Methyltin maleate and preparation method thereof

A technology of dimethyl tin maleate and methyl tin maleate, which is applied in the direction of tin organic compounds, can solve the problems of expensive raw materials, high production costs, complex production processes, etc., and achieve good product quality and low production costs , producing easily controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

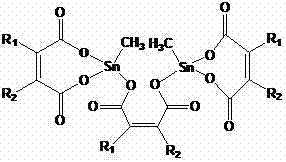

Image

Examples

Embodiment 1

[0024] The preparation method of dimethyl tin maleate: add 165 g of dimethyl tin oxide and 300 g of water to a three-necked flask with stirring, stir until there is no lumpy solid suspension, raise the temperature to 30°C, and slowly add maleic anhydride ( Maleic anhydride) 101g, the reaction time is 6 hours, the reaction temperature is controlled at 30°C, the acid value is measured, and the test is performed every one hour. When the acid value is constant, the result is 17.6 mgKOH / g, and the reaction solution is pumped After filtration, the filter cake was dehydrated under a vacuum of 1.0 KPa until the water content was less than 0.3%, and 259.0 g of a white solid product was obtained, the tin content was 44.6%, and the yield was 98.6%.

Embodiment 2

[0026] The preparation method of monomethyltin maleate: Add 158g of monomethyltin oxide and 300g of water into a three-necked flask with stirring, stir until there is no lumpy solid suspension, heat up to 30°C, and slowly add maleic anhydride ( Maleic anhydride) 152g, the reaction time is 6 hours, the reaction temperature is controlled at 30°C, the acid value is measured, and the test is performed every one hour. When the acid value is constant, the result is 27.6 mgKOH / g, and the reaction solution is pumped After filtration, the filter cake was dehydrated under a vacuum of 1.0 KPa until the water content was less than 0.3%, and 299.5 g of a white solid product was obtained, the tin content was 38.6%, and the yield was 98.2%.

Embodiment 3

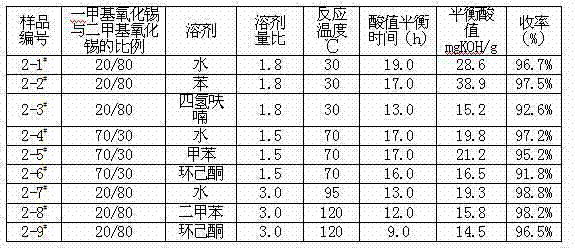

[0028] The preparation method of monomethyl tin maleate and dimethyl tin maleate mixture: add the mixture 165g of monomethyl tin oxide and dimethyl tin oxide in the there-necked flask with stirring, wherein the monomethyl tin oxide The content is 20%, the content of dimethyl tin oxide is 80%, stir until there is no lumpy solid suspension, heat up to 30°C, slowly add 111g of maleic anhydride, the reaction time is 6 hours, and the reaction temperature is controlled at 30 ℃, start to measure the acid value, test once every hour, wait for the acid value to be constant, the result is 16.8 mgKOH / g, filter the reaction solution with suction, and dehydrate the filter cake at 1.0KPa in a vacuum at 80 ℃ until the water content is less than 0.3% , 266.8 g of white solid product was obtained, the tin content was 39.8%, and the yield was 98.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com