Carding machine with linearly movable casing

A covering device, translational motion technology, applied in the direction of deburring device, fiber processing, textile and papermaking, etc., can solve problems such as unsatisfactory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

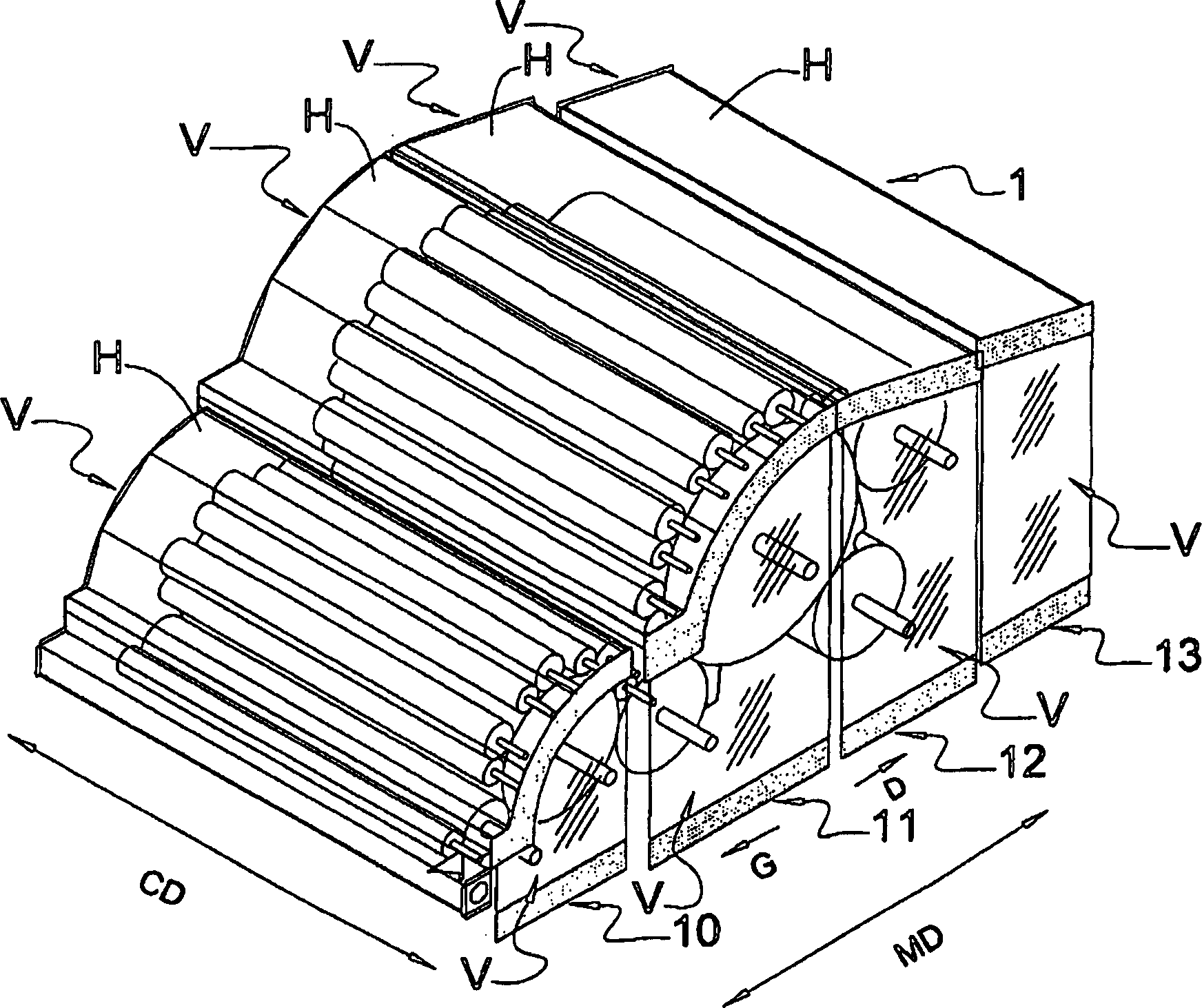

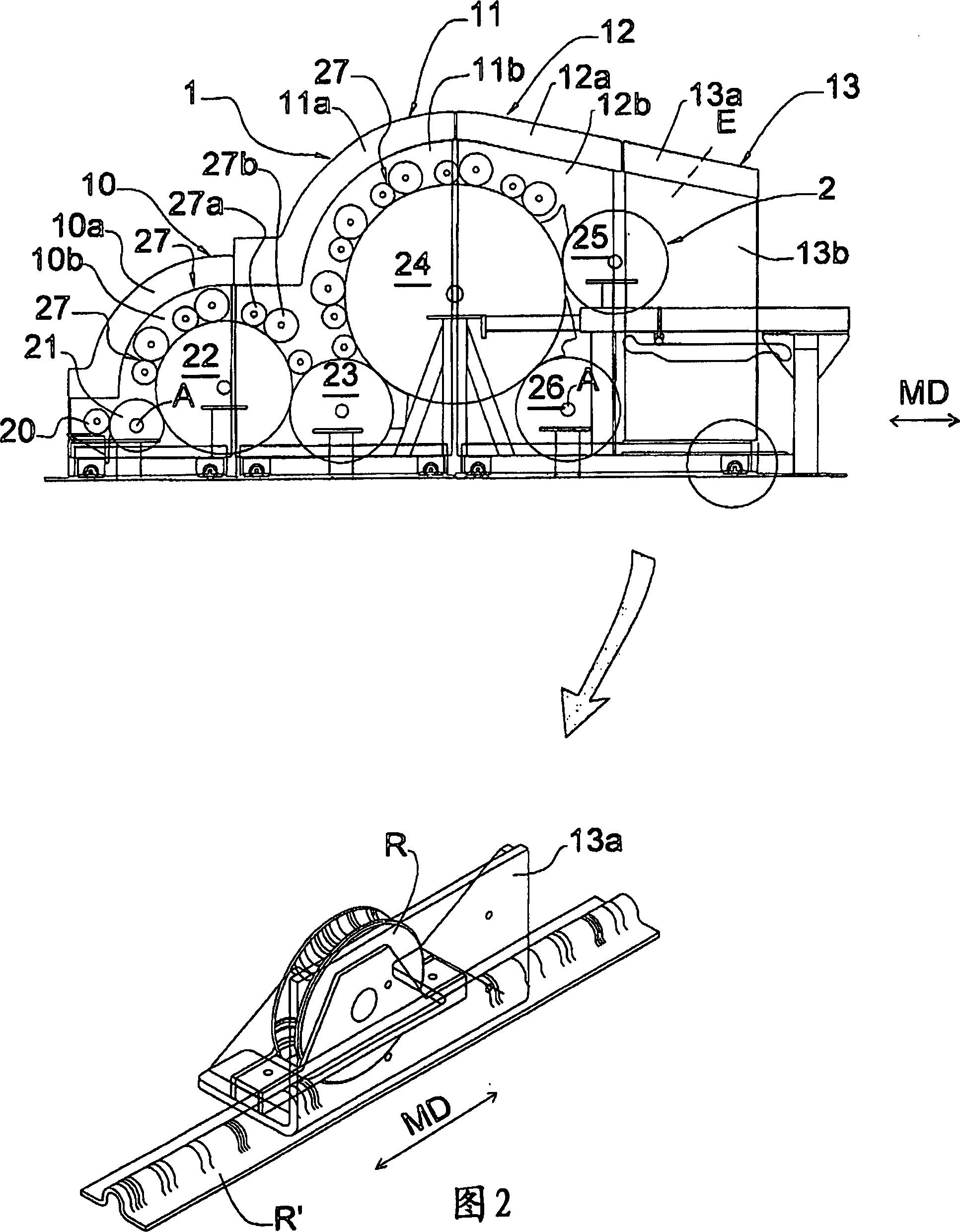

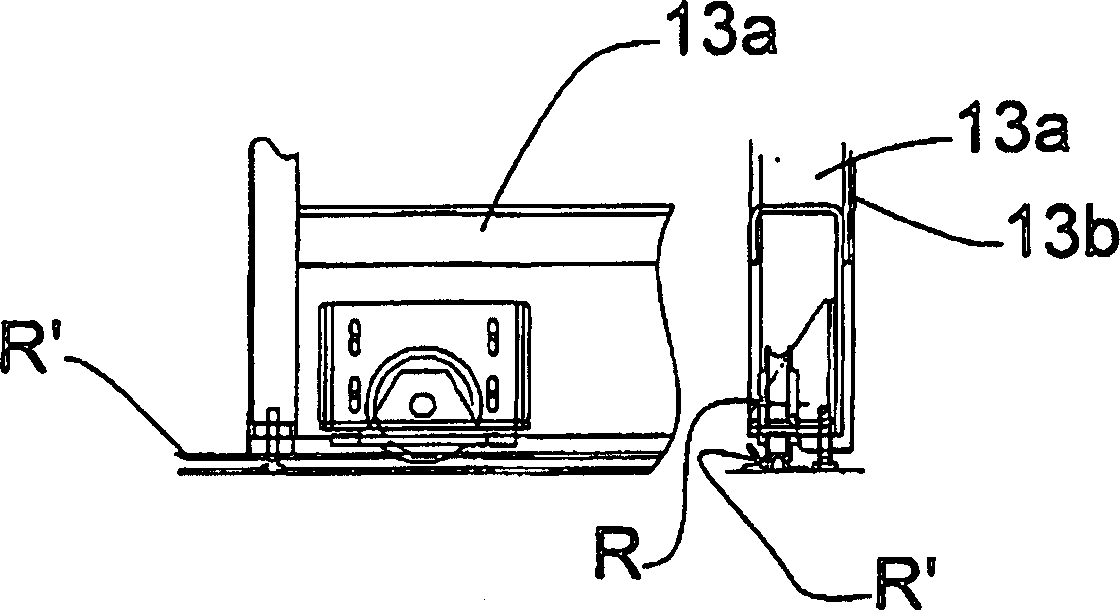

[0031] [31] The accompanying drawings show a carding machine with an assembly 2 of cylinders (20, 21...) - said cylinders being substantially parallel and with covering means 1 - which define a protective cover Shell E, inside which said drum (20, 21...) assembly 2 is housed.

[0032] [32] The cylinder assembly 2 of a carding machine is well known to those skilled in the art and thus only briefly described here. It has from the entrance towards the exit of the carding machine: a supply roller 20, a cylinder 21, a first rotating card cylinder 22 - usually called "front drive cylinder" (avant-train), a transfer cylinder 23 - usually called " Communicator"), a second carding cylinder 24 - commonly referred to as "big cylinder", cloth forming cylinders 25 and 26 (such as combing cylinder and condensing cylinder type) - each of which forms a carding machine outlet. In addition, a plurality of planetary combing groups 27 are installed on the periphery of the front drive drum 22 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com