Polyurethane material, high-elasticity antibacterial polyurethane powder puff and preparation method thereof

A polyurethane material and polyurethane-based technology, applied in the field of cosmetics, can solve problems such as limited, easy aging and high toxicity of natural latex powder puffs, and achieve the effects of broad application prospects, avoiding bacterial growth, and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] The hardening agent is prepared by mixing and reacting the following raw materials in parts by weight: 10 parts of silica sol, 8-12 parts of ethanol, 2-4 parts of silane coupling agent and 5-8 parts of 1,6-hexanediol diacrylate During the reaction, an appropriate amount of dilute hydrochloric acid or dilute sulfuric acid can be added to provide an acidic hybrid reaction environment. The specific preparation method of the hardening agent includes: firstly adding the silica sol and ethanol in the parts by weight into the three-necked flask, and then adding the silane coupling agent dropwise, dilute hydrochloric acid or dilute sulfuric acid can be used in the reaction process Adjust the pH value, the preferred pH value is adjusted to 3-4, under the condition of stirring, after reacting for 3-6 hours, add the 1,6-hexanediol diacrylate in the weight part, and then add the mixed solution In a single-necked flask, at a temperature of 80-100°C, rotary evaporate until a white so...

Embodiment 1

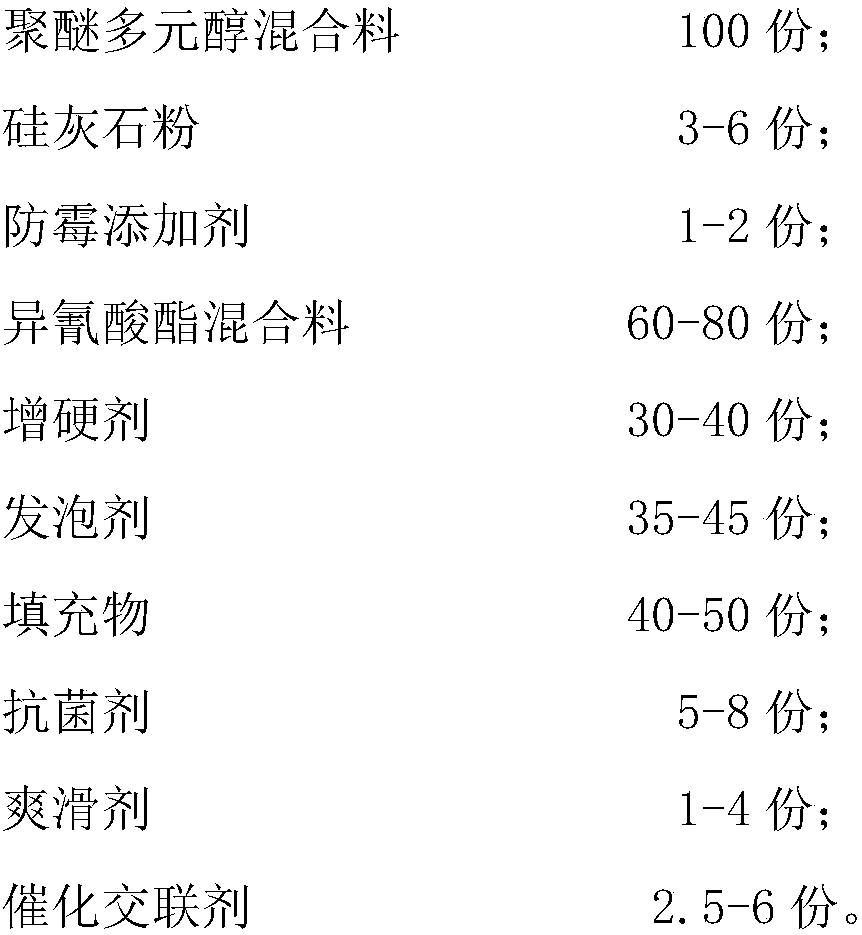

[0076]A kind of polyurethane with high elasticity and antibacterial properties for powder puffs, which is made by mixing and reacting the following raw materials in parts by weight:

[0077]

[0078] The polyether polyol mixture described therein is prepared by mixing and reacting the following raw materials in parts by weight: 10 parts of polytetrahydrofuran ether diol, 5 parts of polyoxypropylene diol, 2 parts of polyoxypropylene triol and tetrahydrofuran-epoxy 1.5 parts of propane copolyether and 4 parts of propylene oxide. The polyether polyol is a polyether polyol with an average molecular weight of 1000-1500 prepared by polyaddition reaction of the raw materials in the above parts by weight.

[0079] The anti-mold additive is prepared by mixing the anti-mold agent and palm wax at a mass ratio of 1:1, and the anti-mold agent is prepared by mixing the following raw materials in parts by weight: dodecyl-α-D glucoside 8 6 parts of isothiazolinone, 2 parts of jasmine essen...

Embodiment 2

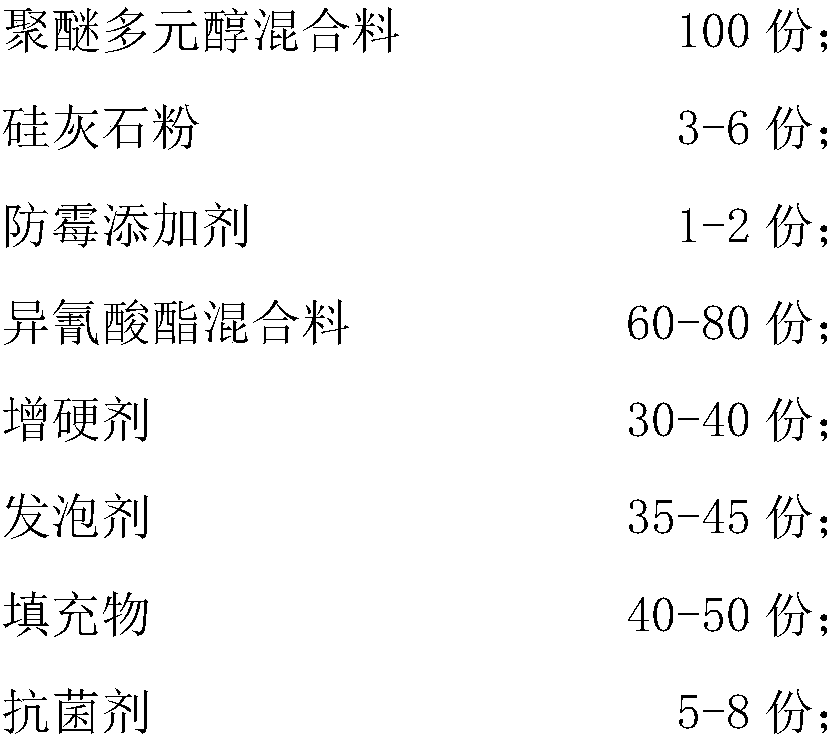

[0091] A high-elastic antibacterial polyurethane powder puff is made by mixing the following raw materials in parts by weight:

[0092]

[0093] The polyether polyol mixture described therein is prepared by mixing and reacting the following raw materials in parts by weight: 10 parts of polytetrahydrofuran ether diol, 8 parts of polyoxypropylene diol, 5 parts of polyoxypropylene triol and tetrahydrofuran-epoxy 4 parts of propane copolyether and 6 parts of propylene oxide, and the polyether polyol is a polyether polyol with an average molecular weight of 2000-3000 prepared by polyaddition reaction of the raw materials in the above parts by weight.

[0094] The anti-mold additive is prepared by mixing the anti-mold agent and palm wax at a mass ratio of 1:1, and the anti-mold agent is prepared by mixing the following raw materials in parts by weight: dodecyl-α-D glucoside 10 8 parts of isothiazolinone, 4 parts of jasmine essential oil, 1 part of simethicone, 6 parts of ketocona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com