Water-based paint for metal color plate surface and preparation method of water-based paint

A technology of water-based paint and color steel plate, applied in the direction of polyester paint, epoxy resin paint, coating, etc., can solve the problem of easy aging of metal color steel plate, achieve good photo-oxidative degradation reaction, photo-oxidative degradation reaction inhibition, and easy operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

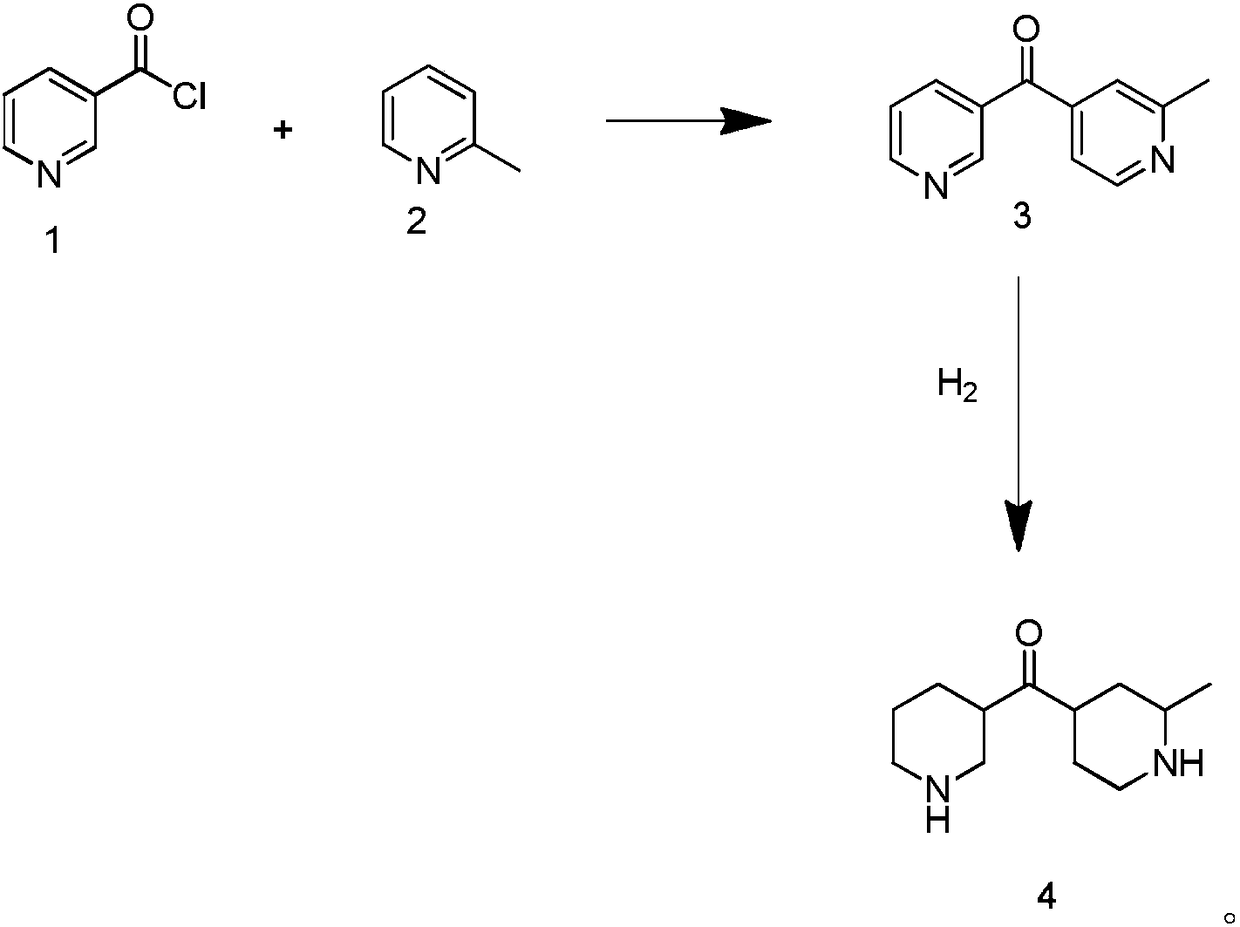

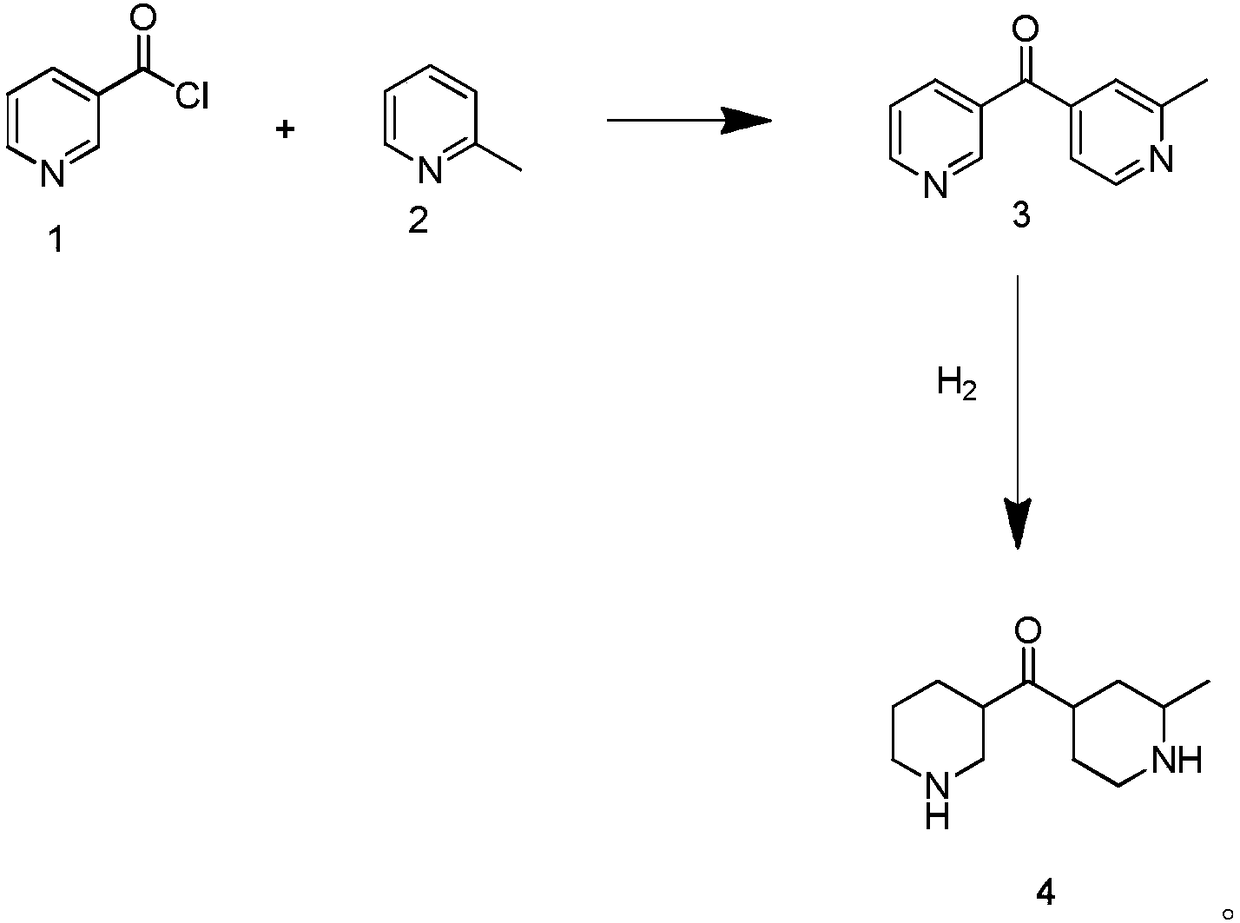

[0025] Preparation of light-stable modifier: 1.5mol 2-picoline 2, 1.15mol boron trifluoride and 5ml of solvent dioxane were sequentially added to the reaction flask, the reaction flask was placed in an ice bath, and slowly stirred while stirring Add 1 mol of 3-acetylpyridine, react for 2 hours, remove the solvent by evaporation under reduced pressure, put the crude product into ethanol for heating and dissolving, then cool to room temperature naturally, then place it in an environment of 6°C and quench to precipitate crystals, filter and depressurize Dry to obtain light yellow crystal intermediate 3, put intermediate 3 and catalyst nickel into the autoclave, feed hydrogen gas when heated to 66°C, continue to heat to 185°C, stop hydrogen flow after hydrogen pressure is 10MPa , heat preservation reaction 1h, filter the reaction solution, take the filtrate and carry out vacuum fractionation, collect the distillate to obtain the light stabilizer 4; the reaction formula is as follow...

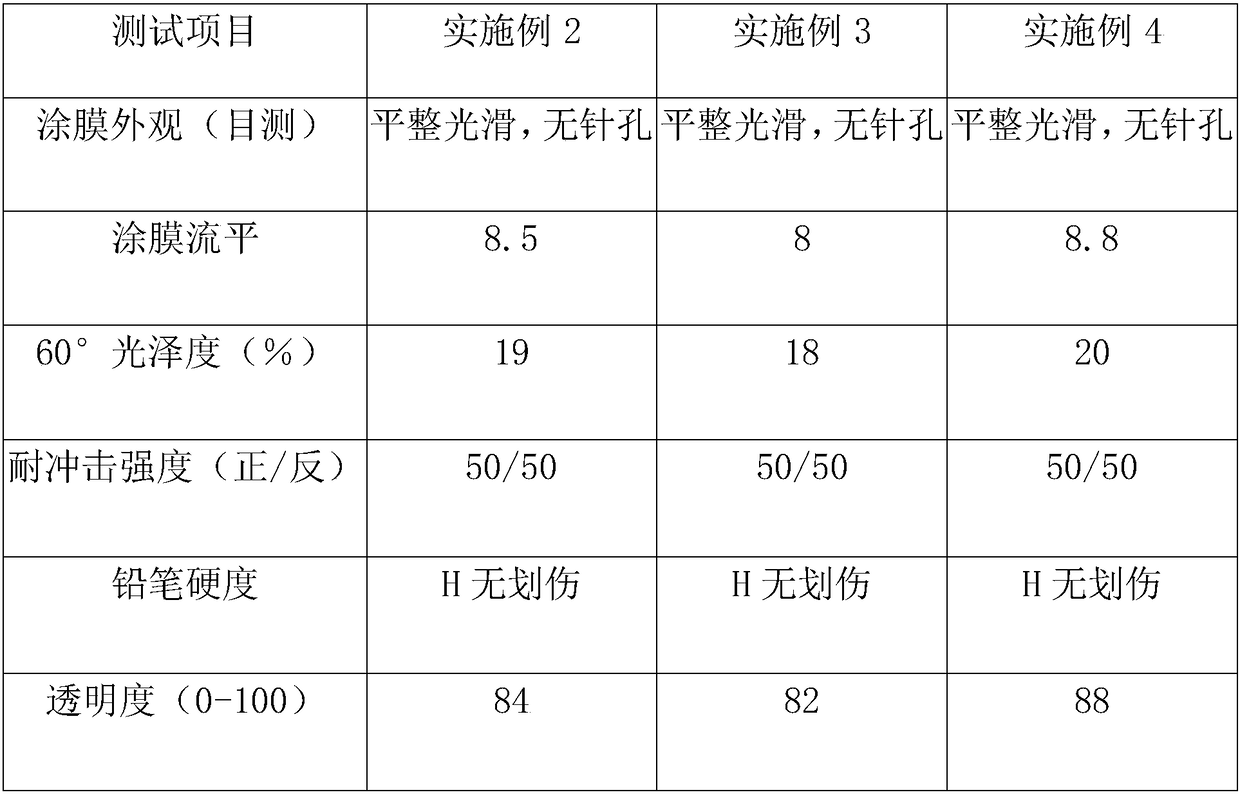

Embodiment 2

[0028] A kind of preparation that is used for the water-based coating on the surface of metal color steel plate, specifically comprises the following steps:

[0029] S1, preparation of modified silicone resin

[0030] Put 50g of phenylsiloxane monomer and 30g of dimethylsiloxane monomer of silicone resin into a mixer for pre-mixing to obtain a mixture of silicone resin monomers; add polymerization solvent xylene into the reaction kettle , heated to 120g°C, and kept at this temperature, slowly added the silicone resin monomer mixture into the reaction kettle, kept at reflux for 2 hours, then added 10g of polyimide and 1.6g of diisopropyl peroxydicarbonate, and raised the temperature to 220g°C After heat preservation modification reaction for 1h, then lower the temperature to 140°C, add 10g of light-stable modifier and 2.4g of titanate coupling agent, heat preservation for secondary modification reaction for 40min, after the reaction, remove the polymerization solvent xylene, th...

Embodiment 3

[0033] A kind of preparation that is used for the water-based coating on the surface of metal color steel plate, specifically comprises the following steps:

[0034] S1, preparation of modified silicone resin

[0035] Put 60g of phenylsiloxane monomer and 27g of dimethylsiloxane monomer of silicone resin into a mixer for pre-mixing to obtain a mixture of silicone resin monomers; add polymerization solvent xylene into the reaction kettle , heated to 130°C, and kept at this temperature, slowly added the silicone resin monomer mixture into the reactor, kept at reflux for 2 hours, then added 8g of polyimide and 2.2g of diisopropyl peroxydicarbonate, and raised the temperature to 235°C After heat preservation modification reaction for 1h, then lower the temperature to 150°C, add 5g of light-stable modifier and 4.6g of titanate coupling agent, heat preservation for secondary modification reaction for 60min, after the reaction, remove the polymerization solvent xylene, the material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com