Vibration feeding device

A technology of vibrating feeding and vibrating material, applied in the direction of vibrating conveyor, packaging, conveyor, etc., can solve the problems of easy blockage of materials, intermittent feeding, feeding interruption, etc., to avoid material blocking, stable and uniform feeding, Guaranteed effect of feeding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

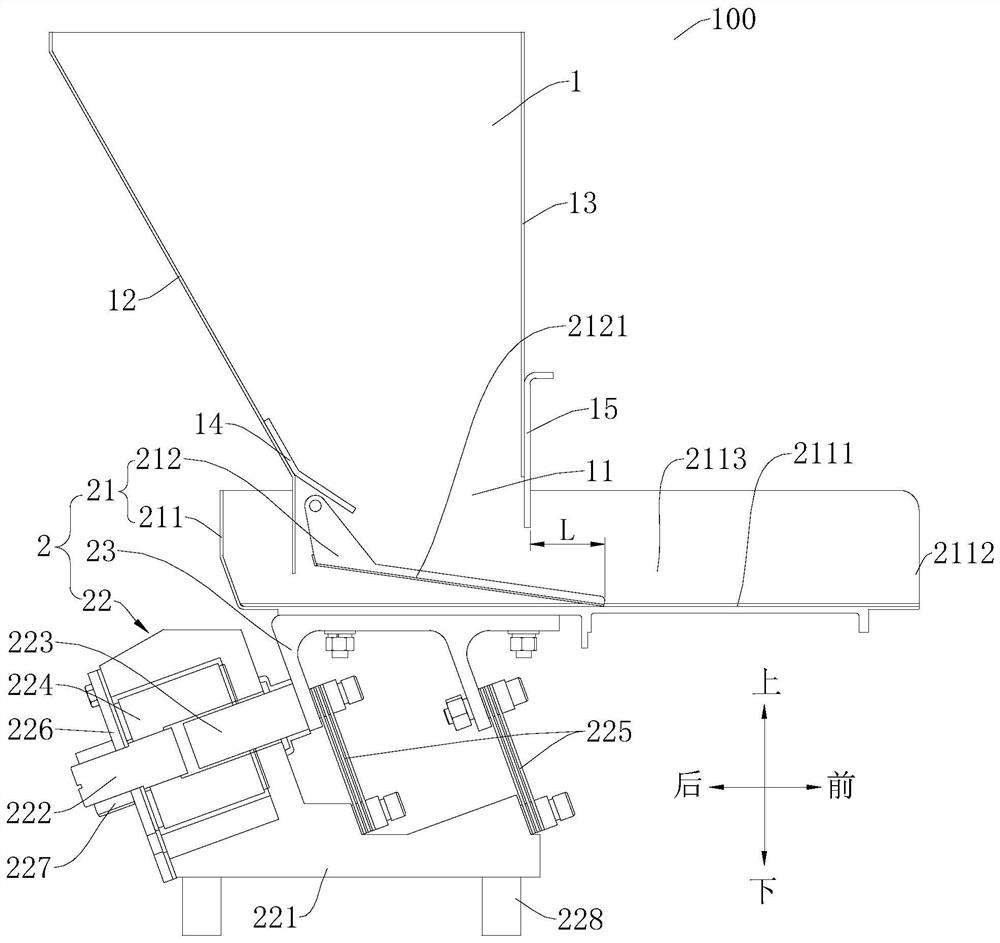

[0097] Such as Figure 1-Figure 3 As shown, the vibration feeding device 100 of the present embodiment consists of a base 221, a lock nut 227, a drive shaft 222, a rear cover plate 226, a coil 224, an armature (magnetic part 223), a primary hopper body 211, and a primary hopper seat 23. An elastic sheet (elastic reset part 225), an elastic foot 228, a feed bin 1, a primary baffle plate 15, a primary slide plate 212 and a material guide plate 14 are formed.

[0098] Wherein, the rear cover 226 is connected to the base 221 by bolts. The drive shaft 222 is threadedly engaged with the rear cover 226 , and the locking nut 227 is used to lock the relative position between the drive shaft 222 and the rear cover 226 . The drive shaft 222 axis is collinear with the armature axis. The armature is fixedly connected to the primary hopper seat 23 by bolts, the primary hopper body 211 is connected to the primary hopper seat 23, the upper and lower ends of the elastic sheet are fixedly con...

Embodiment 2

[0105] Such as Figure 4 As shown, the structure of this embodiment is roughly the same as that of Embodiment 1, wherein the same components use the same reference numerals, the only difference is that: the vibration feeding device 100 described in Embodiment 1 only includes a primary vibration material assembly, However, the vibrating feeding device 100 in the second embodiment includes two levels of vibrating material components: a primary vibrating material component 2 and a secondary vibrating material component 3 .

[0106] Specifically, such as Figure 4 As shown, the vibration feeding device 100 of the embodiment of the present invention includes: a primary vibrator 22, a primary hopper body 211, a primary slide plate 212, a material guide plate 14, a feed bin 1, a primary baffle plate 15, and a slide plate support 33 , secondary slide plate 312, secondary vibrator 32, secondary hopper body 311, baffle support 34, secondary baffle 35 and material level sensor 36.

[0...

Embodiment 3

[0113] Such as Figure 5-Figure 7 As shown, the structure of this embodiment is substantially the same as that of Embodiment 1, wherein the same components use the same reference numerals, and the only difference is that the lower end of the first-stage slide plate 212 in Embodiment 1 rests on the first-stage vibrating material On the bottom wall of the cavity 2113, the lower end of the primary slide plate 212 is roughly in line contact or surface contact with the bottom wall of the primary vibrating material cavity 2113, while the lower end of the primary slide plate 212 in the third embodiment rests on the primary vibrating material cavity. On the side wall of the material cavity 2113 , there is a point contact between the primary slide plate 212 and the side wall of the primary hopper body 211 .

[0114] Specifically, such as Figure 5 As shown, the vibration feeding device 100 of the embodiment of the present invention includes: a primary vibrator 22, a primary hopper bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com