Patents

Literature

202results about "Bookbinding cases" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

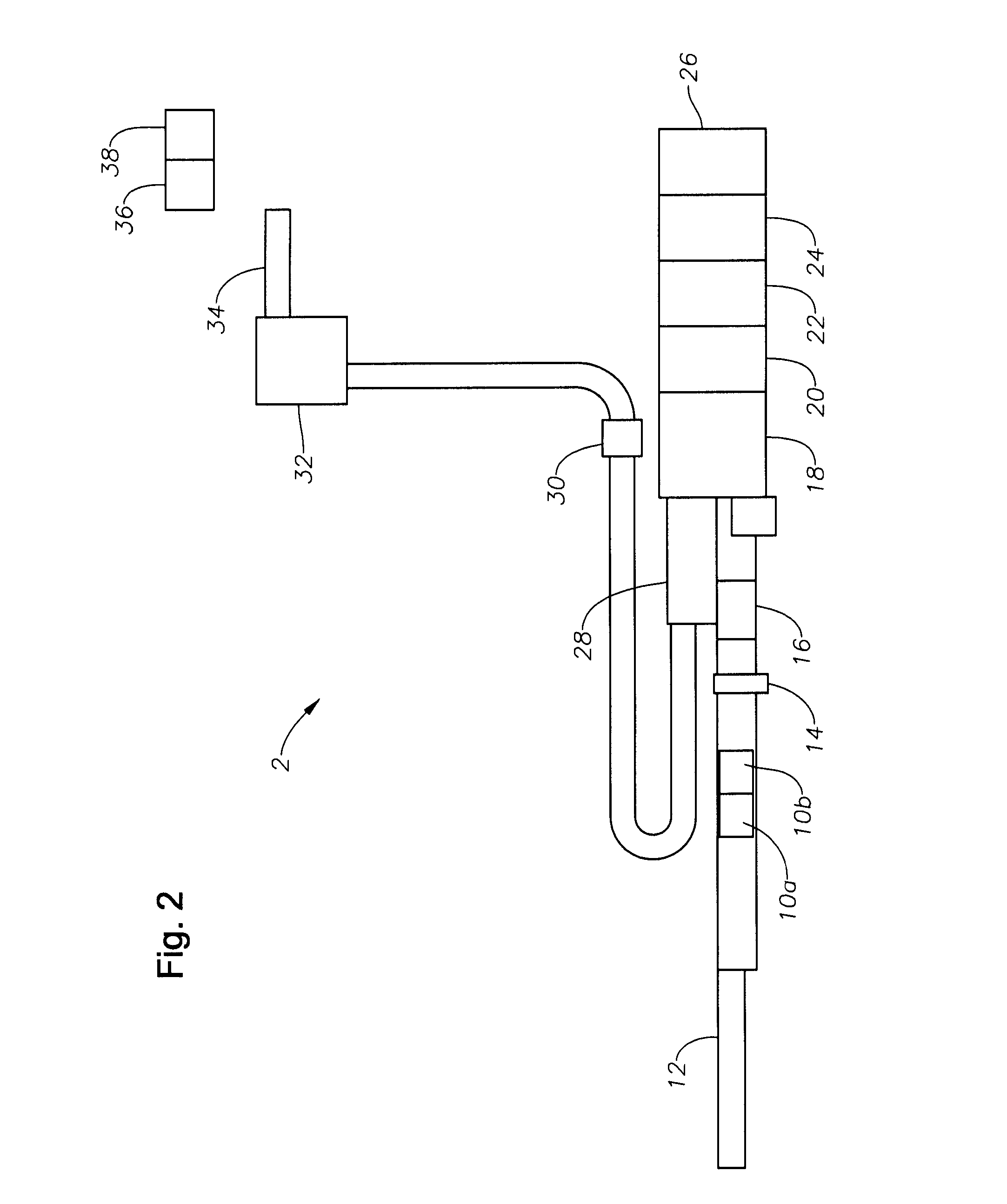

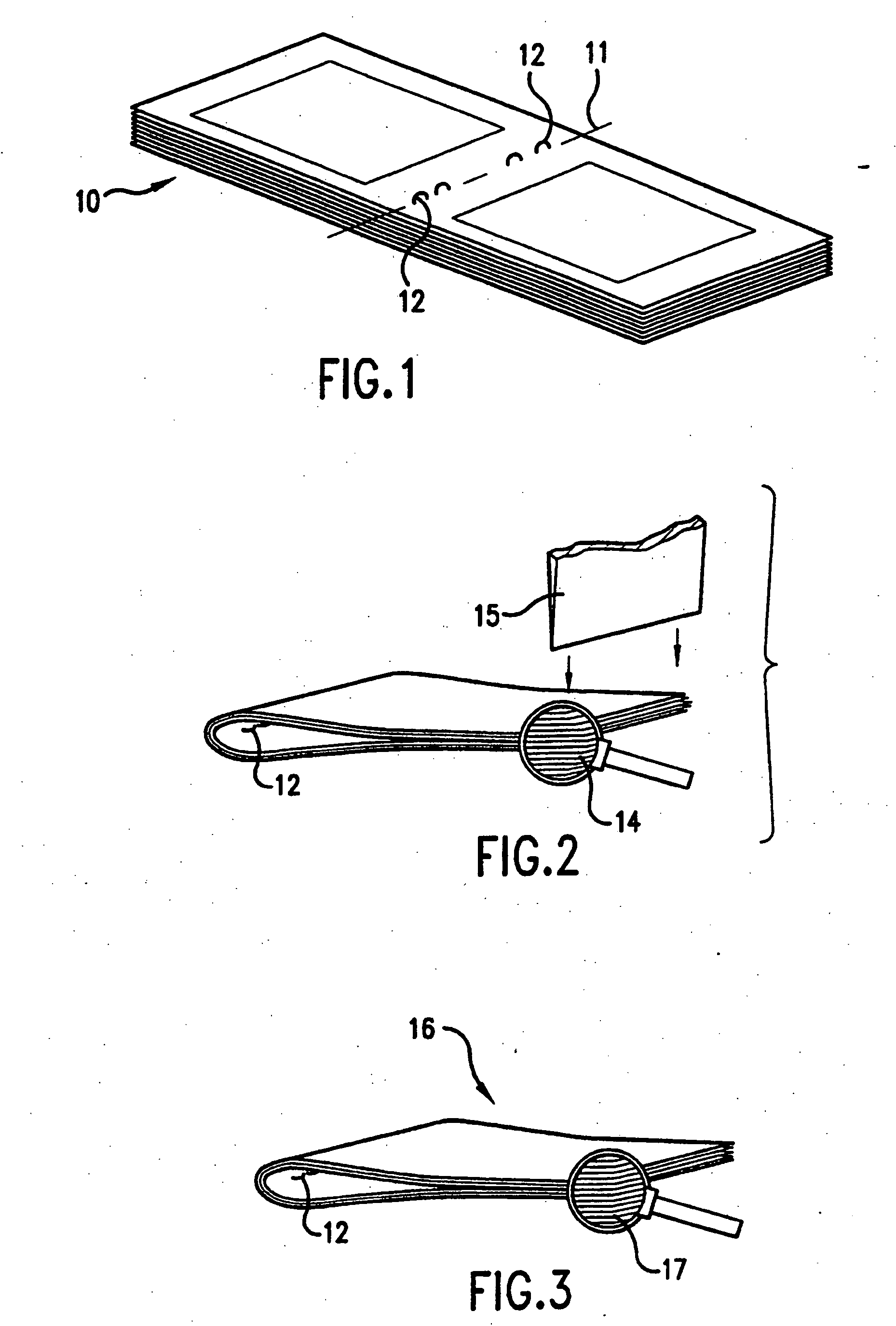

Booklet maker

A low cost, high speed, high resolution laser printer method and apparatus for re-writable media is presented. A method for finishing of printed sheets into booklets is described. Novel mechanical operations permit the manufacture of a very low-cost, off-line booklet maker for use with desktop laser and ink jet printers. The technology can scale to medium-speed, in-line booklet manufacture. The method is novel because most of the finishing operations are performed on a sheet-by-sheet basis using precision paper positioning and a transverse tool carrier that cuts, scores, folds, punches, and staples the sheets. To form a finished saddle-stitched booklet, each sheet is cut to length determined by its sequence in the booklet and paper thickness, scored, punched (if required), folded, accumulated in a stack, and stapled. The sheet-wise method allows finishing operations to be done with low-cost tools and low actuation forces.

Owner:HEWLETT PACKARD DEV CO LP

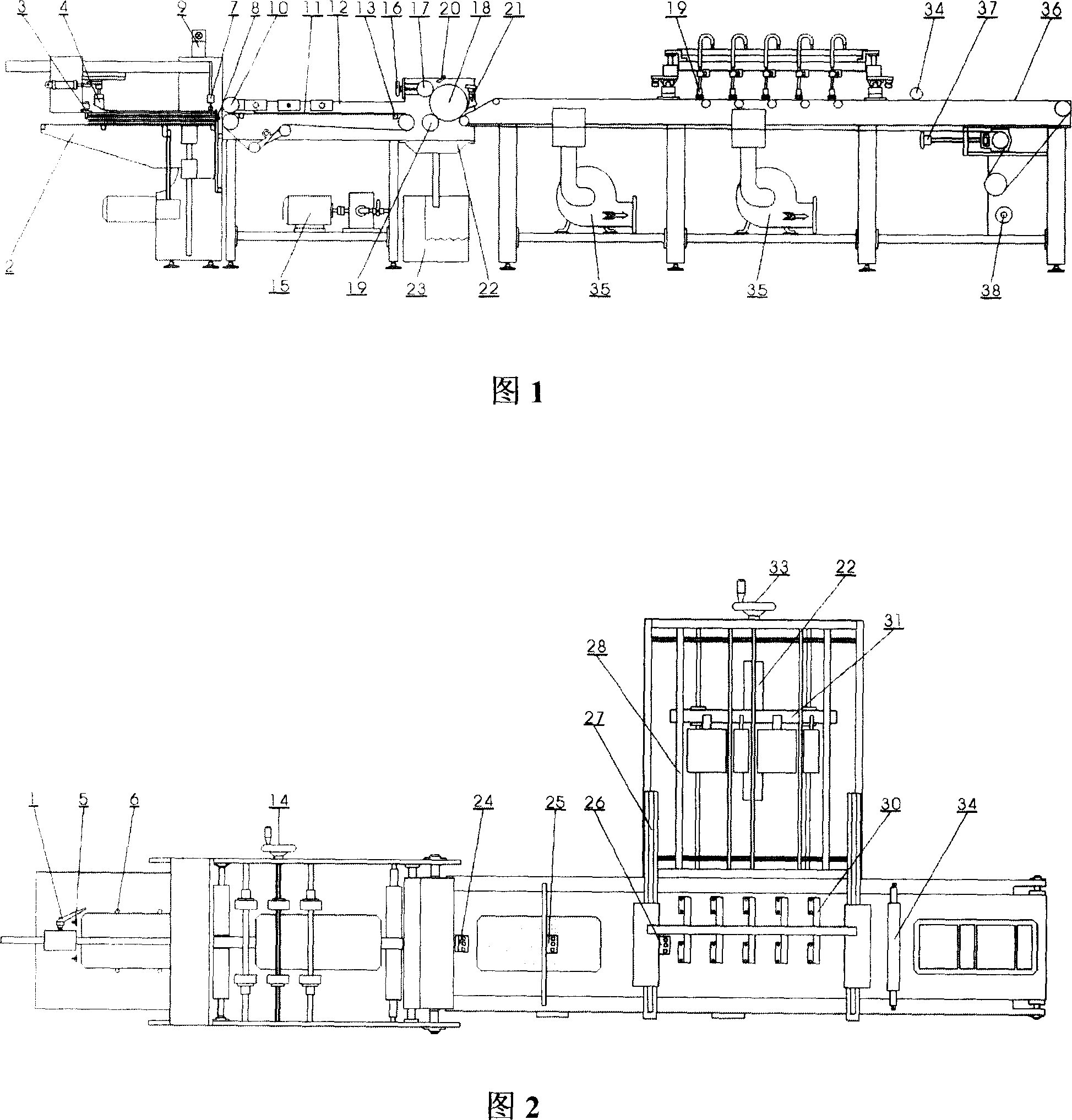

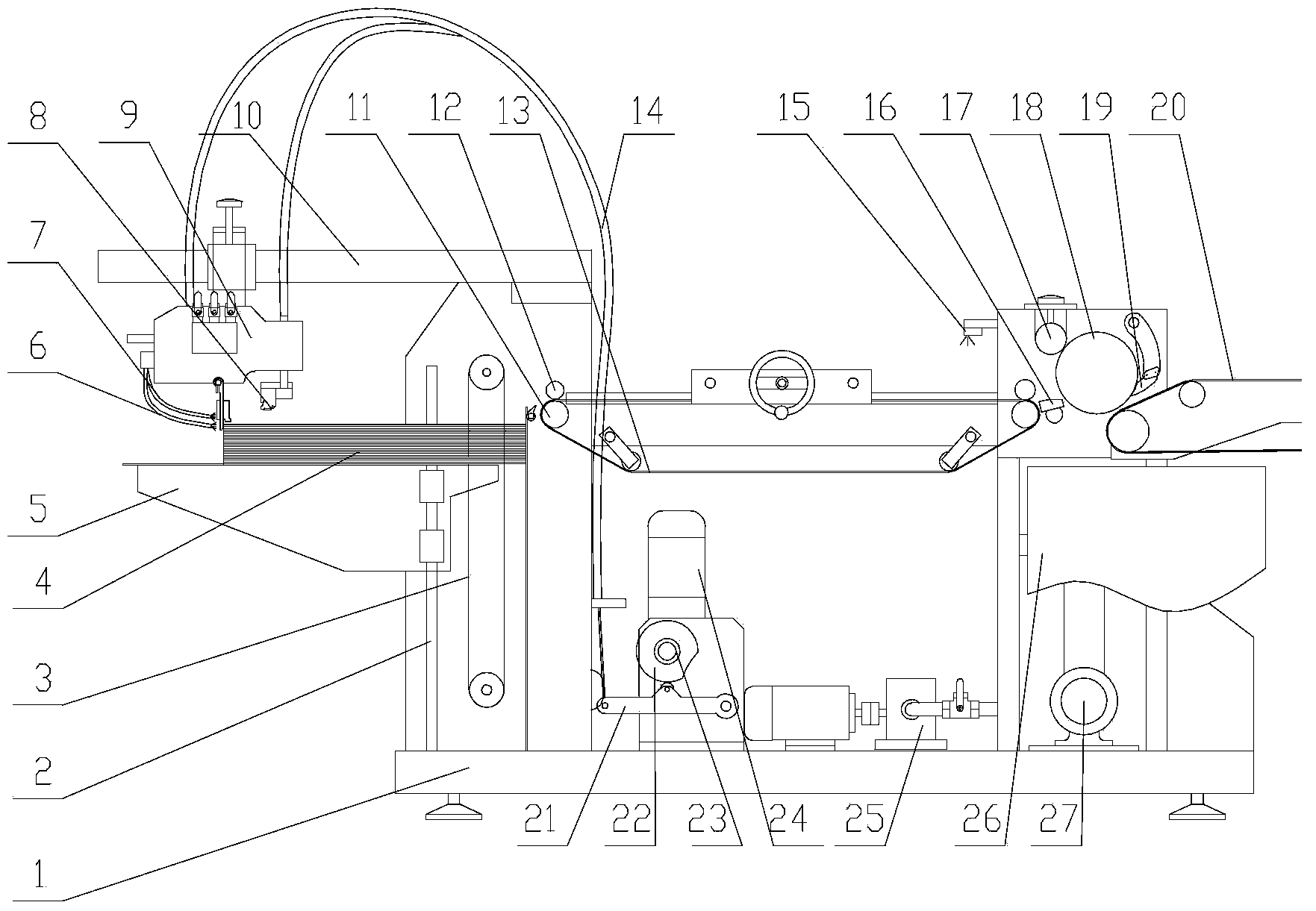

Full-automatic cover making machine

ActiveCN101108565AFast and stable transmissionFacilitates error-free operationBookbinding casesCardboardPulp and paper industry

The invention relates to a paper product cementing, paper board positioning and crimping machine equipment, which is used to produce deluxe binding book cover, calendar, wall calendar, book-shape box, folder and son. The full auto covering machine is composed of a Feida rear push paper feeding structure and the cementing structure and paper board feeding table, the folder part comprises a folder structure and a transmission structure, the structure has simple, reasonable and design, the opened design structure is convenient for the no-error operation; the paper board transmission is quick and stable, the positioning is accurate and reliable, which reduces the waste rate of the product.

Owner:WENZHOU ZHENGRUN MACHINERY

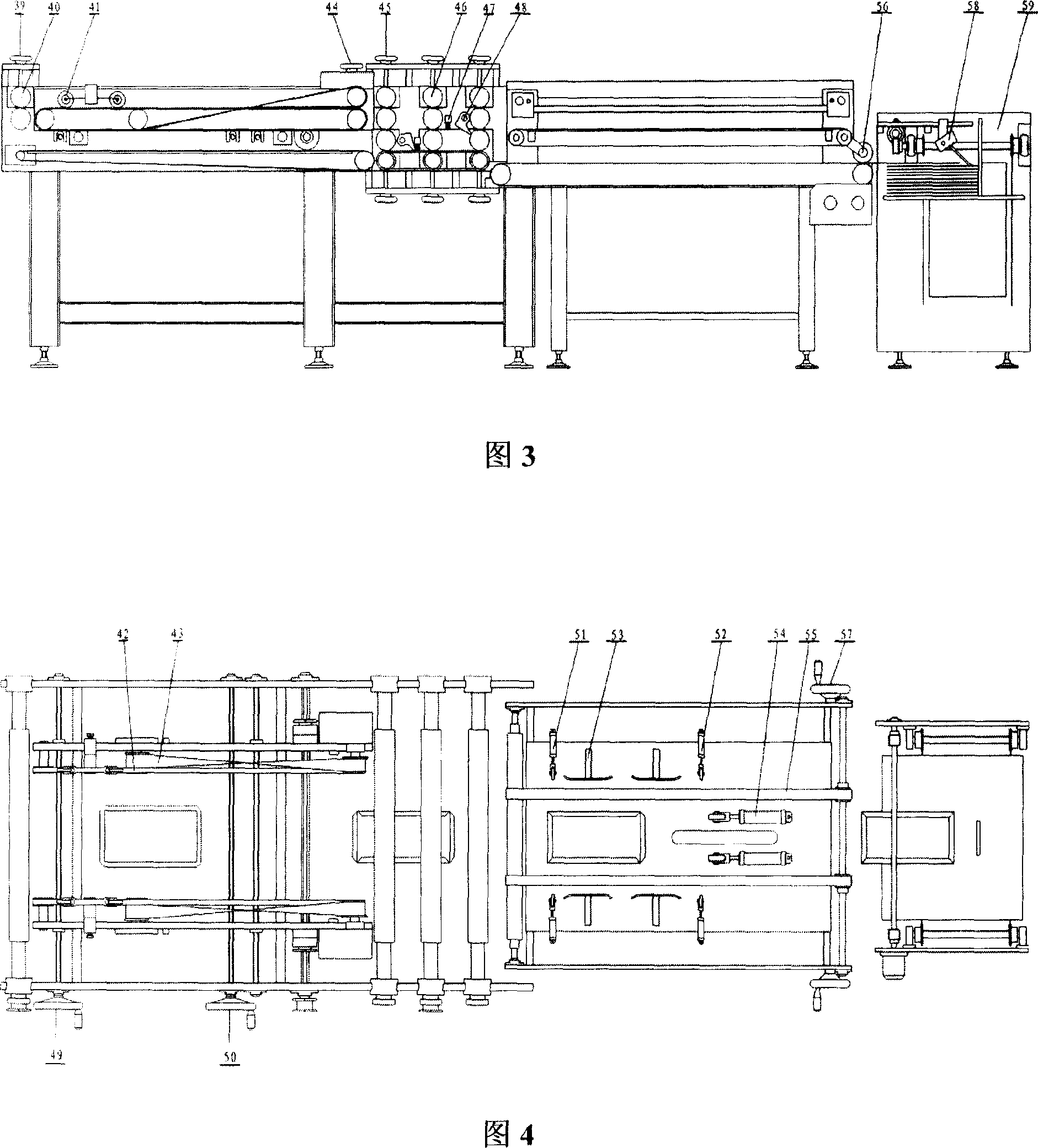

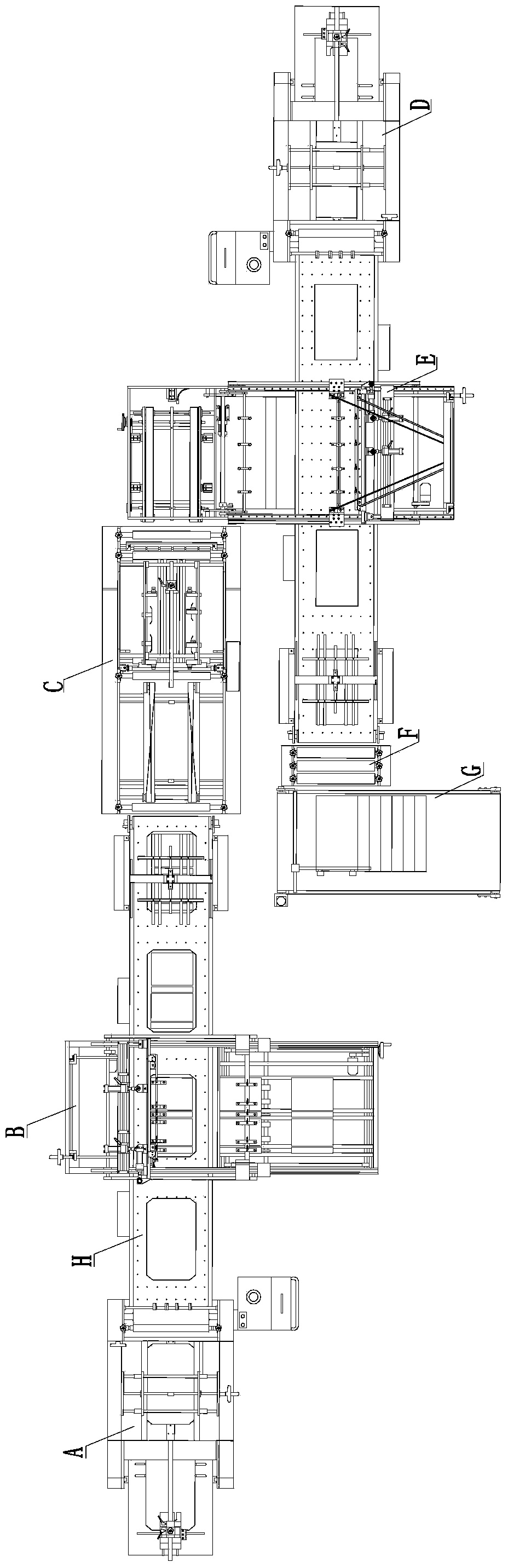

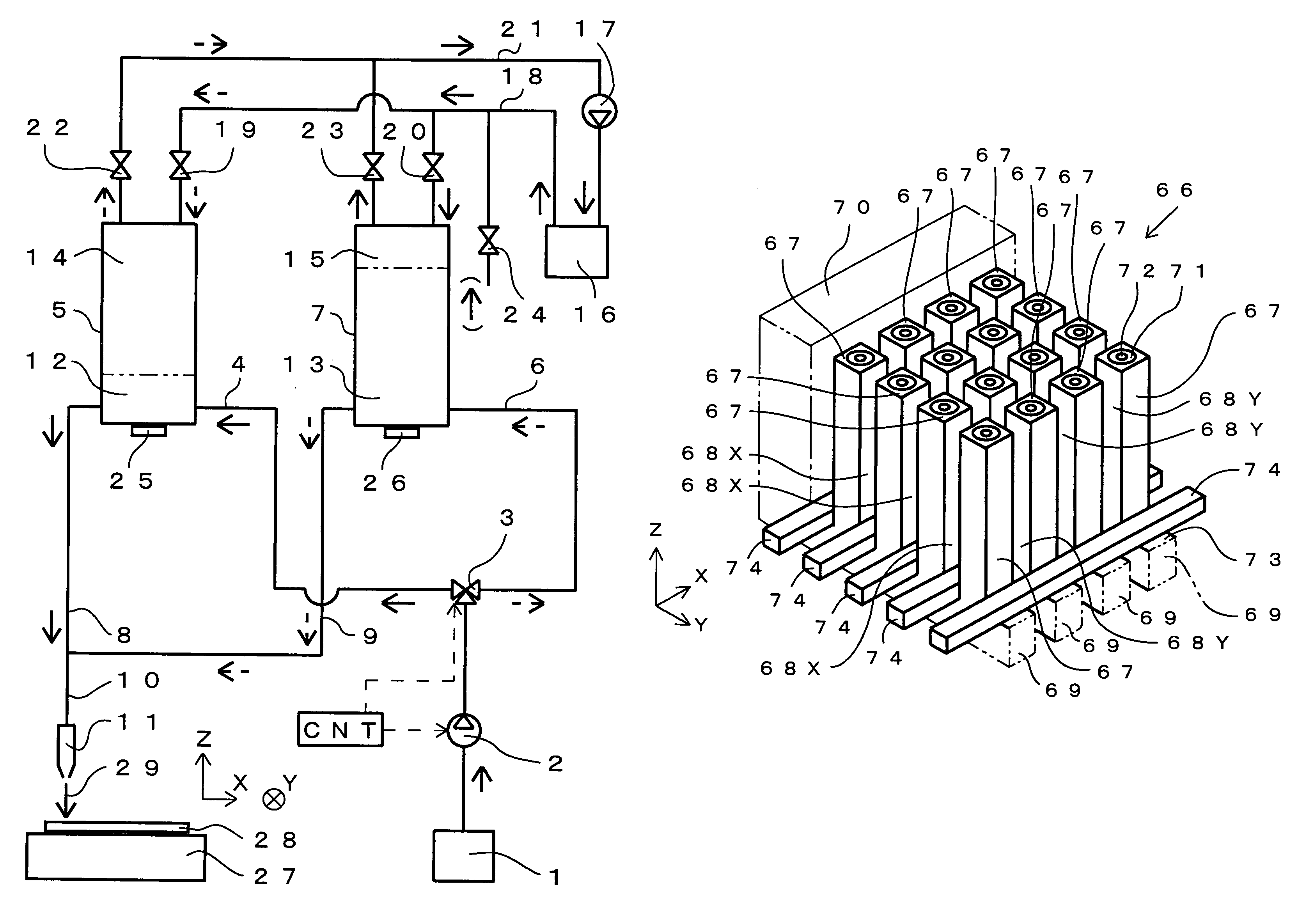

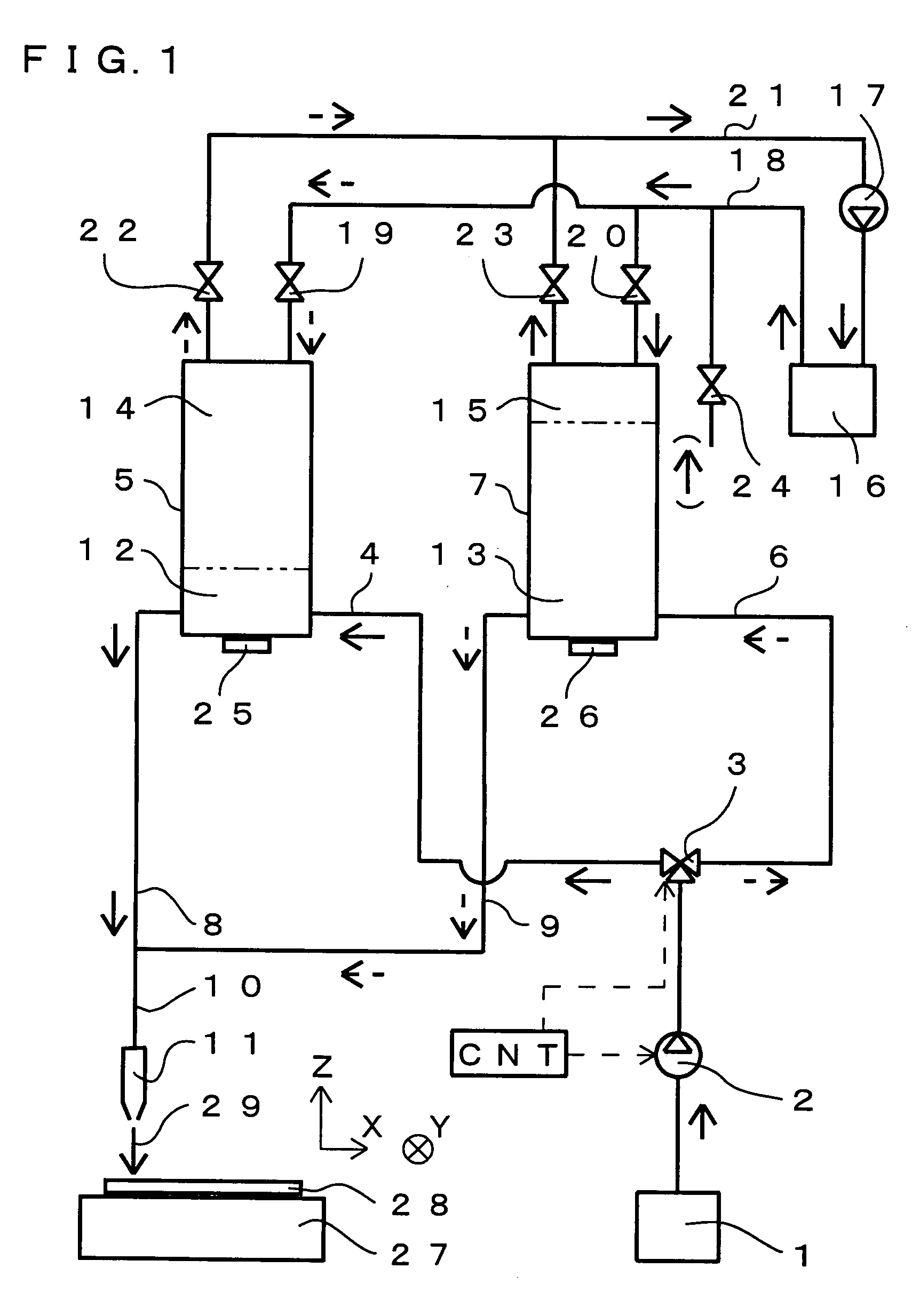

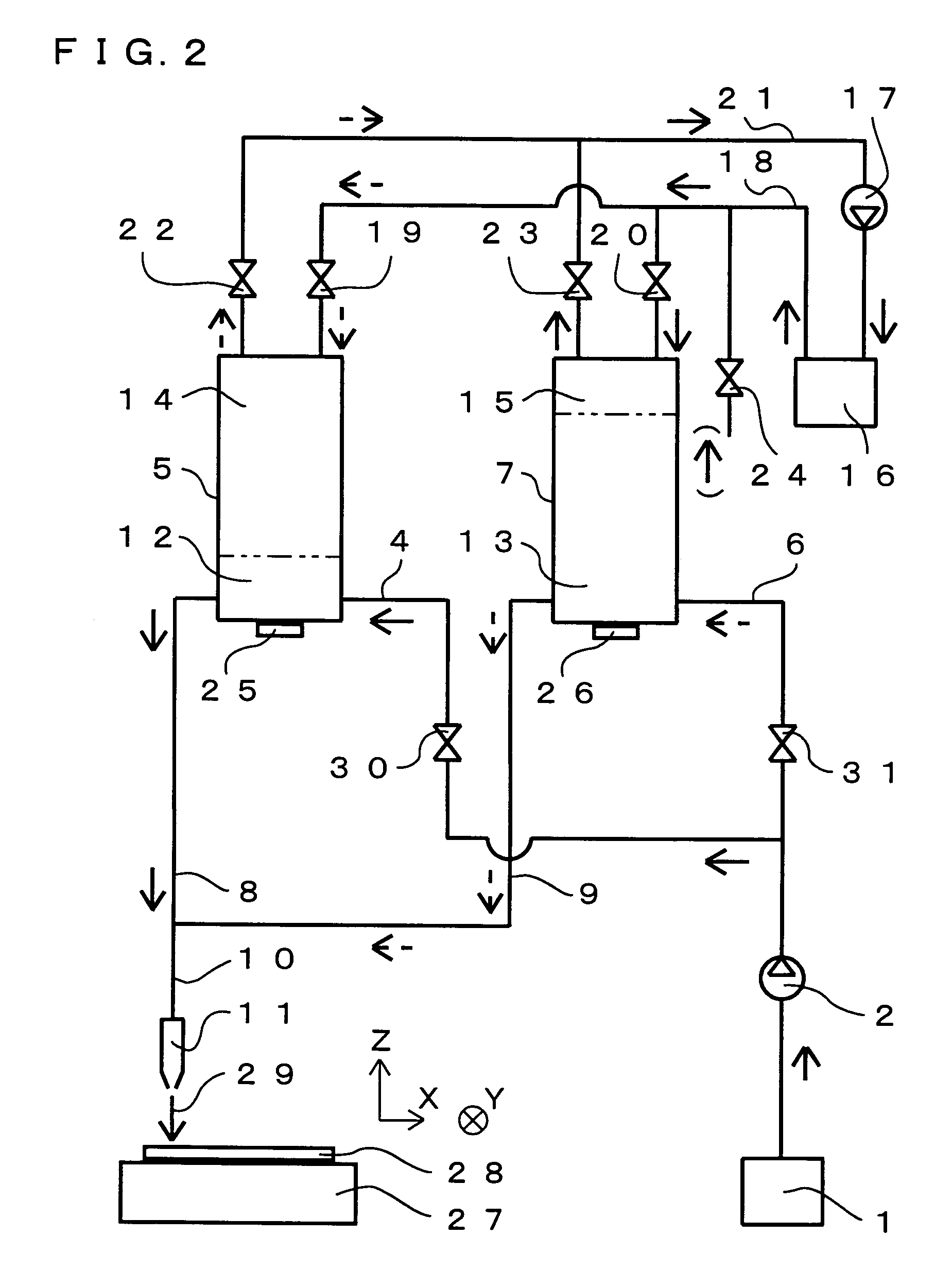

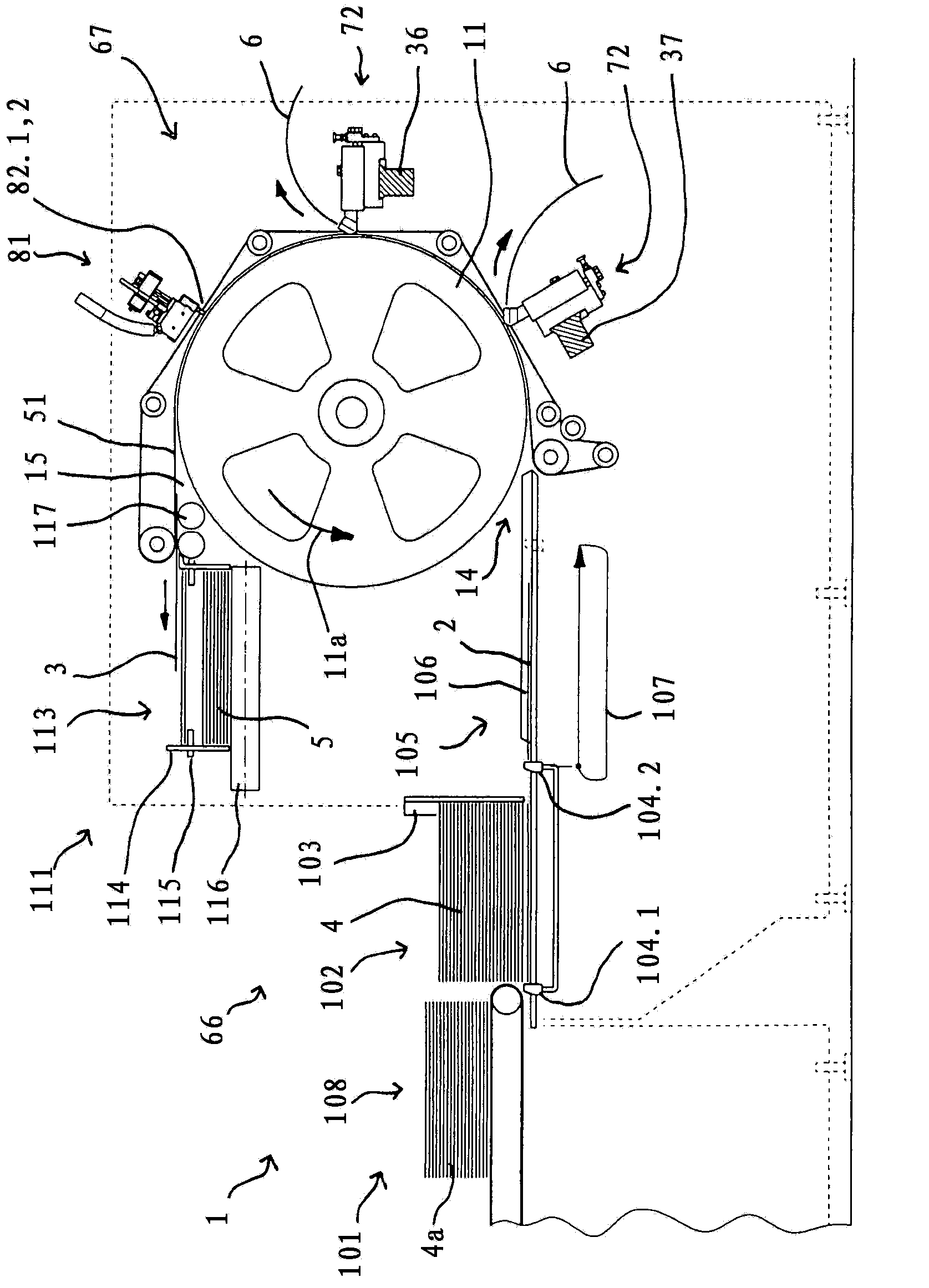

Full-automatic production line for double-surface cover of paper board

The invention discloses a full-automatic production line for a double-surface cover of a paper board. The production line mainly comprises a first working section, wherein the first working section mainly comprises a first surface paper conveying mechanism (1), a first glue coating mechanism (2) and a first surface covering mechanism (3). The production line also comprises a second working section, wherein the second working section mainly comprises a second surface paper conveying mechanism (4), a second glue coating mechanism (5) and a second surface covering mechanism (6); and a semi-finished product horizontal turning mechanism (7) is arranged between the first working section and the second working section. The full-automatic production line can fully automatically attach surface paper to the two surfaces of the paper board.

Owner:ZHEJIANG XINWEI MACHINERY

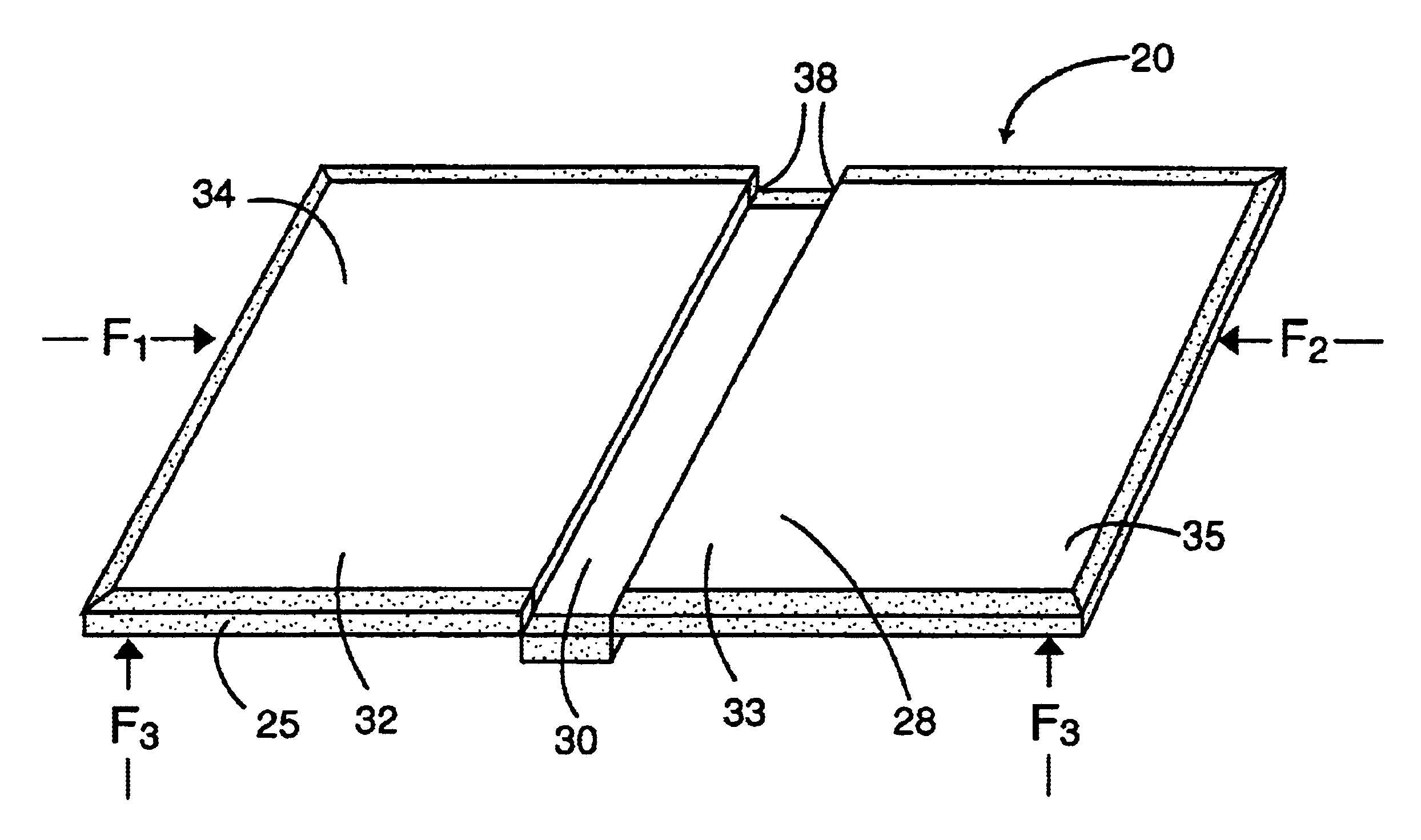

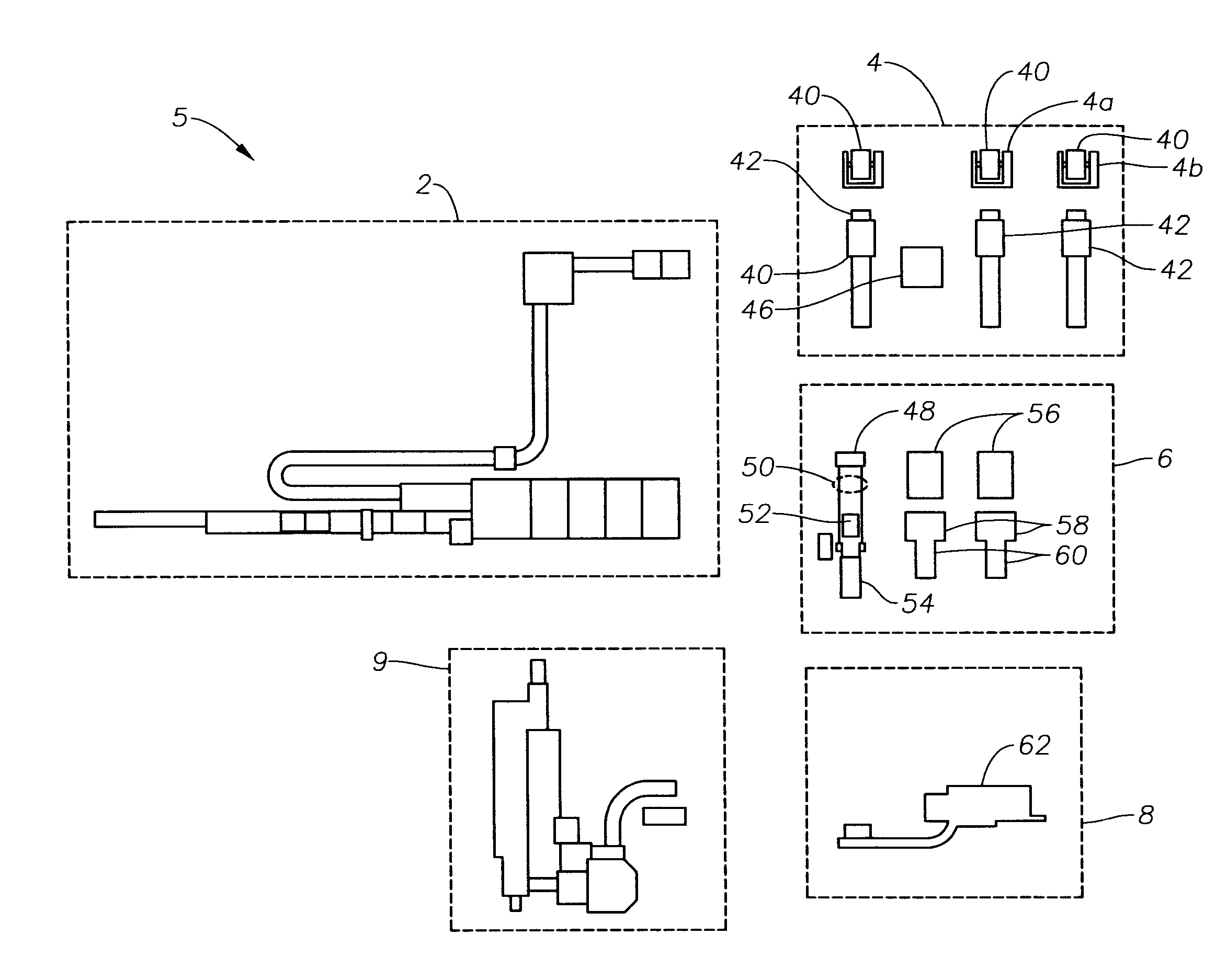

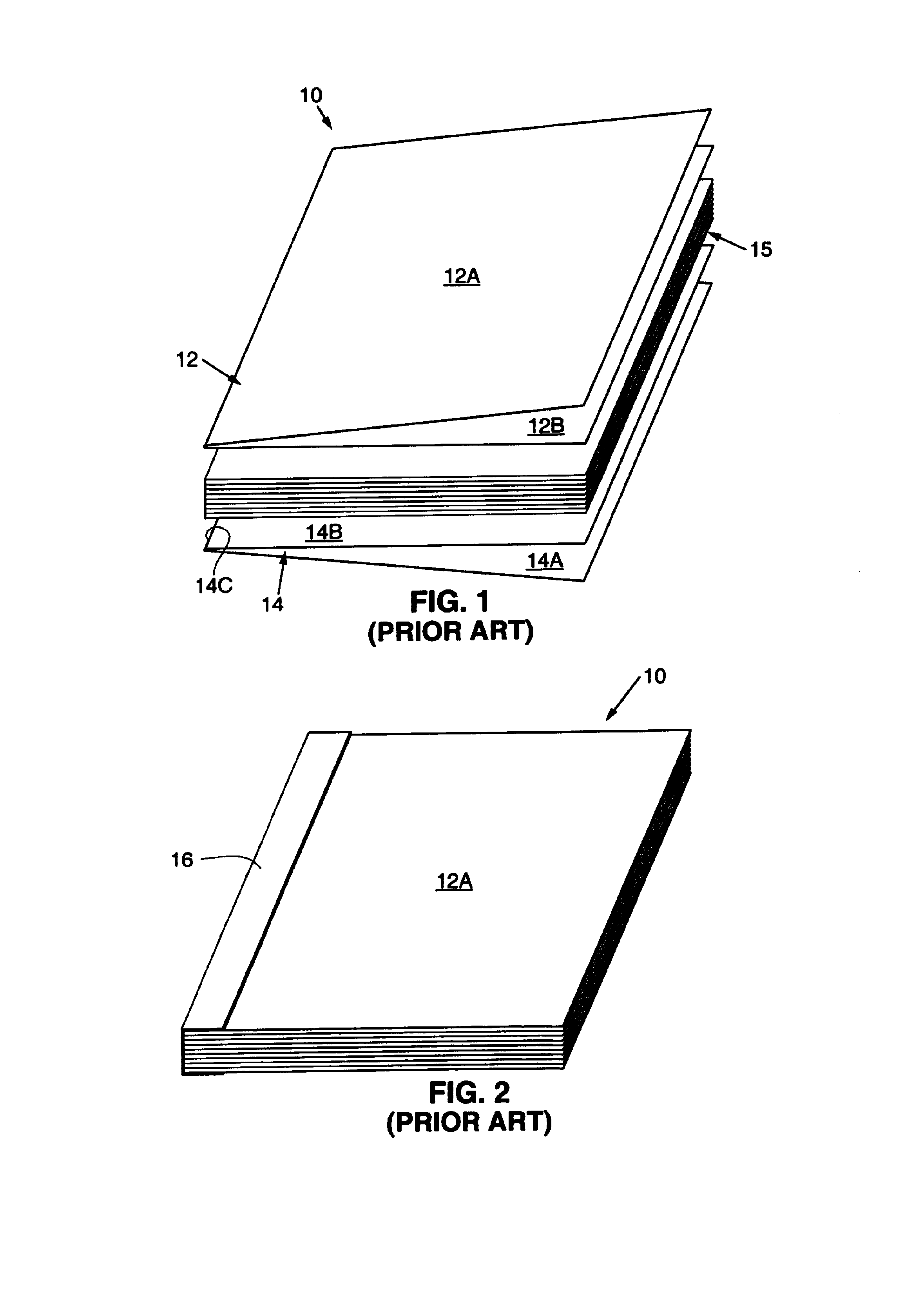

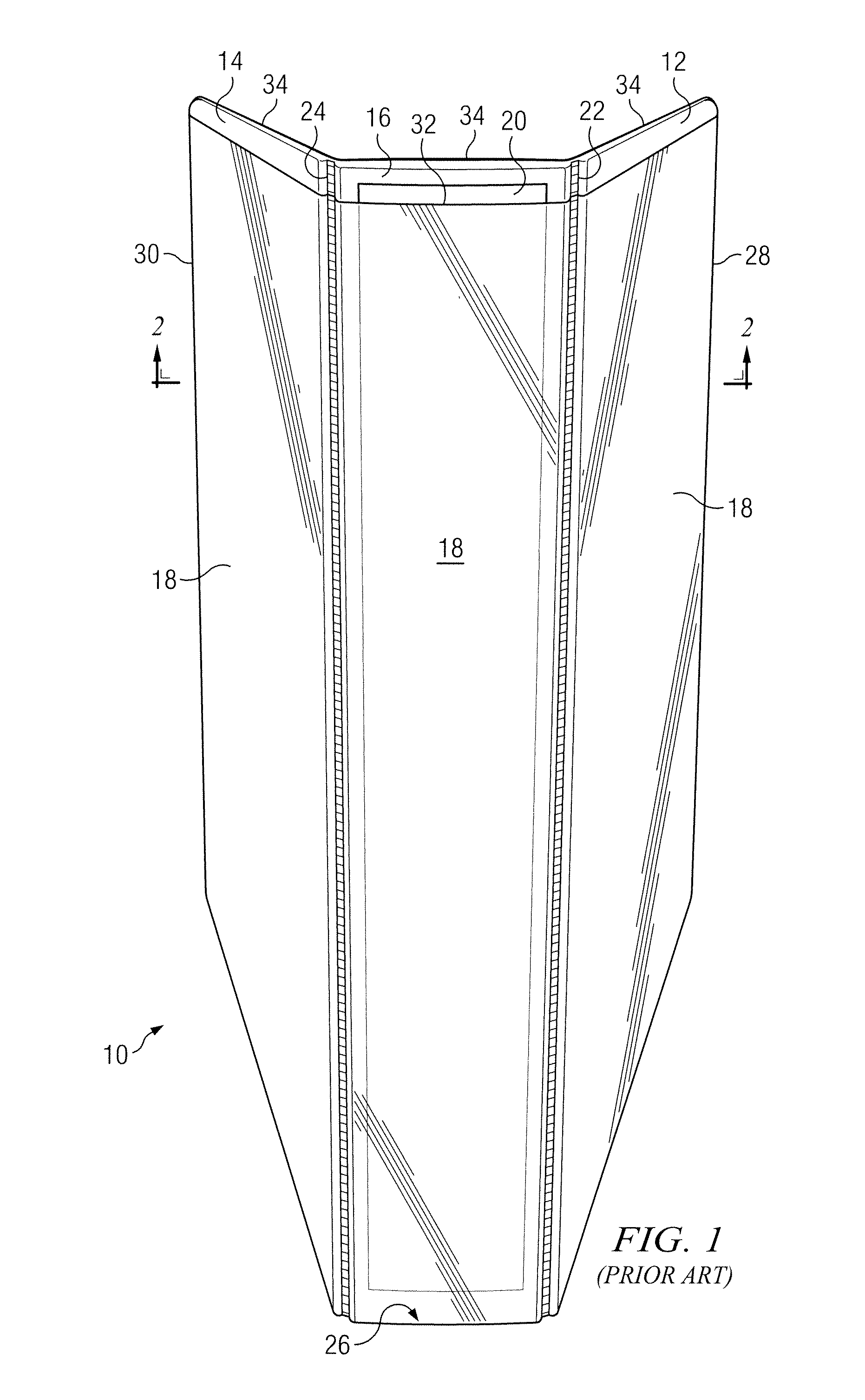

Outside-hinged cover for protecting articles stored therein and method for fabricating same

InactiveUS6910717B1No wasted materialEasy to openBookbinding casesToysEngineeringBiomedical engineering

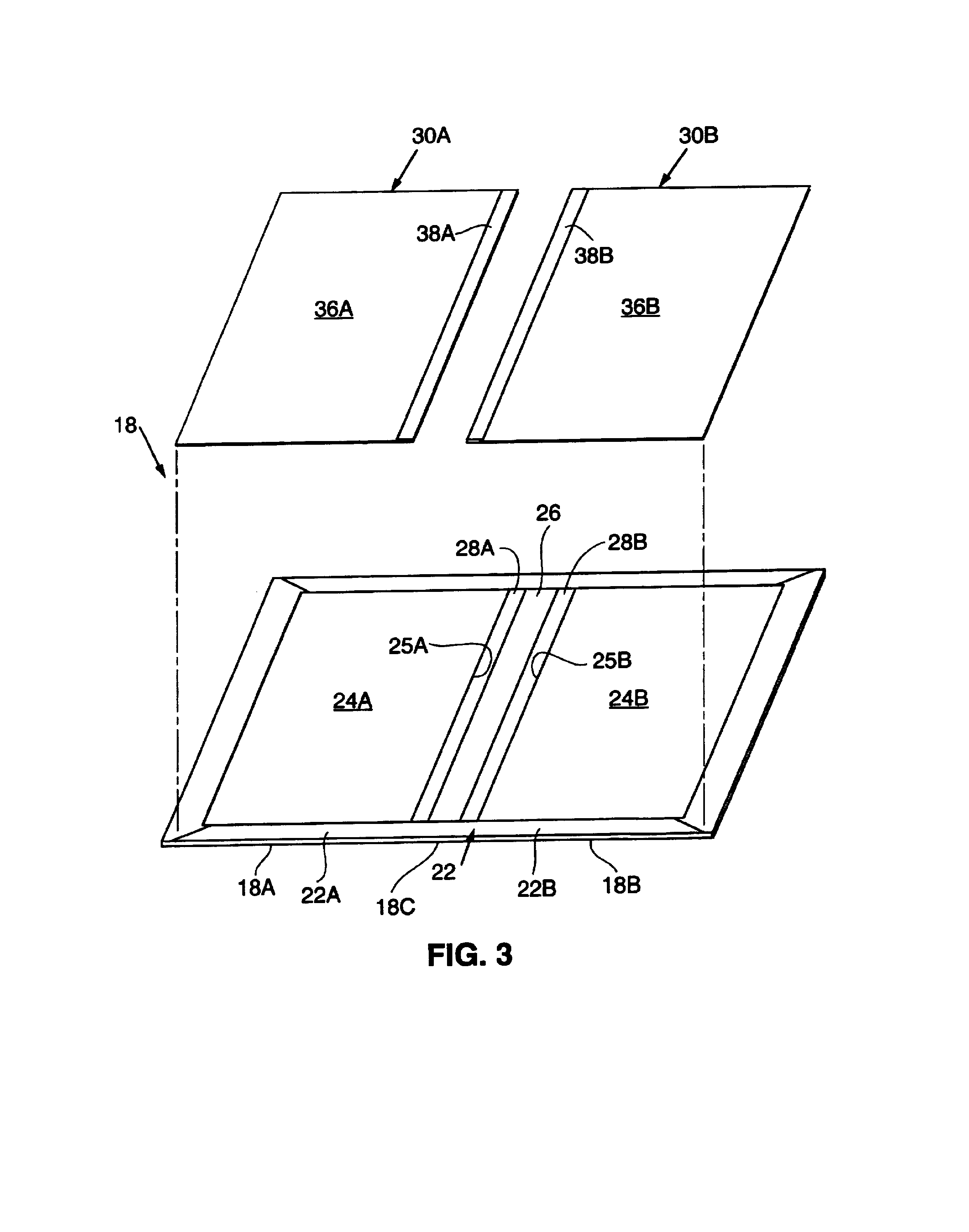

An object resembling the cover of a hardbound book comprises two panels connected by a spine. The outside hinge configuration of the invention prevents the spine from collapsing, even if there are no contents between the two panels. The invention lends itself to a wide variety of book-like products (e.g., a book-like holder for a compact disc and accompanying booklet) where the contents are of changing width (thickness) or where the spine must be of a specific width, irrespective of the width of the contents, and further allows for a binding for a book to be fabricated prior to assembly or insertion of its pages. A hinged cover consistent with the invention comprises a spine and two rigid panels, each panel coupled to the spine and disposed rotatably with respect to the spine, and the spine serves as a hinge stop for each rigid panel, such that each panel, when rotated toward the other panel, is constrained from rotating substantially beyond 90 degrees with respect to the spine. A method of constructing a cover consistent with the invention comprises disposing a rigid front, rear, and spine panel core onto a sheet of pliable material, such that the width of the space between the spine panel core and the other panel cores is based on at least the sum of the thickness of the spine panel core and twice the thickness of the sheet of pliable material.

Owner:MOYER WILLIAM FREDERICK

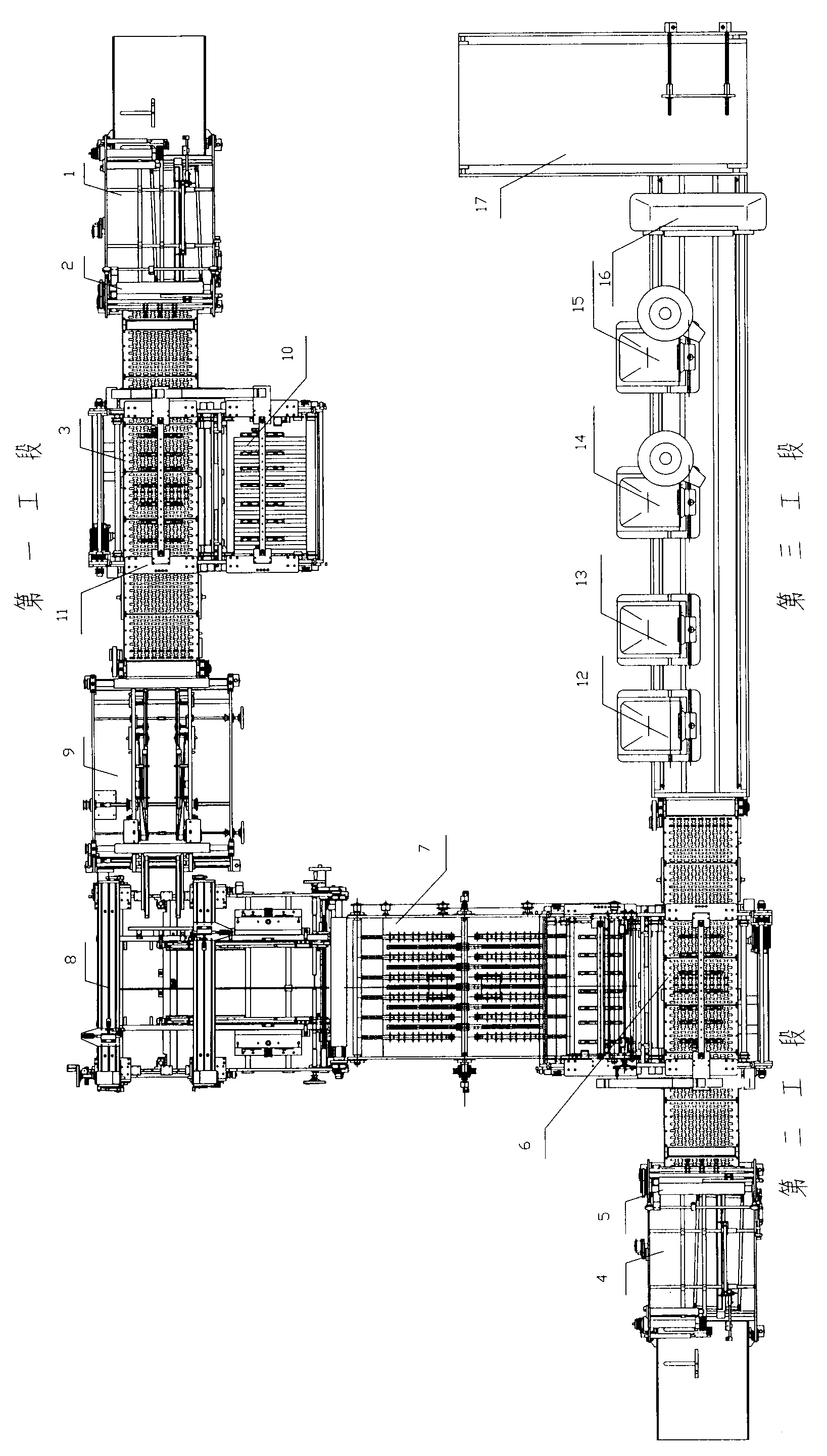

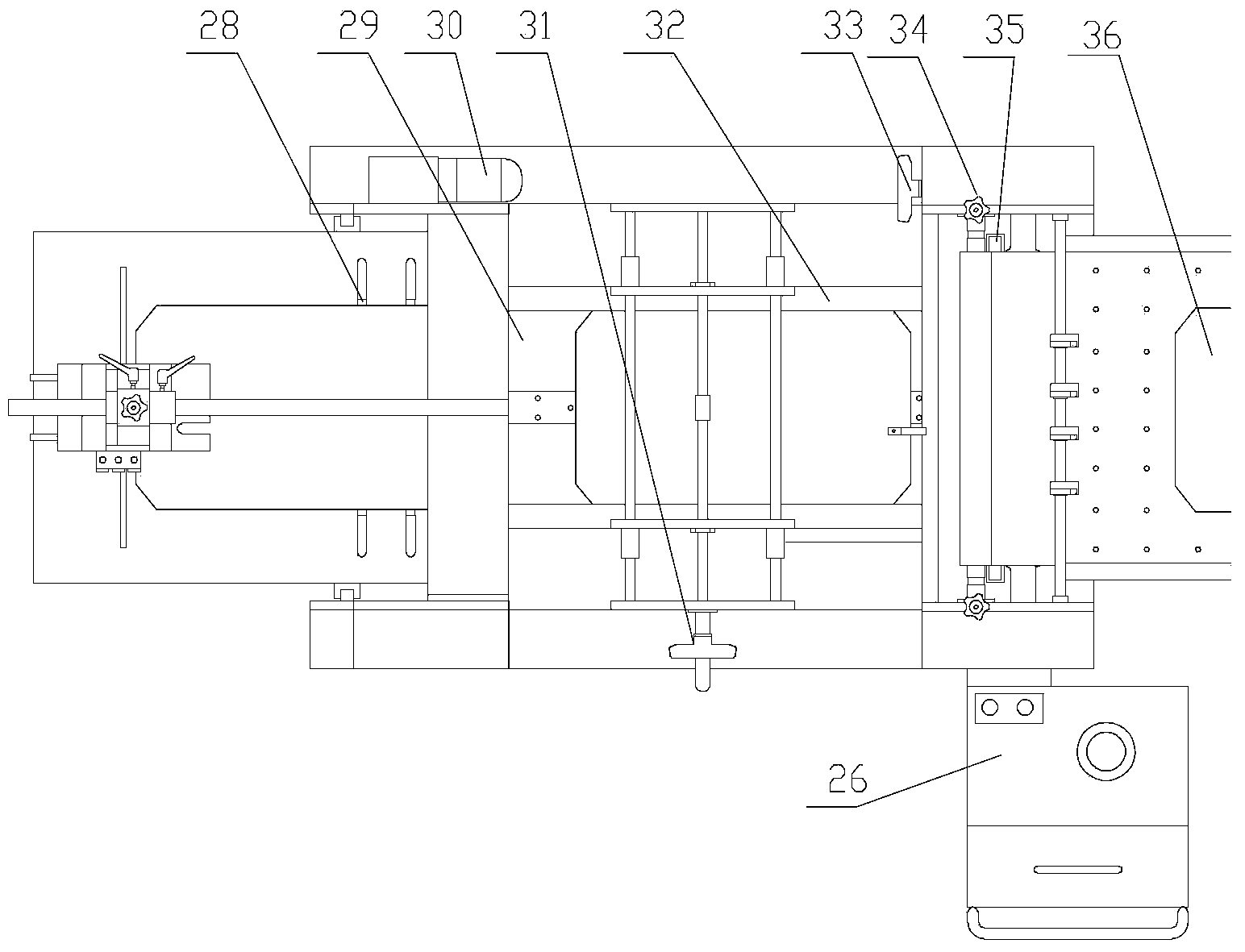

Full-automatic production line of hard covers

The invention relates to production equipment of hard covers for products such as notebooks and desk calendars, and particularly relates to a full-automatic production line of hard covers. According to the technology provided by the invention, the full-automatic cover production line is characterized by comprising a paper gluing device, a panel pushing and positioning device, a conveying device, a cover edge-covering device, a lining-paper gluing device, a cover overturning and positioning device, a flattening device and a material receiving device. The full-automatic production line with the scheme can solve the problems in the prior; after an outer cover of a cover product is well covered, lining paper is directly and automatically overturned and stuck, and the edge covering and the lining paper sticking are finished by one time, so that labor is greatly reduced, and the productivity and the product qualification rate are greatly improved.

Owner:浙江浩达智能装备股份有限公司

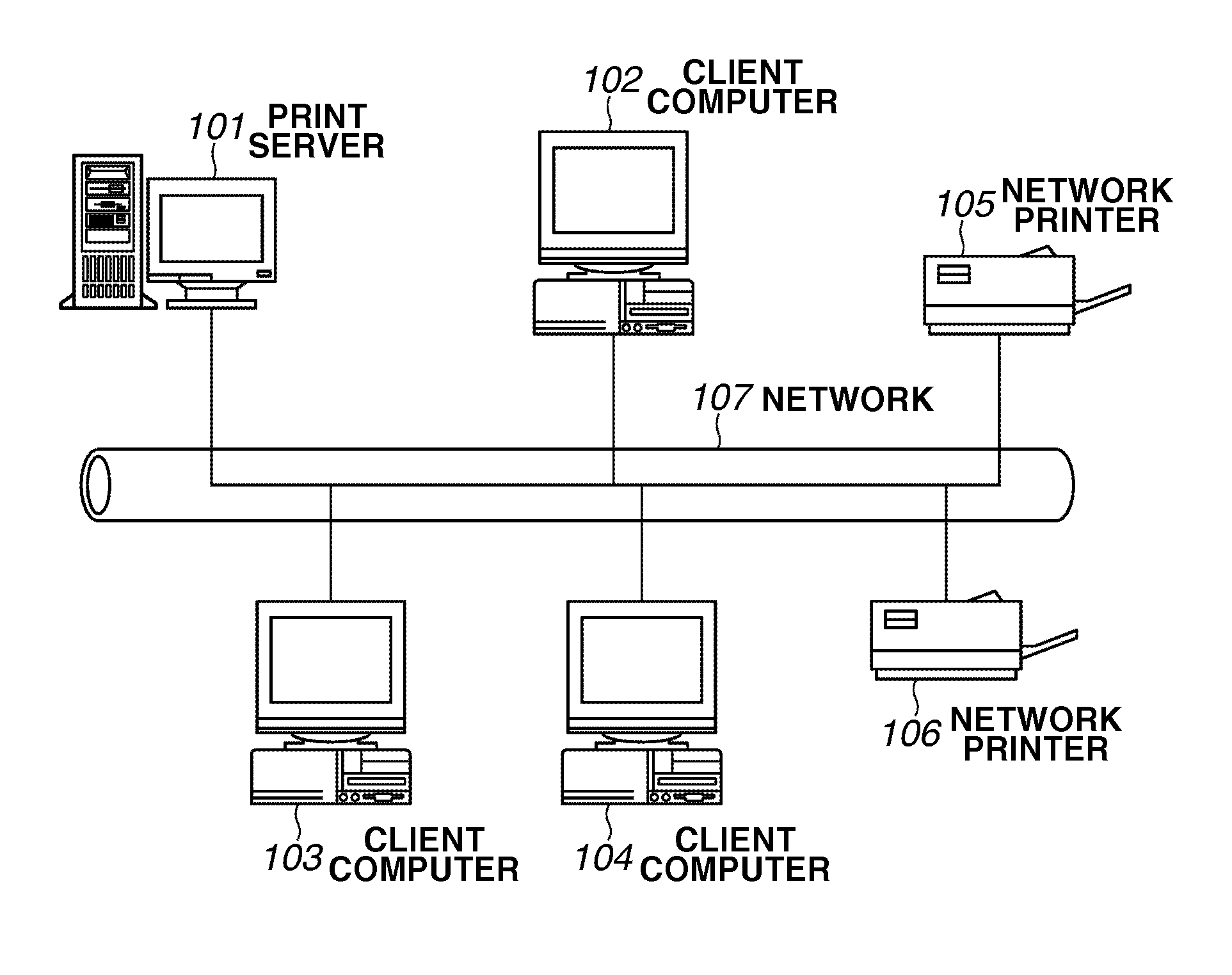

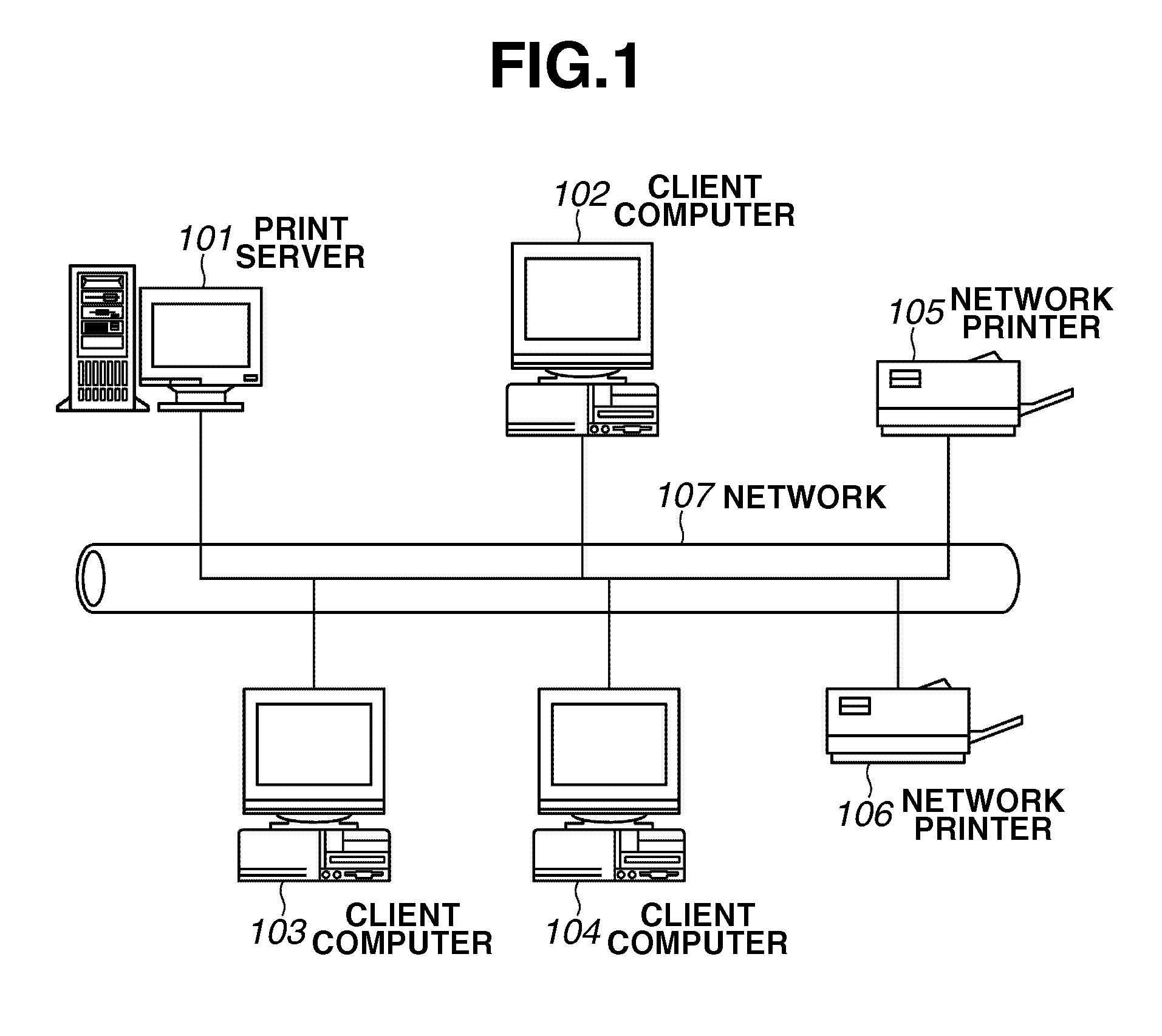

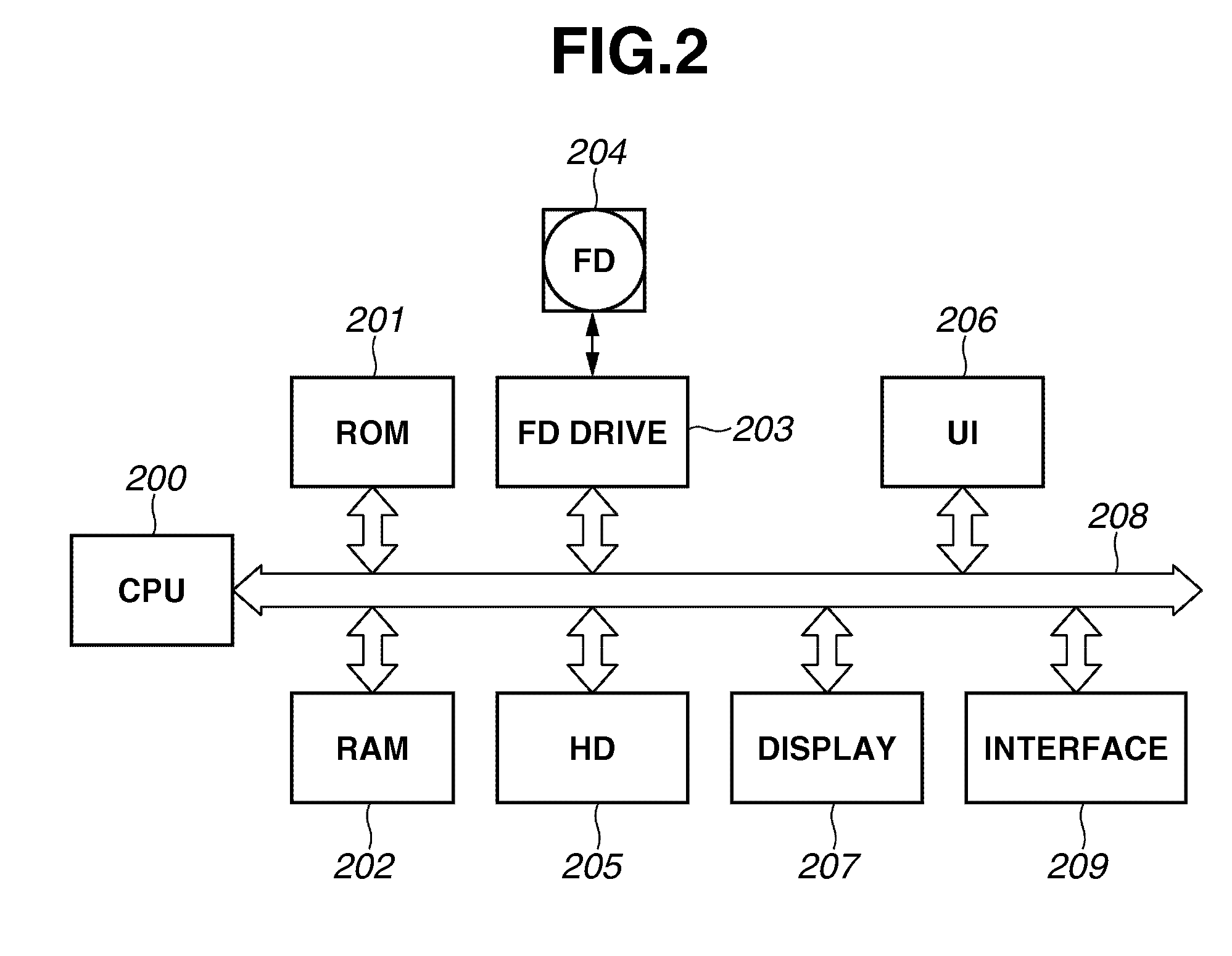

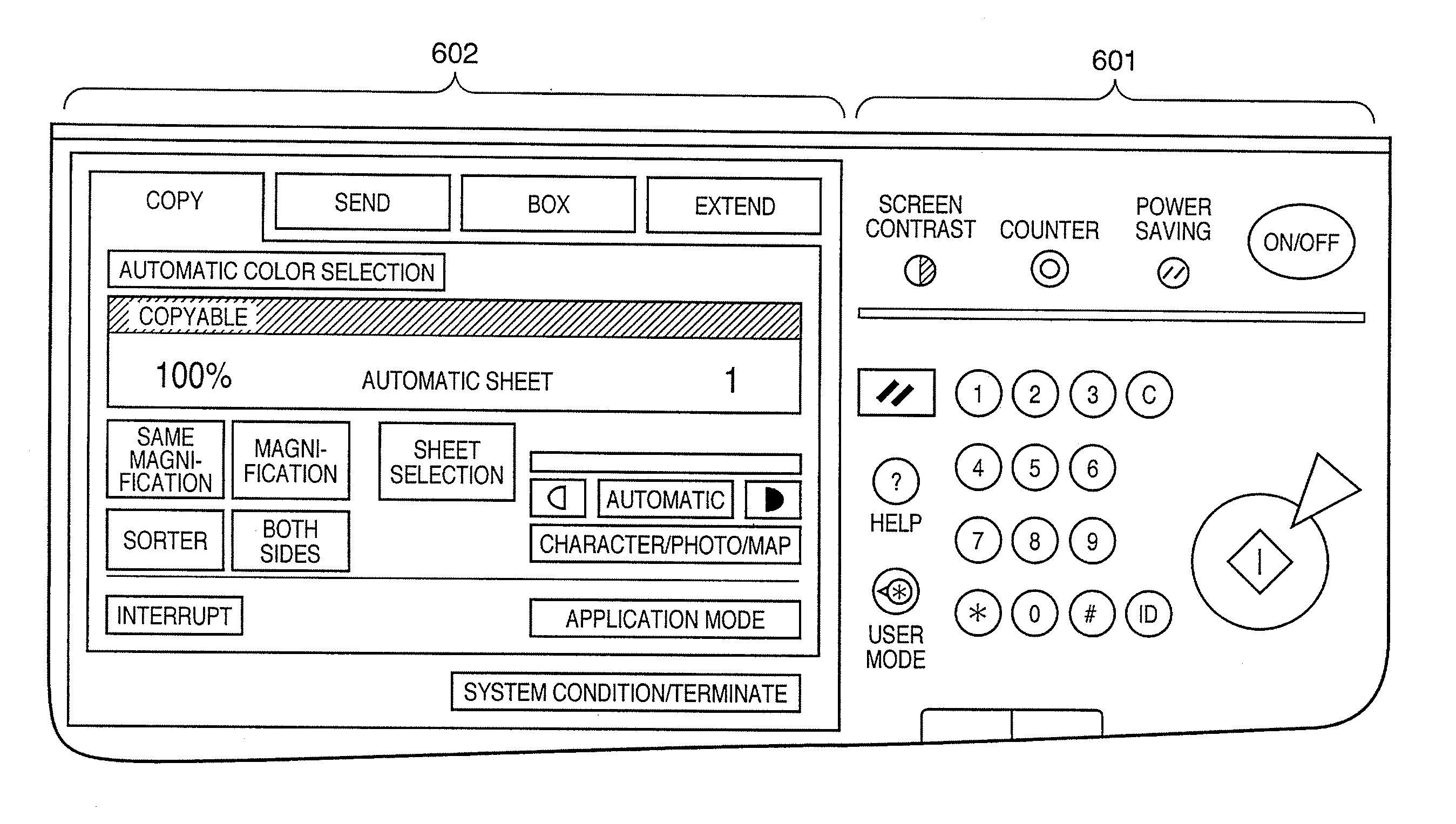

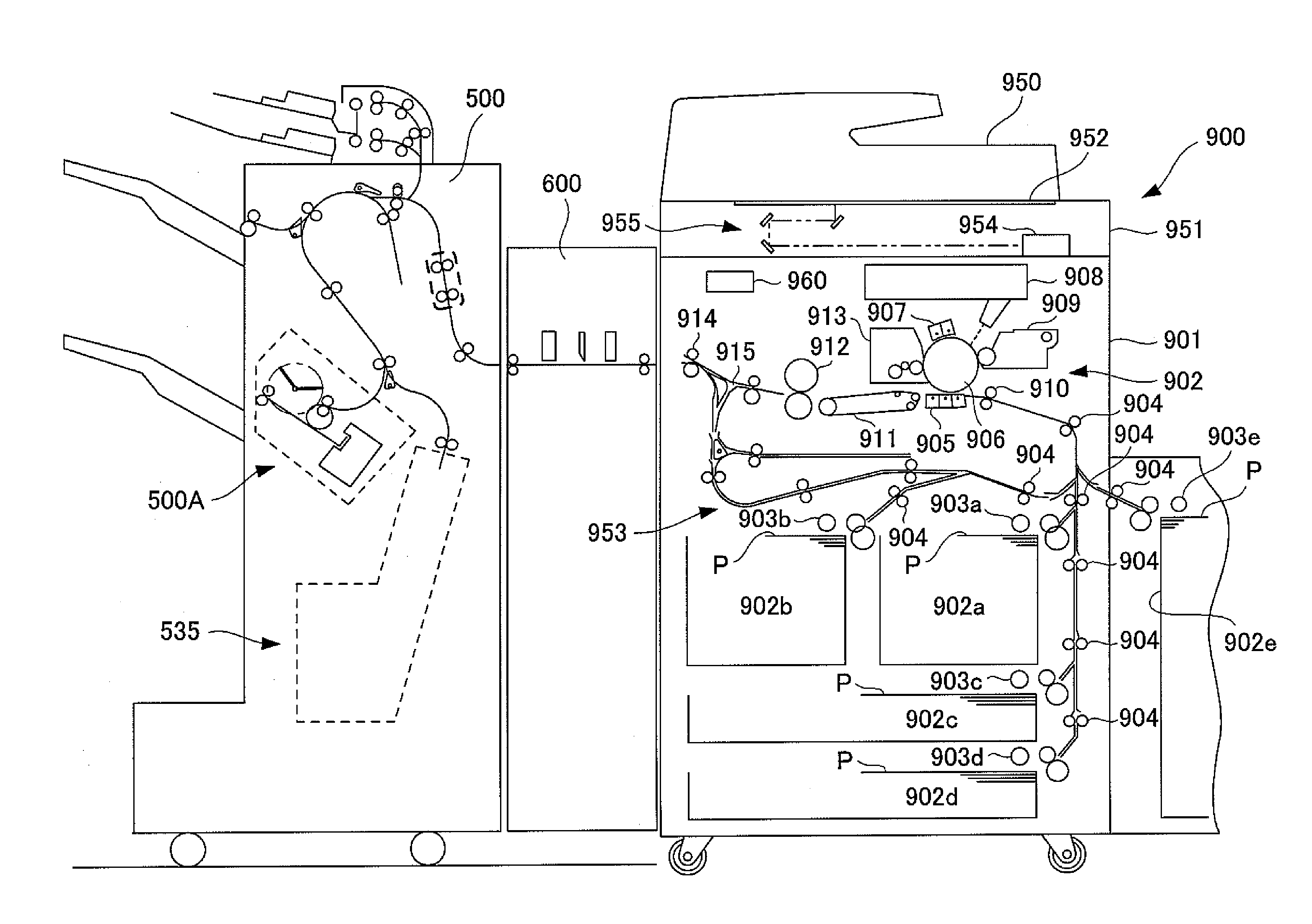

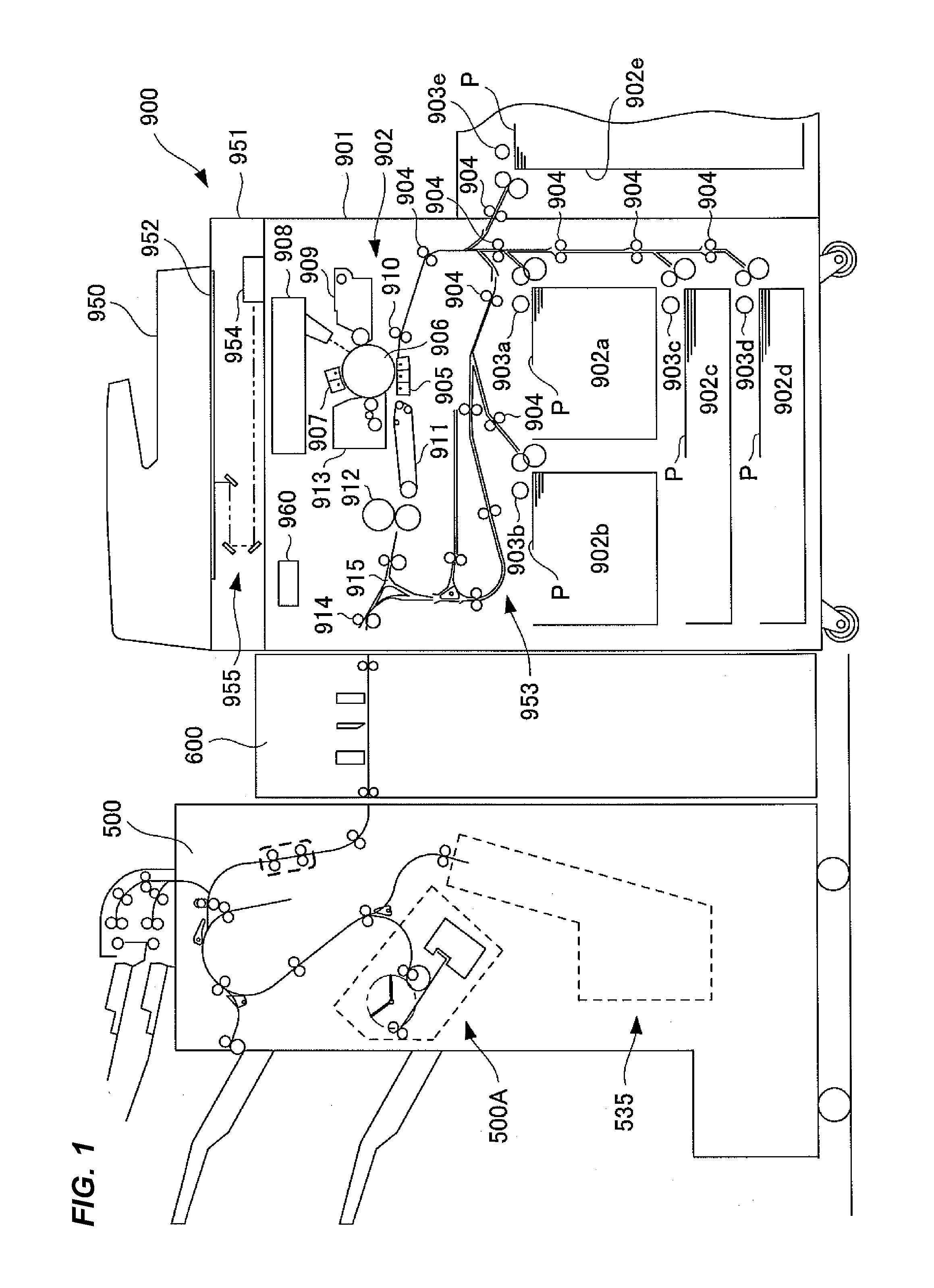

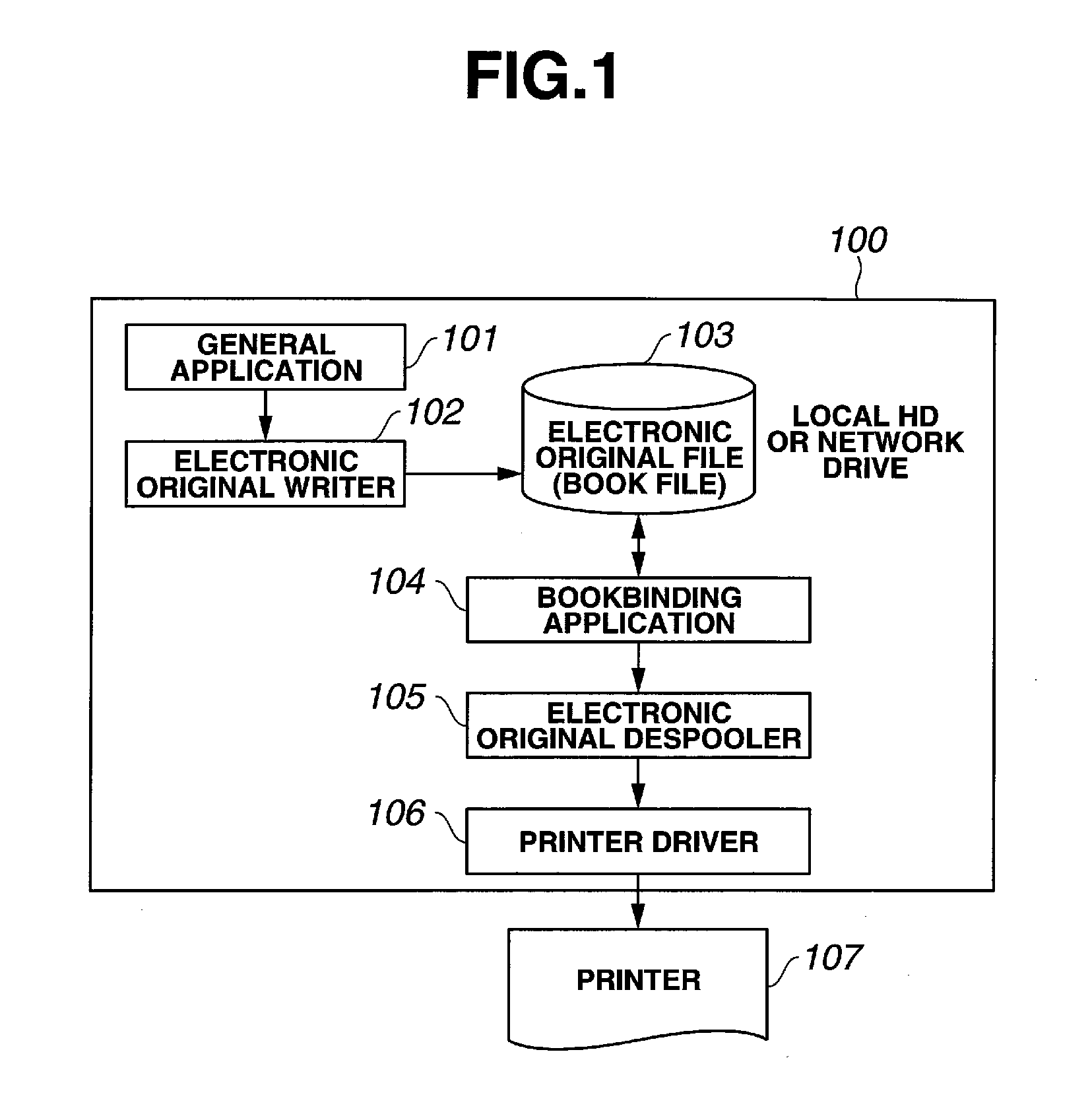

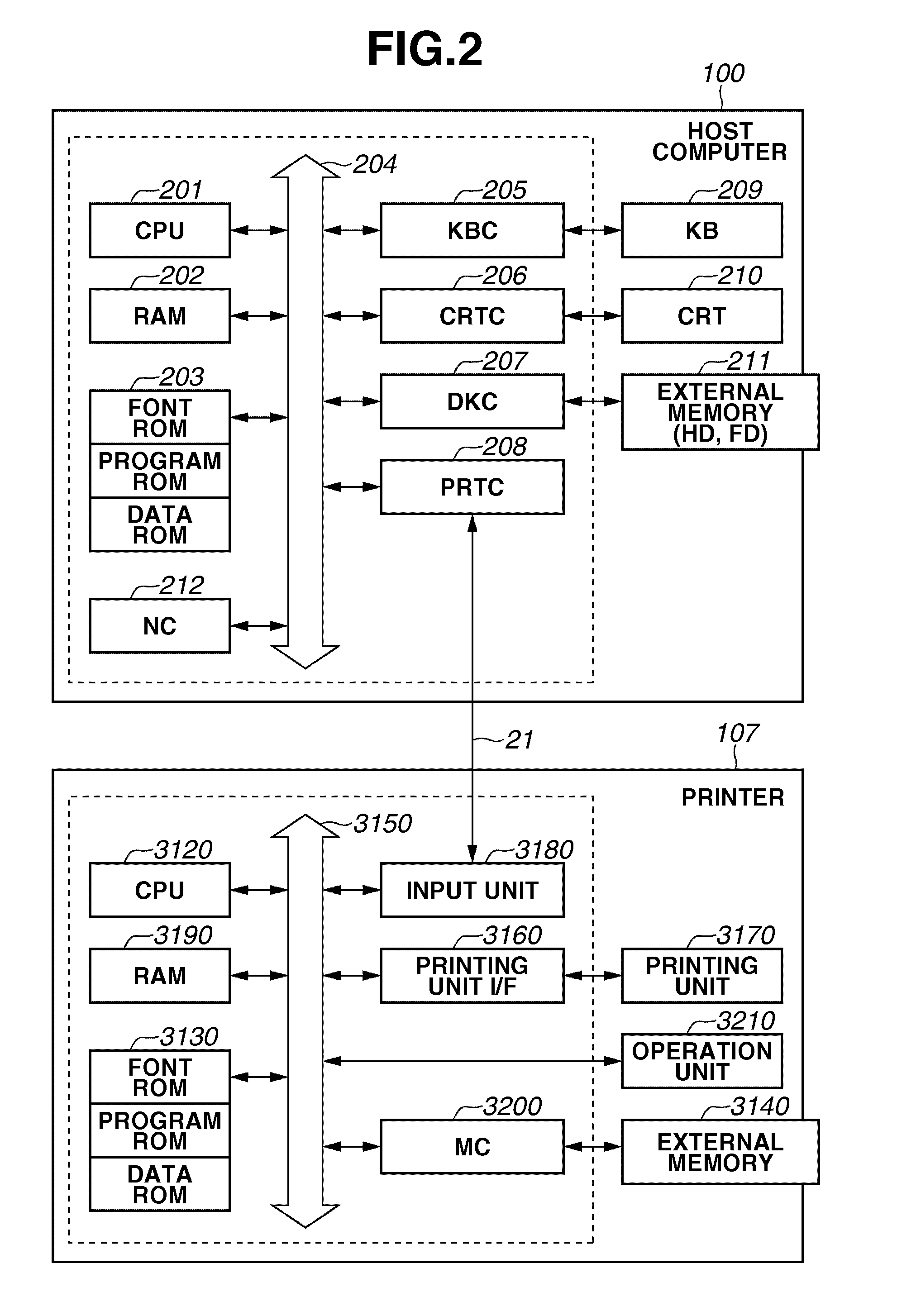

Print processing system, print processing method, and storage medium

InactiveUS20100149565A1Reduces and prevents changeExtra processingDigitally marking record carriersBookbinding casesHandling systemDatabase

A print server checks a job ticket for a print job to be processed. When a method of printing set in the printing attributes of the job ticket is case binding, a first thickness of a bookblock is calculated using the paper type set in the printing attributes. The print server calculates a second thickness of a bookblock using the paper type after a change. The print server changes the paper type set in the job ticket when the difference between the first thickness and the second thickness is within a permissible range.

Owner:CANON KK

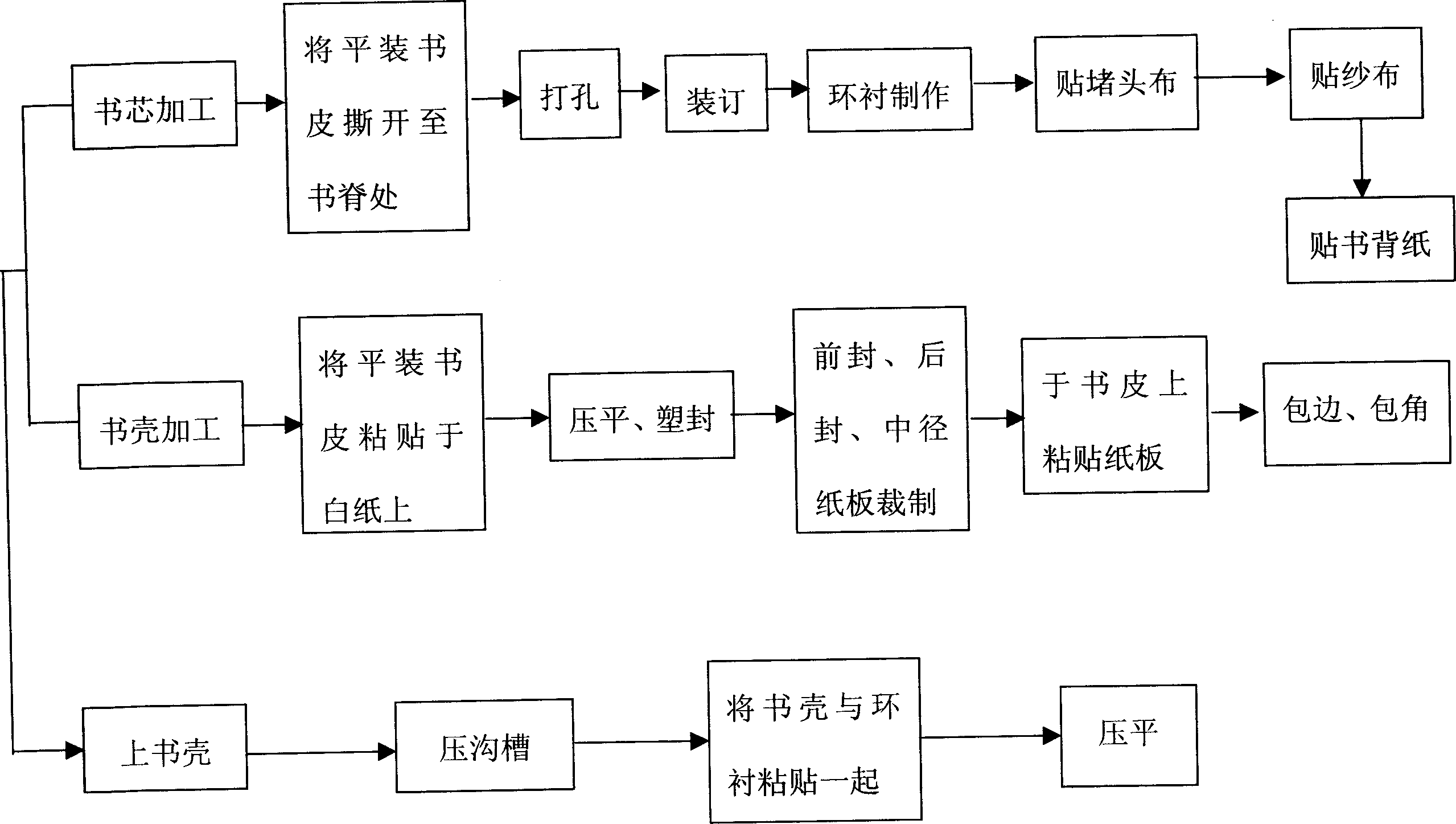

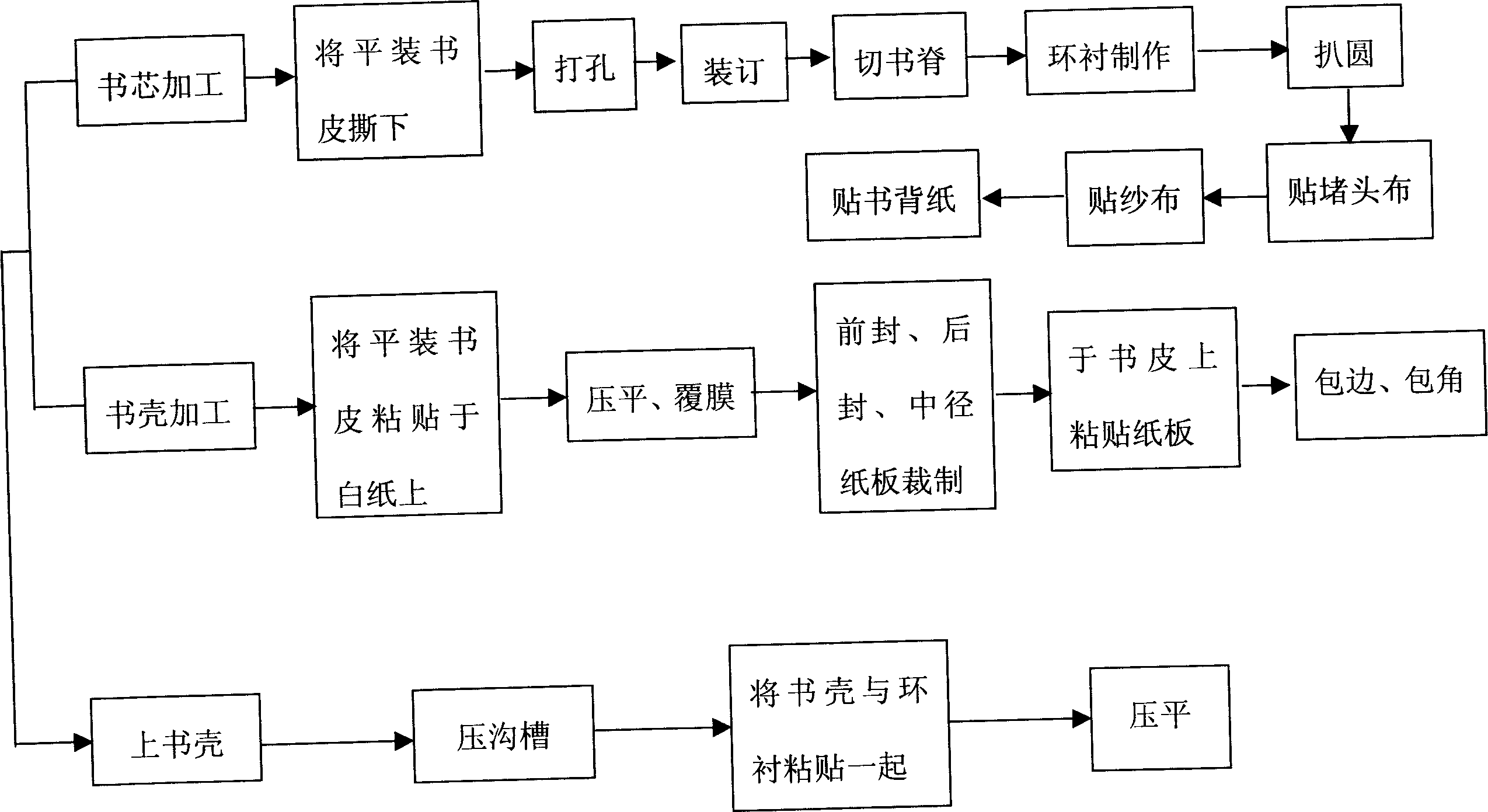

Method for changing paperback to exquisitely binding book

InactiveCN1865018AGood effectMeet quality requirementsBookbinding casesBook rebindingPulp and paper industryPaper sheet

The invention relates to a method for changing the soft-covered book into hard-cover book, which comprises three steps as processing book core, processing book cover, and mounting the book cover. Wherein, first, removing the cover of soft-covered book; then making holes, binding, preparing annular liner, adhering block cloth, adhering gauze, adhering book back paper to complete processing the book core; the second step is that adhering the cover on the white paper, then flattening the coat film, cutting the front and back seal, and the middle paper sheet, then folding edge and packing corner; the third step comprises pressing groove, adhering annular liner and flattening. The inventive method can overcome the defects of present technique, with simple operation and lower cost.

Owner:王超 +1

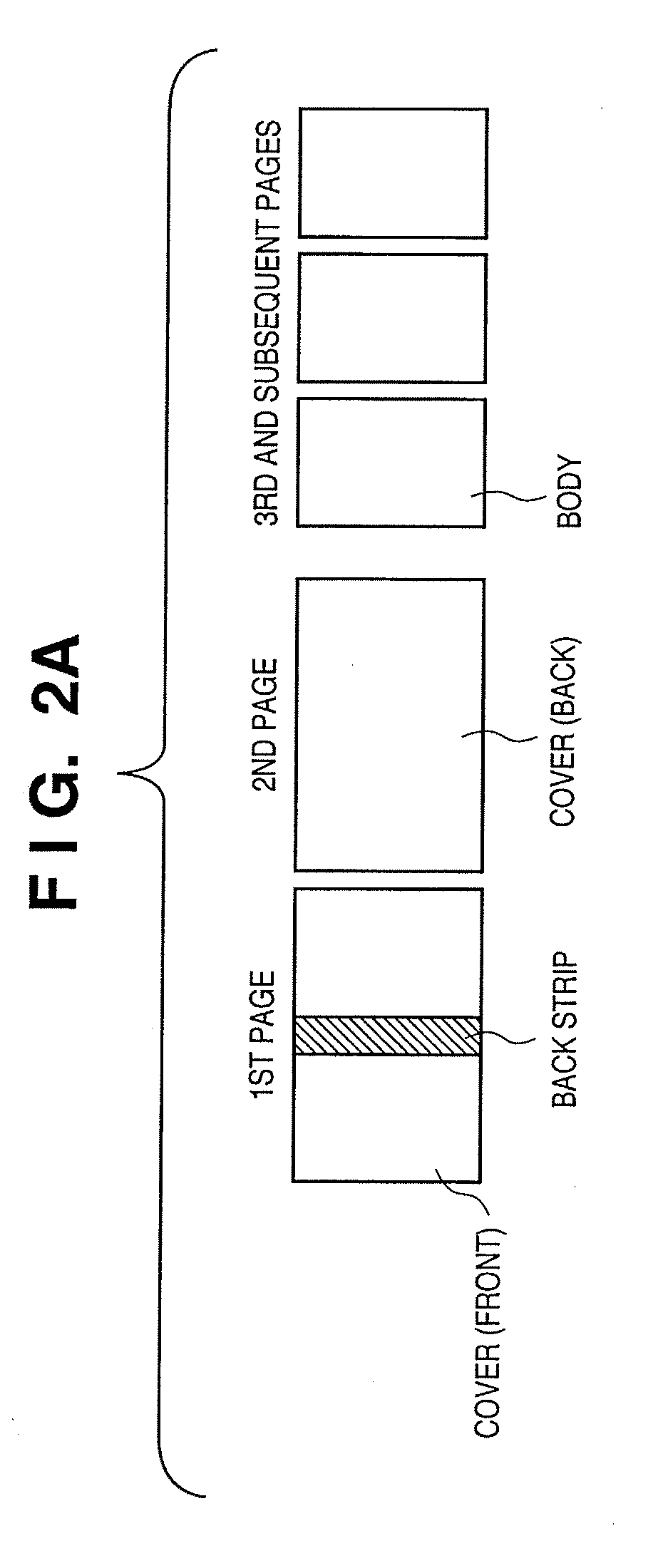

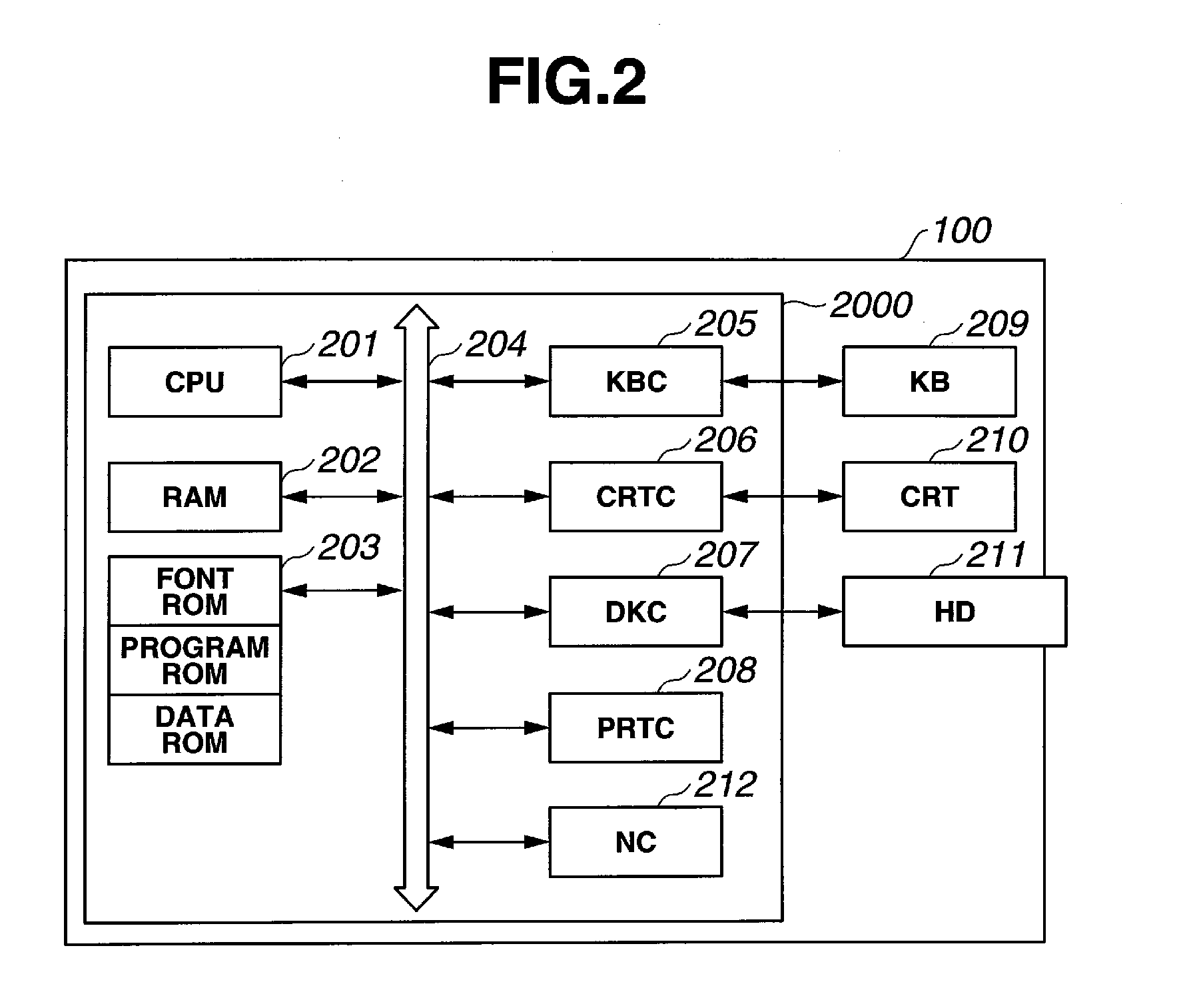

Image processing apparatus and method for controlling the same

InactiveUS20070081180A1Appropriately processedBookbinding casesBook making processesInformation processingImaging processing

It is possible to provide an information processing apparatus capable of appropriately processing a job for case binding without depending on the sequence of page data constituting the job, a method for controlling the apparatus and a program. To accomplish this, a job for case binding is inputted, and the inputted job is stored in storage means of the image processing apparatus. A bookbinding cover attribute is set for page data to be a cover, in the job stored in the storage means. The order of output of page data in the job is determined based on the set attribute. The page data in the job stored in the storage means are read and outputted to a printer unit in accordance with the determined output order.

Owner:CANON KK

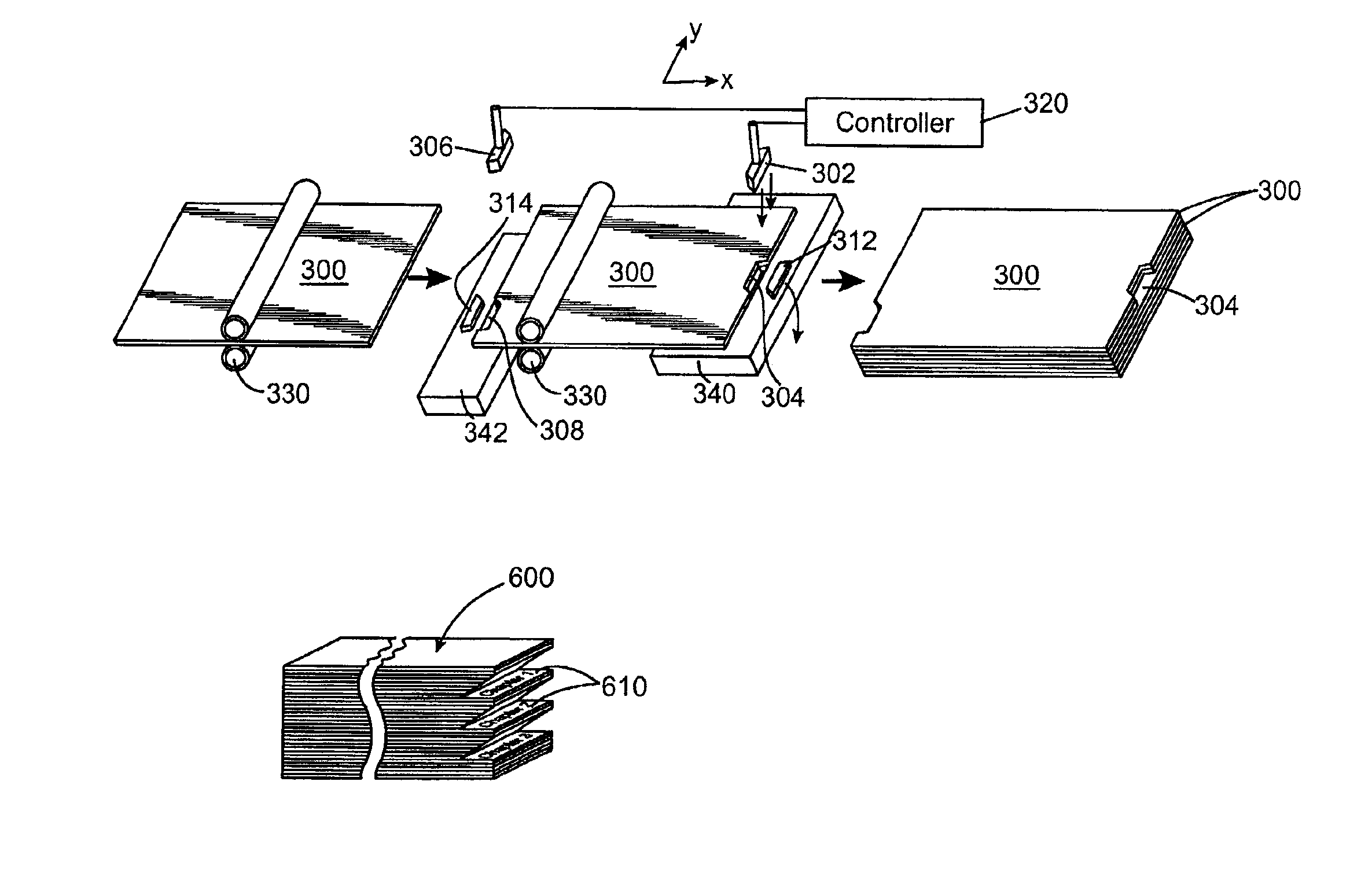

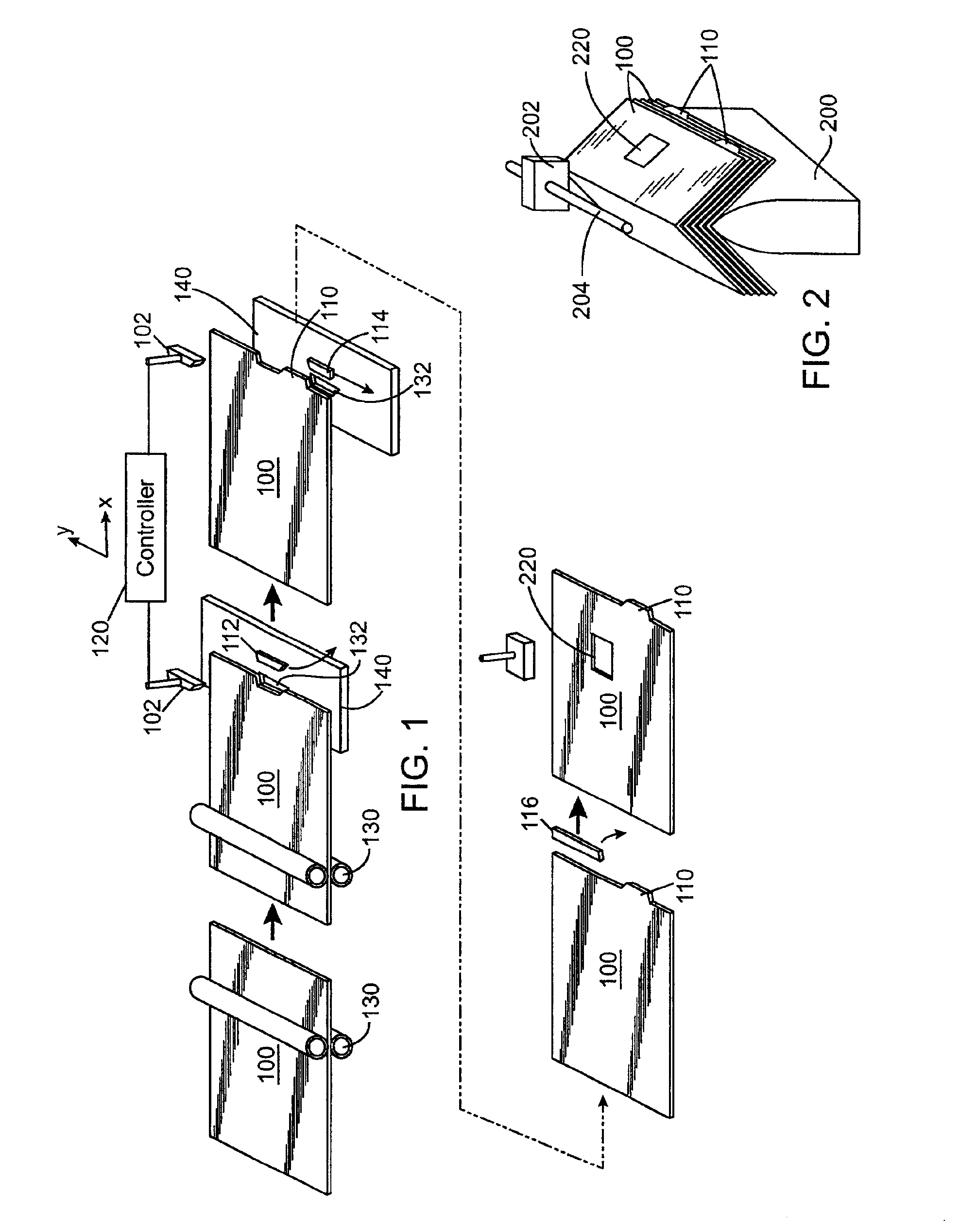

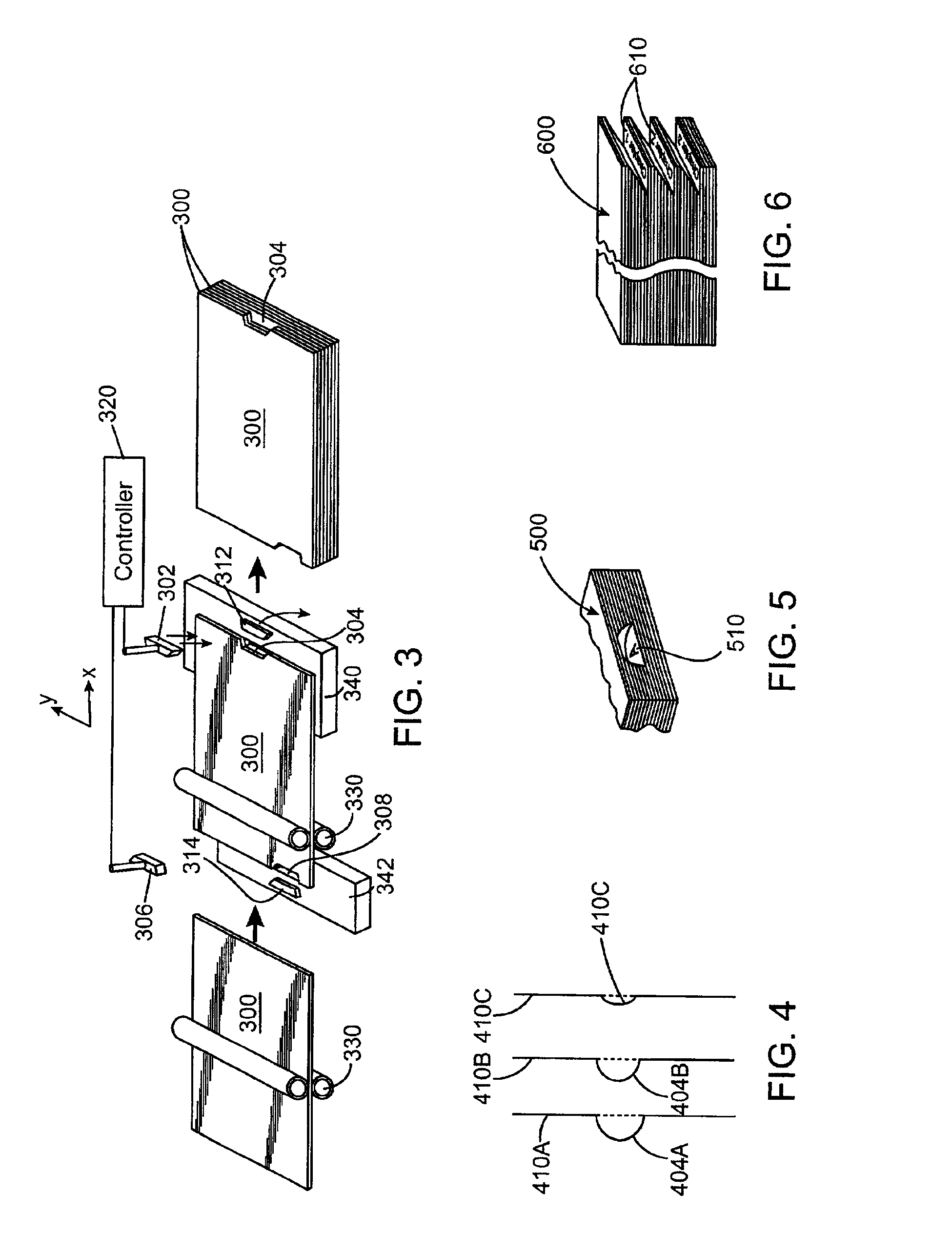

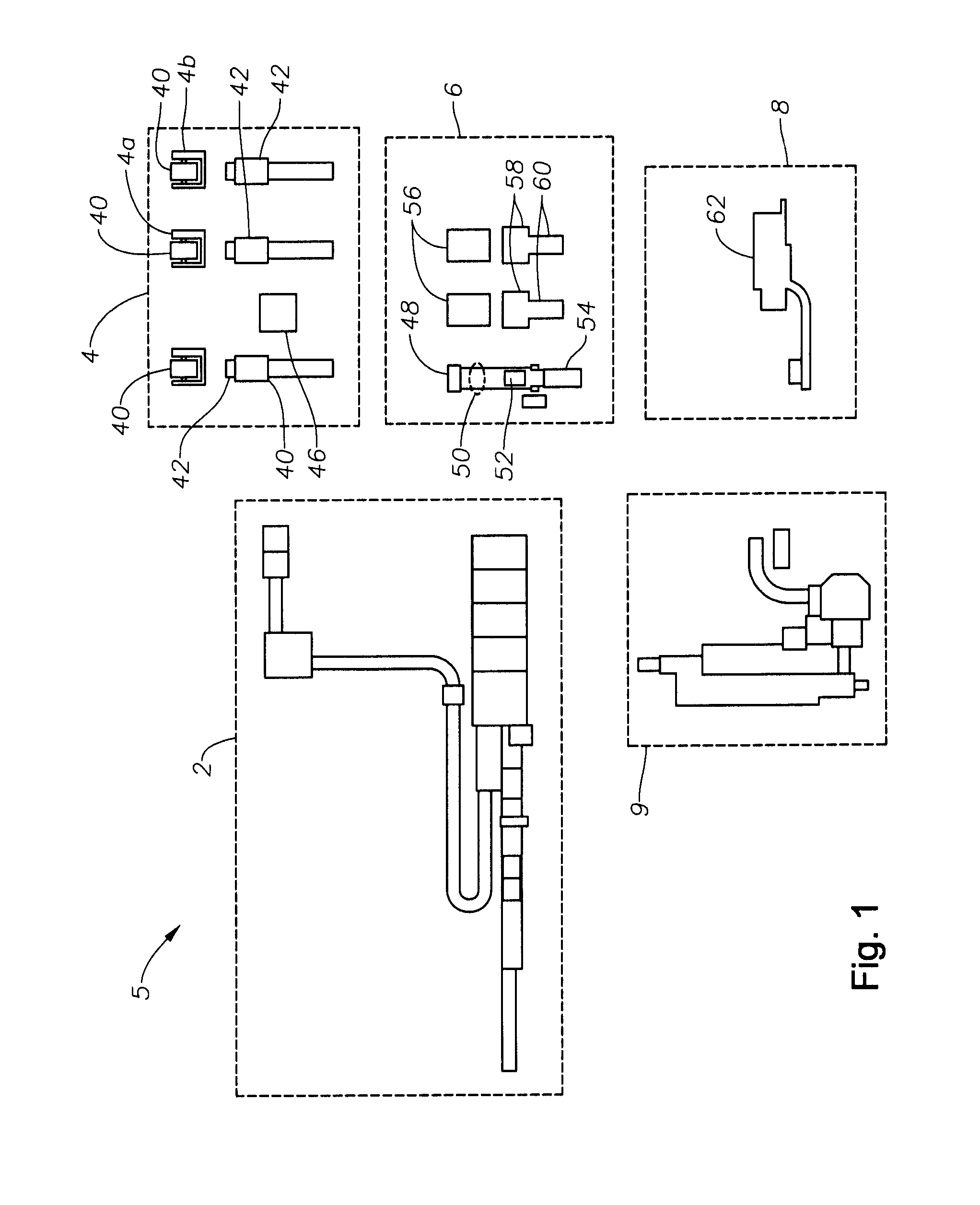

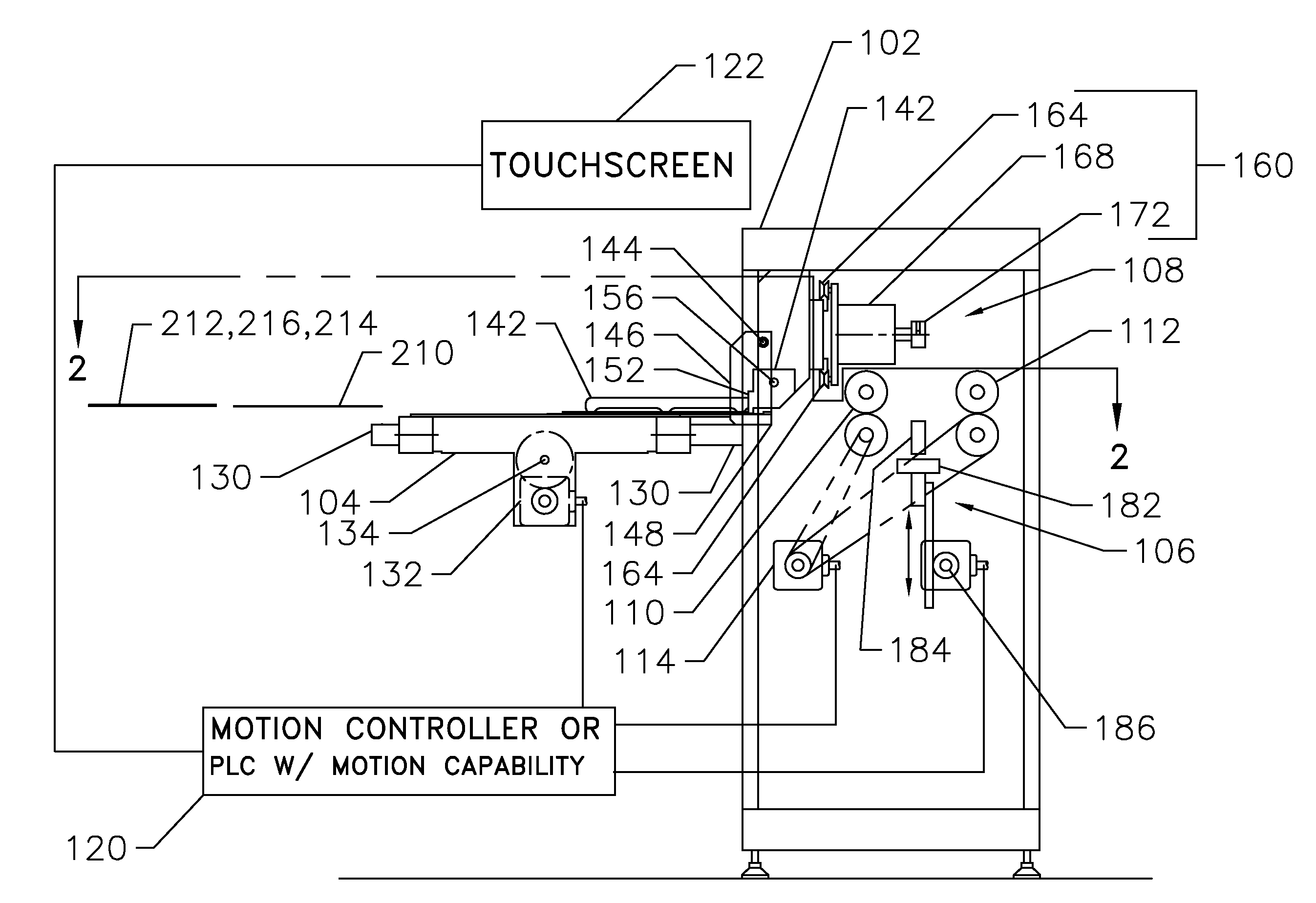

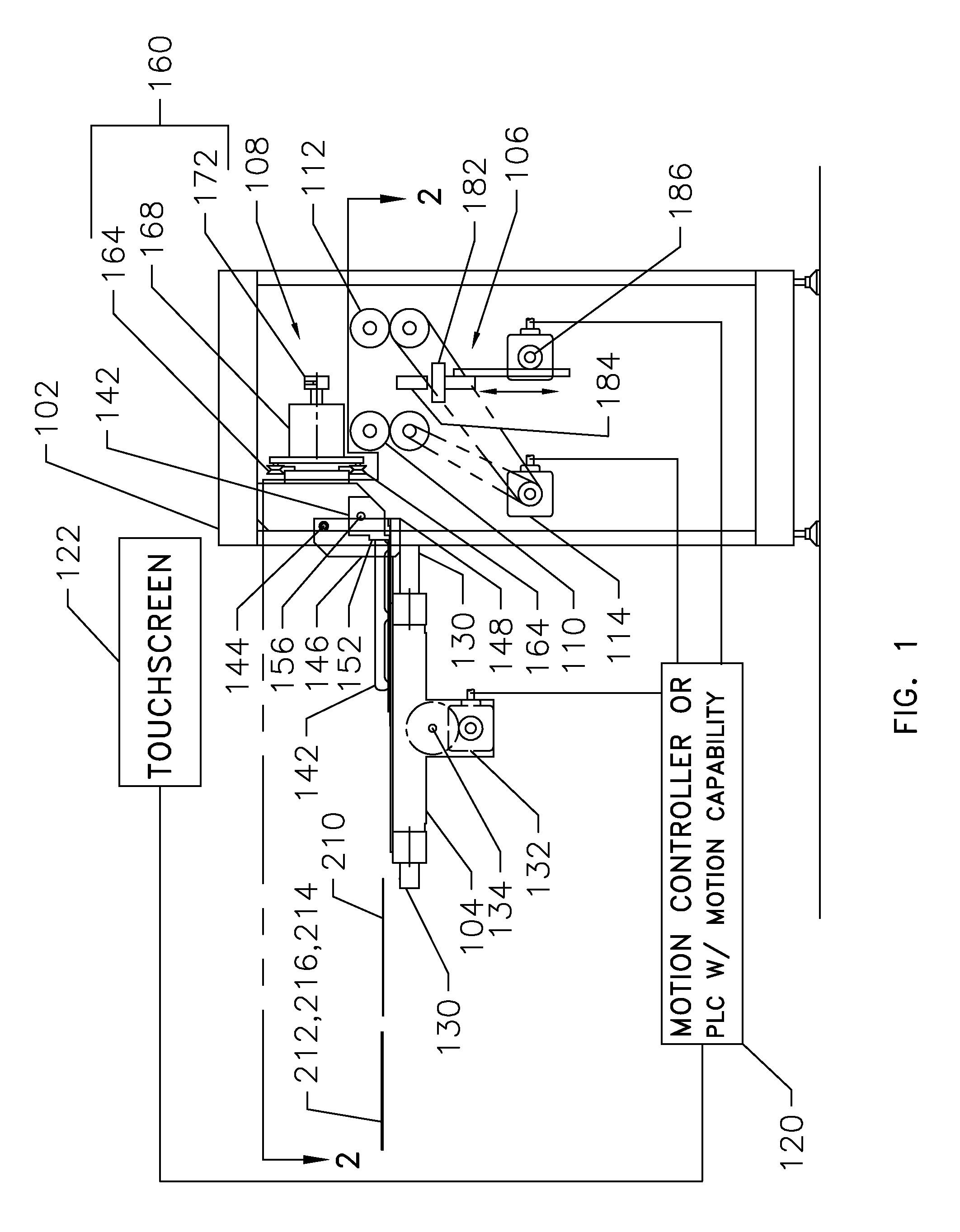

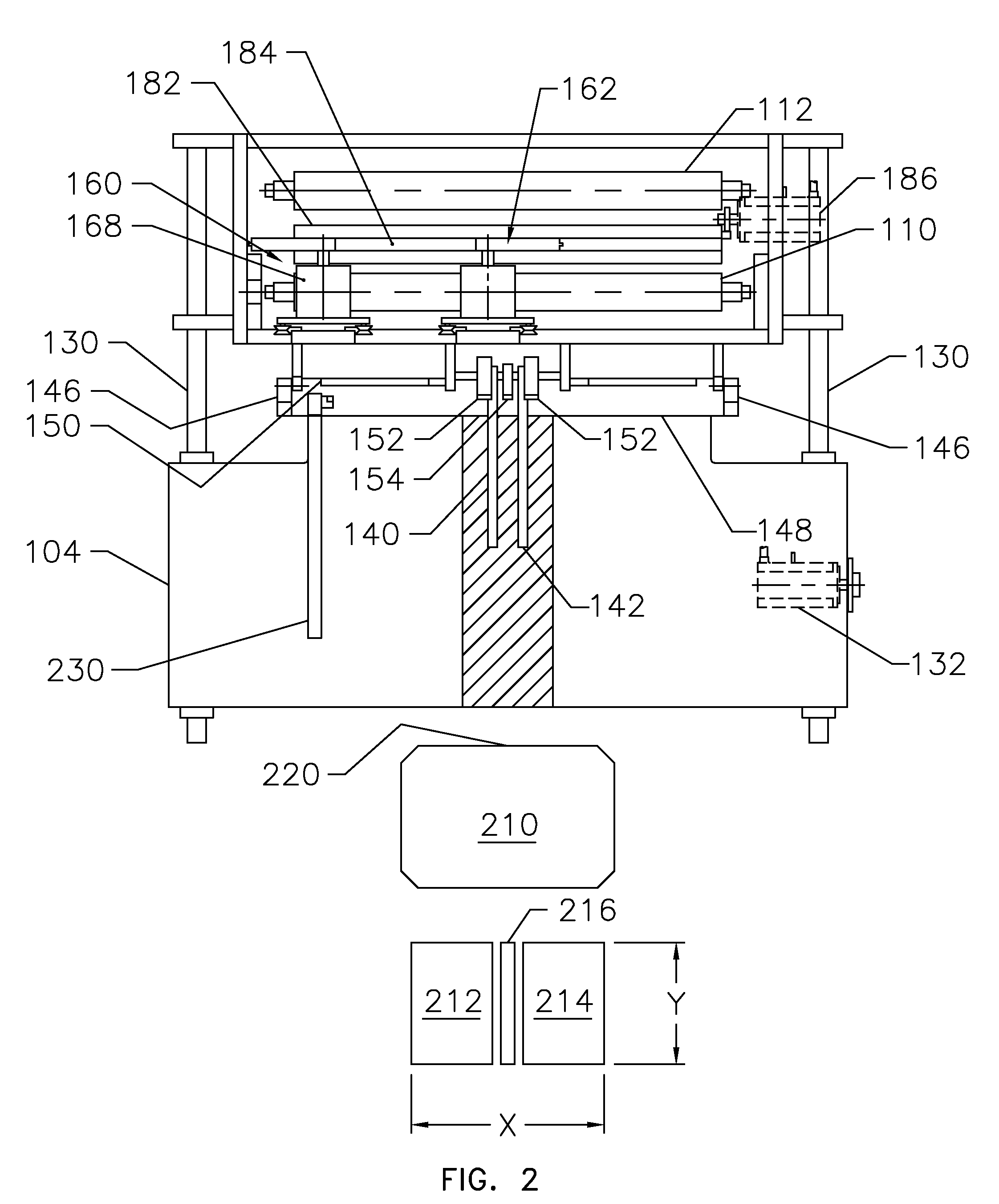

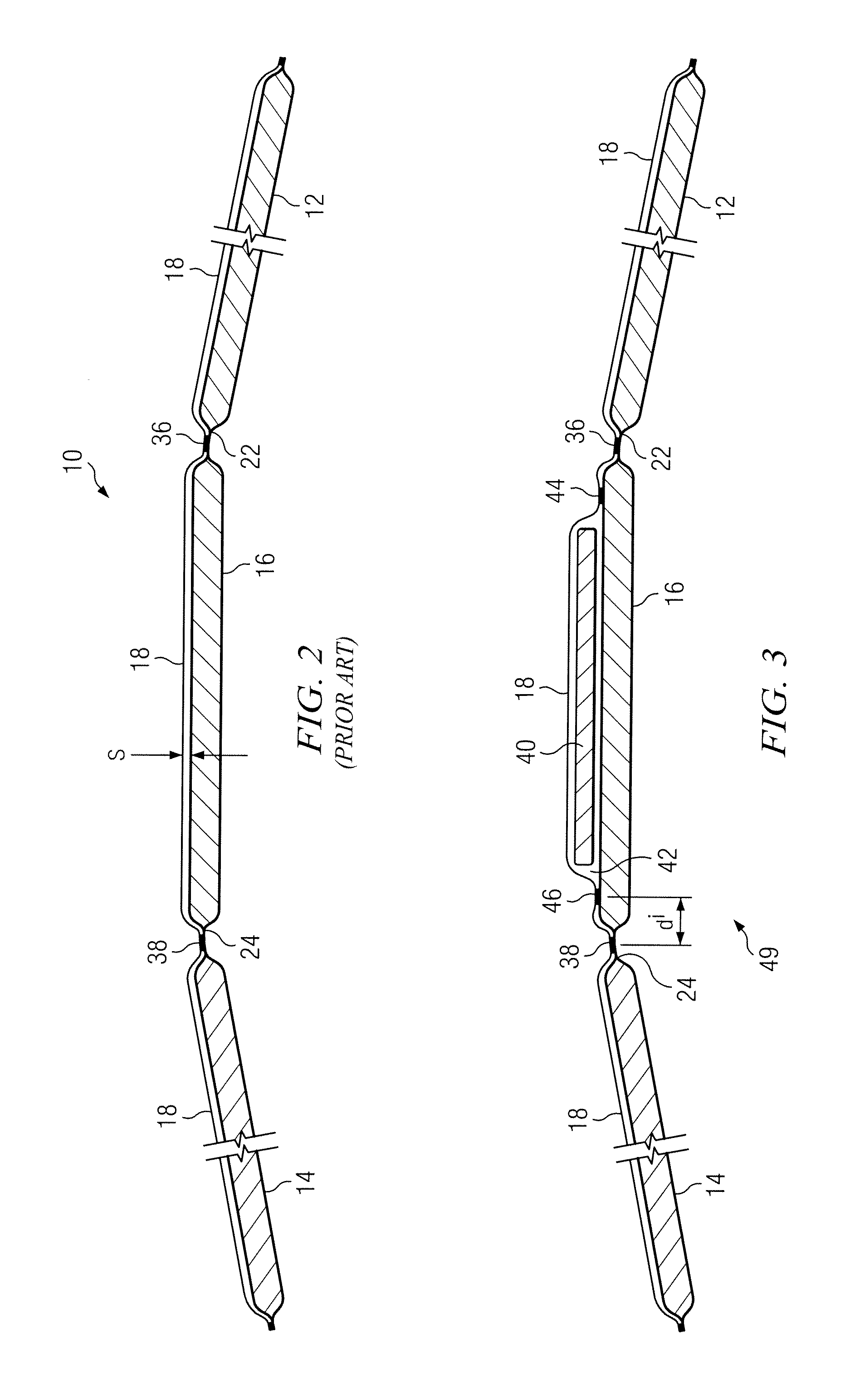

Binding system with sheet-wise formation of features

InactiveUS6966552B2More compactLess expensiveStapling toolsBookbinding casesEngineeringSheet material

The system and method for binding documents as described creates documents having features such as tabs, finger indexes, tear-out cards, and windows. These features are desirable for both their appearance and functionality and are easily added to a document during sheet-by-sheet processing. A sheet-wise binding system includes a sheet transport path for transporting a plurality of printed sheets in a sheet-wise manner and a punch configured to punch a feature into at least one of the sheets traveling through the sheet transport path. A stacking system is provided for stacking the punched and unpunched sheets and a binding system for binding the stacked sheets is used to form a finished document. A controller is programed to control the sheet transport path and the punch to create the features in selected sheets and at selected locations in the sheets according to a punch schedule.

Owner:HEWLETT PACKARD DEV CO LP

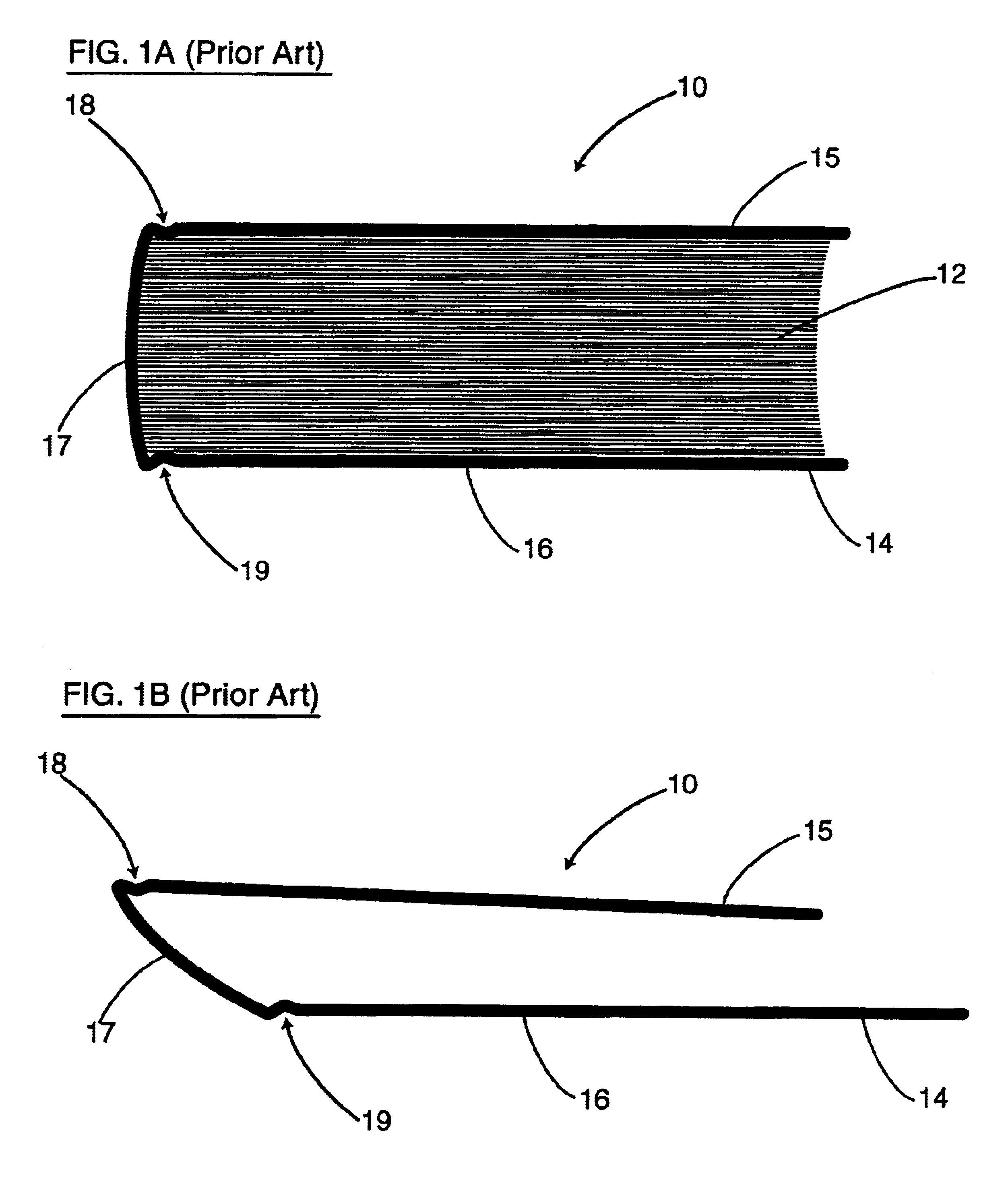

Unibody binder and the process of making the binder

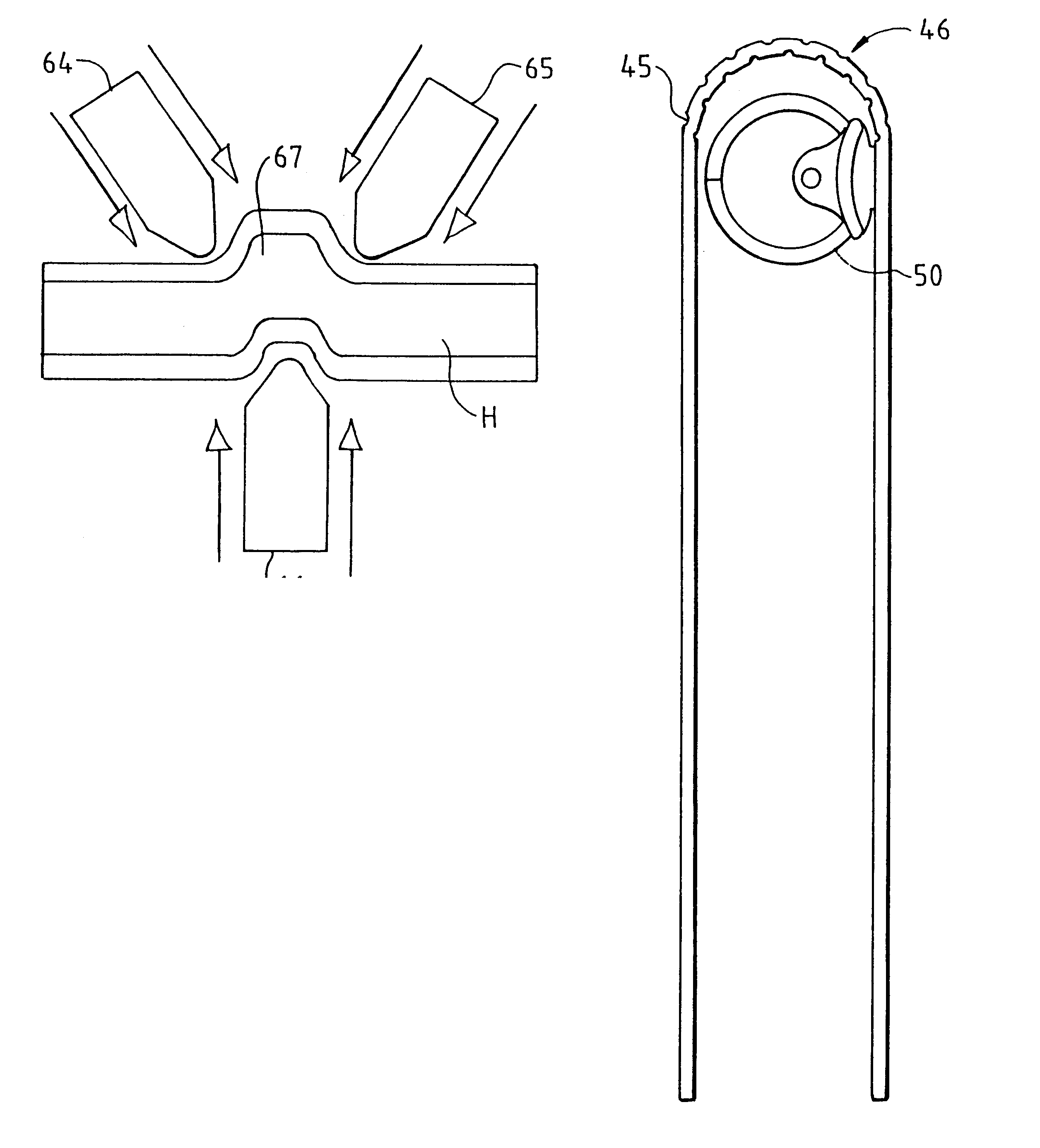

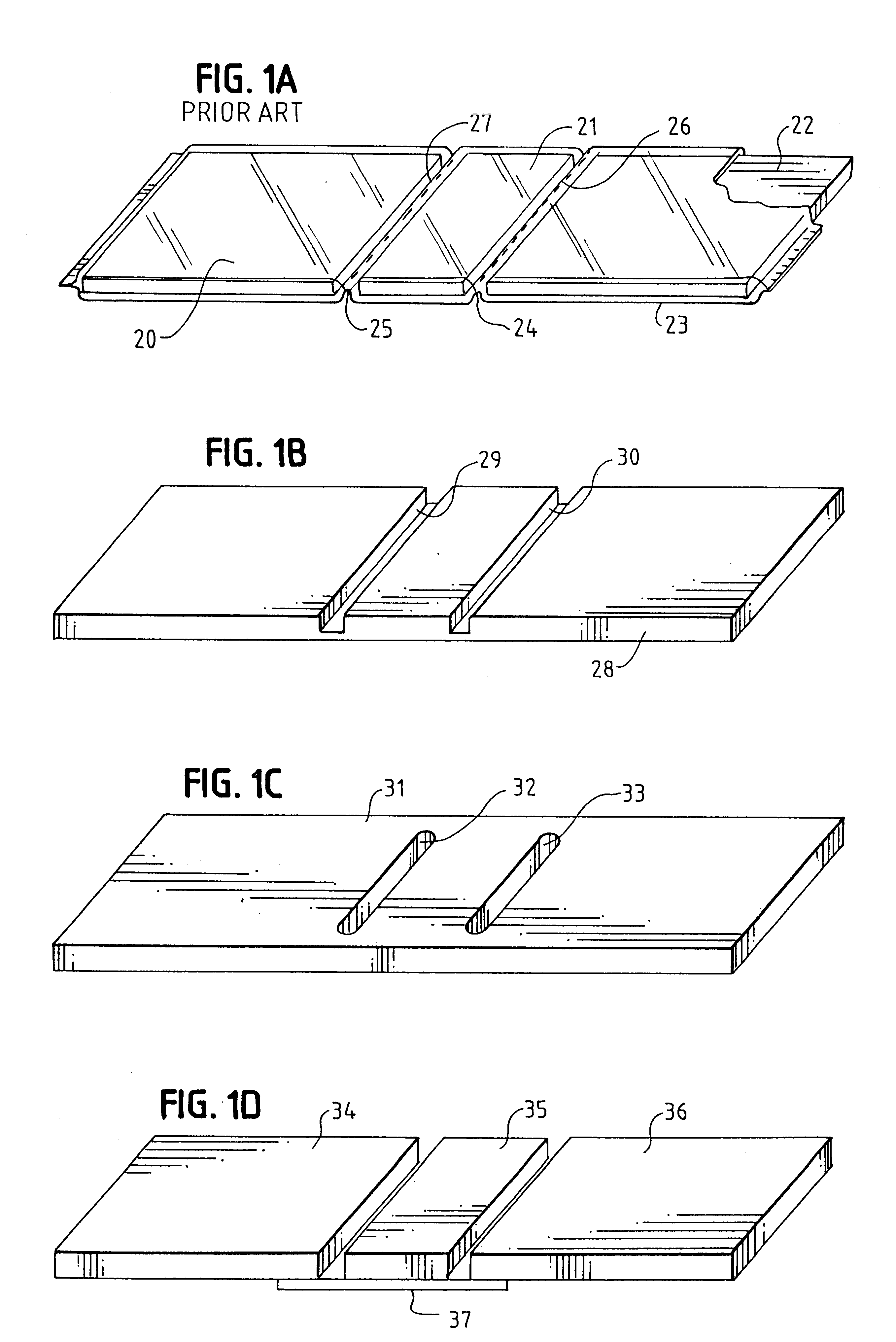

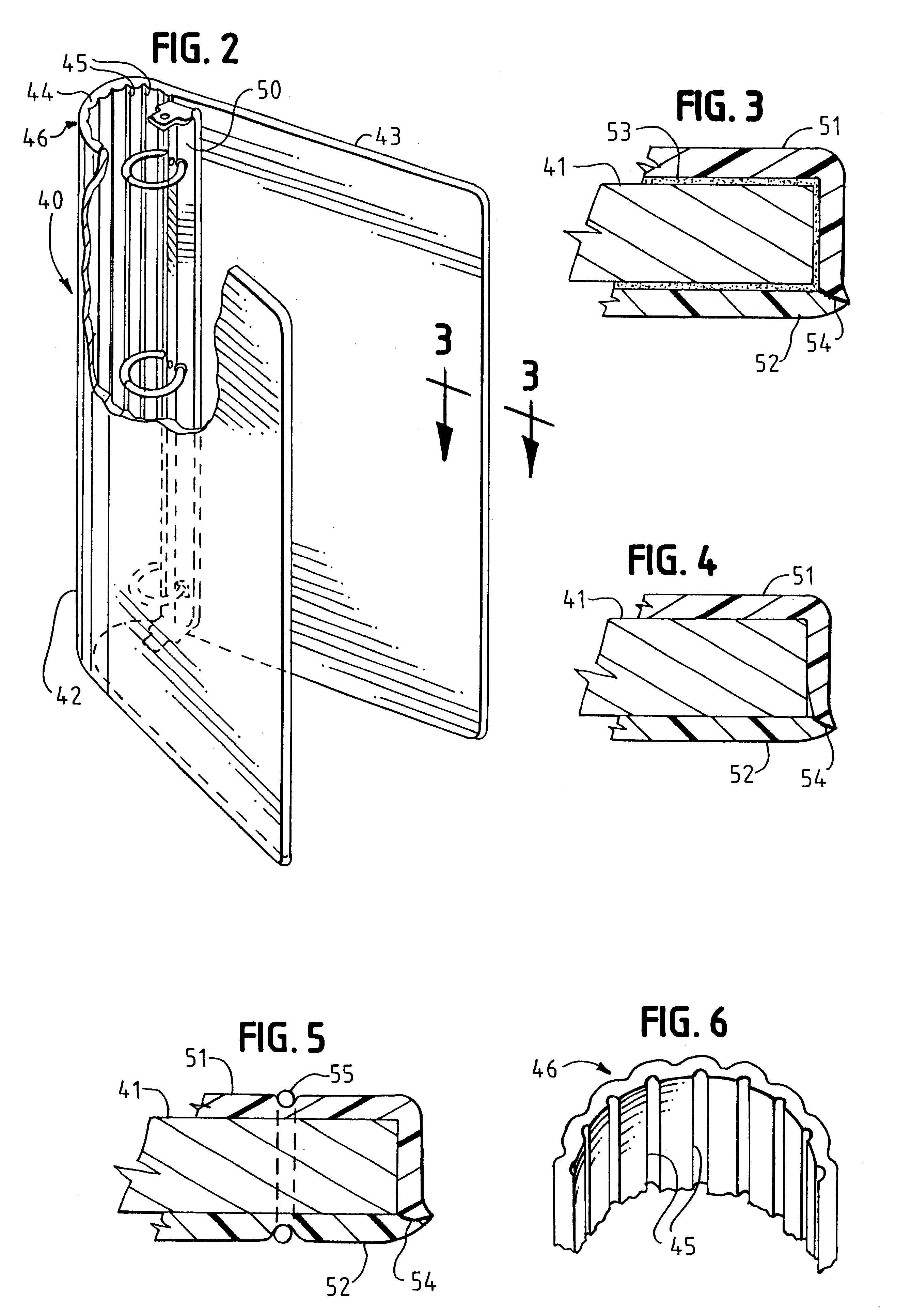

The invention includes novel unibody binder constructions and the process of making same. The binder is composed of two plastic sheets comprising such material as polyvinyl chloride, polyolefin, polypropylene, polyvinyl acetate or other similar plastics. An uncompromised single piece of board or similar rigid material, such as chipboard, microflute board, corrugated board, fiberboard, etc., or a synthetic substrate, is then coated with a glue such as a resin glue, a U.V. adhesive, etc., on both sides and sandwiched between the plastic sheets. This sandwich is then formed into the unibody construction by welding the entire outer perimeter. At the time of welding, the air between the plastic sheets and the board is pressed or vacuumed out. To create the hinges on the binder, the unibody construction is then hydraulically creased to the extent necessary by using three moving blades to provide living hinges. Many different spine configurations may be achieved depending on the number of creases desired for flexibility. Various capacities of ring metals may be accommodated by increasing or decreasing the number of creases or distances therebetween. Also, various round or flat back profiles can be formed after the flat board has been sealed into a sandwich between two plastic sheets that have been welded together. A clear plastic sheet secured to the bottom and side edges of the outer plastic sheet to provide a pocket for visible inserts and plastic sheets can be secured to the inner plastic sheet to provide inner pockets for inserts.

Owner:WELCH STEPHEN R

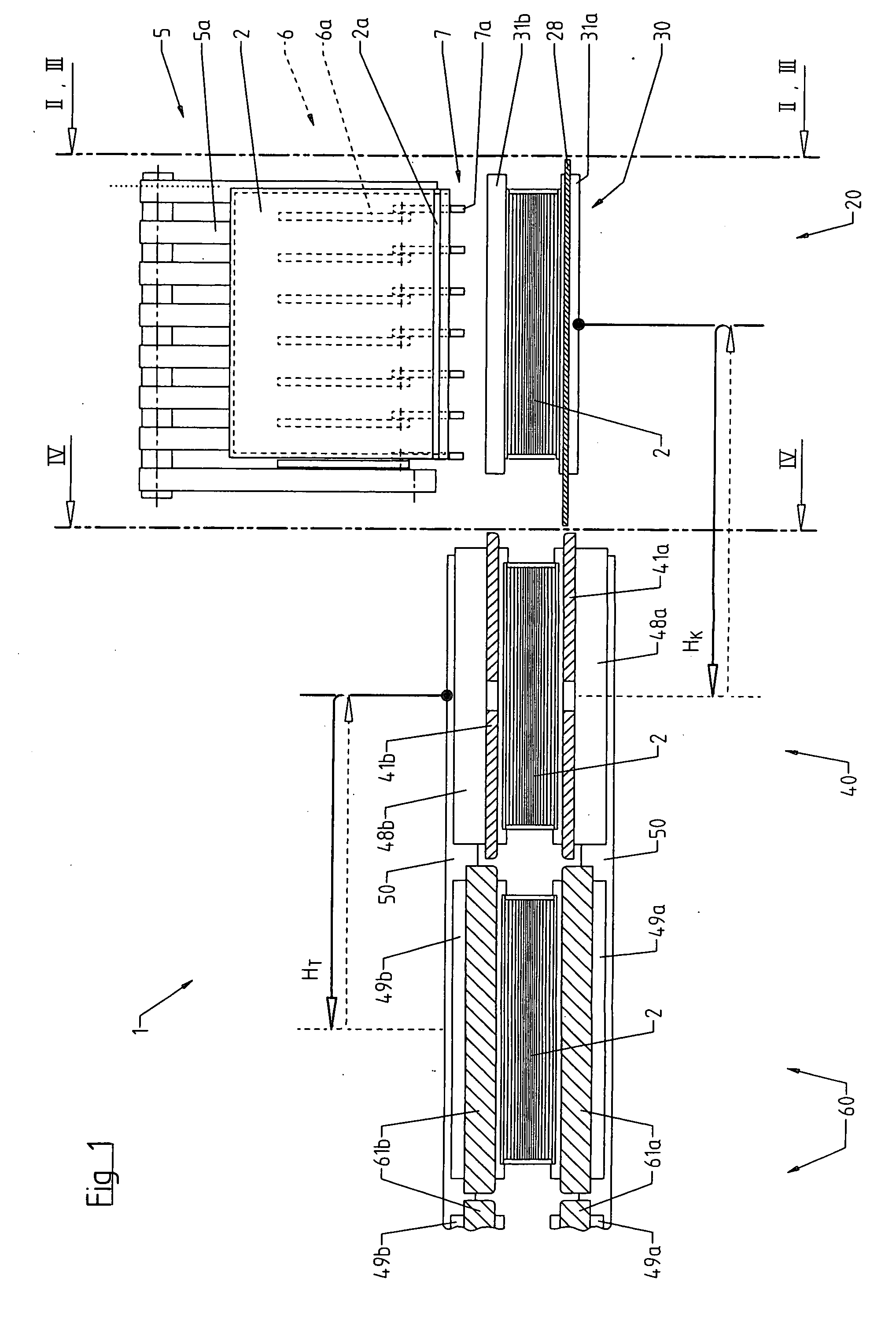

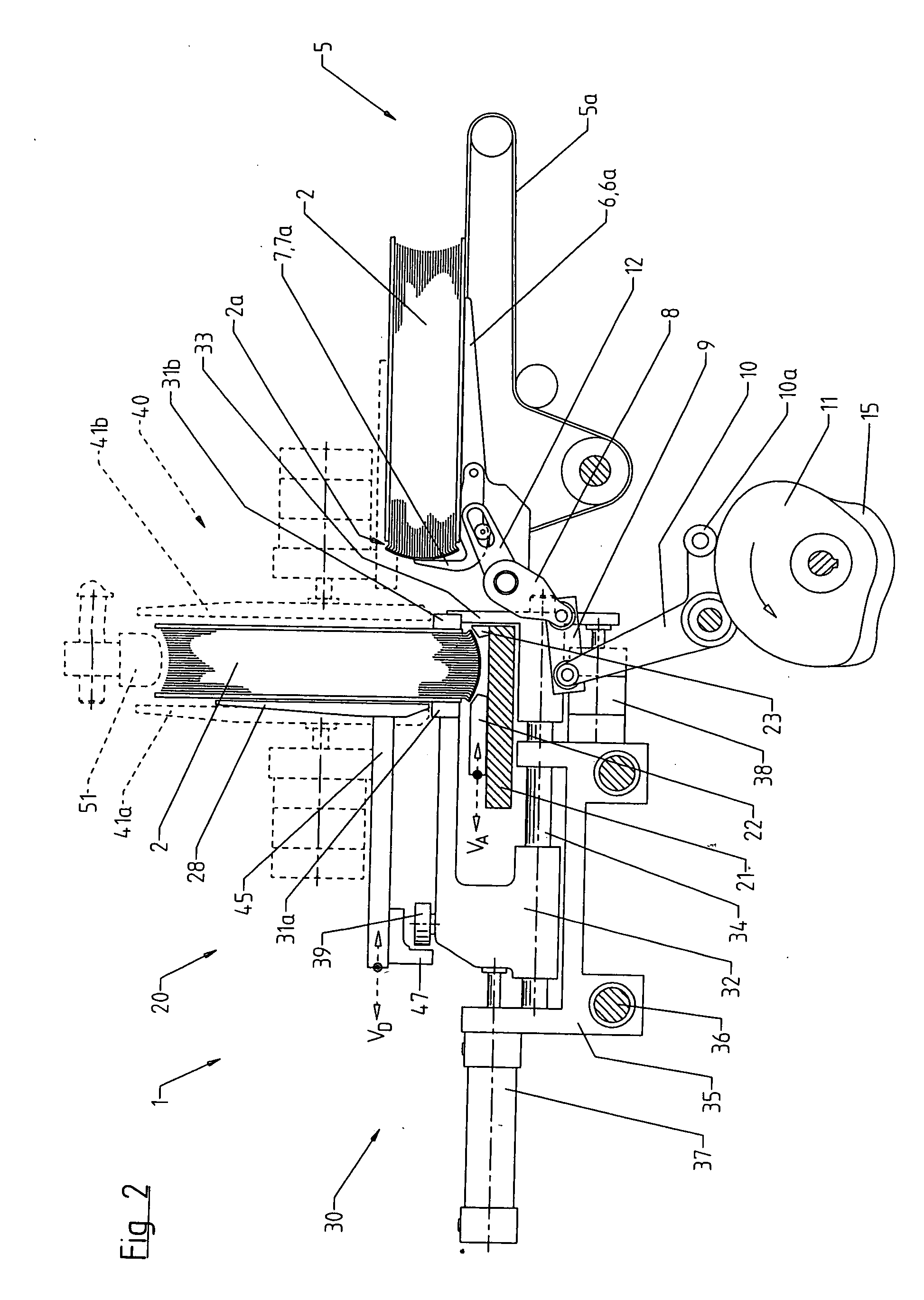

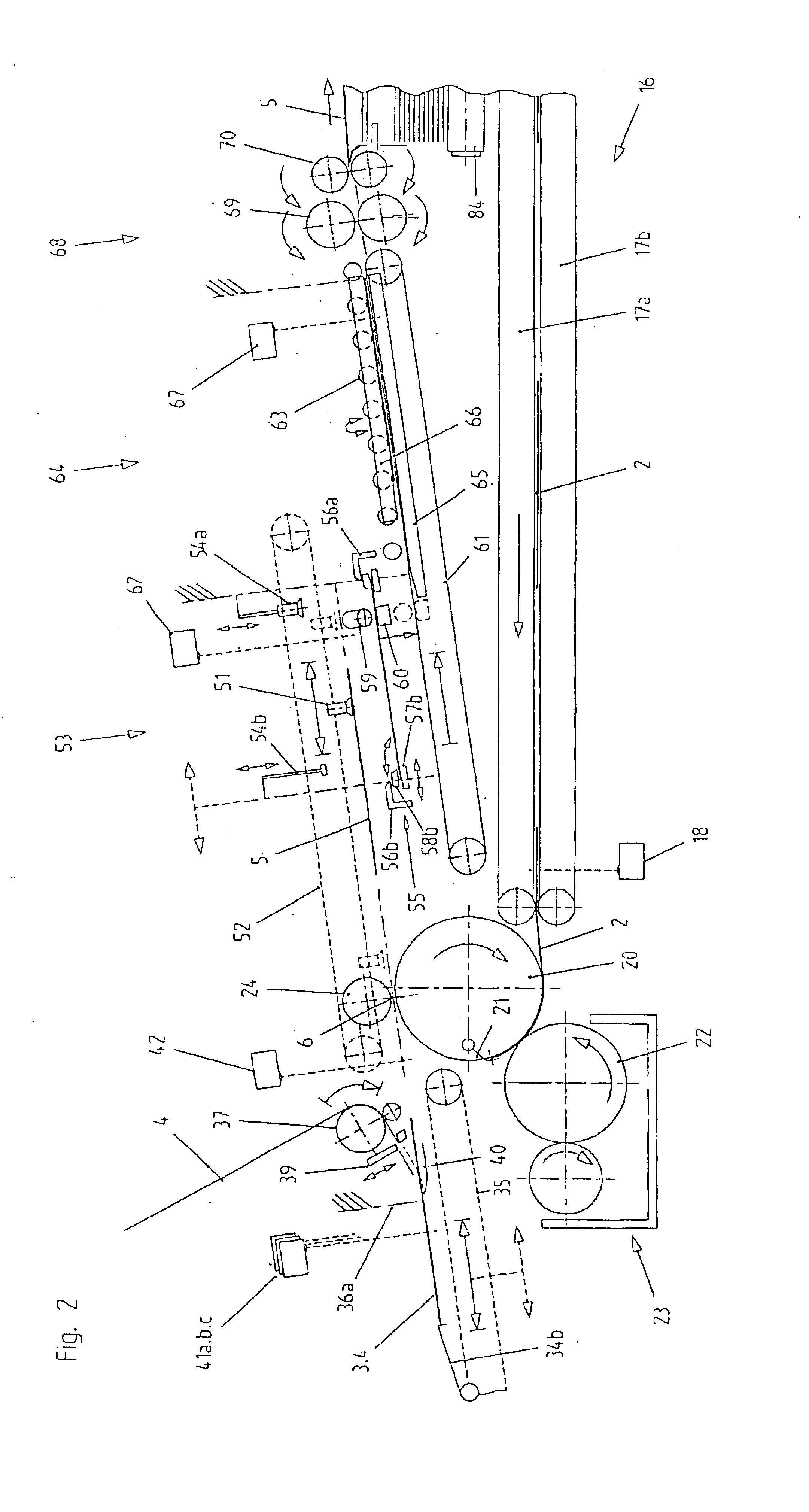

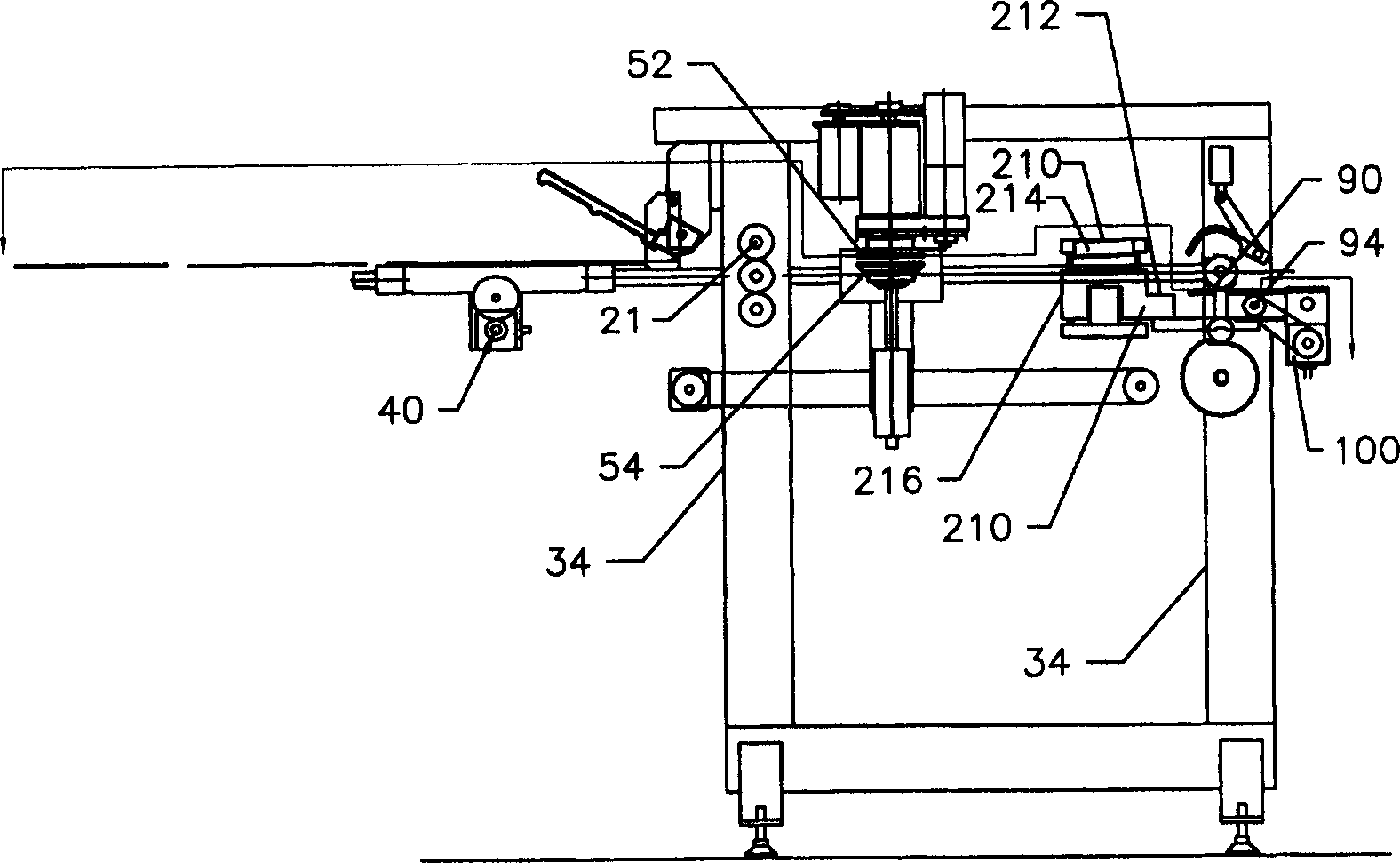

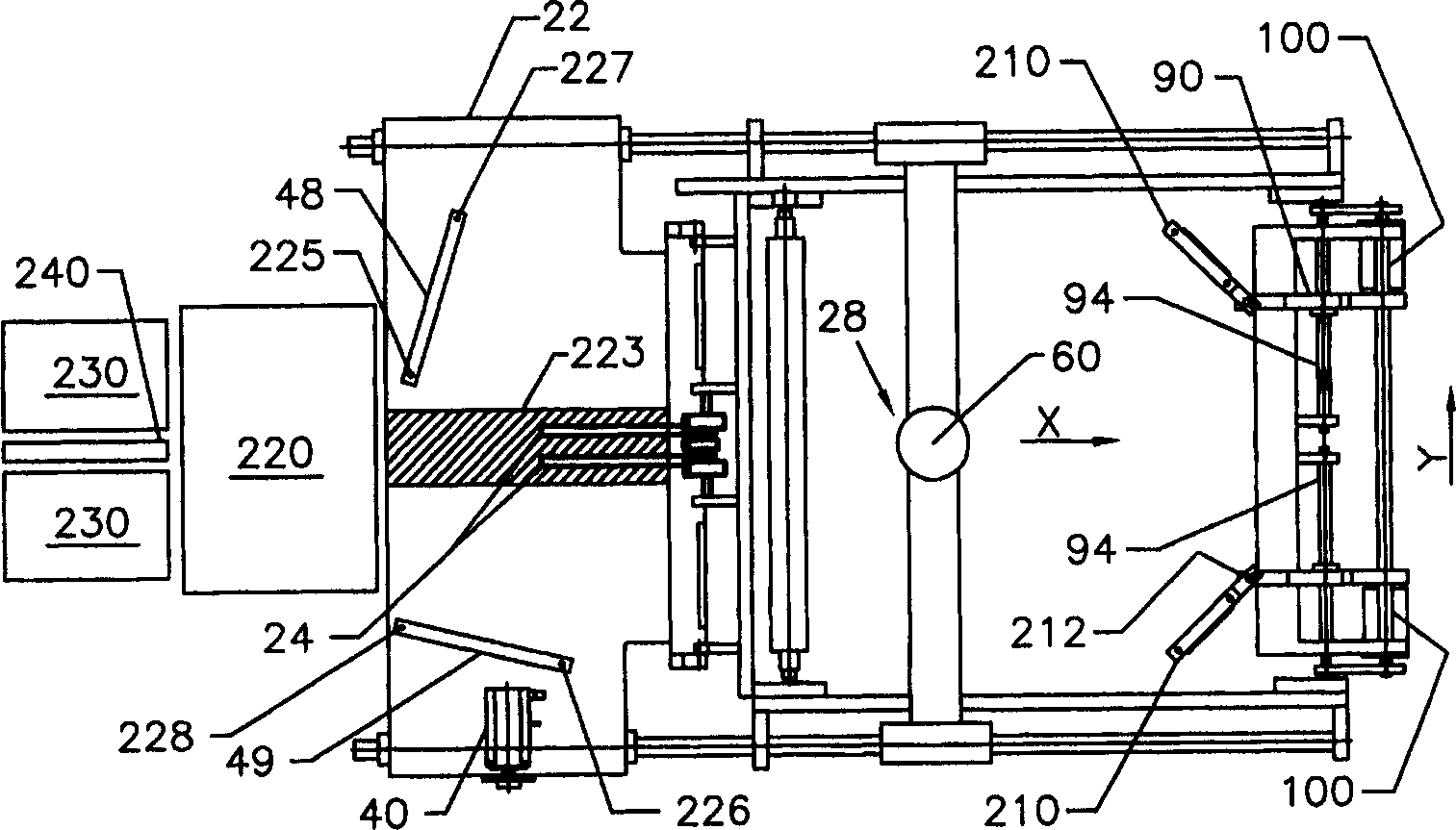

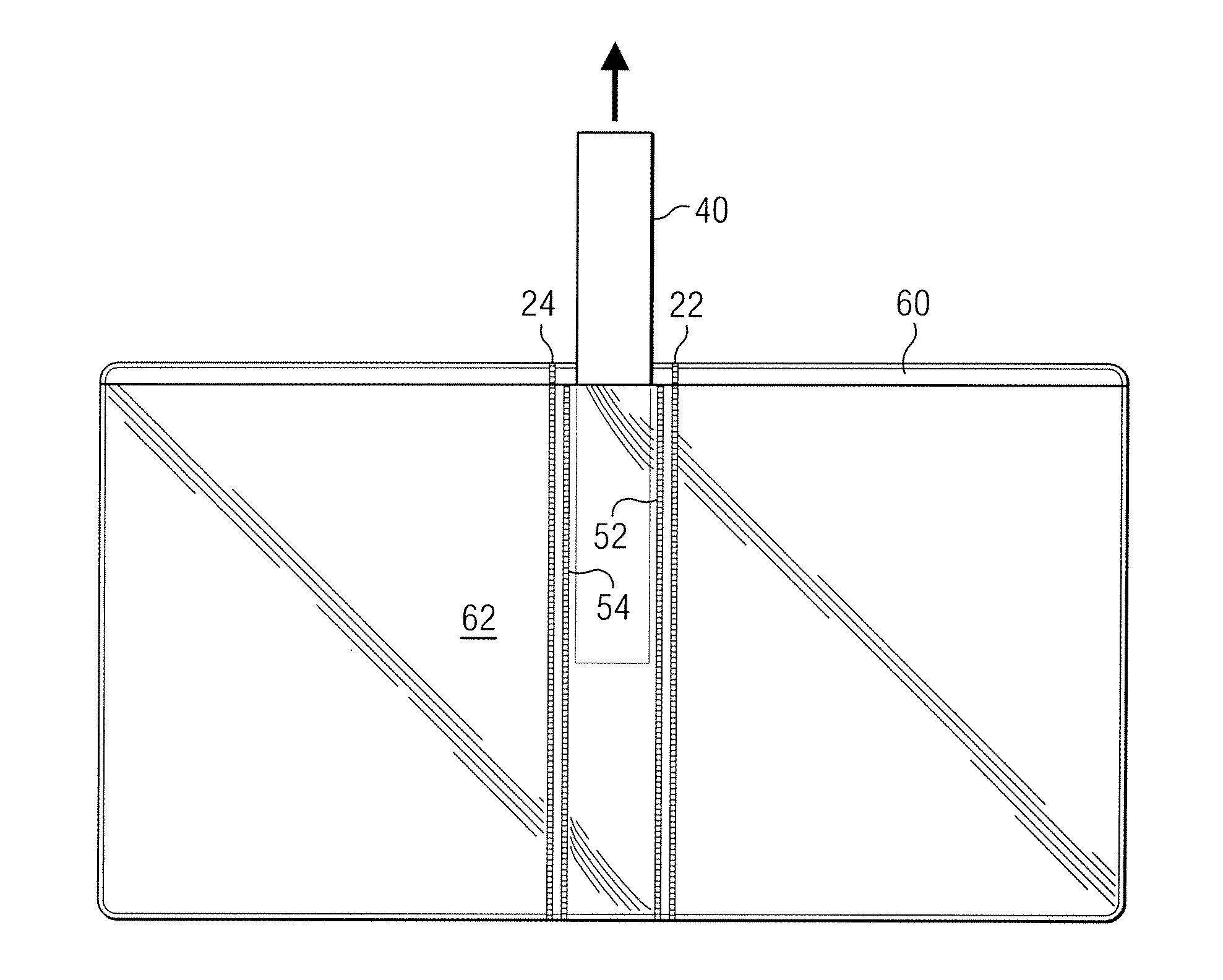

Binding-in and pressing machine

InactiveUS20060140742A1Simple and cost-efficient designQuality improvementBookbinding casesCasing-inLateral regionEngineering

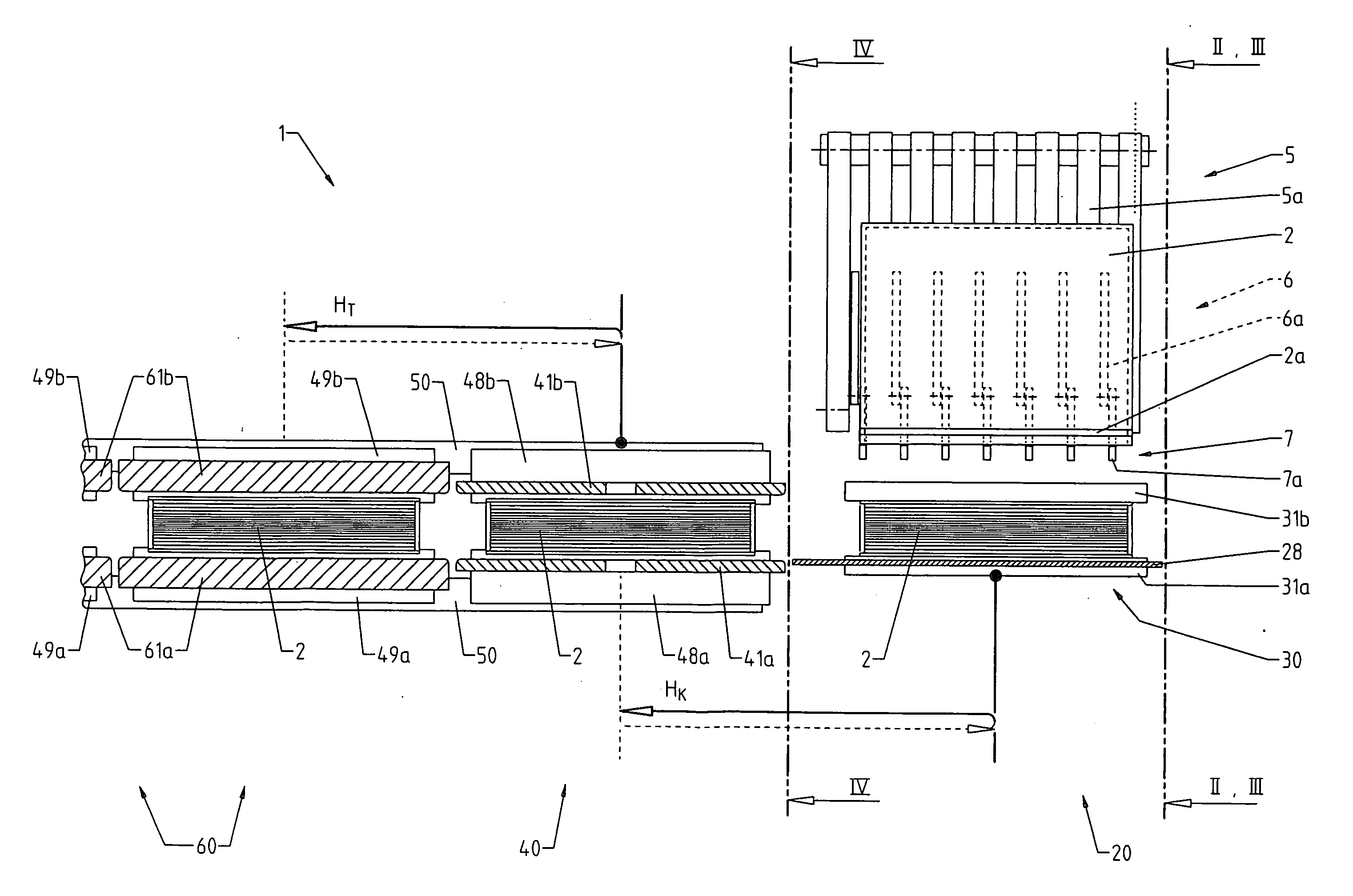

A binding-in and pressing machine (1) with a plurality of pressing stations (60) and heated joint forming rails situated on a reciprocating carriage (50). An alignment station (20) is provided for aligning the book case joints (2a) at the height of the joint forming rails (49a, b), including a height-adjustable alignment table (21) with rails (22, 23) for supporting the book (2) on the outer edges of its spine and guide elements (28, 6) for centering the book on the alignment table. A separate pre-forming station (40) is also provided that comprises the forming rail (51), clamping plates (41a, b), and joint rails (48a, b) that engage into the book case joints (2a) and counteract a downward movement of at least the book case joints (2a). The books (2) aligned in the alignment station (20) are transferred into the pre-forming station (40) while being clamped in lateral regions near the joints. The effective times available for realizing a functionally safe alignment and a permanent pre-forming of the books are extended due to the assignment of the alignment and pre-forming functions to two separate stations.

Owner:KOLBUS

Sheet processing apparatus and image forming apparatus

A current invention provides a sheet processing apparatus and an image forming apparatus capable of obtaining a sheet bundle which can be double-leaved and released without use of any binding device. A slit S to which a projection Pa provided at an end portion opposite to a side to be bound by a binding portion of a front cover P1 is formed in a back cover P3 of a sheet bundle PA by an insertion portion forming portion. Further, creases L1, L2 for inserting the projection Pa into the slit S while surrounding sheets P2 existing between the front cover P1 and the back cover P2 are formed in the back cover P3 of the sheet bundle PA by a crease forming portion.

Owner:CANON KK

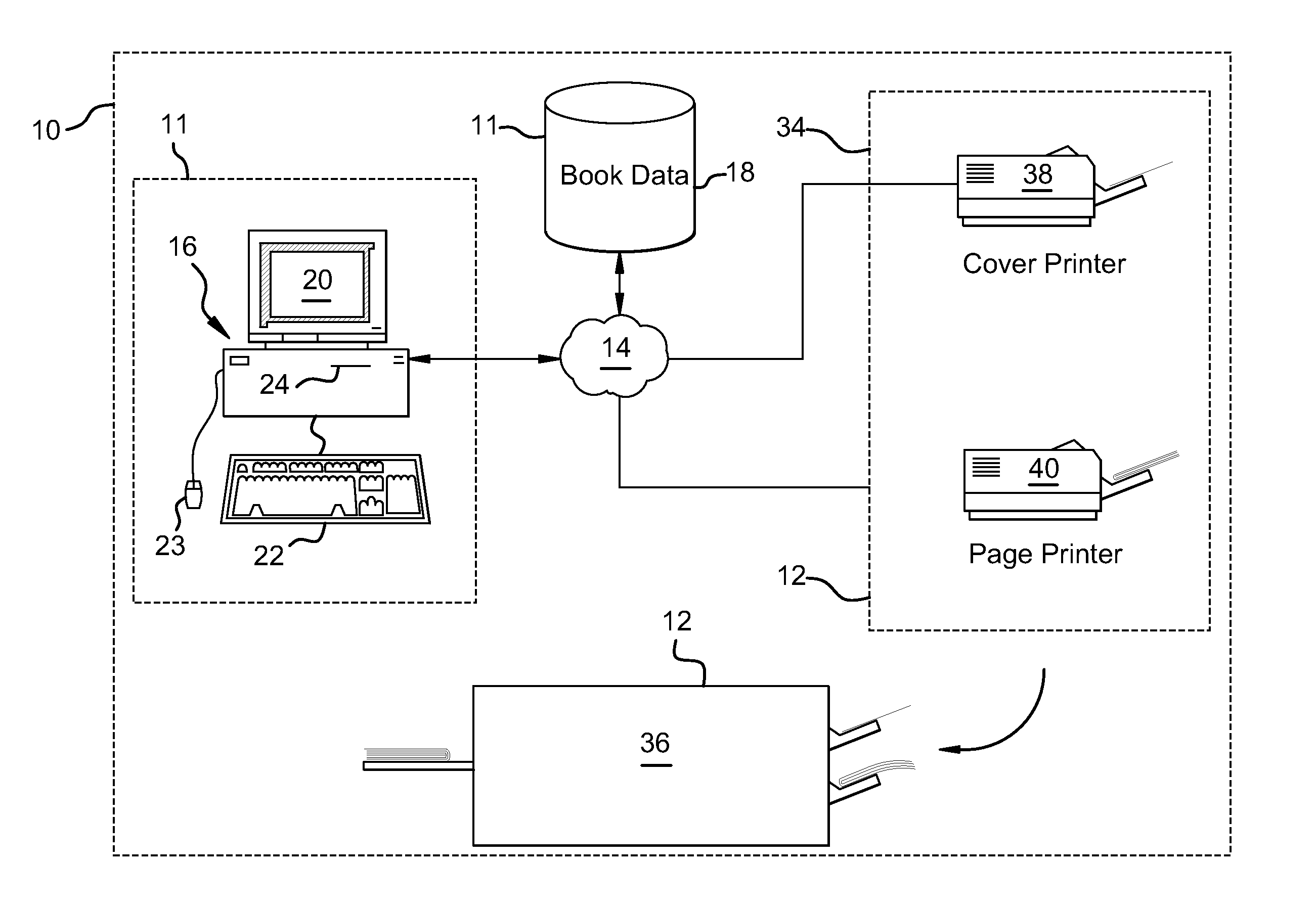

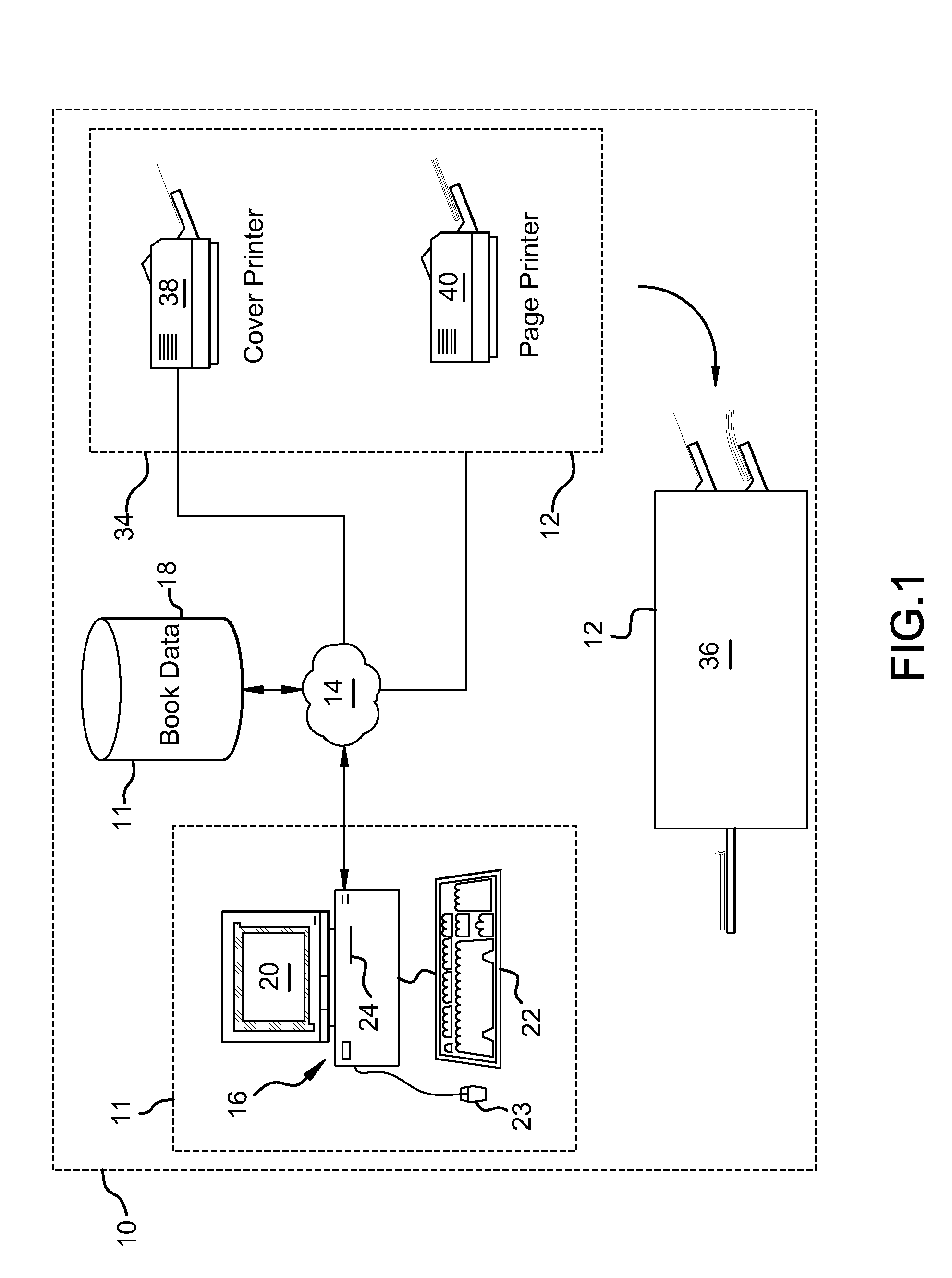

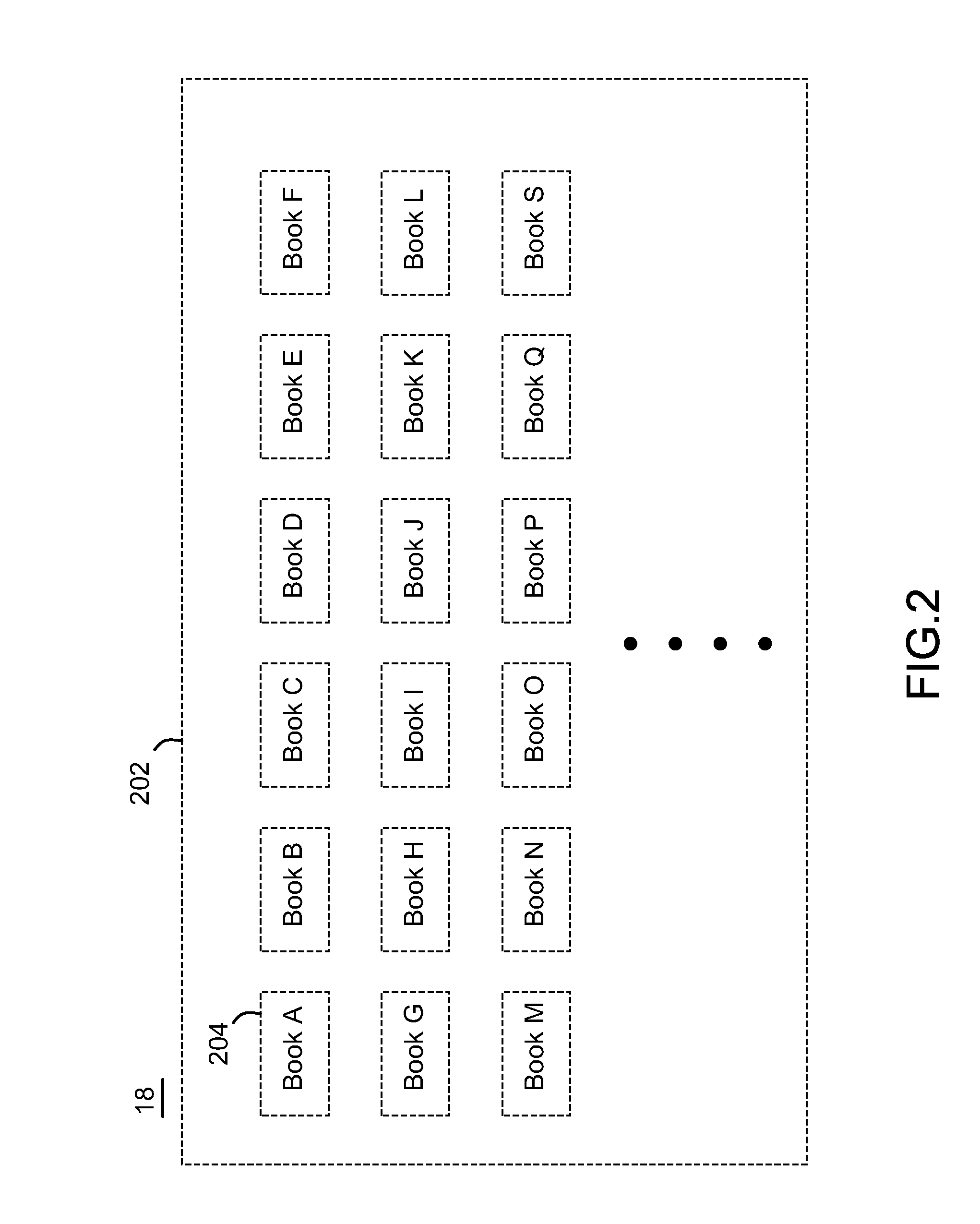

Tailored method and system for custom manufactured books

A book on demand system for manufacturing a set books. The system includes an order placement system and a book manufacturing system. The order placement system includes a computer and a database for storing books in an electronic form. A customer can operate the computer to access the database and to select a set of books to purchase. In addition, the customer can define the storage space will be used to store the set of books. The computer responds to this customer input by manufacturing the set of books so that the books can be placed physically within the storage space.

Owner:HEWLETT PACKARD DEV CO LP

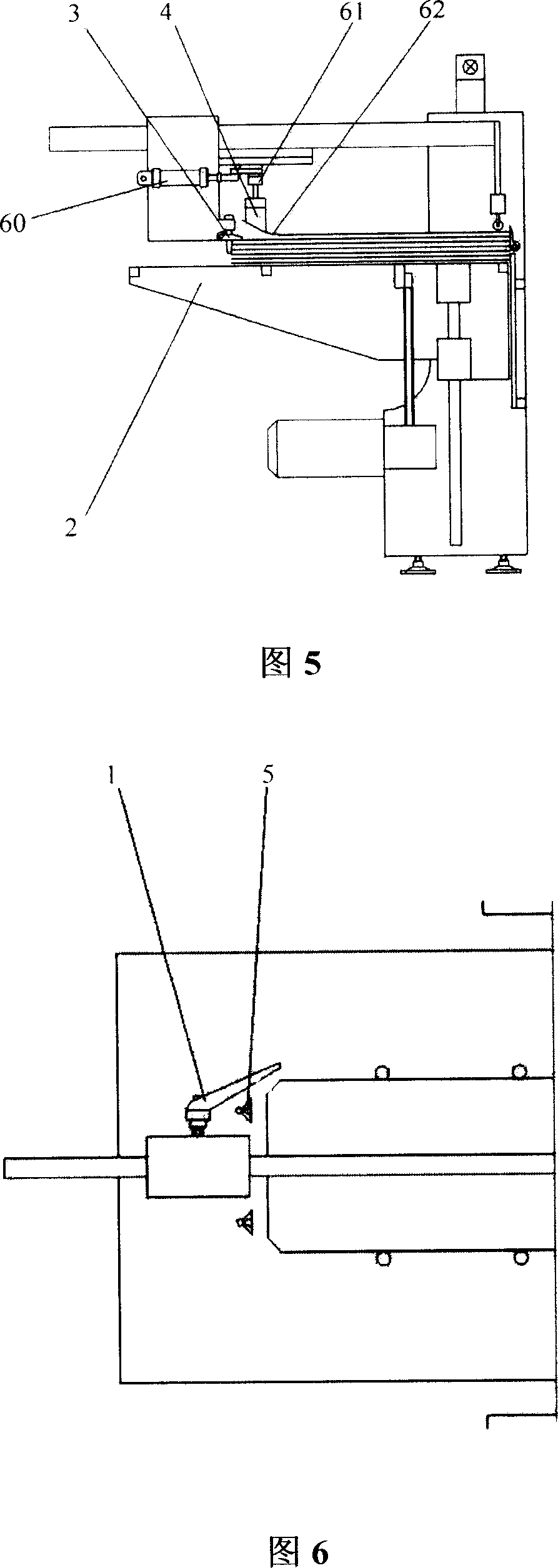

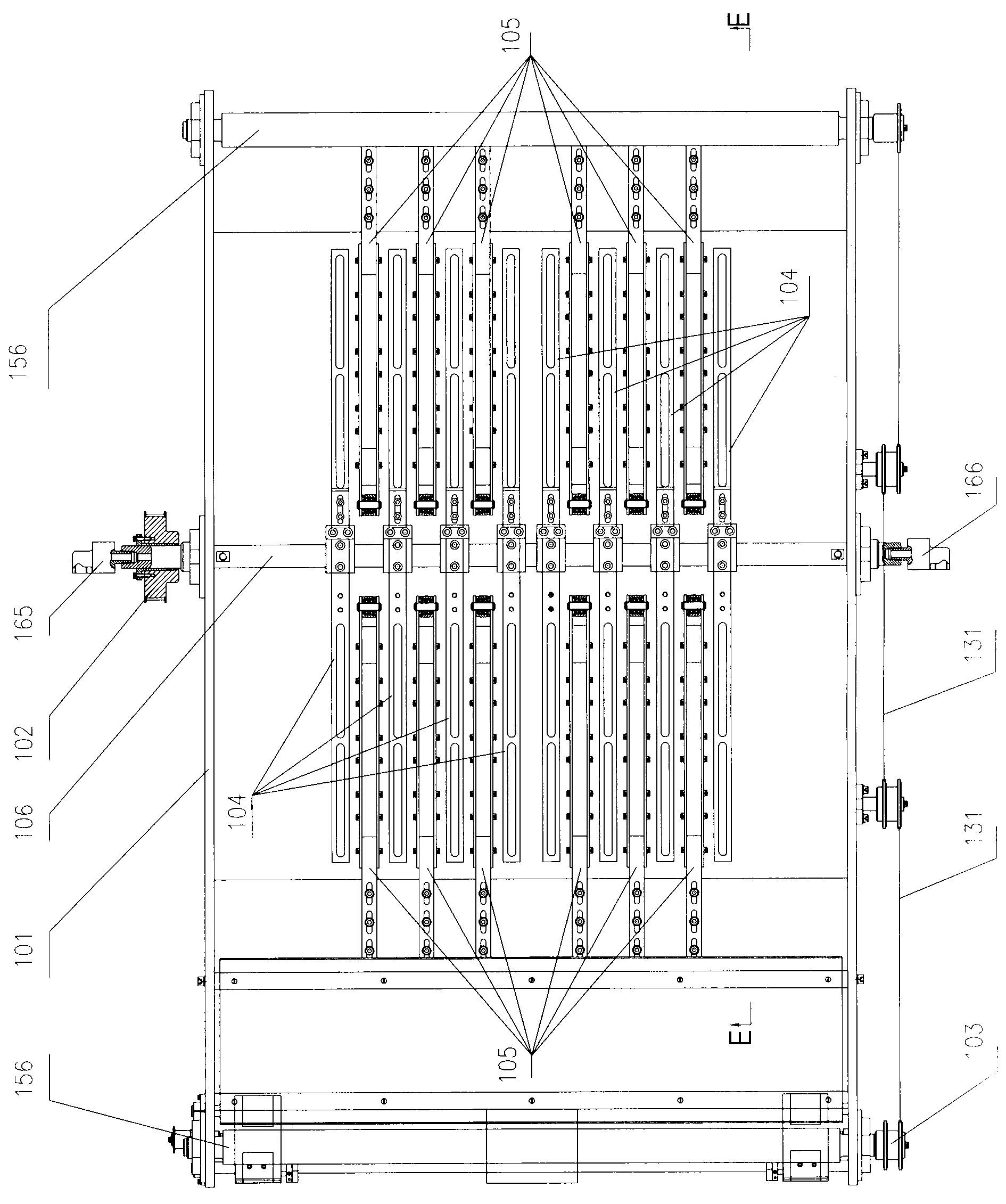

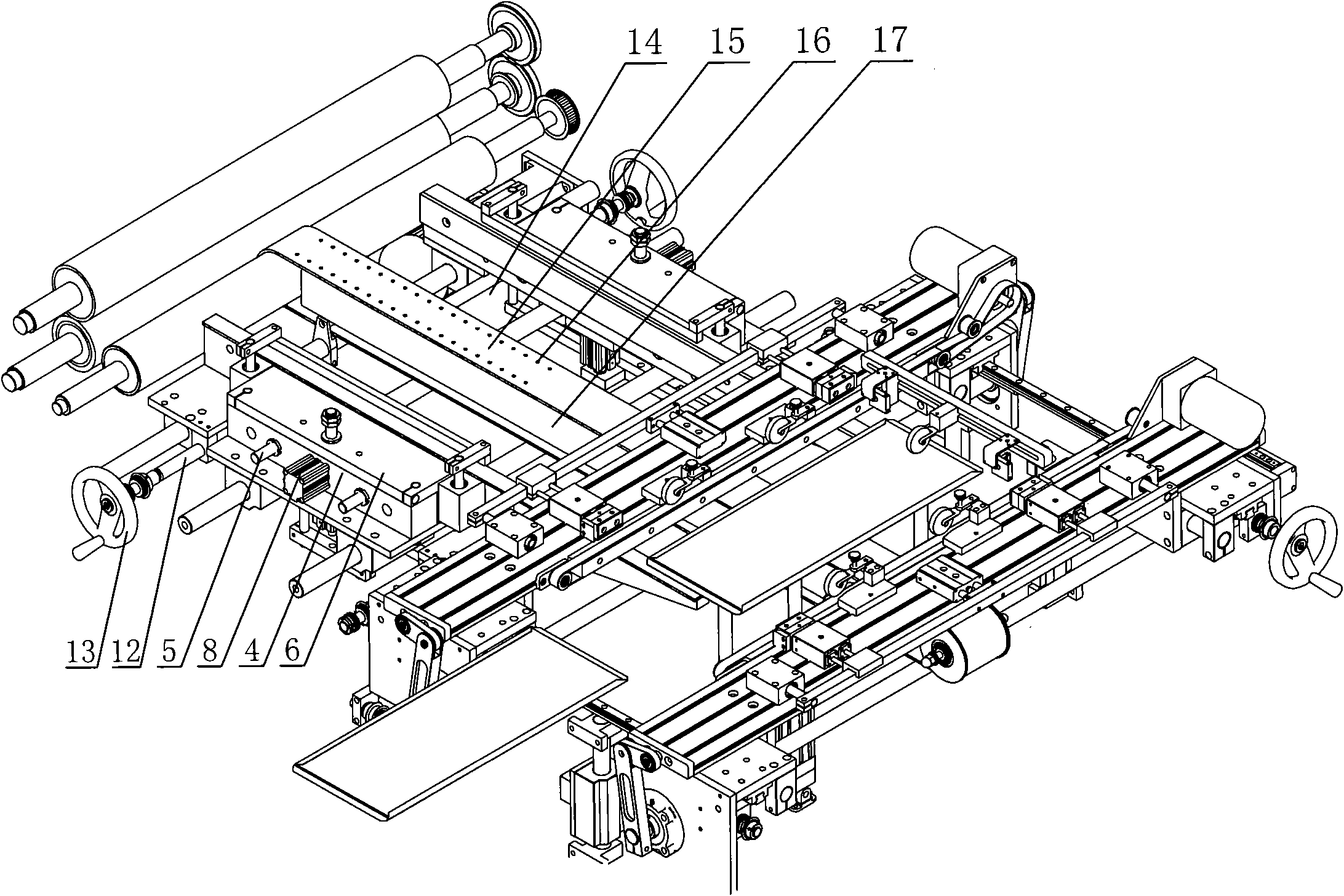

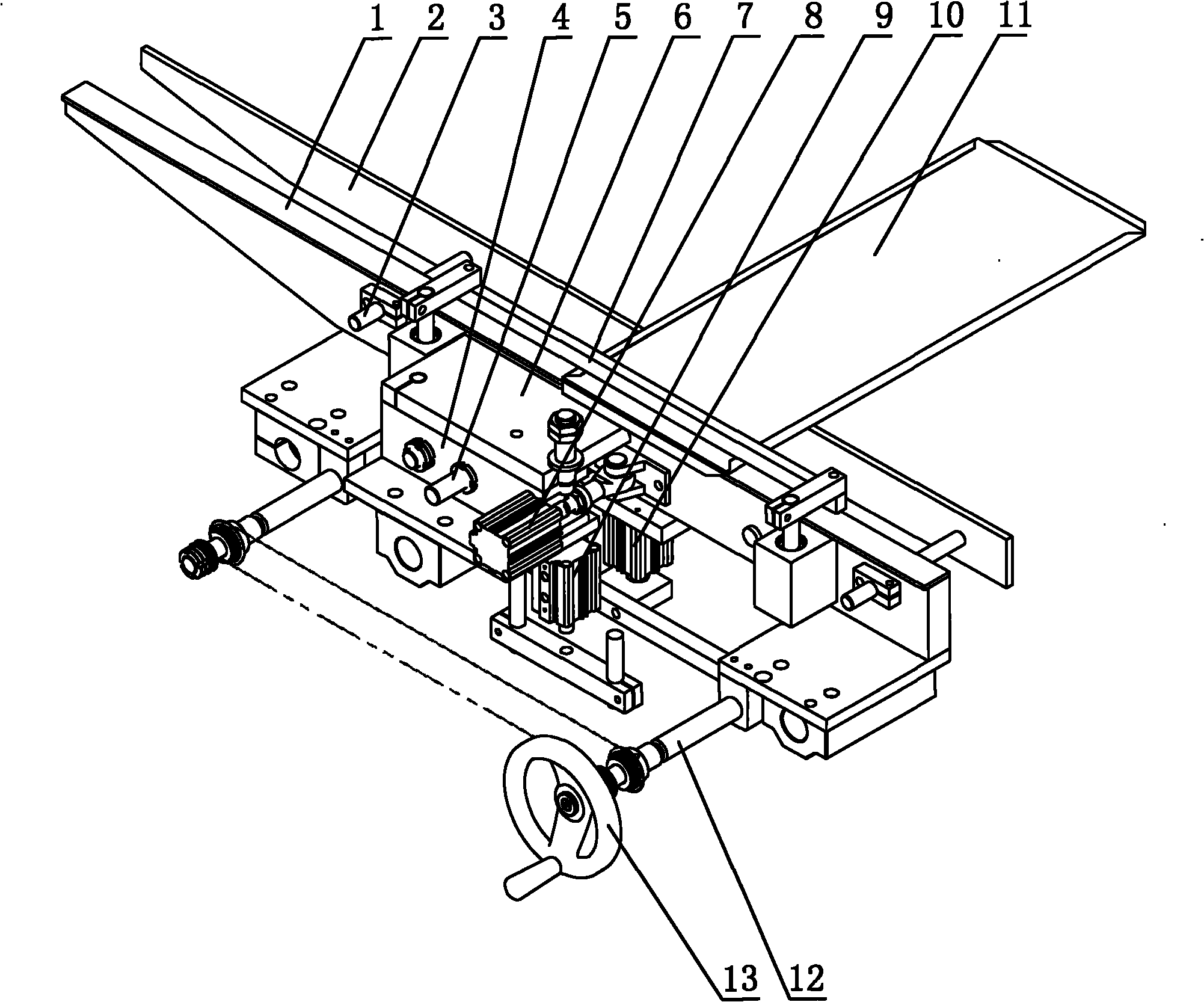

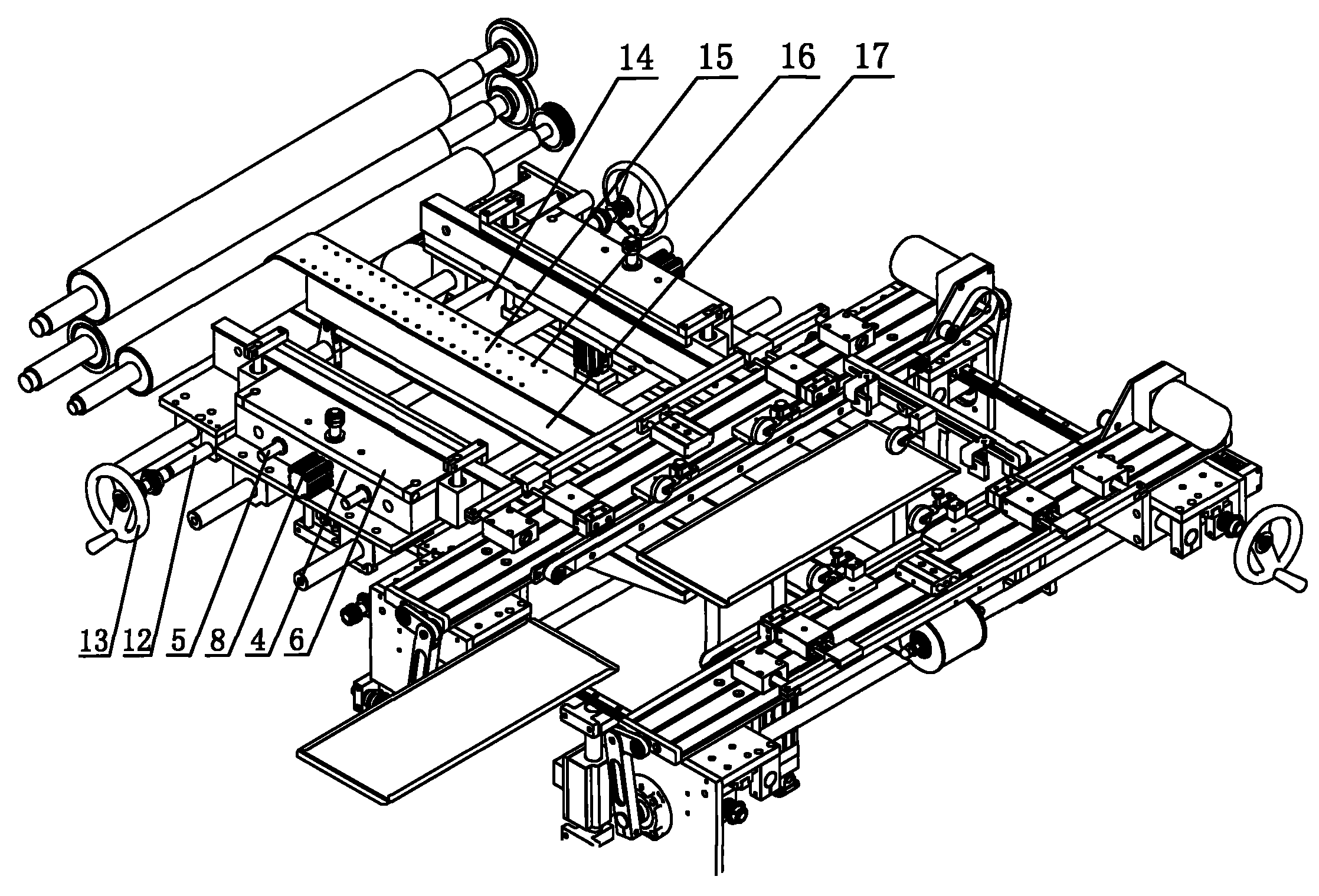

Lateral taping mechanism of full automatic edge bander

The invention discloses the improvement of a lateral taping mechanism of a full automatic edge bander; the lateral taping mechanism is provided with a frame; the frame is provided with a conveying platform; the mechanism is characterized in that both sides of the conveying platform are provided with a positioning beam and a flanging device; the positioning beam can move up and down relative to the conveying platform; the flanging device is installed at the outer side of the positioning beam; the flanging device comprises a flanging base and a flanging plate; the flanging plate is installed onthe flanging base; the flanging plate can move up and down on the flanging base and is mutually matched with the positioning beam; and the flanging base can move left and right relative to the conveying platform of the frame. The mechanism has low requirement for the width of paperboard side, relatively wide use range, clean and flat surface of the produced paperboard.

Owner:薛迪虎

Curable hot melt adhesive for casemaking

InactiveUS6858695B2Minimize warpageFast and efficientBookbinding casesSynthetic resin layered productsMoistureHot-melt adhesive

A curable casemaking adhesive, books and related articles bound thereby. In one embodiment, a UV curable hot melt adhesive is used to form the case, which is preferably also embossed. In another embodiment, a moisture curable hot melt adhesive is used to form the case, which is preferably also embossed.

Owner:HENKEL IP & HOLDING GMBH

System and process for automated high-efficiency book production

InactiveUS20140030043A1Improve efficiencyEasy to processOther printing matterBookbinding casesBarcodeUV coating

Owner:CONSOL GRAPHICS

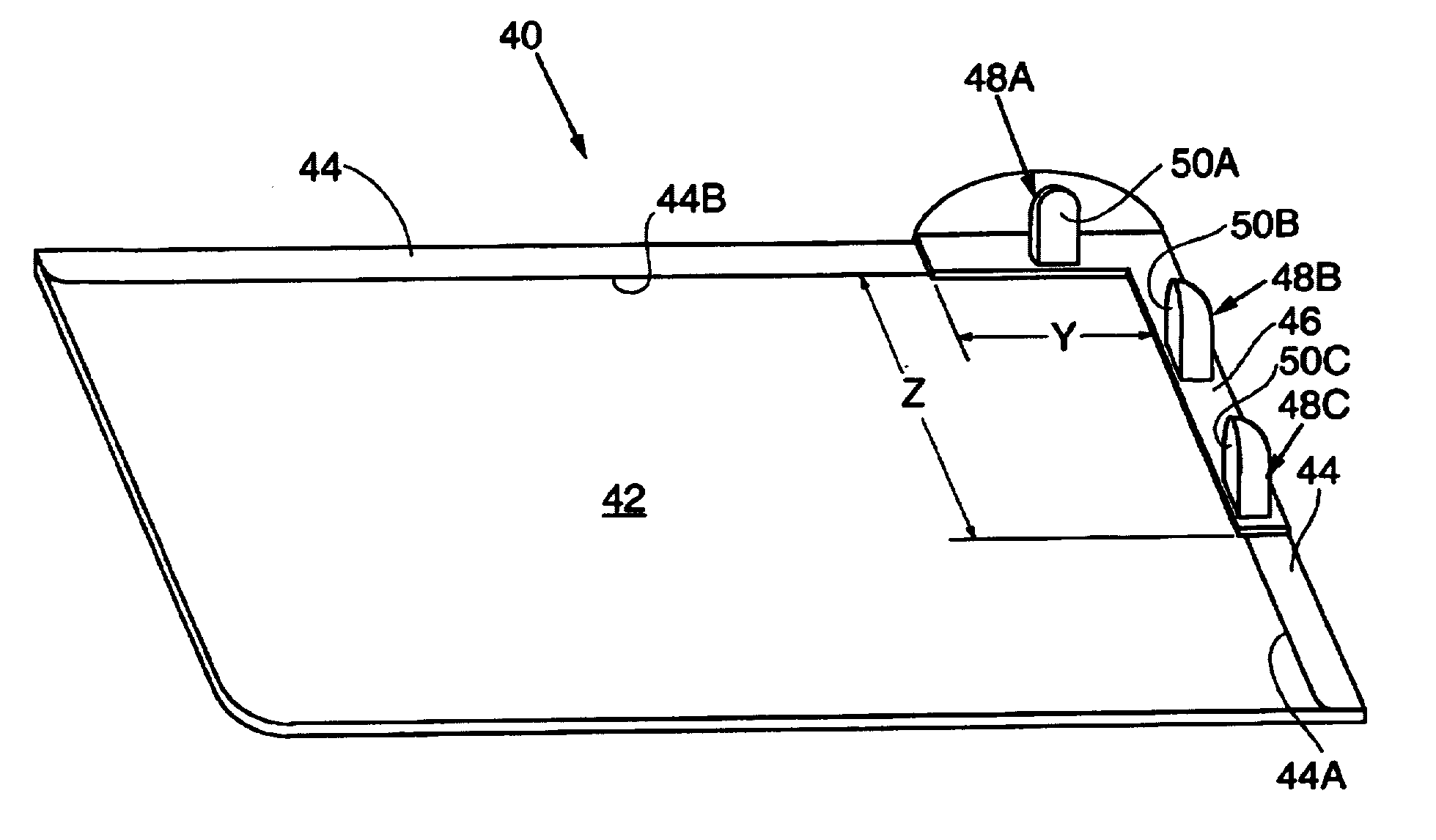

Guide apparatus for use in making a hardcover book

A guide apparatus for applying a cover to a bound stack of sheets, including a base unit which defines a book receiving surface and a first alignment member having a lower cover stop disposed along a reference line, and a first upper cover stop also disposed along the first reference line. A first book stop is included defining a stack engaging surface which is positioned intermediate the cover engaging surfaces of the first upper and lower cover stops and with said stack engaging surface extending a distance past said first reference line towards the book receiving surface. The first upper and lower cover stops are positioned to engage top and bottom cover sections of the cover, with the stack engaging surface being positioned to contact the edge of the stack so as to precisely align the stack with respect to the top and bottom cover sections in one direction. A second alignment member includes elements similar to that of the first alignment member so as to precisely the align the stack with respect to the top and bottom cover sections long a second reference line normal to the first reference line.

Owner:POWIS PARKER INC

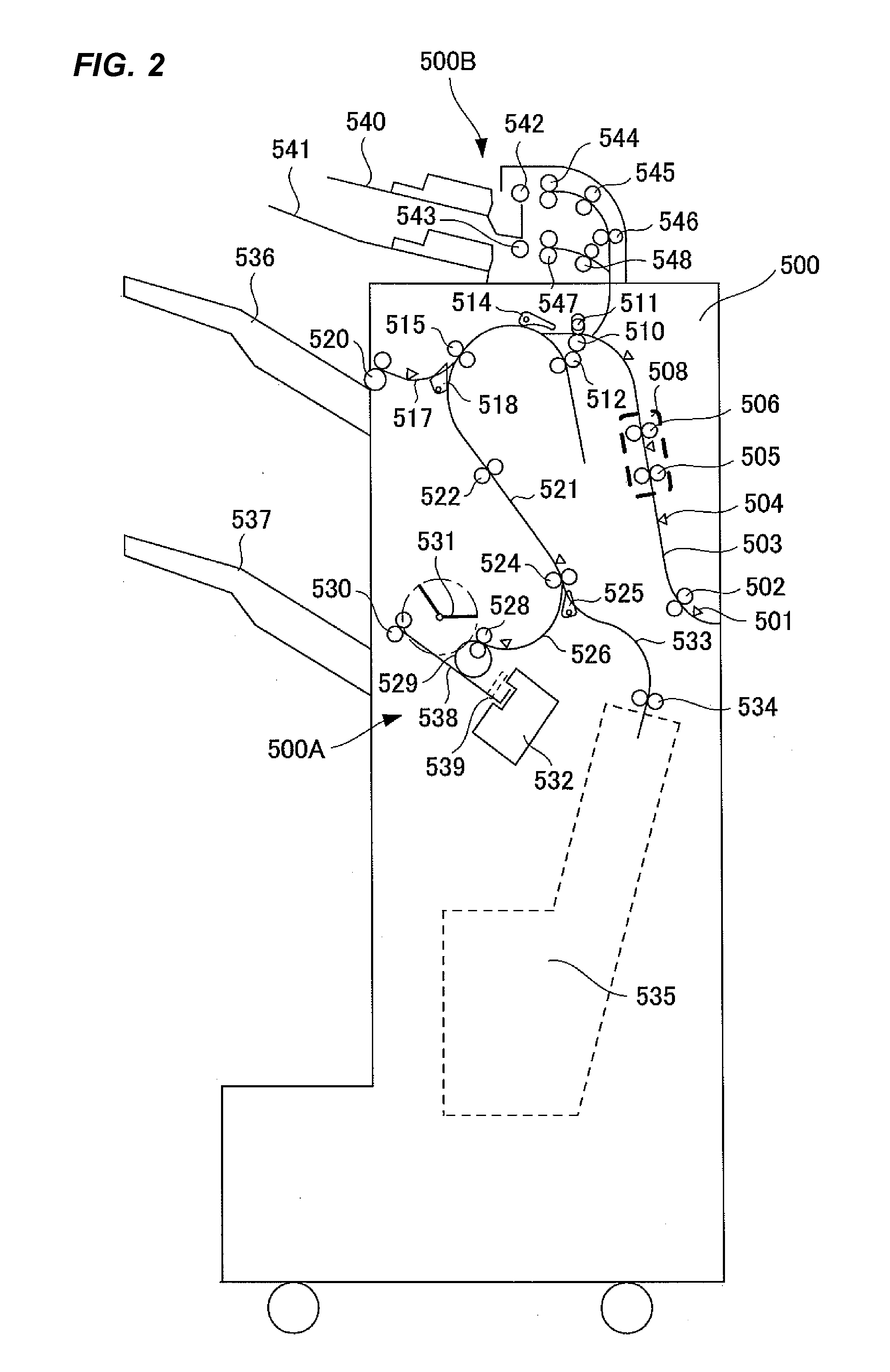

Conveying device, spine forming device, and image forming system

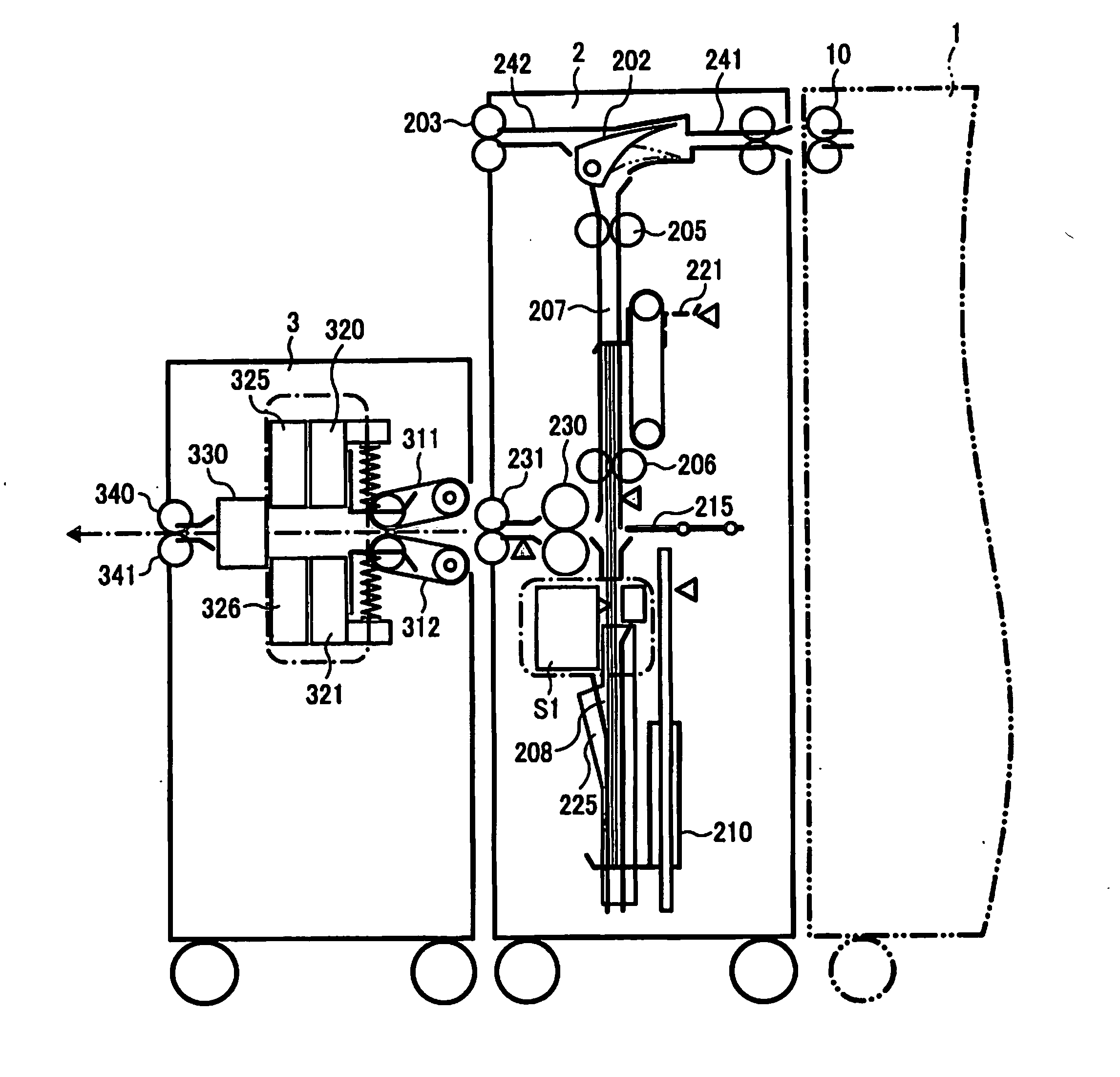

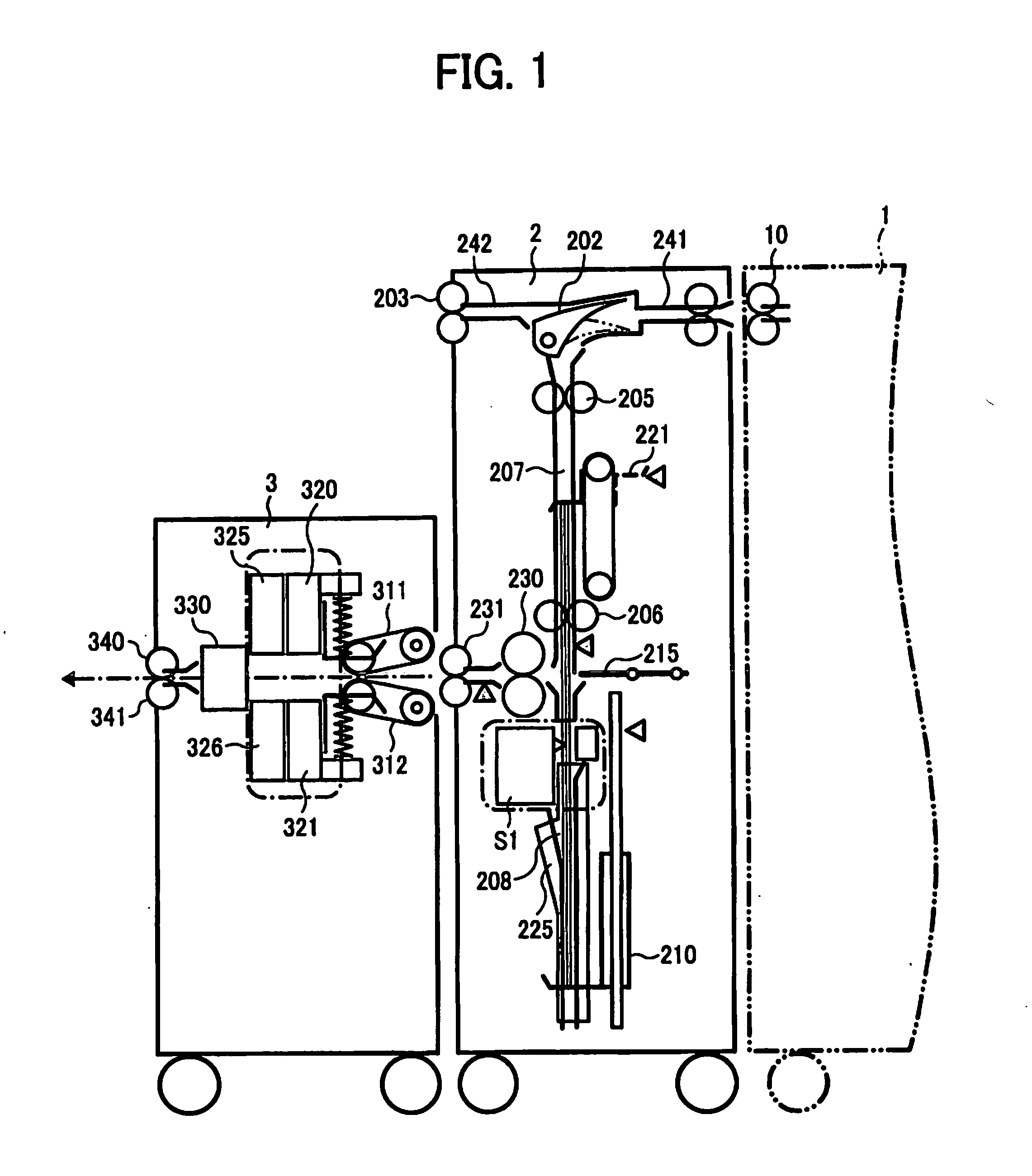

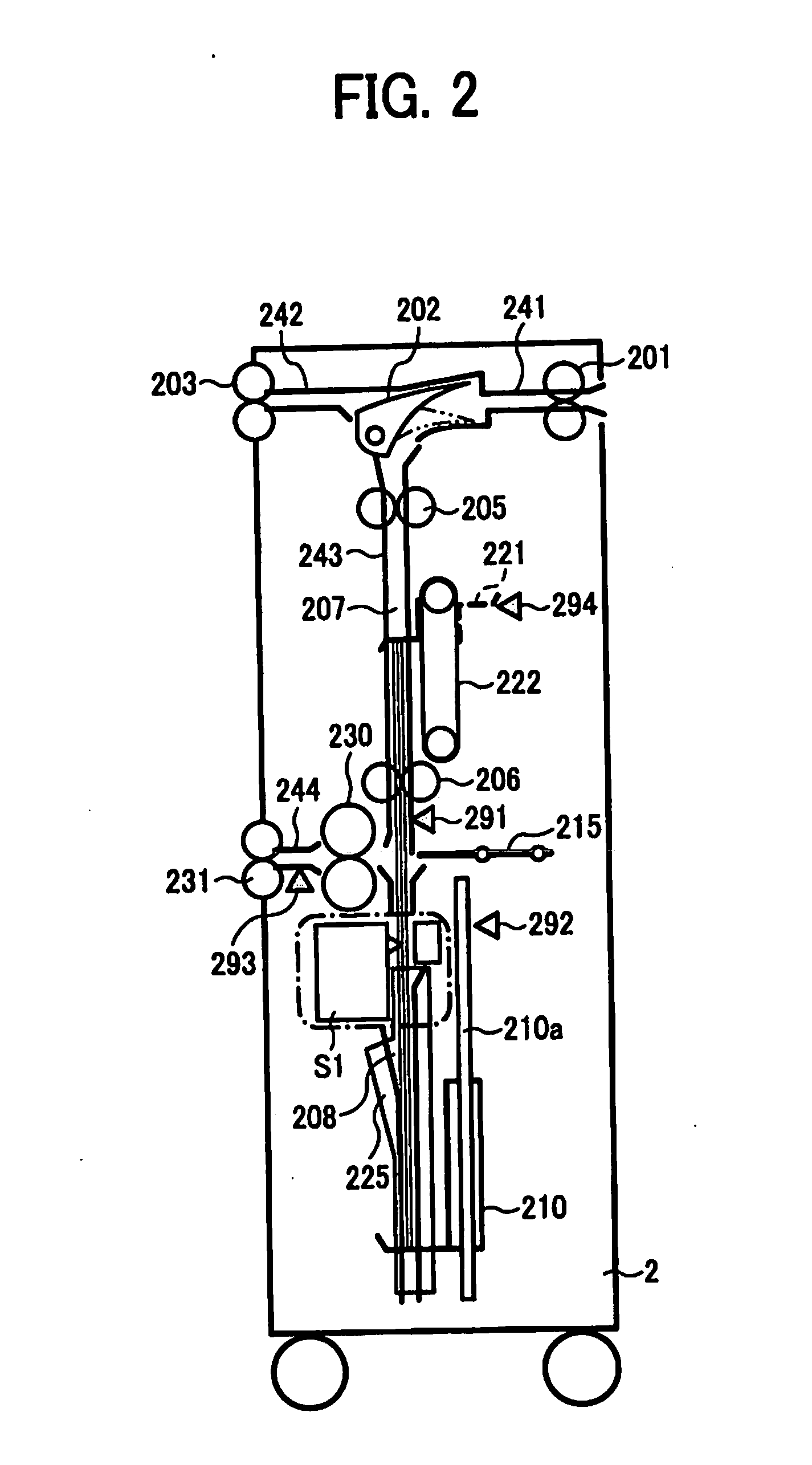

InactiveUS20110103863A1Solve problemsBookbinding casesFolding thin materialsEngineeringMechanical engineering

Owner:RICOH KK

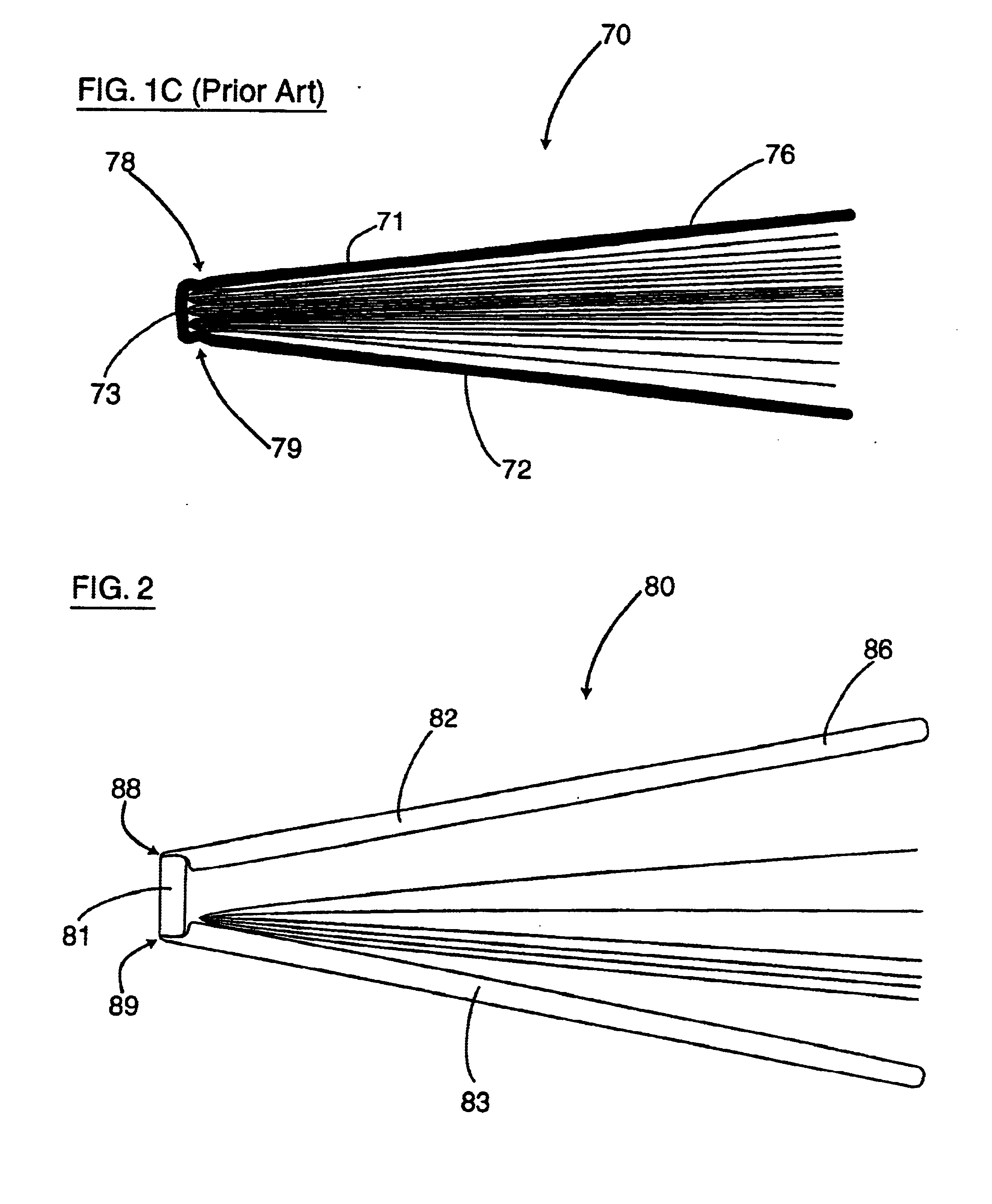

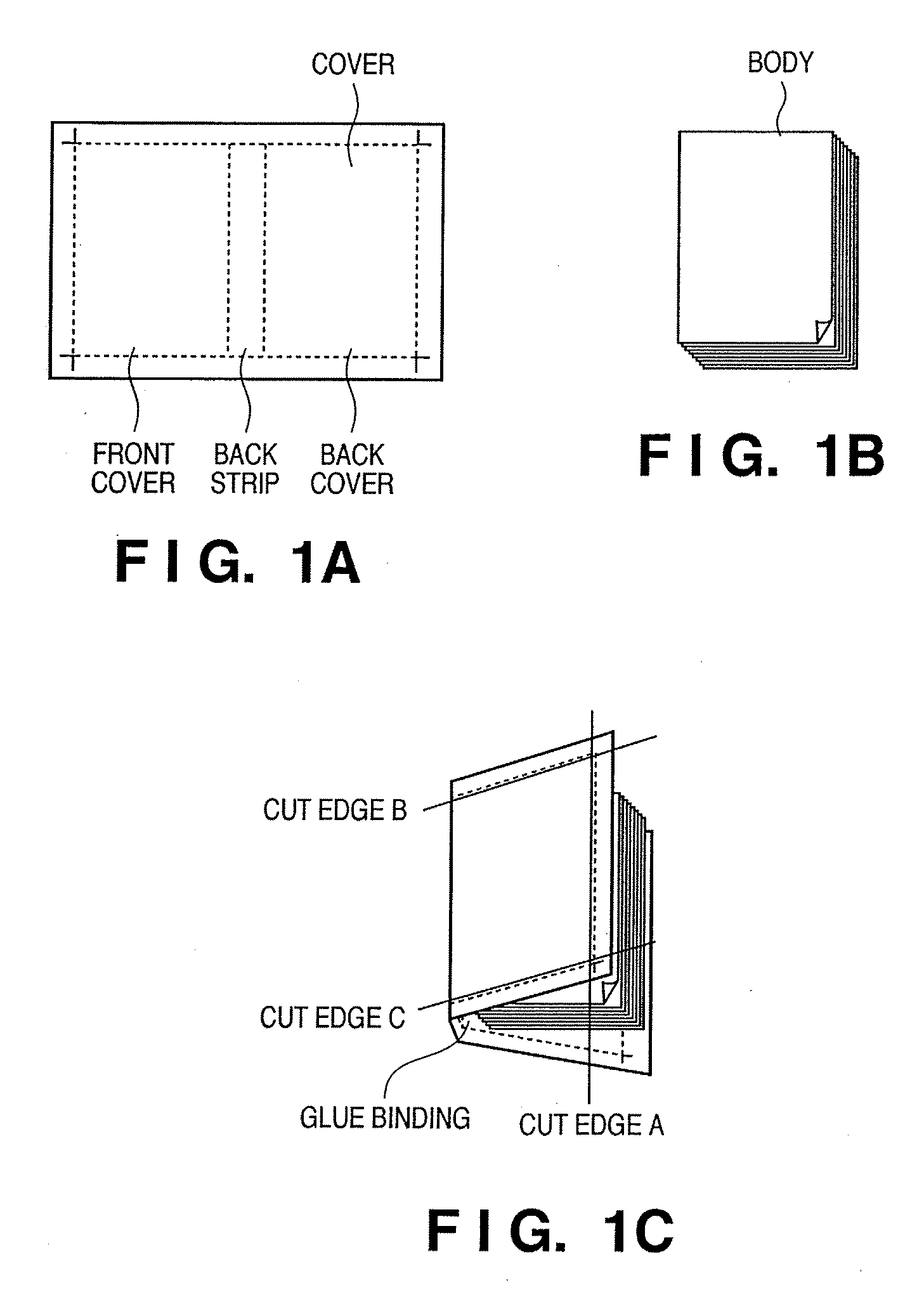

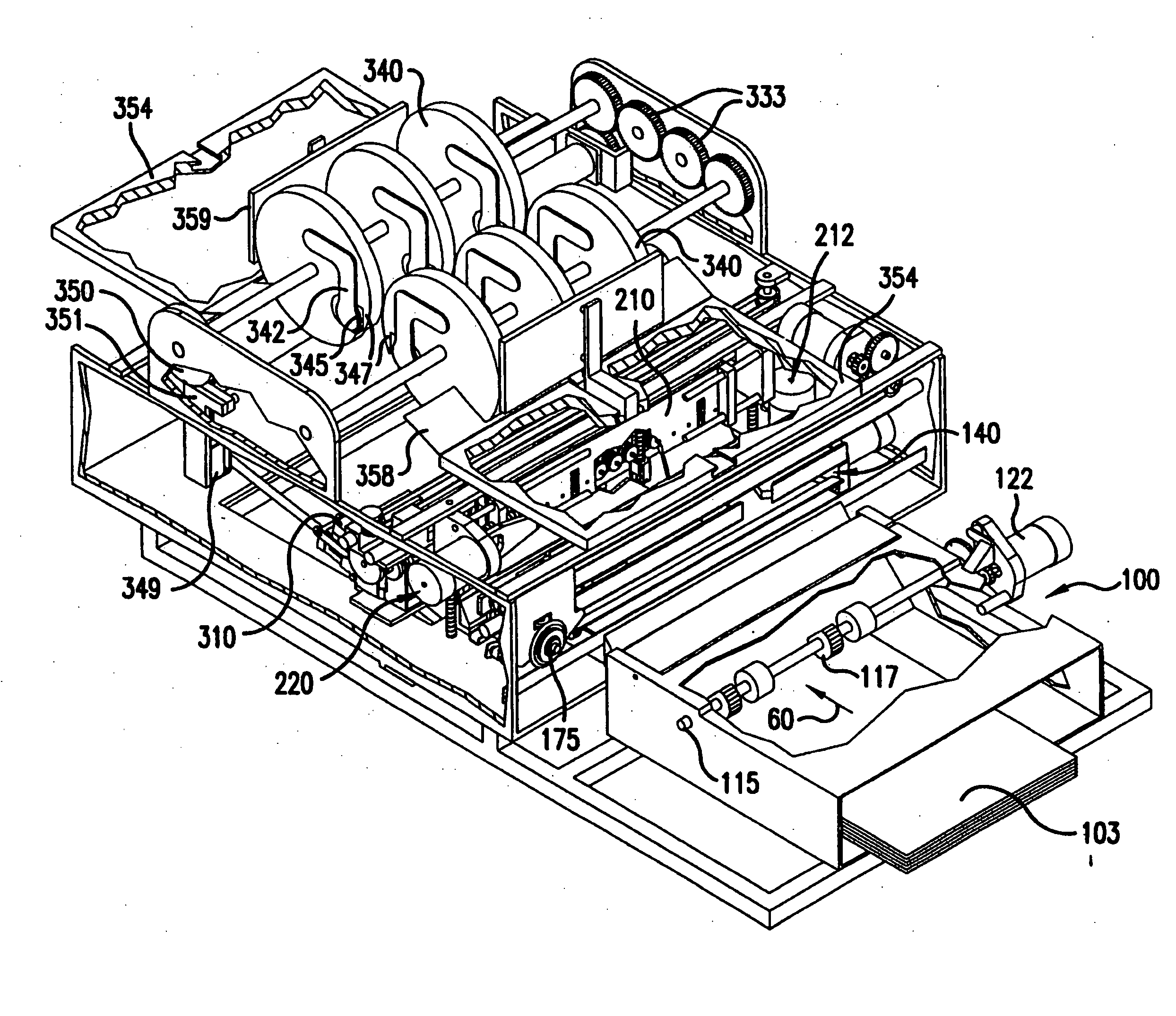

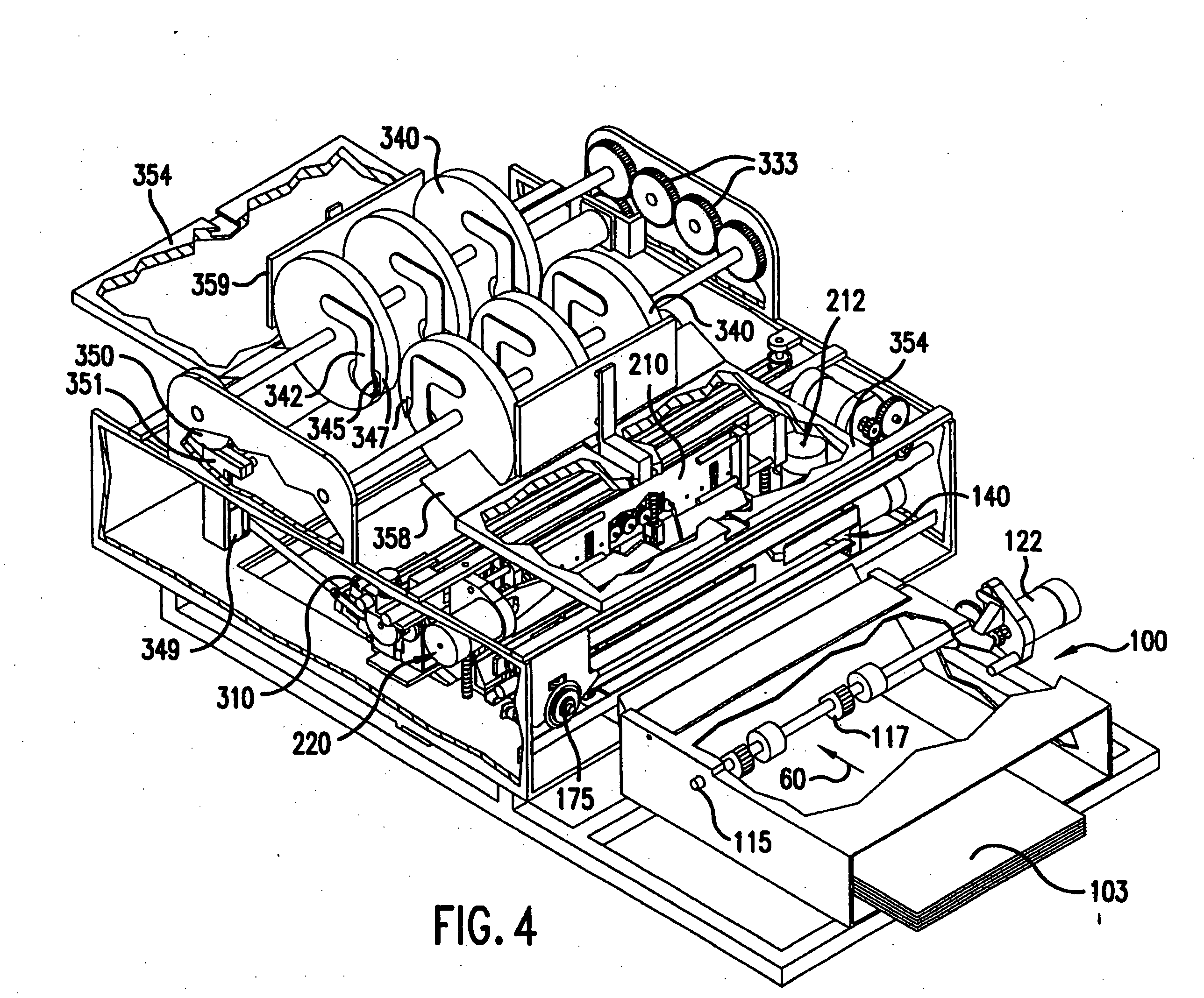

Method and apparatus for making booklets

Method and apparatus for assembling sheets of printing media for booklets. In one aspect the sheets are folded, sheet-by-sheet, and in another aspect the sheets are collected, sheet-by-sheet, and registered on a fold in each sheet. In still another aspect printed sheets are loaded, sheet-by-sheet, into the apparatus. Each sheet is trimmed to a pre-determined width depending on the position of the sheet in the booklet being assembled. The sheets are thereafter folded, sheet-by-sheet, and collected into a stack. The method and apparatus have particular application in finishing duplex printed sheets of paper into saddle-stitched booklets.

Owner:HEWLETT PACKARD DEV CO LP

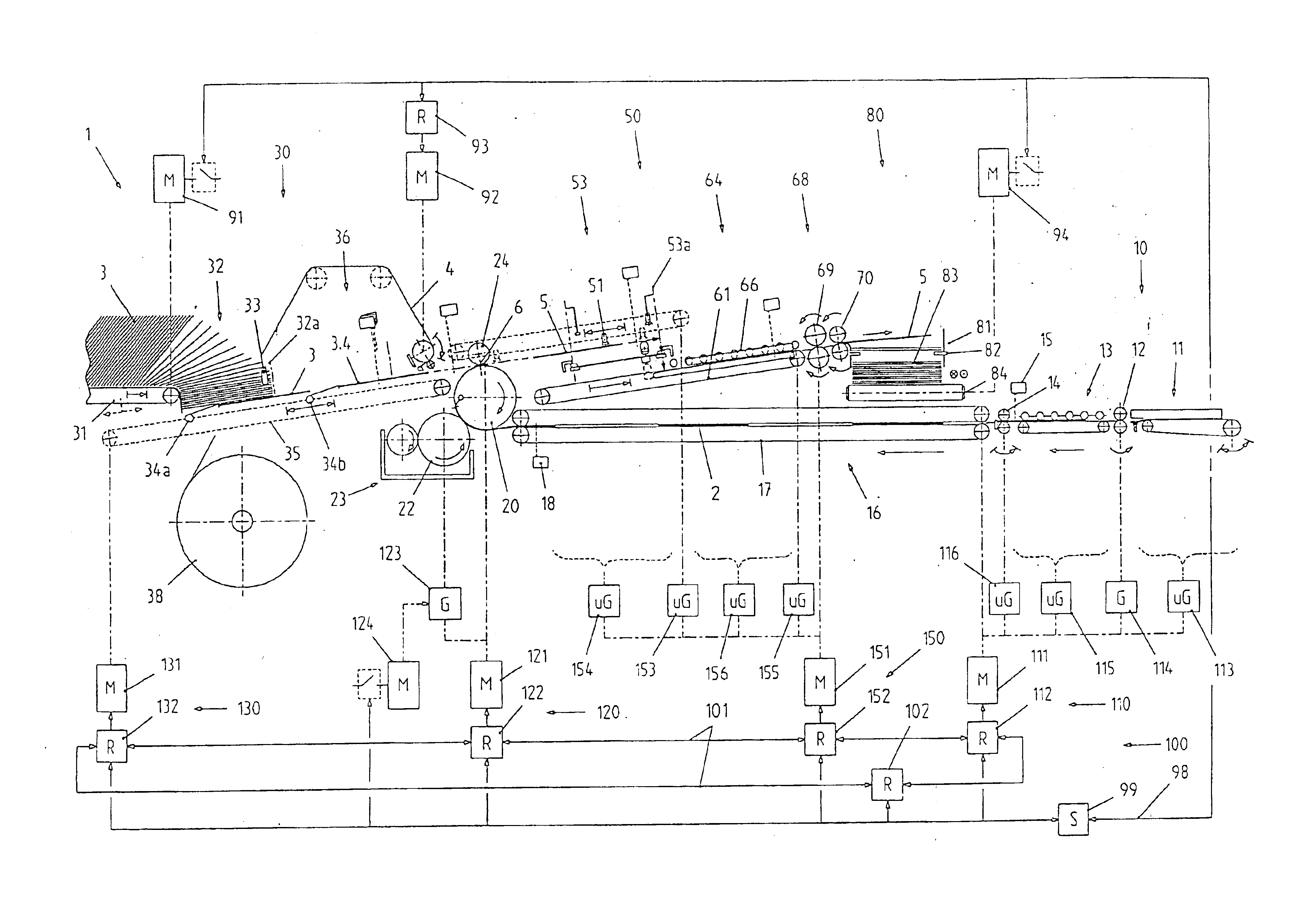

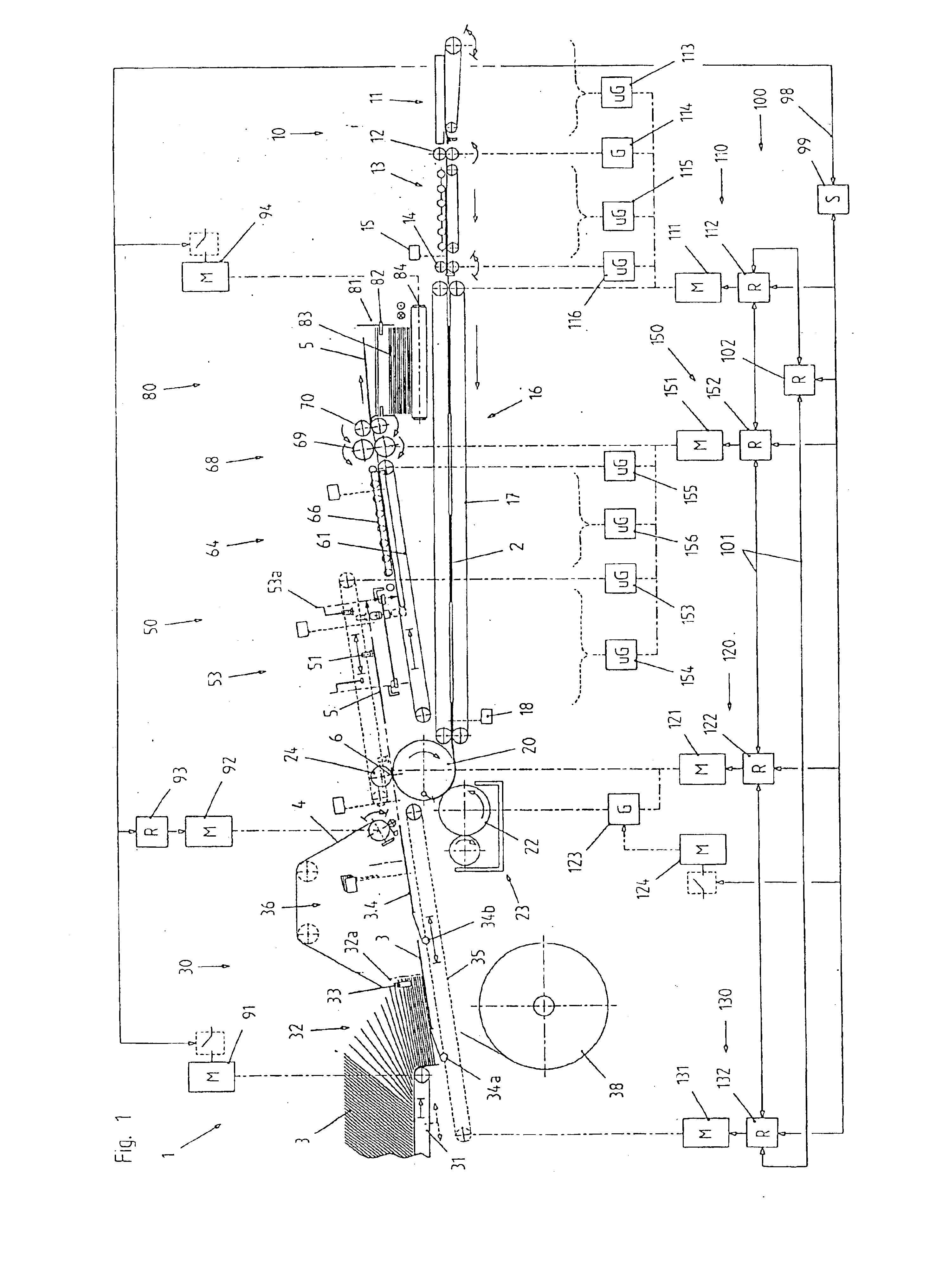

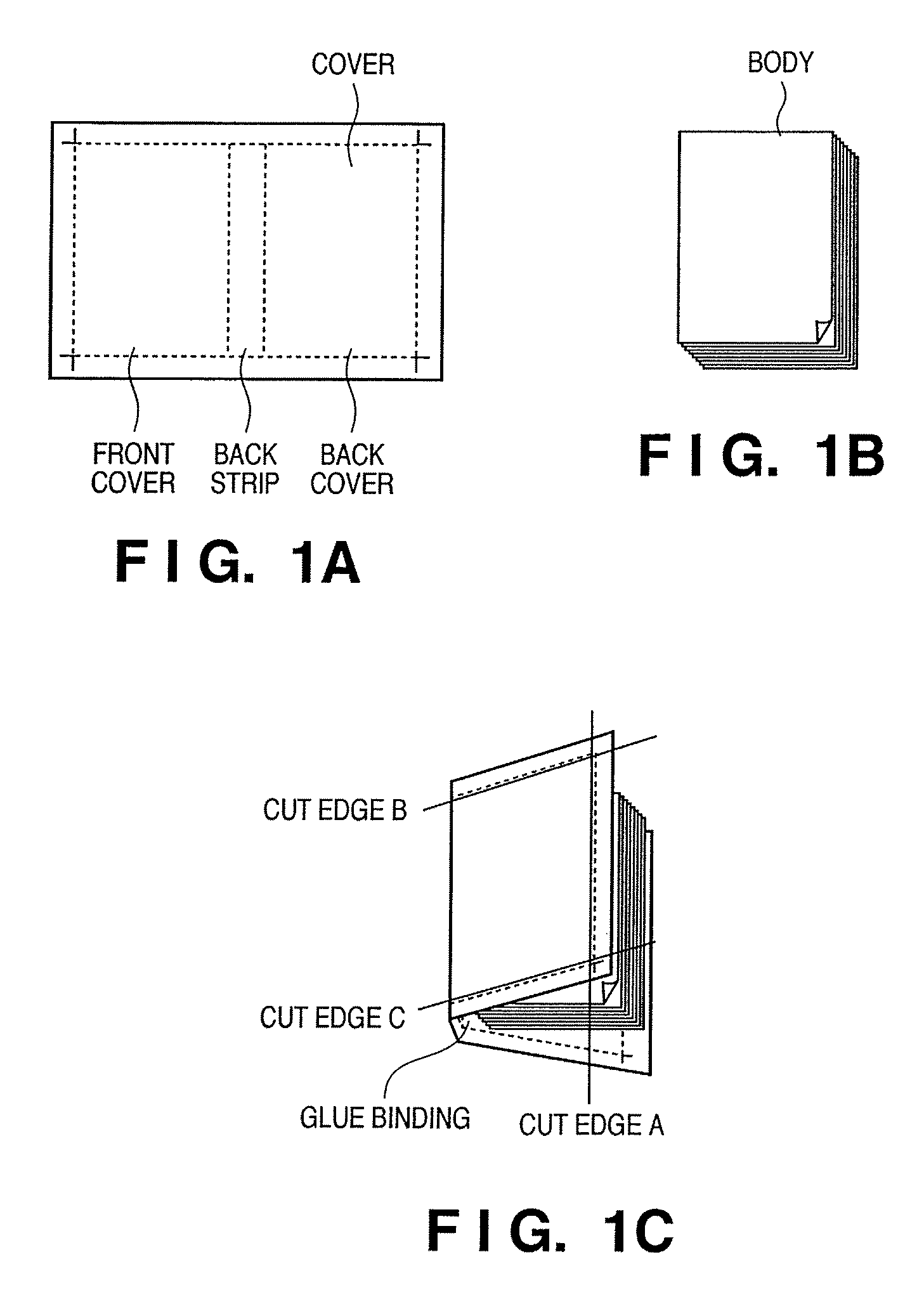

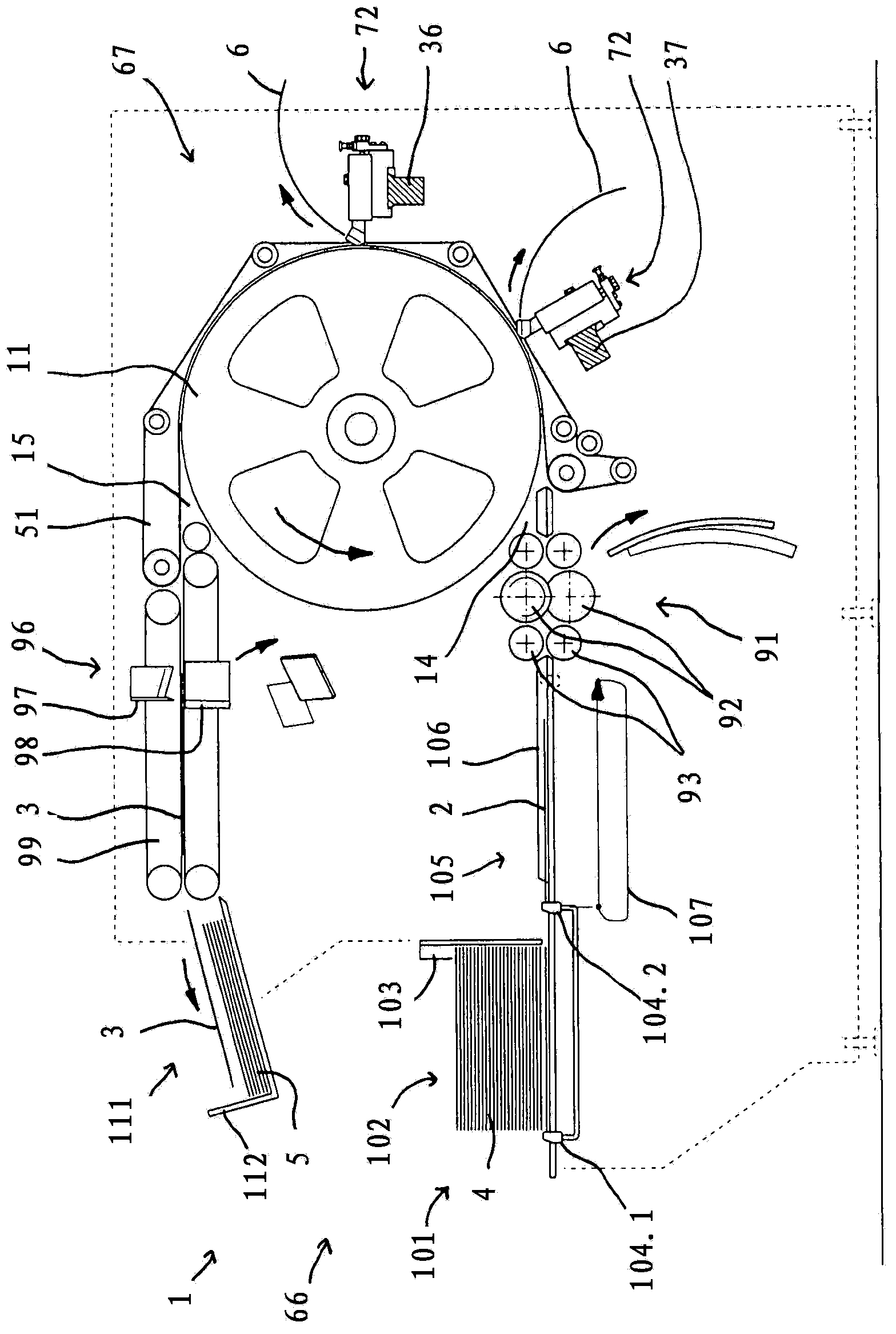

Apparatus for manufacturing book covers

InactiveUS6843473B2Improve effective outputEconomical and simpleBookbinding casesBook making processesCardboardEngineering

An apparatus for manufacturing book covers having a board feed for supplying cover boards and a spine insert having a covering material feed for supplying covering material, having a covering material cylinder, by means of which the supplied covering material is taken over, conveyed past a glue spreading roller and assembled with the supplied cover boards and having a folding and pressing apparatus as well as having a delivery apparatus and having a drive apparatus for the covering material feed, the board feed the covering material cylinder and the folding and pressing apparatus it is provided that at least the covering material feed the board feed and the folding and pressing apparatus are drivable in each case independently of one another. The covering material cylinder is preferably also provided with an independent drive. The independent drives are preferably servomotors, which are designed in each case as a slave and follow a virtual master The essential advantages of said apparatus are product-protecting and efficient fault handling as well as simple setting-up and correction operations.

Owner:KOLBUS

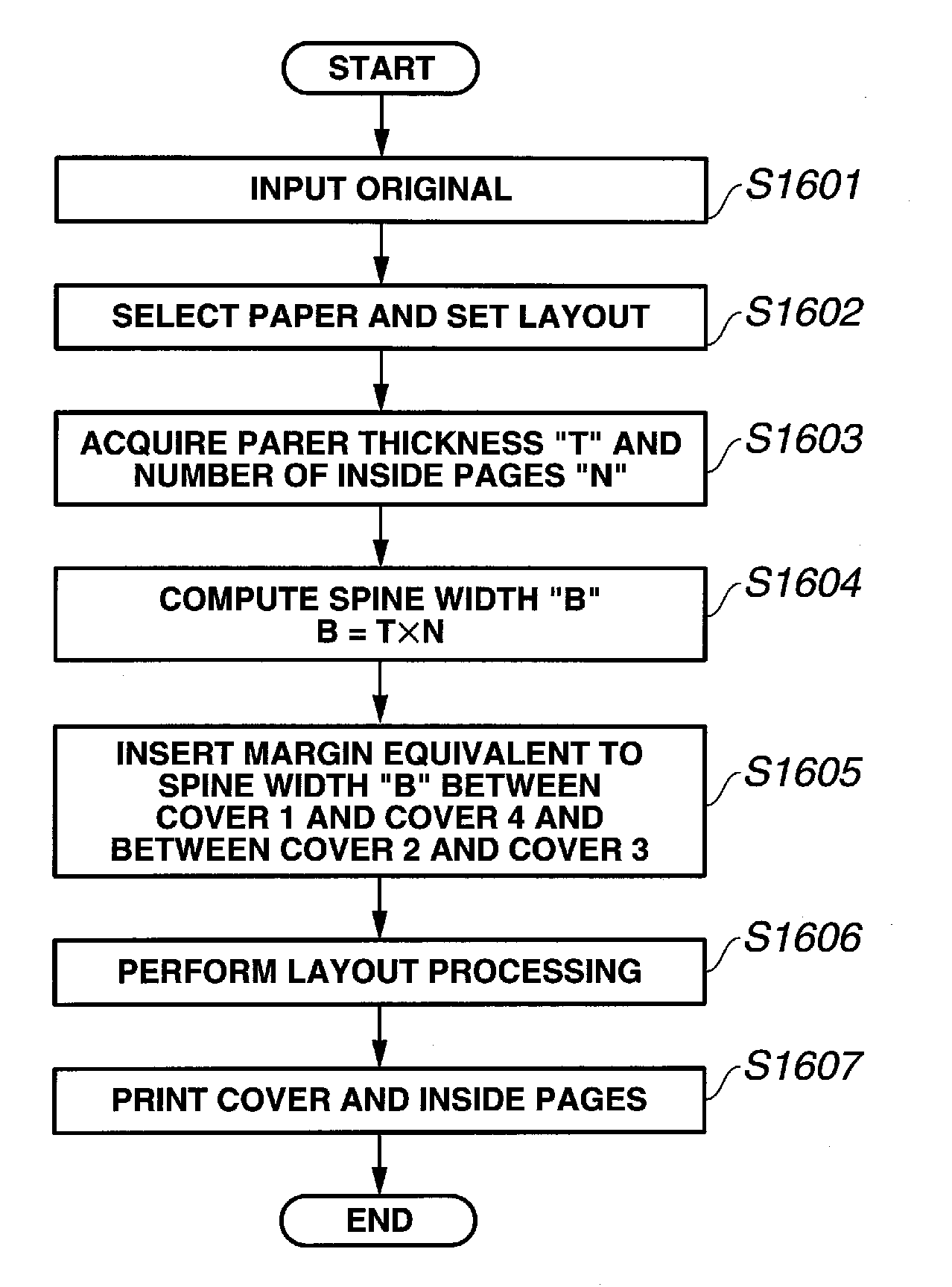

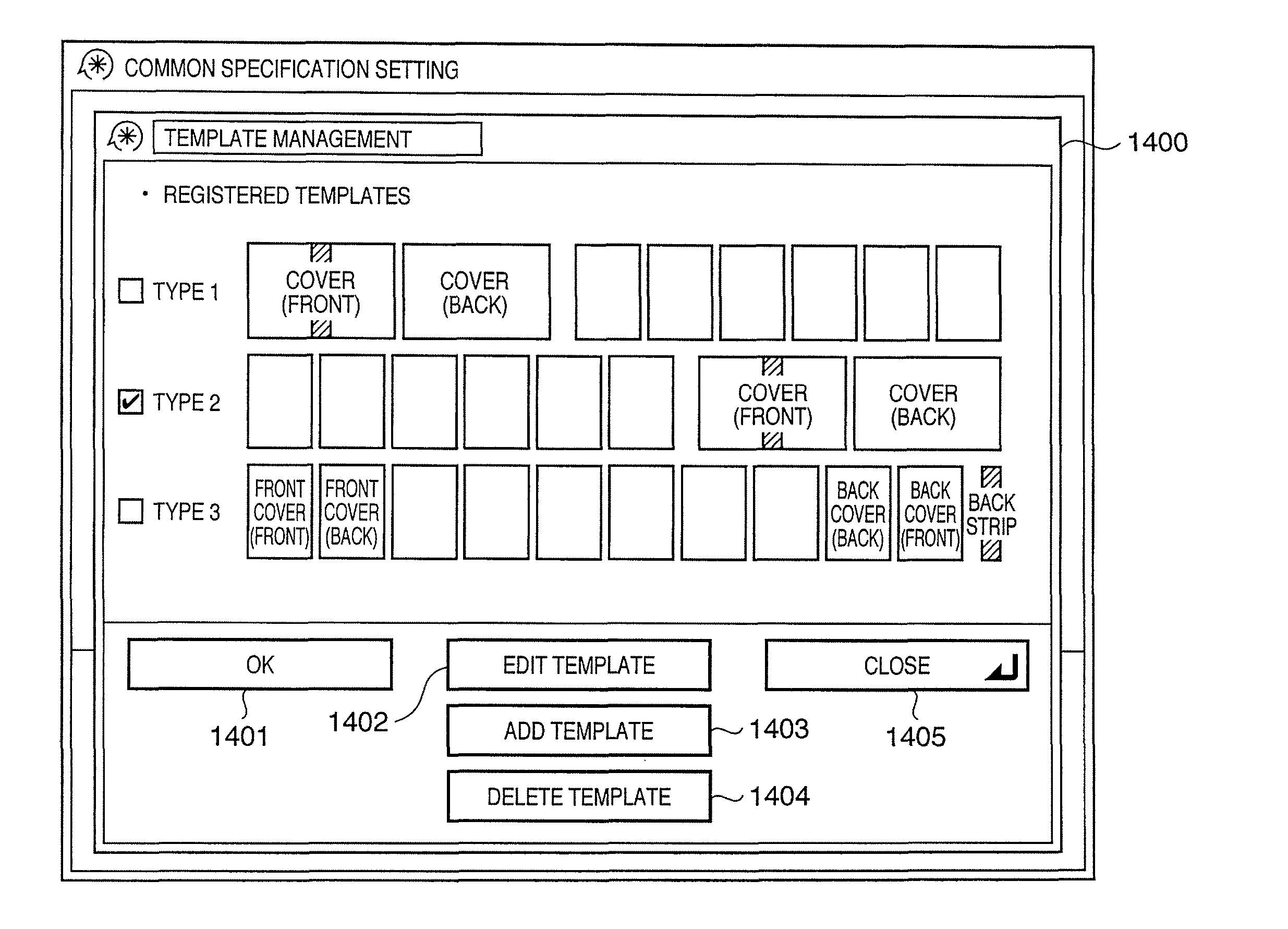

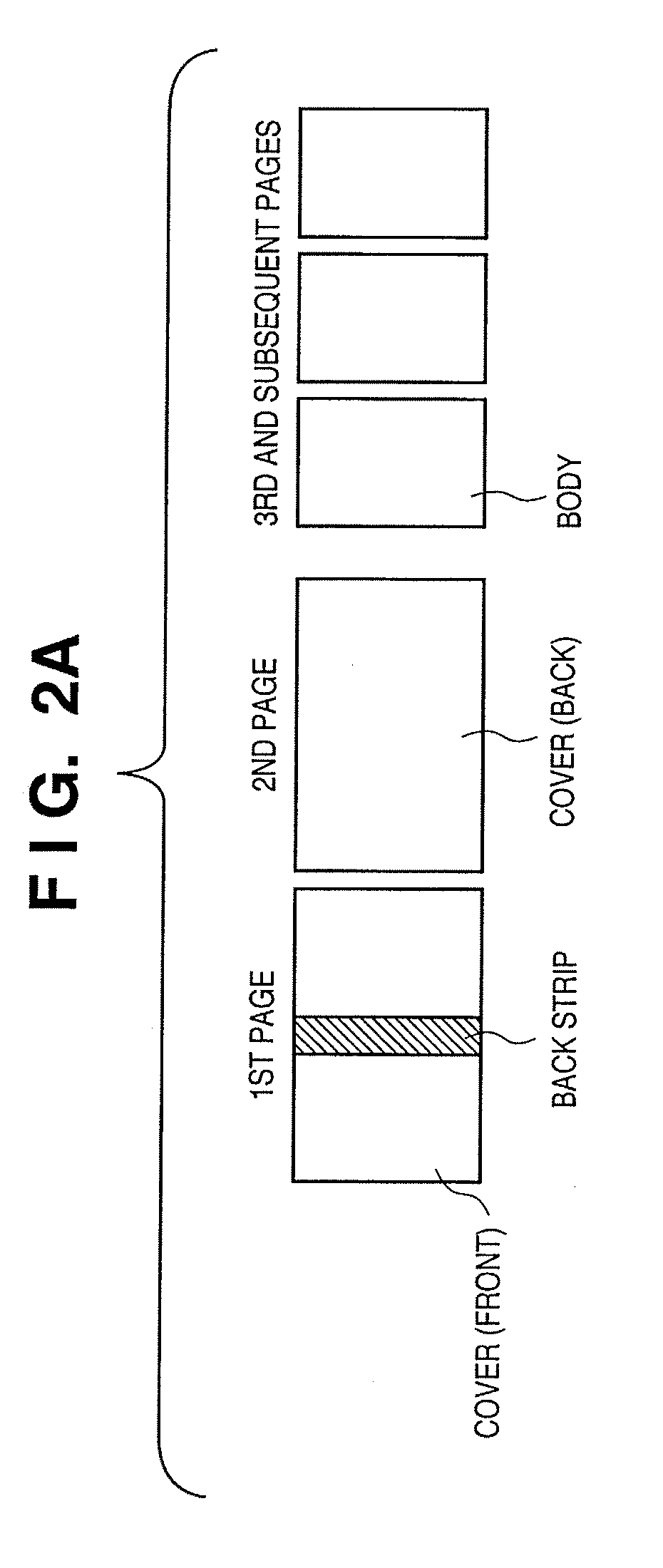

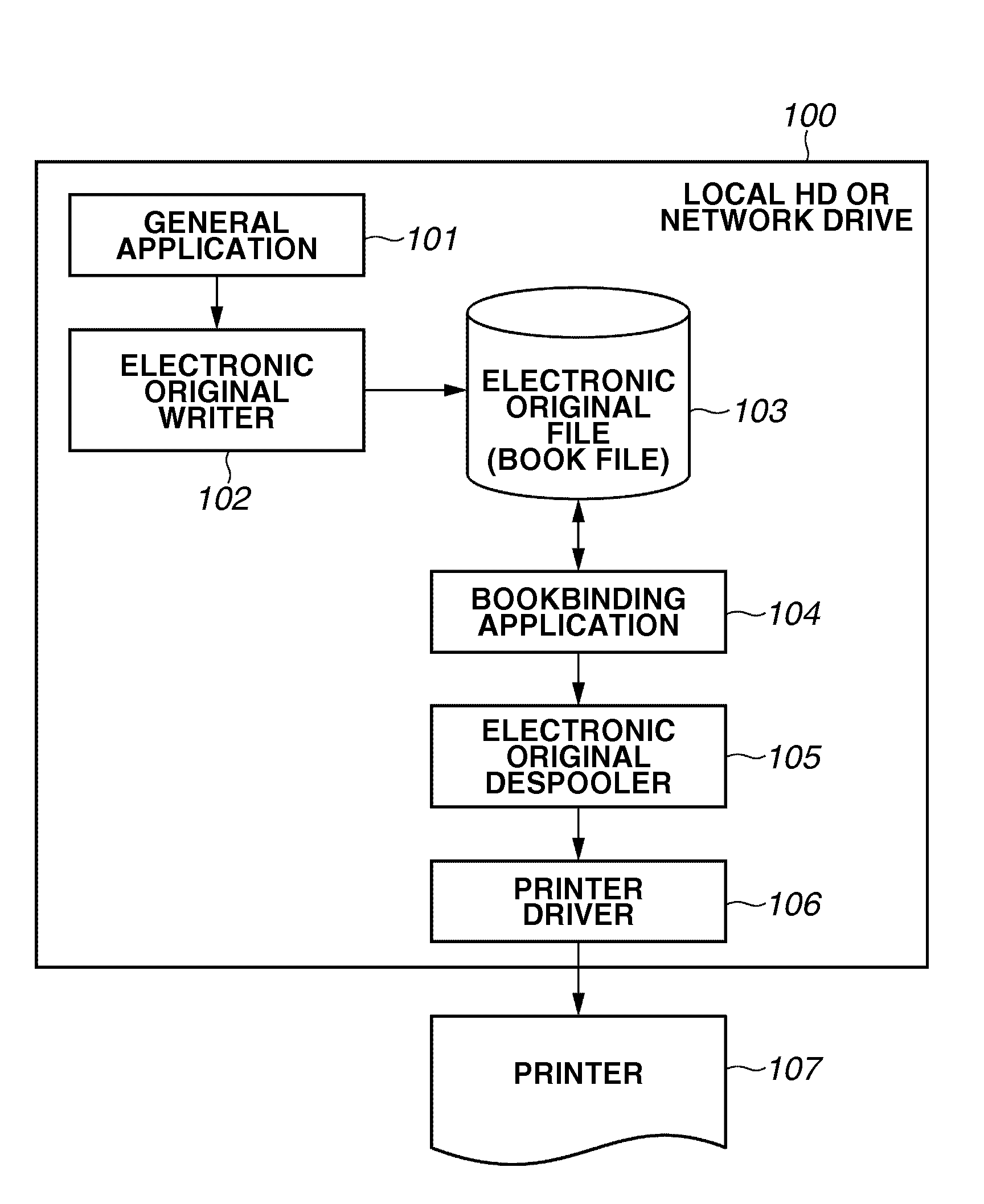

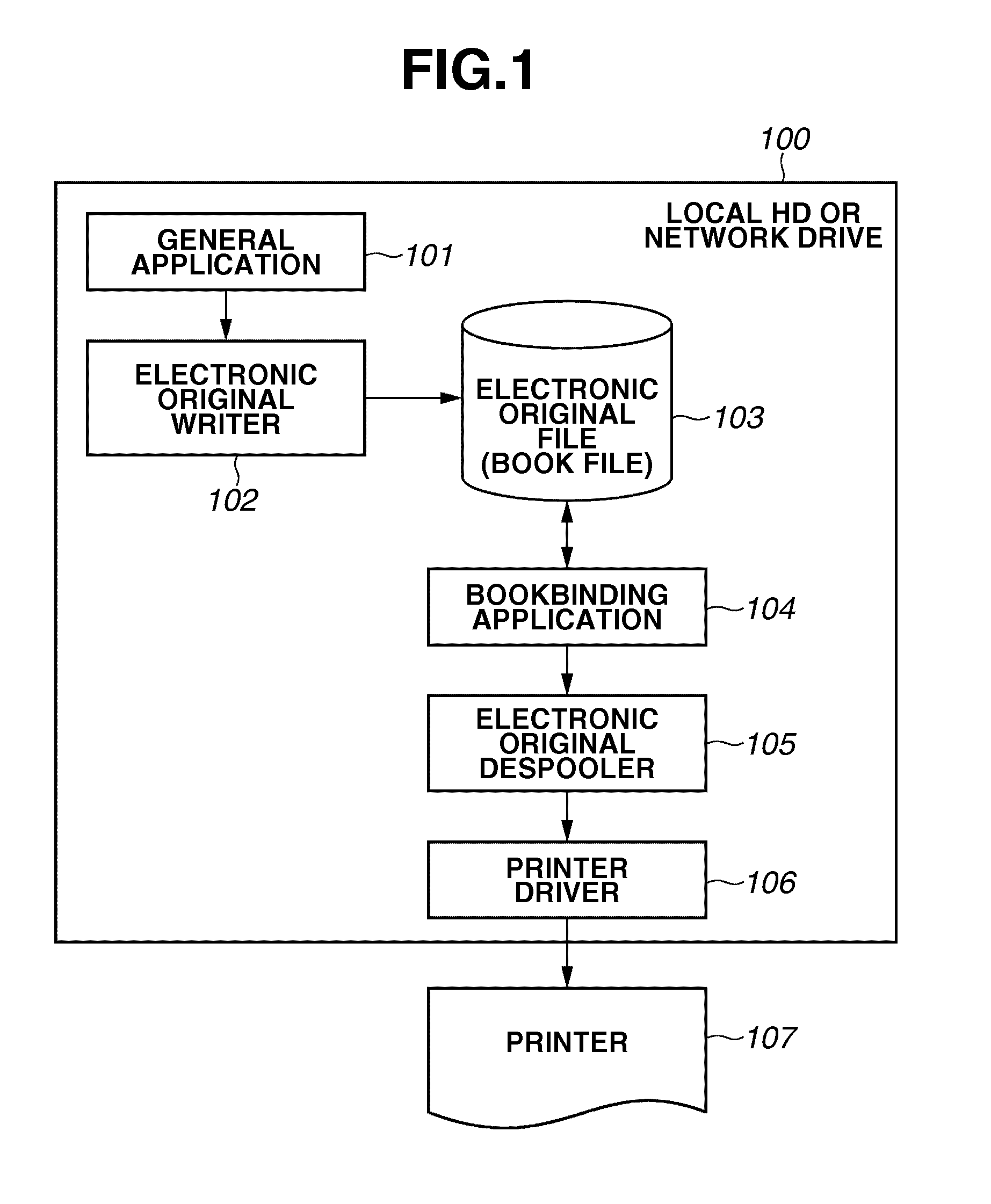

Information processing apparatus, information processing method, and information processing program

ActiveUS20070229901A1Efficient executionOther printing matterBookbinding casesInformation processingOriginal data

An apparatus selects a cover layout type to be used during bookbinding processing from among a plurality of cover layout types, and determines page data to be laid out in a cover area, from among page data included in original data. The apparatus lays out the determined page data in the cover area according to the selected cover layout type, and generates a print job based on the original data and a result of laying out the determined page data in the cover area.

Owner:CANON KK

Single axis apparatus for manufacturing hard book cover

An apparatus for producing hard book cases (covers) can make cases including tucked and folded corners. The apparatus can track the progress of the book case throughout the assembly process and can accurately align the unfinished assembly with the tucking and folding devices of the apparatus. Short runs of different sized book cases may be quickly and efficiently manufactured on a single apparatus.

Owner:GP2 TECH

Cutting apparatus

InactiveUS7207868B2Low costWork lessBookbinding casesGrinding drivesHigh pressureMechanical engineering

Owner:TOWA

Image processing apparatus and method for bookbinding processing

InactiveUS7847968B2Appropriately processedDigitally marking record carriersBookbinding casesInformation processingImaging processing

It is possible to provide an information processing apparatus capable of appropriately processing a job for case binding without depending on the sequence of page data constituting the job, a method for controlling the apparatus and a program. To accomplish this, a job for case binding is inputted, and the inputted job is stored in storage means of the image processing apparatus. A bookbinding cover attribute is set for page data to be a cover, in the job stored in the storage means. The order of output of page data in the job is determined based on the set attribute. The page data in the job stored in the storage means are read and outputted to a printer unit in accordance with the determined output order.

Owner:CANON KK

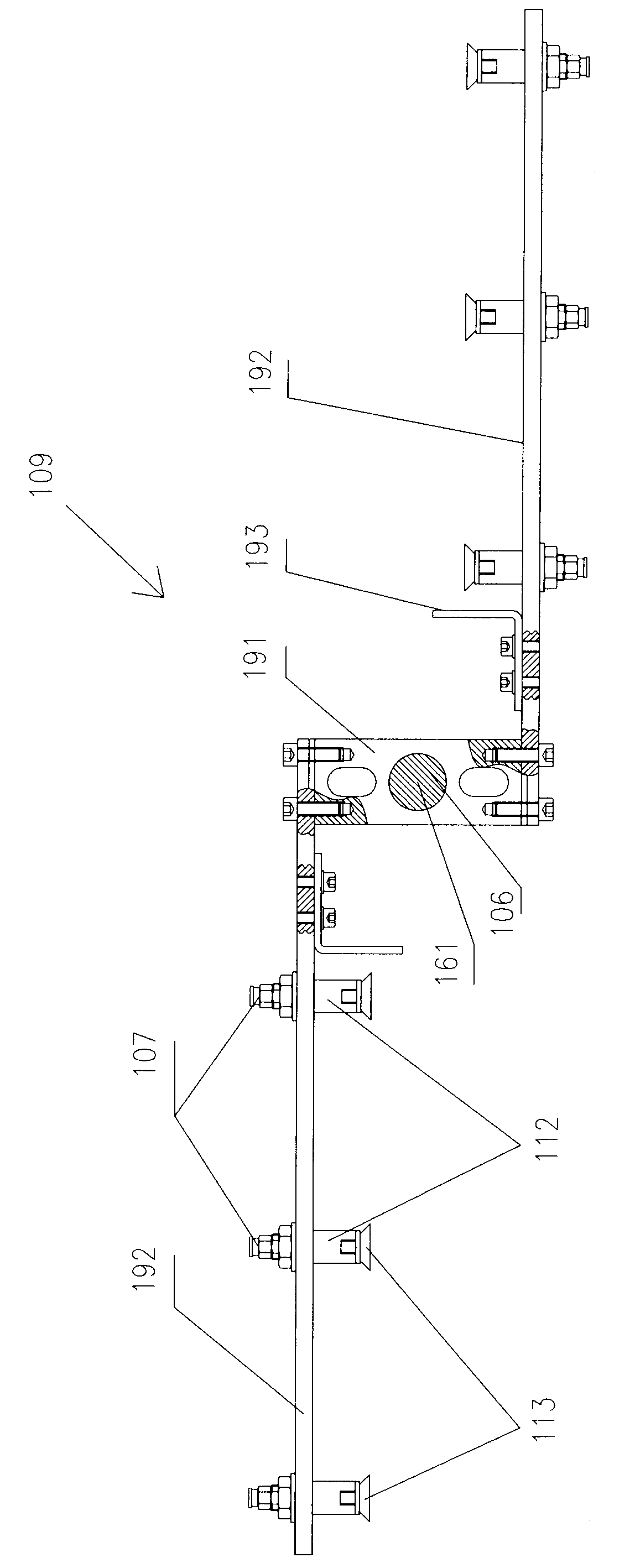

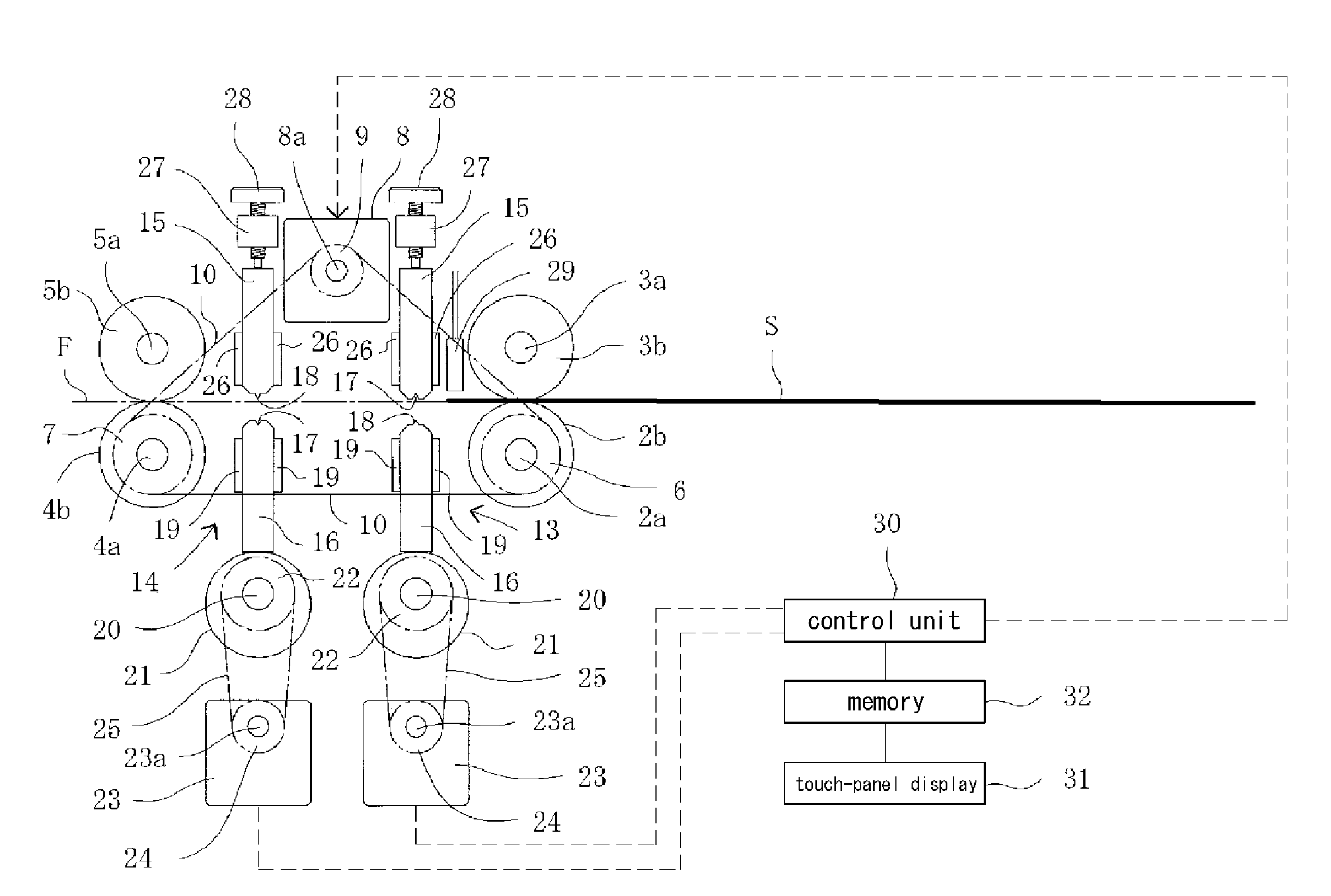

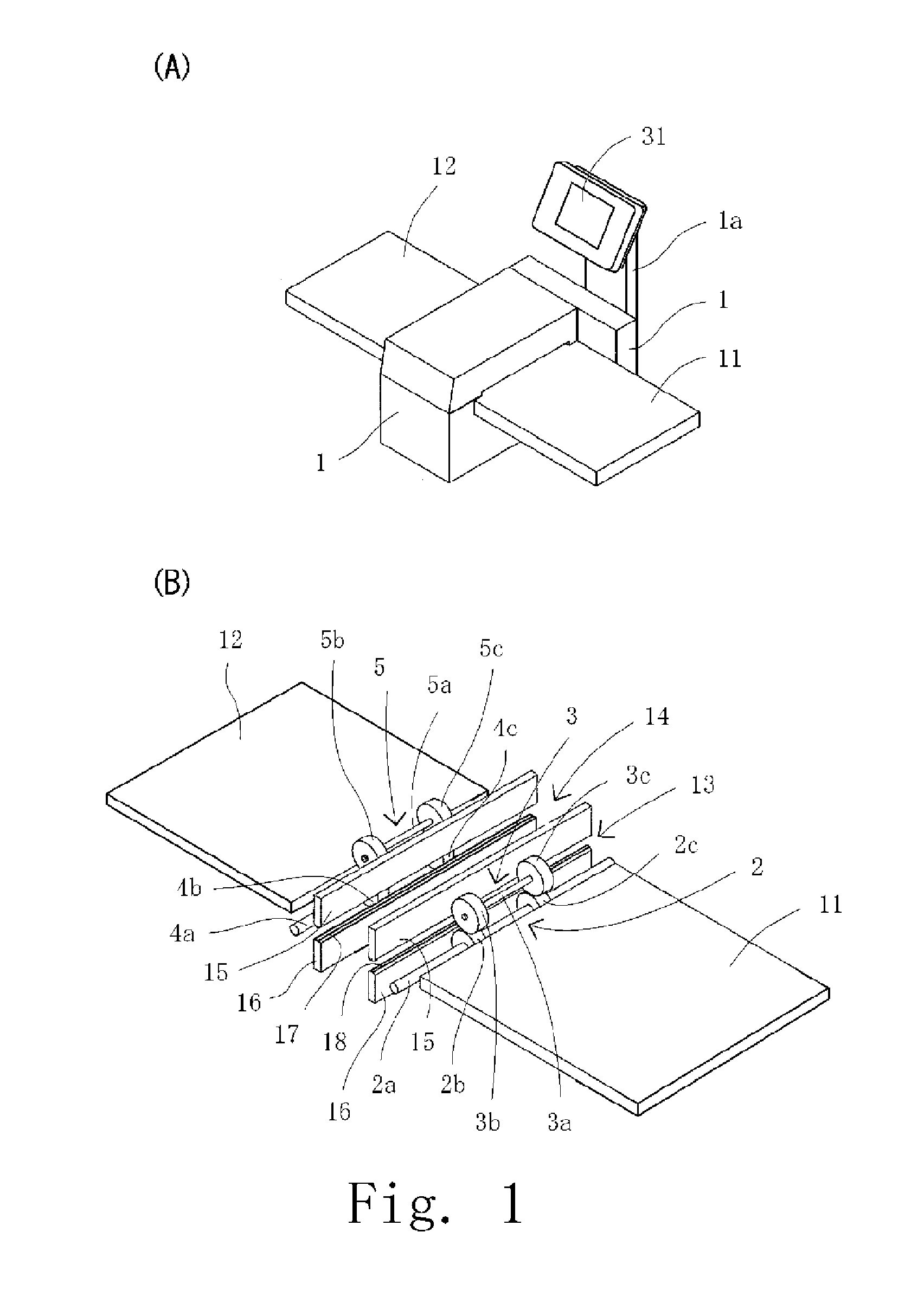

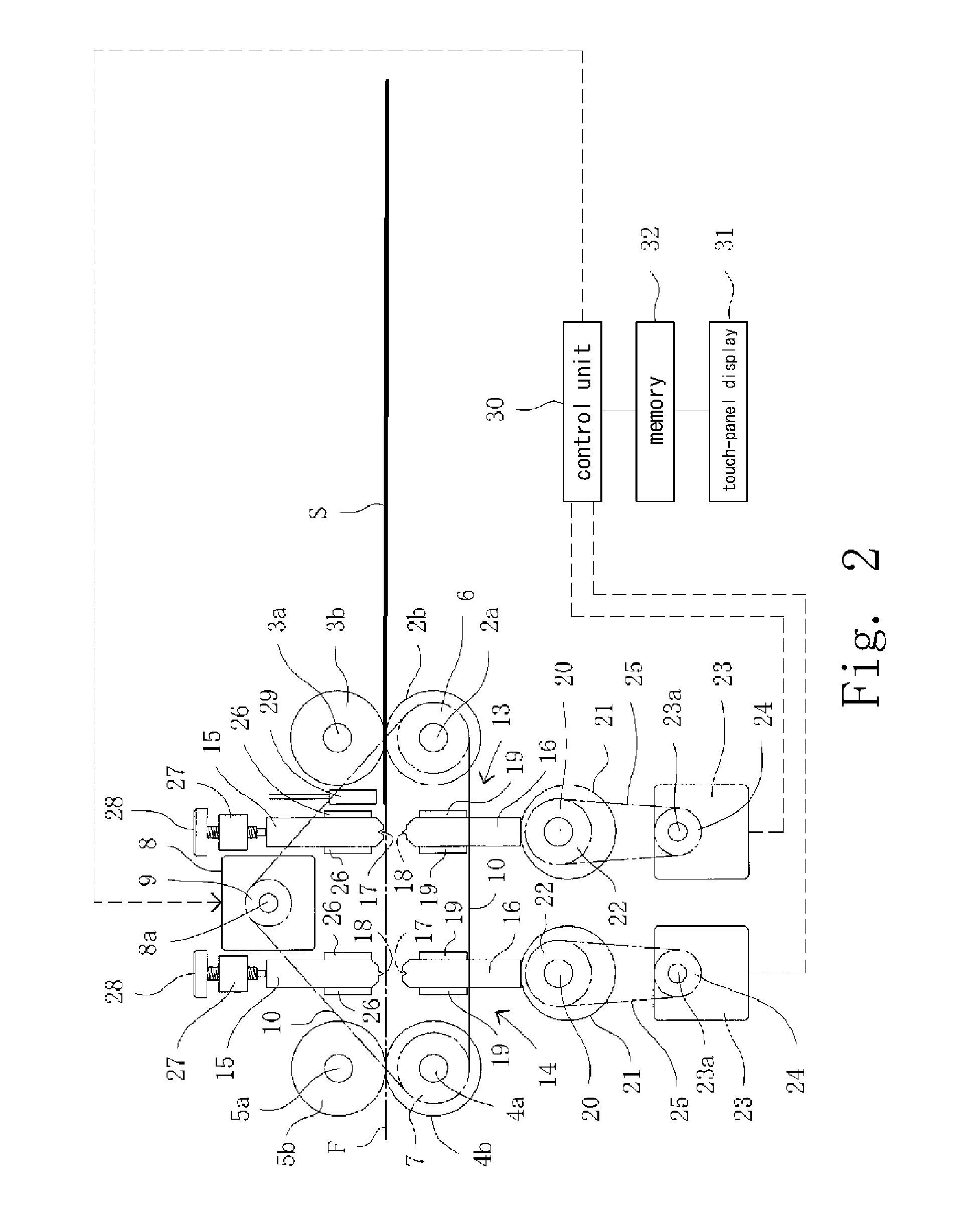

Machine for forming at least one crease on cover before attachment to book binding

InactiveUS20120308334A1Easy to changeRapidly and easily adaptMechanical working/deformationBookbinding casesElectrical and Electronics engineering

Owner:HORIZON INTERNATIONAL INC

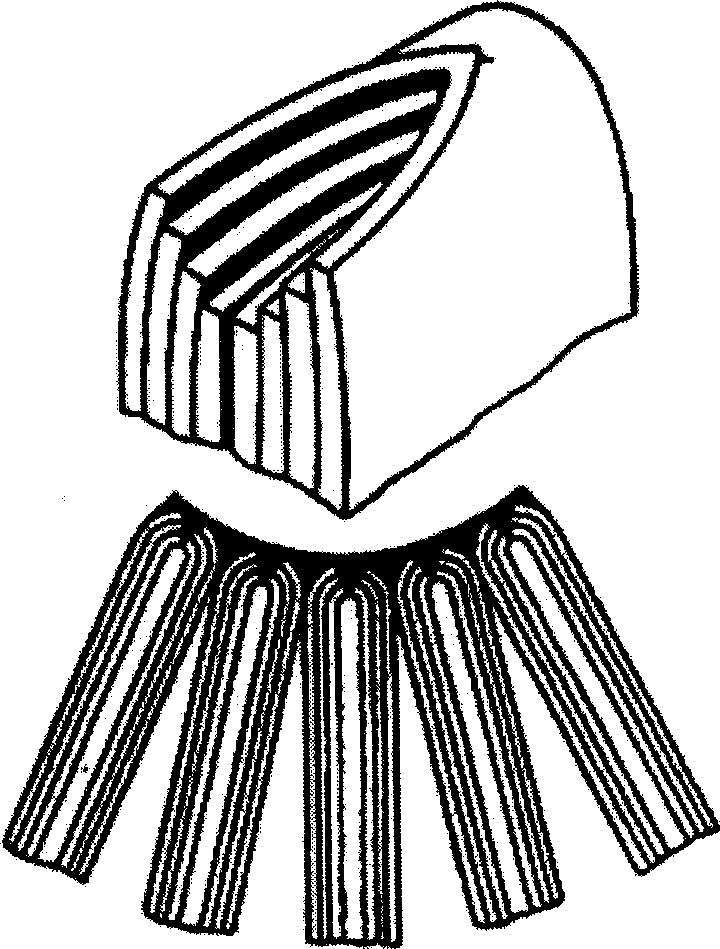

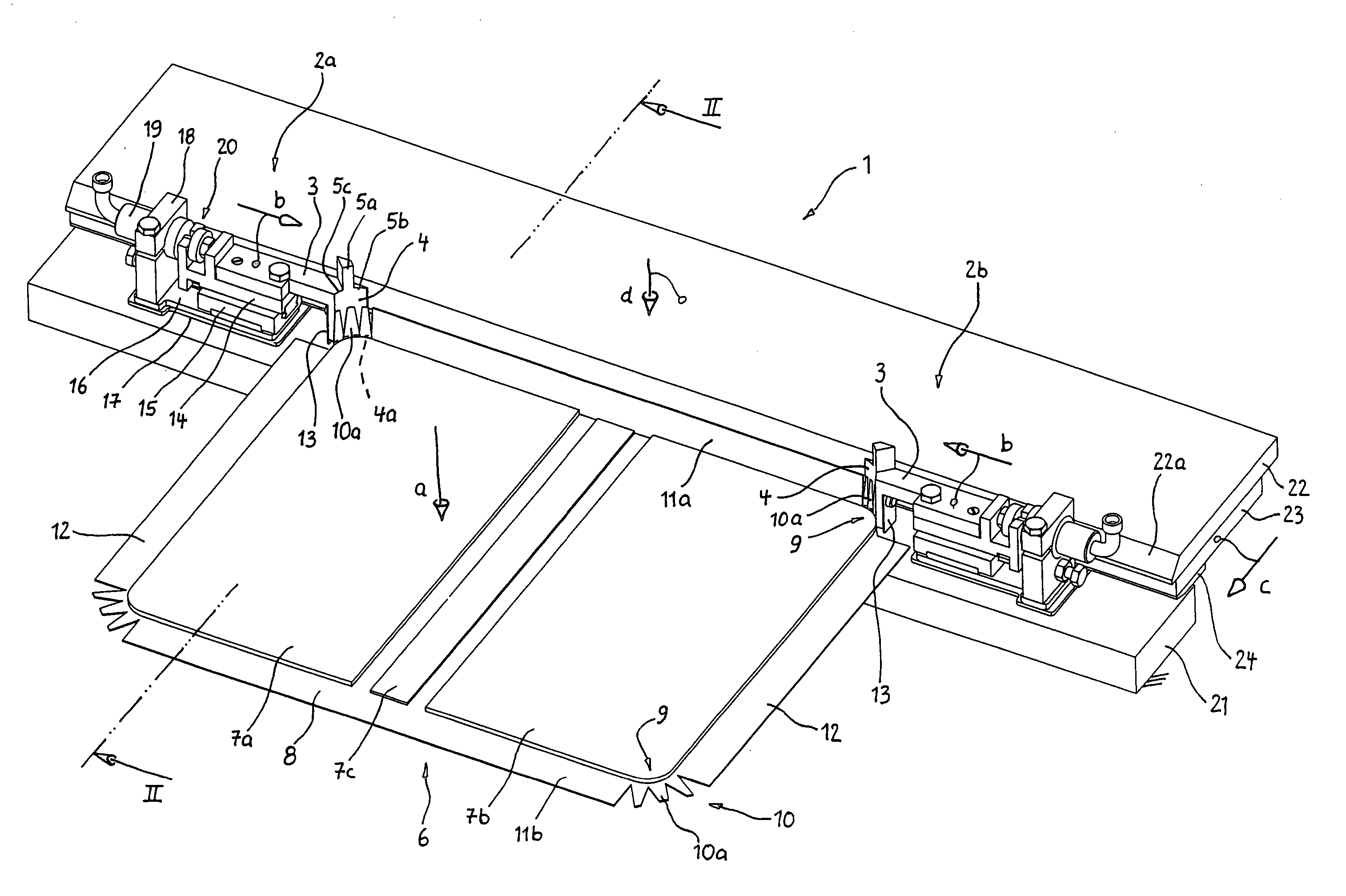

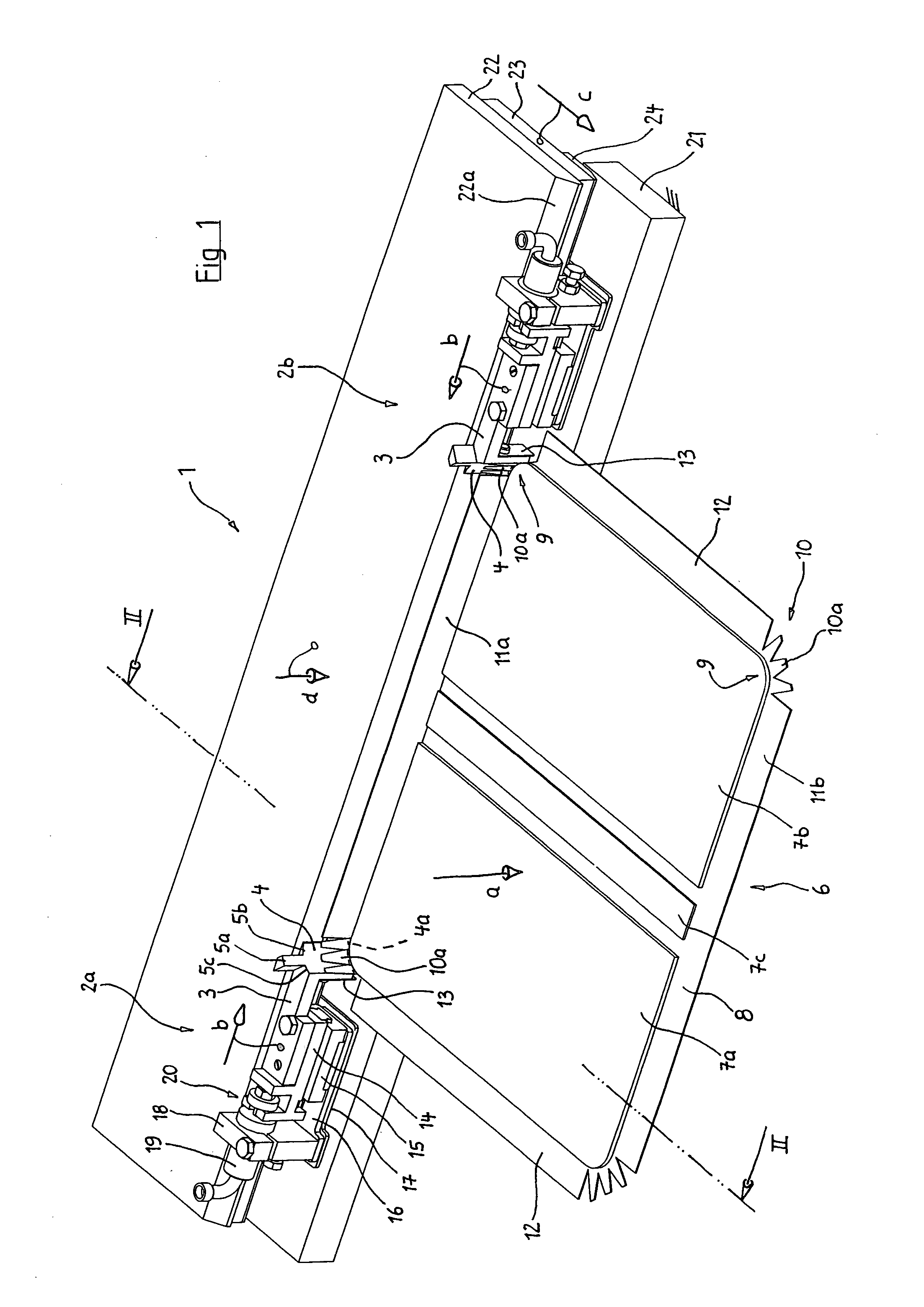

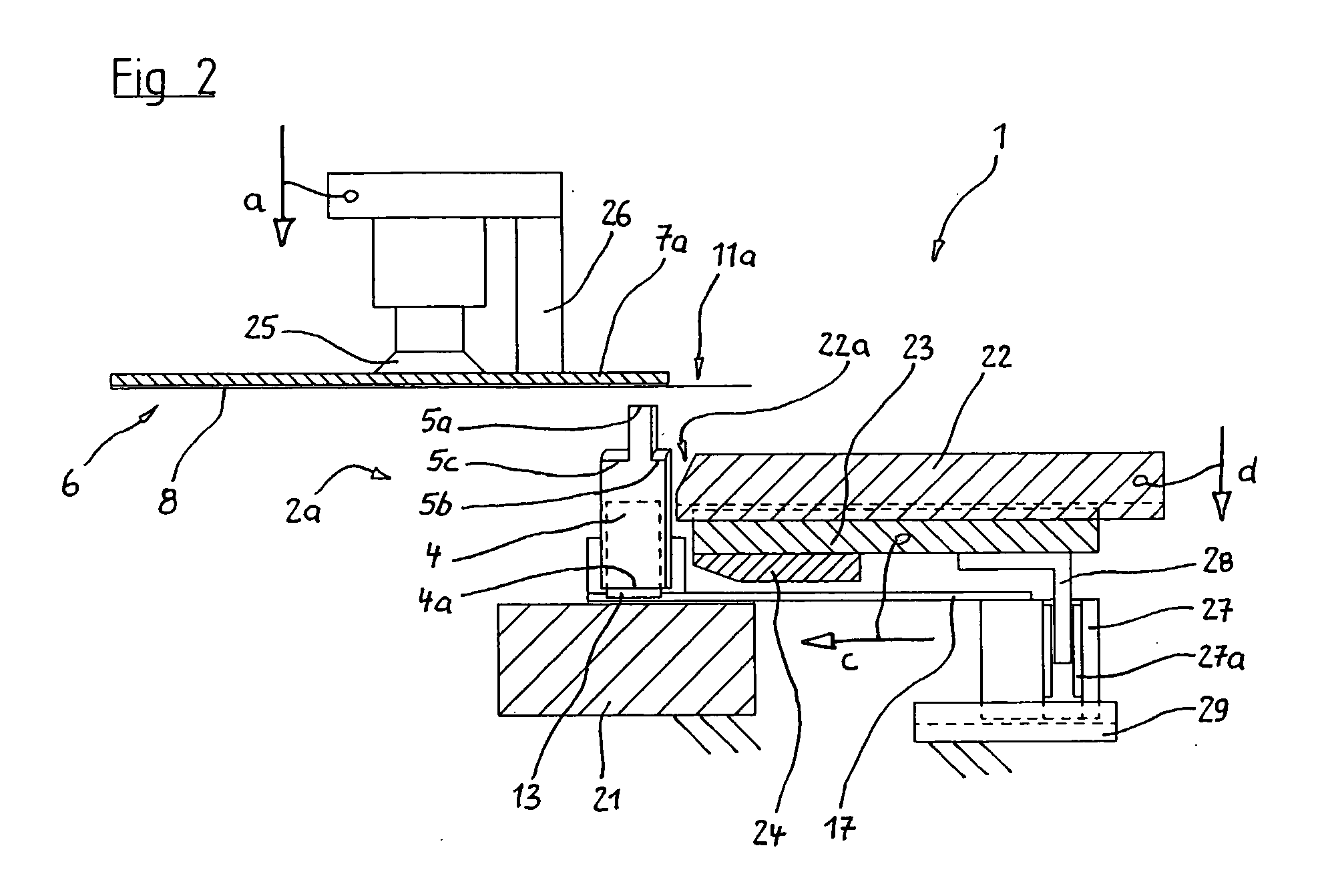

Method and device for producing cases with rounded corners

InactiveUS20060210378A1Simple structure designReliable fashionBookbinding casesCasing-inEngineeringLateral border

The invention pertains to a method and apparatus for producing cases with rounded corners. According to this method, the corner edge (10) that protrudes in the region of a rounded corner (9) is initially uprighted and turned over and subsequently pressed on the cover boards (7a, b, c) together with the turning-over and pressing-on of the lateral edge (11a) of an adjacent lateral border, in the same station (1). The apparatus comprises at least one rounded corner tool (3) that is arranged in the same station (1) in the which the lateral edges (11a, b) of opposed lateral borders that lie parallel to one another are uprighted, turned over, and pressed on the cover. The rounded corner tool (3) can be moved (b) toward the center of the case and out of the effective range of the lateral turn-in device (24) immediately before the turning-over and pressing-on movement (c, d) of the lateral turn-in device (24).

Owner:KOLBUS

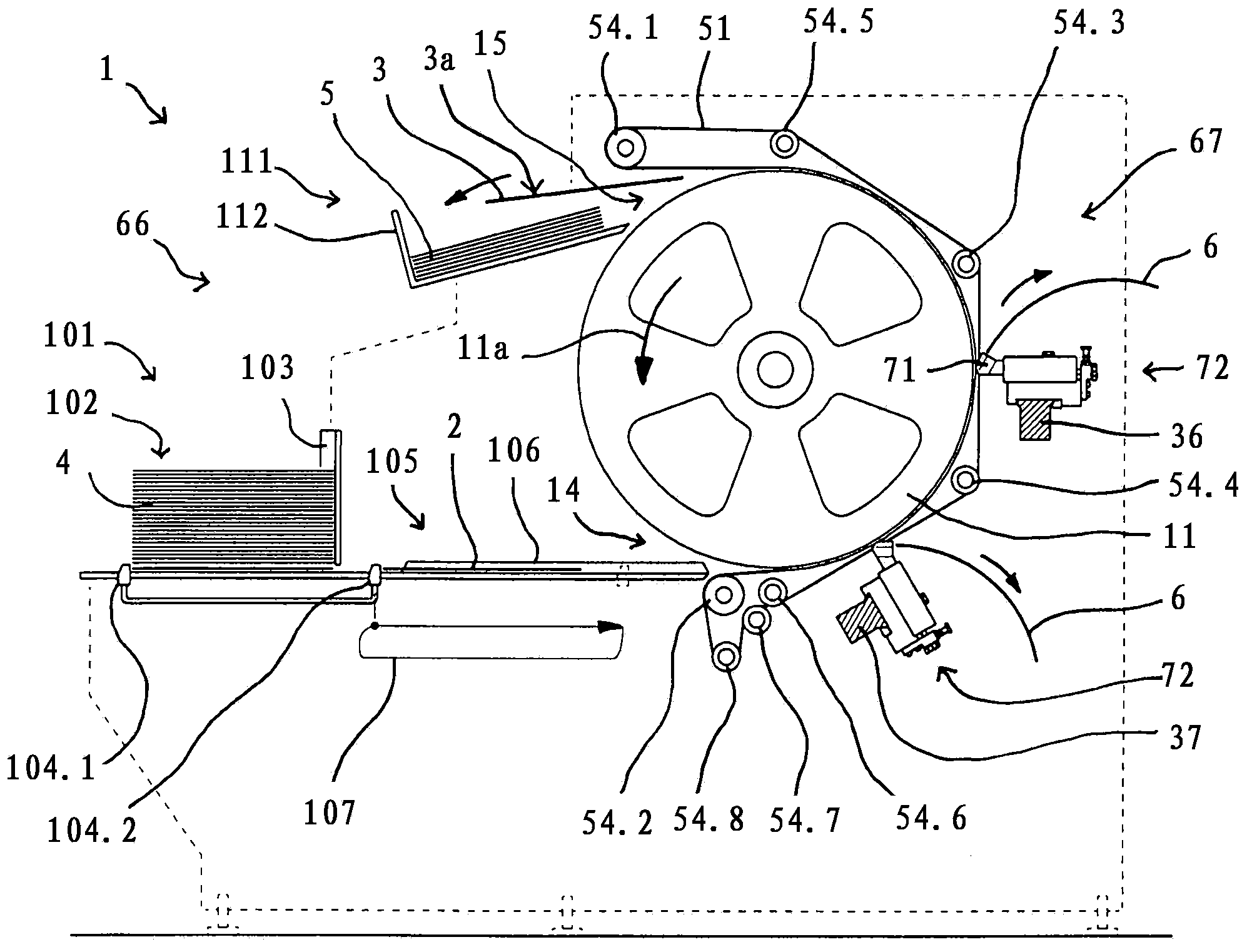

Device for making groove in cardboard blank

InactiveCN103538284ABlow off easilyEasily brush offBookbinding casesPaper-makingCardboardEngineering

The invention relates to a device (1) for making a groove in a cardboard blank according to the roller working principle. The device comprises a driven horizontally-supporting conveying roller (11); a plurality of encircling roller, which are continuously encircled, and spaced from each other, and are used to coil the conveying roller under the condition of forming the inlet and the outlet; and belts (51), which are disposed on the roller housing in a pressed manner, and can be used to conveying the cardboard blank effectively. Groove cutters (72) are disposed between the belts at certain intervals, which are limited by the roller housing. The grooved cardboard blank is not required to be taken out and overturned, when the cut grooves (3a) can be observed from the upper part during the operation. The outlet (15) is disposed in an area of the top point of the upper part of the conveying roller. In addition, the grooved cardboard blank (3) can be discharged at the top point of the upper part to form an material-taking height good for the human engineering, especially when the cardboard is disposed on the outlet (15), and is disposed on the lower stacking bench (112).

Owner:KOLBUS

Spine Label Pocket for a Binder Cover

A binding cover having a transparent overlay cover disposed over and around the spine of the binding is configured to provide a label pocket on the spine portion of the binding cover wherein a label may be inserted easily without tools or rigid label material. In several embodiments the label pocket provides a fixed label space. In another embodiment the label pocket opens along the spine when the binding cover is opened, and returns to a closed position when closed, thereby retaining a label inserted therein. In another embodiment a method for forming the label pocket is provided.

Owner:SAMSILL CORP

Information processing apparatus, information processing method, program, and storage medium

An apparatus includes an instruction unit configured to give an instruction for executing divided stapling, an acquisition unit configured, when the instruction is given, to acquire a number of staplable sheets, a determination unit configured to determine a location at which the divided stapling is executed based on the acquired number of staplable sheets and a number of sheets necessary for each chapter, and a staple setting unit configured to set a staple attribute for instructing a printing apparatus to execute stapling by using the determined location as a unit of the divided stapling.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com