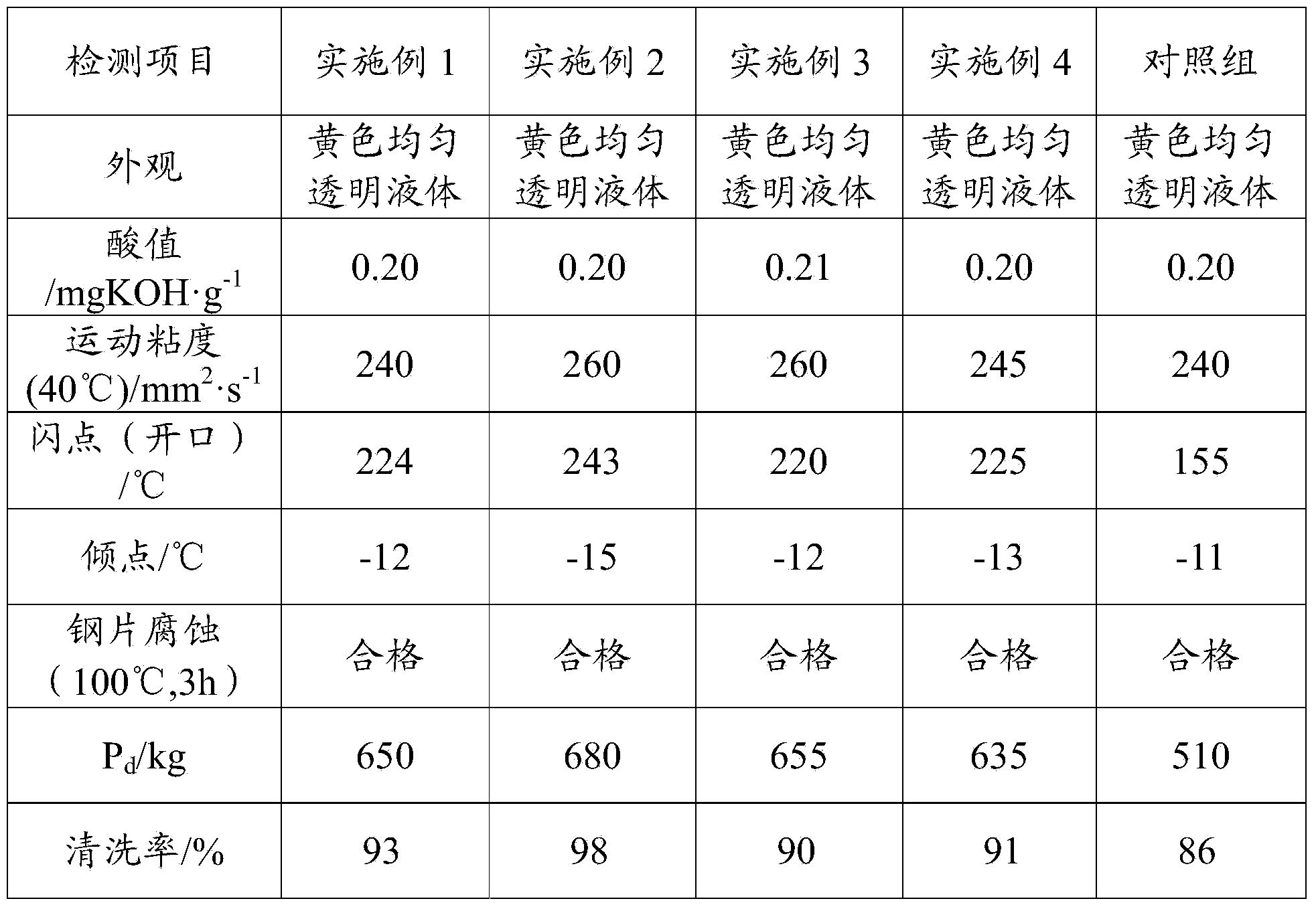

The invention discloses a plant deodorant for treatment of solid waste peculiar smell. The formula of the plant deodorant comprises the following components by weight: 6-10 parts of a plant flavonoidcompound; 6-8 parts of plant organic acid; 25-40 parts of plant essential oil; 1-3 parts of a surfactant; 0.5-1 part of an acid and alkali regulator; 0.5-1 part of an emulsifier; and 45-50 parts of deionized water. The invention also discloses a preparation method of the plant deodorant for treatment of solid waste peculiar smell. The plant deodorant disclosed by the invention has significant deodorization effect not affected by temperature, open space and other environmental conditions, does not depend on the coverage of plant aroma to odor, and the liquid reagent composed of a variety of plant extracted liquid with neutralization, oxidation-reduction capacity and adsorption capacity has neutralization, oxidation and decomposition functions.

Owner:北京泷涛环境修复有限公司

Amorphous state iron phosphorus alloy electroplate liquid and preparation method

InactiveCN101760769AImprove stabilityPrevent oxidationAluminium sulfateSodium Hypophosphite Monohydrate

The invention discloses an amorphous state iron phosphorus alloy electroplate liquid and a preparation method. Each L of electroplate liquid comprises 110-200g of ferrous sulfate, 15-50g of sodium hypophosphite, 15-30g of sodium citrate or 10.5-21g of citric acid, 30g of boric acid, 10g of sodium chloride, 20g of aluminum sulfate, 2g of ascorbic acid and water in balance amount. The preparation of 1 L of electroplate liquid is realizes by the following scheme: dissolving 15-30g of the sodium citrate or 10.5-21g of the citric acid into about 700mL of water; preparing sodium citrate water solution or citric acid water solution; sequentially adding 2g of the ascorbic acid, 30g of the boric acid, 110-200g of the ferrous sulfate, 10g of the sodium chloride and 20g of the aluminum sulfate; completely stirring and dissolving; adding 15-50g of the sodium hypophosphite; completely dissolving in a stirring way; and adding the water in balance amount till than the total volume is 1L. The plated film surface of the amorphous state iron phosphorus alloy which is electroplated with the electroplate liquid has less defects, has silvery white appearance, has no crack, is smooth and compact, and has strong bond with the base body.

Owner:HUAQIAO UNIVERSITY

Galvanized bolt lubricating and stabilizing agent

ActiveCN102080010AStable coefficient of frictionNot allergicLubricant compositionLanolinPurified water

The invention provides a galvanized bolt lubricating and stabilizing agent which is characterized by comprising the following components in percentage by mass: 15% of mineral oil, 2% of emulsifier, 0.5% of barium petroleum sulfonate, 2% of lanolin, 1% of rust inhibitor, 1% of Span-80 and 78.5% of purified water. The components are mixed and stirred at normal temperature and pressure for 8 hours to obtain the galvanized bolt lubricating and stabilizing agent. According to the invention, the galvanized bolt lubricating and stabilizing agent can satisfy the corrosion resistance, and the frictionfactor can be stabilized.

Owner:十堰达克罗涂覆工贸有限公司

High-temperature resistant forming oil for forming stainless steel part of automobile and preparation method of oil

InactiveCN103725384AImprove cooling effectImprove the lubrication effectAdditivesBase-materialsBase oilHot Temperature

The invention discloses high-temperature resistant forming oil for forming a stainless steel part of an automobile and a preparation method of the oil. The forming oil is prepared from the following main raw materials in percentage by weight: 50-60 wt% of used oil base oil, 10-25 wt% of synthetic ester, 5-10 wt% of vulcanized olefin, 5-10 wt% of vulcanized aliphatic ester, 5-15 wt% of chloridized petrolatum, 1-4 wt% of emulsifying agent and 0.1-1 wt% of arylamine antioxygen. The preparation method comprises the step: uniformly mixing the raw materials to obtain the forming oil. The forming oil disclosed by the invention resists high temperature, is environmental friendly, and has excellent cooling, lubricating and rust-preventing and discoloring-preventing effects; by using used oil which is rich in resources and low in price as a raw material, waste materials are recycled, and resource waste and environment pollution are prevented. The preparation method is simple and easy to operate, and wide in application market prospect.

Owner:GUANGZHOU LANDNOK CHEM TECH

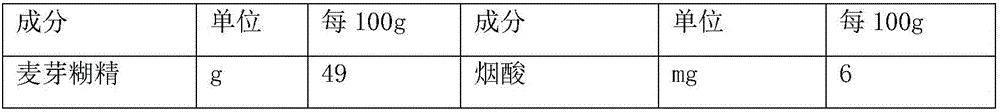

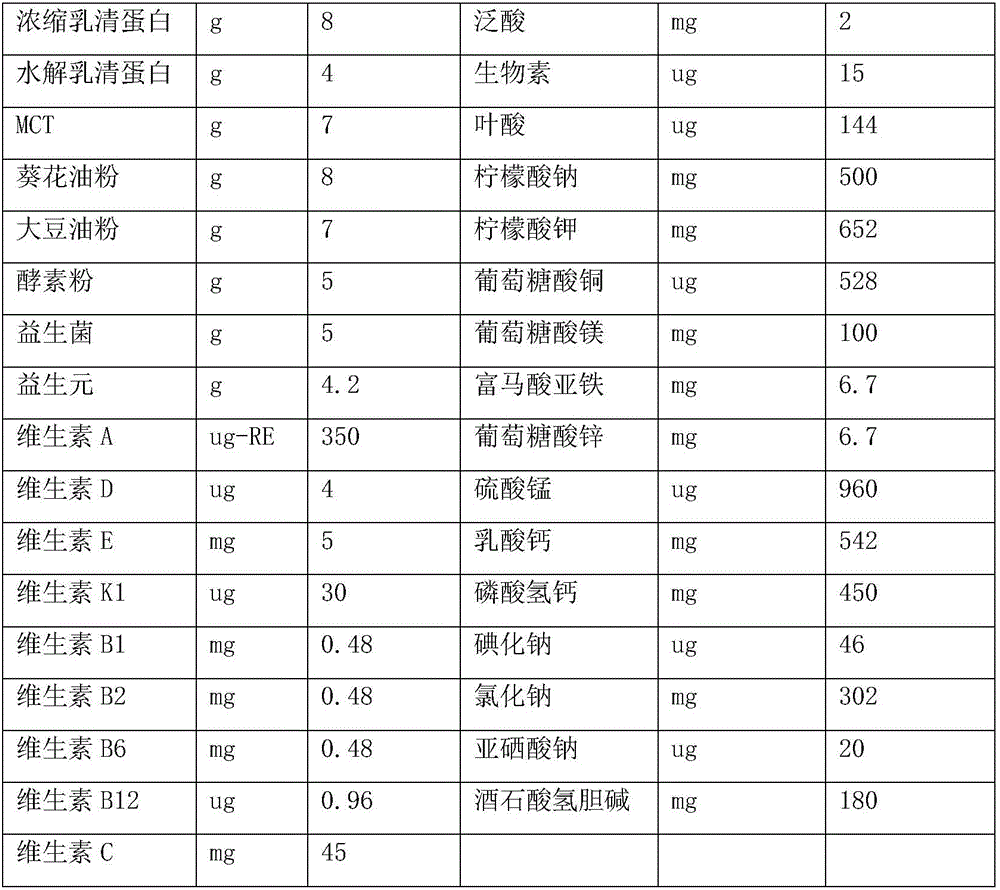

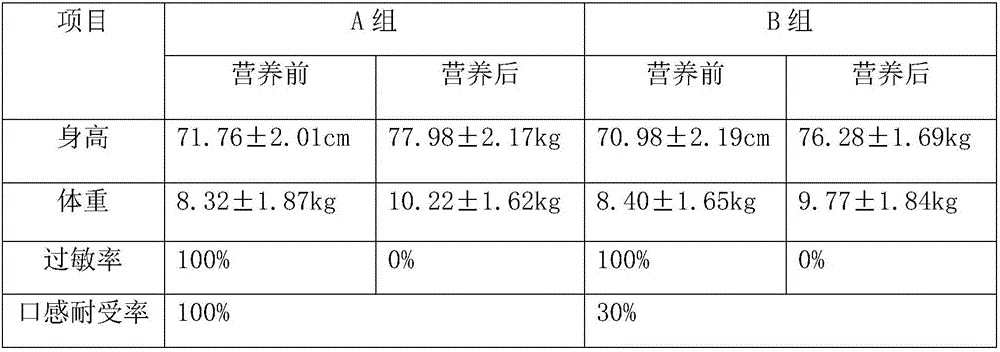

Total-nutrient formula food for preventing protein allergy

InactiveCN106072530AGreat tastePalate intolerance does not causeVitamin food ingredientsLipidic food ingredientsAdditive ingredientVitamin

The invention discloses a total-nutrient formula food for preventing protein allergy. The total-nutrient formula food mainly contains carbohydrate, proteins, fat, necessary vitamins and mineral matters and also contains ferment powder, probiotics and prebiotics. According to protein allergy patient nutrition and metabolism characteristics, the total-nutrient formula food is designed. The total-nutrient formula food has a good taste, balanced nutrition and reasonable functions and effectively improves malnutrition.

Owner:江苏阜丰生物科技有限公司

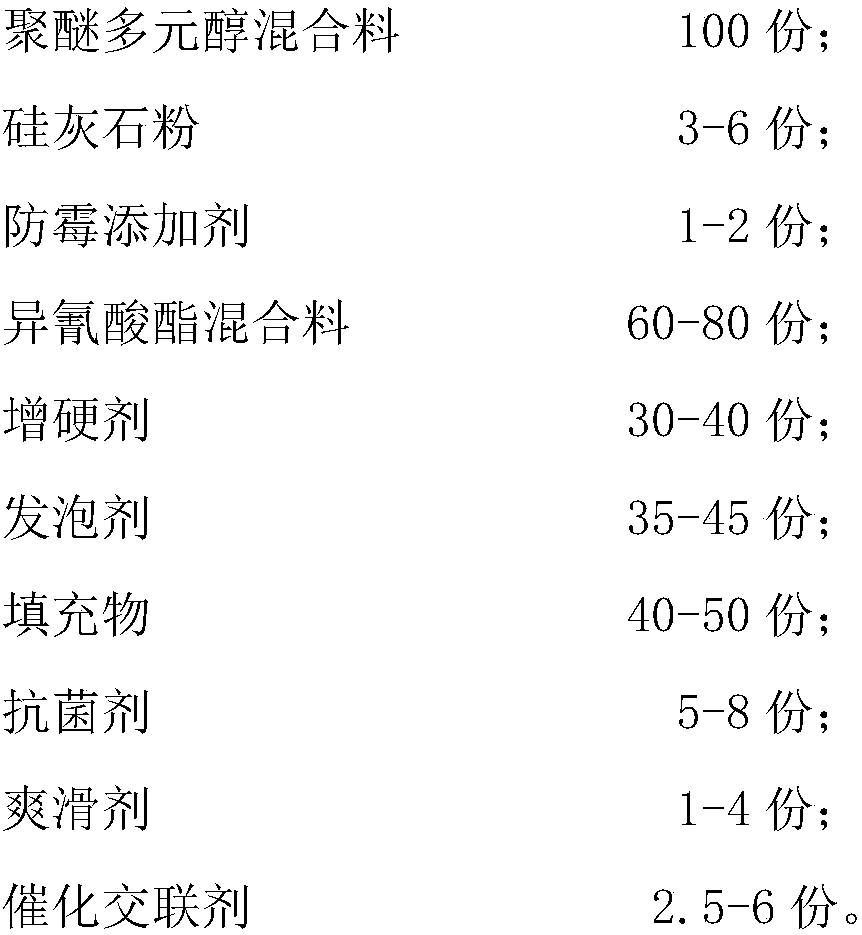

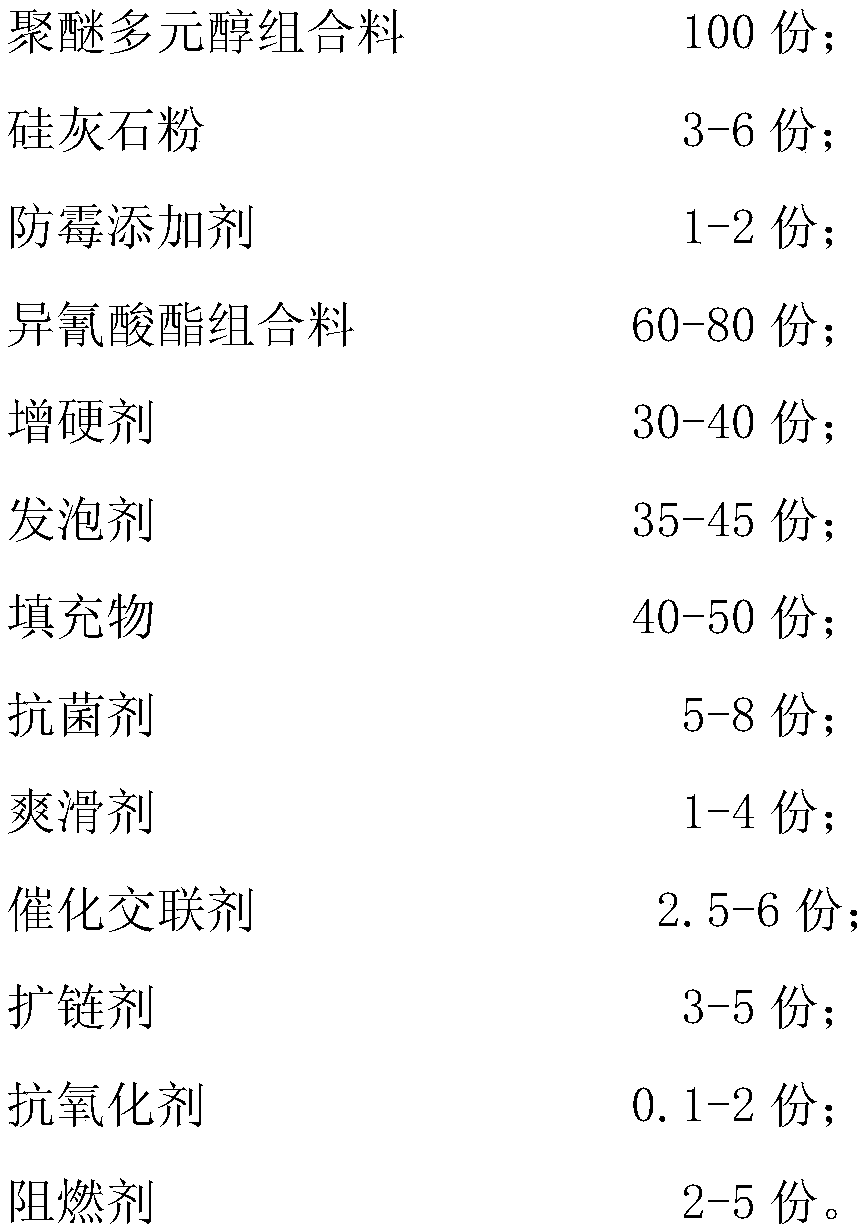

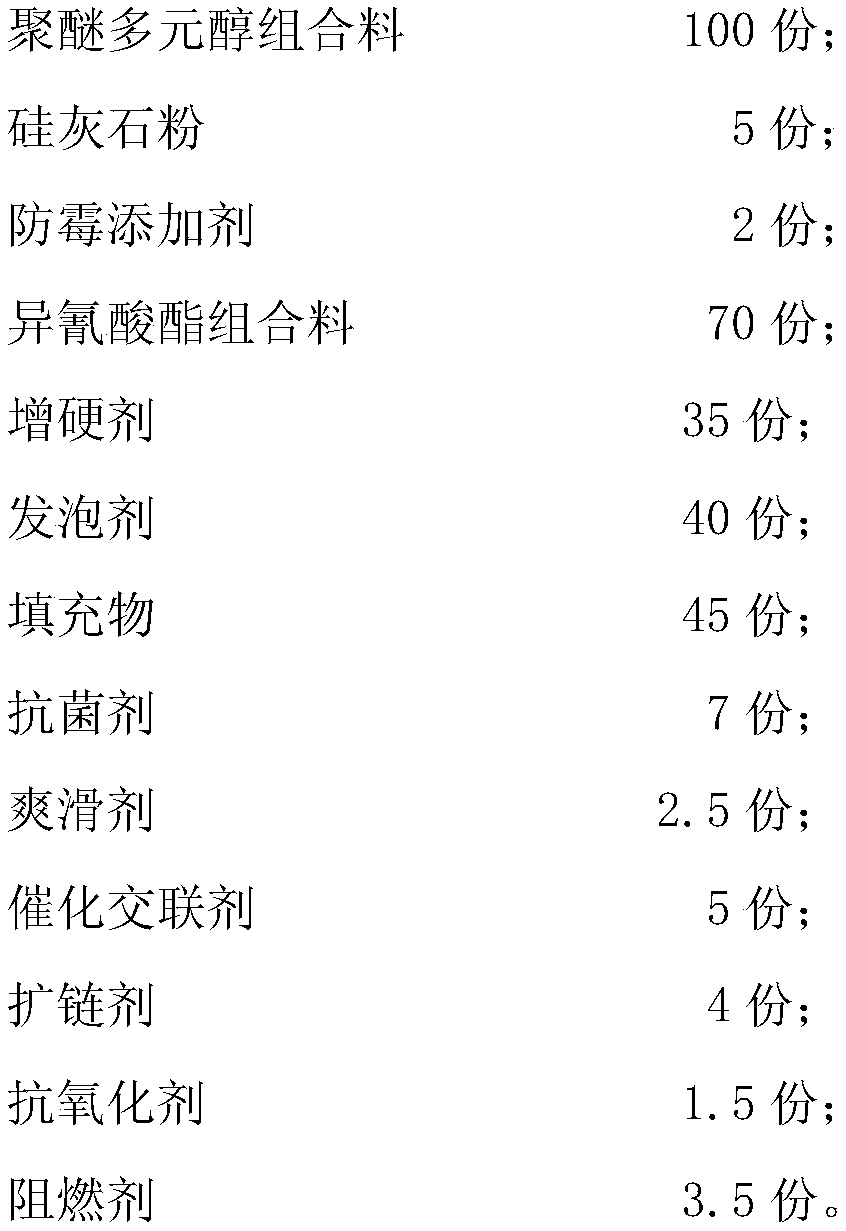

Polyurethane material, high-elasticity antibacterial polyurethane powder puff and preparation method thereof

InactiveCN108484874AIncrease elasticityImprove antibacterial propertiesPackaging toiletriesPackaging cosmeticsFoaming agentSlag

The invention provides a polyurethane material, a high-elasticity antibacterial polyurethane powder puff and a preparation method thereof. The polyurethane material is prepared from the following rawmaterials in parts by weight: 100 parts of a polyether polyol mixture, 3 to 6 parts of a wollastonite powder, 1 to 2 parts of an anti-mildew additive, 60 to 80 parts of an isocyanate mixture, 30 to 40parts of a hardening agent, 35 to 45 parts of a foaming agent, 40 to 50 parts of fillers, 5 to 8 parts of an antibacterial agent, 1 to 4 parts of a refreshing and slipping agent, and 2.5 to 6 parts of a catalytic cross-linking agent. The polyurethane powder puff provided by the invention is researched and developed specifically at the aim of providing good adaptability and compatibility for humanbody skin; compared with the conventional latex and the existing powder puff which is prepared by adopting industrial polyurethane, the polyurethane powder puff has the unique advantages of better skin affinity, no slag drop, odourlessness, bacterial resistance, high elasticity, better oil control capacity, more convenience in cleaning, exquisite hand feeling, environment friendliness and the like, and has a broad popularization and application prospect.

Owner:HUIZHOU YUANAN NEW MATERIALS

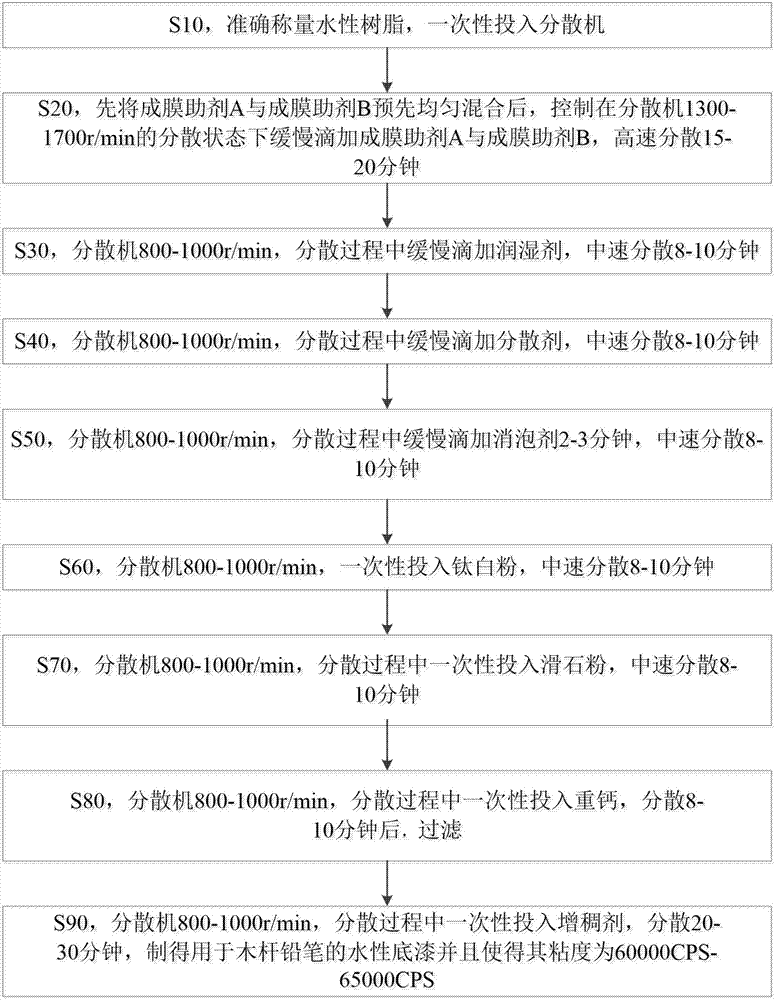

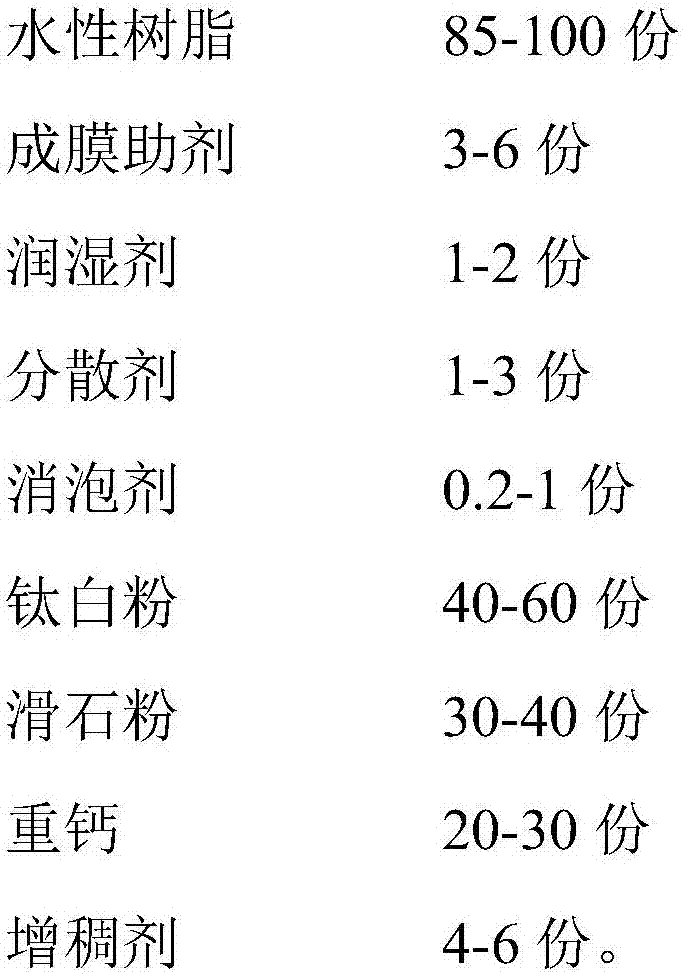

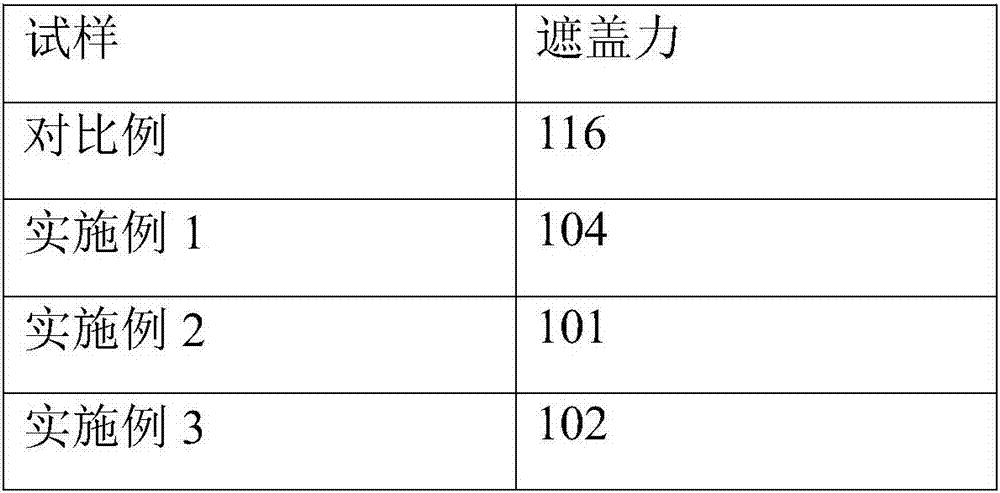

Waterborne primer for wood rod pencil and preparation method thereof

The invention belongs to the field of waterborne paint, and particularly relates to waterborne primer for a wood rod pencil and a preparation method thereof, wherein the primer is prepared from the following ingredients parts by weight: 85 to 100 parts of water-base resin, 3 to 6 parts of coalescents, 1 to 2 parts of wetting agents, 1 to 3 parts of dispersants, 0.2 to 1 part of defoaming agents, 40 to 60 parts of titanium pigment, 30 to 40 parts of talcum powder, 20 to 30 parts of heavy calcium and 4 to 6 parts of thickening agents. The waterborne primer for the wood rod pencil prepared by the preparation method has the advantages that the drying is fast; the attaching force is strong; the shielding power is high; the smoothness is realized in the production line.

Owner:浙江丽水德宇新材料有限公司

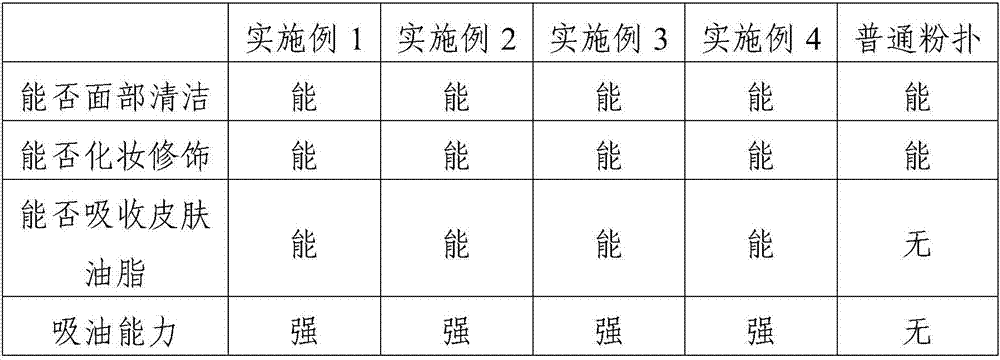

Polymer powder puff with oil-absorbing effect and preparation method thereof

InactiveCN107361506AImprove hydrophilic abilityOdorlessCosmetic preparationsMake-upFoaming agentChemistry

The invention relates to the field of macro-molecular polymers, in particular to a polymer powder puff with an oil-absorbing effect and a preparation method thereof. The polymer powder puff with the oil-absorbing effect is prepared from polyether polyol, isocyanate, reactive hardening agents, foaming agents, catalysts, plant fibers, chamomile extract, alkyl methacrylate, alkyl acetate and cross-linking agents; the preparation method mainly comprises the steps of pretreatment of the plant fibers, preparation of prepolymers, preparation of products and the like. The polymer powder puff with the oil-absorbing effect not only maintains the original and basic effects of powder puffs for facial cleaning and cosmetic modification, but also additionally has the effect of absorbing facial grease, and solves the problems that the face looks grease before makeup and powder is not easy to apply on the face during makeup. The polymer powder puff is soft and delicate in texture, skin-friendly, good in oil-absorbing effect, capable of being recycled and conducive to environmental protection, and has no damage to the skin.

Owner:张艳雪

Spinning synthetic fiber yarn

The invention discloses a spinning synthetic fiber yarn. The spinning synthetic fiber yarn comprises 25-40 wt% of cotton fibers, 25-40 wt% of bamboo fibers, 25-40 wt% of milk protein fibers and 5-7 wt% of silver-plated fibers. The spinning synthetic fiber yarn disclosed by the invention has the advantages of overcoming disadvantages of a single fiber, enabling the synthetic fiber yarn to be good in moisture absorption and air permeability, soft, warm-keeping, anti-bacterial, wear-resisting, anti-pilling, and strong in dyeing power, achieving good skin touch ability and avoiding arousing skin sensibility.

Owner:WUXI YUTONG FABRIC IND

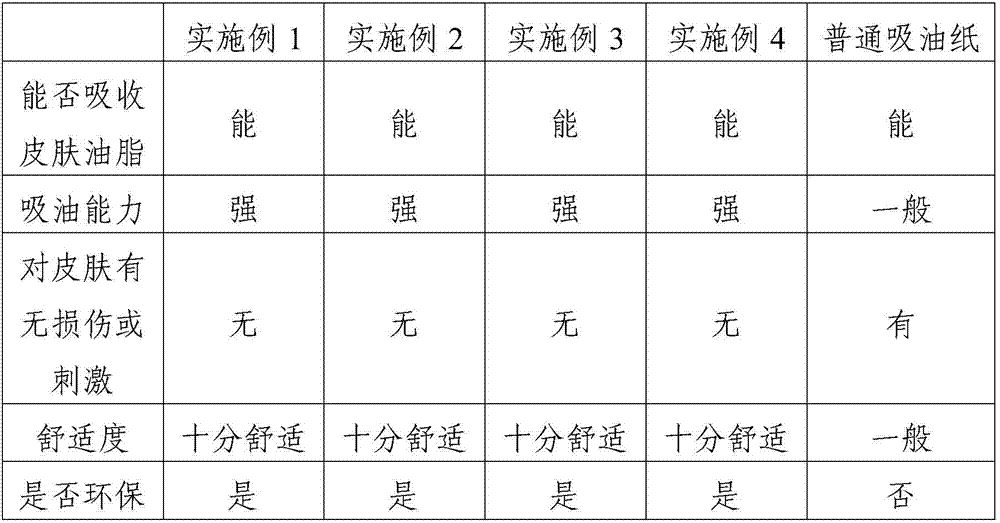

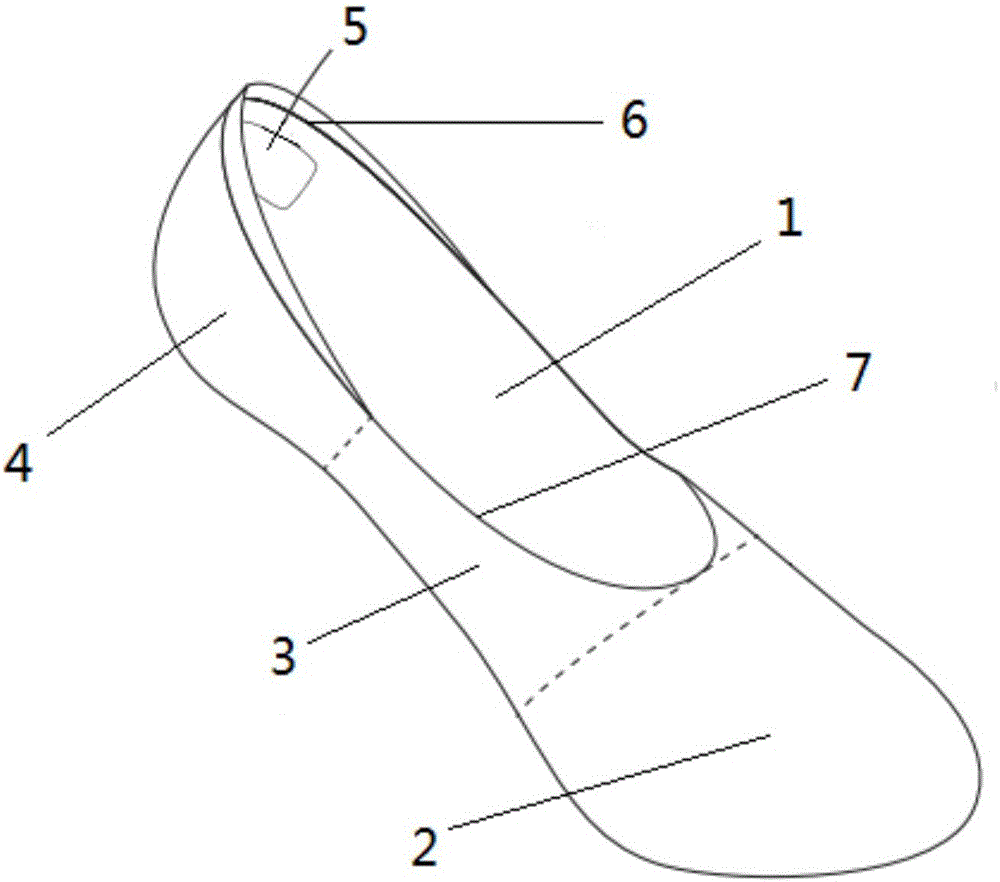

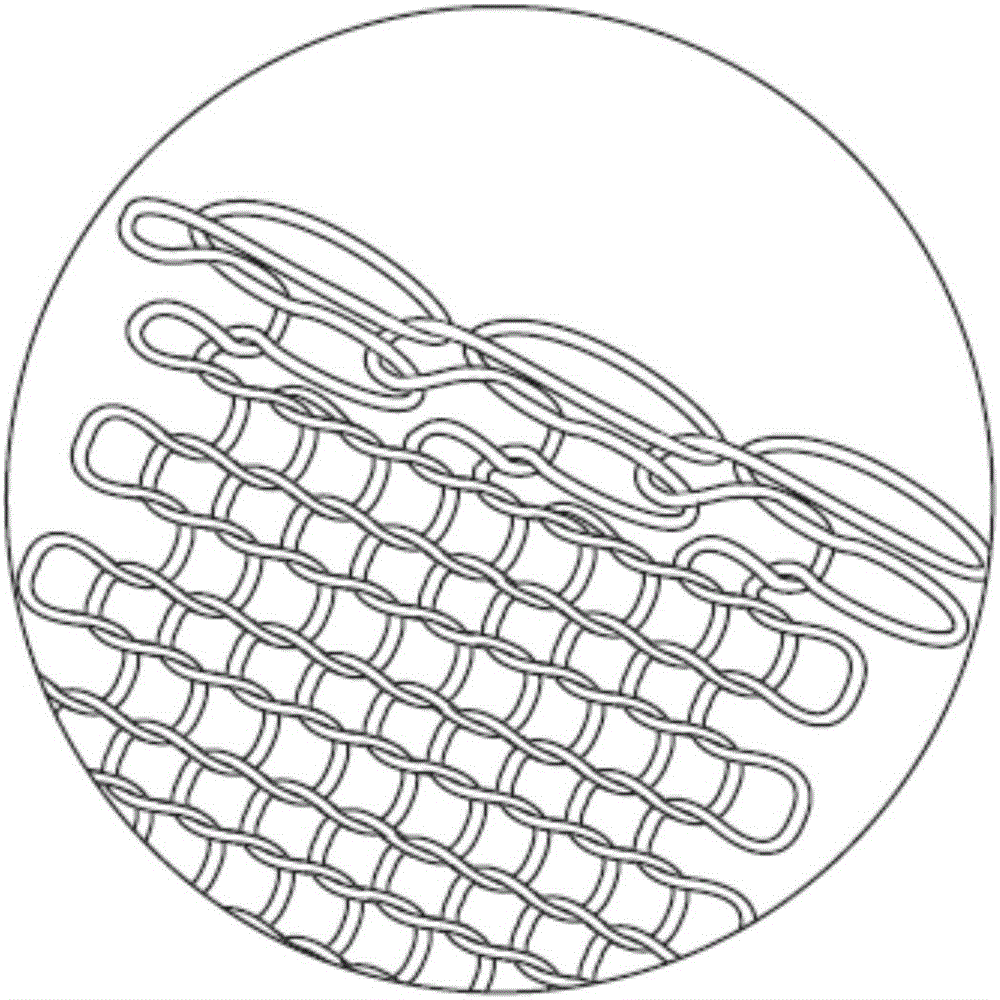

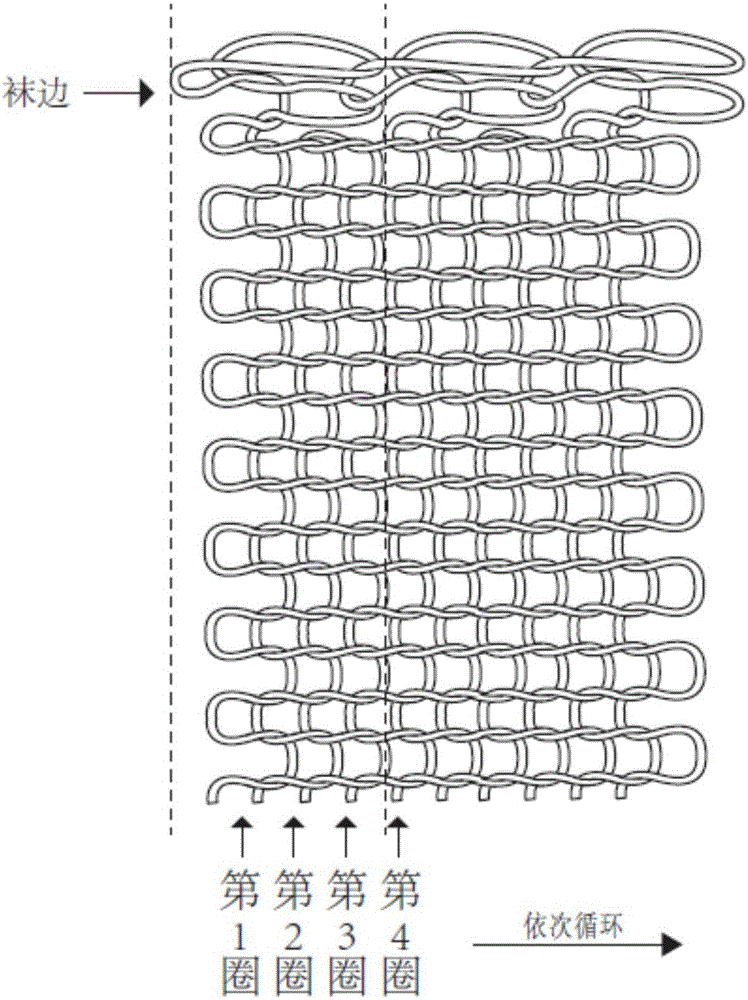

Anti-falling foot cover

The invention provides an anti-falling foot cover which is characterized by comprising a sock body and a rib top, the sock body comprises a heel, a main sock body and a toe, and a sock edge of the main sock body is a structure collocated and knitted by a picking embedding needle. The anti-falling foot cover has enough elasticity, is more compact in fitting, comfortable to wear and not easy to fall off and can effectively avoid the problem of allergy caused by a traditional anti-falling foot cover.

Owner:ZHEJIANG FLYEAGLE KNITTING

Dressing for repairing wound surface and preparing method thereof

InactiveCN106362194AAvoid re-injuryFree from painNon-adhesive dressingsPharmaceutical delivery mechanismSide effectBiocompatibility Testing

The invention relates to a dressing for repairing a wound surface and a preparing method thereof. The dressing comprises a non-woven fabric layer, a keratin layer and a pressure-sensitive adhesive layer, the keratin layer and the pressure-sensitive adhesive layer are both arranged on the non-woven fabric layer, and the pressure-sensitive adhesive layer is arranged on the periphery of the keratin layer and fixedly connected with the keratin layer. Keratin is arranged in the keratin layer and is hair keratin, and the hair keratin is any one of granular hair keratin and gelation hair keratin. The dressing and the preparing method have the advantages that the hemostatic effect is good, and repairing of the wound surface can be effectively accelerated; bacterial infection can be effectively prevented; good biocompatibility is achieved; oozing of the wound surface is controlled and absorbed; air permeability is high; regenerated tissue is protected; toxic and side effects are avoided, and irritability is avoided; utilization is convenient.

Owner:北京东方艾美生物技术股份有限公司

Skin-care soothing composition, cleansing lotion and preparation method of cleansing lotion

PendingCN112156037APromote generationBalance skin surface ecologyCosmetic preparationsMake-upCeramideAmino acid

The invention relates to a skin-care soothing composition. Ceramide, amino acid, squalane and bifida ferment lysate are taken as raw materials, other auxiliary materials are added, and methods of mixing for many times, emulsifying, homogenizing and the like are performed to prepare a Redo skin-care soft and moist cleansing lotion and a Redo skin-care clean and moist cleansing lotion. The skin-caresoothing composition has the beneficial effects that the ceramide, the amino acid, the squalane and the bifida ferment lysate are mainly adopted as a 3+1 barrier soothing formula, the components (theceramide, the amino acid and the squalane) are finely selected from sebum, keratinocytes and lipids of a barrier system to form a bionic barrier system, probiotics are matched to adjust the micro-ecological balance of the skin, and thecomposition enhances the immunity of the skin, is skin-friendly and mild, relieves sensitive red itching and is suitable for any product; and the prepared skin-caresoft and moist cleansing lotion can reduce damage to the skin in a cleansing process, is suitable for sensitive skin, protects the skin, promotes generation of a skin protection barrier, enables theskin to be smooth, soft and tender again, and has the effect of maintaining the stability of the skin.

Owner:上海花飞谷品牌管理有限公司

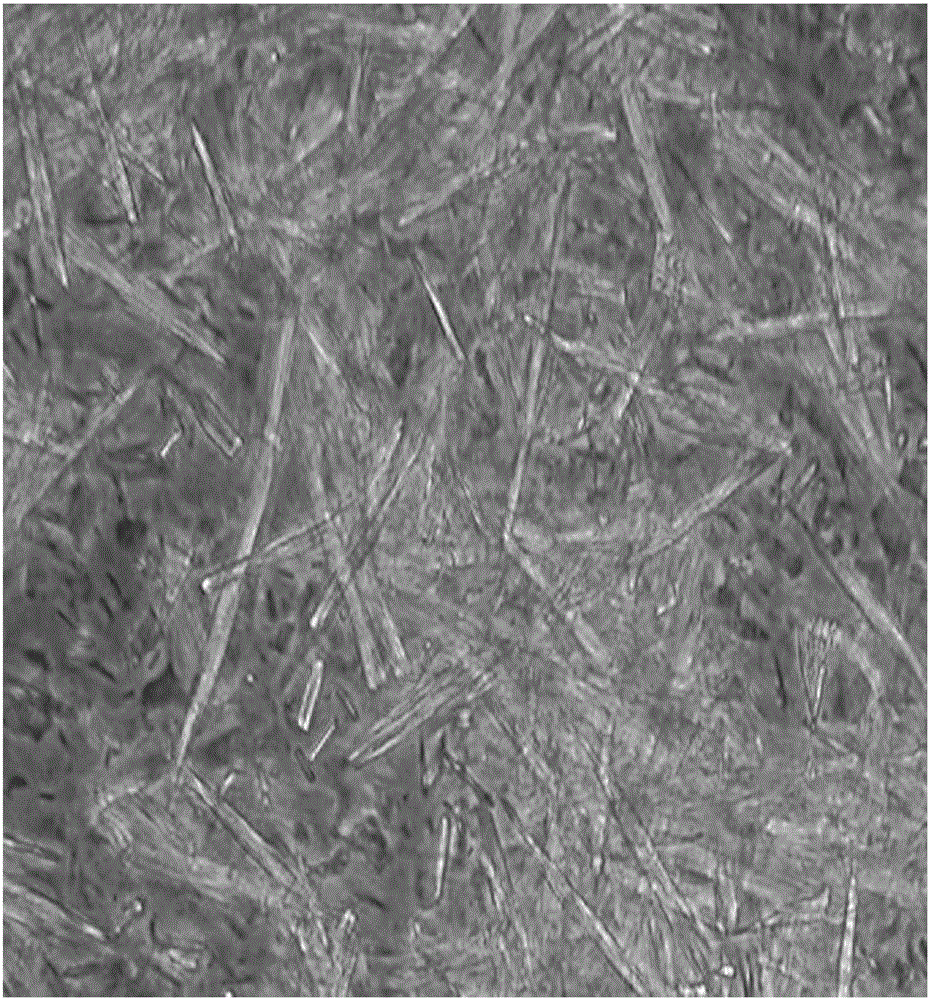

Preparation method for hair keratin-cell tissue composite engineered dressing

The invention relates to a preparation method for a hair keratin-cell tissue composite engineered dressing. The preparation method comprises the following steps: preparation of hair keratin; preparation of a cell suspension; and preparation of the dressing. The engineered dressing provided by the invention is a wound covering material with excellent effect, is capable of efficiently preventing bacterial infection, accelerating wound healing and has the advantages of good biocompatibility, capacity of controlling and absorbing exudates from wounds and allowing permeation of gas and water vapor, good air permeability, protection effect on newborn tissue, no toxic and side effect, etc. More importantly, the engineered dressing can be dissolved and absorbed by the body, so considerable bleeding and pains of patients during removing of the engineered dressing are avoided, no scrap is left to delay wound healing, and an environment beneficial for wound healing is provided for promotion of skin regeneration.

Owner:北京东方艾美生物技术股份有限公司

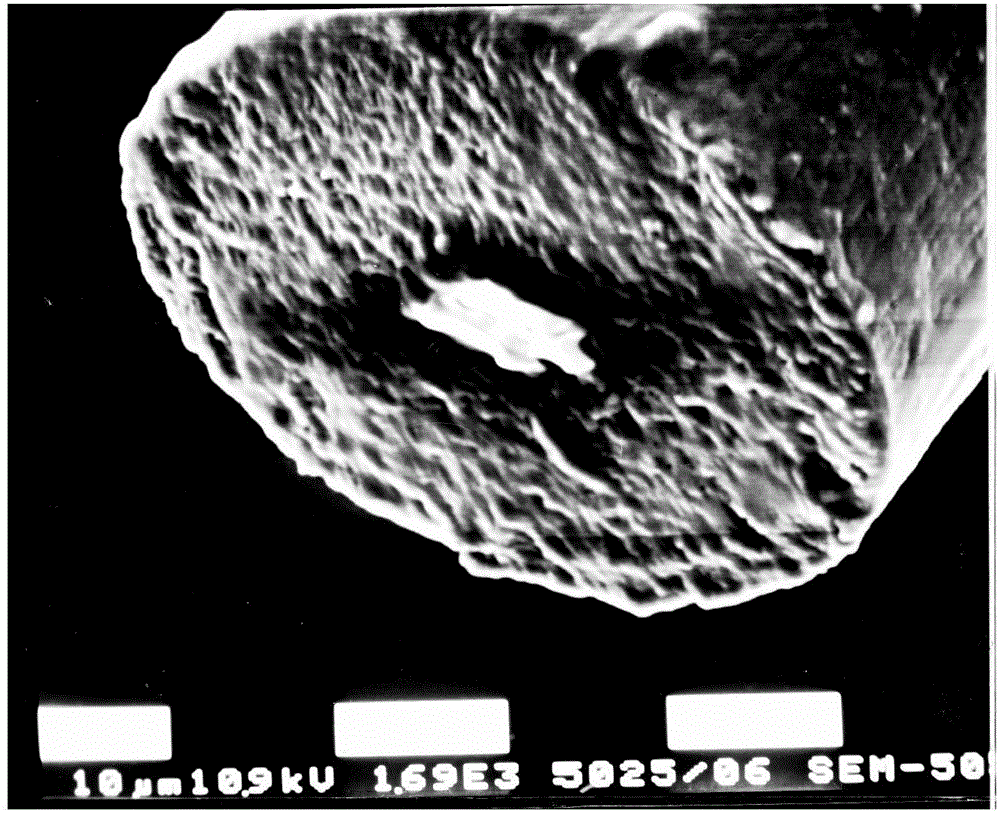

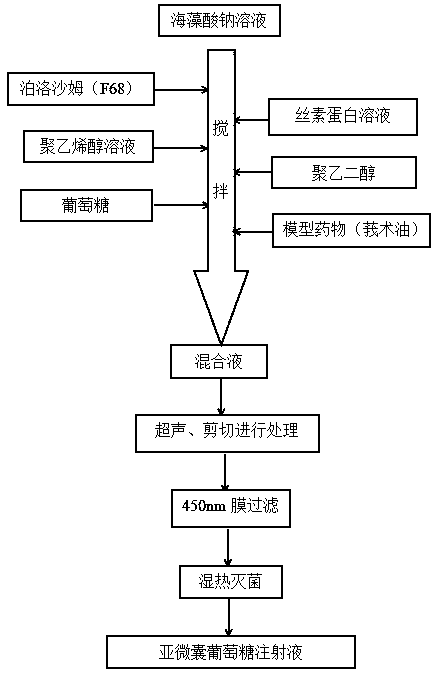

Fat-soluble drug submicron capsule glucose injection and preparation method thereof

ActiveCN107693488AEvenly wrappedUniform particle sizeEmulsion deliveryMacromolecular non-active ingredientsPolyvinyl alcoholPolyethylene glycol

The invention discloses a fat-soluble drug submicron capsule glucose injection and a preparation method thereof. The invention is characterized in that the capsule material comprises the following components in parts by weight: 15-45 parts of sodium alginate, 2.5-9 parts of poloxamer 188, 1.5-5 parts of silk fibroin, 0.5-3 parts of polyvinyl alcohol and 0.2-3 parts of polyethylene glycol. The preparation method comprises the following steps of: sequentially adding the poloxamer, a silk fibroin aqueous solution, a polyvinyl alcohol aqueous solution, the polyethylene glycol and glucose into a sodium alginate aqueous solution at intervals under stirring, and finally dropwise adding a corresponding fat-soluble drug; adopting an ultrasonic and shearing treatment mode; and finally, carrying outfiltration with a 450nm membrane and damp-heat sterilization to obtain the submicron capsule glucose injection. The preparation process of the submicron capsule glucose injection provided by the invention is simple and economic, the particle size of submicron capsules is controllable and uniform, and the biological safety is high.

Owner:CHONGQING UNIV OF TECH

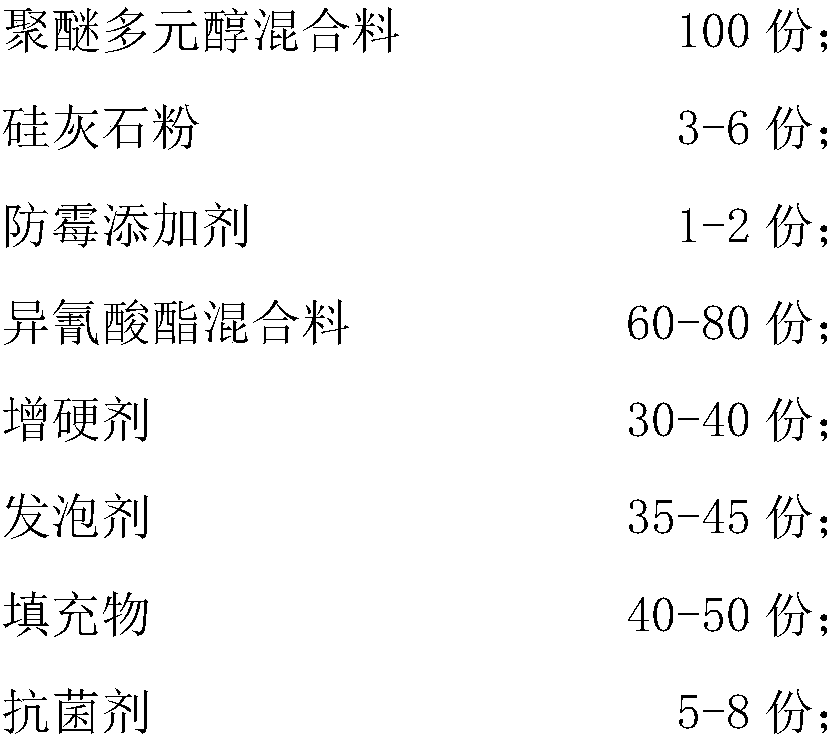

Polyurethane material and preparation method thereof

InactiveCN110358285AGood skin affinityPreparation applicablePackaging toiletriesPackaging cosmeticsPolyolFoaming agent

The invention provides a polyurethane material and a preparation method thereof. The polyurethane material is prepared from the following raw materials in parts by weight: 100 parts of polyether polyol mixed material, 3-6 parts of wollastonite powder, 1-2 parts of mould proof additive, 60-80 parts of isocyanate mixed material, 30-40 parts of a hardening agent, 35-45 parts of a foaming agent, 40-50parts of a filler, 5-8 parts of an antibacterial agent, 1-4 parts of a slipping agent, 2.5-6 parts of a catalytic crosslinking agent, 3-5 parts of a chain extender, 0.1-2 parts of an antioxidant, and2-5 parts of a flame retardant. The polyurethane material is preferentially developed for a powder puff, thus the powder puff prepared based on the material can provide good adaptability and compatibility for the skin of the human body, compared with a powder puff prepared from traditional latex and existing industrial polyurethane, the powder puff prepared based on the material has the unique advantages of being better in skin friendliness, free of chip falling, odourless, antibacterial, high in elasticity, better in oil control property, more convenient to clean, exquisite in hand feeling,environmentally friendly and the like, meanwhile, the invention provides a brand-new polyurethane preparation technology, and the prepared polyurethane material has the wide application prospects.

Owner:焦荣

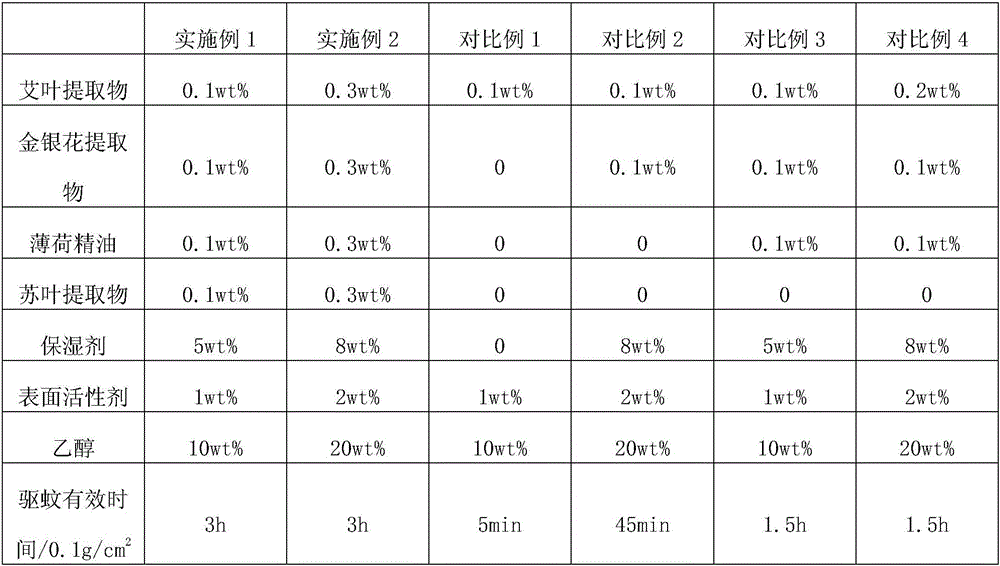

Irritation-free type long-acting mosquito repellent liquid

InactiveCN105943454ANot allergicO other symptomsCosmetic preparationsToilet preparationsLong actingIrritation

The invention relates to irritation-free type long-acting mosquito repellent liquid. De-ionized water is used as a main component and is at least added with the combination of argy wormwood leaf extract, honeysuckle extract, mint essential oil and perilla leaf extract. According to the scheme, a manner of combining argy wormwood leaves, honeysuckles, mints and perilla leaves is adopted and the long-acting mosquito repelling effect is achieved; and meanwhile, the formula is mild to human skins and has no irritation and does not cause allergic or other discomfort symptoms to users.

Owner:JIANGSU QILIKANG SKIN PHARMA

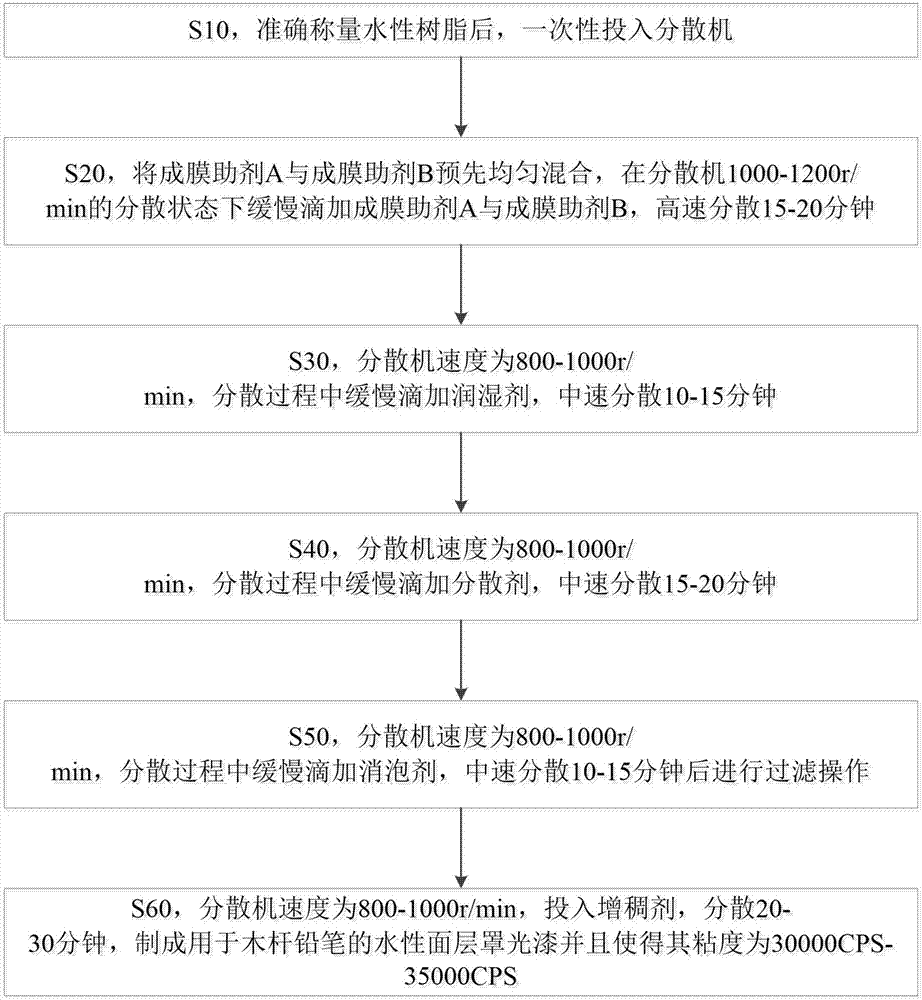

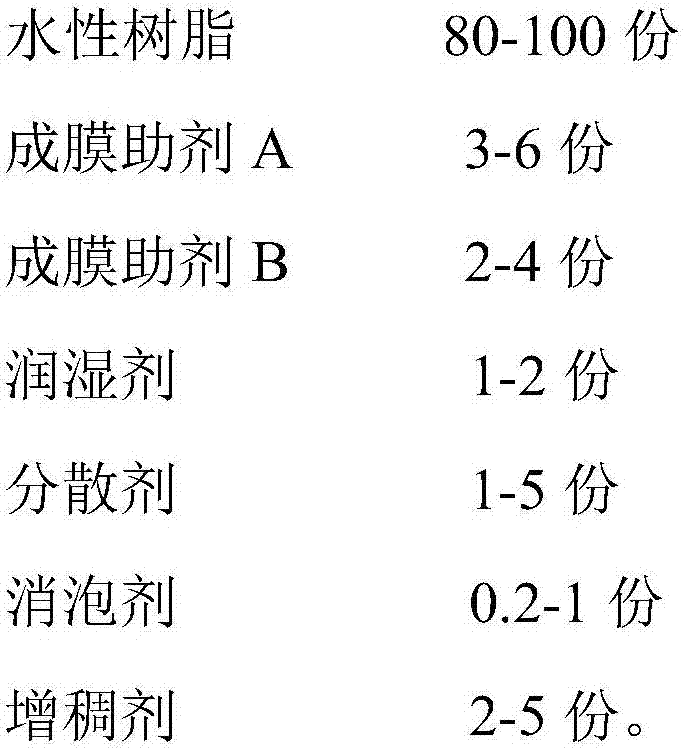

Water-based finish varnish for wood holder pencil and preparation method ofwater-based finish varnish

The invention belongs to the field of water-based paint, and particularly relates to water-based finish varnish for a wood holder pencil and a preparation method thereof. The water-based finish varnish comprises the following components in parts by weight: 80 to 100 parts of water-base resin; 3 to 6 parts of a coalescing agent A; 2 to 4 parts of a coalescing agent B; 1 to 2 parts of a wetting agent; 1 to 5 parts of a dispersing agent; 0.2 to 1 part of a defoaming agent; 2 to 5 parts of a thickening agent. The water-based finish varnishis dried quickly, good in adhesive force, high in smoothness and good in hand feeling.

Owner:浙江丽水德宇新材料有限公司

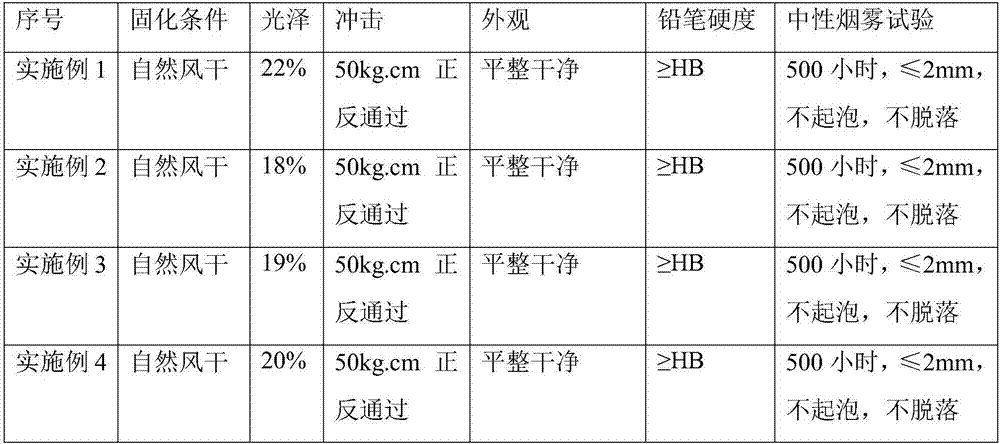

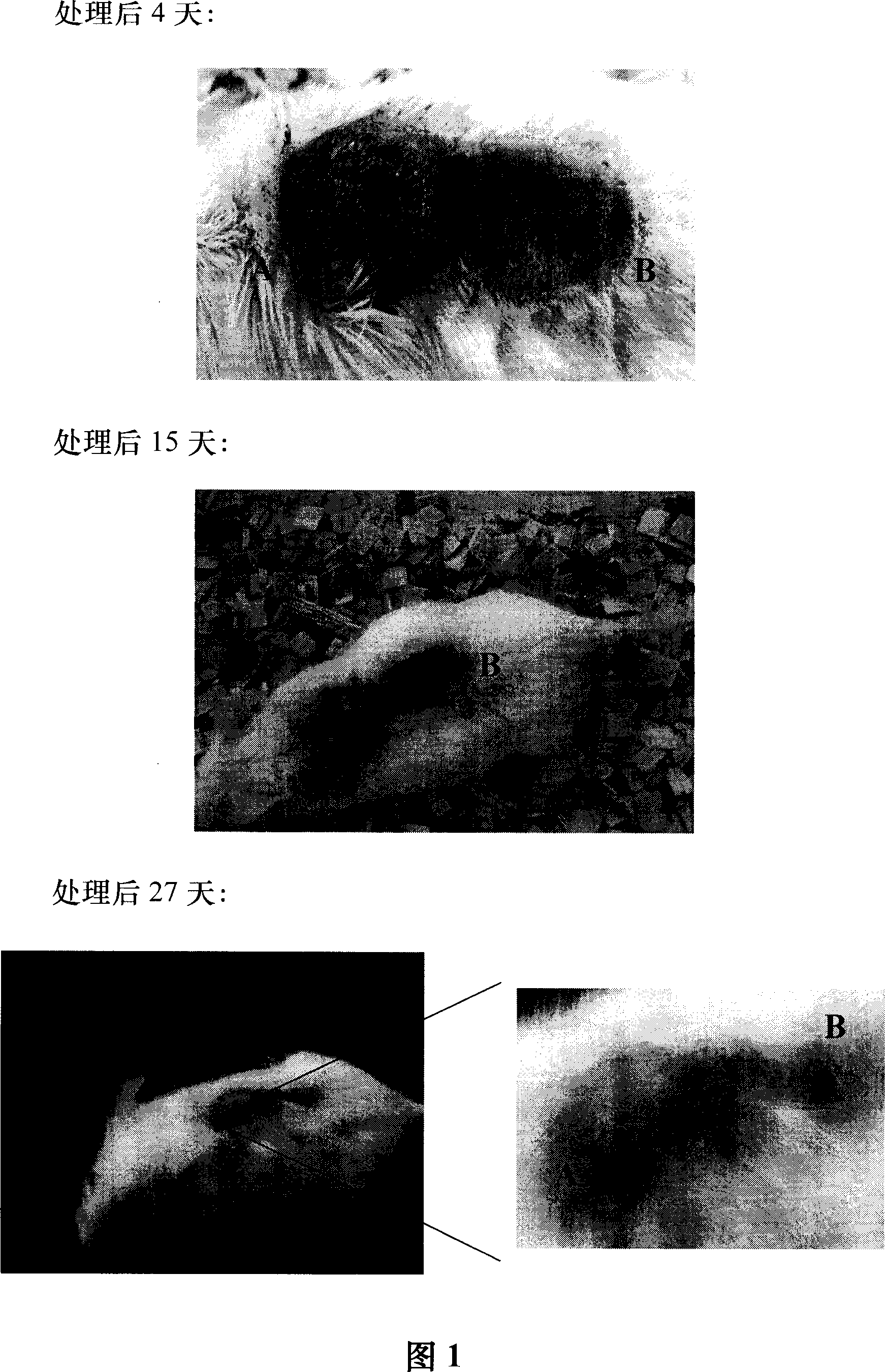

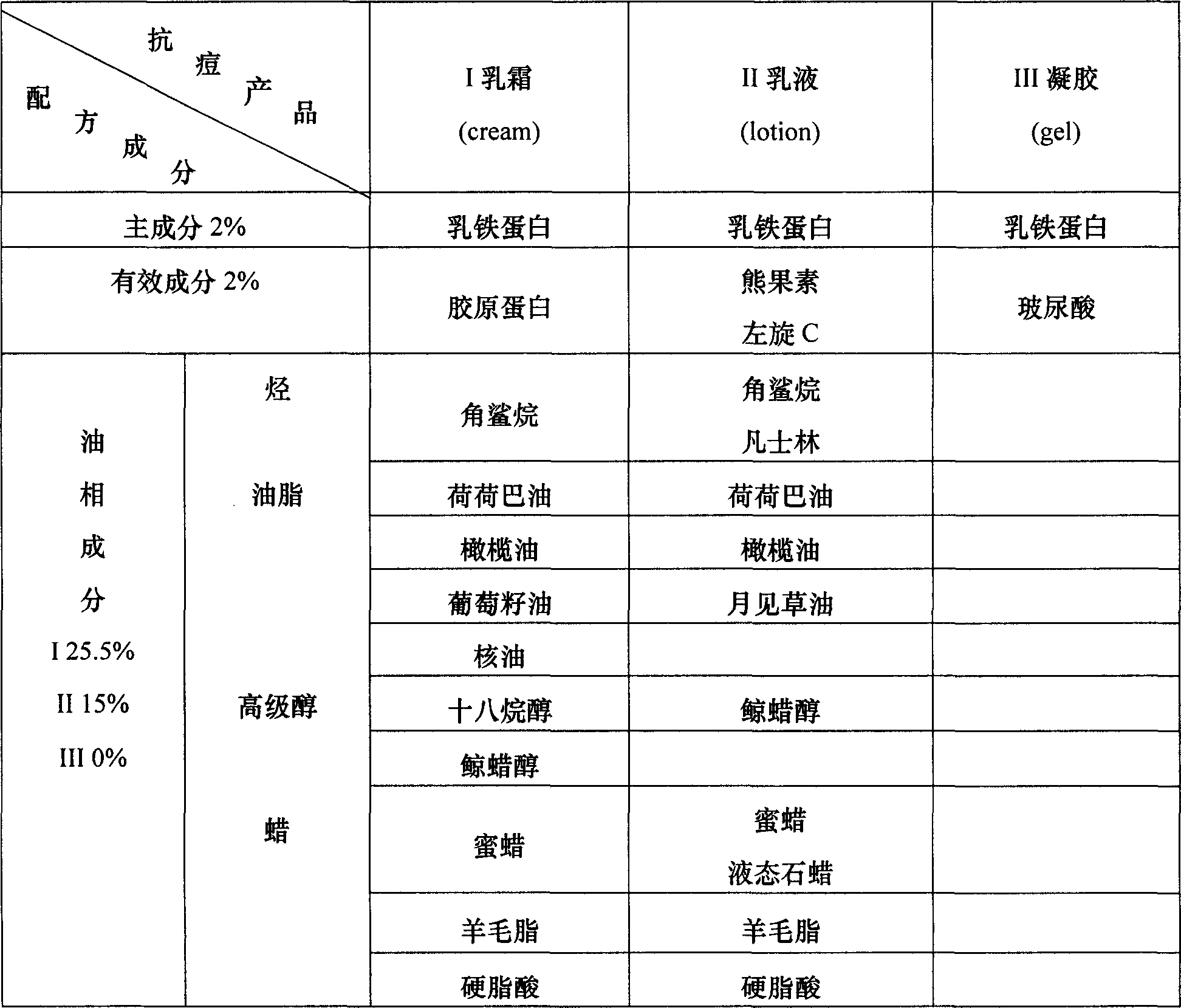

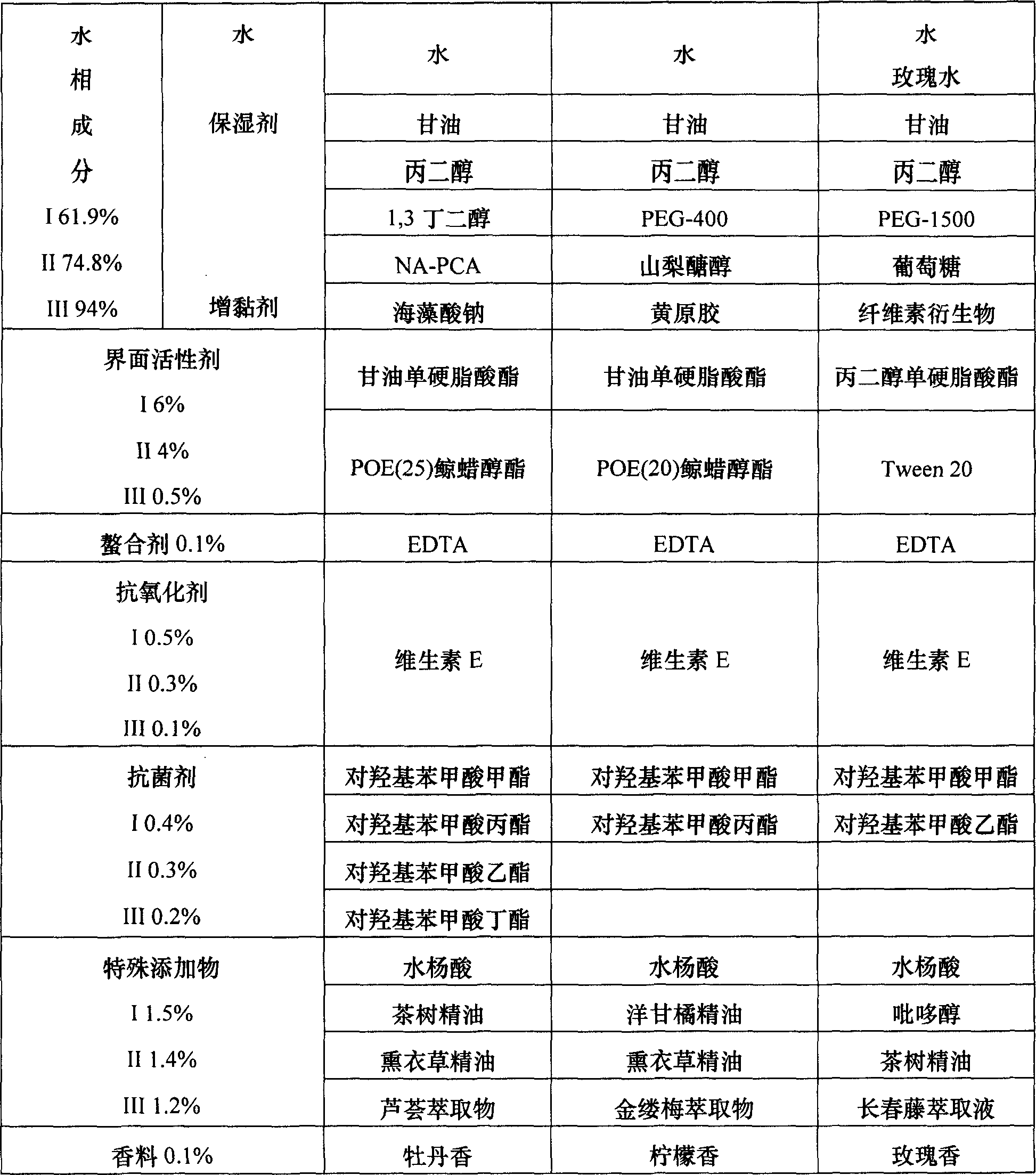

Anti-pox cosmetic composition

InactiveCN1977796AExcellent anti-acne effectNot allergicCosmetic preparationsToilet preparationsActive componentAcne

The present invention relates to a new application of lactoferritin for curing acne. Said invention also provides an anti-zits cosmetic composition containing lactoferritin as active component.

Owner:ANIMAL TECH INST TAIWAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com