Patents

Literature

532 results about "Covers (device)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

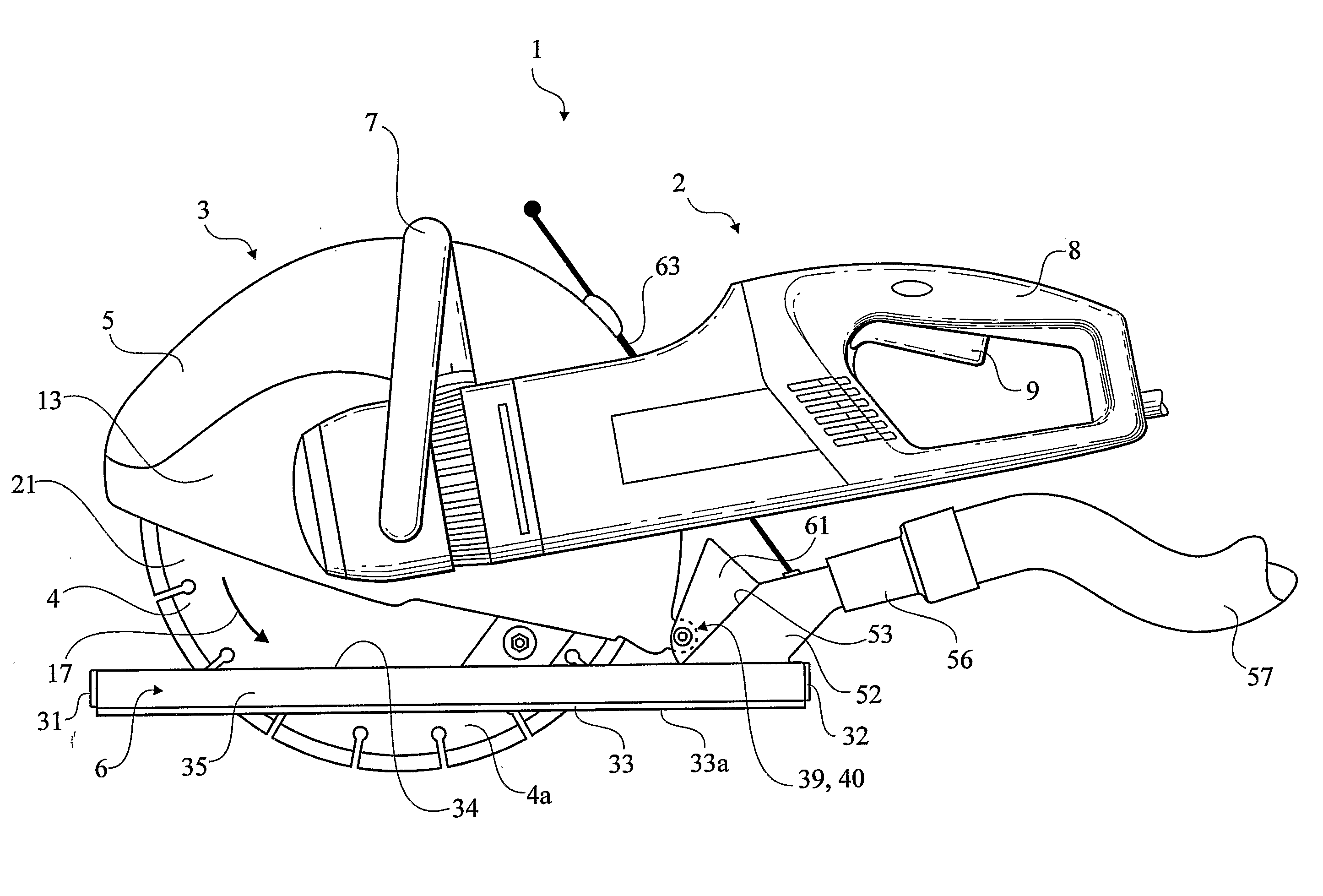

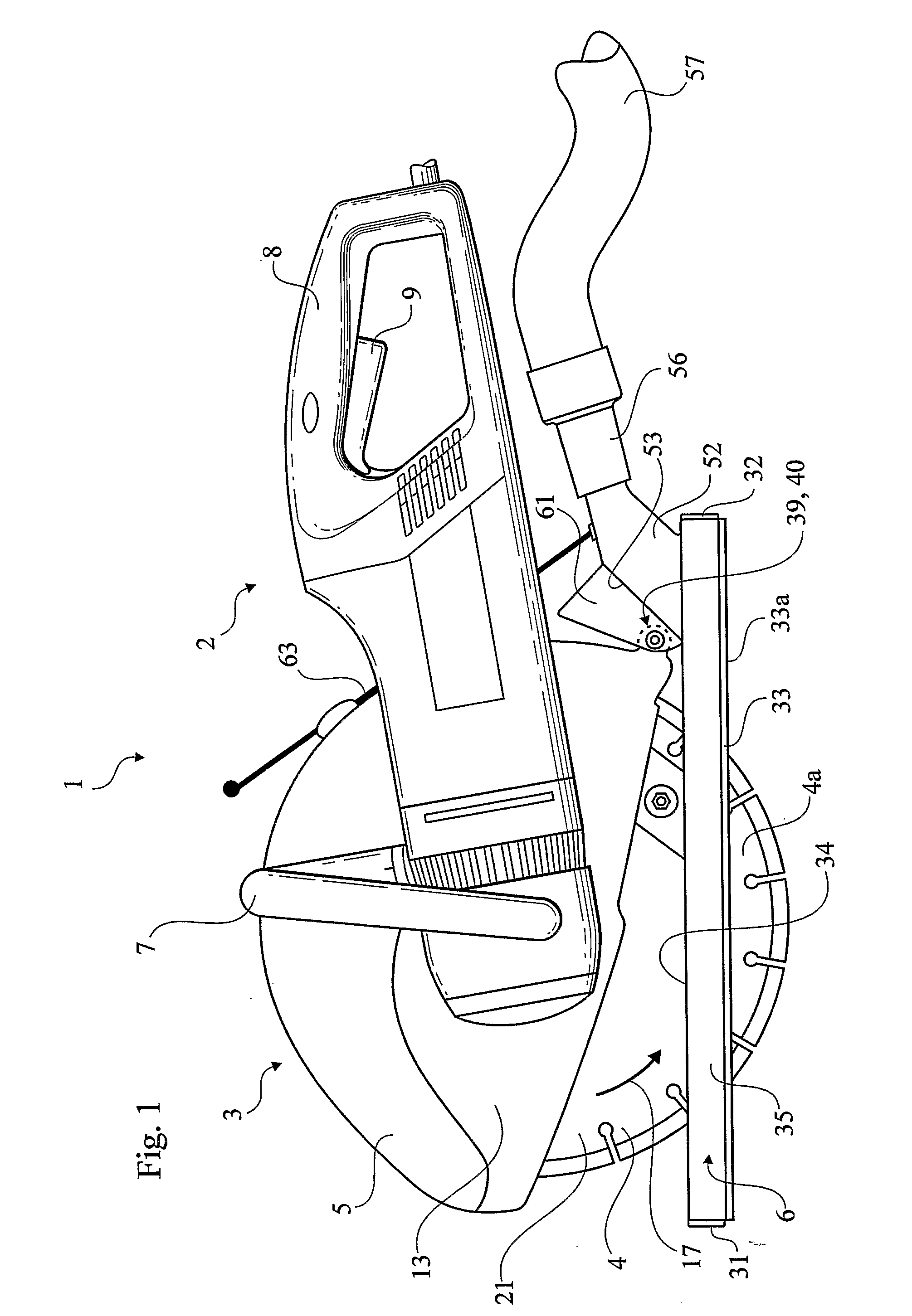

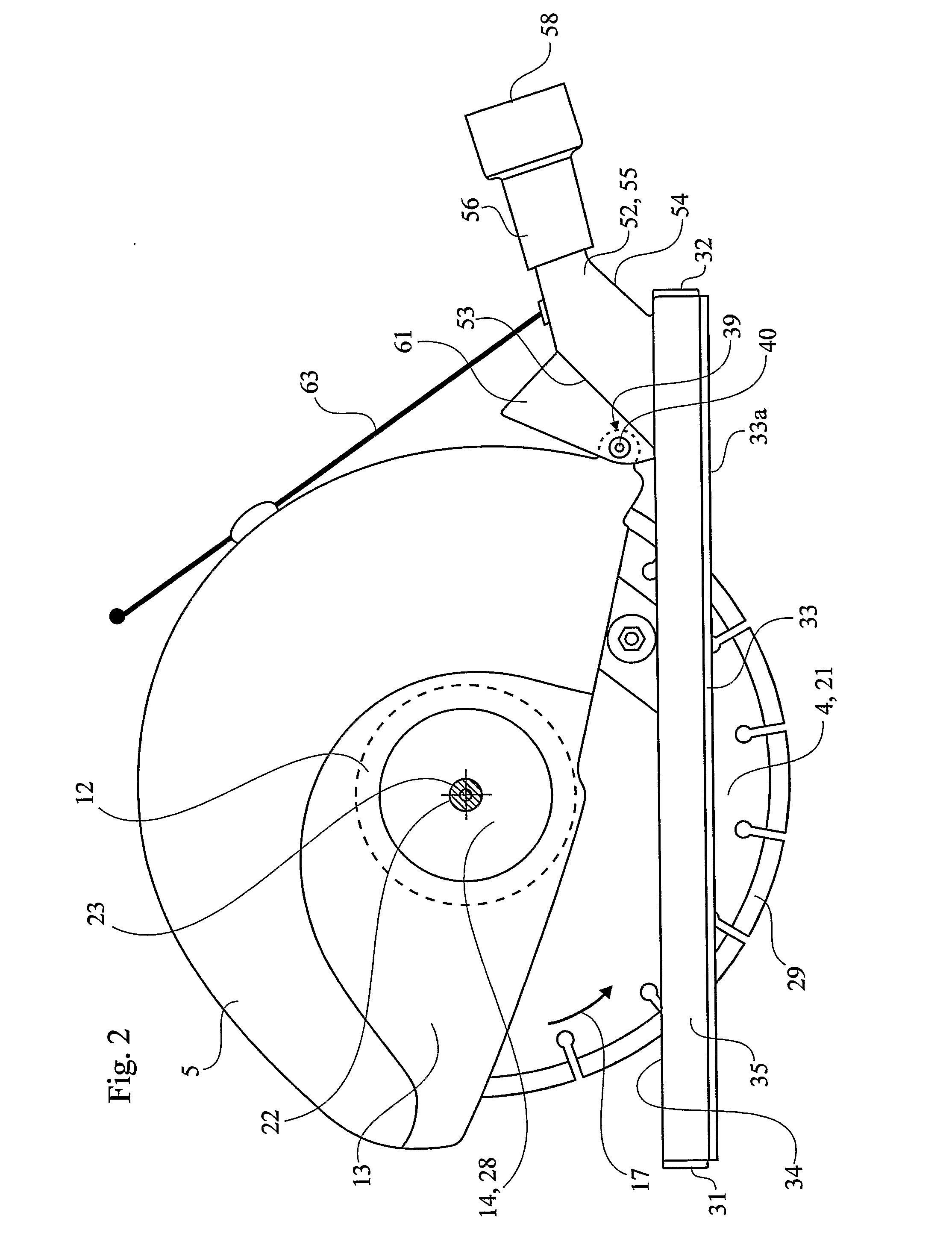

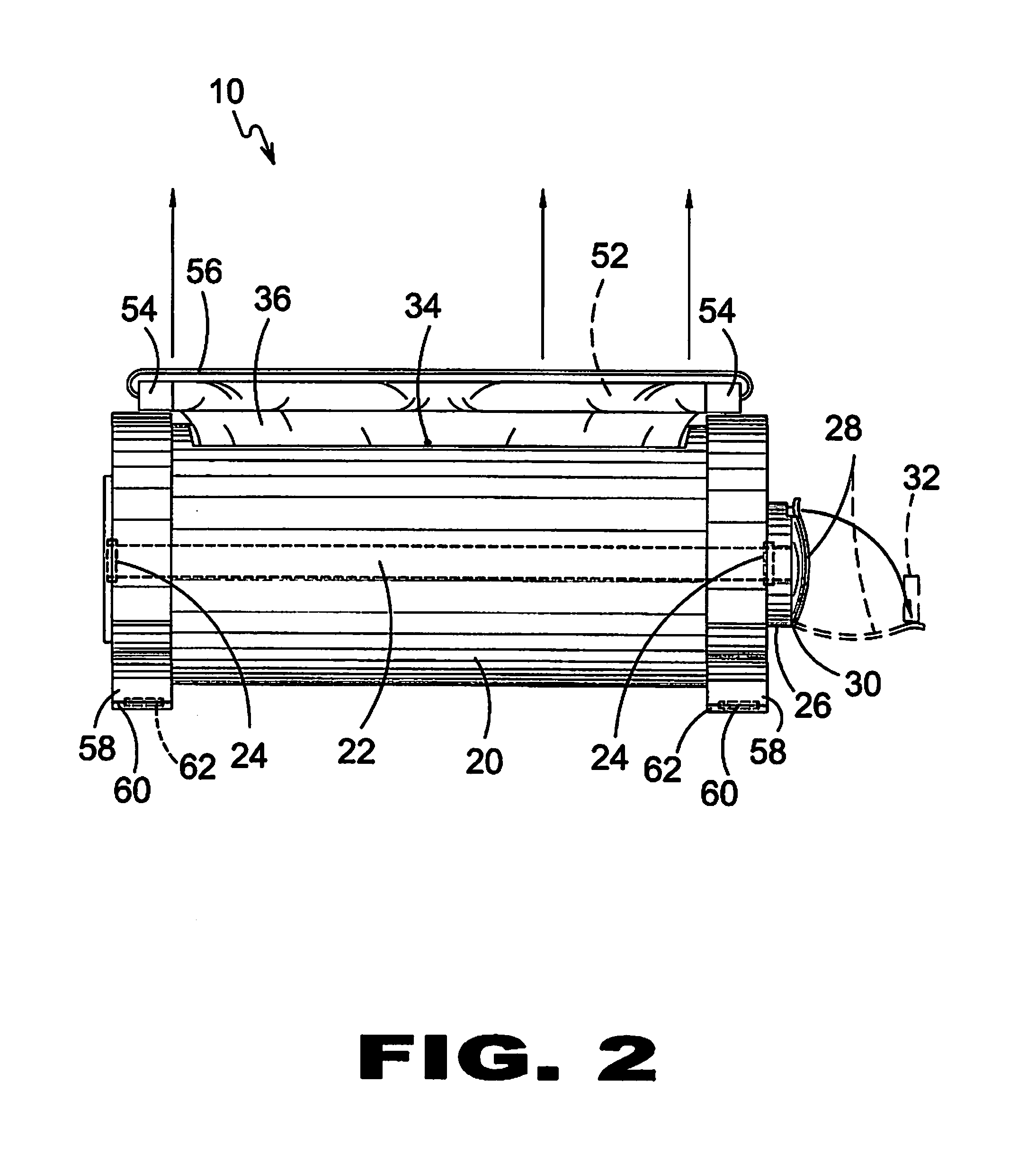

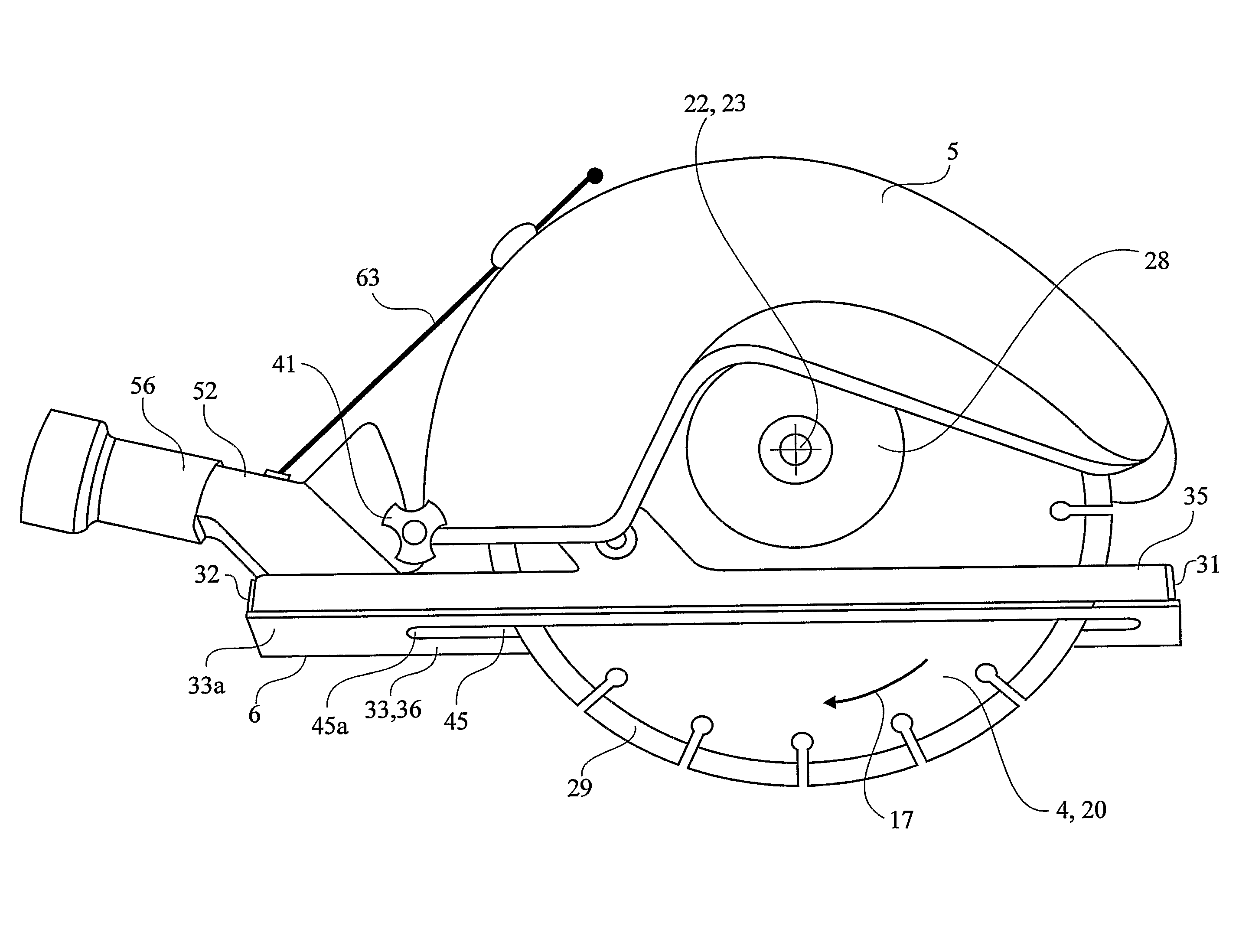

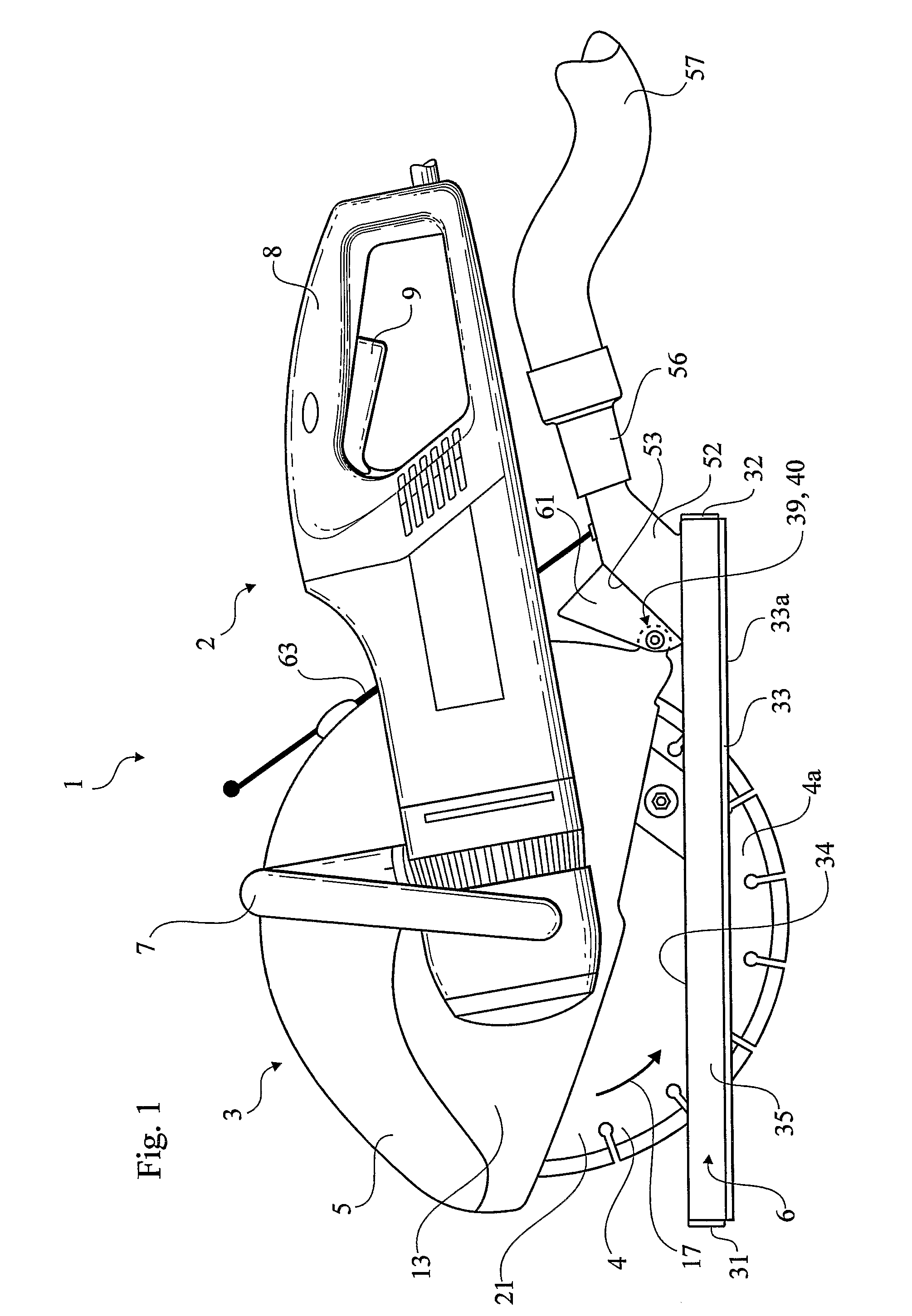

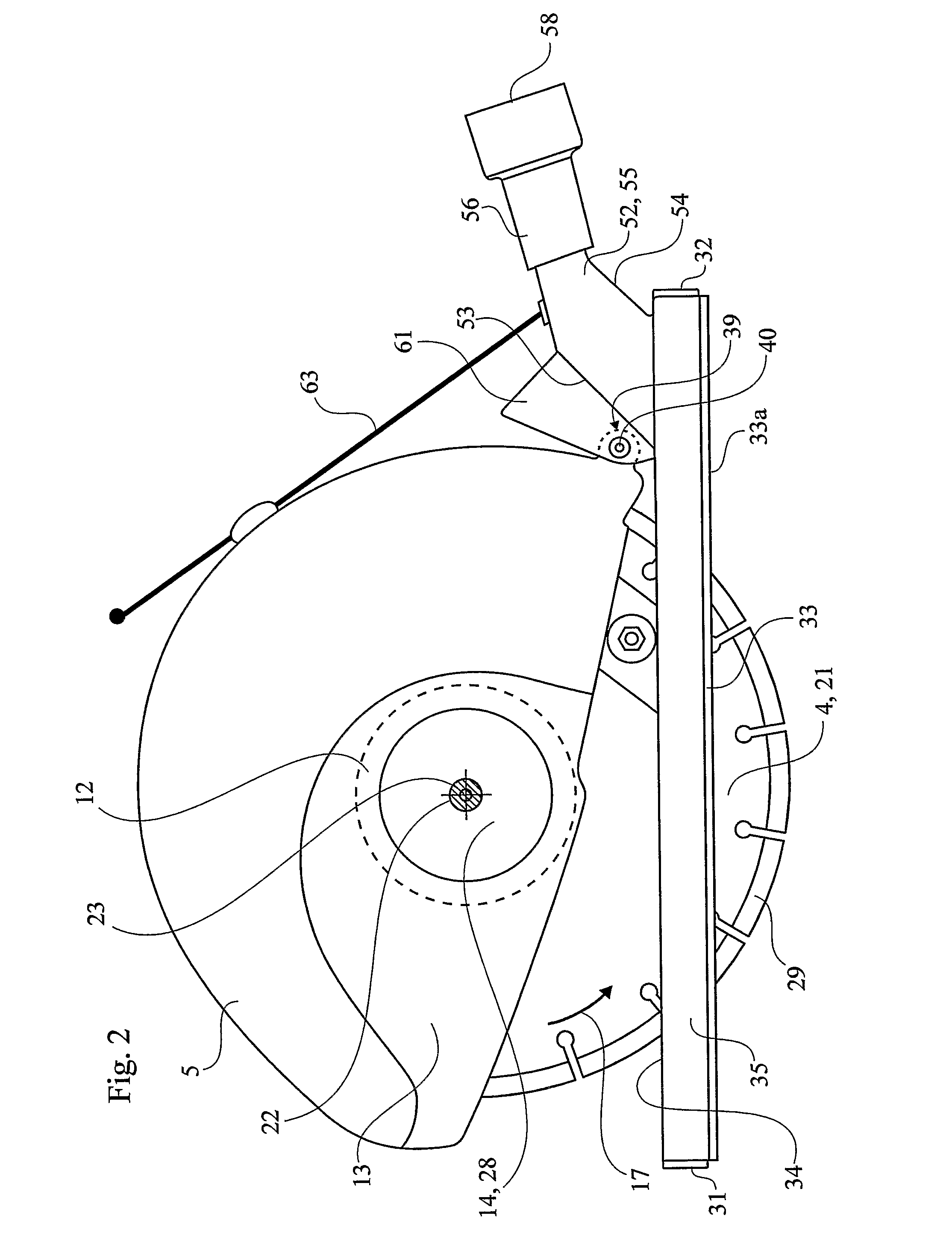

Cutting and Dust Collecting Assembly and Working Machine with Such Assembly

ActiveUS20080163492A1Avoid flyingEfficient collectionMetal sawing devicesMetal sawing accessoriesCircular sawDust control

A cutting and dust collecting assembly comprises a rotatable, circular saw blade (4) having a first side (20), a second side (21), and a cover device (6) with a terminal member (52). The bottom surface (36) of the cover device extends in a plane. A longitudinal passage (45, 46) for the saw blade extends through the cover device from its top surface to its bottom surface. The terminal member comprises a terminal chamber (60) having an inlet (45a), the mouth of which coincides with the plane of said bottom surface. An outlet (58) can be connected to a vacuum source. The direction of rotation of the operating blade is such that the rear part (4a) of the saw blade which has passed beyond the bottom surface of the cover device will move in a direction upwards-rearwards towards the bottom surface. The invention also concerns the cover device, a sealing body belonging to the cover device and a working machine which is provided with the cutting and dust collecting assembly.

Owner:HUSQVARNA AB

Self-propelled amusement device

InactiveUS20010024925A1Easy to operateReduce manufacturing costSelf-moving toy figuresEngineeringPower apparatus

Owner:DOMINGUES FRANCISCO BICALHO

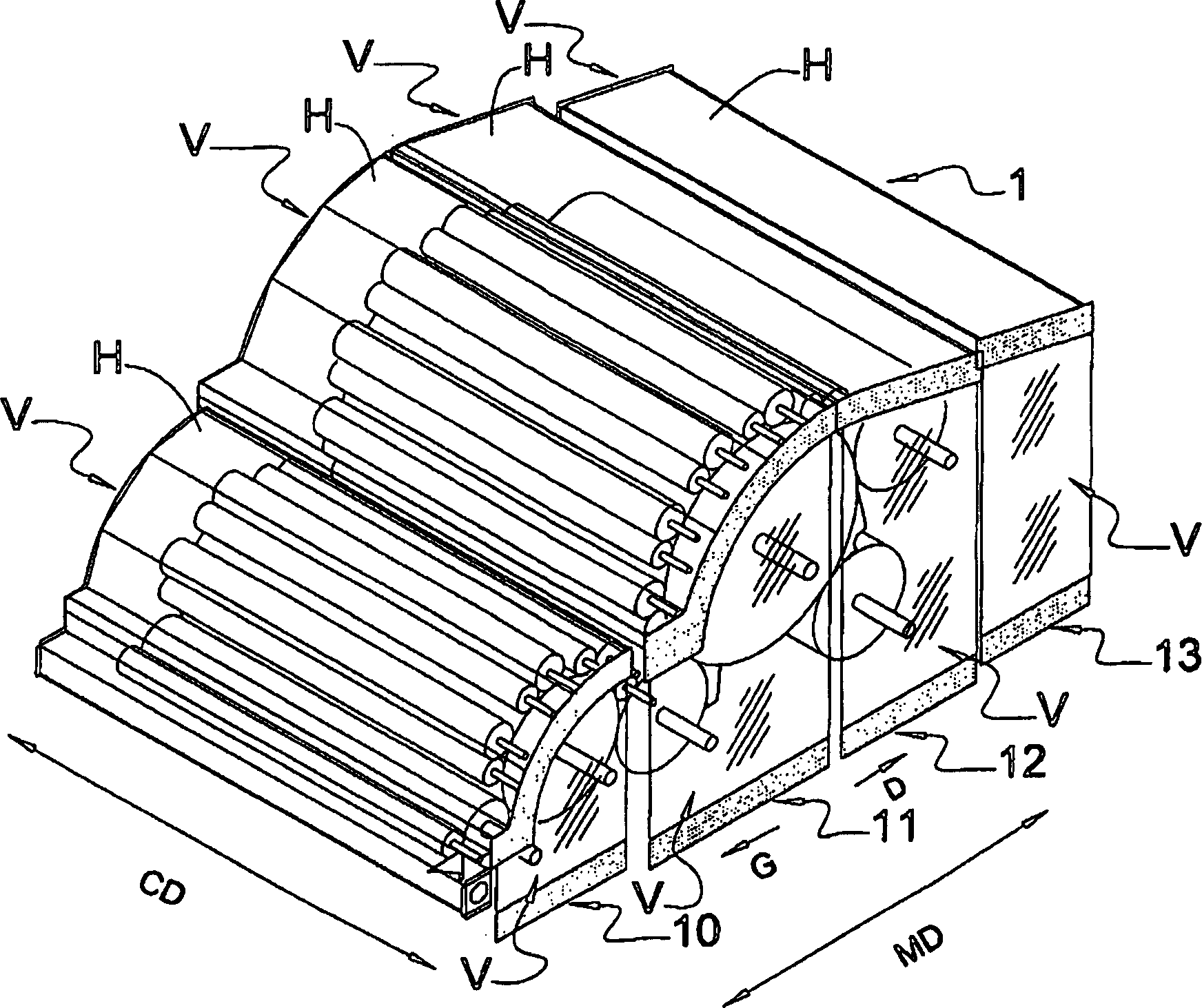

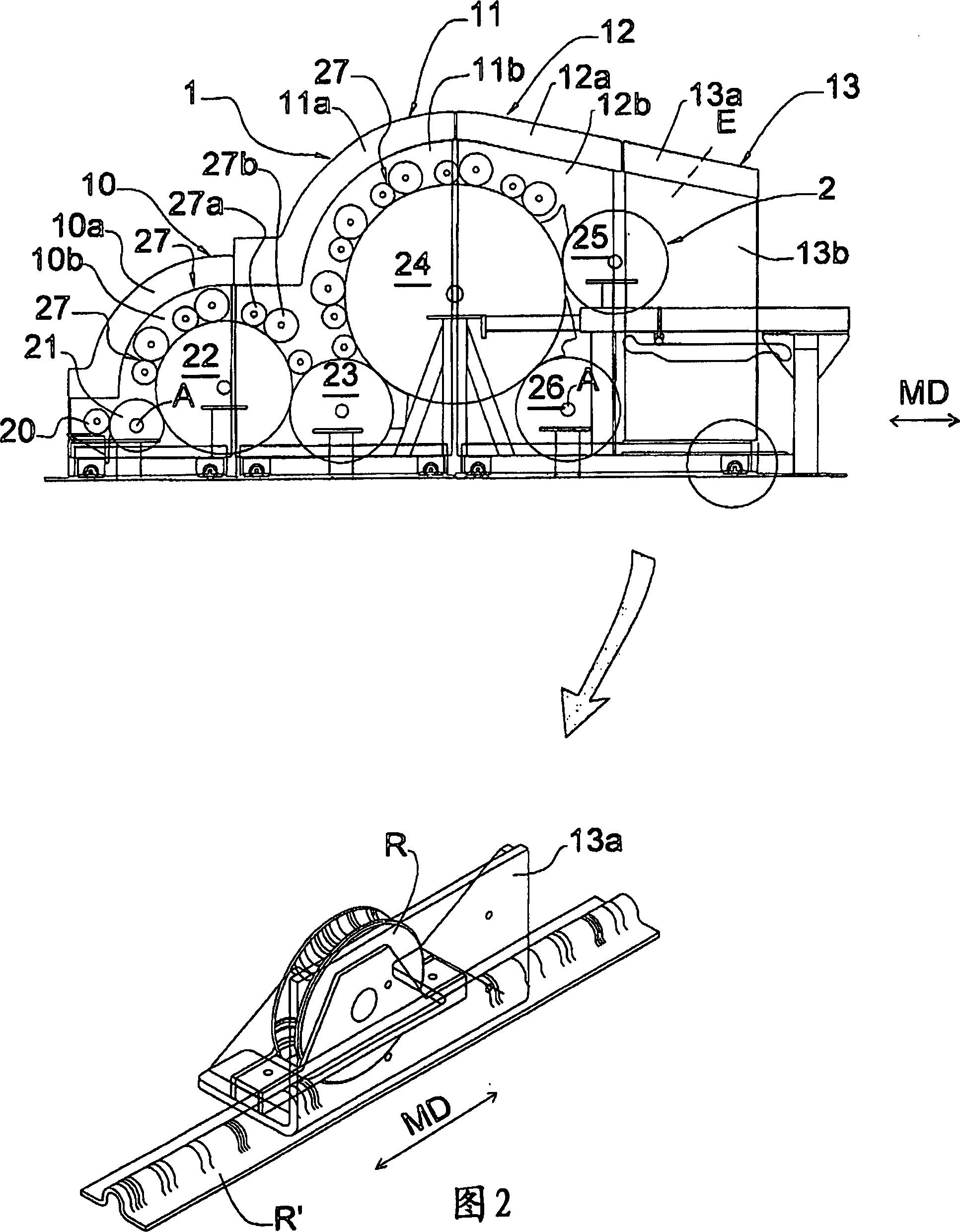

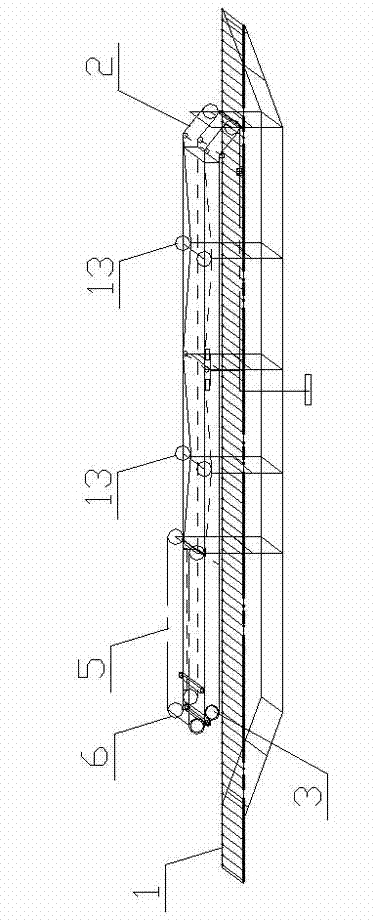

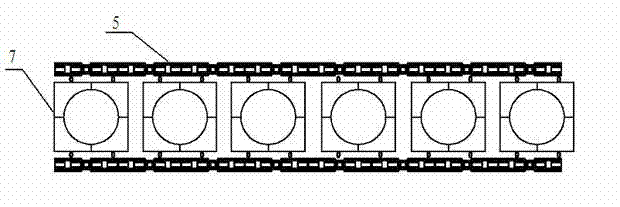

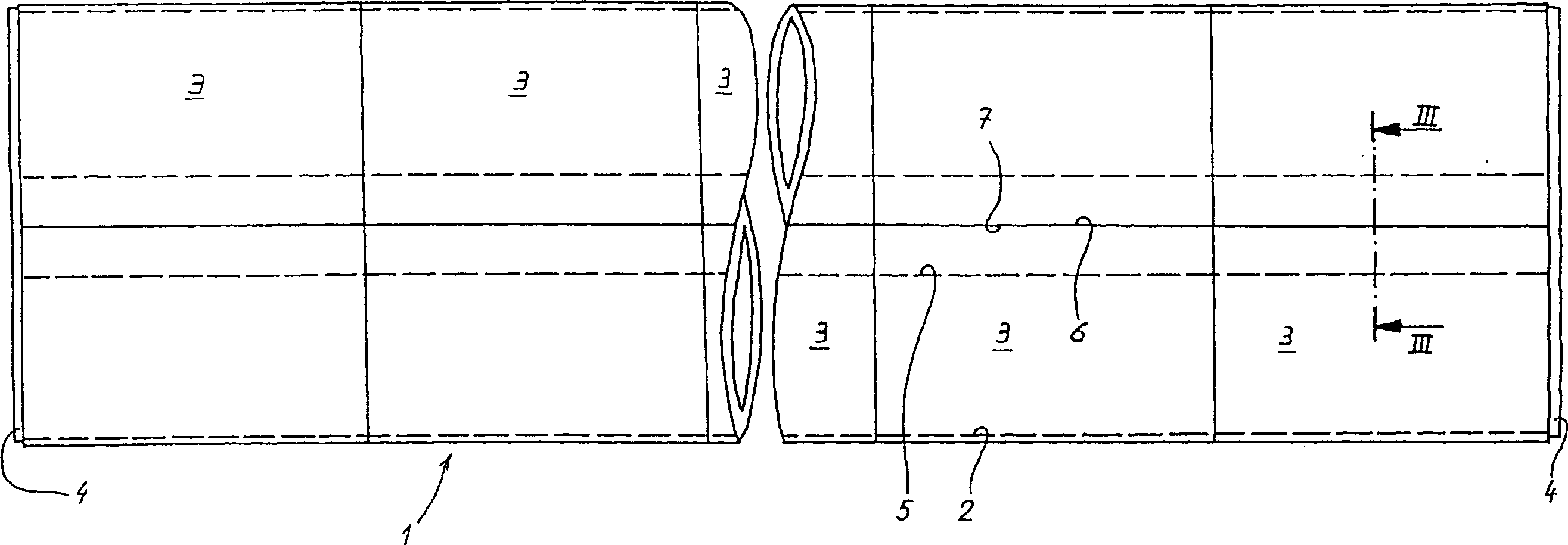

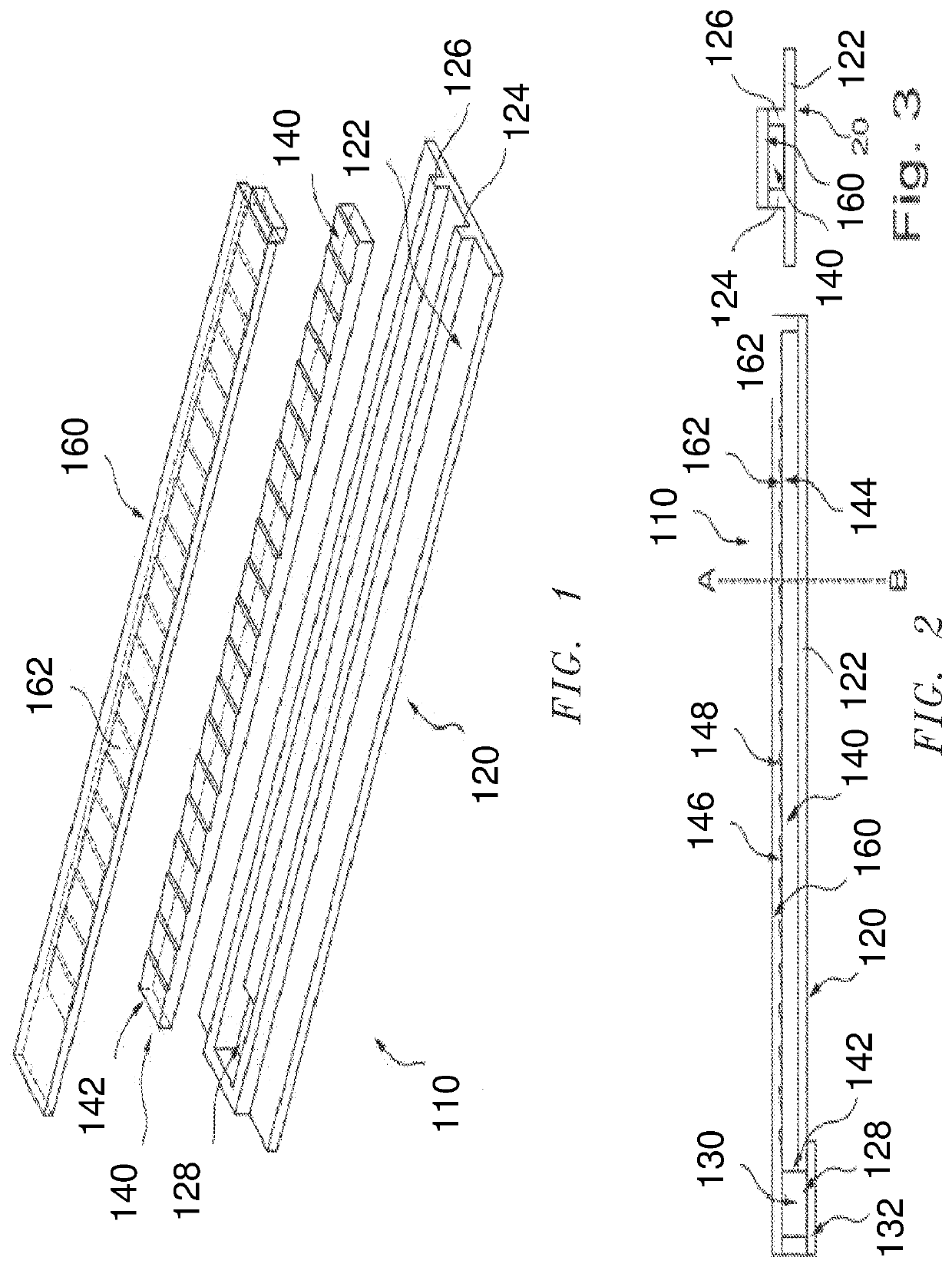

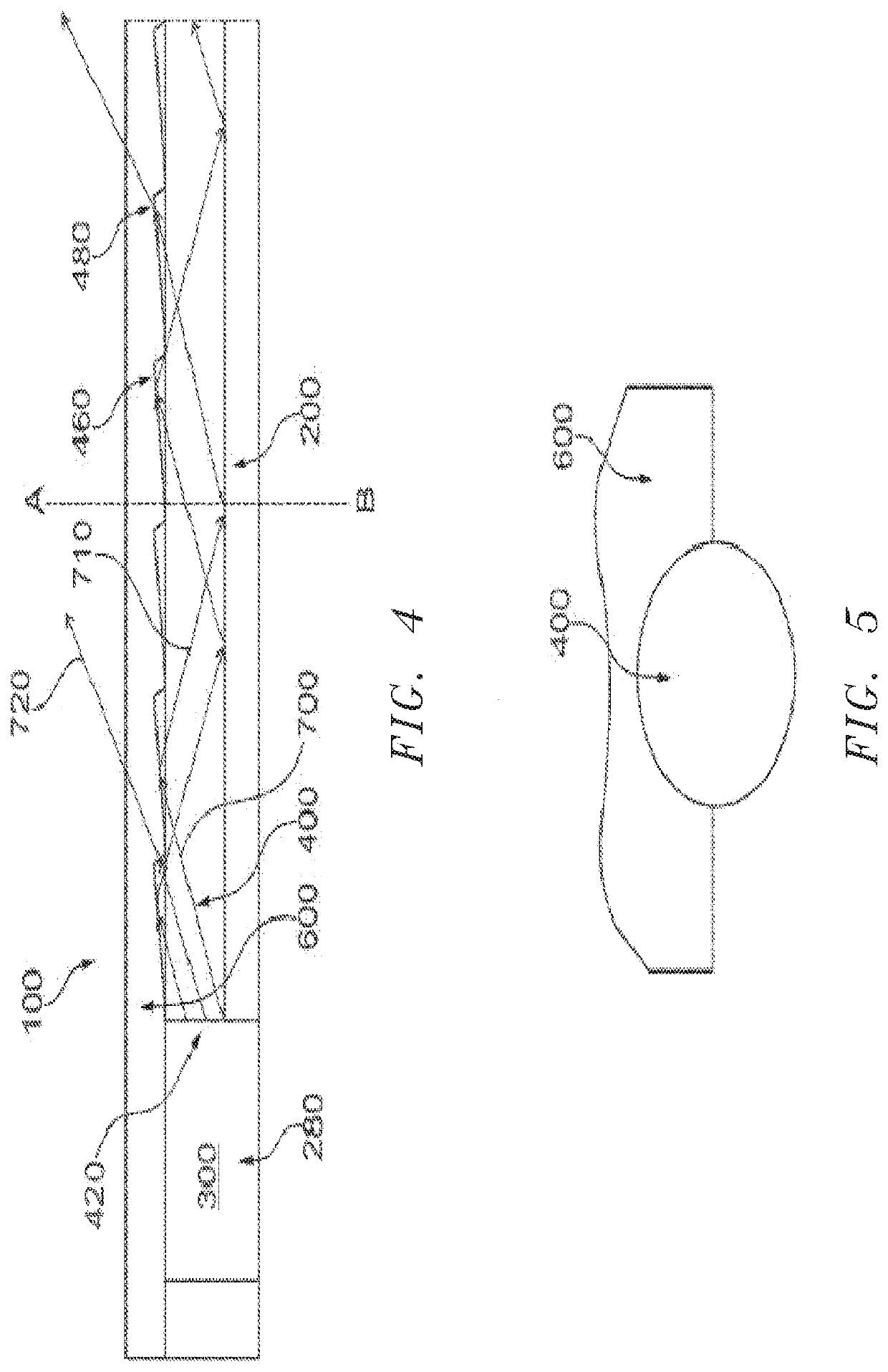

Carding machine with linearly movable casing

InactiveCN1811027AAddress accessibility issuesIncrease contactCarding machinesEngineeringMechanical engineering

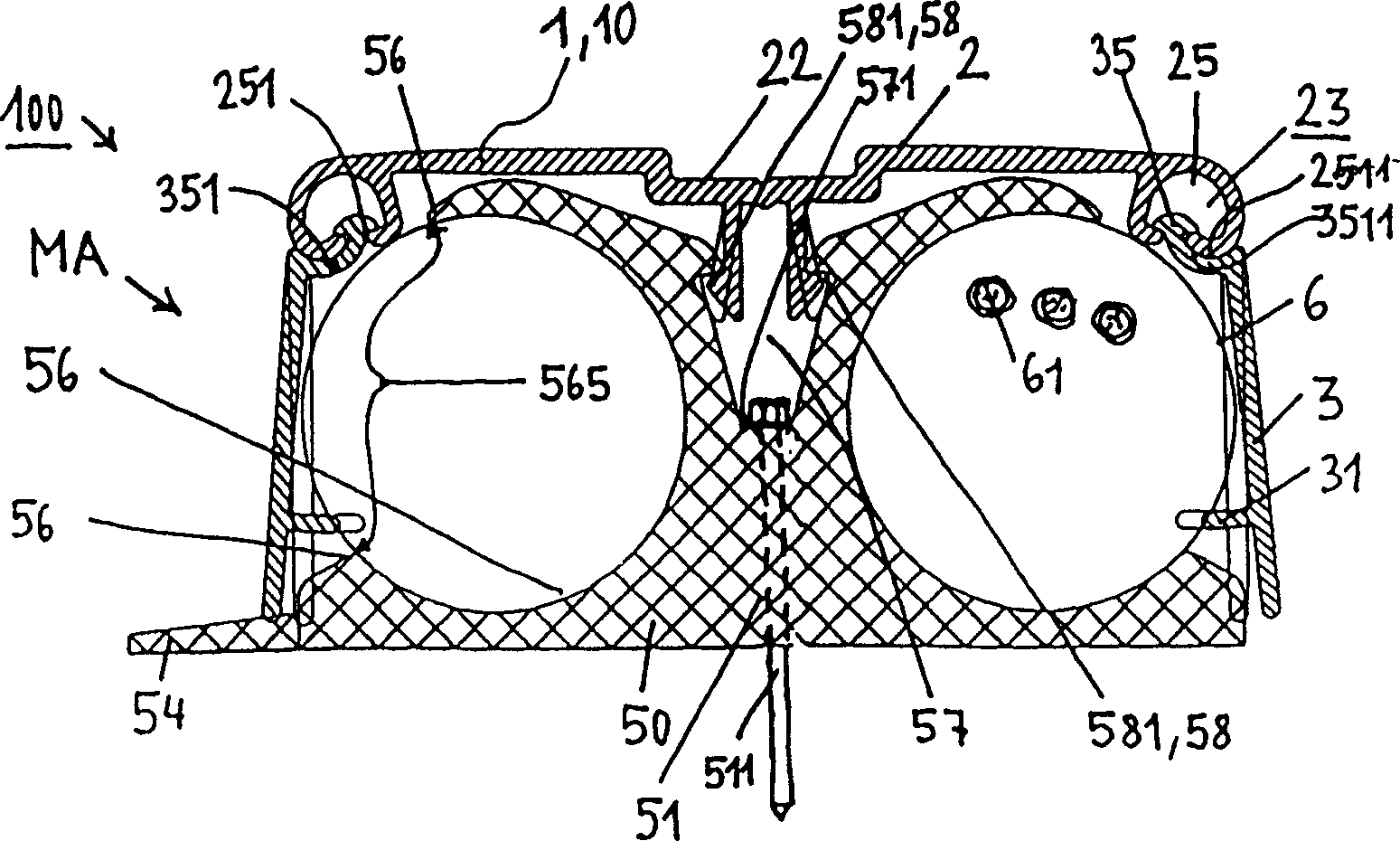

The invention relates to a carding machine which is provided with a plurality of drums (20,21,22 and so on) and a covering device, wherein the covering device (1) can form an encloser (E), and the drums of the carding machine is contained in the encloser. The covering device (1) is provided with at least a covering element (10, 11, 12, and 13), and the covering element is vertical to the vertical direction of the drums of the carding machine along a shaft line (MD) and can do translational motion between a covering position and an end portion opening position, the covering position exclusively belongs to the covering unit on the position, at least one portion of the drums of the carding machine is covered by the covering element, and the drums are not covered by the cover element on the end portion opening position.

Owner:ASSELIN THIBEAU

Installation and cover device for cables and method for installation thereof

InactiveCN1589515ACable installations on groundCable installations in surface ductsFront coverLine tubing

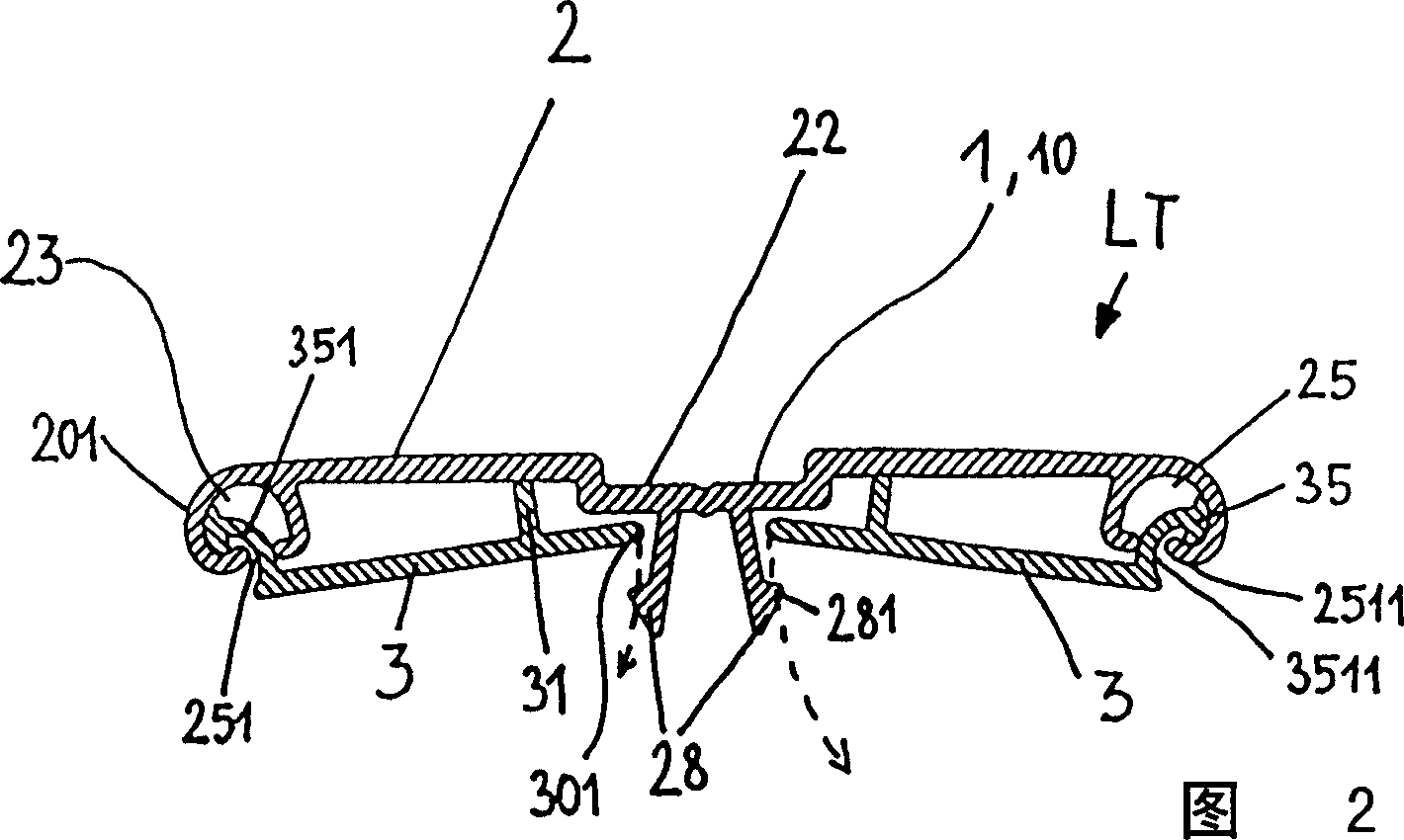

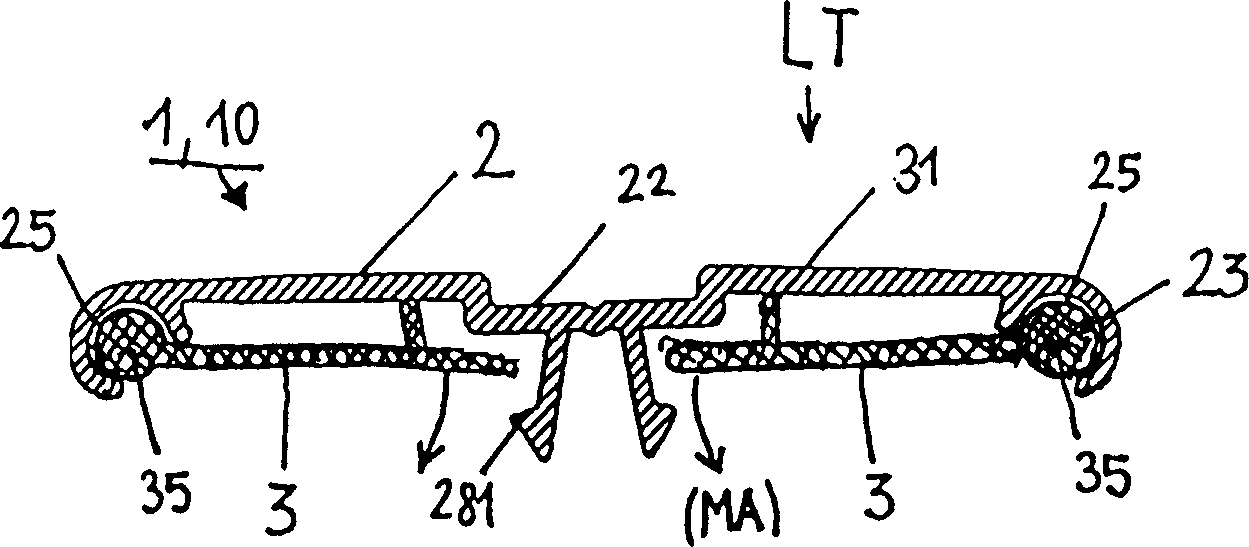

The invention relates to an installation device for cables (6) to be laid along a wall, comprising cable holders (5) and a cover (10). According to the invention, the cover (10) is embodied as a cable cover profile strip (1) which may be wound on a winding body for the installation thereof and comprising a front cover strip (2) and side cover strips (3) extending from the both side edges (201) thereof, whereby the both side cover strips (3) are connected to the front cover strip (2) by means of a folding or jointed connection. The both side cover strips (3) run in the same direction as the front cover strip (2) in the folded state (LT) with the free side edges (301) thereof folded in on each other and each of the both side cover strips (3) may be brought into an installation position (MA),perpendicular to the front cover strip (2) by folding out away from the same.

Owner:CABLERUNNER AUSTRIA GMBH & CO KG

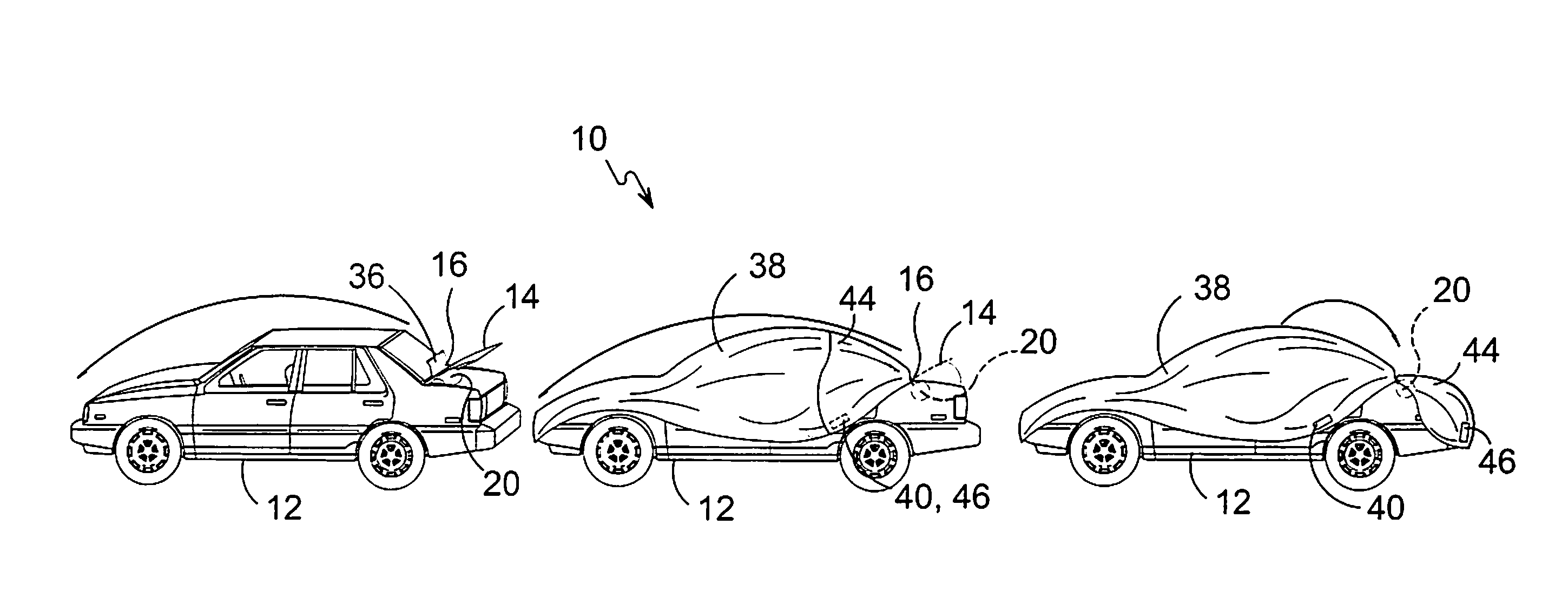

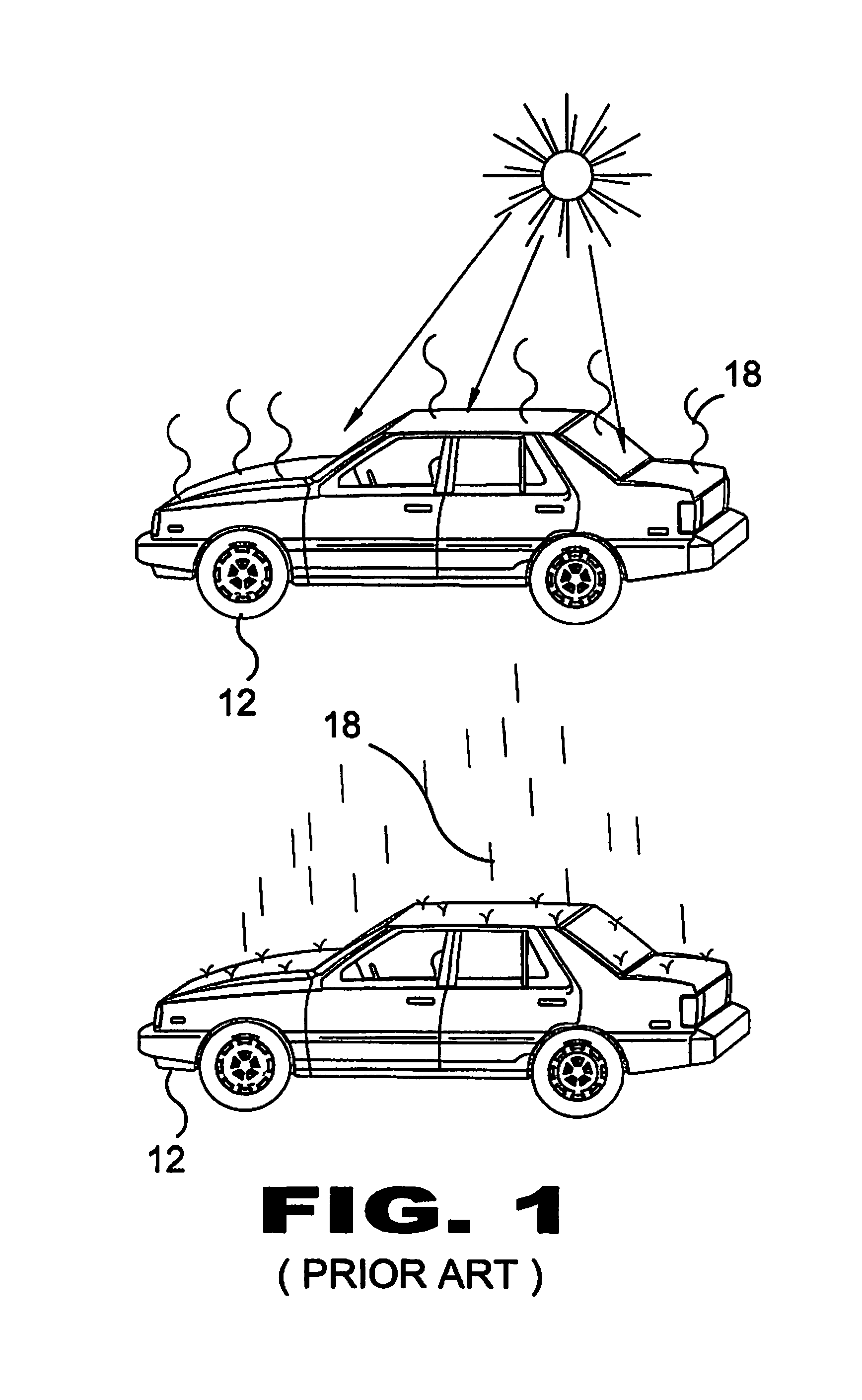

Vehicle protecting cover device

InactiveUS7464982B1Good dispersionEasy to take backSuperstructure subunitsRemovable external protective coveringsEngineeringMechanical engineering

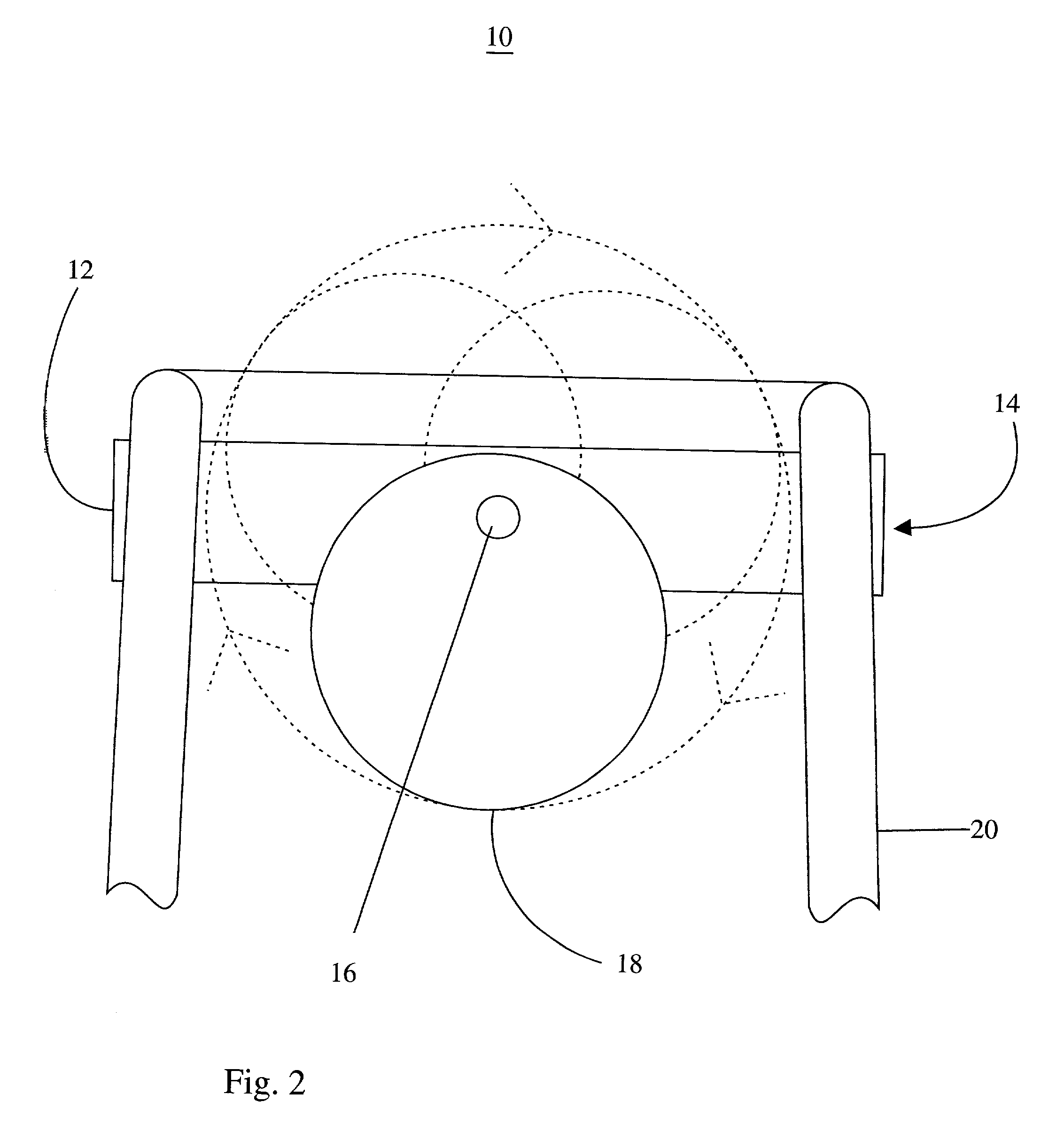

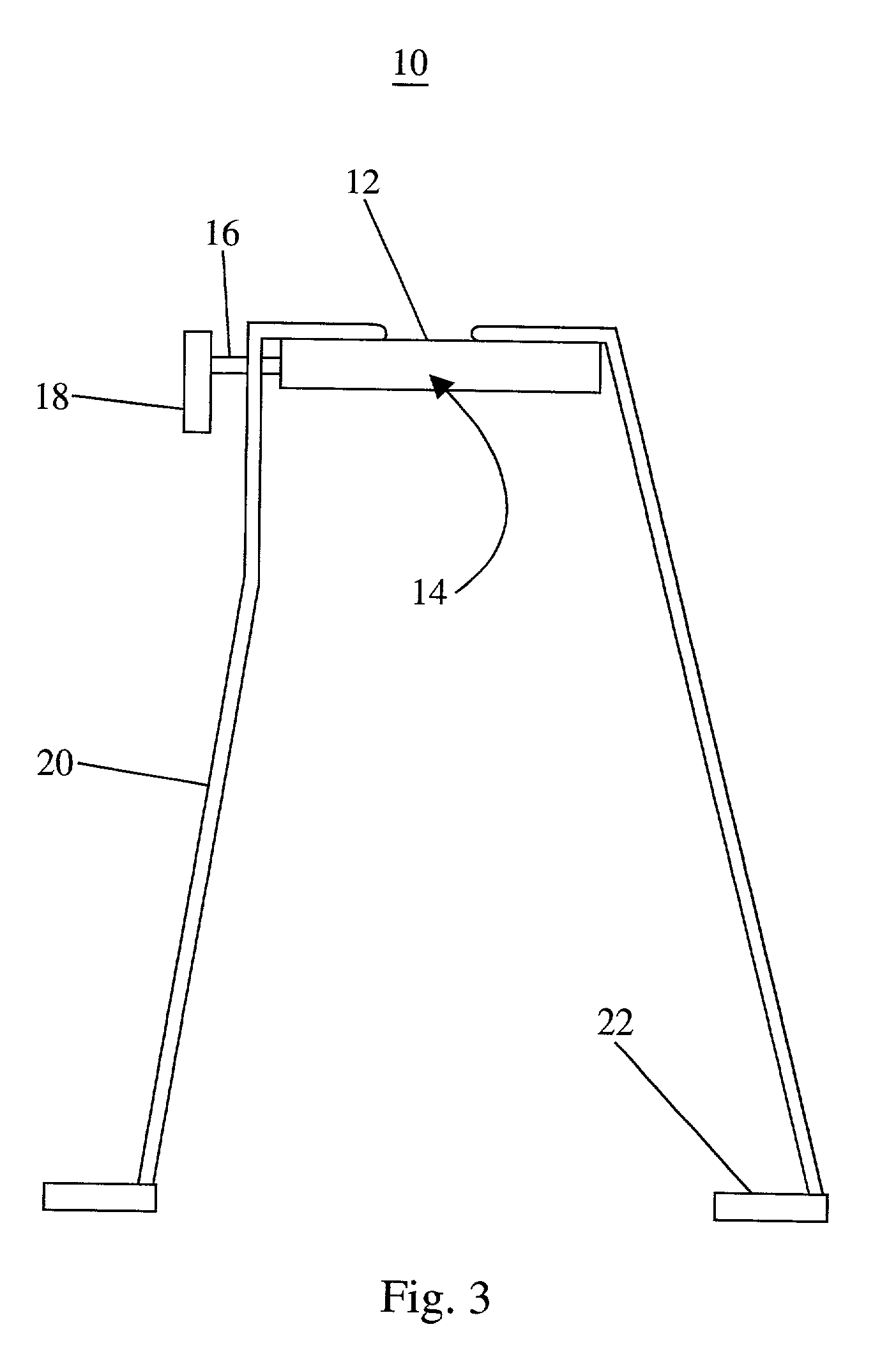

A vehicle covering device having a housing integral with an axle having a folding crank handle to utilize a reeling action useful in the withdrawing and retracting of a folding cover comprised of a sheet like material that when withdrawn can be expanded to cover a vehicles body by manipulation of an end rod attached to said folding covers end portion that is pulled through the jam of a trunk and over a vehicles forward body to effectively protect said vehicle. Additionally the device has base elements integral to its housing for providing support and if desired a secondary rear folding cover that may withdrawn in the same manner that may be utilized to cover the rear or trunk portion of a vehicle as well.

Owner:LIN XIAOGU +2

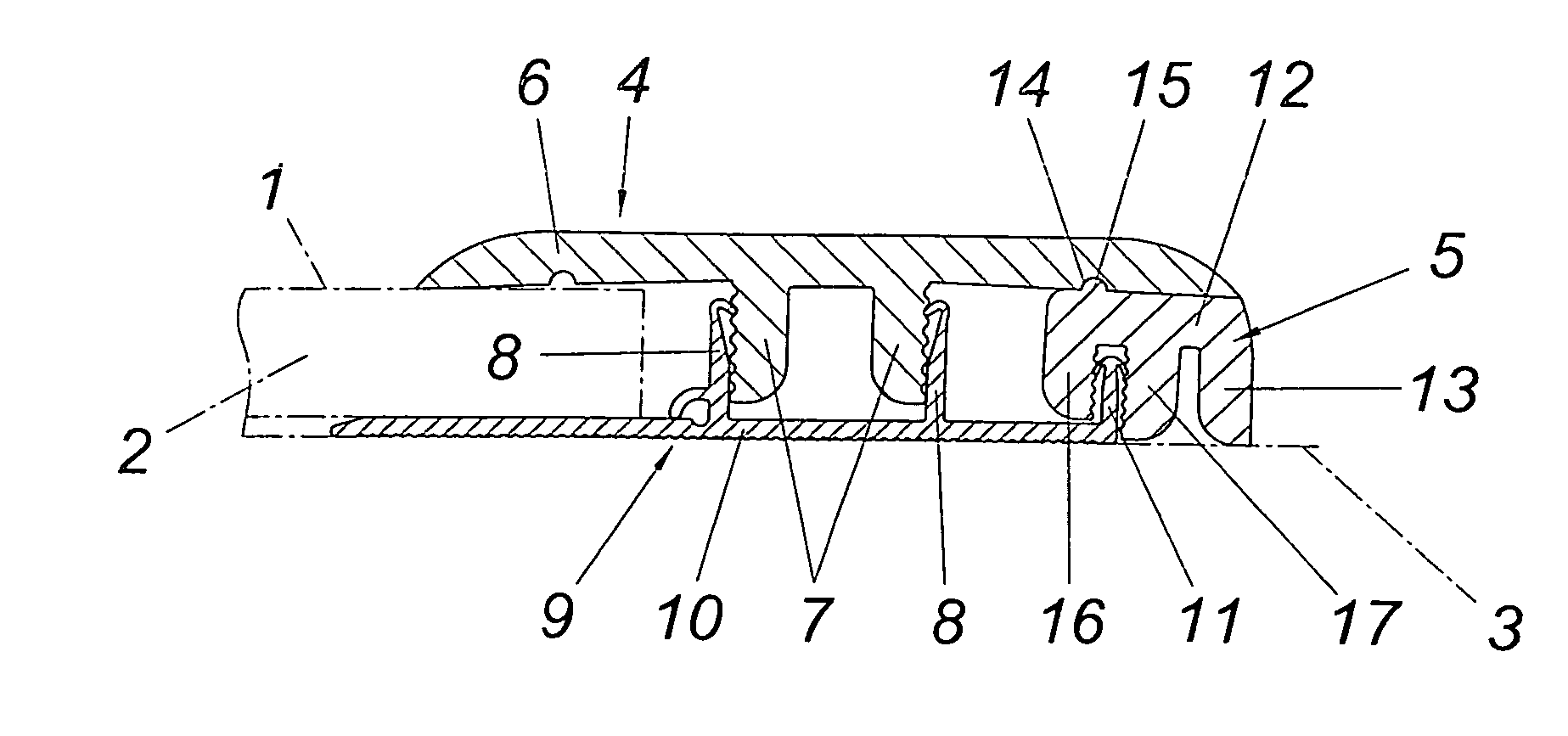

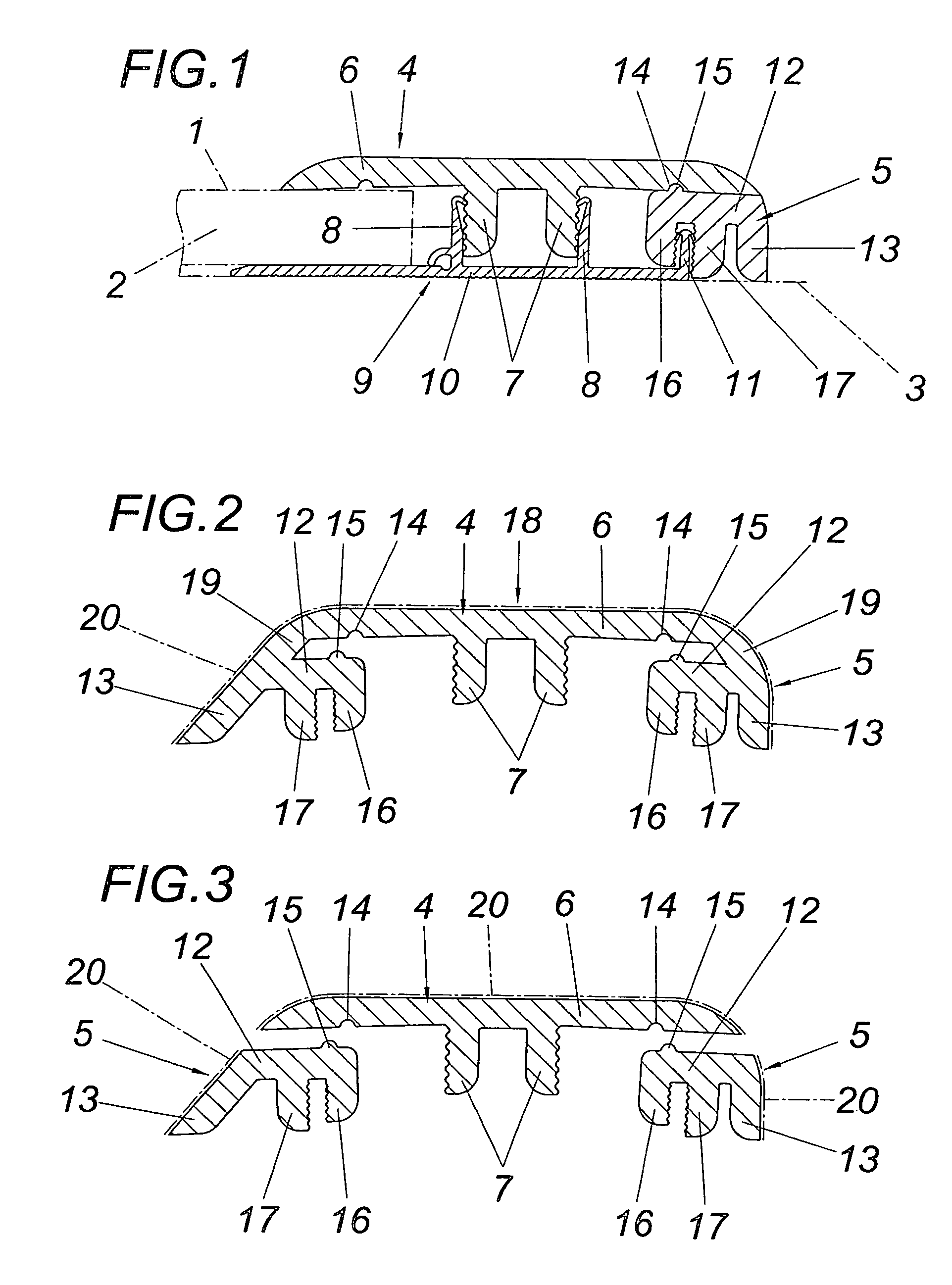

Covering Device for Floor Coverings

ActiveUS20080034696A1Simple manufacturing conditionReliable transmissionRoof covering using tiles/slatesNatural patternsClassical mechanicsTongue and groove

A covering device for floor coverings (2) is described with a profiled cover (4) that is provided with one covering flange (6) and at least one clamping web (7) which protrudes downward from the covering flange (6), extends in the longitudinal direction of the profiled cover (4), and is used for fastening the profiled cover (4) in a fixture (9), with said device also comprising a compensating strip (5) that can be employed if desired, by being fastened to the profiled cover (4) by means of a form-fitting tongue and groove joint connecting to the underside of the covering flange (6). In order to provide advantageous manufacturing conditions it is proposed that the profiled cover (4), developed from an extruded profile, is provided with a tongue and groove joint formed by at least one longitudinal groove (14) for retaining a lug (15) of a compensating strip (5) also developed from an extruded profile.

Owner:NEUHOFER FRANZ JUN

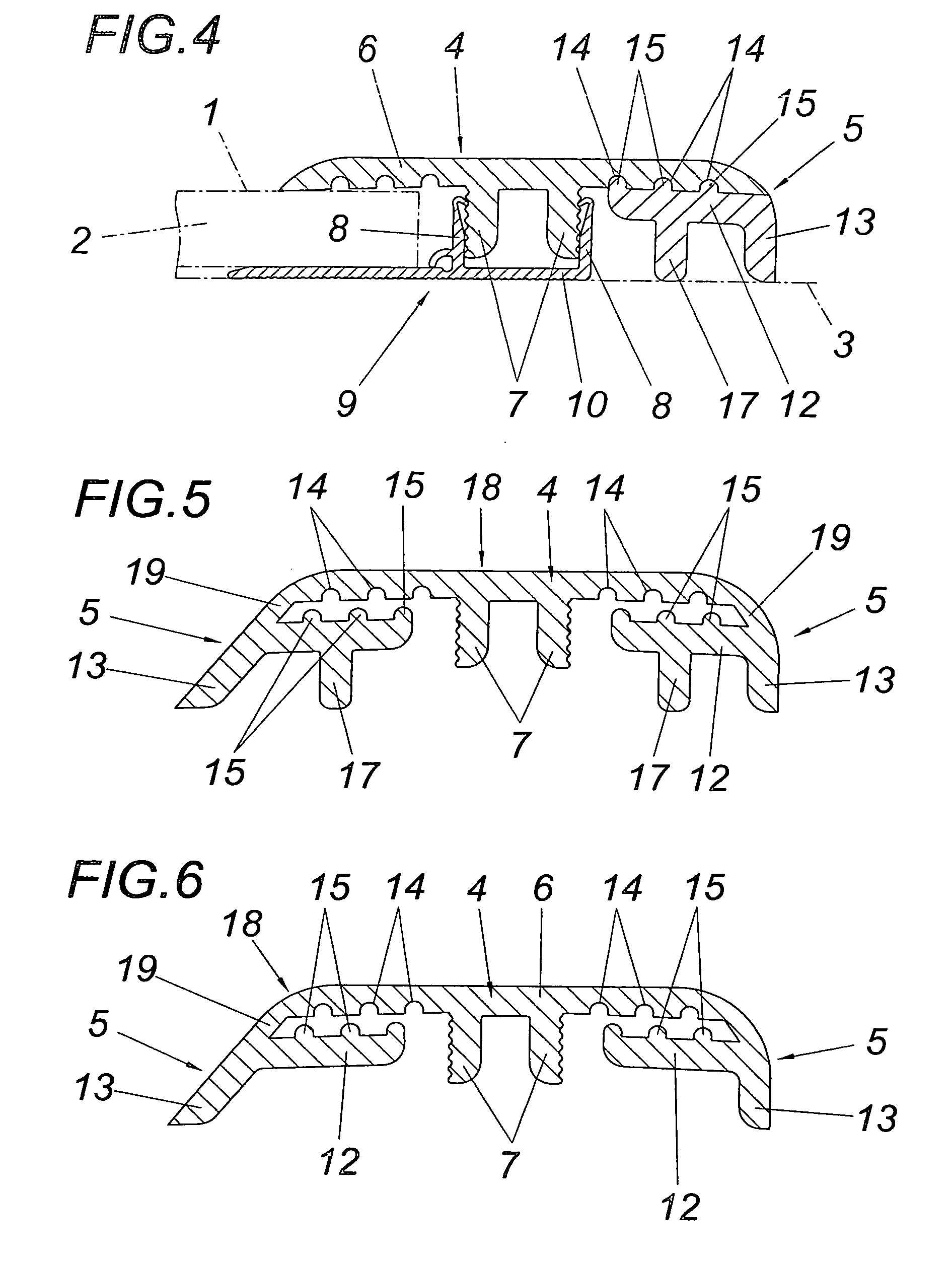

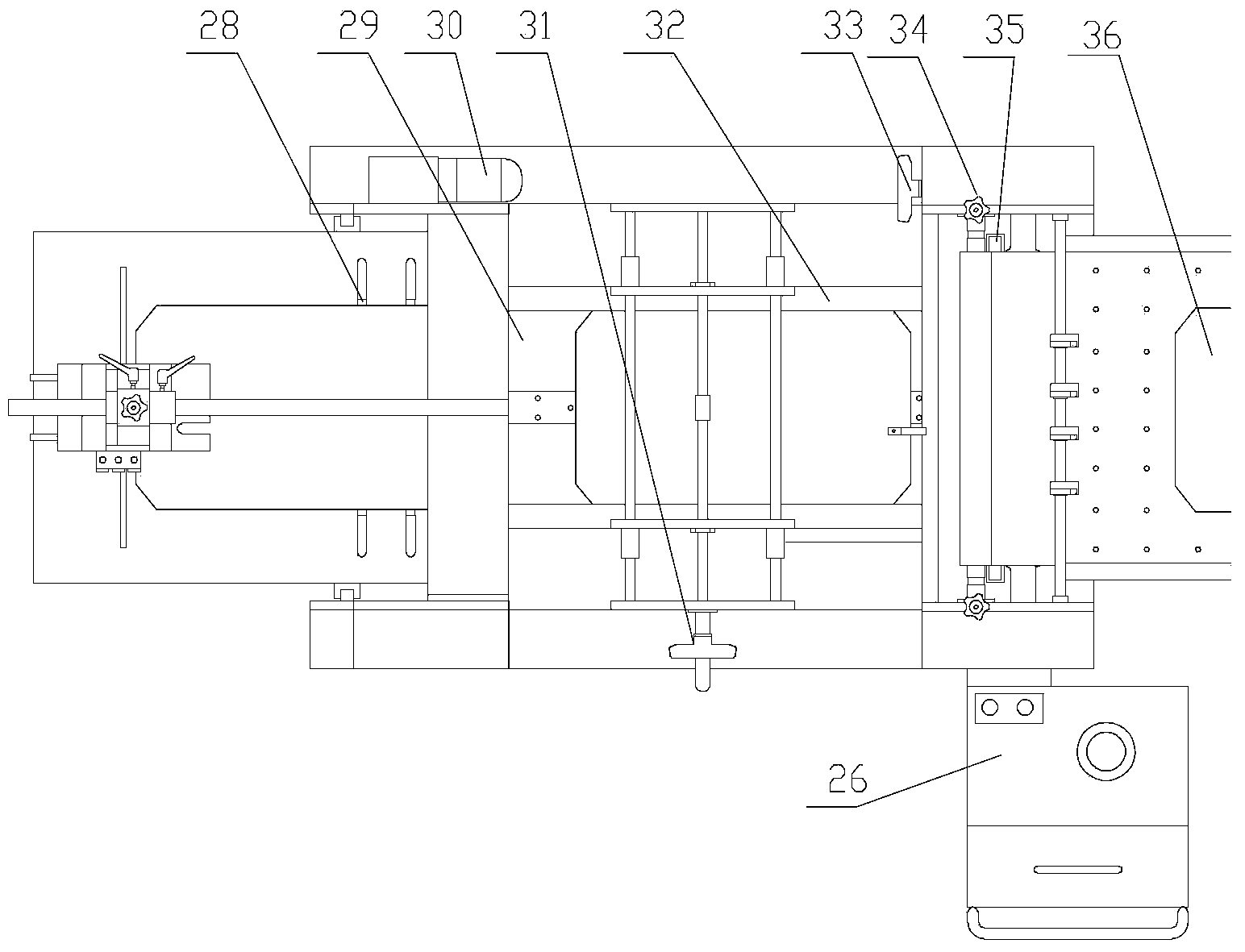

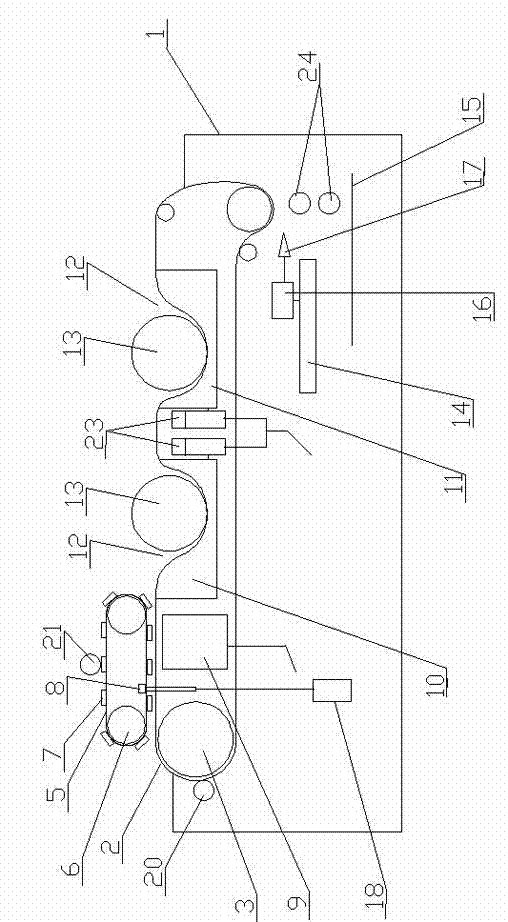

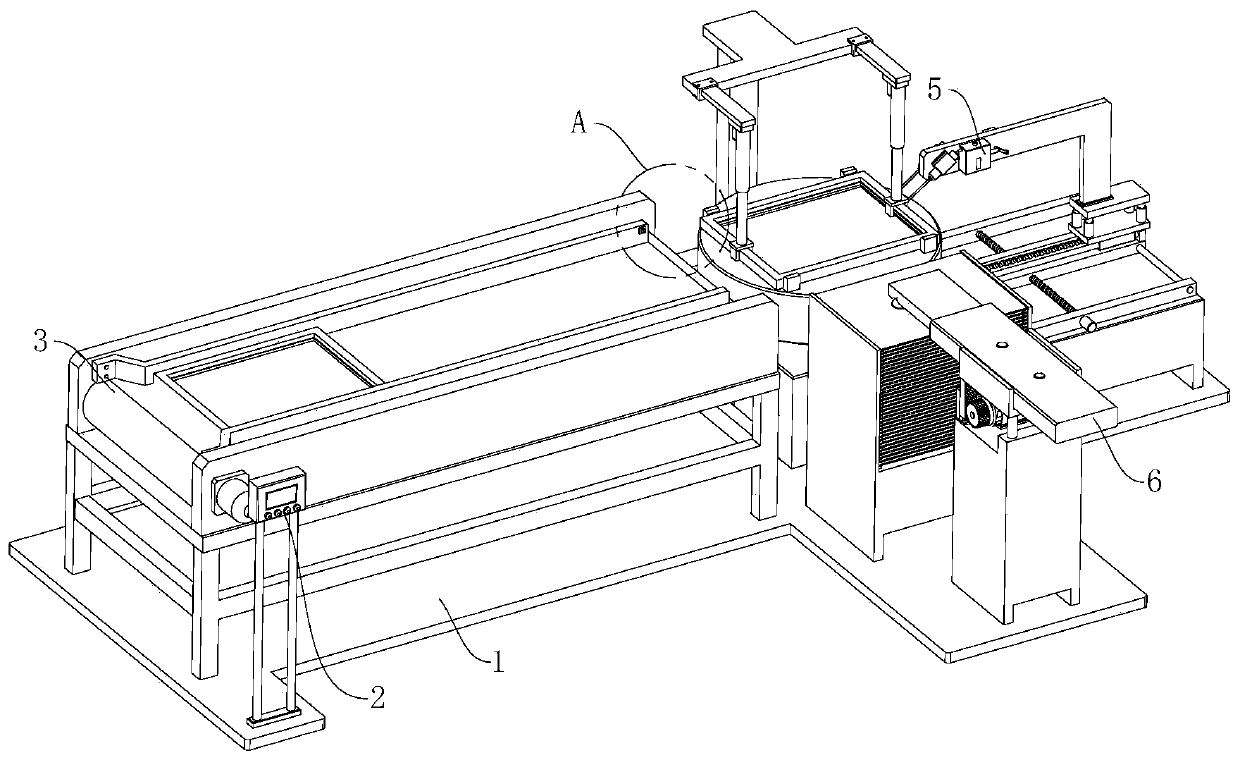

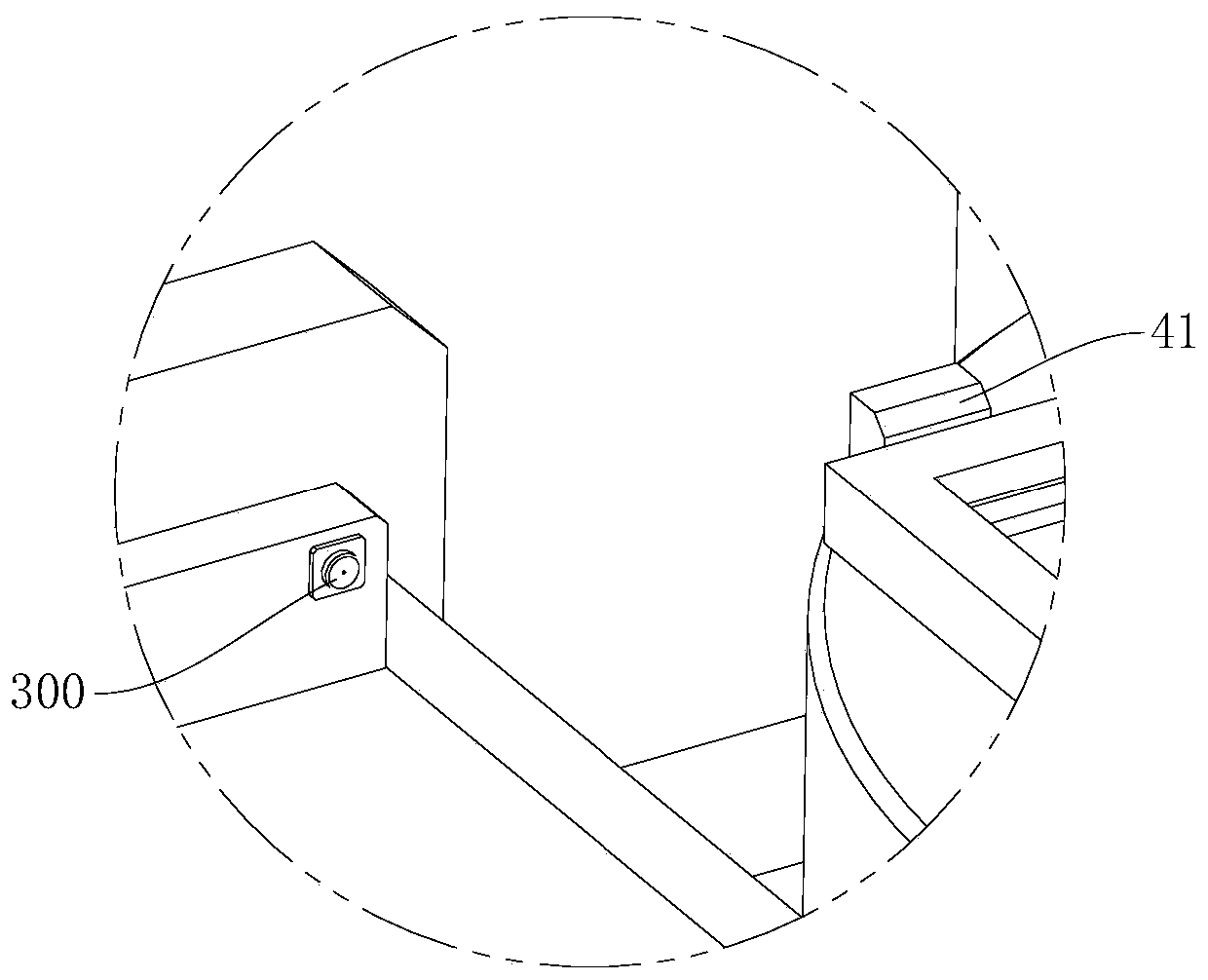

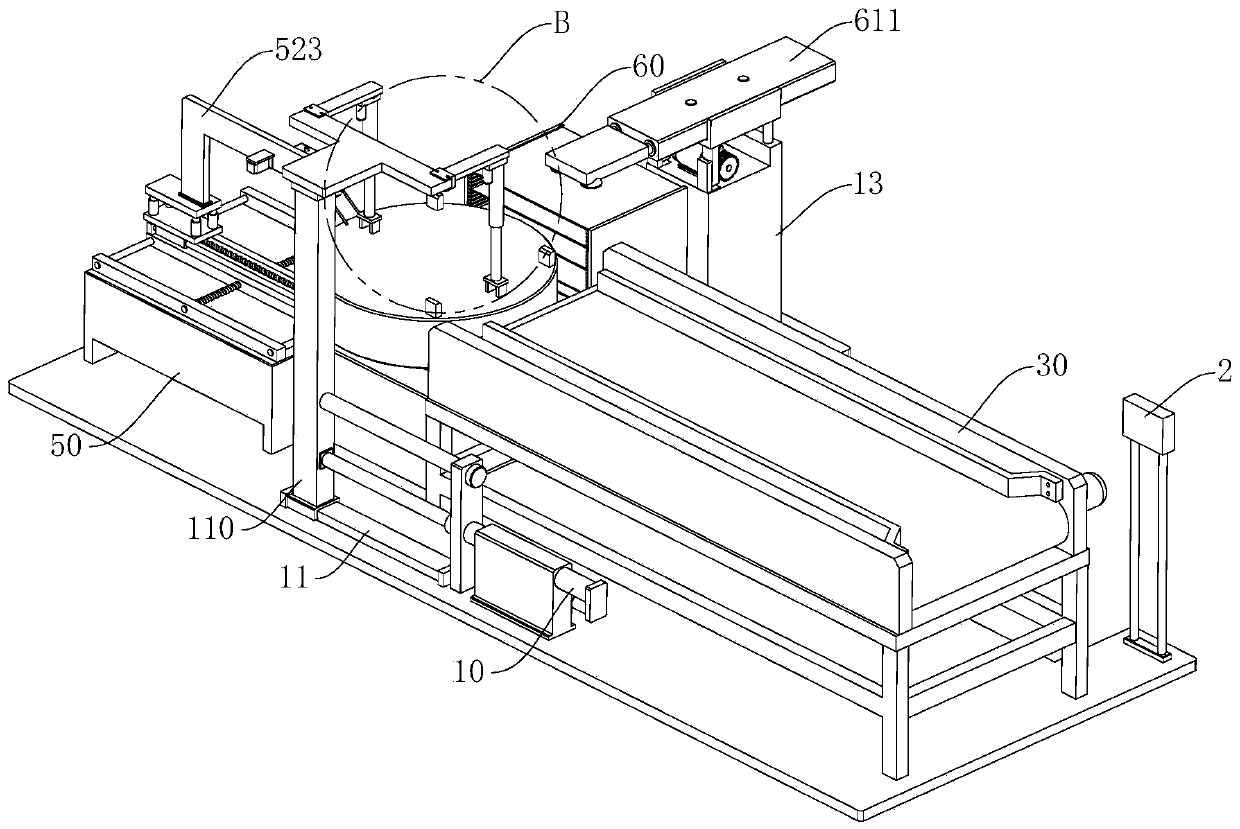

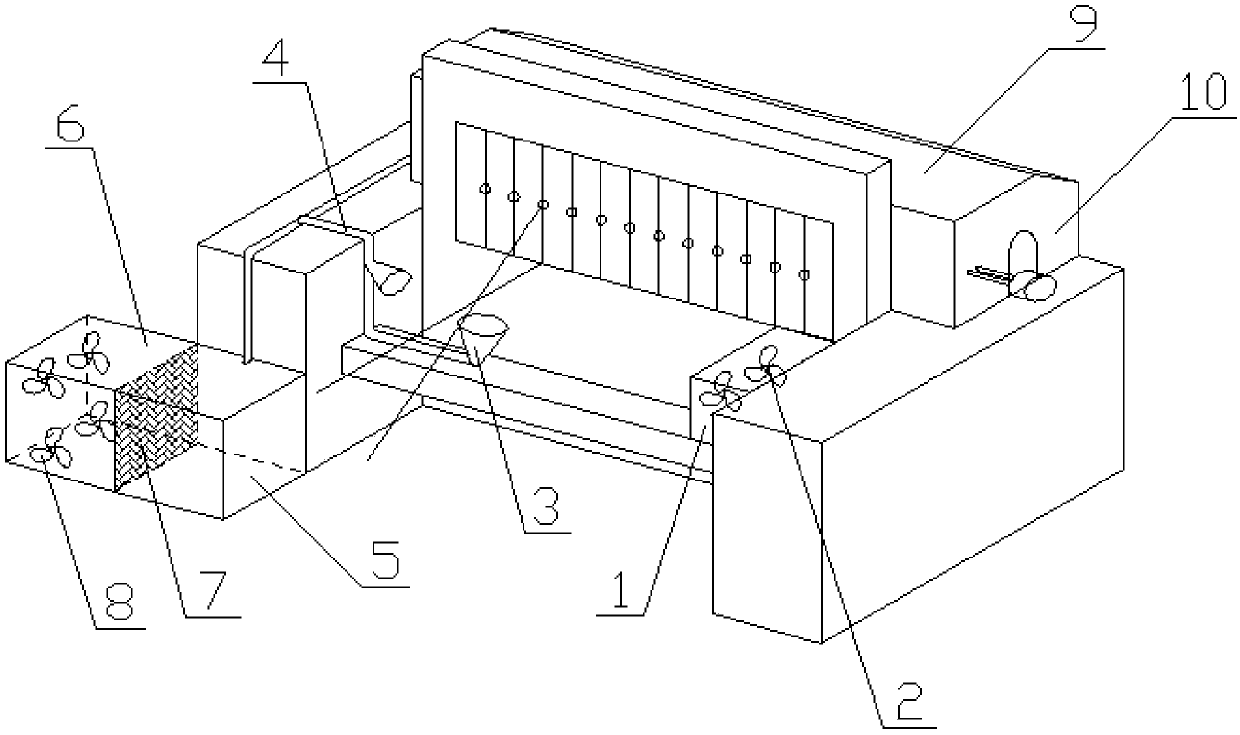

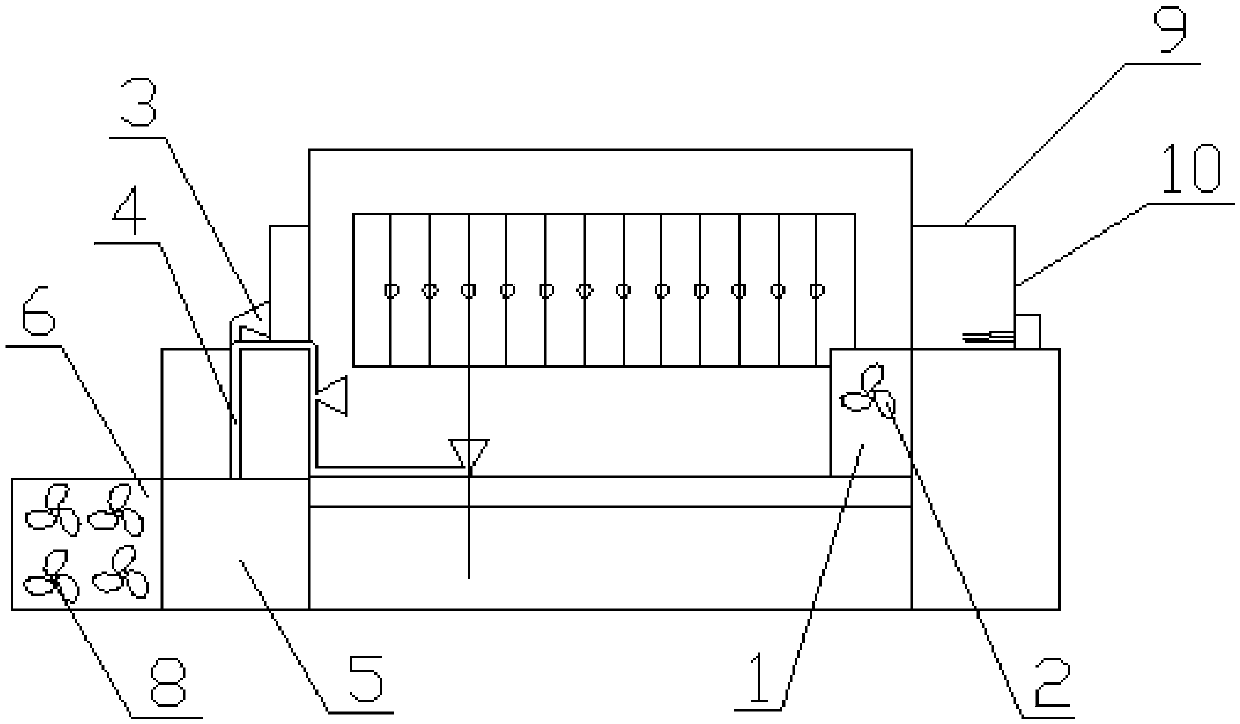

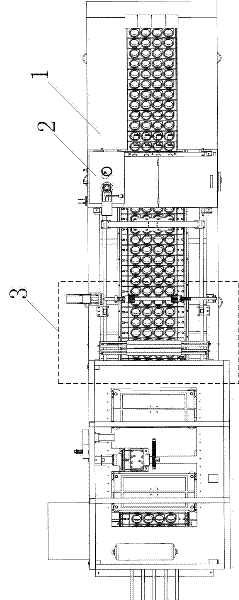

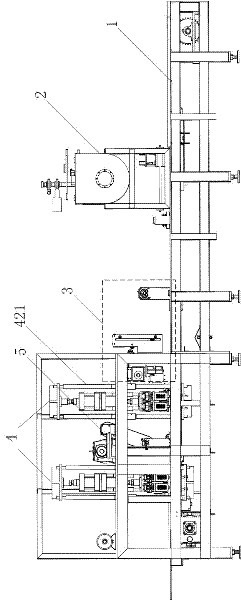

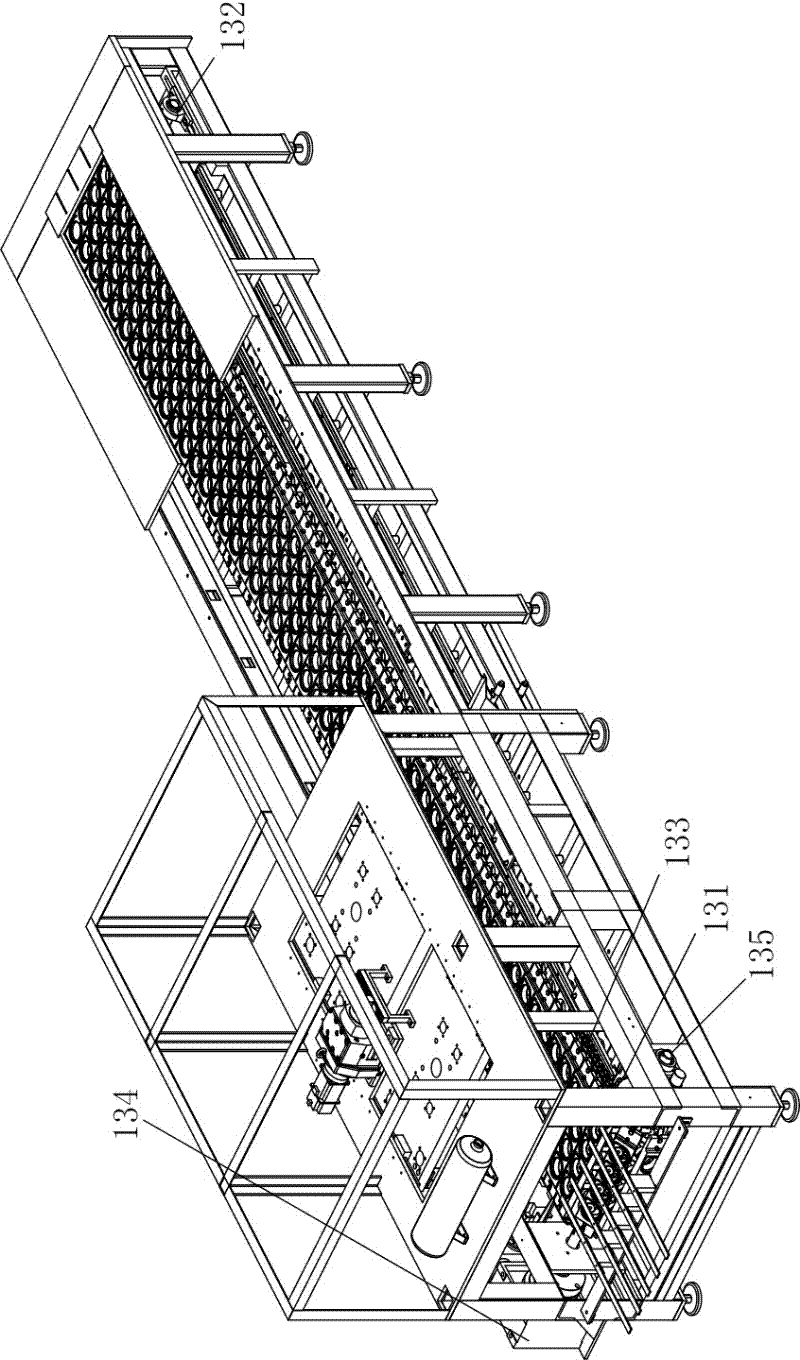

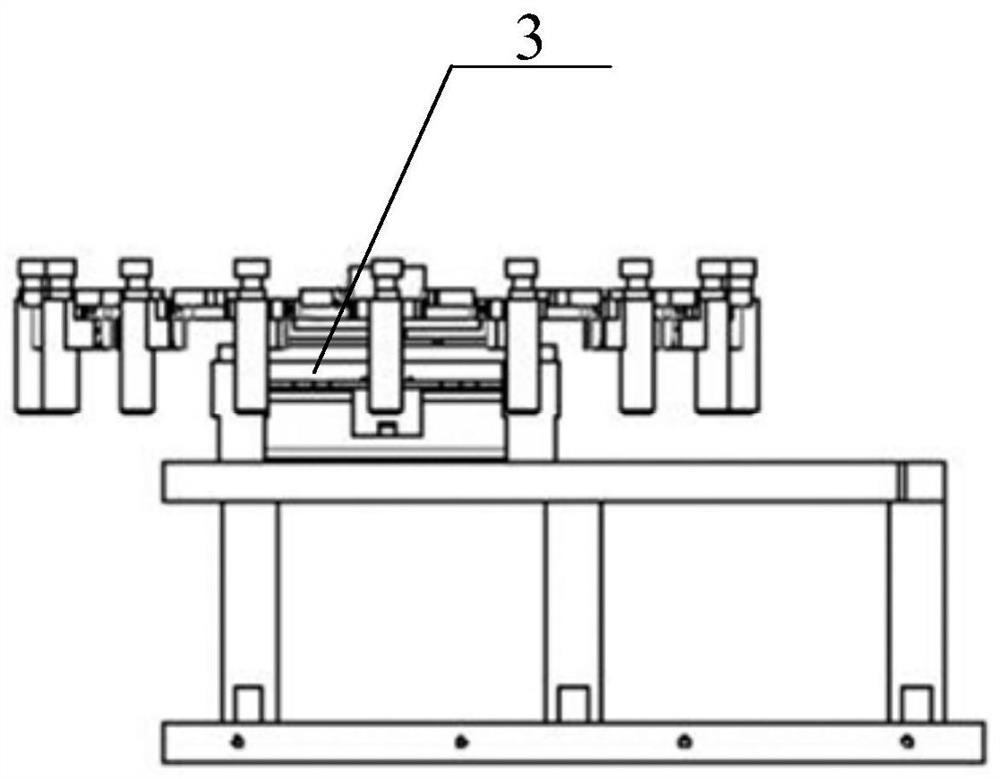

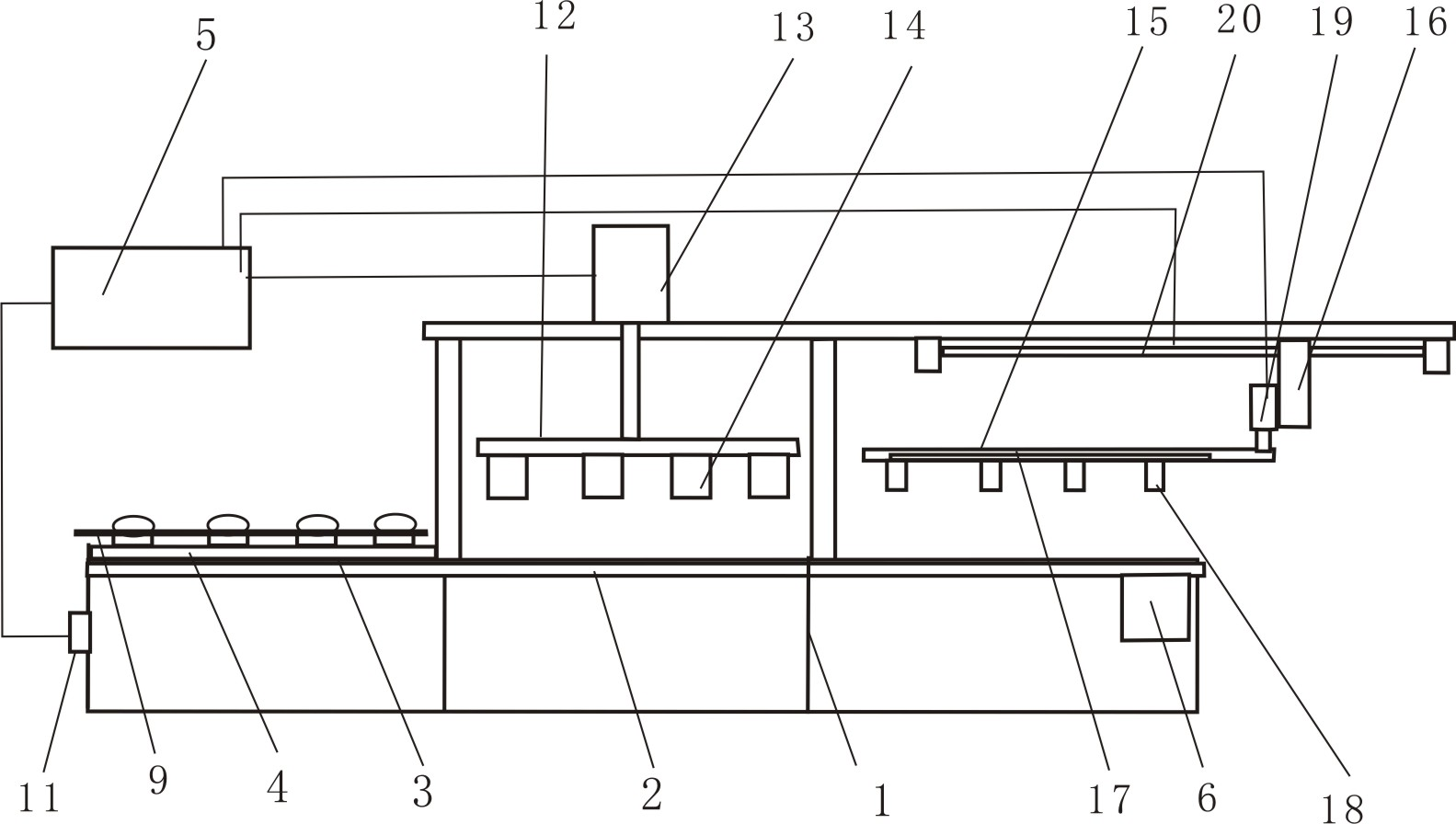

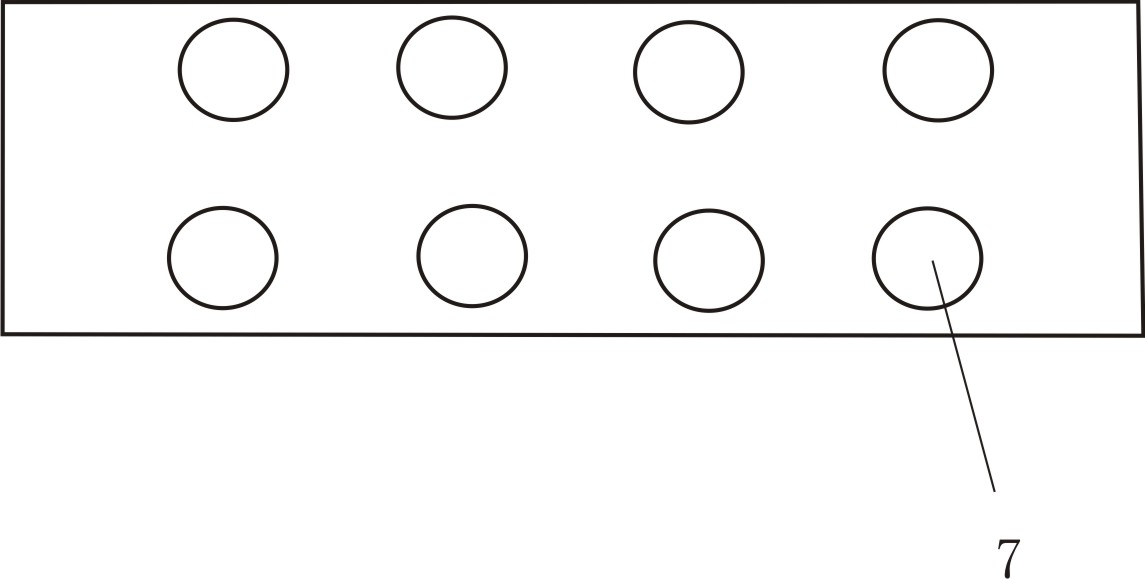

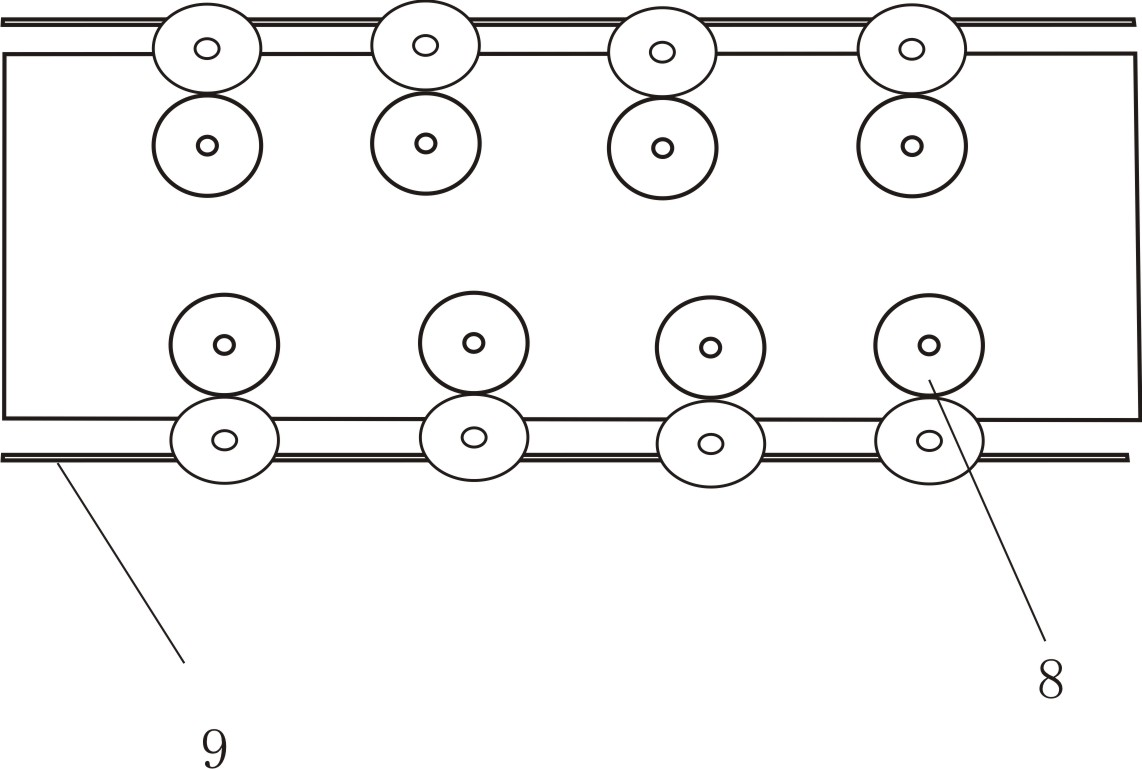

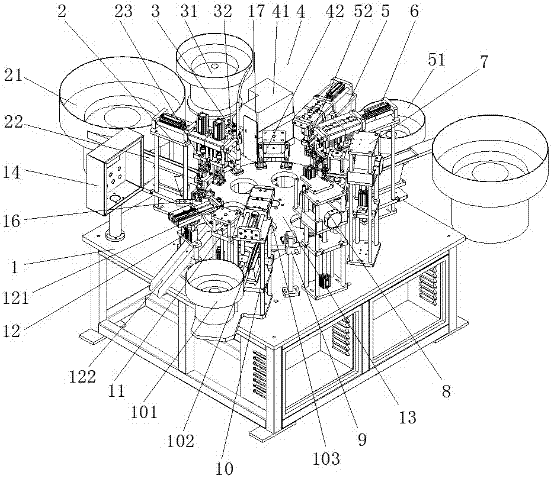

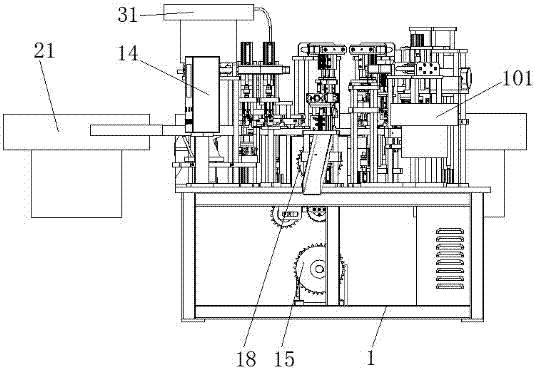

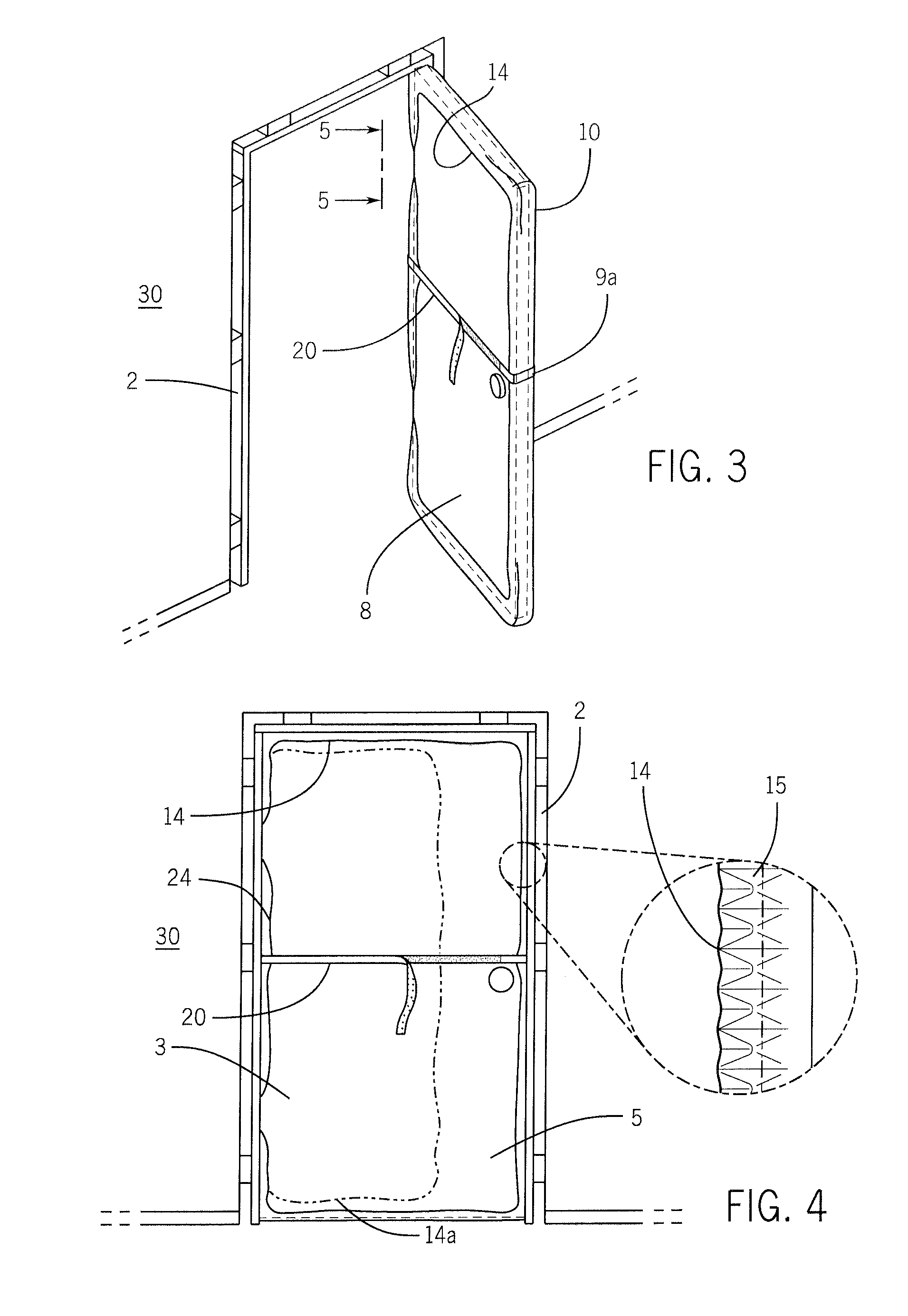

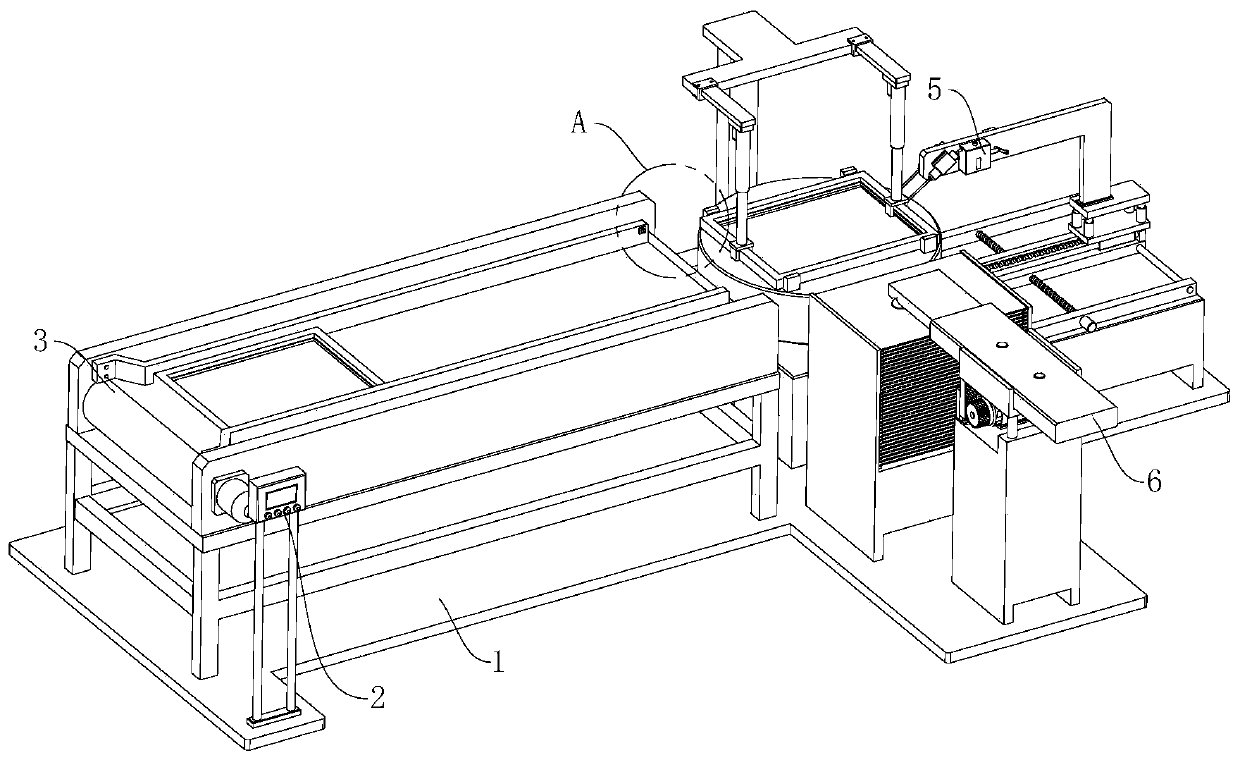

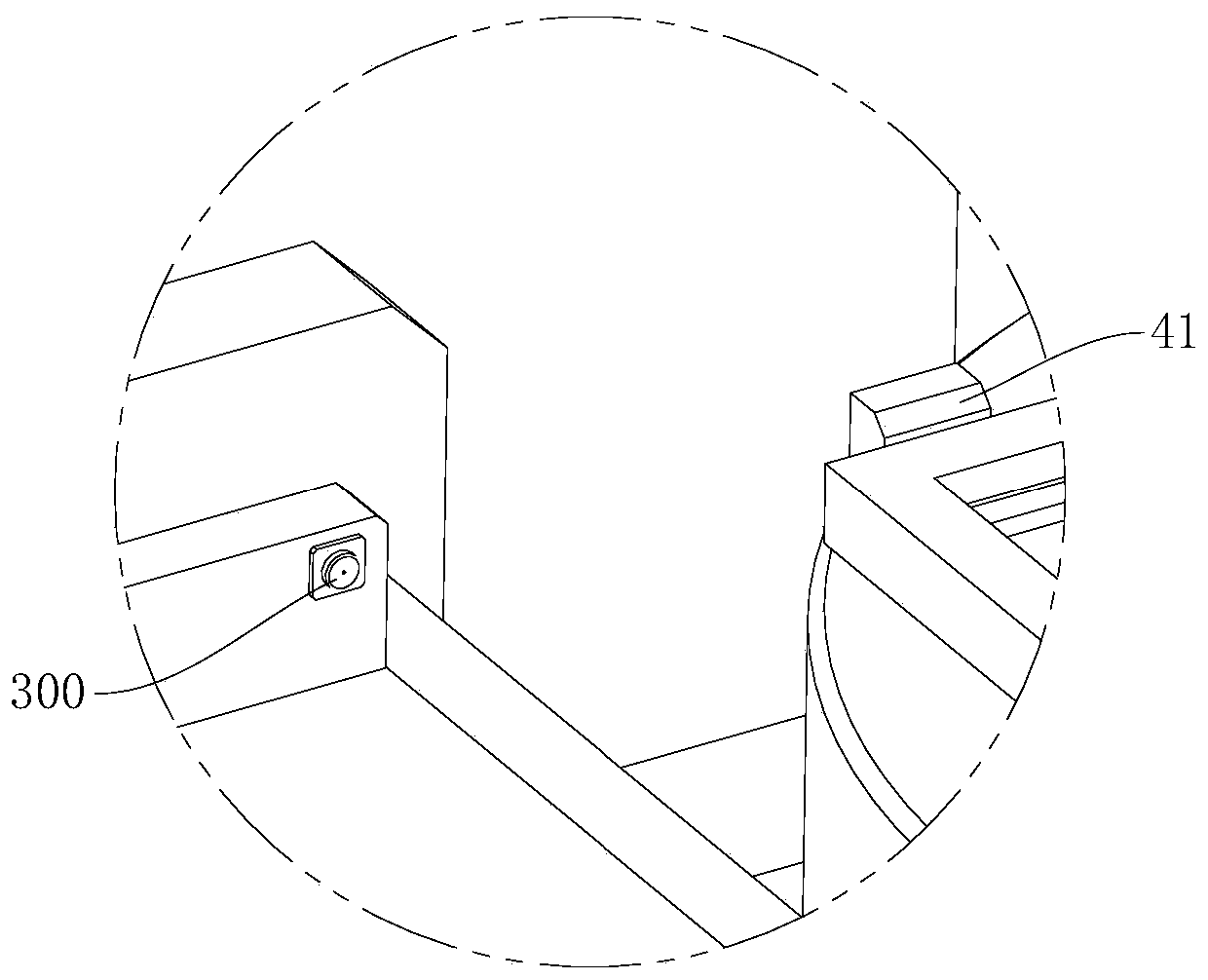

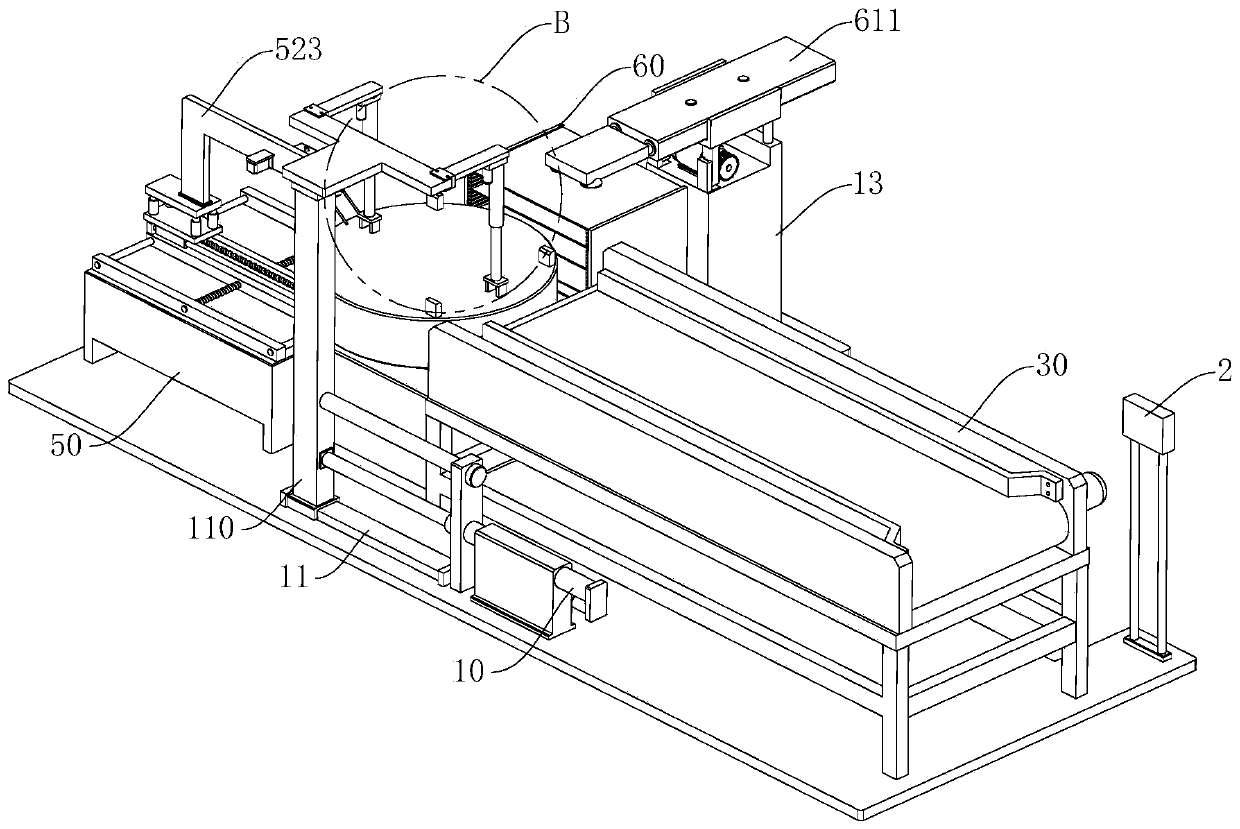

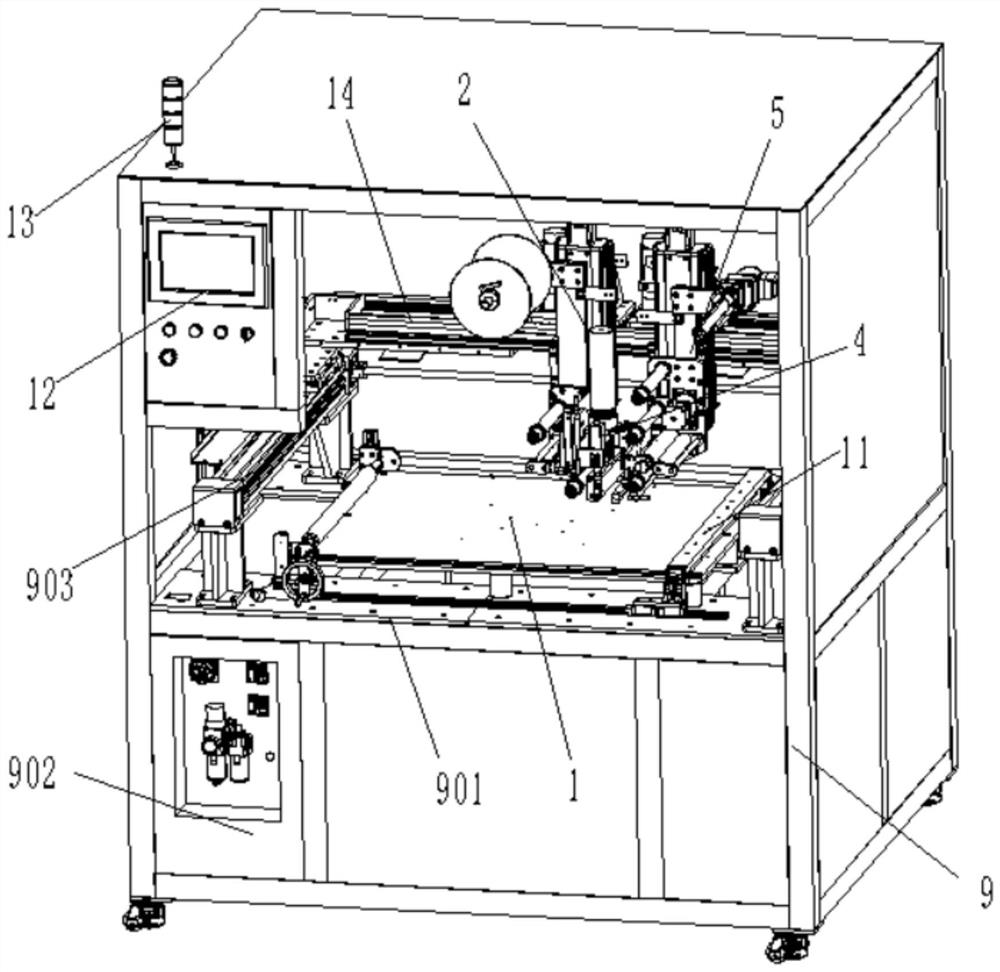

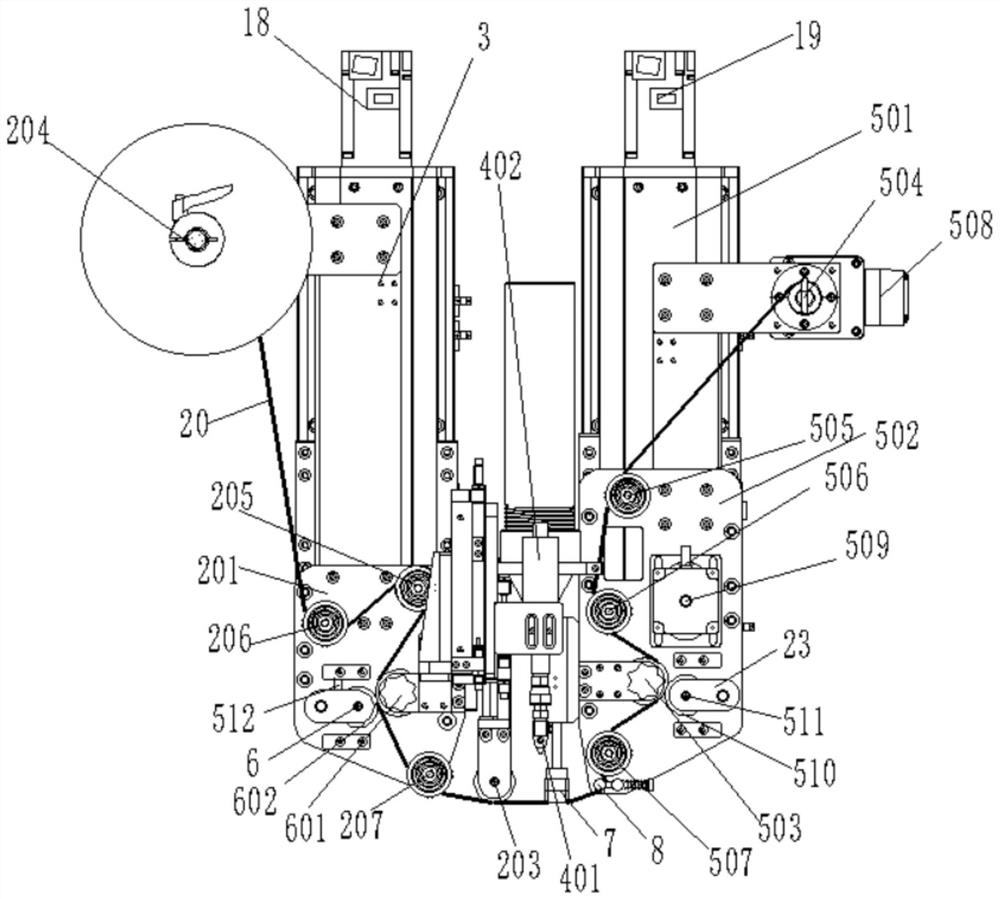

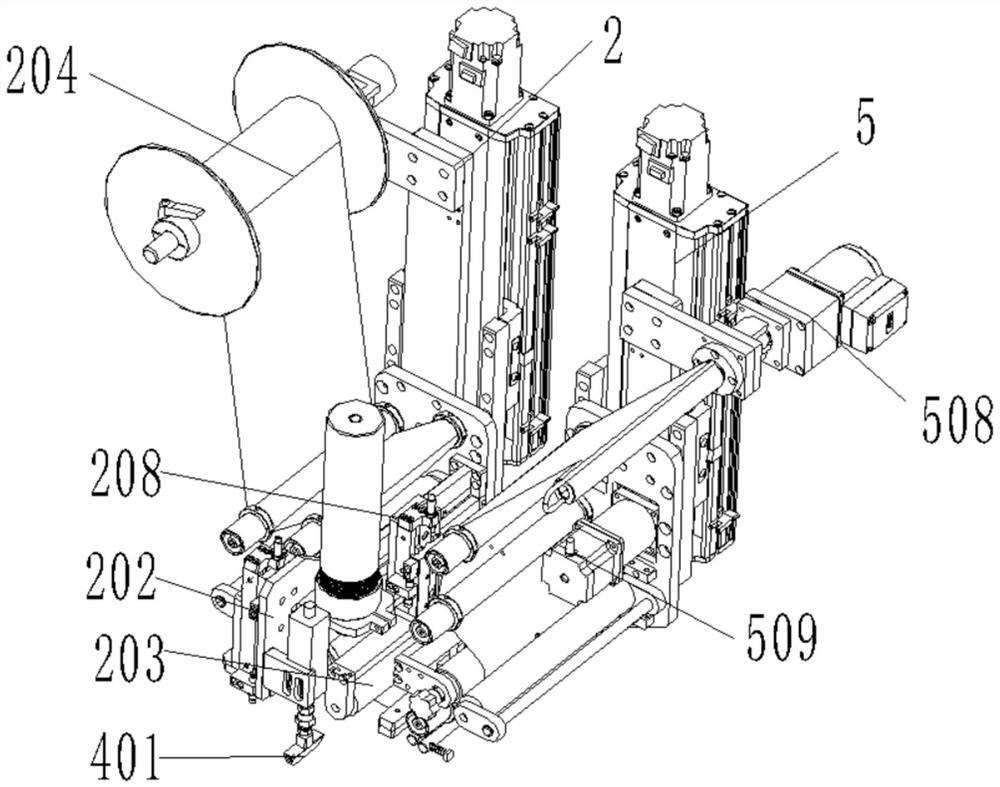

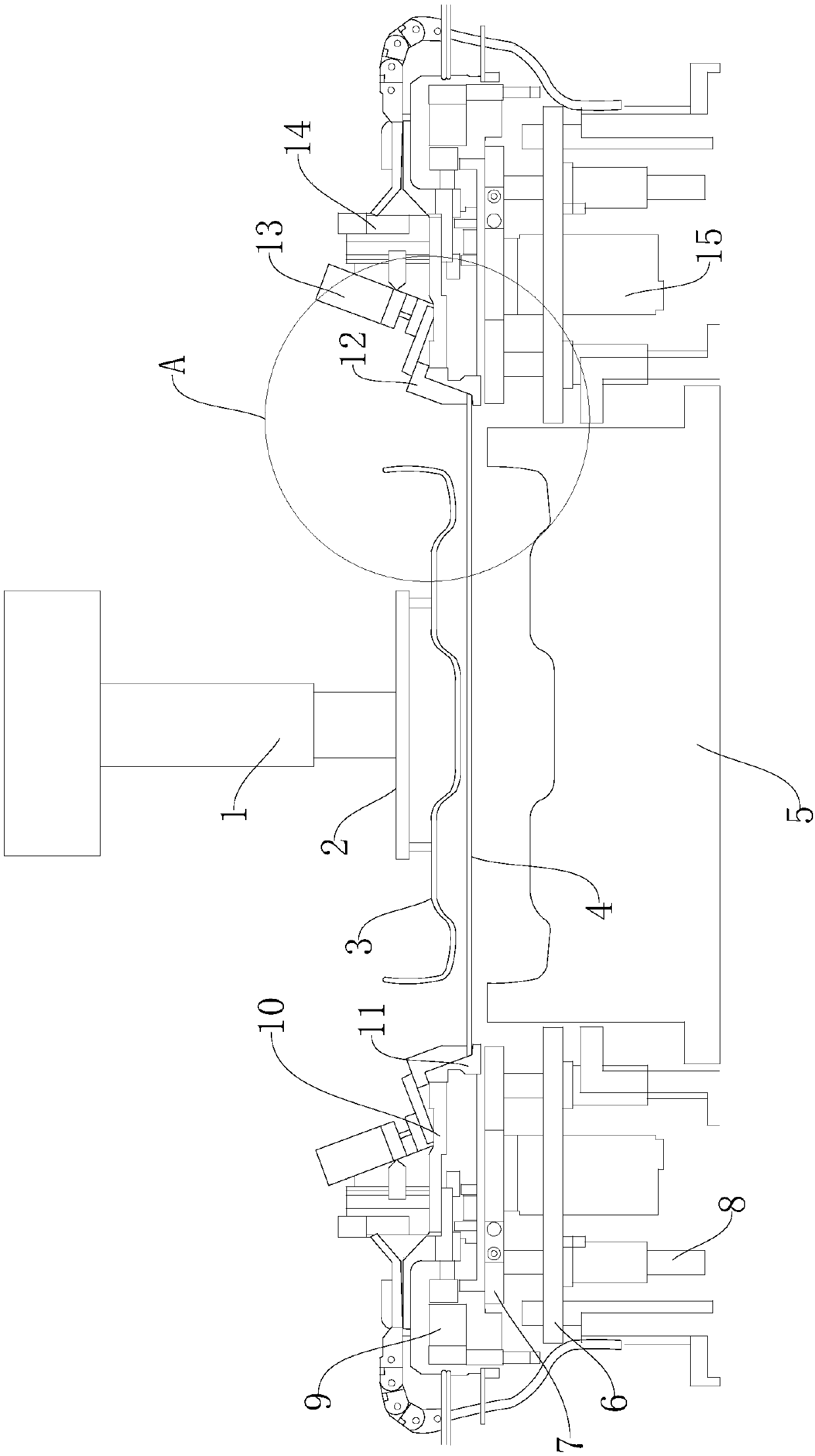

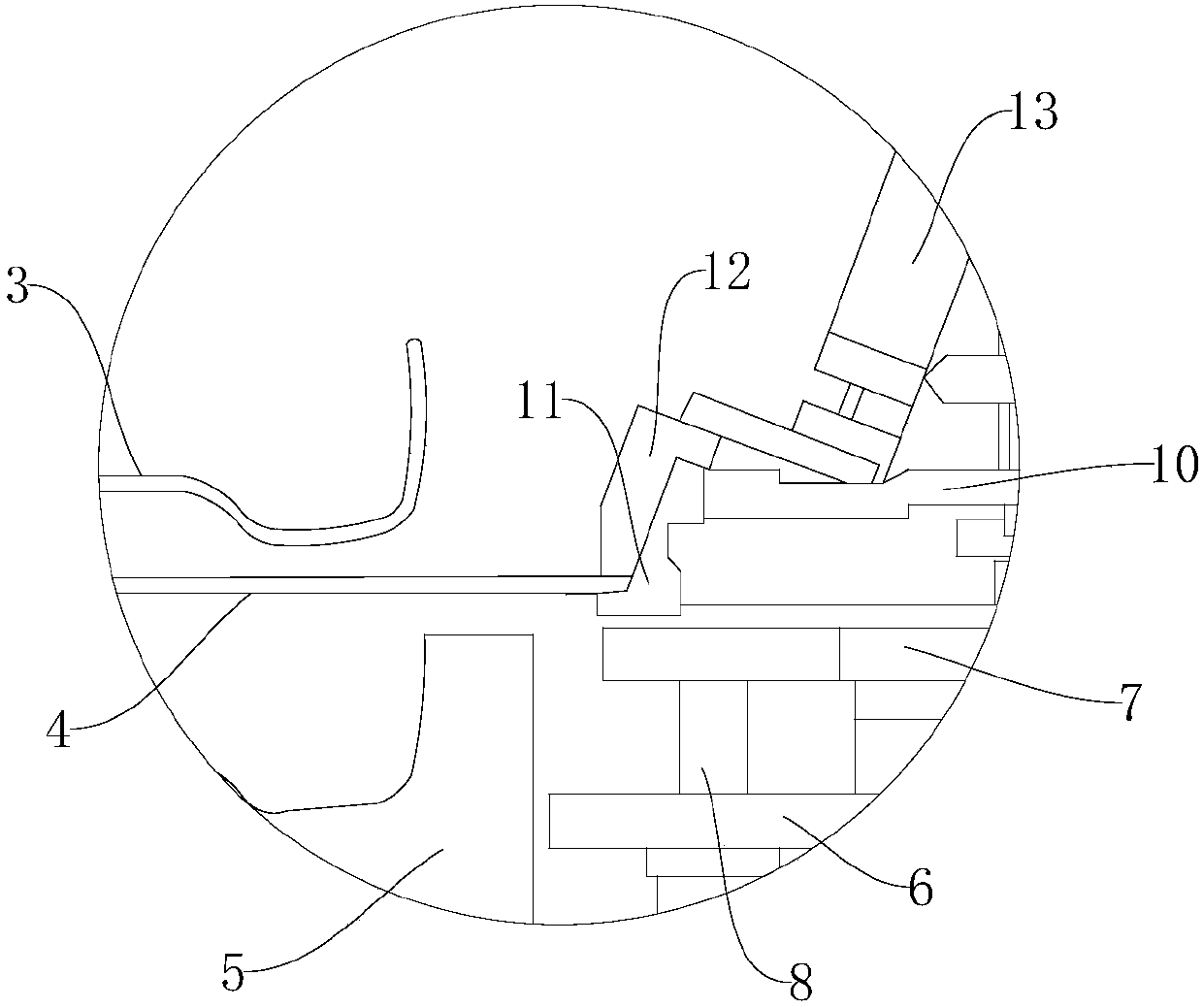

Full-automatic production line of hard covers

The invention relates to production equipment of hard covers for products such as notebooks and desk calendars, and particularly relates to a full-automatic production line of hard covers. According to the technology provided by the invention, the full-automatic cover production line is characterized by comprising a paper gluing device, a panel pushing and positioning device, a conveying device, a cover edge-covering device, a lining-paper gluing device, a cover overturning and positioning device, a flattening device and a material receiving device. The full-automatic production line with the scheme can solve the problems in the prior; after an outer cover of a cover product is well covered, lining paper is directly and automatically overturned and stuck, and the edge covering and the lining paper sticking are finished by one time, so that labor is greatly reduced, and the productivity and the product qualification rate are greatly improved.

Owner:浙江浩达智能装备股份有限公司

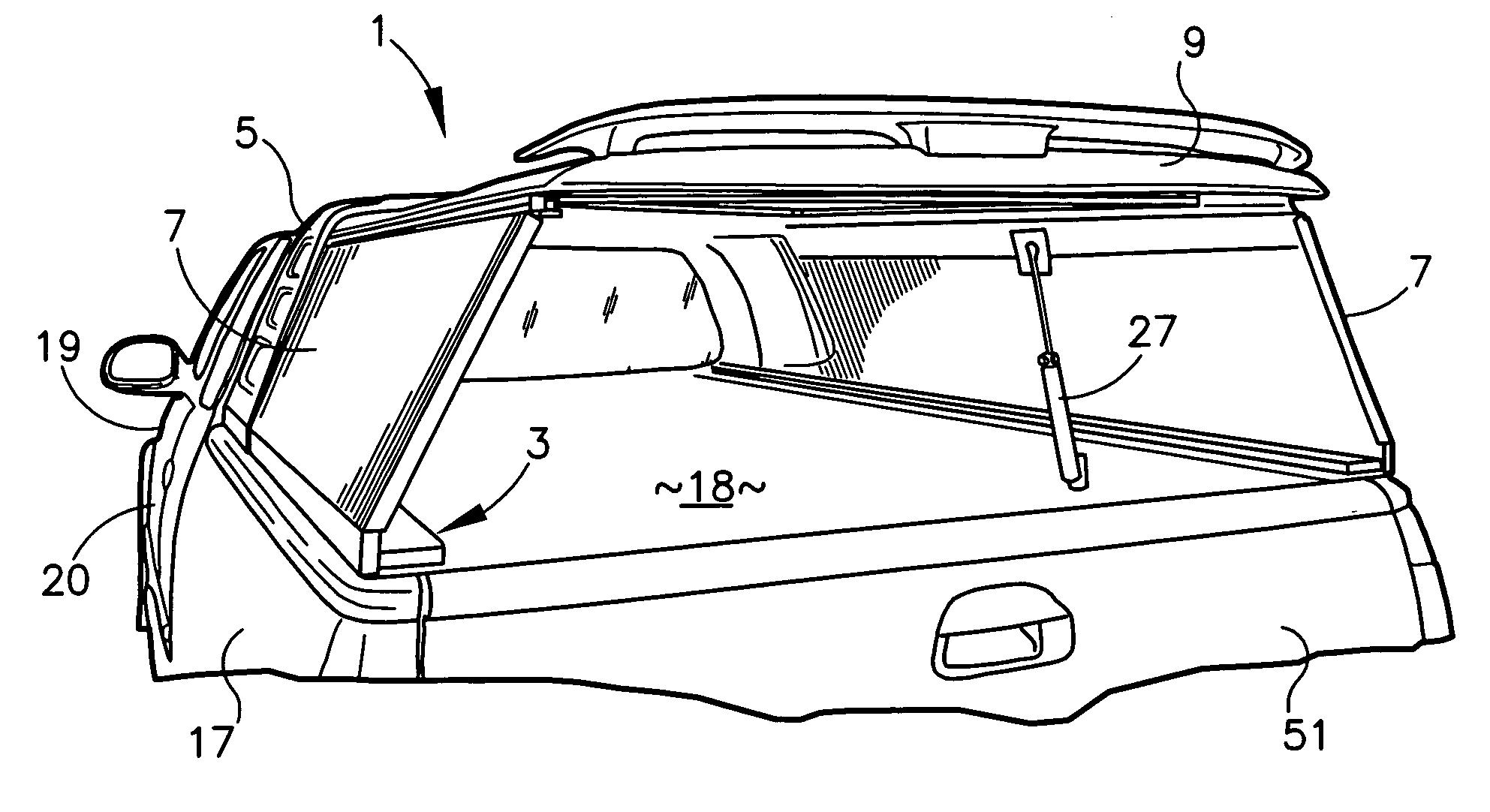

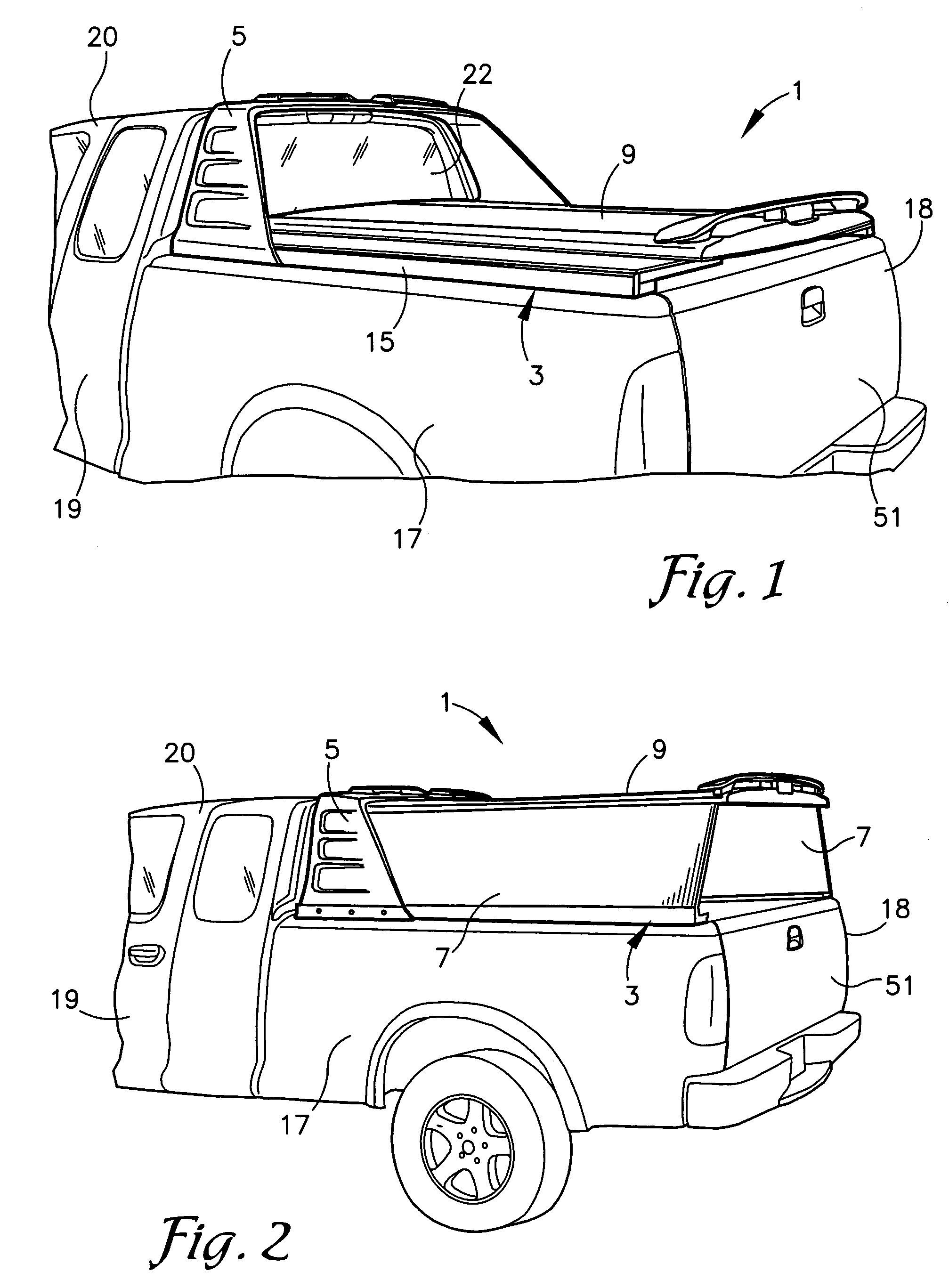

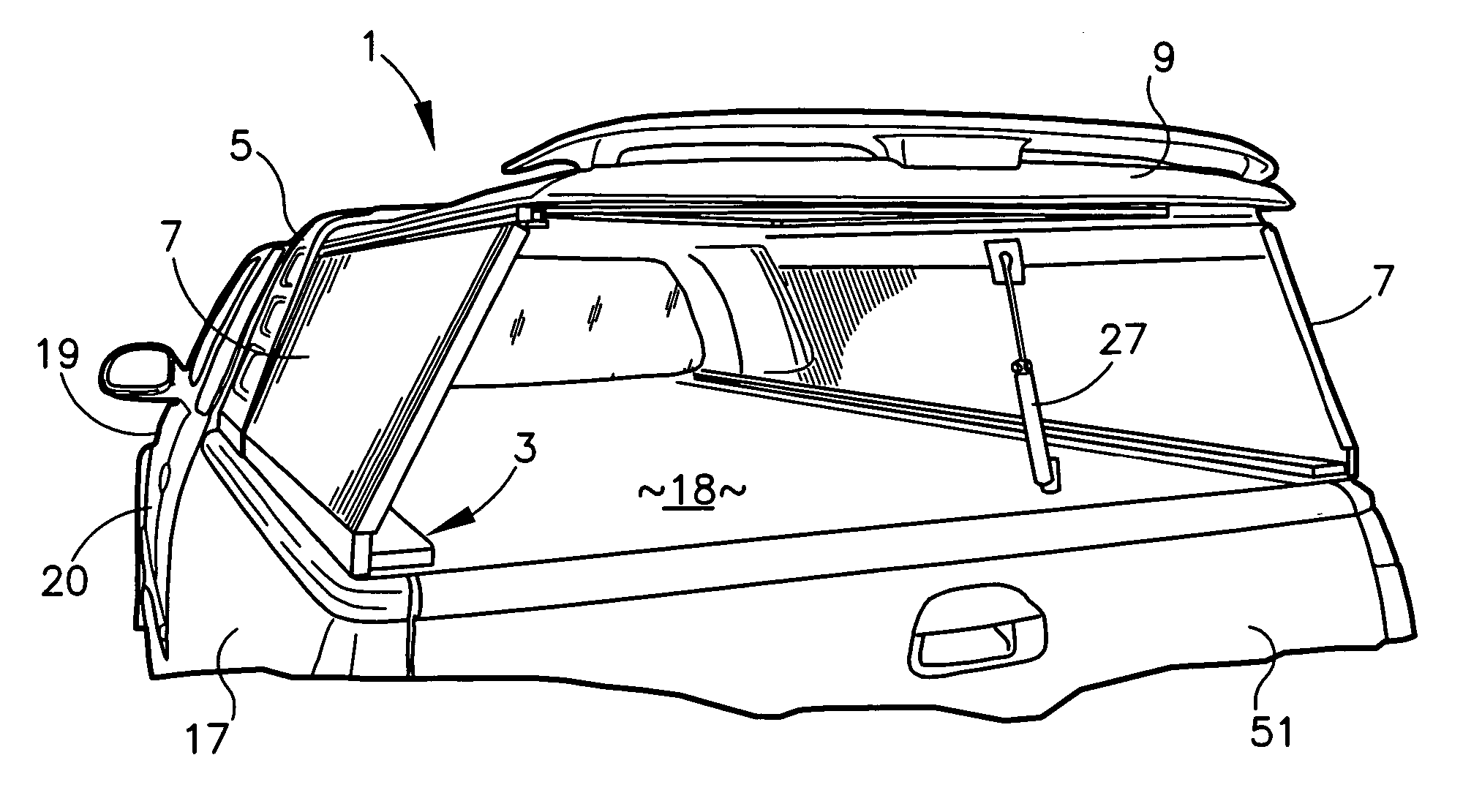

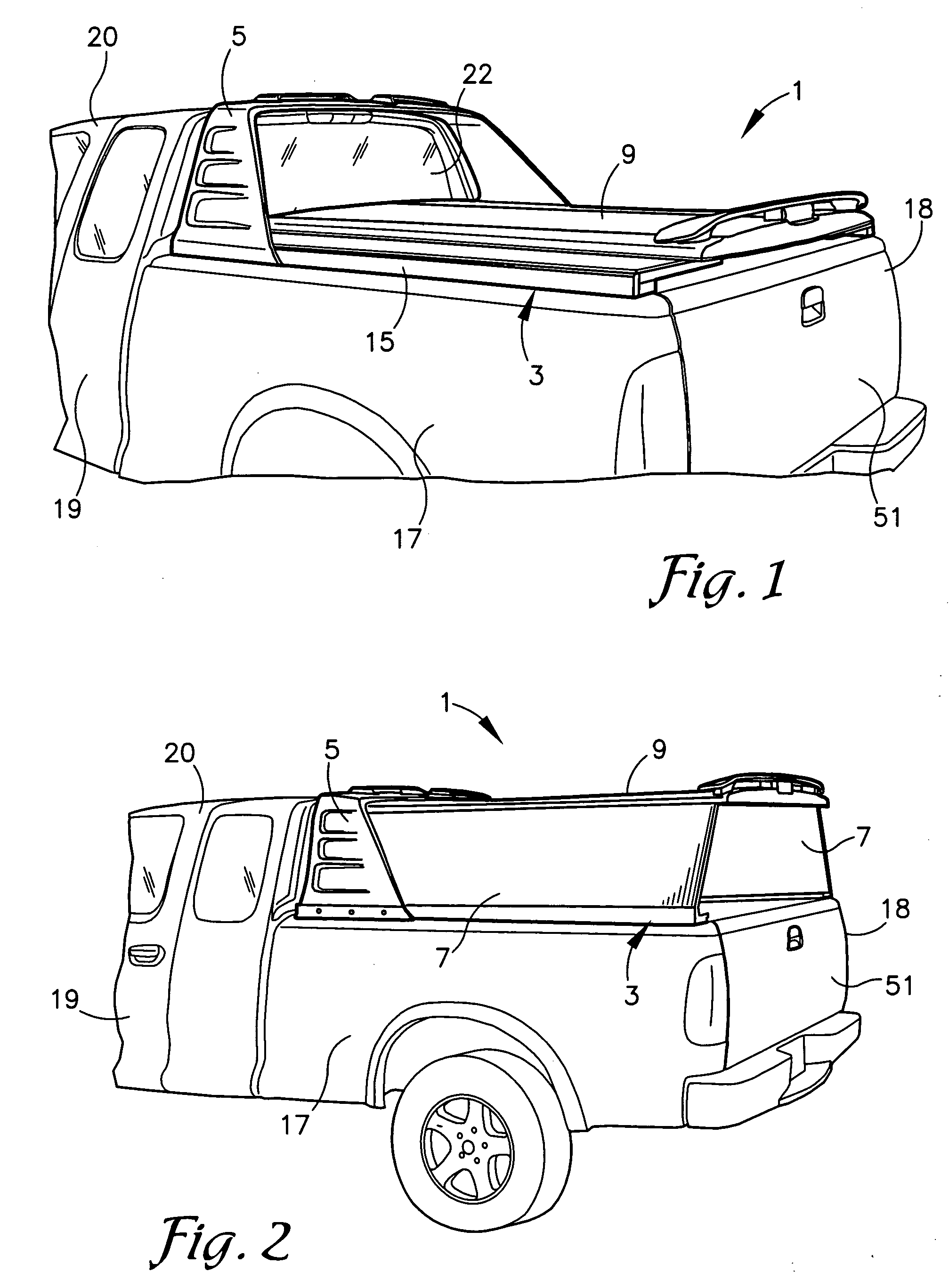

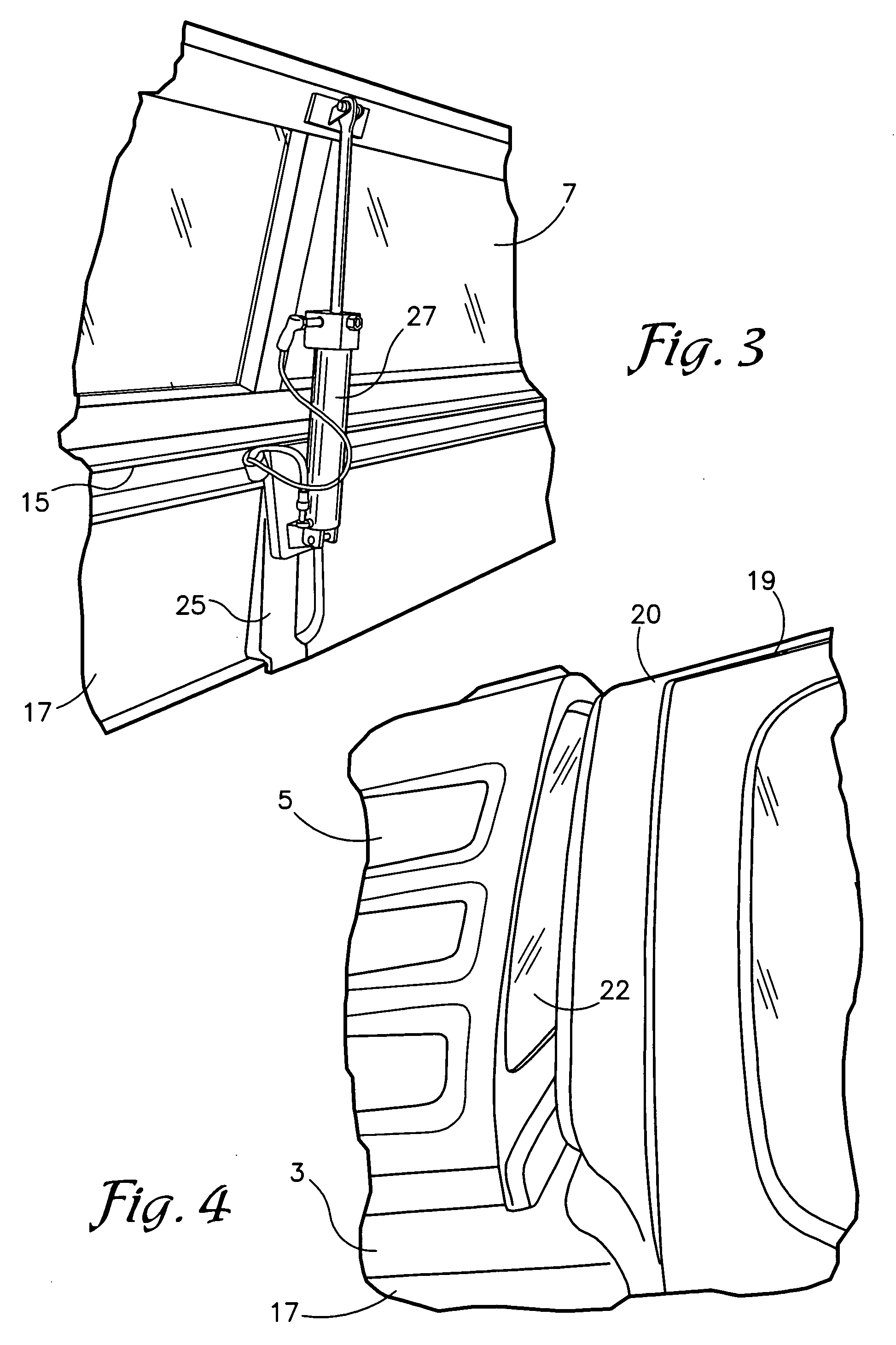

Convertible camper shell and hard tonneau

ActiveUS7243965B2Vehicle with living accommodationItem transportation vehiclesHydraulic cylinderEngineering

A truck bed camper shell and hard tonneau cover device is provided which is activated for movement between a raised truck bed camper shell position and a lowered hard tonneau cover position by remote activation of actuators such as pneumatics or hydraulic cylinders or a screw drive mechanism.

Owner:WOODWORTH INVESTMENT GROUP

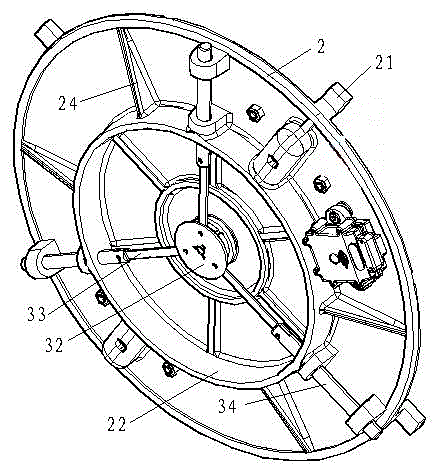

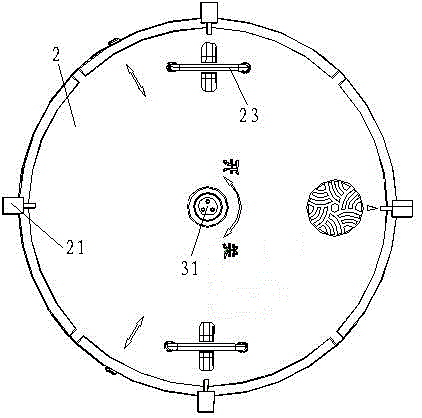

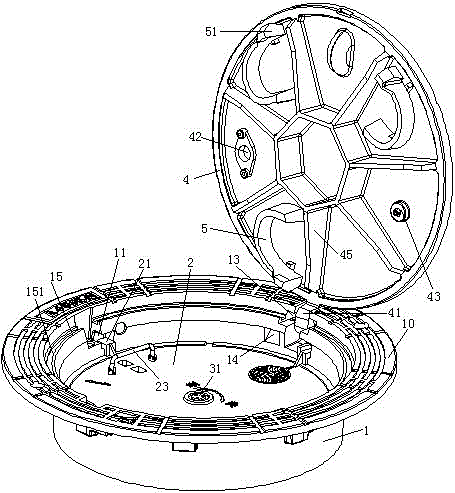

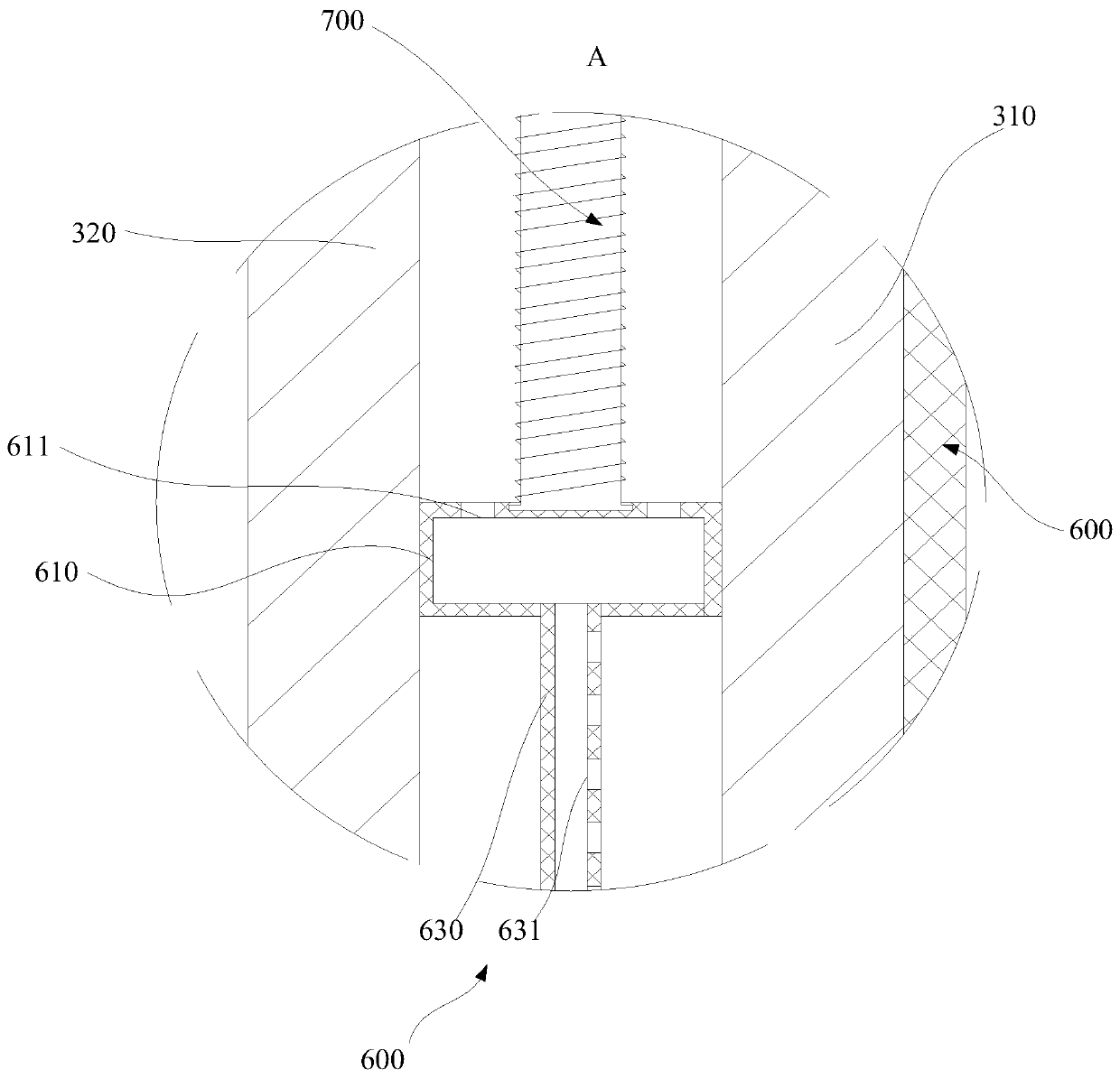

Manhole opening inner cover and combined inner manhole cover and outer manhole cover device with same

InactiveCN104452821ACompact structurePrevent openingArtificial islandsUnderwater structuresCap deviceRotating disc

The invention relates to a manhole opening inner cover and a combined inner manhole cover and outer manhole cover device with the manhole opening inner cover. The manhole opening inner cover comprises an inner cover body installed in a race of a manhole cover. At least two cranked convex blocks are arranged on the circumference of the inner cover body at intervals, a rotating lock cylinder is arranged in the middle of the inner cover body and penetrates out of the middle of the inner cover body from top to bottom, a rotating shaft of the rotating lock cylinder is connected with a rotating disc below the inner cover body, at least two connecting rods are hinged to the circumference of the rotating disc at intervals, and horizontal telescopic sliding rods are hinged to the other ends of the connecting rods and penetrate out of the lower flange of the inner cover body. The inner cover can be prevented from being opened by a lawbreaker, and the combined inner manhole cover and outer manhole cover device can effectively prevent materials in a manhole.

Owner:南京中井物联科技有限公司

Cutting and dust collecting assembly and working machine with such assembly

ActiveUS8011357B2Avoid flyingEfficient collection and removalMetal sawing devicesMetal sawing accessoriesCircular sawEngineering

Owner:HUSQVARNA AB

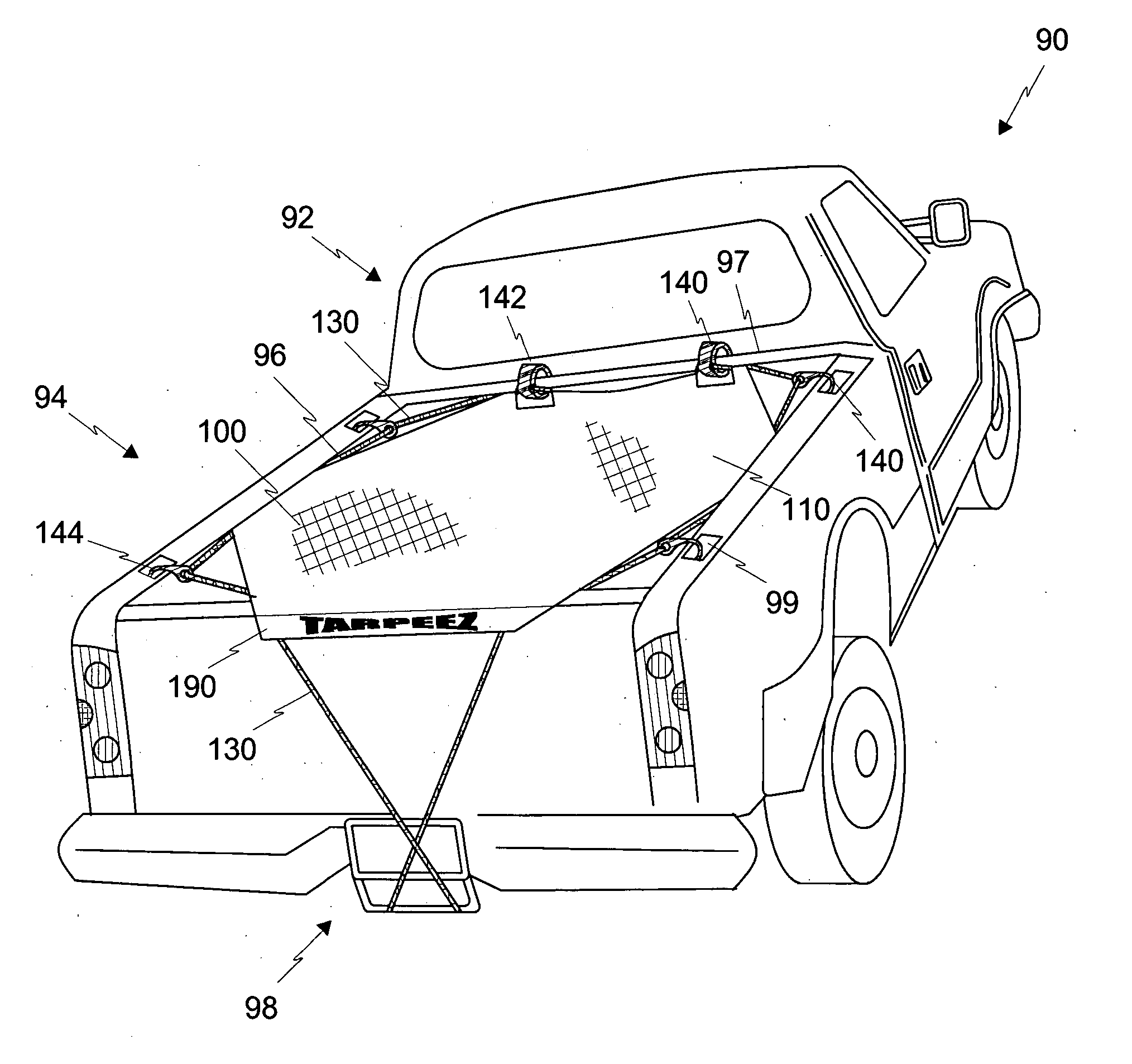

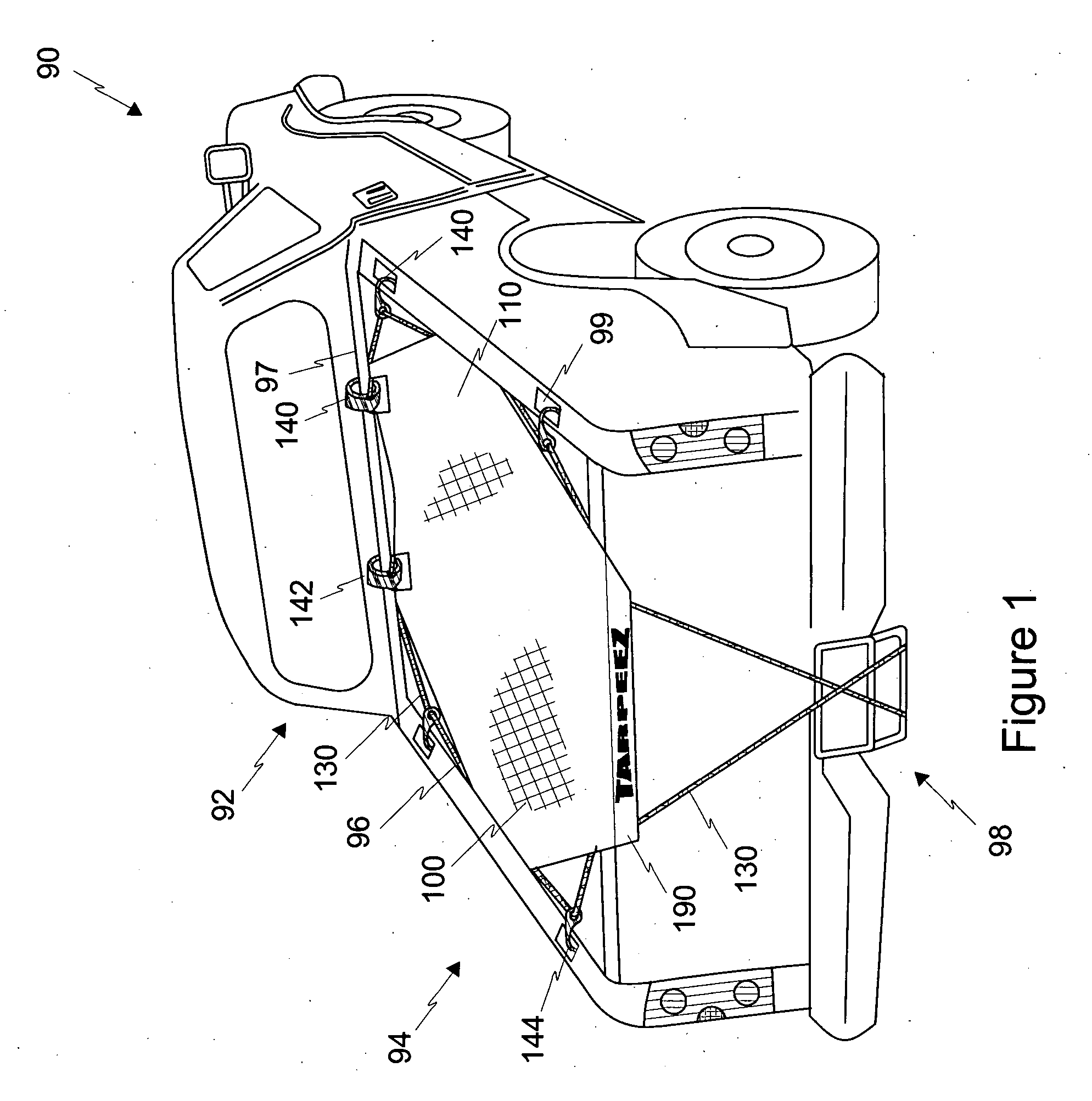

Vehicle cover

Owner:TARPEEZ

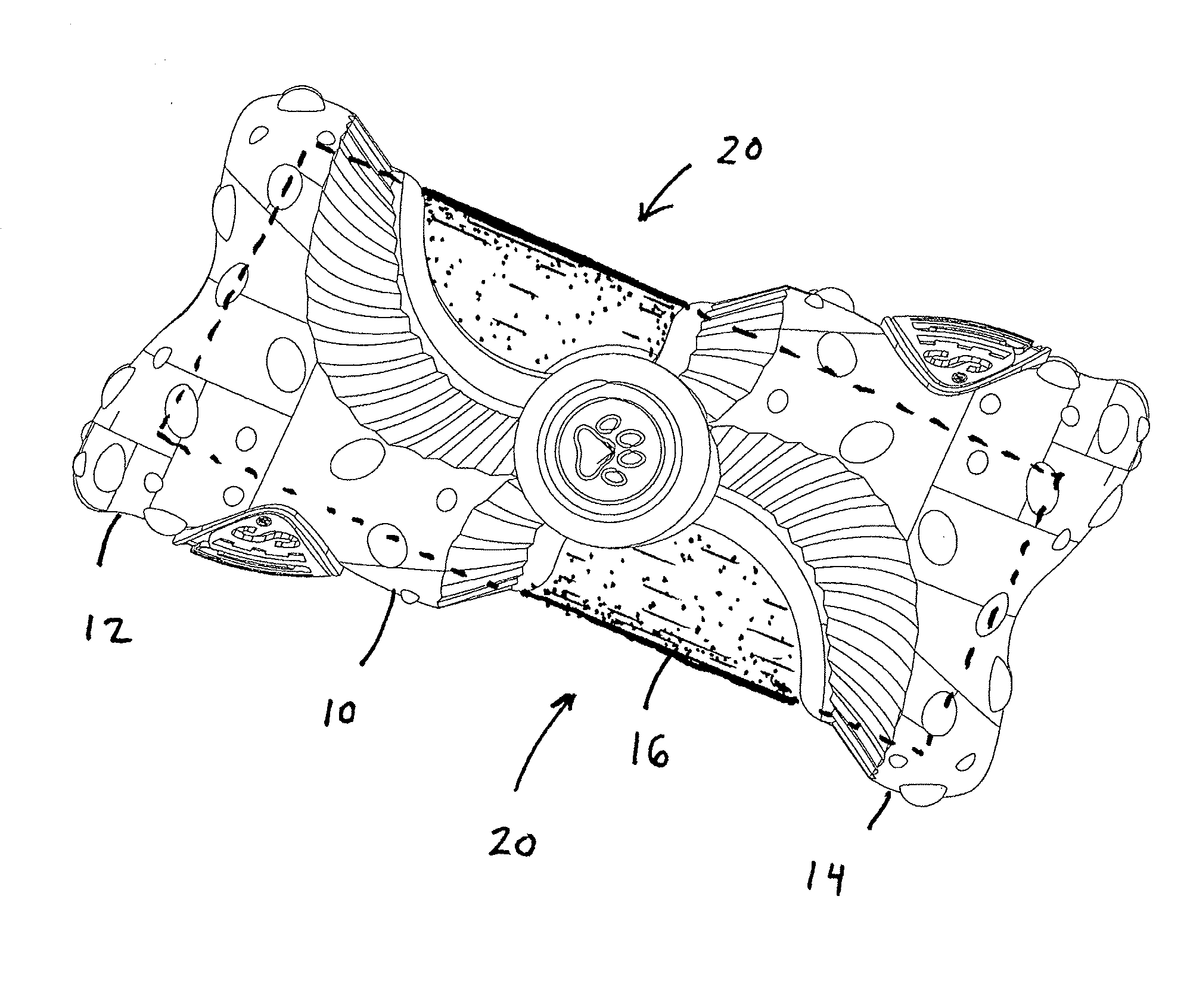

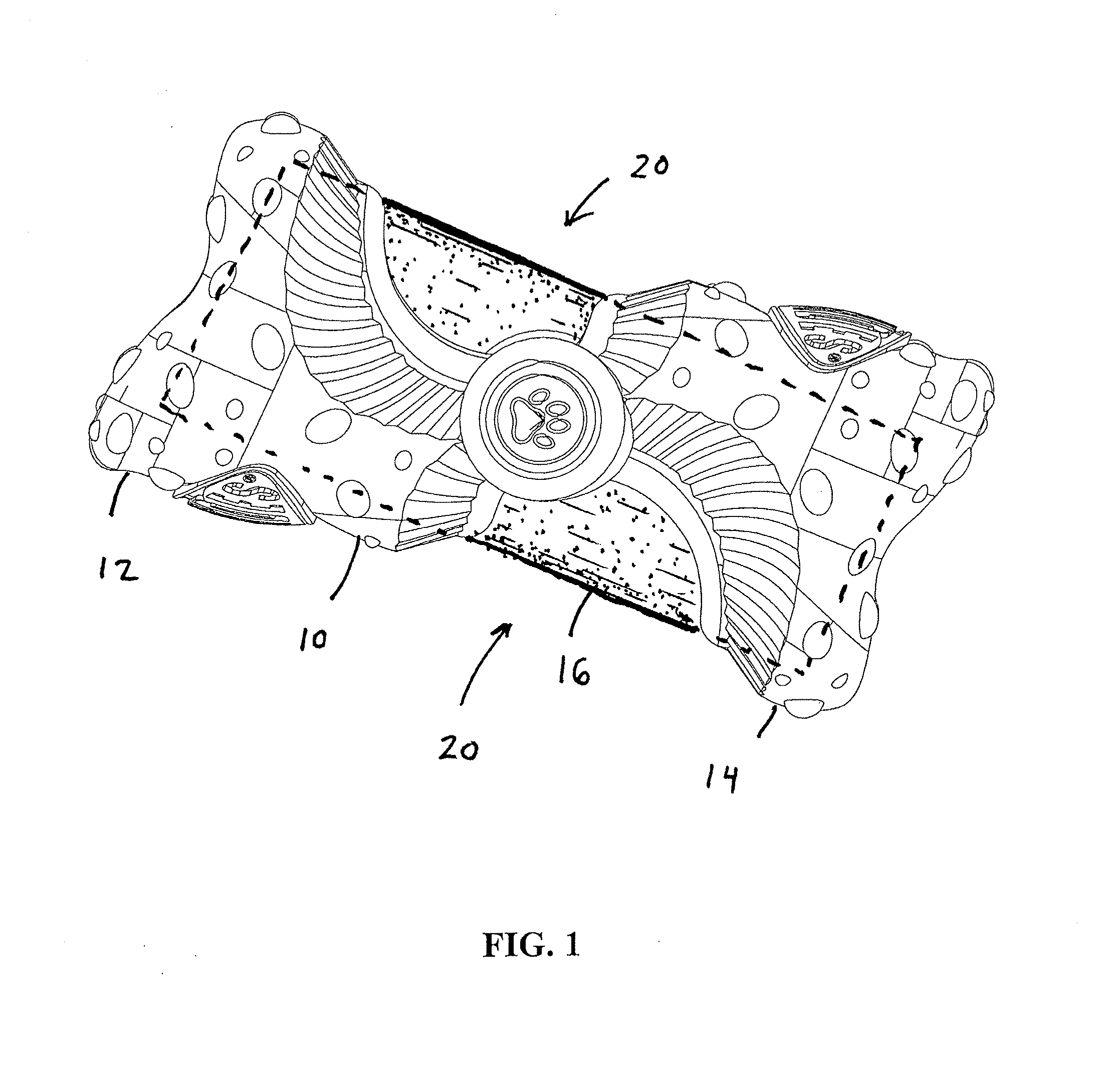

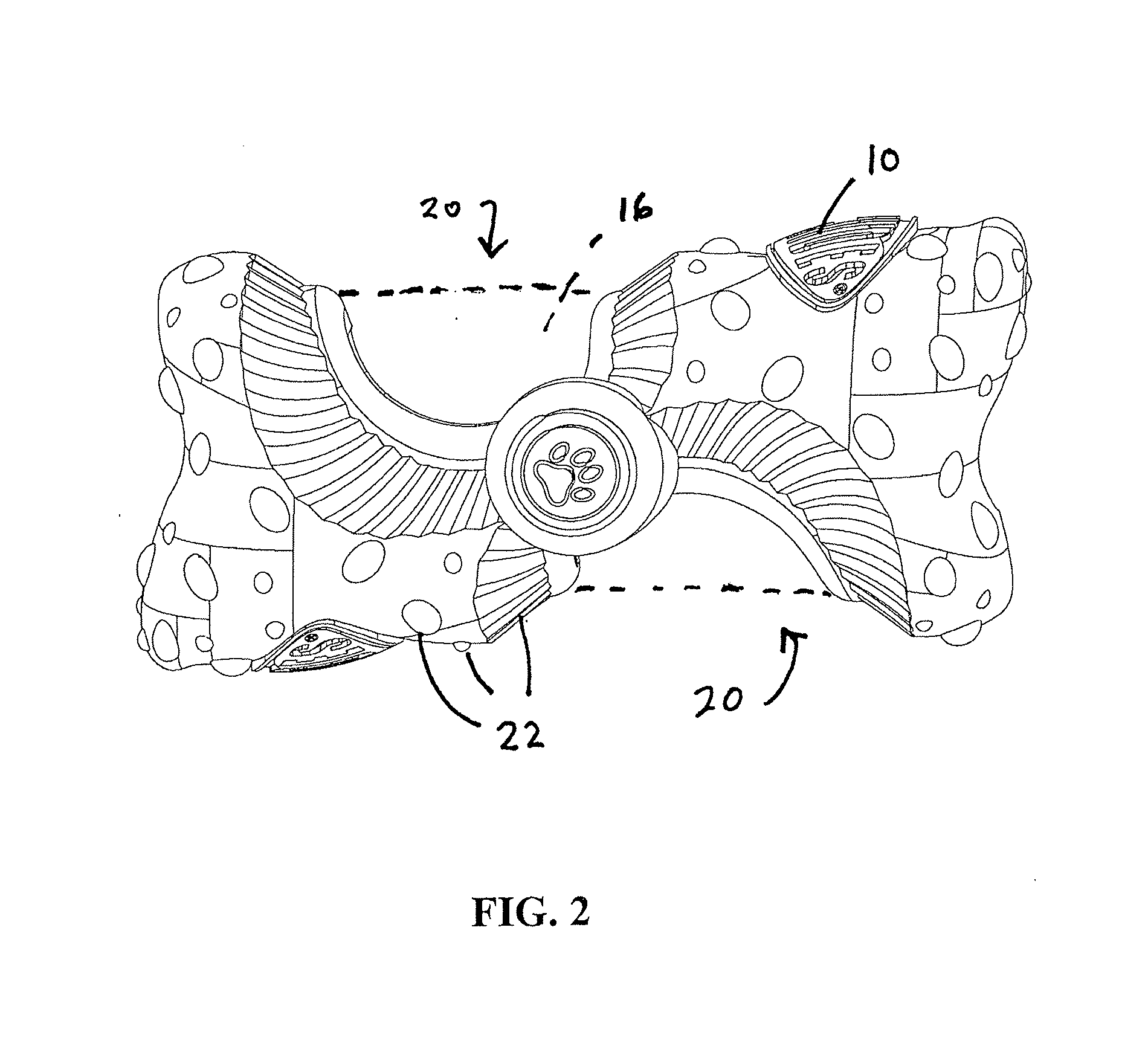

Cover and dispensing device

ActiveUS20140224184A1Safely and economically dispenses edible productsImprove smellAnimal feeding devicesOther apparatusStructural engineeringCompanion animal

Owner:HIMALAYAN DOG CHEW LLC

Vermicelli production process and equipment thereof

The present invention discloses a vermicelli production process and equipment thereof. The process comprises material selection, slurry making, slurry feeding, shaping, water boiling, low temperature cooling, separation and other steps. The equipment comprises a rack, wherein the rack is provided with a first conveying belt, both ends of the first conveying belt are provided with first chains, the first chain is connected with a motor, the upper portion of the rack is provided with a second conveying belt, both ends of the second conveying belt are provided with second chains, the second chain is connected with the motor, the second conveying belt is provided with a vermicelli molding mold, the movement transmission directions of the first conveying belt and the second conveying belt are opposite, the rack is provided with a first slurry covering device, and the rack is sequentially provided with a steam shaping box, a hot water box and a cold water box along the first conveying belt transmission direction. According to the present invention, advantages of simple process, reasonable design, easy operation, capability of performing shape diversification and mass production of vermicelli, and product quality and hygiene quality improvement are provided.

Owner:山东农仆机械科技有限公司

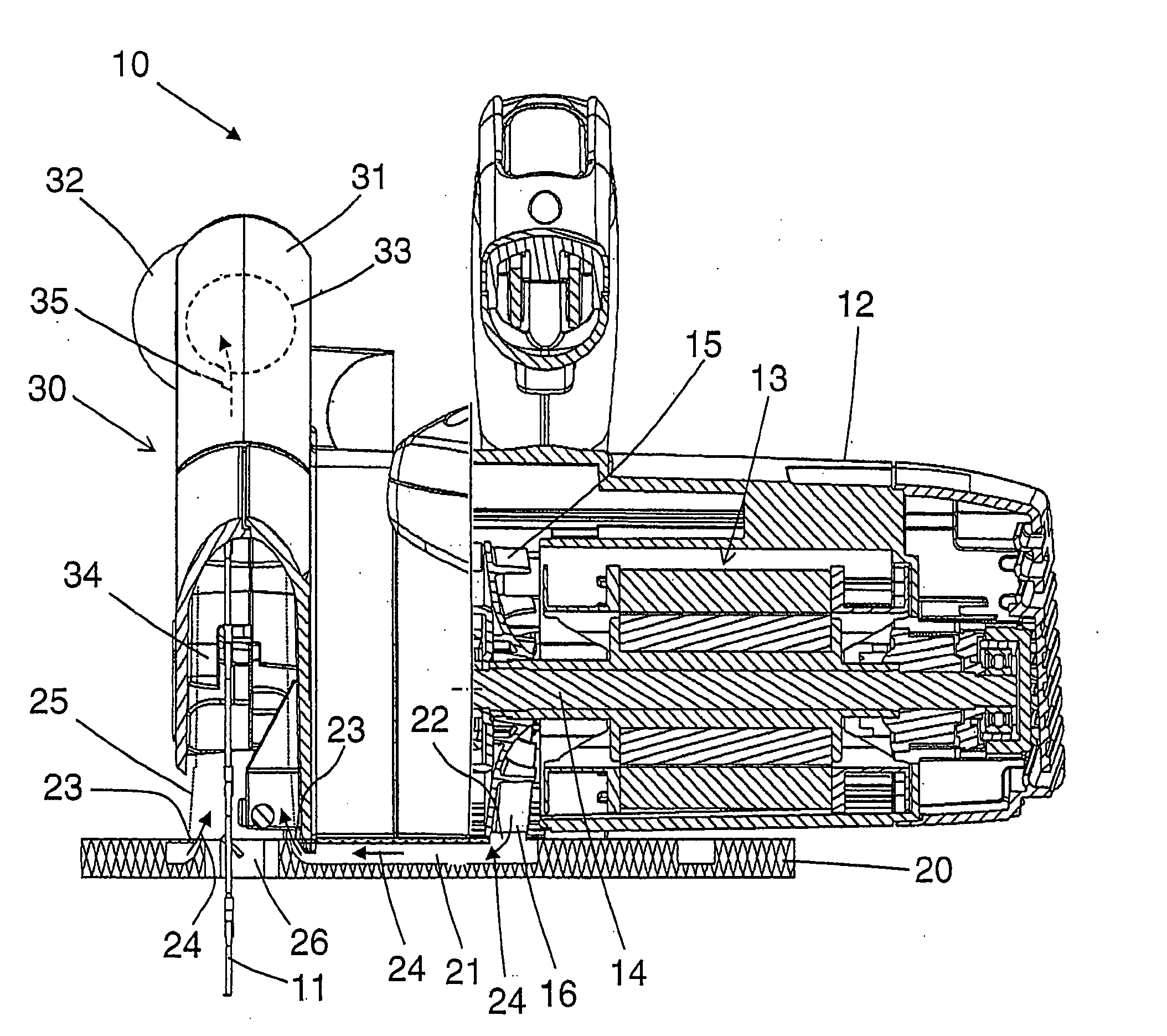

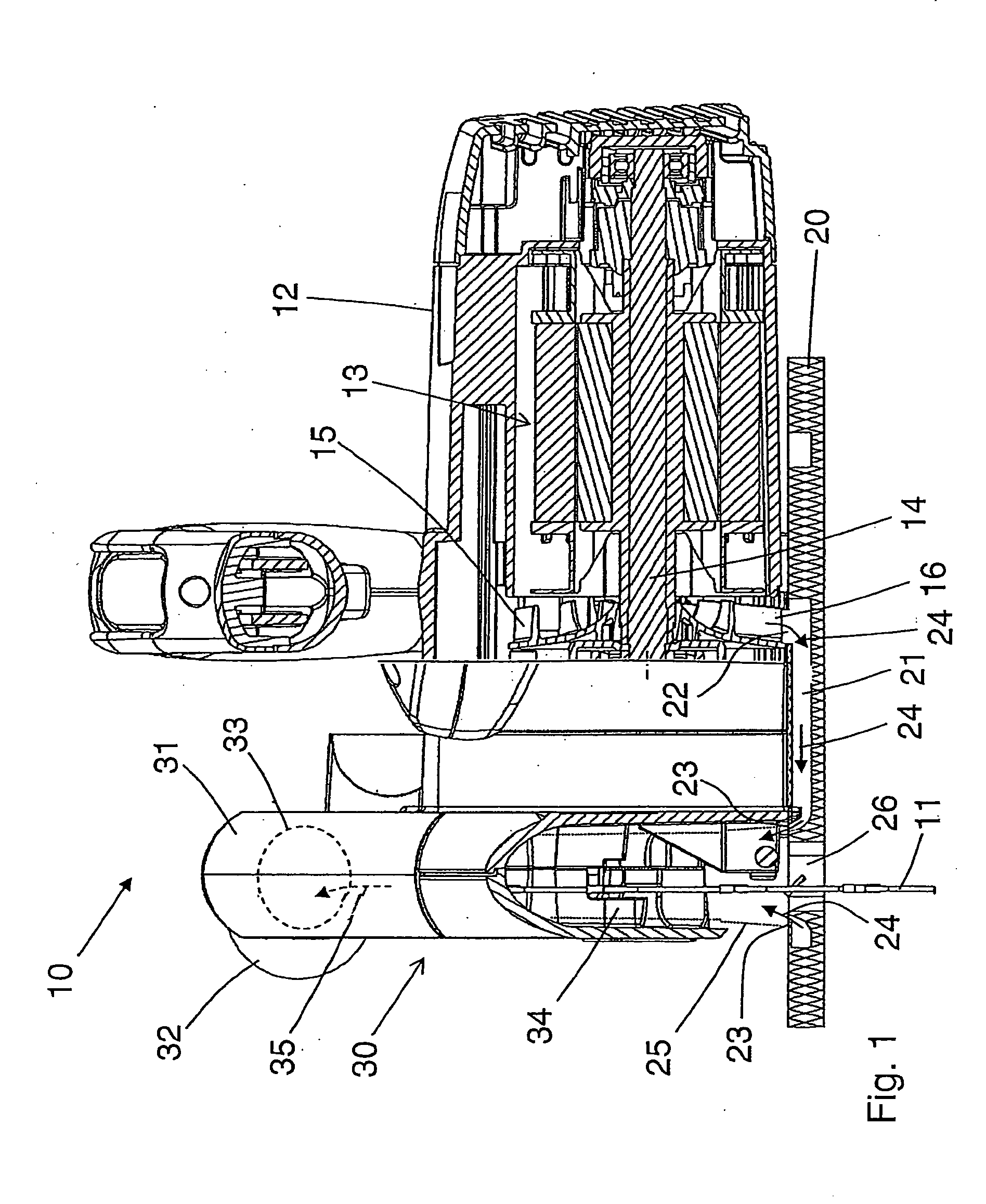

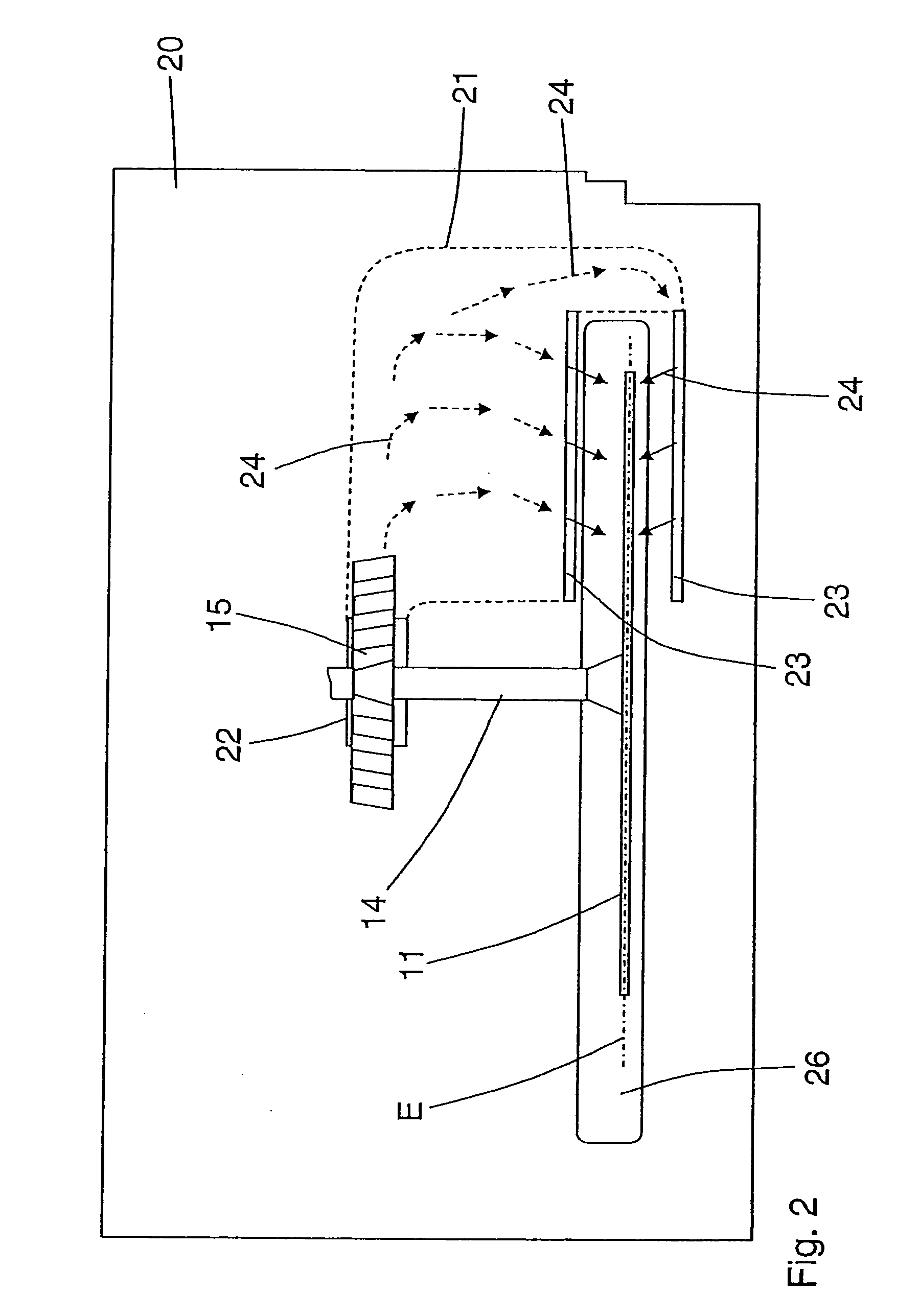

Hand-held power tool

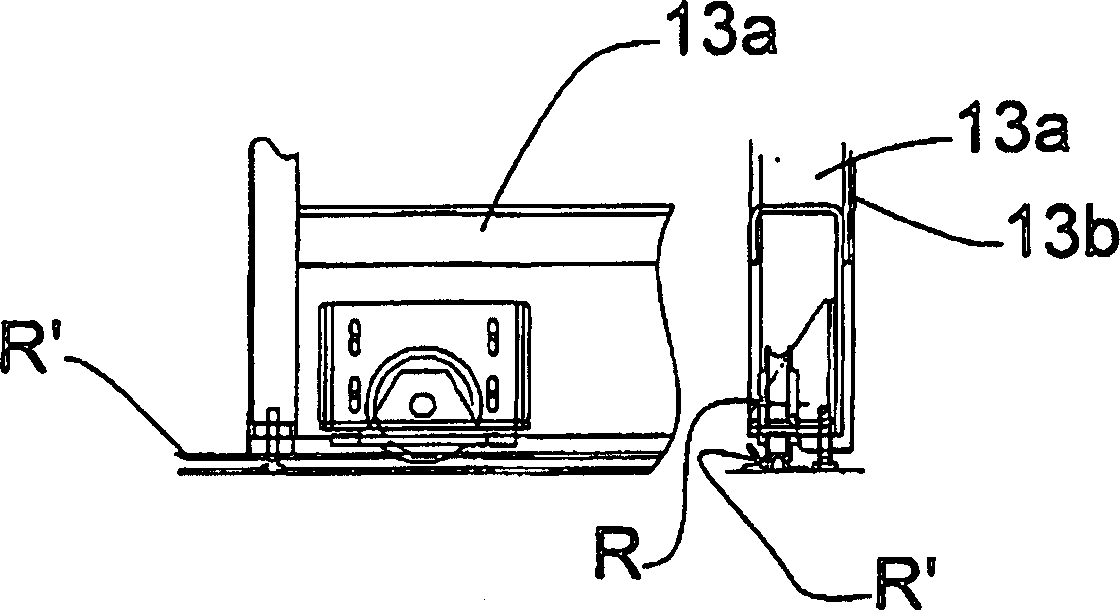

InactiveUS20090165312A1Inhibition formationOptimal air hazeMetal sawing devicesPortable grinding machinesHand heldPower tool

A hand-held power tool includes a motor (13) for driving the cutting or grinding tool (11), a fan (15) for cooling the motor (13), a protective cover device (30) for at least partially covering the cutting or grinding tool (11), and a guide shoe (20) for placing the hand-held power tool on a to-be-treated workpiece and having a tool opening (26) for the cutting or grinding tool (11) and at least one air guide channel (21) having at least one inlet opening (22) for connecting the air guide channel (21) with the fan (15) and at least one blow-out opening (23) arranged sidewise of the tool opening (26).

Owner:HILTI AG

Convertible camper shell and hard tonneau

A truck bed camper shell and hard tonneau cover device is provided which is activated for movement between a raised truck bed camper shell position and a lowered hard tonneau cover position by remote activation of actuators such as pneumatics or hydraulic cylinders or a screw drive mechanism.

Owner:WOODWORTH INVESTMENT GROUP

Automatic edge covering device for aluminum alloy doors and windows and using method

InactiveCN111389660AIncrease incomeImprove hemming efficiencyEngine sealsPretreated surfacesStructural engineeringMachining

The invention relates to the technical field of aluminum alloy machining devices, in particular to an automatic edge covering device for aluminum alloy doors and windows and a using method. The devicecomprises a base and further comprises a controller, a feeding mechanism, a machining table, a gluing mechanism and a mounting mechanism; the feeding mechanism comprises a conveyor and a clamping assembly; the gluing mechanism comprises a supporting table, a gluing assembly and a sliding assembly; the machining table is rotatably arranged between the conveyor and the supporting table to contain the aluminum alloy doors and windows; the mounting mechanism comprises a placing frame and a pressing assembly, and the pressing assembly is arranged beside the placing frame; and the conveyor, the clamping assembly, the gluing assembly, the sliding assembly and the pressing assembly are all electrically connected with the controller. According to the automatic edge covering device for the aluminumalloy doors and windows and the using method, edges of different thicknesses can be covered; and meanwhile, glass and aluminum alloy frames can be tightly assembled together, and the drying functionis achieved so that the next procedure treatment or application can be conveniently and rapidly carried out on the aluminum alloy doors and windows, and the edge covering efficiency is improved.

Owner:段锐东

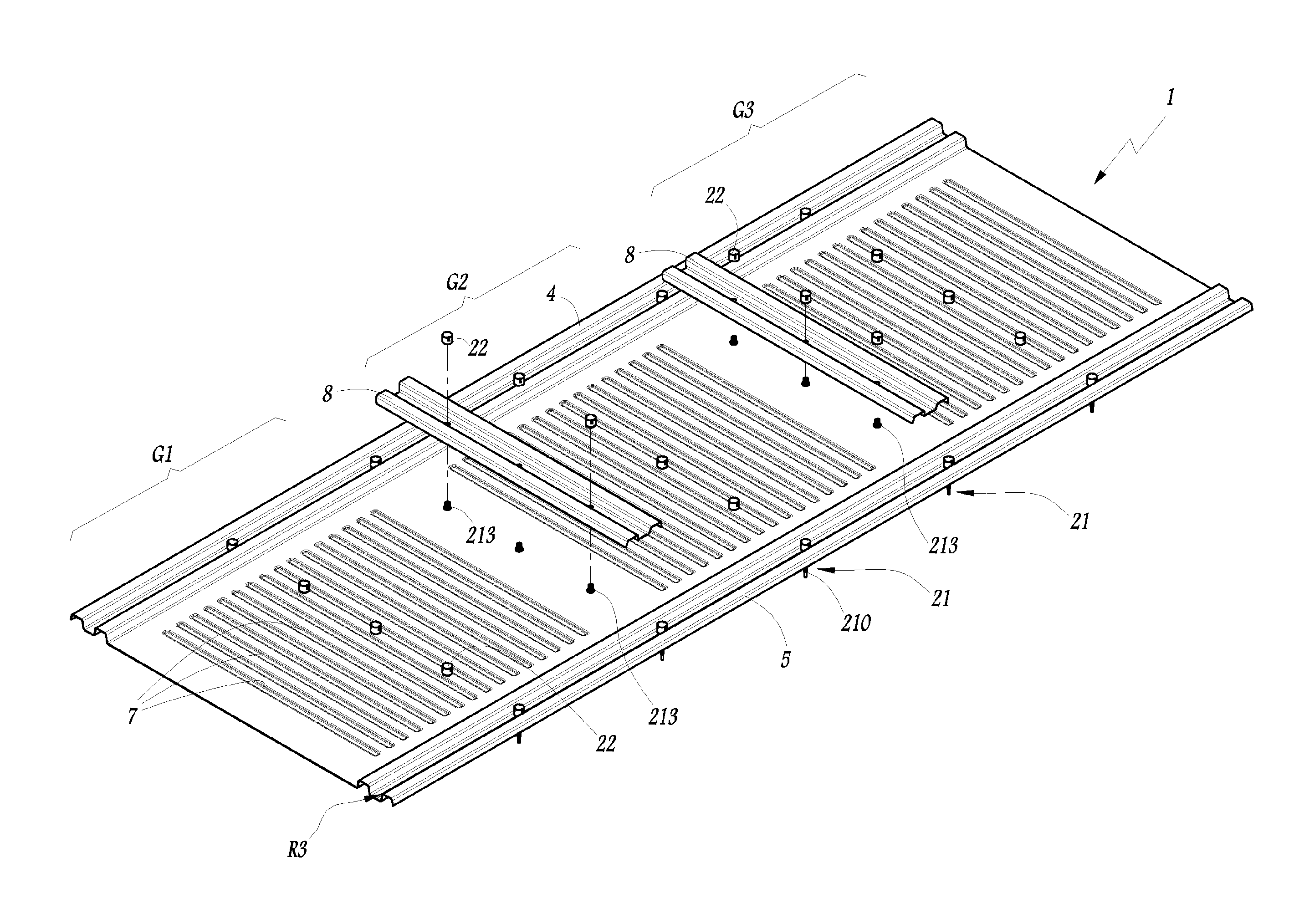

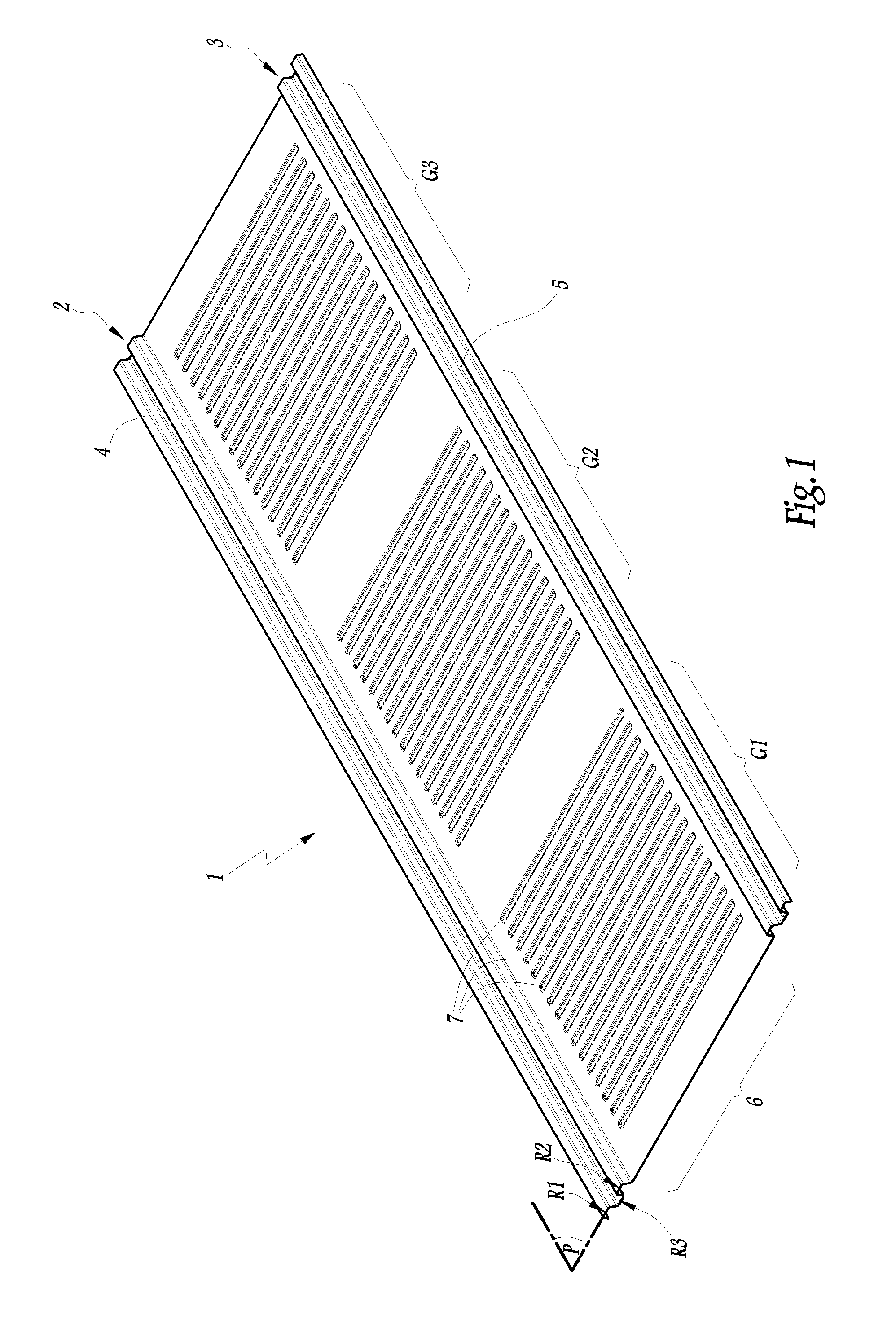

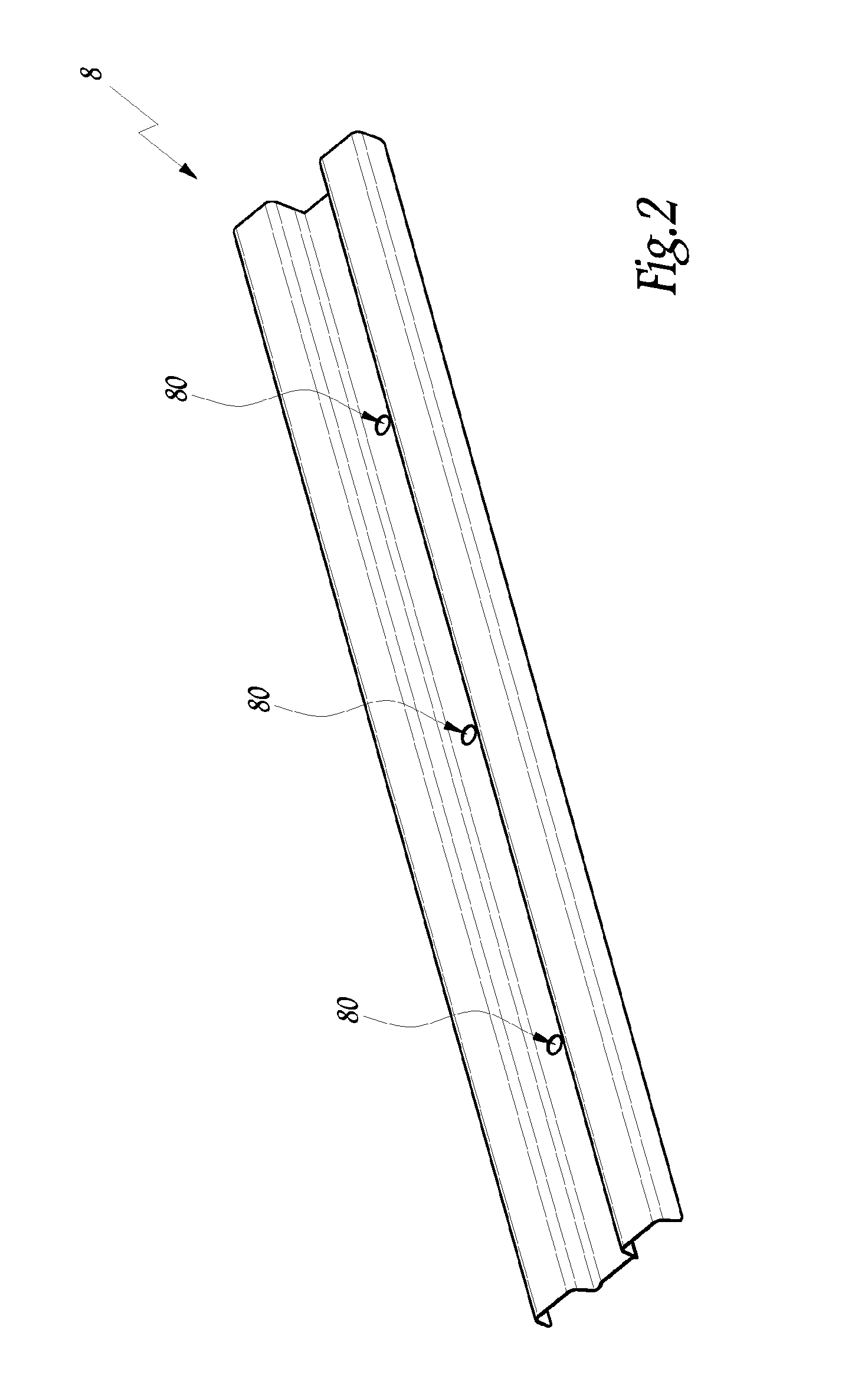

Device for covering a building structure and structure covered by such a device

InactiveUS9523205B2Guaranteed economic efficiencyMaintain structural integrityCovering/liningsSheet joiningMetal sheetBiomedical engineering

The invention relates to a covering device comprising: at least one metal sheet, especially a metal sheet used for cladding, suitable for covering at least one section of a surface of a building structure, fastenings for definitively attaching the metal sheet to the structure, at least one accessory suitable for applying to a receiving area on the metal sheet, and means for removably attaching the accessory to the receiving area, that are suitable for attaching the accessory once the metal sheet is already attached to the structure by means of the fastenings, maintaining the structural integrity of the metal sheet, and also the integrity, especially in terms of tightness, of the attachment of the metal sheet to the structure by means of the fastenings, said attaching means including a head of the fastenings, that can enable the assembly, and if need be, the disassembly, of the accessory, without affecting the attachment of the metal sheet to the structure by means of the fastenings.

Owner:BACACIER 3 S

Self-cleaning system of air-jet loom

The invention relates to a self-cleaning system of an air-jet loom. The self-cleaning system comprises a blowing device, a collecting device and a protective cover device, the blowing device and the collecting device are correspondingly arranged on a left wall plate and a right wall plate on the lower portion of a rear opening of a heald frame of the air-jet loom, and the protective cover device encloses a main nozzle and a front opening of the heald frame of the air-jet loom. The blowing device comprises a blowing port and a blowing structure, and an air outlet of the blowing structure is formed in the inner side of the edge of the blowing port. The collecting device comprises a plurality of collecting ports, pipelines, a cotton collecting box and a fan, the collecting ports are connectedwith the cotton collecting box through the pipelines, the cotton collecting box is connected with the inside of the fan and separated from the fan by a filter screen, a negative-pressure structure isarranged in the fan, and the collecting ports face the air-jet loom. The protective cover device comprises a cover plate and two baffle plates, wherein the two baffle plates are arranged at the leftend and the right end of the cover plate. The system can effectively clean flyings and droppings generated by the front opening and the rear opening of the heald frame, air-jet weft insertion, reed beating-up and the like, and cleanness of a fabric interweaving environment is ensured.

Owner:SUZHOU JIANGSAI TEXTILE TECH CO LTD

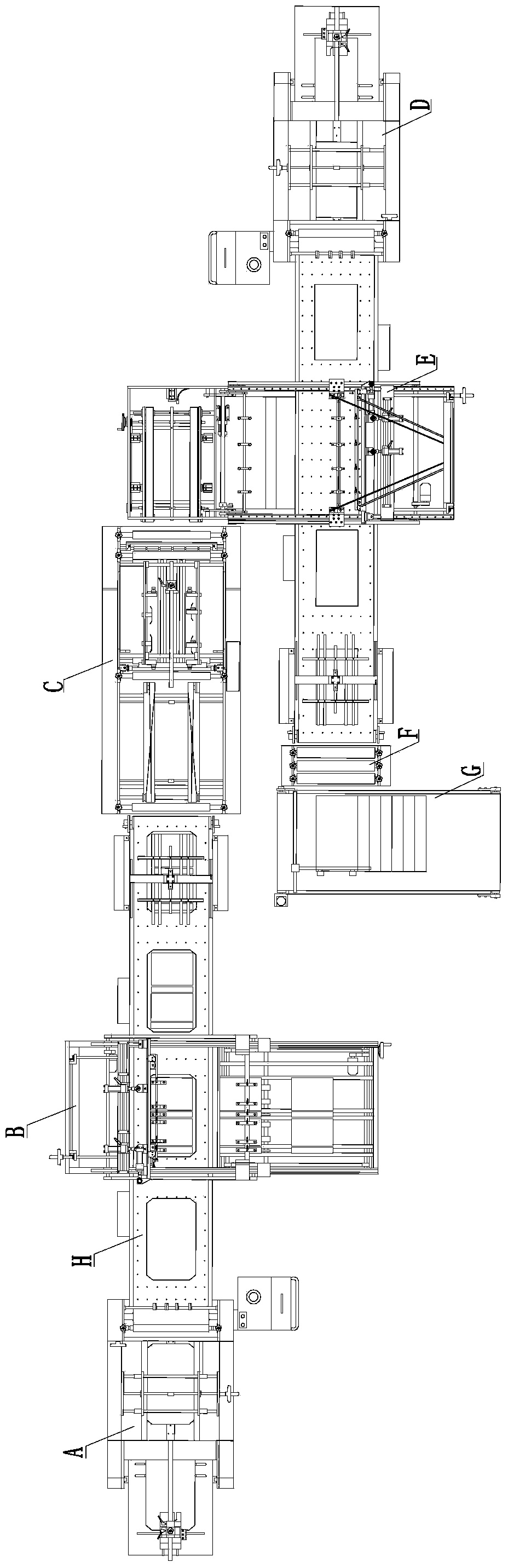

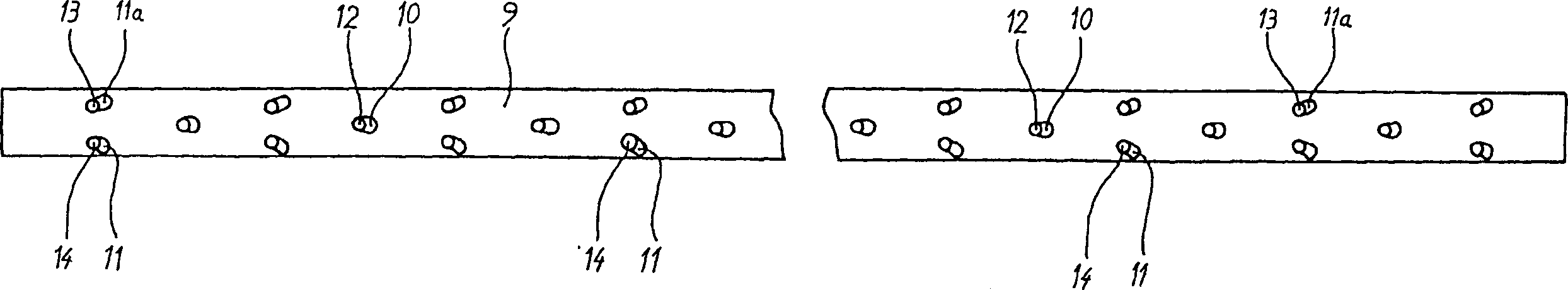

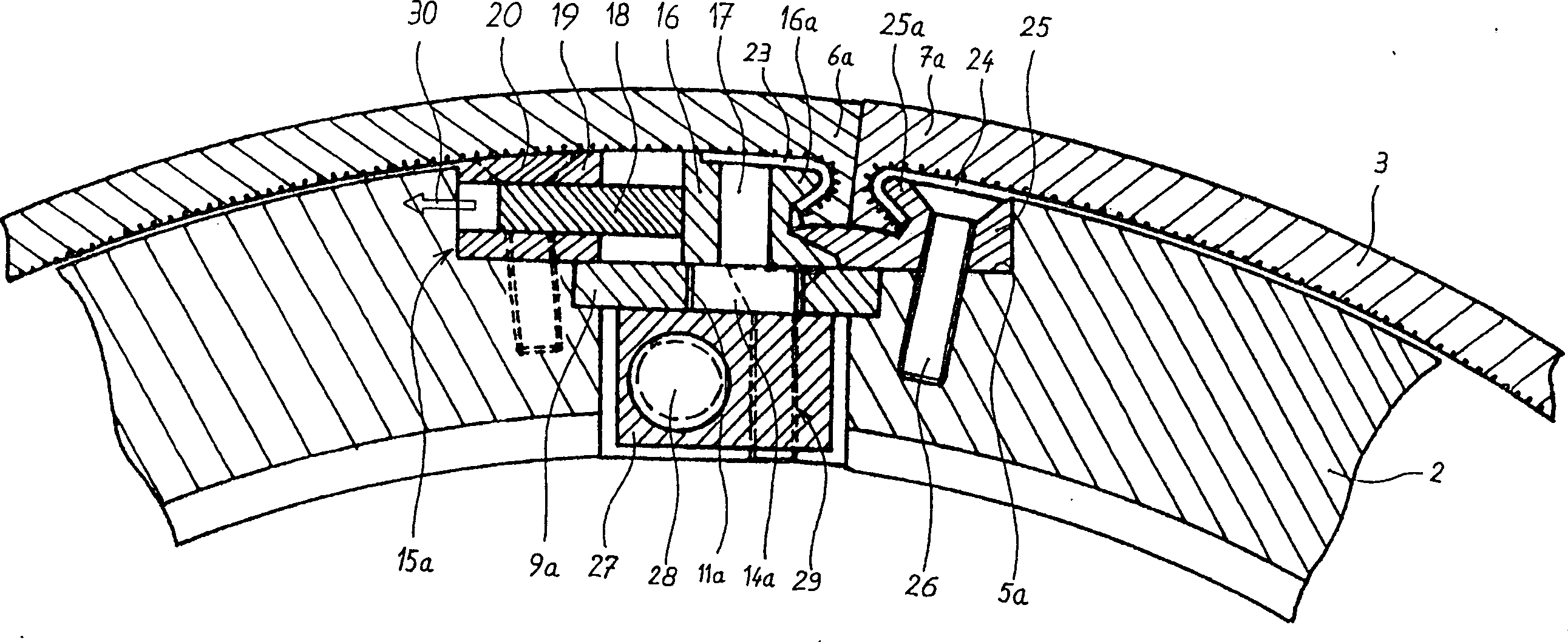

Device for mounting and take-down mould covering device of rotation cutting anvil cylinder

The fastening / dismantling system consists of locking elements for the ends of the counter-cutting cylinder covering strips, each comprising a locking assembly fitting into a slot (5) in the outer edge of the cylinder (2) and incorporating a mobile slider (9) with guide slots (10) and cam slots (11, 11a) engaging with rollers on a jaw gripping one end of the covering strip. The slider is operated by a traction assembly (44) with a screw (49) interacting with a nut (55) fixed to the bottom of the slider.

Owner:MARTIN SA

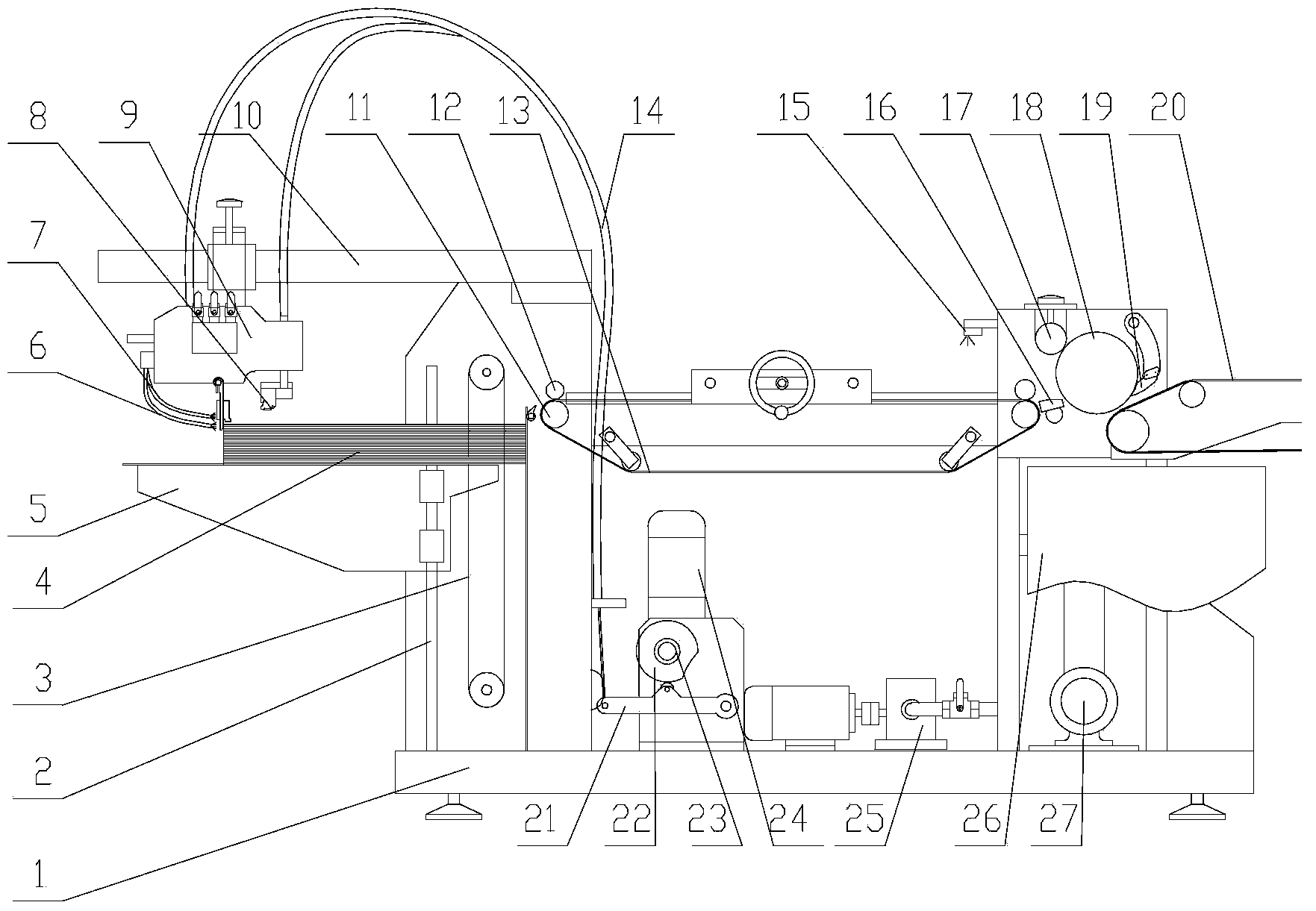

Continuous sealing and cutting machine

InactiveCN102328755AImprove work efficiencyImprove versatilityPackaging machinesProcess engineeringIndustrial engineering

The embodiment of the invention discloses a continuous sealing and cutting machine. The continuous sealing and cutting machine comprises a machine frame, a drive device, a synchronous filling device, a film covering device, a synchronous sealing and cutting device, and a film collecting device, wherein the synchronous filling device comprises a material storage unit and a feeding unit; the material storage unit is fixedly arranged on the machine frame; the feeding unit is arranged on the material storage unit by a sliding rod and is fixedly connected with the synchronous sealing and cutting device by a connecting rod; the synchronous sealing and cutting device comprises a hot sealing and cutting mechanism and a first servo motor; the hot sealing and cutting mechanism comprises a hot sealing and cutting unit and a hot sealing unit; the hot sealing and cutting mechanism is connected with the feeding unit through the connecting rod; and the hot sealing and cutting mechanism and the feeding unit act synchronously under the drive of the first servo motor. By adopting the continuous sealing and cutting machine, the continuous sealing and cutting machine is kept static relative to a template when the processes of filling and sealing are finished, and the template does not need to be stopped conveying momentarily, so that the work efficiency is improved; in addition, the continuous sealing and cutting machine is also provided with a sealing and cutting component replacement device and a film calibrating device, so that the continuous sealing and cutting machine is suitable for different templates, the equipment university is improved and the production investment is reduced.

Owner:GUANGDONG YUEDONG MECHANICAL IND

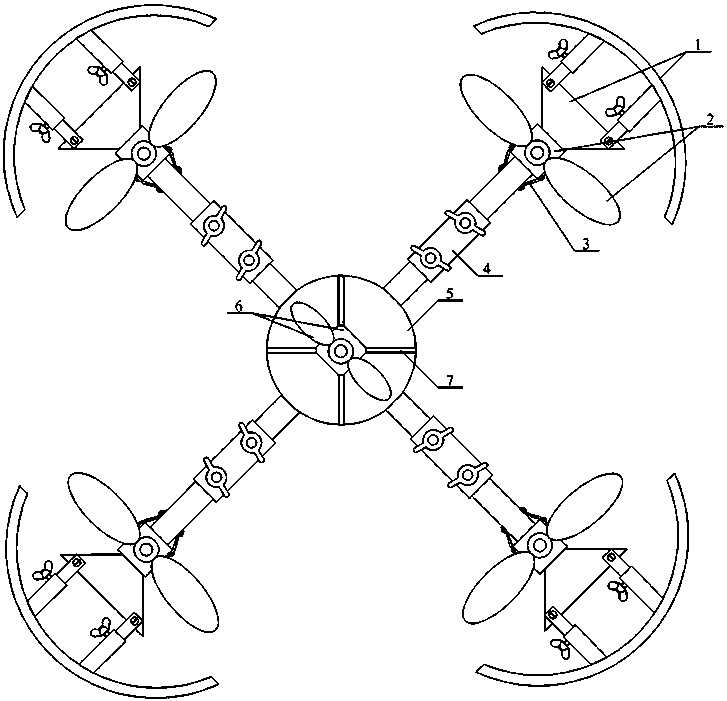

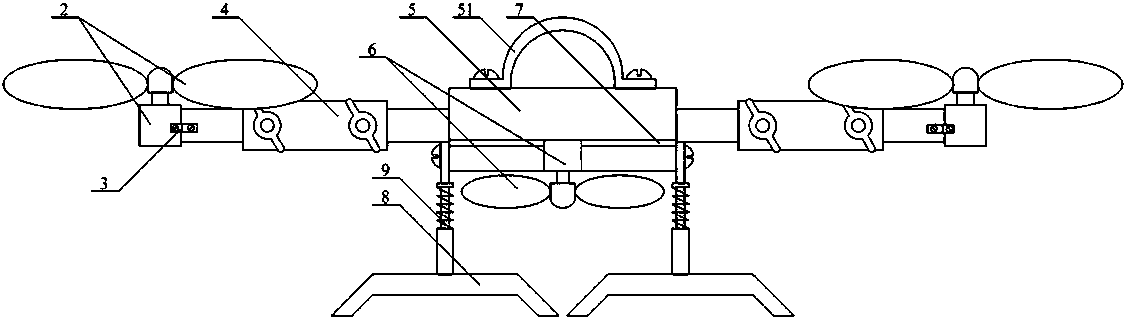

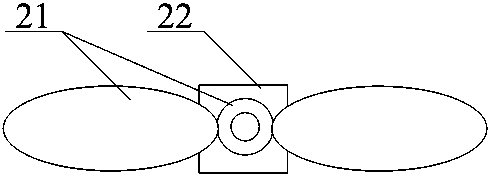

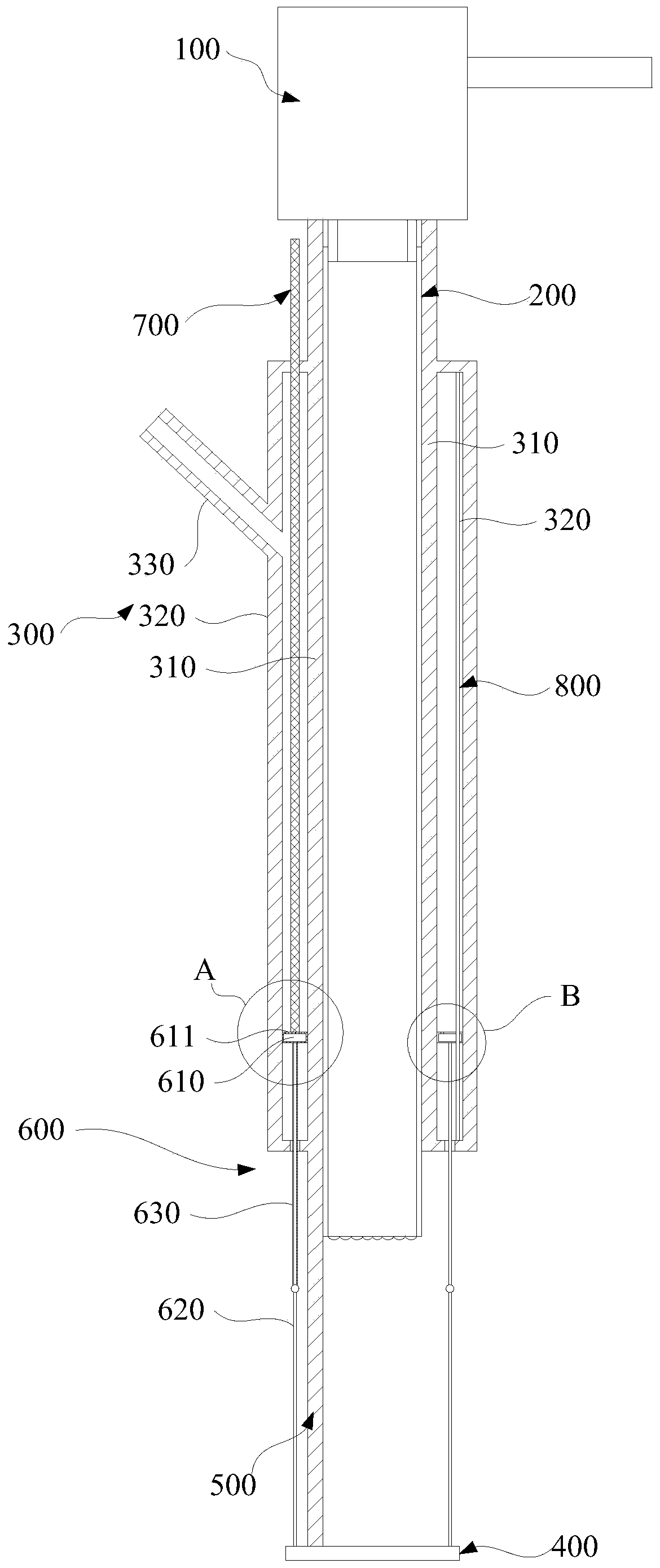

Five-axis hovering aircraft with good hovering power and working principle thereof

InactiveCN107757902AStrong hovering powerRealize five-axis driftingAlighting gearRotocraftControl mannerEngineering

The invention provides a five-axis hovering device with strong hovering force and its working principle, including a protective cover device, a lifting and hovering device, a connecting plate, an adjustable rod device, a fuselage, a floating and attitude changing device, a connecting rod, Lifting seat and buffer rod device; the protective cover device is respectively bolted to the lifting and hovering device, and the lifting and hovering device is installed on the right end of the adjustable rod device through the connecting plate screw, and the adjustable rod device is respectively bolted to the four corners of the fuselage, floating The row and attitude changing device can make the angle and length of the auxiliary propeller change, thereby breaking the airflow balance when the hovering device is hovering, and realizing drifting. The invention uses machinery and structure, cooperates with the flight control control method to make the multi-rotor floater lift into the air and float, and at the same time has a large load capacity, a downward shift of the center of gravity, good stability, increased suspension effect and low manufacturing cost, and can be widely used in airborne vehicles. People, aerial monitoring, suspended lights, suspended speakers, suspended fire hydrants and other suspended appliances.

Owner:郑州航空港飘天下物联网科技有限公司

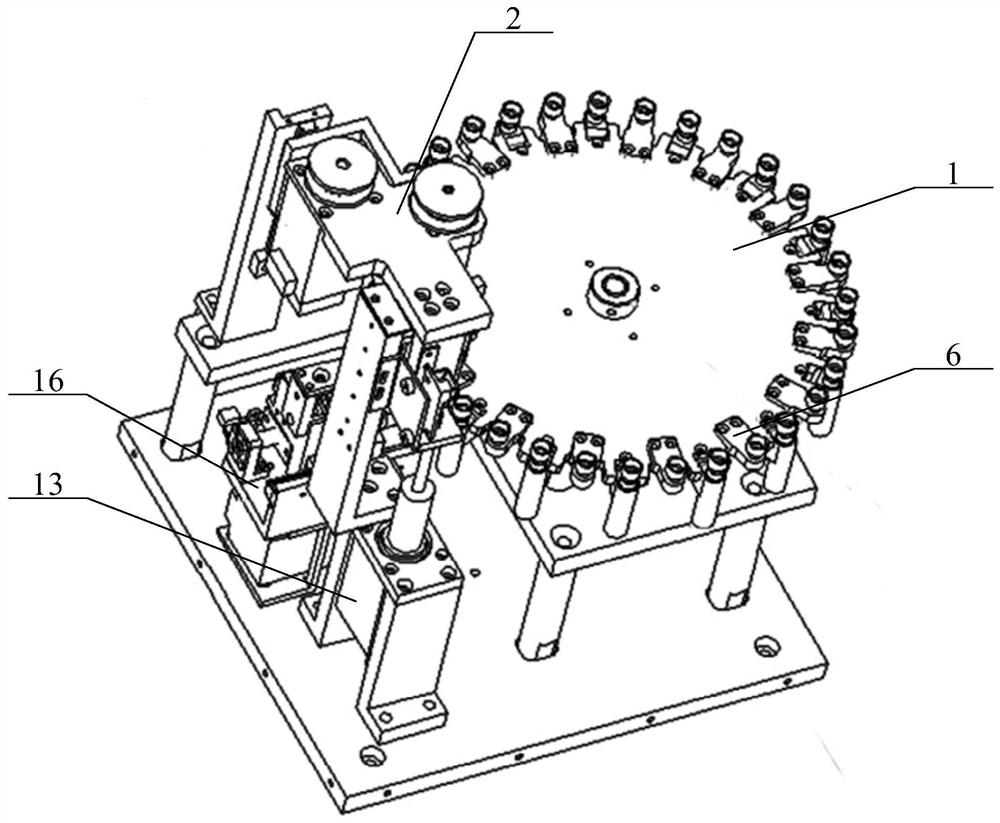

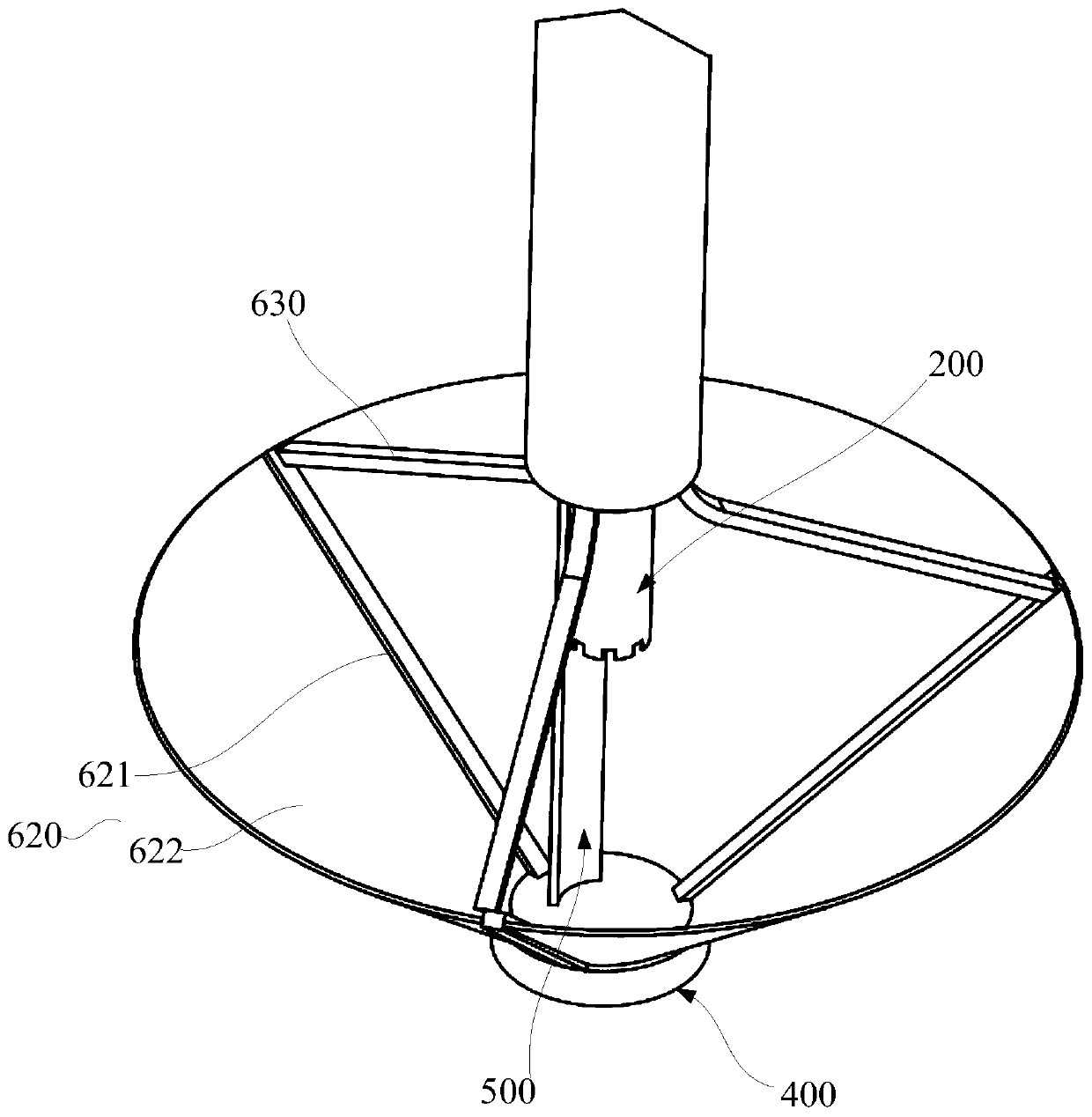

Molecular detection centrifugal opening and closing cover device

ActiveCN113072018AConvenient centrifugationCentrifugal realizationThreaded caps applicationTight-fitting lid removalEngineeringApparatus instruments

The invention provides a molecular detection centrifugal opening and closing cover device, and relates to the technical field of medical instruments. The device comprises a rotating disc, a cover opening and closing assembly and a rotation driving component. A test tube is placed on a rotating disc, a rotating mode of the rotation driving component is started, the test tube is moved to the position below a grabbing part, the grabbing part of the cover opening and closing assembly is used for driving a bottle cover on the test tube to move, and cover opening or cover closing operation is completed; and a centrifugal mode of the rotation driving component is started, the rotating disc rotates at a high speed to drive the test tube to do centrifugal motion, a reagent in the test tube can be centrifuged conveniently, the cover opening and closing function can be achieved, the reagent can be centrifuged, more functions are achieved, and the technical problems that an existing test tube cover opening and closing device can only achieve automatic cover opening and closing and is single in function in the prior art are solved.

Owner:HANGZHOU BIOER TECH CO LTD

Tight covering device of flip type packaging container cover

ActiveCN102320393AIncrease productivityReduce manufacturing costWrapper twisting/gatheringElectric machineryStructural engineering

The invention discloses a tight covering device of a flip type packaging container cover, comprising a rack, a controller and a working platform driving motor, wherein the rack is provided with a towing platform; the towing platform is provided with a guide rail; a working platform is arranged on the guide rail and can move along the guide rail; the working platform driving motor is in transmission connection with the working platform; the working platform is provided with more than one row of container cover holes which are arranged along the direction of the guide rail; the section shape of the container cover hole is matched with that of a lower cover body of the container cover; the towing platform is divided into a flip area, a cover pressing area and a cover moving area. In the tight covering device, a series of structures are designed according to the initial state and the final state of the packaging container cover, the production efficiency of the packaging container cover can be improved and the production cost can be reduced.

Owner:浙江三荣塑胶有限公司

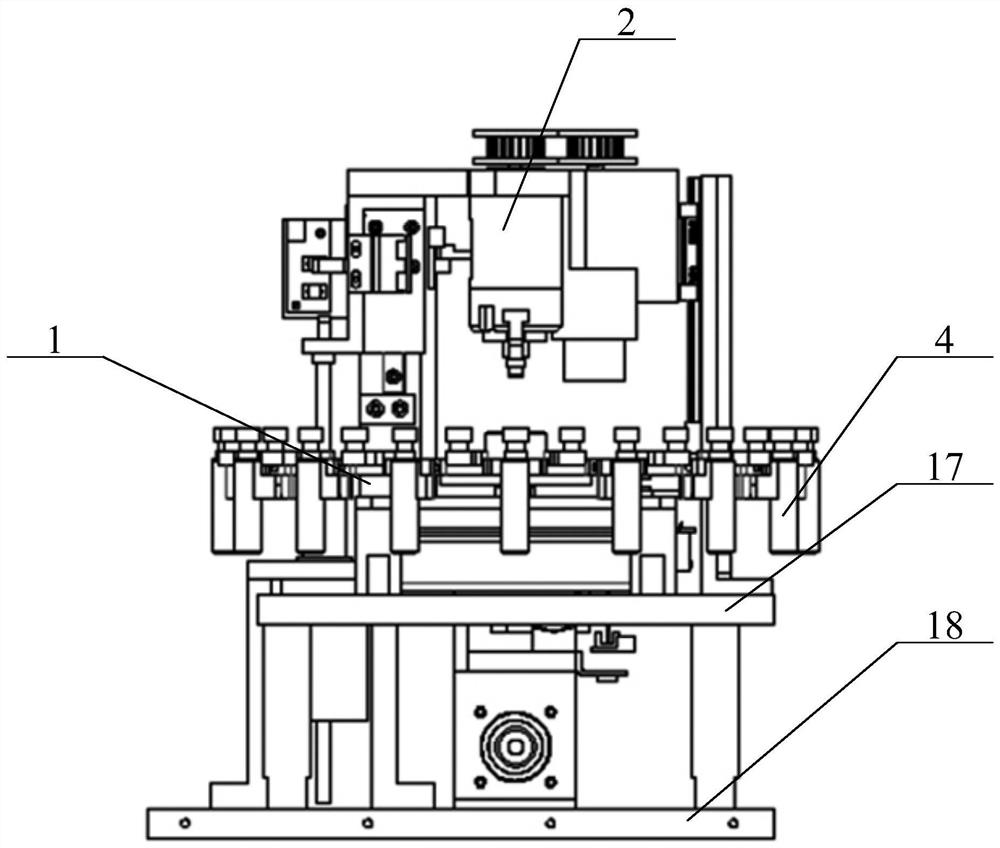

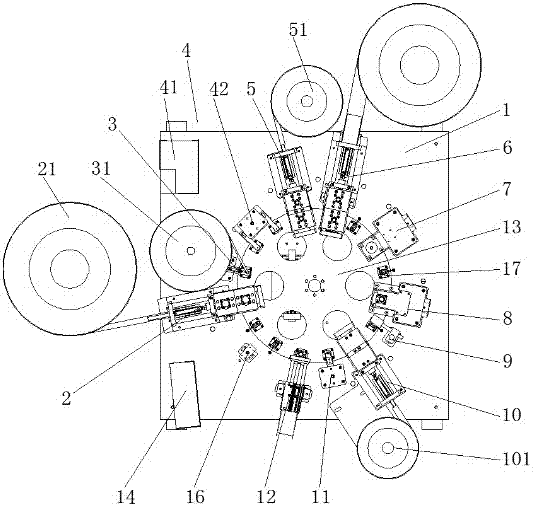

Ink filling unit

PendingCN107176580AFully automatedIncrease productivityBottle-handling machinesControl systemElectric machinery

The invention discloses an ink filling unit comprising a base table, a lower bottle device, a lower iron bar device, a filling device, a lower connecting cover device, a lower inner cover device, a cover screwing device, a connecting cover aligning device, a cover detection device, a lower outer cover device, an outer cover pressing device, a discharge device, a rotary disc, a control system and a return detection device. The lower bottle device, the lower iron bar device, the filling device, the lower connecting cover device, the lower inner cover device, the cover screwing device, the connecting cover aligning device, the cover detection device, the lower outer cover device, the outer cover pressing device and the discharge device are distributed sequentially clockwise in the circumferential direction of the rotary disc. A turbine speed reducing motor is arranged at the bottom of the base table. A plurality of ink bottle installing seats are distributed at the top of the rotary disc evenly in the circumferential direction. Through the ink filling unit, full automation of ink filling is achieved, production efficiency and product quality are improved greatly, a large number of manpower resources are reduced, cost input is reduced, and good application and popularization value is achieved.

Owner:GUANGDONG GENVANA STATIONERY CO LTD

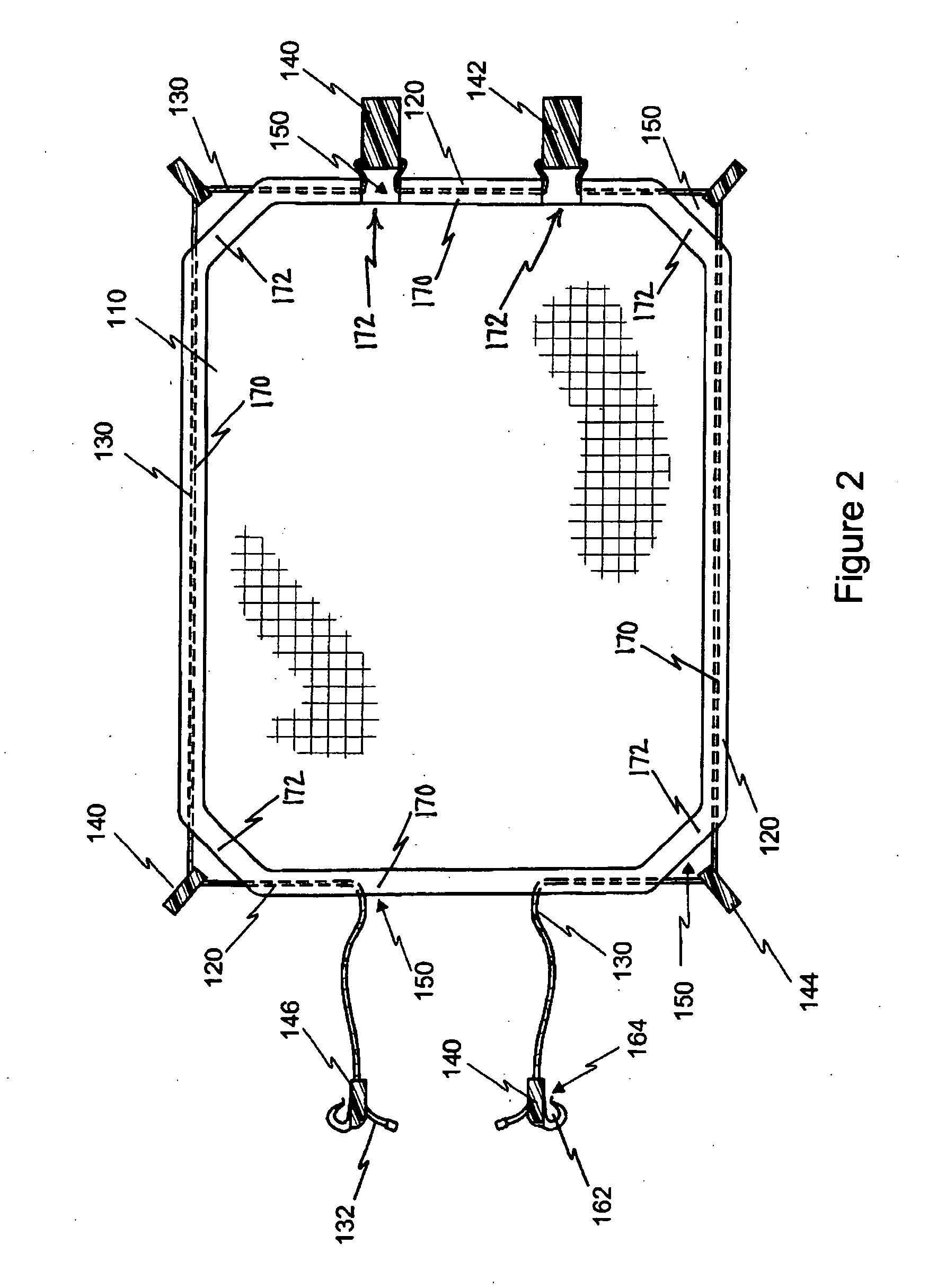

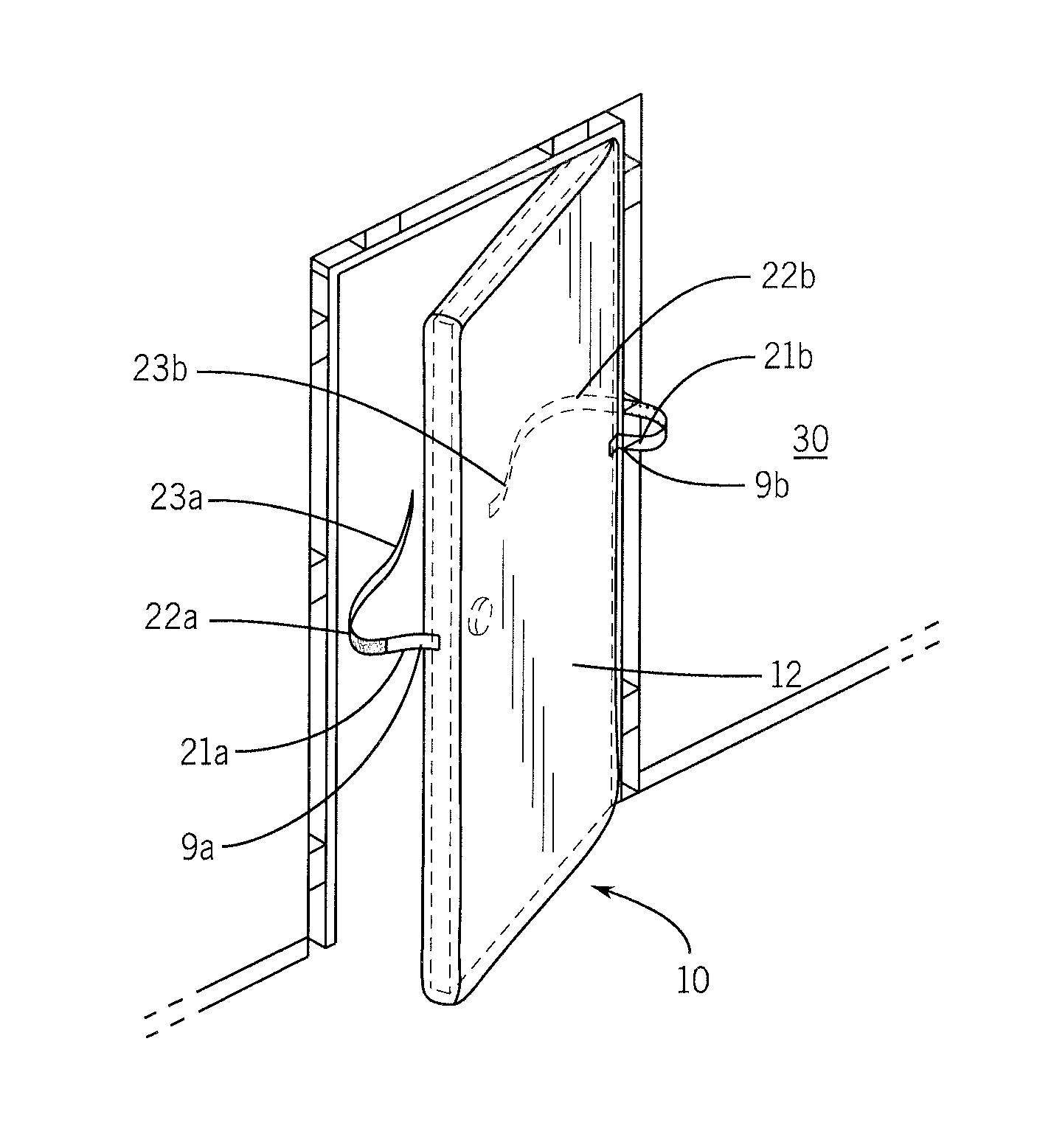

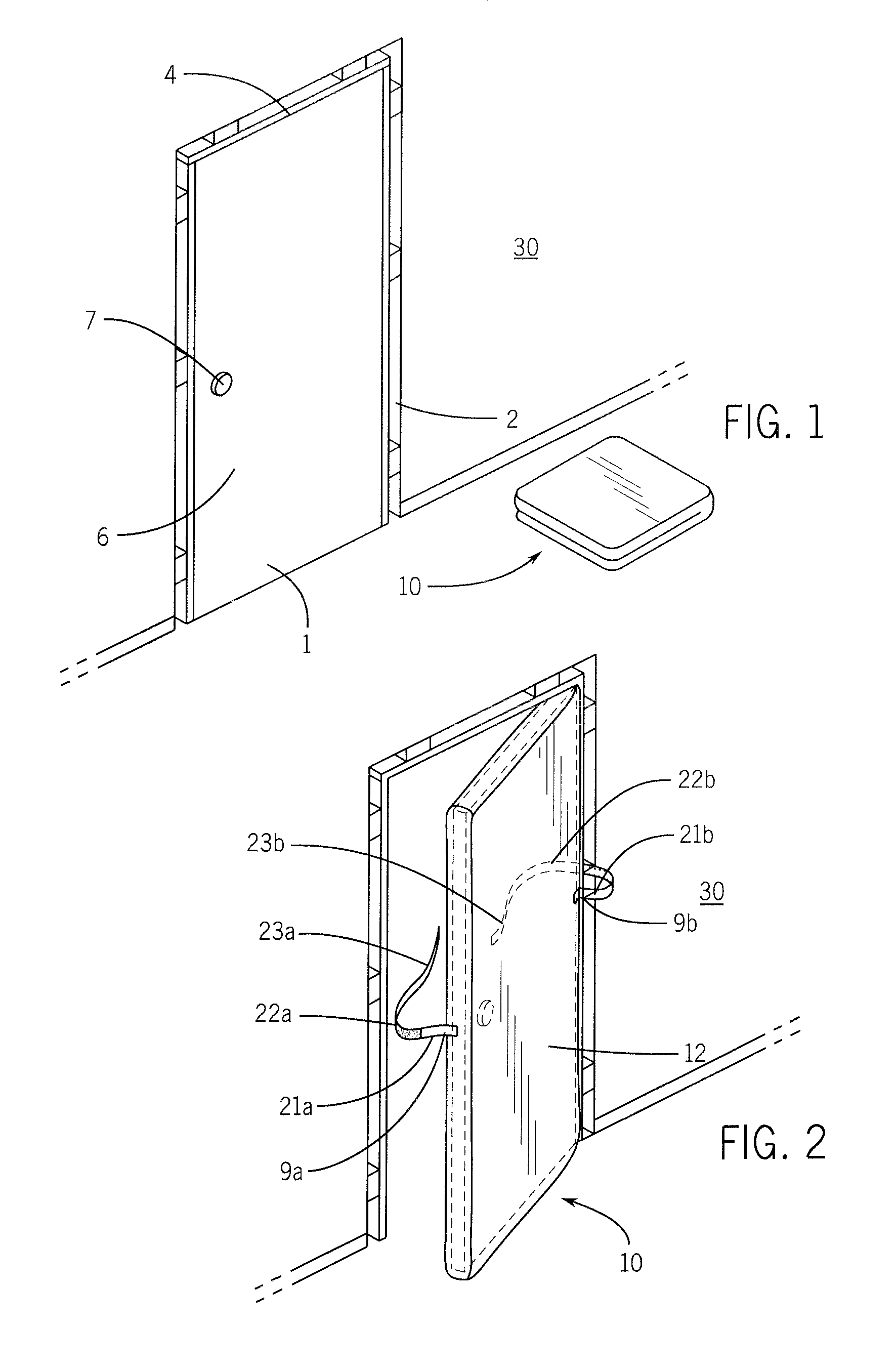

Reusable door covering device and method

InactiveUS20160340963A1Obstruct passageShutters/ movable grillesSpraying apparatusForced-airElectrical and Electronics engineering

A reusable door covering device provides a continuous sheet of protective material having an elastically expandable perimeter which is expanded to lengthen the perimeter and then contracted to shorten the perimeter, allowing the sheet to be used with a wide variety of door sizes. The sheet and its elastically expandable perimeter is the primary means for protecting the door. To prevent the passage of forced air into the space between the door and the sheet of protective material, the door covering device comprises at least one band of material that can be used to secure at least two sides of the door covering device on the side opposite that to which the door covering device is applied. The perimeter of the door covering device also includes additional sealing means for allowing the perimeter to be sealed about the hinge hardware used to hang the door.

Owner:LOCH JERRY

Hysteromyoma rotary cutter

ActiveCN111297453APrevent fallingAvoid implant cancerExcision instrumentsObstetrical instrumentsEngineeringStructural engineering

The present invention discloses a hysteromyoma rotary cutter. The hysteromyoma rotary cutter comprises an electric device, a drilling cylinder, a connecting cylinder, a bottom plate, a connecting plate, a covering device and a push rod. The connecting cylinder sleeves outside the drilling cylinder; the connecting cylinder is a double-layer cylinder and comprises an inner cylinder and an outer cylinder, and two ends of the outer cylinder are connected with side walls of two ends of the inner cylinder to form a cavity; the bottom plate is positioned right under a cutting end of the drilling cylinder at intervals; one end of the connecting plate is connected with one side of the connecting cylinder, and the other end of the connecting plate is connected with an edge of the bottom plate; the covering device comprises a push plate, a cover body and support rods, the cover body is an inverted cone-shaped body, the support rods are uniformly arranged along the outer cylinder at intervals, oneend of each support rod is connected with a top end of the cover body, the other end of each support rod is connected to the push plate, and when the push plate moves towards a direction close to thebottom plate, the support rods can be driven to be dispersed outwards to open the cover body; and a tail end of the push rod is connected to the push plate and the other end of the push rod extends out of the connecting cylinder. The hysteromyoma rotary cutter can prevent fragments from scattering in a pelvic cavity in a hysteromyoma cutting process and avoids occurrence of planting cancer.

Owner:中国人民解放军陆军特色医学中心

Working method of aluminum alloy door-window automatic edge covering device

ActiveCN111389659AIncrease incomeImprove hemming efficiencyEngine sealsPretreated surfacesStructural engineeringMaterials science

The invention relates to the technical field of aluminum alloy processing equipment and specifically relates to a working method of an aluminum alloy door-window automatic edge covering device. The device comprises a base and also comprises a controller, a loading mechanism, a processing table, a gluing mechanism and an installation mechanism, wherein the loading mechanism comprises a conveying machine and a clamping assembly; the gluing mechanism comprises a supporting table, a glue dispensing assembly and a slide assembly; the processing table is disposed between the conveying machine and the supporting table in a rotatable manner to store an aluminum alloy door and an aluminum alloy window; the installation mechanism comprises a placement frame and a pressing assembly; the pressing assembly is disposed by the side of the placement frame; and the conveying machine, the clamping assembly, the glue dispensing assembly, the slide assembly and the pressing assembly are electrically connected to the controller. The aluminum alloy door-window automatic edge covering device and a use method disclosed by the invention have the beneficial effects that different thicknesses of edge covering can be realized; glass can be closely assembled with an aluminum alloy frame; a drying function is provided, so processing or application of a next process can be conducted rapidly; and efficiency of edge covering is increased.

Owner:BINZHOU YUYANG ALUMINUM IND

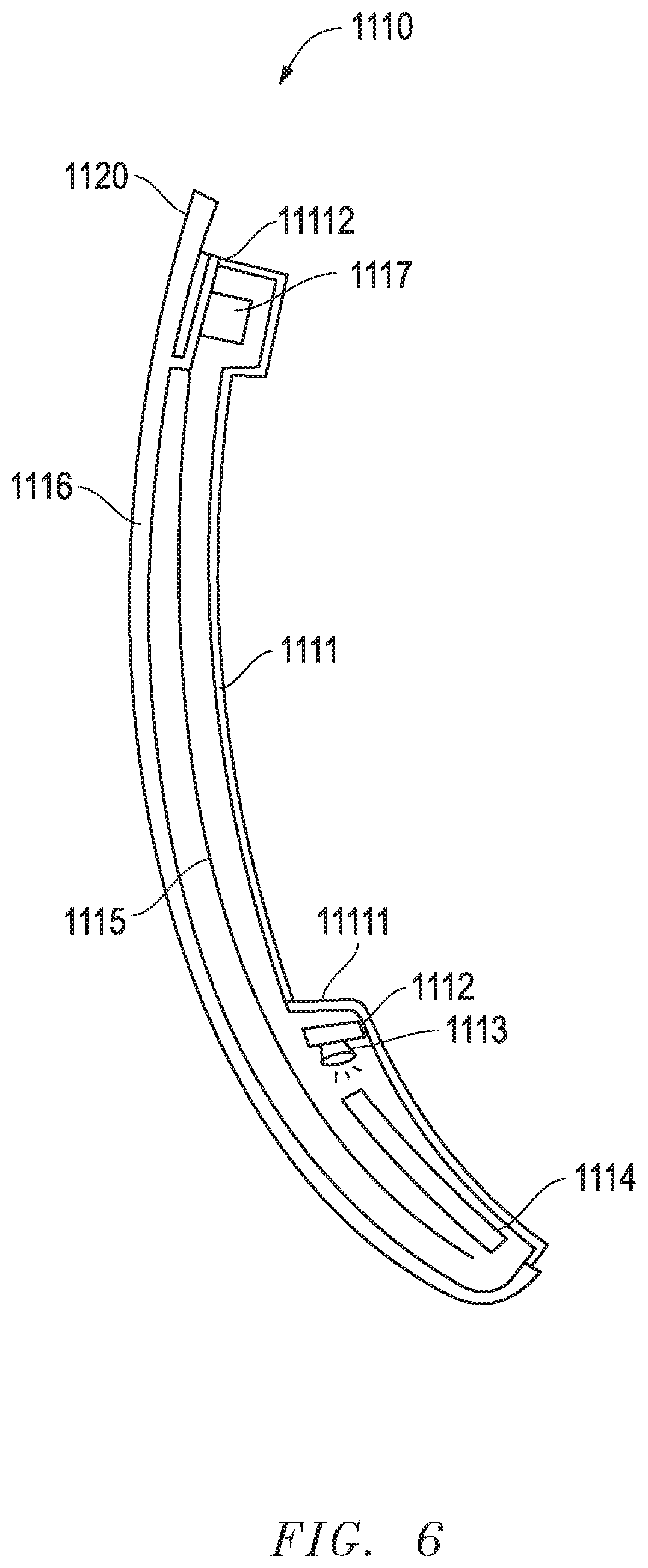

Covering devices for use with vehicle parts

ActiveUS20200103093A1Electric circuit arrangementsSuperstructure subunitsStructural engineeringPolymer

A covering device for fully or partially covering one or more of a recess, a flat portion, a curved portion, and a stepped portion of at least one of a vehicle body component and a vehicle part includes a cover element provided by a strip element or a cap element, and at least one lip element which is fixedly or detachably connected to the cover element on at least one of its longitudinal sides, the covering device is designed so that light from a lighting device can shine through at least a portion of the covering device, at least one of the cover element and the at least one lip element is made at least partly of a polymeric substrate which is coated with a chromium-based reflective coating material, and the polymeric substrate and the chromium-based reflective coating are at least partially translucent.

Owner:SMR PATENTS S A R L

Gluing and film covering device

PendingCN111823564AGuaranteed qualityAvoid tearing and deformationLiquid surface applicatorsCoatingsEngineeringWorkbench

The invention discloses a gluing and film covering device. The gluing and film covering device comprises a workbench used for bearing a product A and extending in the X direction, and further comprises an unwinding and film covering assembly, a gluing assembly and a winding assembly, wherein the unwinding and film covering assembly walks in a reciprocating mode in the X direction and attaches a product B to the upper surface of the product A in an unwinding process; the gluing assembly is arranged on the unwinding and film covering assembly and glues the upper surface of the product A; and thewinding assembly walks in a reciprocating mode in the X direction and winds a protective film on the upper surface of the product B in a winding process. The gluing and film covering device has the characteristics of being high in production efficiency, compact in structure, flexible in operation and stable in gluing quality.

Owner:苏州工业园区多司电子科技有限公司

ESL accurate edge-cutting and film-covering device and technique

PendingCN107795558AReduce tensionImprove efficiencyLamination ancillary operationsMaterial gluingEngineeringFar infrared

The invention discloses an ESL accurate edge-cutting and film-covering device and technique. The ESL accurate edge-cutting and film-covering device comprises a whole device controller, an upper tool and a lower tool, and the whole device controller is connected with the upper tool and the lower tool. The upper tool comprises a workpiece fixing mechanism and a workpiece lifting mechanism, the workpiece fixing mechanism is provided with a far infrared heating system, and the lower tool comprises a mold and a plurality of material storing machines arranged around the periphery of the mold. The material storing machines comprise racks and work tables arranged on the racks, the work tables are provided with horizontal sliding mechanisms, and the horizontal sliding mechanisms are provided with vertical sliding mechanisms. First work arms are connected to the vertical sliding mechanisms, telescopic mechanisms are connected to the vertical sliding mechanisms and connected with second work arms, and the first work arms and the second work arms are matched. When the ESL accurate edge-cutting and film-covering device is adopted for film covering and edge wrapping, a workpiece can be accurately heated, and leather is moved when the workpiece is pressed down and prevented from being excessively tensioned; and edge wrapping is automatically conducted after film covering is completed, and automation of film covering and edge wrapping is achieved.

Owner:三康(成都)机械设备有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com