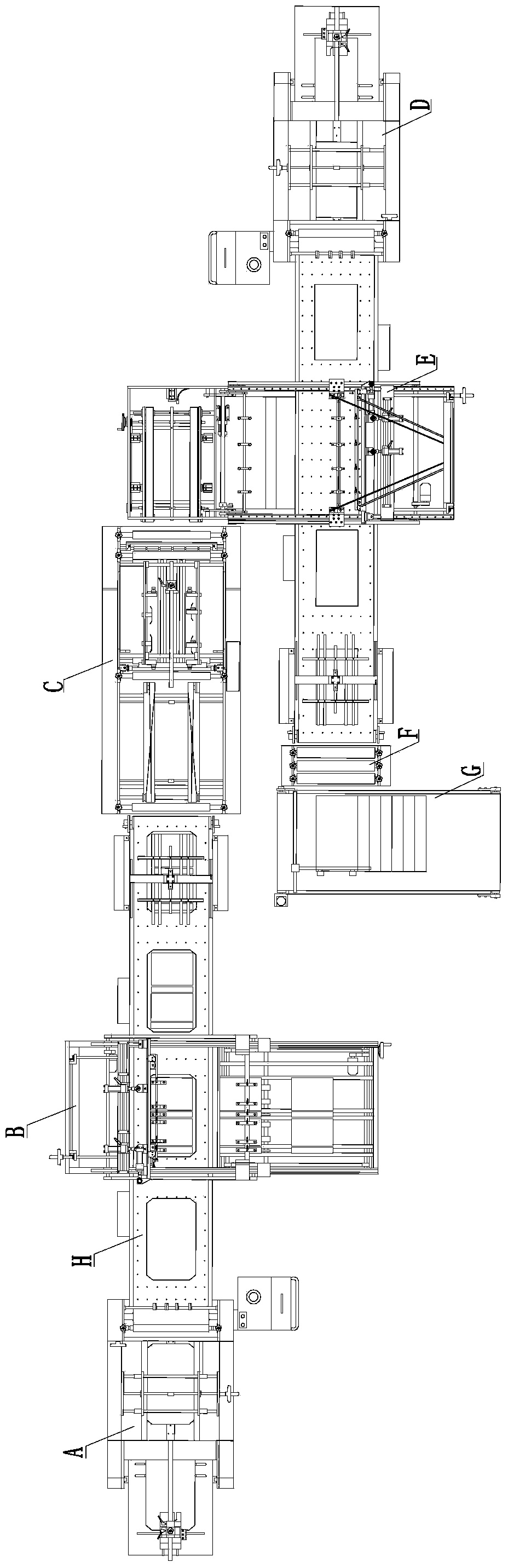

Full-automatic production line of hard covers

A production line, fully automatic technology used in printing, bookbinding, bookcases for bookbinding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

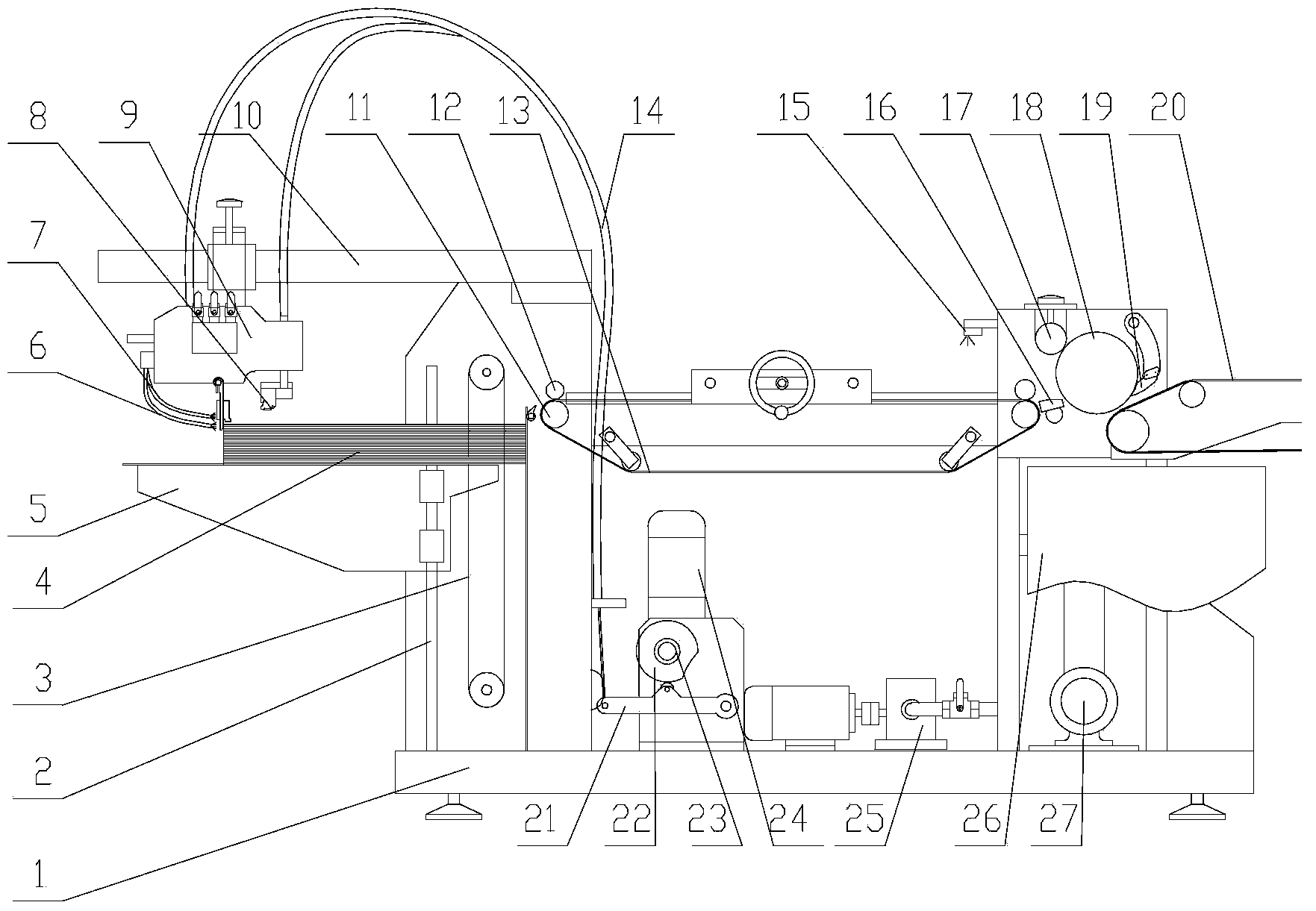

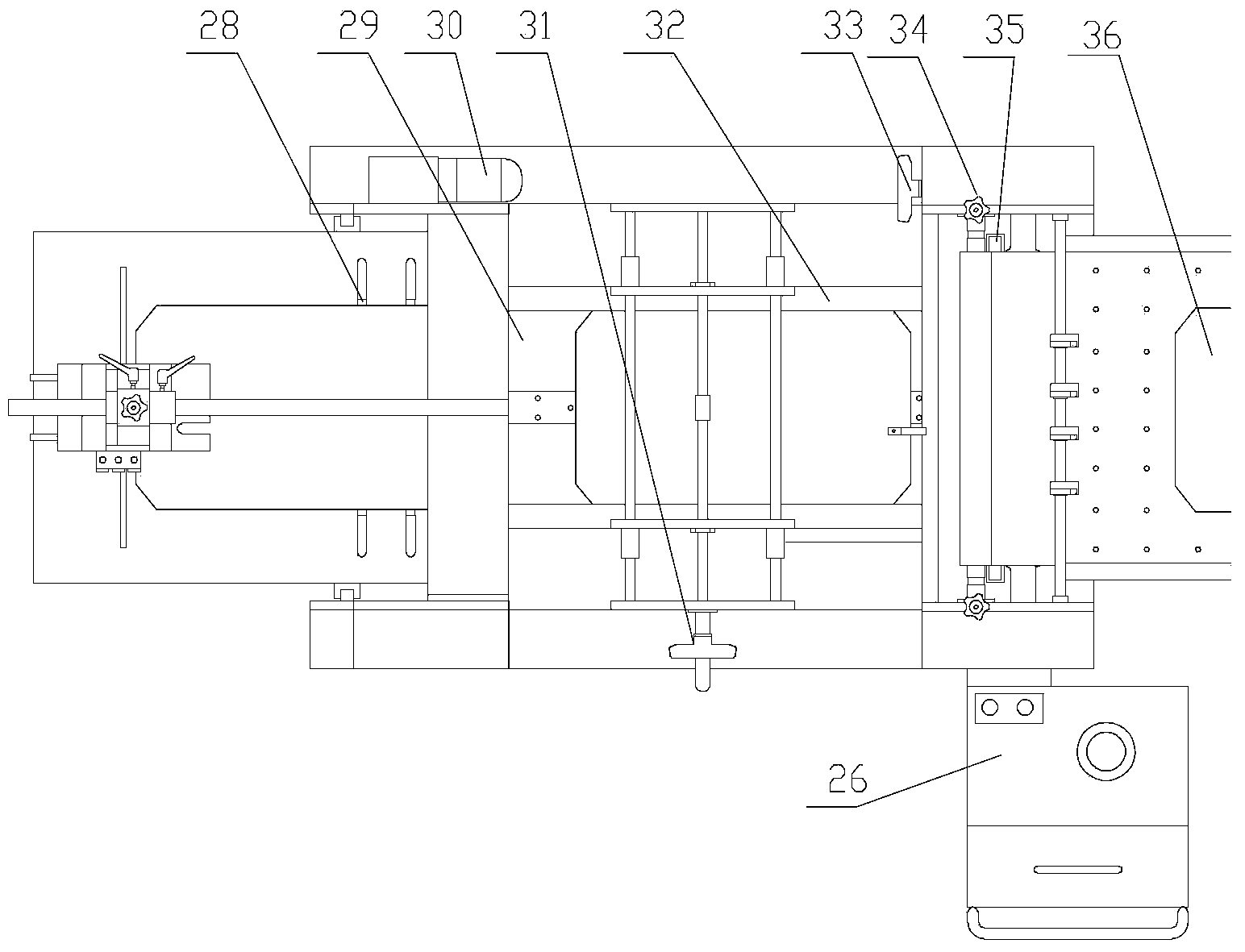

[0021] The names of the parts in the drawings: 1. Gluing part of the frame, 2. Paper stacking platform lifting guide, 3. Lifting chain, 4. Face paper or liner, 5. Stacking platform, 6. Loose paper blowing, 7. . Paper feeding and blowing, 8. Feeder suction nozzle, 9. Feeder height adjustment handwheel, 10. Feeder front and rear adjustment rails, 11. Paper receiving roller, 12. Paper receiving wheel, 13. Paper guide conveyor belt , 14. Feida steel wire flexible shaft, 15. Turn off switch, 16. Feed scraper, 17. Adjust rubber roller, 18. Glue roller, 19. Output scraper, 20. Conveyor belt, 21. Feeder cam pendulum Rod, 22. Feeder cam, 23. Feeder angle encoder, 24. Feeder motor, 25. Glue pump, 26. Glue bucket, 27. Main motor for gluing, 28. Qi paper lever, 29. Paper feeding Table, 30. Lifting motor, 31. Paper guide adjustment handwheel, 32. Paper guide rail, 33. Paper feed adjustment handwheel, 34. Glue thickness adjustment handwheel, 35. Squeegee, 36. Gluing surface paper, 37. Push ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com