Patents

Literature

61results about How to "Fully automatic adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

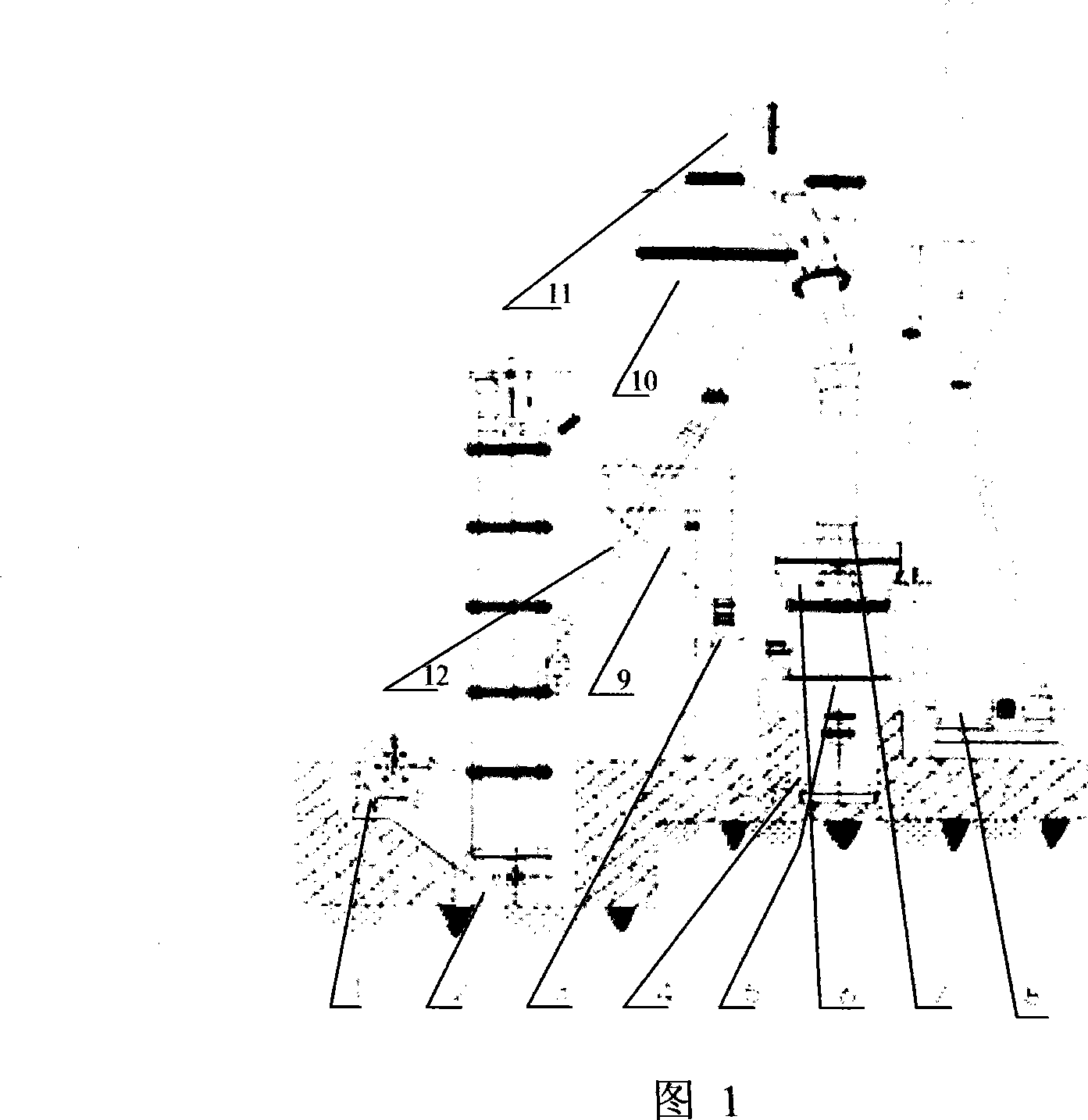

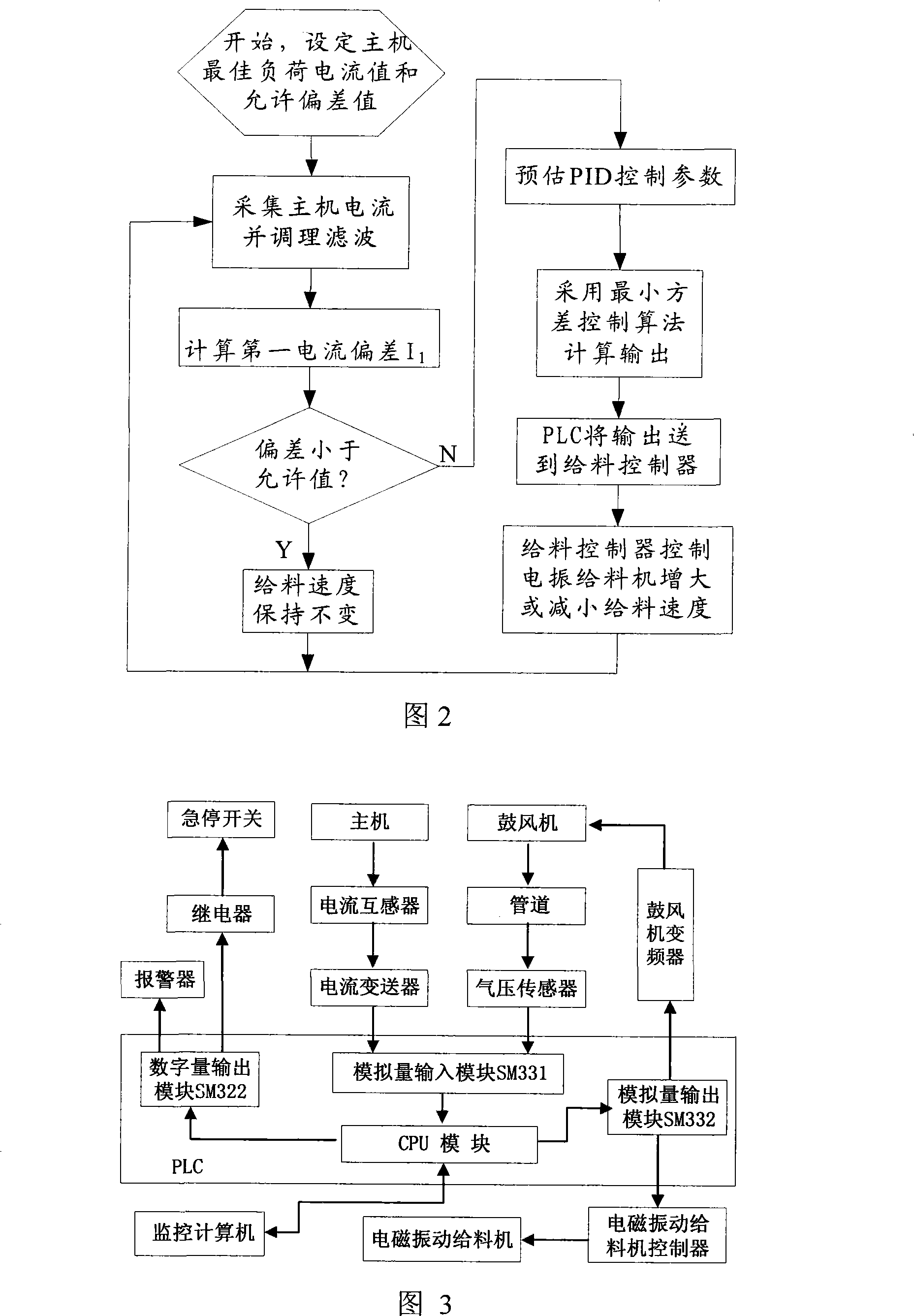

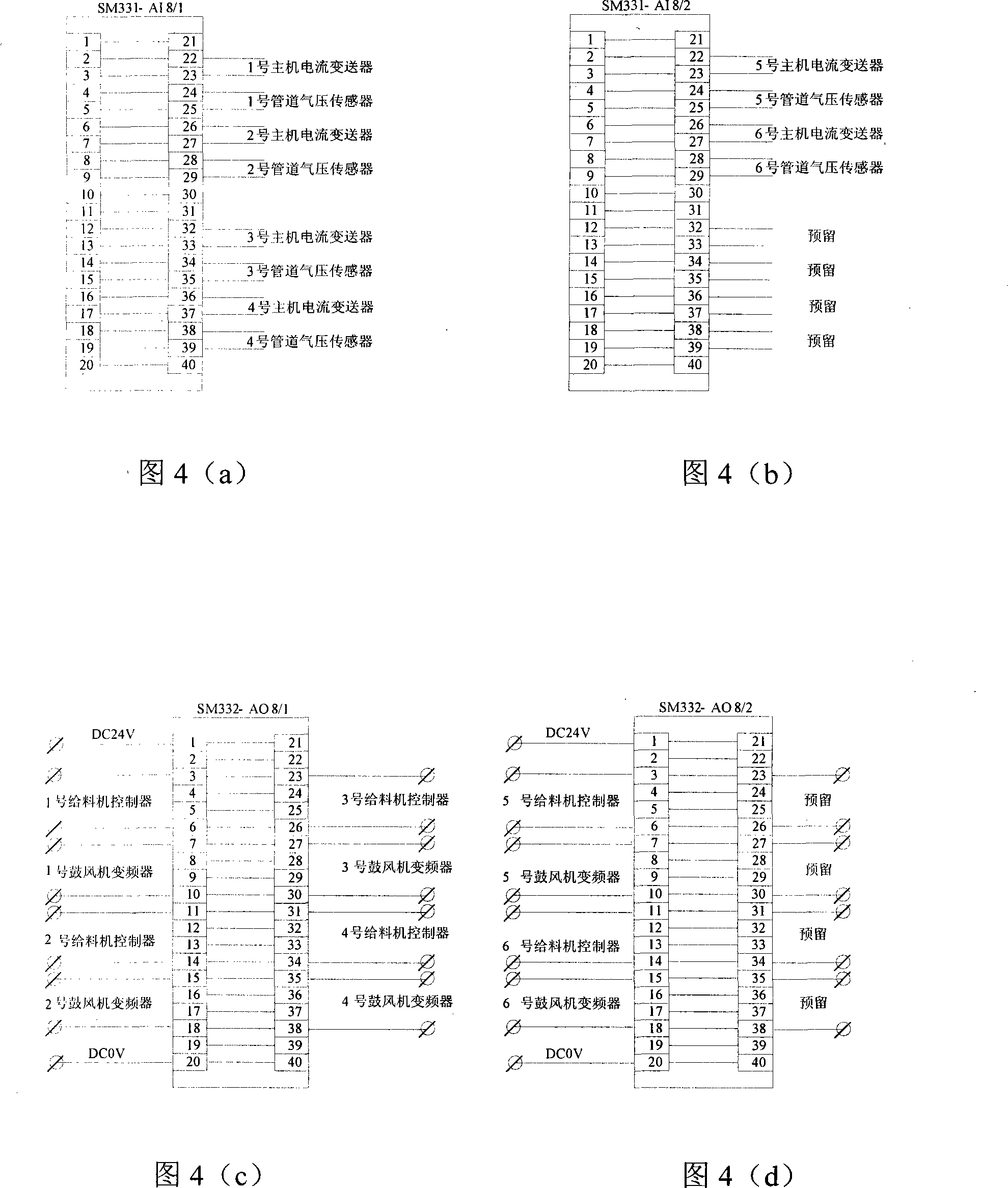

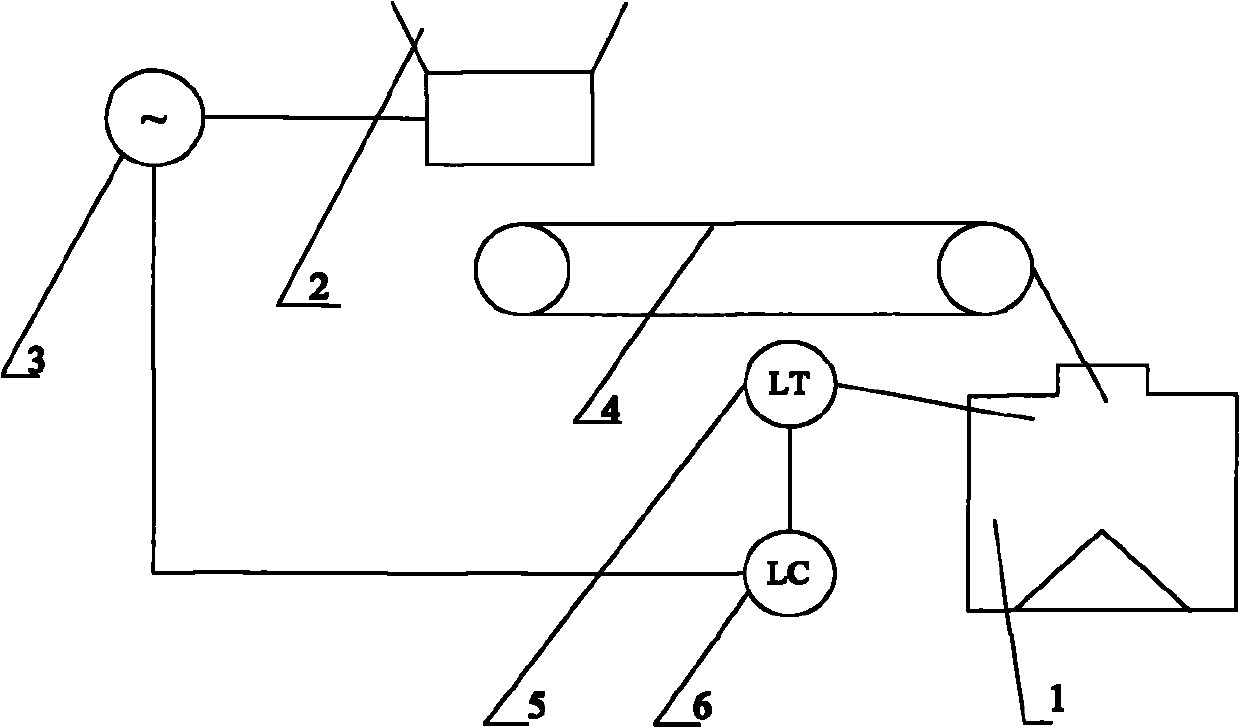

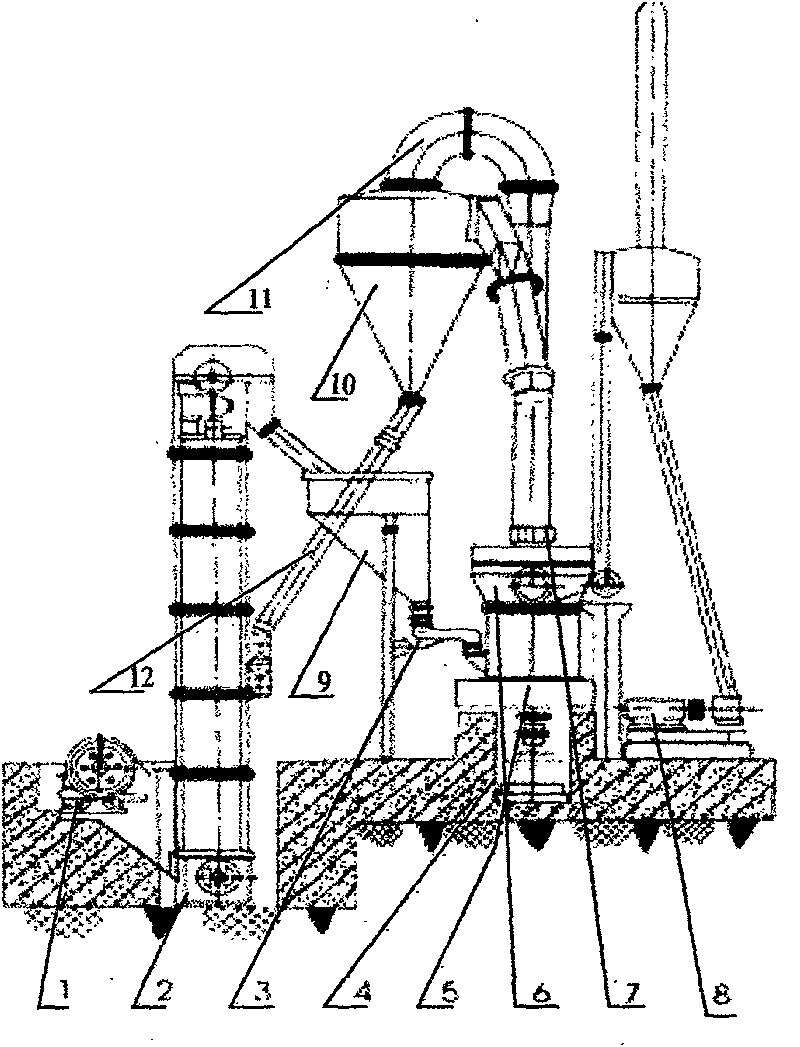

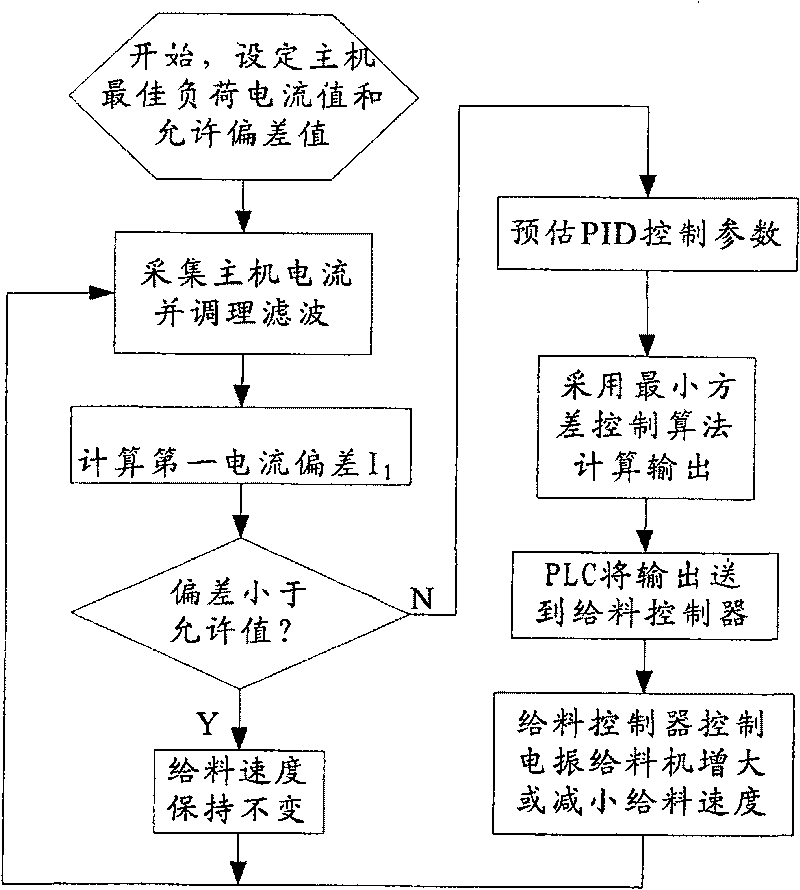

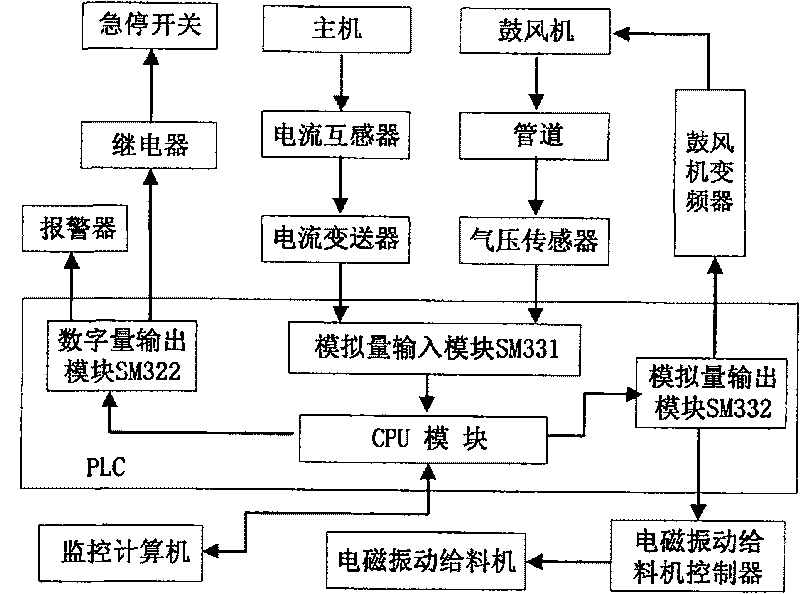

Raymond mill crashing auto control method and equipment thereof

InactiveCN101229525AReduce energy consumptionReduce equipment failure rateGrain treatmentsTotal factory controlAutomatic controlSelf adaptive

The invention discloses an automatic control method of Raymond mill grinding. Equipment can be automatically adjusted so as to ensure that the Raymond mill runs at an optimum load condition. The invention also discloses an automatic control method and an automatic control device for implementing the Raymond mill grinding. The device not only can real-time monitor the operation condition of feeding, grinding, airflow rough separation in a Raymond mill workshop, but also can automatically adjust feeding and grinding according to the main engine load. Furthermore, the invention also can automatically adjust a blower on the basis of technical requirements, which realizes the automation of the airflow rough separation and overcomes the shortcomings of manual operation operated by workers. The invention adopts a self-adaptive control method to adjust and control and employ a programmable logic controller as a control core. No manual operation is needed in the whole production process, thus realizing the fully automatic adjustment of feeding, grinding and airflow rough separation, saving energy, greatly reducing equipment failure rate and increasing productive efficiency; through using a supervisory control computer witch can carry out a real-time monitor, the working parameter and index parameter of the PLC can be modified at any time so as to improve production efficiency.

Owner:SOUTHEAST UNIV

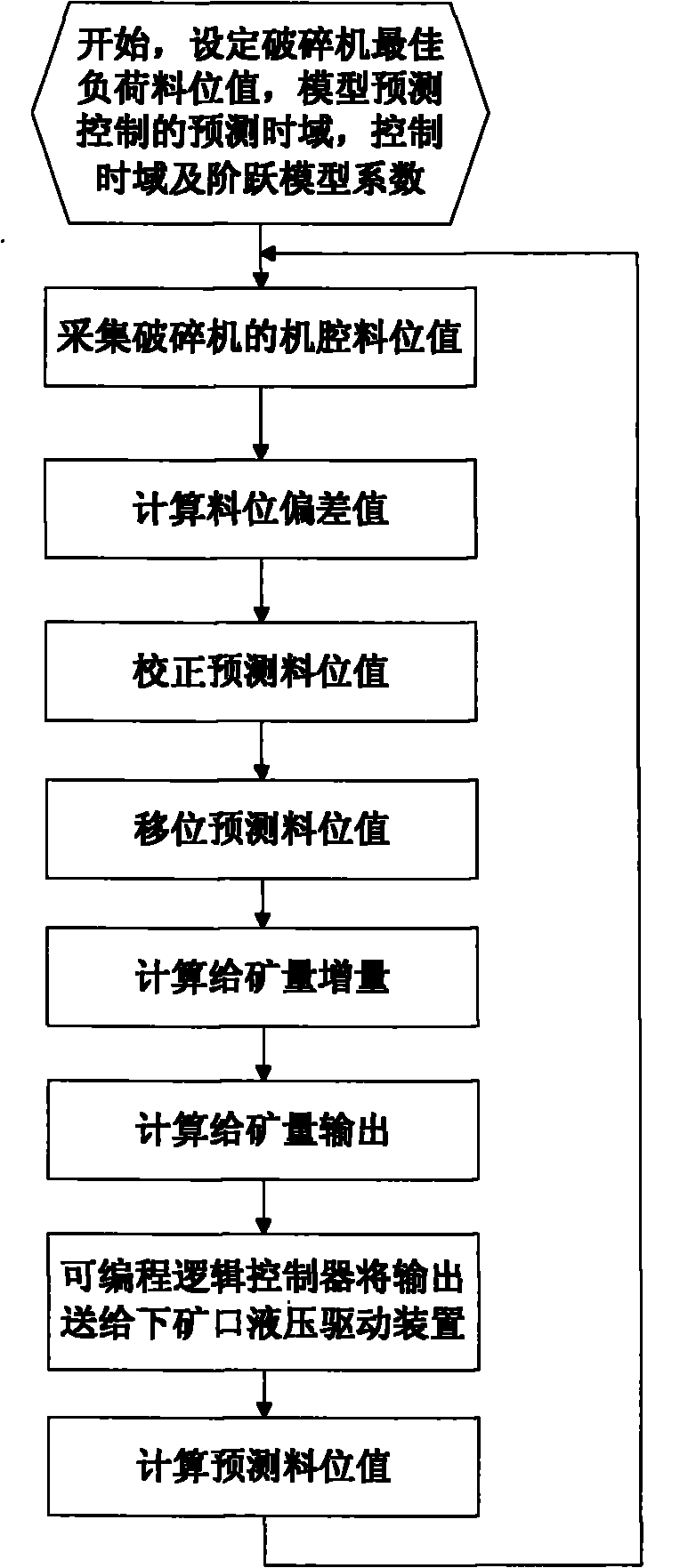

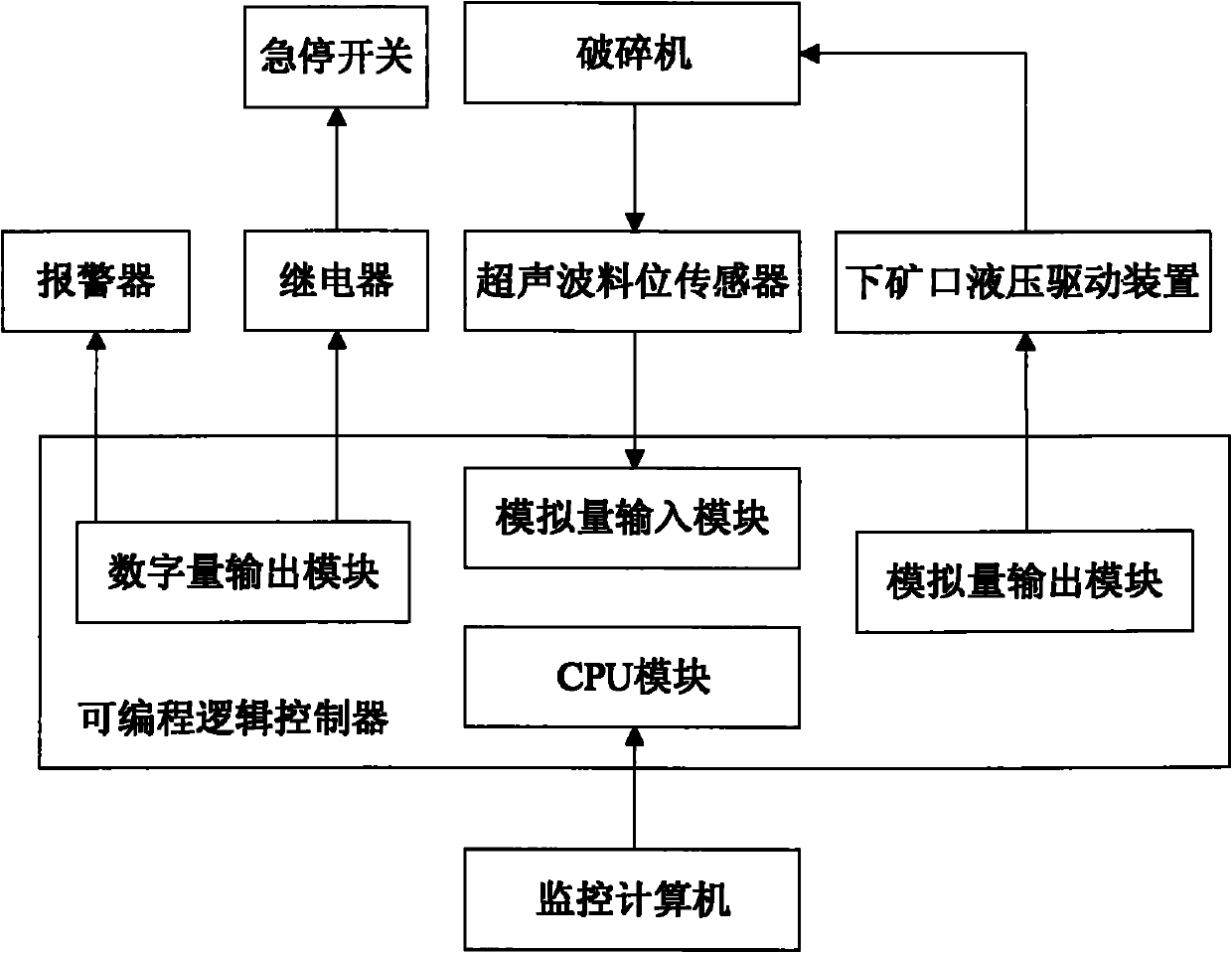

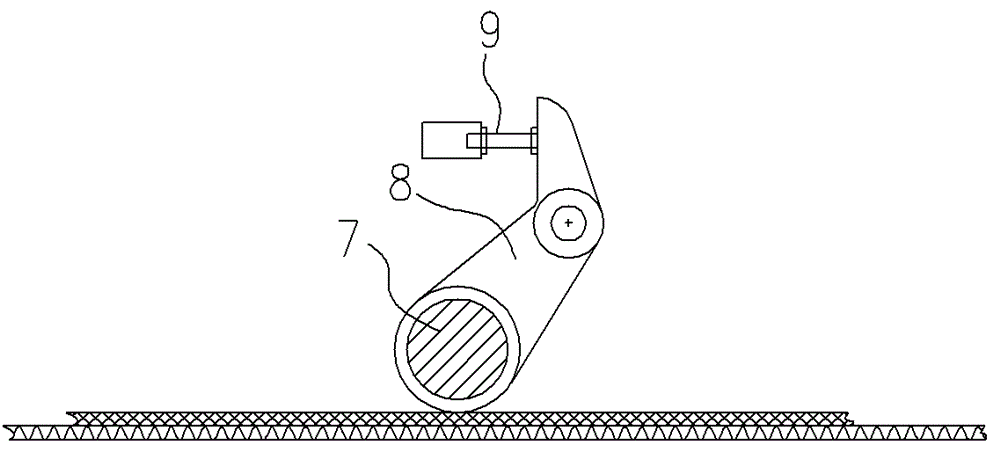

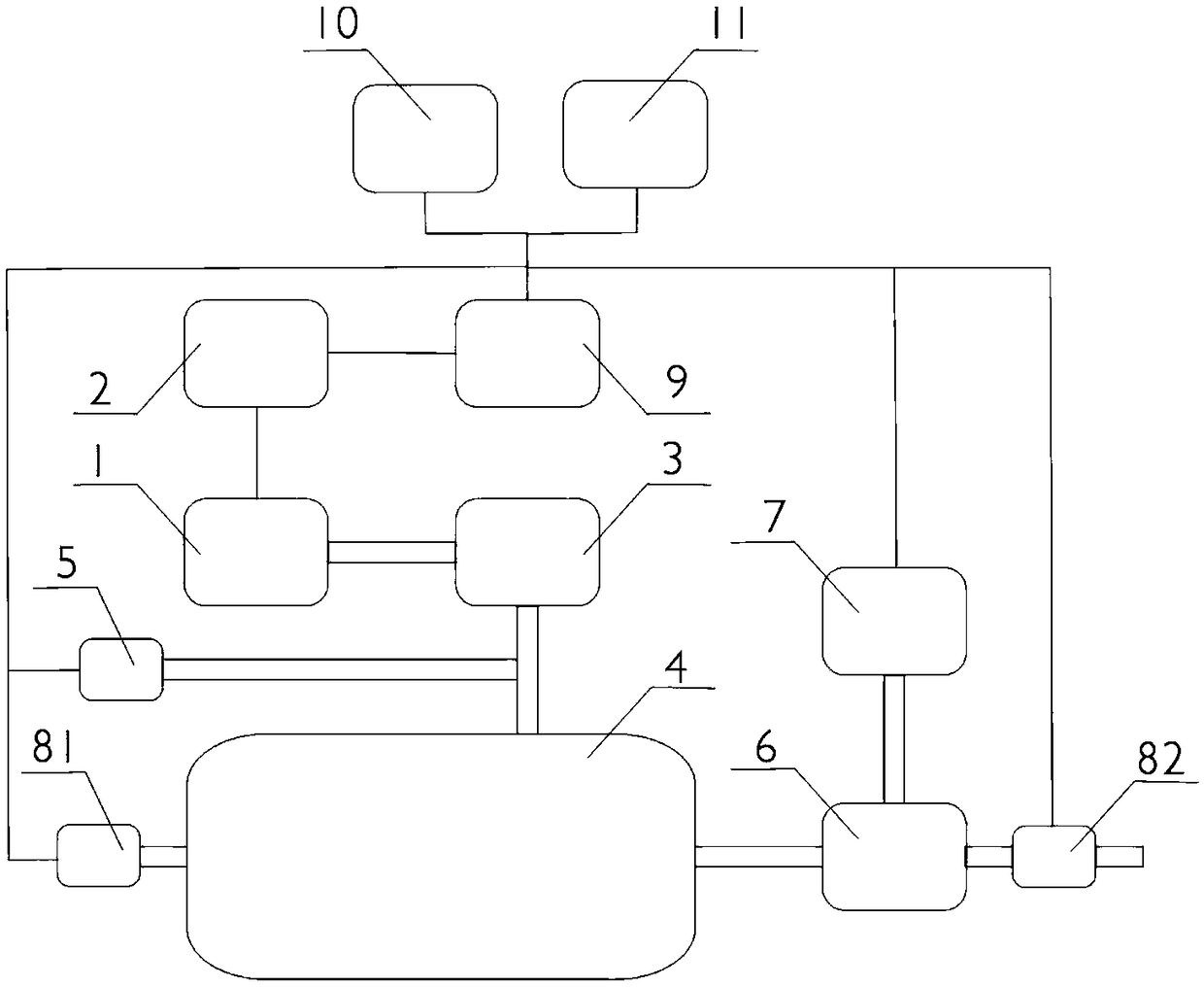

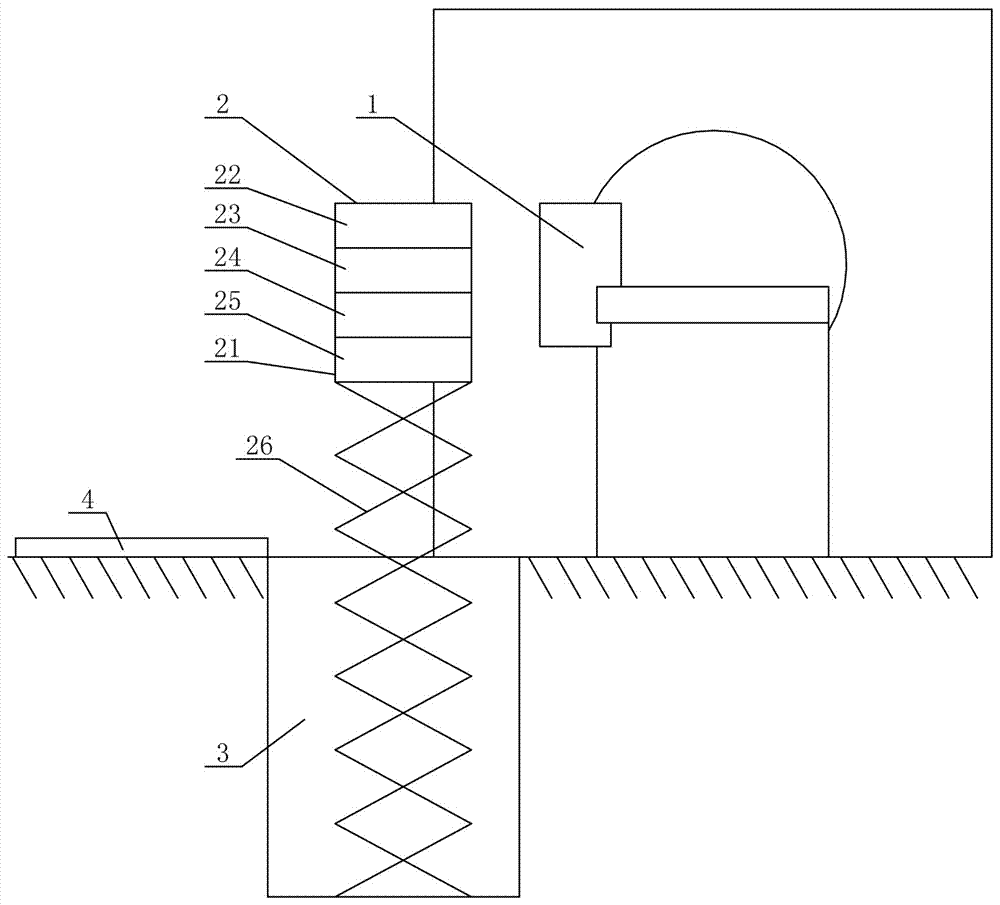

Device and method for automatically controlling choke feed of conical crusher

InactiveCN102000627AFully automatic adjustmentExtended service lifeGrain treatmentsAutomatic controlProgrammable logic controller

The invention discloses device and method for automatically controlling the choke feed of a conical crusher. The device comprises an ultrasonic level sensor, a programmable logic controller and a monitoring computer, wherein the programmable logic controller comprises an analogue input module, a CPU (Central Processing Unit) module and an analogue quantity output module and is taken as a control core; by using a model predicting control method for adjusting and controlling, the fully-automatic adjustment of feeding ore and crushing can be realized, the defect of manual operation can be avoided, the crushing efficiency can be improved, the service life of the crusher can be prolonged, the energy consumption can be reduced and the production benefit can be increased; and by using the monitoring computer for monitoring in real time, work parameters and index parameters of the programmable logic controller can be modified on line and the production efficiency can be improved.

Owner:SOUTHEAST UNIV

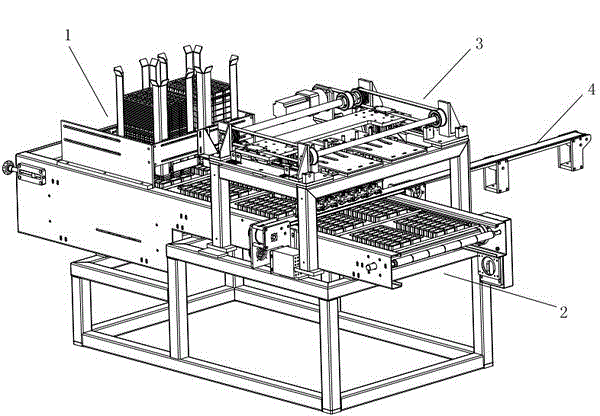

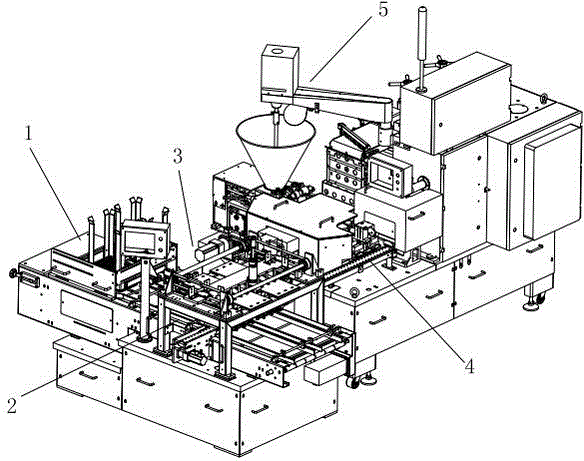

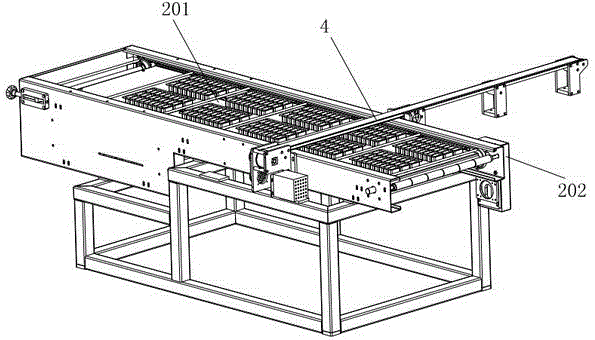

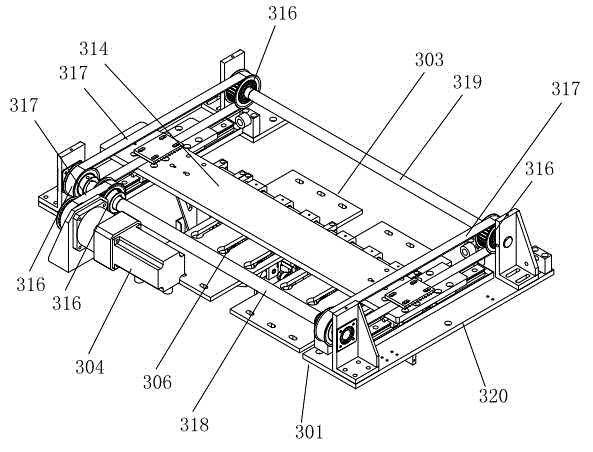

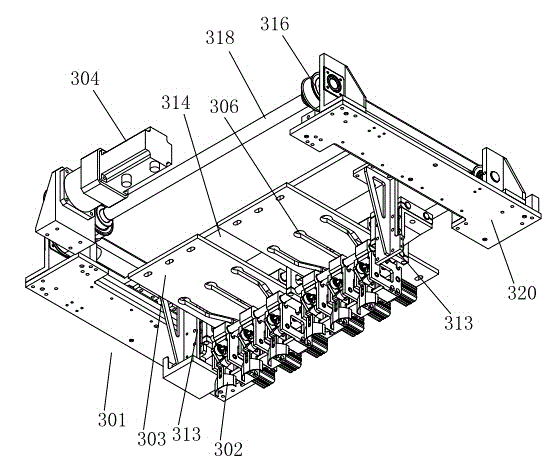

Food boxing machine

The invention relates to the field of a food processing machine, and particularly relates to a food boxing machine. The food boxing machine comprises a box feeding mechanism, a box arranging transport mechanism and a clamping mechanism, wherein the box feeding mechanism and the clamping mechanism are respectively arranged above the box arranging transport mechanism, the box feeding mechanism is arranged on one end of the clamping mechanism, and one side of the clamping mechanism is provided with a conveyor belt for transporting to-be-arranged food; the clamping mechanism comprises an installation framework, and the installation framework is provided with a plurality of mechanical claws. The movement of the mechanical claws in three directions are realized by utilizing a guide device, a horizontal drive mechanism and a vertical drive mechanism; moreover, the full-automatic adjustment can be realized, and the distance adjustment of the mechanical claws can be automatically realized under the situation that no manpower is needed; the food boxing machine can be suitable for various support boxes in various sizes only by replacing a track plate, the artificial anticipation is eliminated, the production efficiency is improved, and the automation degree is improved.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

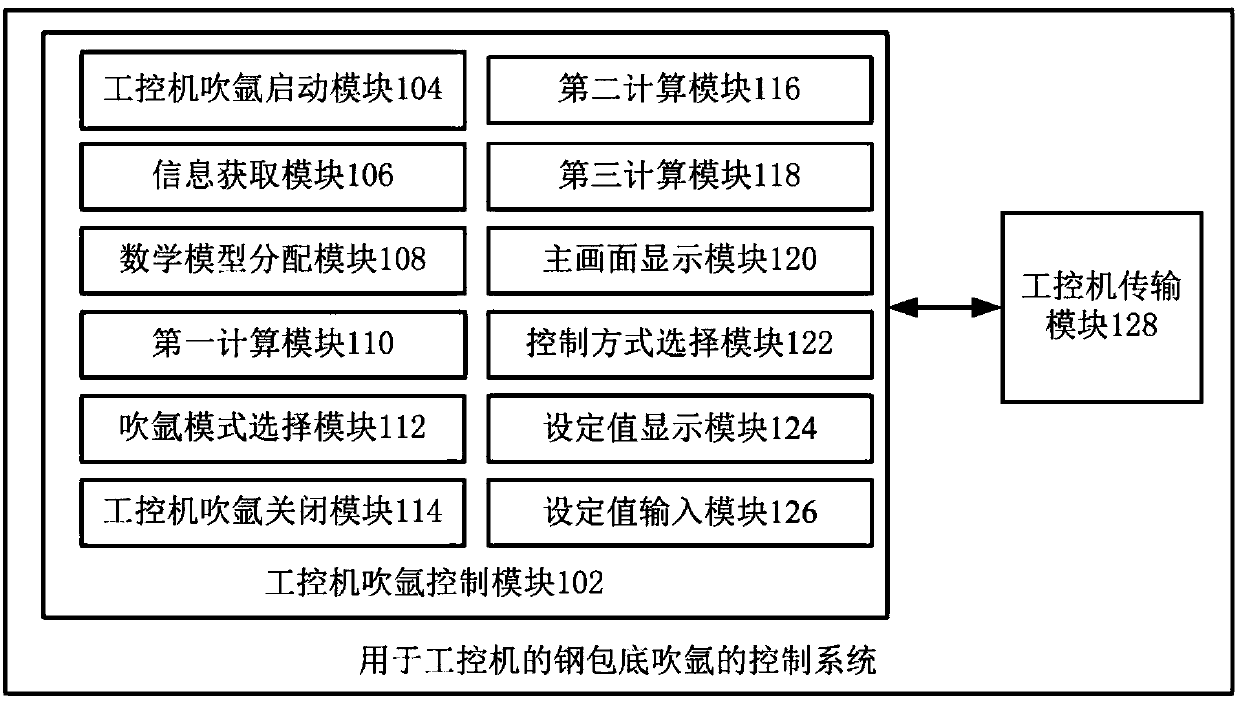

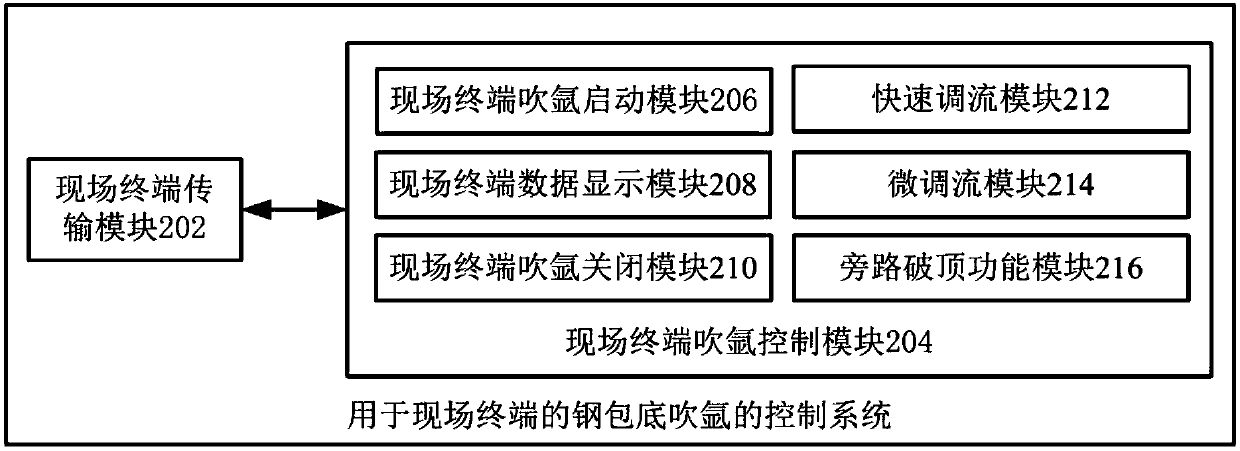

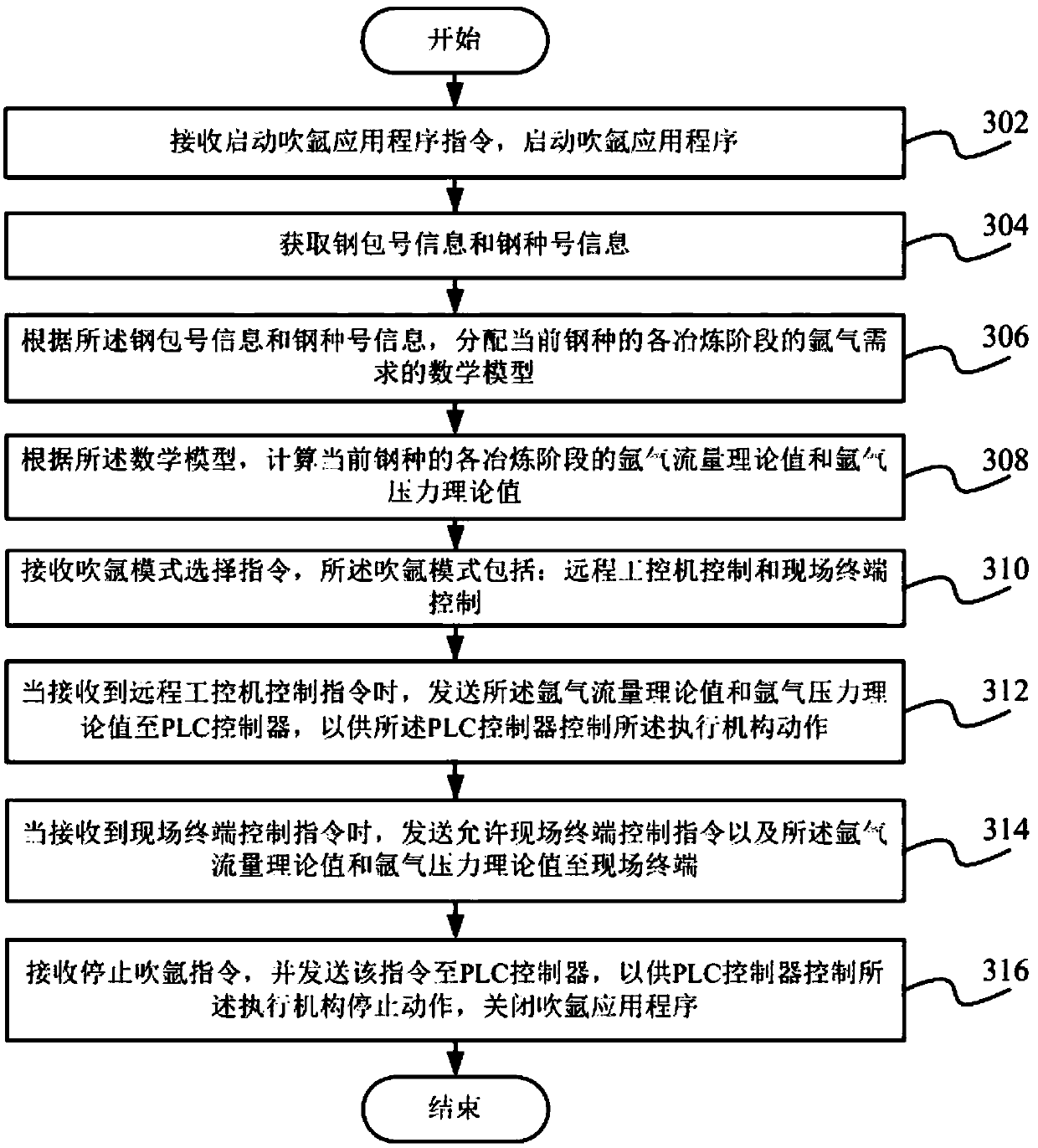

Steel ladle bottom argon blowing control system and method

PendingCN110387454ARealize highly automated operationAdapt to open-loop controlIncreasing energy efficiencyControl systemMathematical model

The invention discloses a ladle bottom argon blowing control system and a method. The ladle bottom argon blowing control system for an industrial personal computer comprises an industrial personal computer argon blowing control module and an industrial personal computer transmission module, wherein the industrial personal computer argon blowing control module interacts with the industrial personalcomputer transmission module, and the industrial personal computer argon blowing control module comprises an industrial personal computer argon blowing starting module, an information acquisition module, a mathematical model distribution module, an argon blowing mode selection module, a first calculation module and an industrial personal computer argon blowing closing module. The ladle bottom argon blowing system for the industrial personal computer establishes an argon blowing mathematical model for the all-steel type smelting outside a furnace, and different mathematical models can be automatically selected according to different steel types to realize the full-automatic adjustment of argon pressure and flow control in the steel ladle argon blowing process, and meanwhile, two control modes of a remote industrial personal computer control and an on-site terminal control are provided, so that different requirements of technical personnel on a steel ladle bottom argon blowing control are adapted.

Owner:沈阳人和机械制造有限公司

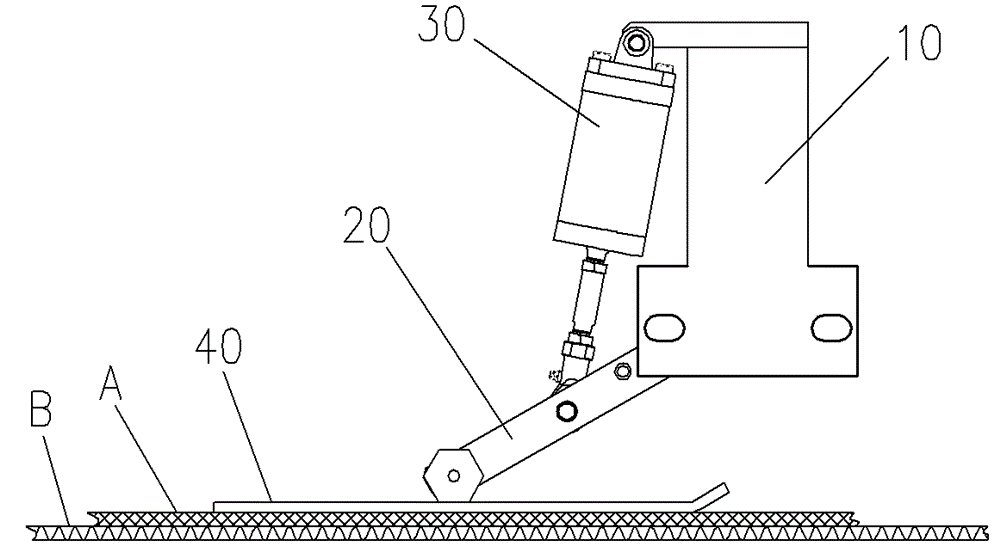

Pressing plate mechanism

InactiveCN105883447AEasy to shapeFully automatic adjustmentFunction indicatorsArticle feedersEngineeringConveyor belt

The invention provides a pressing plate mechanism. The pressing plate mechanism comprises a mounting base, a rocker arm movably connected on the mounting base, an air cylinder used for driving the rocker arm to swing, and a pressing plate arranged above a conveyor belt, wherein one end of the rocker arm is movably connected on the mounting base; the pressing plate is connected to the other end of the rocker arm; the air cylinder is mounted on the mounting base; the piston rod of the air cylinder is movably connected to the middle position of the rocker arm; the piston rod expands and contracts to pull the rocker arm to swing up and down; and the pressing plate is used for downwards transmitting downward pressure from the air cylinder through the rocker arm. By virtue of structuralimprovement, the pressure of the pressing plate can be regulated by the air cylinder, and a proportional valve also can be connected with a production management system, so that fully-automatic regulation is realized.

Owner:佛山市南海富利包装机械有限公司

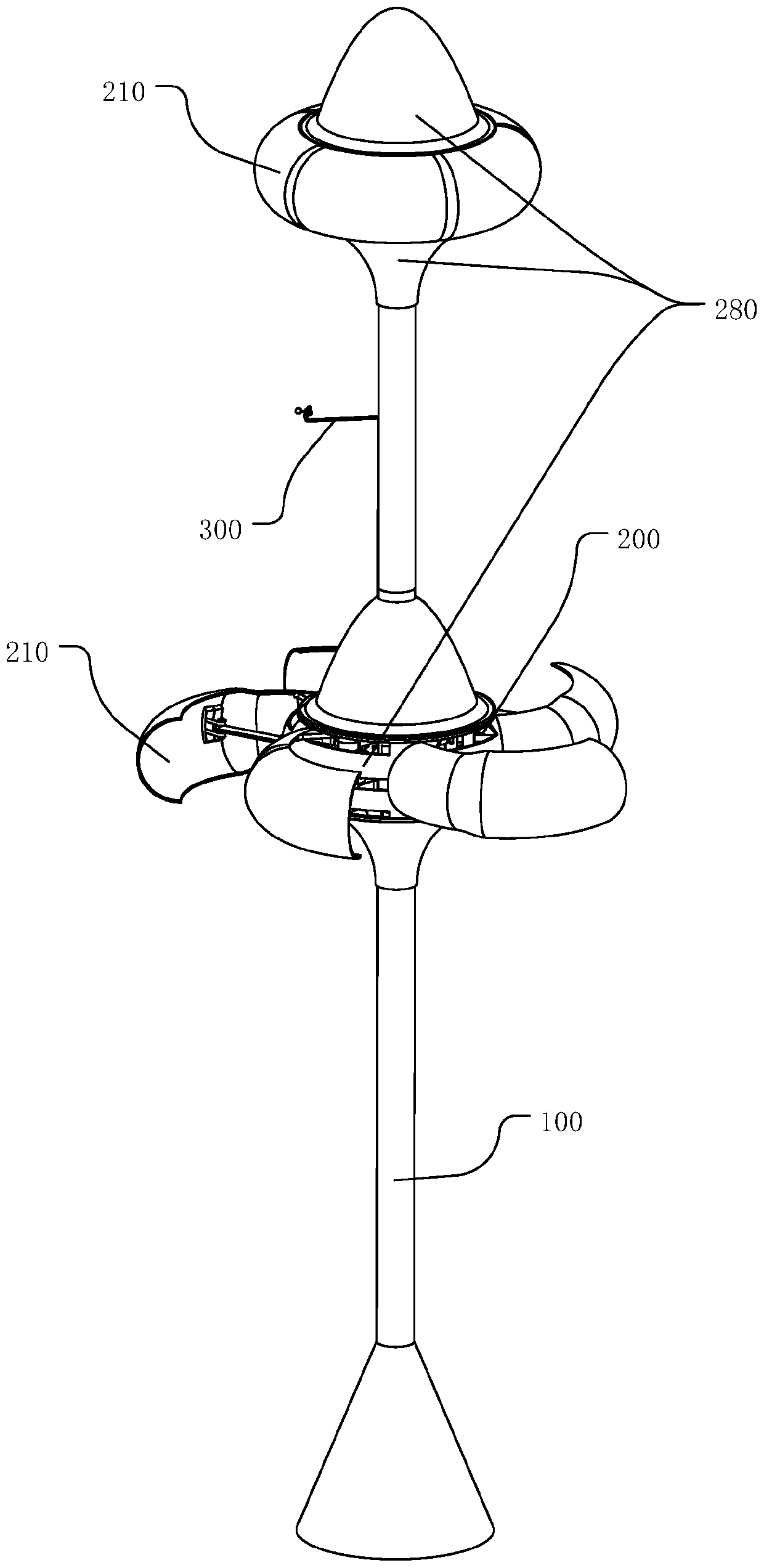

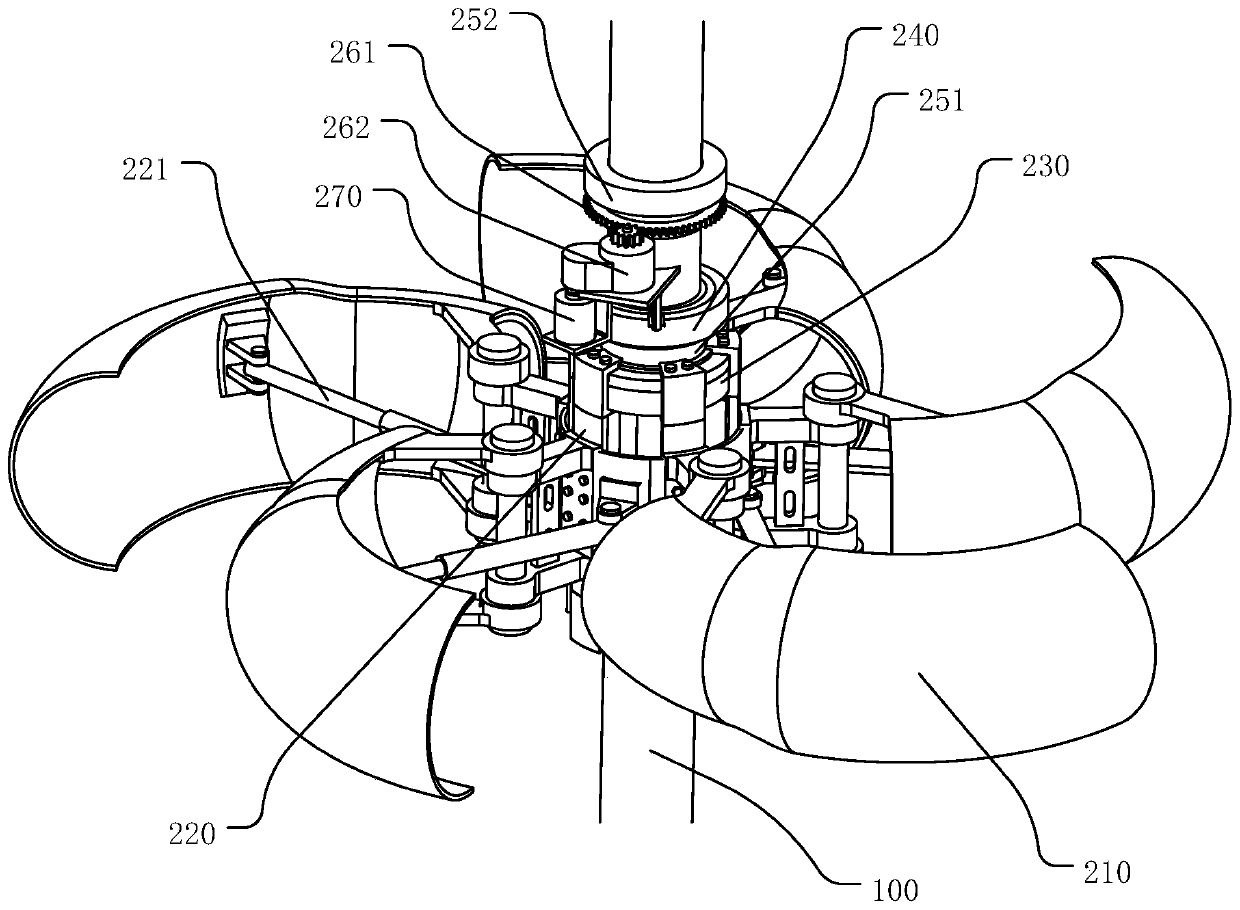

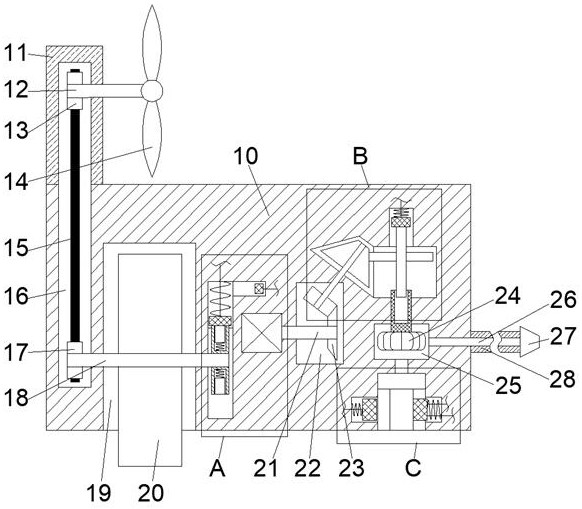

Power generation device

ActiveCN110552844ASolve the problem of excessive rotationReduce wearPhotovoltaic supportsRotational speed controlSolar cellWind force

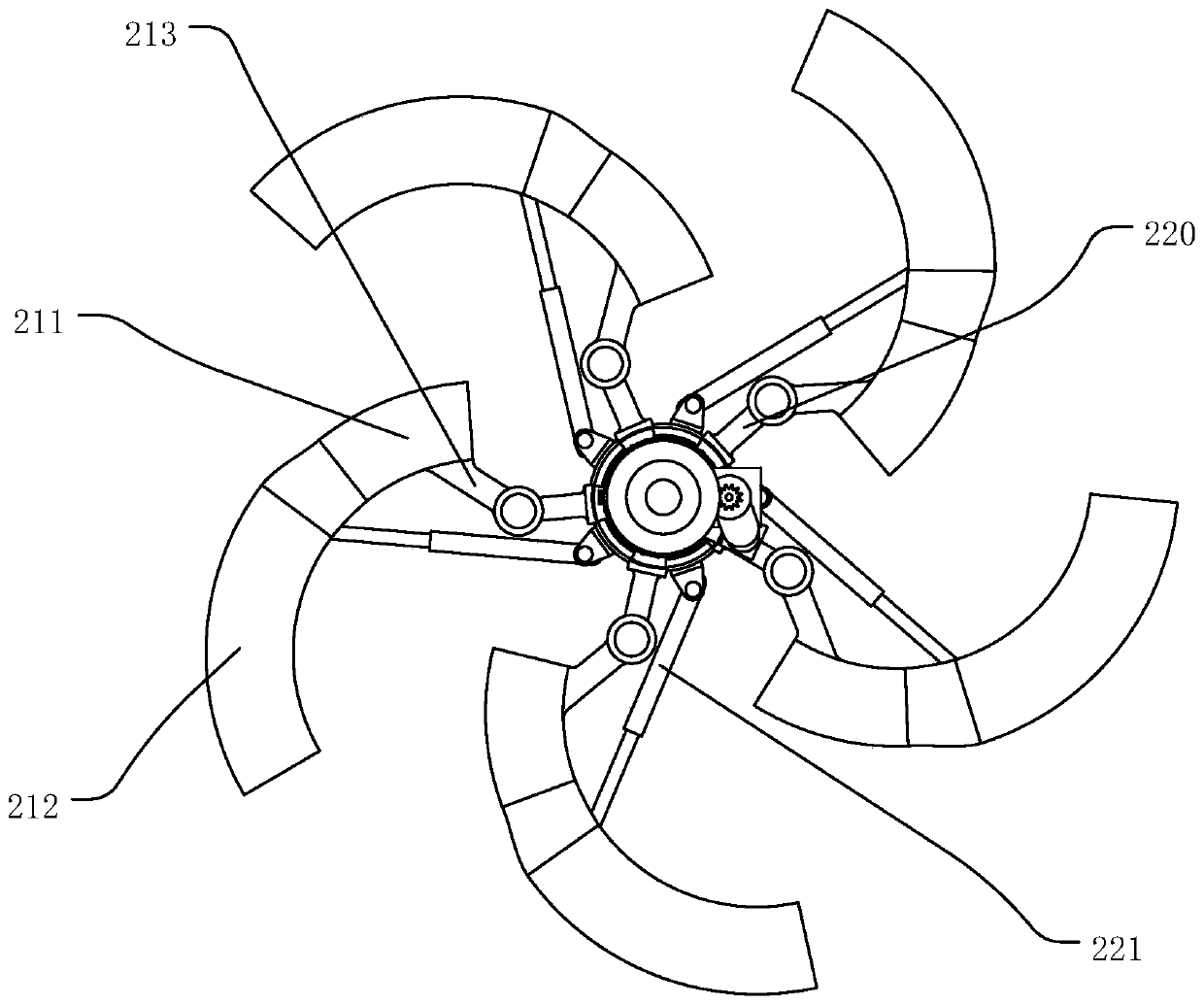

The invention discloses a power generation device to thoroughly solve the problem of the rotating overpseed of generator sets. The power generation device comprises a stand column and at least one generator set located on the same column. Each generator set comprises a support, blades connected with the support and a generator rotationally generating power through the blades. Each generator set further comprises an adjusting device located on the support, wherein the adjusting device is used for moving or rotating the blades so as to adjust the windward area of the blades according to the windspeed. By means of the wind power generation device, when the wind force is too large, the effective windward area can be reduced to zero, the stability of the device and applicability of the devicein various environments are improved, and the service life of the device is prolonged. A solar cell panel can be laid on the outer surface of the power generation device, the device can collect wind energy and solar energy at the same time, and wind force and solar energy combined power generation is achieved. All the parts of the generator sets in the power generation device are directly connected with the stand column or directly connected with the stand column through bearings, demounting and assembling are convenient, application and popularization are facilitated, and very high practicability is achieved.

Owner:靳军

Automatic monitoring system of tobacco-leaf bulk curing barn

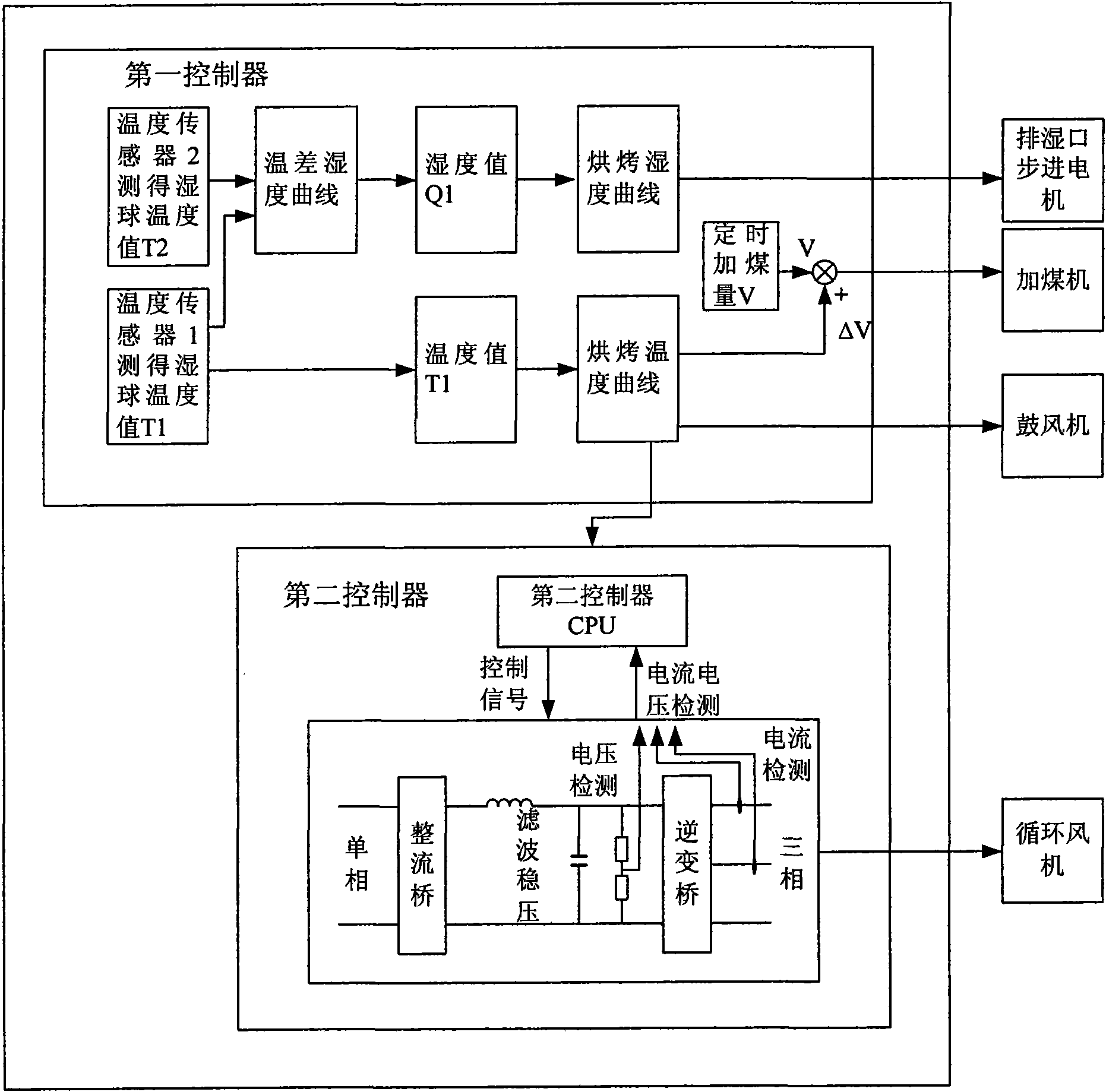

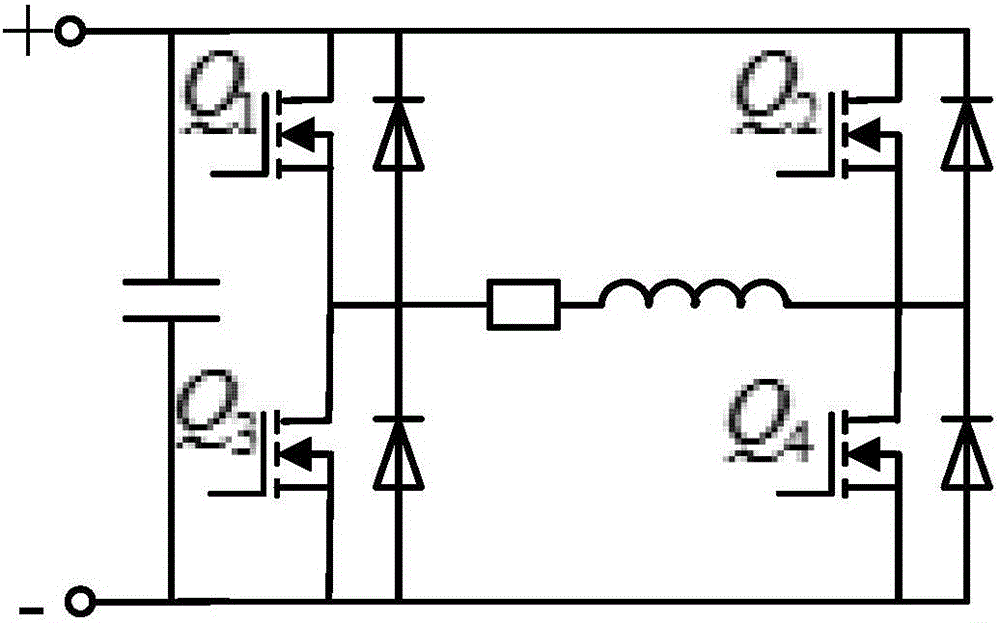

InactiveCN101556479AAvoid difficultiesAchieving a soft startTobacco preparationSimultaneous control of multiple variablesMonitoring systemVoltage regulation

The invention provides an automatic monitoring system of a tobacco-leaf bulk curing barn, comprising a first controller and a second controller, wherein the first controller comprises a dry-bulb temperature sensor, a wet-bulb temperature sensor and a first processor, the first processor is connected with the dry-bulb temperature sensor, the wet-bulb temperature sensor and the second controller, respectively; while the second controller comprises a rectification bridge, a filtered-wave voltage regulation circuit and a triphase inverting bridge that are connected with each in series, wherein one end of a second processor is connected with the triphase inverting bridge, while the other end is connected with the first processor. The invention realizes conversion from one phase supplying power to three phases supplying power and automatically controls the humiture in the barn, the frequency control of the circulating fan and the coal quantity used in the tobacco-leaf curing period, thereby enhancing the quality of the tobacco-leaf as well as saving labour, energy and production cost.

Owner:HUAZHONG UNIV OF SCI & TECH

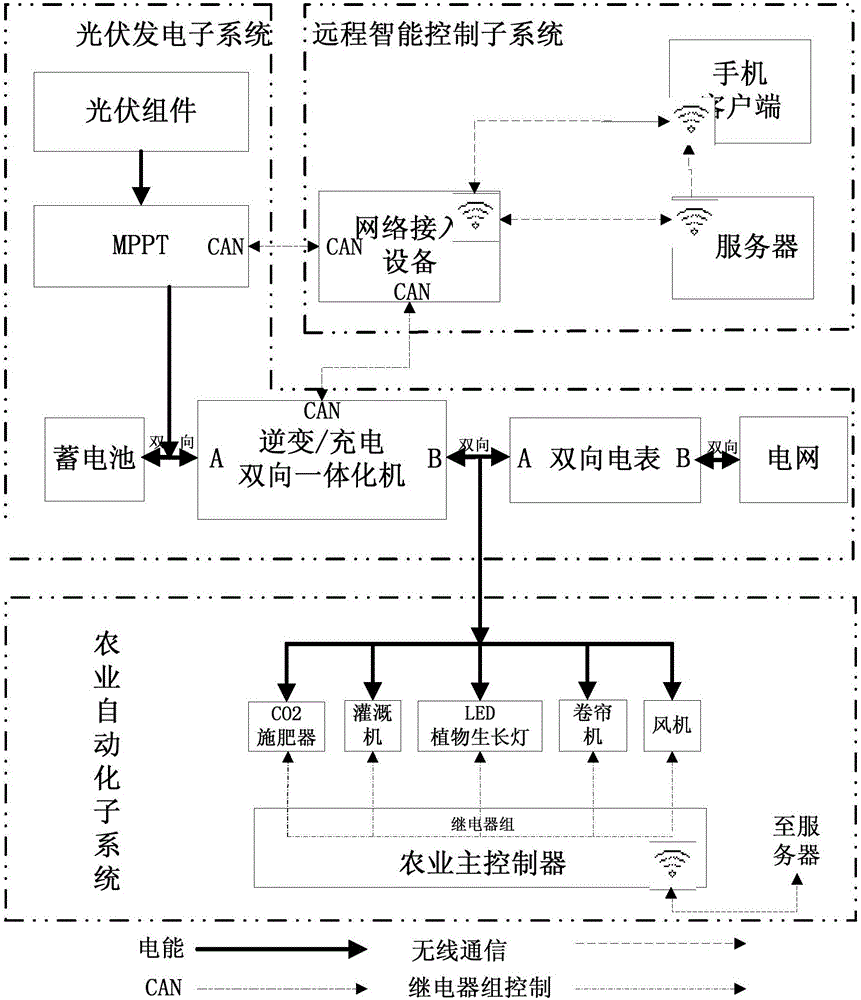

Internet+-based photovoltaic agricultural greenhouse control system

InactiveCN106054841AReduce volumeReduce weightBatteries circuit arrangementsTransmission systemsThe InternetAgricultural engineering

The invention relates to an internet+-based photovoltaic agricultural greenhouse control system comprising a photovoltaic generating subsystem, an agricultural automatic subsystem, and a remote intelligent control subsystem. The photovoltaic generating subsystem carries out energy conversion and conveys the electric energy that is obtained by photovoltaic generating to the agricultural automatic subsystem, charges a storage battery, and sells the excess electric energy to a power grid company. The remote intelligent control subsystem is capable of monitoring information of the photovoltaic generating subsystem and information in a photovoltaic agricultural greenhouse in real time and makes an optimal solution scheme based on the corresponding information. The remote intelligent control subsystem and the agricultural automatic subsystem carry out regulation and control on environmental parameter information inside an agricultural greenhouse by a network access device. According to the invention, on the basis of cross-border fusion of the digital information technology, the internet technology, and the photovoltaic technology, the system has great theoretical research and social practical values.

Owner:复变时空(武汉)数据科技有限公司

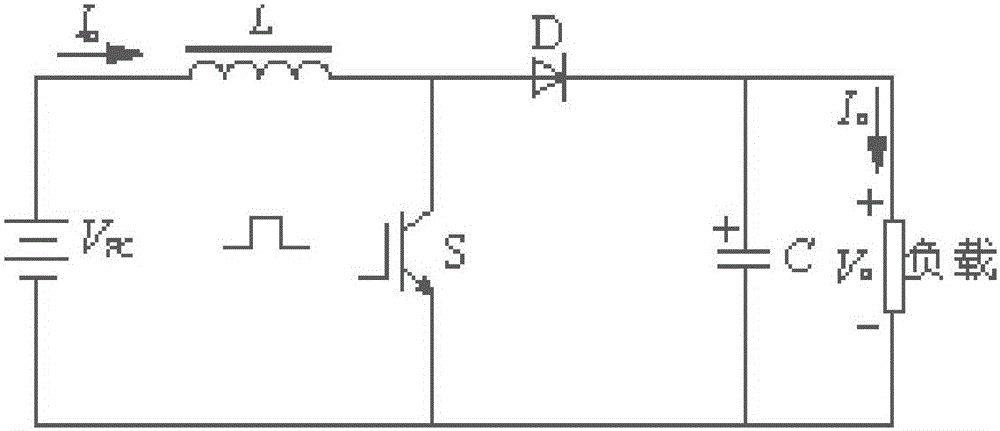

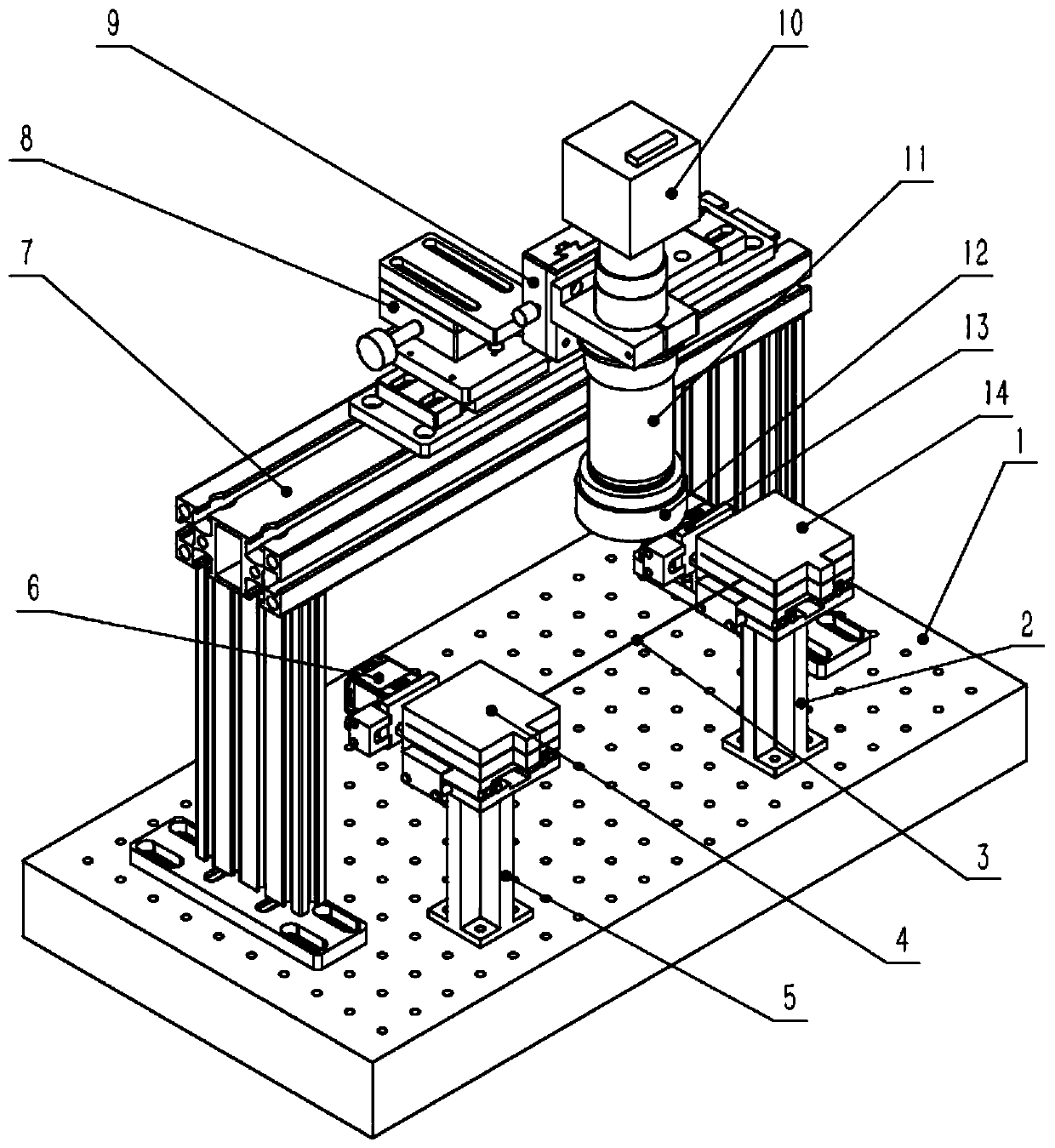

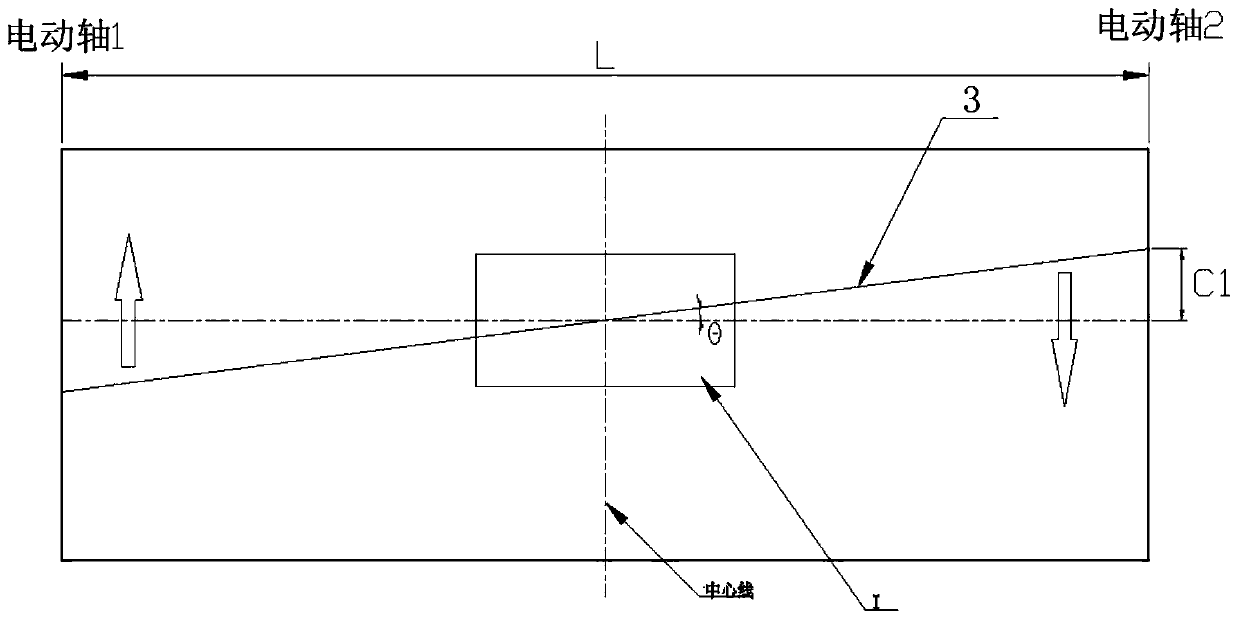

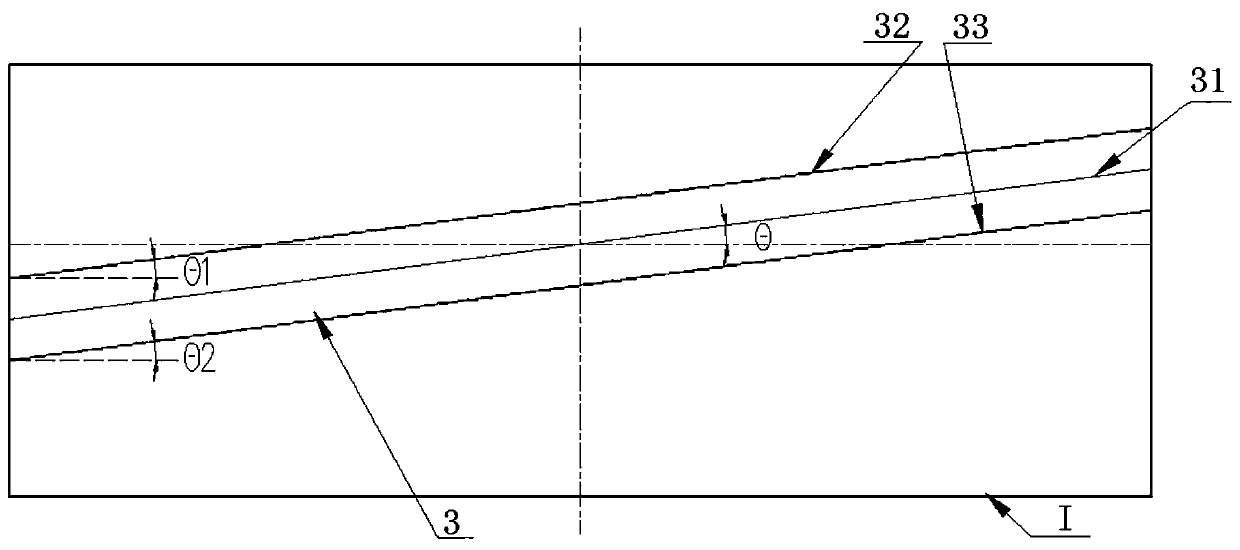

System and method for adjusting position and angle of optical fiber based on machine vision

ActiveCN111598836AHigh adjustment accuracyIncrease productivityImage enhancementImage analysisMachine visionEngineering

The invention discloses a system and method for adjusting a position and an angle of an optical fiber based on machine vision. The system comprises an industrial personal computer, an optical platformand a CCD industrial camera; the CCD industrial camera is mounted on the portal frame; the portal frame is mounted on the optical platform; two support columns are fixed on the optical platform; electric translation tables are respectively fixed on the two supporting columns; the axial leads of the electric shafts of the two electric translation tables are parallel; optical fiber clamps for clamping optical fibers are respectively supported on the two electric translation tables; two ends of the optical fiber are respectively clamped on the two optical fiber clamps; the industrial personal computer shoots the current position of the optical fiber by using an industrial camera, calculates the deviation distance between the current position and the target position and controls the electrictranslation platform to move, adjusts the optical fiber to a target position, detects feedback deviation of the optical fiber in real time for repeated fine adjustment, and controls a deviation valuewithin a precision range, According to the method, the optical fiber can be automatically adjusted to the target position of the CCD shooting area, the requirement for adjusting precision is met, andfull-automatic adjustment is achieved.

Owner:武汉来勒光电科技有限公司

Air compressor full-automatic control system and control method thereof

InactiveCN108644098AAvoid blindnessImprove security measuresPump testingPositive displacement pump componentsAutomatic controlAutomatic train control

The invention relates to an air compressor full-automatic control system and a control method thereof. The air compressor full-automatic control system comprises an engine, a relay, an air pump, an air storing tank, an unloading valve, a pressure adjusting valve, a pressure adjusting motor, sensors and a controller; one end of the engine is connected with a power source through the relay, the other end of the engine is connected with the air pump, the air pump is connected into the air inlet end of the air storing tank, the unloading valve is arranged on a connecting pipe of the air pump and the air inlet end of the air storing tank, the air outlet end of the air storing tank is externally connected with the pressure adjusting valve, the pressure adjusting valve is externally connected with the pressure adjusting motor, air outlets of the air storing tank and the pressure adjusting motor are connected with the sensor a and the sensor b through pipes, and the relay, the unloading valve,the pressure adjusting motor, the sensor a and the sensor b are electrically connected with the controller or are in signal connection with the controller. By means of the control system, engine opening and closing can be achieved, full-automatic adjustment of the air pressure of the air storing tank and pressure adjusting of the pressure adjusting valve can be achieved, the adjusting intelligentdegree is high, the automatic operation provides extra protection measures, and the problems about too high air pressure, engine starting difficulties and the like are solved.

Owner:SHANGHAI LUHONG ELECTRONICS TECH CO LTD

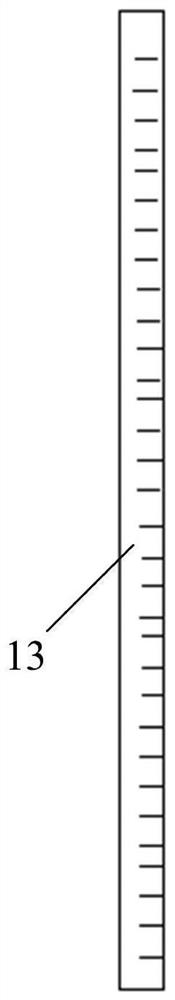

Mobile panel movement testing machine capable of adjusting armrest height automatically

InactiveCN105999623ASimple structureEasy to operateMovement coordination devicesCardiovascular exercising devicesMeasurement deviceEngineering

The invention relates to a mobile panel movement testing machine capable of adjusting the armrest height automatically. Two supporting rods are fixedly mounted above a main machine body, a front adjustable bracket device is mounted above the supporting rods, a two-side adjustable bracket device is arranged above the middle of a walking base, the tail end of the walking base is provided with a height measurement device, the front adjustable bracket device comprises a shaft sleeve fixedly mounted above the supporting rods, the inner side of the shaft sleeve is movably provided with a rotating shaft, one end of the rotating shaft is connected with a rotation motor, the rotation motor is connected with the main machine body through a wire, two rotation supporting rods are fixedly mounted on the rotating shaft, and a front bracket is fixedly mounted between the two rotation supporting rods; a front armrest and a side armrest are arranged to be of adjustable structures, the height measurement device is designed, the main machine body drives the front bracket and a side bracket to be adjusted to the proper height position, fully-automatic armrest height adjustment is achieved, and the mobile panel movement testing machine is efficient, convenient and fast to use and suitable for being used by people of a high height, people of a low height and people of a medium height.

Owner:PEOPLES HOSPITAL OF HENAN PROV

Adjustable furniture dust collecting and polishing machining platform

InactiveCN109015385ASave resourcesImprove efficiencyGrinding carriagesGrinding machinesEngineeringMulti directional

The invention discloses an adjustable furniture dust collecting and polishing machining platform. The adjustable furniture dust collecting and polishing machining platform comprises a machining platform. The bottom of the machining platform is provided with a base. A dust collection box is embedded into the base. A slide rail is welded to one side, in the length direction, of the upper surface ofthe machining platform. The upper surface of the slide rail is provided with a sliding groove. Racks are embedded to the surface walls of the two sides in the sliding groove, and the sliding groove isinternally connected with a sliding base in a sliding manner. According to the adjustable furniture dust collecting and polishing machining platform, a dust collection cover is fixed to an L-shaped fixing frame, the L-shaped fixing frame is connected to the slide rail in a sliding manner through the sliding base, and position adjusting in the X-axis direction can be carried out on the dust collection cover; and a nut moves back and forth on a lead screw, adjustment in the Y-axis direction can be carried out on the dust collection cover, multi-directional adjustment can be carried out on the dust collection cover, and the dust suction efficiency of the dust collection cover is improved.

Owner:陈博海

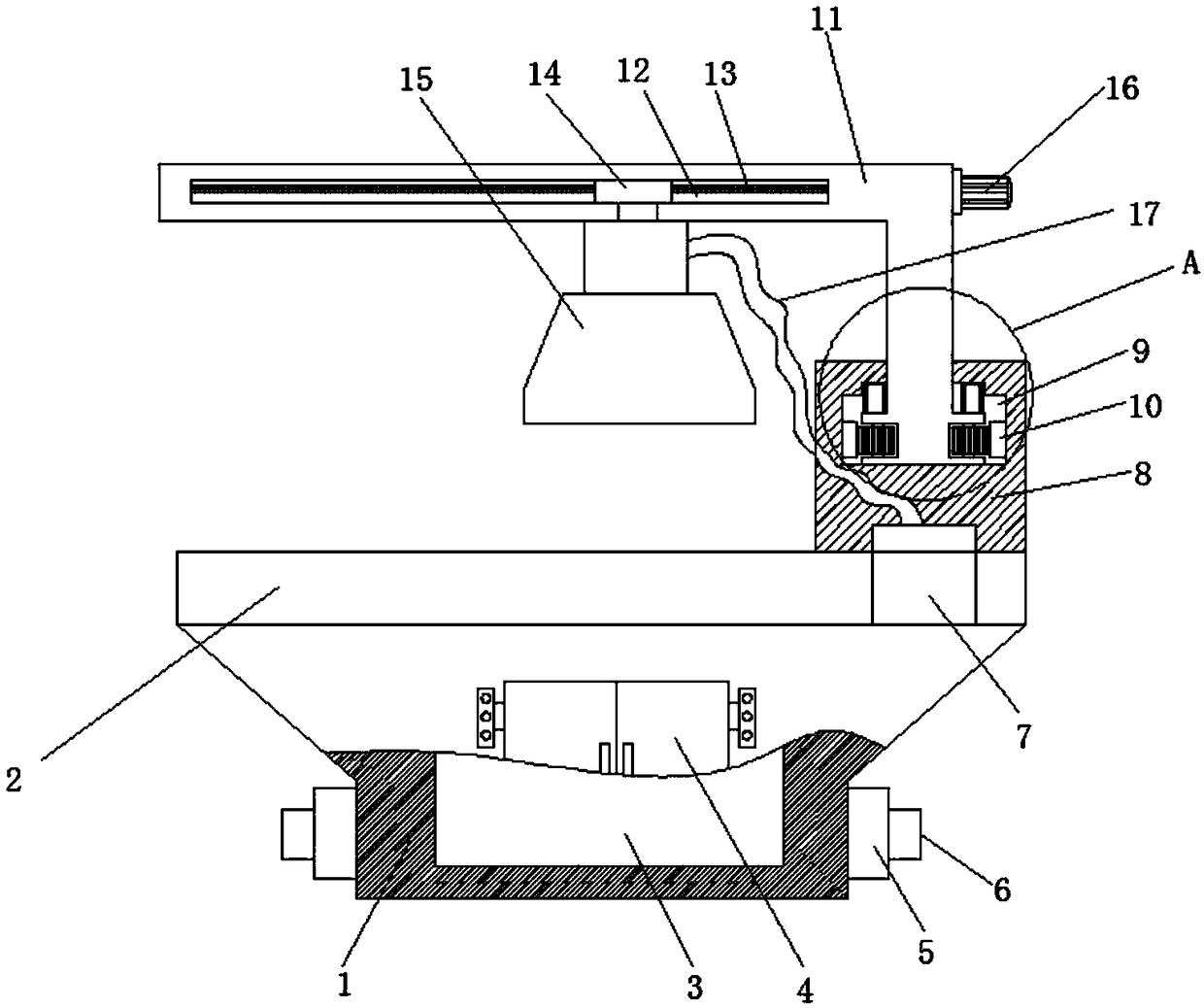

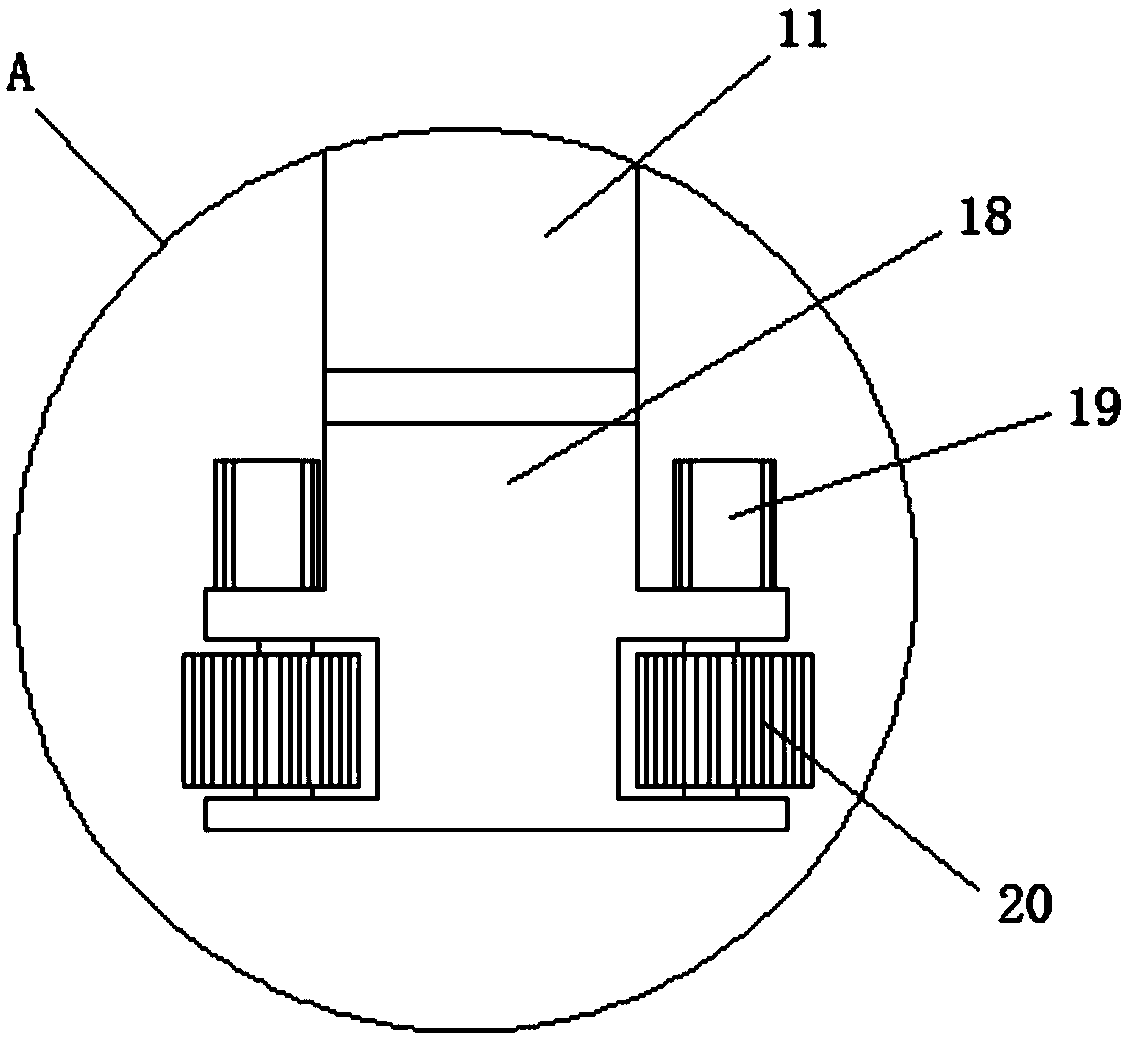

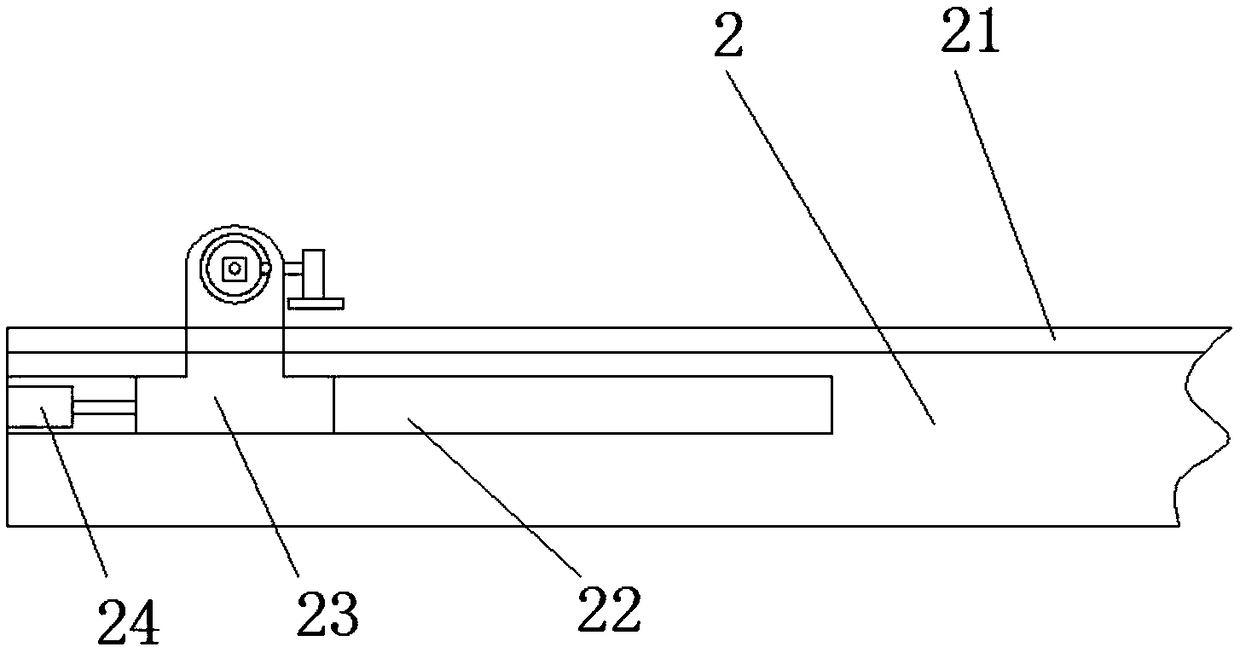

Numerical control lathe auxiliary heat dissipation device capable of automatically adjusting spraying speed of cooling liquid

InactiveCN112171371AFully automatic adjustmentReal-time monitoring of processing speedMaintainance and safety accessoriesPhysicsPersonnel safety

The invention relates to the related field of numerical control lathe heat dissipation equipment, and discloses a numerical control lathe auxiliary heat dissipation device capable of automatically adjusting spraying speed of cooling liquid. The numerical control lathe auxiliary heat dissipation device comprises a main body box, wherein a wind wheel box is fixedly connected to the tail end of the left side of the upper end face of the main body box, a wind wheel transmission belt cavity extending downwards into the main body box is formed in the wind wheel box, and a rotating disc friction wheel cavity which is located in the main body box and is provided with a downward opening is formed in the right side of the wind wheel transmission belt cavity. According to the device, the purpose of monitoring the turning machining rotating speed in real time is achieved through a rotating disc friction wheel abutting against a numerical control lathe rotating chuck, meanwhile, the spraying speedof the cooling liquid can be correspondingly changed in cooperation with the speed adjusting effect of a speed adjusting cavity, and therefore full-automatic adjustment of the cooling liquid is achieved, the personnel safety is guaranteed, and meanwhile the use amount of the cooling liquid is more reasonably reduced; and when the machining rotating speed is too high, the purpose of automatically switching the efficient cooling liquid when the rotating speed is too high is achieved through a triggering magnetic block and switching of a main sliding block valve and an auxiliary sliding block valve, and therefore the machining quality of workpieces is guaranteed.

Owner:杭州悟伦机械科技有限公司

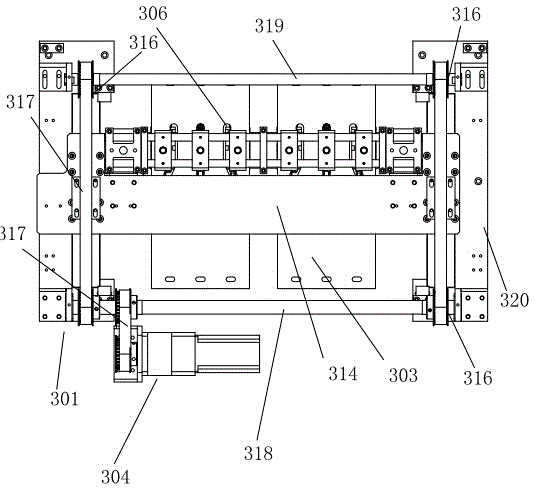

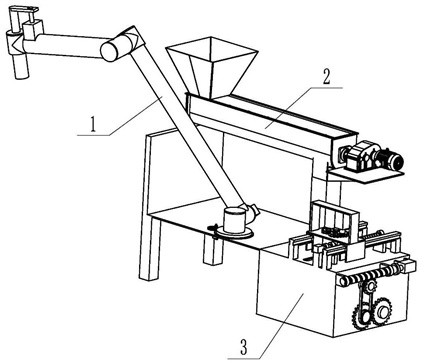

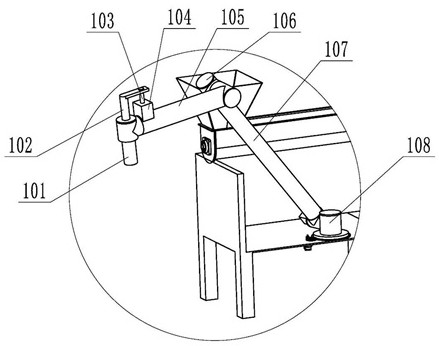

Push-in mechanism of food boxing machine

ActiveCN104803036AAutomatic spacing adjustmentFully automatic adjustmentPackagingEngineeringFood processing

The invention relates to the field of a food processing machine, and particularly relates to a push-in mechanism of a food boxing machine. The push-in mechanism comprises an installation framework, wherein the installation framework comprises a fixed installation plate and a plurality of mechanical push plates which are arranged below the fixed installation plate, the mechanical push plate is provided with a guide device for adjusting the distance between two adjacent mechanical push plates, each mechanical push plate is connected with a horizontal drive mechanism for driving the mechanical push plate to move horizontally, and the fixed installation plate is fixedly provided with the horizontal drive mechanism. The movement of the mechanical push plates in two directions is realized by utilizing the guide device and the horizontal drive mechanism; moreover, the full-automatic adjustment can be realized, the distance adjustment can be automatically realized under the situation that the manpower is not need; the push-in mechanism can be applicable to various support boxes in various sizes only by replacing a track plate, the artificial participation is eliminated, the production efficiency can be improved, and the automation degree is improved.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

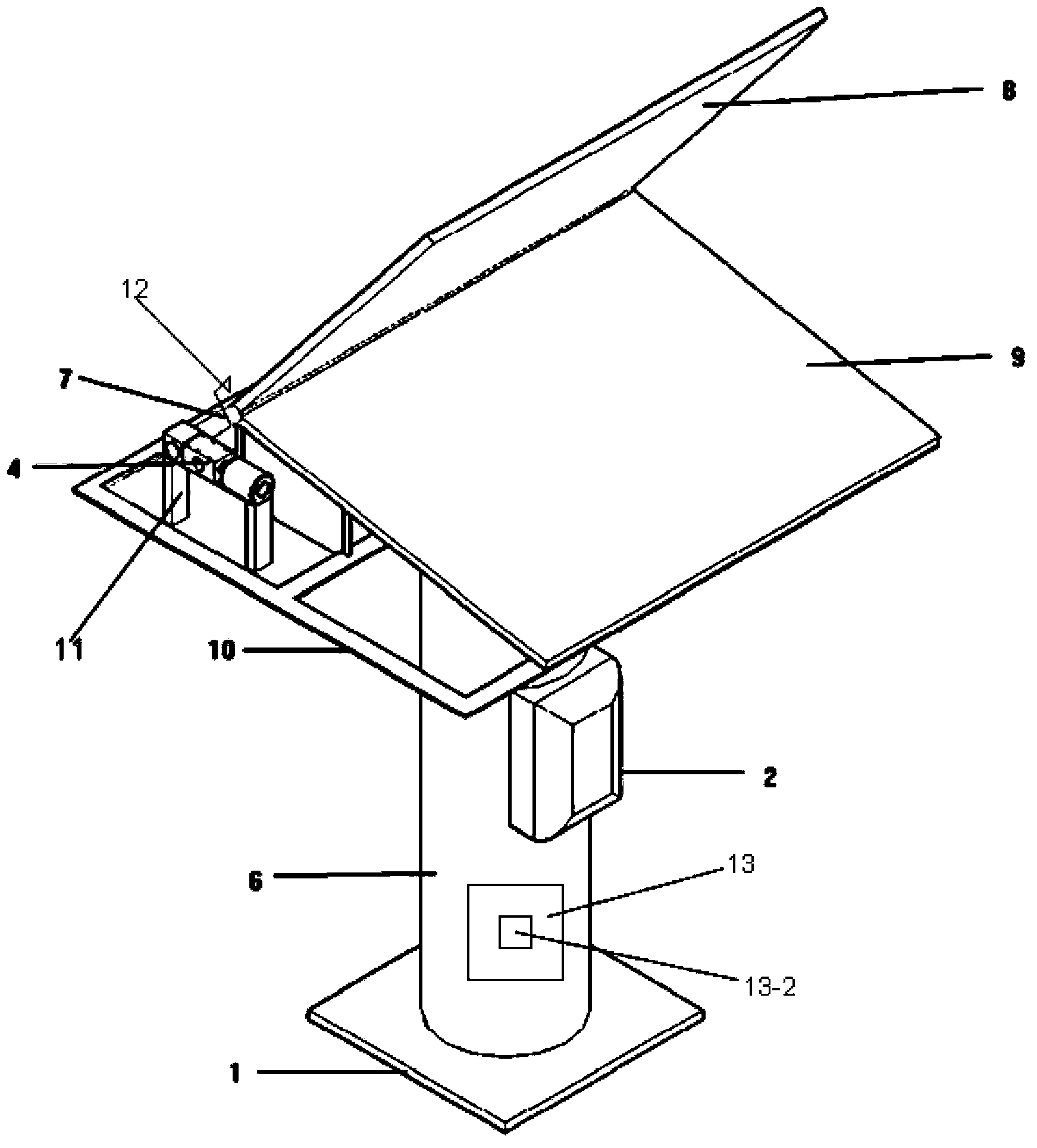

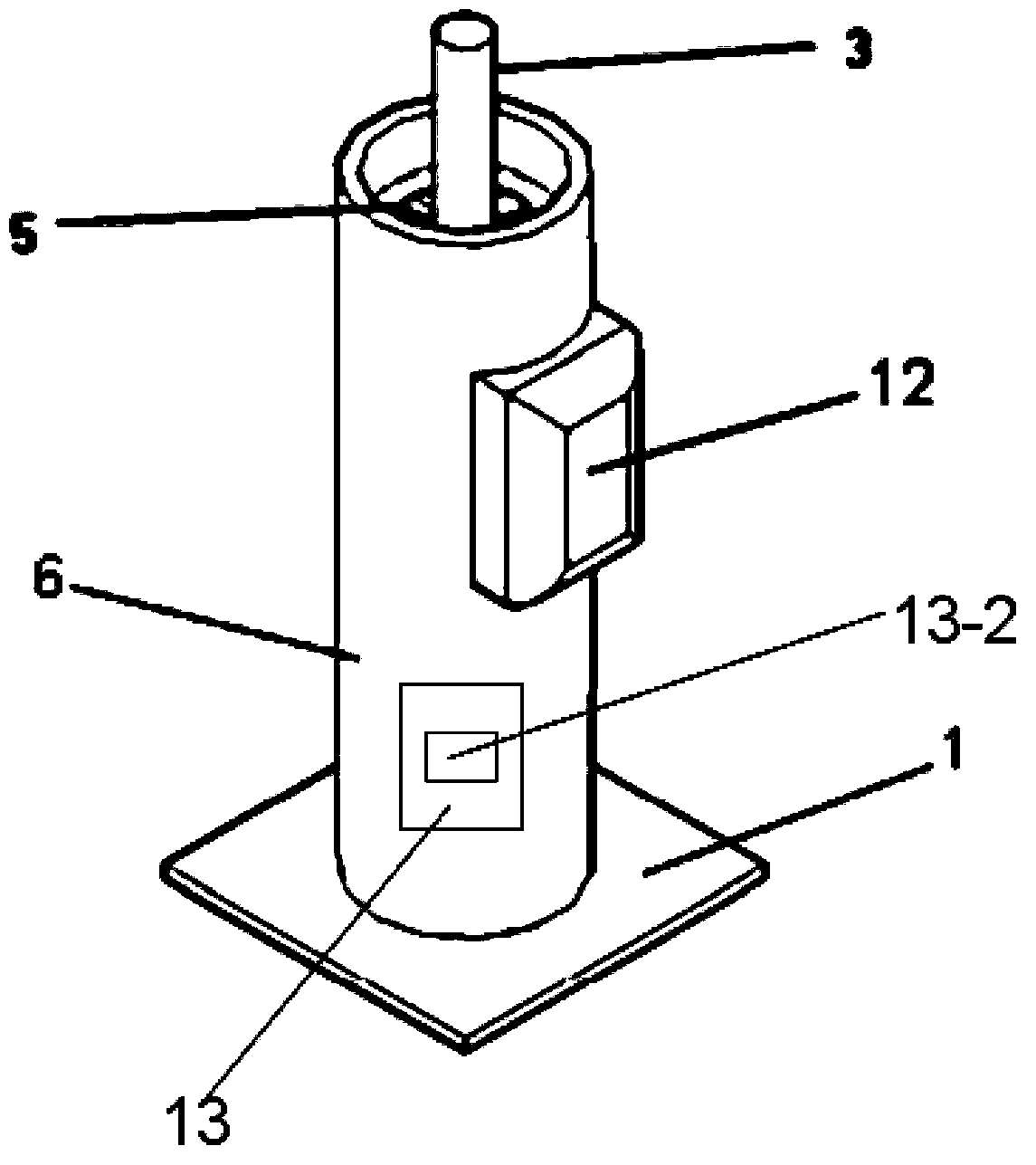

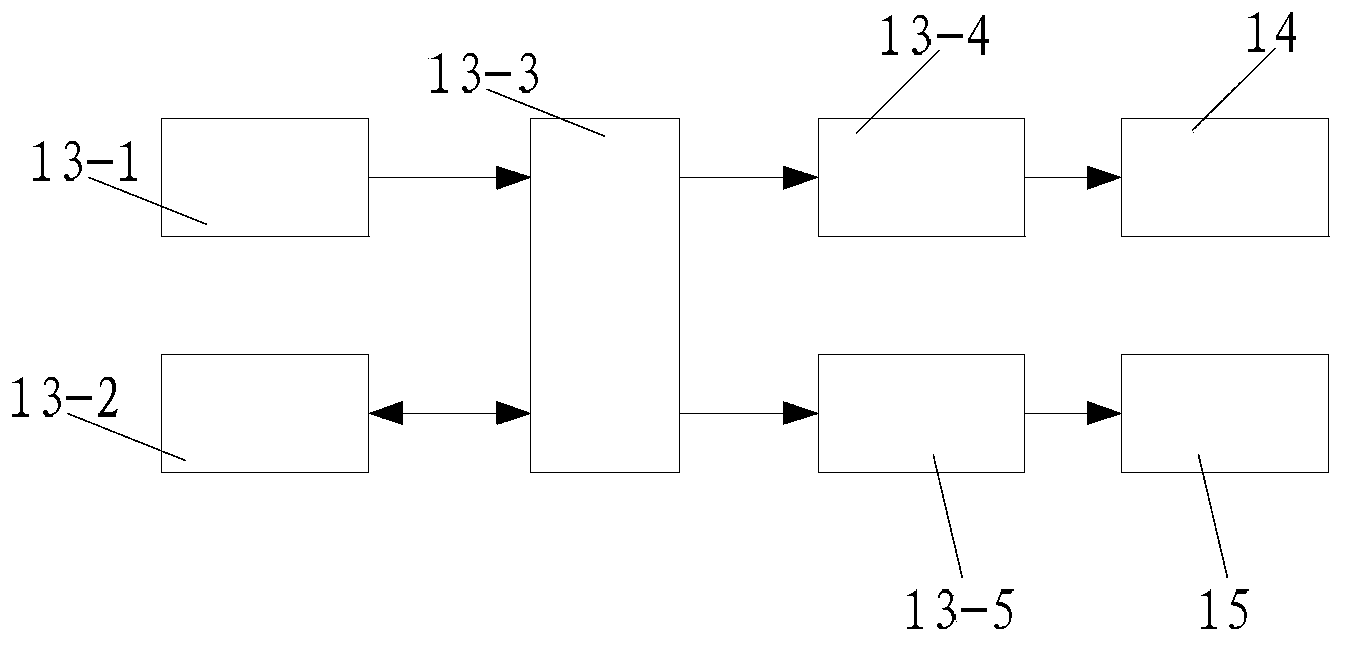

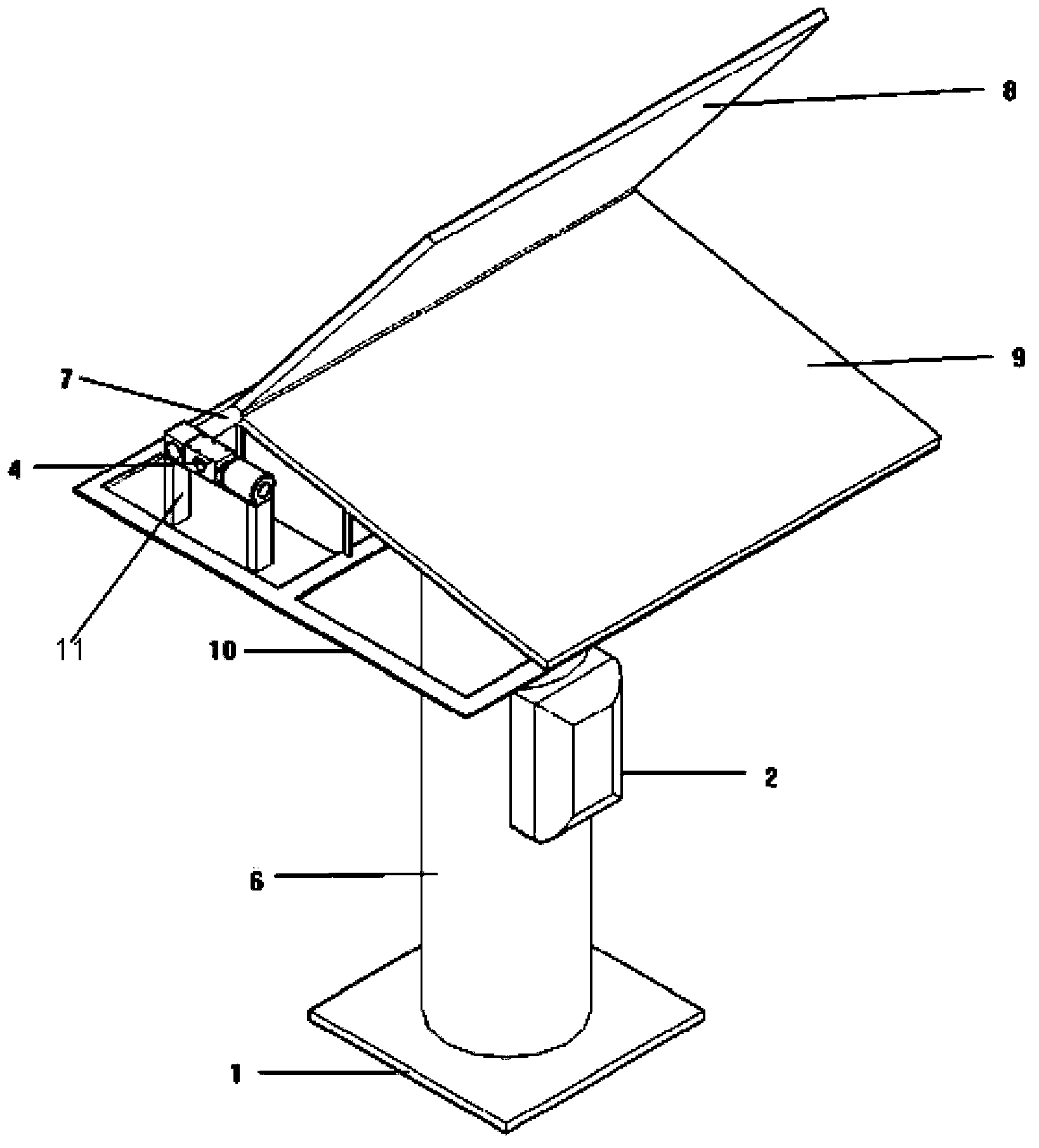

Intelligent sunshine directional reflecting device

InactiveCN103853191ASimple structureReasonable designControl using feedbackLiquid-crystal displayControl system

The invention discloses an intelligent sunshine directional reflecting device. The intelligent sunshine directional reflecting device comprises a sunshine directional reflecting mechanism and a sunshine directional reflecting control system. The sunshine directional reflecting mechanism comprises a base and a longitudinal support shaft sleeve, a longitudinal rotating shaft is installed in the longitudinal support shaft sleeve, a longitudinal power transmission device is installed on the longitudinal support shaft sleeve, and a rotating support is installed at the top end of the longitudinal rotating shaft. A horizontal rotating shaft support is installed on the rotating support. A horizontal rotating shaft and a horizontal power transmission device are installed on the horizontal rotating shaft support. An inclined reflecting mirror is installed on the horizontal rotating shaft. A horizontal reflecting mirror is connected to the inclined reflecting mirror. The sunshine directional reflecting control system comprises a photoelectric sensor and a control box, a control circuit board is integrated into the control box, and a PLC module, a touch liquid crystal display, a longitudinal motor driver and a horizontal motor driver are integrated on the control circuit board. The intelligent sunshine directional reflecting device is high in intelligent degree, wide in application field and capable of achieving directional output of light and saving energy.

Owner:陕西科林能源发展股份有限公司

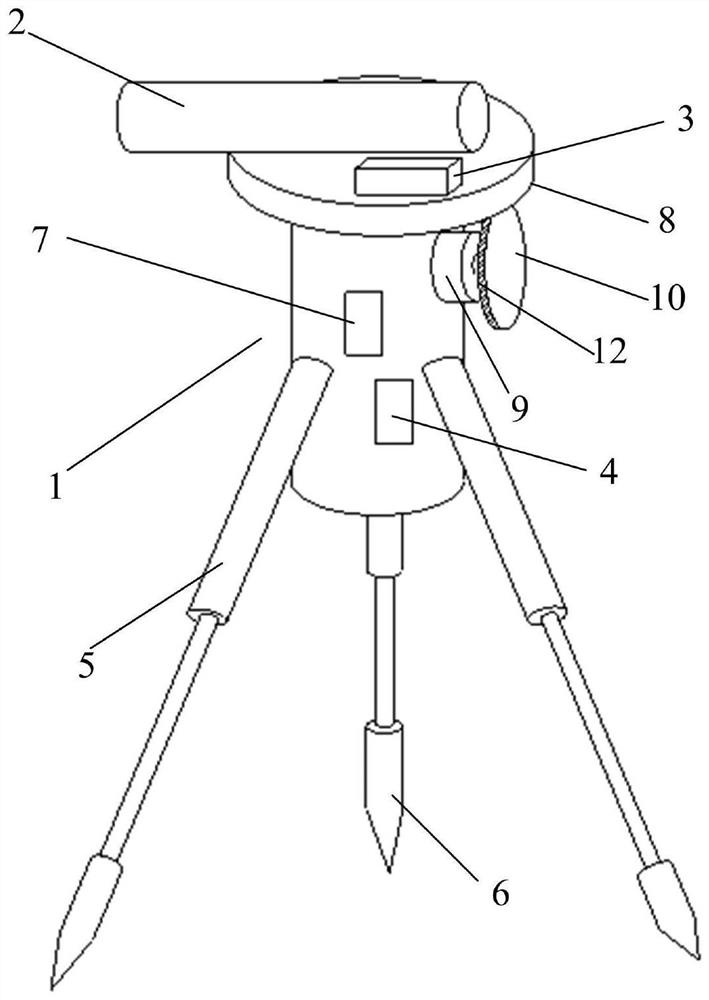

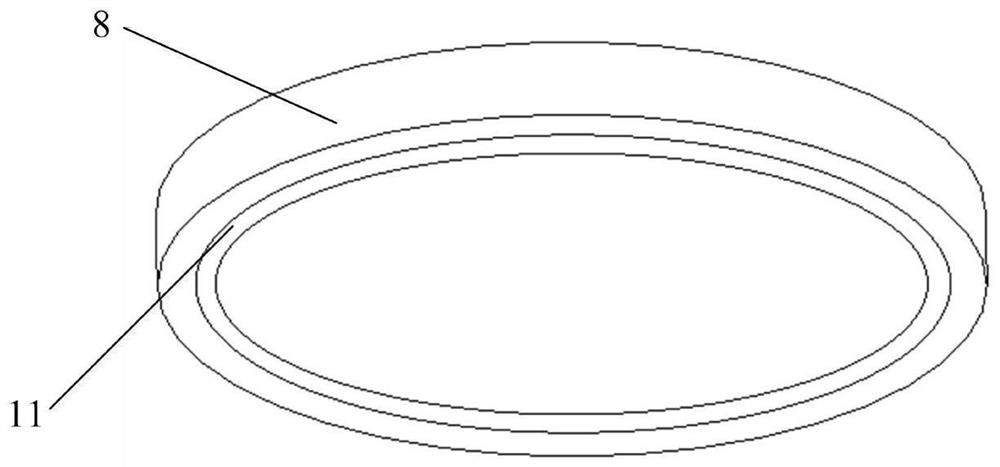

Surveying instrument for building engineering surveying

InactiveCN113915493AImprove measurement accuracyRealize automated surveying and mappingStands/trestlesPhysical medicine and rehabilitationSurvey instrument

The invention relates to a surveying instrument for building engineering surveying. The surveying instrument comprises an adjusting bracket, a surveying instrument body, a horizontal detection device, a driving part and a controller, wherein the surveying instrument body is rotationally arranged on the adjusting bracket; the adjusting bracket is used for adjusting the levelness of the surveying instrument body; the horizontal detection device is arranged on the surveying instrument body and used for detecting the levelness of the surveying instrument body; the driving part is arranged on the adjusting bracket and used for driving the surveying instrument body to rotate relative to the adjusting bracket to adjust the surveying direction of the surveying instrument body; the controller is used for receiving a detection signal of the horizontal detection device and adjusting the adjusting bracket to be horizontal according to the detection signal; and the controller controls the driving part to be electrified to work, the driving part drives the surveying instrument body to move to a preset detection direction, and then the controller controls the surveying instrument body to be electrified to work so as to complete preset surveying work. The levelness of the surveying instrument body is adjusted by using the adjusting bracket, and manual adjustment is changed into automatic adjustment, so that the measurement accuracy of the surveying instrument can be effectively improved.

Owner:张振波

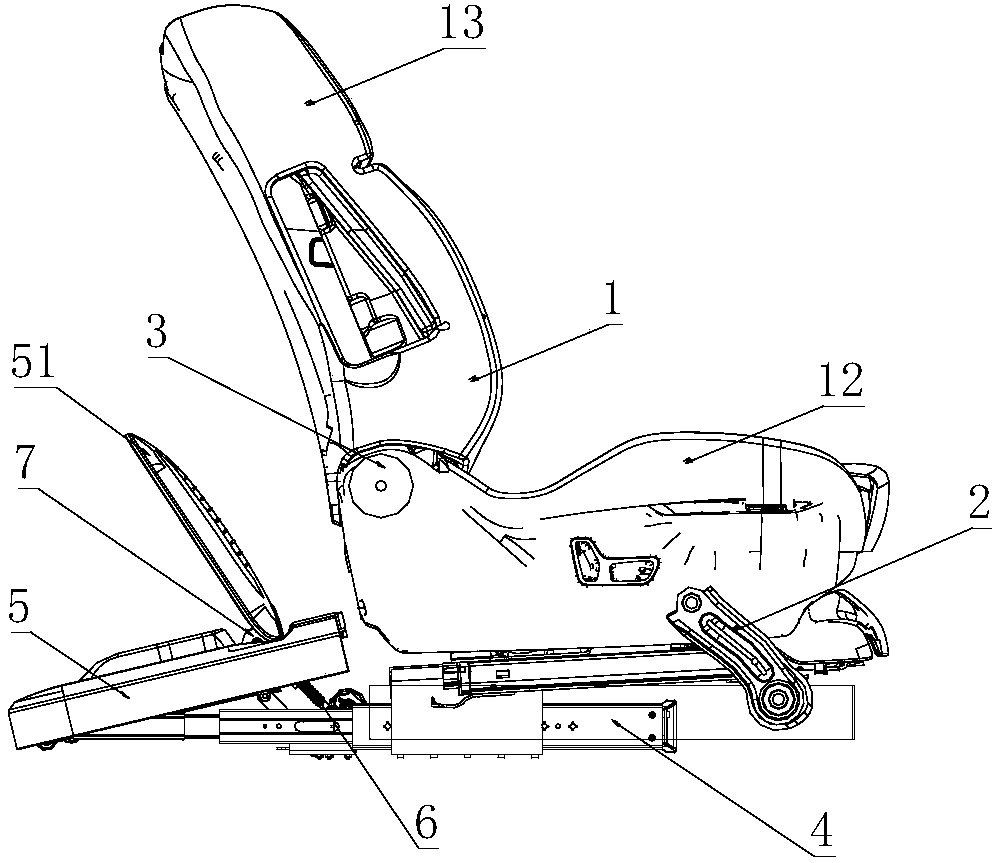

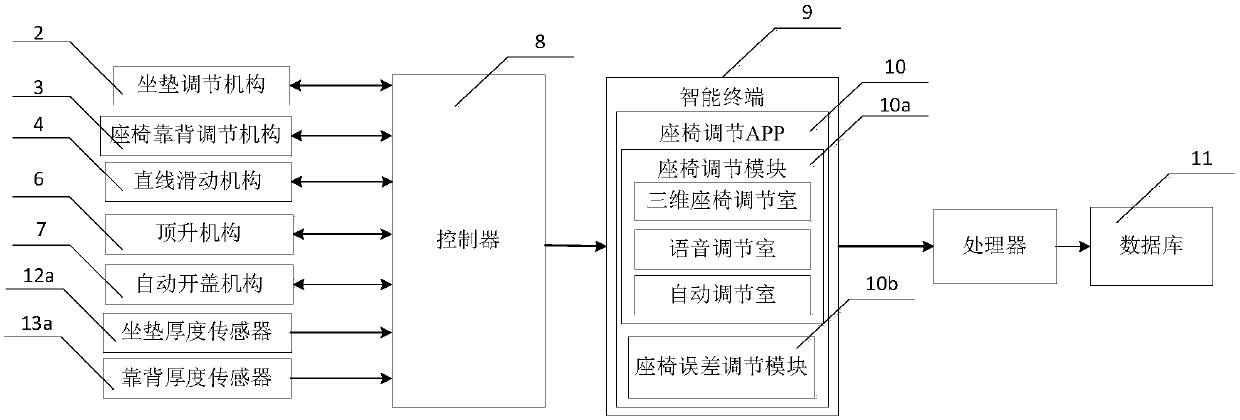

Car seat APP adjusting system with foot massage device

ActiveCN107696923ARealize virtual controlTo achieve the purpose of real controlThigh restsElectric/fluid circuitCar seatMassage

The invention discloses a car seat APP adjusting system with a foot massage device. The car seat APP adjusting system comprises a seat body and further comprises a cushion adjusting mechanism, a seatbackrest adjusting mechanism, a linear sliding mechanism, a jacking mechanism and an automatic uncovering mechanism which are connected with a controller. The controller is further connected with anyone intelligent terminal, each seat adjusting APP is mounted on the corresponding intelligent terminal and provided with a car seat adjusting module, and a three-dimensional seat adjusting chamber isarranged in each seat adjusting module. A three-dimensional view of the seat body with a massager box body is arranged in each three-dimensional seat adjusting chamber. The intelligent terminals are used for obtaining touch operation conducted on the three-dimensional view by a user, so that the massager box body or the seat body is controlled to complete moving operation corresponding to touch operation. The car seat APP adjusting system has the beneficial effects that reality and virtuality are combined, convenience and intelligence are achieved, operation occupies a very small space, and safety is high.

Owner:CHONGQING YANFENG ADIENT AUTOMOTIVE COMPONENTS CO LTD

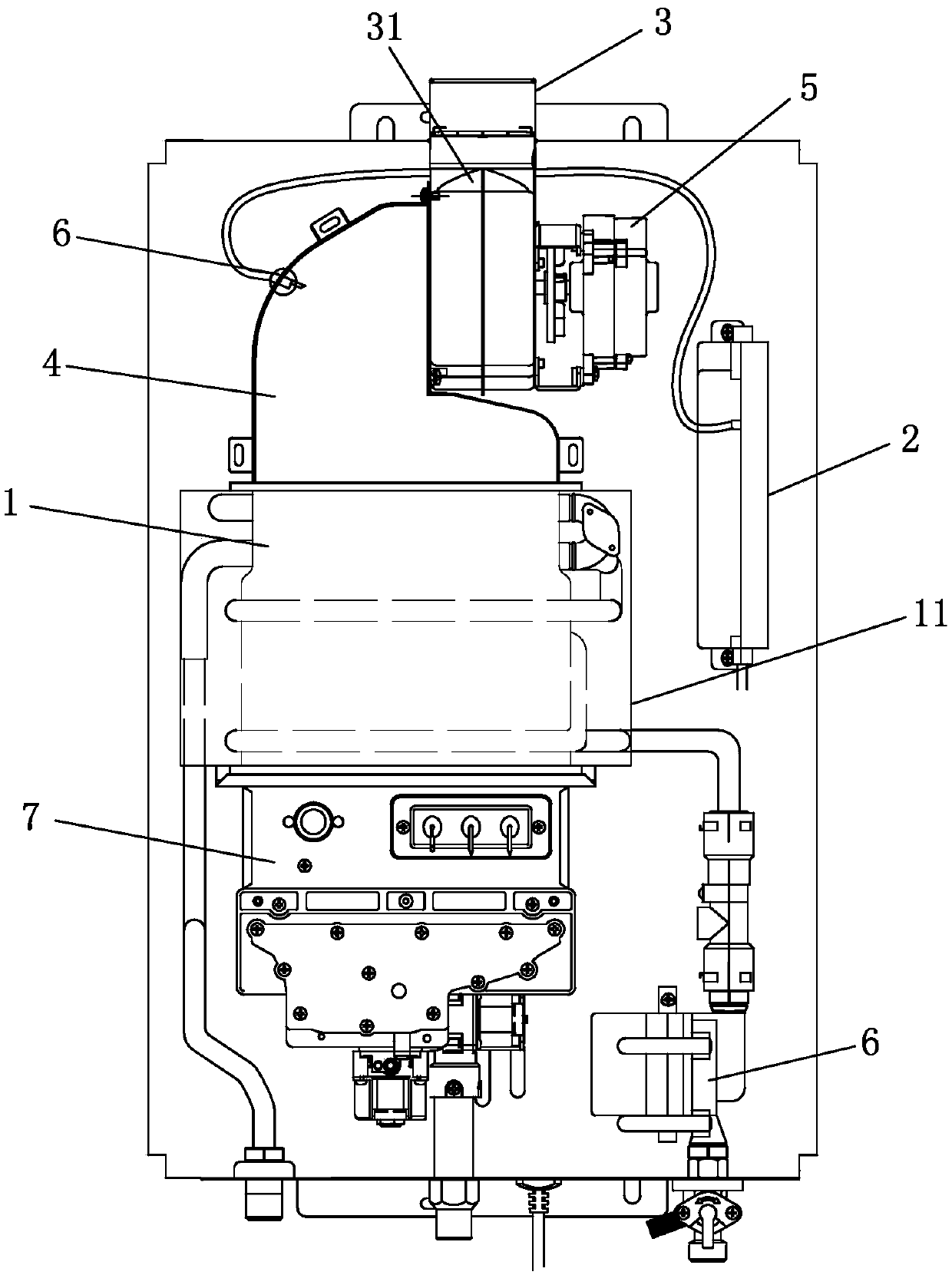

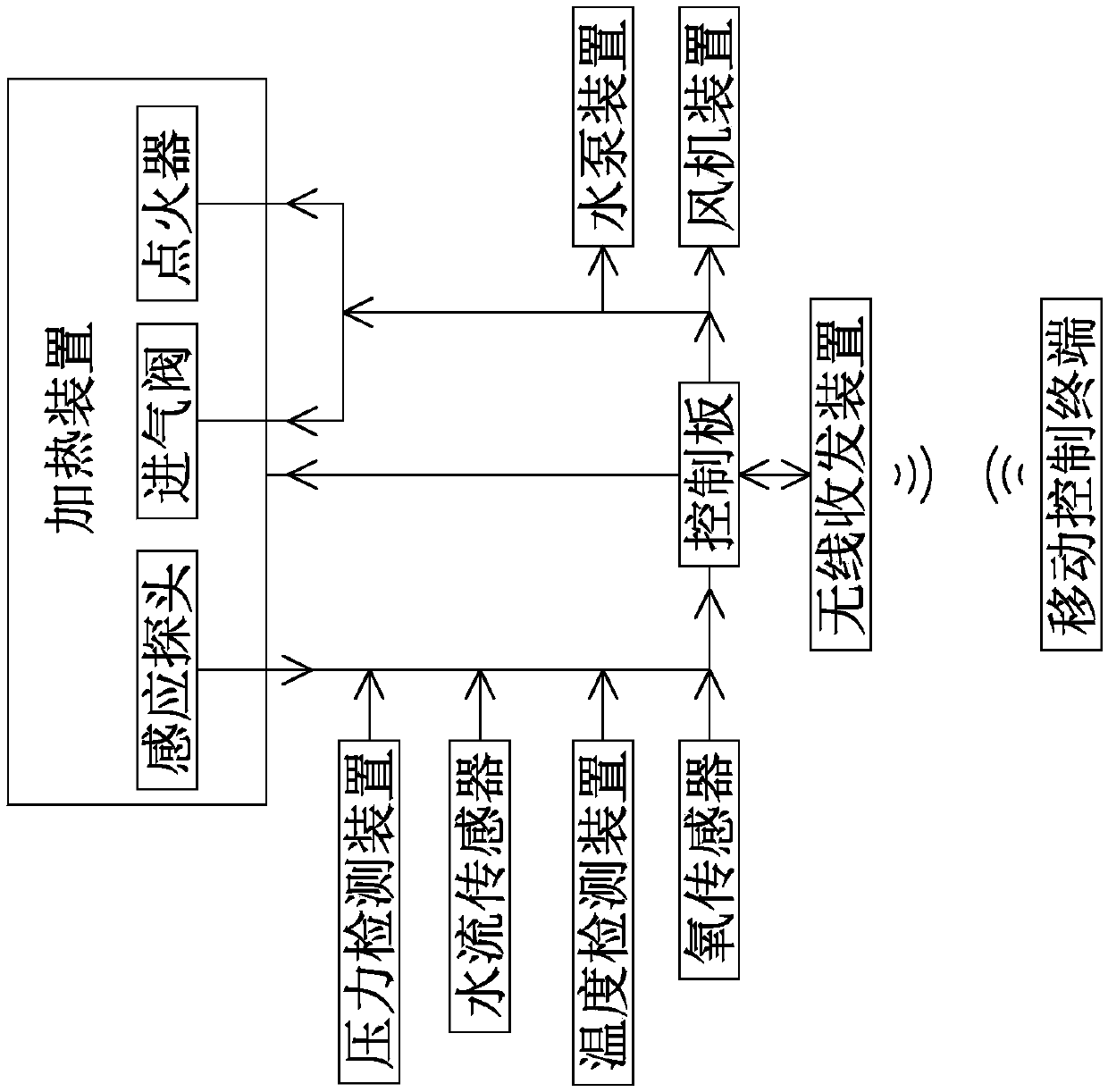

Self-adaptive gas water heater

The invention relates to a self-adaptive gas water heater which comprises a heat exchanger, a control board and a smoke outlet; a flue pipe is arranged between the top of the heat exchanger and the smoke outlet; the smoke outlet is provided with a fan device connected with the flue pipe; the flue pipe is internally provided with an oxygen sensor used for detecting the content of oxygen; the oxygensensor is electrically connected with the control board; and the control board is electrically connected with the fan device. A product realizes full-automatic regulation on air inlet quantity, can be adapted to the use demands of different environments and is expanded in application range.

Owner:广东顺德大派电气有限公司

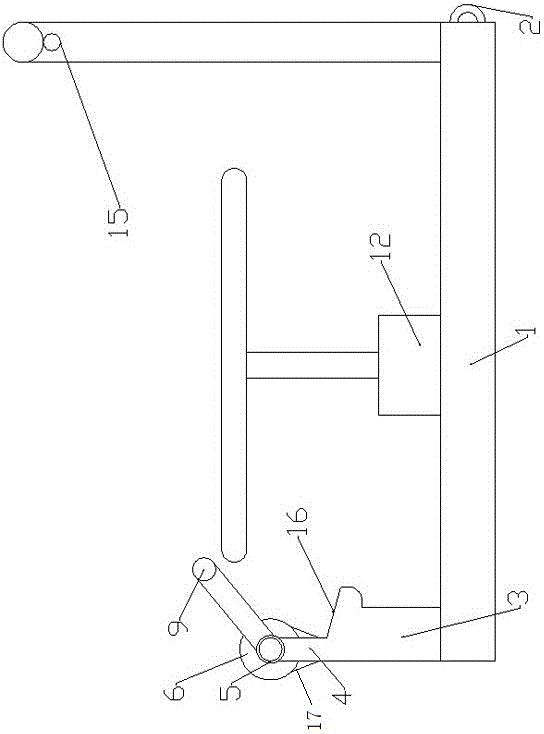

Full-automatic safety cock for press

The invention discloses a full-automatic safety cock for a press. The full-automatic safety cock comprises an adjusting screw, a nut, a support, a spring, a strut, a limit switch, an air cylinder, a connecting rod, a connecting plate, a bearing, a gear, a motor, a pressing block, a cylinder and a support seat. The air cylinder is adopted for controlling advancing and retreat, the motor is in electrical linkage with the press, transmission is conducted through the gear, the height of the adjusting screw is adjusted automatically according to die filling height, and full-automatic adjustment isachieved. The full-automatic safety cock is simple in structure, more convenient to use, high in operability and high in safety, and working efficiency is improved.

Owner:JIER MACHINE TOOL GROUP

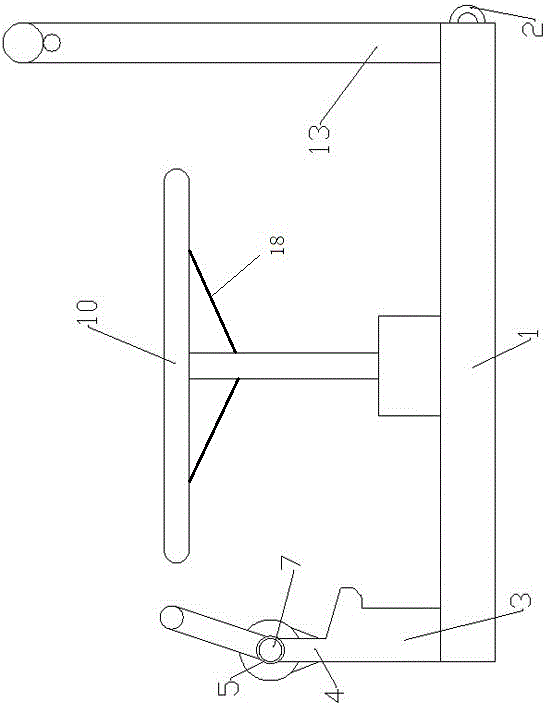

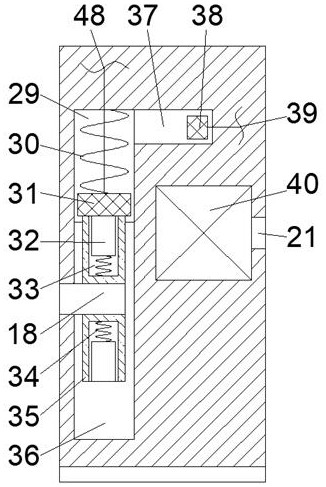

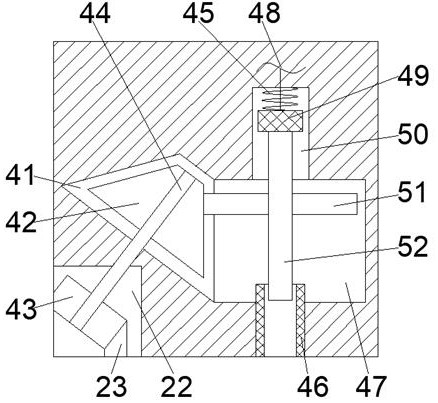

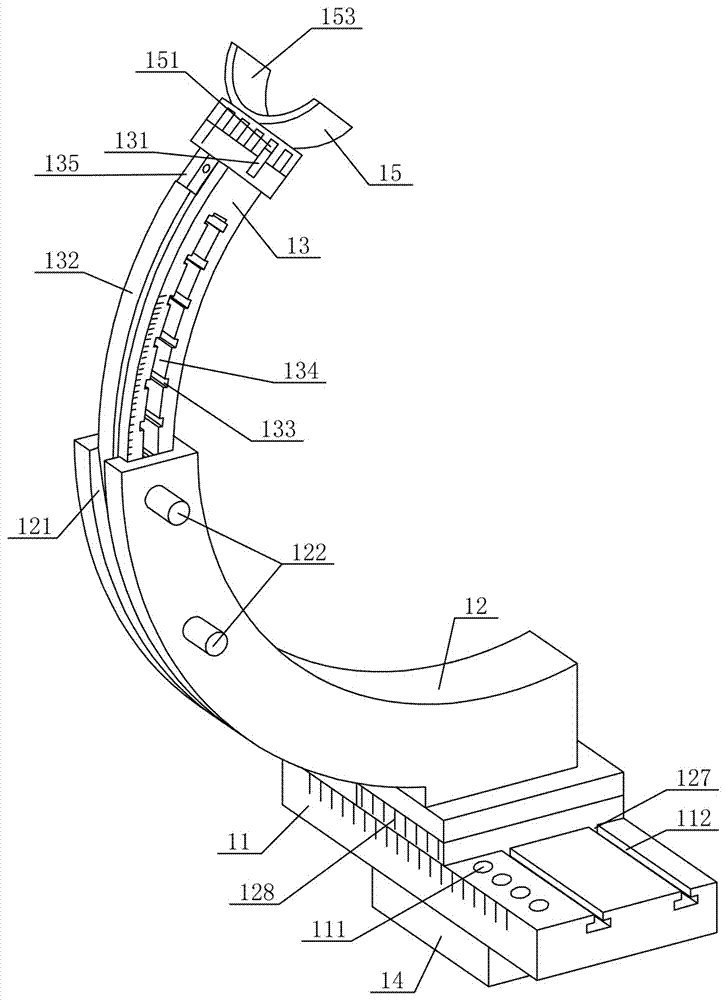

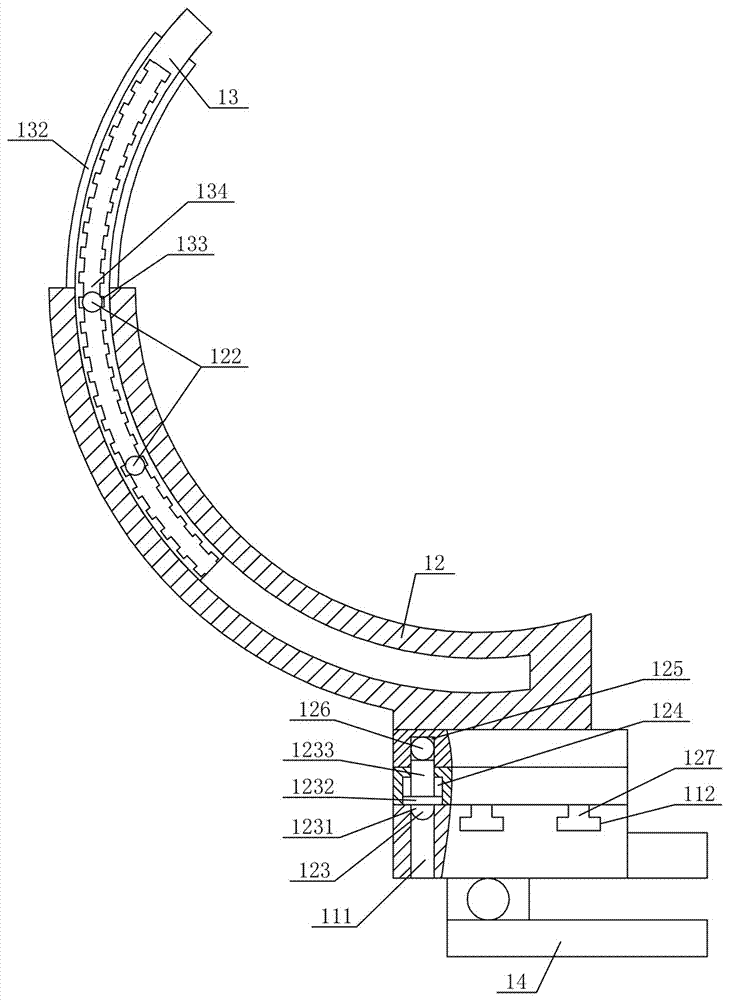

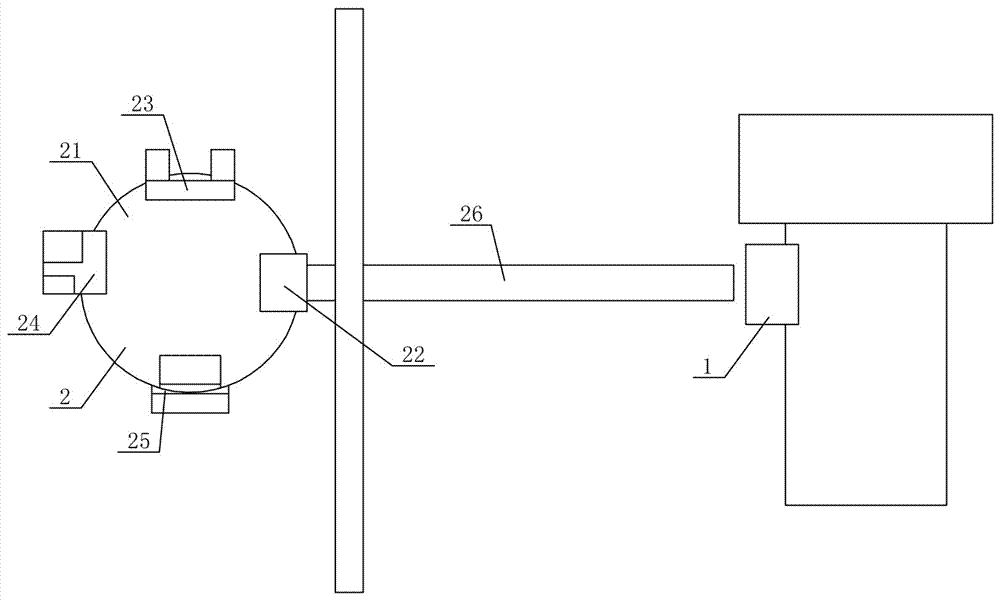

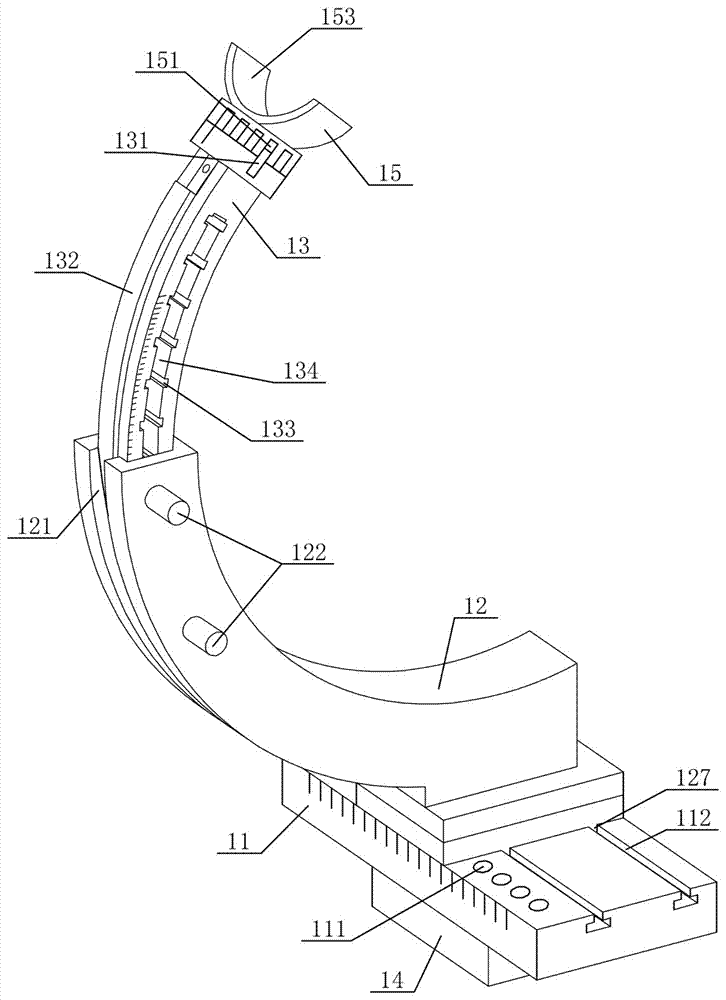

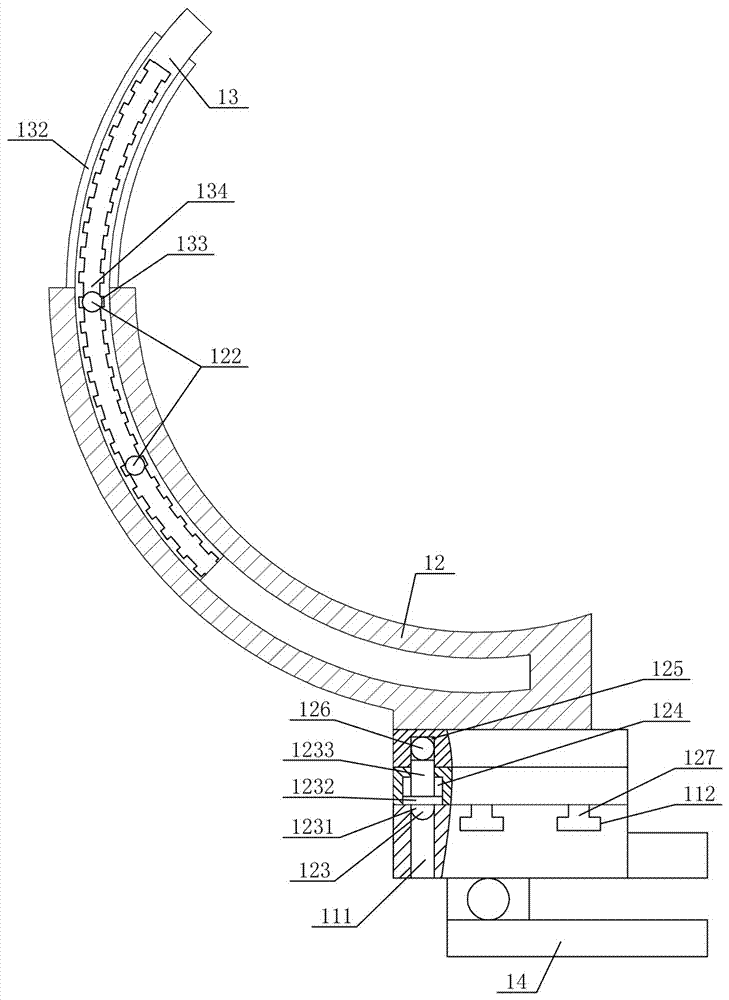

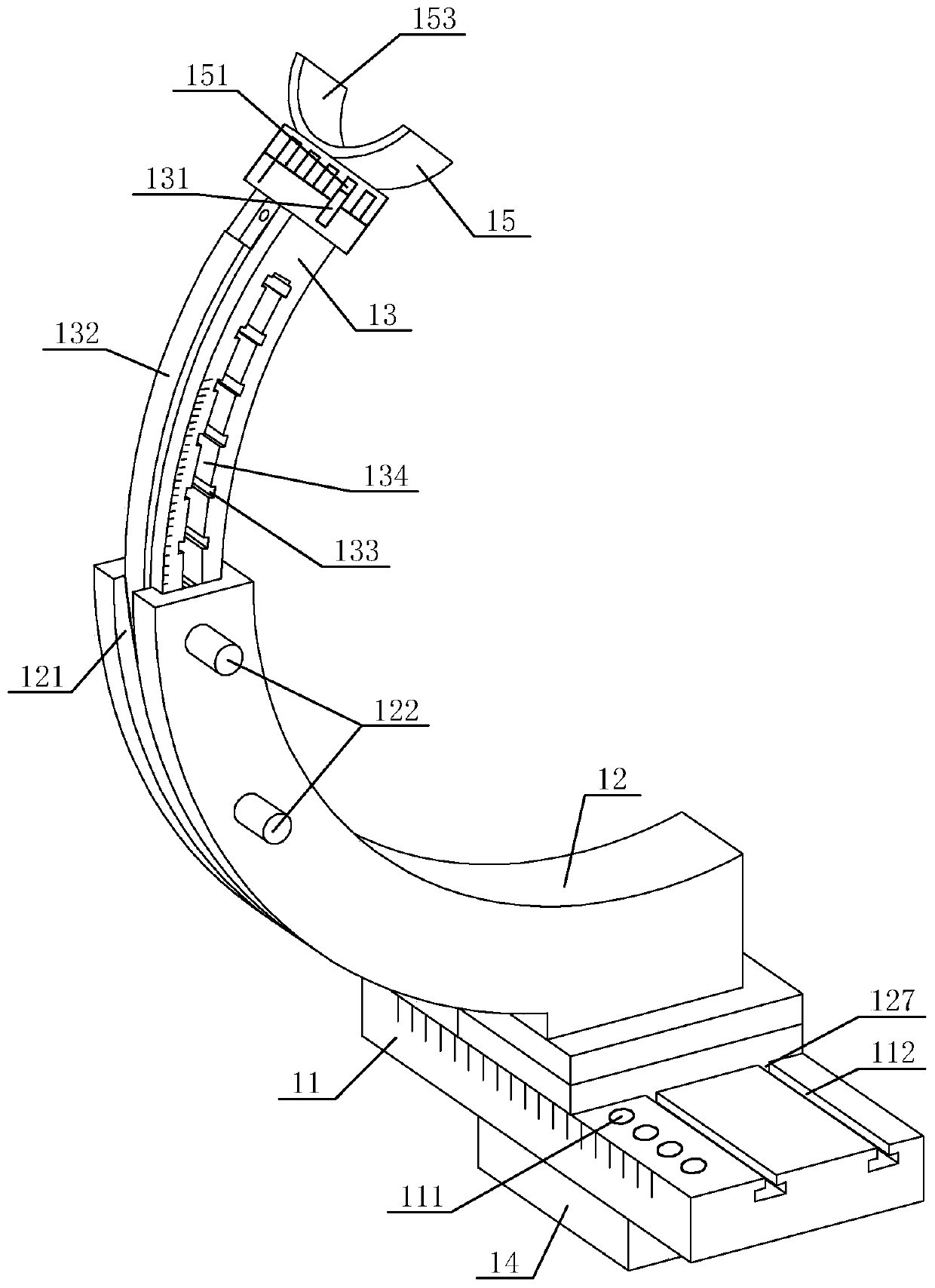

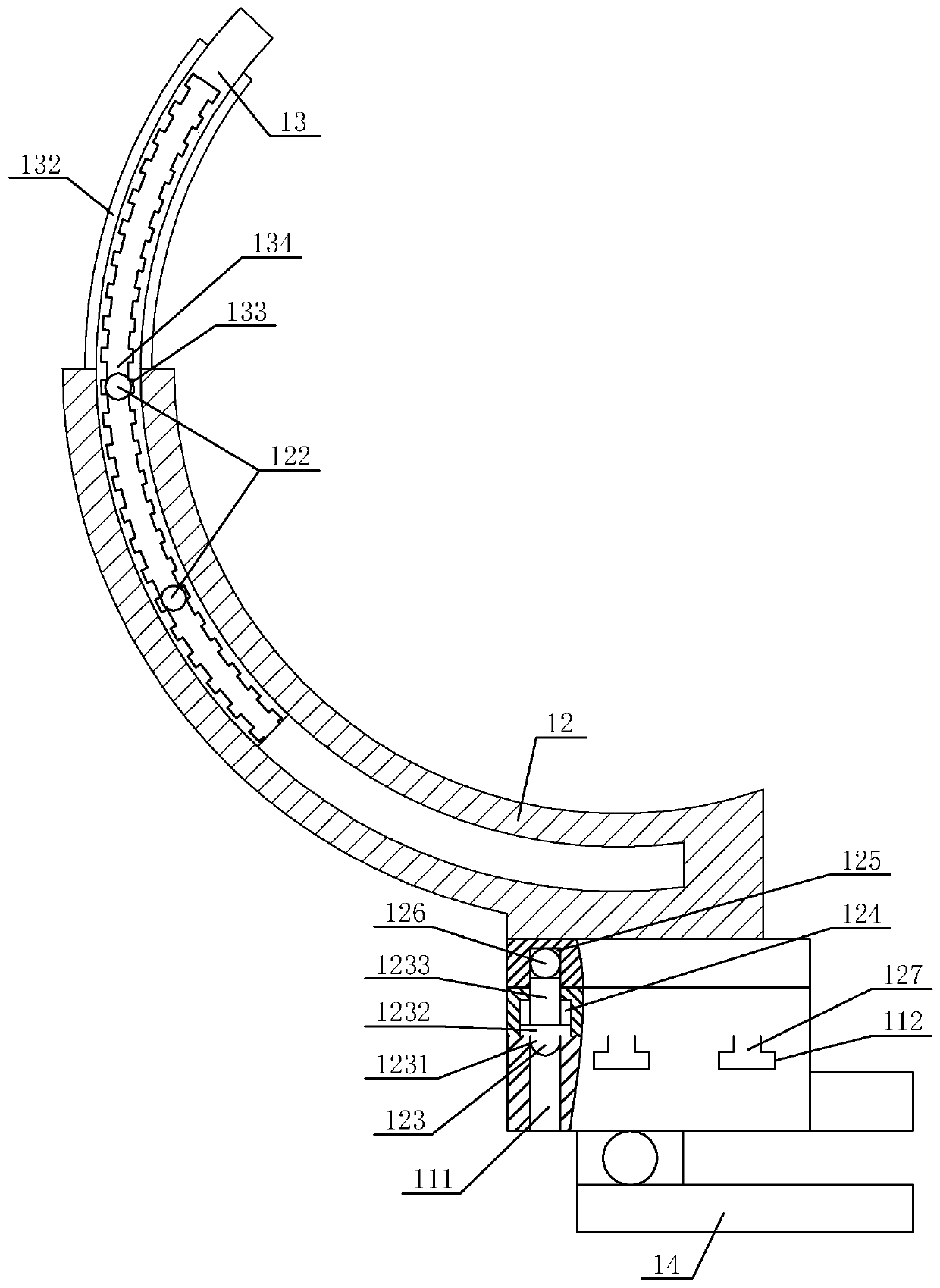

Full-automatic puncture needle positioner

ActiveCN106943182ADepth effectSo as not to damageDiagnosticsSurgical needlesComputed tomographyEngineering

The invention discloses a full-automatic puncture needle positioner. The positioner comprises a puncture needle locating frame and a locating frame adjusting mechanism. The locating frame adjusting mechanism comprises, in a vertically successive manner, a feeding and discharge mechanism, an angle adjusting mechanism, a radian adjusting mechanism and a horizontal position adjusting mechanism, which are installed on an installation rack. When installation rack rises, the feeding and discharge mechanism, the angle adjusting mechanism, the radian adjusting mechanism and the horizontal position adjusting mechanism can orderly perform feeding, angle adjustment, radian adjustment and horizontal position adjustment of puncture needles on the puncture needle locating frame. Therefore, according to an image of CT scanning, the locating frame adjusting mechanism can accurately adjust the puncture needle locating frame and enable the puncture needles to arrive at accurate positions, thereby simplifying work of medical staff and achieving higher accuracy. Medical operators can directly perform puncturing according to the positions of the puncture needles.

Owner:THE SECOND HOSPITAL AFFILIATED TO WENZHOU MEDICAL COLLEGE

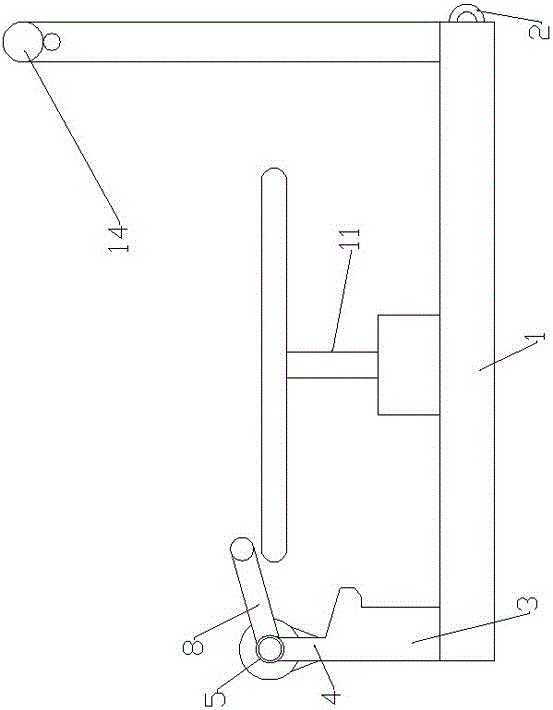

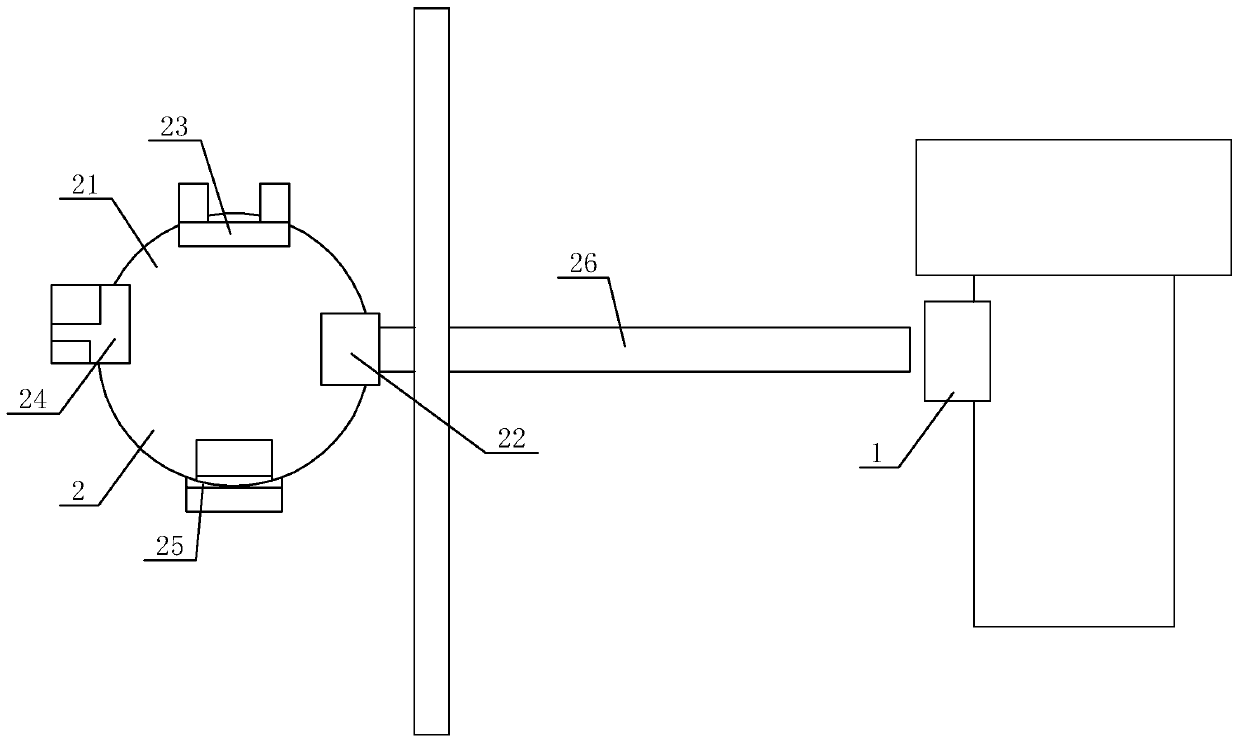

Automatic puncture needle positioner

ActiveCN107041777ADepth effectSo as not to damageSurgical needlesTrocarComputed tomographyNeedle position

The invention discloses an automatic puncture needle positioner comprising a puncture needle locating rack and a locating rack adjusting mechanism; the locating rack adjusting mechanism comprises a feeding and discharging mechanism, an angle adjusting mechanism, a radian adjusting mechanism and a horizontal position adjusting mechanism arranged in order on a rotary plate periphery; the rotary plate rotates to enable the feeding and discharging mechanism, the angle adjusting mechanism, the radian adjusting mechanism and the horizontal position adjusting mechanism to finish puncture needle feeding, angle adjusting, radian adjusting and horizontal position adjusting steps in order on the puncture needle locating rack; by using a CT scanned image, the locating rack adjusting mechanism can accurately adjust the puncture needle locating rack, thus allowing the puncture needle to reach the correct position, and simplifying medical personnel work; the automatic puncture needle positioner is higher in accuracy, and the medical personnel can directly puncture according to the puncture needle position.

Owner:THE SECOND HOSPITAL AFFILIATED TO WENZHOU MEDICAL COLLEGE

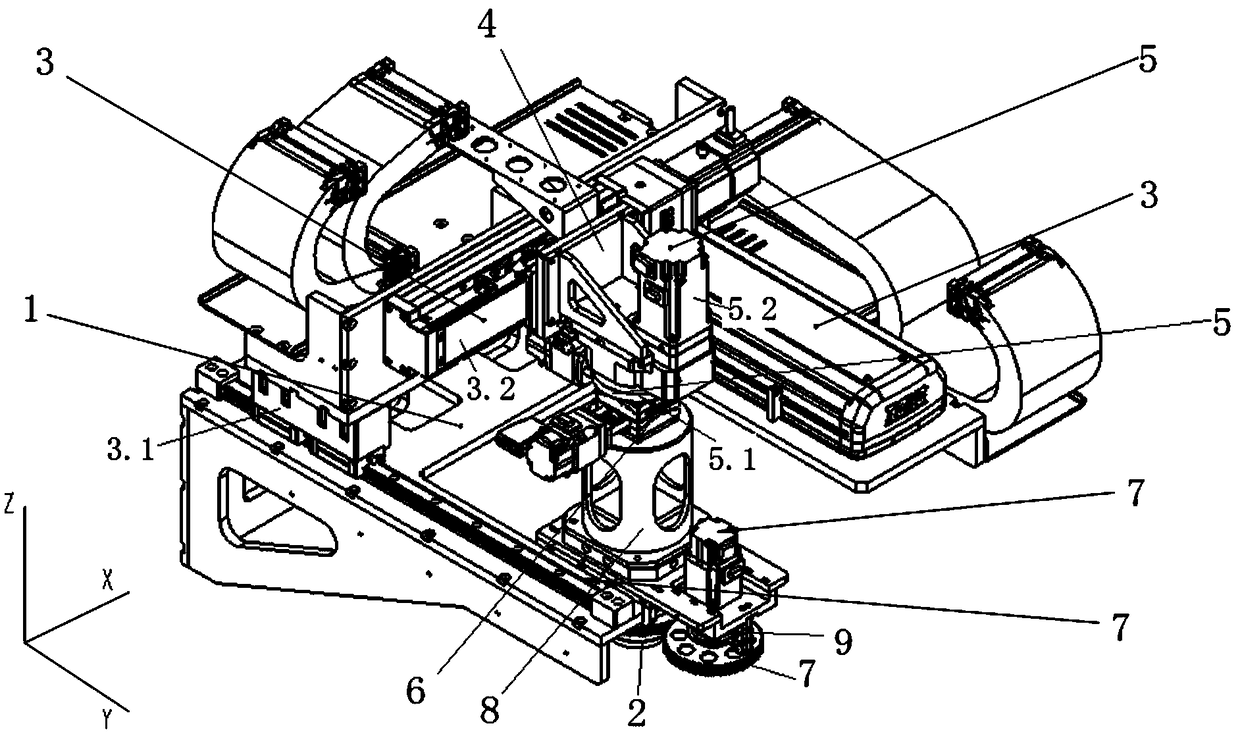

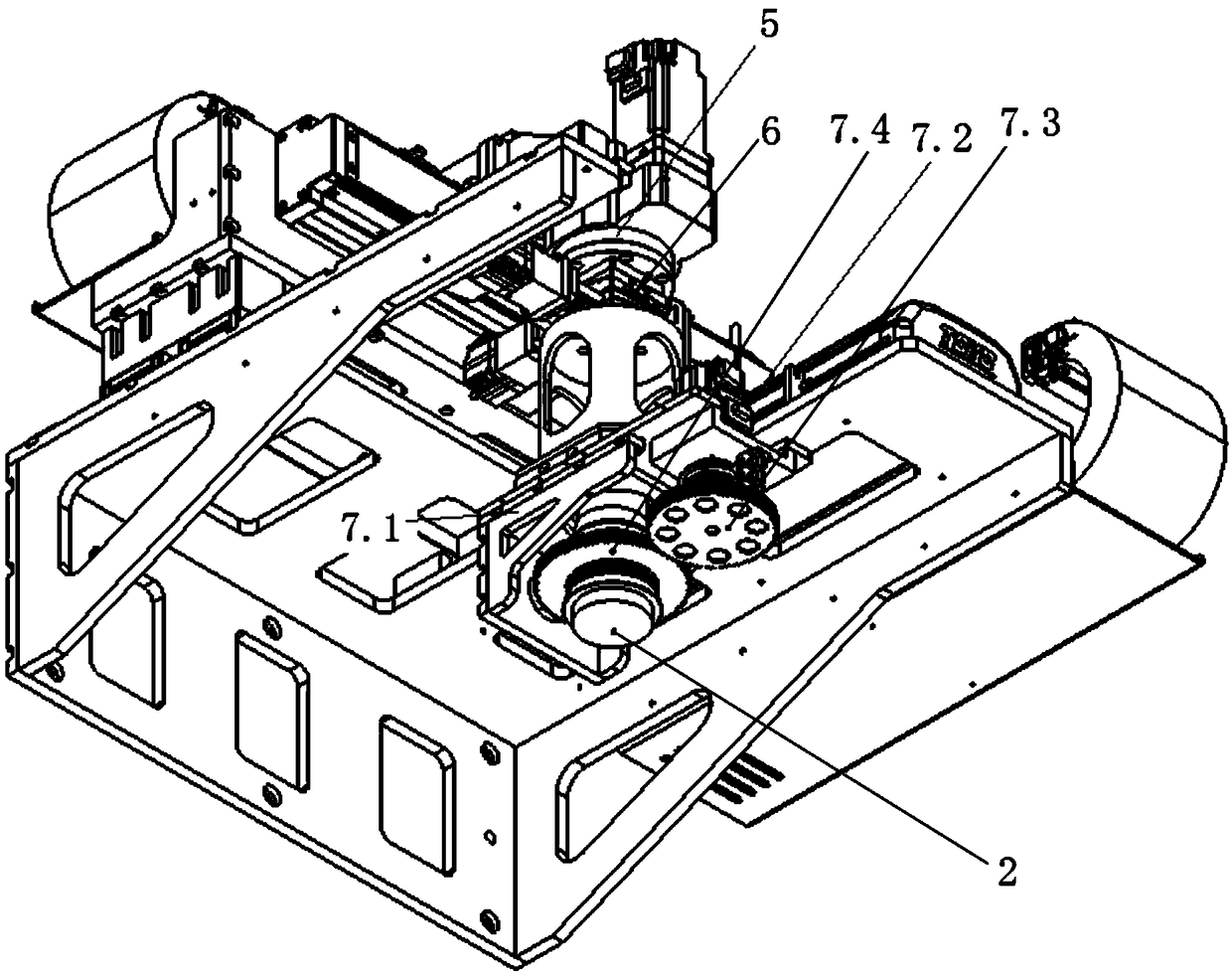

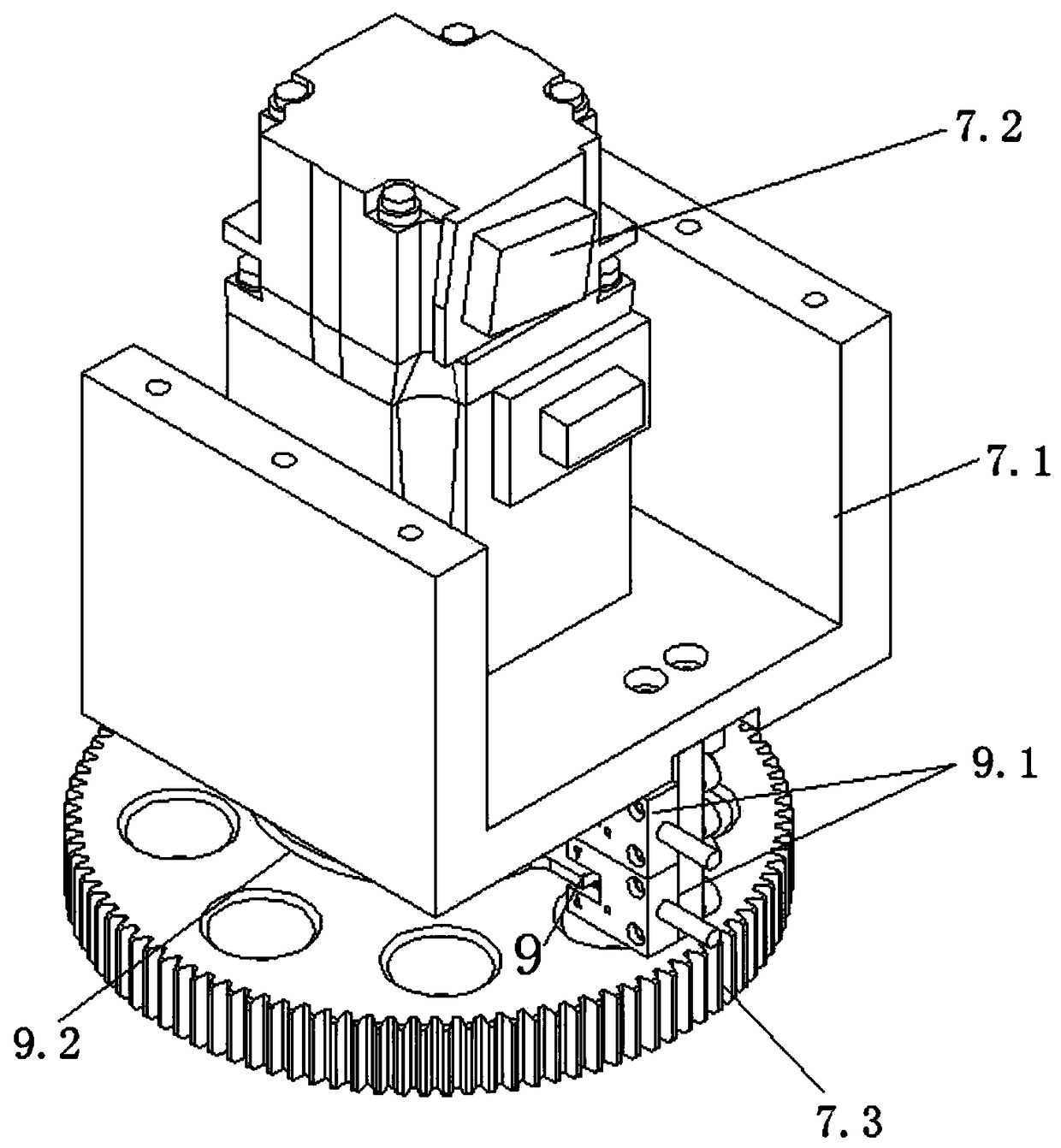

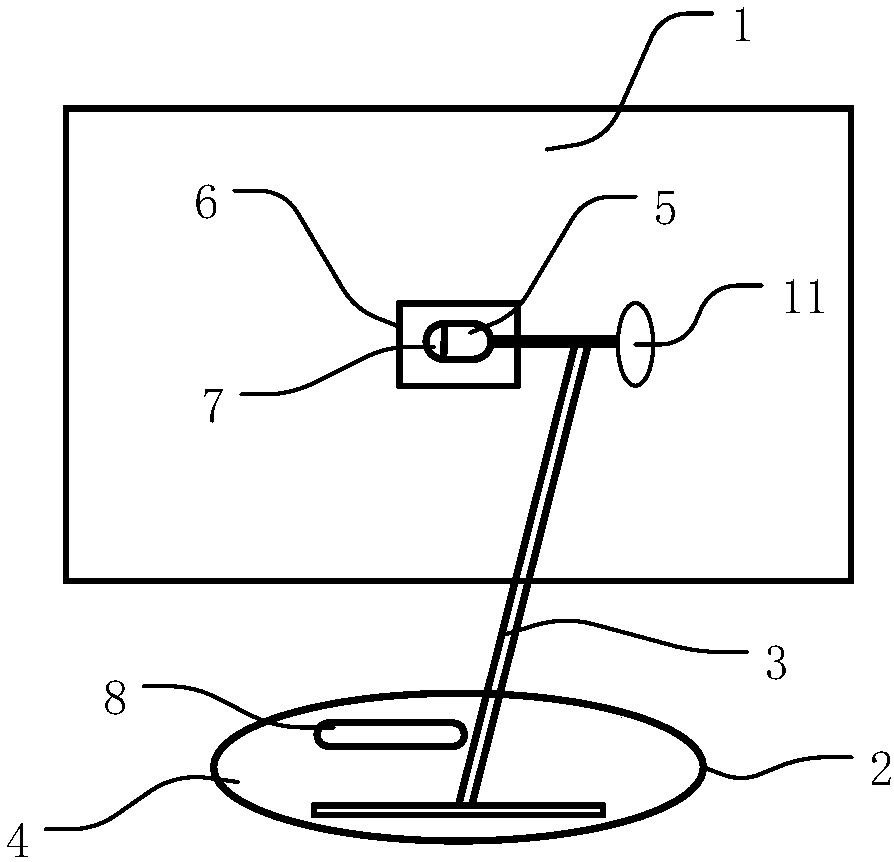

Demura multi-axis full-automatic detection mechanism

PendingCN108918533AReduce size and massAchieve damageOptically investigating flaws/contaminationEngineeringMulti axis

The invention discloses a Demura multi-axis full-automatic detection mechanism. The Demura multi-axis full-automatic detection mechanism comprises a stander and a CCD camera, wherein the stander is provided with a sliding table module, the movable end of the sliding table module is connected with a connecting frame, and the CD camera is connected to the bottom of the connecting frame; a rotary carrying table mechanism, a swinging sliding table and a gear focusing mechanism are successively arranged between the connecting frame and the CCD camera from top to bottom; the gear focusing mechanismcomprises a foundation support, a second drive source, a driving gear and a driven gear; and the rotary carrier table mechanism, the swinging sliding table and the CCD camera are coaxially distributed. Compared with the traditional Demura detection mechanism, the Demura multi-axis full-automatic detection mechanism is simple in structure and convenient in use; the CCD camera can move along the directions of an X axis, a Y axis and a Z axis and can also rotate around the X, Y and Z axis, so that the full-automatic adjustment can be realized; and moreover, the Demura multi-axis full-automatic detection mechanism is provided with a focal length adjusting mechanism, and the inaccuracy in focusing and damage of the camera caused by the large adjustment amplitude of the CCD camera along the Z axis direction can be avoided.

Owner:WUHAN JINGCE ELECTRONICS GRP CO LTD

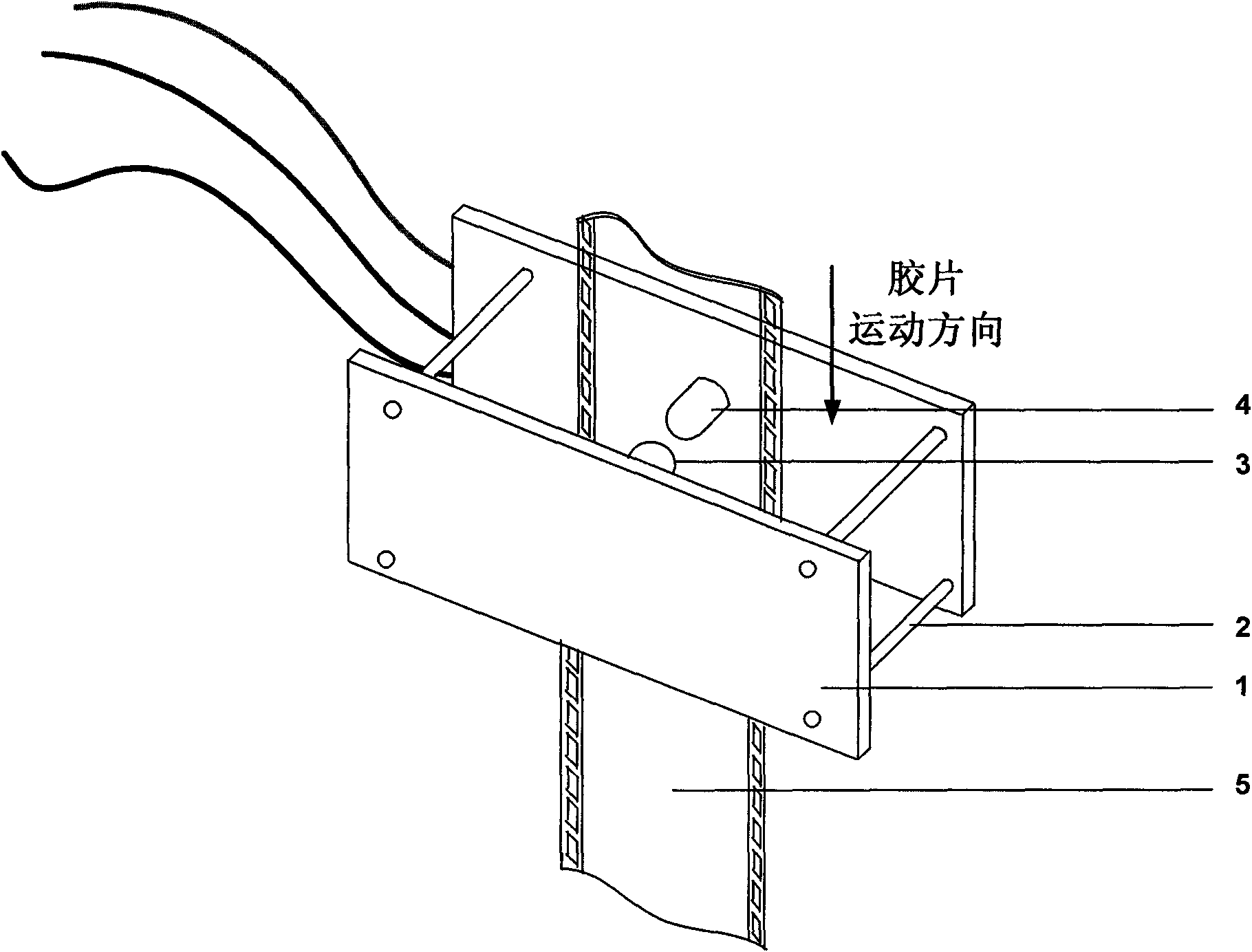

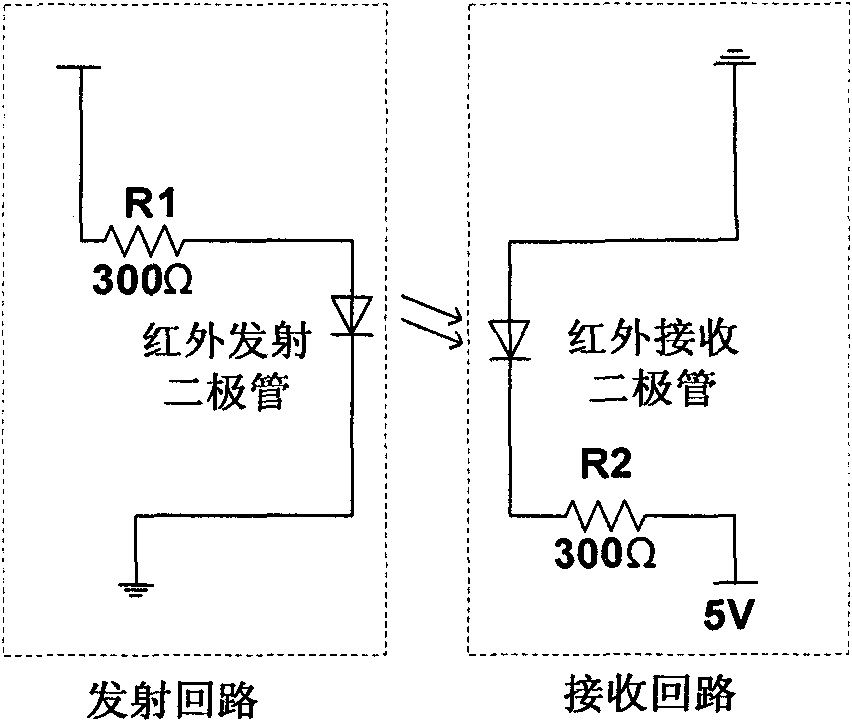

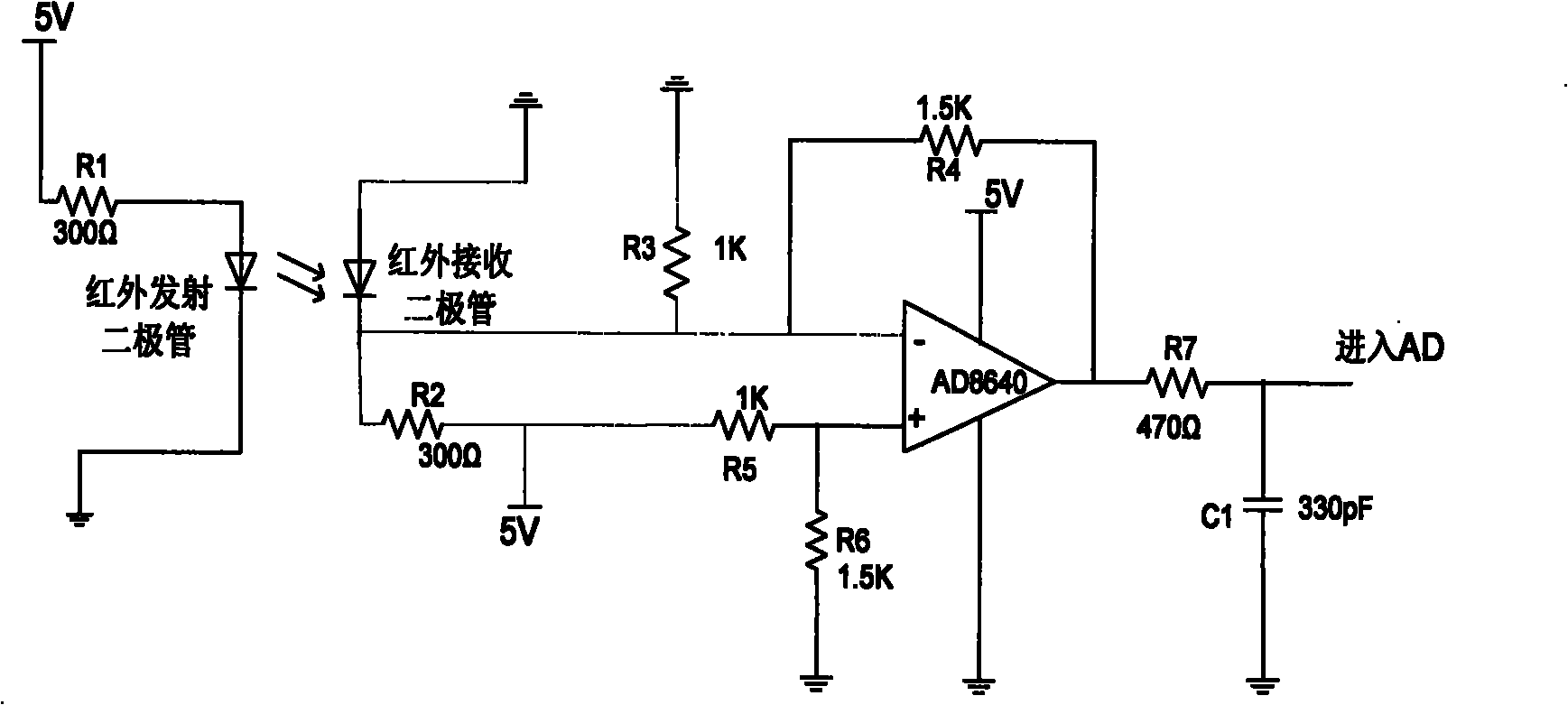

Intelligent detection method for film type

InactiveCN101806922AHigh sensitivityEasy digital connectionOptical detectionTransmissivity measurementsSuperimpositionTest measurement

The invention discloses an intelligent detection method for a film type, which comprises the following steps: (1) manufacturing an infrared detection device which consists of front and rear fixed plates, four brackets, an infrared transmitting loop and an infrared receiving loop; (2) amplifying and filtering a sampling value detected by the infrared detection device, converting a sampling analog value into a digital signal, digitally filtering the sampling digital signal, and finally acquiring a filtered sampling value; and (3) comparing the acquired filtered sampling value with a set threshold value, judging the film as a leader film if the sampling value is greater than the threshold value, and judging the film as a copy film if the sampling value is smaller than the threshold value, wherein a method for determining the threshold value is characterized in that through test measurement, namely when the leader film and the copy film pass the test respectively, the change intervals of the digital values of the both have no superimposition, and a value between the two intervals is defined as the threshold value. The method realizes automatic judgment of the film type, and has high reliability and sensitivity.

Owner:BEIHANG UNIV

Automatic adding and mixing device for marine sewage medicine

PendingCN113735200AFully automatic adjustmentBest ratioRotary stirring mixersGearingPharmacy medicineProcess engineering

The invention discloses an automatic adding and mixing device for marine sewage medicine. The device comprises a sucking and adding mechanism, a conveying and stirring mechanism and a stirring and mixing mechanism, a main shaft of the sucking and adding mechanism is designed to be of a 360-degree omnibearing rotating structure, and a secondary telescopic arm and a vacuum sucking pipe are designed; medicine needing to be added can be automatically and flexibly selected, the required amount of medicine is sucked through the vacuum cavity, then the medicine is put into a feeding opening through pneumatic precise control, the conveying and stirring mechanism conducts primary mixing on the medicine in the conveying process, secondary mixing action is adopted for stirring and mixing, and finally the medicine is discharged through dense small holes in the bottom. The stirring and mixing mechanism adopts a mode that a worm gear and a worm are matched with a gear for transmission, the mixing and stirring speed can be automatically adjusted according to different medicines and dosages, and the medicines are fully and uniformly mixed. According to the full-automatic medicine adding and mixing device, adding and mixing of multiple kinds of medicine can be completed in a full-automatic mode, accurate metering can be achieved, and universality is achieved.

Owner:庞汪良

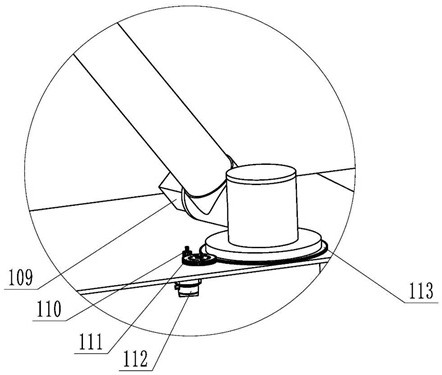

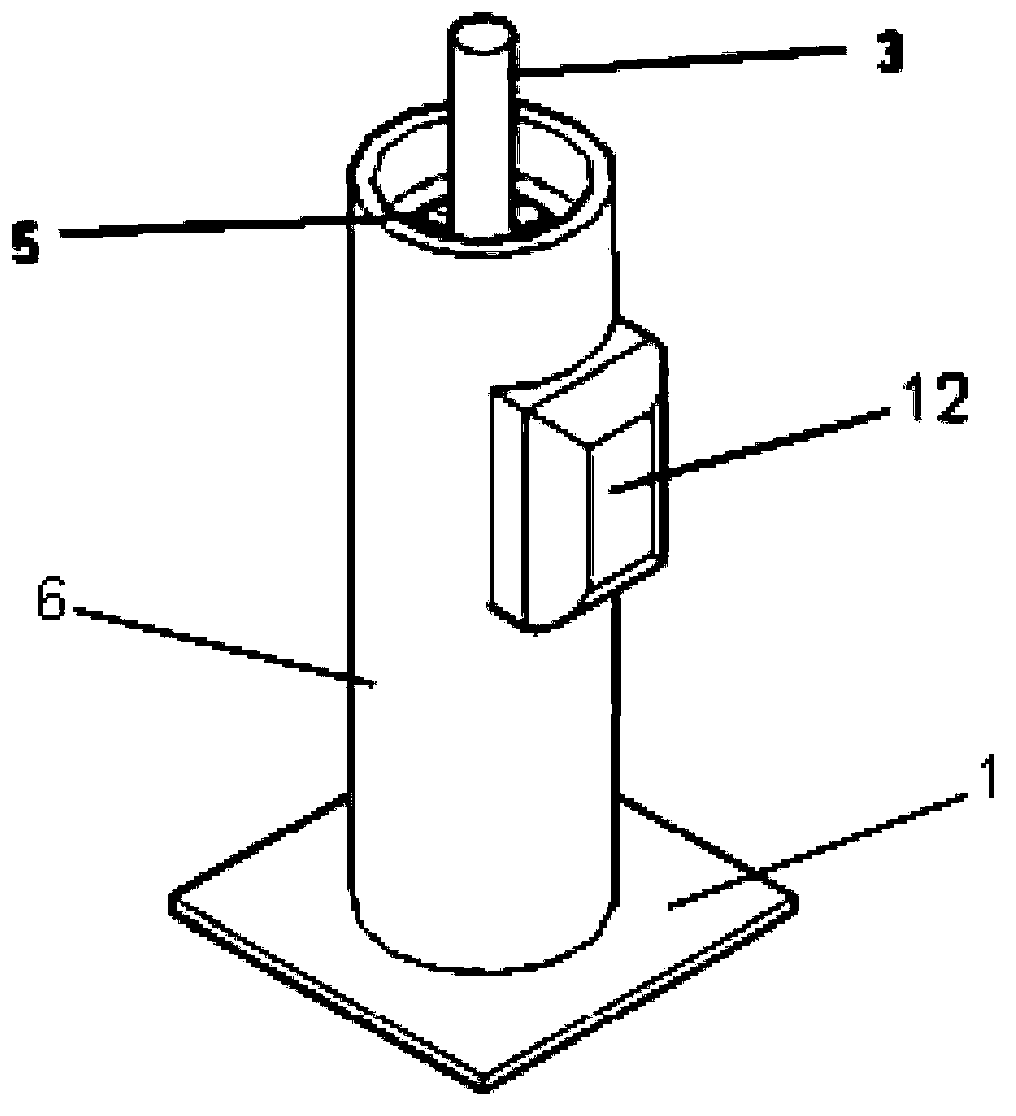

Sunlight directional reflection device with double-sided mirror structure

InactiveCN103853170ASimple structureNovel and reasonable designToothed gearingsPosition/direction controlFixed bearingEngineering

The invention discloses a sunlight directional reflection device with a double-sided mirror structure. The sunlight directional reflection device with the double-sided mirror structure comprises a base and a longitudinal support shaft sleeve, wherein the longitudinal support shaft sleeve is installed at the top end of the base, a longitudinal rotary shaft is installed in the longitudinal support shaft sleeve through a longitudinal shaft installation fixing bearing, a longitudinal power transmission device used for driving the longitudinal rotary shaft to rotate is installed on the longitudinal support shaft sleeve, a rotary support is installed at the top end of the longitudinal rotary shaft, a horizontal rotary shaft support is installed on the rotary support, a horizontal rotary shaft and a horizontal power transmission device are installed on the horizontal rotary shaft support, the horizontal power transmission device is used for driving the horizontal rotary shaft to rotate, a slope mirror is installed on the horizontal rotary shaft, a horizontal mirror is connected to the slope mirror, and the horizontal mirror is fixedly connected with the rotary support. The sunlight directional reflection device with the double-sided mirror structure is simple in structure, novel and reasonable in design, and convenient to machine, manufacture and install, can achieve directional output of light, and is large in number of application fields, energy is saved, practicability is high, the using effect is good, and popularization and use are convenient.

Owner:陕西科林能源发展股份有限公司

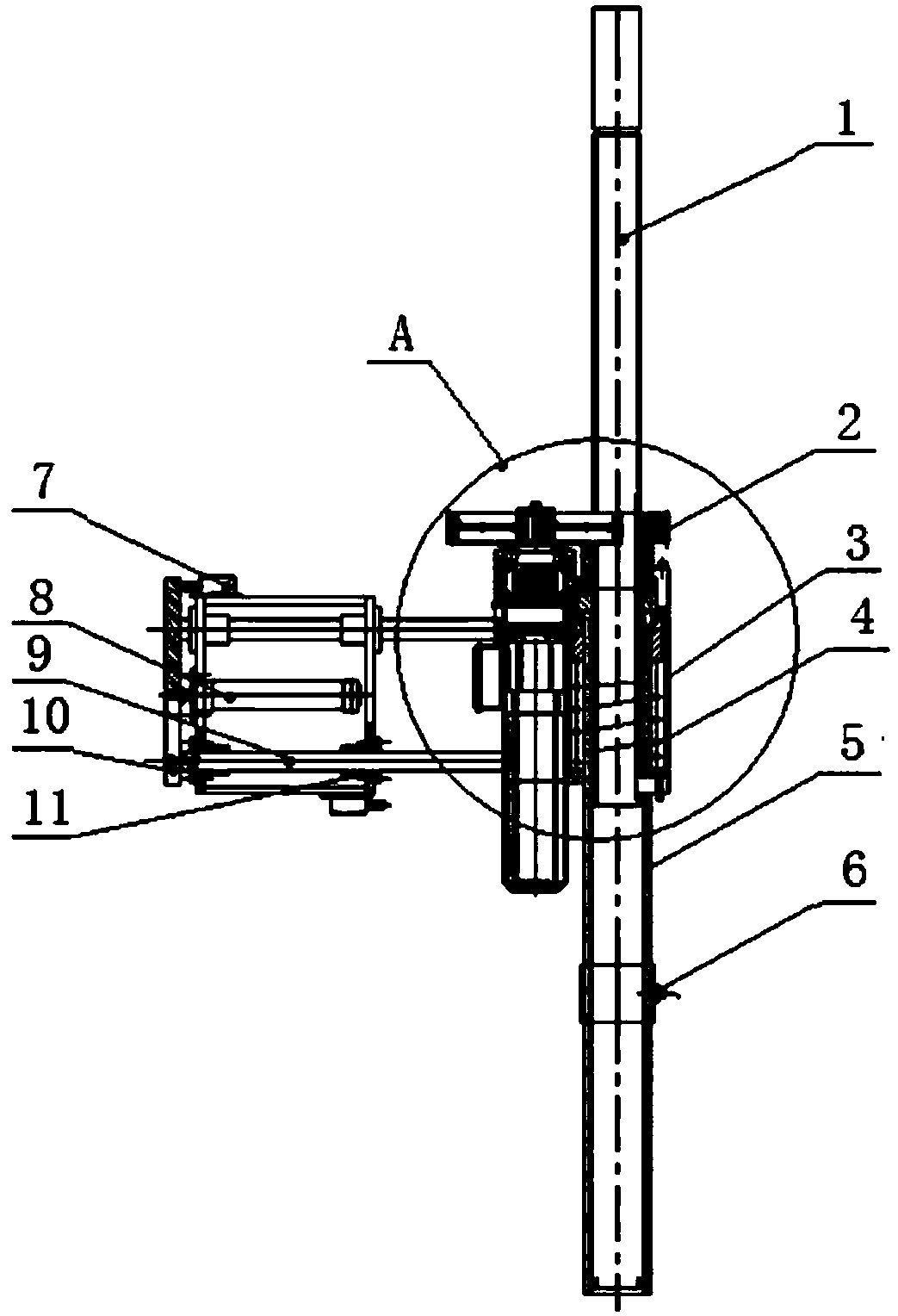

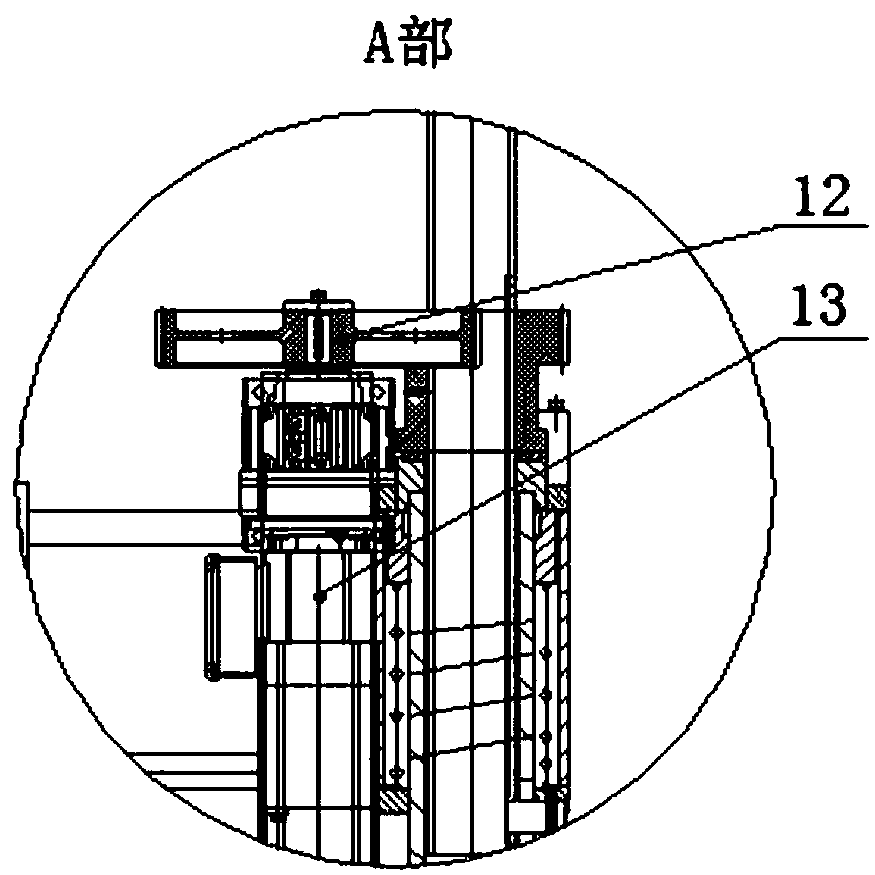

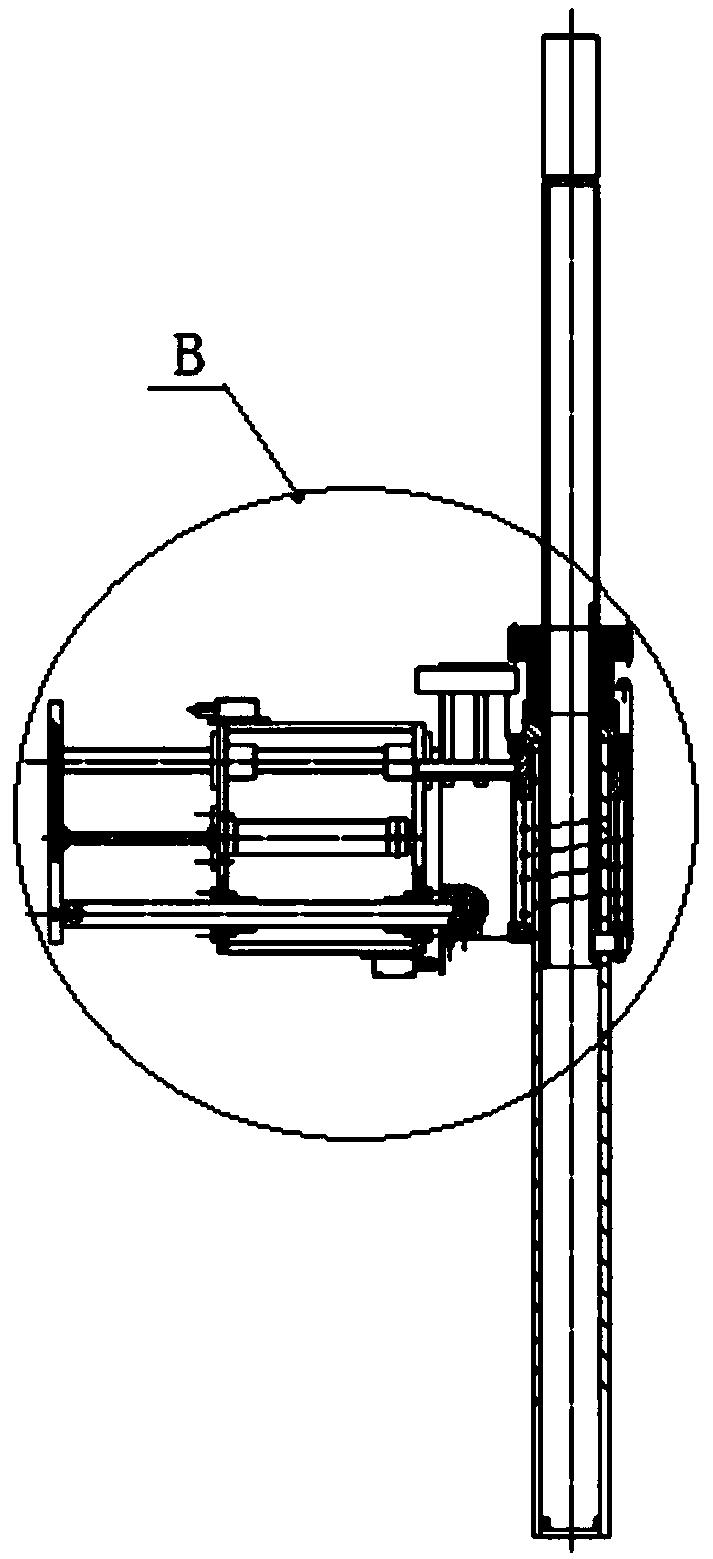

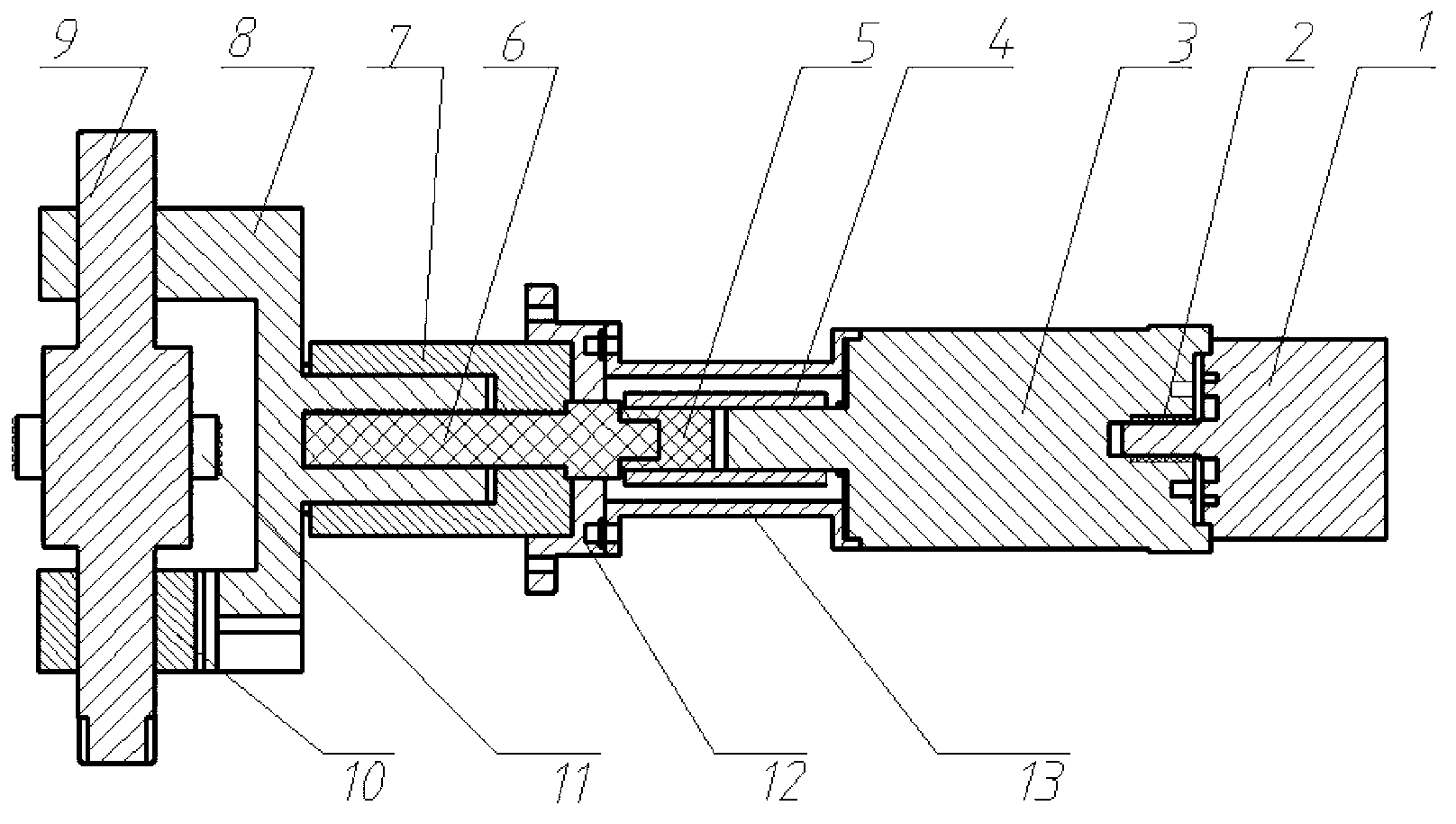

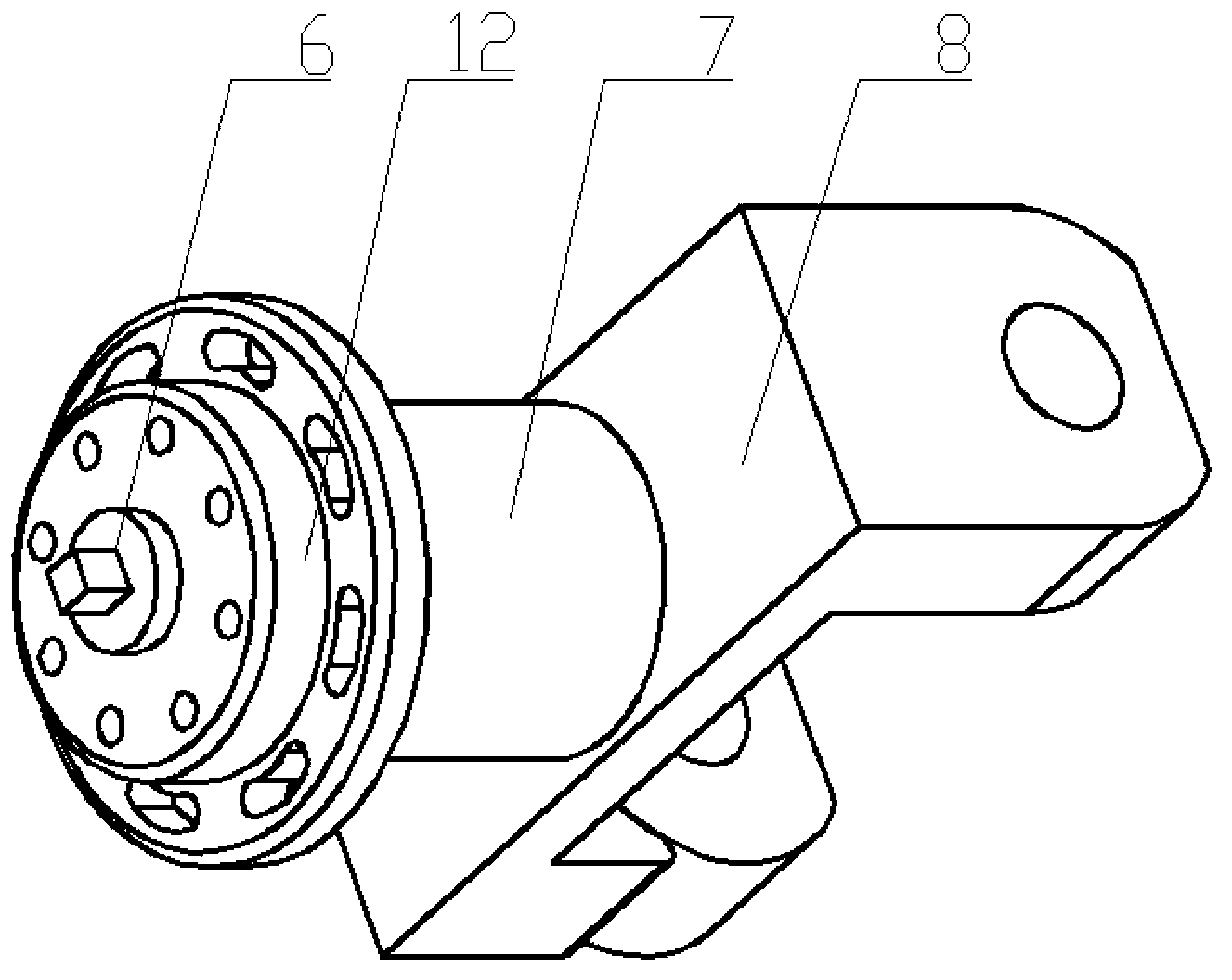

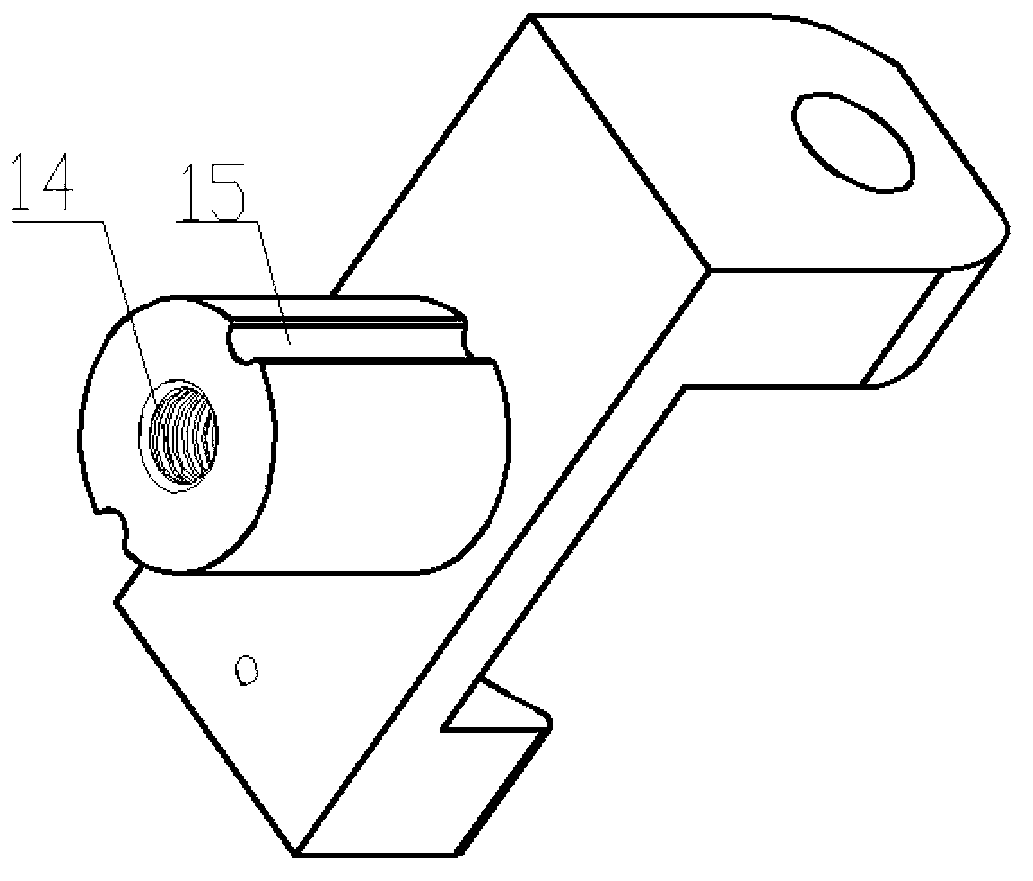

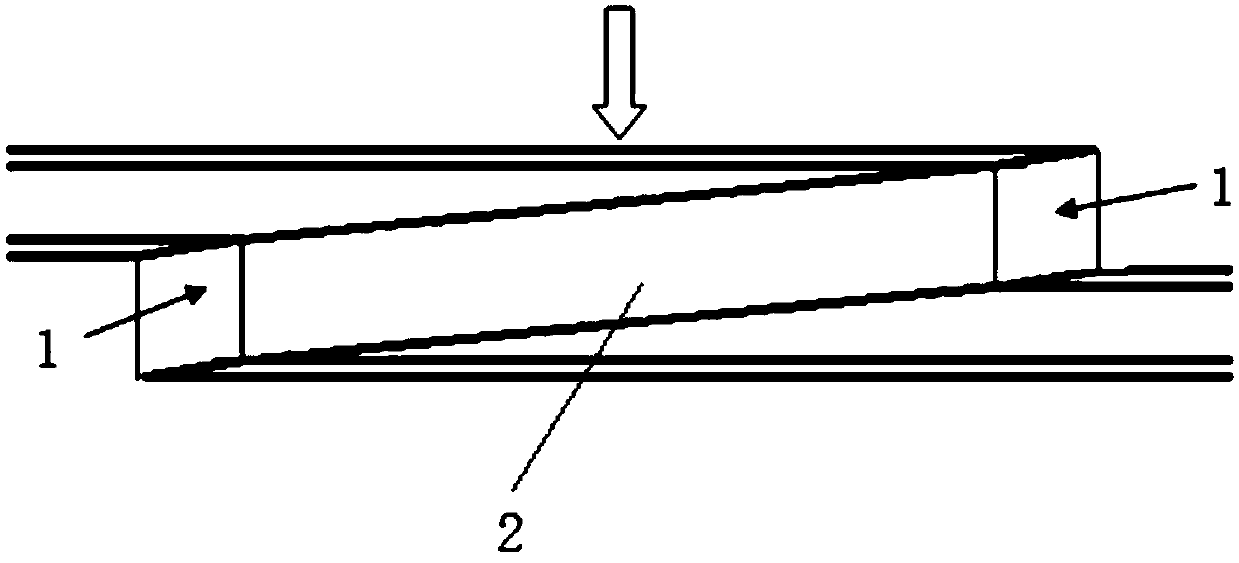

Cutter feeding mechanism of high-efficiency heat exchange tube processing equipment

ActiveCN103264064APrecise position controlControl speedExtrusion control devicesPower apparatusFlange

The invention relates to a cutter feeding mechanism of high-efficiency heat exchange tube processing equipment. The cutter feeding mechanism is characterized by comprising a cutter mounting shaft (9), a cutter connecting piece (8), a sleeve (7), a screw rod (6), a connecting flange (12), a screw rod connecting block (5) and a sleeve connector (4), wherein one end of the sleeve connector (4) is connected with an output shaft of a power device, and the other end of the sleeve connector (4) is connected with the screw rod connecting block (5); one end of the screw rod (6) is connected with the screw rod connecting block (5), and the other end of the screw rod (6) is screwed into a threaded end (14) of the cutter connecting piece (8) by a thread (17) at the end of the sleeve (7); the threaded end of the cutter connecting piece (8) is inserted into the sleeve (7) and only axially moves in a straight line in the sleeve (7); the cutter mounting shaft (9) is arranged on the end, outside the sleeve (7), of the cutter connecting piece (8); a cutter (11) is arranged on the cutter mounting shaft (9); and the connecting flange (12) is fixed on the sleeve (7) and is connected with the power device by a fixed flange (13). The cutter feeding mechanism is simple in structure and convenient to adjust, and can be used for adjusting and processing high-efficiency heat exchange tubes such as a corrugated tube in a full-automatic way so as to obtain high-accuracy and high-efficiency heat exchange tubes.

Owner:江苏中圣压力容器装备制造有限公司

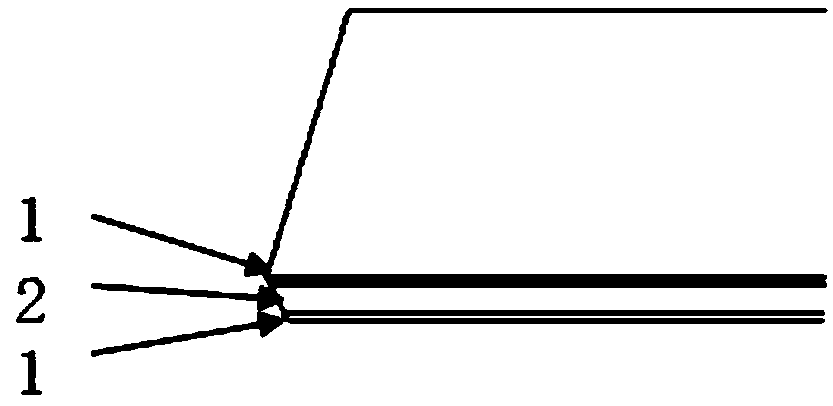

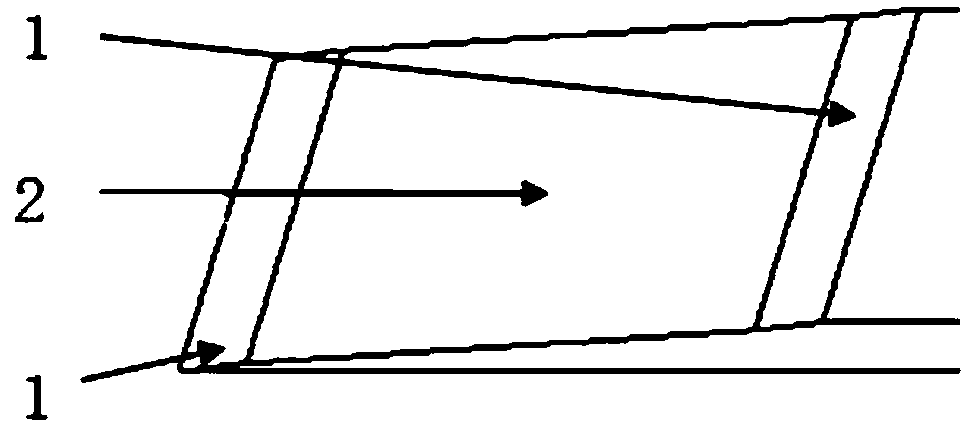

Full-automatic industrial flat belt splicer machine and control method thereof

PendingCN109094033AFully automatic adjustmentEasy to controlBeltsLocking mechanismAgricultural engineering

The invention discloses a fully automatic industrial flat belt splicer machine, which comprises a support base and a controller. The support base is fixed with a support arm and an upper mold with opening and closing mechanism. The upper part of the support arm is provided with a lower mold base, and on the lower mold base a lower heating plate is provided. The upper mold is provided with a rotating shaft, one end of the rotating shaft is fixed with the upper mold, and an upper heating plate is arranged on the lower surface of the upper mold, and the upper heating plate and the lower heating plate are connected with a heater. Between the upper mold and the lower base, a locking mechanism is arranged, while an air bag and a gas pressure regulating valve are installed on the upper surface ofthe upper mold. A water inlet and a water outlet are arranged on the lower base, and hydraulic control valves are at the water inlet and outlet. The upper mold, the locking mechanism, the heater, thegas pressure regulating valve and the hydraulic control valves are connected to the controller respectively. The controlling method is based on the process and the preset control parameters, and to control the actuators through the controller to realize the automatic joint, which has the advantages of high efficiency, accurate identification and easy standardization.

Owner:GUANGDONG IND TECHN COLLEGE +1

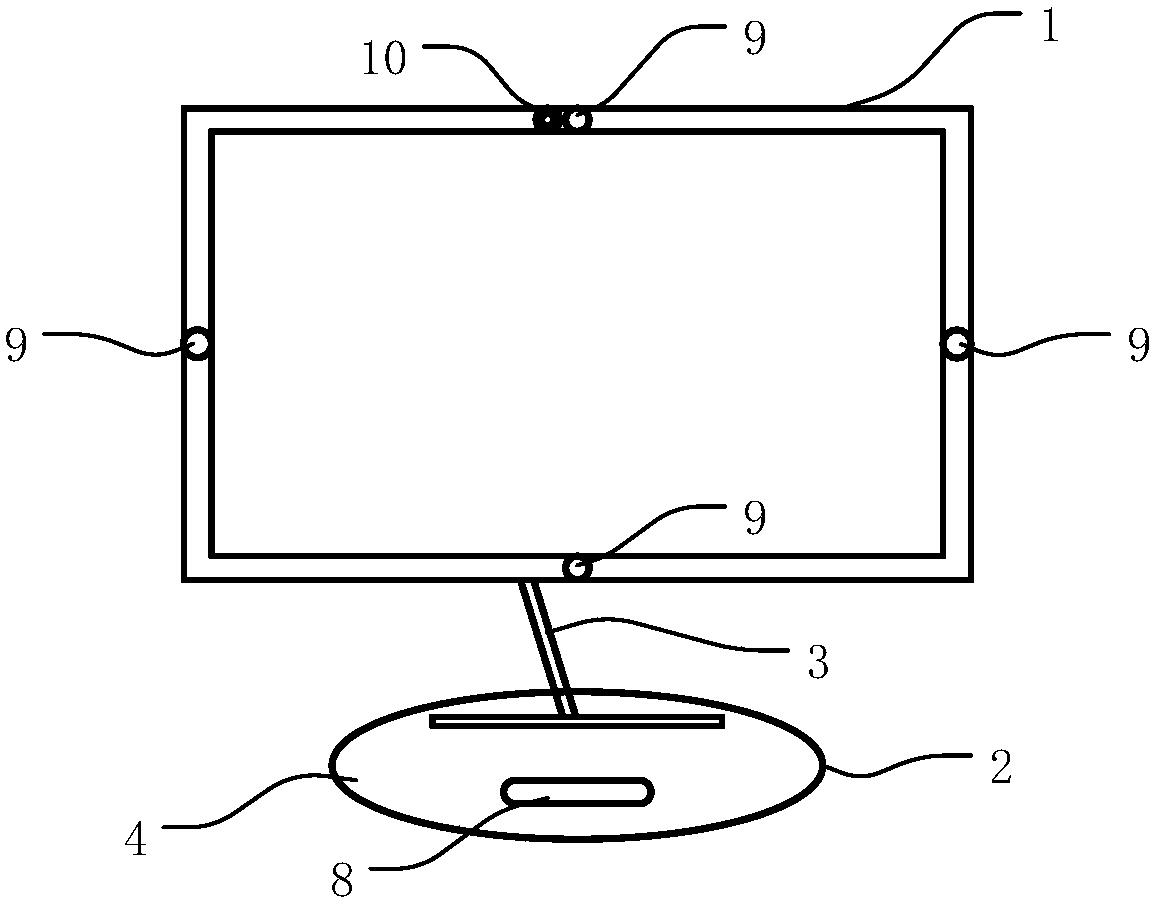

Adaptive display

InactiveCN107908228AFully automatic adjustmentInput/output for user-computer interactionDigital data processing detailsDisplay deviceAgricultural engineering

The invention discloses an adaptive display, which comprises a bulb, a connecting rod and a pulley, wherein the bulb comprises an upper lamp holder and a lower light diffusion cover, and one end of the connecting rod is detachably connected with the bulb and the lamp holder, and the other end of the connecting rod is detachably connected with the pulley. The adaptive display also comprises a guiderail, wherein the guide rail is arranged on an indoor ceiling and is provided with a guide rail groove; the pulley is arranged in the guide rail groove; the lamp holder is also provided with a powersupply control module; and the power supply control module is connected with the lamp holder. The movable ceiling lamp exhibits good mobility through the guide rail arranged on the ceiling, in addition, the ceiling can follow the movement path of a user at a certain speed, and therefore, the user can enjoy good illumination environment at any time. In addition, the movable ceiling lamp can automatically start or close illumination according to a practical situation, and energy is saved.

Owner:北海市天硌打印耗材有限公司

Raymond mill crashing auto control method and equipment thereof

InactiveCN101229525BRealize automatic adjustmentGuaranteed feeding speedGrain treatmentsTotal factory controlAuto regulationAutomatic control

The invention discloses an automatic control method of Raymond mill grinding. Equipment can be automatically adjusted so as to ensure that the Raymond mill runs at an optimum load condition. The invention also discloses an automatic control method and an automatic control device for implementing the Raymond mill grinding. The device not only can real-time monitor the operation condition of feeding, grinding, airflow rough separation in a Raymond mill workshop, but also can automatically adjust feeding and grinding according to the main engine load. Furthermore, the invention also can automatically adjust a blower on the basis of technical requirements, which realizes the automation of the airflow rough separation and overcomes the shortcomings of manual operation operated by workers. Theinvention adopts a self-adaptive control method to adjust and control and employ a programmable logic controller as a control core. No manual operation is needed in the whole production process, thusrealizing the fully automatic adjustment of feeding, grinding and airflow rough separation, saving energy, greatly reducing equipment failure rate and increasing productive efficiency; through using asupervisory control computer witch can carry out a real-time monitor, the working parameter and index parameter of the PLC can be modified at any time so as to improve production efficiency.

Owner:SOUTHEAST UNIV

A fully automatic puncture needle positioning device

ActiveCN107041777BDepth effectSo as not to damageSurgical needlesTrocarComputed tomographyNeedle position

The invention discloses an automatic puncture needle positioner comprising a puncture needle locating rack and a locating rack adjusting mechanism; the locating rack adjusting mechanism comprises a feeding and discharging mechanism, an angle adjusting mechanism, a radian adjusting mechanism and a horizontal position adjusting mechanism arranged in order on a rotary plate periphery; the rotary plate rotates to enable the feeding and discharging mechanism, the angle adjusting mechanism, the radian adjusting mechanism and the horizontal position adjusting mechanism to finish puncture needle feeding, angle adjusting, radian adjusting and horizontal position adjusting steps in order on the puncture needle locating rack; by using a CT scanned image, the locating rack adjusting mechanism can accurately adjust the puncture needle locating rack, thus allowing the puncture needle to reach the correct position, and simplifying medical personnel work; the automatic puncture needle positioner is higher in accuracy, and the medical personnel can directly puncture according to the puncture needle position.

Owner:THE SECOND HOSPITAL AFFILIATED TO WENZHOU MEDICAL COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com