Aluminum foil edge covering mechanism

A technology of wrapping and aluminum foil, applied in the field of machinery, can solve the problems of difficult to guarantee the quality of wrapping, high labor intensity and high labor cost, and achieve the effect of small occupied space, simple and ingenious structure, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with specific drawings and embodiments.

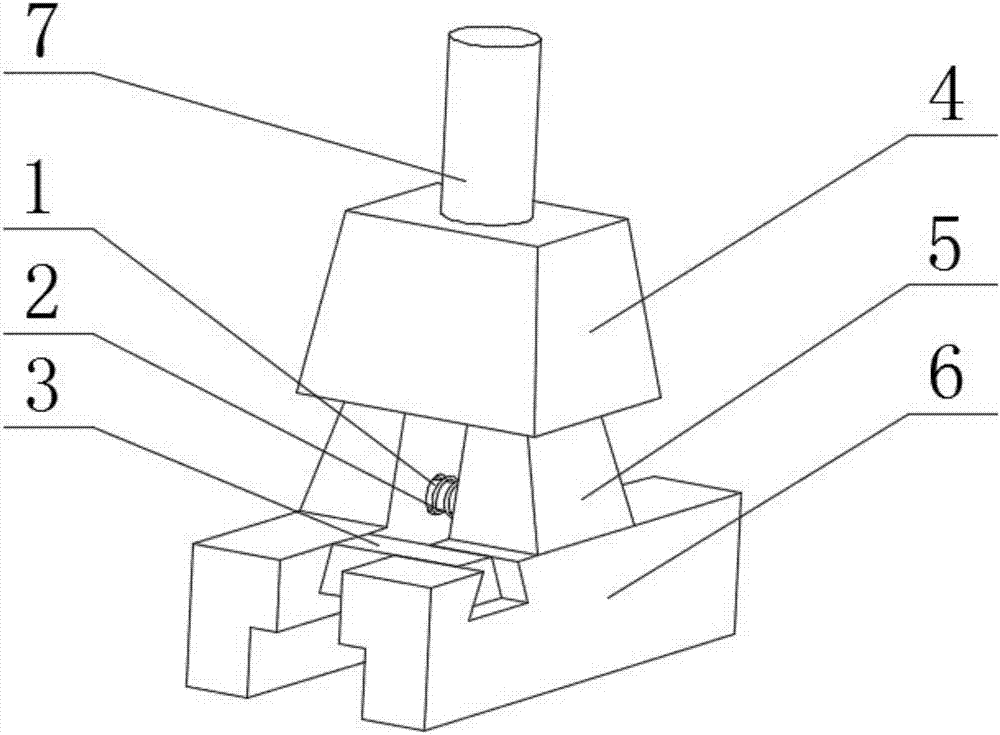

[0009] As shown in the figure: the present invention is mainly composed of a guide post 1, a compression spring 2, a dovetail guide rail 3, a wedge-shaped guide sleeve 4, a wedge-shaped block 5, a wrapping pressure plate 6, and a pull rod 7; the left base plate 1 and the right base plate 2 pass through The bottom plate connecting pin 15 is connected, and the left boss 5 and the right boss 6 can be blocked mutually. The working part of the aluminum foil hemming mechanism is made up of two hemming pressing plates 6, and a dovetail guide rail 8 is respectively arranged on both sides of the aluminum foil hemming mechanism, and the dovetail guide rail 8 can slide in the hemming pressing plate 6. The wedge block 5 is fixed on the wrapping pressure plate 6; the guide post 1 is connected to the wedge block 5; The pull rod 3 is fixed on the wedge-shaped guide sleeve 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com