Patents

Literature

57results about How to "Easy to graft" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

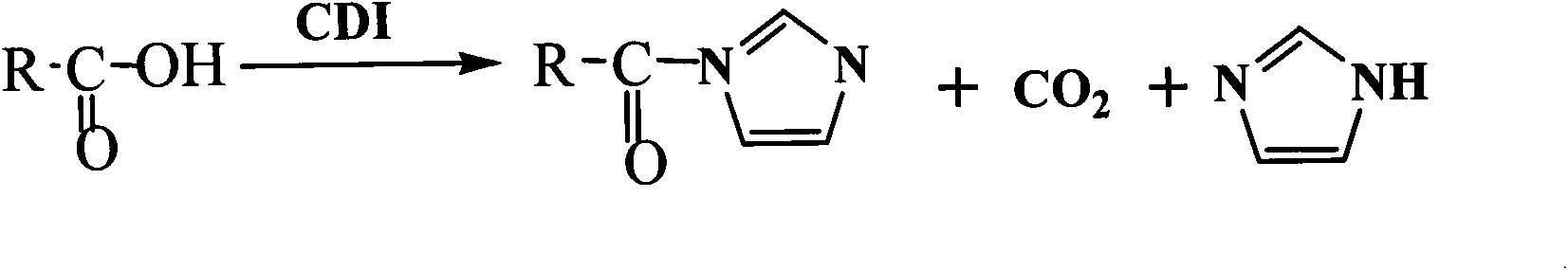

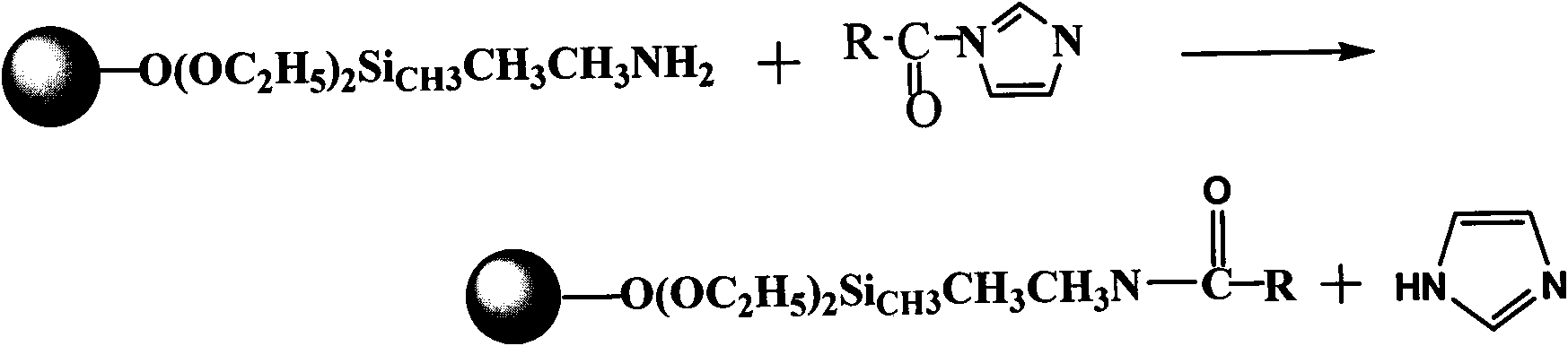

Method for modifying nano metal oxide by coupling graft

InactiveCN101880482AHigh grafting rateImprove grafting efficiencyPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsCarbonyldiimidazoleEnergy conservation

The invention discloses a method for modifying a nano metal oxide by coupling graft, and belongs to the technical field of nano granule surface modification. The nano metal oxide is used as a raw material, N,N'-carbonyl diimidazole (CDI) is used as an activating agent, and a finished product is obtained by simple processes of drying treatment, coupling reaction, separation and purification, coupling graft, re-separation and re-purification. The method has the advantages of simplicity, mild reaction conditions, high grafting efficiency which reaches 87 percent, energy conservation, emission reduction, low cost and suitability for large-scale industrial production. The nano metal oxide prepared by using the method can be widely applied in the fields of rubber, coating, ink, dye, glass, piezoelectric ceramics, photoelectrons, medicament and the like.

Owner:CHONGQING UNIV

Cultivating method for promoting cassava production

The invention relates to a cultivation method for the improvement of cassava production, in which the grafting techniques of whip grafting and budding are used. The wild cassava twig or bud is taken as a scion and the stalk of cassava cultivar is taken as a parental stock for the implementation of the grafting between the same family, the same genre or different varieties. With the new cassava plant formed after the grafting, the cassava production can be substantially improved, which is increased by 2000 to 4000kg than the varieties without grafting, and the increasing rate is up to 100 to 200%. Or the twig or bud of high-volume low starch content cassava varieties is taken as the scion, and the twig or bud of low-volume high starch content cassava varieties is taken as a parental stock for the implementation of the grafting between the same family, the same genre or different varieties. Thus a new cassava plant is formed, in which the cassava product not only can be in the maintenance of the starch content quality of the cassava varieties as the parental stock , but also the production volume can be substantially improved to the volume of the cassava varieties as the scion. The cultivation method of the invention can be promoted and applied in the cassava planting, which is also suitable for the grafting of flexible hollow plants such as castor-oil plant, jatropha curcas, papaya and so on.

Owner:广西亚热带作物研究所

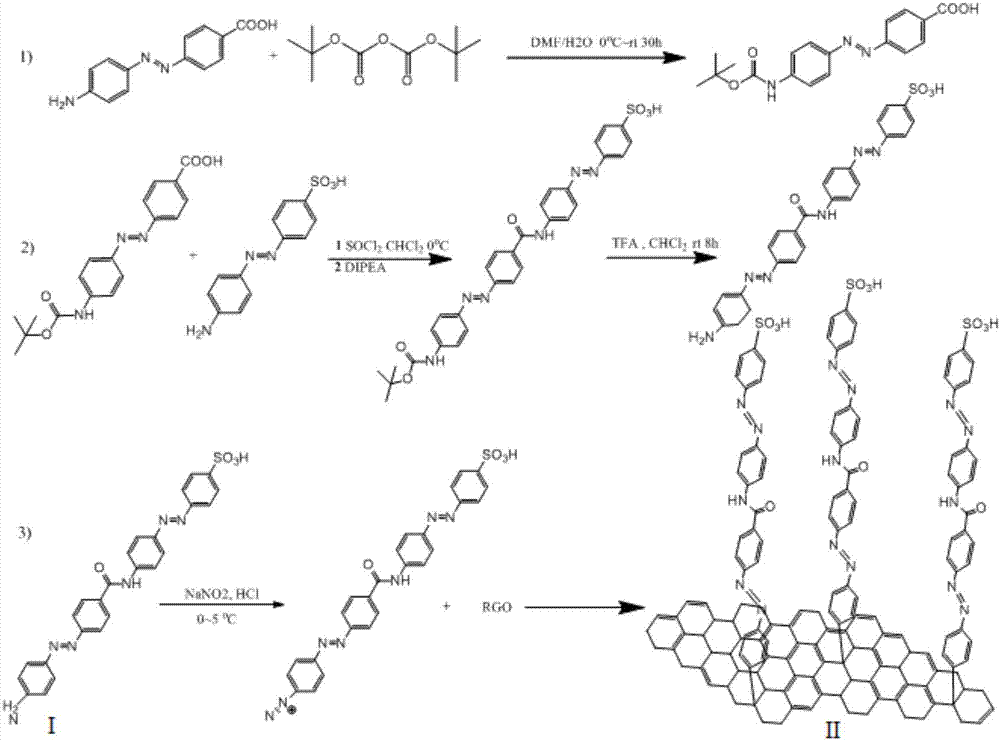

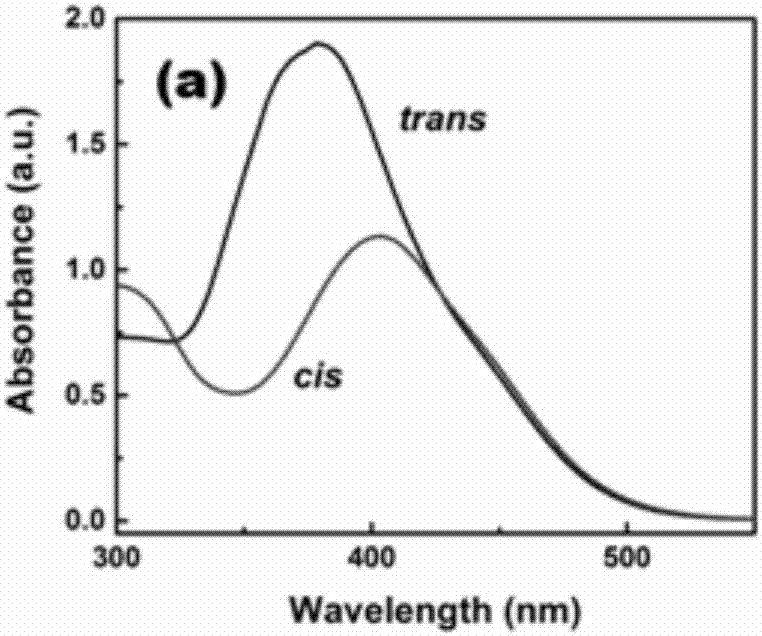

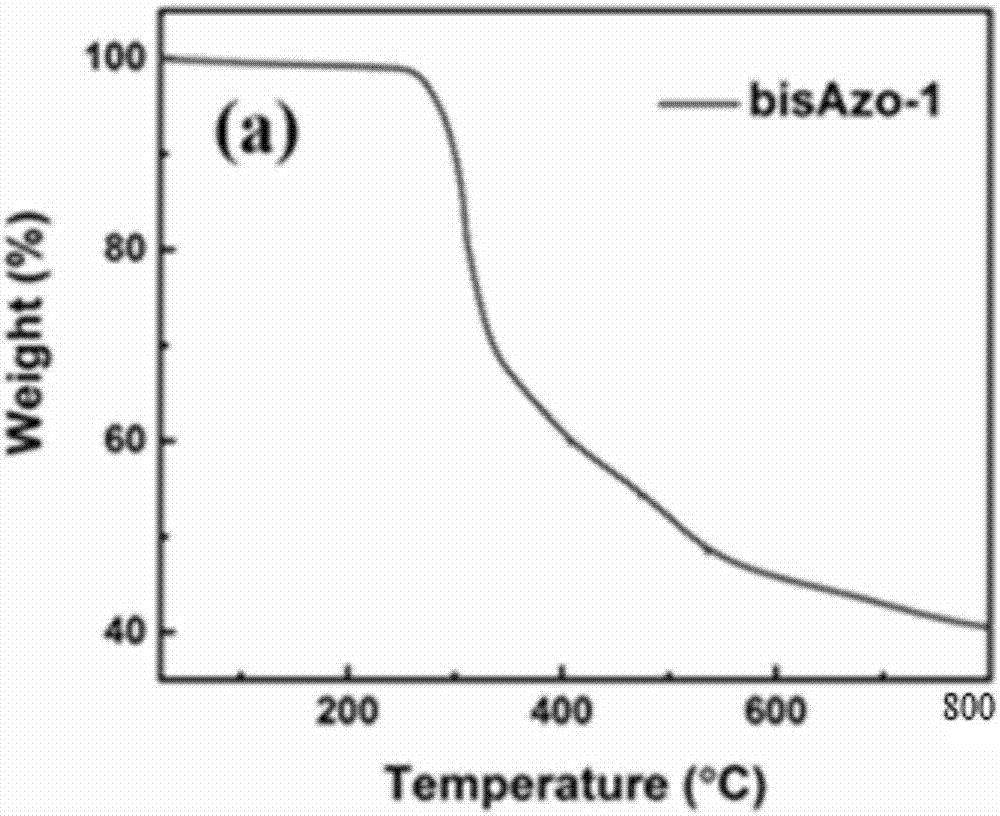

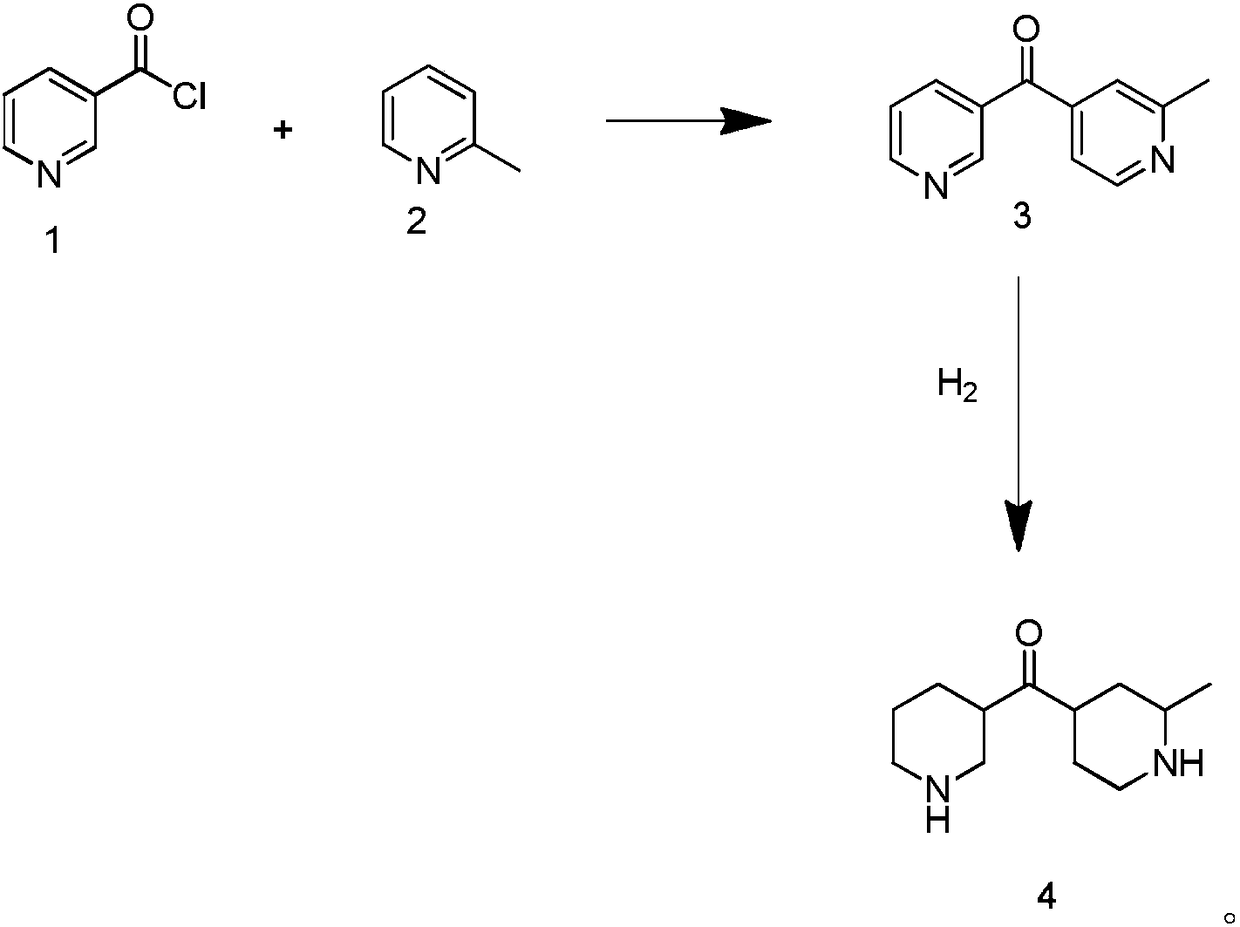

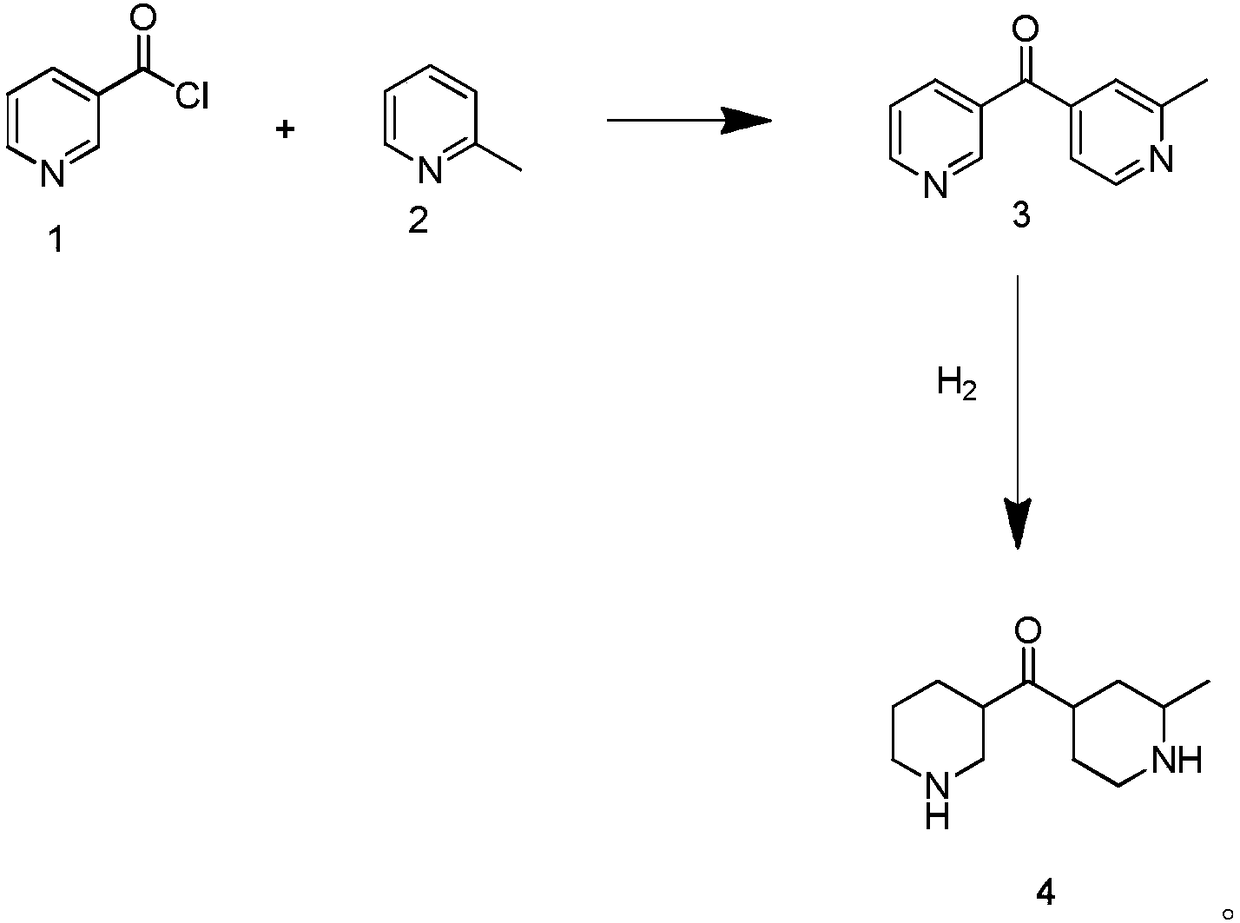

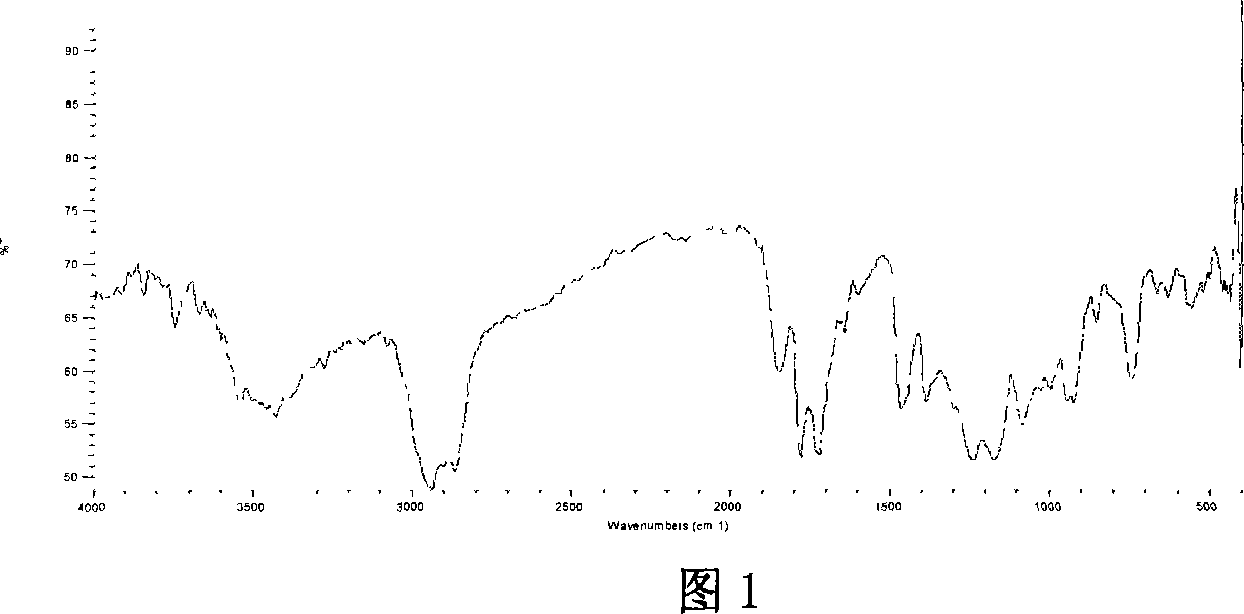

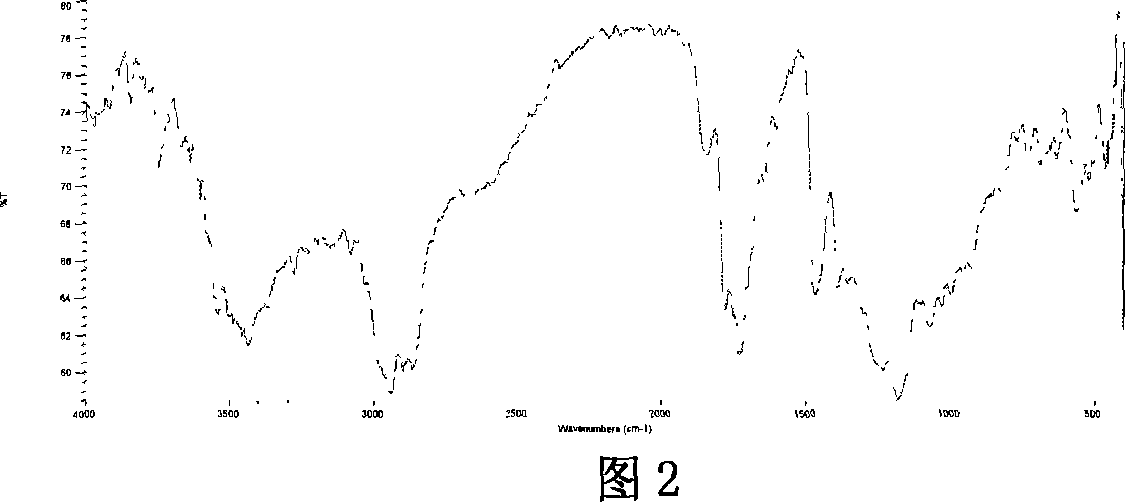

Linear double-branch azobenzene/graphene composite material and preparation method and application thereof

ActiveCN106966929AEasy to graftSmall space volumeCarbamic acid derivatives preparationOrganic compound preparationHalf-lifeP-Aminobenzoic acid

The invention discloses a linear double-branch azobenzene / graphene composite material and a preparation method and application thereof. The linear double-branch azobenzene / graphene composite material is characterized in that linear double-branch azobenzene is grafted to single-layer graphene. The preparation method includes: performing diazotization on 4-aminobenzoic acid, allowing the processed 4-aminobenzoic acid to have reaction with aniline to generate azobenzene molecules, performing amino protection on the azobenzene molecules, and performing amidation on the azobenzene molecules and para amino azobenzene-4-sulfonic acid to obtain amino protected double-branch azobenzene; removing amino protection, and hybridizing and compositing the prepared double-branch azobenzene and reduced graphene oxide through diazotization to obtain the linear double-branch azobenzene / graphene composite material. The prepared double-branch azobenzene / graphene hybrid material has the advantages that the energy value and half-life period of the material are greatly improved as compared with those of azobenzene small molecules, the energy density of the material is stabilized at 158Wh / Kg, the half-life period of the material is prolonged to above 1000 hours, and the material is good in thermal stability and circulating performance and beneficial to solar heat storage.

Owner:TIANJIN UNIV

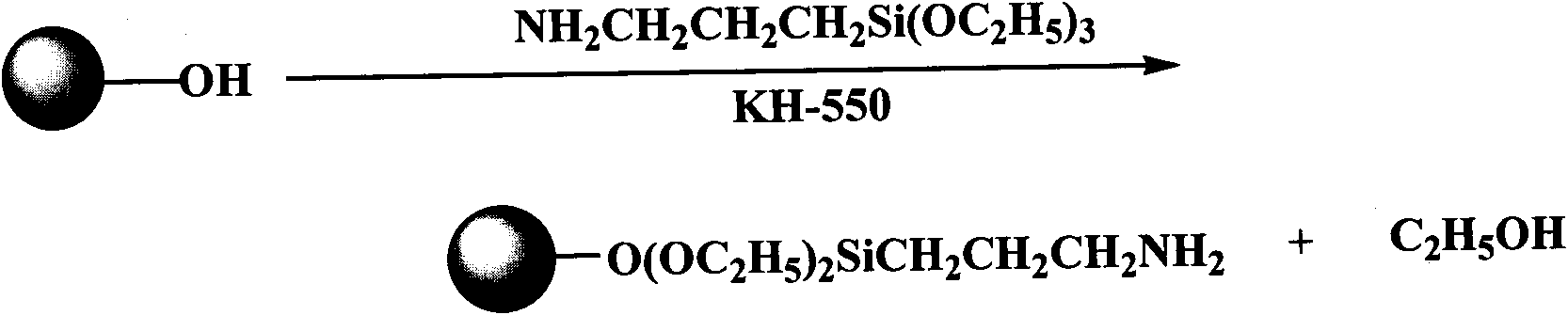

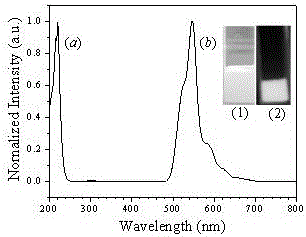

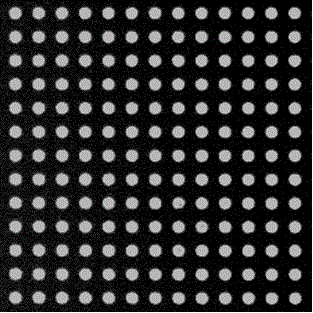

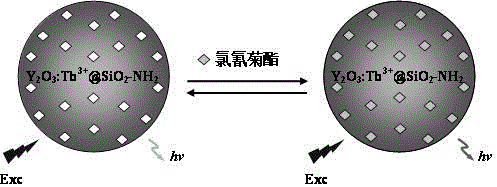

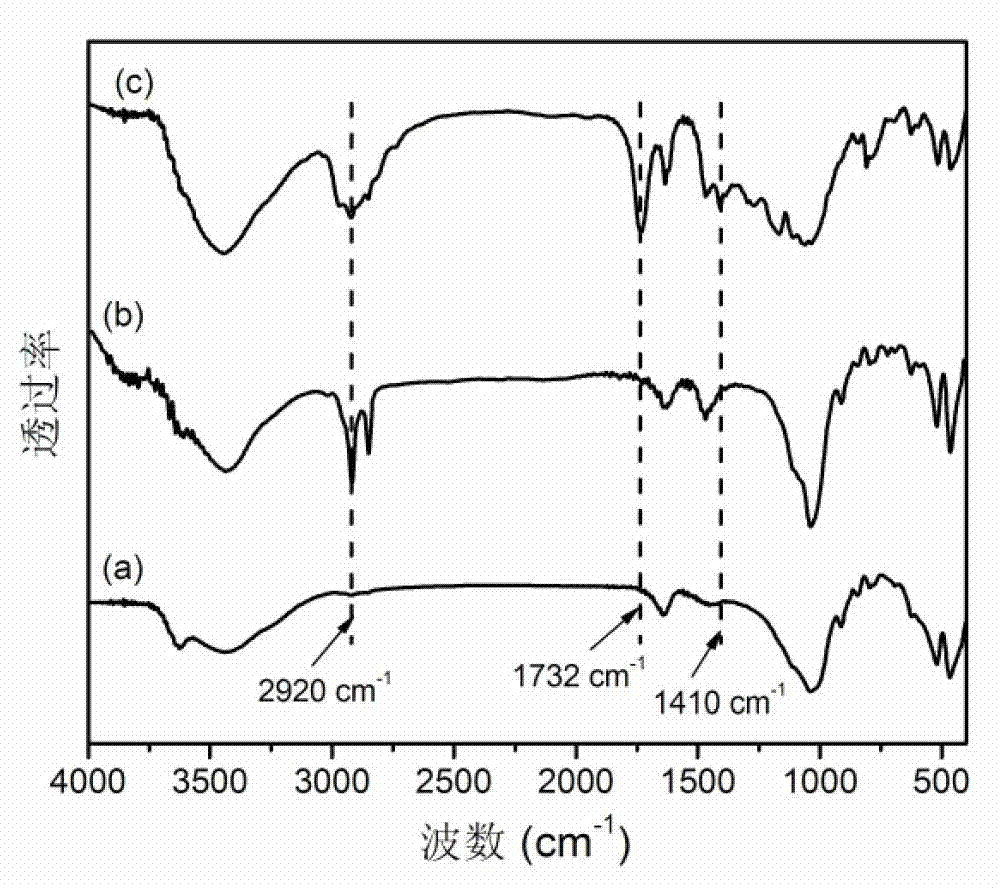

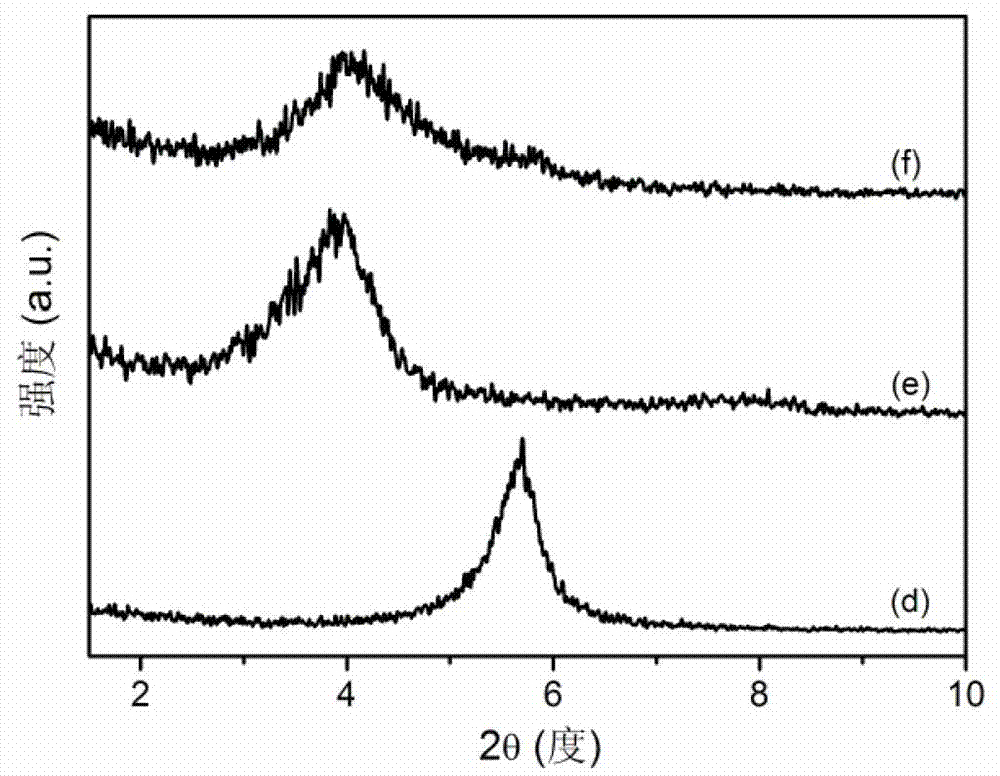

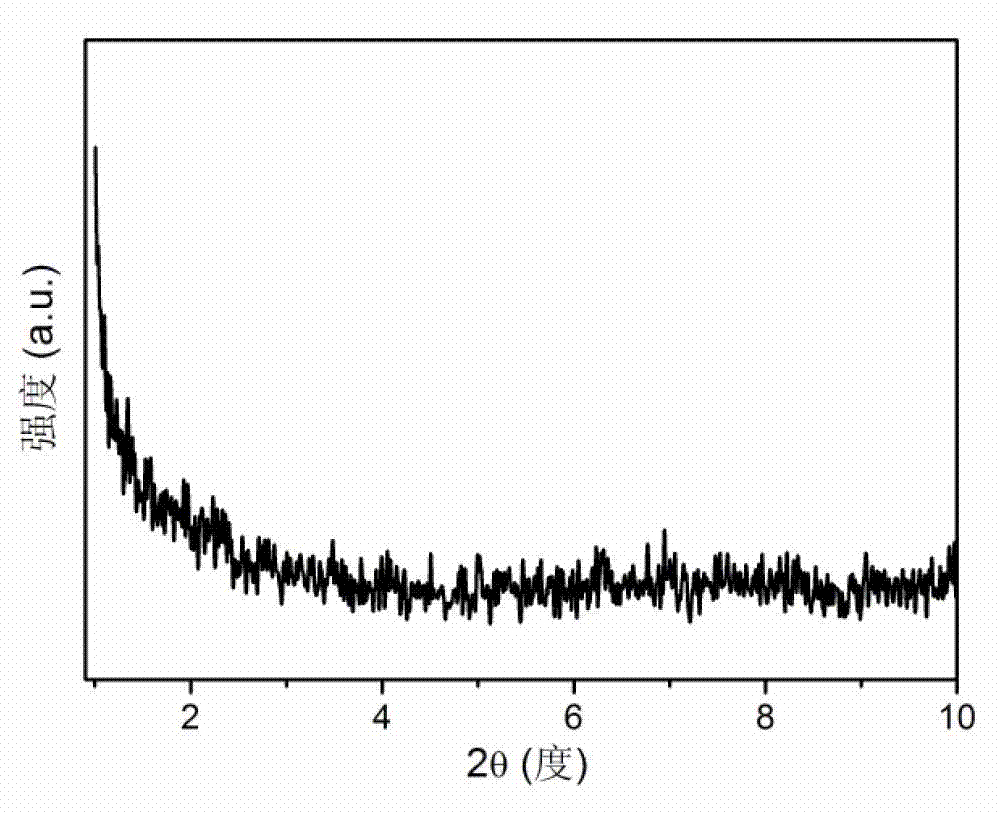

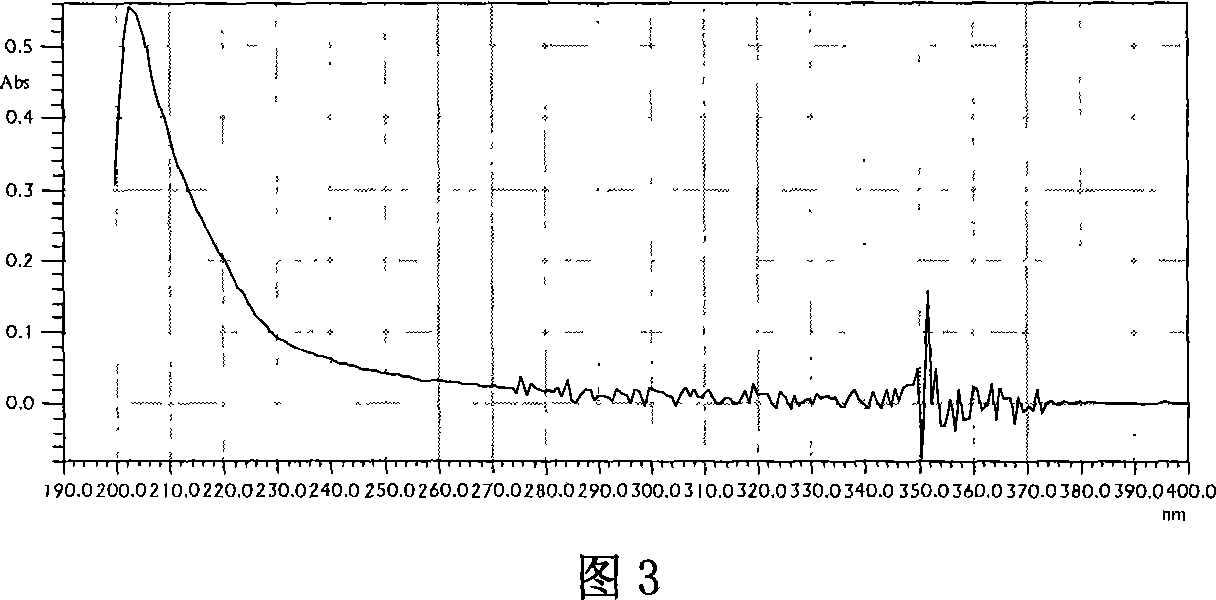

Method for preparing Y2O3:Tb<3+>@SiO2-NH2 fluorescence sensor array used for detecting organic chlorine pesticide

ActiveCN106092983AIncreased sensitivityStrong selective recognition abilityFluorescence/phosphorescenceSensor arrayHigh sensitive

The invention relates to a method for preparing a Y2O3:Tb<3+>@SiO2-NH2 fluorescence sensor array used for detecting an organic chlorine pesticide. The marking recognition sites in the fluorescence sensor array are mutually effected with organic chlorine pesticide molecules (target molecules), the target molecules and Tb<3+> on the recognition sites form an organic ligand through coordination, and change of the fluorescence intensity of Tb<3+> is used for detecting the target molecules. The method comprises the following three steps: preparing Y2O3:Tb<3+> fluorescent powder, then synthesizing a Y2O3:Tb<3+>@SiO2-NH2 fluorescence probe having capability for identifying the marking target molecules, finally, through a micromachining technology and a plasma etching method, dropping the fluid suspension of the fluorescence probe having the capability for identifying the marking target molecules on a silicon chip, naturally drying the silicon chip, and spontaneously putting the fluorescence probe materials in a micro hole to obtain the fluorescence sensor array for high-selectivity identification and high sensitive signal detection on the target molecules.

Owner:HEFEI UNIV

Sulfhydryl-double bond reaction-based acrylate ester/montmorillonite composite and preparation method

The invention discloses a sulfhydryl-double bond reaction-based acrylate ester / montmorillonite composite and a preparation method. The preparation method is characterized by comprising the steps of: firstly, forming intercalation modification chemical bond grafted acrylic ester functionalized nano-montmorillonite, then mixing the synthesized polyfunctional group sulfur alcohol, acrylate ester oligomer, acrylate monomer and a light initiator, and finally performing ultraviolet light irradiation to obtain the acrylate ester / montmorillonite ultraviolet cured nano composite. A line for synthesizing a polyfunctional group acrylate ester silane coupling agent and the polyfunctional group sulfur alcohol is simple and easy without toxicity; compared with the traditional method in which the initiator takes up 3 to 5% of total mass, the preparation method disclosed by the invention has the advantages that the usage amount of the light initiator is greatly reduced and only takes up 0.1-0.8% of the total mass, the residual light initiator can be effectively reduced, the harm of fragments to the environment and the health of a human body can be reduced, and higher reaction activity and conversion rate can be achieved; and the compatibility between inorganic components and organic components in the composite is good, and the mechanical property and heat-resistant property are obviously improved.

Owner:ZHANGJIAGANG DAWN CHEM

Method for grafting 2-methacryloyloxyethyl phosphorylcholine (MPC) polymer on titanium-base material surface

InactiveCN102000359AImprove bindingNot easy to fall offCoatingsProsthesis2-methacryloyloxyethyl phosphorylcholineMpc polymer

The invention discloses a method for grafting 2-methacryloyloxyethyl phosphorylcholine (MPC) polymer on a titanium-base material surface. A layer of middle bridging groups, namely organic phosphate or phosphate monoester which respectively forms chemical bonding with the titanium-base material surface and the MPC polymer is prepared on the titanium-base material surface and the MPC polymer by a self-assembled monolayer method; and the MPC polymer is grafted on the titanium-base material surface by a surface-initiated atom transfer radical polymerization method. In the prepared simulative functionalized titanium-base material of the method, the MPC polymer on the surface of the simulative functionalized titanium-base material has strong bonding force with the titanium-base material and has better histocompatibility and better blood compatibility. The invention has simple process and is easy to realize.

Owner:SOUTHWEST JIAOTONG UNIV

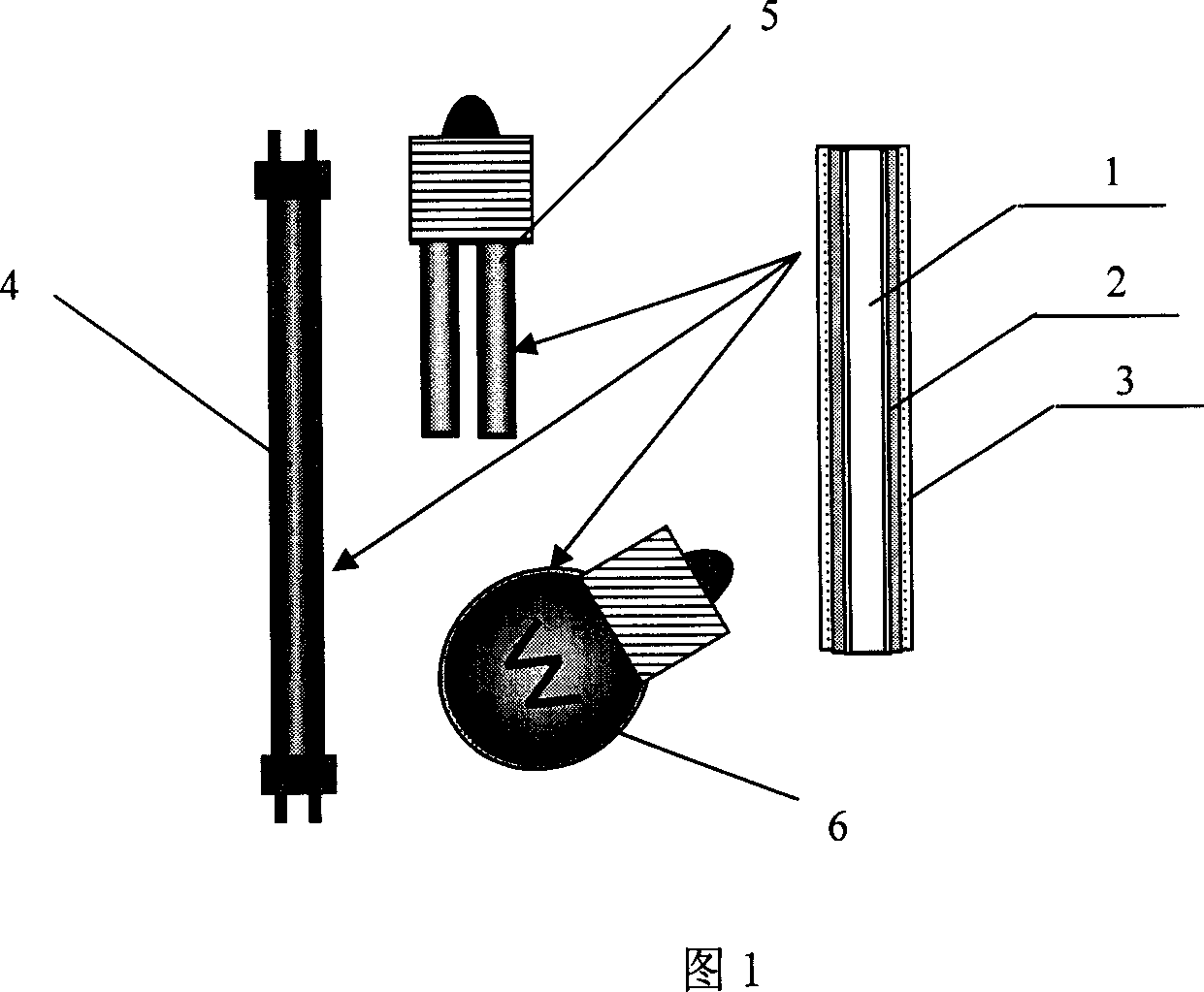

Photocatalysis thin film with illumination and purifying coupling function and manufacture method thereof

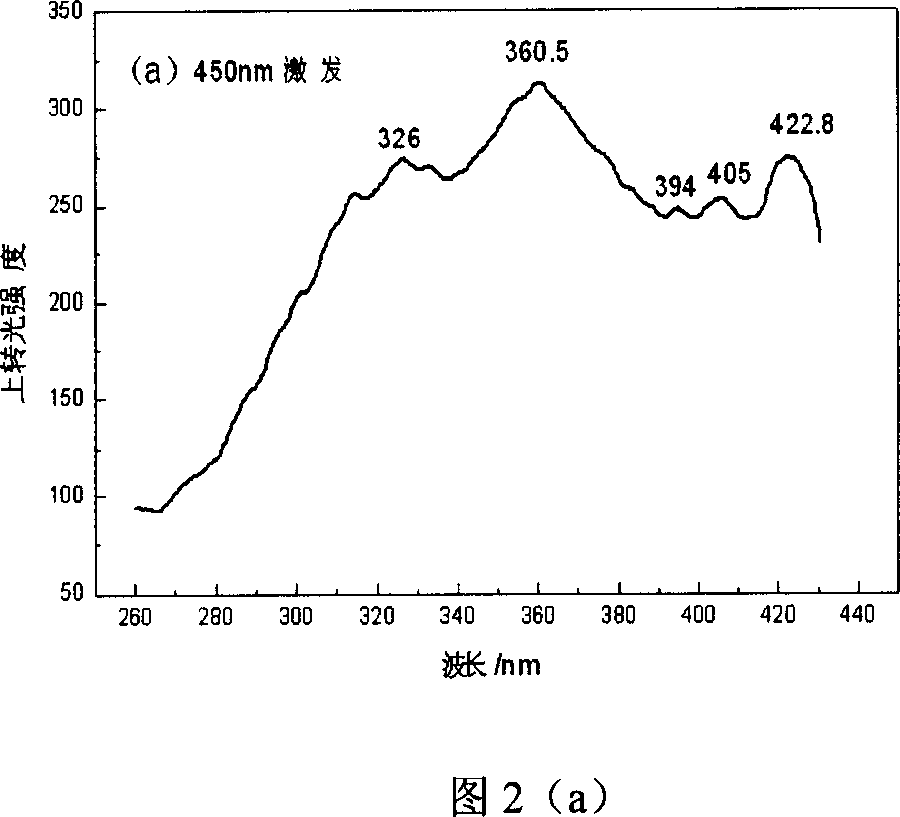

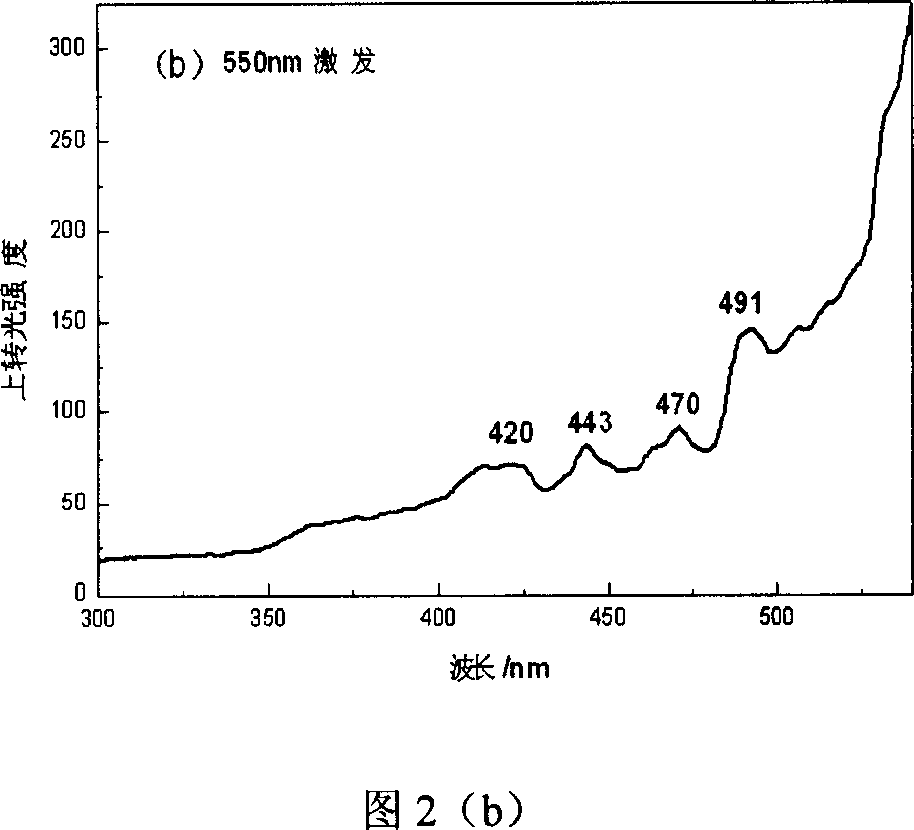

InactiveCN1919769ASignificant up-converting light performanceSignificant visible light response effectPhysical/chemical process catalystsPhysical chemistryPhoto catalysis

The invention discloses a preparing method of titanium dioxide nanometer film excited by visible light, which comprises the following steps: covering a layer of upper rotary optical transparent glass and titanium dioxide optical catalytic film with doped rare earth oxide on the external case of luminous glass; predisposing the surface of luminous glass; depositing the upper rotary optical transparent film; sedimenting nanometer titanium dioxide film; doping titanium dioxide catalytic film at original position.

Owner:TSINGHUA UNIV

Chitosan modified nylon fabric and manufacturing method thereof

The invention discloses a chitosan modified nylon fabric, which is grafted with 0.1 to 0.2 mass percent of chitosan. The invention also discloses the manufacturing method of the fabric, which comprises: (1) weighing nylon fabric and immersing the nylon fabric in nylon oxidant aqueous solution, heating in a water bath according to a bath ratio ranging from 1:10 to 1:40, and stirring; (2) dissolving the chitosan in 1 to 6 percent of glacial acetic acid, stirring to dissolve the glacial acetic acid to form saturated solution of the glacial acetic acid; (3) weighing chitosan oxidant and adding the chitosan oxidant into the saturated solution of the chitosan prepared in the step (2), stirring uniformly and heating in a water bath; (4) adding the chitosan mixed solution obtained by the step (3)into the nylon oxidant aqueous solution in which the nylon fabric is immersed, heating in a water bath and stirring, wherein the added volume of the chitosan mixed solution is 0.5 to 3 times that of nylon oxidant aqueous solution; and (5) taking finished nylon fabric, washing with a soap, and drying in the air. The modified nylon fabric is smoother and has the effects of inhibiting bacteria, resisting static electricity and the like. The method discloses by the invention is simple, easy to implement and low in cost.

Owner:WUYI UNIV

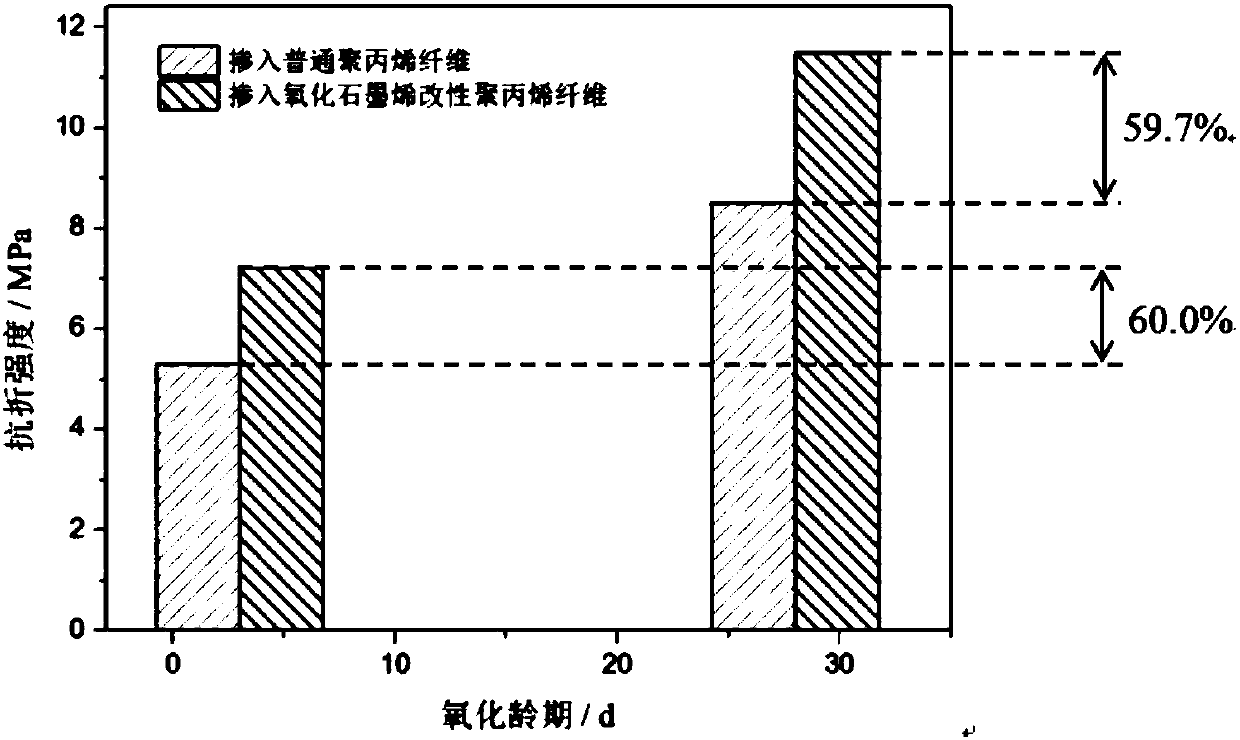

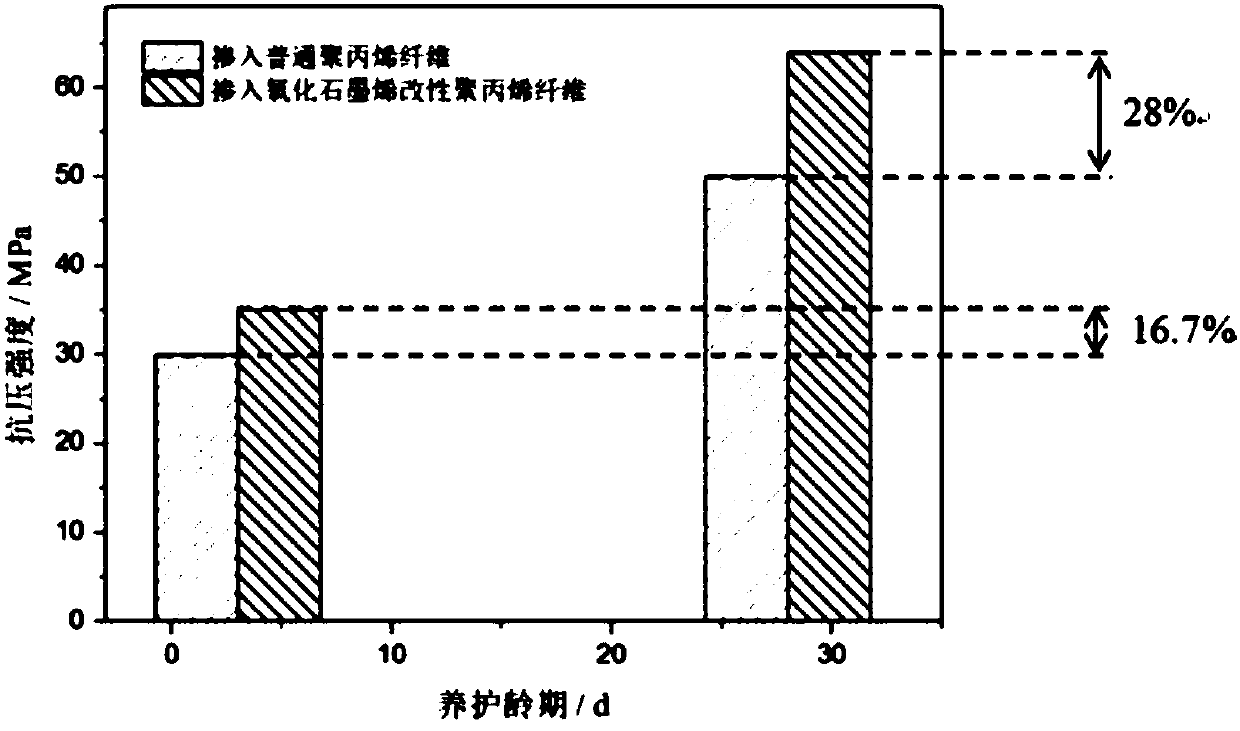

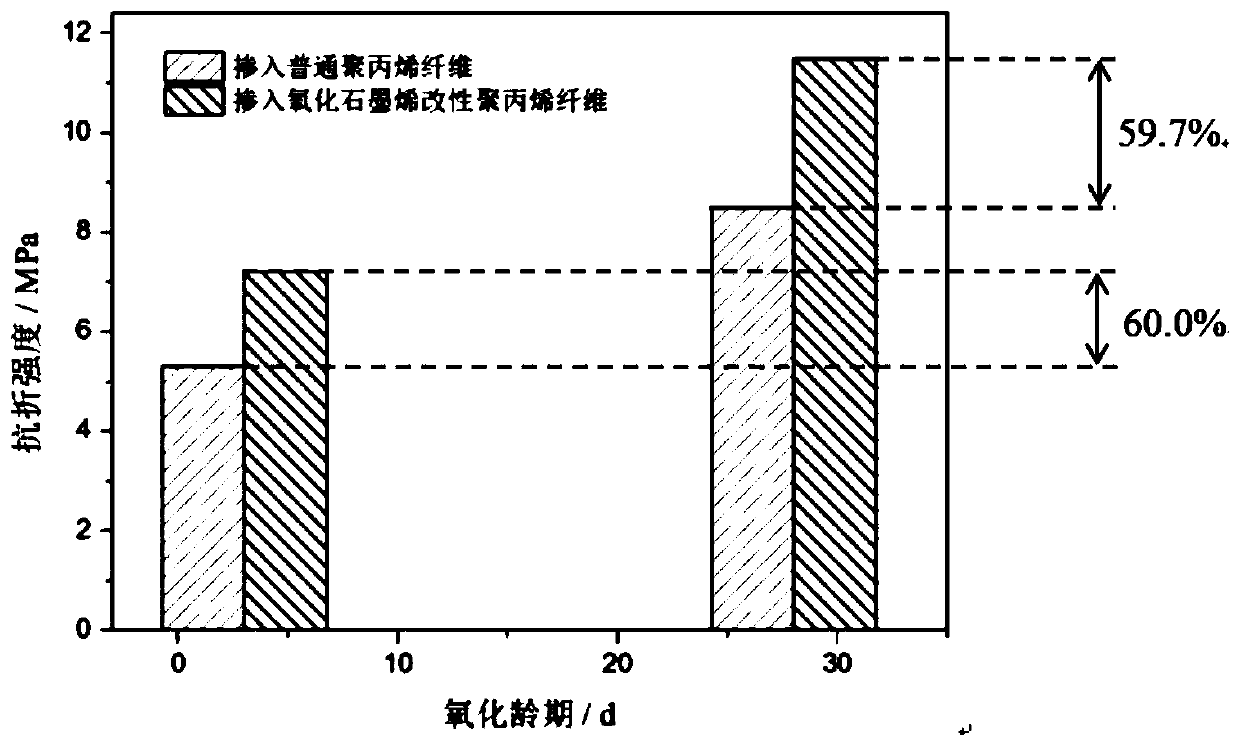

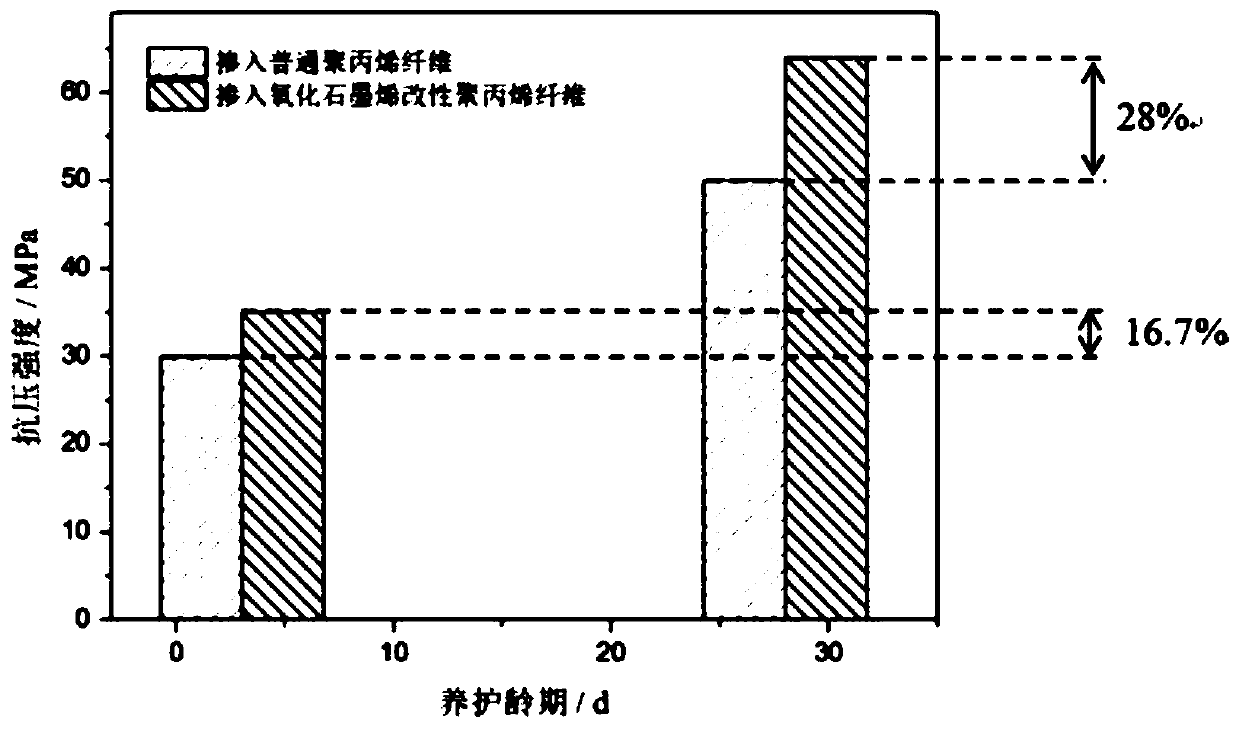

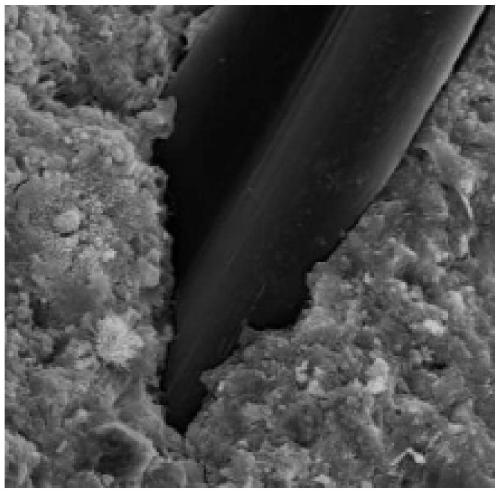

Modified polypropylene composite fibers and preparation method thereof

The invention relates to the field of materials, in particular to modified polypropylene composite fibers and a preparation method thereof. The preparation method comprises the following steps: carrying out reaction on 1-2wt% of polypropylene fiber aqueous solution, diisocyanate and an oxidizing agent for 50-70 minutes at the temperature of 50-60 DEG C, heating to 90-100 DEG C, and reacting with an initiator for 1-2 hours, so that the modified polypropylene fibers are obtained. A mixed solution of of a graphene oxide aqueous solution and modified polypropylene fibers react for 1-2 hours at thetemperature of 50-60 DEG C, and then washing and drying are carried out. Diisocyanate and the oxidizing agent oxidize the polypropylene fibers, activity of the polypropylene fibers is enhanced, the modified polypropylene fibers are grafted with graphene oxide, and high-activity carbon-oxygen double bonds are connected with hydroxyls and carboxyls on the surface of graphene oxide. When the modified polypropylene composite fibers are doped into a cement-based material, toughness of concrete is improved from macroscopical and microcosmic double levels, and adhesion between the cement and the fibers is also beneficially improved.

Owner:中建西部建设新疆有限公司 +1

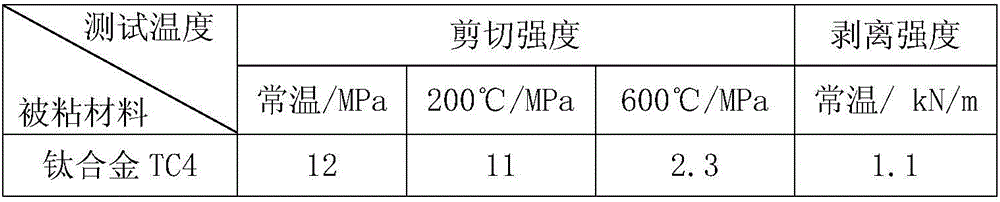

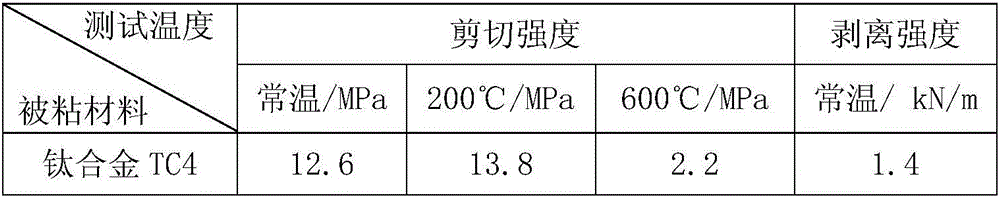

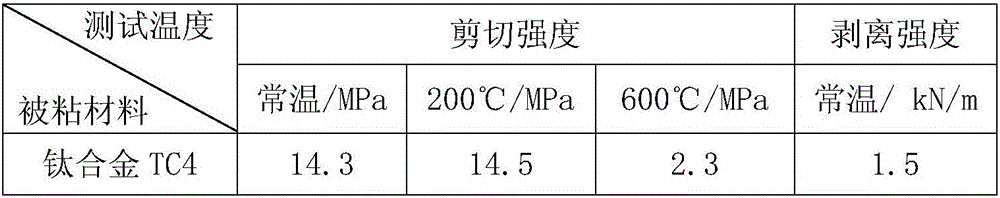

Vinyl polycarbosilane modified phenol-formaldehyde adhesive and preparation method thereof

InactiveCN105801785AHigh activityHigher than the moldAldehyde/ketone condensation polymer adhesivesAdhesiveDistillation

The invention relates to a vinyl polycarbosilane modified phenol-formaldehyde adhesive and a preparation method thereof. The invention aims at solving the technical problems of existing phenol-formaldehyde adhesive that fragility is high, toughness is poor and peel strength is low. The vinyl polycarbosilane modified phenol-formaldehyde adhesive is prepared from phenol, formaldehyde, an alkaline catalyst, vinyl polycarbosilane and ethyl acetate. The preparation comprises the following steps of: firstly weighing phenol, formaldehyde, alkaline catalyst and vinyl polycarbosilane; secondly, mixing raw materials; and thirdly, carrying out reaction and pressure distillation, and preparing solution. According to the invention, vinyl polycarbosilane with excellent heat resistance is grafted with POSS modified phenol-formaldehyde adhesive for preparing phenol-formaldehyde adhesive with high heat resistance, and adhesion of ceramic materials and high temperature resistant metal materials is met. The preparation method provided by the invention is used for preparing the vinyl polycarbosilane modified phenol-formaldehyde adhesive.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

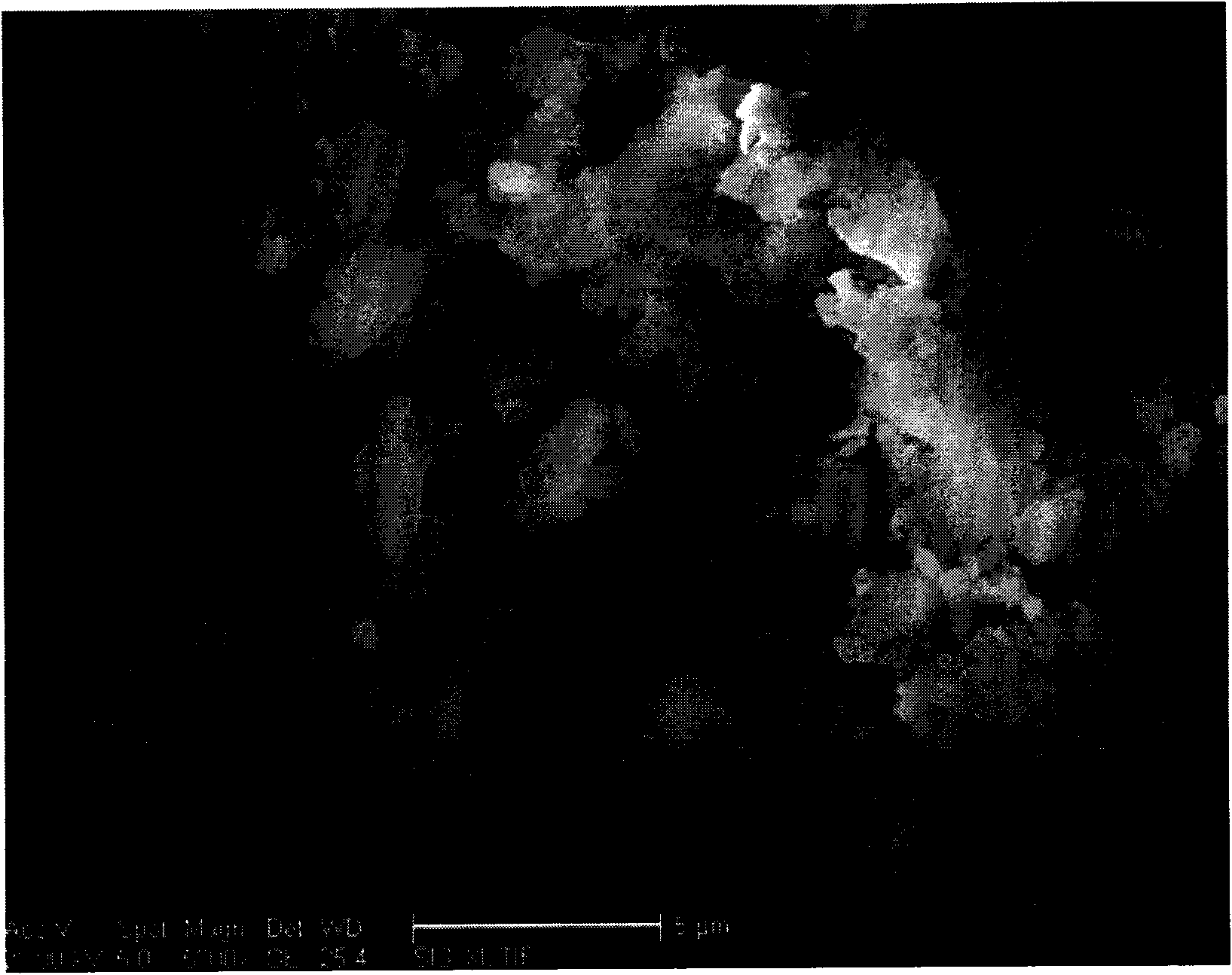

Photographic paper ink absorbing layer material

ActiveCN101561624AStable absorptionImprove dispersionPhotosensitive material auxillary/base layersIonPhotographic paper

The invention provides a photographic paper ink absorbing layer material, and relates to a material for a photographic paper coating. The material solves the problem that the prior photographic paper ink absorbing layer material easily generates ink diffusion phenomenon on the surface of an ink absorbing layer. The material consists of 0.5 to 10 portions of polyhedral oligomeric silsesquioxane, 25 to 75 portions of ethylene-vinylacetate copolymer latex and 50 to 75 portions of deionized water. The photographic paper ink absorbing layer material obtained by the invention can be used as a photographic paper inkjet ribbon and a picture of the ink absorbing layer; through observation, the ribbon and the picture subjected to spraying and printing have high color saturation and lustrousness, good definition and no ink diffusion phenomenon; and after the material is subjected to heat preservation for one hour in an oven of 200 DEG C, heat preservation for seven days in an oven of 70 DEG C, or insolation for half a year under the sun, the saturation, the lustrousness and the definition of the ribbon and the picture subjected to spraying and printing are unchanged, and no ink diffusion phenomenon generates. By testing of a scanning electron microscope SEM, grains of the photographic paper ink absorbing layer material have uniform granular diameter, favorable dispersion and no aggregation phenomenon.

Owner:HARBIN INST OF TECH

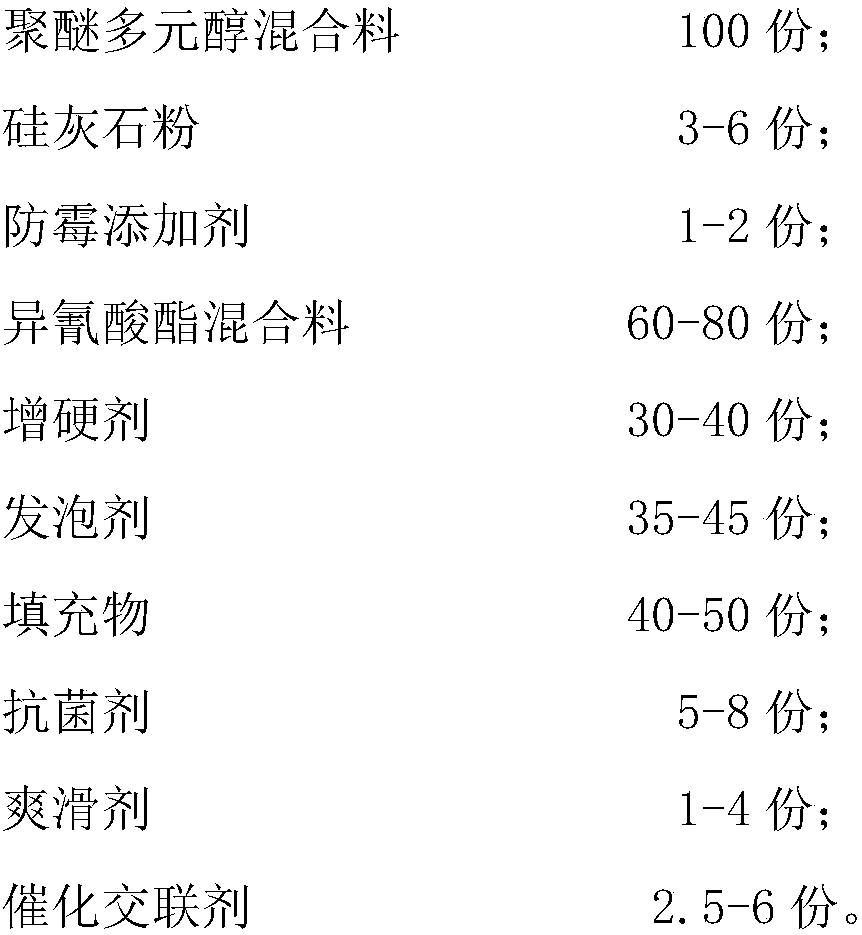

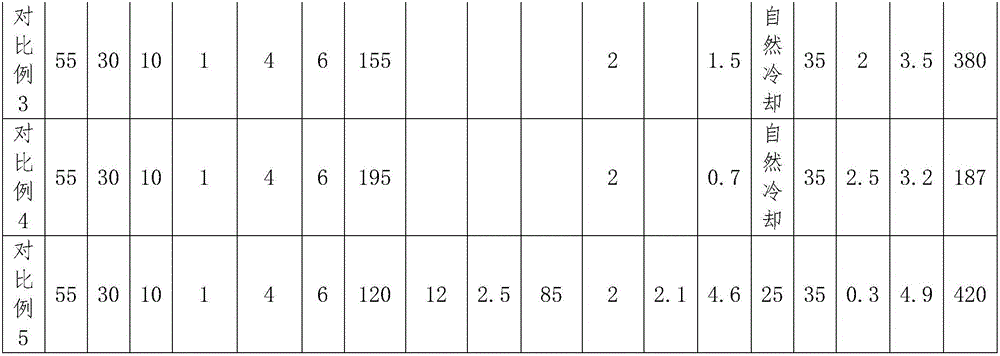

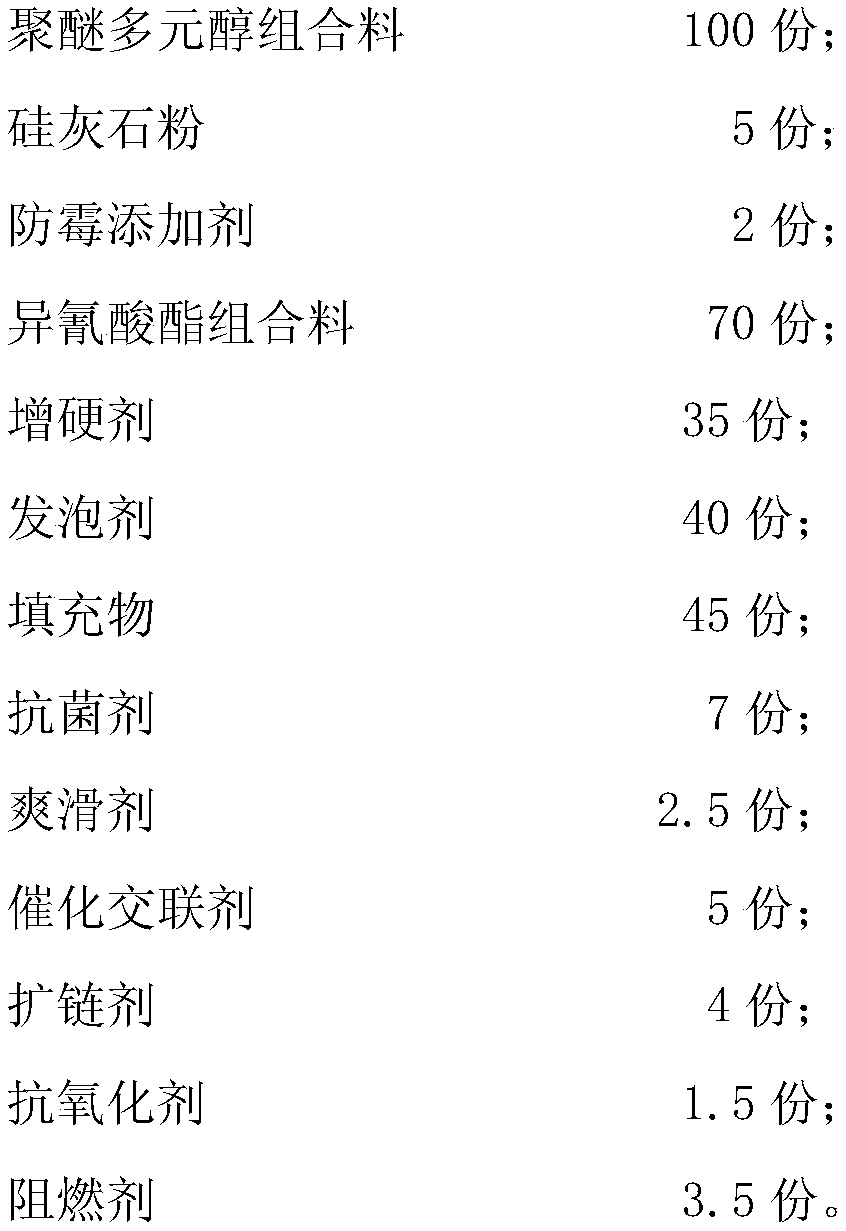

Polyurethane material, high-elasticity antibacterial polyurethane powder puff and preparation method thereof

InactiveCN108484874AIncrease elasticityImprove antibacterial propertiesPackaging toiletriesPackaging cosmeticsFoaming agentSlag

The invention provides a polyurethane material, a high-elasticity antibacterial polyurethane powder puff and a preparation method thereof. The polyurethane material is prepared from the following rawmaterials in parts by weight: 100 parts of a polyether polyol mixture, 3 to 6 parts of a wollastonite powder, 1 to 2 parts of an anti-mildew additive, 60 to 80 parts of an isocyanate mixture, 30 to 40parts of a hardening agent, 35 to 45 parts of a foaming agent, 40 to 50 parts of fillers, 5 to 8 parts of an antibacterial agent, 1 to 4 parts of a refreshing and slipping agent, and 2.5 to 6 parts of a catalytic cross-linking agent. The polyurethane powder puff provided by the invention is researched and developed specifically at the aim of providing good adaptability and compatibility for humanbody skin; compared with the conventional latex and the existing powder puff which is prepared by adopting industrial polyurethane, the polyurethane powder puff has the unique advantages of better skin affinity, no slag drop, odourlessness, bacterial resistance, high elasticity, better oil control capacity, more convenience in cleaning, exquisite hand feeling, environment friendliness and the like, and has a broad popularization and application prospect.

Owner:HUIZHOU YUANAN NEW MATERIALS

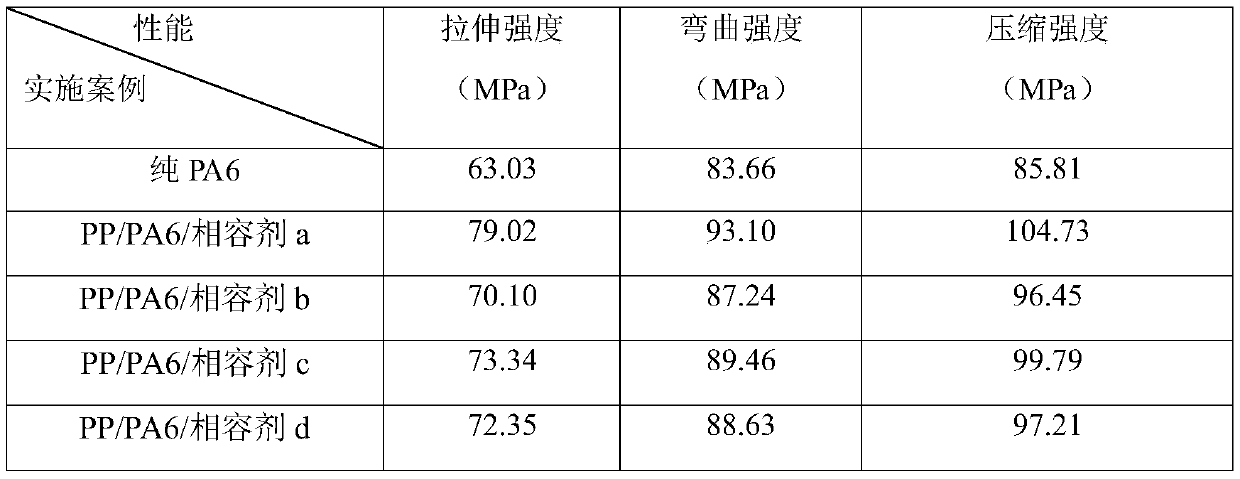

Preparation method of high-polymer composite nanoparticle compatilizer

ActiveCN110551289AEliminate intermediate reaction stepsSimple preparation processPolyolefinComposite nanoparticles

The invention relates to a preparation method of a polymer composite nanoparticle compatibilizer. The method includes the following steps: (1) a nanoparticle aqueous solution is dropwise added into asolution containing polyethyleneimine for a reaction, and finally an intermediate 1 is obtained; and (2) an intermediate 1 solution and a non-polar high-polymer graft solution are subjected to a stirring reaction to obtain the nanoparticle compatibilizer. A polar part of the compatibilizer obtained by the preparation method is the polyethyleneimine which not only contains secondary amine and tertiary amine, but also contains primary amine and is easily grafted on nanoparticles, thus the grafting rate of a non-polar polyolefin graft on the nanoparticles is increased, the preparation process issimple, and treatment is convenient.

Owner:HEBEI UNIV OF TECH

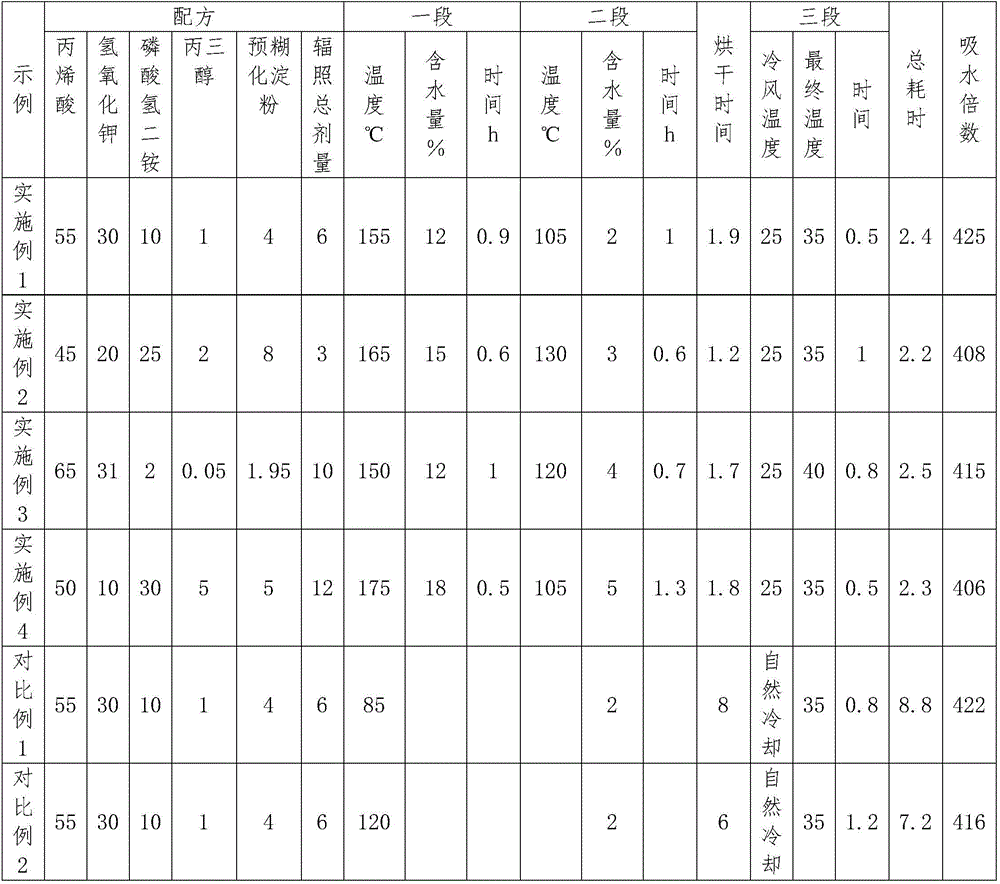

Method for preparing environment-friendly and multi-functional agro-forestry super absorbent polymer

ActiveCN106084132ANo residueNo pollution in the processOrganic fertilisersSoil conditioning compositionsEnvironmental resistanceCross-link

The invention discloses a method for preparing an environment-friendly and multi-functional agro-forestry super absorbent polymer, belonging to the field of preparation of agro-forestry superabsorbent polymers. The method sequentially comprises the following steps: (1) carrying out a neutral reaction, namely adding water into pregelatinized starch and stirring for 15-30 minutes to prepare gelatinized liquid, slowly adding potassium hydroxide and diammonium hydrogen phosphate, or ammonia water and dipotassium phosphate, or diammonium hydrogen phosphate and dipotassium phosphate for dissolving, slowly adding acrylic acid for neutralizing, and finally adding a cross-linking agent for uniformly mixing; (2) performing irradiation polymerization, namely separately packaging the neutralization solution into a polymerization container, and performing irradiation polymerization in an irradiation chamber, wherein the total irradiation dose is 3-15kGy; (3) drying, namely mincing gel blocks, and drying; and (4) crushing, namely crushing in a crusher, screening, thereby obtaining the agro-forestry absorbent polymer. The method disclosed by the invention is a method for preparing an energy-saving and environment-friendlyagro-forestry super absorbent polymer, and the prepared agro-forestry superabsorbent polymer has effects of preserving moisture and fertility, supplying plant nutrition and promoting growth.

Owner:SAAS BIOTECH & NUCLEAR TECH RES INST

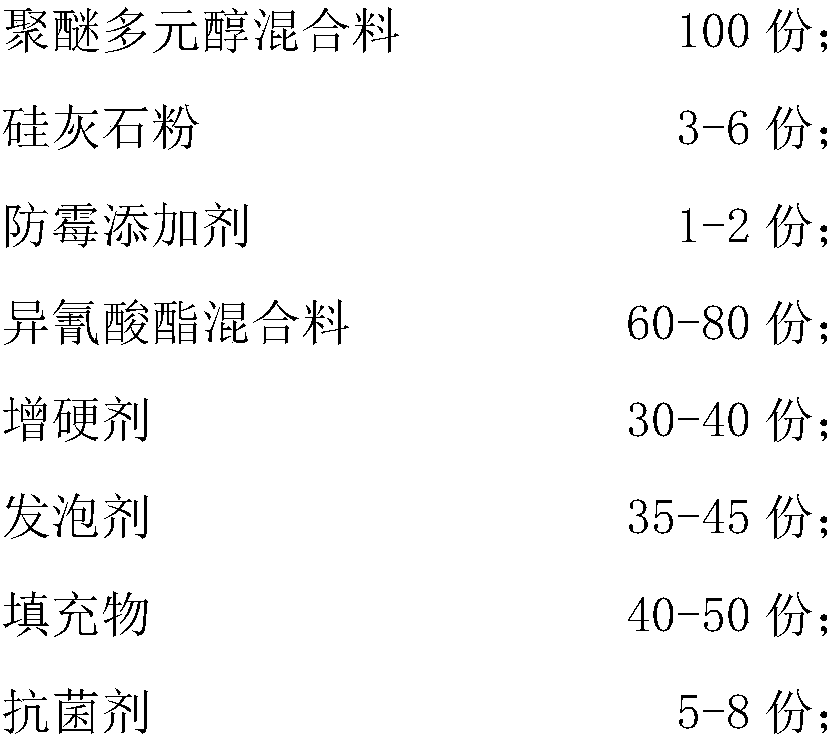

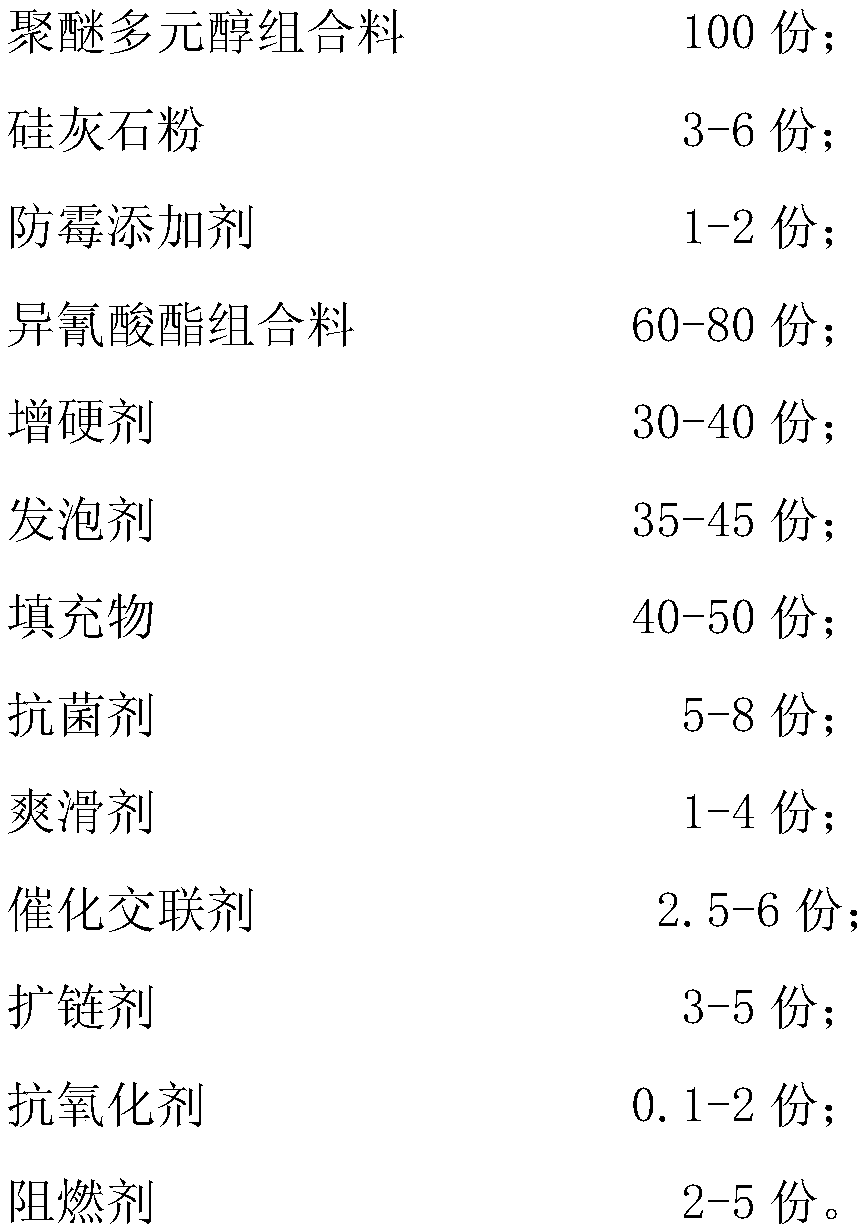

Polyurethane material and preparation method thereof

InactiveCN110358285AGood skin affinityPreparation applicablePackaging toiletriesPackaging cosmeticsPolyolFoaming agent

The invention provides a polyurethane material and a preparation method thereof. The polyurethane material is prepared from the following raw materials in parts by weight: 100 parts of polyether polyol mixed material, 3-6 parts of wollastonite powder, 1-2 parts of mould proof additive, 60-80 parts of isocyanate mixed material, 30-40 parts of a hardening agent, 35-45 parts of a foaming agent, 40-50parts of a filler, 5-8 parts of an antibacterial agent, 1-4 parts of a slipping agent, 2.5-6 parts of a catalytic crosslinking agent, 3-5 parts of a chain extender, 0.1-2 parts of an antioxidant, and2-5 parts of a flame retardant. The polyurethane material is preferentially developed for a powder puff, thus the powder puff prepared based on the material can provide good adaptability and compatibility for the skin of the human body, compared with a powder puff prepared from traditional latex and existing industrial polyurethane, the powder puff prepared based on the material has the unique advantages of being better in skin friendliness, free of chip falling, odourless, antibacterial, high in elasticity, better in oil control property, more convenient to clean, exquisite in hand feeling,environmentally friendly and the like, meanwhile, the invention provides a brand-new polyurethane preparation technology, and the prepared polyurethane material has the wide application prospects.

Owner:焦荣

Glass fiber composite material and preparation method thereof

ActiveCN112694715AImprove mechanical propertiesHigh glass transition temperatureFirming agentPolyester resin

The invention discloses a glass fiber composite material. The glass fiber composite material is prepared from the following raw materials by weight: 40-60 parts of epoxy resin; 30-40 parts of unsaturated polyester resin; 60-70 parts of modified glass fiber; 5-10 parts of modified montmorillonite; 6-15 parts of graphite; 1-2 parts of chicken feather fiber; 0.3-0.5 part of an initiator; and 0.5-1 part of a curing agent; according to the invention, glass fiber is modified, and the hyperbranched polymer with hydroxyl grows on the glass fiber to improve the mechanical properties of the epoxy composite material; in addition, by modifying hydroxyl on the surface of the glass fiber, the crosslinking density of the epoxy matrix and the glass fiber is improved, and the segmented movement of the epoxy matrix is inhibited, so that the glass-transition temperature of the composite material is increased; in addition to improving the mechanical properties, the glass fiber can also serve as a chemical barrier, thereby reducing the water absorption of the composite material.

Owner:徐州关高研磨科技有限公司

Photographic paper coating material

ActiveCN101561625AStable absorptionImprove dispersionPhotosensitive material auxillary/base layersPhotographic paperDefoaming Agents

The invention provides a photographic paper coating material, and relates to a material for a photographic paper coating. The material solves the problem that the prior photographic paper coating material easily generates ink diffusion phenomenon on the surface of the coating ink. The material consists of polyhedral oligomeric silsesquioxane, polyvinyl alcohol latex, a dispersing agent, a water retention agent and a defoaming agent. The photographic paper coating material obtained by the invention can be used as a photographic paper inkjet ribbon and a picture of the coating; through observation, the ribbon and the picture subjected to spraying and printing have high color saturation and lustrousness, good definition and no ink diffusion phenomenon; and after the material is subjected to heat preservation for one hour in an oven of 200 DEG C, heat preservation for seven days in an oven of 70 DEG C, or insolation for half a year under the sun, the saturation, the lustrousness and the definition of the ribbon and picture subjected to spraying and printing are unchanged, and no ink diffusion phenomenon generates. By testing of scanning electron microscope SEM, grains of the photographic paper coating material have uniform granular diameter, favorable dispersion and no aggregation phenomenon.

Owner:HARBIN INST OF TECH

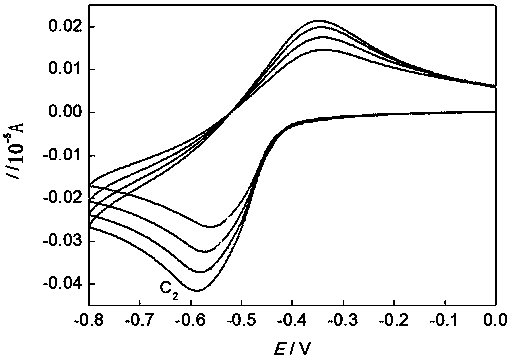

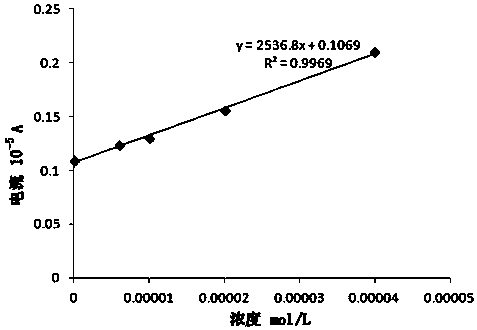

Electrochemical detection method for uric acid in urine and detection electrode material

InactiveCN107941875AImprove detection stabilityEasy to graftMaterial electrochemical variablesCyanideRelative standard deviation

The invention relates to an electrochemical detection method for uric acid in urine and a detection electrode material, and belongs to the technical field of detection. The electrochemical detection method for uric acid in urine provided by the invention is mainly used for conducting hydroxyl modification on the surface of graphene, cyanide-containing groups can be grafted more easily, and then acatalyst is deposited on the surface in an electrolytic deposition manner, so that the electrode material with preferable catalytic effect on uric acid is prepared; and when the material is applied todetection in urine, the material has preferable detection stability for uric acid, and the relative standard deviation among the detection results of electrodes prepared in batches is relatively low.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

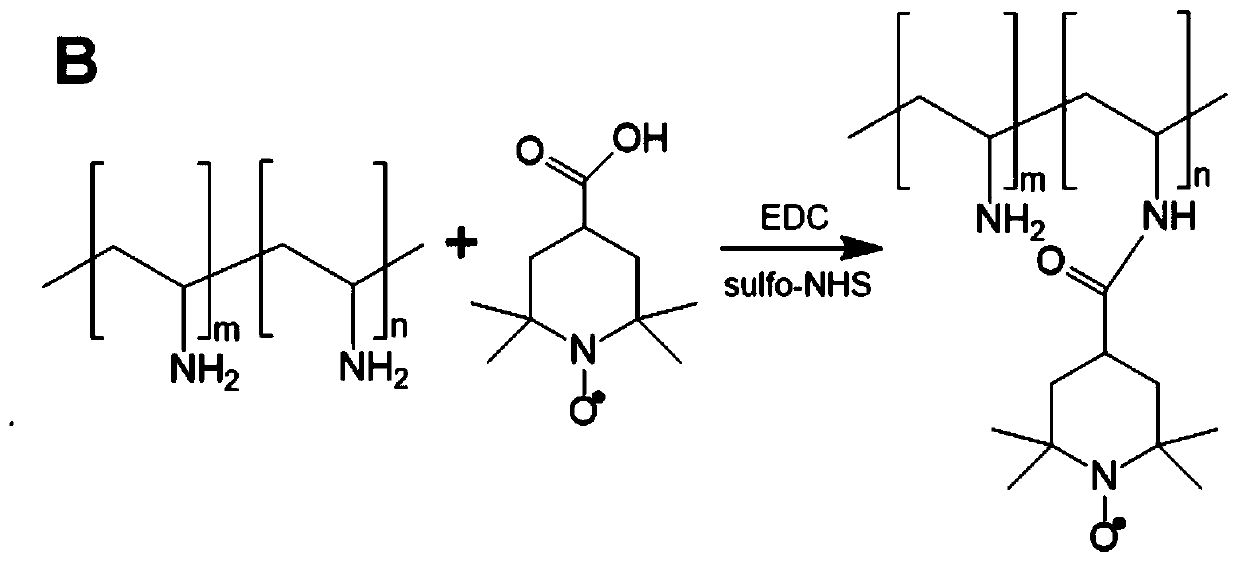

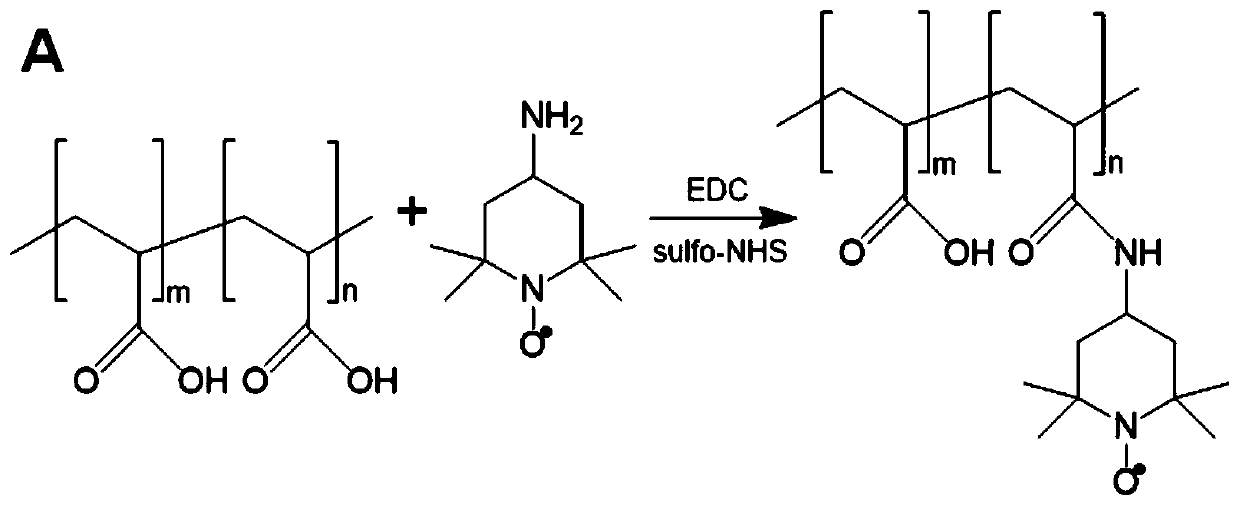

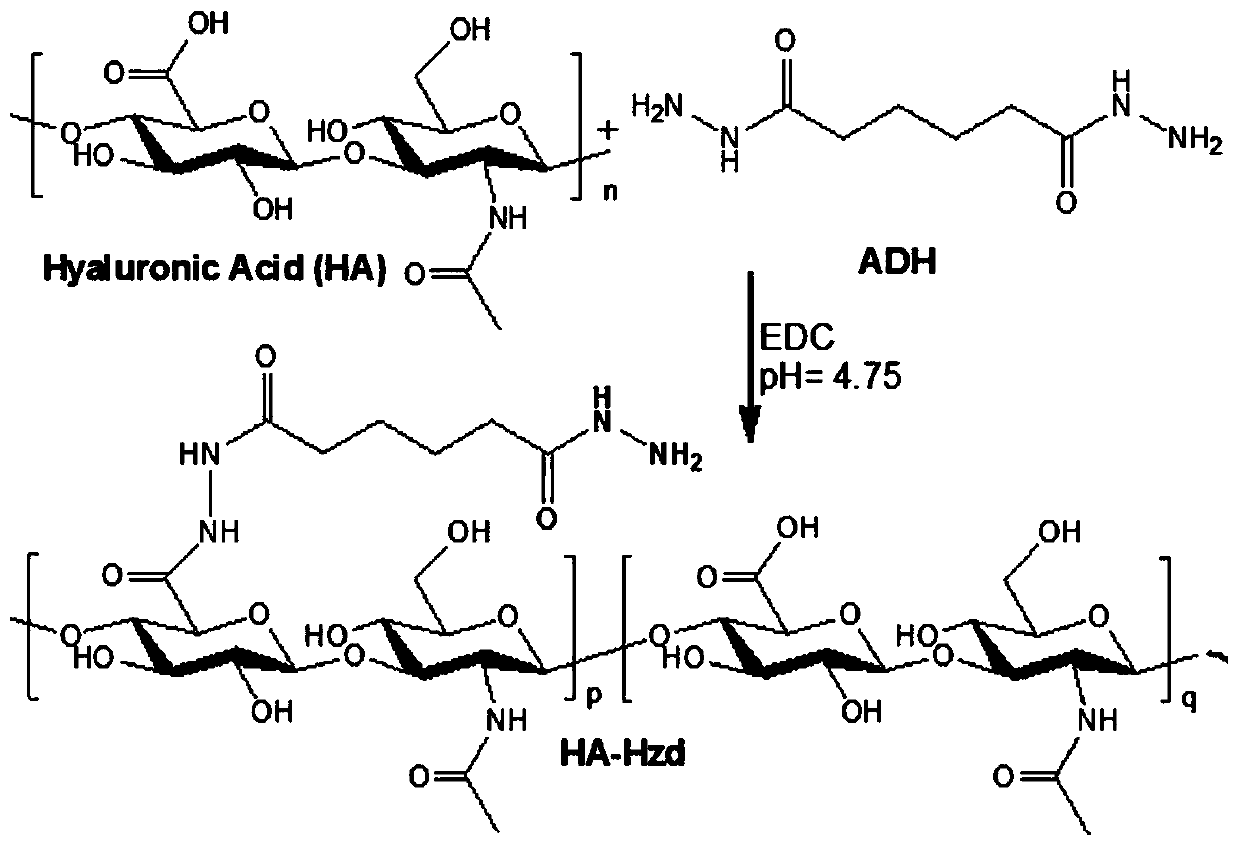

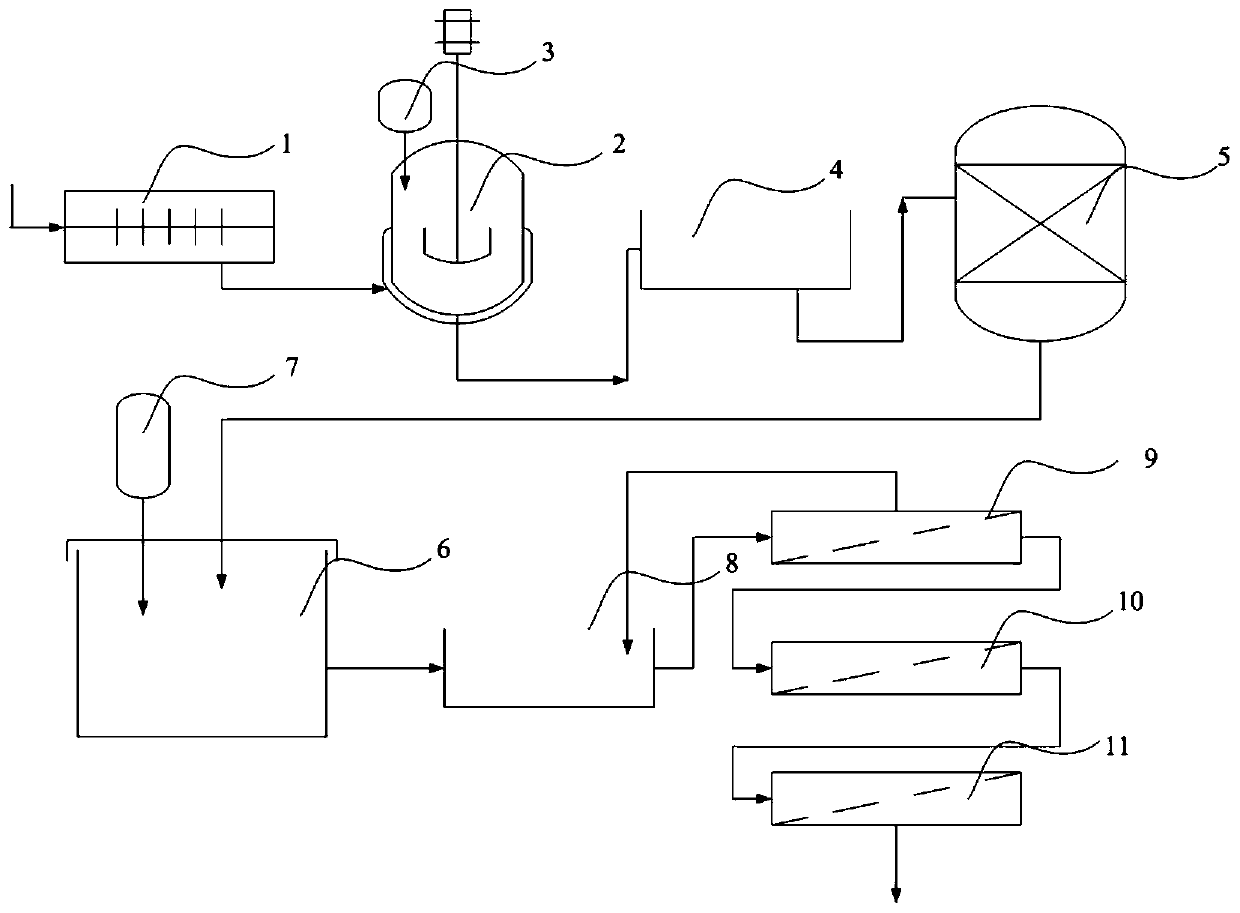

Method for catalytic oxidation and functional modification of hydrogel material

The invention discloses a method for catalytic oxidation and functional modification of a hydrogel material, which is characterized by comprising the following steps: step 1, soaking the hydrogel material in a buffer solution dissolved with a piperidine compound to obtain a mixed system; step 2, adding a laccase solution into the mixed system obtained in the step 1, and then introducing oxygen forcatalytic oxidation to obtain an oxidized hydrogel material; and 3, soaking the hydrogel material oxidized in the step 2 in a hyaluronic acid-adipic dihydrazide solution, and carrying out functionalmodification under a stirring condition to obtain the modified hydrogel material. The method has the advantages that the process is controllable, the water-soluble polymer range is wide, experimentalreagents are easy to obtain, large experimental equipment is not needed, and the reaction is carried out under the conditions of normal temperature and normal pressure. The modified hydrogel materialprepared by the method disclosed by the invention has the advantages of high moisture retention, low protein adsorption capacity, unchanged appearance, light permeability and refractive index and thelike.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Zero-discharge treatment process and device for oily emulsion wastewater

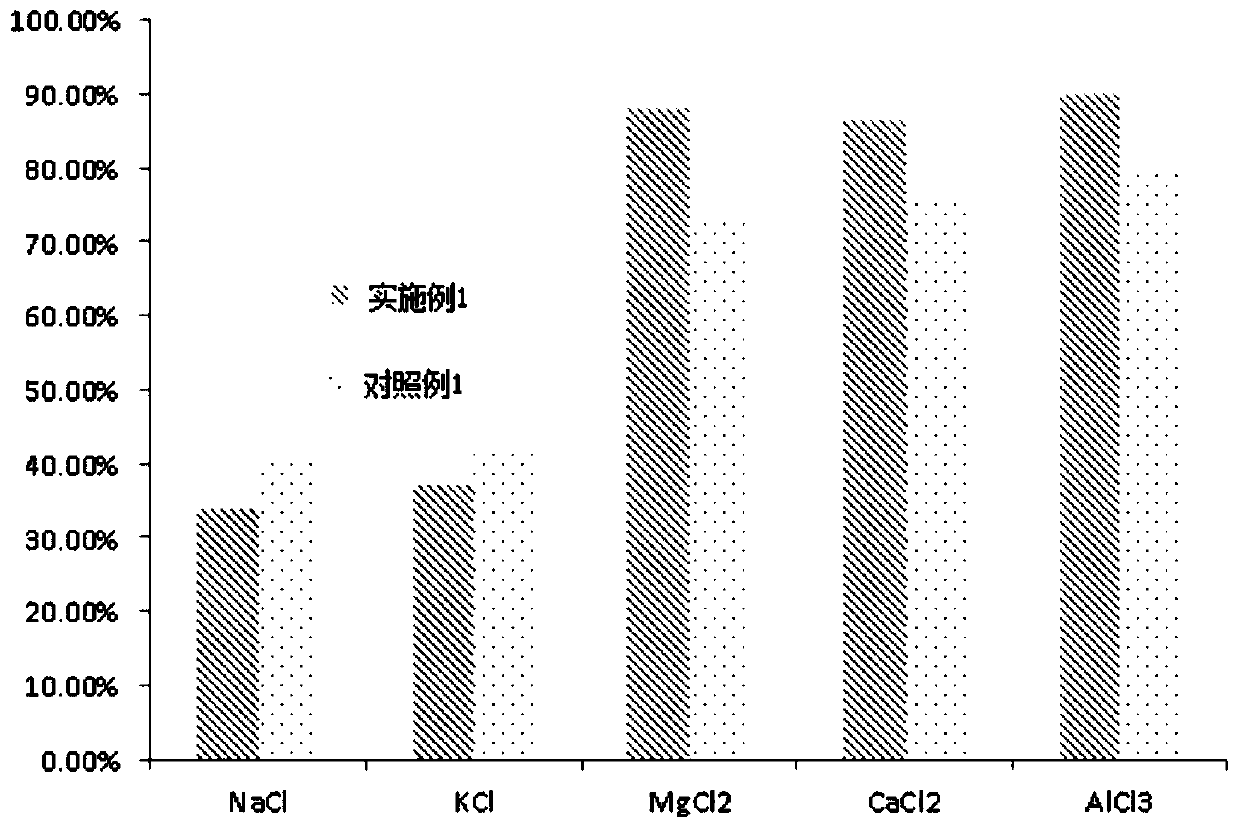

ActiveCN111056664AEffective demulsification treatmentTo achieve the goal of zero discharge treatmentWaste water treatment from quariesFatty/oily/floating substances removal devicesInorganic saltsDemulsifier

The invention relates to a zero-discharge treatment process and a zero-discharge treatment device for oily emulsion wastewater, and belongs to the technical field of water treatment. According to themethod, a demulsifier based on a starch material is adopted, on one hand, a demulsification treatment can be effectively conducted on crude oil production emulsion wastewater, on the other hand, biodegradation and oxidative degradation of the demulsifier are easy, after a subsequent treatment, the difficulty of subsequent deep treatment is reduced, and the purpose of zero-discharge treatment of the crude oil production emulsion wastewater is achieved. According to the method, the influence of the existence of inorganic salts in the crude oil production emulsion on the demulsification process is considered, adsorption of Al<3+>, Ca<2+>, Mg<2+> and other ions is achieved through a modification treatment of melamine, and the demulsification effect is improved through enrichment of the inorganic salt ions.

Owner:济南灵秀环保科技有限公司

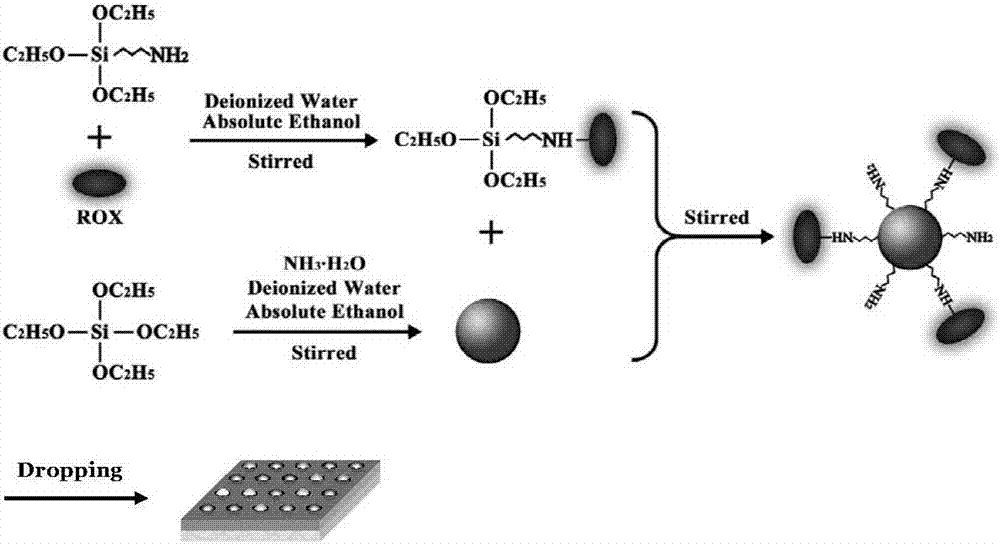

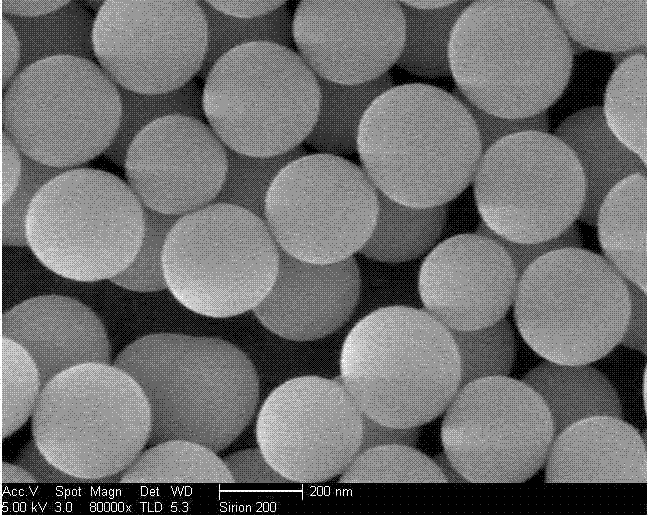

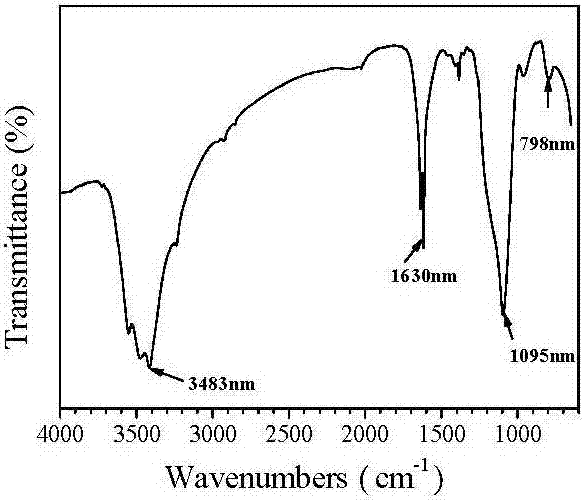

Method for preparing SiO2@ROX nanoparticle fluorescent probe array for detecting malachite green

ActiveCN107421938AMild conditionsHigh fluorescence intensityFluorescence/phosphorescenceMalachite greenMalachite green stain

The invention discloses a method for preparing a SiO2@ROX nanoparticle fluorescent probe array for detecting malachite green. The method comprises the following steps: coupling APTS (3-Amimopropyl Triethoxysilane) and an organic dye ROX (5-Carboxy-X-Rhodamine N-Succinimidyl Ester), and dehydrating with TEOS (Tetraethylorthosilicate) under an alkali condition to synthesize SiO2@ROX nanoparticles of surface functionalized modified aminopropyl; and preparing the SiO2@ROX nanoparticle fluorescent probe array on an etched silicon wafer. The method comprises the following three steps: firstly, preparing an ROX-APTS precursor in an ethanol system, performing functionalized modification on aminopropyl and an ROX dye onto the surfaces of SiO2 nanoparticles by using a sol-gel method, and finally dropping a SiO2@ROX nanoparticle fluorescent probe onto a silicon wafer etched with micro-pores, and removing excessive particles on the surface, thereby obtaining the SiO2@ROX nanoparticle fluorescent probe array which is large in specific surface area, rich in recognition site and good in sensitivity for selective recognition and trace detection on a target analyte, namely malachite green.

Owner:HEFEI UNIV +1

Chitosan modified nylon fabric and manufacturing method thereof

The invention discloses a chitosan modified nylon fabric, which is grafted with 0.1 to 0.2 mass percent of chitosan. The invention also discloses the manufacturing method of the fabric, which comprises: (1) weighing nylon fabric and immersing the nylon fabric in nylon oxidant aqueous solution, heating in a water bath according to a bath ratio ranging from 1:10 to 1:40, and stirring; (2) dissolving the chitosan in 1 to 6 percent of glacial acetic acid, stirring to dissolve the glacial acetic acid to form saturated solution of the glacial acetic acid; (3) weighing chitosan oxidant and adding the chitosan oxidant into the saturated solution of the chitosan prepared in the step (2), stirring uniformly and heating in a water bath; (4) adding the chitosan mixed solution obtained by the step (3)into the nylon oxidant aqueous solution in which the nylon fabric is immersed, heating in a water bath and stirring, wherein the added volume of the chitosan mixed solution is 0.5 to 3 times that of nylon oxidant aqueous solution; and (5) taking finished nylon fabric, washing with a soap, and drying in the air. The modified nylon fabric is smoother and has the effects of inhibiting bacteria, resisting static electricity and the like. The method discloses by the invention is simple, easy to implement and low in cost.

Owner:WUYI UNIV

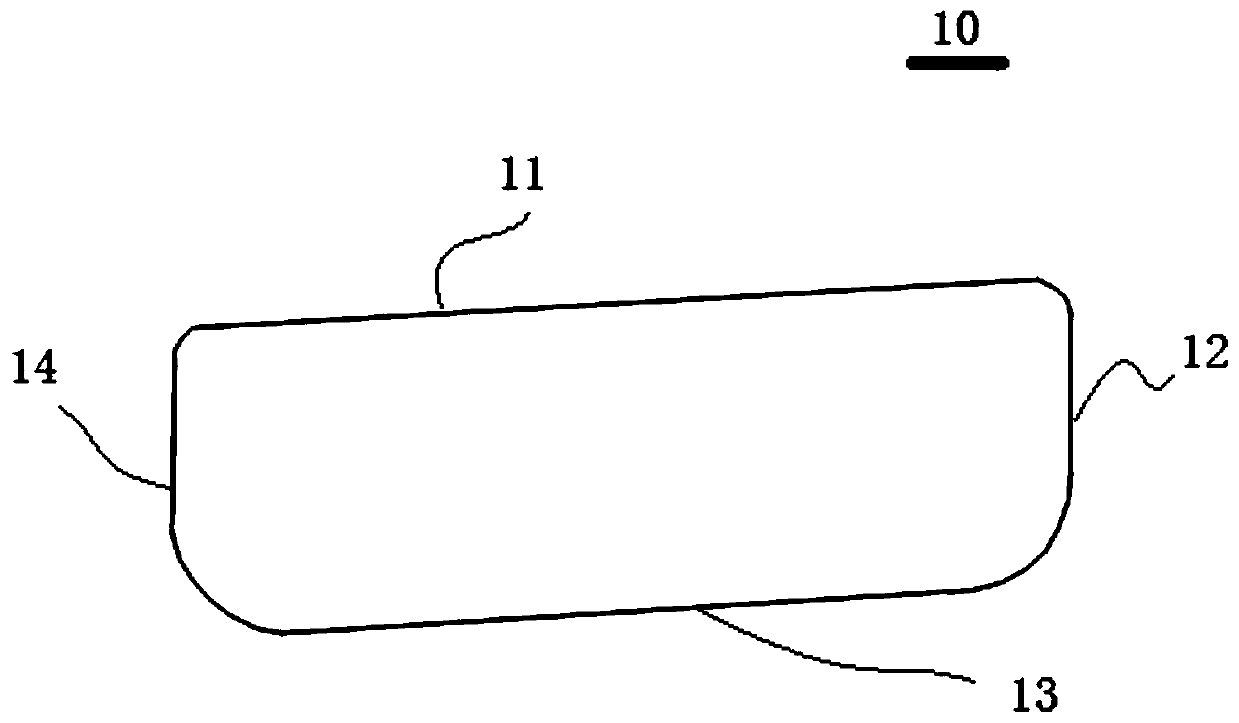

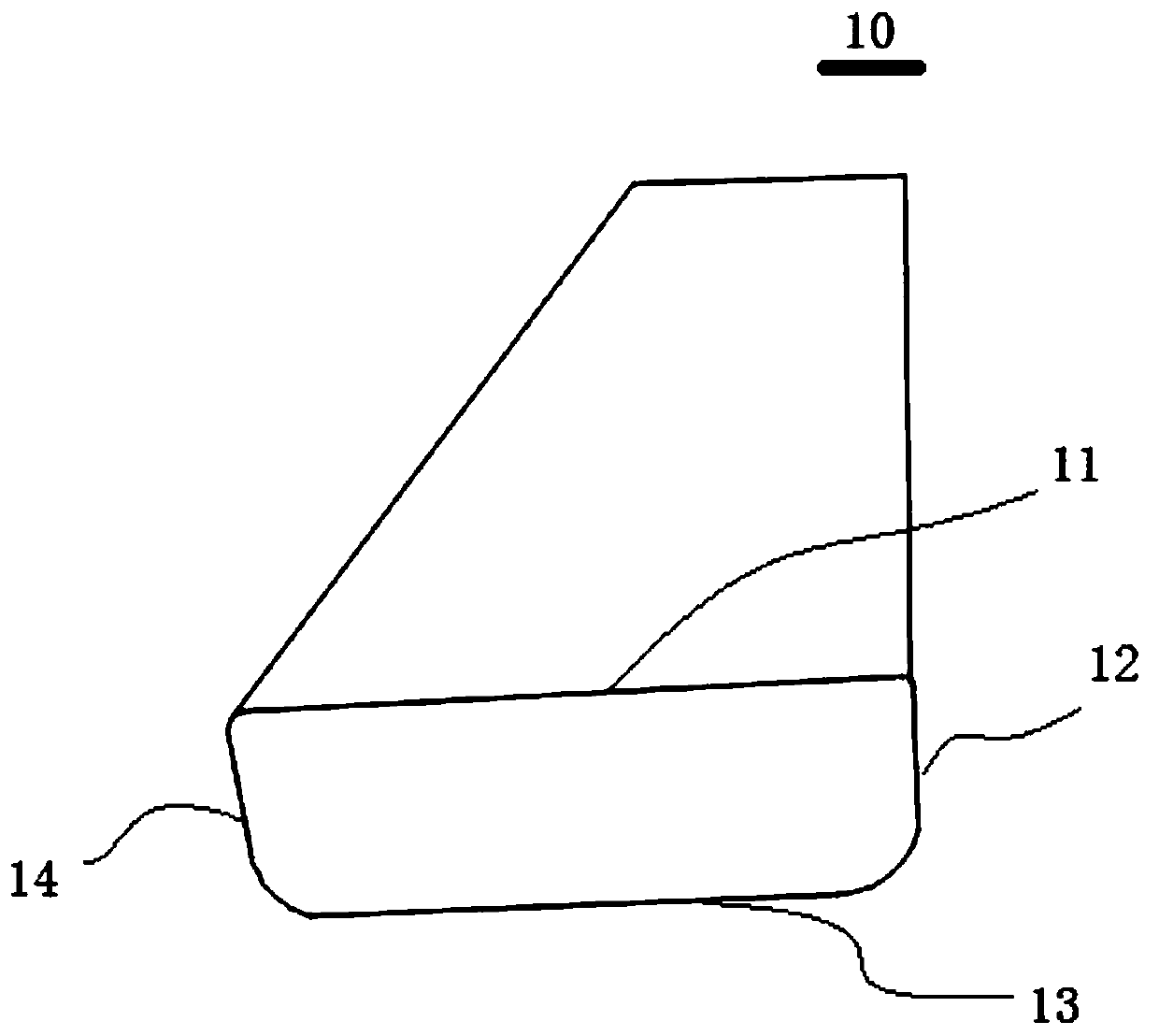

Manufacturing method of N-warping-degree false eyelashes, manufacturing tool and N-warping-degree false eyelashes

PendingCN110432574ANatural and beautiful shapeMeet needsHair accessoriesToupeesEngineeringTechnician

The invention discloses a manufacturing method of N-warping-degree false eyelashes, a manufacturing tool and the N-warping-degree false eyelashes, and relates to the field of false eyelash manufacturing. The manufacturing tool comprises a forming tool; the forming tool is a flat strip body; and the cross section of the forming tool is composed of an upper side line, a right side line, a lower sideline and a left line. An included angle formed by the upper side line and the right side line, and an included angle formed by the upper side line and the left side line are both inverted small arcs;and an included angle formed by the lower side line and the right side line, and an included angle formed by the lower side line and the left side line are both inverted large arcs. An area where thelower side line and the right side line are located, and an area where the lower side line and the left side line are located are both working faces and are used for being in contact with the false eyelashes, and the false eyelashes are attached to the working faces so as to form N warping degree. By using the method and the tool disclosed by the invention, the N-warping-degree false eyelashes can be manufactured. Due to the fact that the shape of the N-warping-degree false eyelashes is more natural and attractive, the market demand is high. For customers, an ideal effect can be achieved, andthe requirements of the customers can be met. For eyelash technicians, the N-warping-degree false eyelashes can be more easily grafted.

Owner:SHANGHAI XIJIAN ELECTRONICS SCI & TECH CO LTD

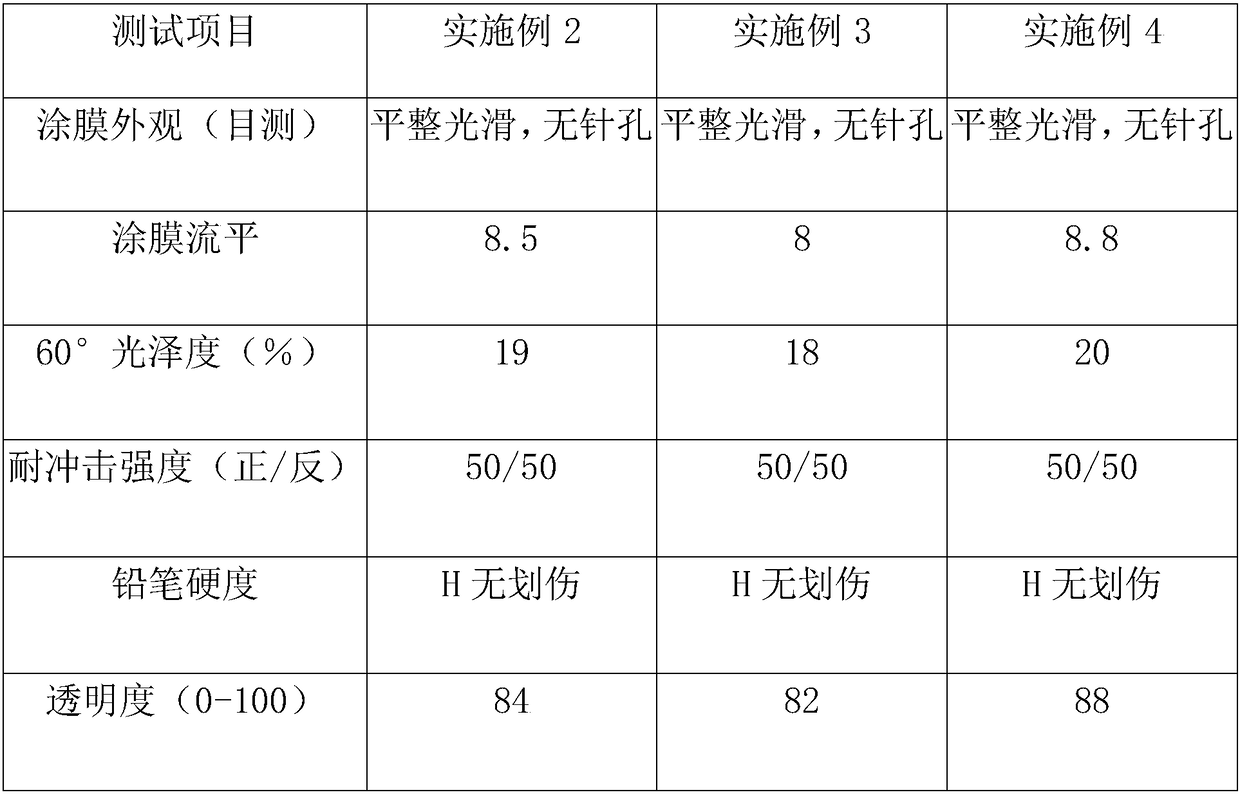

Water-based paint for metal color plate surface and preparation method of water-based paint

ActiveCN108384453AAvoid yellowingImprove high temperature resistanceEpoxy resin coatingsPolyester coatingsWater basedExcited state

The invention discloses water-based paint for a metal color plate surface and a preparation method of the water-based paint. The paint is prepared from the following raw materials by weight percent: 50 to 70 percent of modified organic silicon resin, 5 to 10 percent of epoxy resin, 5 to 10 percent of alkyd resin, 3 to 8 percent of aliphatic diisocyanate, 2 to 5 percent of isooctyl p-methoxycinnamate, 5 to 10 percent of mica powder, 0.5 to 2 percent of antioxidant, 2 to 4 percent of film forming additive, 0.5 to 1.2 percent of zinc stearate, and 10 to 15 percent of glycerol. The method is convenient in operation and suitable for commercialized production; the prepared light stable modifier contains two piperidine rings, the energy of the prepared light stable modifier for capturing the freeradicals and transferring the excited-state molecules is higher than that of the ordinary light stabilizer; and the prepared light stable modifier is easy to graft the organic silicone resin and canbe polymerized to generate the stable modified organic silicon resin, no additional light stabilizer is needed, and the non-uniform phenomenon of the paint is avoided.

Owner:深圳雅联新材料有限公司

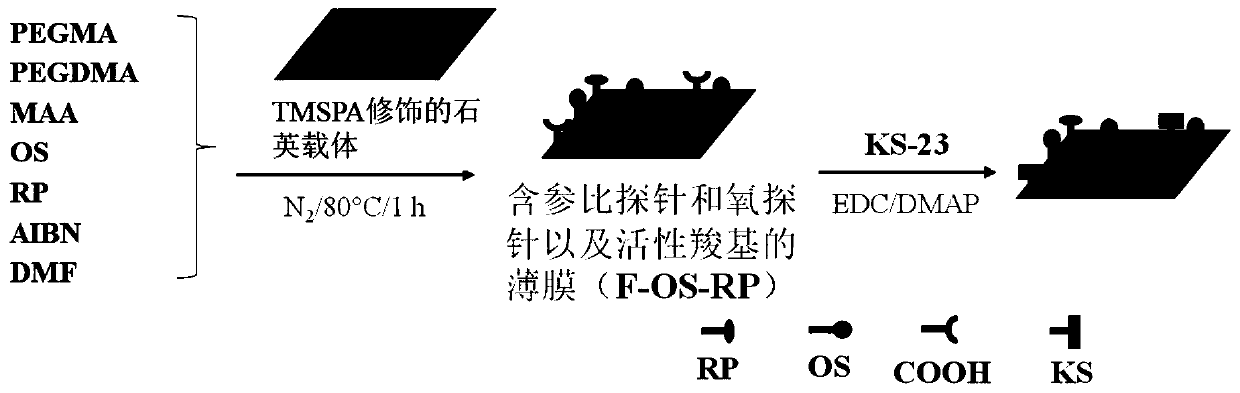

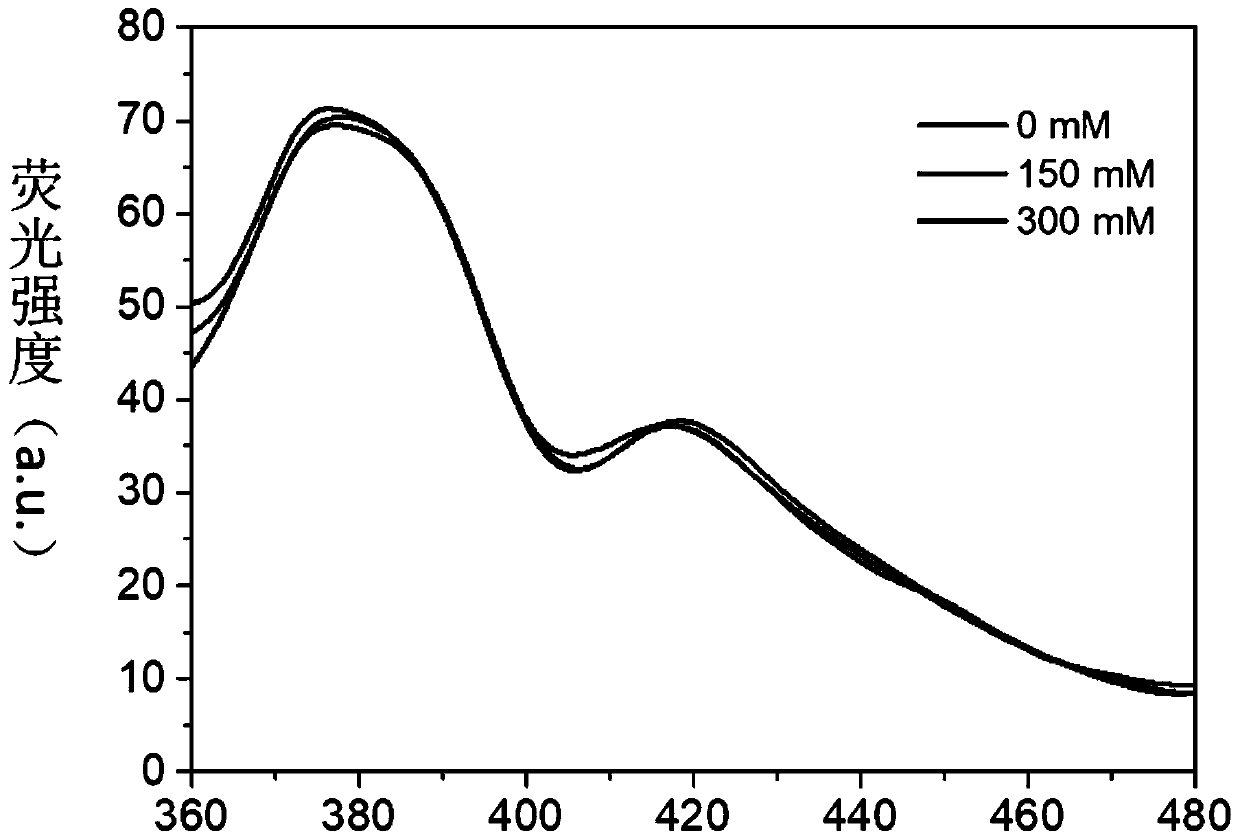

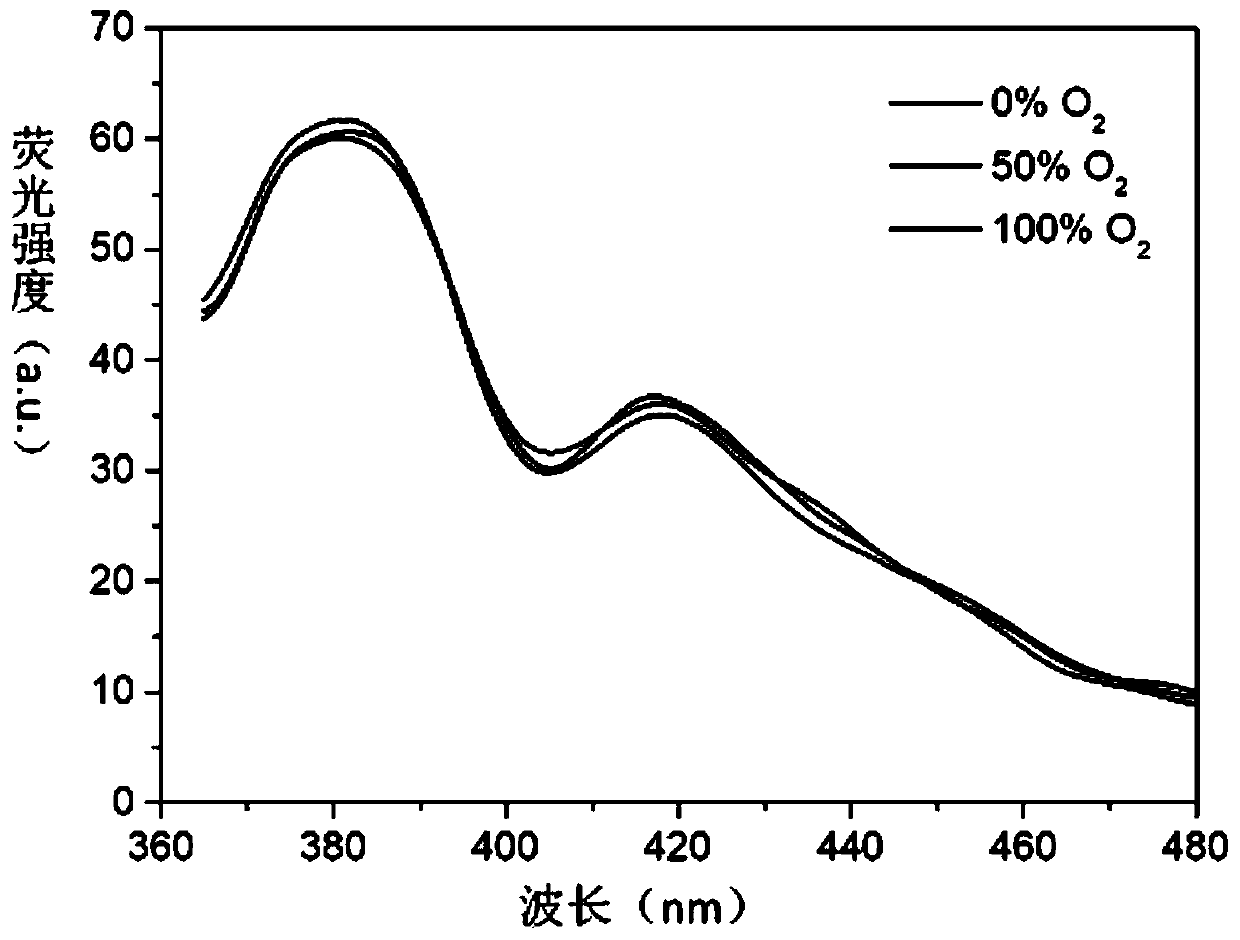

Potassium ion probe, preparation method and applications thereof

ActiveCN110437268AImplement multiple responsesEasy to graftGroup 3/13 element organic compoundsFluorescence/phosphorescenceFluorescencePhysical chemistry

The invention relates to a potassium ion probe, a preparation method and applications thereof, wherein the potassium ion probe has high selectivity to potassium ions, can emit green fluorescence and detect K<+> concentration, contains hydroxyl so as to be easily grafted on a carrier, and can be co-grafted on a carrier with other types of probes so as to achieve multiple responses of the same sensing film. The present invention further provides a potassium ion and dissolved oxygen dual function sensing film, which comprises a carrier, the potassium ion probe, an oxy gen probe and a reference probe, wherein the potassium ion probe, the oxy gen probe and the reference probe are fixed on the surface of the carrier through chemical bonding, the film has red, green and blue three-color fluorescence, the three fluorescent colors do not interfere with each other, the potassium ion and the dissolved oxygen can be precisely and simultaneously measured by using a fluorescence colorimetric method,and the film has high stability.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Crosslinking kinetic energy based high polymer, and preparation method

Owner:GUANGXI UNIV FOR NATITIES

Preparation method of fluorescence sensor for performing high sensitivity detection on Hg(II) in water body

InactiveCN103364376AHigh fluorescence responsivenessEasy to combineFluorescence/phosphorescenceSilicon oxideNitrogen gas

The invention discloses a preparation method of a fluorescence sensor for performing high sensitivity detection on Hg (II) in a water body. The method comprises the following steps of: preparing a porous silicon coating layer with a divergent perforated structure on the surface of a template made from silicon oxide nanoparticles; and assembling fluorescent probe molecules to pore passages of surface porous silicon in a high density mode by means of sol-gel reaction. The preparation process of the fluorescence sensor comprises the following steps of: synthesizing a porous silicon layer with a surface porous structure on the surface of the silicon oxide nanoparticles; performing silanization on synthesized rhodamine 6G derivatives by the fluorescent probe molecules; assembling the fluorescent probe molecules to the pore passages of prepared surface porous silicon in a high density mode by means of silanization reaction in a methanol solution; and centrifuging, washing and drying an obtained solid material to obtain the Hg (II) fluorescence sensor with high specific surface area and high sensitivity.

Owner:傅绪成

Porous active polyethylene fiber as well as preparation method and application thereof

PendingCN112725919AEasy to dyeEasy dippingSpinning solution de-aeratingSpinnerette packsPolymer scienceSpinning

The invention discloses a porous active polyethylene fiber as well as a preparation method and application thereof, and belongs to the technical field of textiles. The monofilament diameter of the porous active polyethylene fiber is 20 mu m to 100 mu m, and the surface of the porous active polyethylene fiber is provided with a micropore structure. The preparation method of the porous active polyethylene fiber comprises the following steps of melting polyethylene resin to obtain a spinning melt; metering the spinning melt, and extruding from spinneret orifices to obtain melt trickles; cooling and molding the melt trickles to obtain solid filaments; enabling the solid filaments to be subjected to thermal stretching treatment to obtain polyethylene fibers, wherein in any process or after the solid filaments are subjected to thermal stretching to obtain the polyethylene fibers, at least one time of ultrasonic water bath treatment is performed to obtain the porous active polyethylene fibers. The invention also relates to the application of the porous active polyethylene short fibers for dispersion into cement. The polyethylene fiber prepared by the method has a microporous structure on the surface, has relatively high activity, and has the characteristics of easy dyeing, easy gum dipping, easy crosslinking, easy grafting and the like.

Owner:CHINESE TEXTILE ACAD

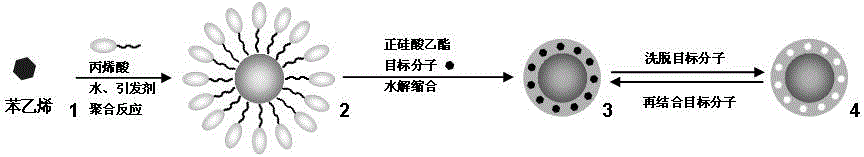

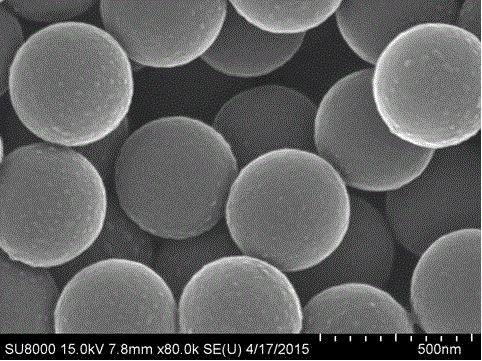

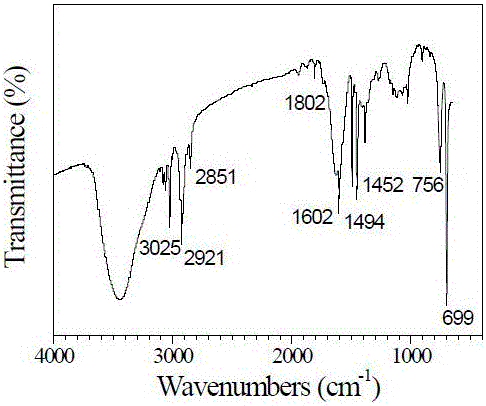

A ps@sio for the detection of paraquat molecules 2 Preparation method of artificial antibody

The invention provides a preparation method of a PS@SiO2 artificial antibody for detecting paraquat molecules. The preparation method is characterized in that mark molecules in a SiO2 shell layer are eluted from the artificial antibody; a hole structure which can be complementary with structures, sizes and functions of the mark molecules is formed in the SiO2 shell layer; the artificial antibody has specific identification sites of target analyte molecules and selective identification and detection can be realized. The preparation method comprises the following two steps: firstly, synthesizing a mono-dispersed PS micro-sphere carrying a carboxyl functional monomer on the surface; then covering one SiO2 shell layer with a controllable shell thickness on the surface of the mono-dispersed PS micro-sphere through the static mutual effect of the carboxyl on the surface and the paraquat molecules; and eluting paraquat to form the artificial antibody for identifying and detecting the paraquat molecules. The nano shell layer has controllable thickness, strong rigidity and large specific surface area; the space for forming the identification sites has a stable structure, a plurality of effective sites and good selectivity, and has high identification efficiency on the target molecules.

Owner:HEFEI UNIV

A kind of modified polypropylene composite fiber and preparation method thereof

The invention relates to the field of materials, in particular to modified polypropylene composite fibers and a preparation method thereof. The preparation method comprises the following steps: carrying out reaction on 1-2wt% of polypropylene fiber aqueous solution, diisocyanate and an oxidizing agent for 50-70 minutes at the temperature of 50-60 DEG C, heating to 90-100 DEG C, and reacting with an initiator for 1-2 hours, so that the modified polypropylene fibers are obtained. A mixed solution of of a graphene oxide aqueous solution and modified polypropylene fibers react for 1-2 hours at thetemperature of 50-60 DEG C, and then washing and drying are carried out. Diisocyanate and the oxidizing agent oxidize the polypropylene fibers, activity of the polypropylene fibers is enhanced, the modified polypropylene fibers are grafted with graphene oxide, and high-activity carbon-oxygen double bonds are connected with hydroxyls and carboxyls on the surface of graphene oxide. When the modified polypropylene composite fibers are doped into a cement-based material, toughness of concrete is improved from macroscopical and microcosmic double levels, and adhesion between the cement and the fibers is also beneficially improved.

Owner:中建西部建设新疆有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com