Systems for transshipment of goods lined up on handling equipment

A technology for loading and unloading equipment and cargo, which is applied in the field of cargo systems, can solve problems such as the impact of conveying capacity, achieve great flexibility, shorten debugging time, and reduce investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

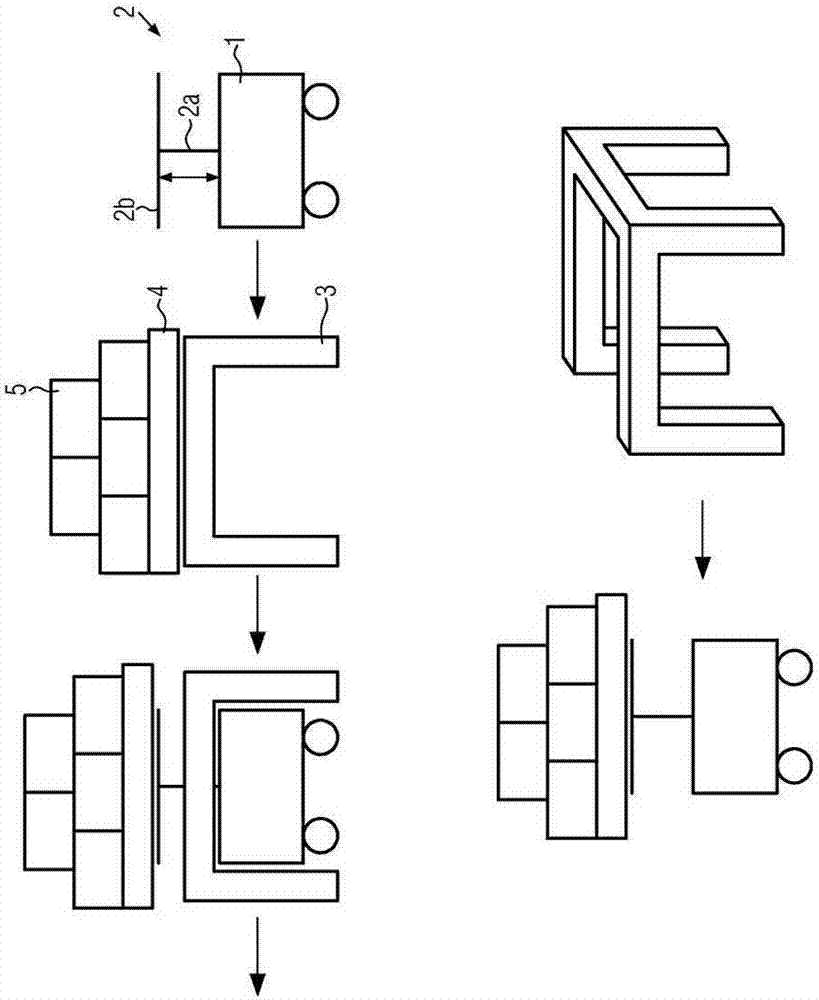

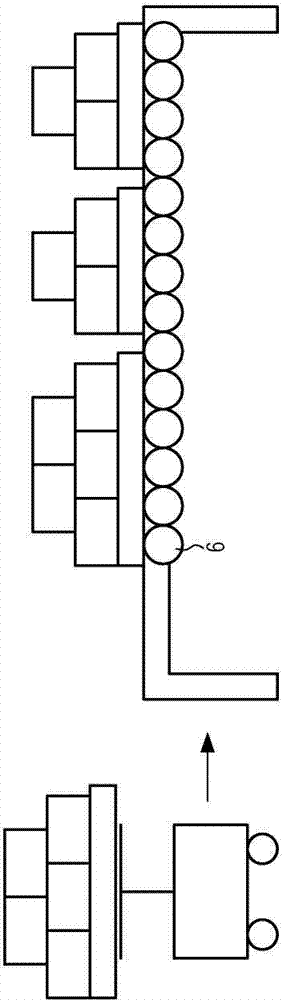

[0029] Figure 1 to Figure 4 Different views of an embodiment of the transport system according to the invention are shown.

[0030] here, figure 1 Indicates that a transfer trolley 1 is loaded at the transfer station 3 . The transfer trolley 1 is an unmanned transfer trolley with a compact design, that is, it is preferably designed to be close to the ground. The lifting device 2 is arranged above the transfer trolley 1 . The lifting device 2 includes an adjustment member 2a and a support member 2b, and the support member 2b can be raised or lowered vertically through the adjustment member 2a. When it is in its rest position, it is recommended that the support 2b be arranged as close as possible to the surface of the transfer trolley 1 in order to support this compact design as much as possible, especially when the transfer trolley is parked in the rest position. The transfer trolley implemented here can move freely, that is, the trolley can move freely through the wheels ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com