Patents

Literature

49results about How to "Guaranteed feeding speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

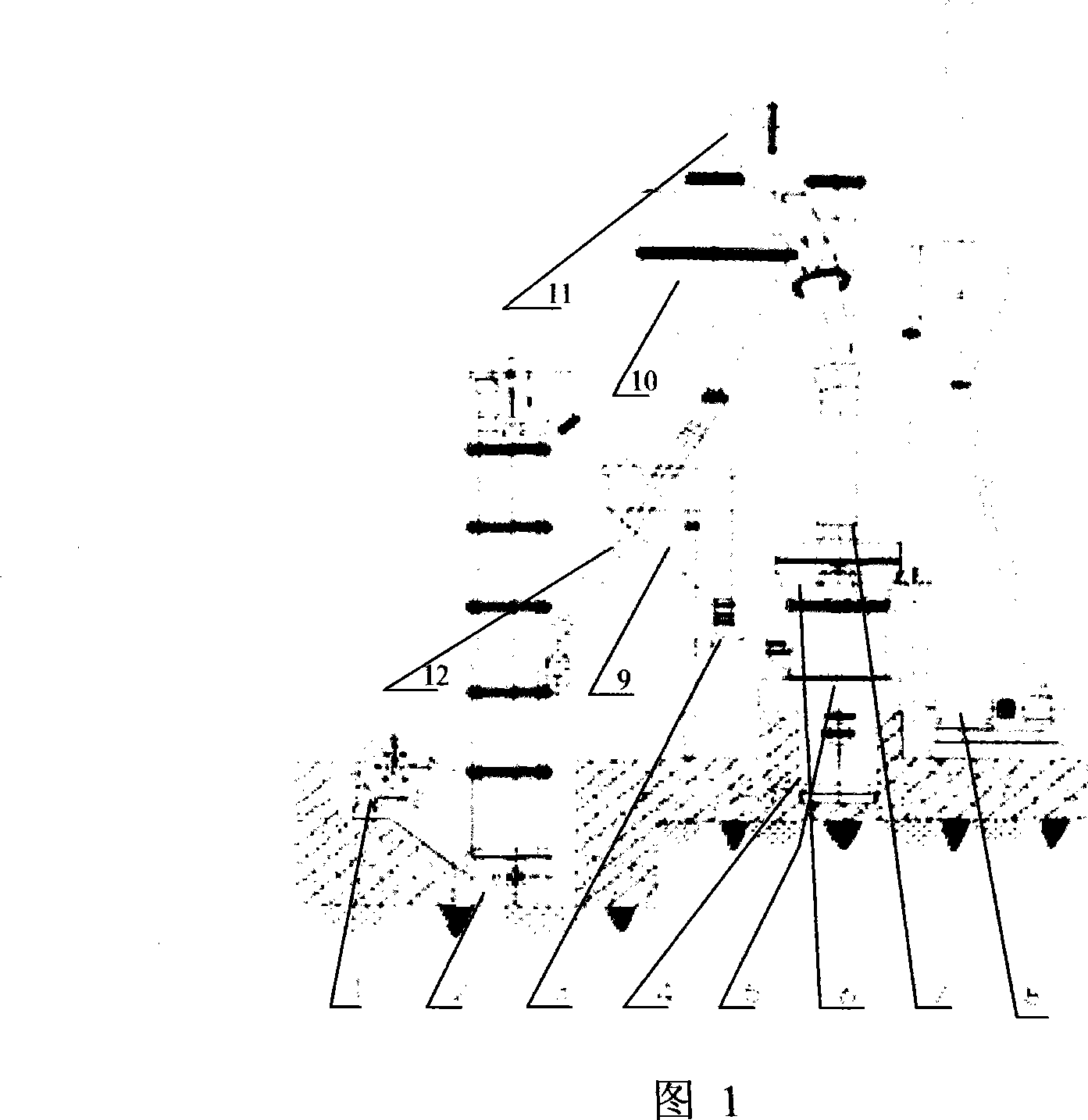

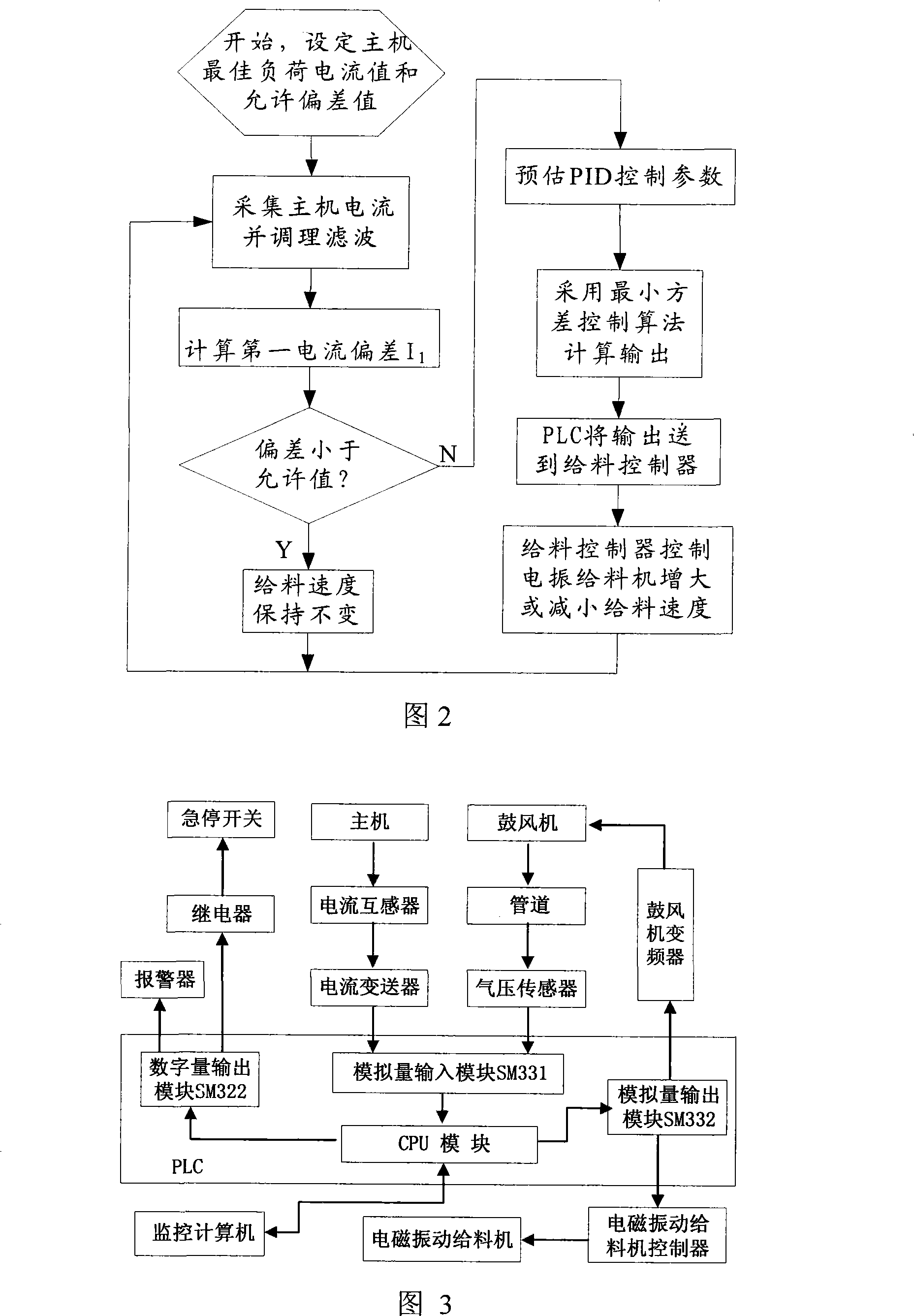

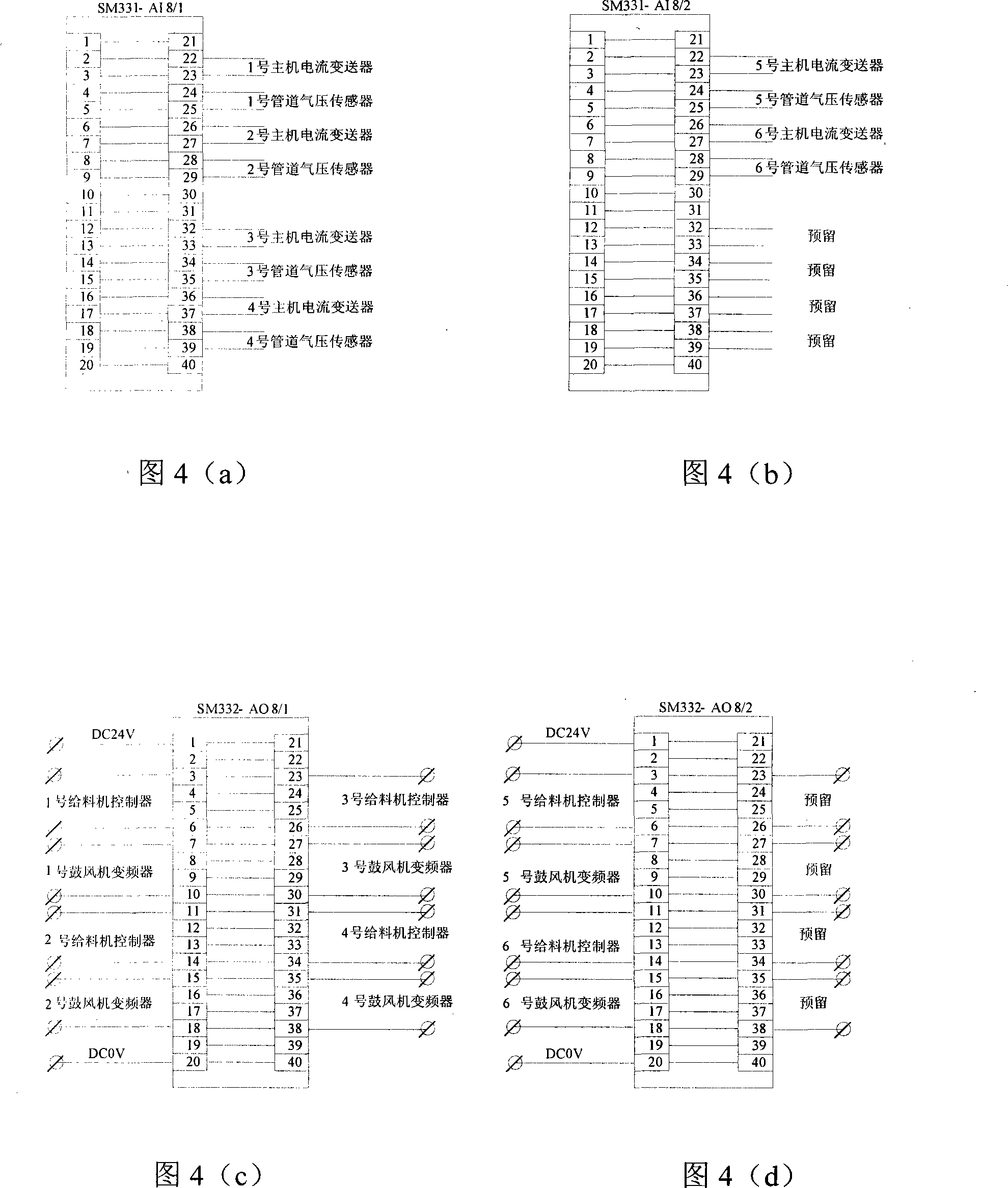

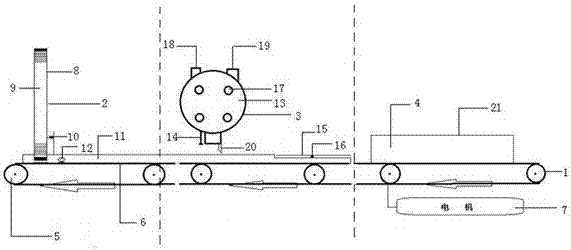

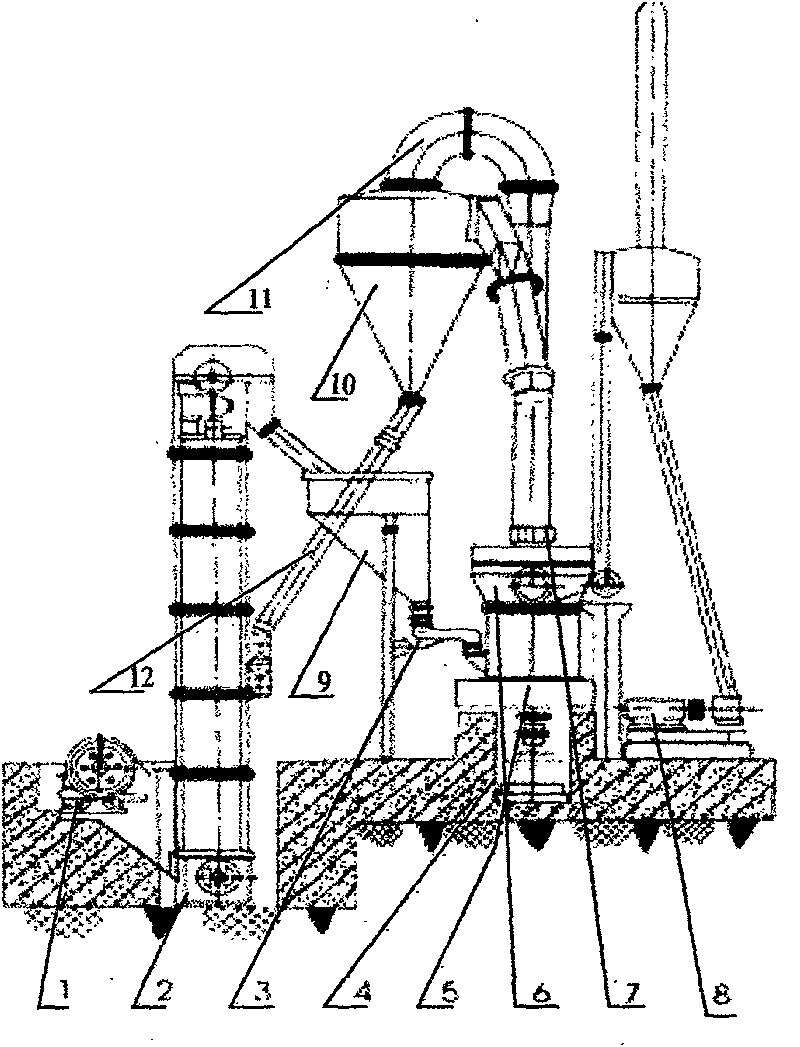

Raymond mill crashing auto control method and equipment thereof

InactiveCN101229525AReduce energy consumptionReduce equipment failure rateGrain treatmentsTotal factory controlAutomatic controlSelf adaptive

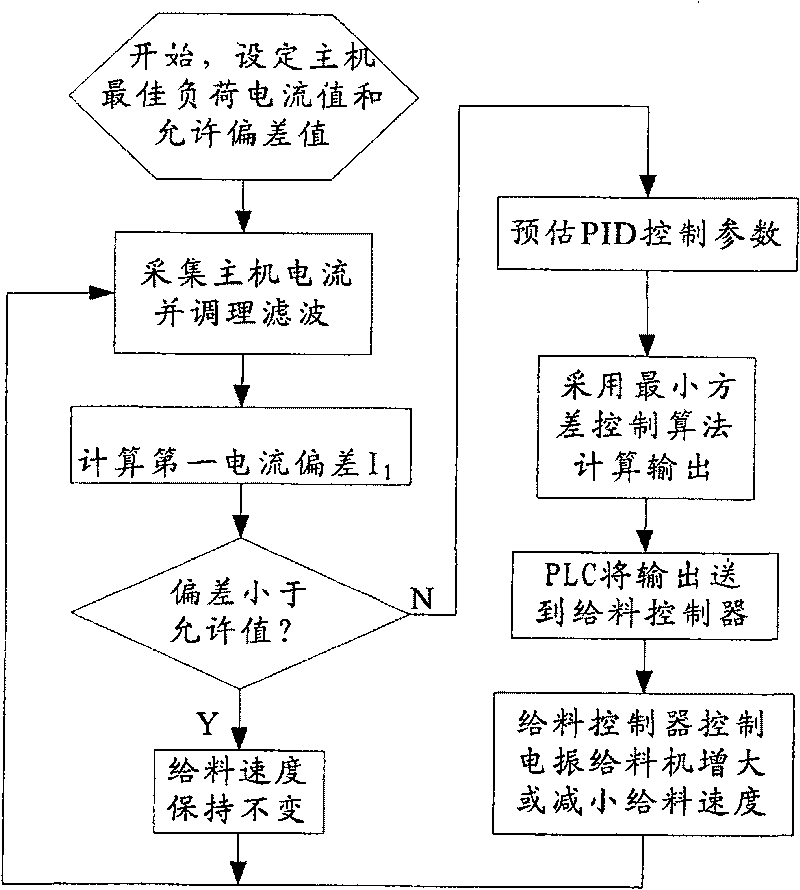

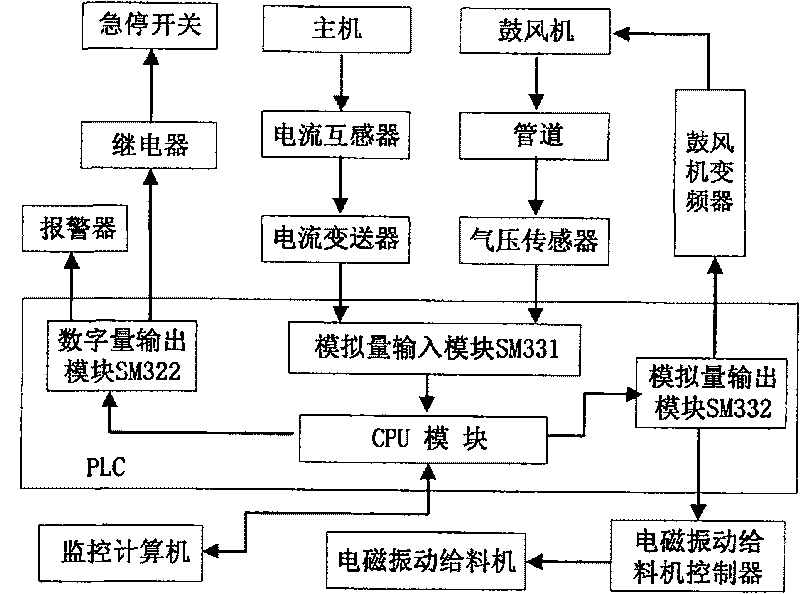

The invention discloses an automatic control method of Raymond mill grinding. Equipment can be automatically adjusted so as to ensure that the Raymond mill runs at an optimum load condition. The invention also discloses an automatic control method and an automatic control device for implementing the Raymond mill grinding. The device not only can real-time monitor the operation condition of feeding, grinding, airflow rough separation in a Raymond mill workshop, but also can automatically adjust feeding and grinding according to the main engine load. Furthermore, the invention also can automatically adjust a blower on the basis of technical requirements, which realizes the automation of the airflow rough separation and overcomes the shortcomings of manual operation operated by workers. The invention adopts a self-adaptive control method to adjust and control and employ a programmable logic controller as a control core. No manual operation is needed in the whole production process, thus realizing the fully automatic adjustment of feeding, grinding and airflow rough separation, saving energy, greatly reducing equipment failure rate and increasing productive efficiency; through using a supervisory control computer witch can carry out a real-time monitor, the working parameter and index parameter of the PLC can be modified at any time so as to improve production efficiency.

Owner:SOUTHEAST UNIV

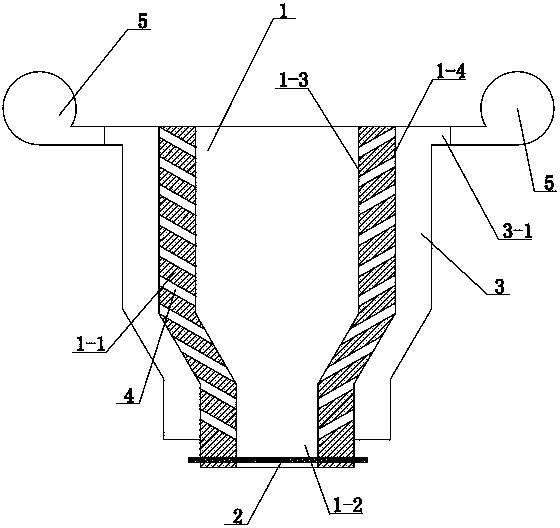

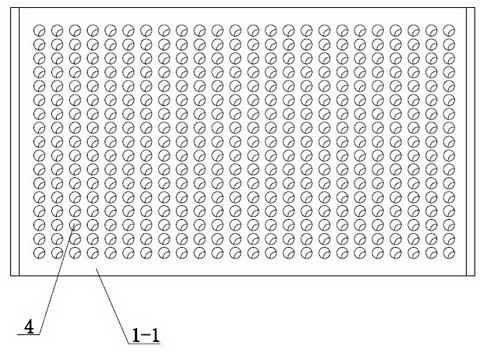

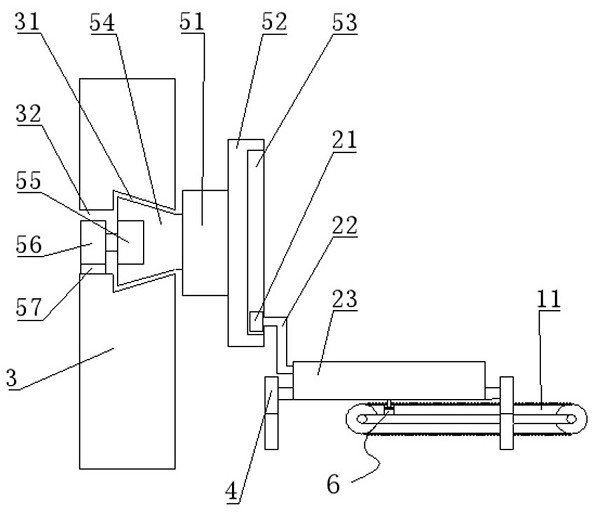

Wood powder conveying hopper and feeding system for wood plastic composite sheet material production

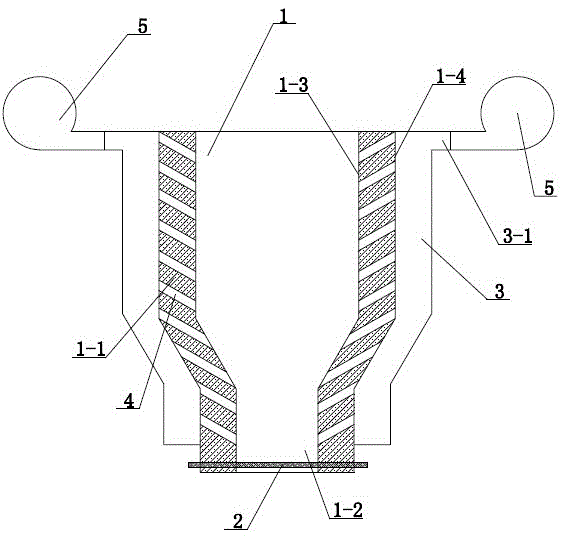

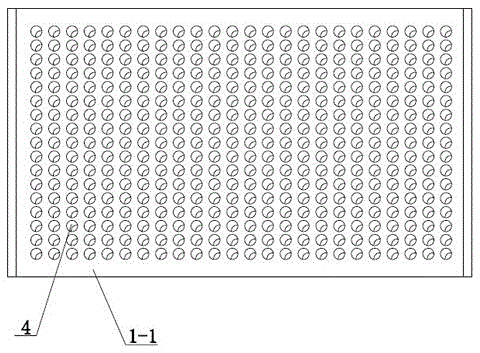

The invention discloses wood plastic composite sheet material production equipment, and especially refers to a wood powder conveying hopper in wood plastic composite sheet material production; the wood powder conveying hopper comprises a hopper body; the bottom of the hopper body is provided with a feed opening having a switch valve; a sealing air path is arranged around a side wall of the hopper body; an air inlet position of the sealing air path is connected with an air source; the side wall of the hopper body is tightly provided with air through holes penetrating an inner surface and an outer surface; the air through holes are arranged facing the feed opening of the bottom of the hopper body in an oblique manner; the hopper of invention solves the plugging technical problem of wood powder conveying hopper in wood plastic composite sheet material production, thereby reducing plugging condition in the usage of the hopper; simultaneously the air generated by the air source uniformly enters the hopper body around the hopper body, thereby effectively ensuring blanking speed of wood powder batch mixture in the hopper.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

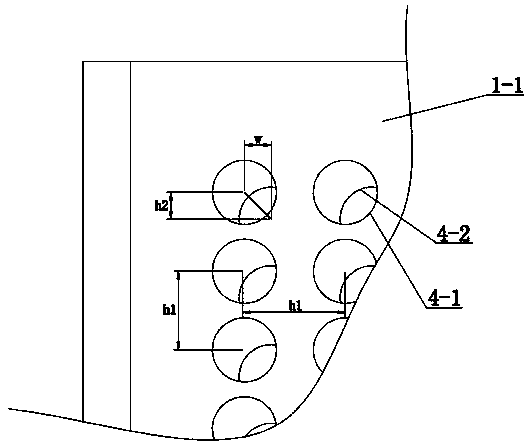

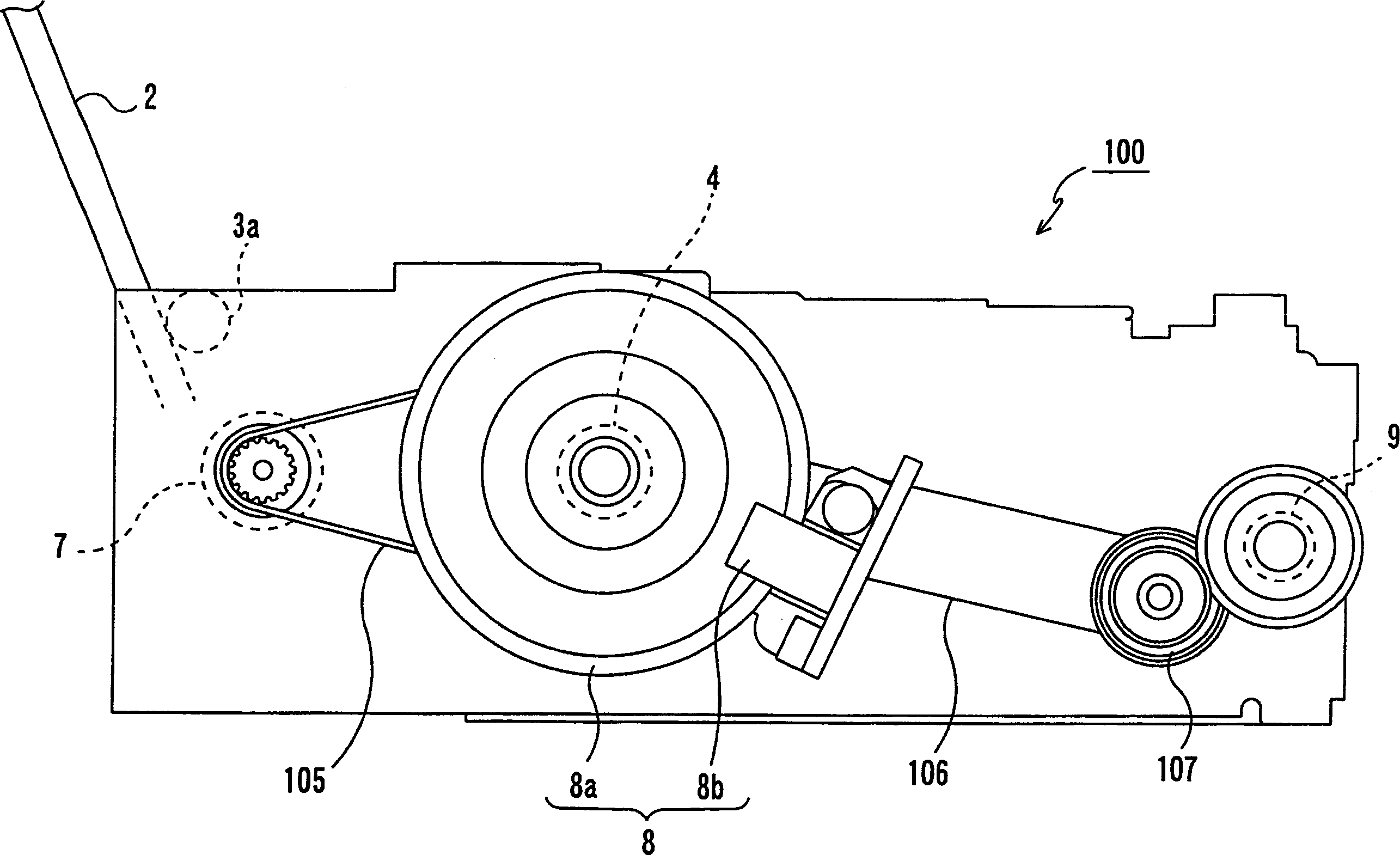

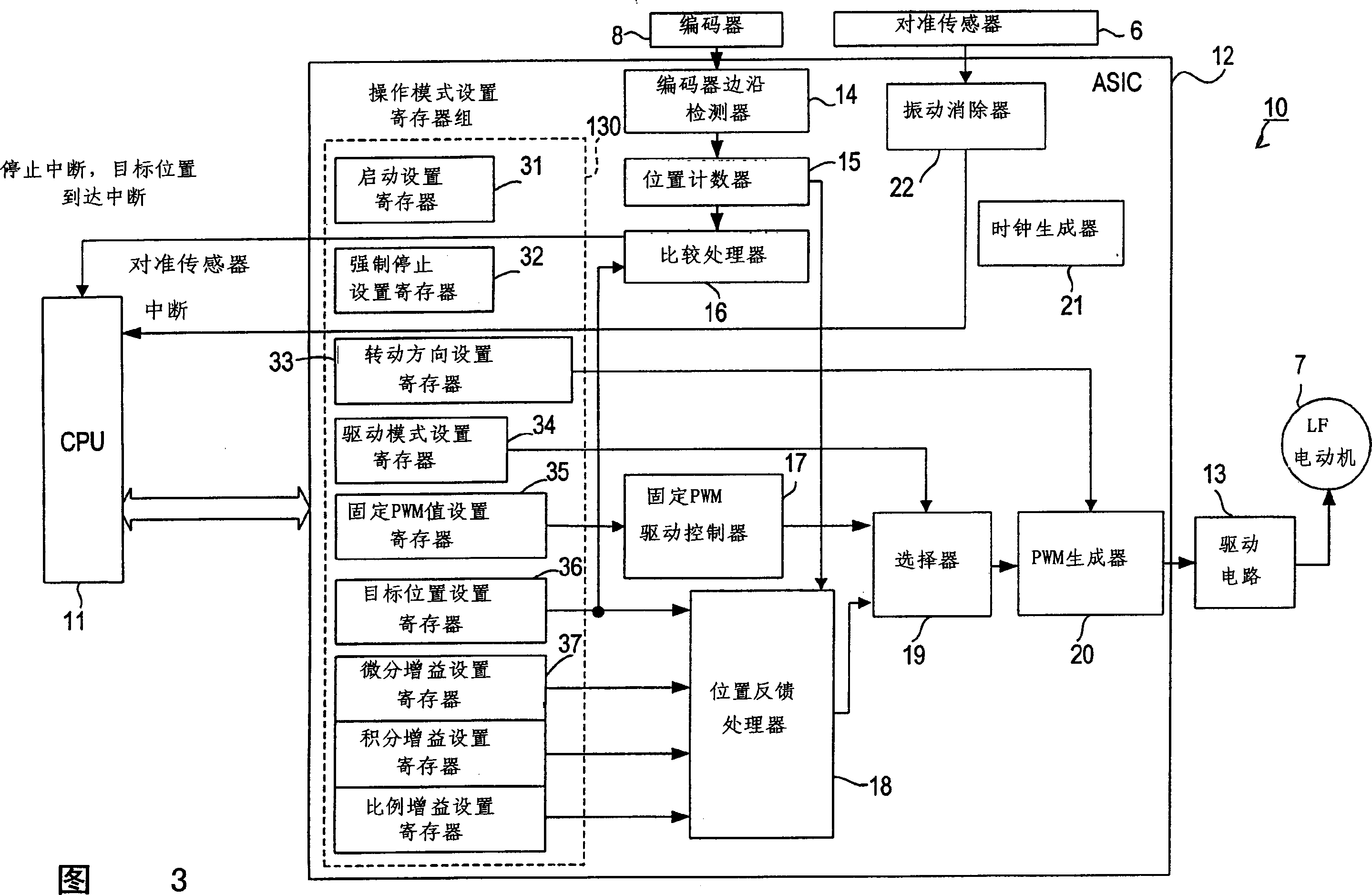

Paper feeding device

InactiveCN1477470AGuaranteed feeding speedDuration of actionFunction indicatorsSpeed/accelaration controlEngineeringNoise reduction

When the sheets are taken out sheet by sheet and started to be fed, in a first predetermined section, a driving mode is set to a fixed PWM driving mode, and a DC motor is driven in response to a PWM signal of a fixed duty to perform the sheet feed operation (S110, S120). When the tip end of the fed sheet is detected by a registration sensor (S140: YES), the sheet feed operation is once stopped (S150), and the driving mode is changed to a position feedback control mode (S170). Thereafter, the sheet is fed to a registration position by a position feedback control, the sheet reaches the registration position, the sheet feed is completed (S200: YES), and the process enters the next transfer operation. The transfer operation is also performed in the position feedback control mode. When a control method is changed before / after the registration sensor in this manner, the speeding-up and noise reduction of the sheet feed operation are realized.

Owner:BROTHER KOGYO KK

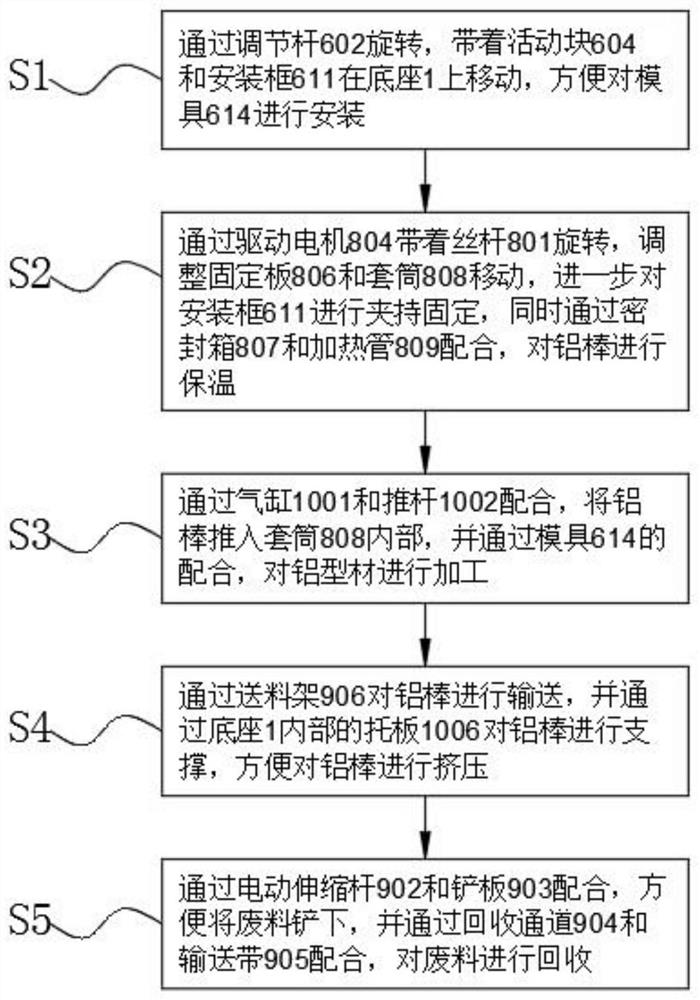

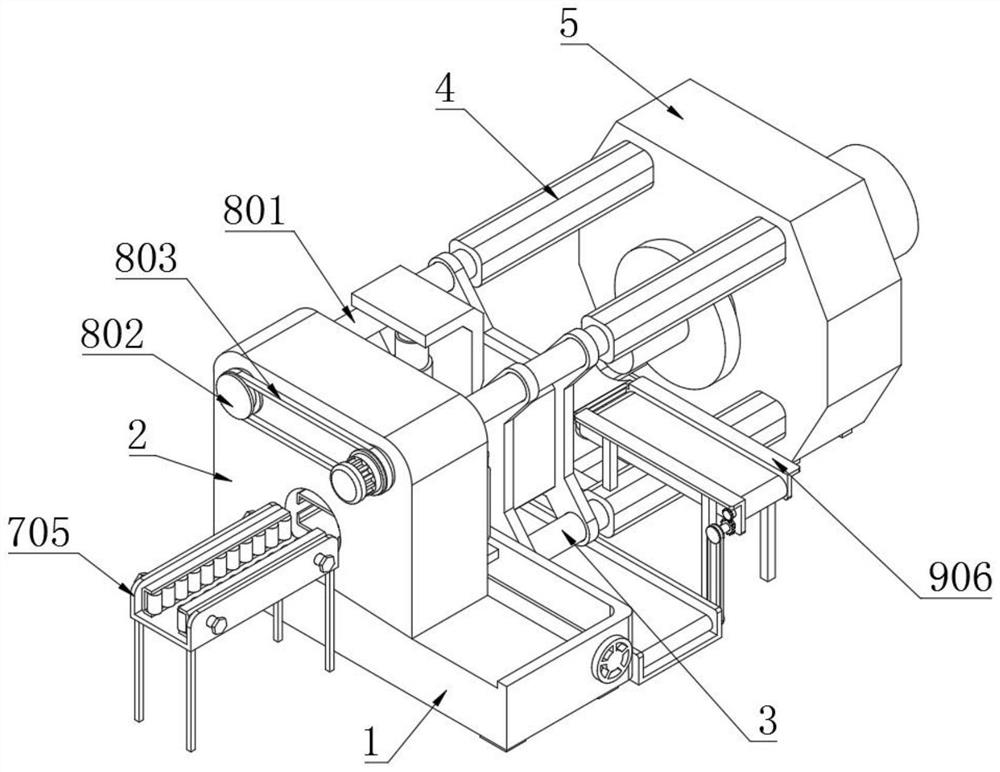

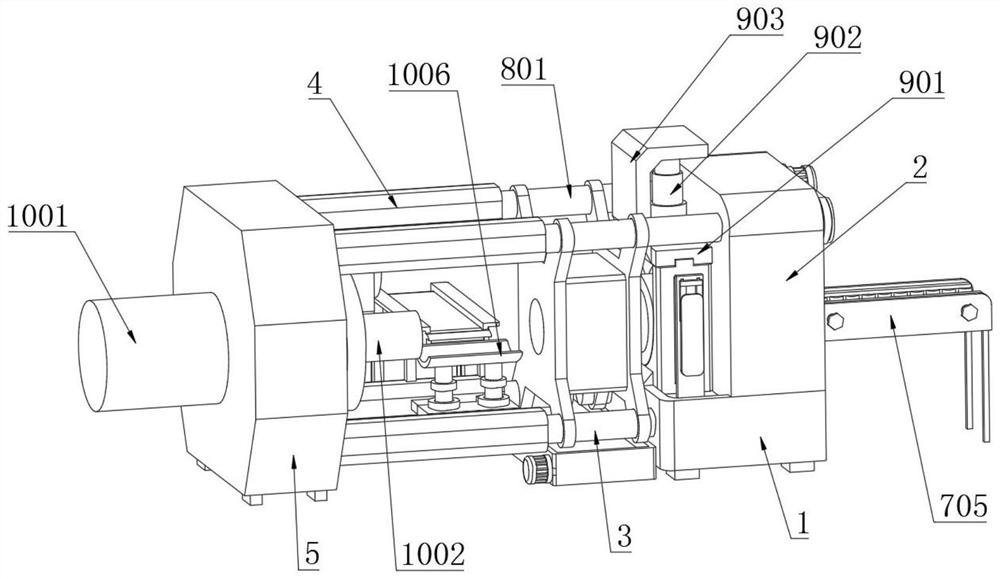

Efficient aluminum profile extrusion method

The invention discloses an efficient aluminum profile extrusion method. The method comprises the following steps that S1, a movable block and an installation frame are driven to move on a base through rotation of an adjusting rod to facilitate installation of a mold; and S2, fixing plates and a sleeve are adjusted to move through rotation of lead screws driven by driving motors to further clamp and fix the installation frame, and meanwhile an aluminum bar is cooled through cooperation of a sealing box and heating pipes. According to the method, the structure is scientific and reasonable, and use is safe and convenient. A mold plate assembly mechanism is arranged, arc-shaped plates are pushed by magnetic plates to clamp and fix the mold in the installation frame, the stability of the mold is guaranteed, the situation that the mold shakes during extrusion is avoided, and the aluminum profile extrusion quality is improved. Sliding rods and limiting plates are driven to move through the stretching and retracting characteristic of tensioning springs, so that the distance between the two limiting plates is reduced, the installation frame can be conveniently fixed to the movable block, and the mold installation speed is increased.

Owner:陕西良鼎瑞金属新材料有限公司

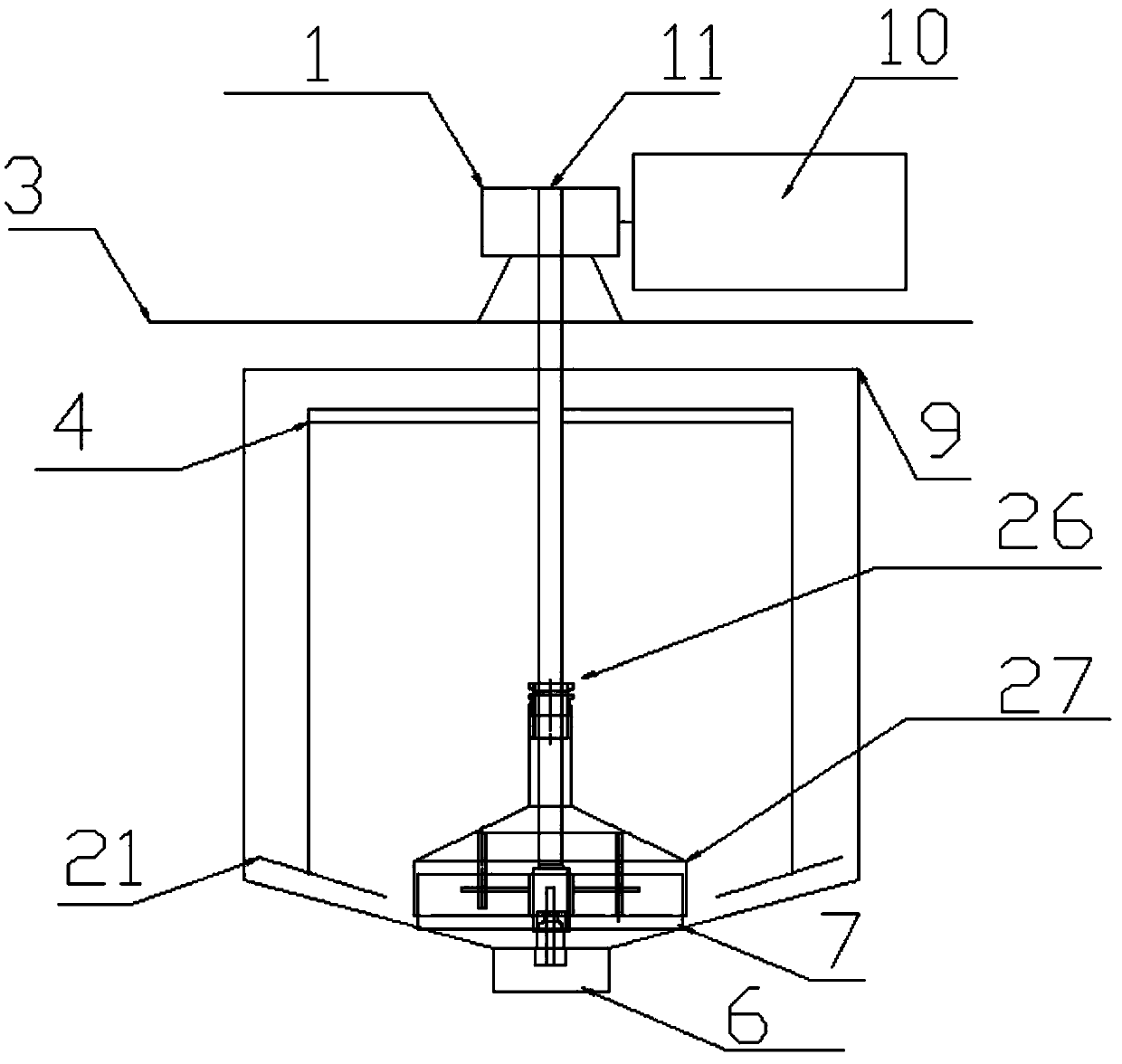

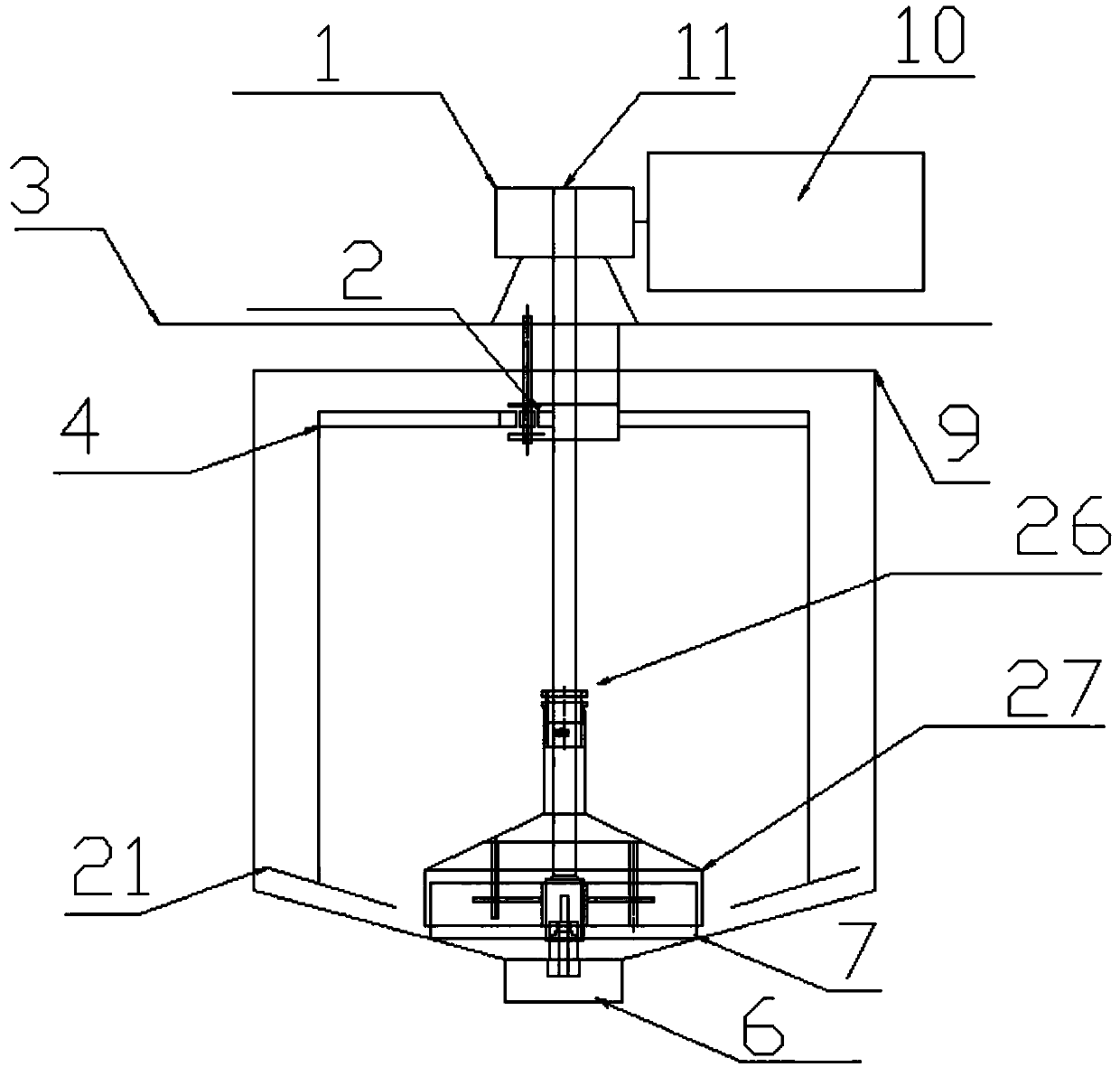

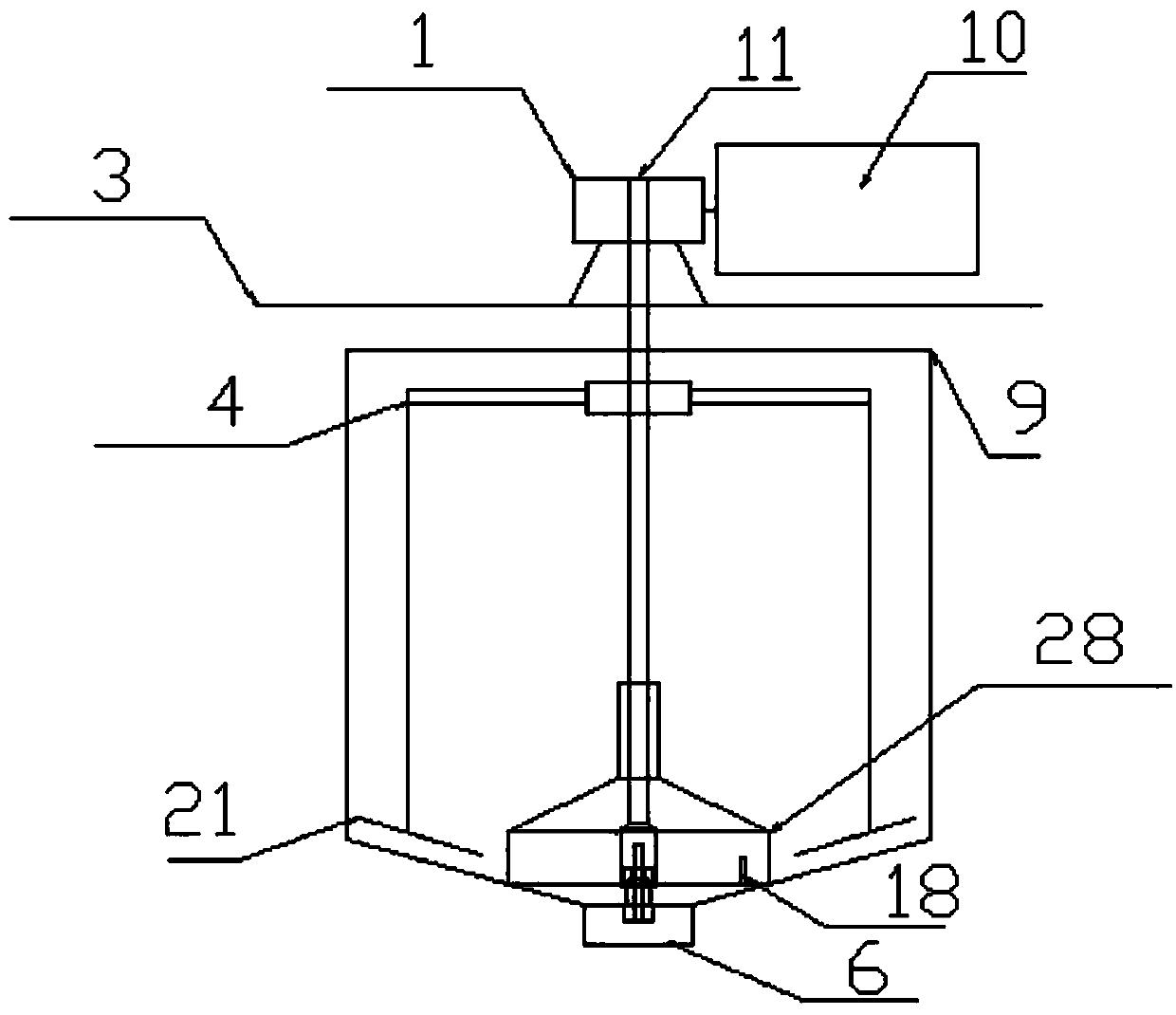

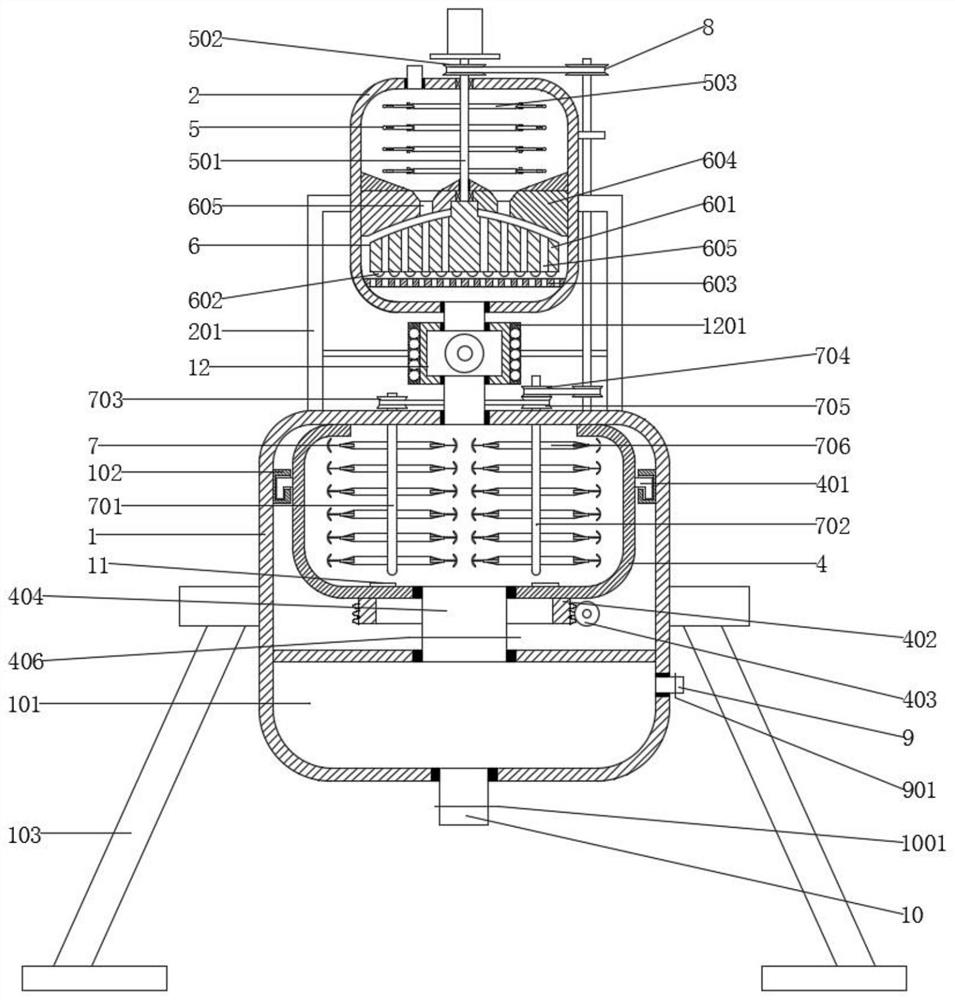

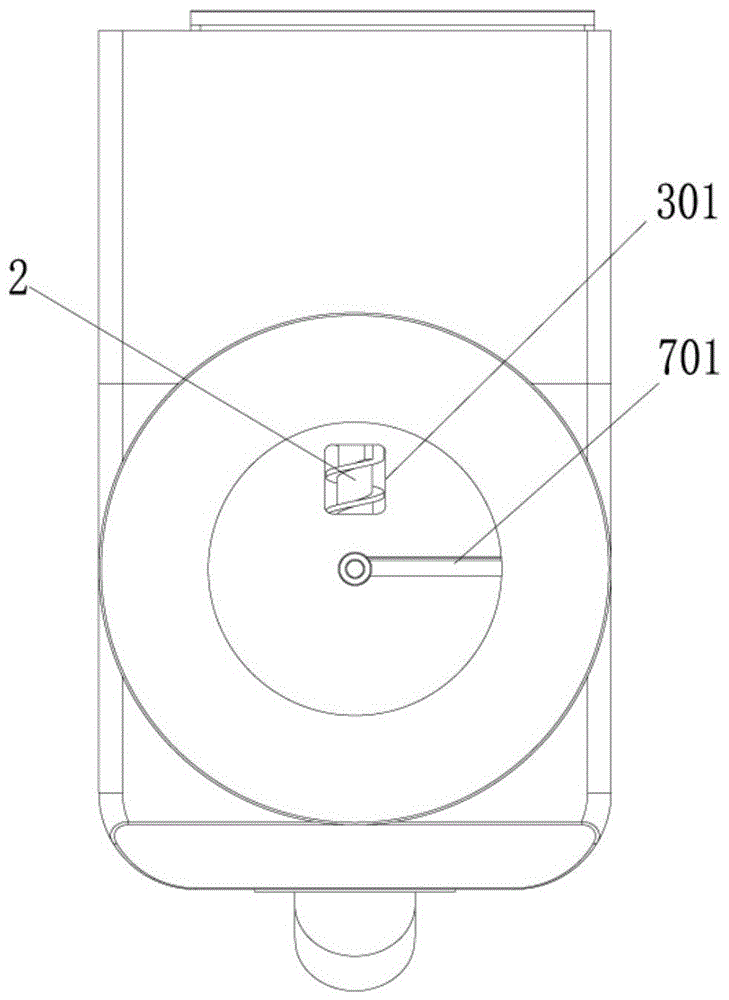

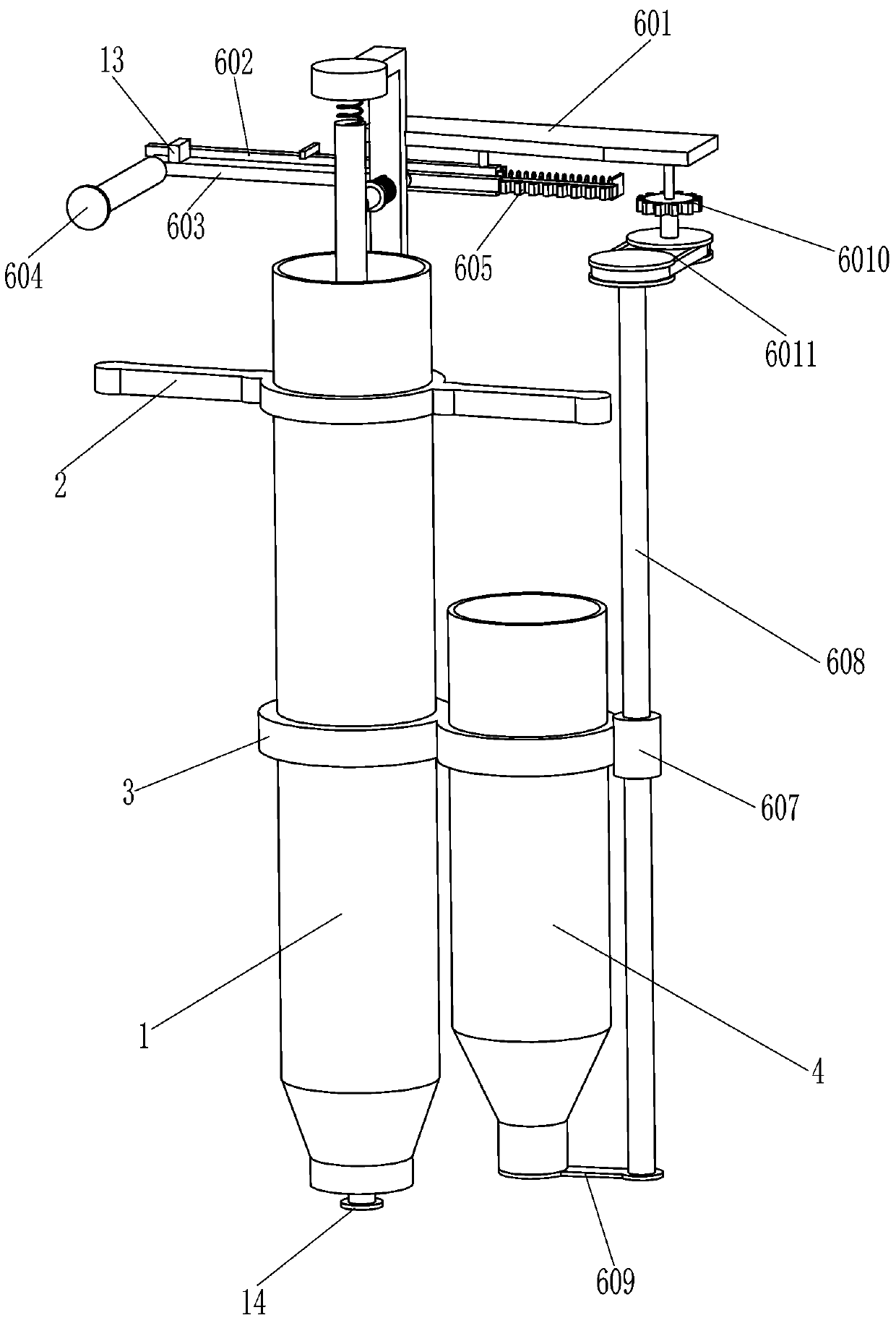

Uniform powdery material feeding device

InactiveCN104210856AIncrease starting torqueNot easy to stallLarge containersLoading/unloadingPowderControl engineering

The invention relates to a uniform powdery material feeding device which comprises a tank body, wherein the top of the tank body is provided with a stepping motor and a speed reducer, wherein the stepping motor is connected with the speed reducer; the speed reducer is used for transferring power to a transmission shaft; the middle upper part of the transmission shaft positioned in the tank body is connected with a material overturning tool fixing rack which is connected with a material overturning tool used for overturning materials in the tank body; the lower end of the transmission shaft is connected with a uniform feeding control component. According to the scheme, the powder material feeding precision can be precisely controlled, and the uniform powdery material feeding device is high in popularization value.

Owner:张永利

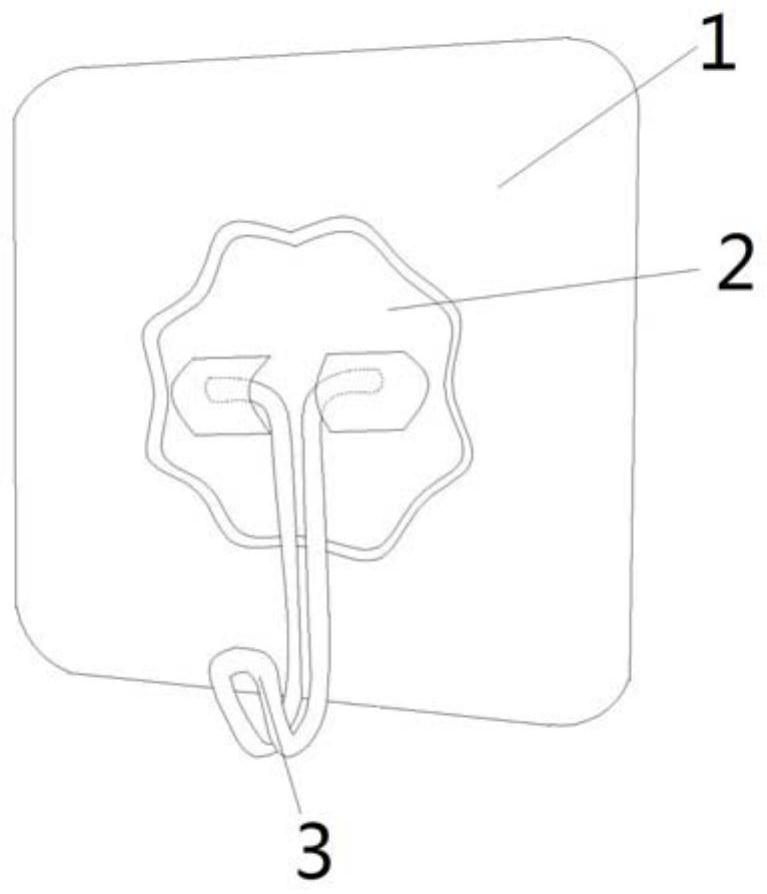

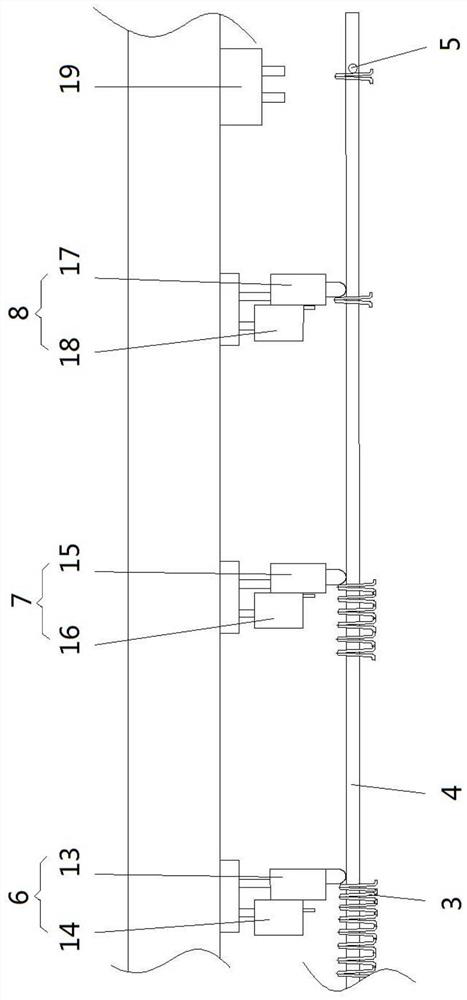

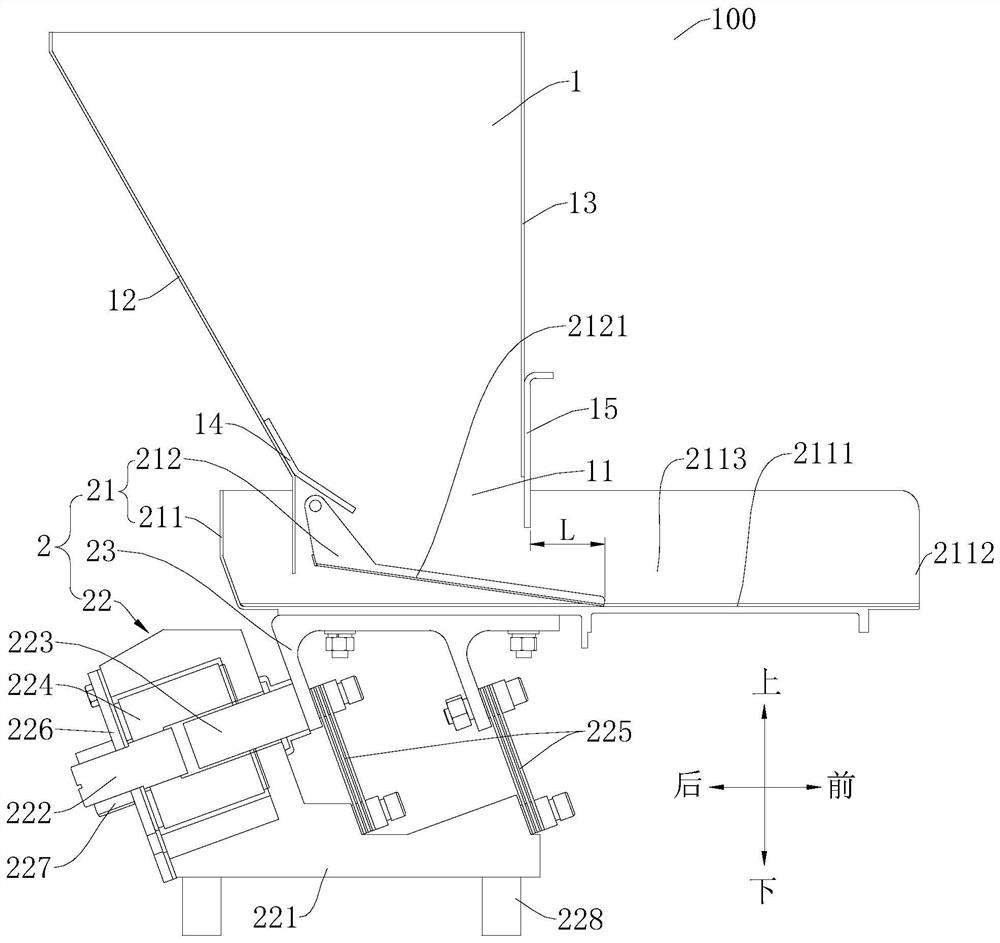

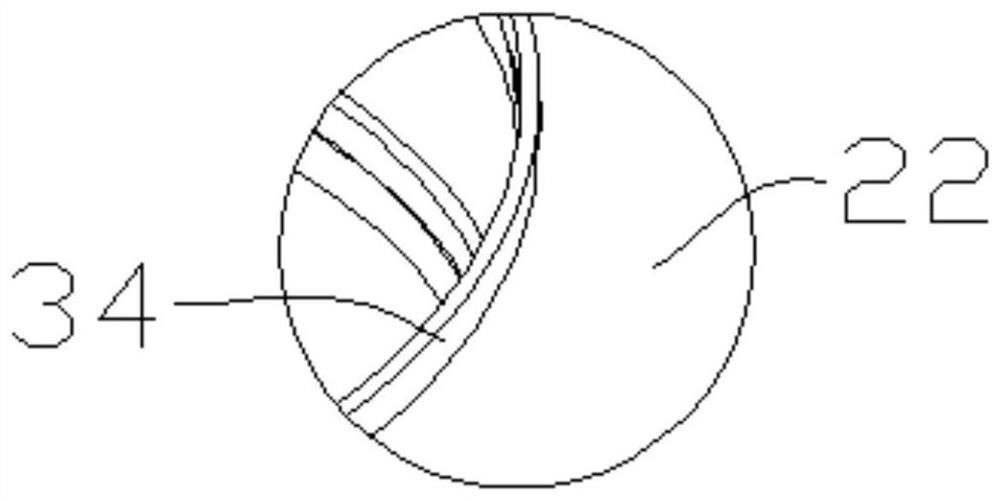

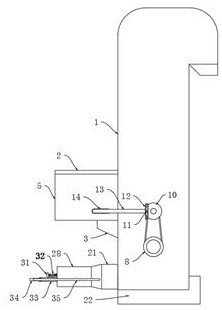

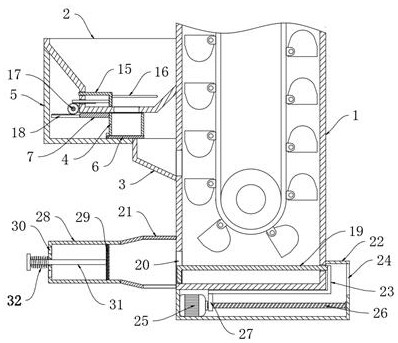

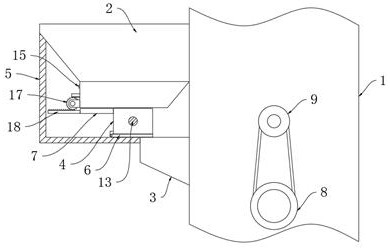

One-by-one feeding device and feeding method for hooks

ActiveCN111634654AGuaranteed feeding speedIncrease the feeding speedControl devices for conveyorsJigging conveyorsControl engineeringMachine

The invention discloses a one-by-one feeding device and feeding method for hooks. The one-by-one feeding device comprises multiple stages of blocking mechanisms which are arranged corresponding to a hook conveying track and used for blocking the hooks on the track to achieve stage-by-stage feeding, wherein the blocking mechanisms are sequentially arranged at intervals from front to back in the hook conveying direction; detection heads used for detecting the in-place condition of the hooks are arranged corresponding to the blocking mechanisms correspondingly; and starting of the previous stageof blocking mechanism is controlled by detection signal feedback of the detection head corresponding to the adjacent next stage of blocking mechanism. By means of the device, the three stages of blocking mechanisms and the four stages of detection heads are matched, a controller is assisted in controlling actions of all the devices, the problem that machine feeding is not stable is solved, the irregular hooks are sequentially cached and distributed on the conveying track in a graded manner, the feeding process is stable and continuous and free of the chain breaking phenomenon, the hook feedingspeed is within one second of single-hook feeding, the feeding speed is increased, the probability of machine jamming is reduced, and the production efficiency is improved.

Owner:LINYI YANUO DAILY NECESSITIES CO LTD

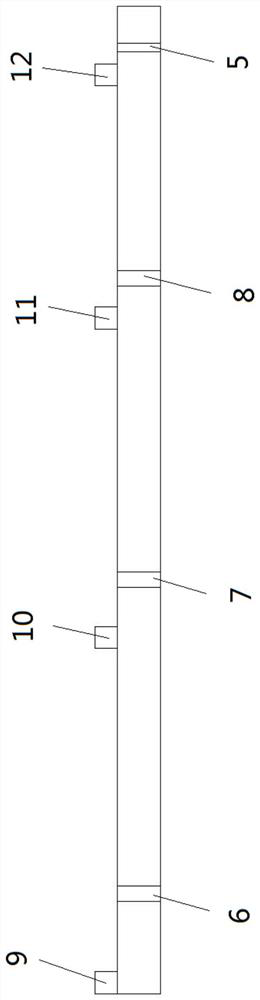

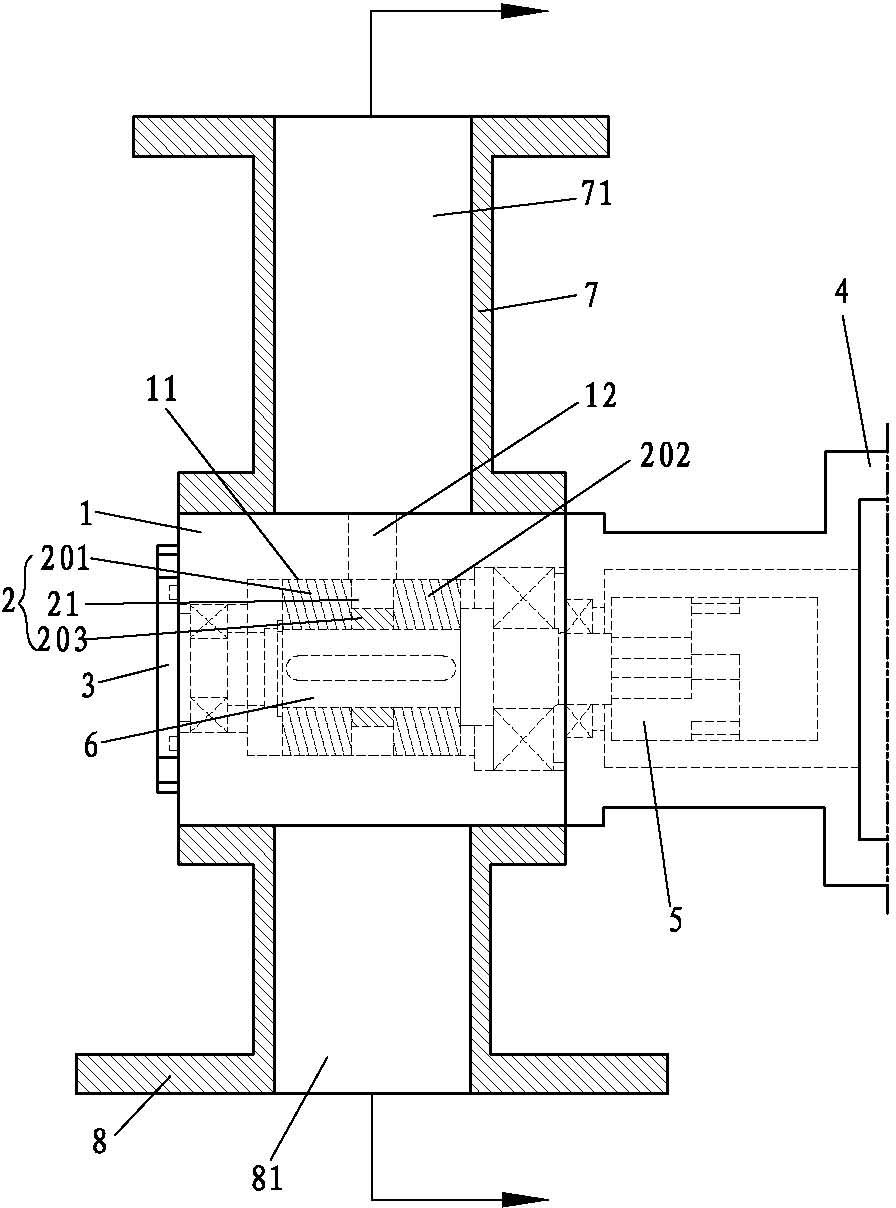

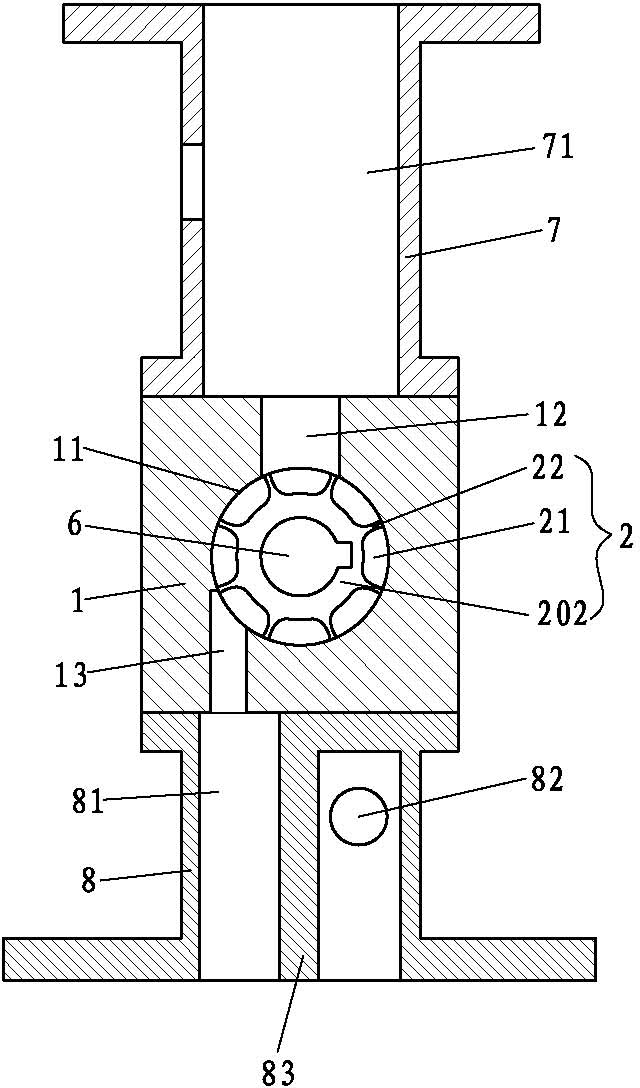

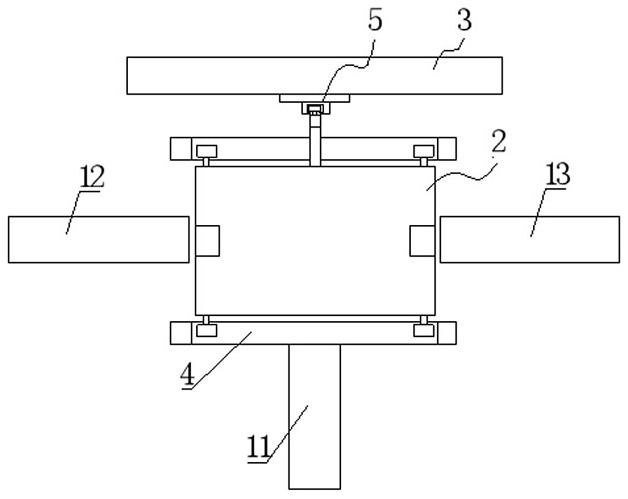

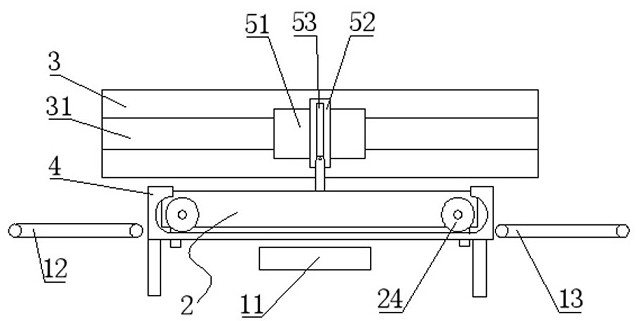

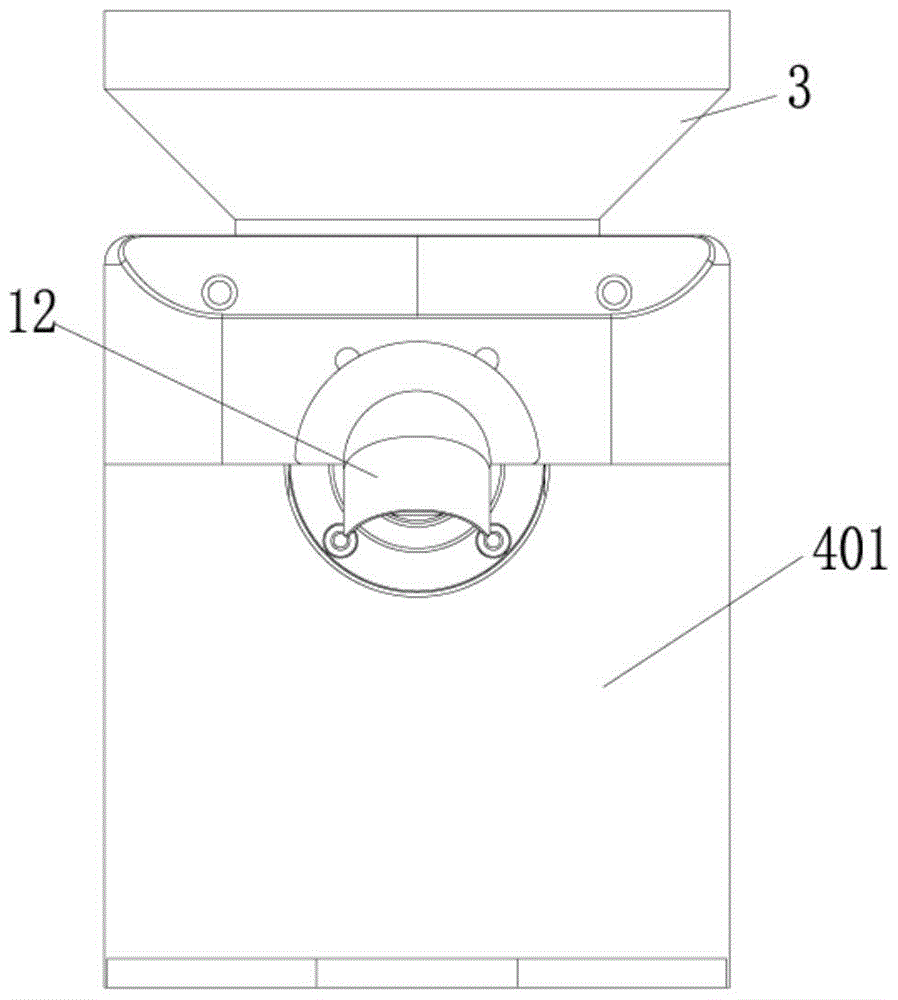

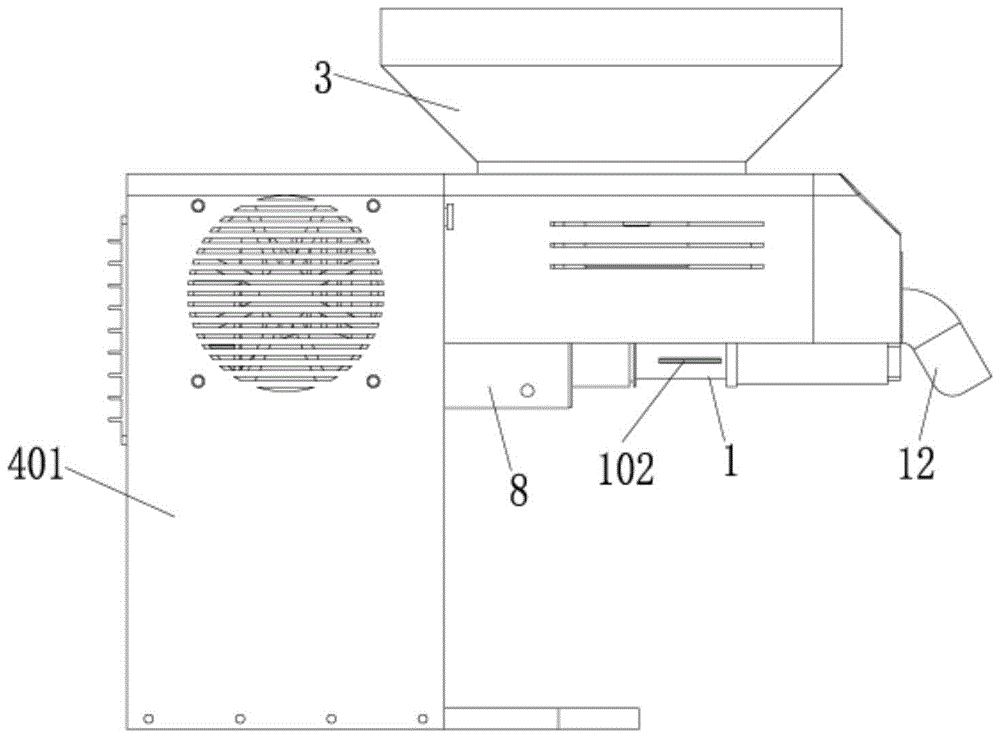

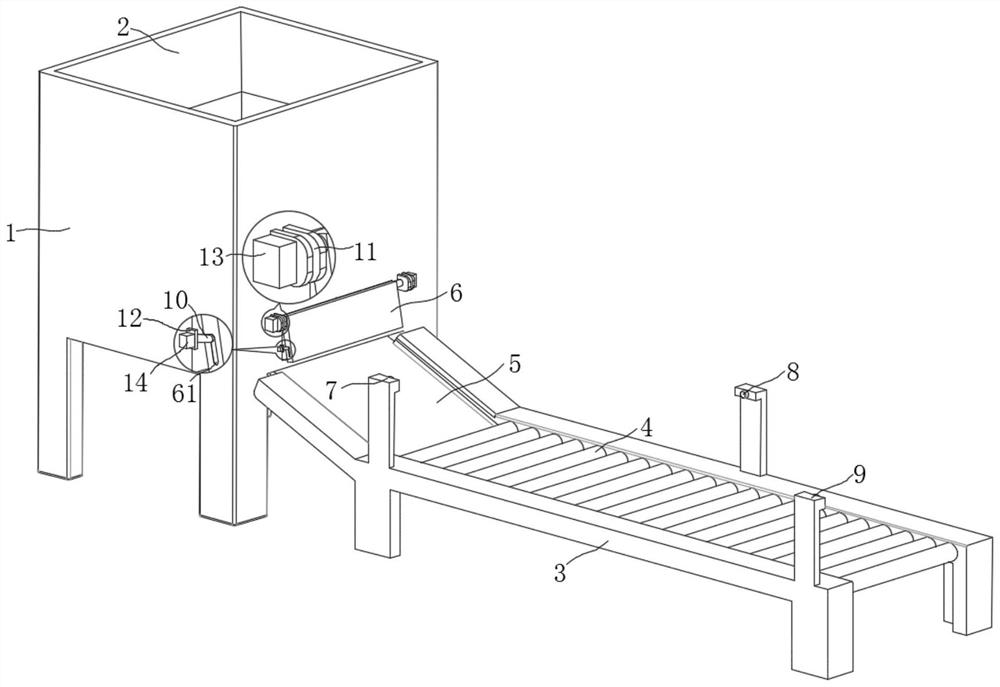

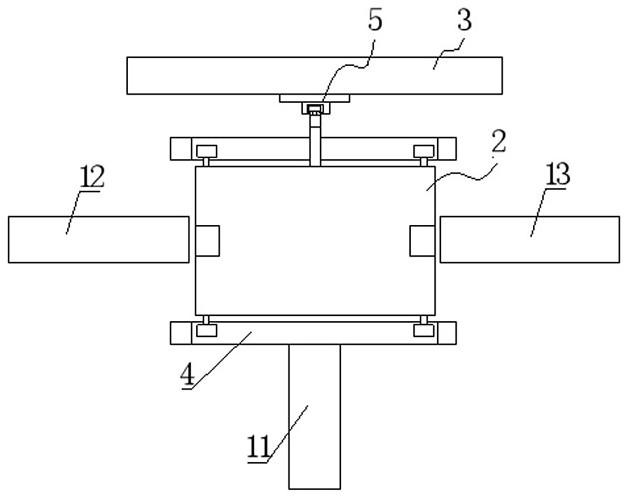

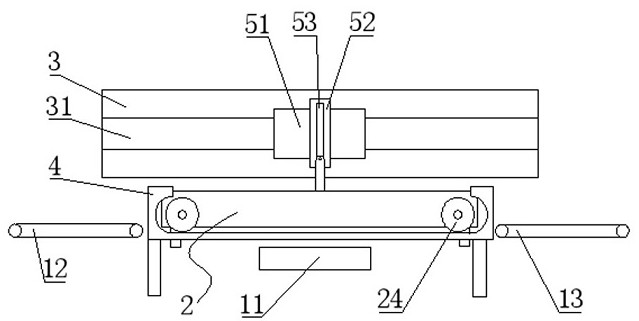

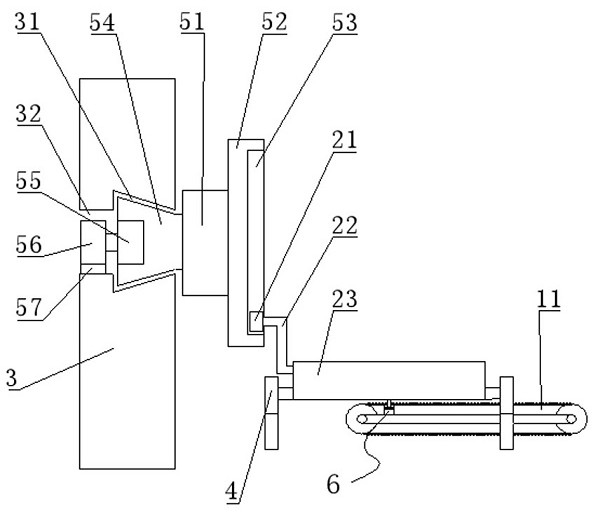

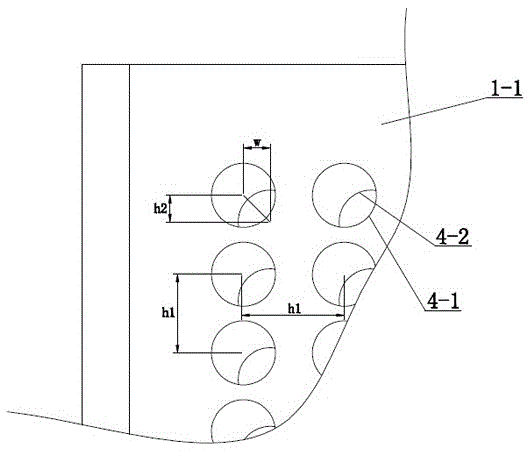

Automatic metering structure and automatic feeding device

ActiveCN102602671AGuaranteed feeding speedGuaranteed measurement accuracyRotary conveyorsMechanical engineeringControl engineering

The invention discloses an automatic metering structure comprising a shell and a rotor; a rotor drum, and a feed opening and a discharge opening communicated with the rotor drum are formed on the shell; the rotor is inserted in the rotor drum, the rotor and the rotor drum are in sealed fit, a metering groove corresponding to the feed opening and the discharge opening is formed on the outer wall of the rotor, and the rotor is connected with a motor and is driven by the motor to rotate in the rotor drum to realize automatic and precise metering. The invention further discloses an automatic feeding device comprising an upper connecting seat, a lower connecting seat and the automatic metering structure; the upper connecting seat is installed above the shell, and a feed opening formed on the upper connecting seat is communicated with the feed opening of the shell; the lower connecting seat is installed between the lower side of the shell and a cabinet, a blanking opening formed on the lower connecting seat is communicated with the discharge opening of the shell and the cabinet, an extract opening further formed on the lower connecting seat is communicated with the cabinet, and a baffle is arranged between the blanking opening and the extract opening to realize automatic feeding, guarantee the blanking speed and improve the quality and the yield of the product.

Owner:XIAMEN BANGZHONG TECH

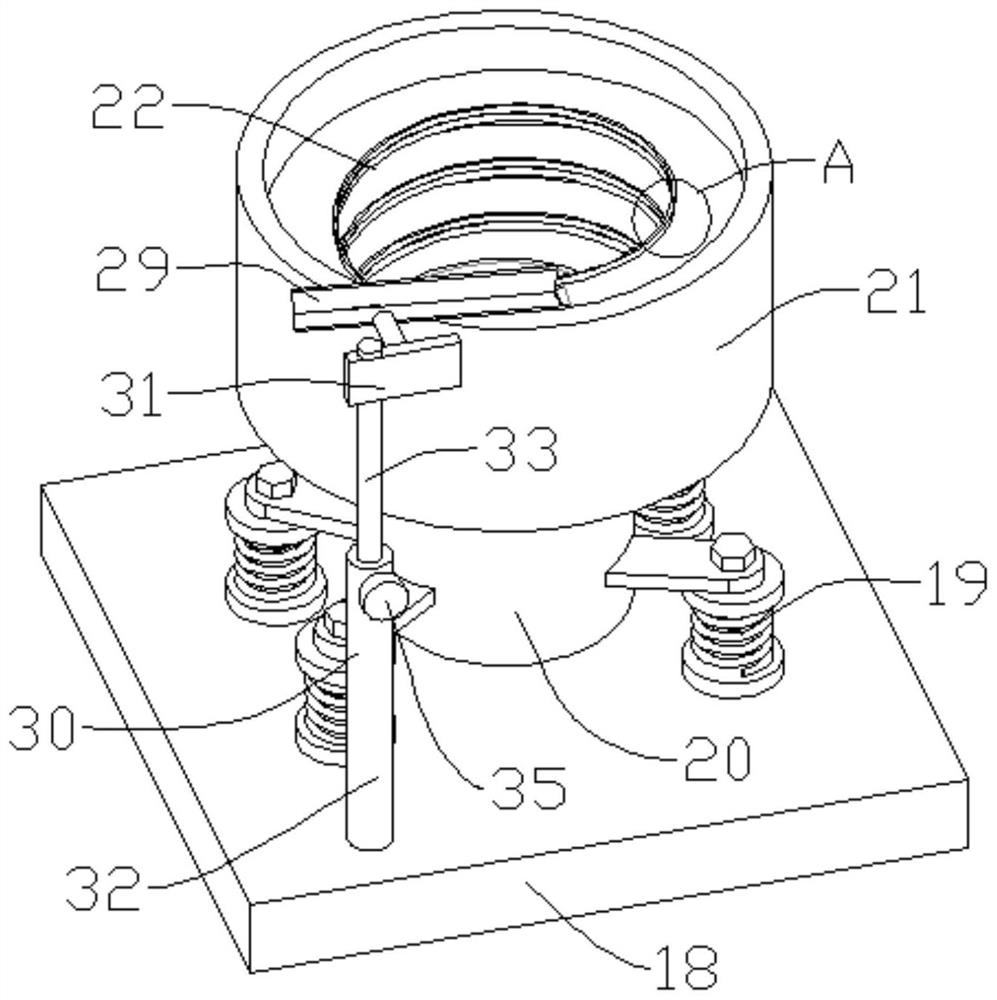

Mortar processing device with environment-friendly dust-proof collectable blanking feeding barrel

ActiveCN111745825AAvoid pollutionImprove processing efficiencyMixing operation control apparatusPretreatment controlStructural engineeringPolluted environment

The invention discloses the technical field of mortar production, and discloses a mortar processing device with environment-friendly dust-proof collectable blanking feeding barrel. The mortar processing device comprises a rack, the top of the rack is provided with a stirring barrel, the bottom of the stirring barrel is provided with a discharge port, the right side of the top of the stirring barrel is provided with a cement feeding port, the top of the cement feeding port communicates with a dustproof barrel, and a sand feeding port is formed in the left side of the top of the stirring barrel.Through the arrangement of the dustproof barrel, a cement bag does not need to be opened manually, dust generated when cement enters the cement feeding port cannot leak out, environment pollution isavoided, and meanwhile, through a vibration assembly in the dustproof barrel, cement can be accelerated to enter the cement feeding port, fan blades can be driven to rotate, the broken cement bag canbe blown into a door body, constructors can conveniently take out the broken cement bag, and the mortar processing and manufacturing efficiency is improved.

Owner:天门市天西天安干混砂浆有限公司

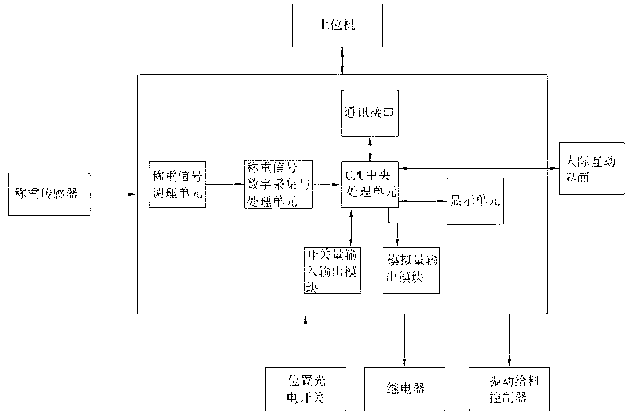

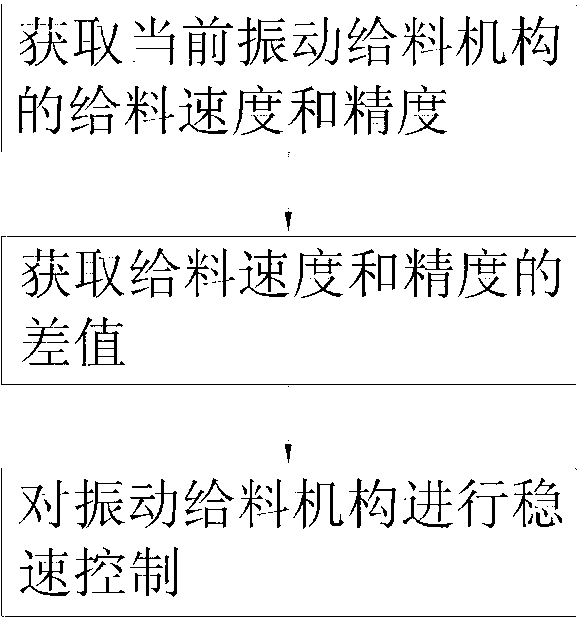

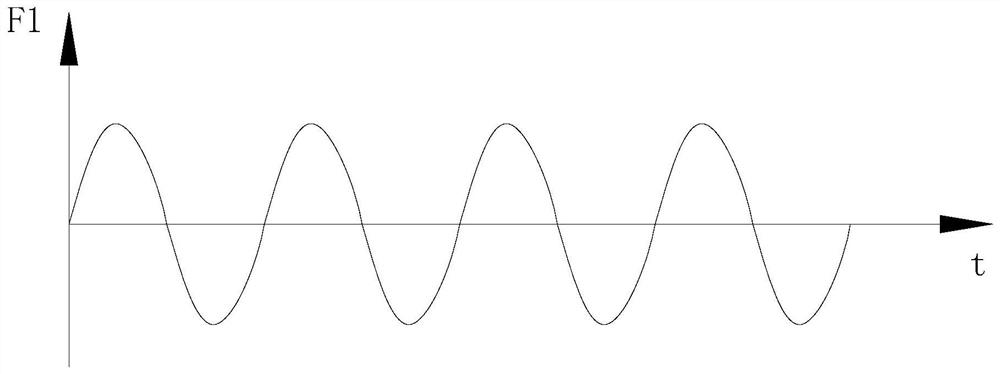

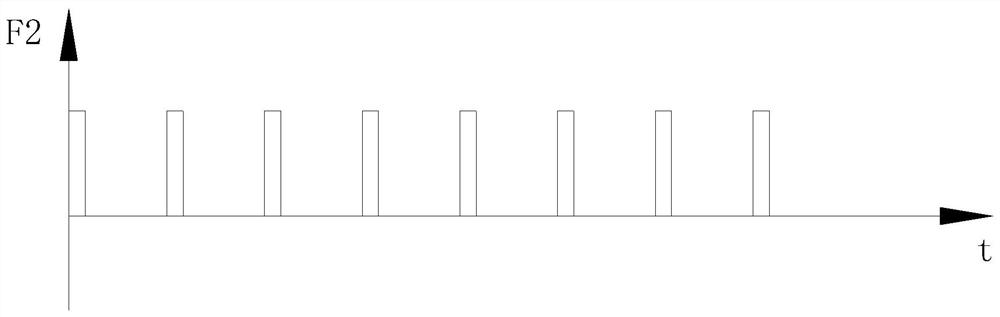

System and method for controlling vibration feeding in speed stabilizing mode

ActiveCN103253405ASmooth vibrationReduce labor intensityPackaging automatic controlSolid materialCommunication interfaceSignal conditioning

The invention discloses a system for controlling vibration feeding in a speed stabilizing mode and a control method of the system, wherein the control system and the control method have stable feeding speed and stable feeding precision, the automation degree of the control system and the control method can be greatly improved, labor intensity of workers is reduced, and cost is relatively reduced. The system for controlling the vibration feeding in the speed stabilizing mode comprises a vibration feeding mechanism and a weighing mechanism, and further comprises a weighing sensor, a weighing signal conditioning unit, a weighing signal digital acquisition and processing unit, a CPU, an on-off input and output module, a communication interface, a displaying unit and an analog quantity output module. The control method of the control system comprises the controlling steps of obtaining feeding speed and feeding precision of the vibration feeding mechanism at present, obtaining a difference value between the feeding speed and the feeding precision, and controlling the stable speed of the vibration feeding mechanism. The system for controlling the vibration feeding in the speed stabilizing mode can be applied to the field of feeding control.

Owner:合肥长陆工业科技有限公司

Overturning, distributing and conveying device

ActiveCN113460638ARealize interval deliveryRoll over stabilityConveyor partsEngineeringTransfer line

The invention is applicable to the technical field of square workpiece conveying, and provides an overturning, distributing and conveying device. The overturning, distributing and conveying device comprises a supporting seat arranged on the upper portion of the tail end of a first conveying assembly, wherein a distributing and conveying assembly is arranged on the supporting seat; a second conveying assembly is arranged on the left side of the distributing and conveying assembly; a third conveying assembly is arranged on the right side of the distributing and conveying assembly; the side, opposite to the first conveying assembly, of the distributing and conveying assembly is fixedly connected with an overturning driving assembly; and the overturning driving assembly is movably connected to a supporting plate. Therefore, the overturning, distributing and conveying device is simple in structure and low in cost, stable overturning of square workpieces can be achieved, the square workpieces on the same conveying line can be divided into two conveying lines, the conveying direction of the square workpieces can be changed, and interval conveying of the square workpieces can be achieved.

Owner:SHANDONG VOCATIONAL COLLEGE OF SCI & TECH

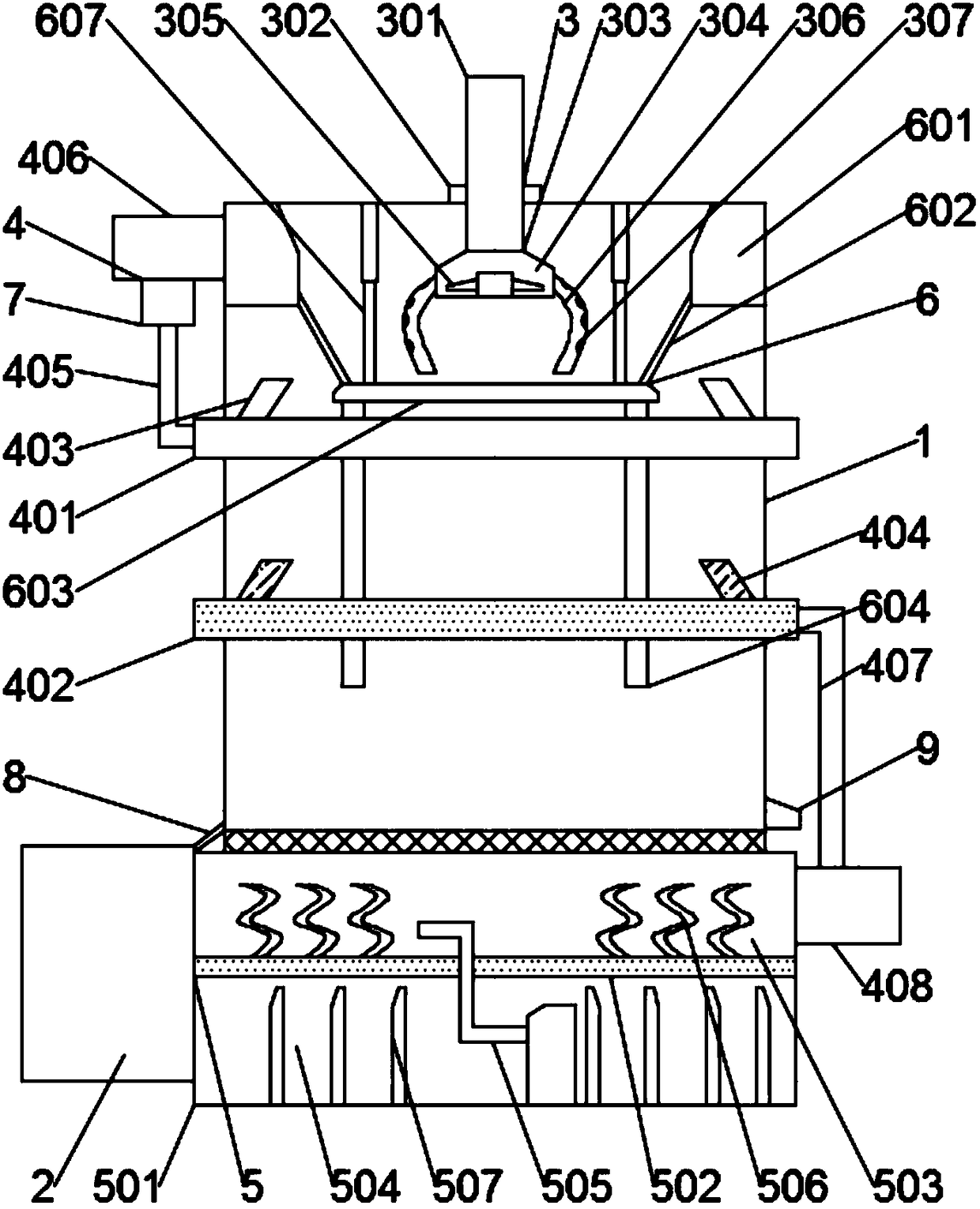

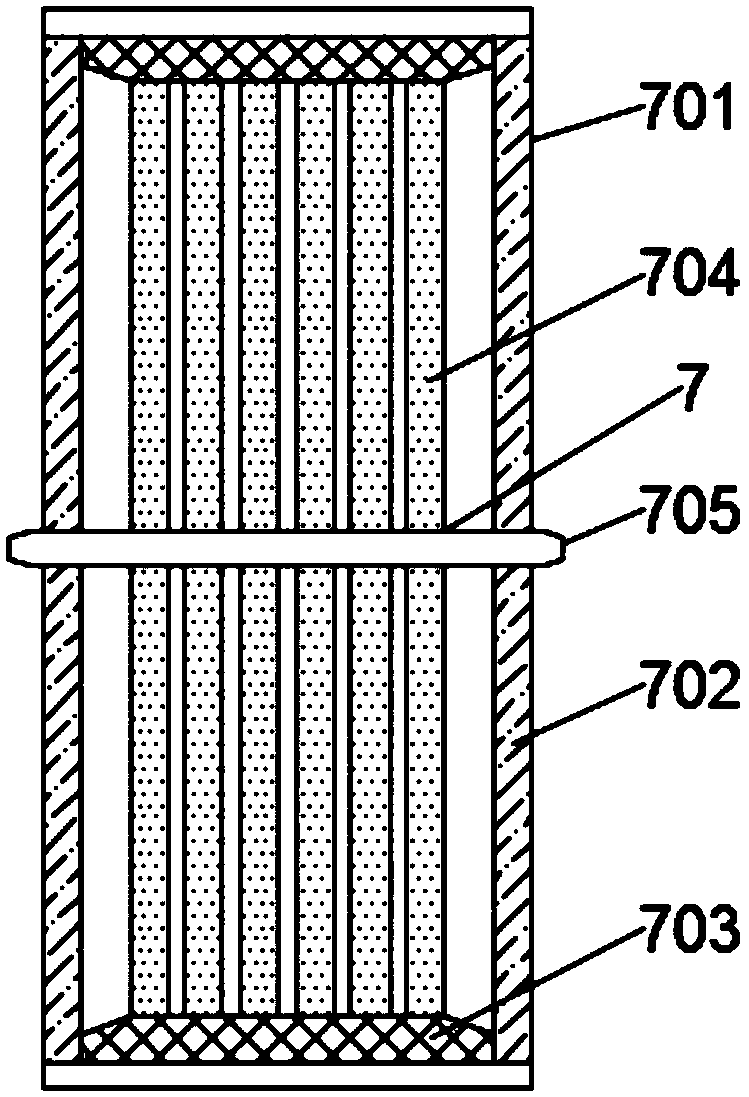

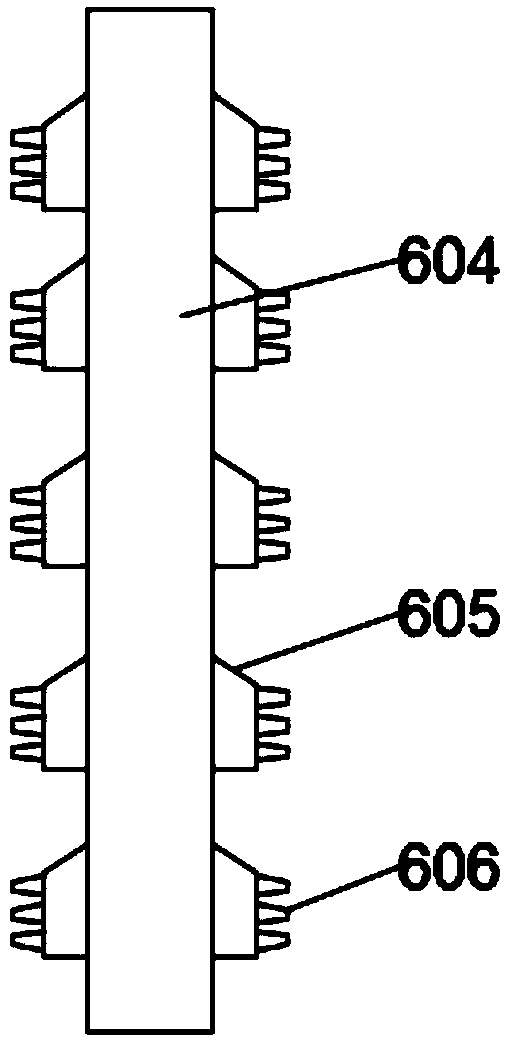

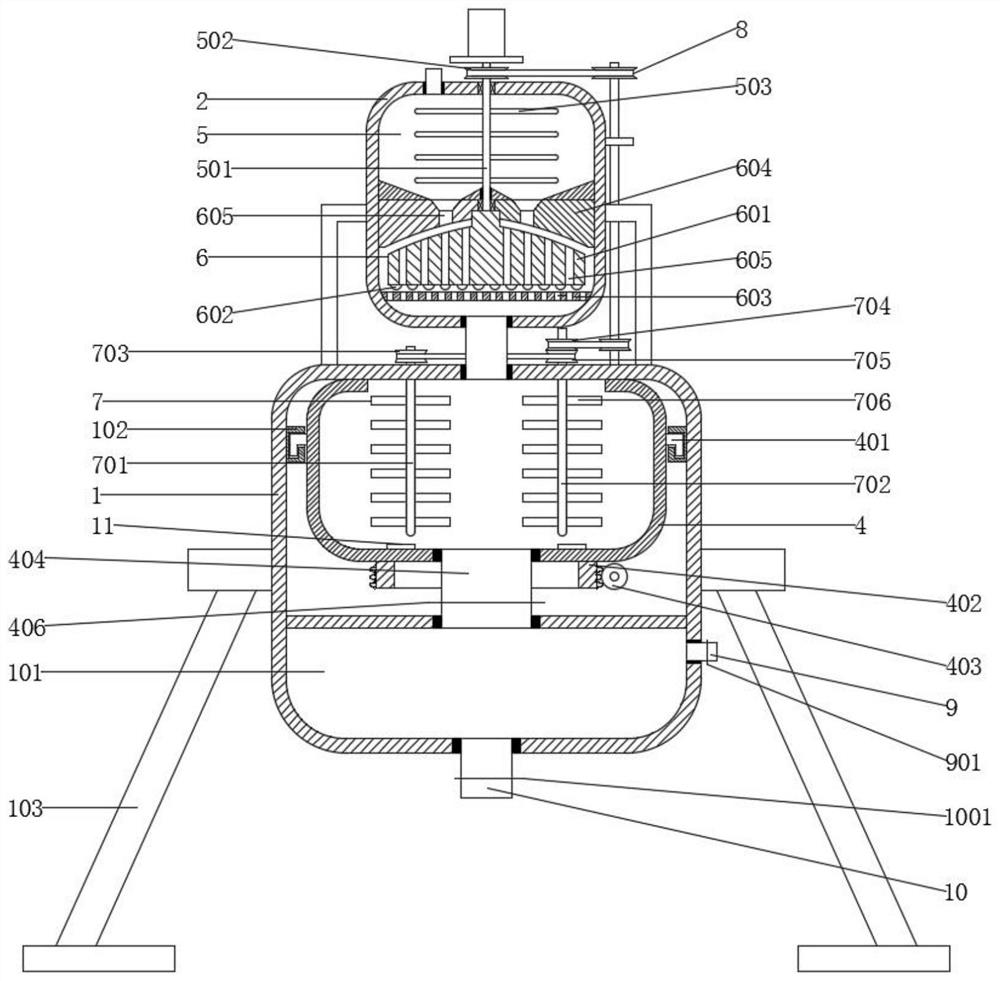

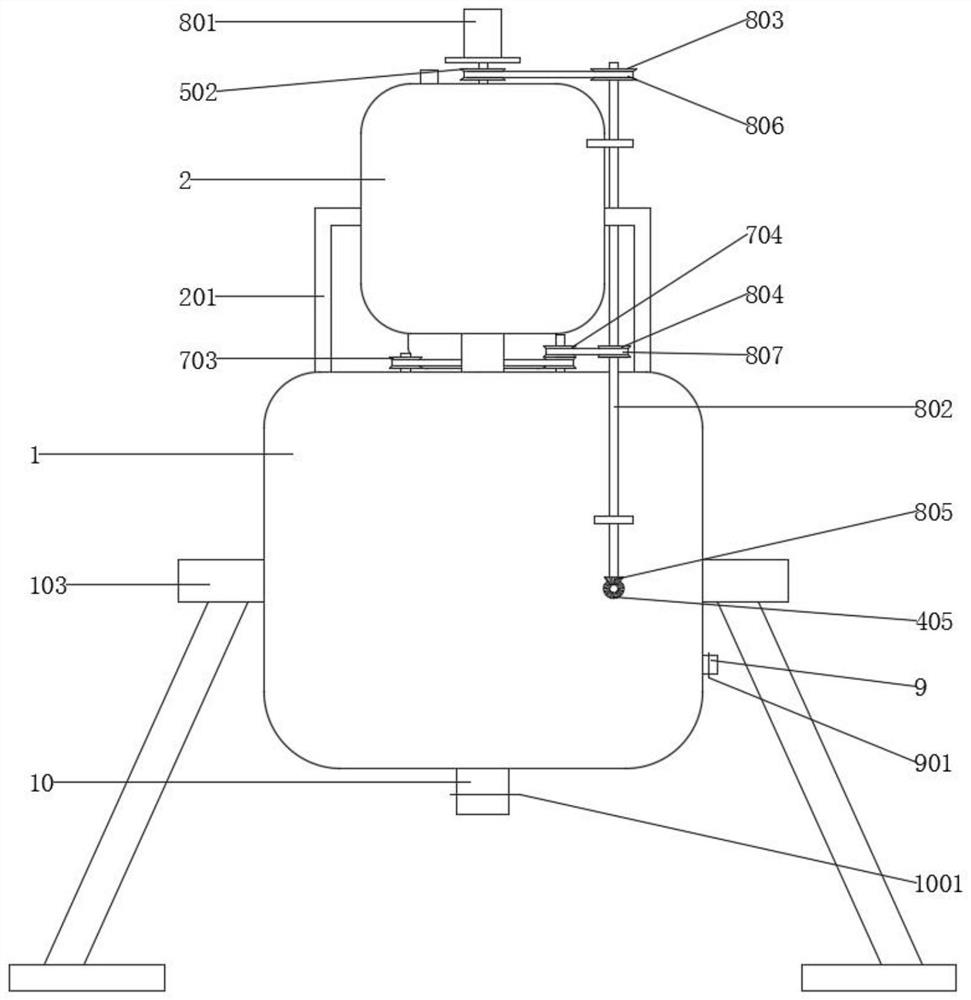

Yogurt fermentation device and yogurt preparation method

InactiveCN108740007AReduce sputteringGuaranteed feeding speedMilk preparationAdditive ingredientFresh air

The invention discloses a yogurt fermentation device and a yogurt preparation method. The yogurt fermentation device comprises a fermentation tank body and a cleaning tank body, the fermentation tankbody is connected with a feeding mechanism and an air exchange mechanism, respectively, the bottom end of the fermentation tank body is also equipped with a heat preservation mechanism, the inside ofthe fermentation tank body is also provided with a self-cleaning module, the air exchange mechanism includes a hollow air supply ring and a hollow air exhaust ring installed on the surface of the fermentation tank body, the feeding mechanism includes a charge pipe installed at the top end of the fermentation tank body through a sealed bearing, and the bottom end of the charge pipe is connected with a rapid diffusion module. The yogurt preparation method includes the following five steps: sterilizing raw materials; carrying out first time homogenization; subjecting the initially homogenized mixture to mixing with auxiliary materials, sterilization and second time homogenization; subjecting the additionally homogenized mixture to mixing with ingredients and third time homogenization; and carrying out constant temperature fermentation and making yogurt take shape. The yogurt fermentation device creates good conditions for yogurt fermentation, and can not only quickly supply clean fresh air, but also accurately control the fermentation temperature. Characteristics of the yogurt produced by the preparation method are that the yogurt is rich in nutrients and easy to absorb, so that the yogurt can meet the use needs of different groups of people.

Owner:解莉

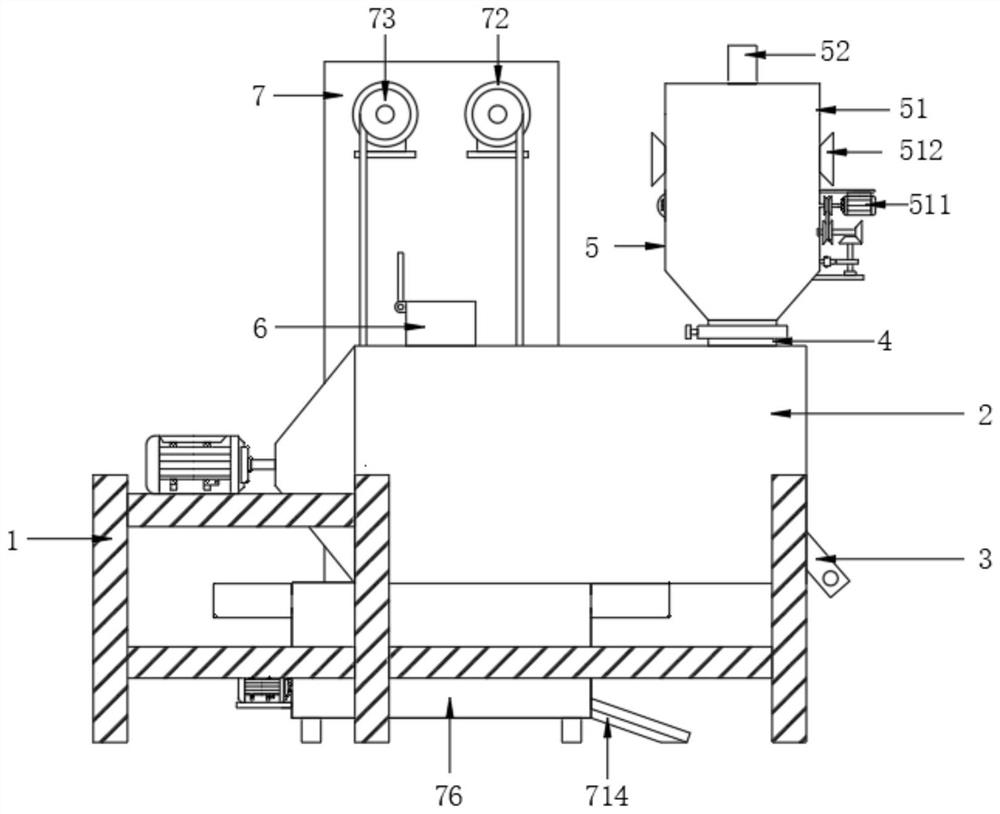

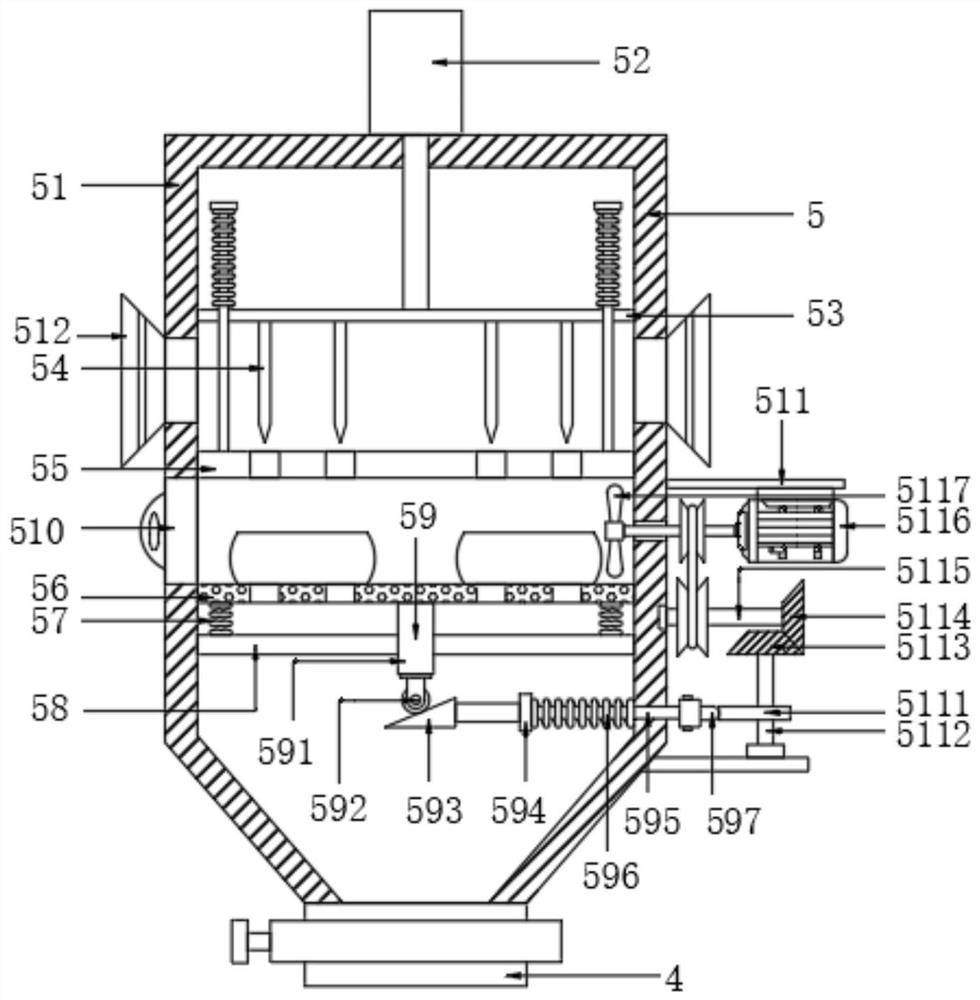

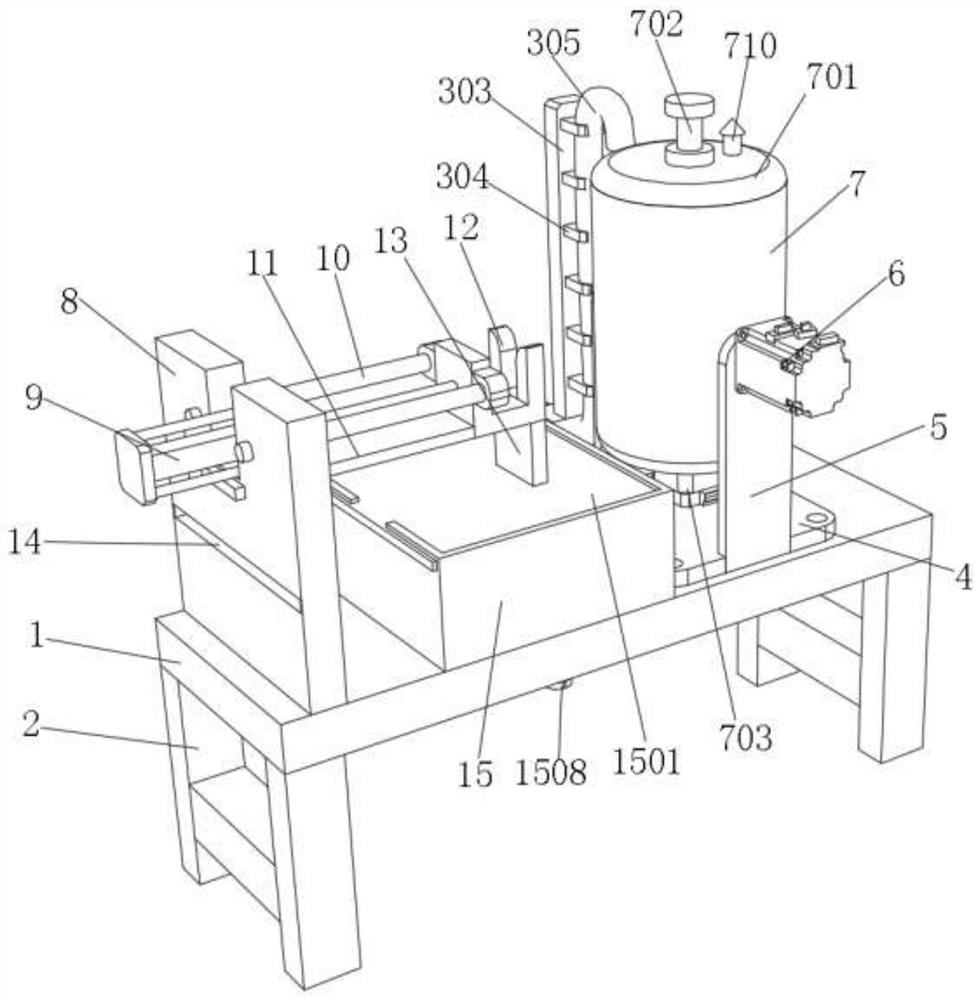

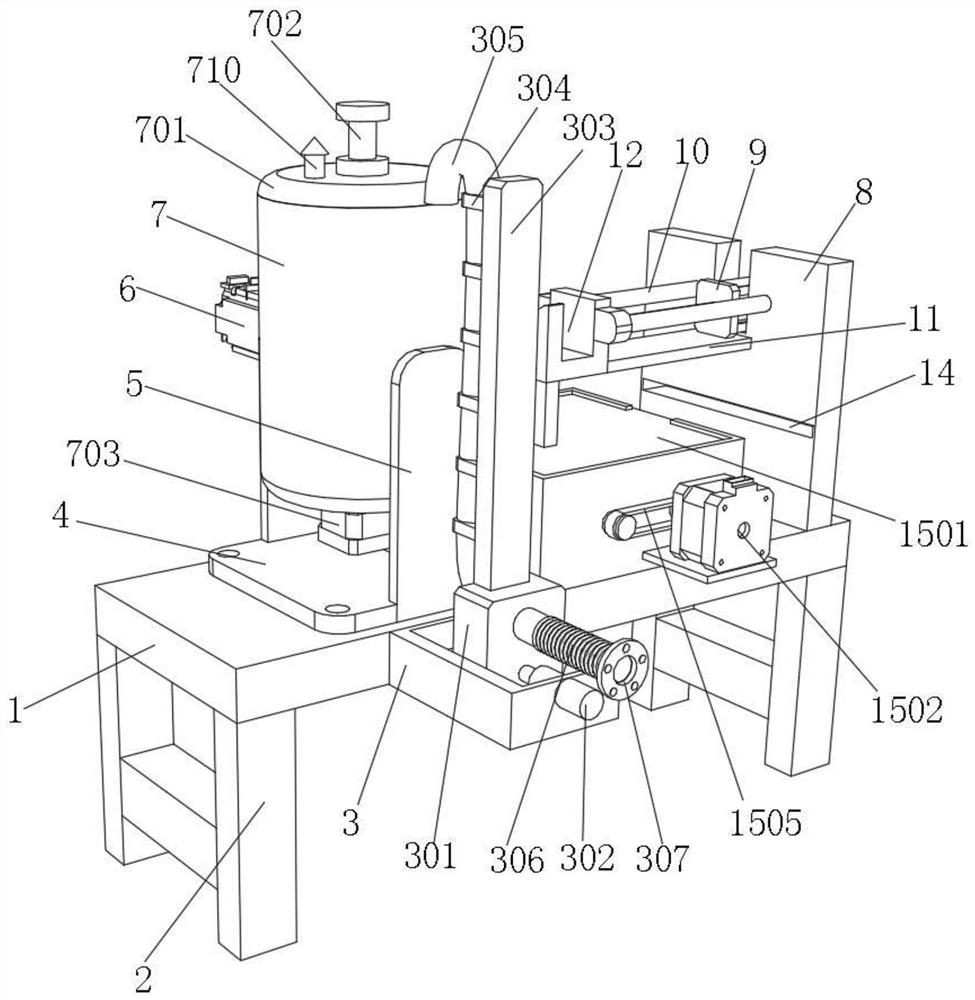

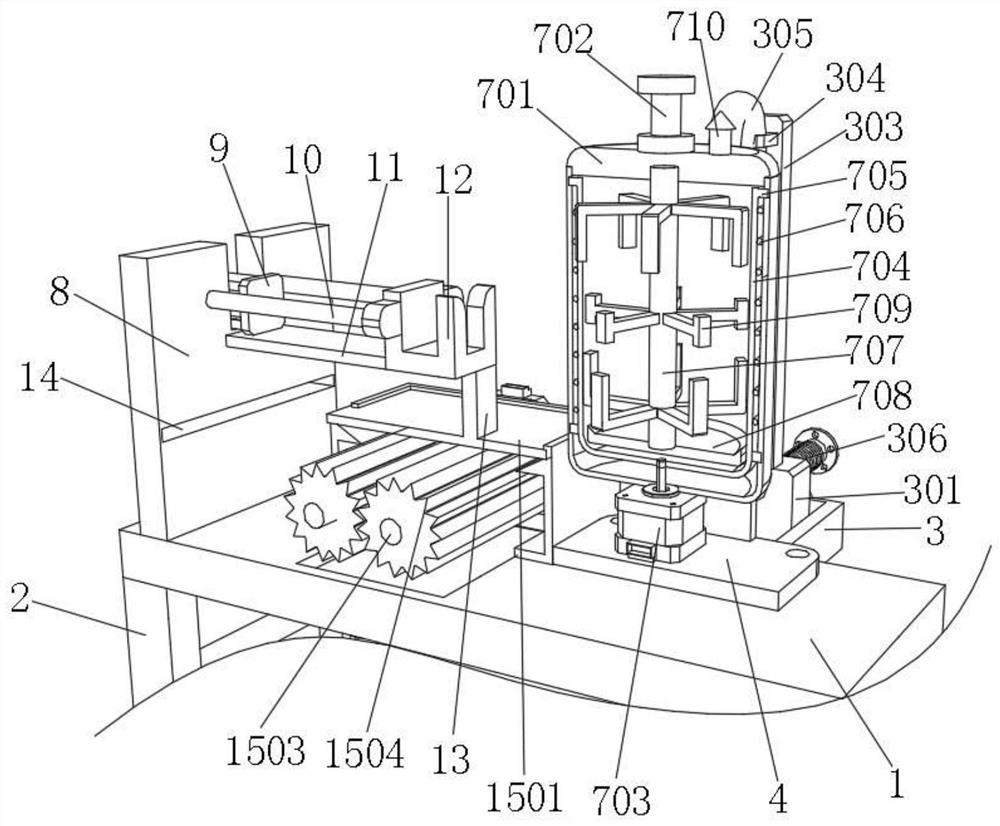

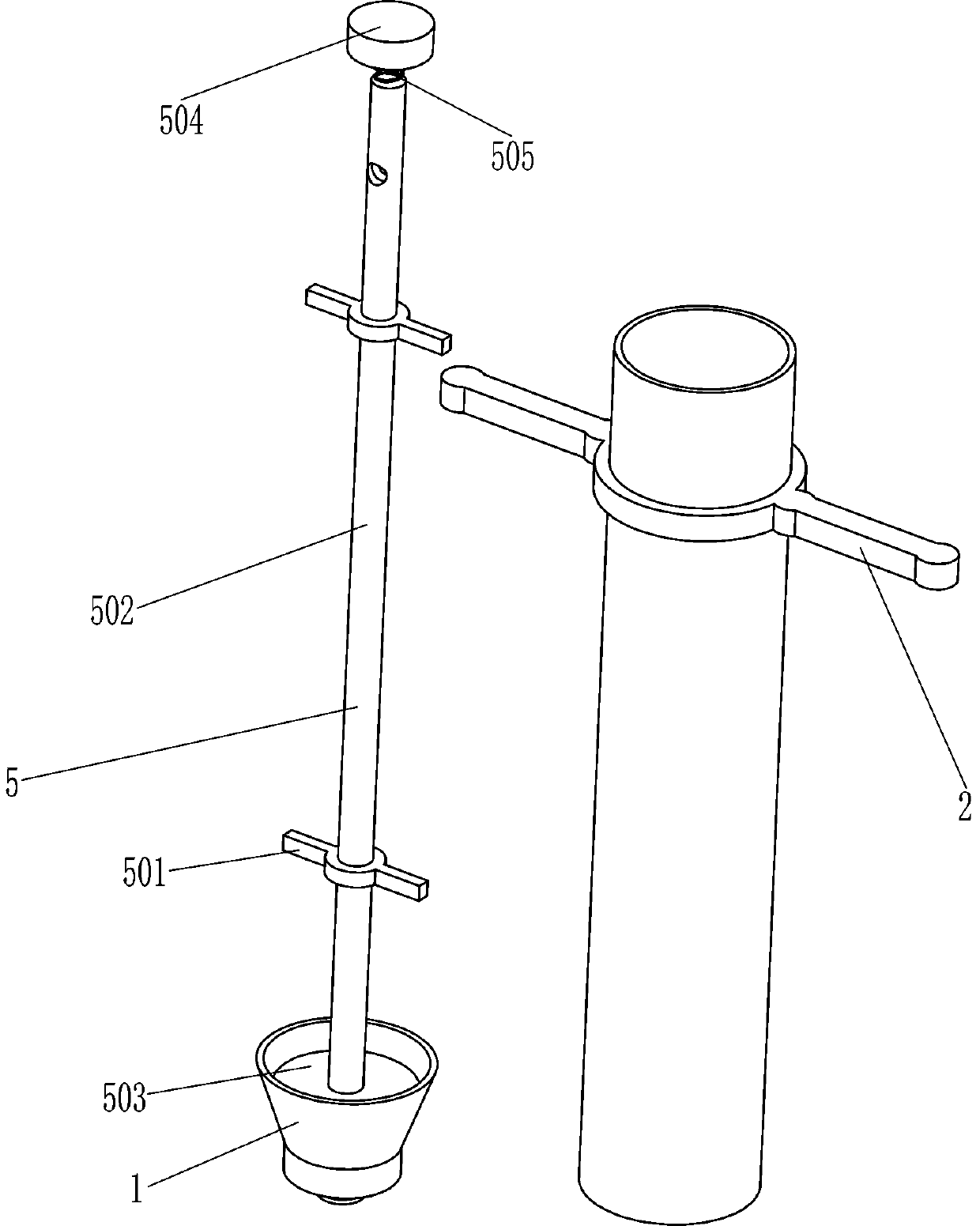

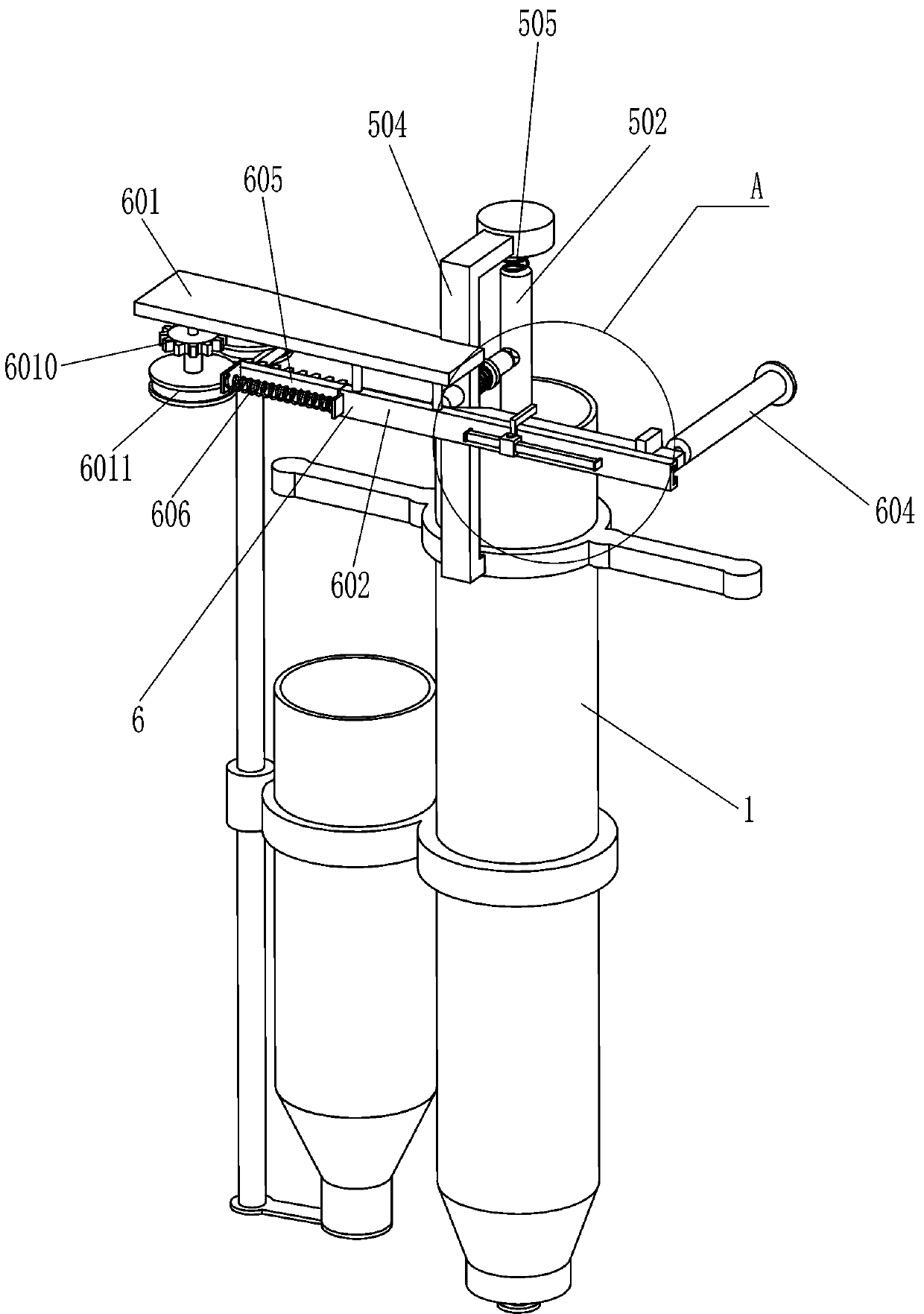

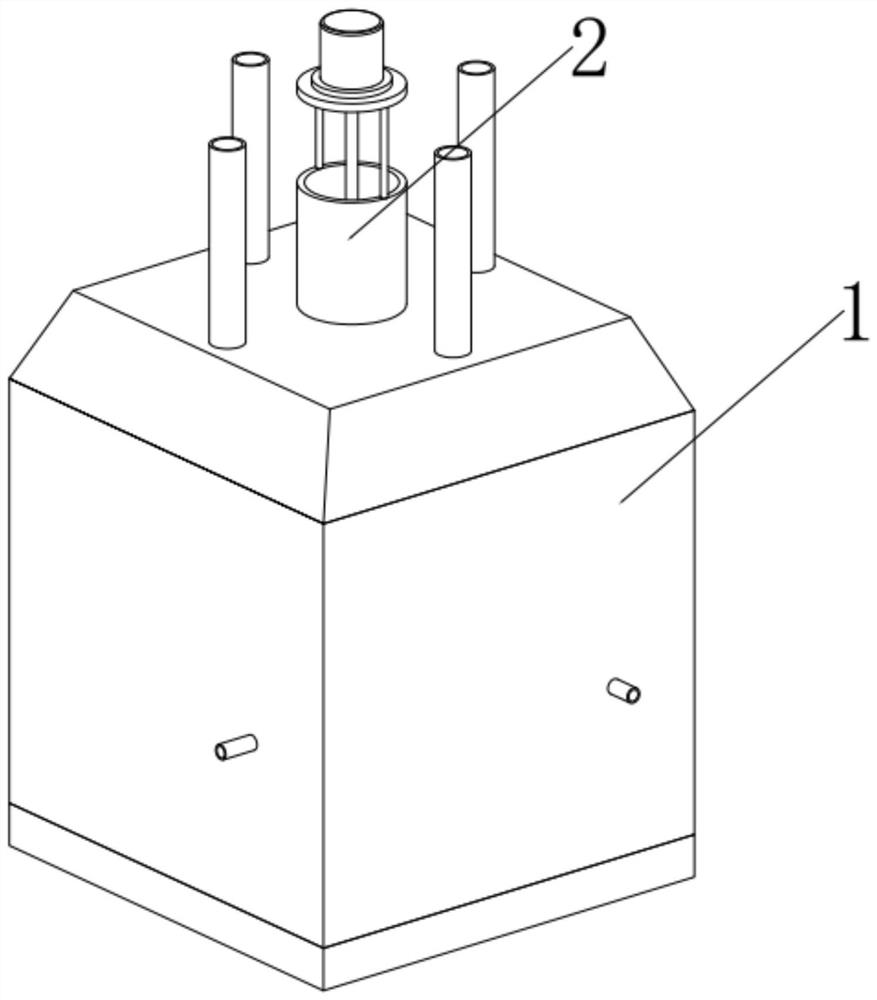

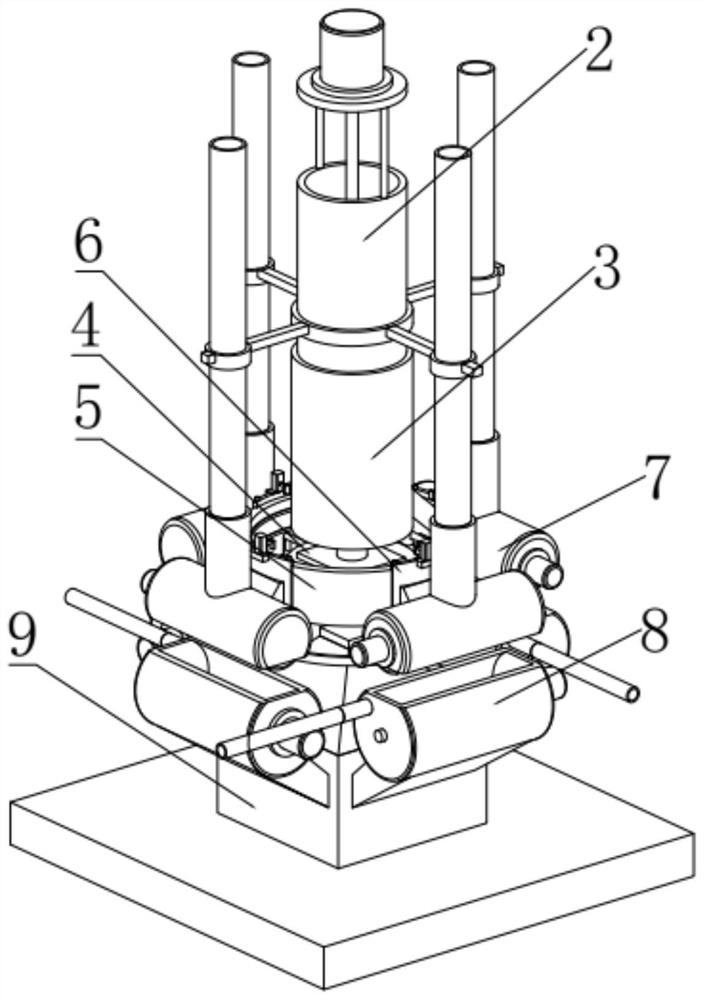

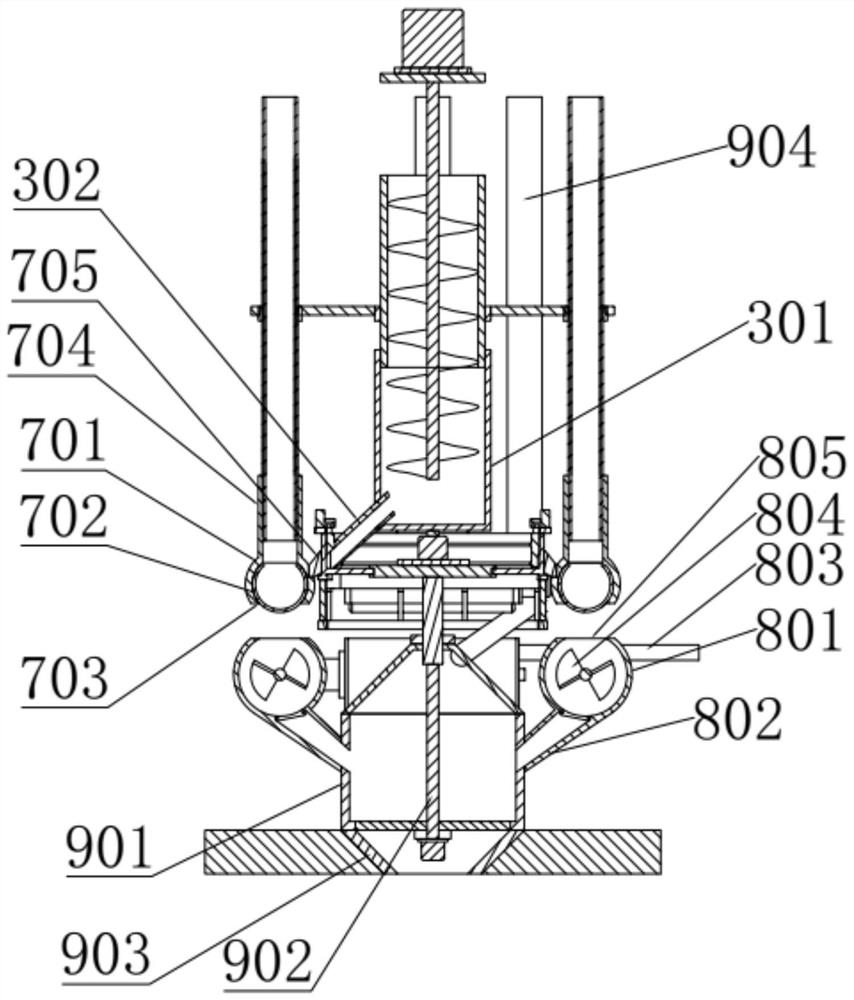

Purification equipment for protein polypeptide in peanut meal

ActiveCN111808163AThe mixed reaction is thoroughGuaranteed ExtractionPeptide preparation methodsEngineeringPeanut meal

The invention relates to the technical field of purification of protein polypeptide in peanut meal, in particular to purification equipment for protein polypeptide in peanut meal. The peanut meal is pretreated through a grinding box, condensed peanut meal is dispersed through a material dispersing mechanism, the peanut meal is ground into fine particles through a grinding mechanism, subsequent peanut meal and a solution are effectively mixed and react thoroughly, the extraction amount of the protein peptide is guaranteed, waste of peanut meal raw material is reduced, and the conversion rate isincreased; a turbine and a worm are matched to drive a reaction box to rotate, the reaction box drives the internal solution and the peanut meal to rotate and mix, and a mixing mechanism continuouslystirs the solution and the peanut meal, so that the mixing speed and the mixing uniformity are improved, the reaction time is shortened, and the mixing efficiency and the processing efficiency are improved; and a premixing box premixes the solution and peanut meal, a preheating layer preliminarily heats the solution and the peanut meal, the reaction speed is increased, the mixing time in the reaction box in the later period is shortened, and a solution box is arranged at the rear end of the grinding box, so that the interior of the premixing box is convenient to clean.

Owner:江西天禹科技协同创新有限公司

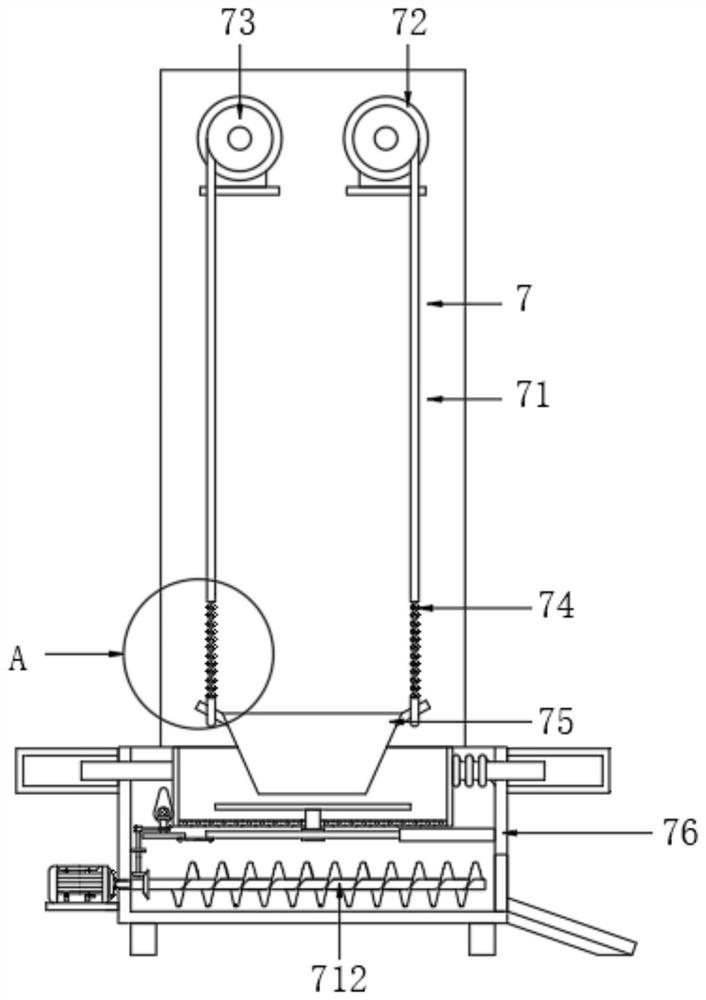

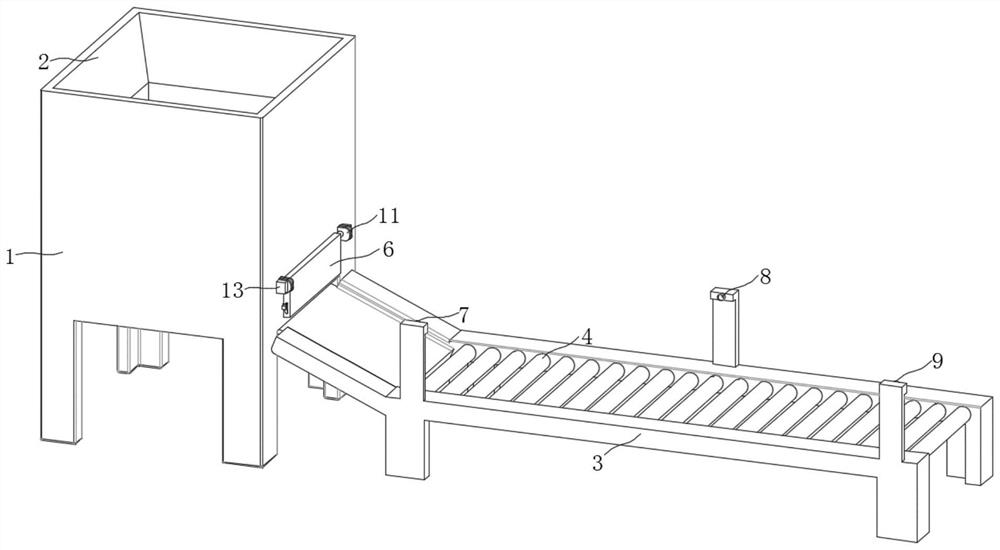

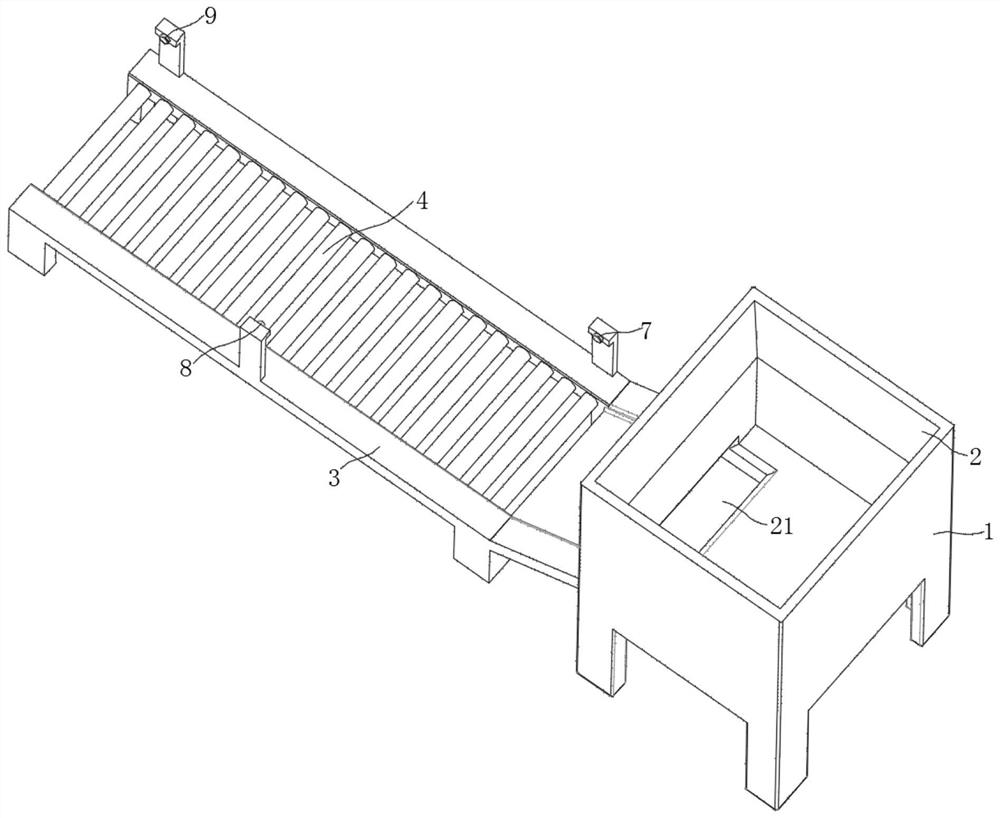

Vibration feeding device

The invention discloses a vibration feeding device. The vibration feeding device comprises a feeding bin, a first-stage material vibrating hopper and a first-stage vibrator. The first-stage material vibrating hopper is arranged below the feeding bin and comprises a first-stage hopper body and a first-stage sliding plate. A first-stage material vibrating cavity with an open top is formed in the first-stage hopper body, one side of the first-stage material vibrating cavity is open to form a first-stage discharging port communicated with the first-stage material vibrating cavity, and at least part of the first-stage sliding plate is arranged in the first-stage material vibrating cavity. The first-stage sliding plate obliquely extends downwards, the first-stage sliding plate can rotate arounda first-stage fixed axis close to the upper end of the first-stage sliding plate, and the lower end of the first-stage sliding plate is detachably erected on the first-stage hopper body; and the first-stage vibrator is connected with the first-stage material vibrating hopper. According to the vibration feeding device, materials can be prevented from being blocked, impurity materials are preventedfrom flowing into a finished product, the feeding speed is guaranteed, and stable and uniform conveying and feeding of the materials which are bonded and are easy to hook and connect are achieved.

Owner:HEFEI MEIYA OPTOELECTRONICS TECH

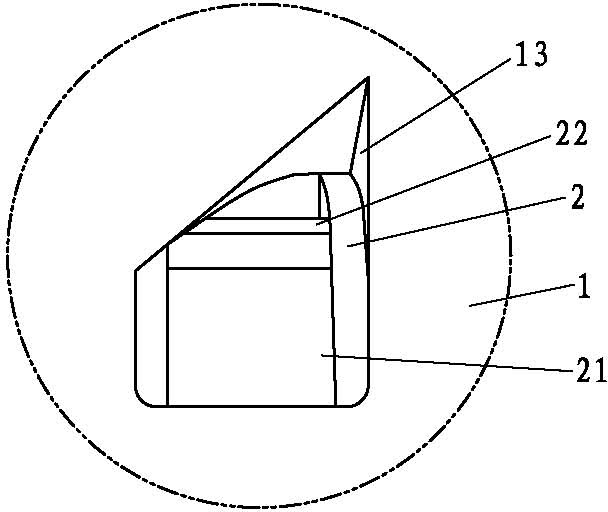

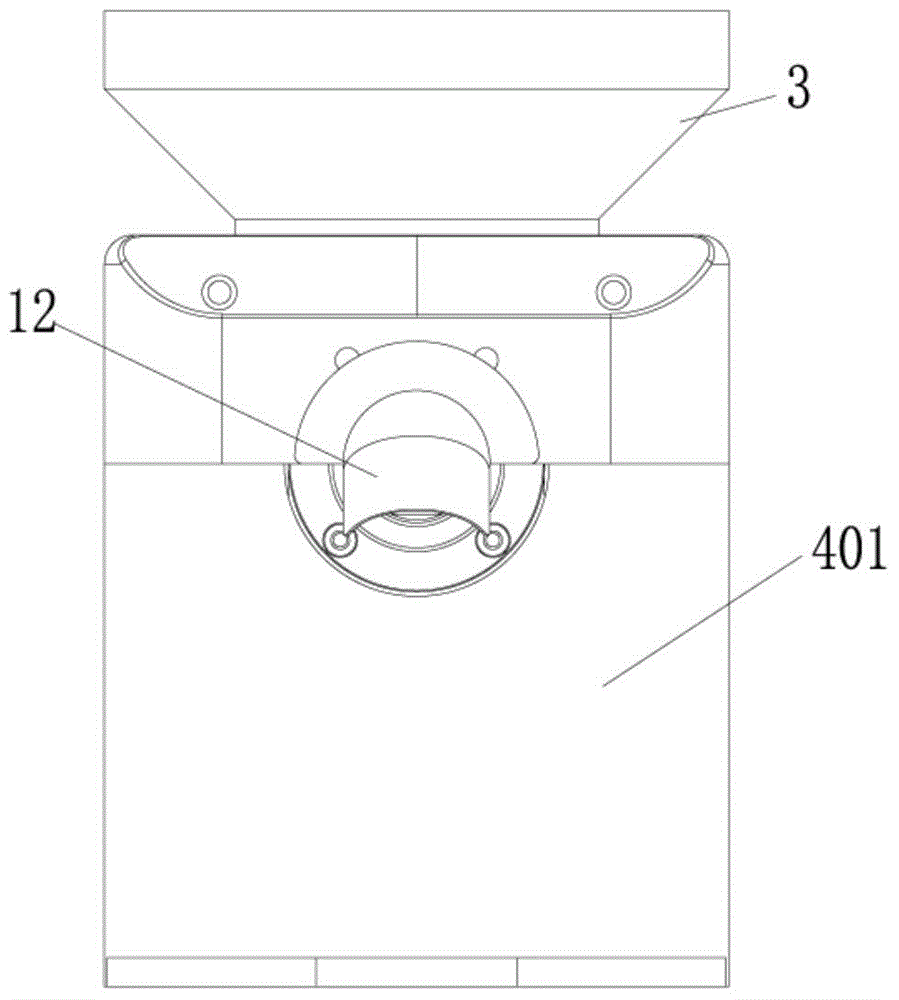

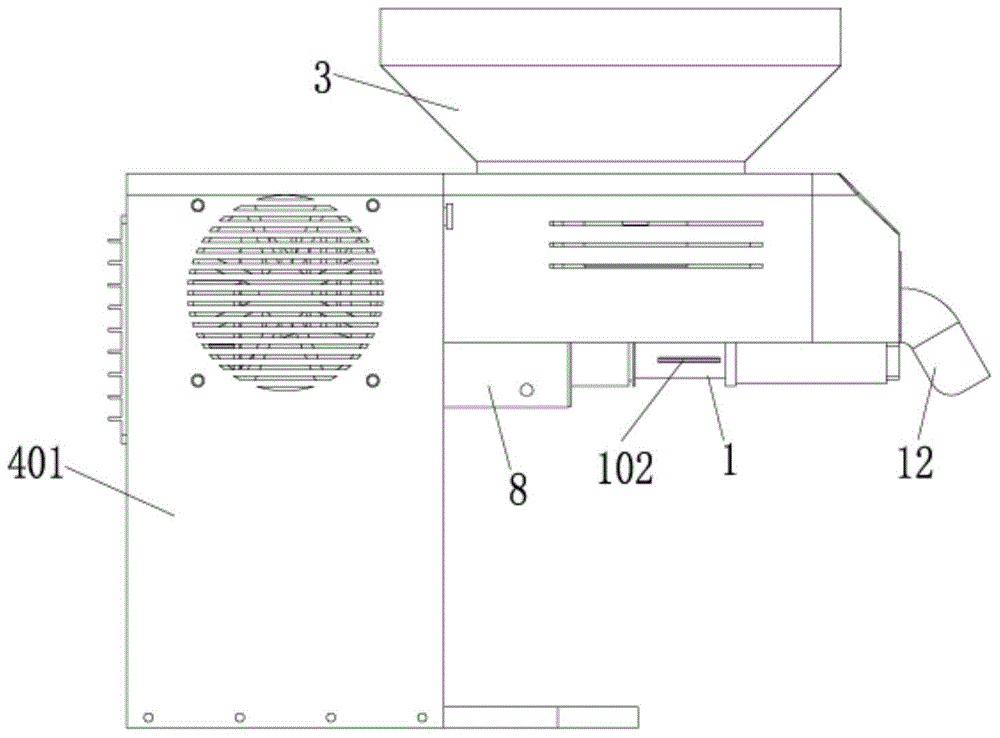

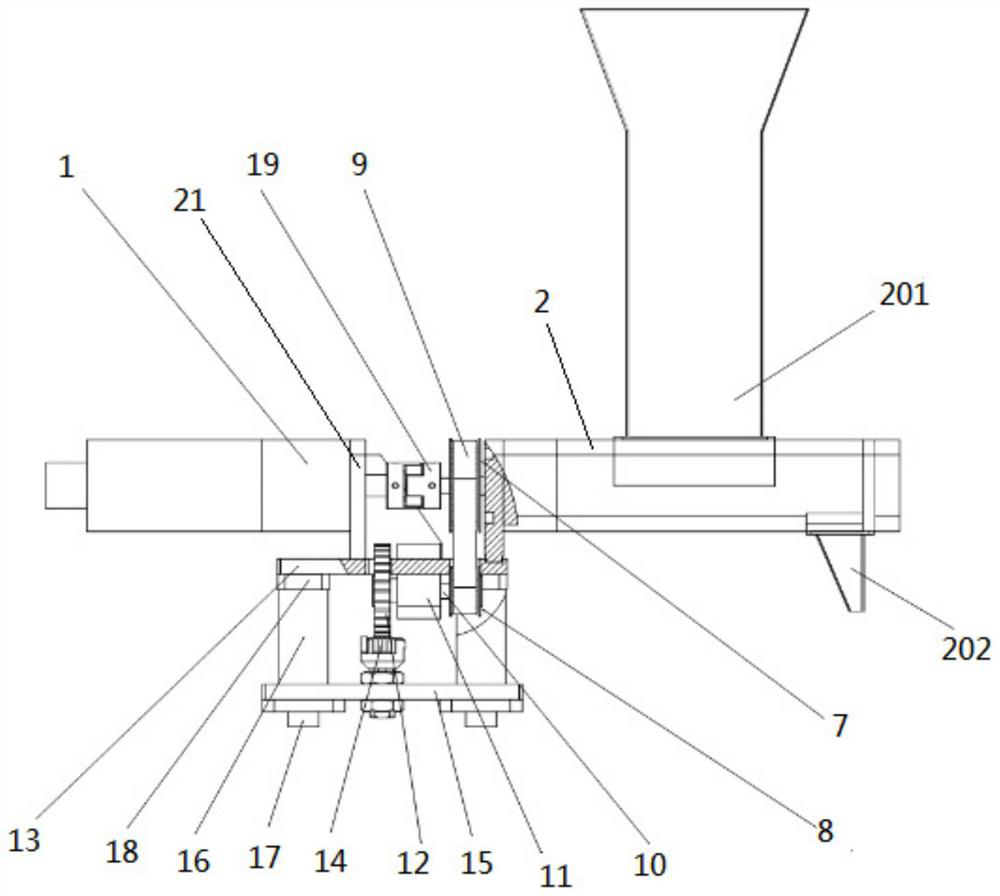

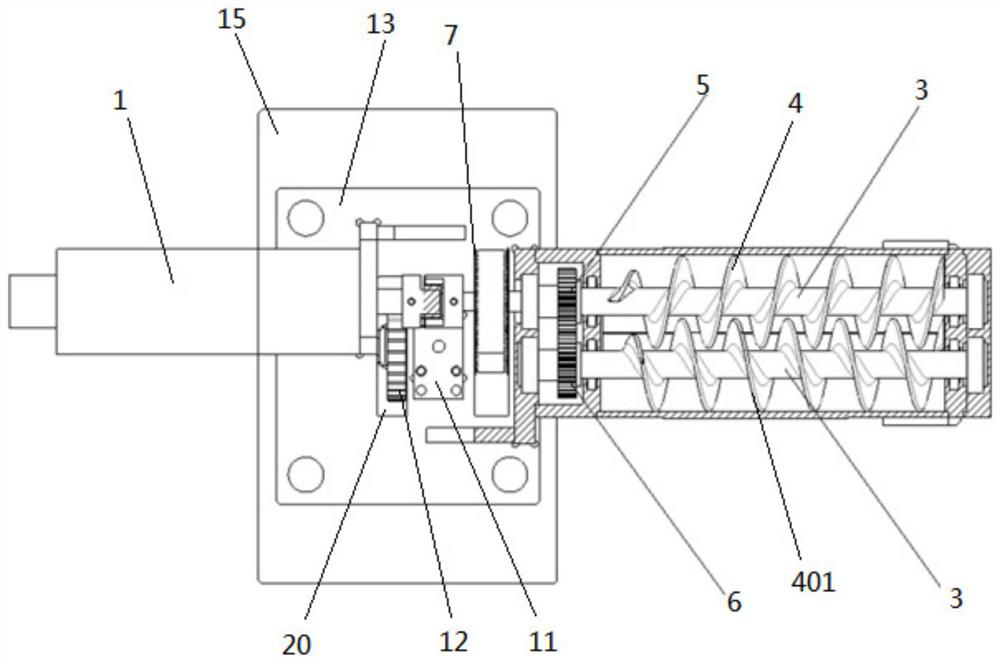

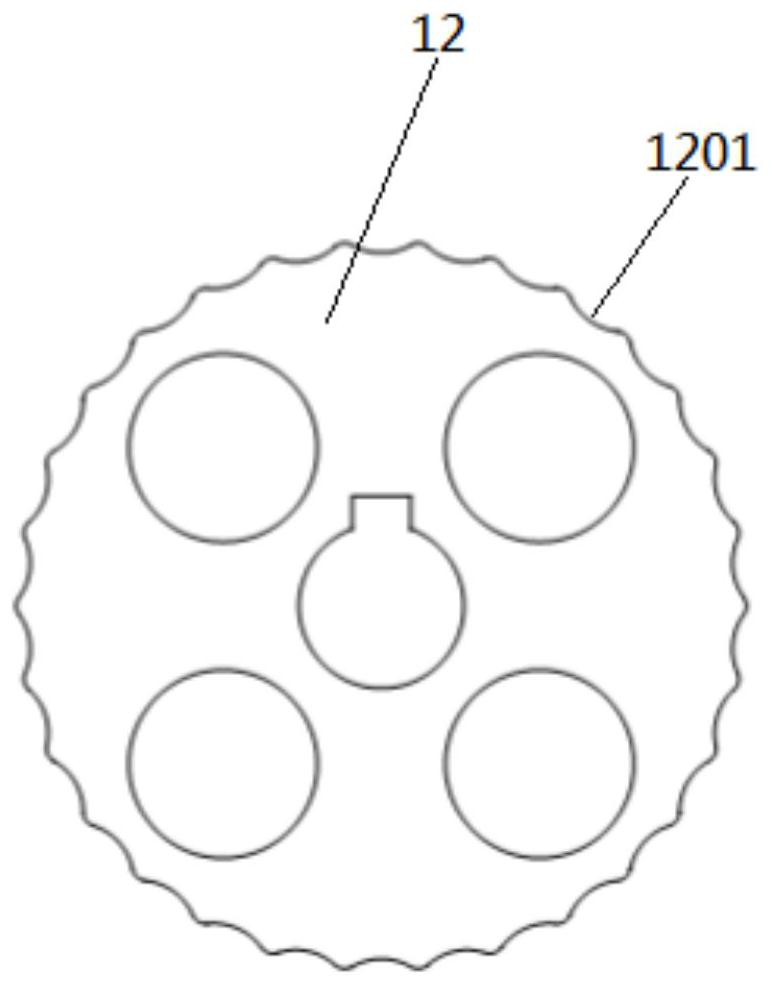

Oil press

The invention discloses an oil press which comprises a barrel, a press rod, a hopper, a host and a heating unit. A feeding port is formed in the portion, at the feeding end of the barrel, of a barrel body, a hollow residue discharging head is connected with the port of the residue discharging end of the barrel, multiple strip-shaped oil outlets are circumferentially distributed in the portions, at the two ends of the barrel, of the barrel body, and an inner cavity of the barrel is a right hex socket straight hole. The hopper is arranged above the barrel. Each side of the right hex socket straight hole corresponds to one strip-shaped oil outlet and the strip-shaped oil outlets deviate from the corresponding midpoints of the right hex socket straight hole. The press rod is a conic push screw sleeved with the right hex socket straight hole of the barrel, one end of the press rod penetrates through the feeding port of the barrel to be connected with the host, the other end of the press rod extends into a cavity of the hollow residue discharging head, and a residue discharging gap is kept between the other end of the press rod and the inner cavity wall of the hollow residue discharging head. The heating unit is installed at the portion, of the residue discharging end of the barrel, of the barrel body. The oil press has the advantages of being high in oil outflow rate, oil outflow quality and adaptability and the like.

Owner:ZHONGSHAN ZHENDEMEI PRECISION MASCH CO LTD

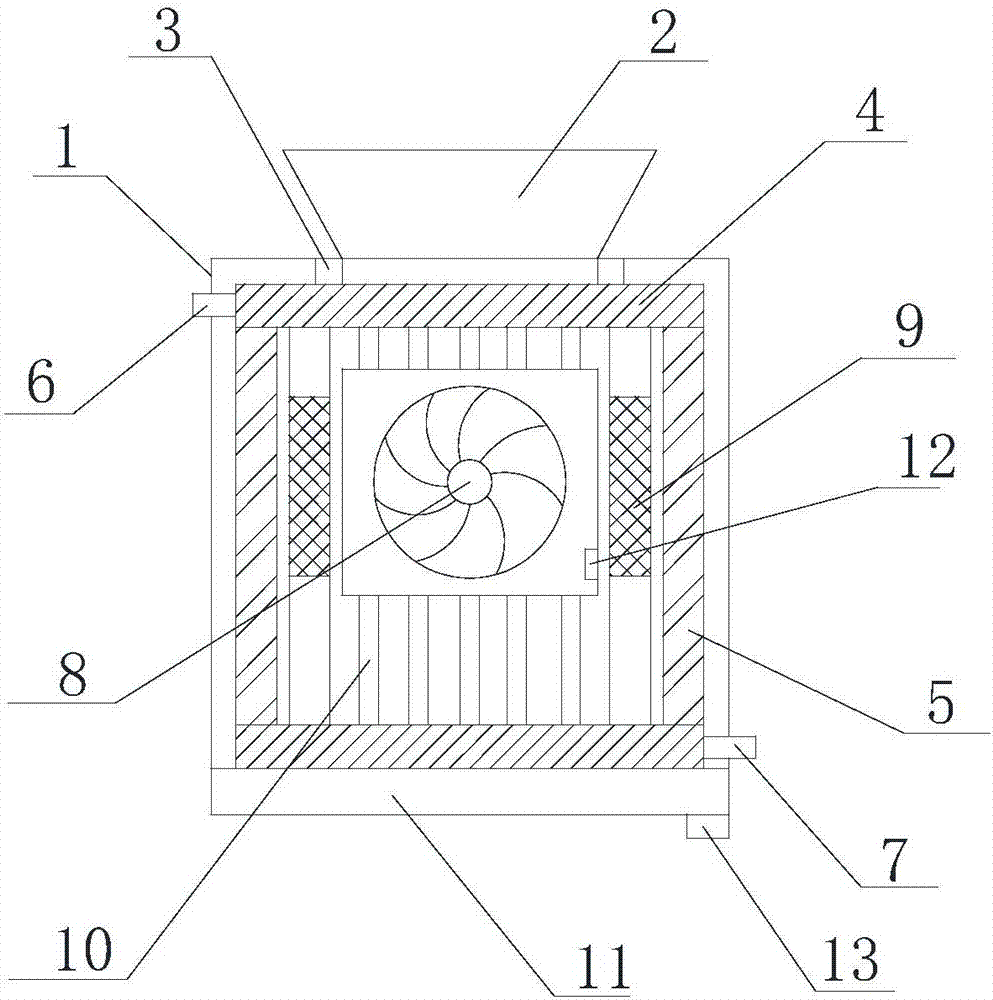

Cooling device of plastic injection molding machine

InactiveCN107364095AImprove cooling efficiencyAvoid clumpingPlastic injection moldingWater circulation

The invention provides a cooling device for a plastic injection molding machine. Temperature sensors are arranged on both sides of the feed hopper. A surrounding horizontal cooling pipe and a vertical cooling pipe are arranged in the body of the cooling device. One side is provided with a water inlet, one side of the longitudinal cooling pipe is provided with a water outlet, and the middle of the surrounding horizontal cooling pipe and the longitudinal cooling pipe is provided with a main cooling fan, and the two sides of the main cooling fan are provided with temperature For the controller, several cooling fins are arranged around the main cooling fan, and a secondary cooling fan is arranged at the lower part of the cooling device body. The beneficial effect of the present invention is that the cooling device of the injection molding machine is equipped with a main cooling fan, and the cooling temperature is transmitted through the cooling fins, and the water circulation of the horizontal and vertical cooling pipes is used for cooling, effectively avoiding plastic particles during the feeding process. Agglomeration occurs due to the absorption of a large amount of heat, which ensures the feeding speed and improves the working efficiency.

Owner:天津星特电子有限公司

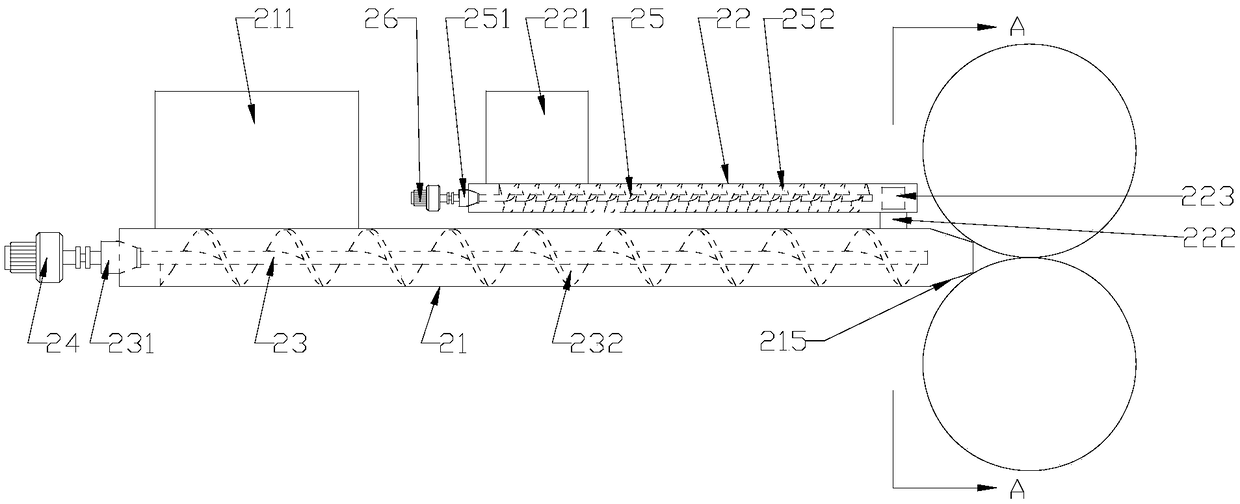

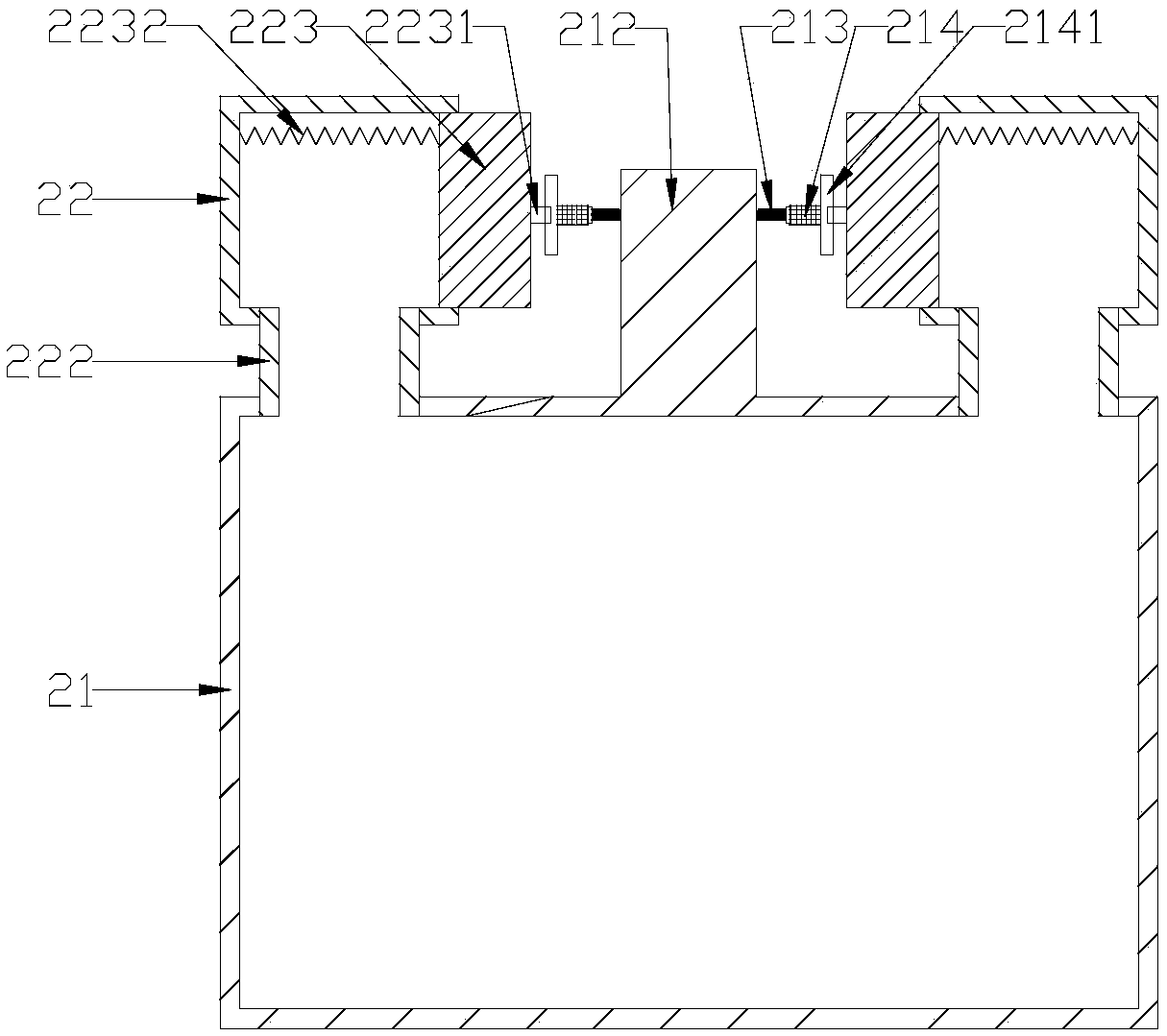

Spiral conveyer

PendingCN109230303AGuaranteed uniformityReduce the unevenness of thicknessConveyorsPackagingCouplingEngineering

The invention discloses a spiral conveyor, which comprises a main conveying unit and an auxiliary conveying unit, wherein the main conveying unit comprises a first material conveying shell, a first rotating rod and a first motor; the auxiliary conveying unit comprises two groups of second material conveying shells, a second rotating rod and a second motor; the auxiliary conveying unit is positioned at upper and lower sides of the main conveying unit, the first rotating rod and the second rotating rod are respectively fixed on the first material conveying shell and the second material conveyingshells through a first bearing seat and a second bearing seat, the output shafts of the first motor and second motor are respectively connected with the first rotating rod and the second rotating rodthrough couplers, the first material conveying shell is provided with a first material feeding channel, the second material conveying shells are provided with a second material feeding channel and amaterial supplementing channel, and the other end of the material supplementing channel is communicated with the first material conveying shell, so that the distribution uniformity of the material pushed out by a frustum-shaped contraction end can be kept, and the phenomenon of different thicknesses of pressed sheets can be reduced.

Owner:欣好科技有限公司

Integrated thin-layer chromatography plate paving instrument

InactiveCN107051828ANo dopingGuaranteed distanceLiquid surface applicatorsCoatingsThin layer chromatographicEngineering

The invention belongs to the field of chromatographic analysis and particularly relates to an integrated thin-layer chromatography plate paving instrument. The specific structure of the integrated thin-layer chromatography plate paving instrument comprises a conveying device, a chromatography plate conveying area, a material paving area and a drying area. The integrated thin-layer chromatography plate paving instrument integrates raw material grinding, plate paving and drying, influence on follow-up experiments can be greatly reduced, and meanwhile labor force and time are saved, so that the plate paving process is finished in high efficiently and high quality.

Owner:DALIAN UNIV

an oil press

The invention discloses an oil press which comprises a barrel, a press rod, a hopper, a host and a heating unit. A feeding port is formed in the portion, at the feeding end of the barrel, of a barrel body, a hollow residue discharging head is connected with the port of the residue discharging end of the barrel, multiple strip-shaped oil outlets are circumferentially distributed in the portions, at the two ends of the barrel, of the barrel body, and an inner cavity of the barrel is a right hex socket straight hole. The hopper is arranged above the barrel. Each side of the right hex socket straight hole corresponds to one strip-shaped oil outlet and the strip-shaped oil outlets deviate from the corresponding midpoints of the right hex socket straight hole. The press rod is a conic push screw sleeved with the right hex socket straight hole of the barrel, one end of the press rod penetrates through the feeding port of the barrel to be connected with the host, the other end of the press rod extends into a cavity of the hollow residue discharging head, and a residue discharging gap is kept between the other end of the press rod and the inner cavity wall of the hollow residue discharging head. The heating unit is installed at the portion, of the residue discharging end of the barrel, of the barrel body. The oil press has the advantages of being high in oil outflow rate, oil outflow quality and adaptability and the like.

Owner:ZHONGSHAN ZHENDEMEI PRECISION MASCH CO LTD

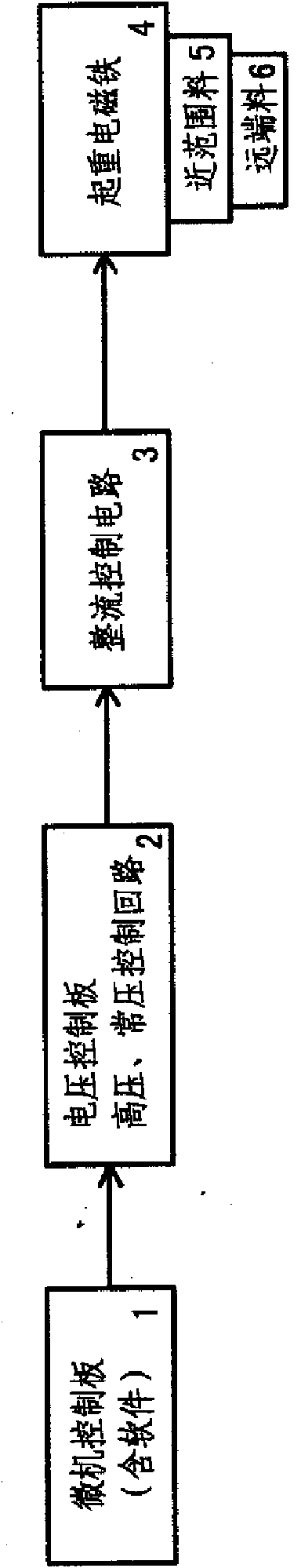

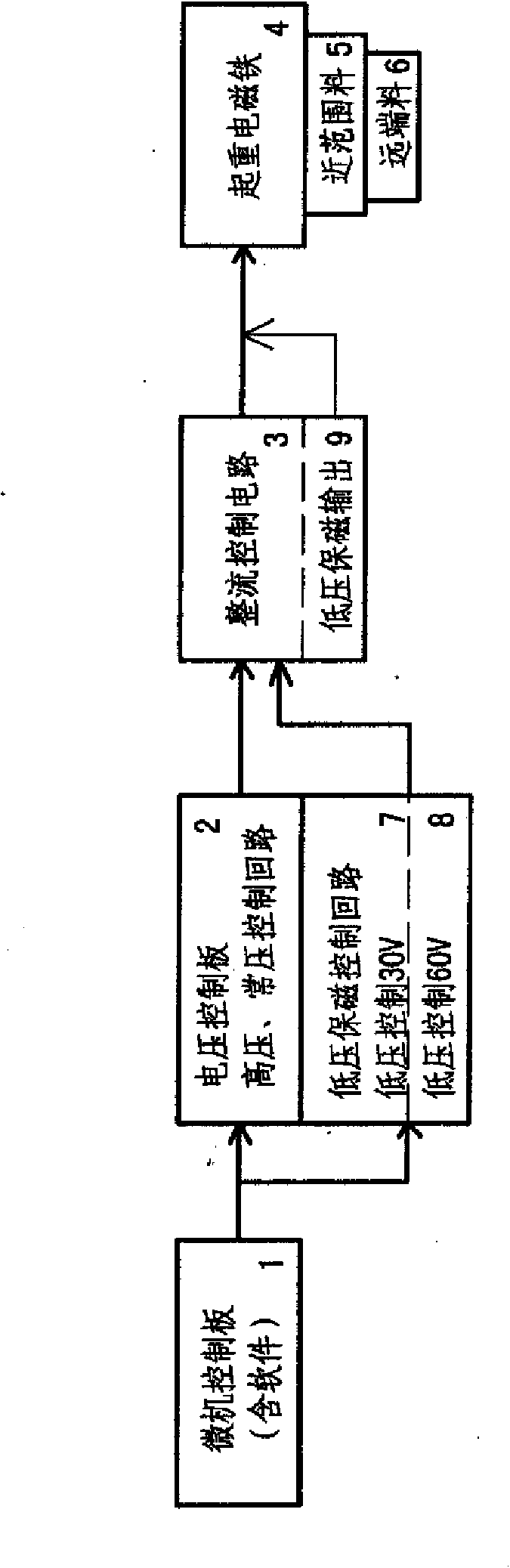

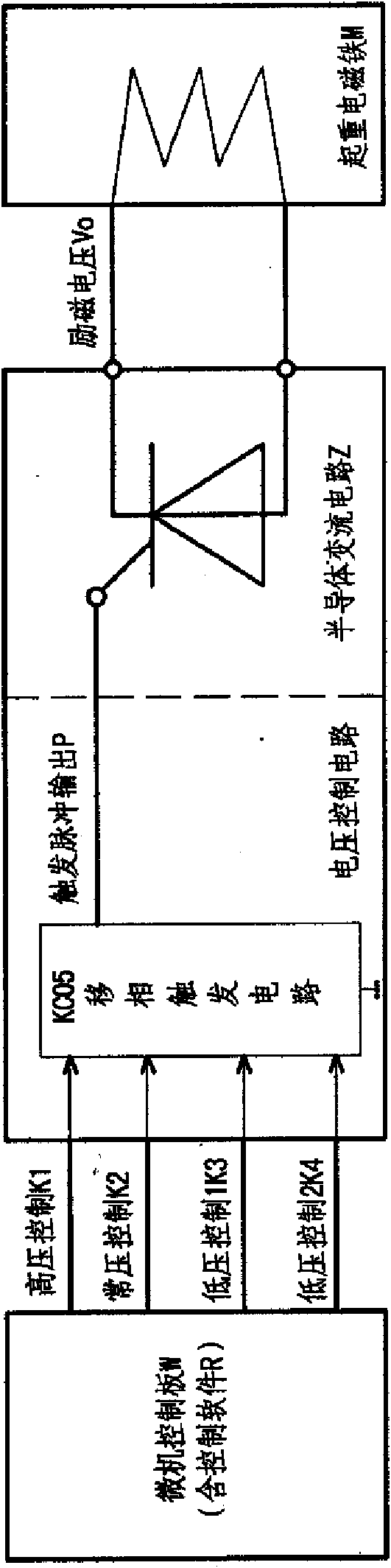

Computerized electromagnet controller and control method thereof of low-voltage electromagnet keeping technology

The invention relates to a computerized electromagnet controller and a control method thereof of a low-voltage electromagnet keeping technology. The computerized electromagnet controller comprises a computer control circuit, a high-voltage and normal-voltage control loop, a rectification control circuit and a lifting electromagnet and is characterized in that high voltage and normal voltage especially used for low-voltage electromagnet keeping ingredient mixing are added on the high-voltage and normal-voltage control loop, and low-voltage electromagnet keeping output is arranged in the rectification control circuit. The high voltage and the normal voltage especially used for the low-voltage electromagnet keeping ingredient mixing are added on a high-voltage and normal-voltage regulation circuit of the prior electric control cabinet of an electromagnetic disk; in automatic ingredient mixing, the power is not completely cut off, and low-voltage electromagnet keeping ingredient mixing isautomatically selected by a computer according to the size of the fixed ingredient mixing value; and in this way, the control of the electromagnetic disk over remote charging can be strengthened. Theinvention can enhance the ingredient mixing precision, and the precision can be enhanced to be within 2% by practical measurement so that molten iron ingredients are stable. The invention can also largely reduce the failure rate within 3% by the practical measurement. Because the ingredient adding and mixing time period is shortened, the feeding speed and the melting speed are ensured.

Owner:YUEYANG HUAZHONG ELECTROMAGNET TECH CO LTD

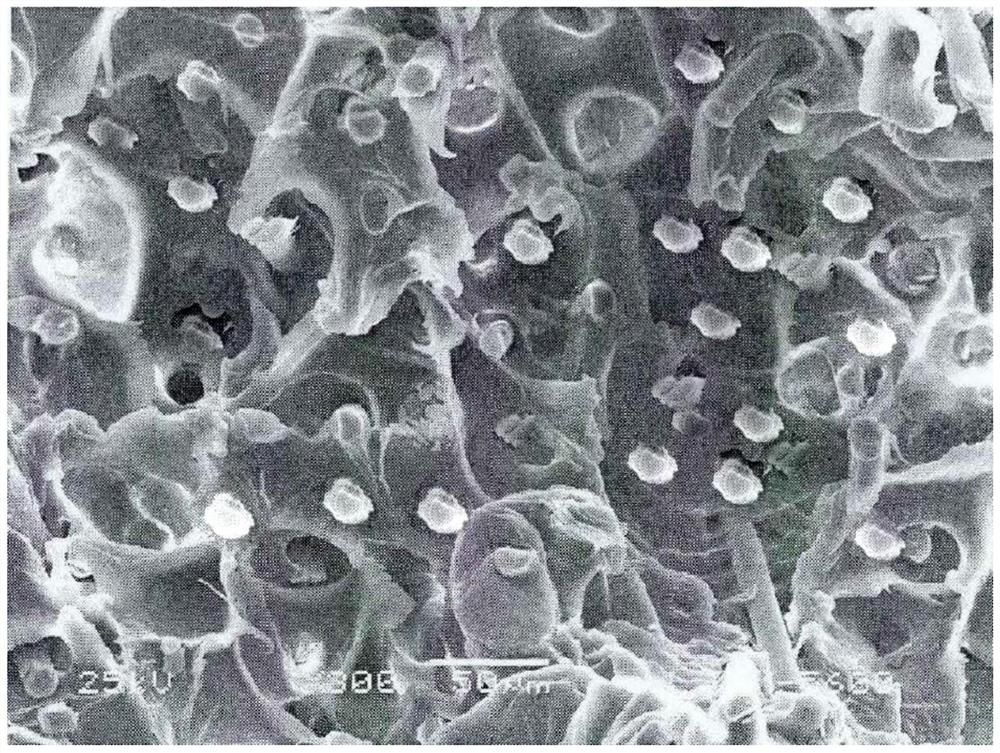

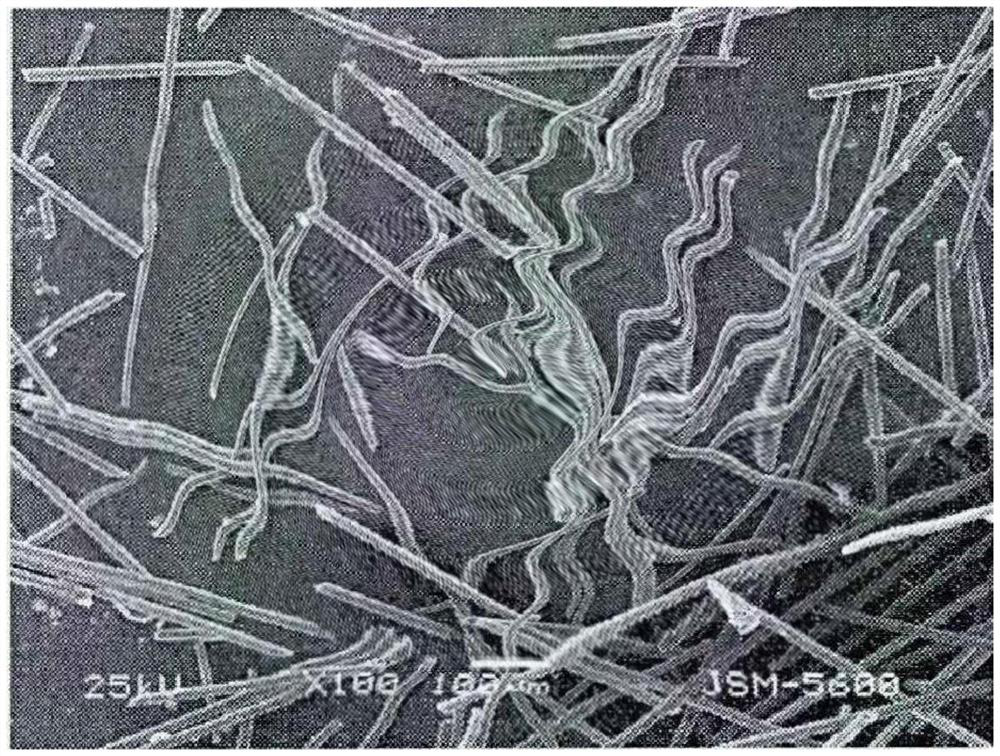

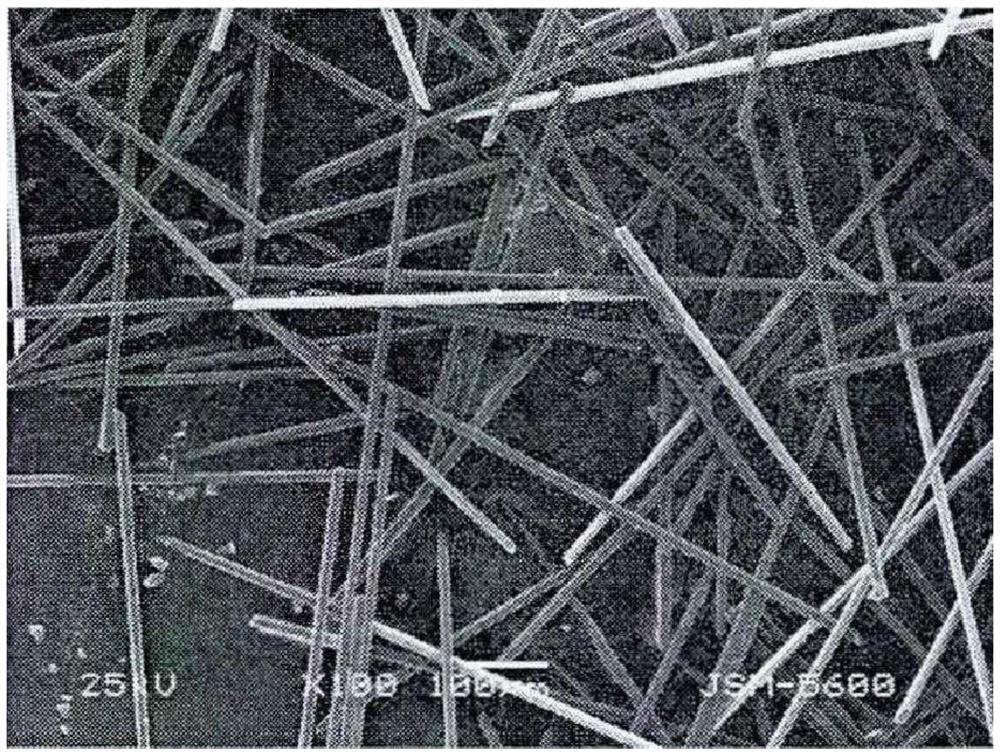

Glass fiber reinforced nylon 6 composite material

The invention relates to a glass fiber reinforced nylon 6 composite material, which is prepared from the following ingredients in parts by weight: 40 to 60 parts of nylon 6 resin, 5 to 30 parts of high-temperature nylon resin, 23 to 27 parts of glass fibers, 1 to 15 parts of toughening agents, 0.1 to 3 parts of coupling agents, 0.1 to 3 parts of dispersion lubricating agents, 0.1 to 1 part of antioxidants and 0.1 to 3 parts of color master batches. In order to solve the problems of low melt strength, low extrusion speed and poor tensile strength during production of a nylon 6 heat insulation strip product, the invention further provides a preparation method of the glass fiber reinforced nylon 66 heat insulation strip material, and the glass fiber reinforced nylon 66 heat insulation strip material is prepared by virtue of a double-screw extruder with the screw diameter of 60mm and the length-diameter ratio L / D of 48. The obtained special glass fiber reinforced nylon 6 composite material for the heat insulation strip has excellent performance.

Owner:广东博事达新材料有限公司

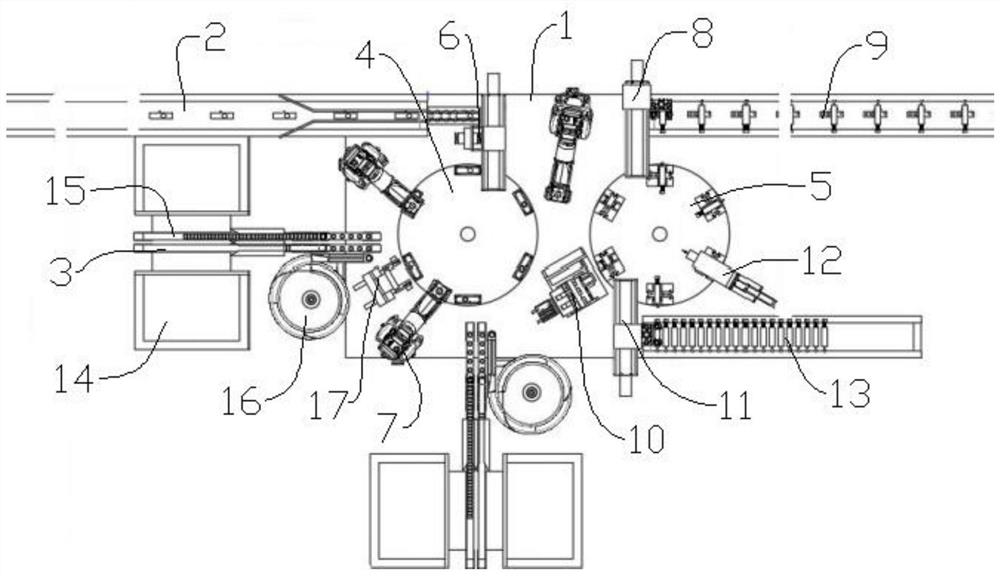

Automatic pressurizing line and processing technology thereof

InactiveCN112809364AIncrease productivityImprove production accuracyAssembly machinesMetal working apparatusElastomerProcess engineering

The invention discloses an automatic pressurizing line and a processing technology thereof. According to the technical scheme, the automatic pressurizing line is characterized in that the automatic pressurizing line comprises an operation table and a temporary storage conveying line which penetrates through the operation table and is used for conveying elastomers, and two feeding mechanisms used for conveying pressing blocks and silica gel plates are arranged on one side of the operation table. A first index plate and a second index plate which are used for driving materials to rotate are arranged at the top of the operation table, an elastomerfeeding device used for clamping the elastomers is arranged between the temporary storage conveying line and the first index plate, and a plurality of six-axis robots used for transferring the materials are further arranged at the top of the operation table. The six-axis robot comprises a three-jaw clamping jaw used for clamping the pressing blocks and the silica gel plates and a suction cup. A finished product discharging device and a discharging temporary storage line are arranged at the position, on the second index plate, of the operation table. The effects of high production effect, excellent feeding speed, high positioning precision and efficient station rhythm are achieved.

Owner:ANHUI KELI ELECTRIC MFG

Bucket elevator with anti-blocking mechanism

PendingCN113955392APrecise bucket feedingReduce accumulation speedConveyorsCleaningMachineControl theory

The invention discloses a bucket elevator with an anti-blocking mechanism. The bucket elevator comprises a machine body, a falling material cleaning device is arranged at one end of the bottom of the machine body, a feeding hopper is fixedly connected to one end of the bottom of one side of the machine body, and a feeding anti-blocking device is arranged at one end of the bottom of the feeding hopper. The feeding anti-blocking device comprises a sub-hopper feeding mechanism and a powder scattering mechanism which are arranged at one end of the bottom of the feeding hopper. Through the arrangement of the anti-blocking device, not only can the anti-blocking device be matched with a hopper which intermittently reaches a material opening, the hopper can be accurately fed in a hopper separation mode, material scattering in the continuous feeding process is reduced, the material accumulation speed at the bottom of the machine body is reduced, the feeding efficiency of the elevator is improved, but also materials in the feeding hopper can be scattered at the same time, the discharging speed of the materials is guaranteed, and the phenomena that discharging is difficult and even a feeding port is blocked due to material caking are prevented.

Owner:ANHUI QIANGHUI MACHINERY MFG

Harmless treatment device for sludge

InactiveCN113105099AImprove the effect of harmless treatmentAvoid stickinessSludge treatment by de-watering/drying/thickeningBio-organic fraction processingSludgeProcess engineering

The invention relates to the technical field of sludge treatment, and discloses a sludge harmless treatment device, which comprises a bottom plate, wherein a supporting frame is fixedly connected to the bottom of the bottom plate, a feeding adjusting mechanism is arranged on one side of the bottom plate, a fixing plate is fixedly connected to one side of the upper surface of the bottom plate, two fixing frames are fixedly connected to the upper surface of the fixing plate, one side of each fixing frame is fixedly connected with a servo motor, a sludge treatment mechanism is rotatably connected between the two fixing frames, the sludge treatment mechanism comprises an outer cylinder and an inner cylinder, a sliding ring is integrally formed on one side of the inner cylinder, the sliding ring is movably connected with the inner wall of the outer cylinder, a top cover is clamped to the top of the outer cylinder, and a clamping shaft is fixedly connected to the upper surface of the top cover. According to the invention, discharging and cleaning are convenient, the discharging speed of solid sludge is guaranteed to a great extent, certain creativity is achieved, the sludge harmless treatment effect is improved, the dried and sterilized sludge can be subjected to smashing pretreatment, and the composting effect is improved.

Owner:李玲

Raymond mill crashing auto control method and equipment thereof

InactiveCN101229525BRealize automatic adjustmentGuaranteed feeding speedGrain treatmentsTotal factory controlAuto regulationAutomatic control

The invention discloses an automatic control method of Raymond mill grinding. Equipment can be automatically adjusted so as to ensure that the Raymond mill runs at an optimum load condition. The invention also discloses an automatic control method and an automatic control device for implementing the Raymond mill grinding. The device not only can real-time monitor the operation condition of feeding, grinding, airflow rough separation in a Raymond mill workshop, but also can automatically adjust feeding and grinding according to the main engine load. Furthermore, the invention also can automatically adjust a blower on the basis of technical requirements, which realizes the automation of the airflow rough separation and overcomes the shortcomings of manual operation operated by workers. Theinvention adopts a self-adaptive control method to adjust and control and employ a programmable logic controller as a control core. No manual operation is needed in the whole production process, thusrealizing the fully automatic adjustment of feeding, grinding and airflow rough separation, saving energy, greatly reducing equipment failure rate and increasing productive efficiency; through using asupervisory control computer witch can carry out a real-time monitor, the working parameter and index parameter of the PLC can be modified at any time so as to improve production efficiency.

Owner:SOUTHEAST UNIV

Platform continuous feeding control system

PendingCN114506695APlay a guiding roleEasy dischargeConveyorsCasting safety devicesControl systemControl engineering

The platform continuous feeding control system comprises a material screening box and a double-row conveying platform frame, the double-row conveying platform frame is fixedly installed on the outer wall of one side of the material screening box, an opening is formed in the outer wall of one side of the material screening box, and an induction opening and closing plate is arranged on the outer wall of the side, close to the double-row conveying platform frame, of the material screening box; the induction opening and closing plate is located at the opening end. A feeding monitor is arranged on the outer wall of one side of the screening box, the feeding monitor comprises a processor and a position collecting module, the processor is connected with the position collecting module, the processor comprises a discharging driving motor and a hopper monitor and is located at the two ends of an induction opening and closing plate of the discharging driving motor, and the hopper monitor is fixedly installed in the screening box. According to the platform continuous feeding control system, the feeding monitor is arranged on the material screening box, and when materials in the material screening box are lower than the preset distance of the opening gathering groove, the mobile terminal connected with the PC terminal is automatically started, so that the mobile terminal is prompted.

Owner:JIANGSU FEIJINDA TECH

A flipping material conveying device

ActiveCN113460638BRealize interval deliveryRoll over stabilityConveyor partsEngineeringMaterial distribution

Owner:SHANDONG VOCATIONAL COLLEGE OF SCI & TECH

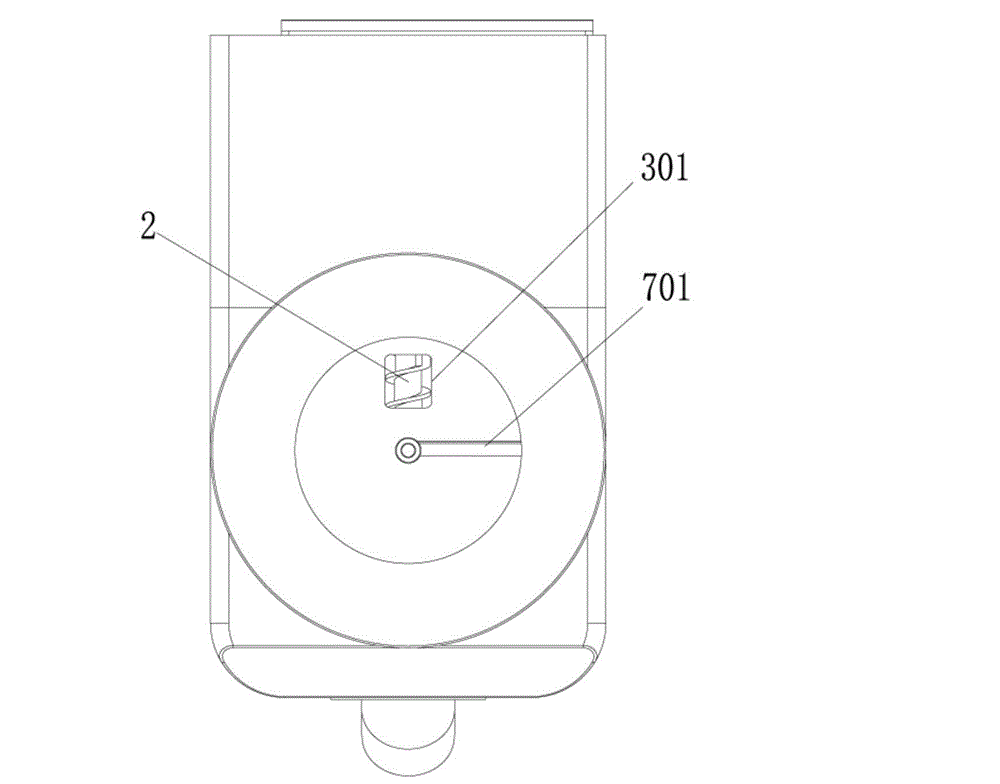

Powder trace sample adding device

ActiveCN113998484APrevent outflowGuaranteed feeding speedWeighing apparatus for materials with special property/formLoading/unloadingCircular discMotor vibration

The invention discloses a powder trace sample adding device, and relates to the technical field of material conveying. The device comprises a supporting structure, a vibration structure and a double-screw conveying structure, the supporting structure is provided with rollers, the vibration structure comprises a motor arranged on a vibration plate, a vibration shaft, a vibration disc and the vibration plate which is movably arranged on the supporting structure, the vibration plate is rotatably connected with the vibration shaft, a plurality of grooves are uniformly distributed in the periphery of the vibration disc, and the rollers are matched with the grooves; the double-screw conveying structure comprises a stock bin arranged on the vibration plate and two screw rods in transmission connection with the motor, the two screw rods are both located in the stock bin and are both arranged in the direction from the feeding port to the discharging port, the peripheries of the two screw rods are both provided with screw blades, each of the two screw blade comprises a plurality of connected screw parts, and the screw part of one screw blade extends into the space between the two adjacent screw parts of the other screw blade. Through the arrangement, the feeding speed and the feeding precision are guaranteed at the same time, and the cost is low.

Owner:北京华胜信安电子科技发展有限公司

A wood powder conveying hopper and feeding system for wood-plastic composite board production

The invention discloses wood plastic composite sheet material production equipment, and especially refers to a wood powder conveying hopper in wood plastic composite sheet material production; the wood powder conveying hopper comprises a hopper body; the bottom of the hopper body is provided with a feed opening having a switch valve; a sealing air path is arranged around a side wall of the hopper body; an air inlet position of the sealing air path is connected with an air source; the side wall of the hopper body is tightly provided with air through holes penetrating an inner surface and an outer surface; the air through holes are arranged facing the feed opening of the bottom of the hopper body in an oblique manner; the hopper of invention solves the plugging technical problem of wood powder conveying hopper in wood plastic composite sheet material production, thereby reducing plugging condition in the usage of the hopper; simultaneously the air generated by the air source uniformly enters the hopper body around the hopper body, thereby effectively ensuring blanking speed of wood powder batch mixture in the hopper.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Quick fertilizer applicator with quantitative control function

PendingCN111512757AIncrease contact areaIt is convenient to control fertilization and feedingFertiliser distributersFertilizerAgricultural engineering

The invention relates to a fertilizer applicator, in particular to a quick fertilizer applicator with a quantitative control function. The technical problem to be solved by the invention is to providethe quick fertilizer applicator which can apply fertilizer by manually operating equipment without bending down and can control the fertilizer application amount, so that the fertilizer can be conveniently saved, and the operation is simple and easy. The quick fertilizer applicator with the quantitative control function comprises a long charging barrel, a grab handle and a discharging device, wherein the grab handle is arranged on the upper portion of the long charging barrel; the discharging device is arranged in the long charging barrel. People control the fertilizer application amount by adjusting the position of an L-shaped strip, push a pull handle to move rightwards to drive an arc-shaped plate and a square strip to move rightwards, and when the square strip moves rightwards to makecontact with the L-shaped strip, the arc-shaped plate and a rack are prevented from moving rightwards, so that the rotation degree of a driving gear can be controlled, and the situation that people exert too much force to enable a second baffle to rotate and an opening of a short charging barrel is too large, and consequently the fertilizer consumption is too high is avoided.

Owner:刘强

Resource utilization device for arsenic-containing waste

The arsenic-containing waste resource utilization device comprises an outer shell, a mounting frame and an arsenic removal treatment device are fixedly mounted in the outer shell, a quantitative feeding mechanism is arranged at the top of the outer shell, a discharging opening in the lower end of the quantitative feeding mechanism is rotationally connected to a selective feeding structure, and the mounting frame comprises an annular frame; a plurality of hot phase separation devices are evenly arranged on the outer side of the annular frame in the circumferential direction, each hot phase separation device is provided with a feeding port, the feeding ports are in separable butt joint with a feeding port of the selective feeding structure, and a plurality of mixing and stirring devices in one-to-one correspondence with the hot phase separation devices are arranged on the outer side of the arsenic removal treatment device; and the bottom of the mixing and stirring device is communicated with the inner cavity of the arsenic removal treatment device through a channel provided with an electric control valve. According to the invention, the cured material can be continuously supplied and subjected to a series of process steps of thermal phase separation, additive mixing and arsenic removal treatment, and a fault device can be skipped for continuous treatment, so that the influence of faults on the treatment efficiency is reduced.

Owner:内蒙古新创环境科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com