Patents

Literature

50results about How to "Improve hemming efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

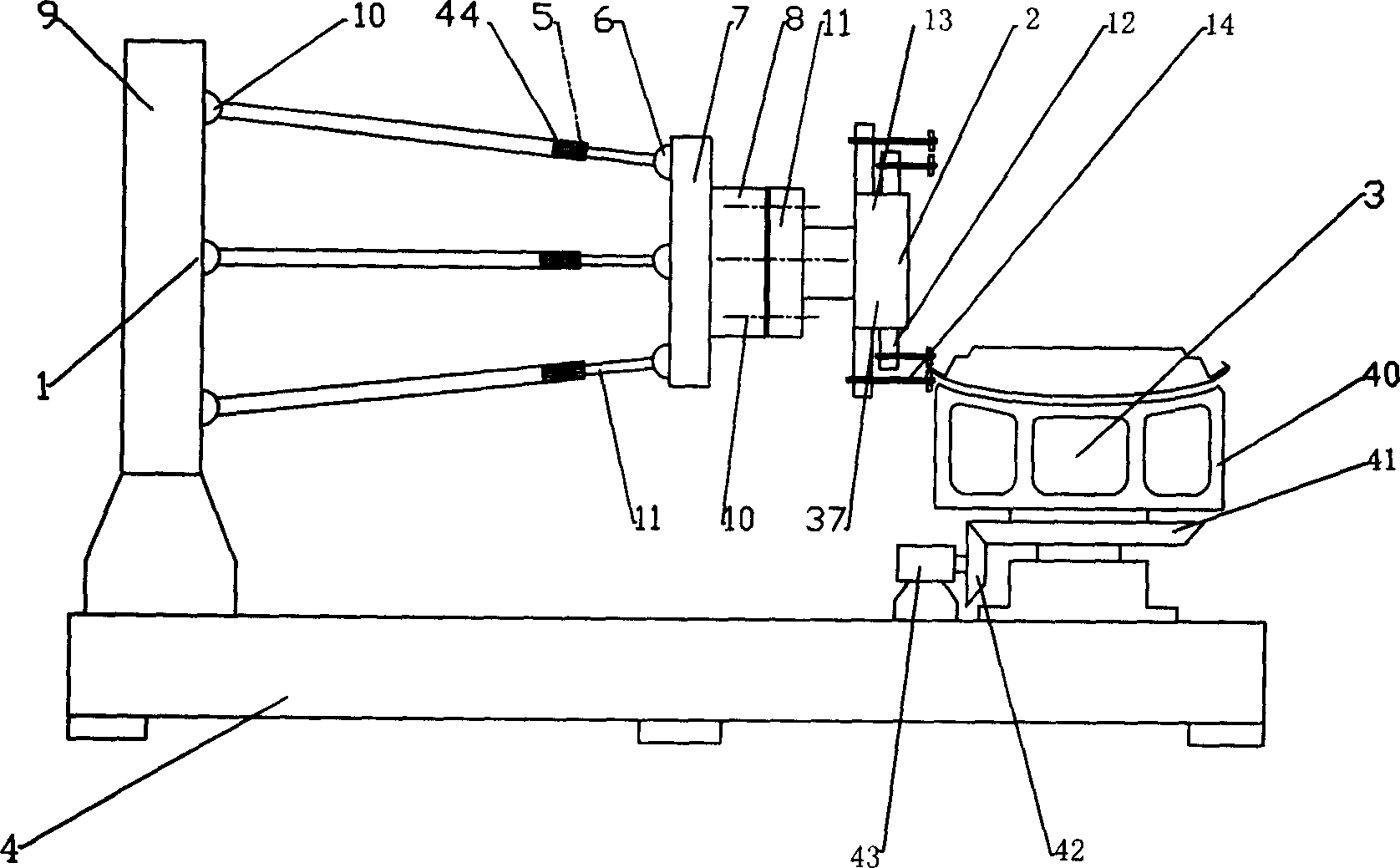

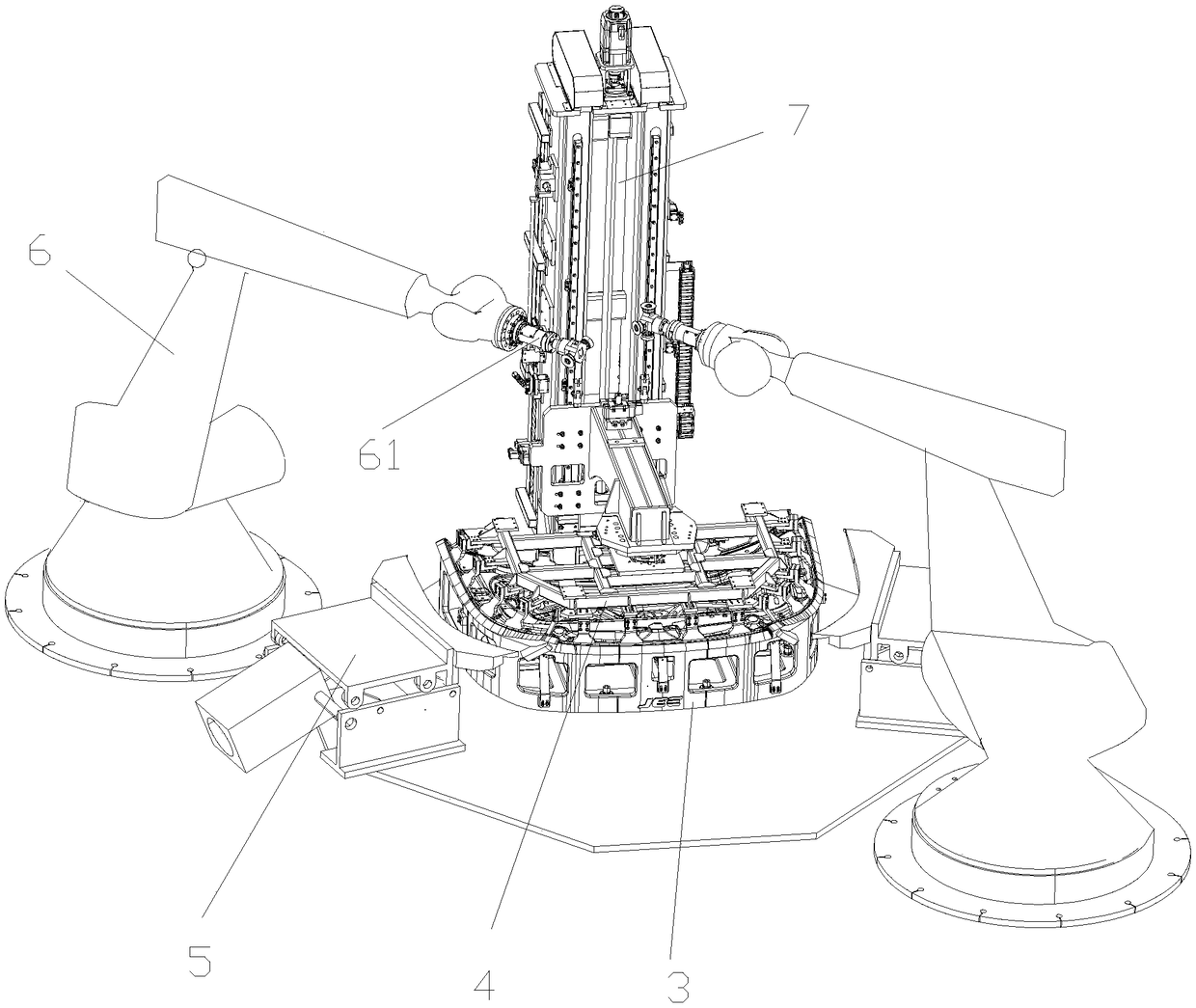

Parallel robot edge-coating system with a rotary table

InactiveCN1669694AHigh precisionTroubleshoot workspace issuesProgramme-controlled manipulatorLarge fixed membersCoating systemEngineering

This invention relates to parallel-type robot system for edge covering with rotating table, comprising six-degrees freedom parallel-type robot attached with rolling machine and driving it to move roller along edge direction; rolling machine equipped with work piece and rotating table preparing the other side of work piece to be ready-covered edge. The invention has the advantages of high accuracy to improve edge-covering efficiency and quality.

Owner:SHANGHAI JIAO TONG UNIV

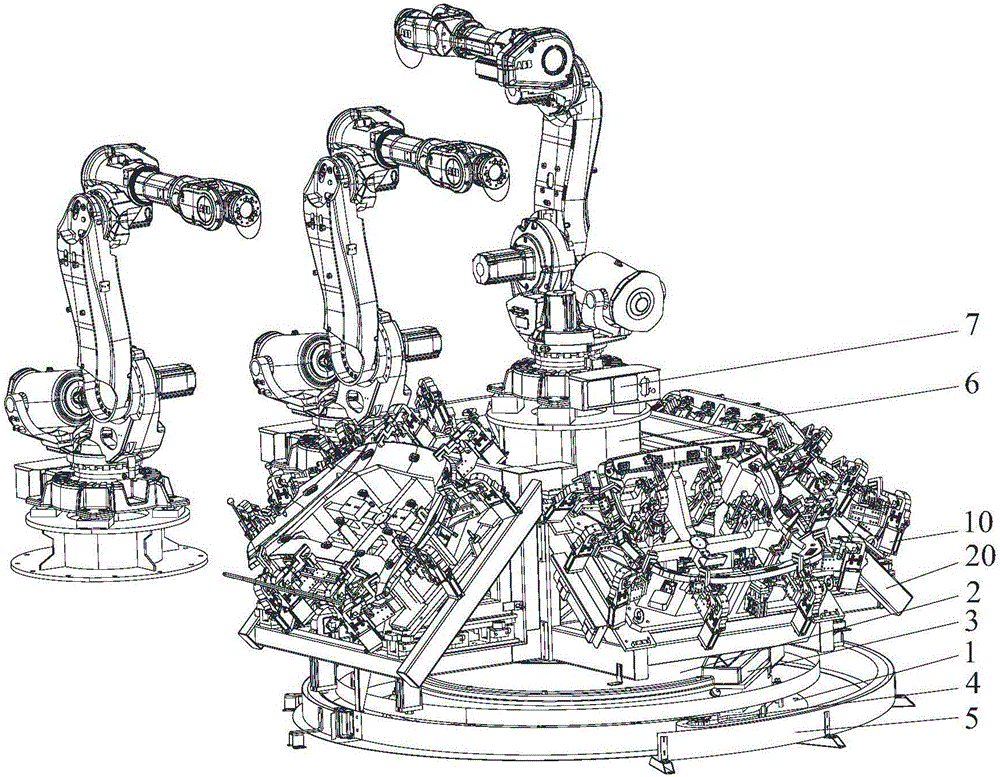

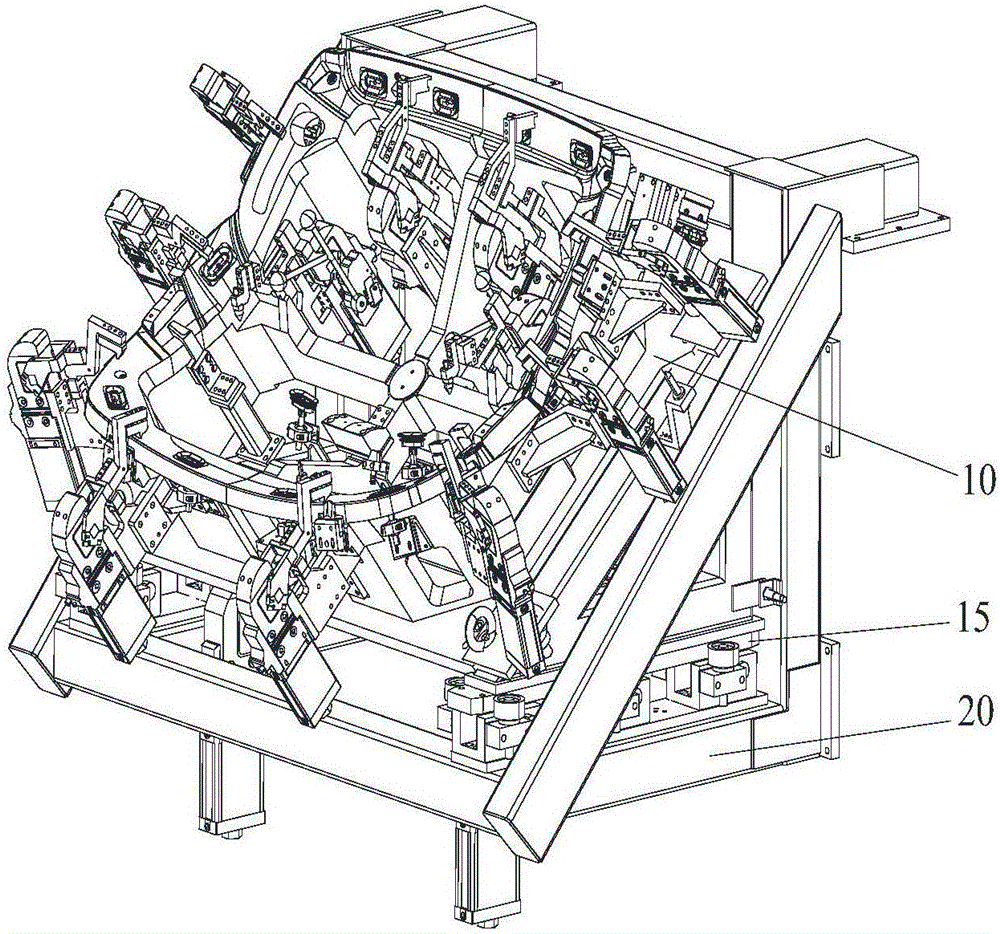

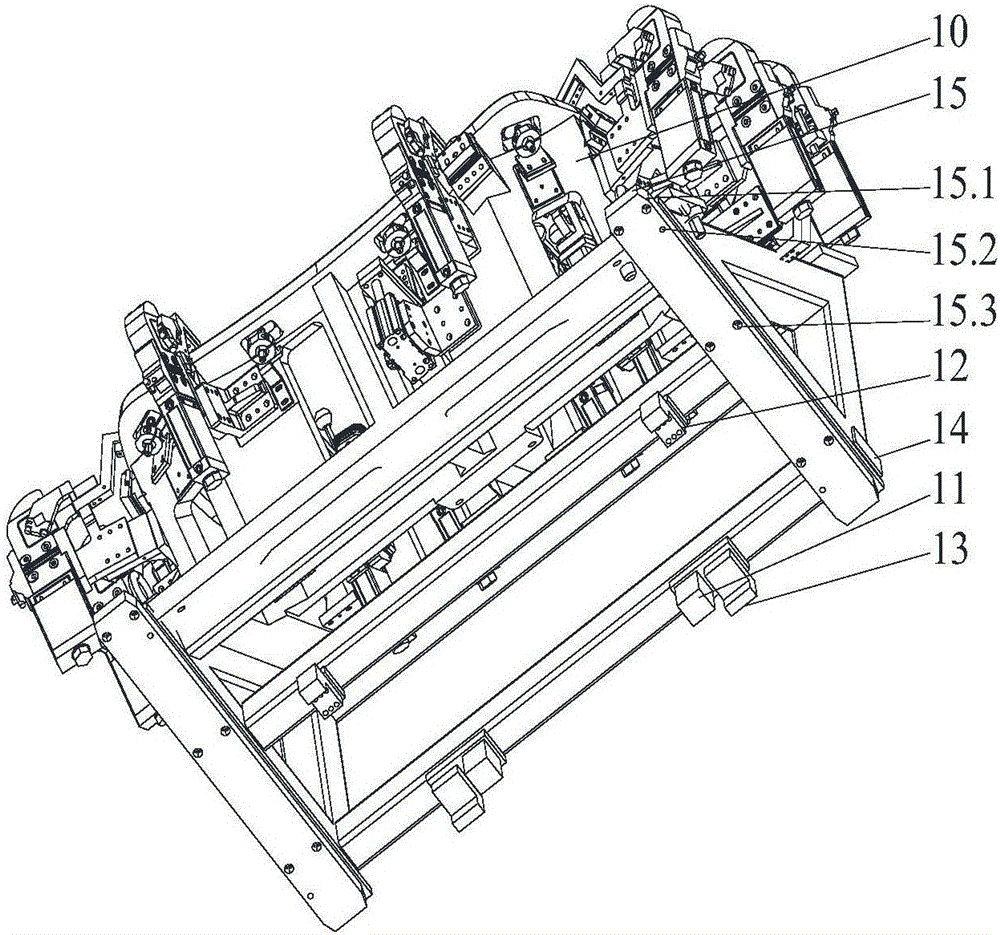

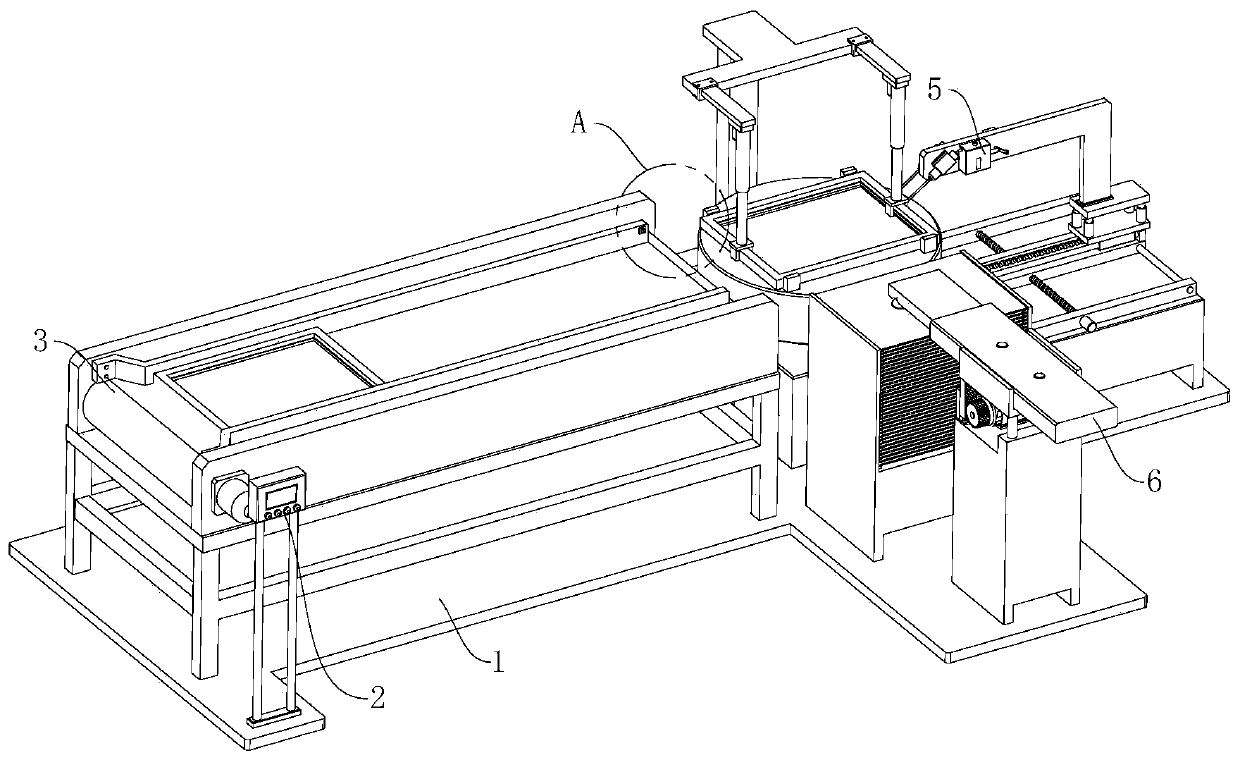

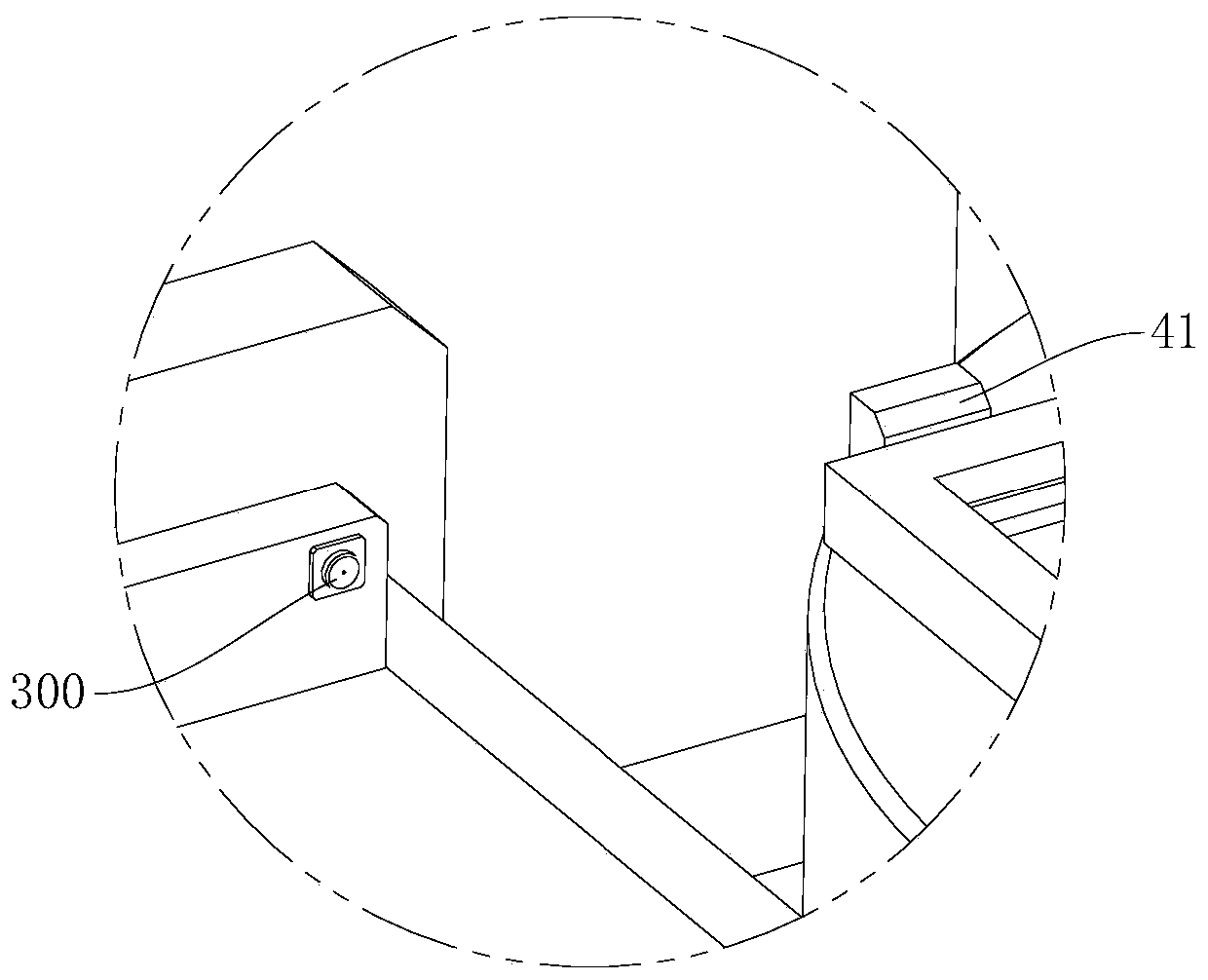

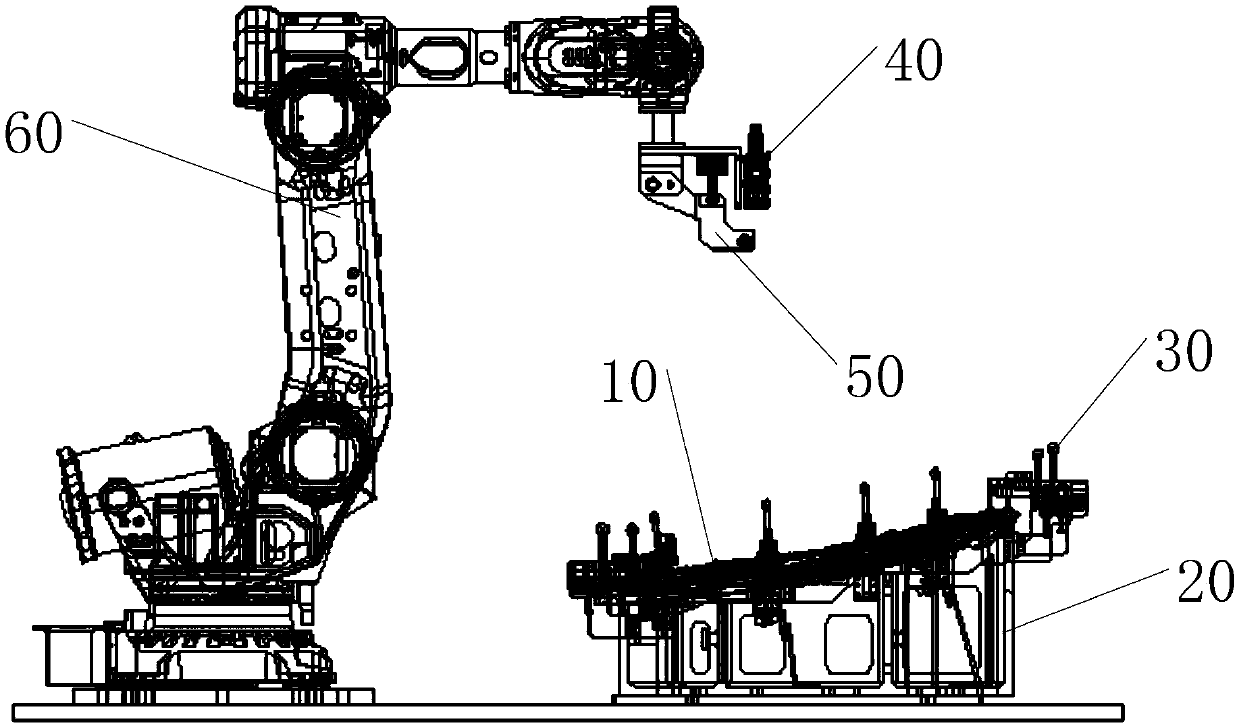

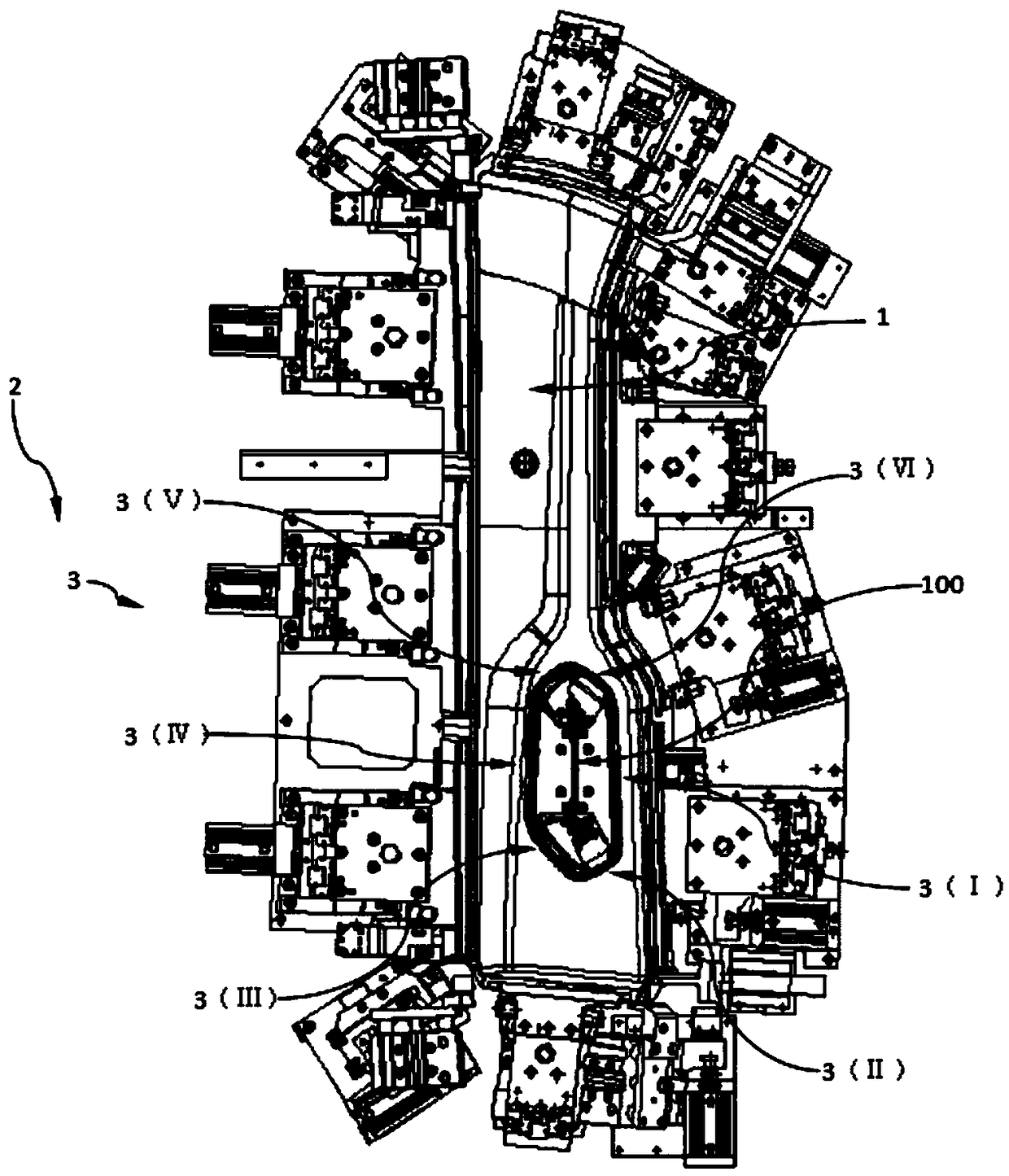

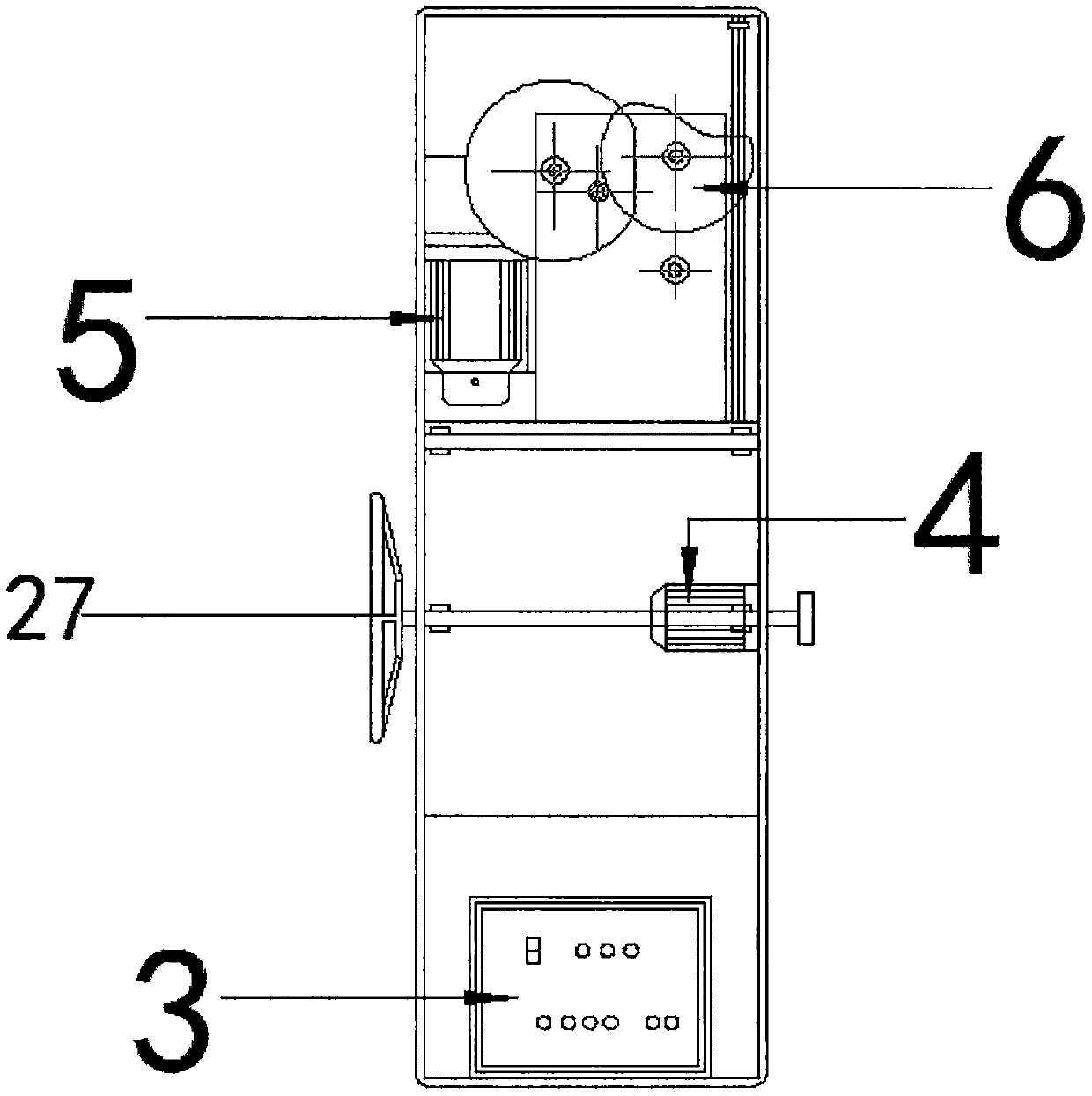

Efficient and flexible robot edge-rolling island for door panel

The invention discloses an efficient and flexible robot edge-rolling island for a door panel. The efficient and flexible robot edge-rolling island comprises a base and edge rolling robots. A rotary table and a driving motor are mounted on the base. The rotary table is provided with a plurality of mold jig assemblies which are rotatably and symmetrically arranged on the periphery of the rotary table. Each mold jig assembly comprises a mounting frame and a mold jig, wherein the mounting frame is fixedly connected to the rotary table, and the mold jig is connected with the mounting frame in a sliding fit mode. The efficient and flexible robot edge-rolling island is suitable for high-takt automatic line-mixed edge rolling of various vehicle models, and the mold jigs can be quickly replaced; operation is convenient, switching is rapid, and assembling and using are facilitated.

Owner:DONGFENG MOTOR CORP HUBEI

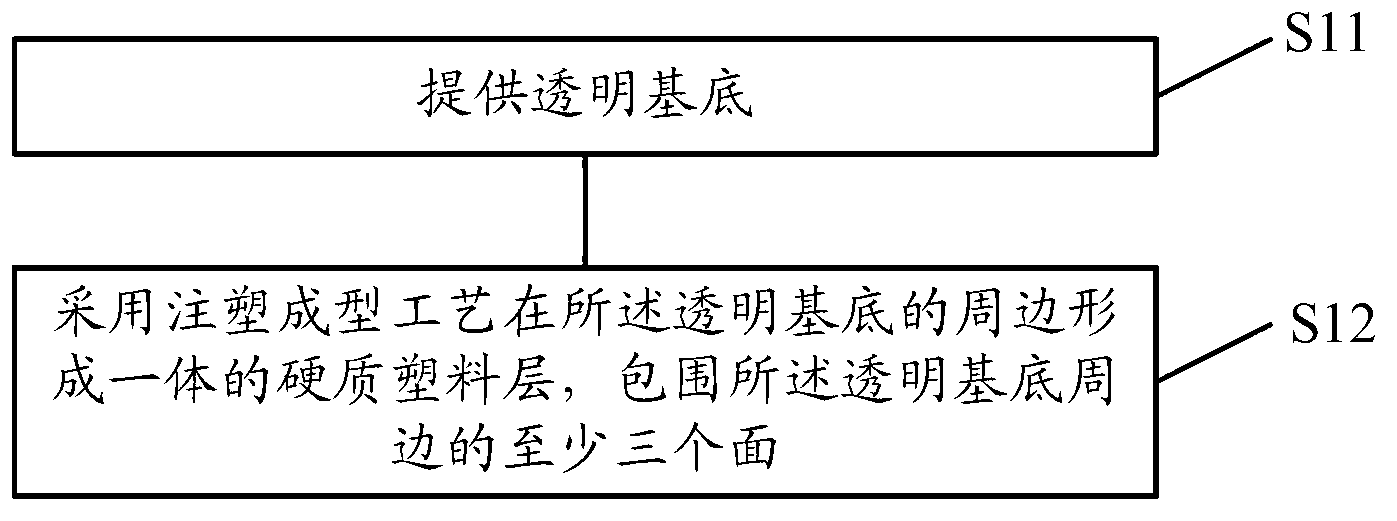

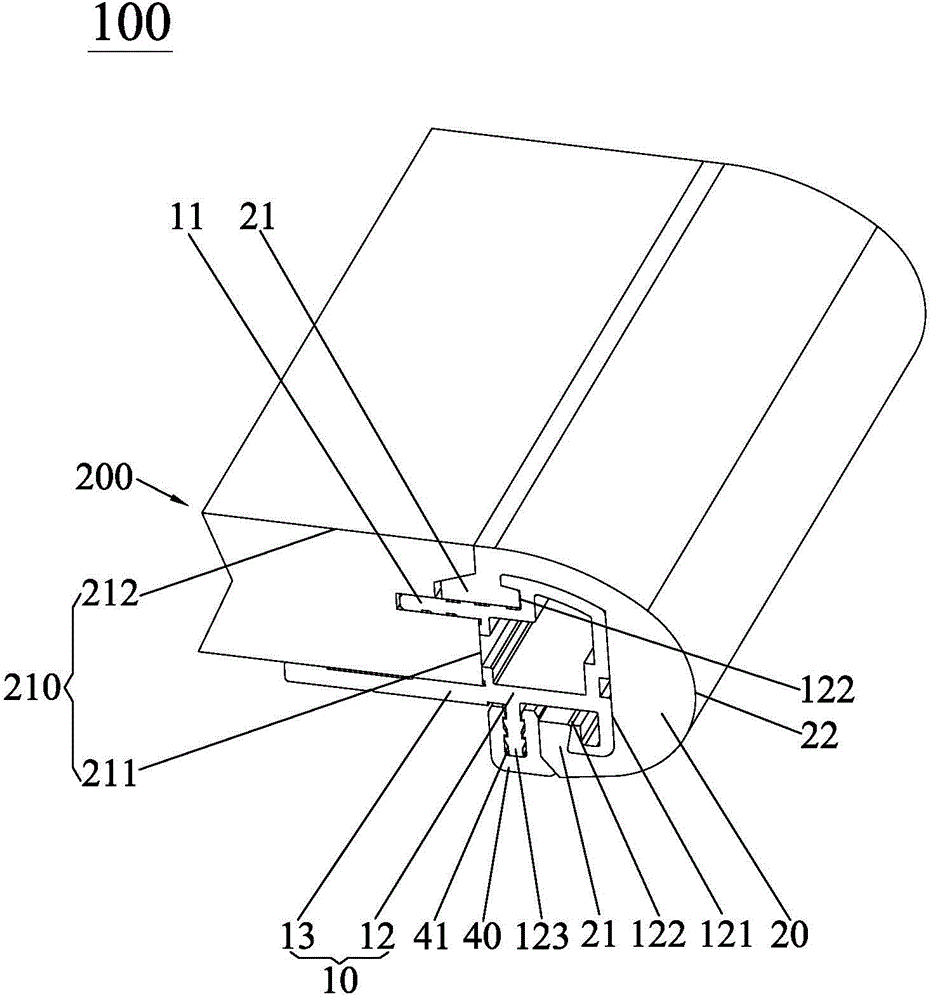

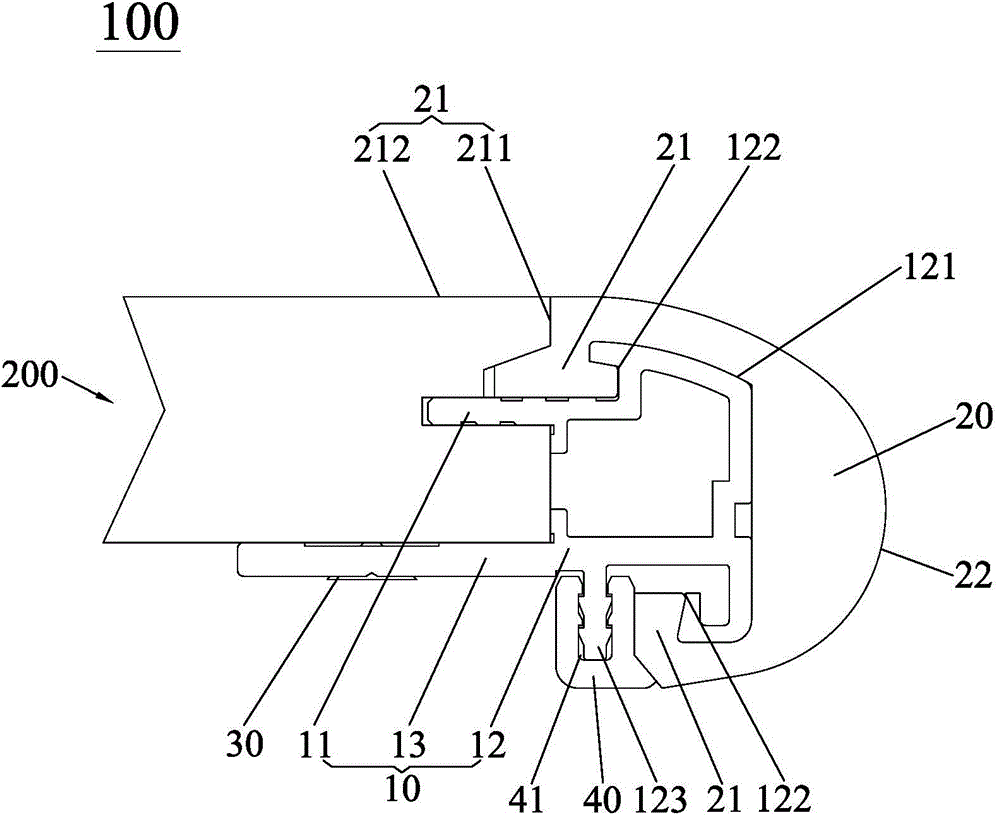

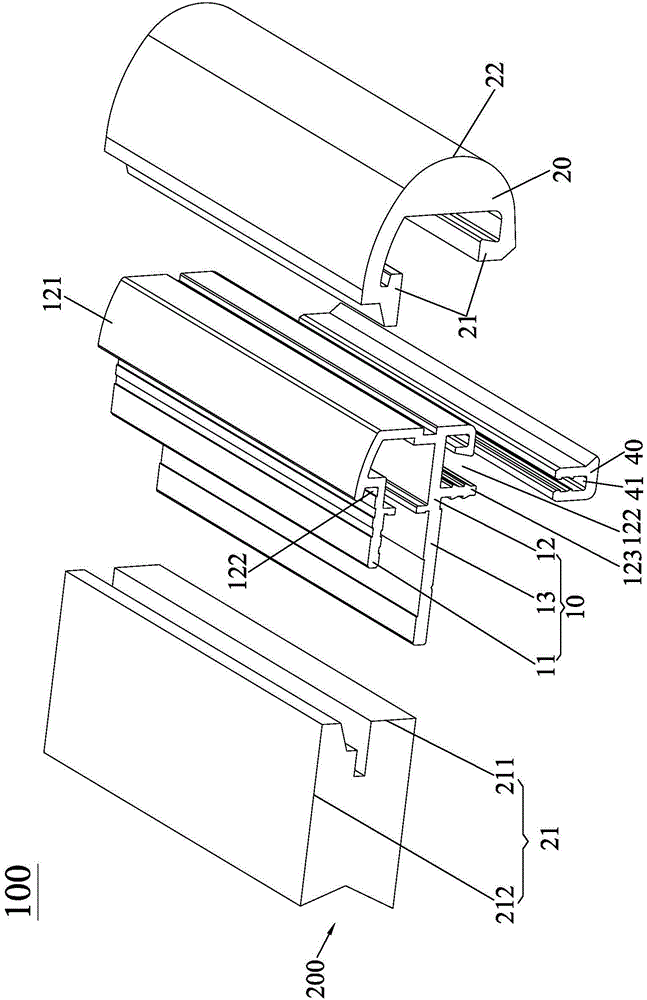

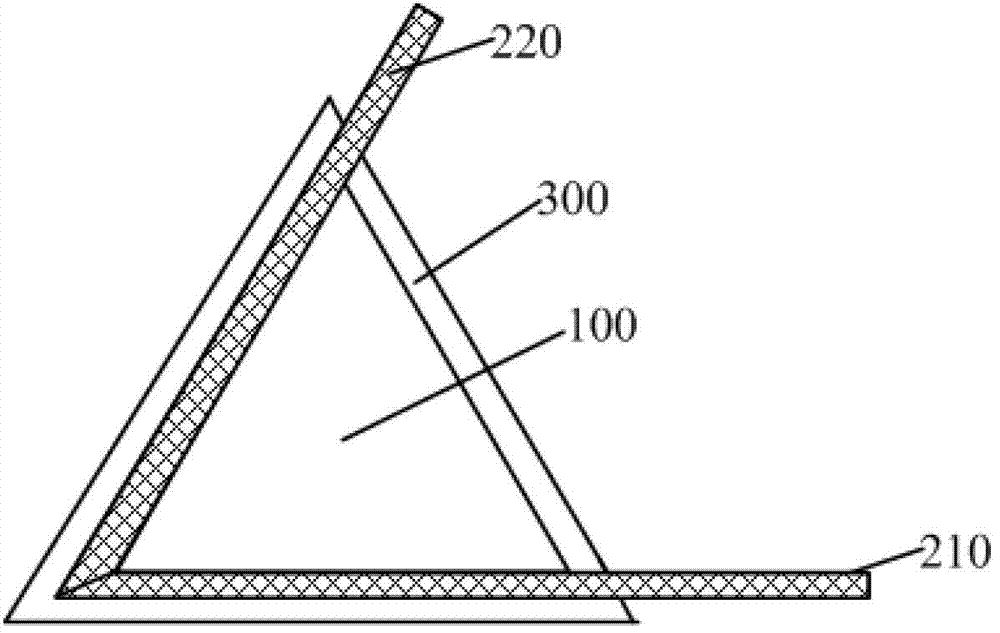

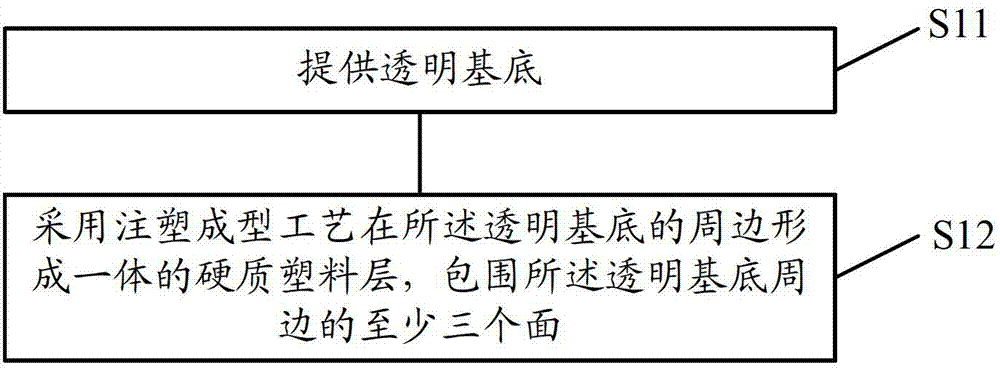

Car window assembly and binding method thereof

ActiveCN103057384AImprove adhesionImprove hemming efficiencyWindowsWindscreensEngineeringInjection moulding

Disclosed are a car window assembly and a binding method thereof. The car window assembly comprises a transparent base and an integrated hard plastic layer covering at least three peripheral sides of the transparent base. The binding method of the car window assembly includes: providing the transparent base; forming the integrated hard plastic layer on the periphery of the transparent base by injection molding to cover at least three peripheral sides of the transparent base. Bond between the plastic layer and glass in the car window assembly is higher, no dislocation occurs, binding efficiency is higher, and production cost is lowered.

Owner:SAINT-GOBAIN GLASS FRANCE

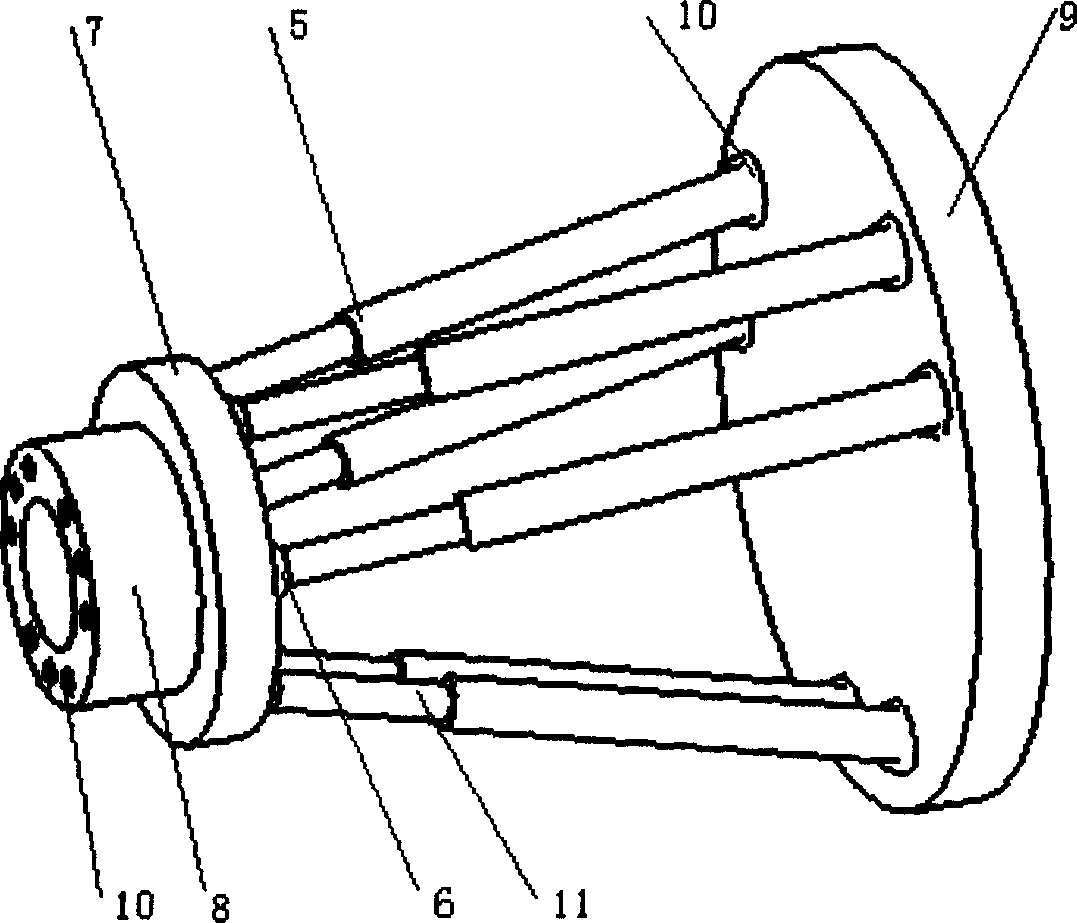

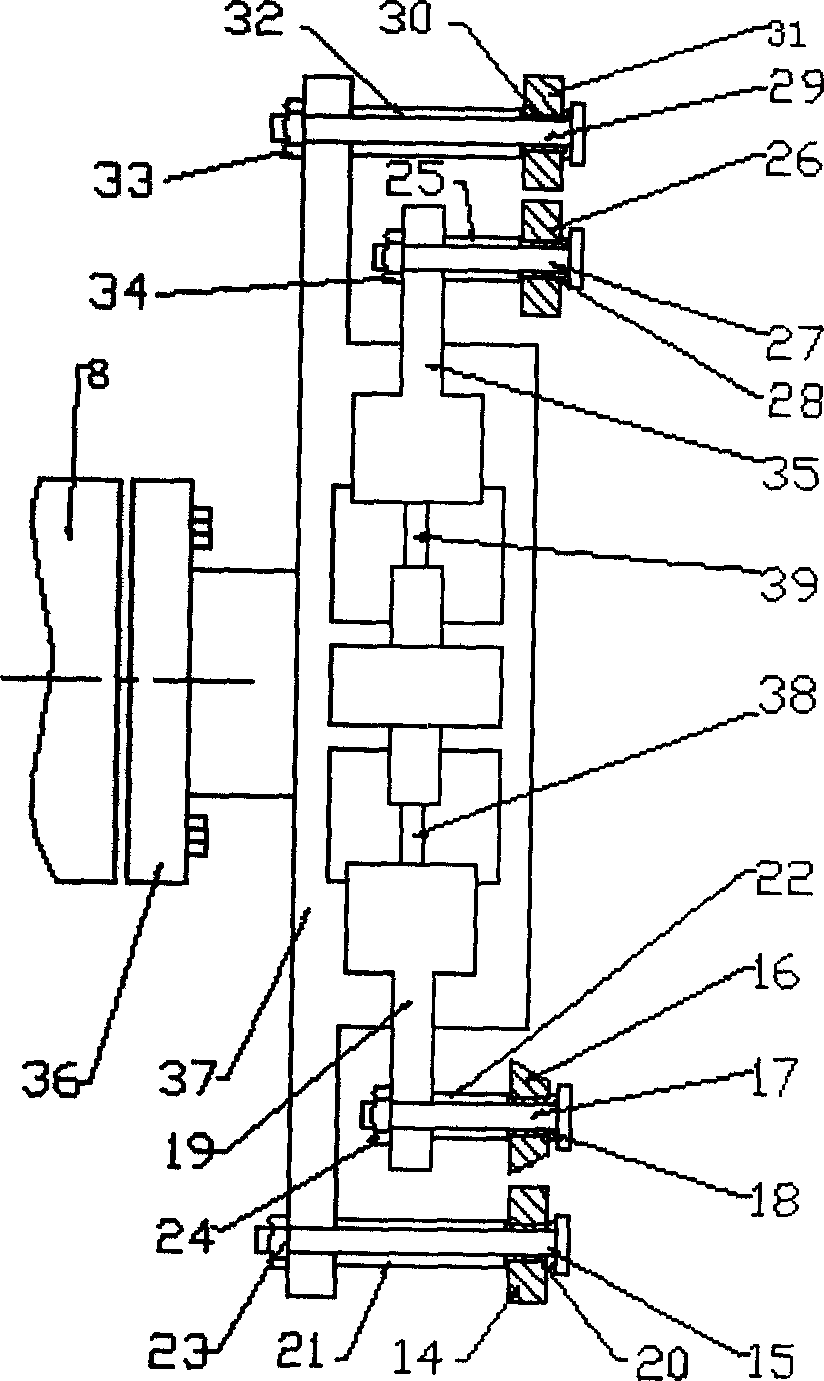

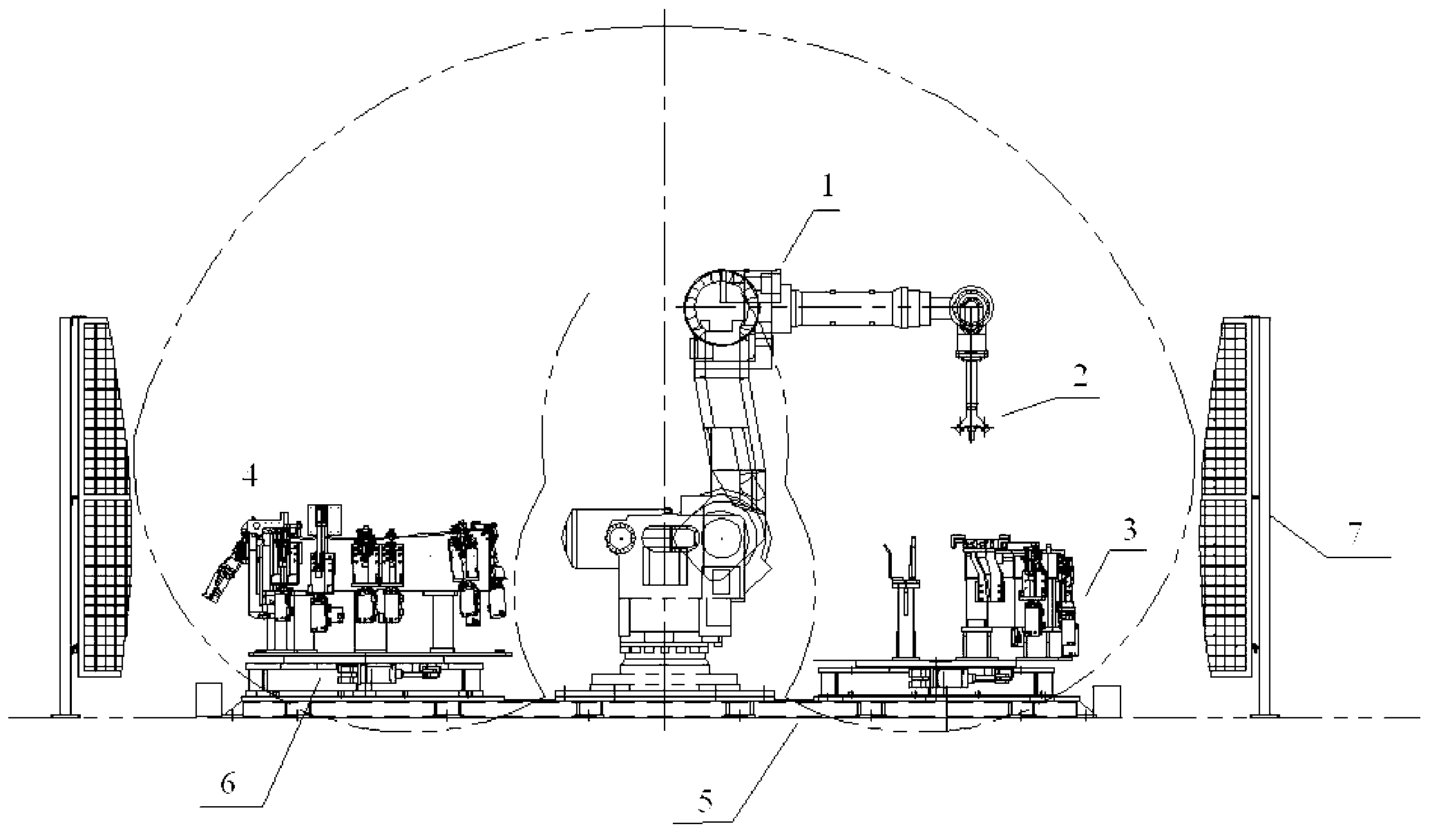

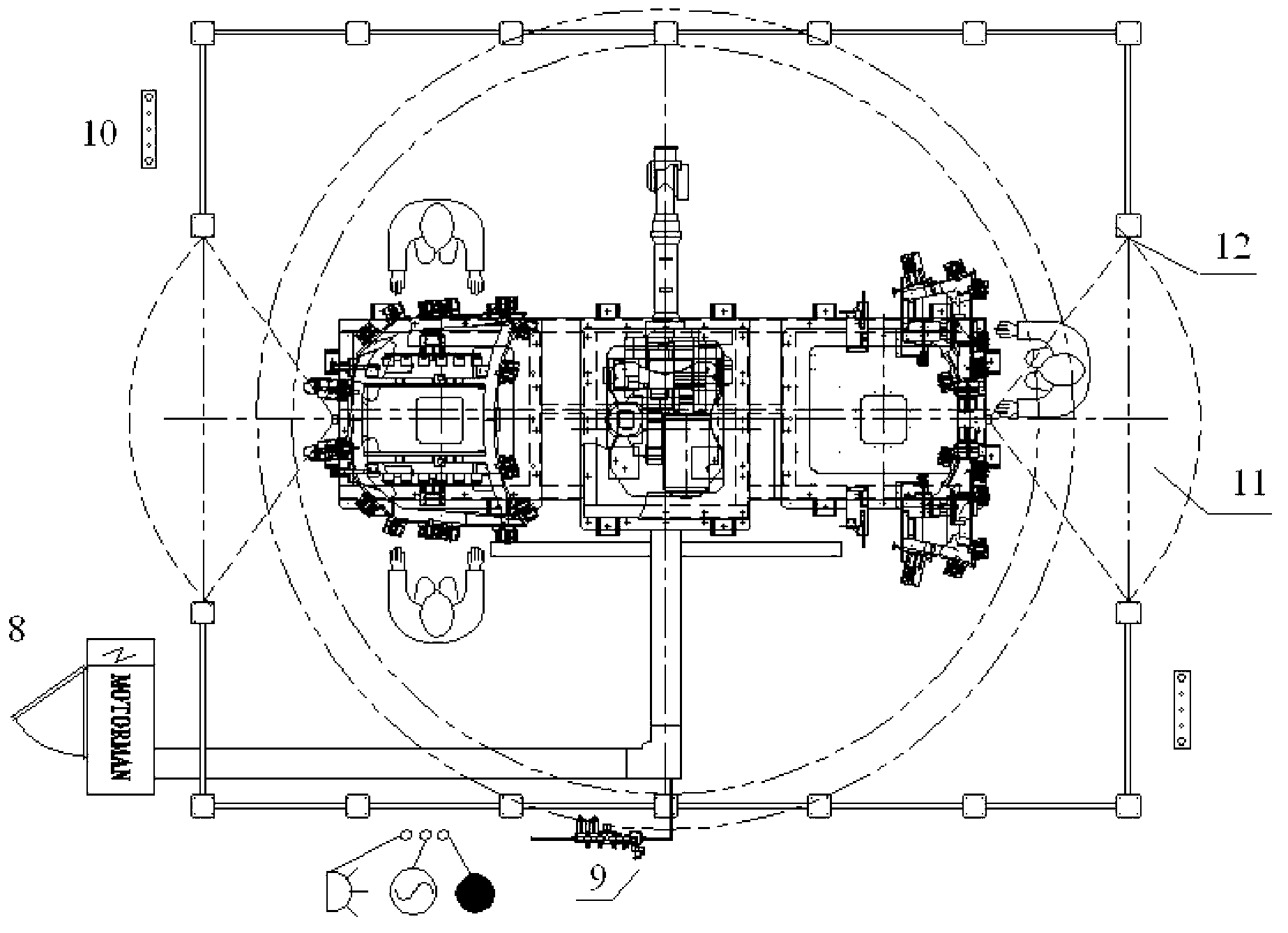

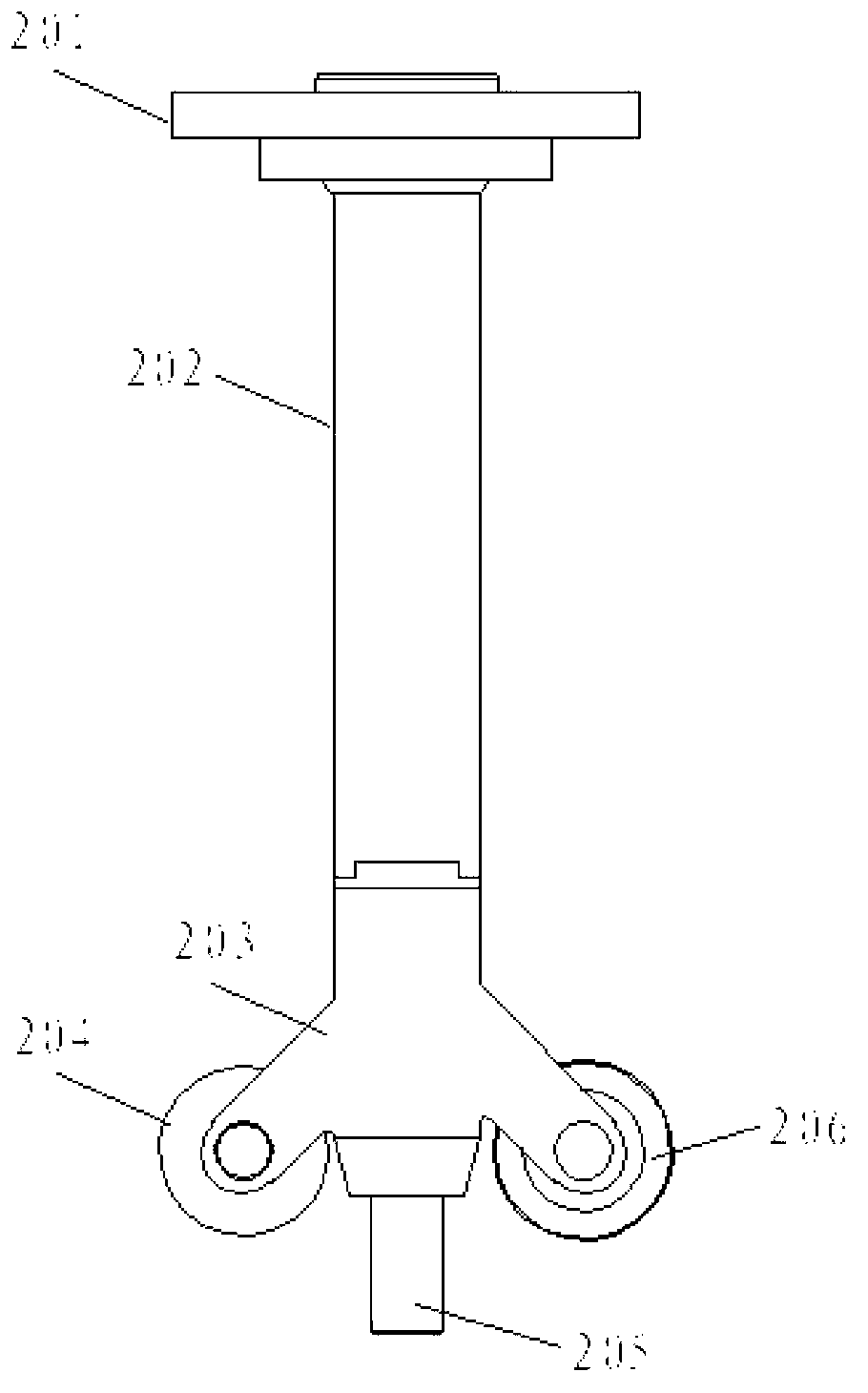

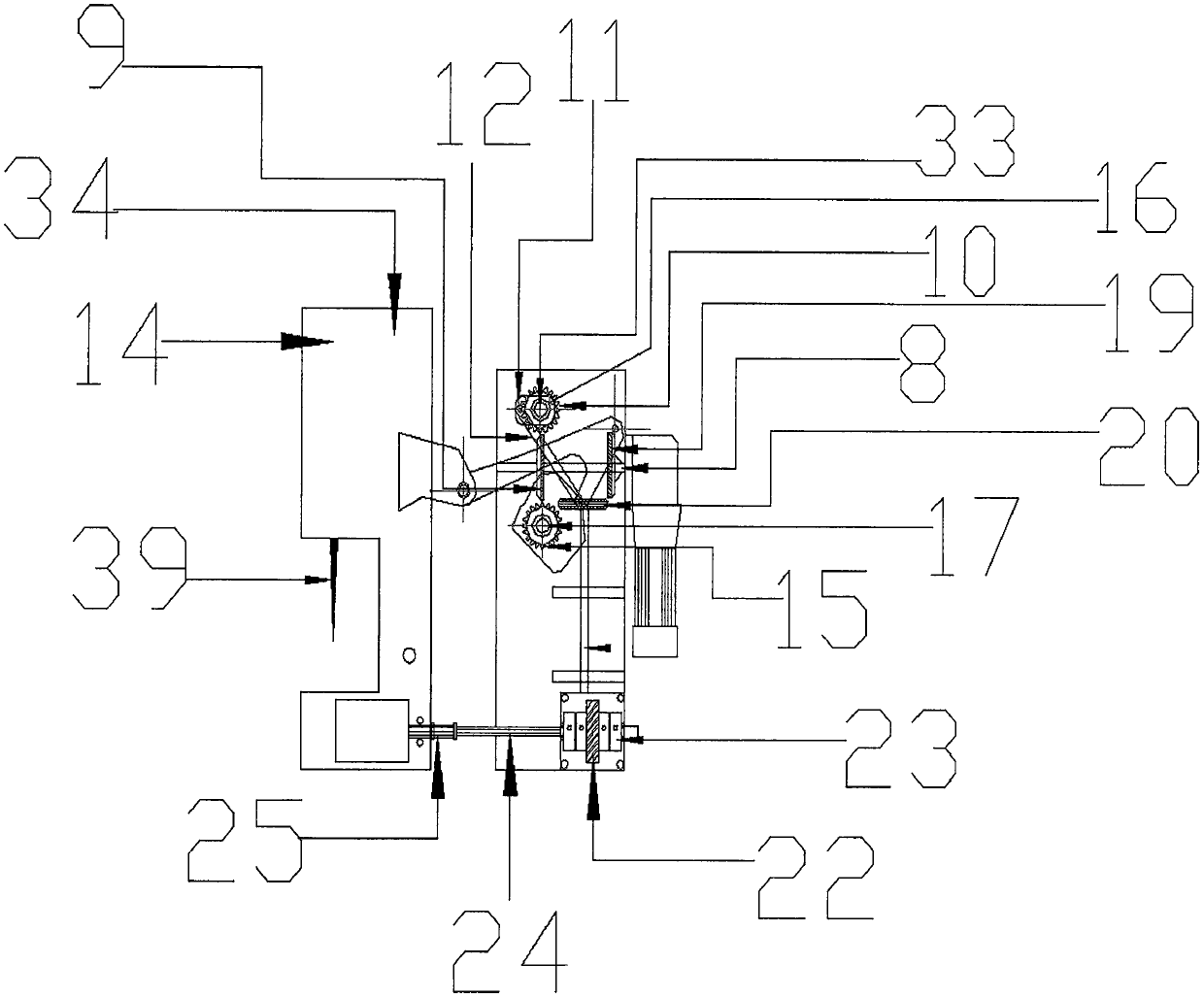

Intelligent rolled edge pressing system for robot and process method

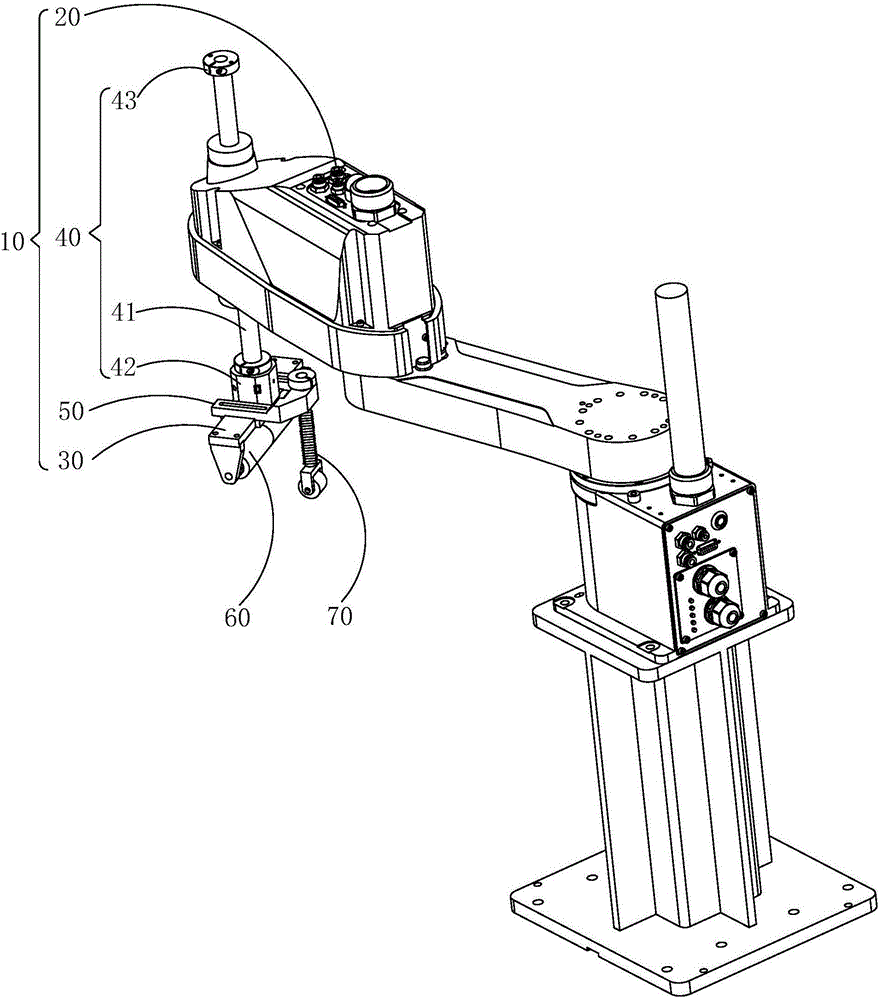

The invention discloses an intelligent rolled edge pressing system for a robot and a process method. The intelligent rolled edge pressing system for the robot comprises a six-degree-of-freedom parallel robot, a rolling mechanism, a rotary workbench, a pressing bottom die, automatic-control equipment and safe equipment, wherein the rolling mechanism consists of a flange plate, a connecting rod, a rolling head mounting block, a flat idler wheel, a straight idler wheel and a step wheel, and the flat idler wheel, the straight idler wheel and the step wheel are installed on the mounting block. The connection relationship of a main body is as follows: the six-degree-of-freedom parallel robot is connected by the flange plate and drives the rolling mechanism to enable a roller to move along the wrapping direction, a workpiece is arranged on the rotary workbench, and the other edge of the workpiece becomes an edge to be wrapped due to the rotation of the rotary workbench. The intelligent rolled edge pressing system for the robot, which is disclosed by the invention, has the advantage of high precision, and the wrapped edge forming quality is enabled to be good; a workbench has a bigger flexibility on workpieces of various shapes due to the controllability of the workbench; arrangement errors introduced in by multi-time clamping are avoided; and the processing time is shortened so as to improve the wrapping efficiency and the wrapping quality.

Owner:CHANGSHA CTR ROBOTICS

Automatic edge covering device for aluminum alloy doors and windows and using method

InactiveCN111389660AIncrease incomeImprove hemming efficiencyEngine sealsPretreated surfacesStructural engineeringMachining

The invention relates to the technical field of aluminum alloy machining devices, in particular to an automatic edge covering device for aluminum alloy doors and windows and a using method. The devicecomprises a base and further comprises a controller, a feeding mechanism, a machining table, a gluing mechanism and a mounting mechanism; the feeding mechanism comprises a conveyor and a clamping assembly; the gluing mechanism comprises a supporting table, a gluing assembly and a sliding assembly; the machining table is rotatably arranged between the conveyor and the supporting table to contain the aluminum alloy doors and windows; the mounting mechanism comprises a placing frame and a pressing assembly, and the pressing assembly is arranged beside the placing frame; and the conveyor, the clamping assembly, the gluing assembly, the sliding assembly and the pressing assembly are all electrically connected with the controller. According to the automatic edge covering device for the aluminumalloy doors and windows and the using method, edges of different thicknesses can be covered; and meanwhile, glass and aluminum alloy frames can be tightly assembled together, and the drying functionis achieved so that the next procedure treatment or application can be conveniently and rapidly carried out on the aluminum alloy doors and windows, and the edge covering efficiency is improved.

Owner:段锐东

Edge rolling process and device for aluminum alloy door cover with large opening angle

InactiveCN109454140AQuality assuranceReduce the number of hemming stepsMaterials scienceAluminium alloy

The present invention discloses an edge rolling process and an edge rolling device for an aluminum alloy door cover with a large opening angle; the edge rolling process comprises the following steps of: Step 1, feeding: placing plates on a forming die, and positioning and pressing the plates downward by an upper edge rolling gripping tool which moves downwards; Step 2, edge pre-wrapping: operatingan edge wrapping mechanism located around the forming die to conduct edge pre-wrapping of a part with the large opening angle of an outer plate edge; after the opening angle of the outer plate edge is less than 90 degrees, controlling the edge wrapping mechanism to leave the outer plate edge so as to complete edge pre-wrapping; and Step 3, edge rolling: operating an edge rolling robot located around the forming die; and conducting edge rolling to an entire edge of the outer plate through an edge rolling tool on the edge rolling robot before completely wrapping an edge of an inner plate with the edge of the outer plate. The edge rolling device comprises the forming die, the edge rolling gripping tool, the edge wrapping mechanism and the edge rolling robot. Compared with a prior art, the device and the method in present invention have the following advantages that: the number of edge rolling times is reduced, edge rolling cracks are eliminated, and the edge rolling efficiency is improved.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

Working method of aluminum alloy door-window automatic edge covering device

ActiveCN111389659AIncrease incomeImprove hemming efficiencyEngine sealsPretreated surfacesStructural engineeringMaterials science

The invention relates to the technical field of aluminum alloy processing equipment and specifically relates to a working method of an aluminum alloy door-window automatic edge covering device. The device comprises a base and also comprises a controller, a loading mechanism, a processing table, a gluing mechanism and an installation mechanism, wherein the loading mechanism comprises a conveying machine and a clamping assembly; the gluing mechanism comprises a supporting table, a glue dispensing assembly and a slide assembly; the processing table is disposed between the conveying machine and the supporting table in a rotatable manner to store an aluminum alloy door and an aluminum alloy window; the installation mechanism comprises a placement frame and a pressing assembly; the pressing assembly is disposed by the side of the placement frame; and the conveying machine, the clamping assembly, the glue dispensing assembly, the slide assembly and the pressing assembly are electrically connected to the controller. The aluminum alloy door-window automatic edge covering device and a use method disclosed by the invention have the beneficial effects that different thicknesses of edge covering can be realized; glass can be closely assembled with an aluminum alloy frame; a drying function is provided, so processing or application of a next process can be conducted rapidly; and efficiency of edge covering is increased.

Owner:BINZHOU YUYANG ALUMINUM IND

Edge wrapping mechanism for furniture table

The invention discloses an edge wrapping mechanism for a furniture table. The edge wrapping mechanism is suitable for edge wrapping on the table edge of the furniture table. The edge wrapping mechanism for the furniture table comprises a framework and a flexible edge wrapping block. The framework comprises a mounting support and an embedding support connected with the mounting support. The mounting support is arranged along the table edge and mounted on the furniture table. The embedding support is arranged along the table edge. The edge wrapping block is detachably connected to the embedding support in a sleeved mode, and blocks the table edge. On one hand, the edge wrapping processing rate of the furniture table can be increased, and the overall cost of the furniture table can be lowered; on the other hand, a user is protected against injury when colliding with the table edge of the furniture table. More importantly, the edge wrapping mechanism for the furniture table can reduce the quality requirements for boards of the furniture table and improve the quality and grade of the furniture table.

Owner:照彰实业(东莞)有限公司

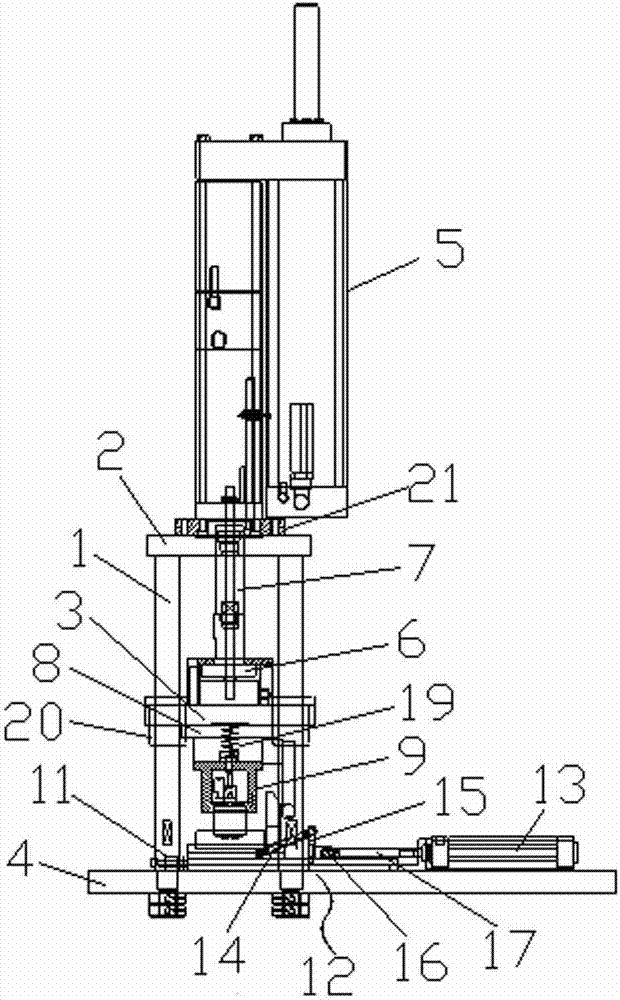

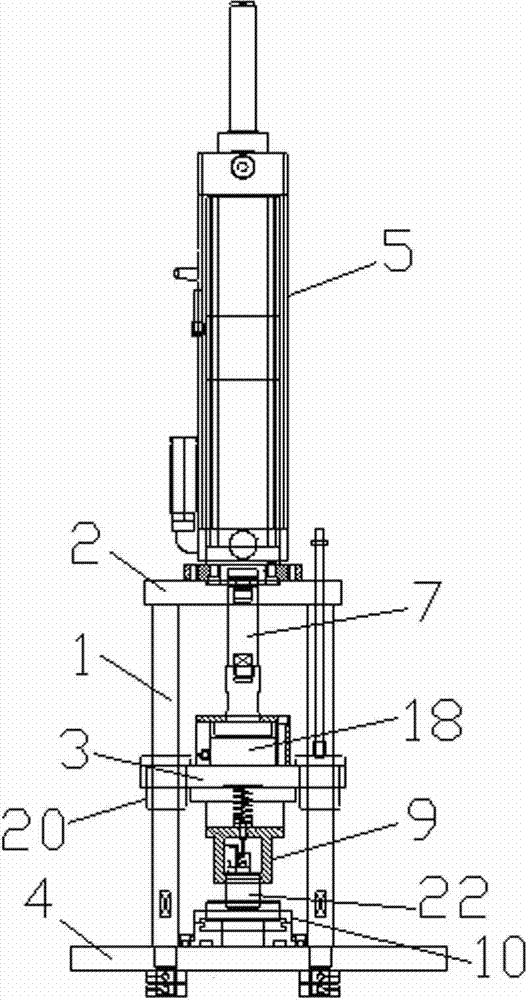

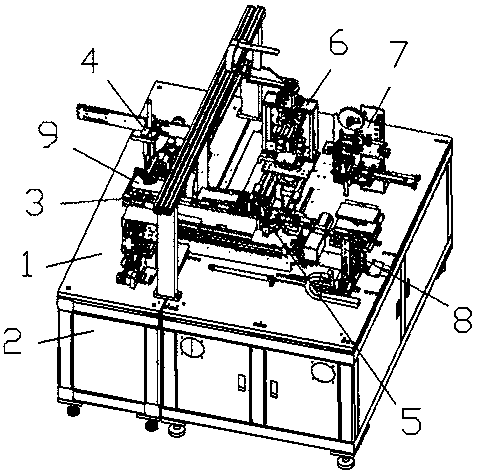

Edge wrapping device for electromagnetic switches

ActiveCN102779670AReduce labor intensityReduce manufacturing costElectric switchesRelaysOptical axisEngineering

The invention relates to an edge wrapping device for electromagnetic switches. The edge wrapping device comprises an optical axis guide rod, a top plate, a pressure plate and a bottom plate, wherein the top plate, the pressure plate and the bottom plate are mounted on the optical axis guide rod. A pneumatic-hydraulic pressurizing cylinder is arranged on the top plate, a first floating connector is connected to the upper end of the pressure plate through a first floating connector seat and connected with the pneumatic-hydraulic pressurizing cylinder, a mould base and an edge wrapping mould are mounted at the lower end of the pressure plate, a sliding table and a limiting block are arranged on the bottom plate, and the sliding table is connected with an air cylinder through a tension spring component. The edge wrapping device is simple in structure, convenient and practical, labor intensity is greatly relieved for operators, edge wrapping quality and efficiency are high, misoperation is avoided, and production cost is reduced for enterprises.

Owner:WUJIANG JINLAN MACHINERY MFG

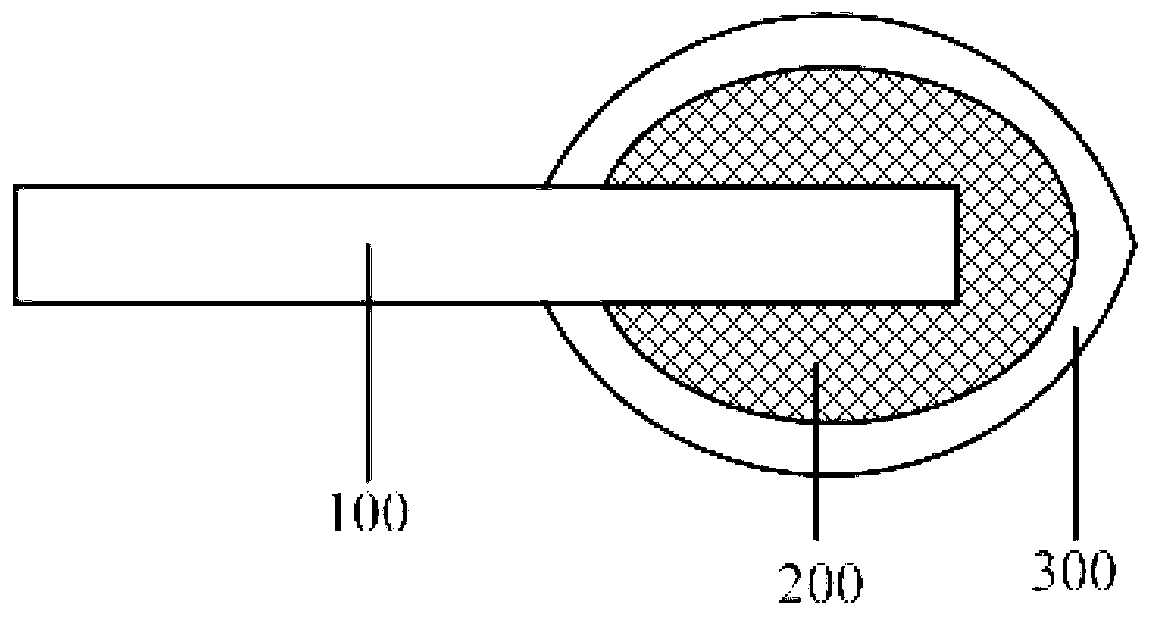

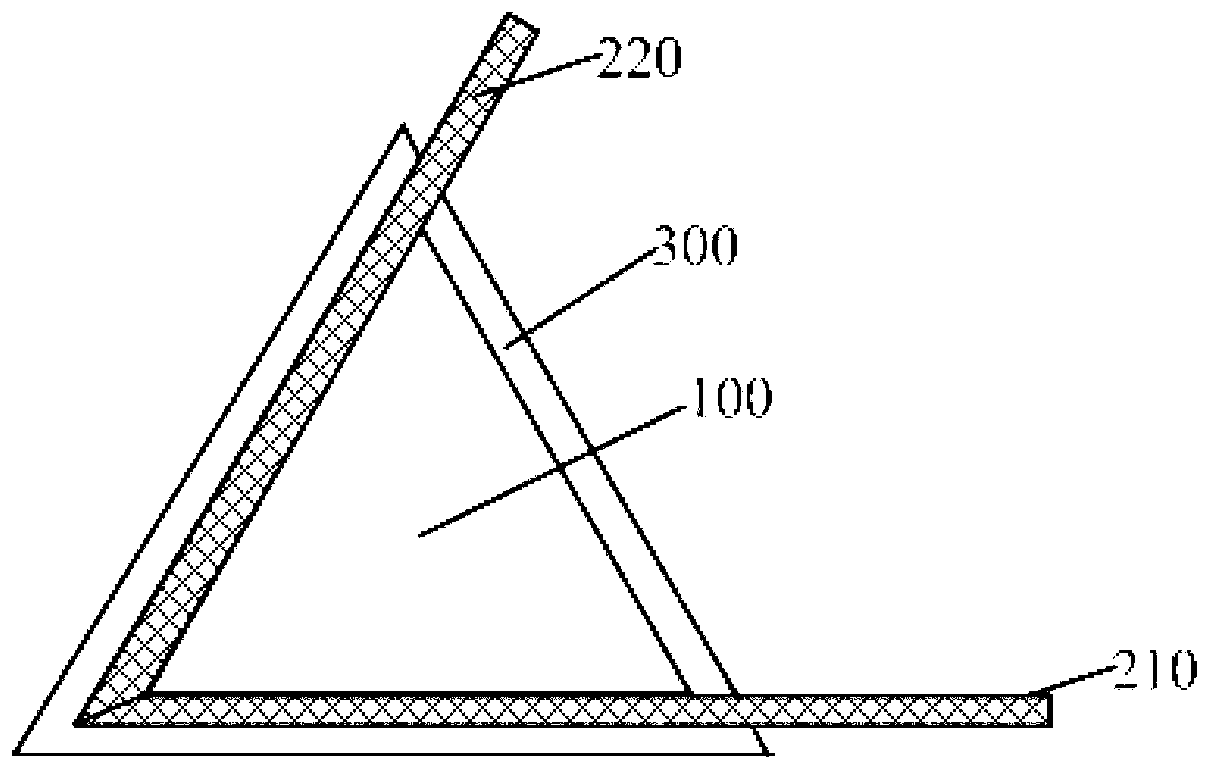

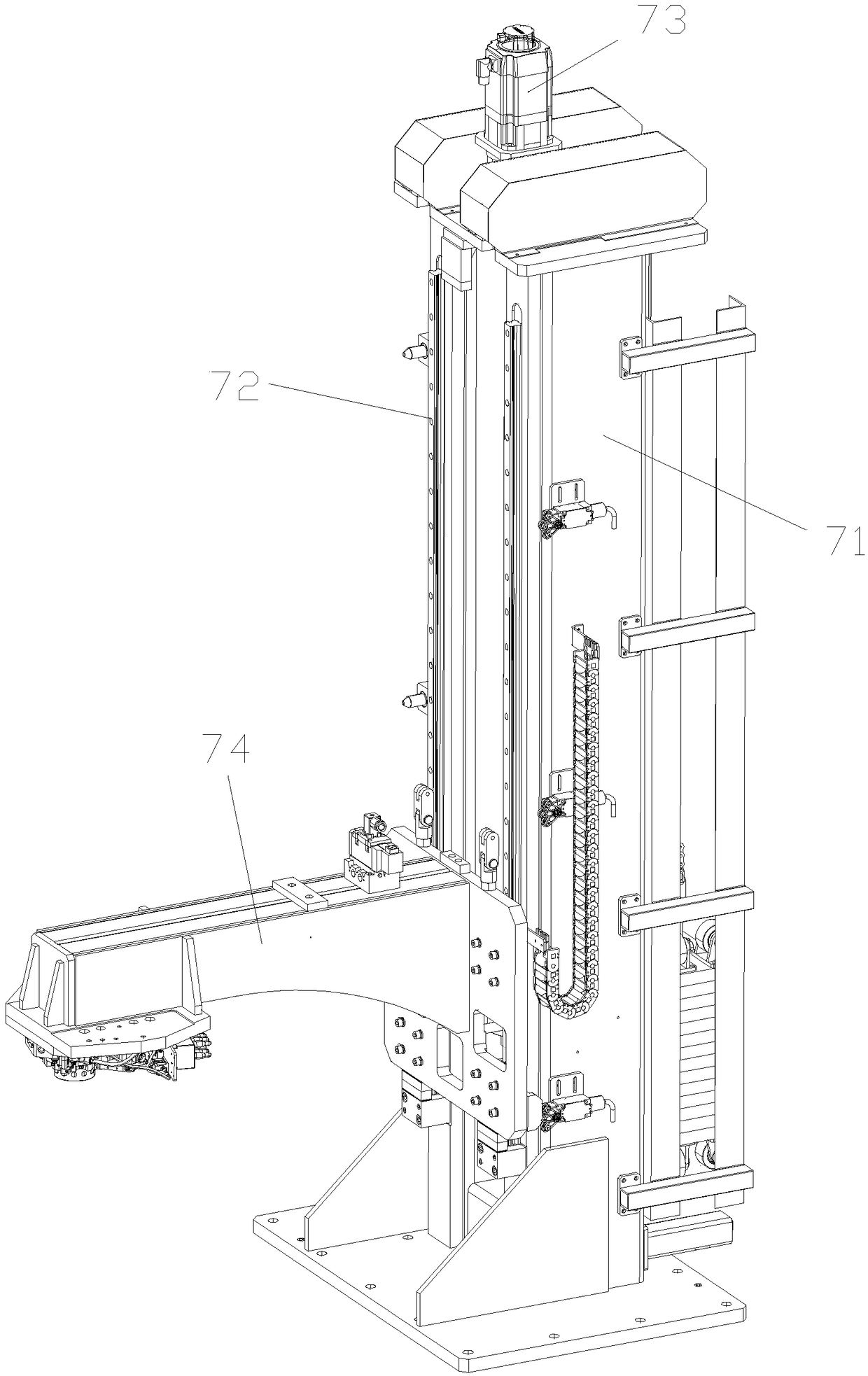

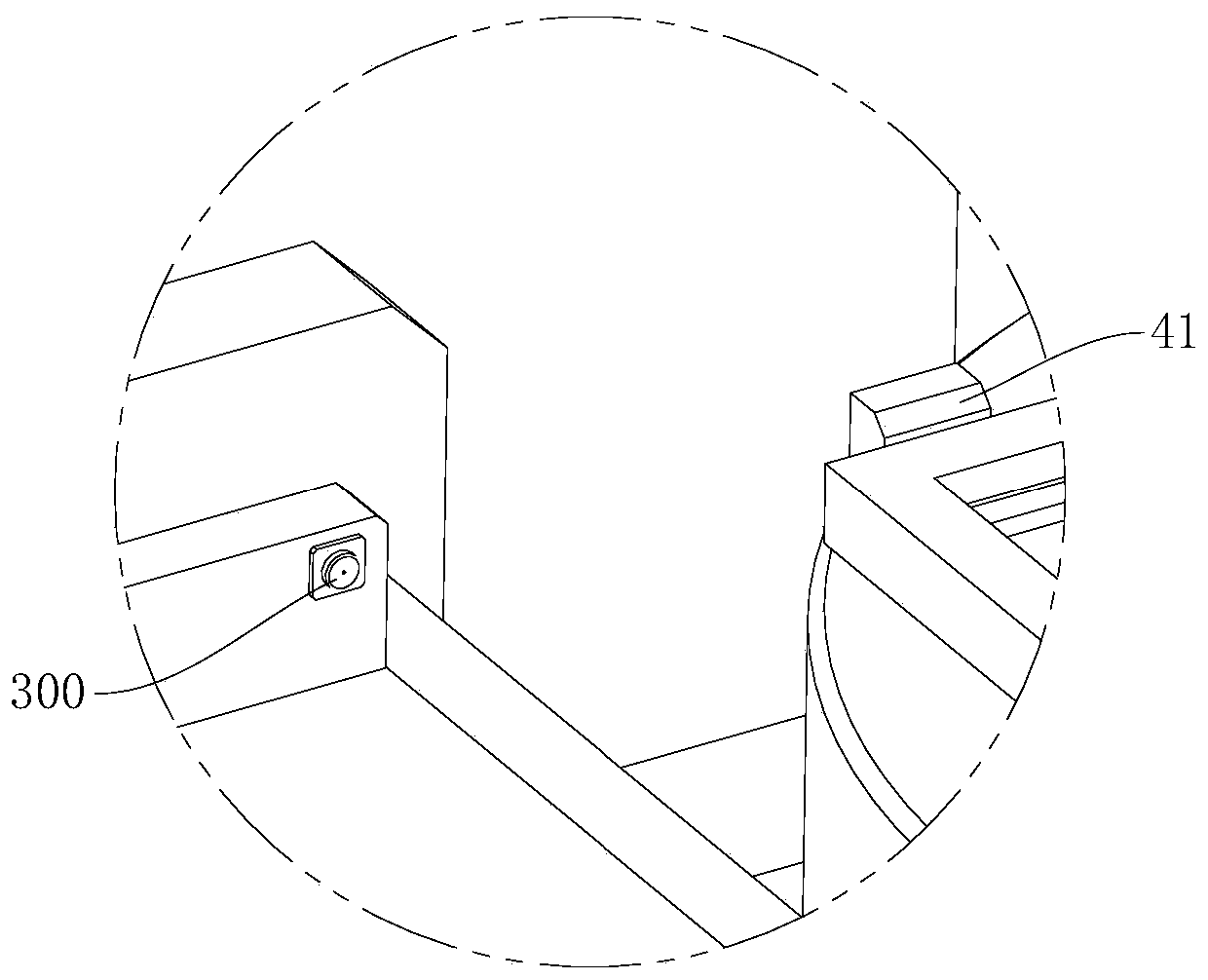

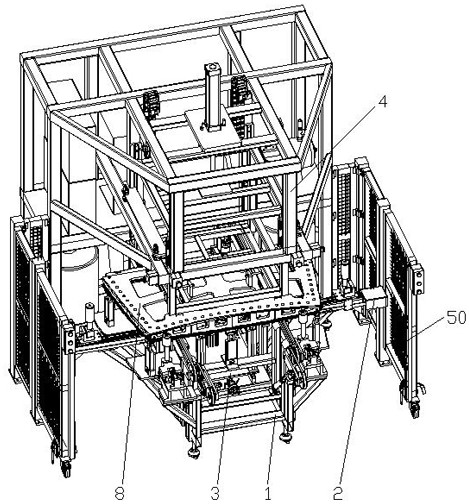

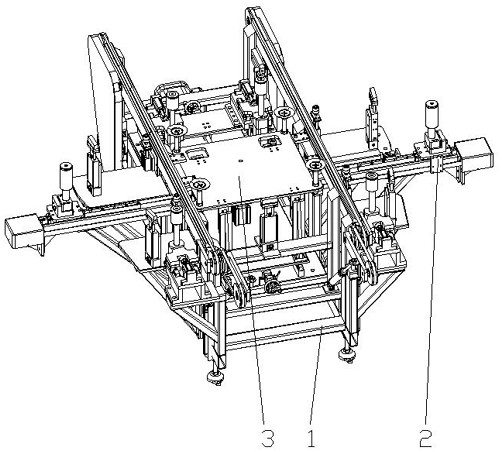

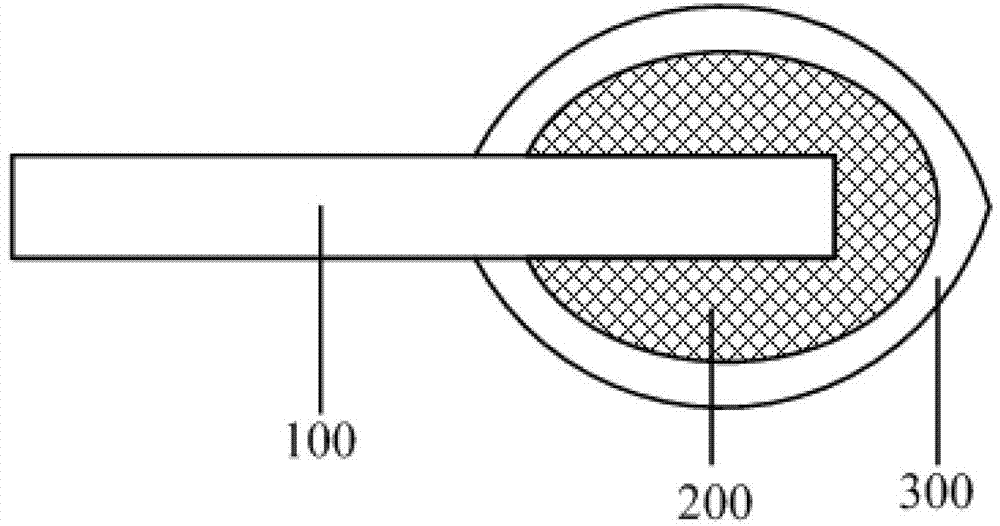

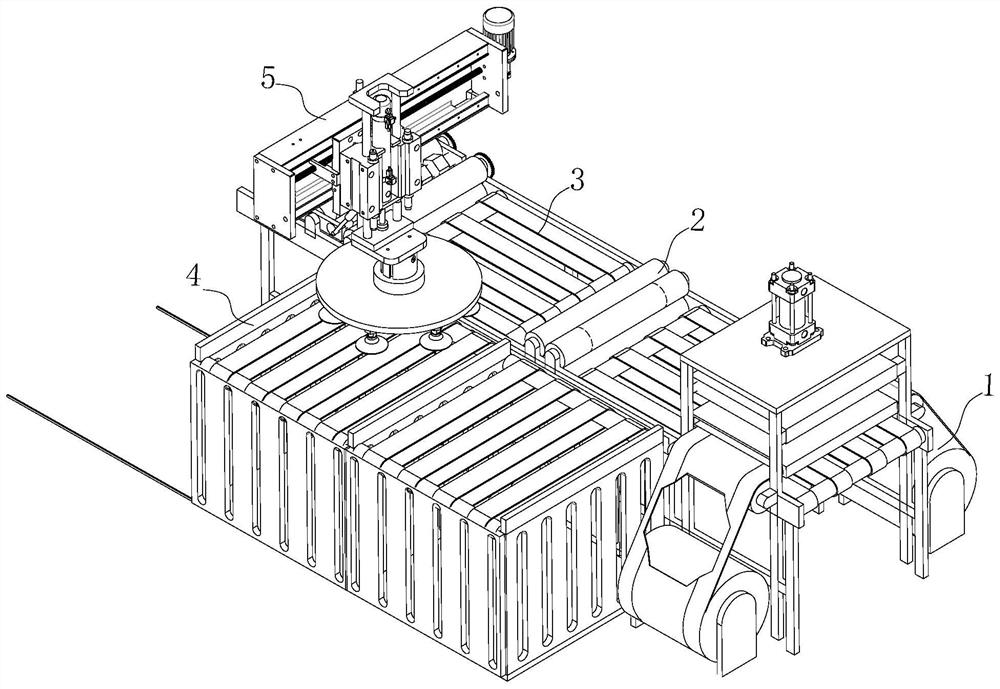

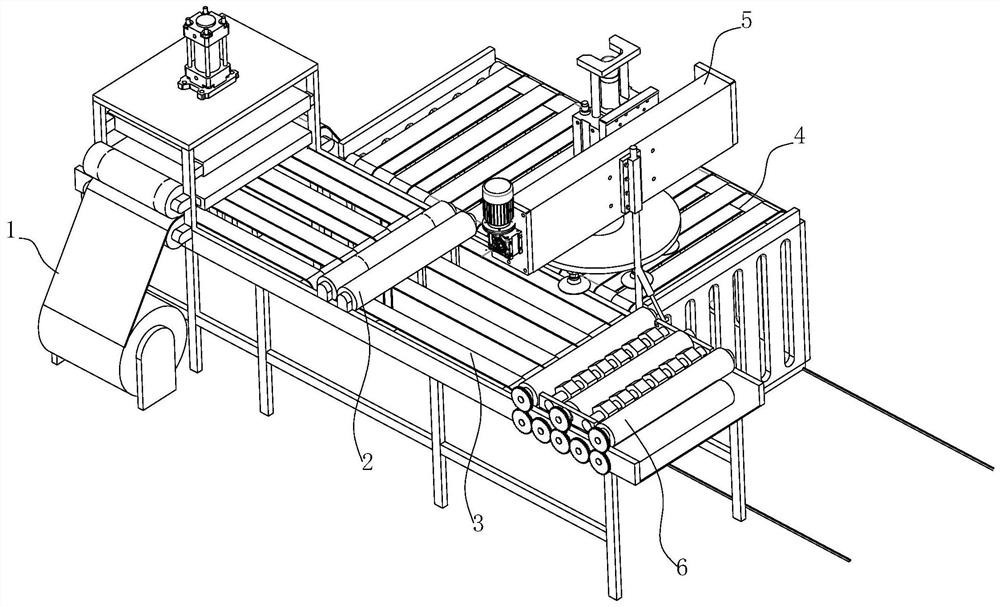

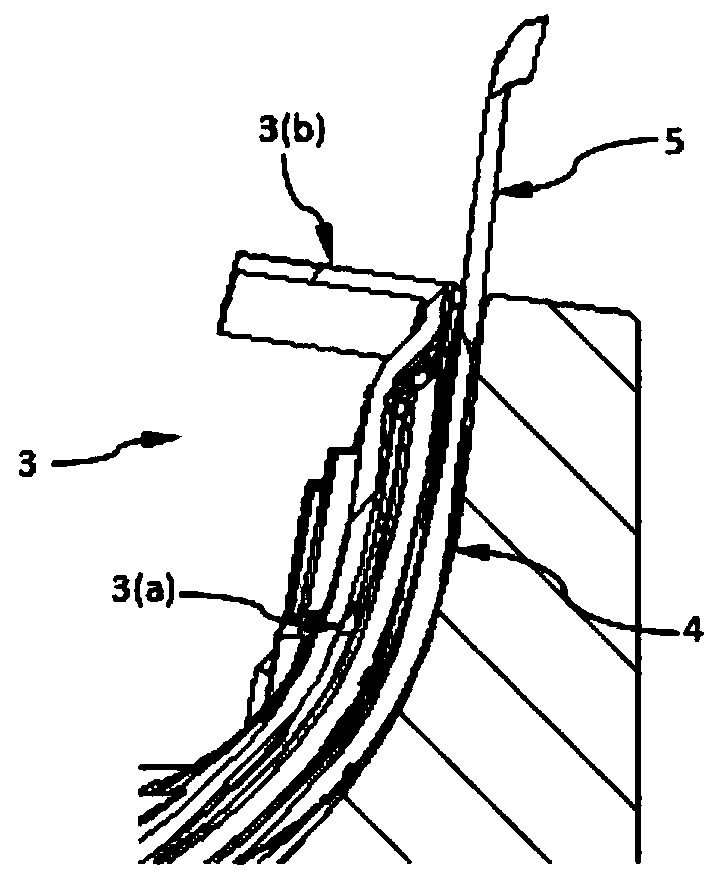

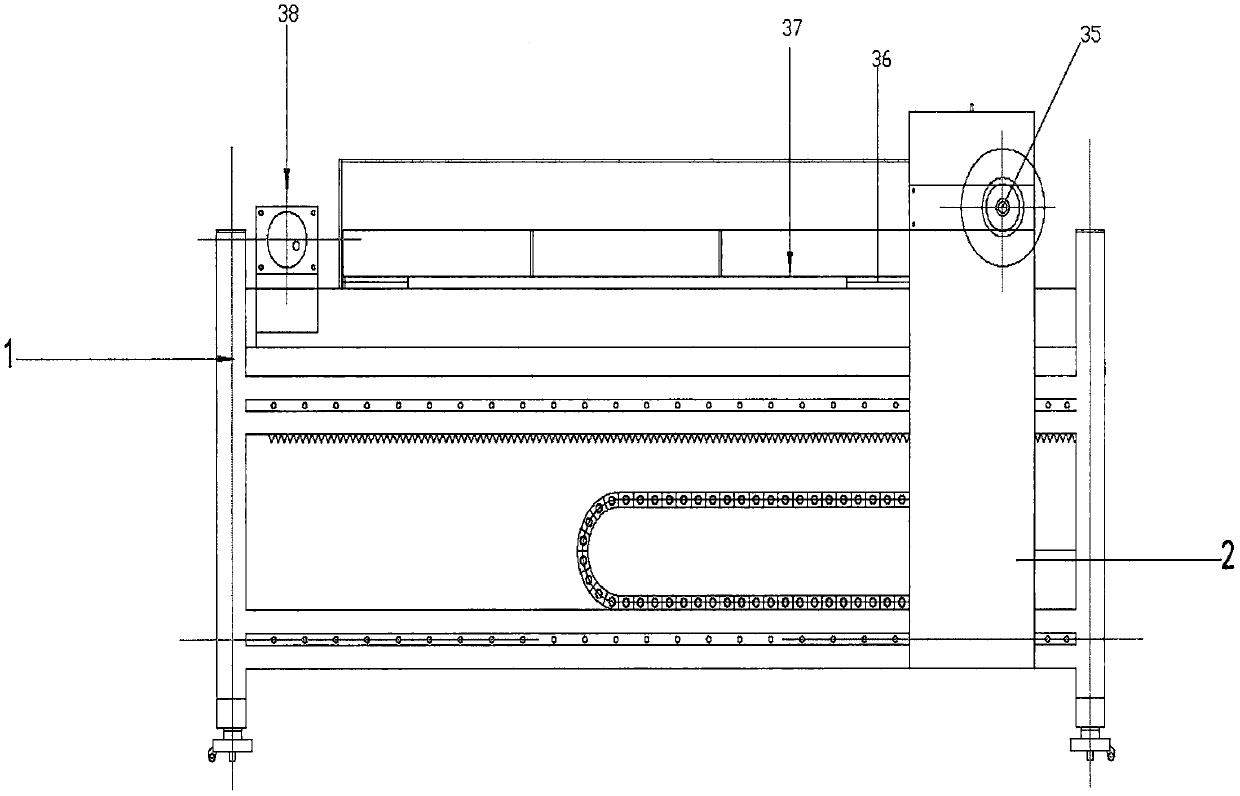

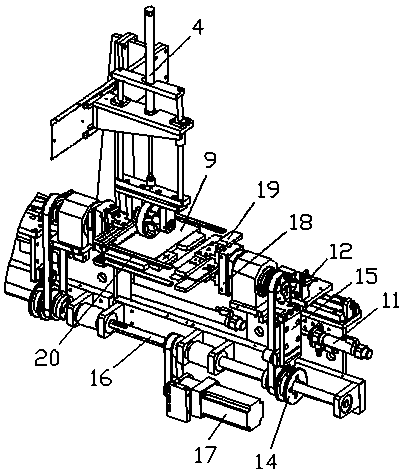

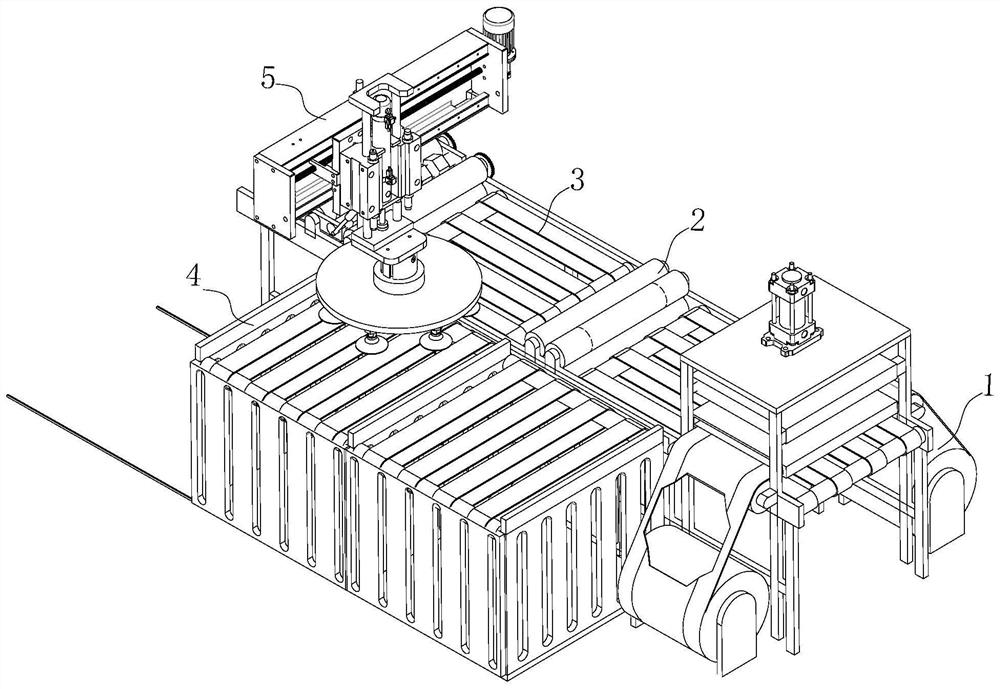

Universal three-edging mounting tool for front bumper

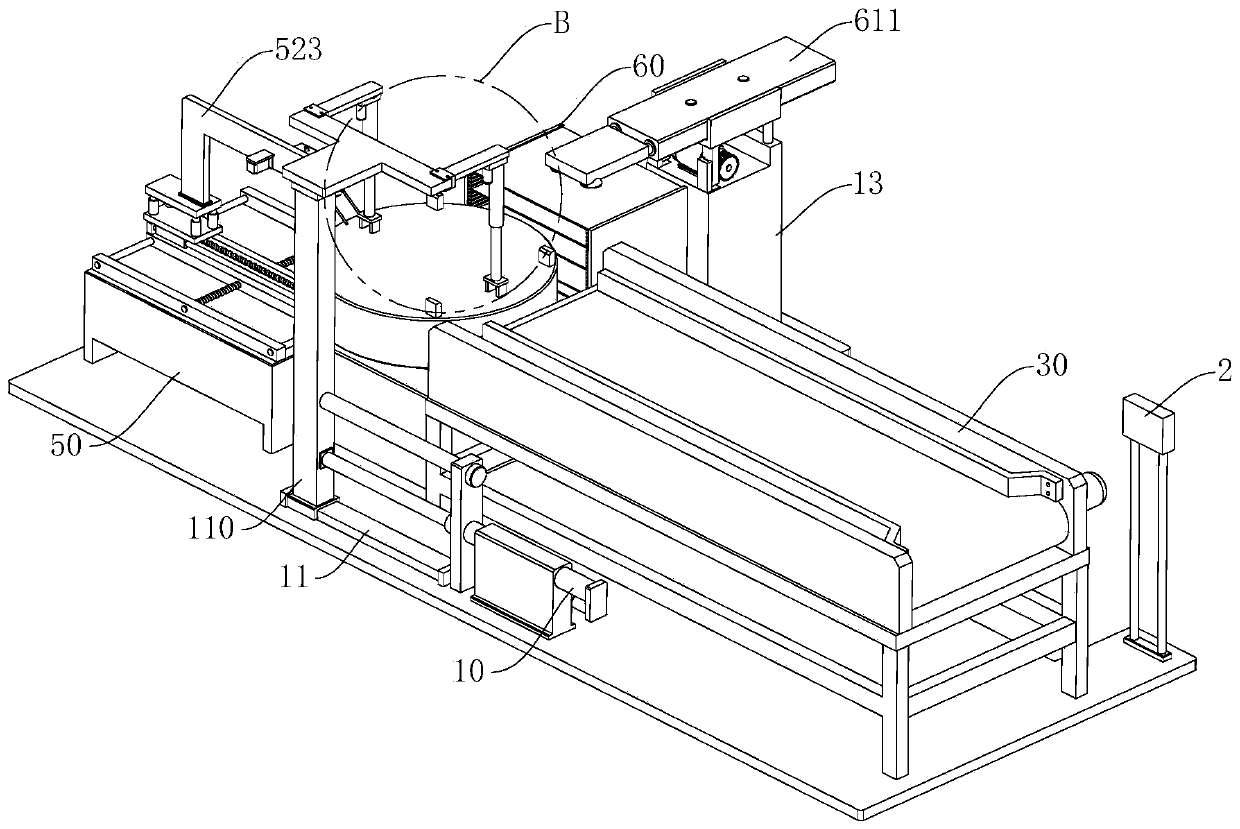

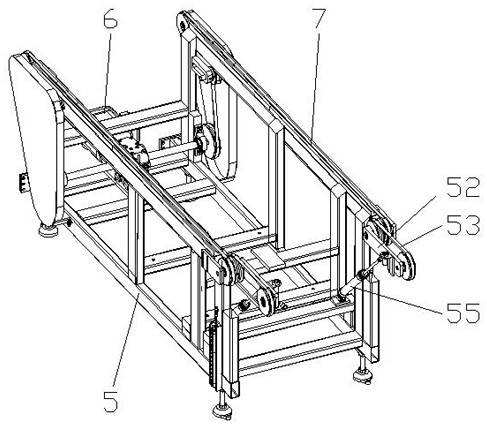

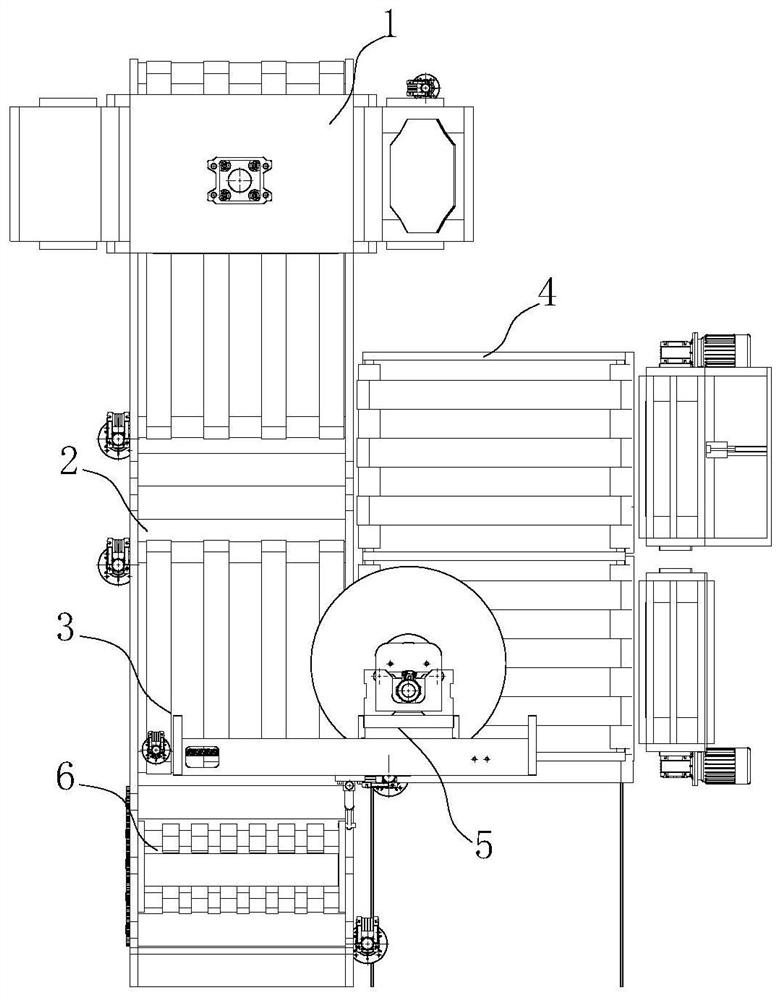

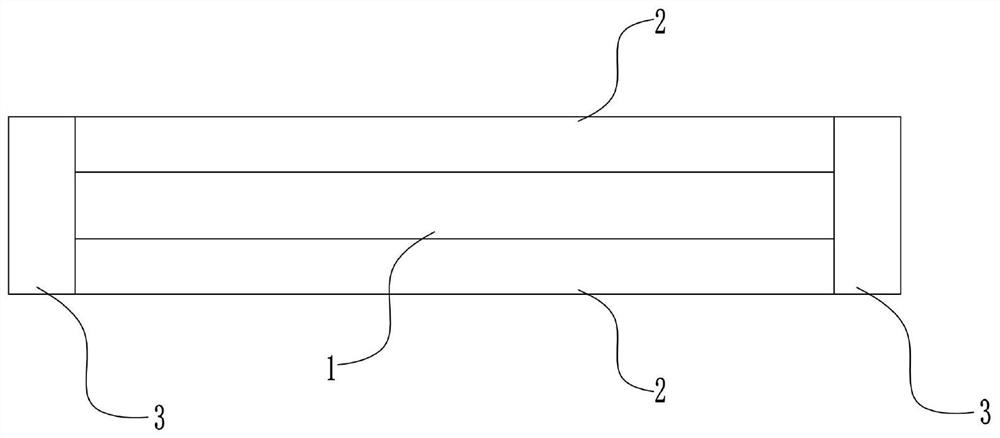

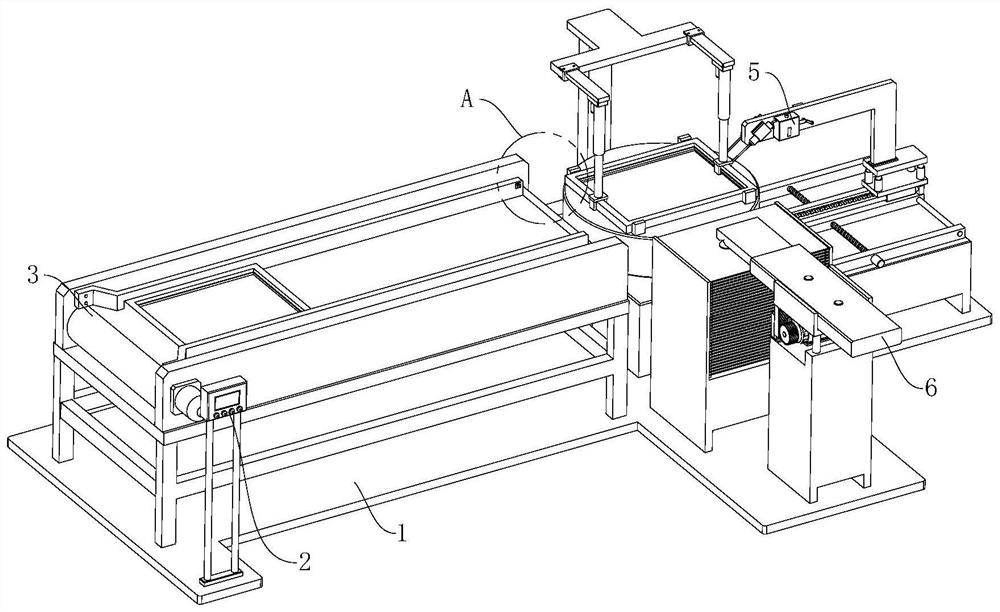

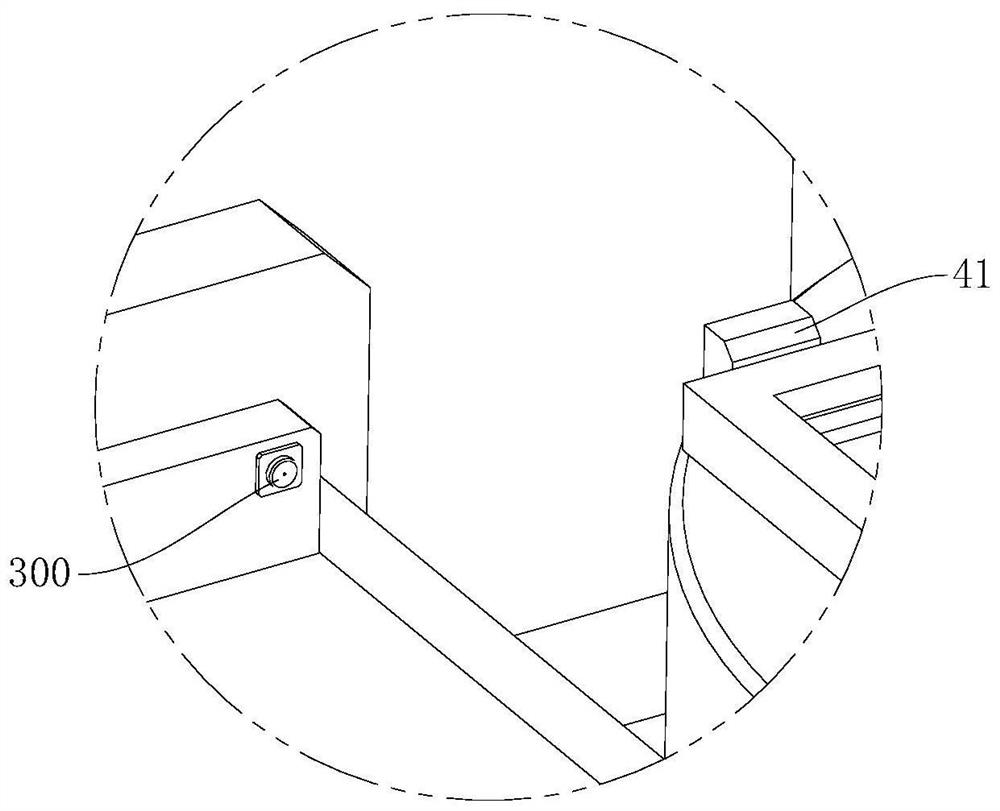

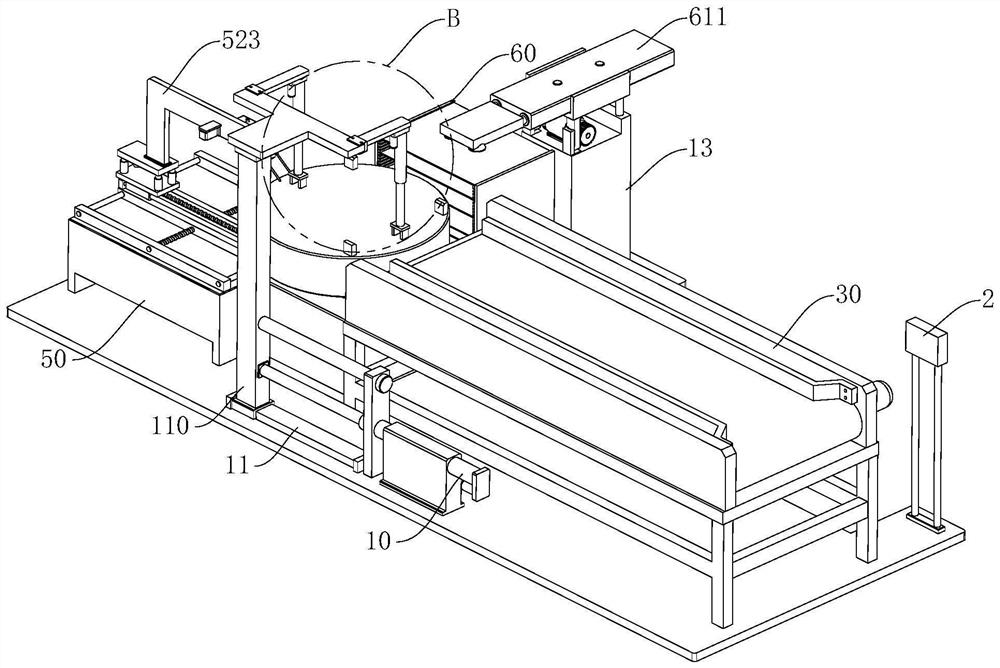

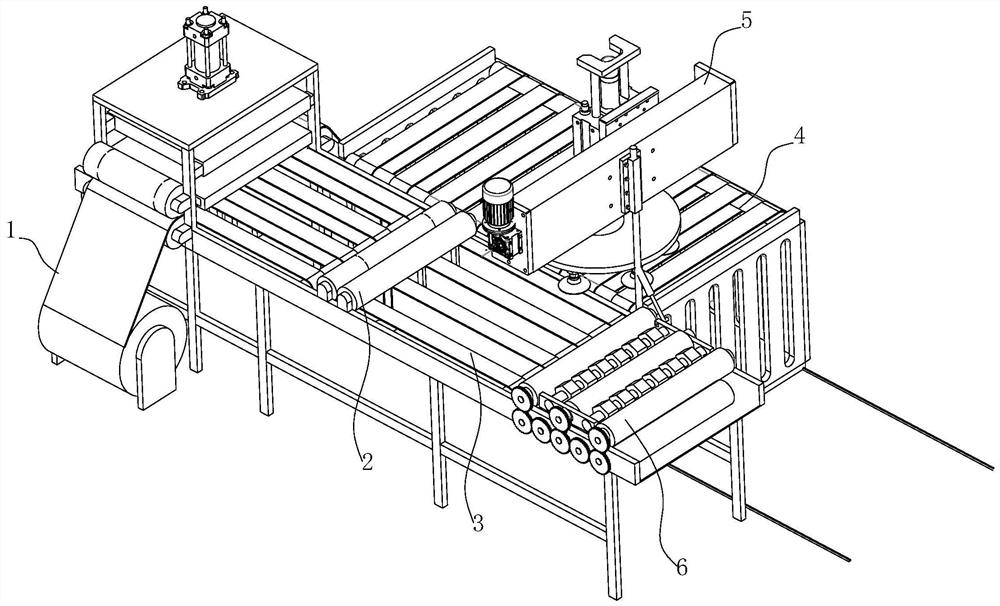

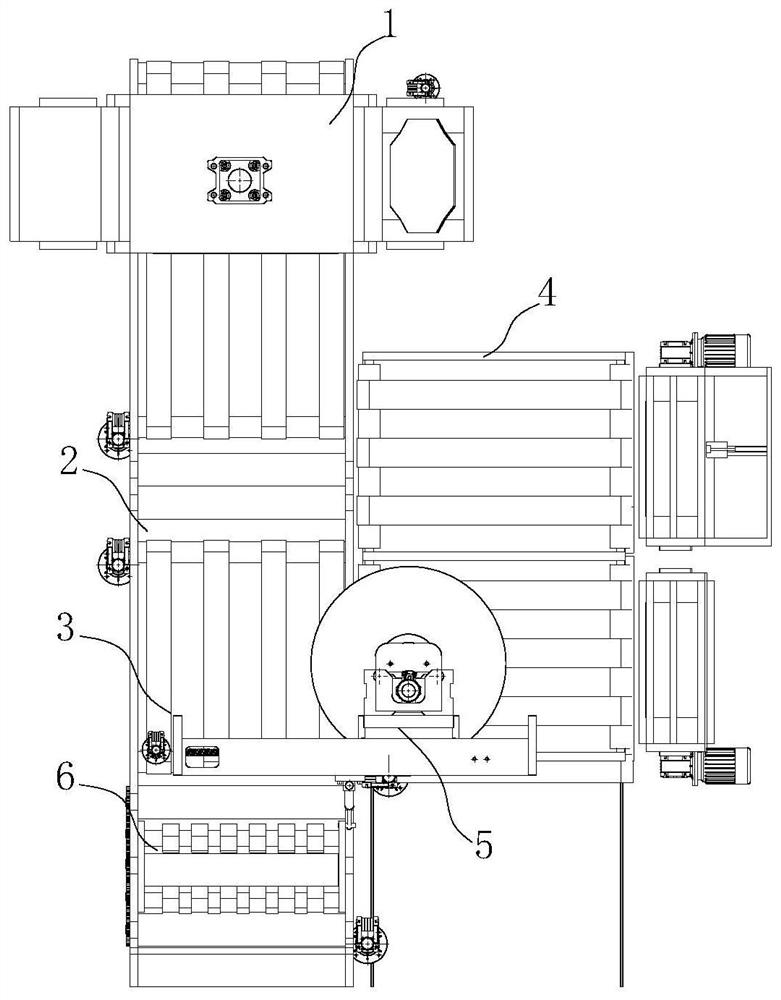

The invention relates to a universal three-edging mounting tool for a front bumper. The universal three-edging mounting tool comprises a glass conveyor (1), a glass centering and positioning mechanism(2), a glass lifting mechanism (3), a profiling block lifting mechanism (4) and a profiling pressing block (8), the glass conveyor (1) comprises a conveying rack (5) and a conveying motor speed reducer (6), and primary conveying belts (7) are separately arranged on two sides of the conveying rack (5). A transmission shaft for controlling the two primary conveyor belts (7) to rotate synchronouslyis arranged on the conveying rack (5), and the conveying motor speed reducer (6) is mounted on the conveying rack (5) and drives a transmission shaft to rotate. The universal three-edging mounting tool for the front bumper has the advantages that glass is quickly positioned and centered on the conveyor through the glass centering and positioning mechanism, the glass lifting mechanism rises, all the side edges of laminated glass are supported through a set of supporting air cylinders, the profiling block lifting mechanism is pressed downwards to enable an edge covering strip and the glass to belaminated and bonded, actions are coherent, positioning is accurate, and the edge covering quality and the edge covering efficiency are greatly improved.

Owner:FUYAO GRP CHANGCHUN

Sheet metal part edge covering device

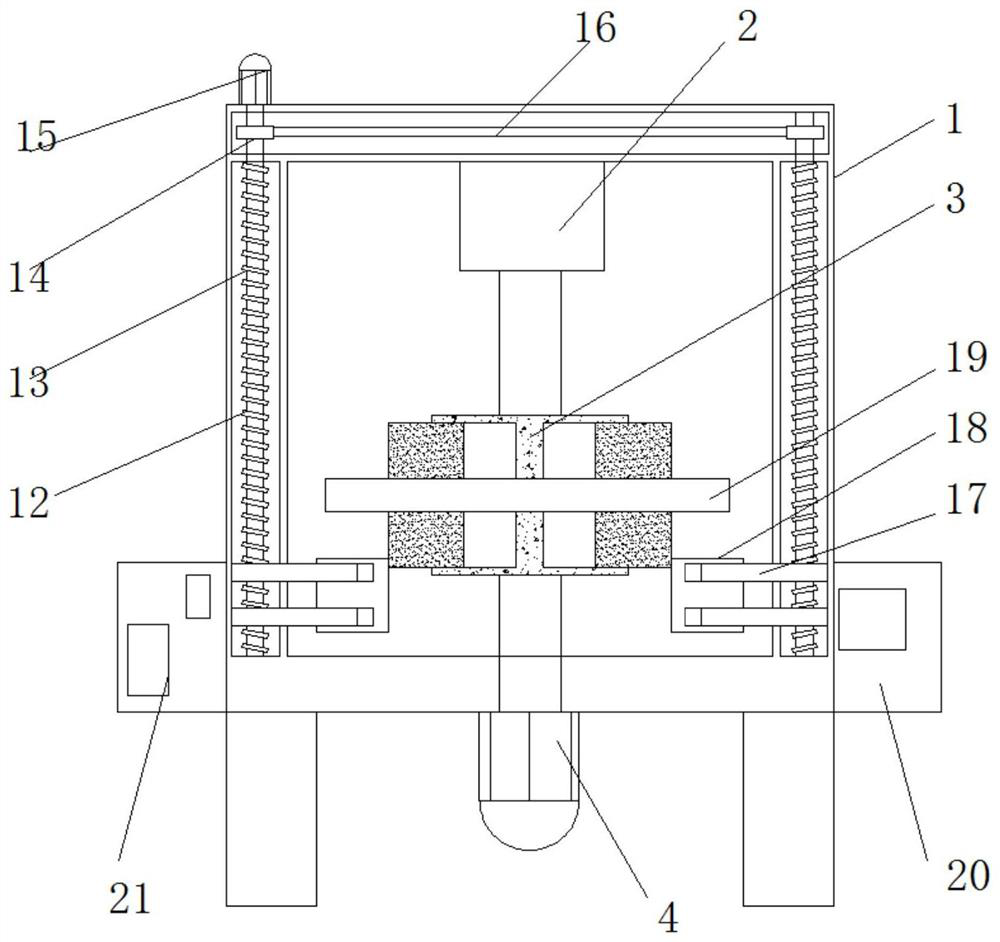

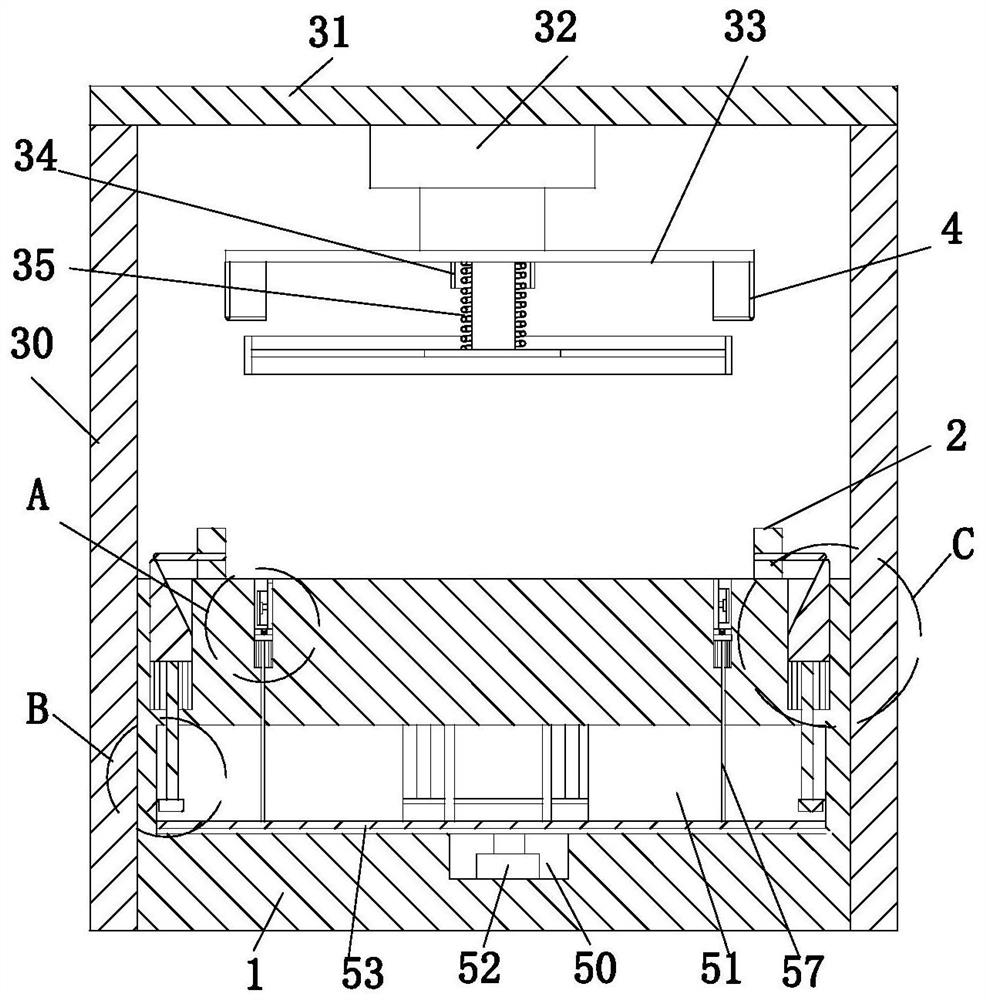

PendingCN114433688AHigh precisionImprove efficiencyMetal-working feeding devicesExtrusion cleaning devicesGear wheelServo

The invention discloses a sheet metal part edge covering device which comprises a box body, an air cylinder is fixed to the inner wall of the top of the box body, a clamping mechanism is fixed to the bottom of the air cylinder, a first servo motor is fixed to the bottom of the box body, and an output shaft of the first servo motor is fixed to the bottom of the clamping mechanism through a linkage device. The clamping mechanism comprises a fixing plate, a mounting plate, a connecting rod, a strip-shaped gear, a rotating gear, an infrared sensor and a laser displacement sensor, mounting grooves are formed in the two ends of the bottom of the fixing plate, and the inner walls of the mounting grooves are in sliding fit with the mounting plate. By using the air cylinder, the first servo motor and the clamping mechanism and arranging a fixing plate, a mounting plate, a connecting rod, a strip-shaped gear, a rotating gear, an infrared sensor and a laser displacement sensor, a sheet metal part can be clamped and fixed, the edge covering efficiency is prevented from being influenced by shaking, meanwhile, the edge covering position of the sheet metal part can be accurately measured, rapid adjustment is conducted, and the production efficiency is improved. And the edge covering precision and efficiency of the sheet metal part are improved.

Owner:无锡君骄机械有限公司

Edge covering method and device of high-strength steel

InactiveCN109550855AImprove ductilityExpand the scope of processingShaping toolsMetal-working feeding devicesHardnessUltimate tensile strength

The invention discloses an edge covering method and device of high-strength steel. The edge covering method and device of the high-strength steel are used for operating edge covering on a high-strength steel assembly, the high-strength steel assembly comprises an outer plate and an inner plate, and the outer plate is provided with a bending part. The edge covering method comprises the following steps that the outer plate and the inner plate to be subjected to edge covering are placed on a locating mechanism, and locating is carried out; the outer plate and the inner plate after being located are tightly clamped by a clamping mechanism; the bending part of the outer plate is heated by a heating mechanism, and thus the temperature of the bending part of the outer plate is made to be above 800 DEG C; and a press-fitting mechanism operates press fitting on the outer plate after being heated until the inner plate is wrapped by the outer plate. According to the technical scheme, edge covering of the high-strength steel assembly with superhigh intensity and hardness after the heat treatment can be carried out, the machining range of the edge covering technology is expanded, and the technical support is provided for further development of lightweight of automobile.

Owner:SUZHOU PRESSLER ADVANCED FORMING TECHNOLOGIES CO LTD

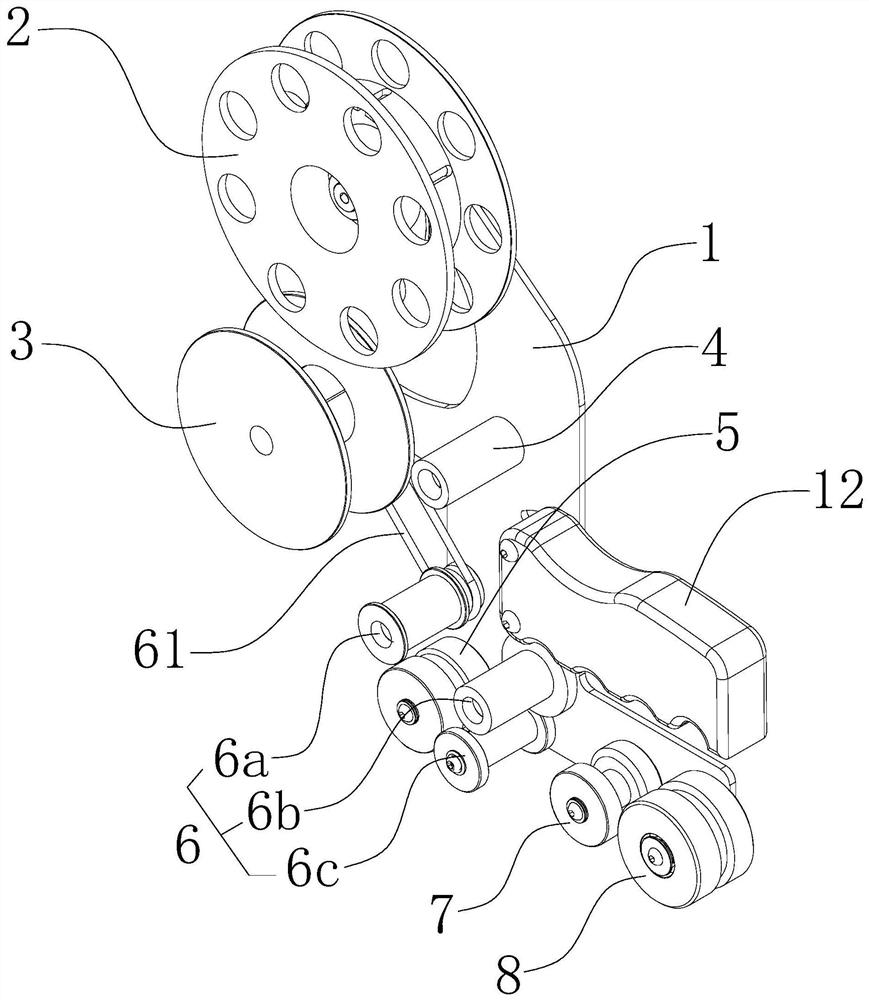

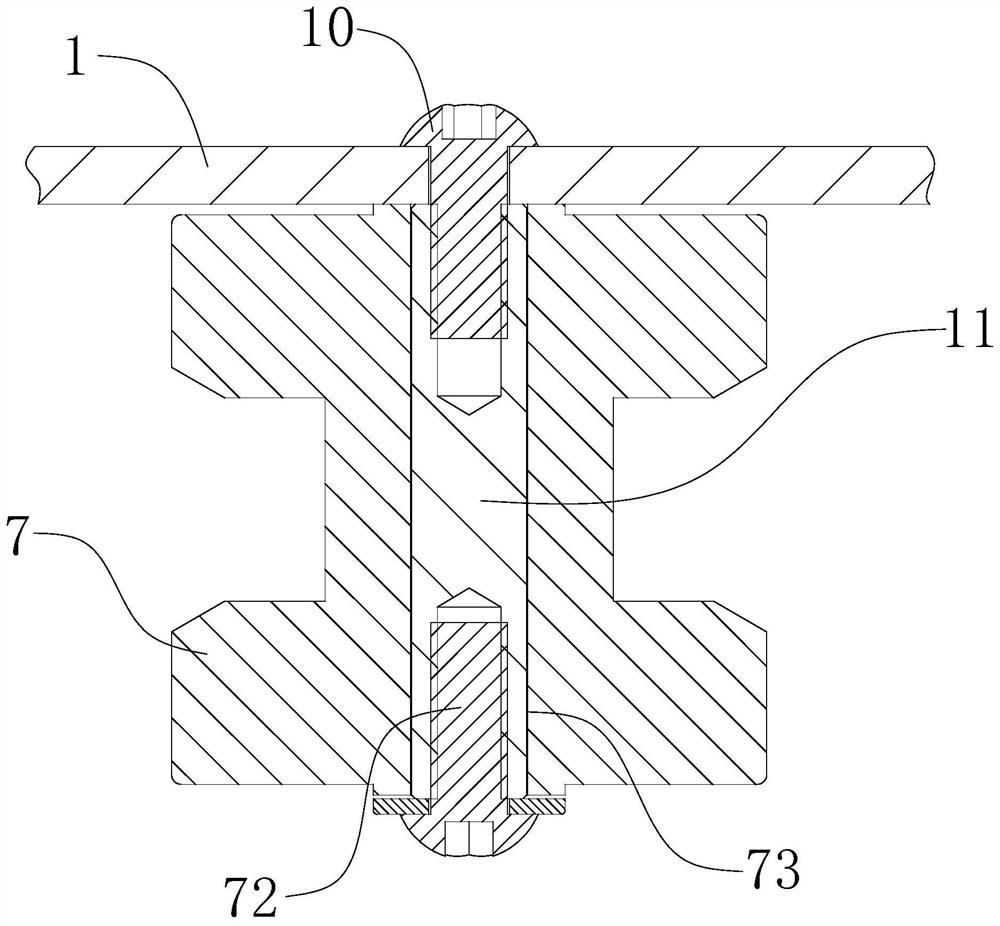

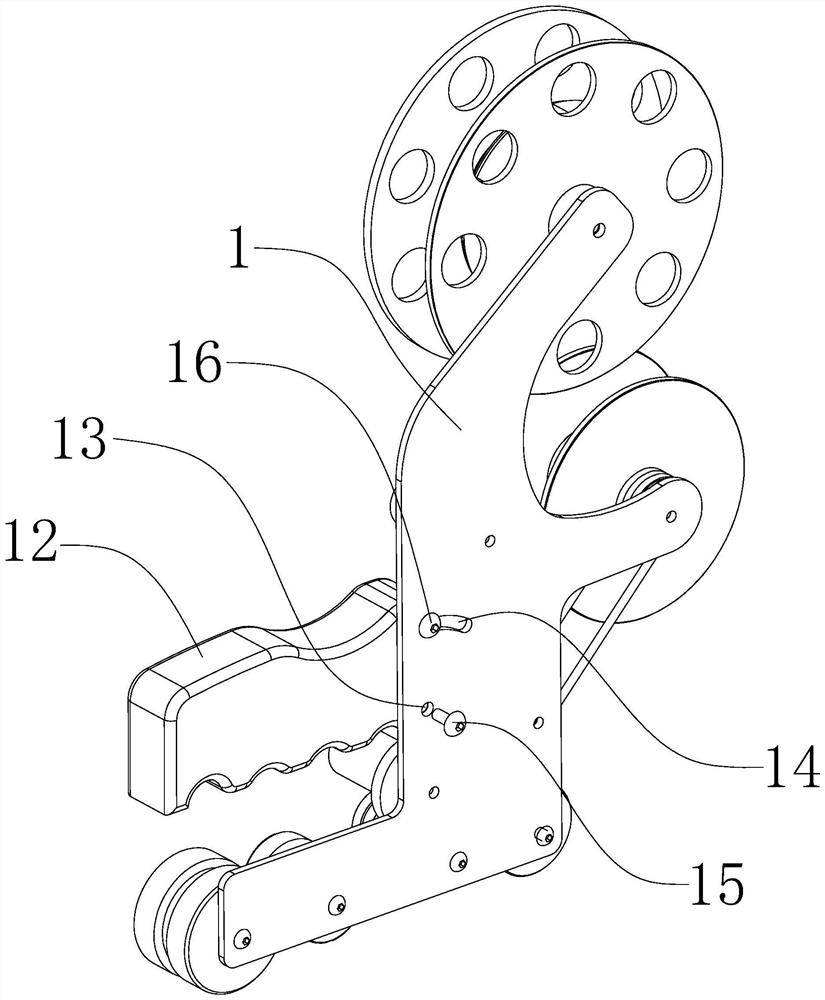

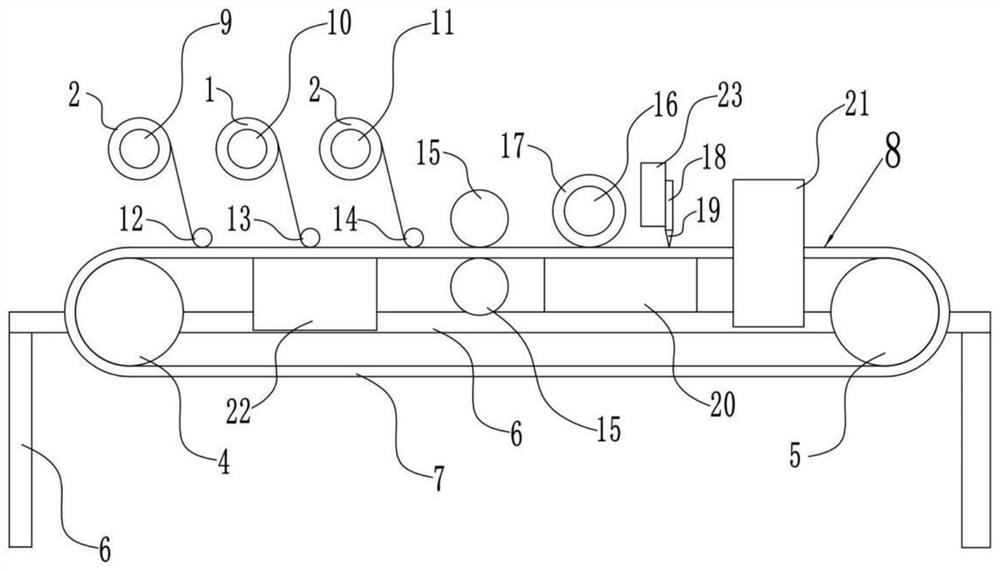

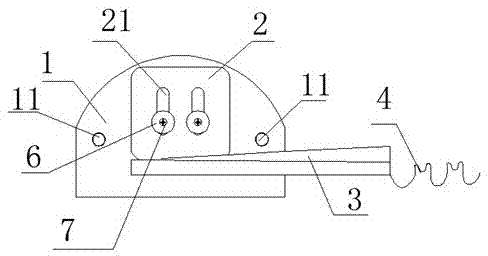

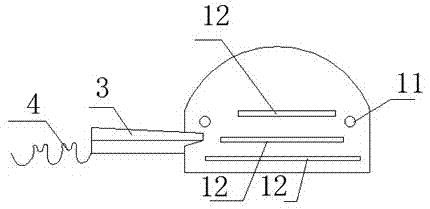

Handheld adhesive tape edge covering tool and photovoltaic double-glazed assembly edge sealing method

InactiveCN111994682AImprove hemming efficiencyExtended service lifePhotovoltaic energy generationArticle deliveryHand heldStructural engineering

The invention discloses a handheld adhesive tape edge covering tool and a photovoltaic double-glazed assembly edge sealing method. The handheld adhesive tape edge covering tool comprises a frame, an adhesive tape disc, a rolling disc, a separation wheel, a guide wheel set and a compression wheel, and the adhesive tape disc, the rolling disc, the separation wheel, the guide wheel set and the compression wheel are rotationally connected to the frame. An adhesive tape roll is placed on the adhesive tape disc, and after adhesive tape of the adhesive tape roll is guided out of the separation wheel,a release liner of the adhesive tape is wound to the winding disc. An adhesive tape layer of the adhesive tape sequentially passes through the guide wheel set and the compression wheel, and the guidewheel set drives the winding disc to rotate; and an annular edge covering groove is formed in the compression wheel, the edge covering groove is in matched connection with an object to be pasted, andis used for covering the edge of the object to be pasted with the adhesive tape. Meanwhile, by means of moving of the adhesive tape layer in the edge covering process, discharging of the adhesive tape disc and collection of the winding disc can be automatically driven, operation is very convenient, and the adhesive tape edge covering efficiency is high.

Owner:CYBRID TECHNOLOGIES INC

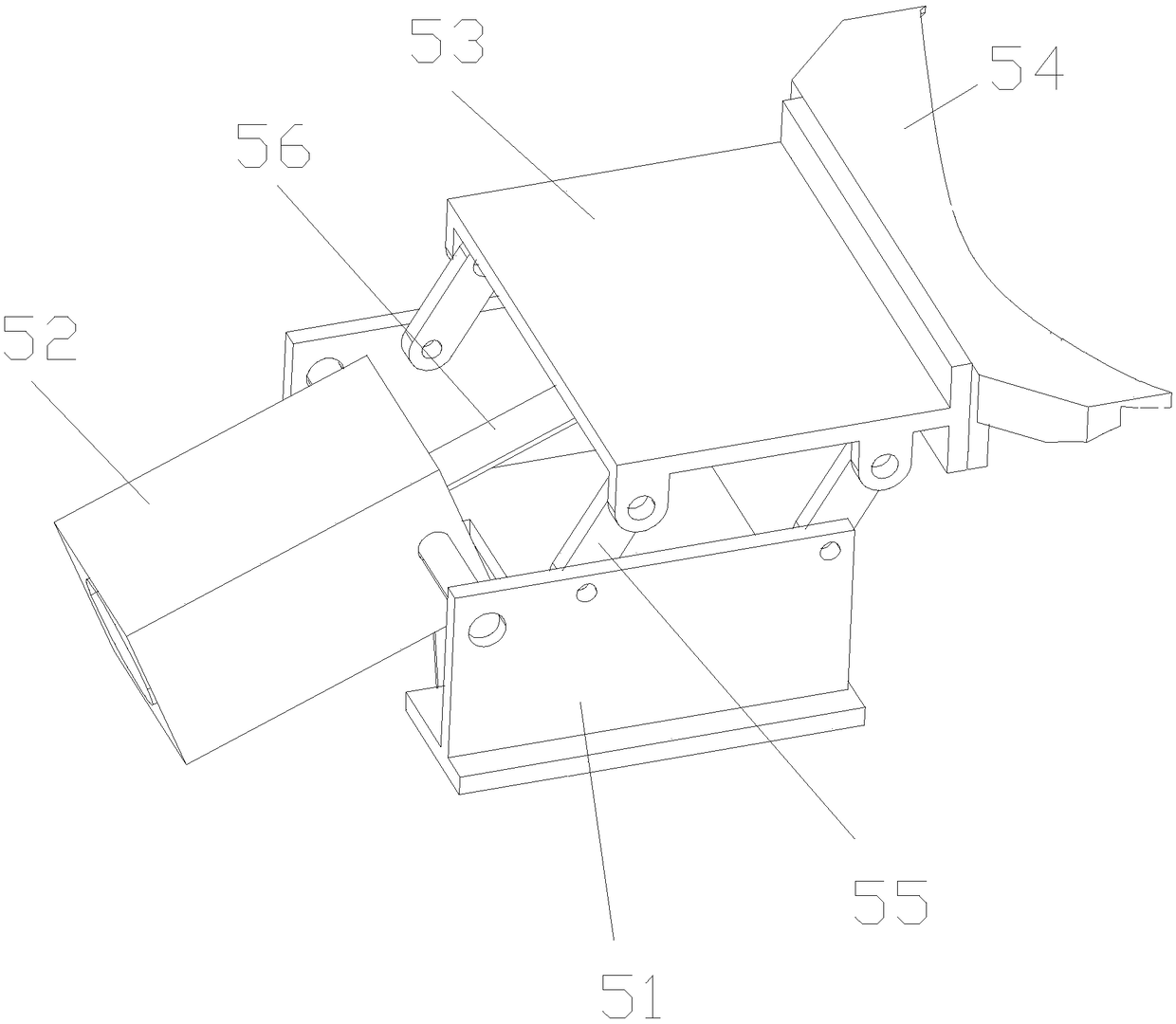

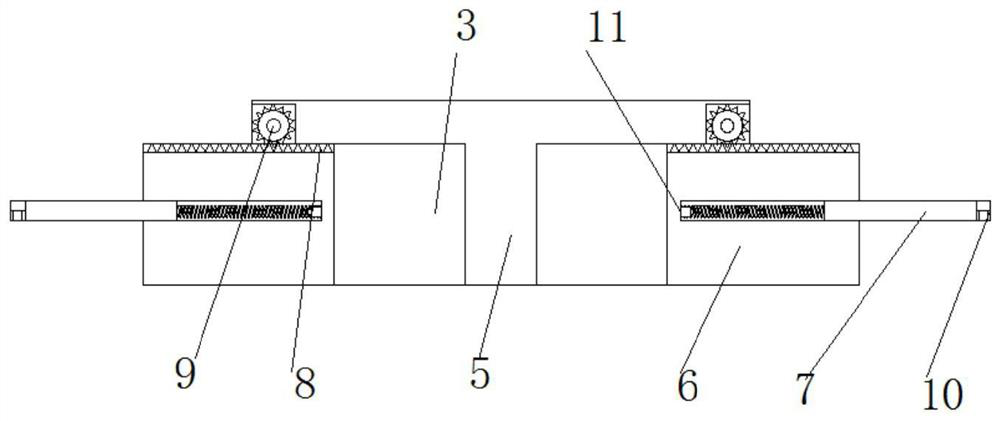

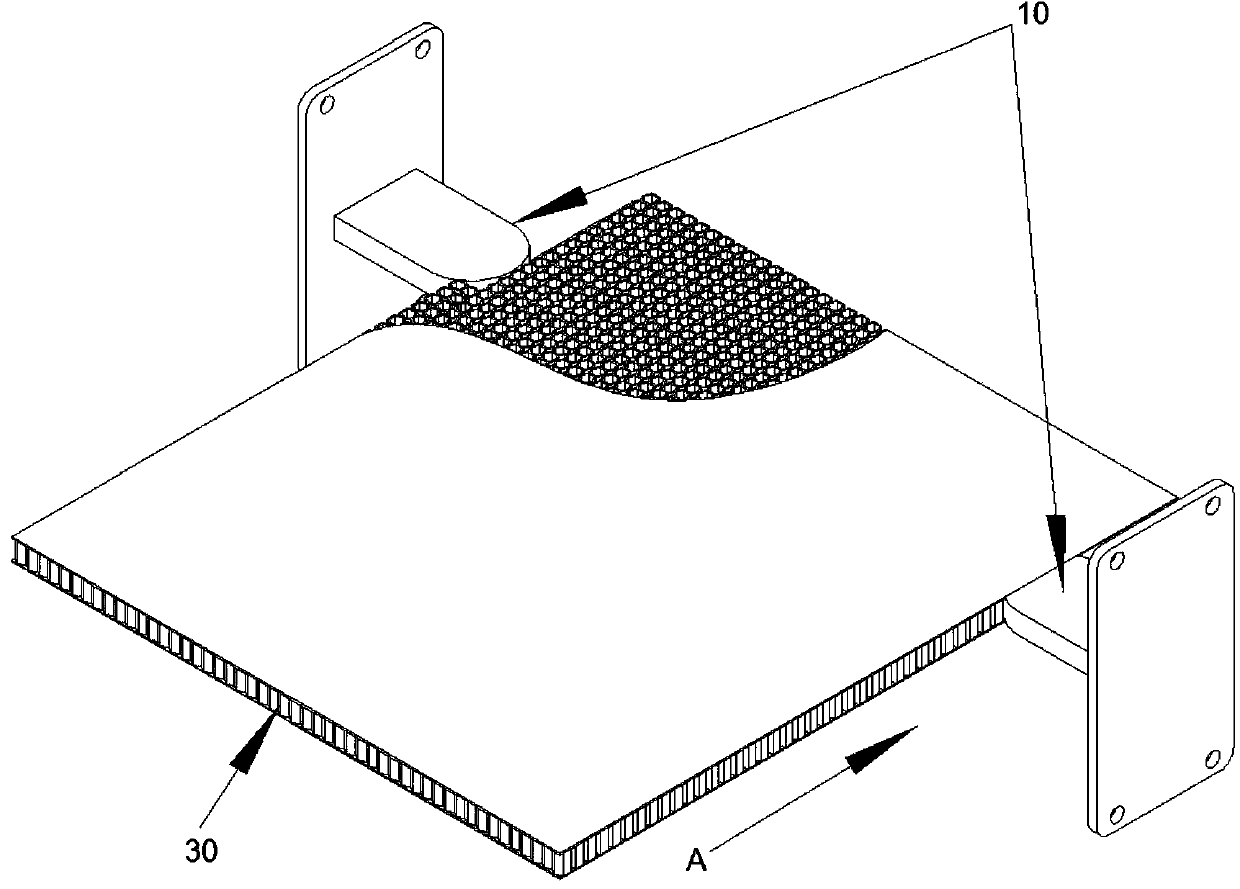

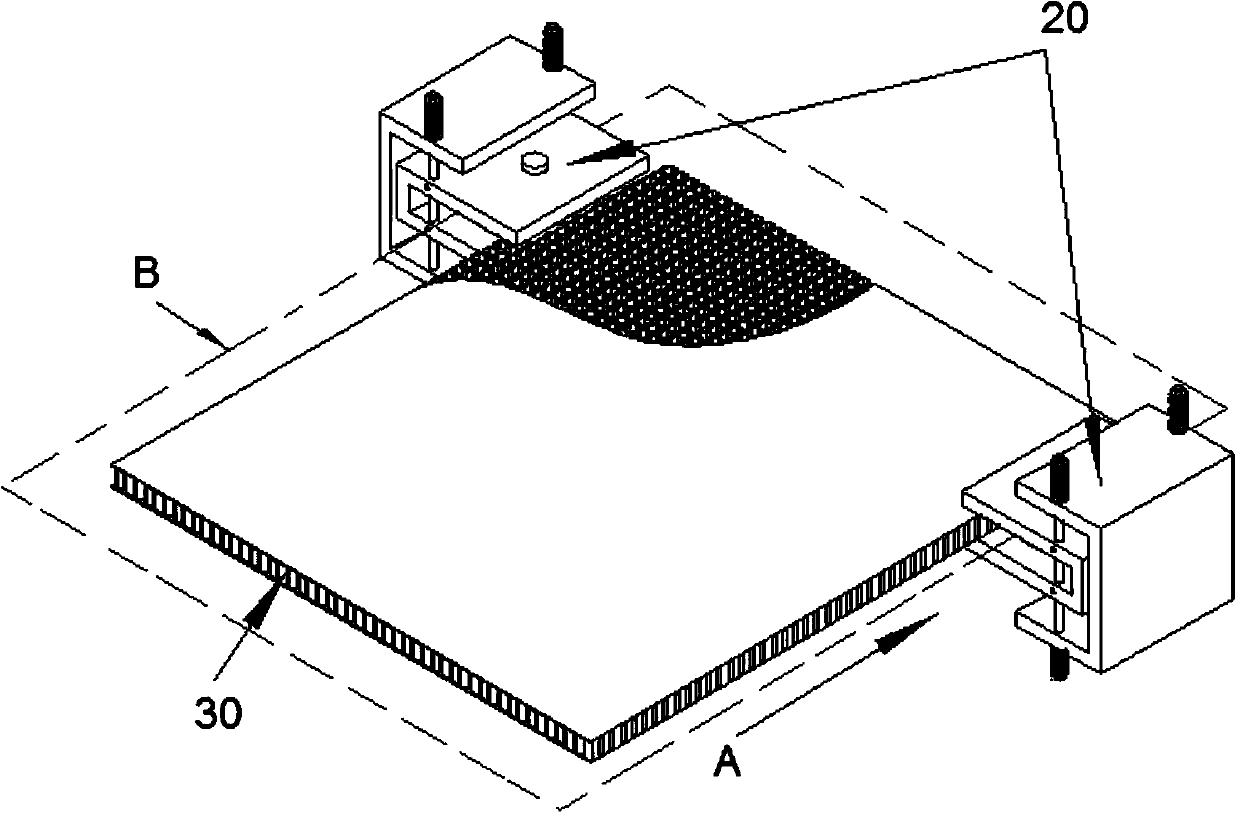

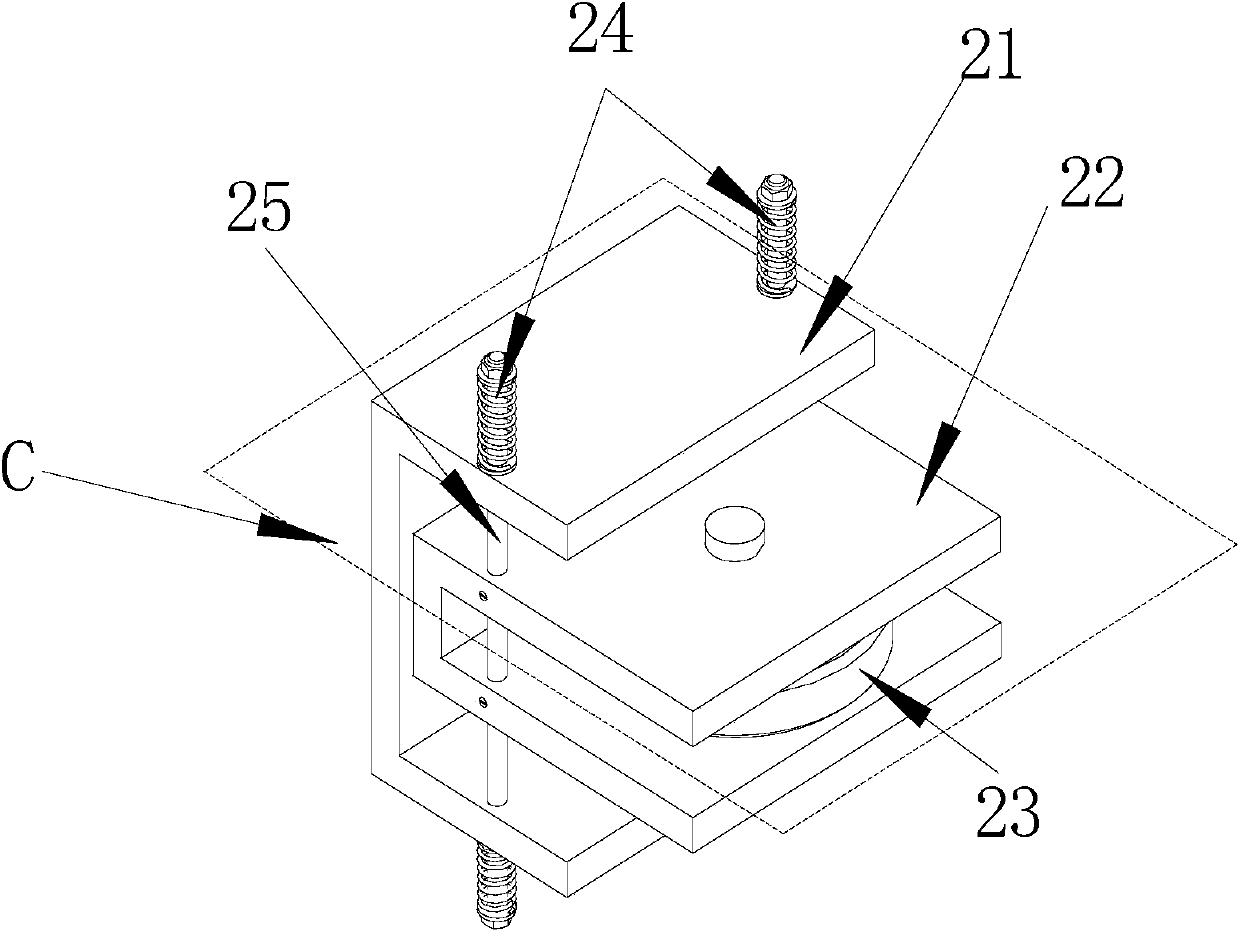

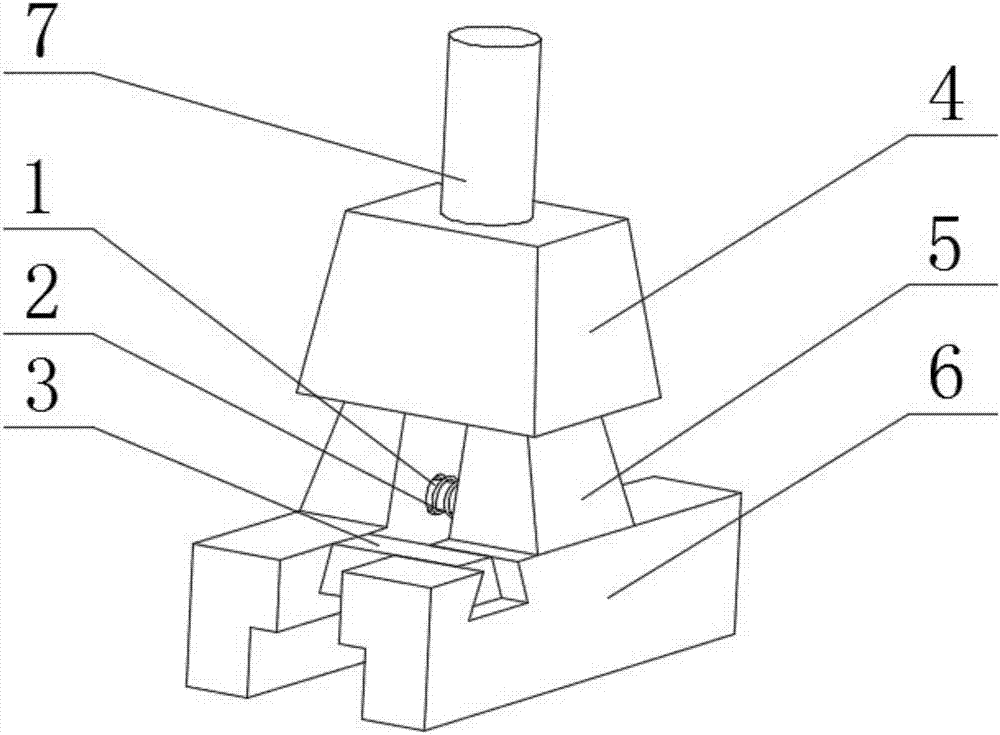

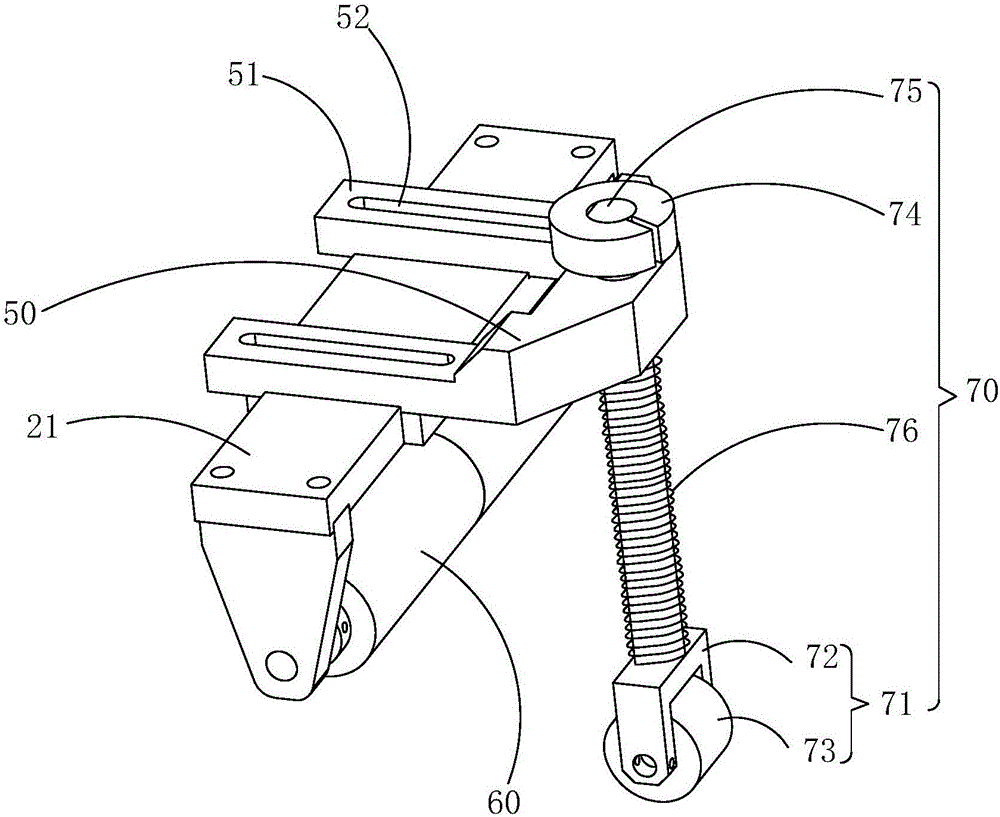

An Extrusion Forming Mechanism Used in a Passive Honeycomb Paperboard Hemming Machine

ActiveCN104002508BOvercoming plate crowning issuesAvoid scratchesMechanical working/deformationCardboardHoneycomb

The invention relates to an extrusion forming mechanism for a passive honeycomb paperboard covering machine. A honeycomb paperboard comprises an upper surface, a lower surface and a honeycomb paper core arranged between the upper surface and the lower surface. The number of the extrusion forming mechanisms is two. The two extrusion forming mechanisms are symmetrically arranged on the two sides of the honeycomb paperboard. Each extrusion forming mechanism comprises a fixed block, a movable block, an extrusion block, a spring and a sliding rod, wherein the fixed block and the movable block are connected through the sliding rod, the end of the sliding rod is sleeved with the spring, and the extrusion block is fixed into the movable block through a bolt; the extrusion block extrudes the honeycomb paper core, and the movable block drives the extrusion block to move vertically according to the roughness of the honeycomb paperboard under the elasticity of the spring, so that a neutral surface of the honeycomb paperboard coincides with a neutral surface of the movable block. Compared with the prior art, the extrusion forming mechanism can quickly move along with the neutral surface of the honeycomb paperboard with the strip crown so that the paper core on the side face of the extrusion forming mechanism can be smoothly extruded and formed.

Owner:SHANGHAI UNIV OF ENG SCI

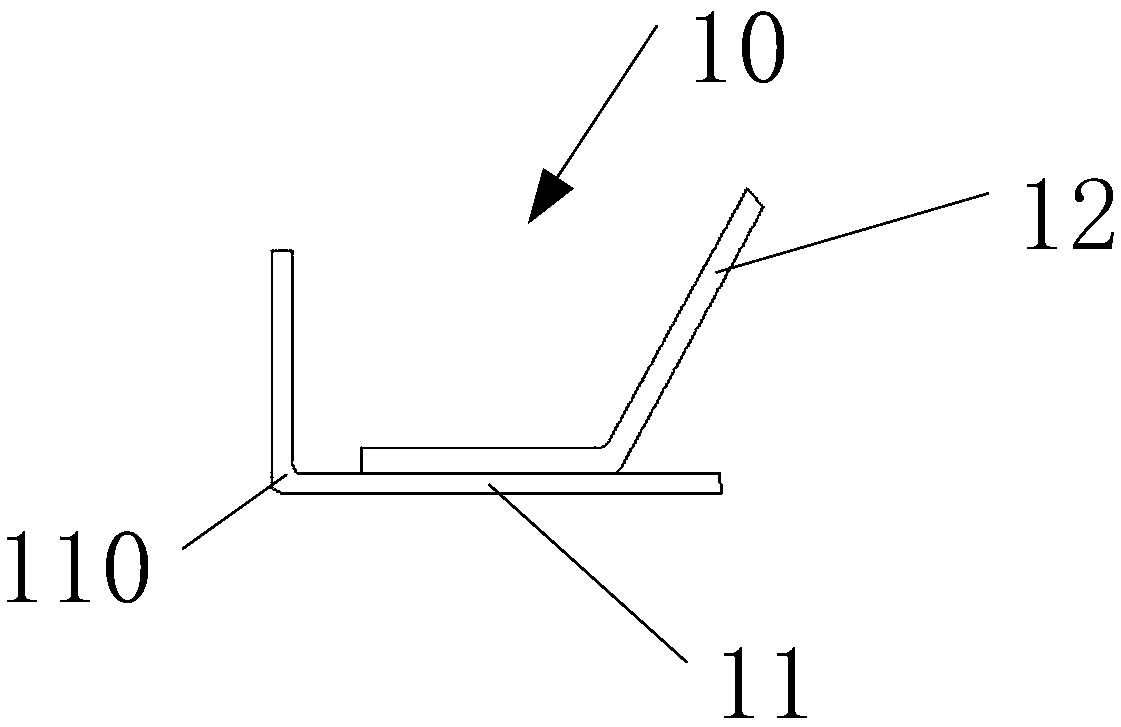

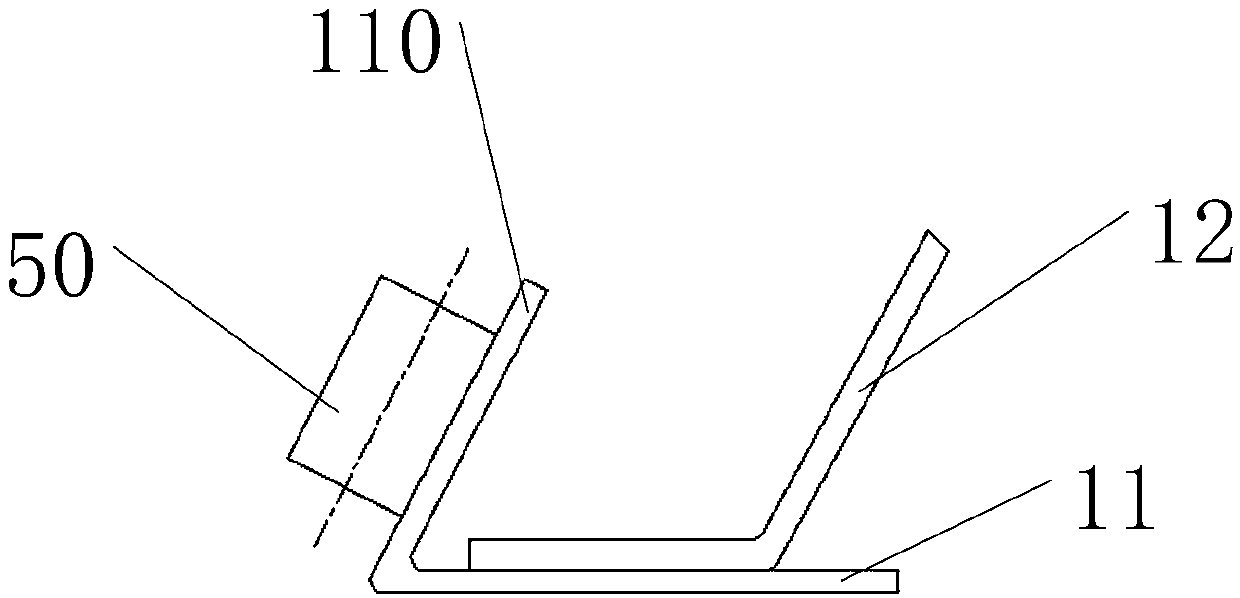

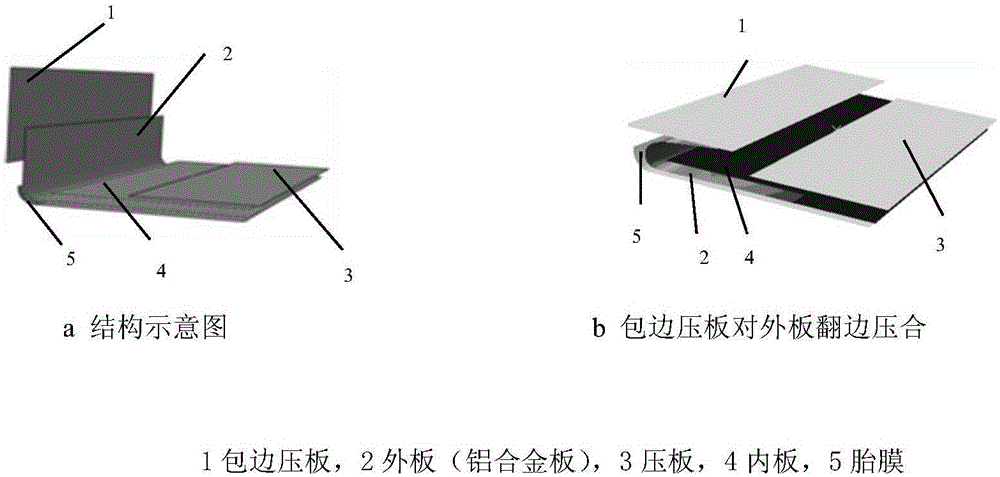

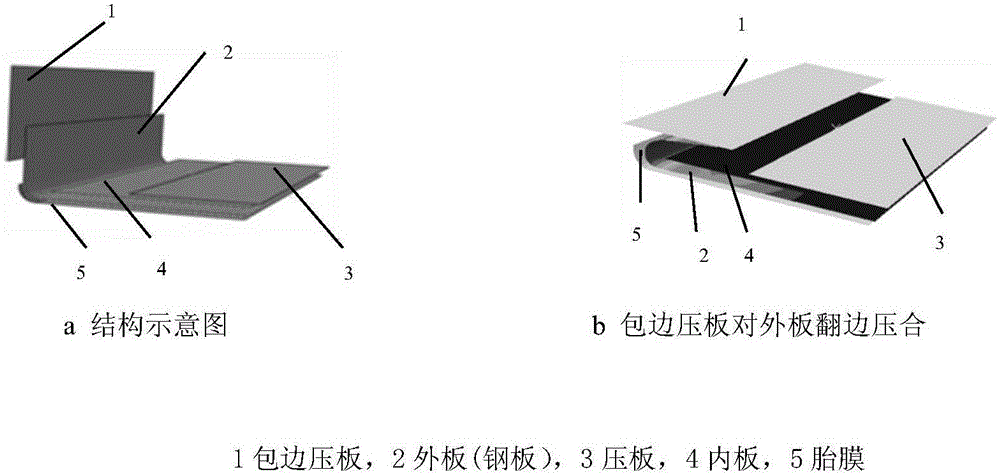

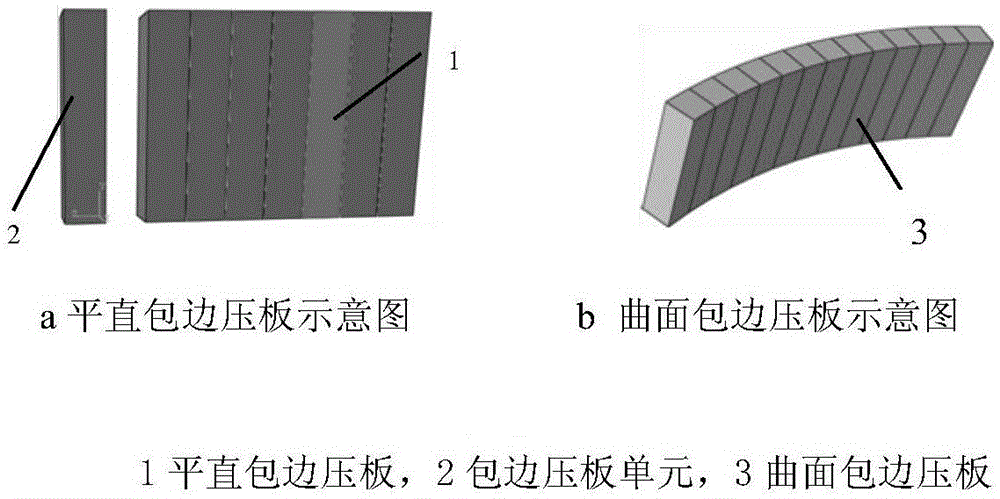

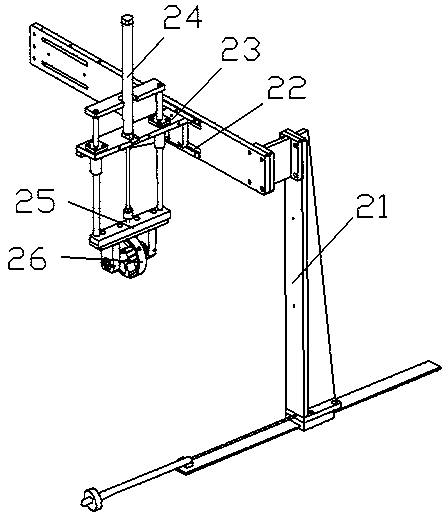

Edge wrapping method and structure of wrapping press plate controlled by robot

The invention discloses a method and a structure used for increasing robot edge wrapping efficiency. One-step rapid edge wrapping is realized by arranging an edge wrapping press plate, and the molding quality is better than that of a roller. The structure combines the flexibility advantage of robot edge rolling and the high production efficiency advantage of press die-pressing edge wrapping and has great economical benefit and practical significance.

Owner:GUANGZHOU NANYANG POLYTECHNIC

Vehicle window assembly and method for encapsulating the same

ActiveCN103057384BImprove adhesionImprove hemming efficiencyWindowsWindscreensEngineeringInjection moulding

Disclosed are a car window assembly and a binding method thereof. The car window assembly comprises a transparent base and an integrated hard plastic layer covering at least three peripheral sides of the transparent base. The binding method of the car window assembly includes: providing the transparent base; forming the integrated hard plastic layer on the periphery of the transparent base by injection molding to cover at least three peripheral sides of the transparent base. Bond between the plastic layer and glass in the car window assembly is higher, no dislocation occurs, binding efficiency is higher, and production cost is lowered.

Owner:SAINT-GOBAIN GLASS FRANCE

Paperboard edge covering method

InactiveCN111907131AImprove efficiencyHigh precisionMechanical working/deformationAdhesivePaperboard

The invention provides a paperboard edge covering method. The invention provides a paperboard edge covering method. The paperboard edge covering method comprises the procedures of paper conveying, paper gluing, paperboard conveying, paperboard feeding, primary paperboard edge covering, secondary paperboard edge covering and the like. According to the method, a paperboard edge covering device is used, wherein a paper conveying mechanism is used for conveying paper of a preset size for edge covering to a conveying table; a gluing mechanism is used for coating the upper surface of the paper withan adhesive in the conveying direction of the paper; a trolley is used for conveying paperboards; a grabbing mechanism is used for grabbing the paperboards on the trolley and placing the paperboards on a first conveying belt, or grabbing the paperboards on the first conveying belt and placing the paperboards on the trolley; and an edge covering mechanism is used for carrying out edge covering treatment on the paperboards and conveying the paperboards subjected to edge covering to the first conveying belt. The paperboard edge covering device is high in automation degree, compact in structure, small in floor area, high in equipment utilization rate, low in production and manufacturing cost, capable of greatly reducing labor intensity and saving labor cost, and particularly suitable for industrialized paperboard edge covering operation.

Owner:朱蓉

High-power graphite wrapping, wrapping method and equipment based on CVD processing technology

ActiveCN112918067BImprove hemming efficiencySo as not to damageLamination ancillary operationsLaminationEngineeringGraphite

The invention provides a high-power graphite wrapping based on CVD processing technology, comprising: a graphite film, the upper and lower surfaces of the graphite film are respectively covered with a first colloid, and the graphite film and the circumferential edge of the first colloid are both covered. Covered with a second colloid, and the second colloid is used to connect the two first colloids on the upper and lower surfaces of the graphite film into a whole; the circumferential edge of the first colloid and the circumferential edge of the graphite film overlap. The object of the present invention is to provide a graphite wrapping that protects the graphite film structure from being damaged.

Owner:SUZHOU KANRONICS ELECTRONICS TECH CO LTD

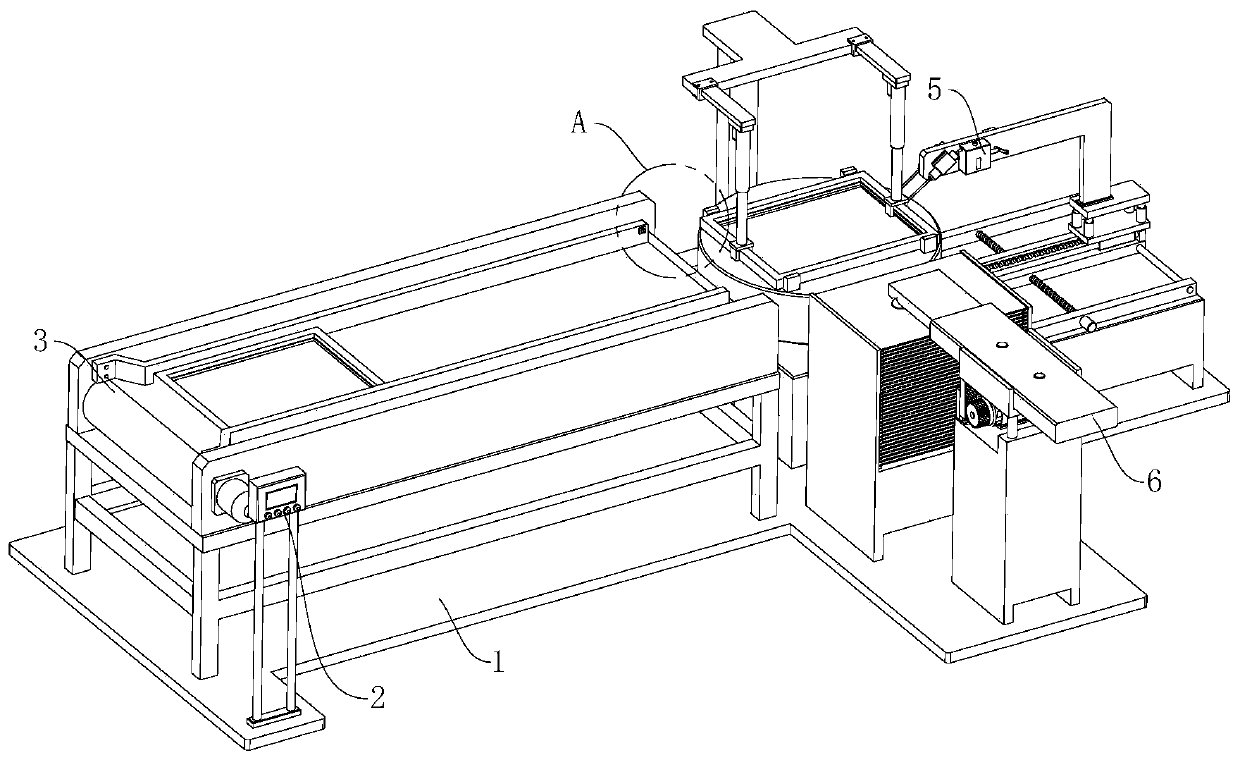

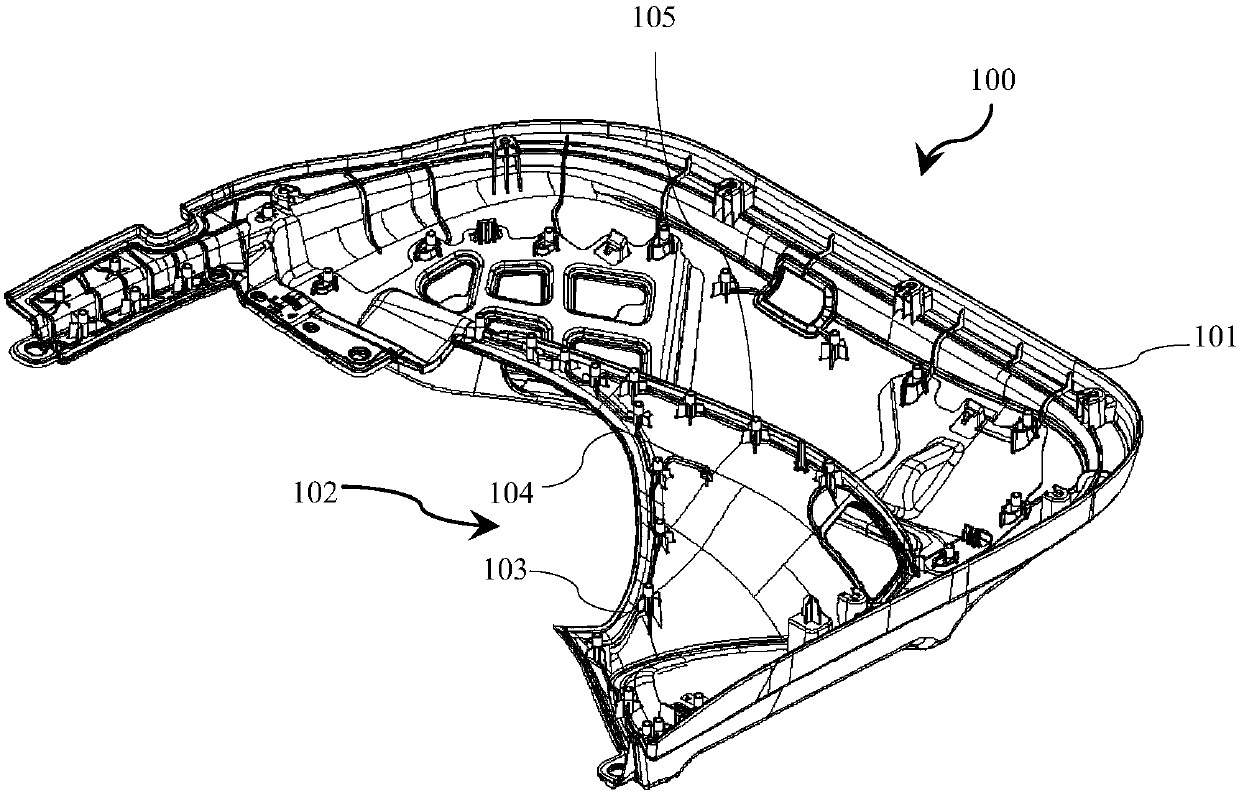

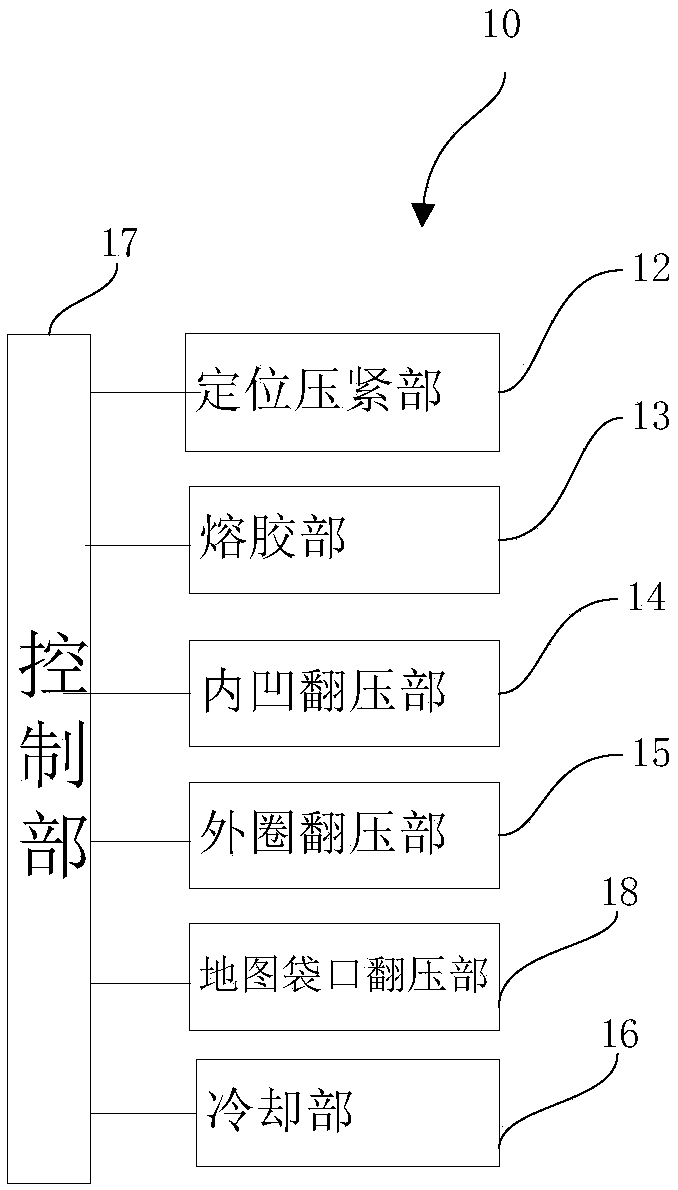

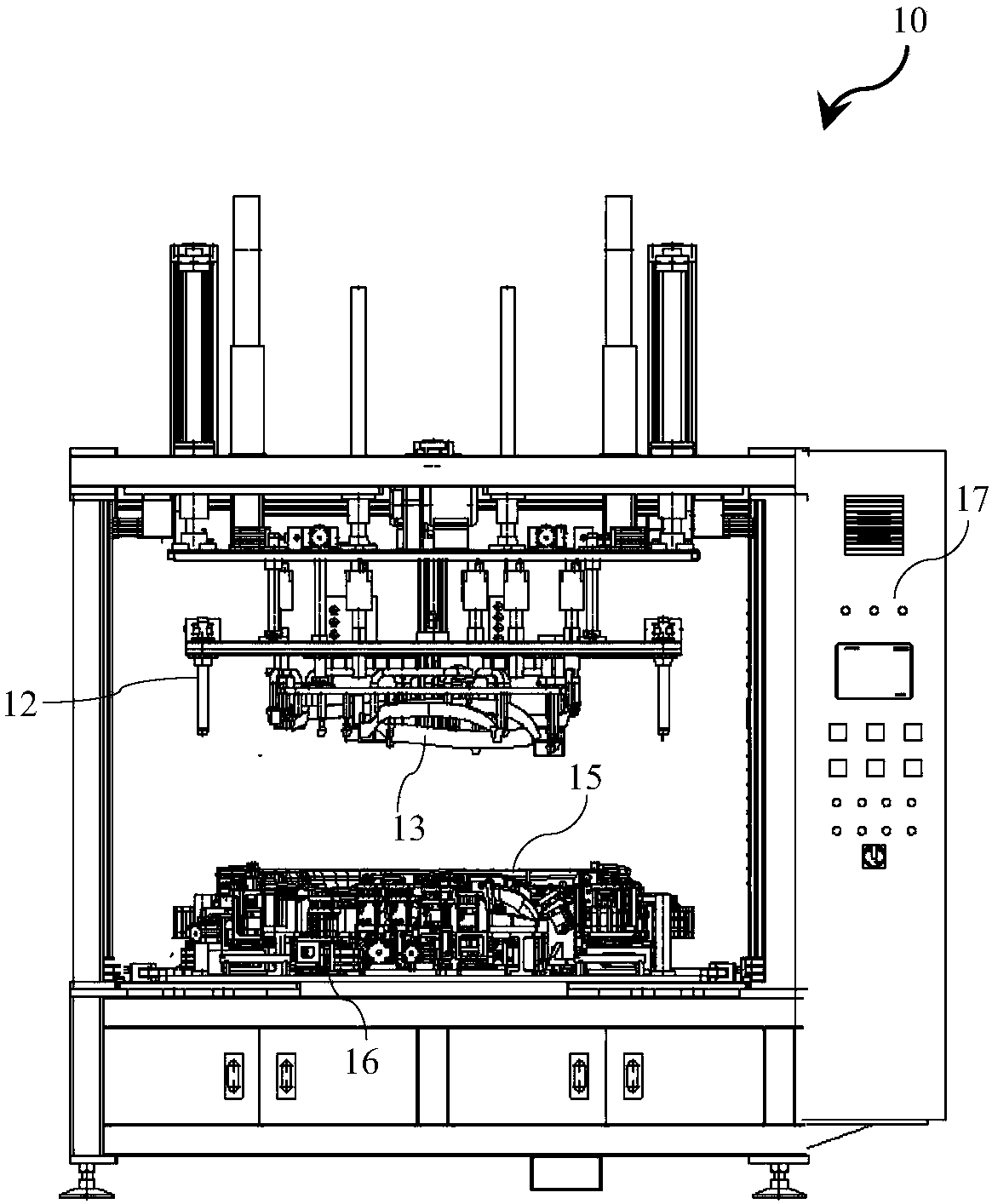

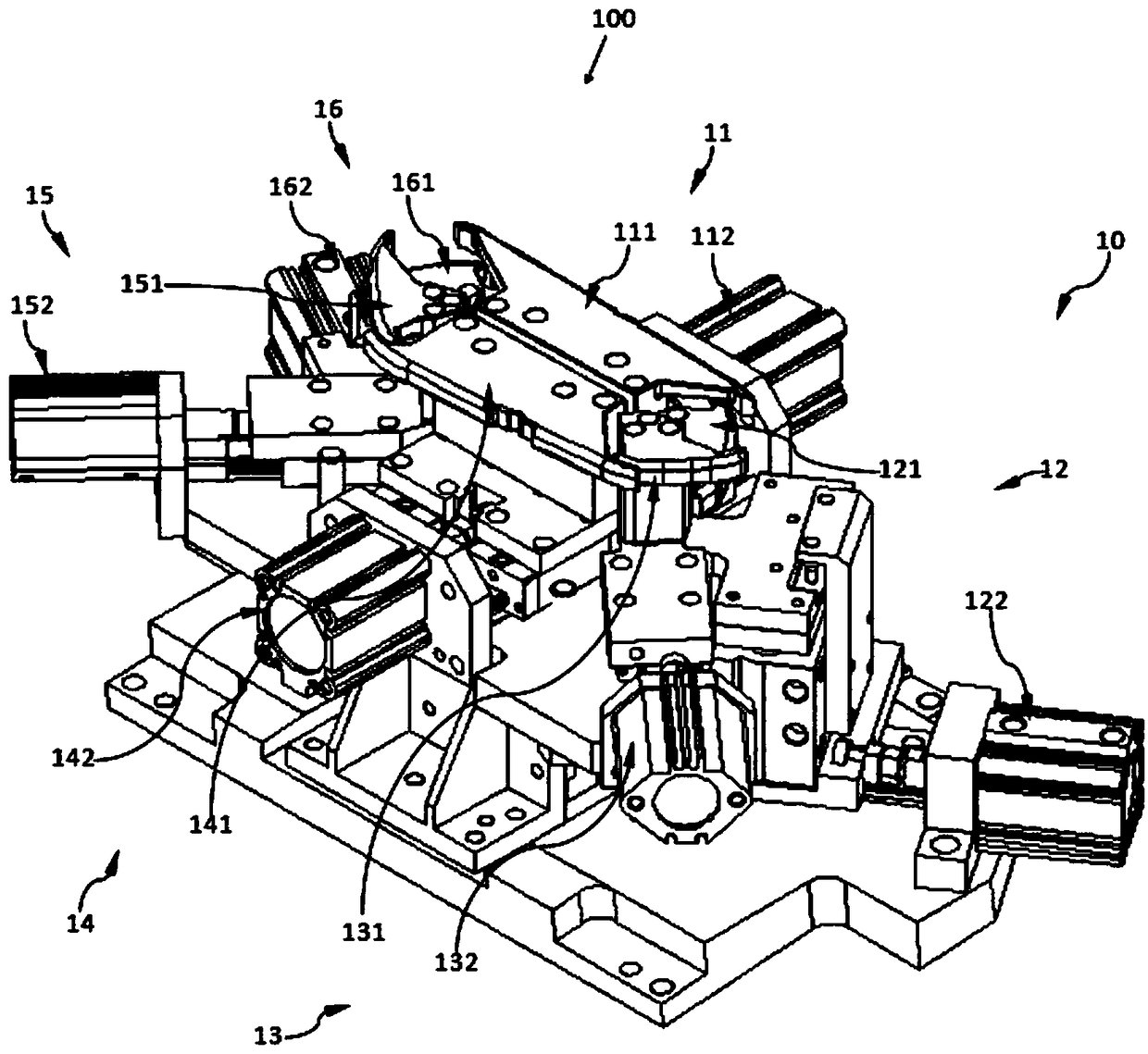

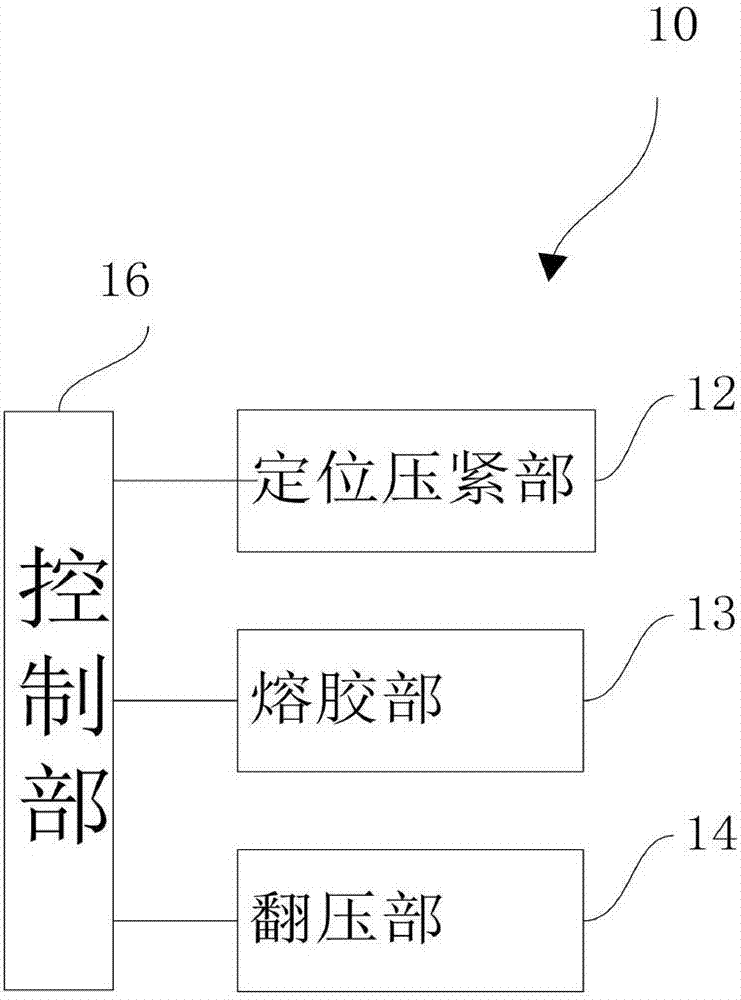

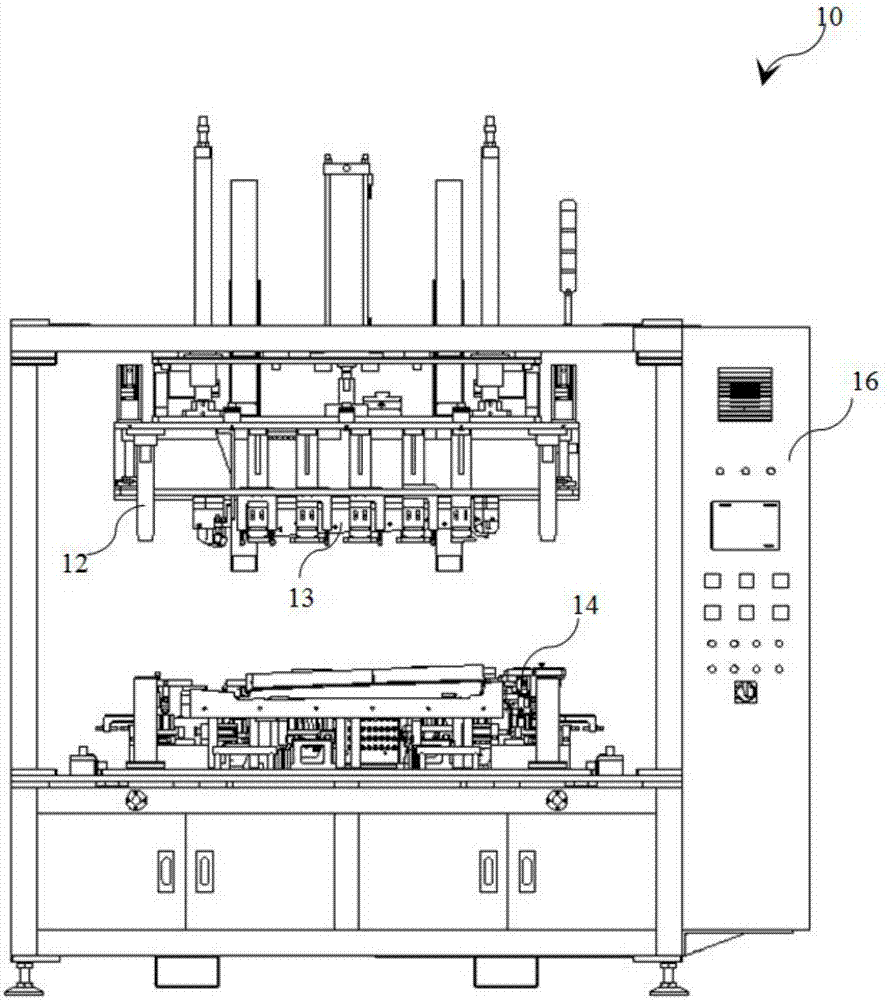

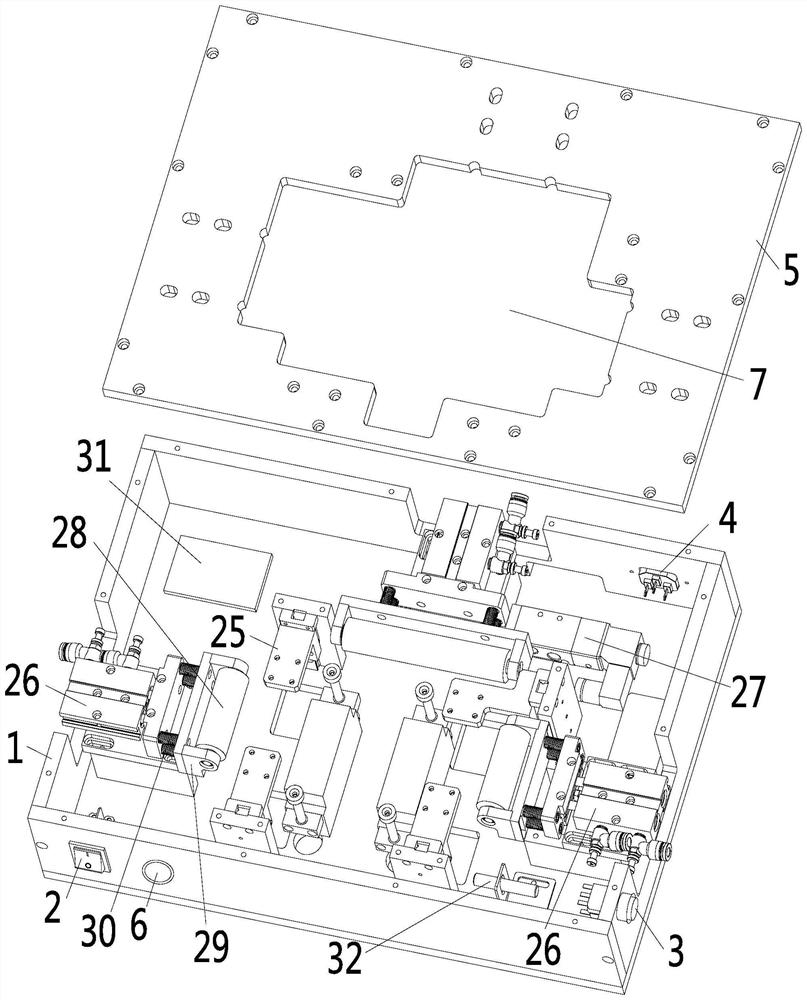

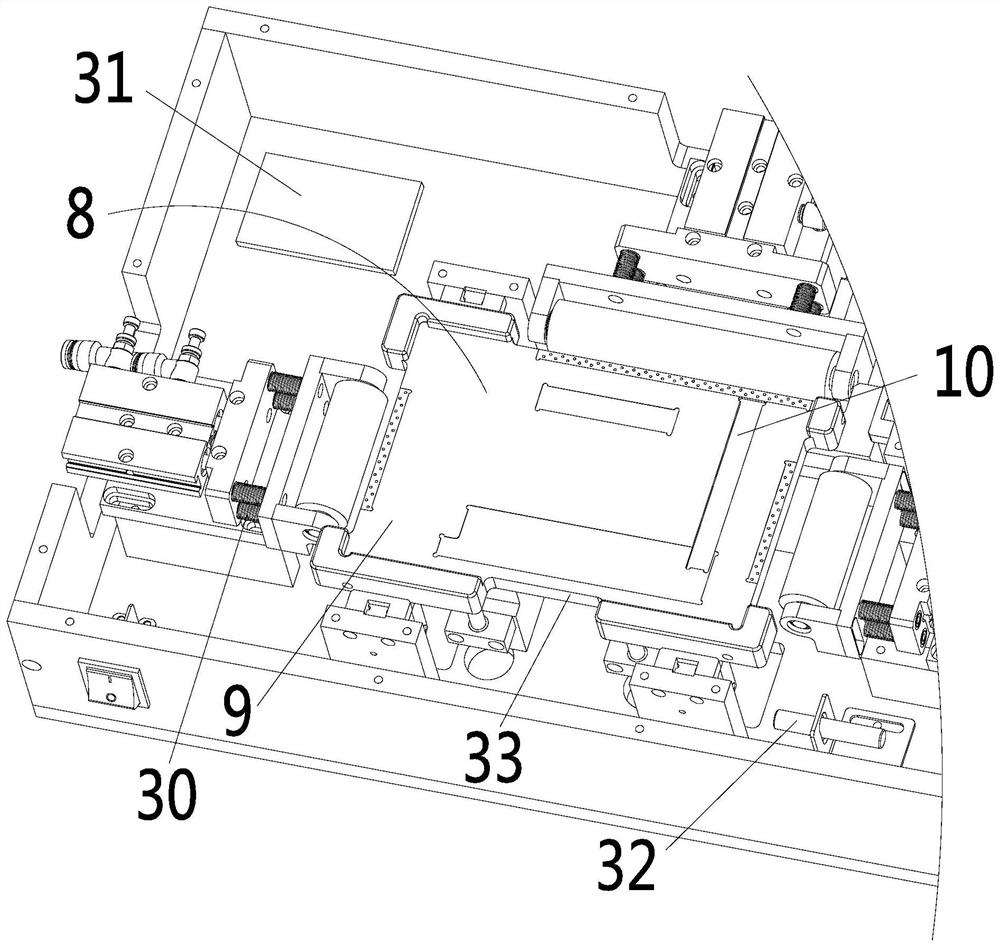

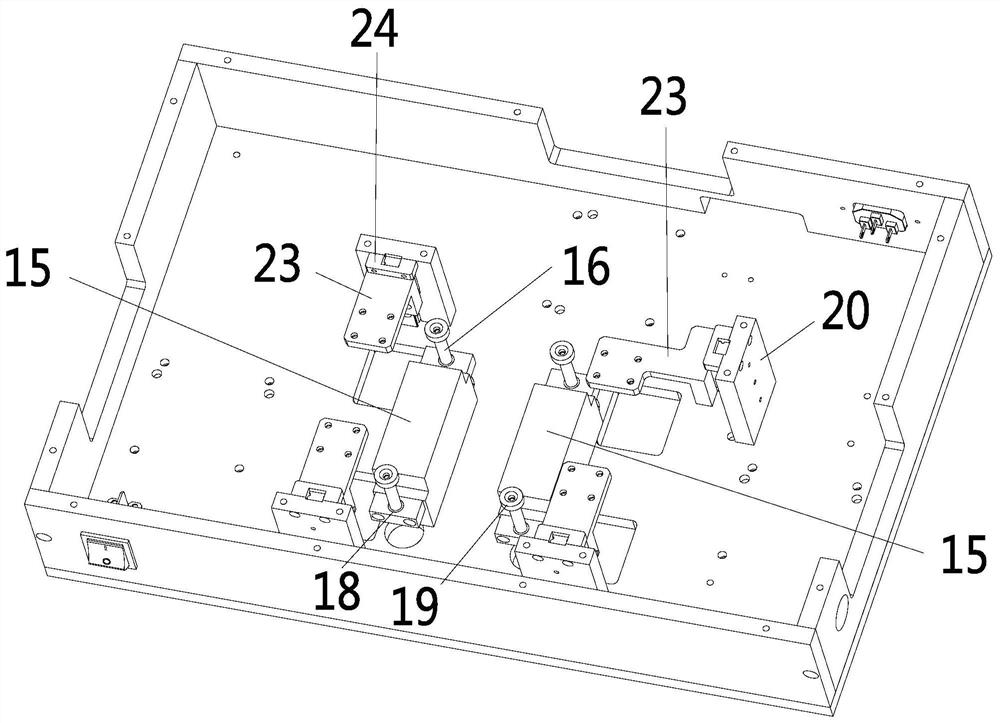

Door trim panel hemming device

The invention provides a car door main plaque edge covering device. The car door main plaque edge covering device is characterized in that the car door main plaque edge covering device comprises a positioning and pressing part, a glue smelting part, an outer ring turning and pressing part, an inwards-concave turning and pressing part and a control part; an inwards-concave edge part is an inwards-concave arc-shaped edge part and comprises two narrow edge parts and a middle part located between the two narrow edge parts; the inwards-concave turning and pressing part comprises narrow edge turning and pressing blocks corresponding to the narrow edge parts in shape, a middle turning and pressing block corresponding to the middle part in shape, a horizontal drive component and a vertical drive component; the horizontal drive component is used for driving the narrow edge turning and pressing blocks and the middle turning and pressing block to advance or retreat successively; the middle turning and pressing block makes close contact with the narrow edge turning and pressing blocks on the two sides after the narrow edge turning and pressing blocks and the middle turning and pressing block complete the advancing action; and the vertical drive component is used for driving the narrow edge turning and pressing blocks and the middle turning and pressing block to conduct the rising or downwards-moving action at the same time. By means of the car door main plaque edge covering device, automatic edge covering of main plaques is achieved, and the percent of pass of products is increased.

Owner:CENMOY AUTOMATION TECH SHANGHAI CO LTD

Aluminum foil edge covering mechanism

InactiveCN106881401AImprove hemming efficiencyRealize the wrapping functionEngineeringBlock structure

The invention relates to an aluminum foil wrapping mechanism, which can satisfy aluminum foil wrapping of aluminum foil packaging products, and the mechanism improves the efficiency and reliability of aluminum foil wrapping. The aluminum foil hemming mechanism includes compression springs, guide posts, dovetail guide rails, wedge-shaped guide sleeves, wedge blocks, hemming pressure plates, pull rods and other components; The closing and opening of the side pressing plate has a simple and ingenious structure, which realizes the function of aluminum foil wrapping, and has the characteristics of small space occupation and high reliability.

Owner:JIANGNAN UNIV

A working method of automatic edge wrapping equipment for aluminum alloy doors and windows

ActiveCN111389659BIncrease incomeImprove hemming efficiencyEngine sealsPretreated surfacesRapid processingMechanical engineering

Owner:BINZHOU YUYANG ALUMINUM IND

Wrapping device

ActiveCN106713541ARealize automatic hemmingGuaranteed precise hemmingTelephone set constructionsMechanical engineeringMobile phone

The invention provides a wrapping device which is used for pressing four sides of the upper diaphragm which is affixed to the back of a mobile phone casing onto four side parts of the mobile phone casing, so as to wrap the mobile phone casing. The mobile phone casing is fixed on a positioning fixture. The wrapping device comprises a roller brush, a pressing mechanism and a drive mechanism which drives the roller brush and the pressing mechanism to be close to or away from the mobile phone casing. The roller brush and the pressing mechanism are connected with the drive mechanism. The pressing mechanism is arranged on one side of the roller brush. When one side part of the mobile phone casing is wrapped, the pressing mechanism is driven by the drive mechanism to first contact the mobile phone casing and press the mobile phone casing against the positioning fixture. The roller brush contacts the side part of the mobile phone casing to fold the side, which is corresponding to the side part, of the diaphragm and press the side against the side part to realize wrapping. According to the invention, automatic wrapping of the mobile phone casing is realized, and the wrapping efficiency and the fit precision are improved.

Owner:GUANGDONG TIANJI IND INTELLIGENT SYST CO LTD

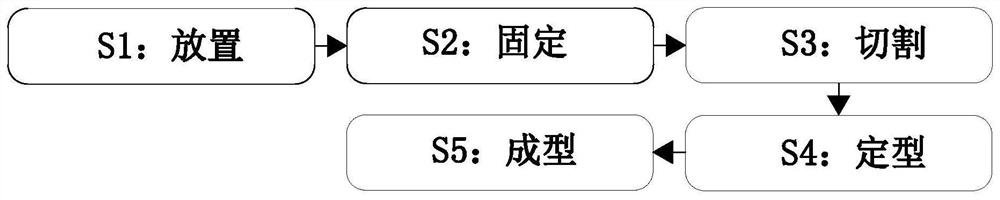

Nanometer polyurethane synthetic leather preparation method

InactiveCN112647272AEasy to sew and shapeAccurate hemming positionSevering textilesHeating/cooling textile fabricsPolymer scienceKnife blades

The invention relates to a nanometer polyurethane synthetic leather preparation method which comprises a work table, a limiting frame, a fixing mechanism, four cutting blades and a pressing and shaping mechanism, the limiting frame is mounted on the upper end surface of the work table, the limiting frame is of a concentric-square-shaped structure, the fixing mechanism is arranged above the work table, and the cutting blades are arranged on the fixing mechanism. The four cutting blades are arranged in a matrix mode, the pressing shaping mechanism is arranged on the work table, the fixing mechanism is used for fixing the position of the synthetic leather, the cutting blades are used for beveling the corners of the synthetic leather, and the edge of the synthetic leather is covered with the material of the synthetic leather. The pressing and shaping mechanism is used for positioning the folding position of the covered edge of the synthetic leather and then pressing and shaping, so that the subsequent sewing and shaping of the synthetic leather are facilitated, the covered edge position of the synthetic leather is accurate, and meanwhile, the covered edge efficiency of the synthetic leather is improved.

Owner:合肥荣茁信息科技有限公司

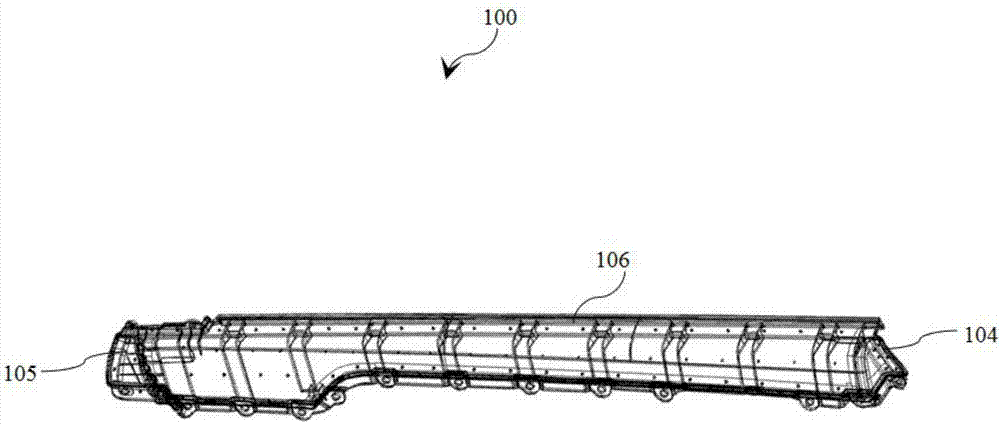

Edge-covering device and edge-covering method for buckle component of decorative plate on car door

The invention provides an edge-covering device for a buckle component of a decorative plate on a car door. The edge-covering device is used for overturning the edge part leftovers of decorative fabrics bonded onto the inner surface of the edge part of the buckle component of the decorative plate on the car door onto the outer surface of the edge part from the inner surface of the edge part of thebuckle component, wherein the edge part is of a hexagonal structure, and provided with a first edge part, a second edge part, a third edge part, a fourth edge part, a fifth edge part and a sixth edgepart which are sequentially connected in the clockwise direction, and the first edge part is the longest. The edge-covering device is characterized by comprising a location mechanism, an edge overturning mechanism, an electrifying mechanism and a control mechanism, wherein the edge overturning mechanism comprises a first edge overturning unit, a second edge overturning unit, a third edge overturning unit, a fourth edge overturning unit, a fifth edge overturning unit and a sixth edge overturning unit. The invention further provides an edge-covering method. The edge-covering method is used for overturning the edge part leftovers of the decorative fabrics bonded onto the inner surface of the edge part of the buckle component of the decorative plate on the car door onto the outer surface fromthe inner surface of the edge part of the buckle component.

Owner:德奥福臻越智能机器人(杭州)有限公司

Hemming device for upper door trim

The invention provides an edge wrapping device for a car door trim, which is characterized in that it includes: a positioning and pressing unit; a melting part; a turning part; and a control for controlling the positioning and pressing unit, the melting part and the turning part part, wherein the positioning pressing unit includes a pressing unit, and the pressing unit includes a point pressing block capable of pressing down the bottom surface of the upper trim panel; and a side pressing block for laterally pressing the left baffle, melt The portion has a heating member conforming to the shape of the edge portions of the front and rear aprons and the left side apron; , the front end of the overturning pressure block is provided with a step conforming to the shape of the edges of the front and rear baffles and the edges of the left side baffle. The hemming device for the upper decorative panel of the car door of the invention realizes the automatic hemming of the upper decorative panel, and solves the problem of wrinkling of the decorative fabric after hemming.

Owner:CENMOY AUTOMATION TECH SHANGHAI CO LTD

Palm plate edge covering machine

PendingCN111501212AImprove hemming efficiencySave the manpower to lock and pull the clothWork-feeding meansPressersElectric machineryStructural engineering

The invention belongs to the technical field of sewing machinery, and particularly relates to a palm plate edge covering machine. The palm plate edge covering machine comprises a main machine frame, amain machine, a computer control terminal, a travelling motor, a main power motor and a variable presser foot, wherein the main machine is arranged on the main machine frame, and the travelling motorand the main power motor are connected with the computer control terminal and controlled by instructions of the computer control terminal. The palm plate edge covering machine is high in edge covering efficiency and attractive in covered edges; one third of the lower portion of an outer body below the variable presser foot is provided with an inclined face, a variable turning plate can incline downwards when being subjected to stress, the edge covering presser foot presses in an angular mode, an edge belt tightener on the edge drives a motor to rotate to tighten edge covering cloth, manual counter-locking cloth pulling is omitted, and edge covering can be directly achieved, so that the working efficiency is remarkably improved; and in addition, the palm plate edge covering machine is reasonable in structural design, high in edge covering efficiency, convenient to use and suitable for being popularized and used in related technical fields.

Owner:郑玲玲

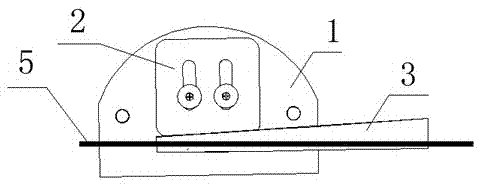

Guiding nozzle for covering machine

InactiveCN106988025AImplement bootstrapImprove hemming efficiencyWork-feeding meansNozzleEngineering

The invention relates to a guide nozzle of a hemming machine, comprising a fixing plate, a mounting plate, a guiding groove, a guiding spring, and hemming cloth. The mounting plate is installed on the fixing plate, and the guiding groove is welded on the mounting plate. Below, the guide spring is on one side of the guide groove, the hemming cloth is wound on the guide spring in an S shape, and the hemming cloth is in the guide groove. The present invention realizes the guiding of the hemming cloth through the setting of the guide nozzle of the hemming machine, improves the hemming efficiency and reduces the cost.

Owner:天津新来服饰有限公司

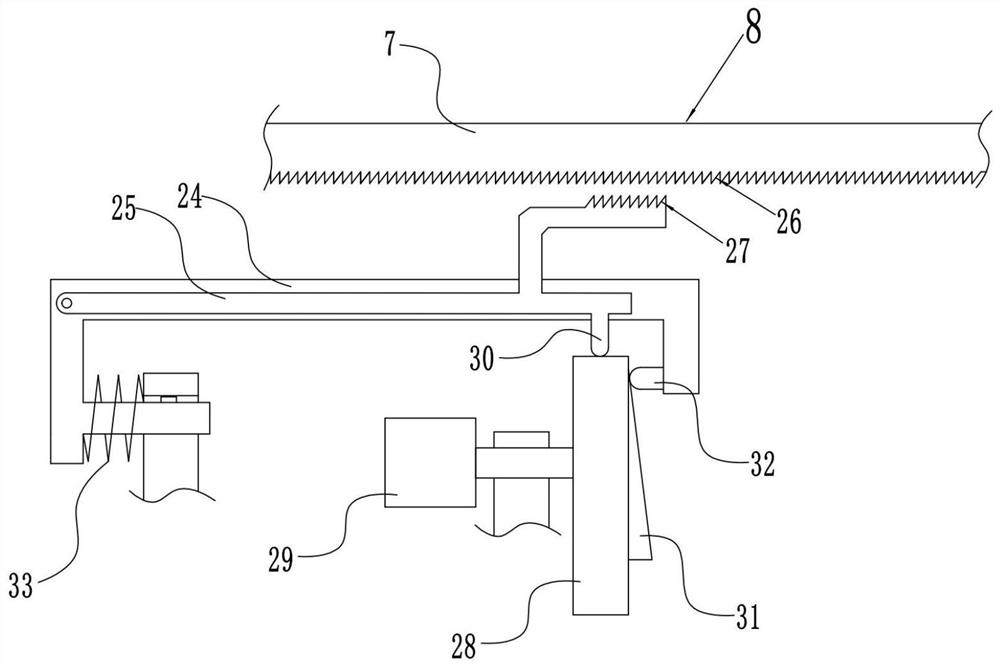

A lithium battery edge wrapping machine with integrated positioning, discharging and belt pressing

ActiveCN107732308BSimple structureImprove hemming efficiencyAssembling battery machinesFinal product manufactureDistribution controlActuator

The invention relates to a lithium battery hemming machine integrating positioning discharging and belt pressing, which includes a frame and a power distribution control box. , The right side is equipped with a feeding device, the feeding device is equipped with a loading device, and the right side of the loading device is equipped with a gluing mechanism. The upper part of the upper part is provided with a glue-pressing front and rear movable device, a glue-pressing movable seat is arranged on the glue-pressing movable device, a glue-pressing lifting cylinder is arranged on the glue-pressing movable seat, and a glue-pressing lifting cylinder is connected with a glue-pressing limit wheel. The upper part of the discharge turning device is equipped with a limit glue device, which can not only limit the position of the unloaded product, but also perform glue treatment on the glued product, which simplifies the structure of the glue device and can realize continuous The material is glued and glued, which greatly improves the efficiency of the overall wrapping.

Owner:JIANGXI HUAHAO NEW ENERGY CO LTD

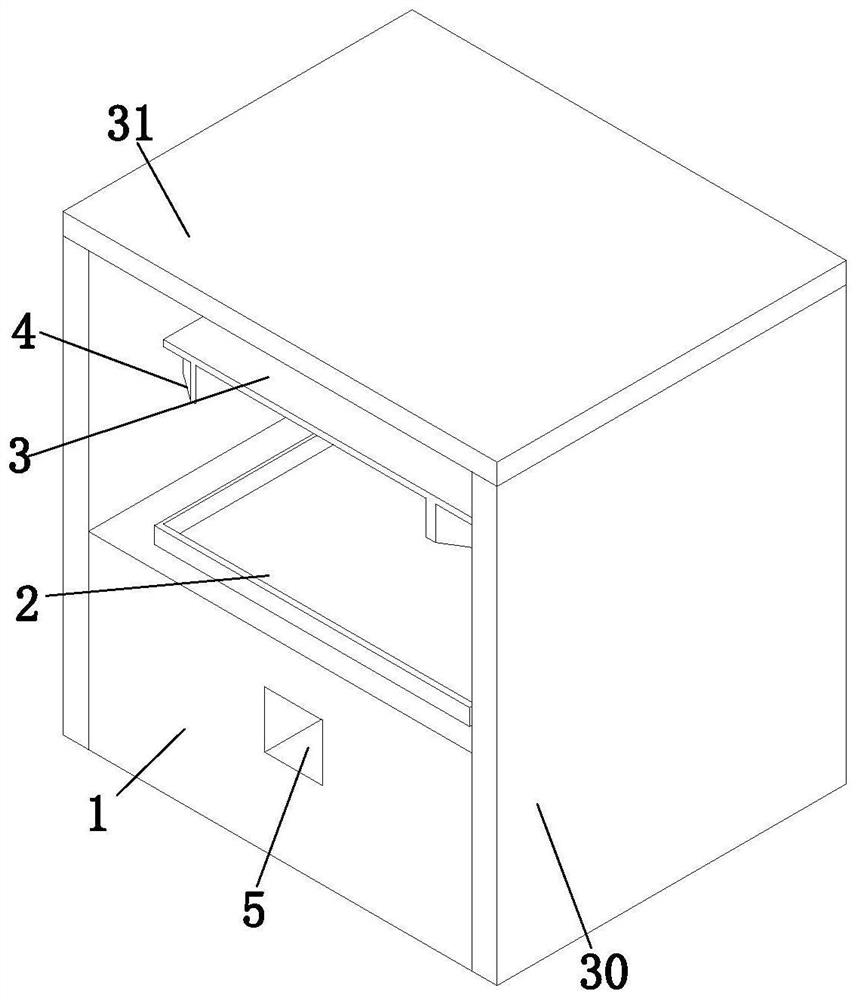

Adhesive tape edge covering device

PendingCN114314148AImprove hemming efficiencyPress evenlyArticle deliveryStructural engineeringCovers (device)

The invention relates to an adhesive tape edge covering device which comprises a tool box, a power switch arranged on the front side of the tool box, a start key arranged on one side of the tool box, an alternating current wire inlet port formed in the rear side of the tool box, a cover plate arranged on the upper side of the tool box and a pressing mechanism arranged above the middle of the cover plate. An assembly table is arranged in the tool box right opposite to the assembly window, a rebound mechanism is arranged on the lower side of the assembly table, sliding mechanisms are arranged at four corners of the assembly table, a plurality of edge covering mechanisms are arranged on multiple sides of the assembly table, a plurality of adsorption mechanisms are arranged on the edge, close to the edge covering mechanisms, of the surface of the assembly table, and a control mechanism and a direct-current power source are arranged in the tool box. The scheme has the following advantages: 1, the adhesive tape edge covering efficiency is improved; 2, the adhesive tape is pressed uniformly without bubbles, so that the quality is ensured; and 3, a plurality of strips can be pasted at one time, so that other abnormities such as pollution caused by frequent taking are reduced.

Owner:惠州市福瑞尔光电有限公司

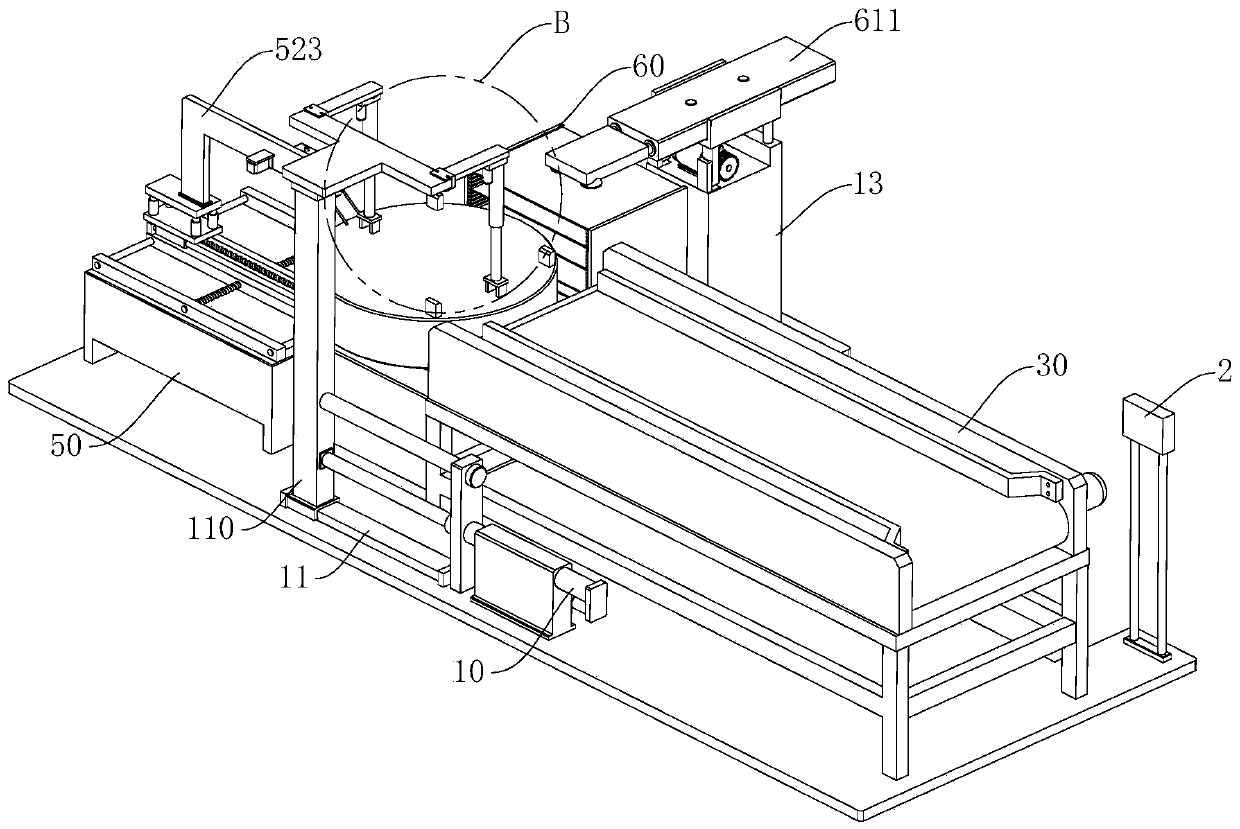

Cardboard edge wrapping device

ActiveCN111844922AImprove efficiencyHigh precisionMechanical working/deformationPaperboardSmall footprint

The invention provides a cardboard edge wrapping device. A paper conveying mechanism is used for conveying paper of the predetermined size for edge wrapping to a conveying table. A gluing mechanism isused to coat the upper surface of the paper with glue in the conveying direction of the paper. The conveying table is provided with a first conveyor belt for conveying a cardboard into an edge wrapping mechanism in the transverse direction. A cardboard conveying mechanism comprises a trolley and a grabbing mechanism, the trolley is used to convey the cardboard, and the grasping mechanism is usedto grab the cardboard on the trolley and place the cardboard on the first conveyor belt, or grab the cardboard on the first conveyor belt and place the cardboard on the trolley. The edge wrapping mechanism is used for wrapping edges of the cardboard and transporting the edge-wrapped cardboard to the first conveyor belt. The device has high degree of automation, compact structure, small floor space, high equipment utilization rate, and low production and manufacturing cost, can greatly reduce labor intensity, and save the labor cost, and is especially suitable for factory cardboard edge wrapping operations.

Owner:朱蓉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com