Guiding nozzle for covering machine

A technology of hemming machine and guide groove, which is applied in the direction of cloth feeding mechanism, sewing machine components, textiles and paper making, etc., can solve the problems of affecting production efficiency and slow speed, and achieve the effect of improving hemming efficiency and reducing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

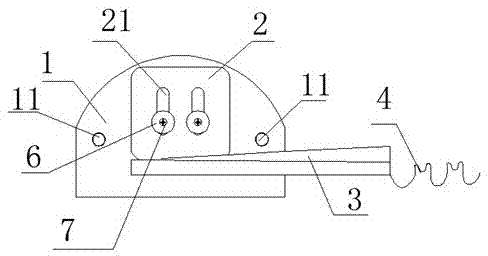

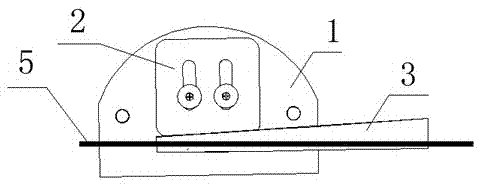

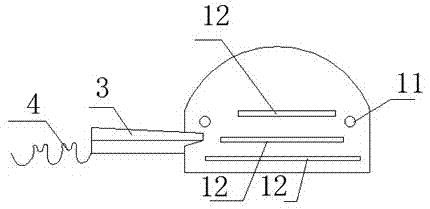

[0019] Such as Figure 1-4 As shown, a guide nozzle of a hemming machine includes a fixed plate 1, a mounting plate 2, a guide groove 3, a guide spring 4, and a hemming cloth 5, and the described mounting plate 2 is installed on the fixed plate 1, and the described The guide groove 3 is welded under the mounting plate 2, the guide spring 4 is on one side of the guide groove 3, the hemming cloth 5 is wound on the guide spring 4 in an S shape, and the hemming cloth 5 is on the Inside the guide groove 3.

[0020] Further, mounting holes 11 are provided on both sides of the fixing plate 1 , and the mounting plate 2 is mounted on the fixing plate 1 through screws 6 . The setting of the mounting holes 11 facilitates the positioning of the fixing plate 1 .

[0021] Further, the installation plate 2 is provided with an adjustment notch 21 , and the adjustment of the height of the guide groove 3 is facilitated by setting the adjustment notch 21 .

[0022] Further, a washer 7 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com