Compensation tank for a hydraulic motor vehicle brake system

A technology of hydraulic brake and container, applied in the direction of hydraulic brake transmission, etc., can solve the problems of loss and forget to install, and achieve the effect of eliminating the effect of the filter and avoiding the cost of the mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

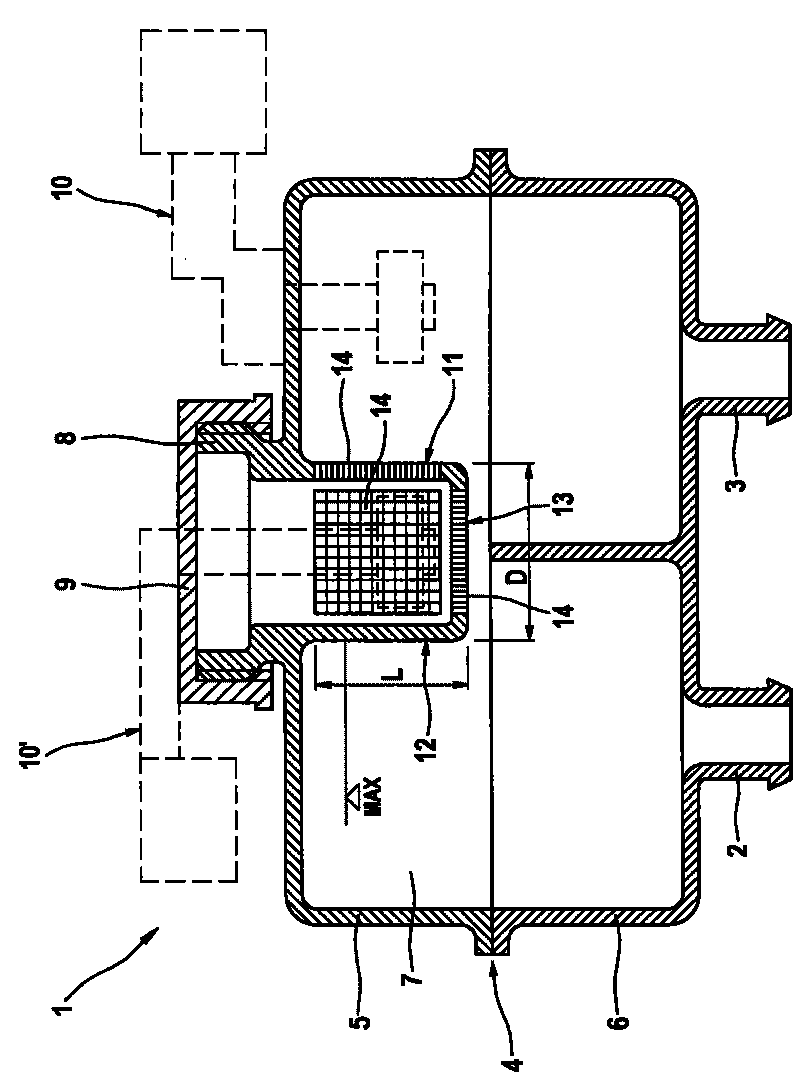

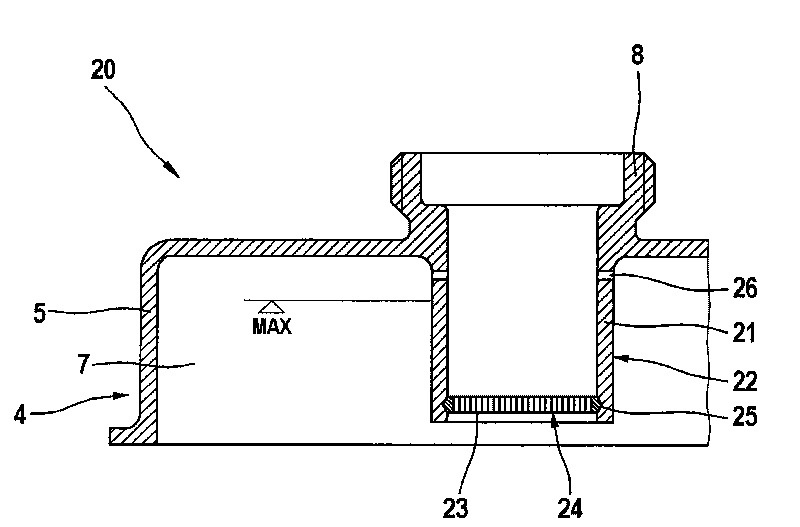

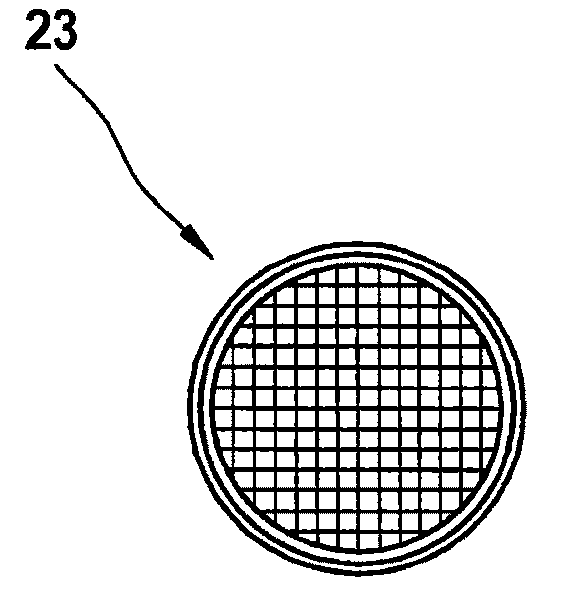

[0029] Figure 1 to Figure 5 An embodiment of a resupply container 1 , 20 , 40 according to the invention is shown, the structure and function of which substantially correspond to those of known resupply containers.

[0030] Such as figure 1 As shown, the supply container 1 is usually connected via container sockets 2 , 3 to a master cylinder (not shown) and fastened thereto. The replenishment container 1 has a housing 4 with at least one pressure medium chamber 7, wherein the housing 4 comprises a housing upper part 5 and a housing lower part 6, which at their edges and the not-shown partition walls are welded to each other.

[0031] For filling the replenishment container 1 , a cylindrical filling connection 8 is provided which protrudes at right angles from the upper side of the housing upper part 5 . The cap 9 is used to close the filling connection 8 . In order that the changing liquid level does not cause a pneumatic pressure to build up, structures are provided for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com