Patents

Literature

40results about How to "Uniform and stable delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

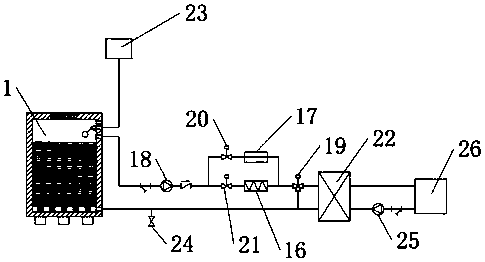

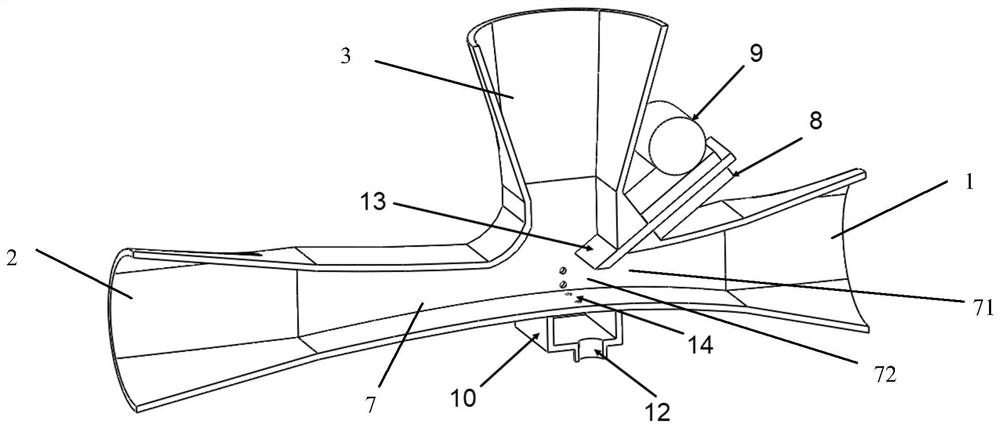

Recyclable particle jet descaling device

ActiveCN108772784AEfficient recyclingImprove rust removal efficiencyAbrasive machine appurtenancesGas solidEngineering

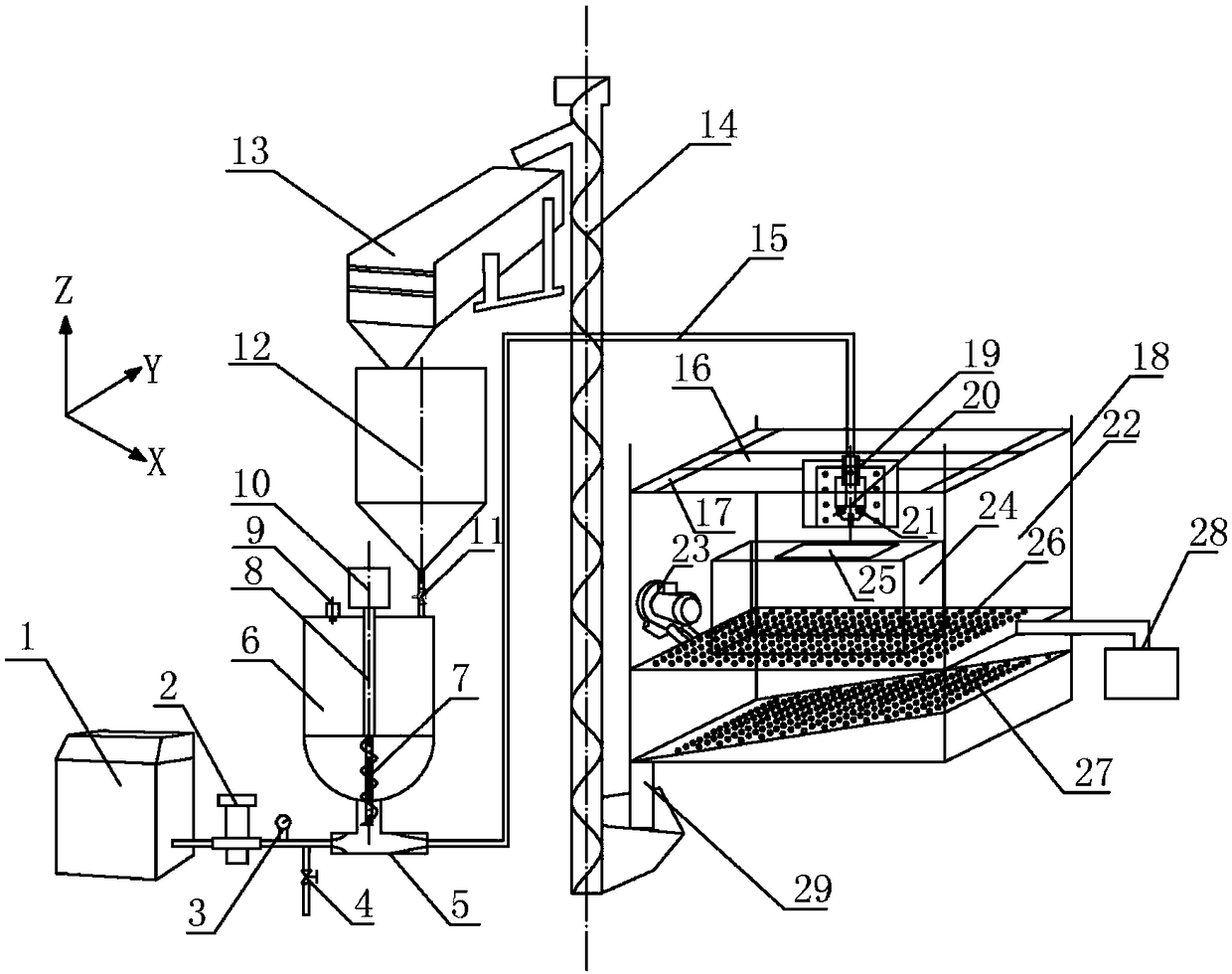

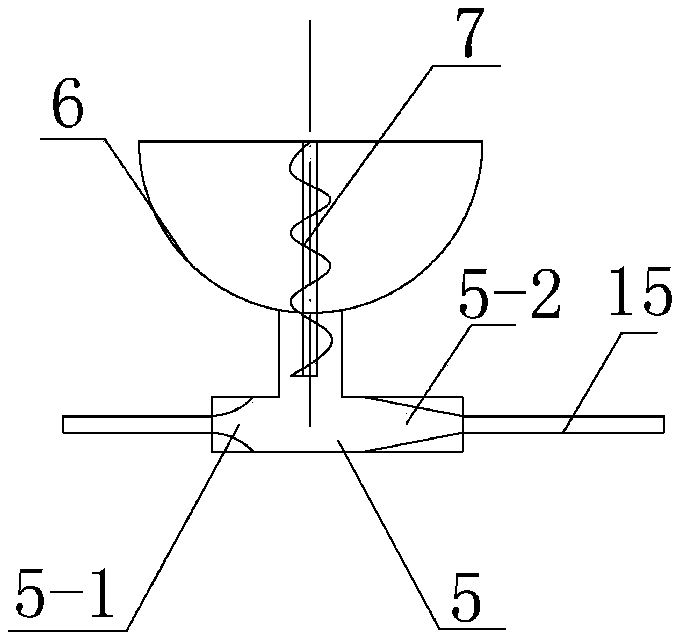

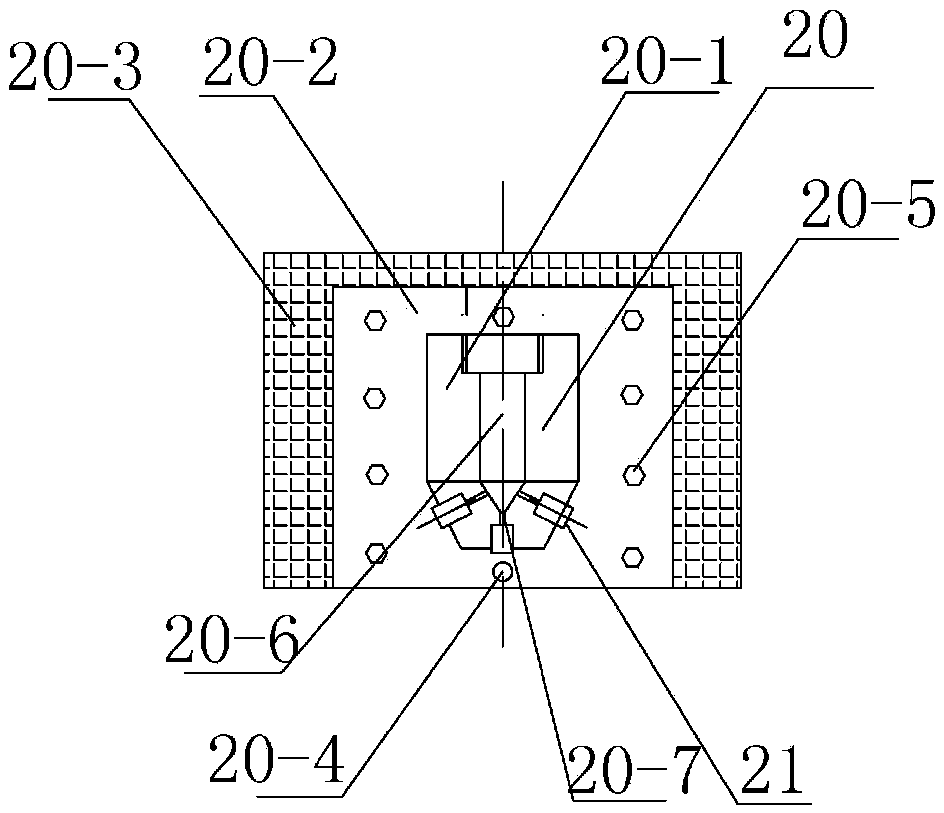

The invention belongs to the field of rust surface treatment, in particular relates to a recyclable particle jet descaling device comprising an air compressor, a pressure dividing valve, a mixing chamber, a high pressure particle tank, a screw, a 3D particle amount detector, a speed regulating motor, a particle storage tank, a double-layer vibrating screen, a vertical screw conveyor, an X-direction rail, a Y-direction rail, a Z-direction rail, a nozzle assembly, a nozzle, a dust cover, a blower, a horizontal filter pore plate, an inclined filter pore plate, a dust removal cloth bag, and the like. The recyclable particle jet descaling device can realize rapid particle addition, real-time particle amount monitoring, uniform, stable and controllable gas-solid mixing, injection position three-dimensional movement and angle adjustment, multi-stage particle separation and recycling, effective dust recovery, significant improvement of part surface rust removal efficiency, and enhancing of part surface strength.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

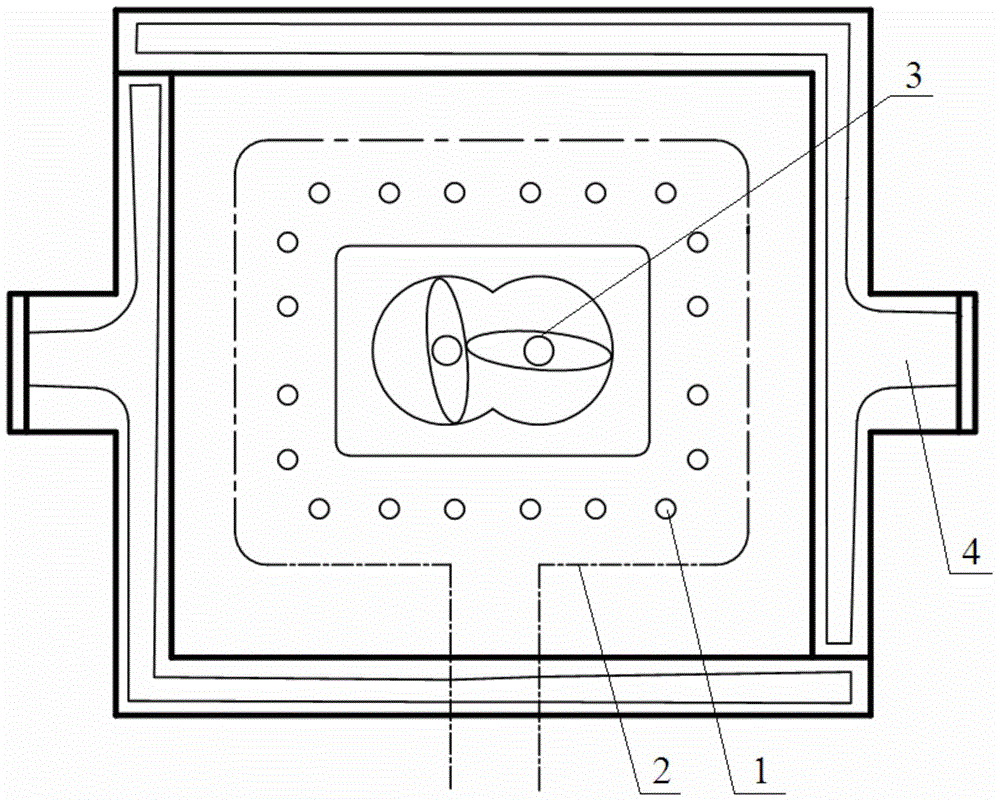

Fixed fluidized bed powder metering and distributing delivery device and methed of realizing high stability transferring and distributing powder

The present invention discloses a fixed fluidized bed powder body metering, distributing and conveying equipment and method for implementing high-stable conveyance and distribution of powder body. Said invention includes the following several components: fluidizing tank, powder body feeding pipe, gas feeding pipe, powder body level indicator, fluidized gas distributor, mechanical stirring paddle and power-conveying pipeline, etc. Besides, said invention also provides its extensive application fields.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI +1

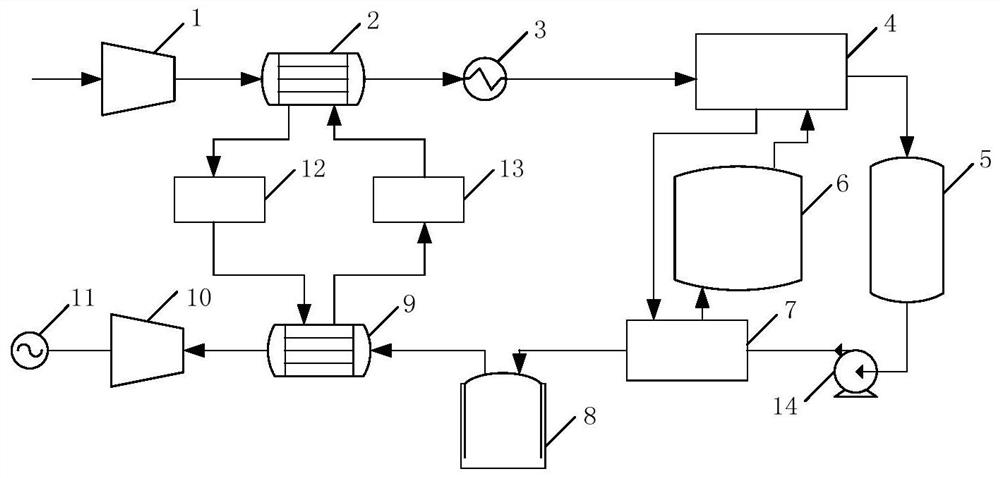

Liquefied air energy storage system

ActiveCN111648833AShort response timeImprove FM capabilityHeat storage plantsEnergy storageLiquid stateProcess engineering

The invention discloses a liquefied air energy storage system. The liquefied air energy storage system comprises an energy storage unit, a liquidation unit, a liquid storage unit storing a liquid-state working medium, a gasification unit and an energy release unit, wherein the energy storage unit comprises a compression device, a first heat exchanger and a cooler which are sequentially connected;the energy release unit comprises an expansion unit and a second heat exchanger which are sequentially connected; the liquidation unit comprises a liquidation device with an inlet end which communicates with an outlet end of the cooler; the gasification unit comprises an evaporation device with an outlet end which communicates with an inlet end of the second heat exchanger; the liquid storage unitcomprises a liquid storage device connected between the liquidation unit and the evaporation device; a gas buffer device is further communicated between the evaporation device and the second heat exchanger; and a gas-state working medium generated in the evaporation device is temporarily stored in the gas buffer device and then enters the second heat exchanger. The gas buffer device is arranged between the evaporation device and the second heat exchanger, so that a response time in a process of adjusting output frequency of the liquefied air energy storage system can be shortened, and the frequency adjustment performance of the liquefied air energy storage system is improved.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

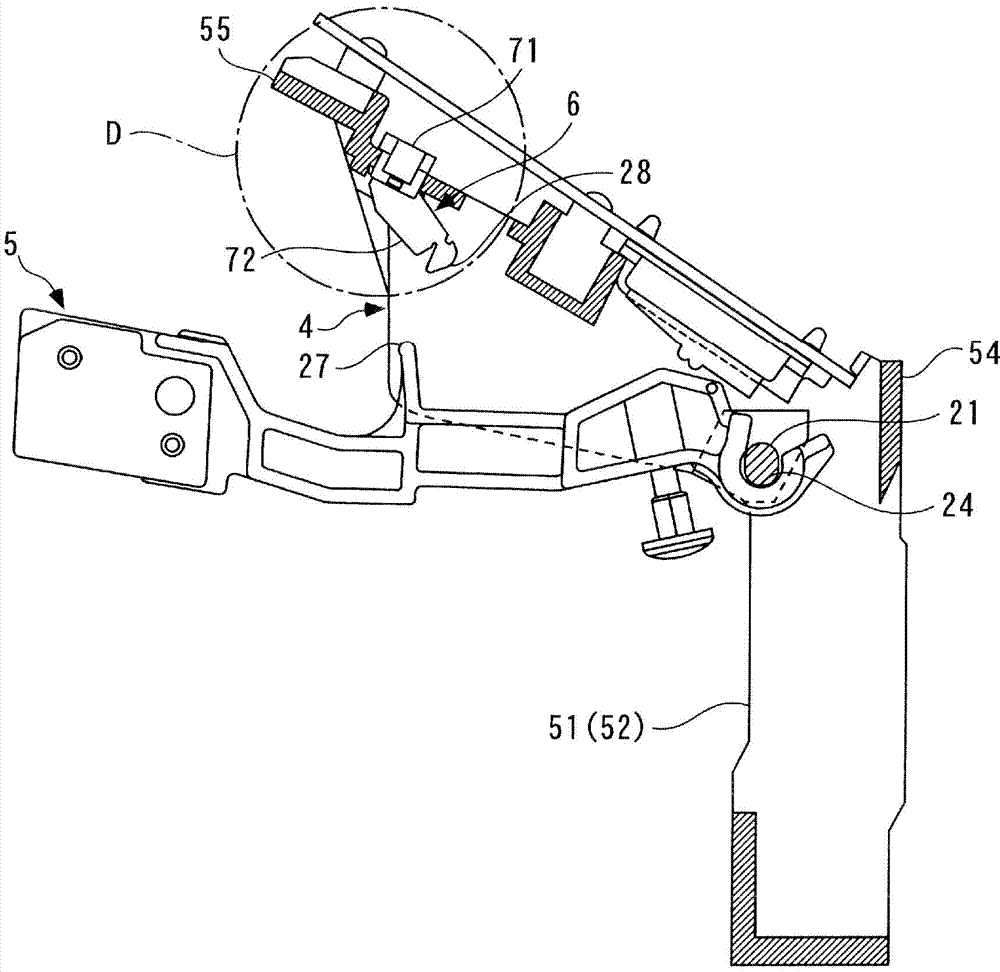

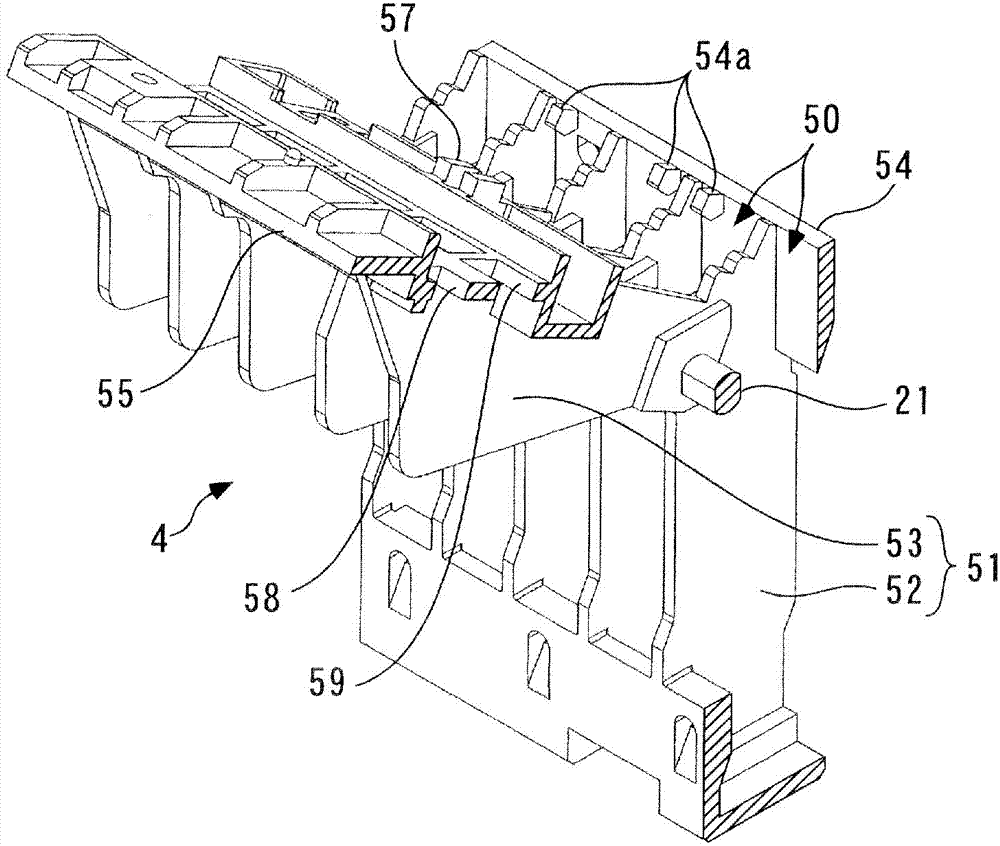

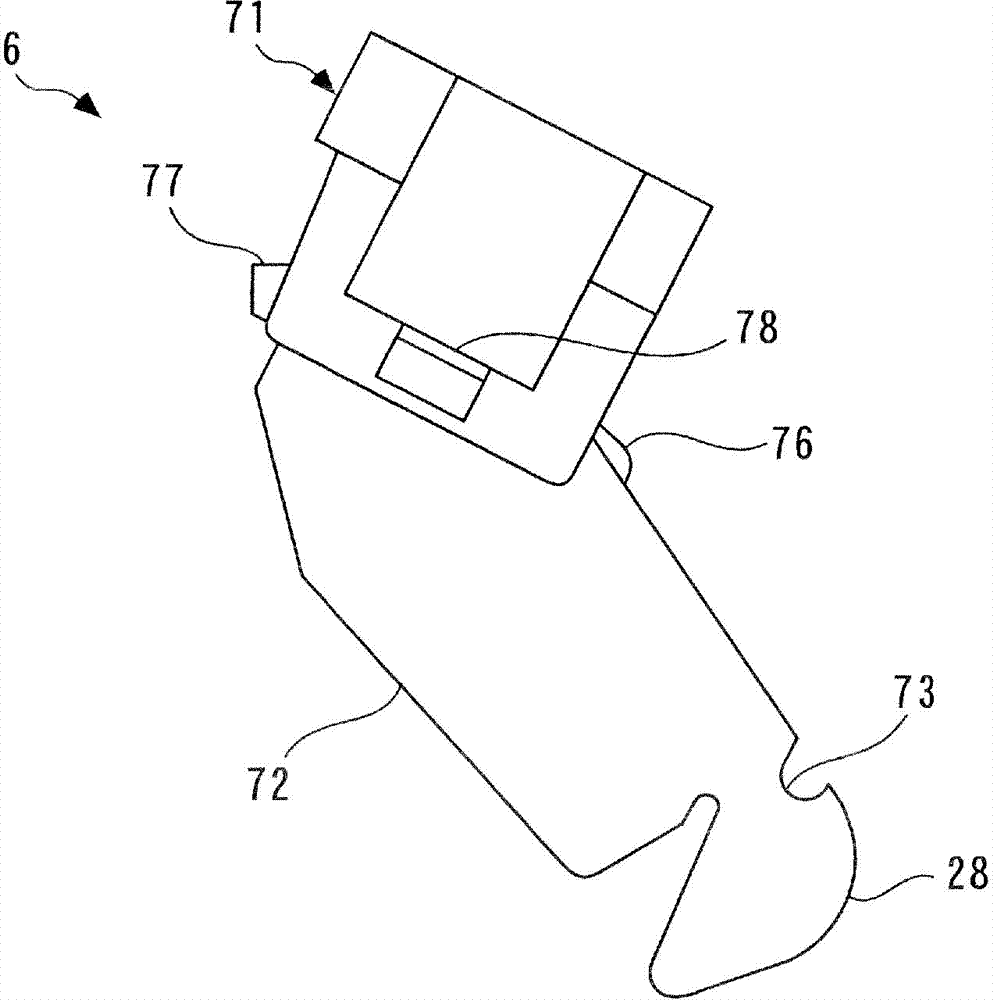

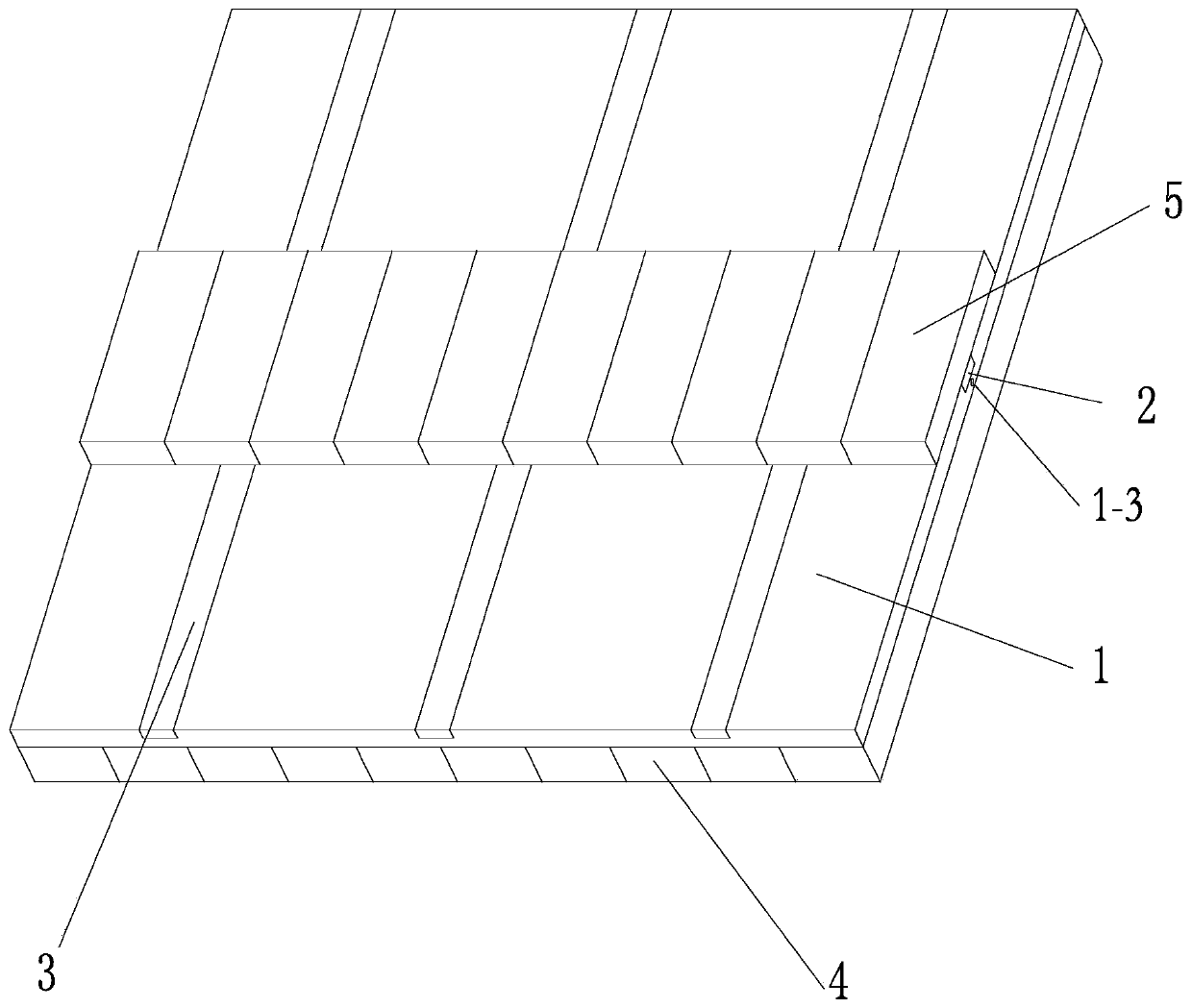

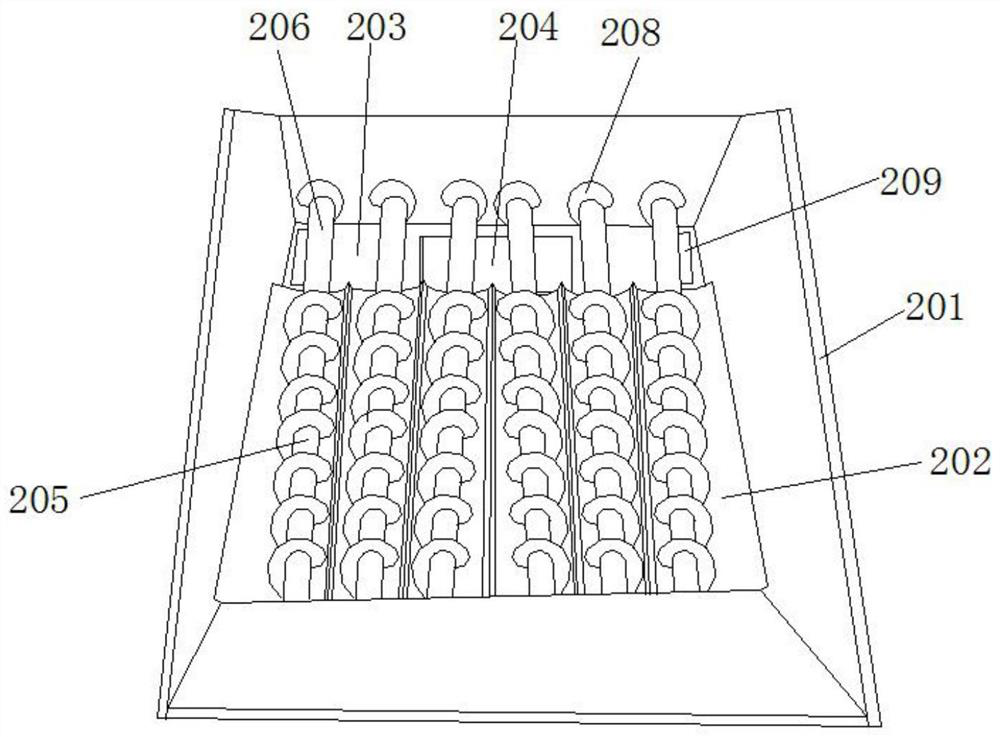

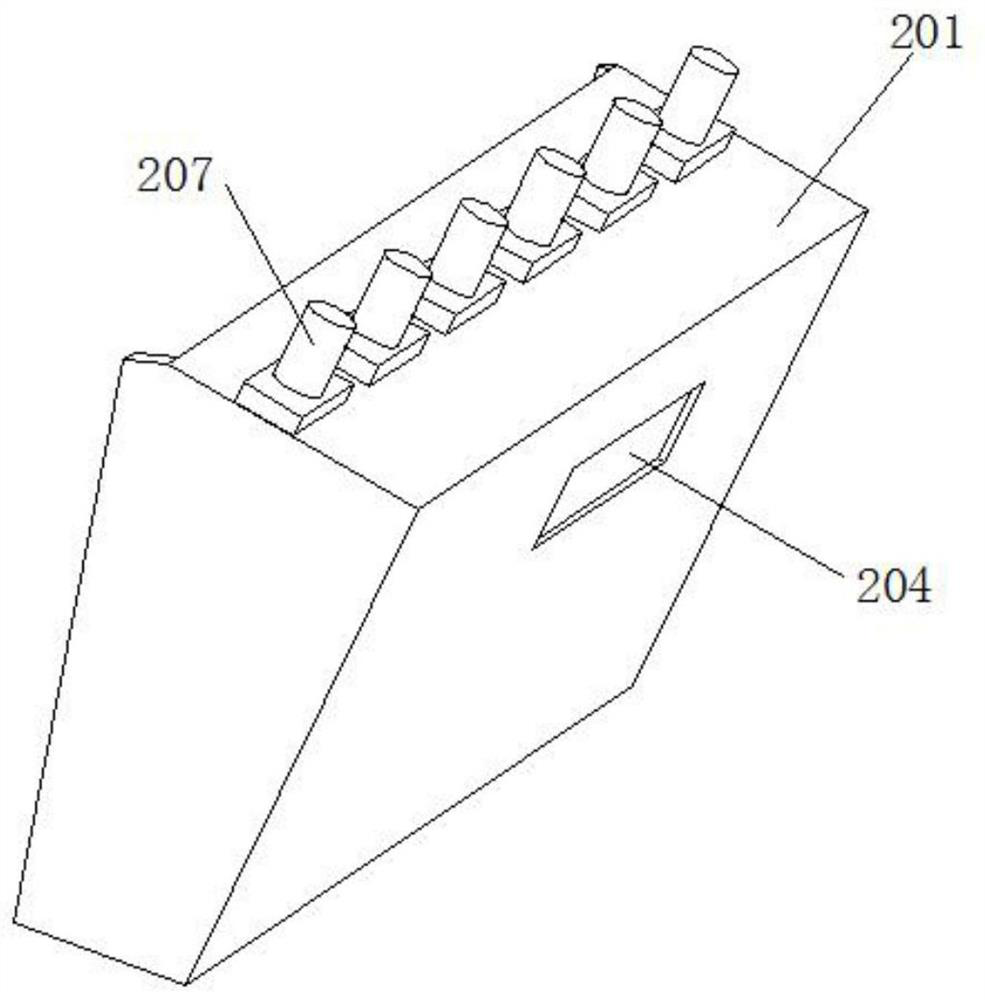

Keyboard device for electronic keyboard instrument and mounting structure of let-off imparting member for electronic keyboard instrument

ActiveCN103035224ACompact Depth DimensionsEasy to installElectrophonic musical instrumentsWind musical instrumentsPianoSynthetic resin

A keyboard device for an electronic keyboard instrument, which enables facilitation of work for mounting and dismounting a key switch and install hammers and the key switch with high accuracy, and provision of a touch feeling similar to one provided by an acoustic grand piano while keeping the device compact in depth. The device comprises swingable keys, a hammer support formed by a synthetic resin molded article, hammers pivotally supported by the hammer support, and a key switch including switch bodies provided in association with the hammers and a switch board. The hammer support has a switch mounting part formed with an opening vertically extending therethrough. The key switch is removably mounted to the switch mounting part, with the switch bodies facing the hammers from above via the opening and the switch board placed on the upper surface of the switch mounting part.

Owner:KAWAI MUSICAL INSTR MFG CO

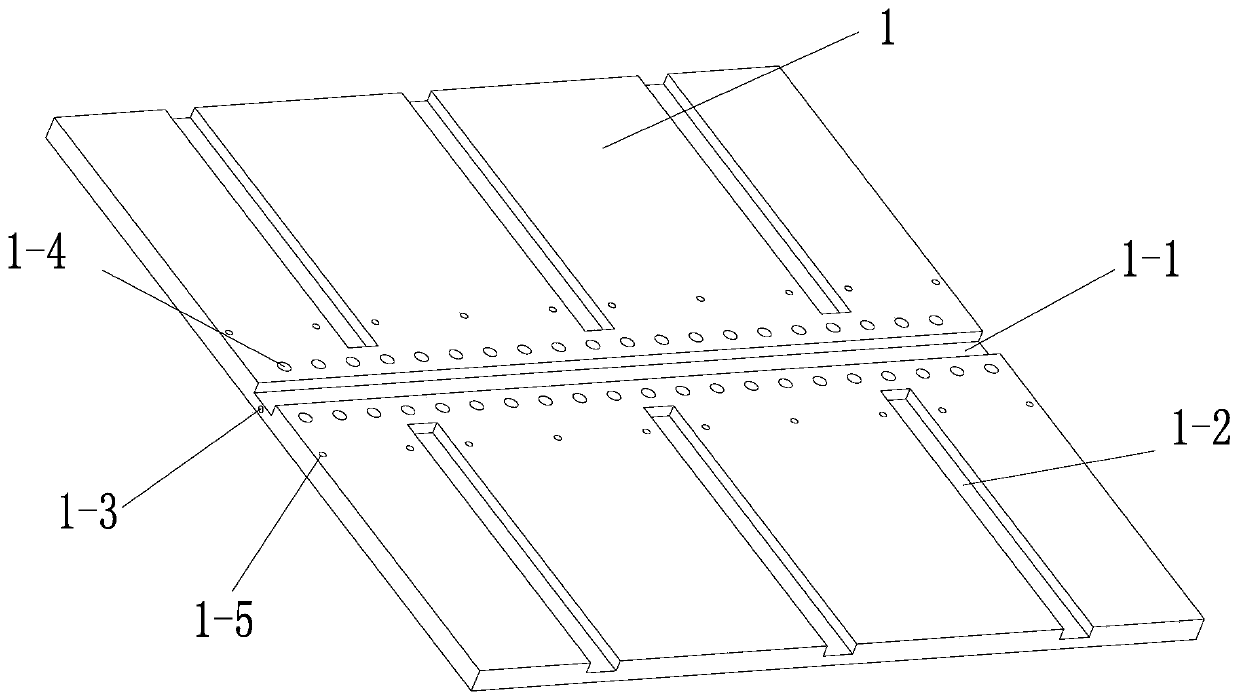

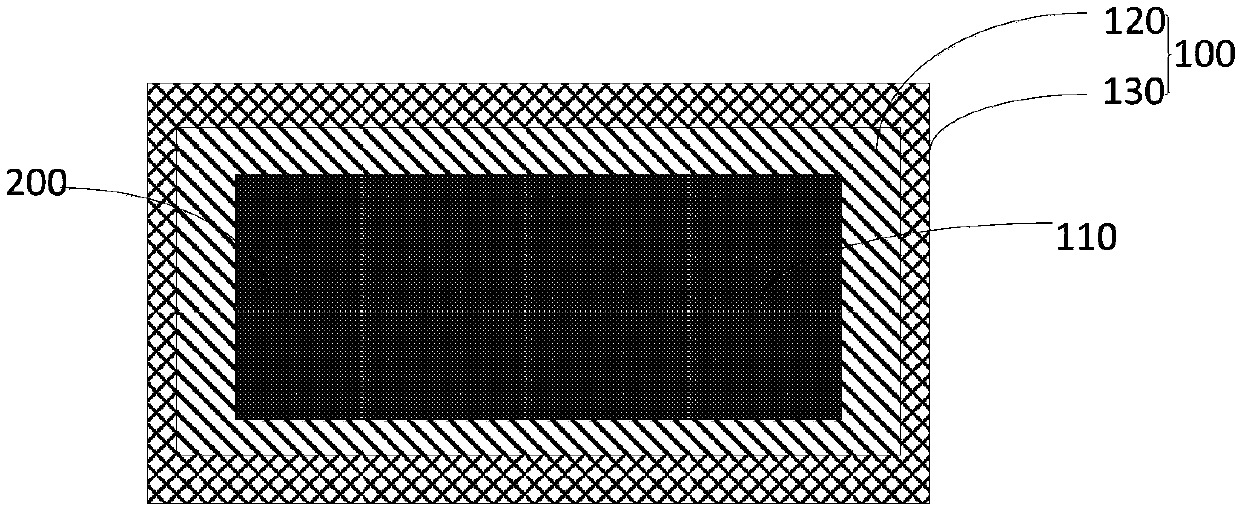

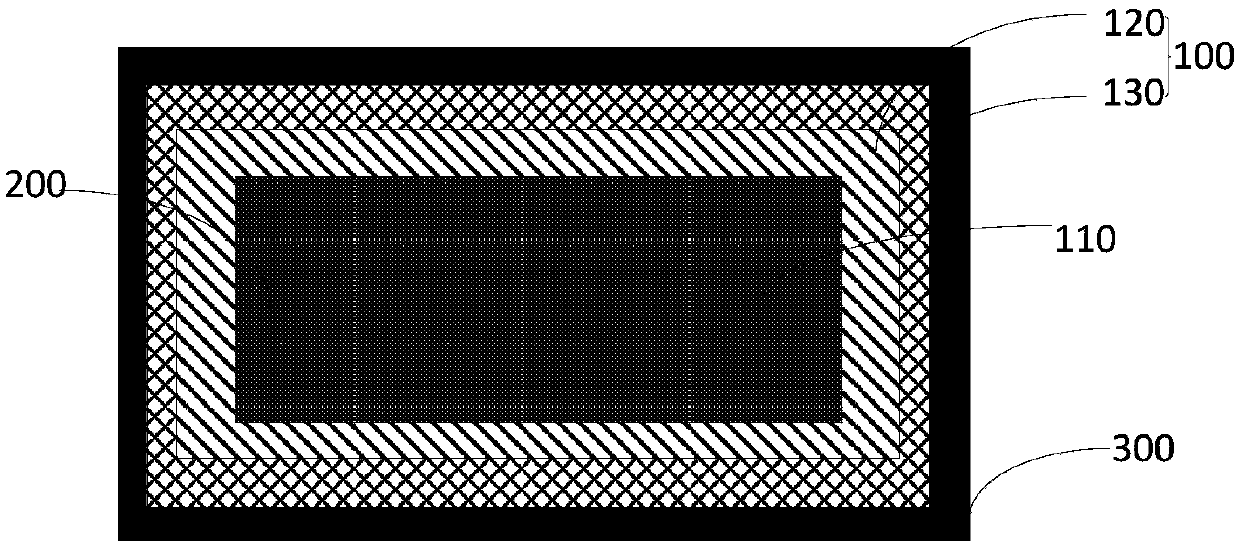

Lightweight thermal control support structure of space-borne antenna and space-borne antenna

InactiveCN110416692AStable supportImprove cooling effectAntenna supports/mountingsDe-icing/drying-out arrangementsPhase changePhase-change material

The invention relates to a lightweight thermal control support structure of a space-borne antenna and the space-borne antenna. The support structure comprises a bearing heat dissipation plate with twosides which are used for being connected with an antenna unit and a TR module. The bearing heat dissipation plate has a hollow structure with a lattice structure inside. The hollow structure is divided into a phase change material filling lattice region and an outer lattice region. The phase change material filling lattice region is corresponding to the TR module. The phase change device and theantenna array panel are integrated into one body and arranged as the bearing heat dissipation plate so that the phase change heat dissipation can be realized while realizing the weight reduction design, the structure is compact and good support and heat dissipation effect for the antenna unit and the TR module can be realized.

Owner:BEIJING INST OF RADIO MEASUREMENT

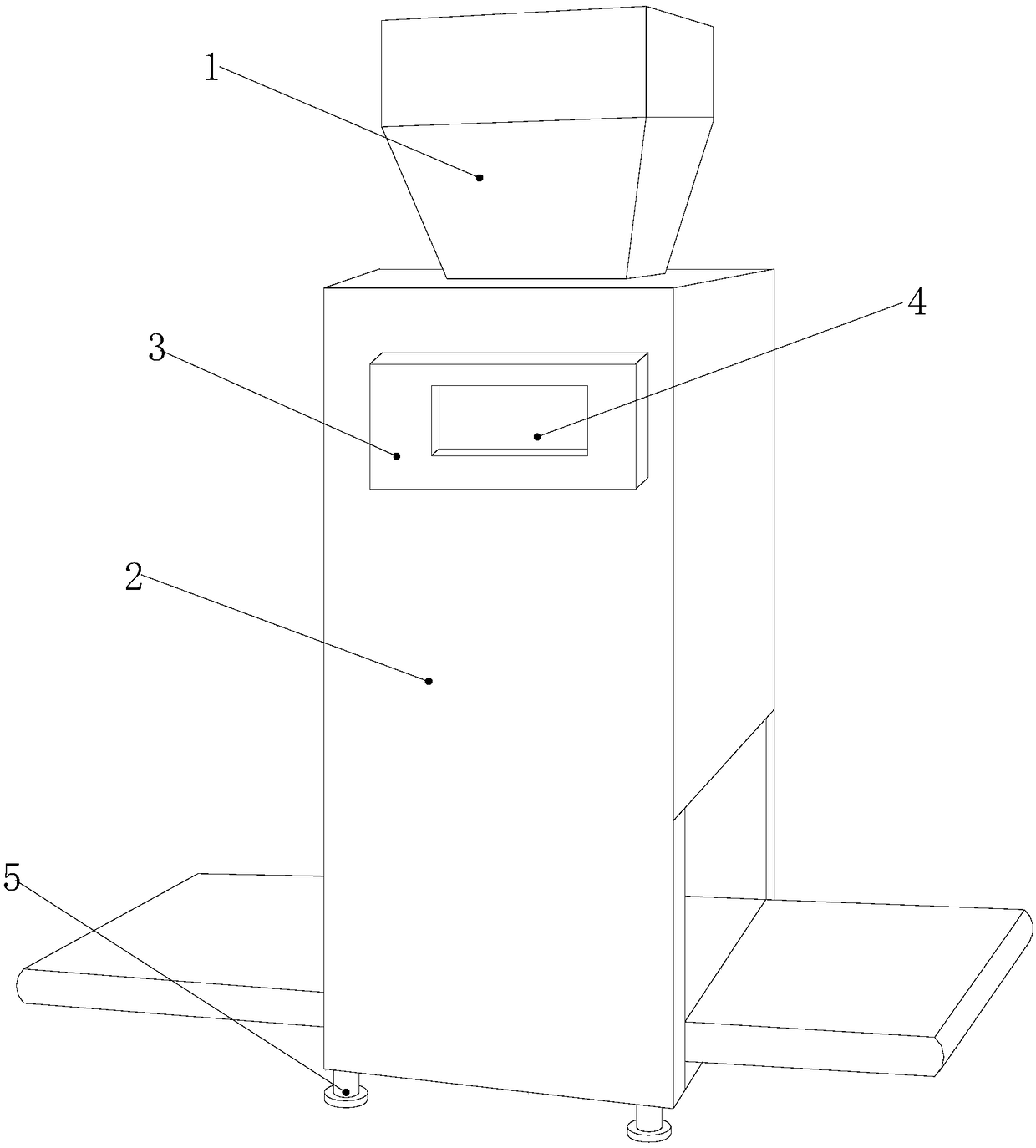

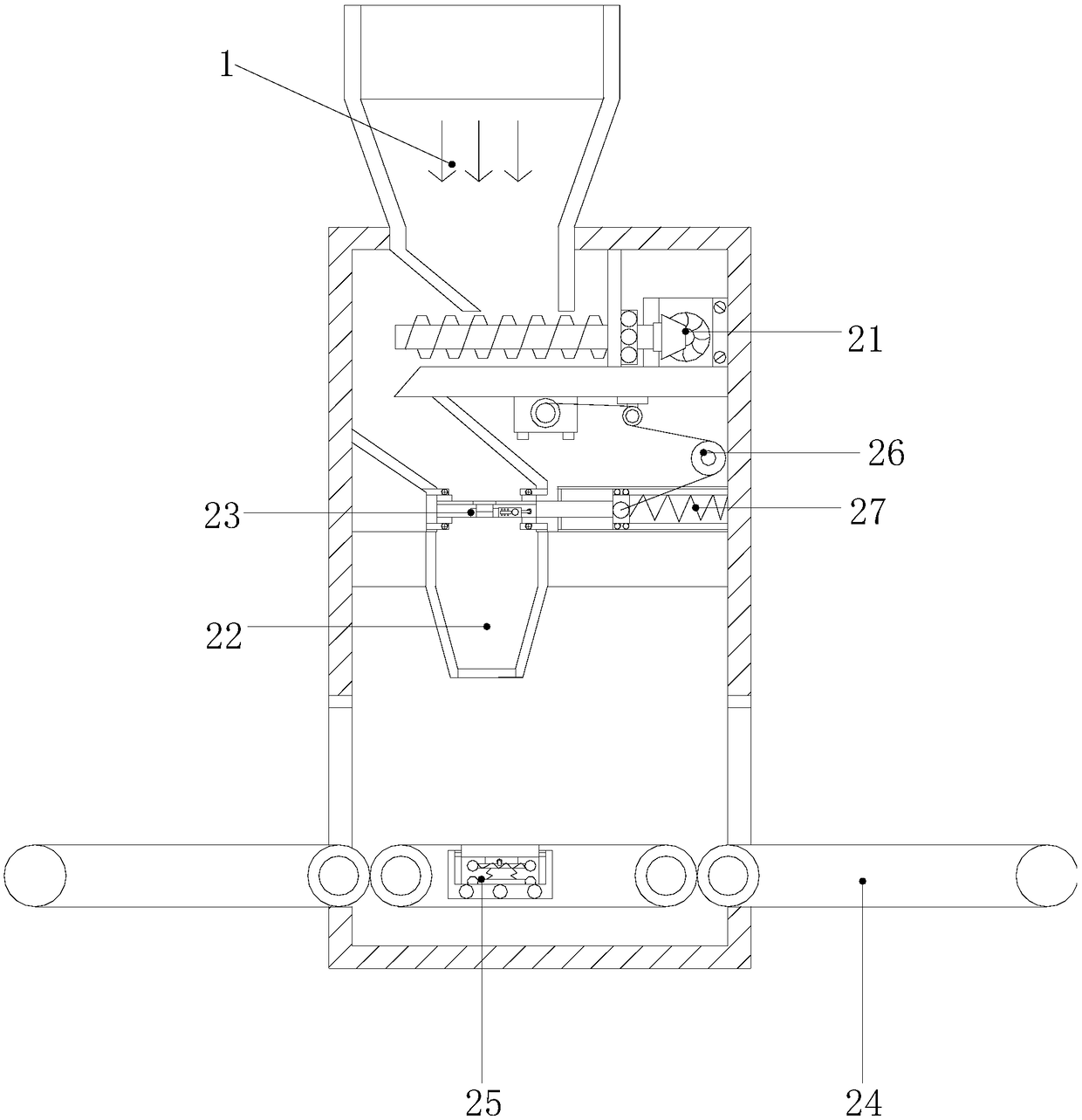

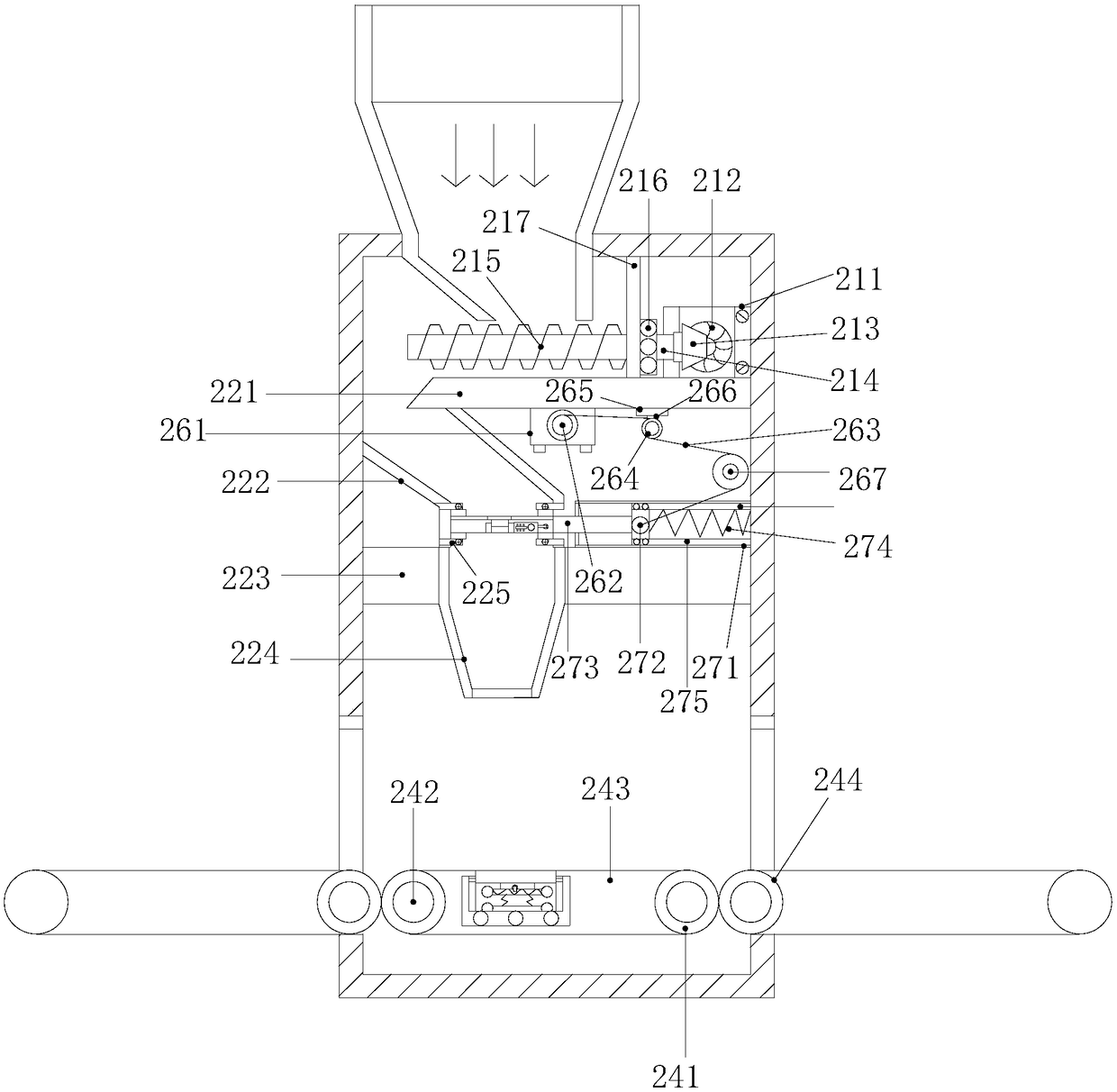

Automatic sub-packaging device for food packaging

The invention discloses an automatic sub-packaging device for food packaging. The automatic sub-packaging device structurally comprises a food feeding hole, a uniform anti-blocking automatic sub-packaging device, a control panel, a digital display and device support feet, wherein the bottom part of the food feeding hole is connected with the top part of the uniform anti-blocking automatic sub-packaging device; the rear end of the control panel is attached to the front end of the uniform anti-blocking automatic sub-packaging device; and the digital display is mounted on the surface of the control panel in an embedding manner. According to the sub-packaging device for food packaging, when packaging boxes are conveyed to a designated position, a power supply switch arranged under a conveyor belt can be automatically triggered to automatically open a discharging hole, so that food reaching the fixed quantity numerical values is discharged and is sub-packaged, the phenomenon that a person needs to wait aside the machine and turn on the switch for discharging is avoided, the automatic sub-packaging device for food packaging can uniformly convey the food above by rotating an accurate conveying rod, and blocking of the larger and sticky food in the automatic sub-packaging device is prevented.

Owner:沈峥

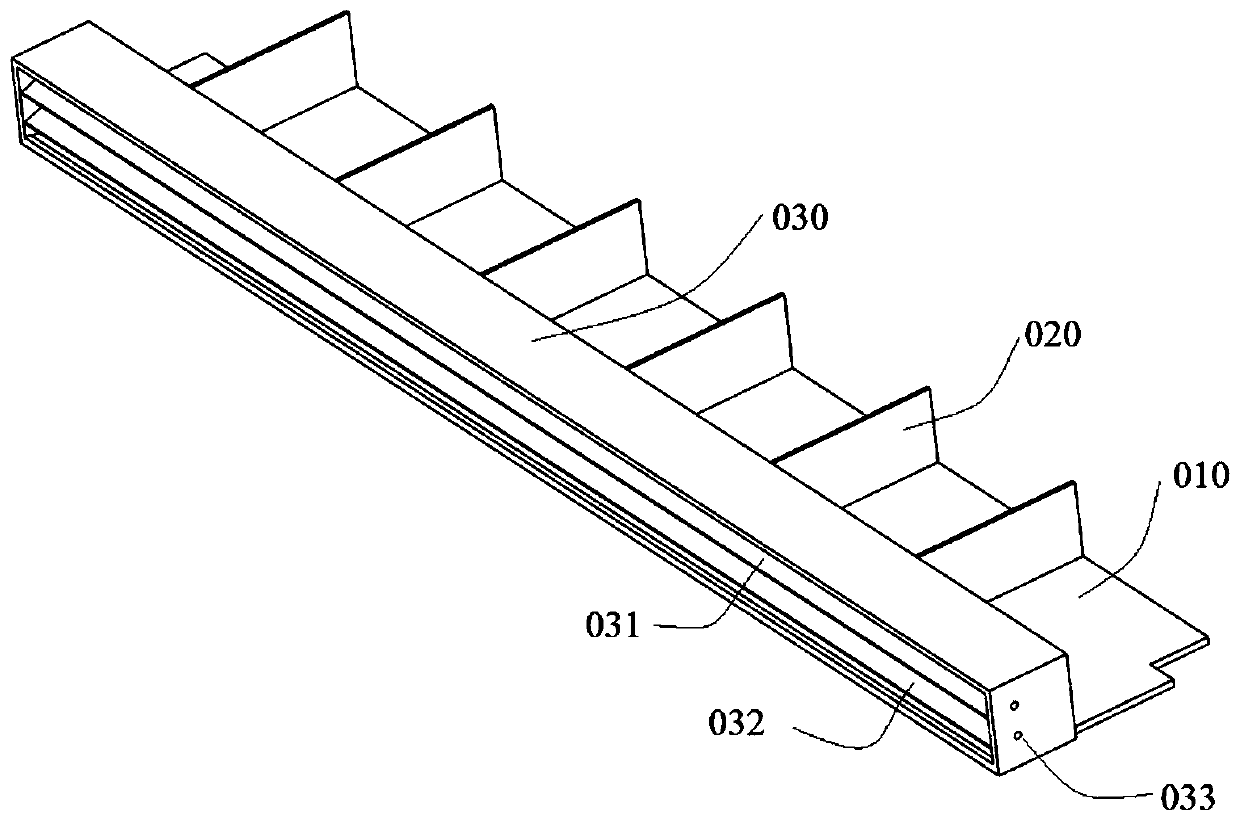

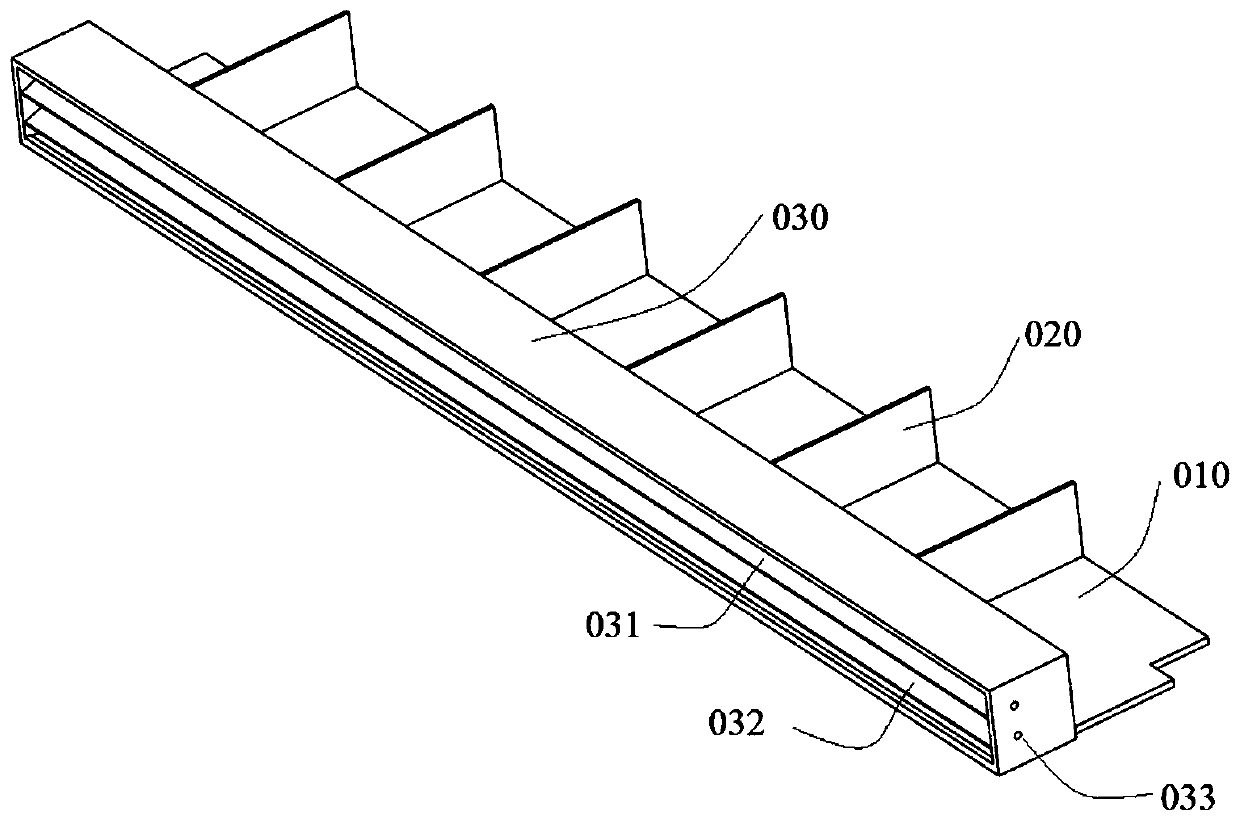

Laminar flow type adjustable air guide device

InactiveCN110014152AReduce reflectionReduce scatterAdditive manufacturing apparatusIncreasing energy efficiencyLaser processingEngineering

The invention relates to a laminar flow type adjustable air guide device. The device comprises an air guide device bottom plate, lengthened type flow diverting plates, an air guide device shell, an adjustable upper flow guide plate, an adjustable lower flow guide plate and flow guide plate fixing bolts, the air guide device bottom plate is arranged at the front end of the bottom of the air guide device shell, the lengthened type flow diverting plates are uniformly distributed on the air guide device bottom plate, and the adjustable upper flow guide plate and the adjustable lower flow guide plate are connected in the air guide device shell through the flow guide plate fixing bolts. According to the device, the production problem of gas turbulence generated in existing 3D printing productioncan be solved, the possibility that pollutants enter a powder bed is reduced, fine particles are prevented from being dispersed in a forming cavity, and the laser processing efficiency is improved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

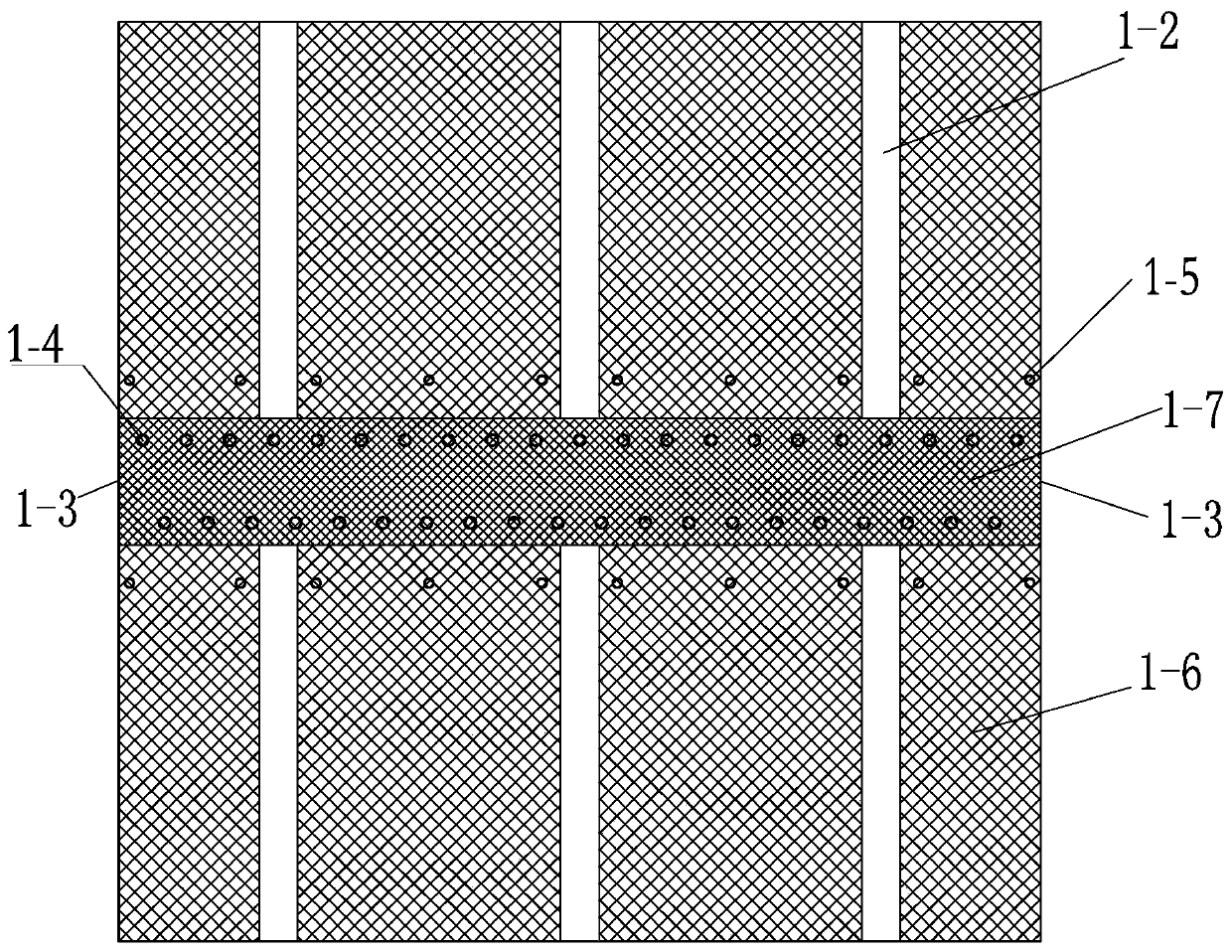

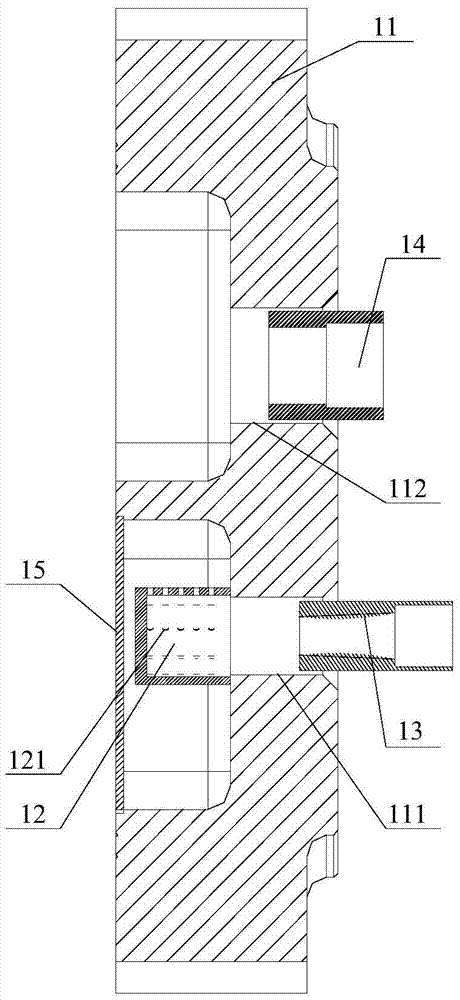

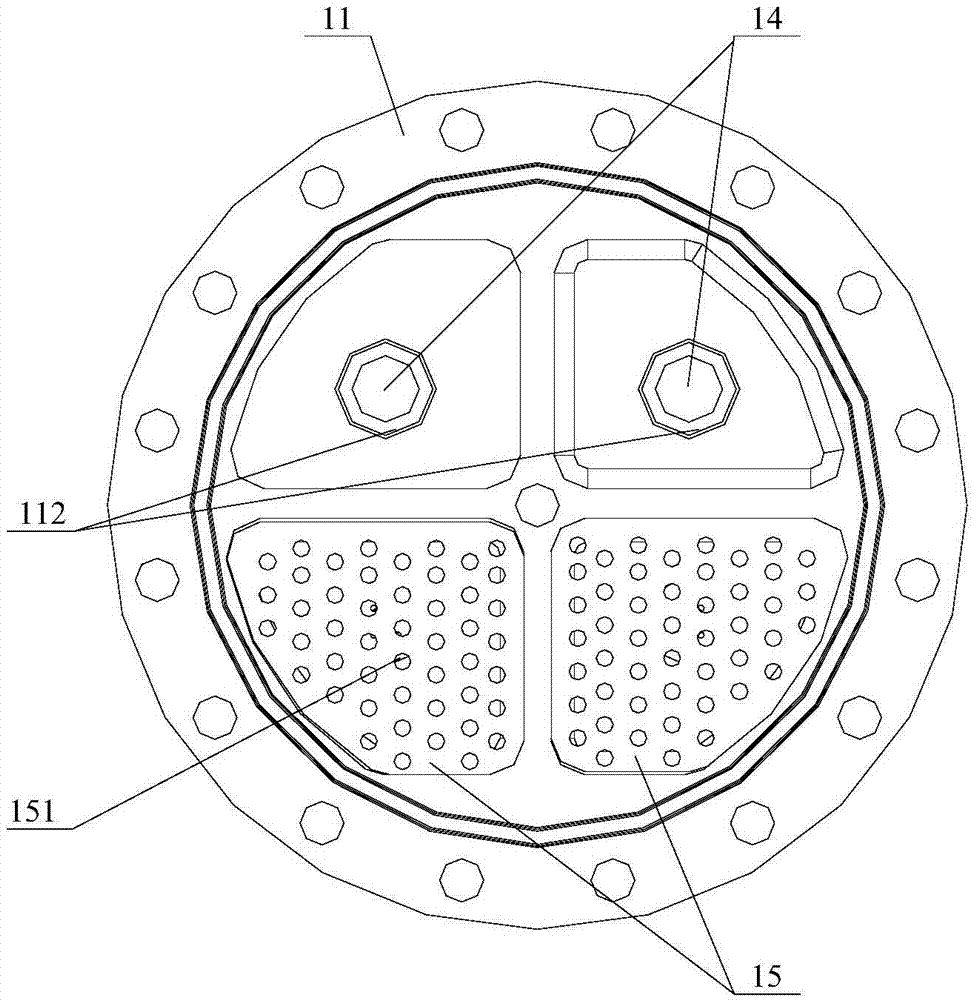

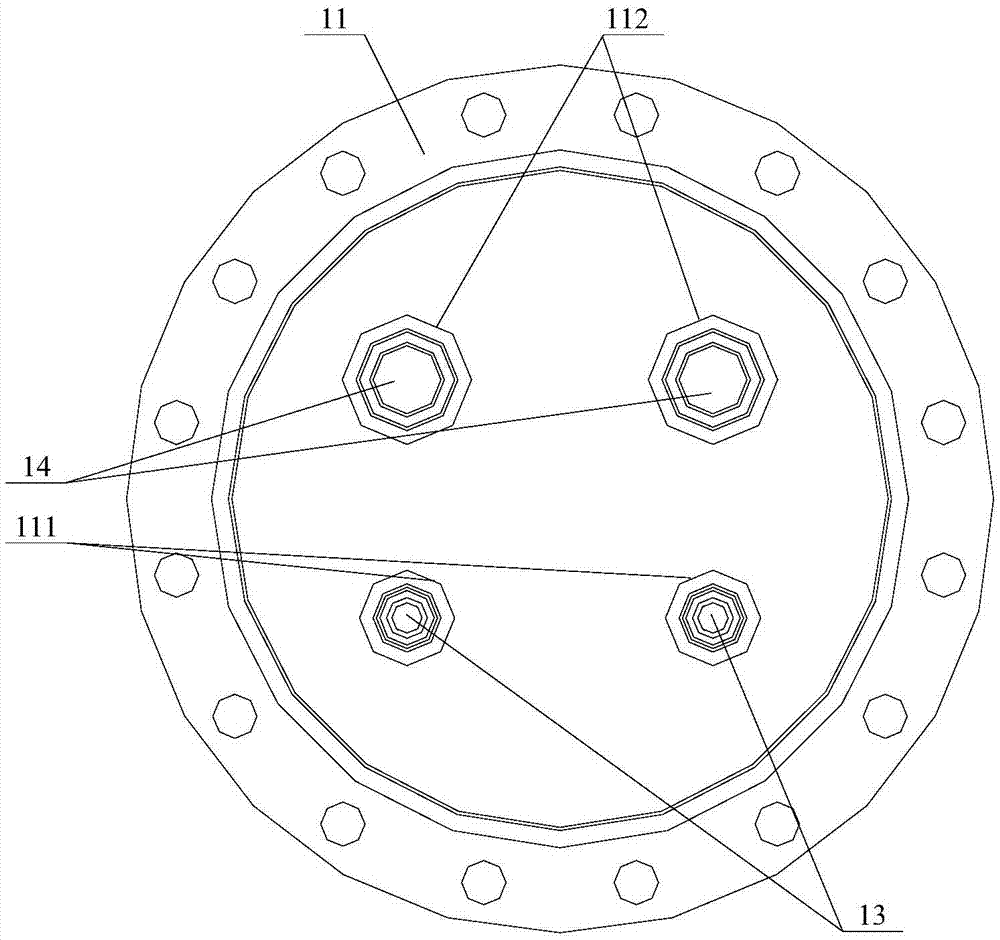

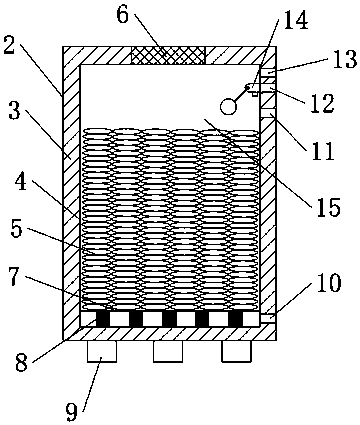

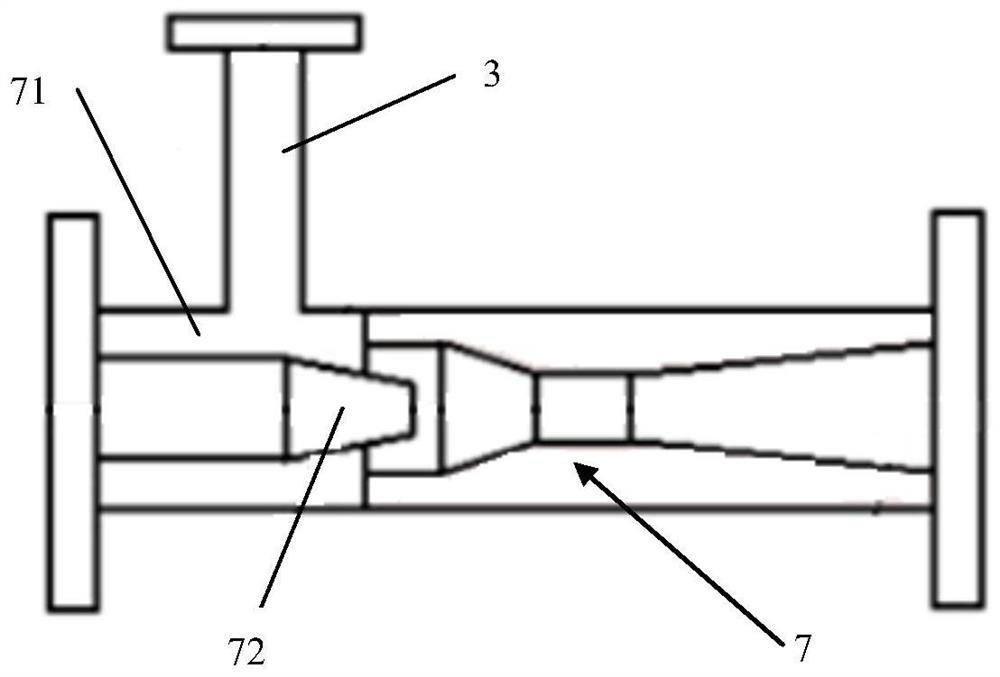

Dry-type evaporator and channel assembly thereof

InactiveCN105444471AUniform and stable deliveryImprove running stabilityEvaporators/condensersHeat exchanger casingsElectrical and Electronics engineeringCurrent sharing

The invention discloses a channel assembly. The channel assembly comprises a shell which is matched with a tube plate, wherein a current sharing tube with the sealed inner end part is arranged in the middle of the shell; a plurality of first-stage current sharing holes are formed in the sealing surface and side wall of the current sharing tube; a refrigerant air outlet tube and a refrigerant liquid inlet tube which is coaxially communicated with the current sharing tube axially penetrate the shell; a current sharing plate which is matched with the current sharing tube is arranged on the end surface of the shell, which is matched with the tube plate; and a plurality of second-stage current sharing holes which are in one-one-to-one correspondence with heat exchange tubes of the tube plate and adapt to the heat exchange tubes mutually are arranged on the current sharing plate. The channel assembly can improve the heat exchange efficiency of a dry-type evaporator and causes the overall operation of the dry-type evaporator to be relatively stable and efficient. The invention also discloses the dry-type evaporator adopting the channel assembly.

Owner:GREE ELECTRIC APPLIANCES INC

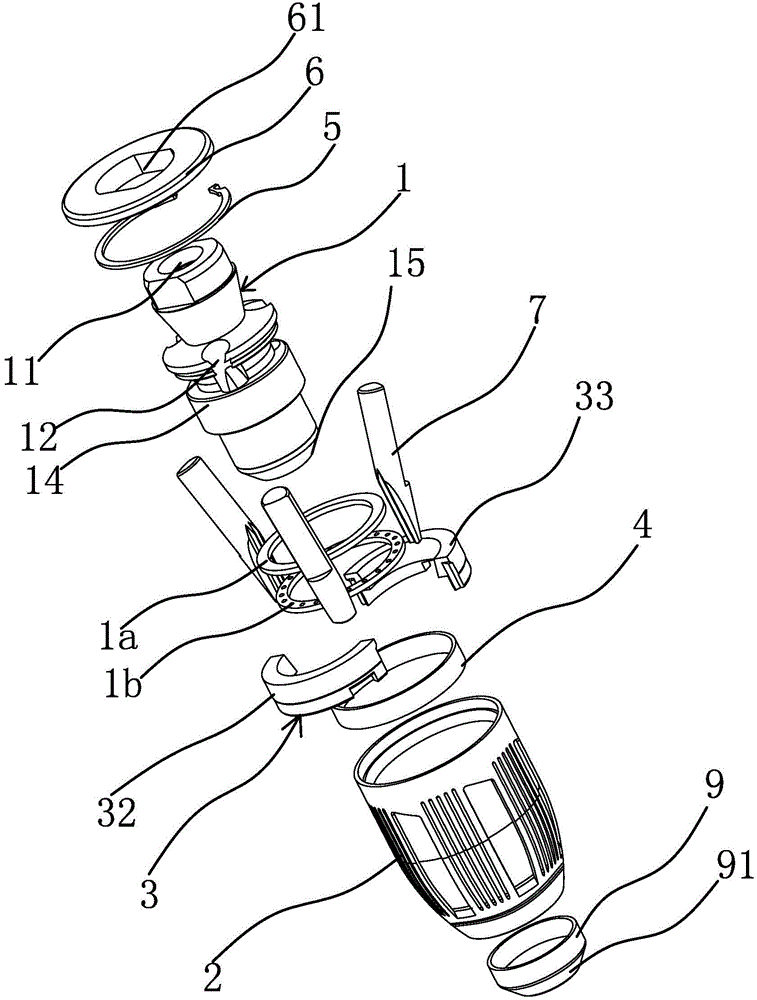

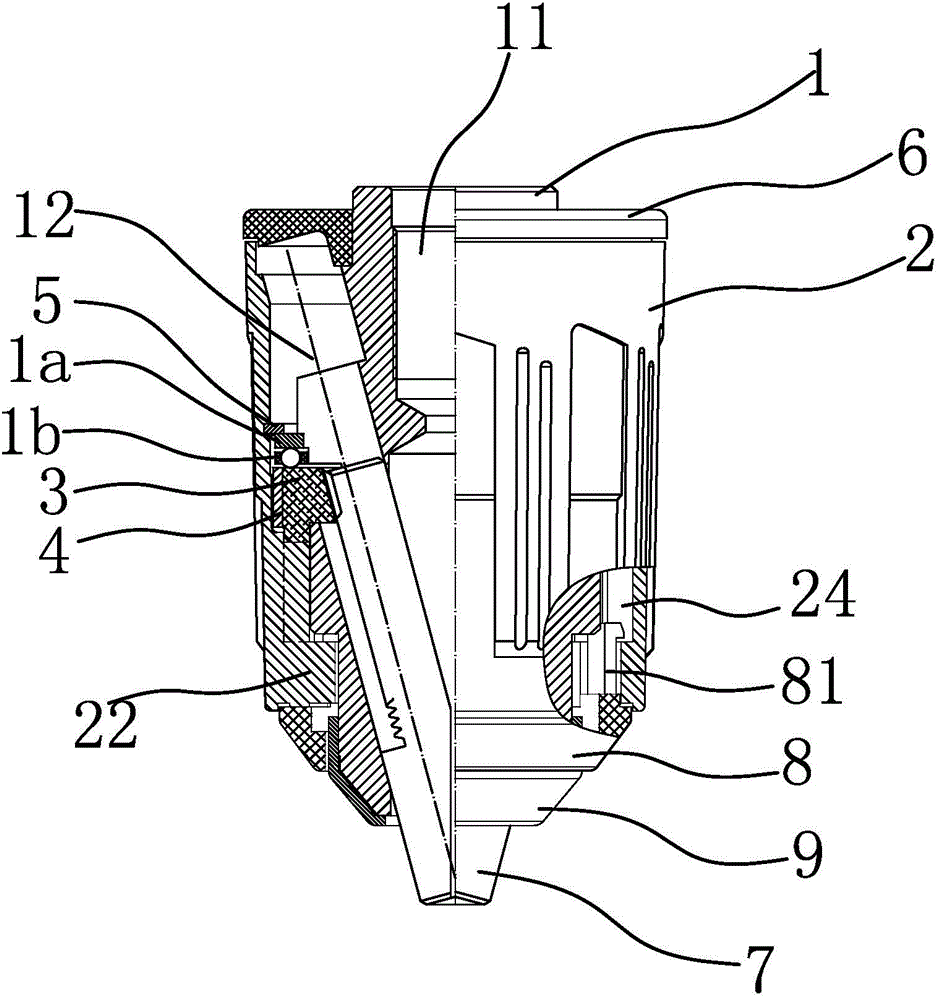

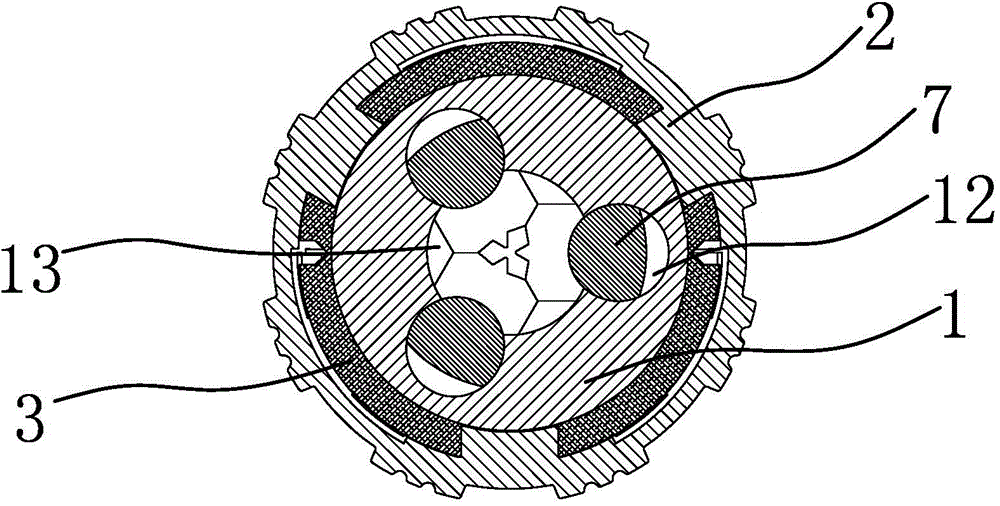

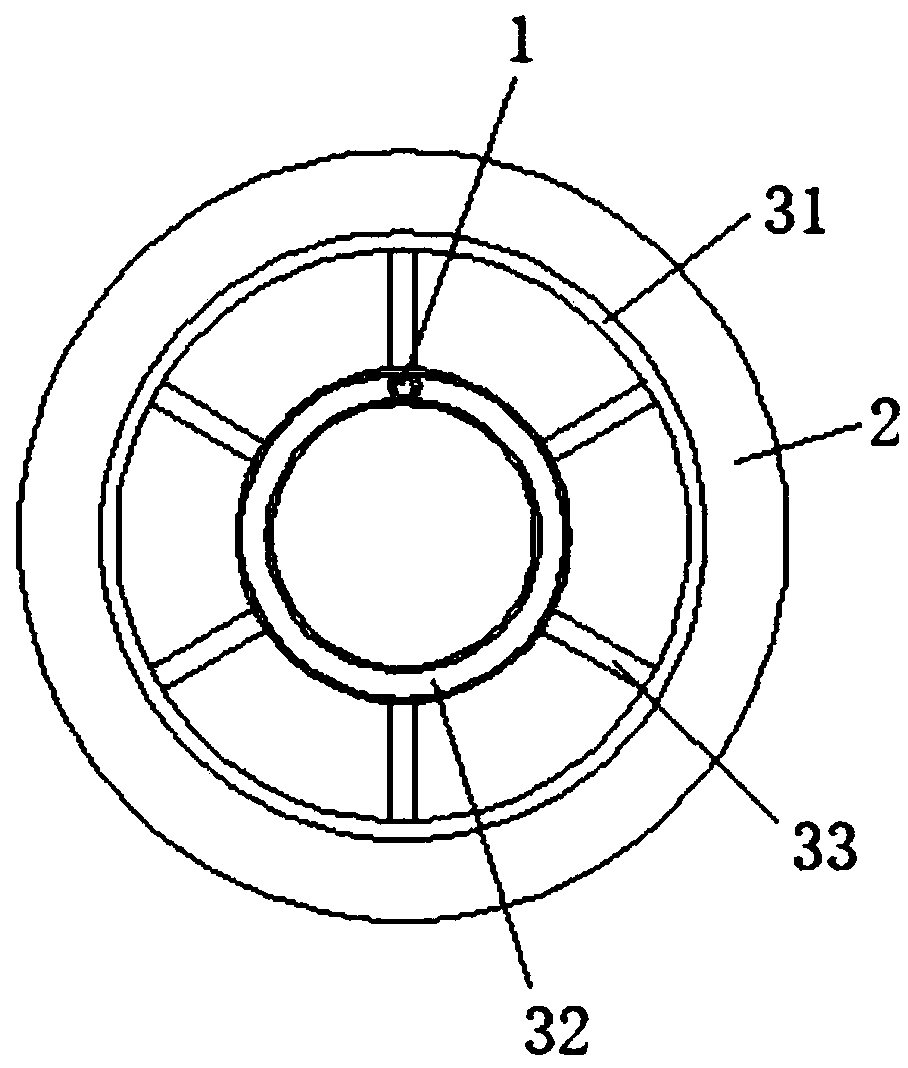

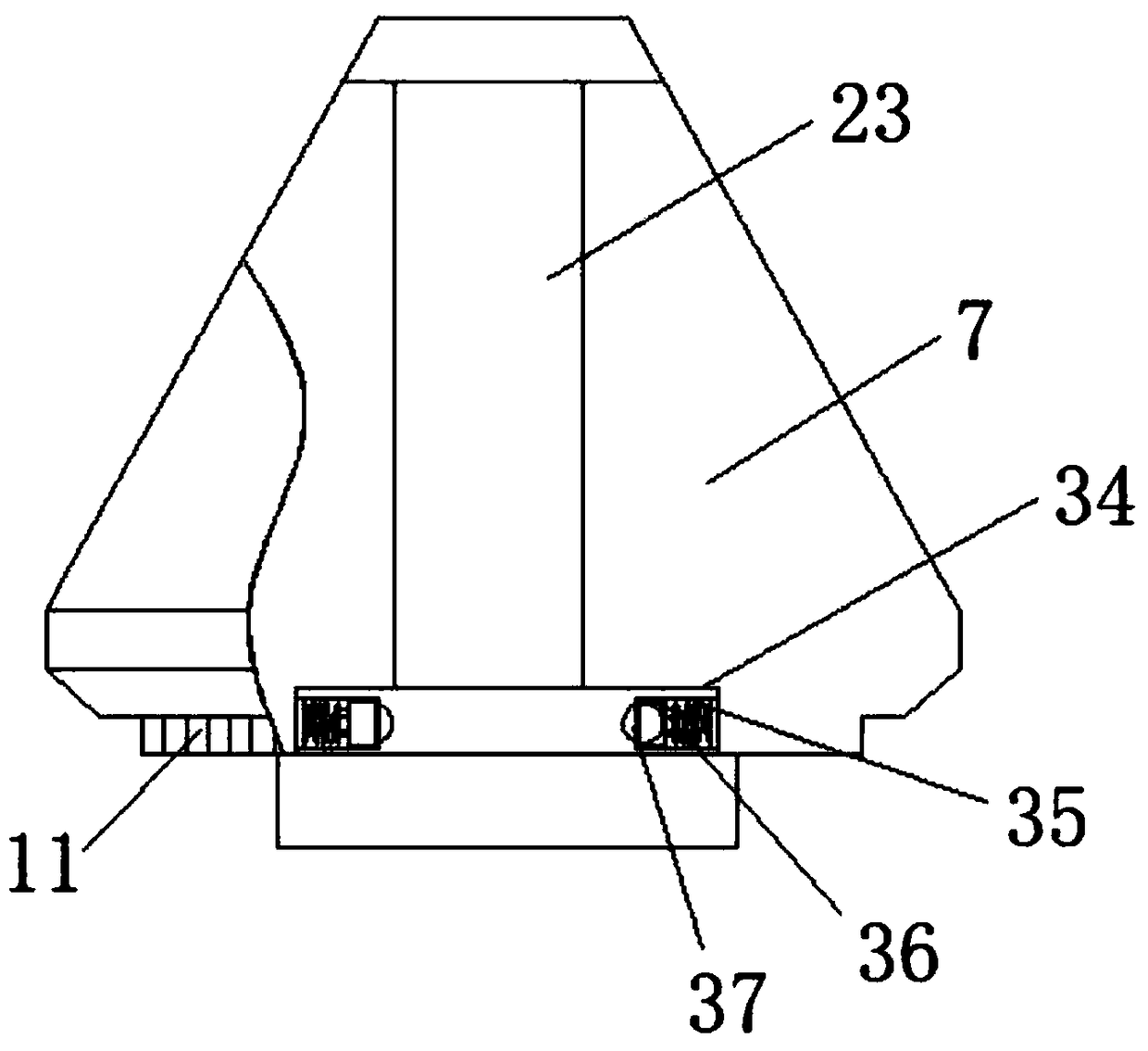

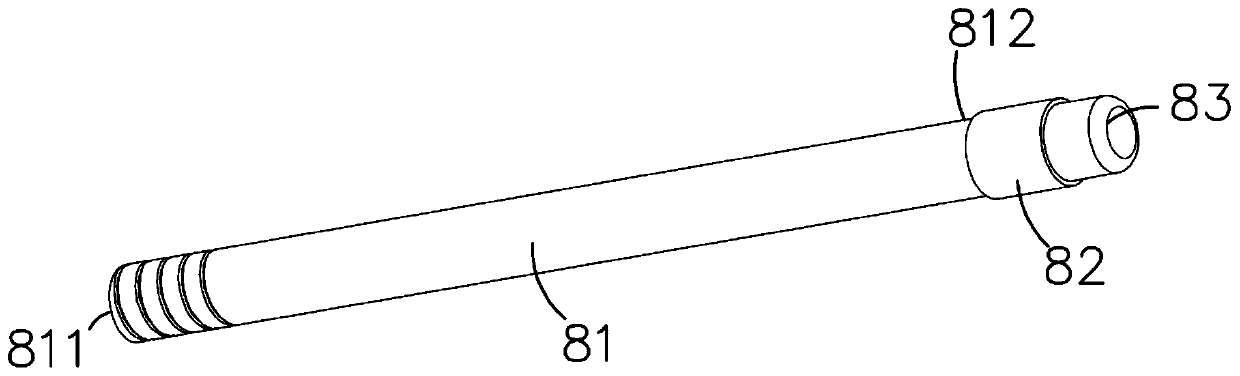

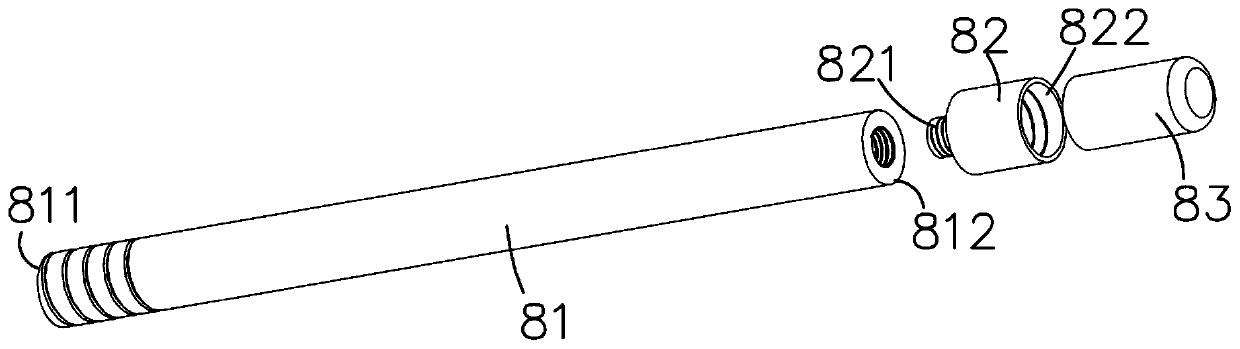

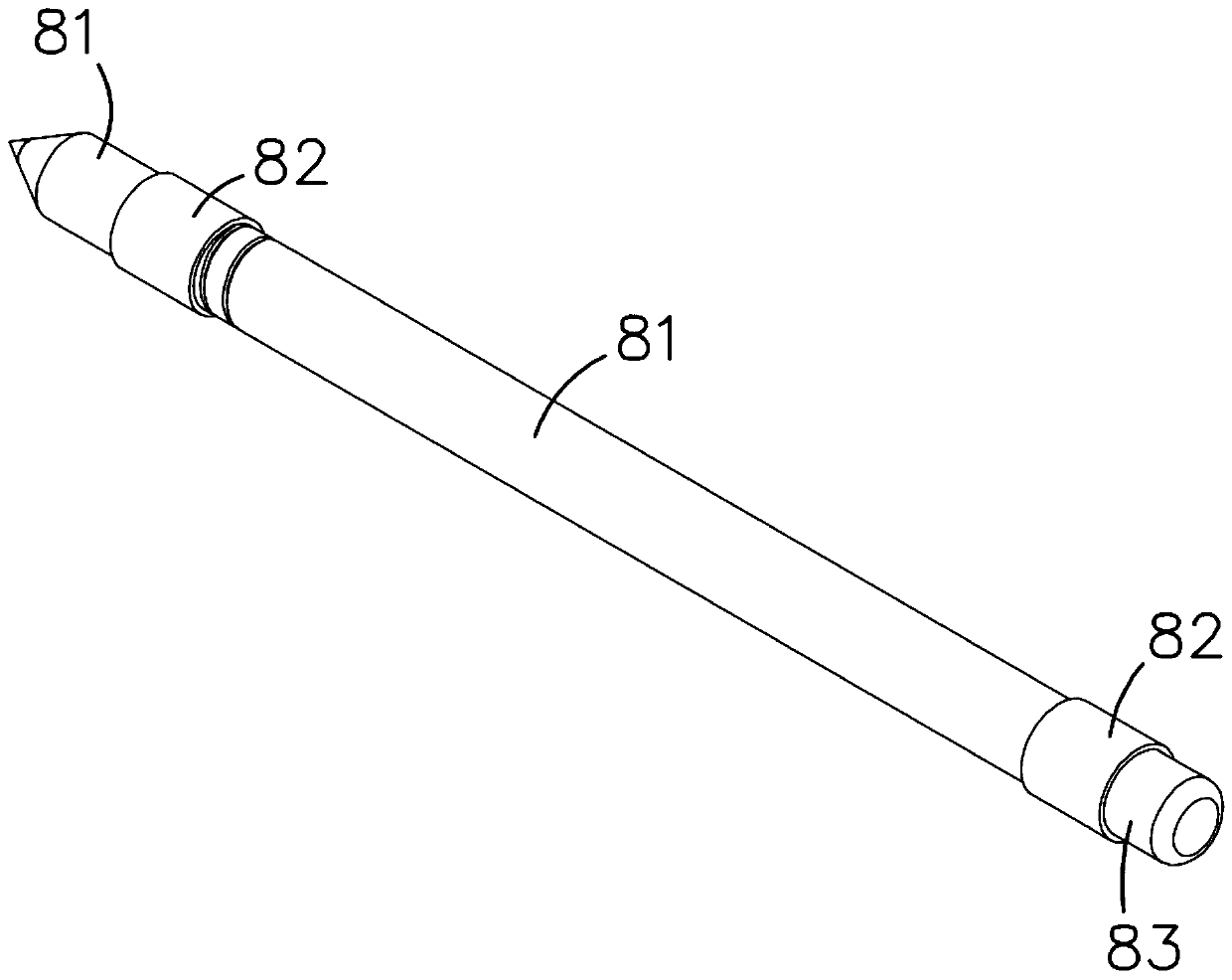

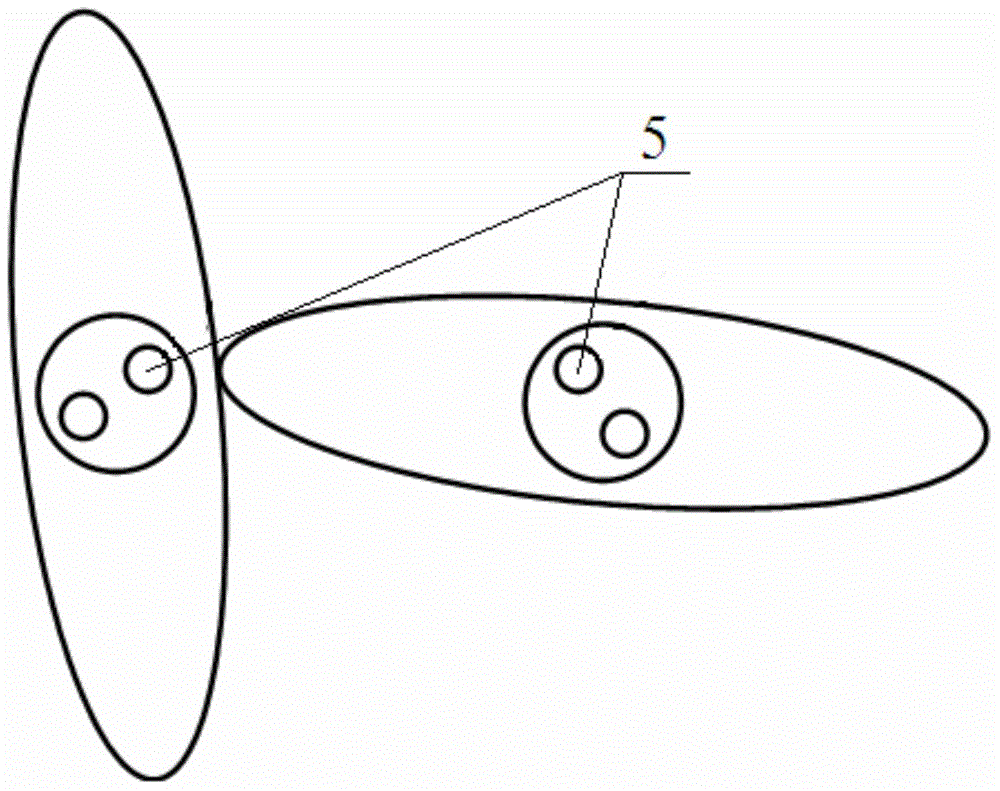

Safety drill chuck

The invention provides a safety drill chuck, and belongs to the technical field of machines. The safety drill chuck achieves the aims of improving the safety and effectively guaranteeing torque transmission when clamping jaws in the drill chuck are adjusted. The safety drill chuck of the improved structure comprises a drill clamping sleeve and a cylindrical drill body. The drill clamping sleeve is arranged on the drill body in a sleeving mode and can rotate around the drill body. A plurality of sliding ways inclined towards the lower end of the drill body are distributed in the drill body in the circumferential direction. Clamping jaws capable of sliding in the sliding ways are arranged in the sliding ways. A nut in threaded connection with the clamping jaws is further arranged between the drill clamping sleeve and the clamping jaws. Grooves are formed in the lower end face of the nut, and convex keys are arranged on the inner wall of the drill clamping sleeve and connected to the interiors of the grooves in a clamped mode. A back cover is further fixedly arranged at the upper end of the drill body. The upper end of the drill clamping sleeve can abut against the back cover. The safety drill chuck of the improved structure is high in safety performance and even and stable in torque transmission.

Owner:ZHEJIANG CHAOLI MECHANICAL TOOLS

Phase-change energy storage device and system

InactiveCN109297336AIncrease contact areaGood dimensional stabilityHeat storage plantsAir conditioning systemsPhase changePhase-change material

The invention discloses a phase change energy storage device and system. The phase change energy storage device comprises a shell, an inner container, a plurality of phase-change energy storage elements, a circulating medium inlet, a circulating medium outlet and circulation medium, wherein an inner container used for containing the phase-change energy storage elements is arranged in the shell, acirculating medium inlet and a circulating medium outlet are formed in the side surface of the inner container, the circulating medium is filled in the inner container, and the phase-change energy storage elements comprises a phase-change material and a plastic package body used for containing the phase-change material. The phase-change energy storage device solves the problem of leakage of the phase-change material from the phase-change energy storage elements, so that the energy is rapidly stored and released, the heat exchange power is large, is safe and reliable, and can continuously and stably output energy.

Owner:谦茂节能科技(上海)有限公司

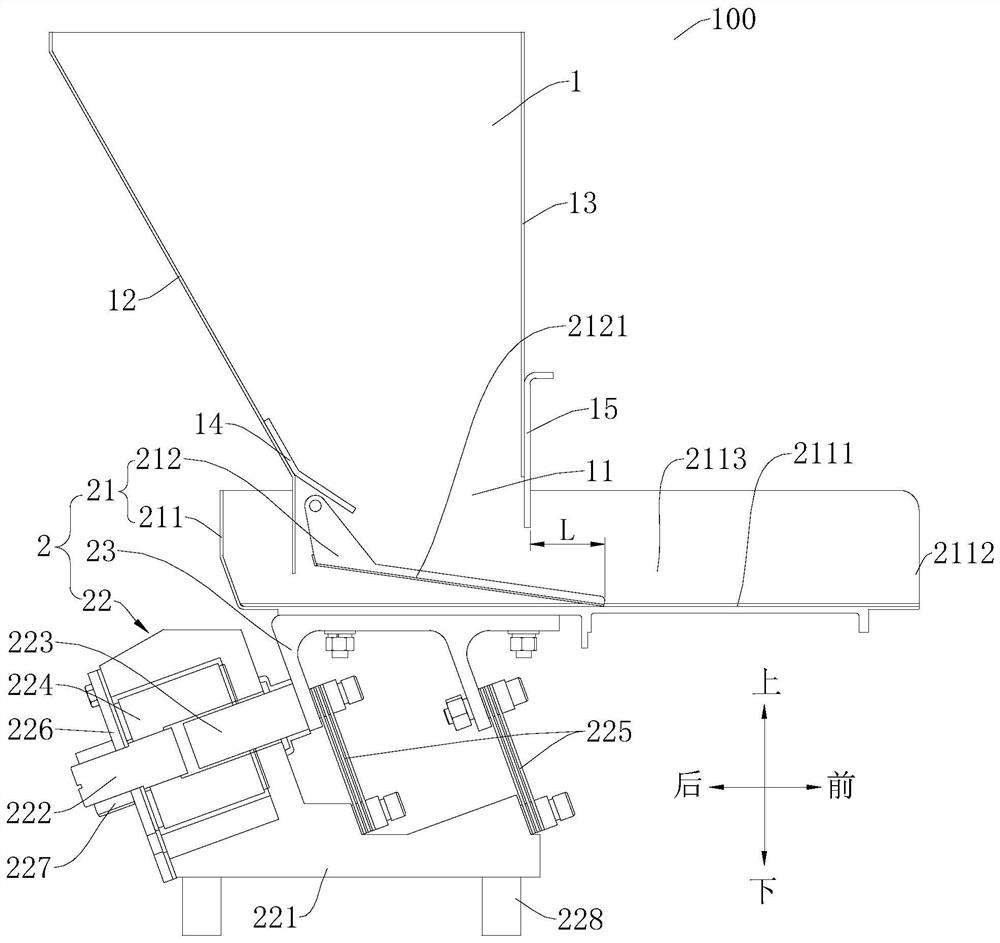

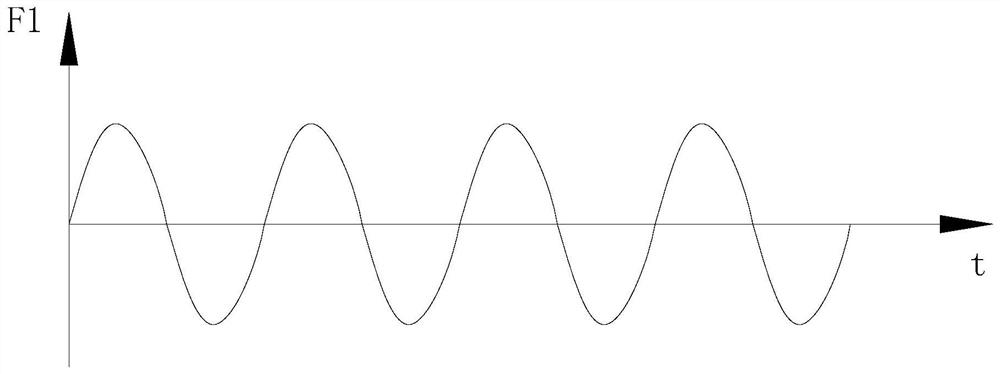

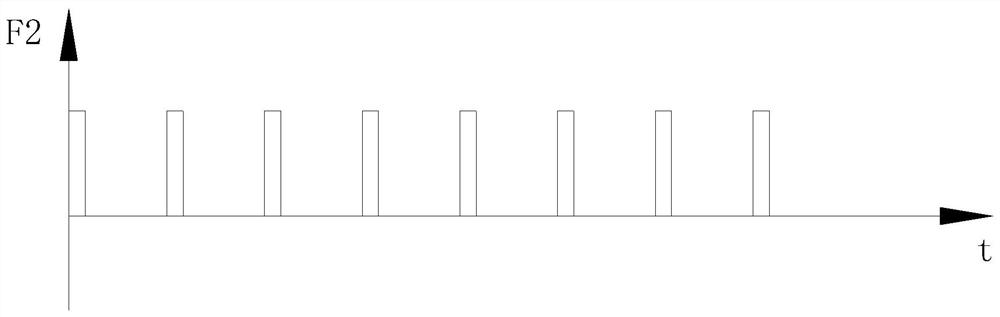

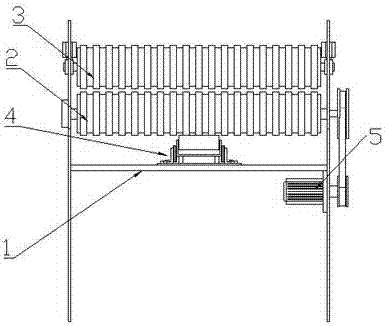

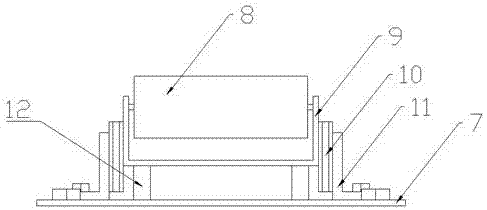

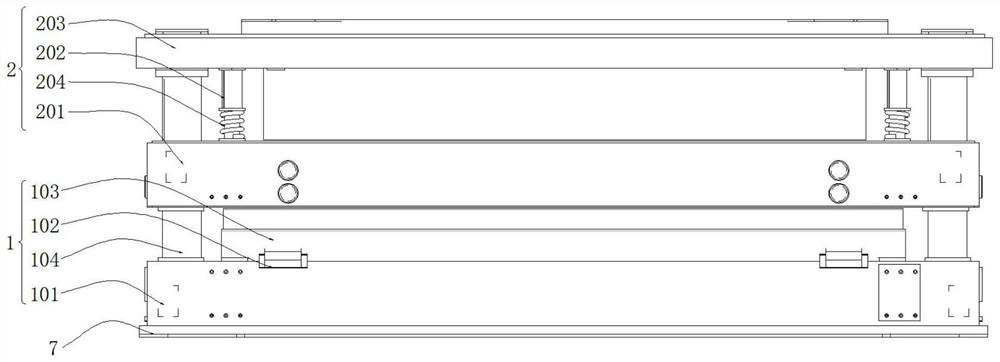

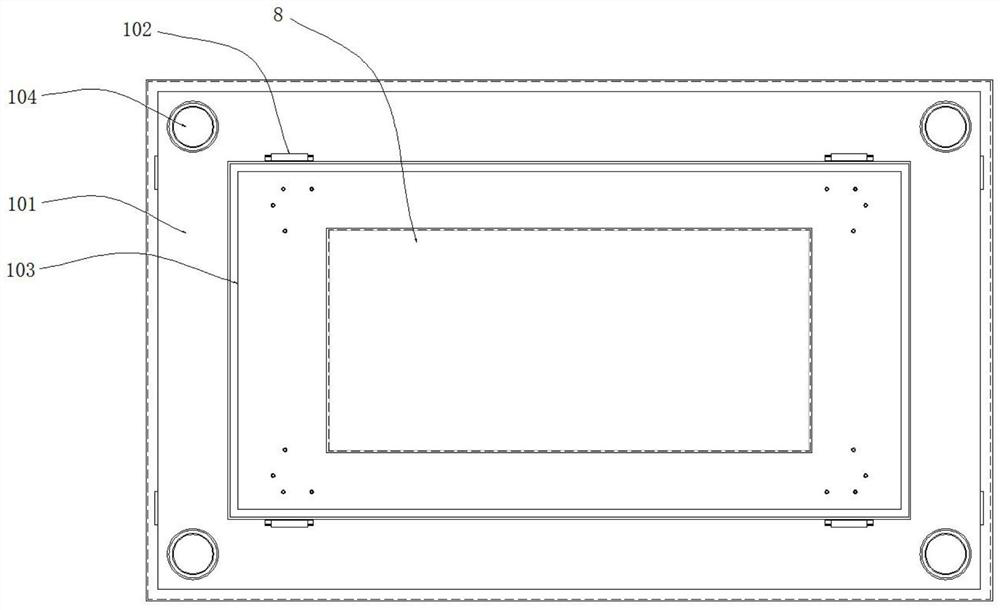

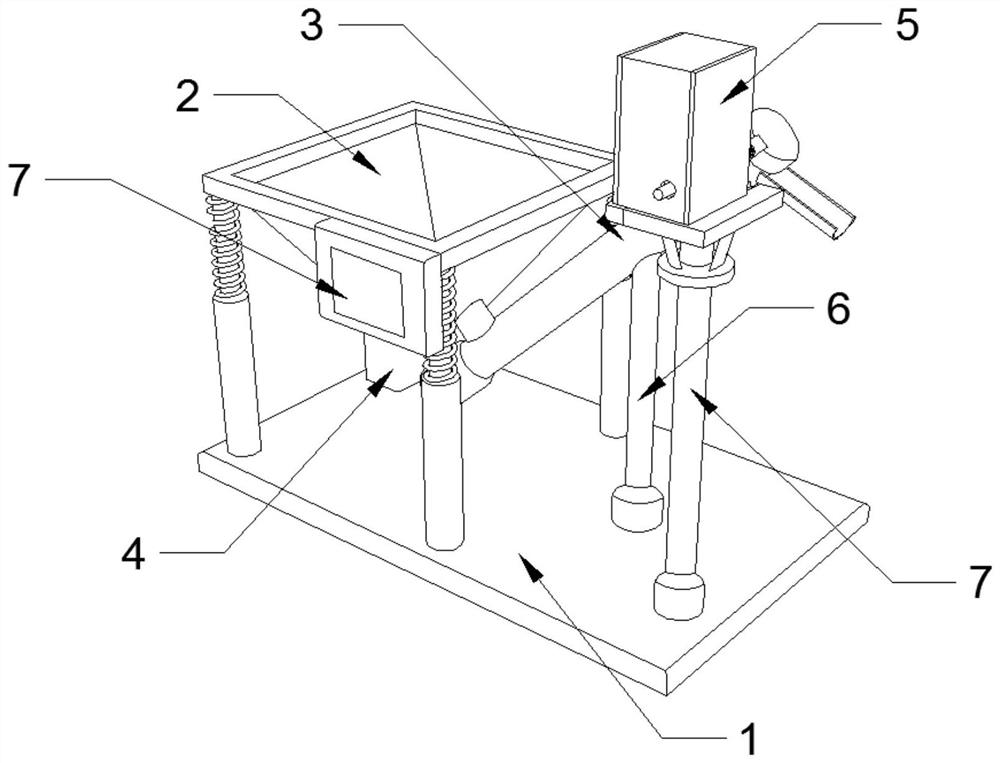

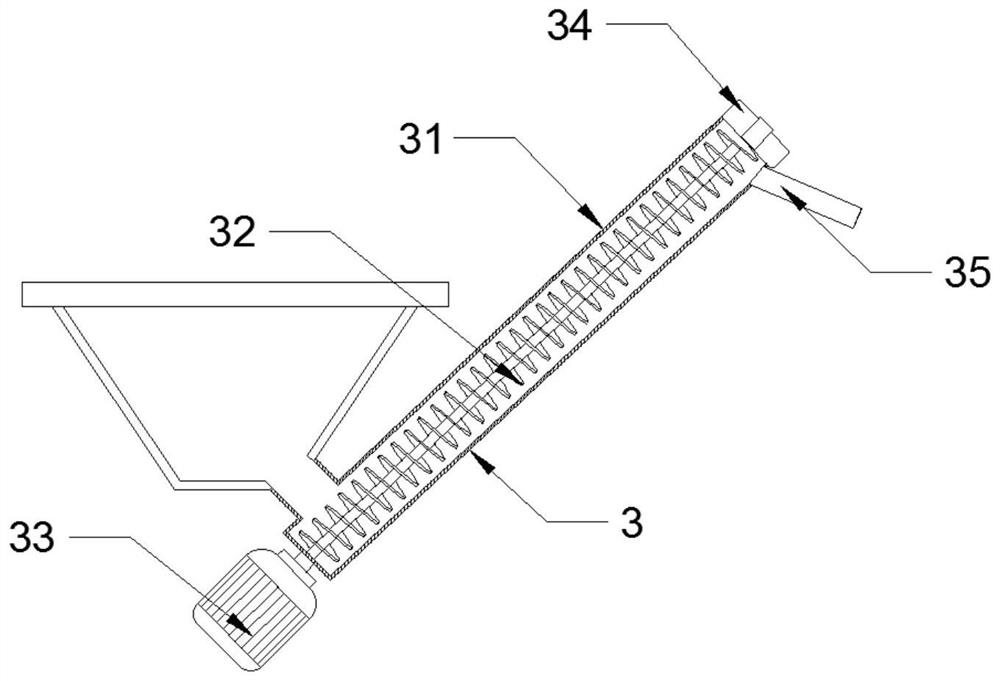

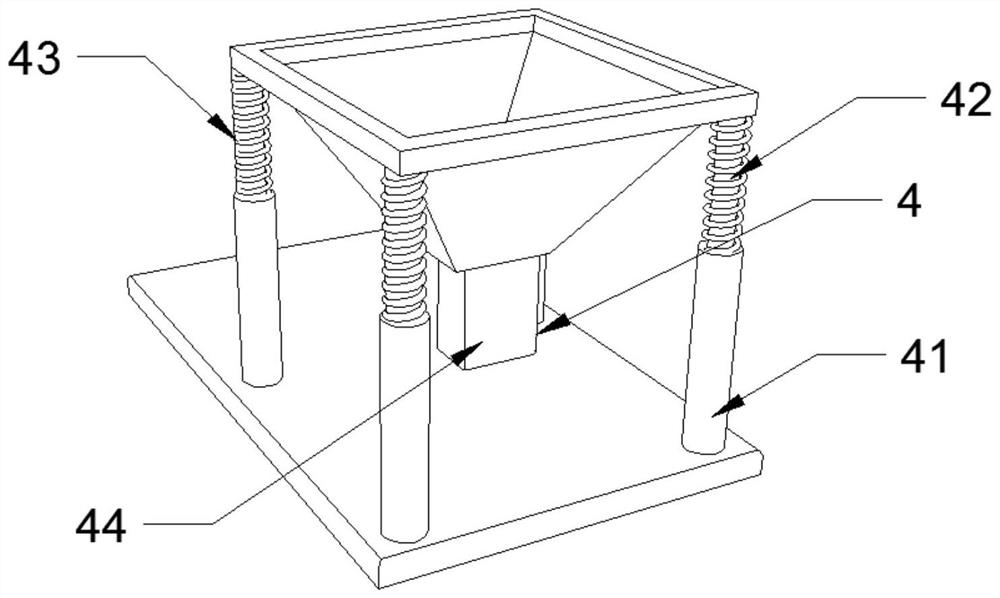

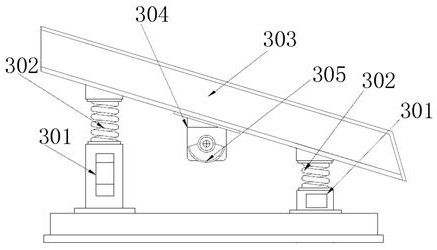

Vibration feeding device

The invention discloses a vibration feeding device. The vibration feeding device comprises a feeding bin, a first-stage material vibrating hopper and a first-stage vibrator. The first-stage material vibrating hopper is arranged below the feeding bin and comprises a first-stage hopper body and a first-stage sliding plate. A first-stage material vibrating cavity with an open top is formed in the first-stage hopper body, one side of the first-stage material vibrating cavity is open to form a first-stage discharging port communicated with the first-stage material vibrating cavity, and at least part of the first-stage sliding plate is arranged in the first-stage material vibrating cavity. The first-stage sliding plate obliquely extends downwards, the first-stage sliding plate can rotate arounda first-stage fixed axis close to the upper end of the first-stage sliding plate, and the lower end of the first-stage sliding plate is detachably erected on the first-stage hopper body; and the first-stage vibrator is connected with the first-stage material vibrating hopper. According to the vibration feeding device, materials can be prevented from being blocked, impurity materials are preventedfrom flowing into a finished product, the feeding speed is guaranteed, and stable and uniform conveying and feeding of the materials which are bonded and are easy to hook and connect are achieved.

Owner:HEFEI MEIYA OPTOELECTRONICS TECH

Thin film conveying device

PendingCN107879171AIngenious structureIngenious and reasonable structureWebs handlingEngineeringMechanical engineering

Owner:江阴市汇通印刷包装机械有限公司

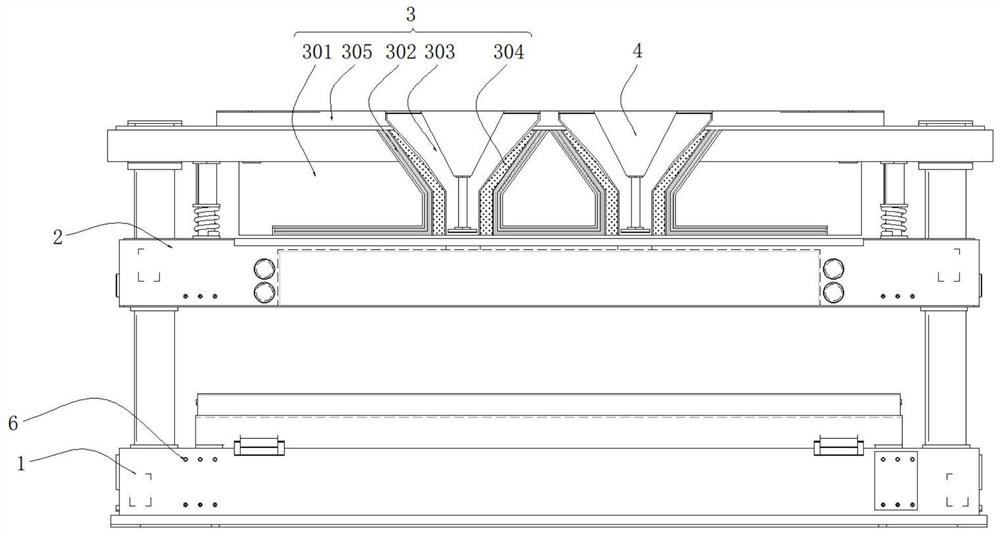

Round pin-point gate pouring molding structure

The invention discloses a round pin-point gate pouring molding structure. The structure comprises a supporting mechanism, a mold closing mechanism is arranged at the top of the upper end of the supporting mechanism, a base plate is arranged at the bottom of the lower end of the supporting mechanism, screws are arranged on the periphery of the outer side of the supporting mechanism, and a lower mold cavity is formed in the top of the upper end of the supporting mechanism. A molding mechanism is arranged on the inner side of the upper end of the mold closing mechanism. Auxiliary feeding mechanisms are arranged on the two sides of the interior of the molding mechanism. According to the structure, a heating wire layer is used for heating the upper mold cavity, so that the situation that the temperature in the mold cavity is too low, water vapor is generated due to direct contact with melt, even the water vapor is accumulated in the mold cavity, flowing and molding pressure of the melt are affected, and bubbles are generated in a product is avoided. Through the heating of the heating wire layer, preheating operation can be carried out before molding, so that the situation that melt flows discontinuously in the mold cavity due to too large mold temperature difference is avoided.

Owner:深圳市华中思明通科技有限公司

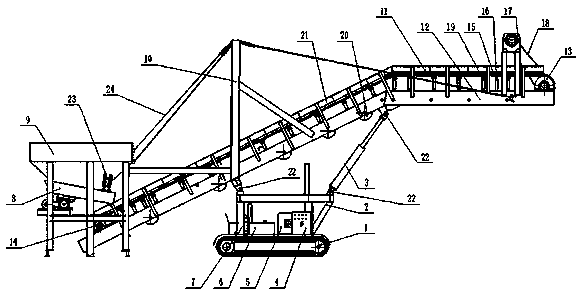

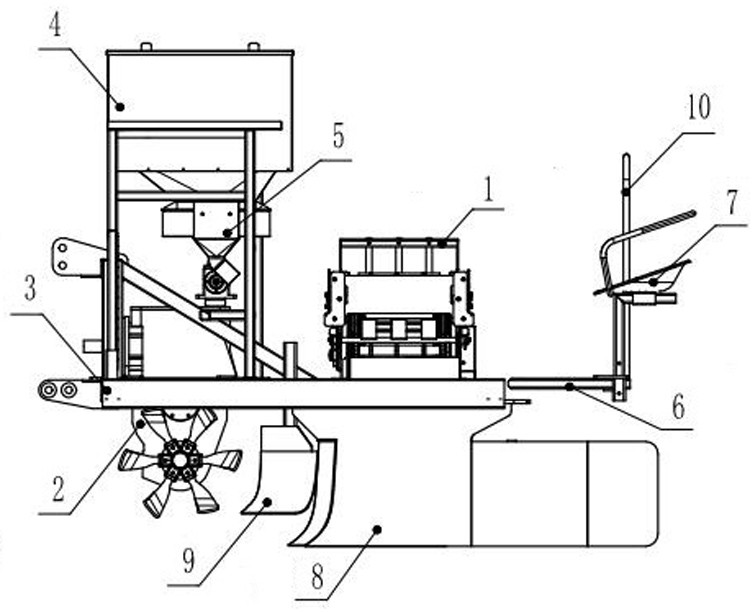

Movable rubber belt conveyor

PendingCN110937321AUniform and stable deliverySimple structureConveyorsRollersHydraulic cylinderAdhesive belt

The invention relates to a movable rubber belt conveyor in the technical field of material transfer devices. The movable rubber belt conveyor comprises a rubber belt conveyor, a walking mechanism anda vibrating feeder, wherein the rubber belt conveyor comprises a horizontal section and an inclined section connected to the tail part of the horizontal section, a bracket platform is arranged above the walking mechanism, the front end of the bracket platform is connected with a hydraulic cylinder through a pin shaft, the top of the hydraulic cylinder is connected below the top of the inclined section of the rubber belt conveyor through a pin column, the rear end of the bracket platform is connected with a cable-stayed support through a pin shaft, a hopper is connected above the tail part of the inclined section of the rubber belt conveyor, a vibrating feeder is connected below the hopper through a spring, a discharging port of the vibrating feeder is formed above a material guide groove in the tail part of the inclined section of the rubber belt conveyor, and the top of the cable-stayed support is connected with the hopper and the head part of the horizontal section of the rubber beltconveyor through round steel. The movable rubber belt conveyor is simple in structure, light in weight, low in operation power, capable of meeting the requirement for stable transportation of the muck in tunnel construction and high in reliability.

Owner:河南中业重工机械有限公司

Lump coal crusher with quantitative control function

InactiveCN108786984AProtect normal rotationExtended service lifeGrain treatmentsControl functionCoal

The invention belongs to the technical field of lump coal crushers and particularly relates to a lump coal crusher with the quantitative control function, and aims to solve the problems that the existing lump coal crusher cannot timely control the descending speed of lump coal and is unstable in feeding to cause blockage easily, so that the device is likely to be damaged, and the service life is affected. To solve the technical problems, the invention discloses the lump coal crusher with the quantitative control function. The lump coal crusher with the quantitative control function comprises abase, an upper machine body, a lower machine body, a conveyor belt, a weighing valve, a hydraulic control cabinet, a motor fixing table, a hydraulic cylinder, an eccentric shaft, a second gear, a floating bush and an eccentric shaft sleeve, wherein the lower machine body is positioned between the hydraulic control cabinet and the motor fixing table; the top of the lower machine body is fixedly connected with the hydraulic cylinder through a bolt; the top of the hydraulic cylinder is connected with the upper machine body through a hydraulic rod; and the eccentric shaft is mounted at the bottomof the interior of the lower machine body. The lump coal crusher has the effects of reasonably controlling the quantity of lump coal, adjusting the space of the machine body device and better treating the size effect of the lump coal.

Owner:汤佳

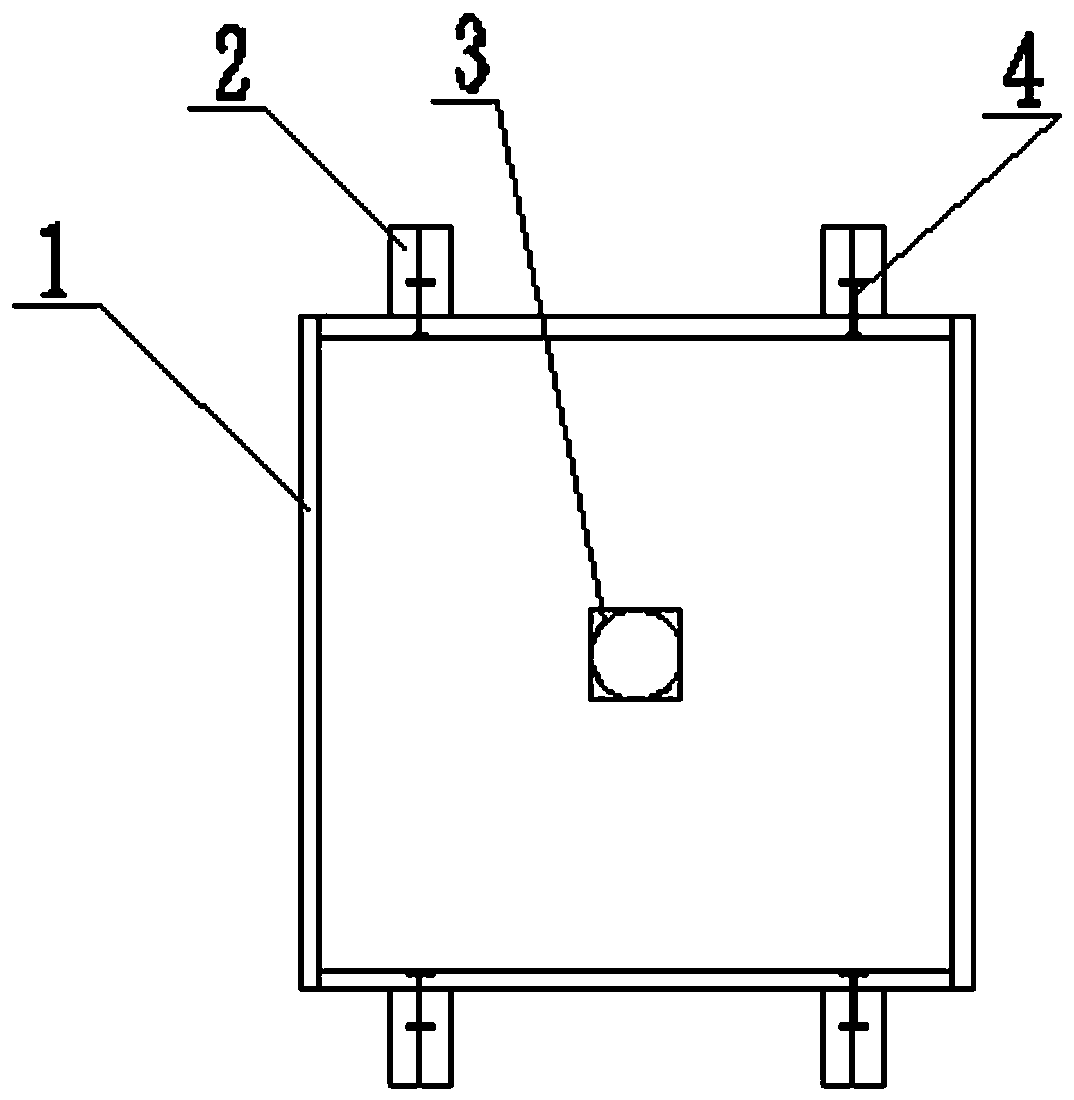

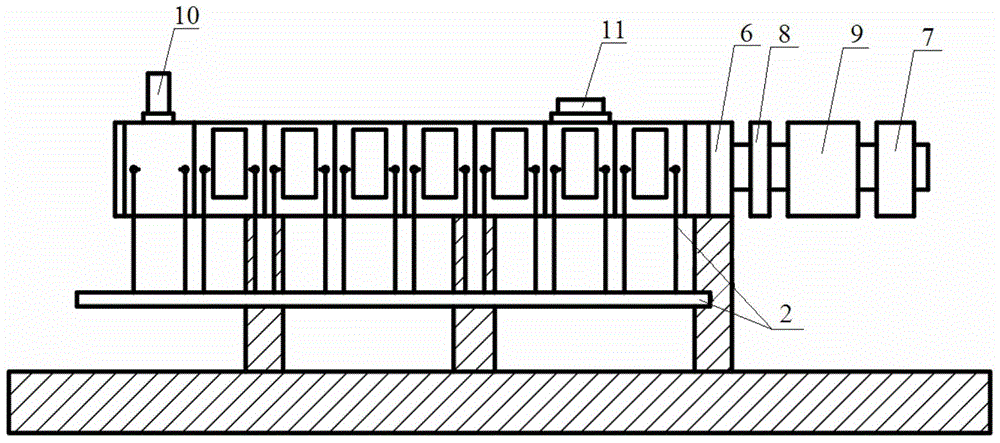

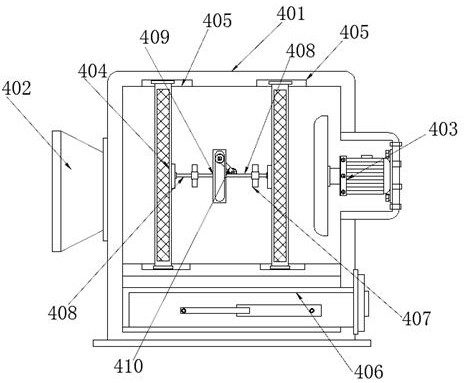

Intermittent feeding device for intelligent machining

InactiveCN111731801AUniform and stable rotation speedUniform and stable deliveryLarge containersConveyor partsFixed frameControl theory

The invention discloses an intermittent feeding device for intelligent machining. The intermittent feeding device comprises a substrate, a material dumping barrel and a material conveying device. Thematerial dumping barrel is fixedly mounted above the substrate. The bottom side of the material dumping barrel is fixedly connected with the material conveying device used for rotating and upwards conveying materials. A vibration device achieving extrusion through rotating is fixedly mounted on the bottom side of the material dumping barrel. A supporting column is fixedly mounted at the position,located on the bottom side of the material conveying device, of the upper surface of the substrate. A fixed frame is fixedly mounted on the upper surface of the substrate. A quantitative device used for intermittently and quantitatively discharging materials is fixedly mounted at the corresponding position, located at the top end of the material dumping device, of the upper surface of the fixed frame. By means of the arrangement of the device, programming intelligent control over the rotating speed of a drive device is achieved through a controller, the material quantity during feeding can becontrolled conveniently, the trouble of manual feeding is omitted, and feeding work becomes safer, more time-saving and more labor-saving.

Owner:钱泽袁

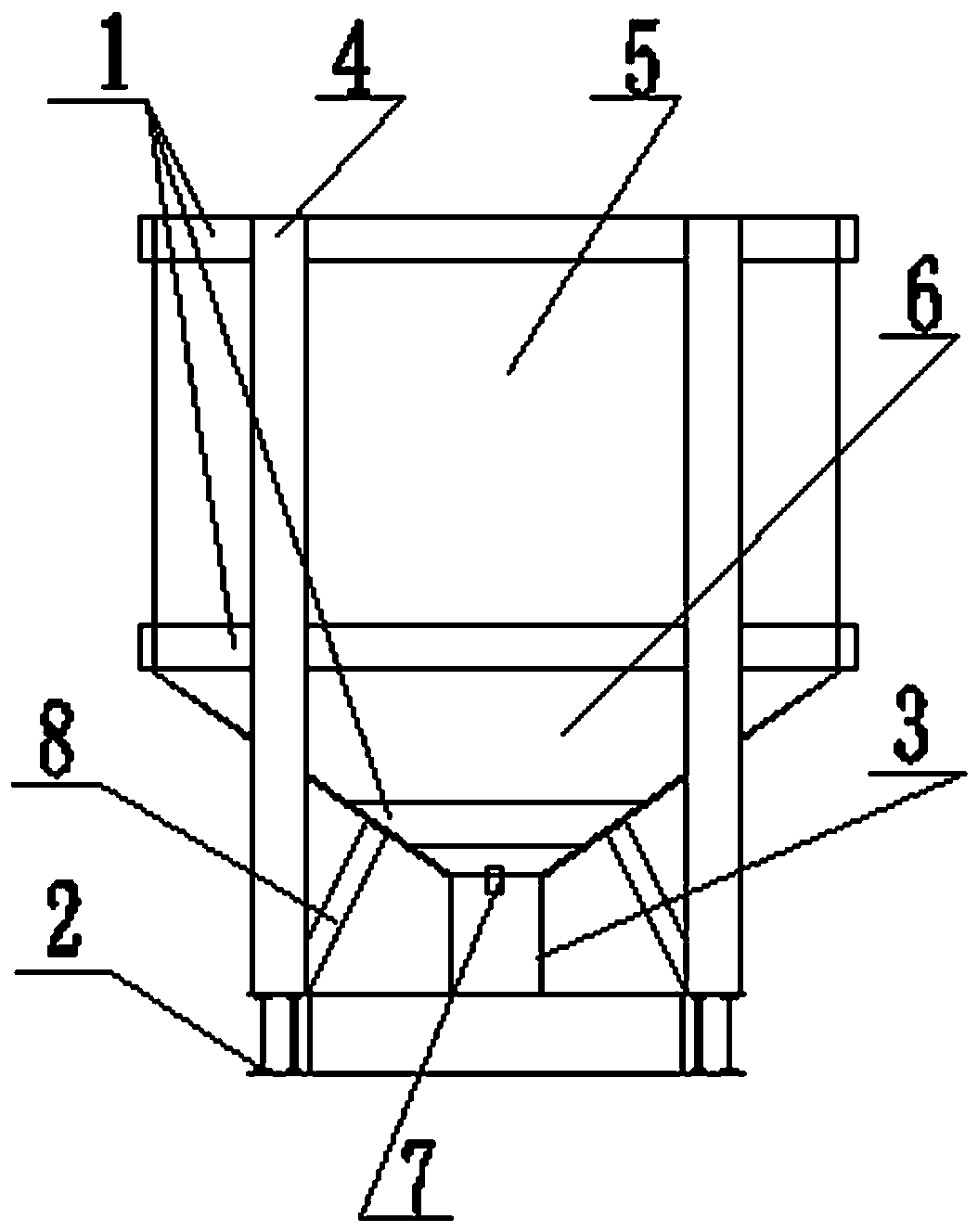

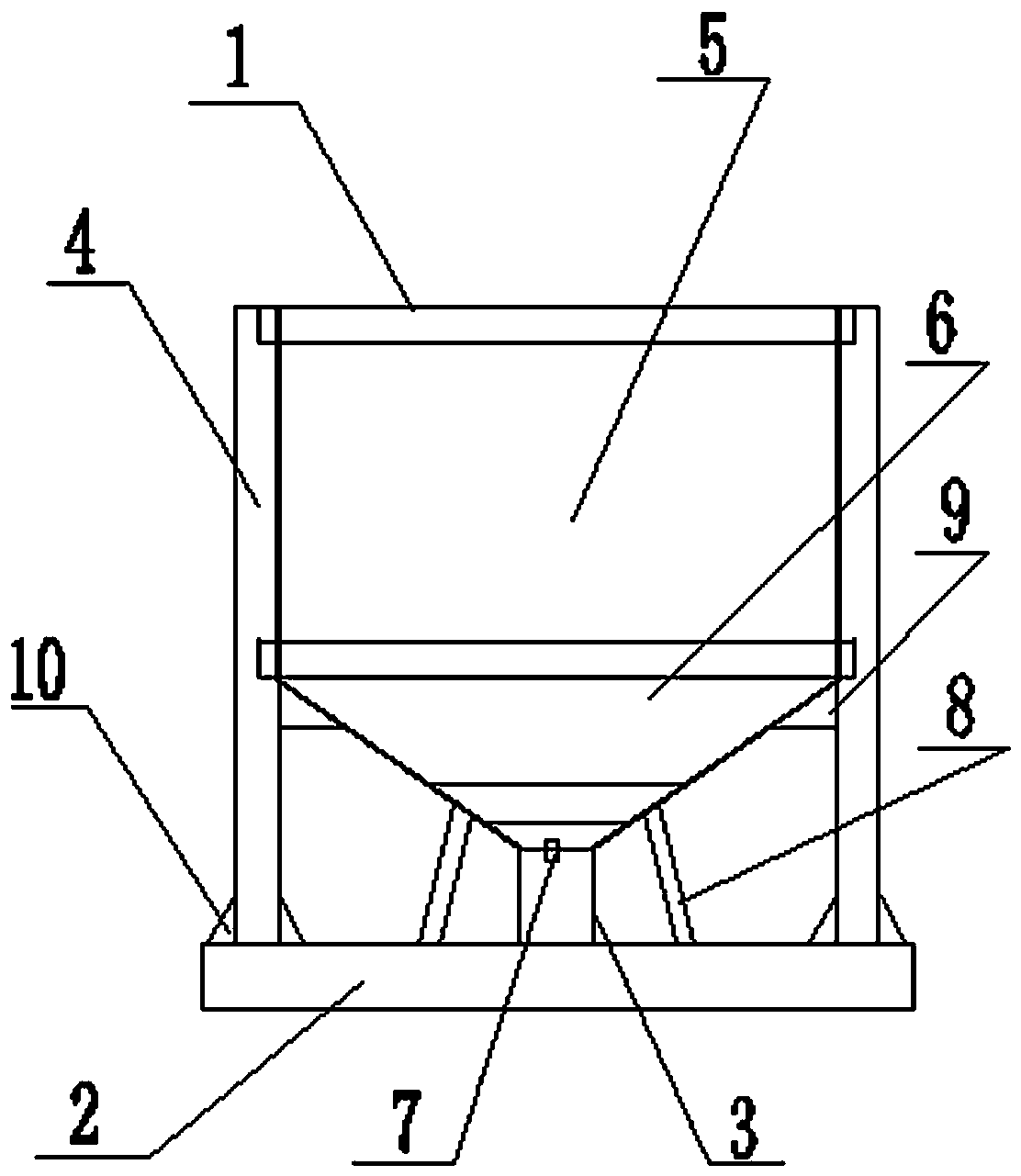

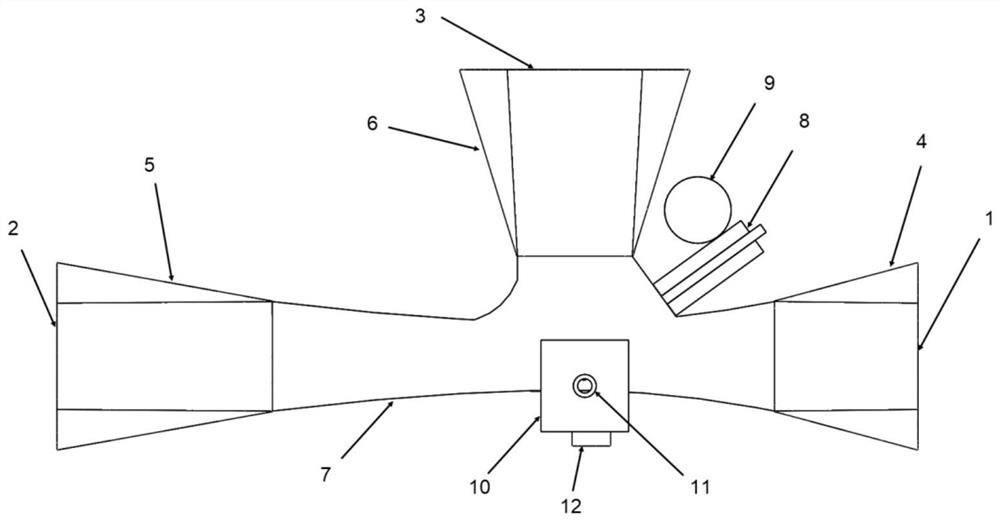

A grouting method for underwater large-diameter bored piles in corrosion geology

ActiveCN106245628BUniform and stable deliveryGuaranteed perfusion qualityBulkheads/pilesTank truckEngineering

The invention discloses a grouting method for a corrosion geological underwater large-diameter drilled pile. The grouting method comprises the following steps of: (1) hole opening; (2) drilling to form the hole; (3) hole cleaning; (4) steel reinforcement cage placement, (5) guide tube lowering; (6) first batch concrete grouting, namely hoisting a large hopper, which is connected to the guide tube, onto a guide tube platform; arranging 2-4 concrete tank trucks and 2-4 ground pumps on the shore, wherein pump lines of the ground pumps are connected to the large hopper by means of a temporary floating bridge; the concrete tank trucks deliver concrete to the ground pumps, and the ground pumps pump concrete into the large hopper; after the large hopper is full of concrete, a ball is pulled out; and 2-4 ground pumps are employed to feed concrete at the same time; and (7) subsequent concrete grouting, namely after the completion of first batch concrete grouting, replacing the large hopper by a small hopper having the capacity of 2-5 m3 for grouting to a designed elevation. By means of the grouting method for a corrosion geological underwater large-diameter drilled pile, the construction difficulties of the corrosion geological condition and a wide river channel can be overcome, and the quality of the drilled pile can be improved so as to ensure the stability of the main tower of a bridge.

Owner:SHANGHAI CIVIL ENG GRP FIFTH +1

Production device for pencil processing

PendingCN110774799AConvenient processing workUniform and stable deliveryConveyorsDrilling machinesStructural engineeringMachining process

Owner:靖州县金心笔业有限责任公司

Waveguide, preparation method thereof, and electronic device

The invention provides a waveguide, a preparation method thereof, and an electronic device. The waveguide includes: a conductive tube body in which a receiving space is defined; and an insulating substrate filling the receiving space. The waveguide with the above structure is simple in structure and easy to machine and form, and does not require huge machining equipment. Since the insulating substrate has a good support effect, the waveguide has good rigidity or strength. The conductive tube body of the waveguide has a thin wall. The waveguide can be easily machined into various complex shapes(such as a small turning radius, a tree or star shape and the like) through the molding of the insulating substrate, which greatly saves conductive materials, and reduces material costs, processing costs, or installation and maintenance cost. The waveguide is easy to install and low in weight and can be used in the aerospace field.

Owner:BYD CO LTD

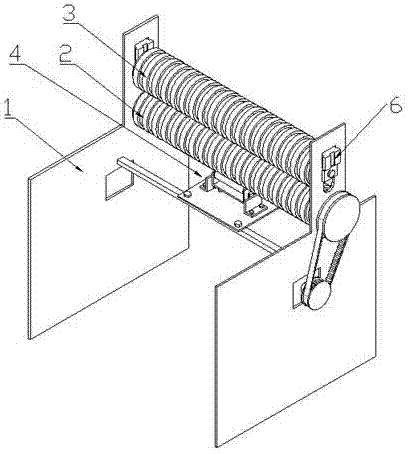

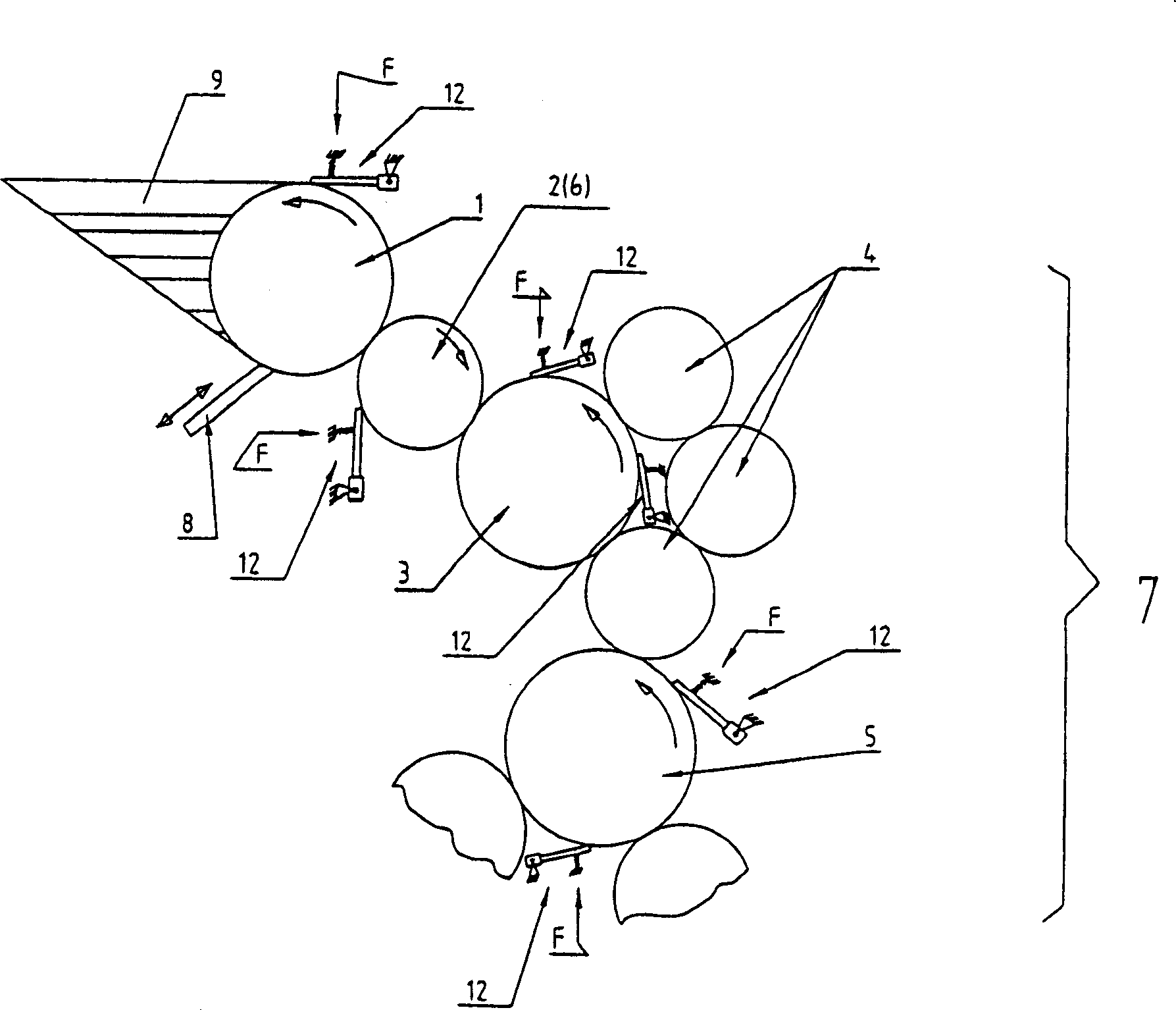

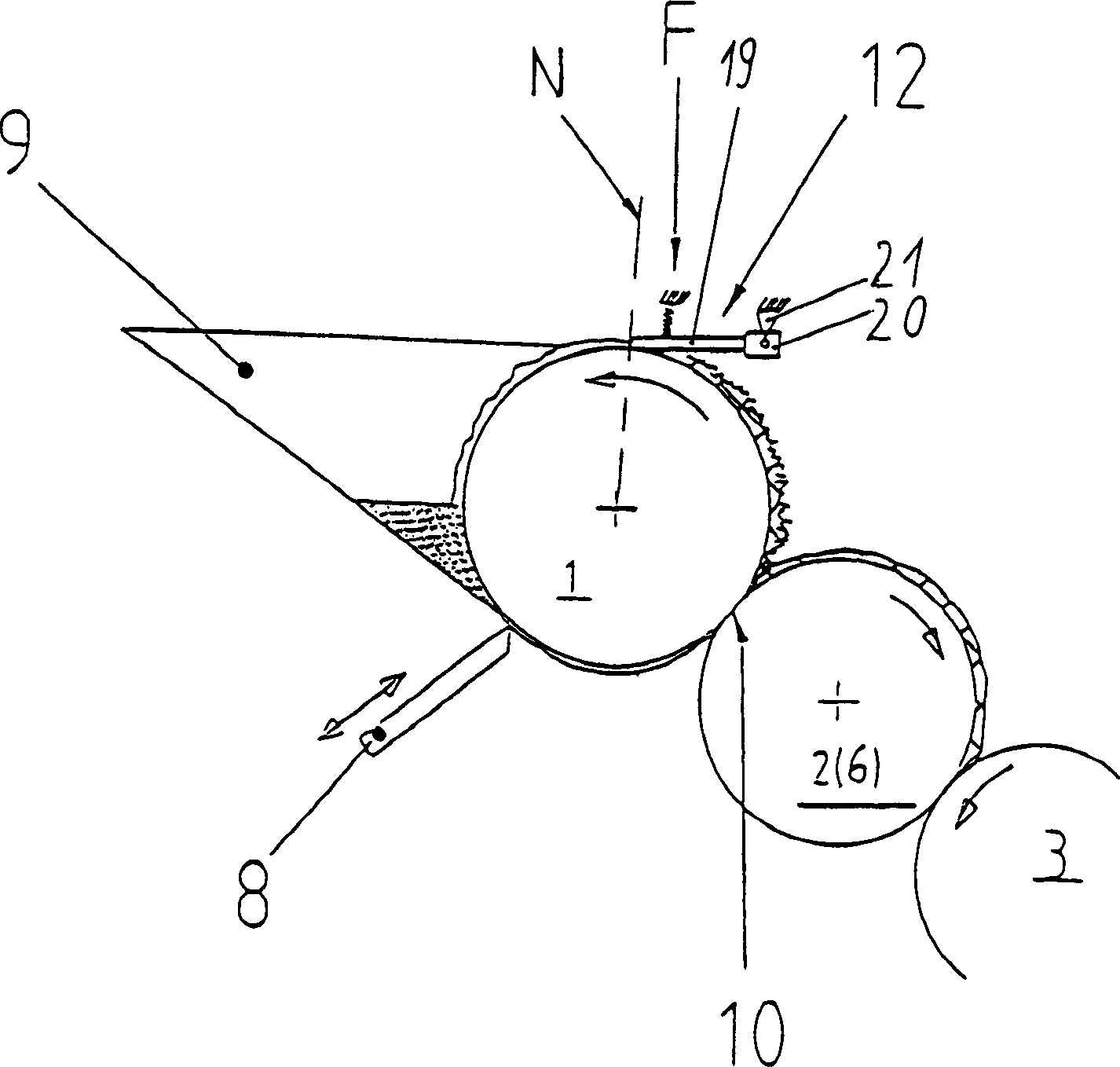

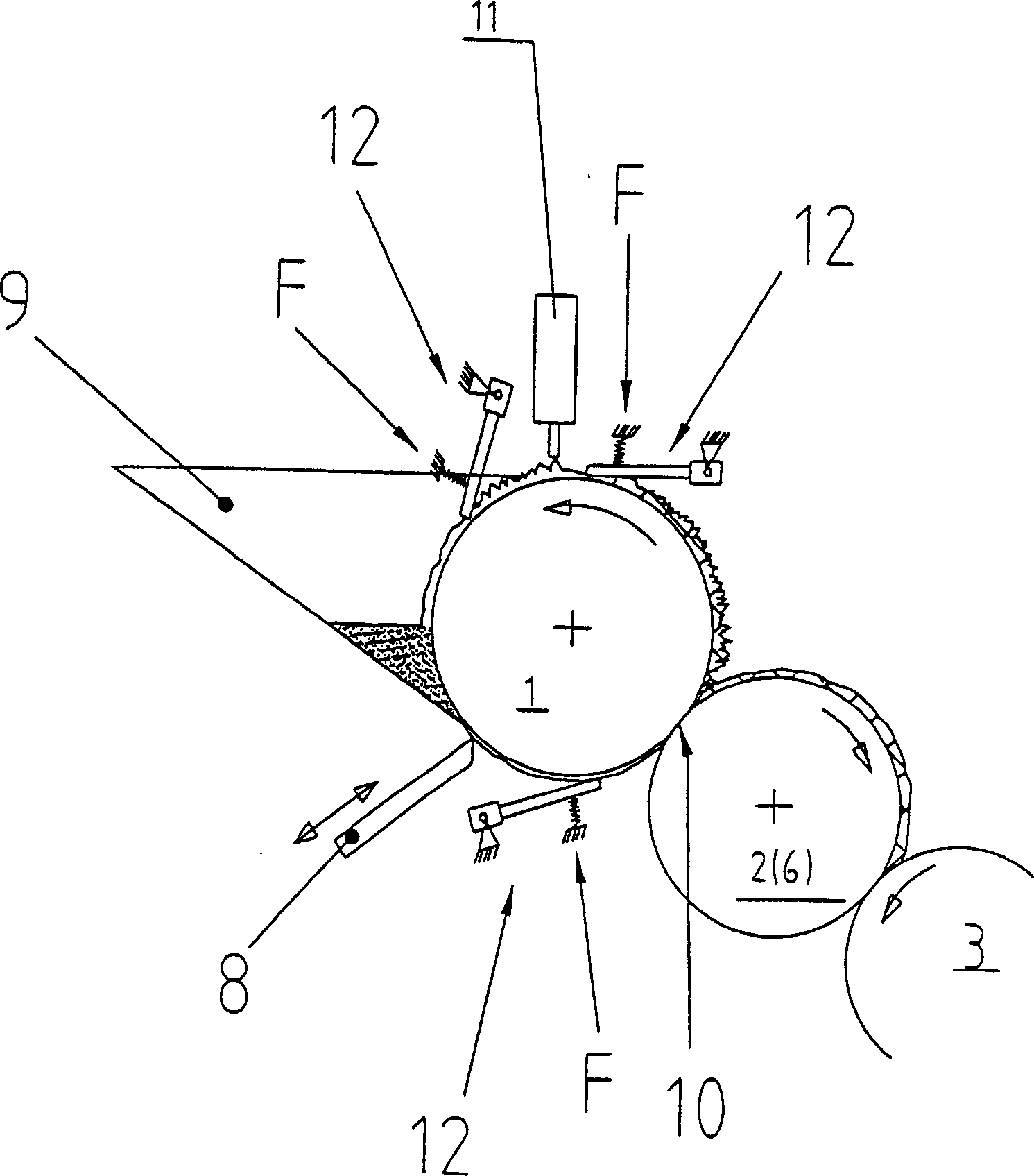

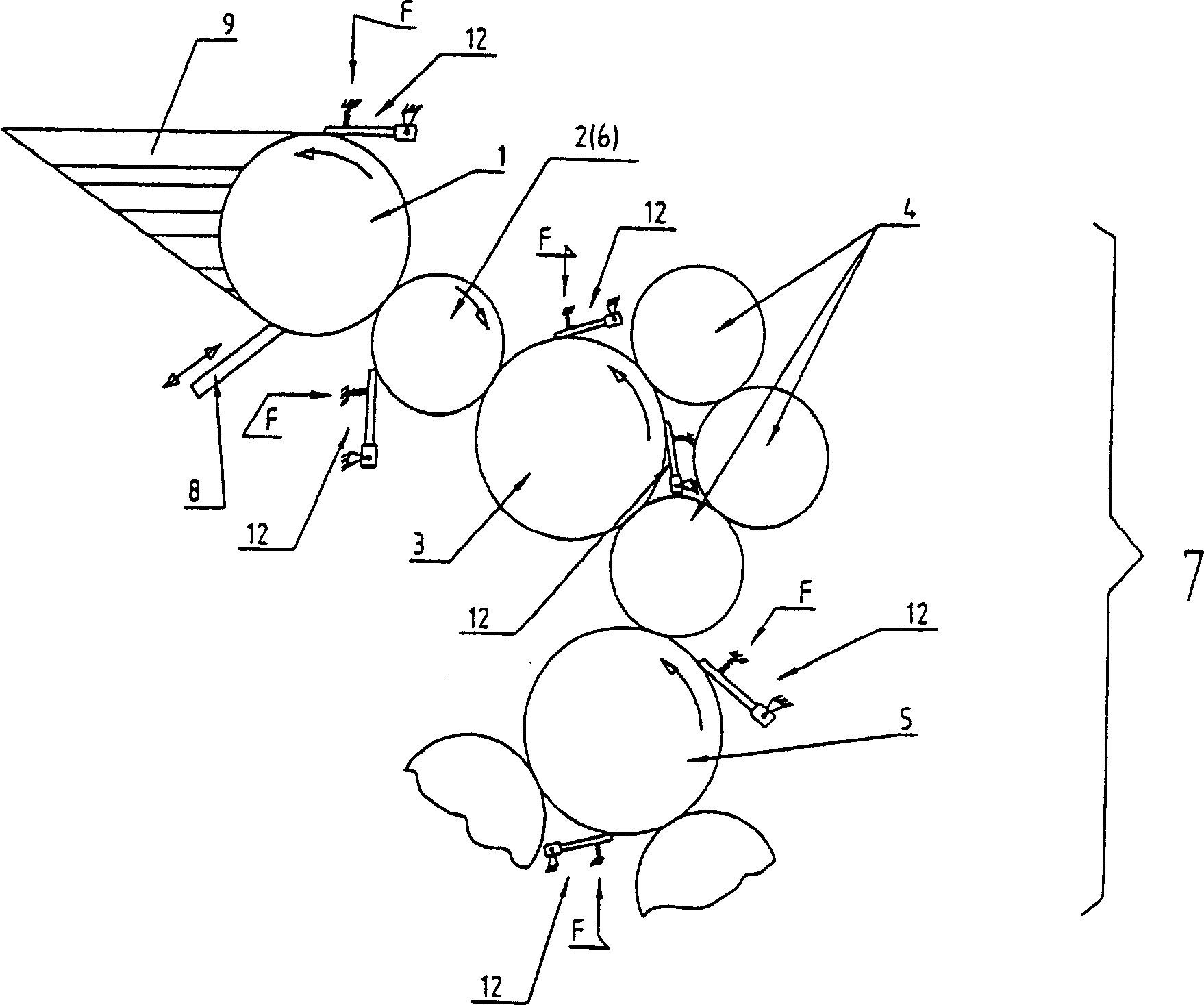

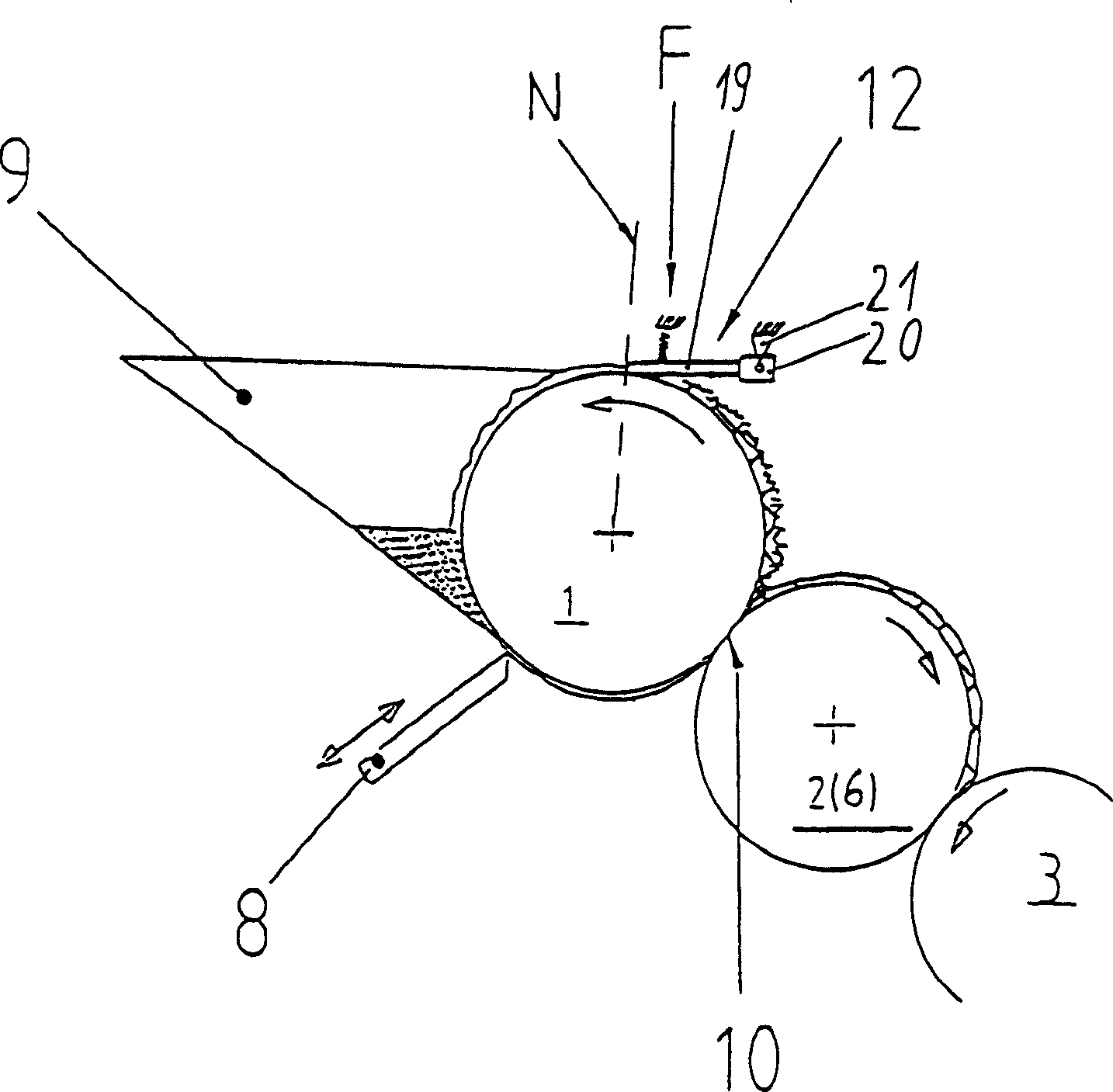

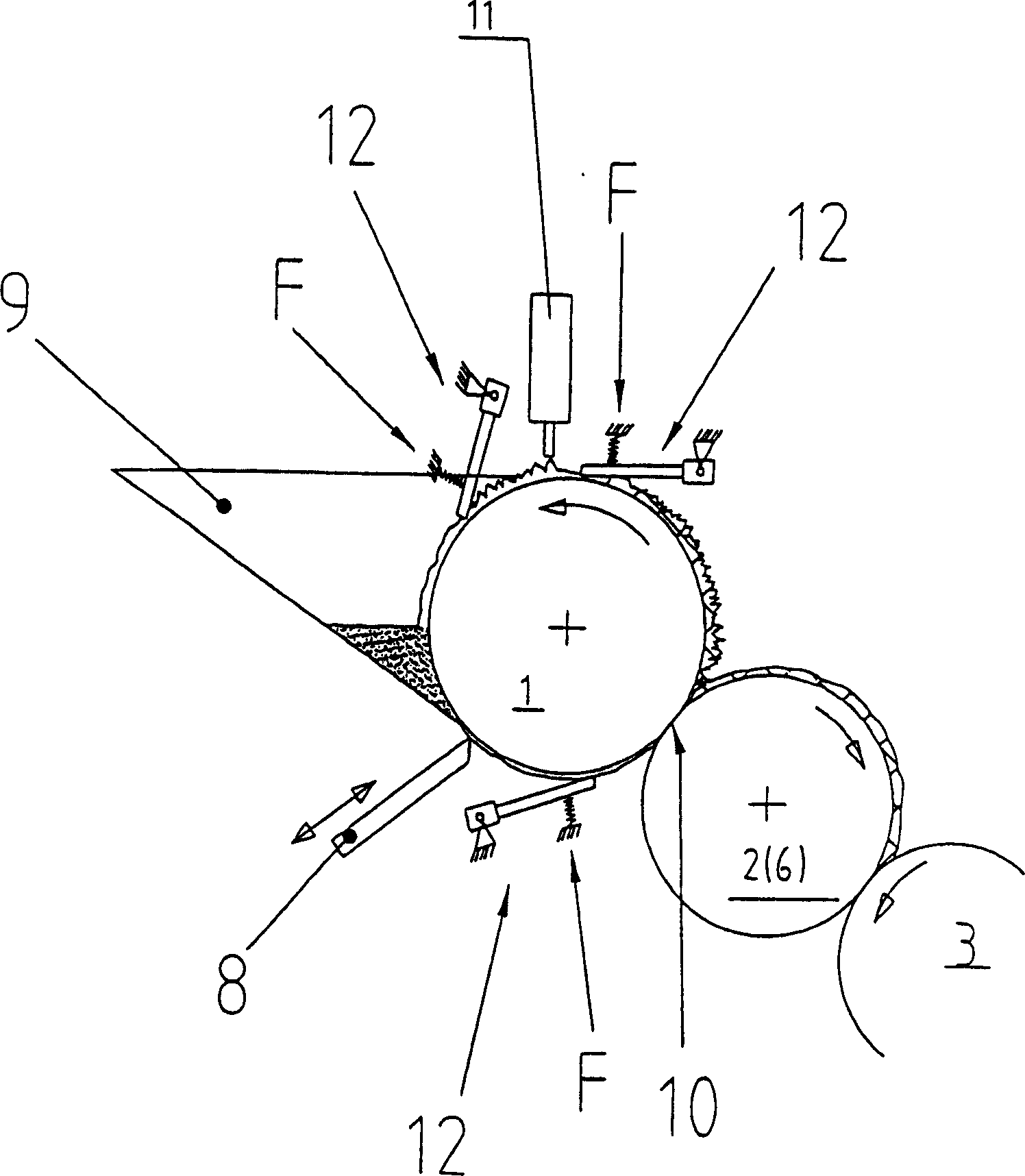

Dosing system for inking up rollers in printing machine

InactiveCN1426353AThe change in density is reducedQuality improvementPrinting press partsEngineeringPrinting press

The invention relates to a dosing system for inking up rollers in a printing machine. The aim of the invention is to create a dosing system which achieves, with a low level of complexity, a uniform and steady ink guidance on a roller surface and which noticeably improves the printing quality. To these ends, the invention provides that a coating device (12) is, in the rotational direction of a roller, engageably arranged on the outer surface of the roller (1), preferably after a contact zone (10) in which an ink separation occurs.

Owner:MAN ROLAND MASCHINEN AG

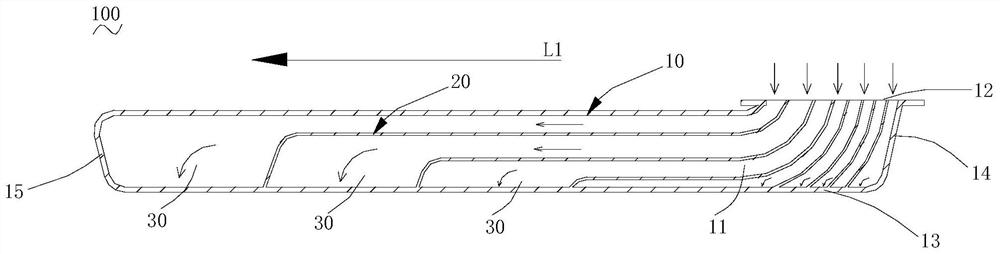

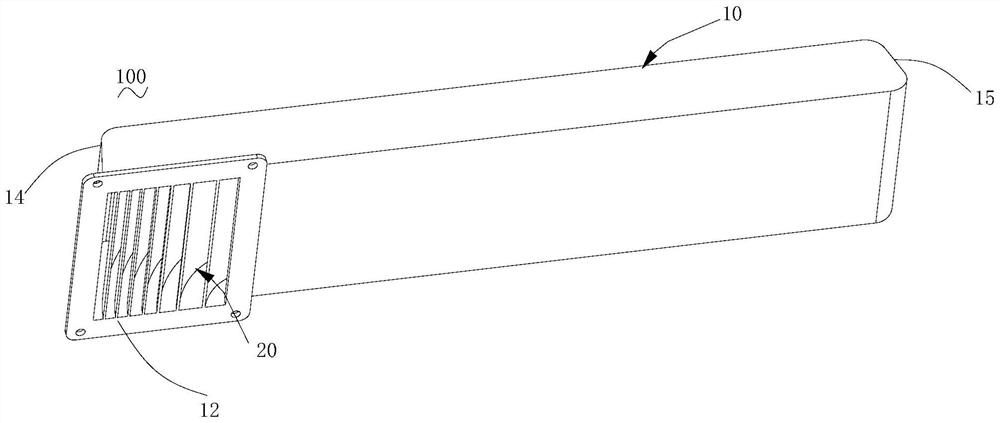

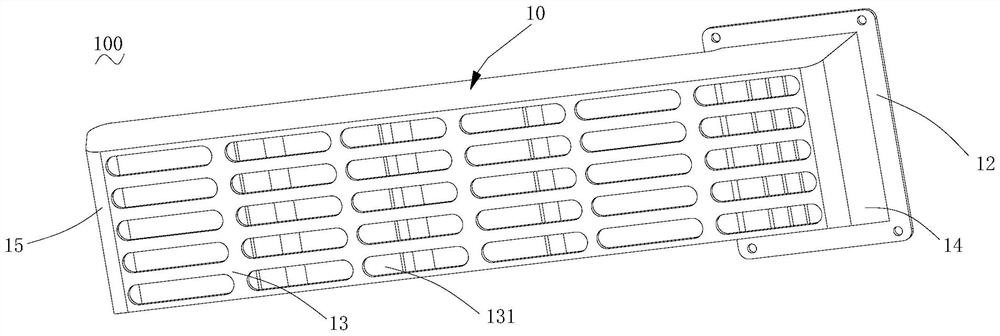

Air outlet device and air conditioner

PendingCN114110774AUniform deliveryUniform and stable deliveryLighting and heating apparatusAir conditioning systemsEngineeringMechanical engineering

The air outlet device comprises a shell and a partition piece, the shell is provided with a flowing cavity, an air inlet end and an air outlet end, the air inlet end and the air outlet end communicate with the flowing cavity, the air inlet end is used for feeding air into the flowing cavity, and the air outlet end is used for discharging air in the flowing cavity out of the flowing cavity. The partition piece is arranged in the flowing cavity and extends from the air inlet end to the air outlet end, and the partition piece is used for dividing the flowing cavity into at least two airflow channels. Air flow entering the flowing cavity from the air inlet end is divided into the at least two air flow channels, flows in the extending direction of the corresponding air flow channels and then is discharged out of the flowing cavity from the air outlet end. Therefore, according to the scheme, airflow can enter from the air inlet end and then is shunted to the airflow channel with smaller volume, so that the airflow can be uniformly and stably transmitted to the air outlet end, the air outlet is more uniform and smooth, and the use experience of a user is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Dosing system for inking up rollers in printing machine

InactiveCN1227110CFlat surfaceThe change in density is reducedPrinting press partsPrinting pressMechanical engineering

The invention relates to a dosing system for inking up rollers in a printing machine. The aim of the invention is to create a dosing system which achieves, with a low level of complexity, a uniform and steady ink guidance on a roller surface and which noticeably improves the printing quality. To these ends, the invention provides that a coating device (12) is, in the rotational direction of a roller, engageably arranged on the outer surface of the roller (1), preferably after a contact zone (10) in which an ink separation occurs.

Owner:MAN ROLAND MASCHINEN AG

Double-screw extruder for producing polyolefin pipe and production process thereof

The invention provides a double-screw extruder for producing a polyolefin pipe. A cooling channel in the axial direction of a double-screw mandrel is arranged in the double-screw mandrel of the extruder; an air hole channel and a water cooling channel are formed in a cylinder of the extruder; the air hole channel is in the axial direction of the cylinder of the extruder; and the water cooling channel is externally connected with a circulating water pipe. The invention further provides a production process for producing the polyolefin pipe by using the double-screw extruder; and the double-screw extruder is used for producing the polyolefin pipe, so that the yield is high, the production steps are simple and continuous, the production efficiency is high, and the cost is low.

Owner:WUHAN KINGBULL ECONOMIC DEV

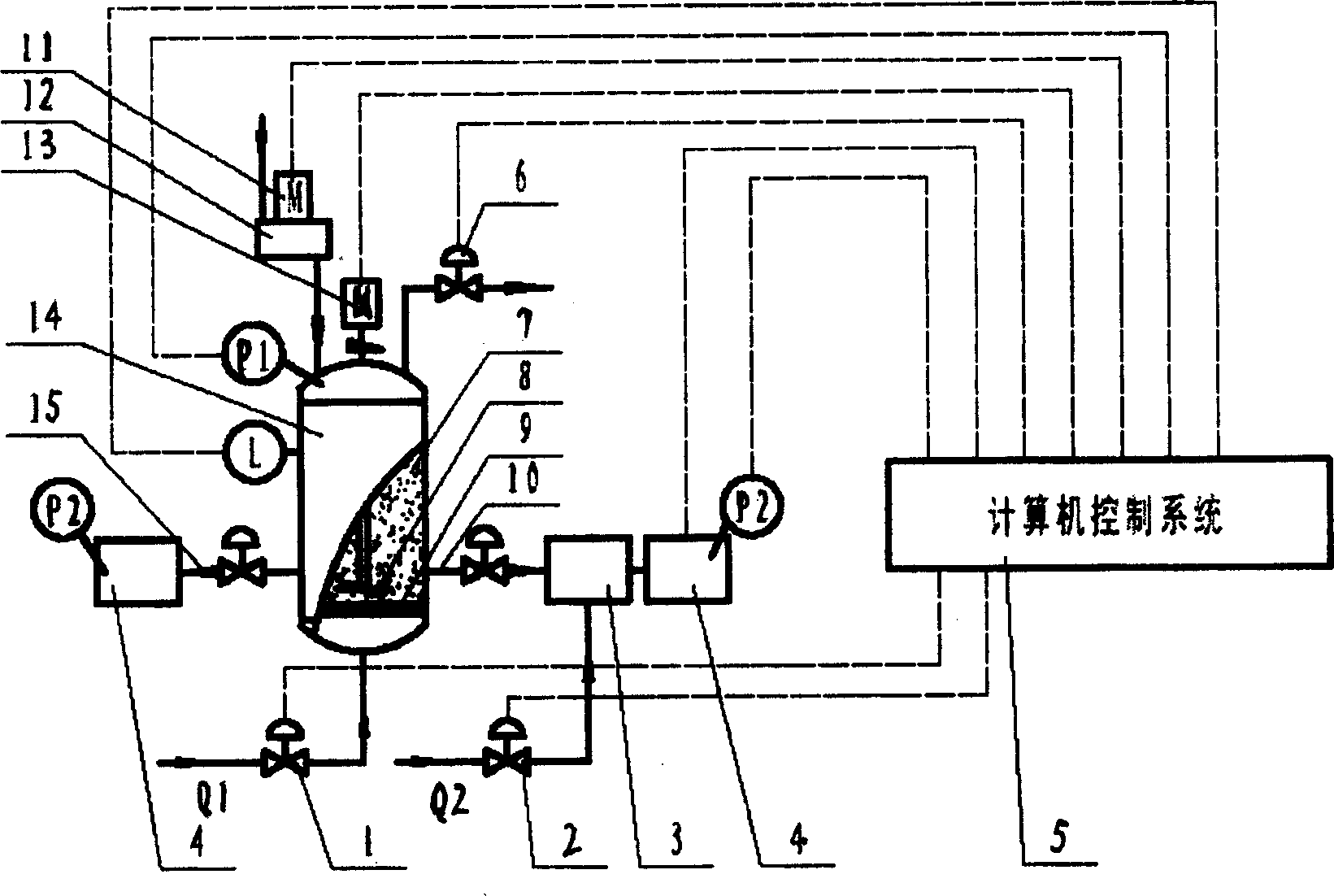

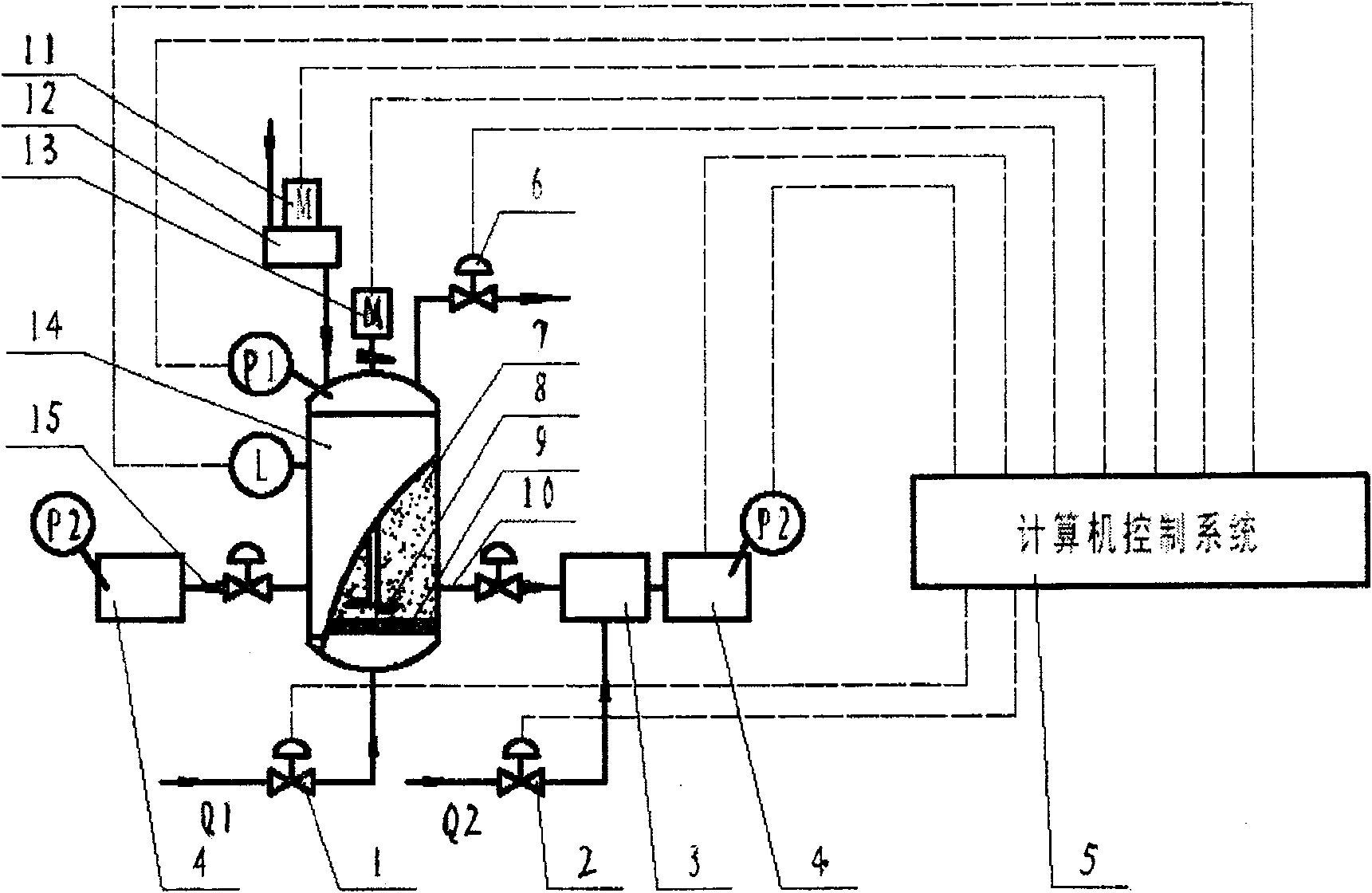

Fixed fluidized bed powder metering and distributing delivery device and method of realizing high stability transferring and distributing powder

InactiveCN100564206CReduce transmission errorReduce investment and maintenance workloadBulk conveyorsChemical industryFluidized bed

The invention discloses a powder metering, distributing and conveying device for a fixed fluidized bed, which comprises a fluidized tank, a powder feed pipe connected to the top of the fluidized tank, and a fluidized gas inlet pipe connected to the bottom of the fluidized tank. A powder level gauge is installed on the tank, a filter cloth fluidization gas distributor is installed at the lower end of the fluidization tank cavity, a mechanical stirring paddle is installed in the fluidization tank, and a mechanical stirring paddle is installed above the filter cloth fluidization gas distributor There are powder feeding pipelines on the side wall at the same height or slightly higher. This device is used to achieve high-stable metering, conveying and distributing powder, according to the physical characteristics of powder conveying, fluidized gas and powder feeding pipeline, as well as the diameter and length of powder feeding pipeline, the pressure between the fluidized tank and the powder receiving device, etc. The parameters are calculated precisely for each component. Only one piece of equipment is used to realize stable and continuous conveying, accurate metering and distribution of powder under high gas-solid ratio. The present invention is especially suitable for thermal plasma cracking coal direct production of acetylene powder feeding device and coal gasification device, and can be widely used in environments where powder is used, such as plastic processing, chemical industry, steel industry and the like.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI +1

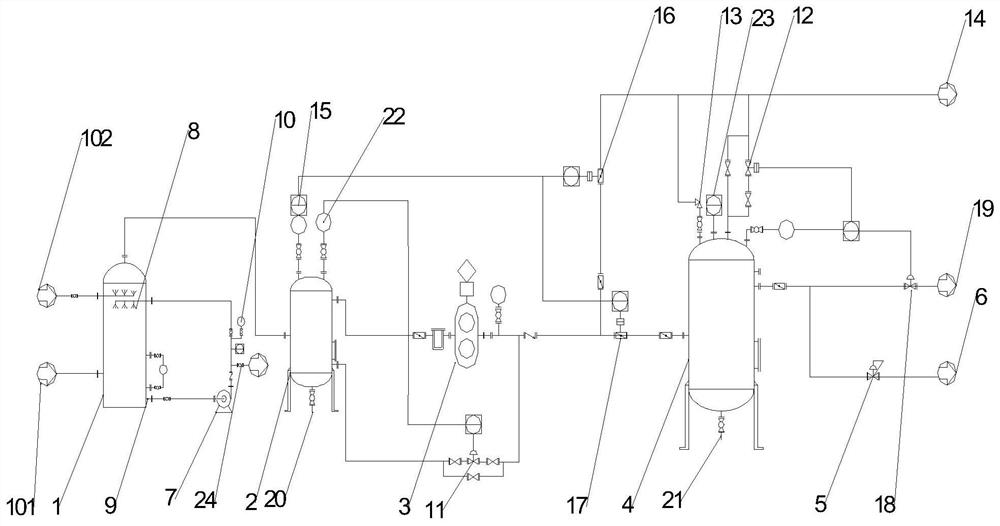

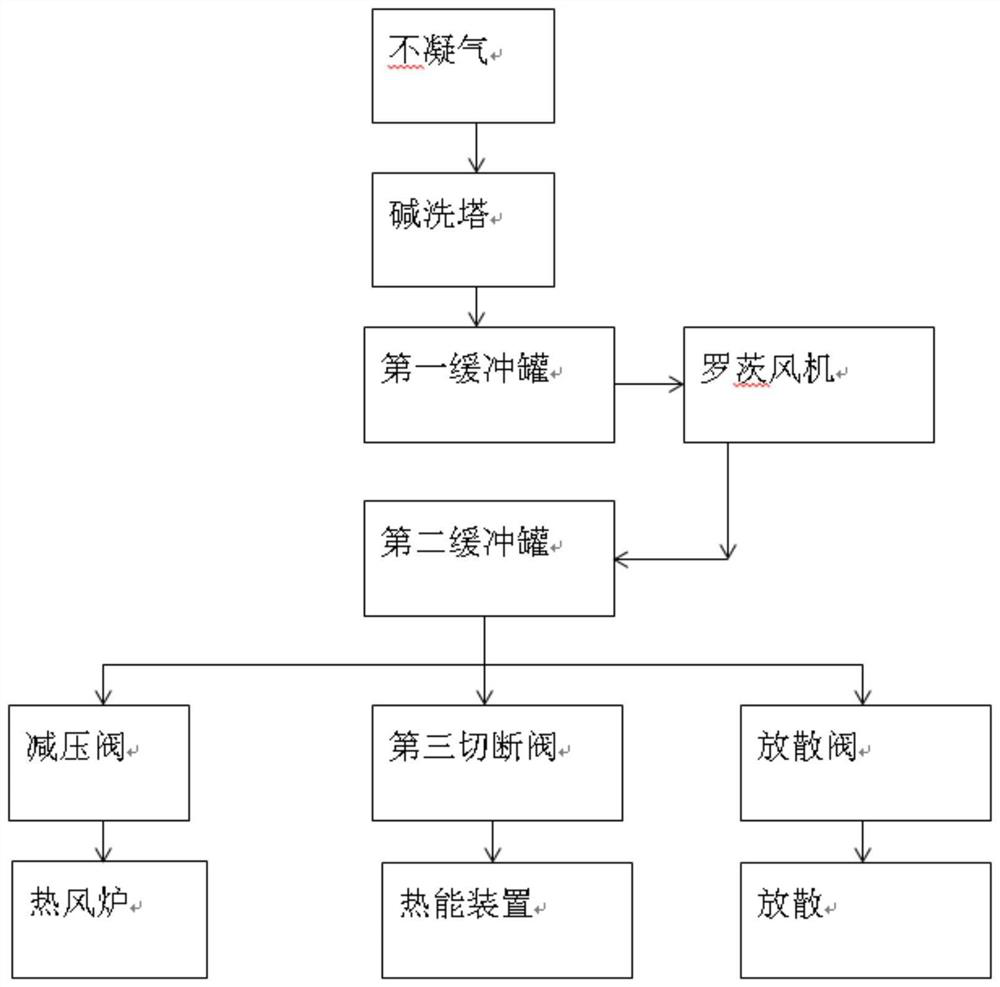

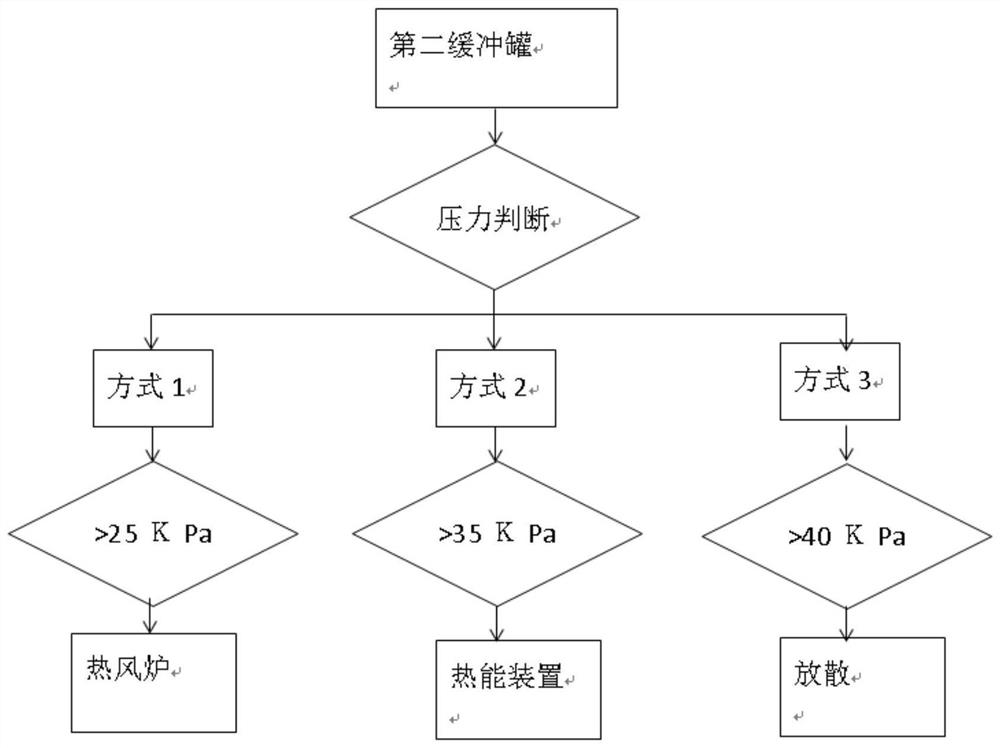

Pyrolyzing furnace non-condensable gas collecting, pressure-stabilizing, utilizing and treating method

PendingCN113493705ASolve difficult problemsHigh degree of automationCombustible gas purificationHot air ovenBuffer tank

The invention discloses a pyrolyzing furnace non-condensable gas collecting, pressure-stabilizing, utilizing and treating method, which comprises: allowing non-condensable gas generated by a pyrolysis furnace to enter an alkaline washing tower through a gas inlet, carrying out a neutralization reaction to remove acidic materials in the non-condensable gas, and allowing the non-condensable gas to enter a first buffer tank for buffer storage; adopting a Roots blower to pressurize and convey the non-condensable gas in the first buffer tank into a second buffer tank for buffering; and conveying the non-condensable gas cached in the second buffer tank to a hot blast stove in the pyrolyzing furnace through a pressure reducing valve for combustion and heat supply. The non-condensable gas does not corrode equipment during combustion after being deacidified by the alkaline washing tower, and meanwhile, the problems of difficulty in tail gas treatment and the like are solved. A collecting, pressure-stabilizing, utilizing and treating system for the non-condensable gas is high in automation degree, high in safety design degree and easy to operate. The pressure in the pyrolyzing furnace can be effectively controlled to be stable, and the gas of the hot blast stove is stably and uniformly conveyed, so that the whole pyrolyzing system continuously and stably runs.

Owner:HUNAN VARY TECH

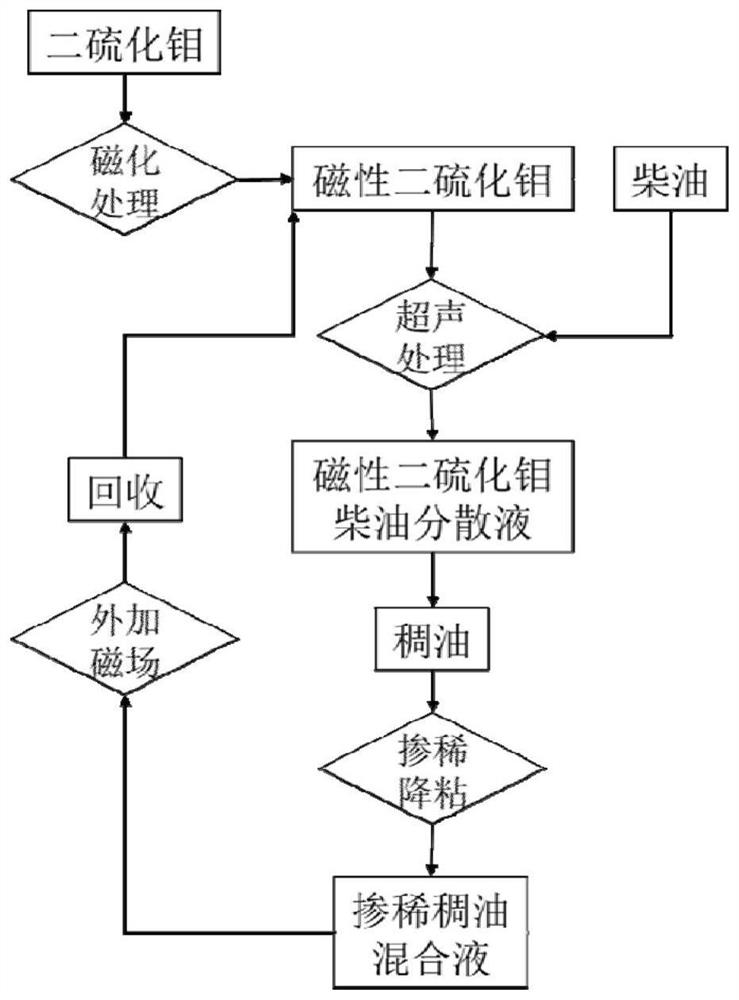

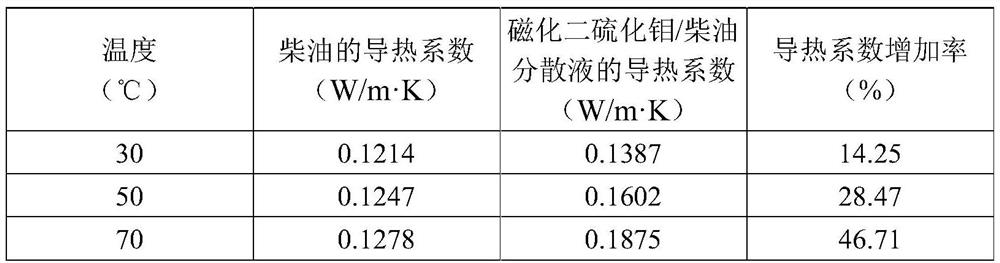

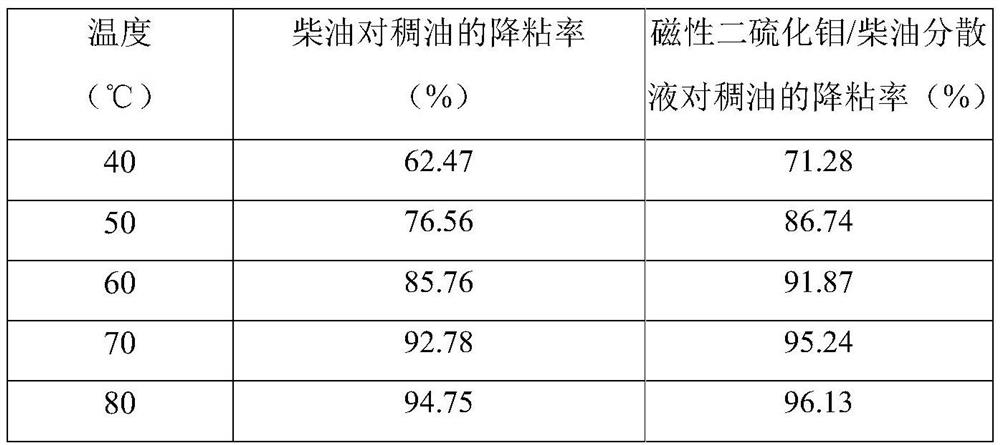

Method for reducing viscosity of thick oil by blending thin oil based on oil-based nano fluid

ActiveCN113528108AImprove thermal conductivityGood dispersionDrilling compositionMolybdenum sulfidesVegetable oilPhysical chemistry

The invention discloses a method for reducing the viscosity of thick oil by blending thin oil based on oil-based nano fluid. The method comprises the following steps: magnetizing molybdenum disulfide to obtain magnetic molybdenum disulfide; dispersing the obtained magnetic molybdenum disulfide in thin oil, which is selected from one of diesel oil, bio-diesel and vegetable oil, to obtain magnetic molybdenum disulfide / thin oil dispersion liquid; and mixing the magnetic molybdenum disulfide / thin oil dispersion liquid into thick oil for viscosity reduction treatment. The high-thermal-conductivity magnetic nano molybdenum disulfide is introduced into the thick oil thin oil blending viscosity reduction process, heat of thin oil can be transferred into thick oil more evenly and more efficiently, the heat utilization rate is increased, meanwhile, the thick oil viscosity reduction rate is increased, and the thick oil recovery cost is reduced; and the high-thermal-conductivity nano molybdenum disulfide is magnetized, the obtained magnetic molybdenum disulfide can be efficiently recycled under the condition that an artificial magnetic field is added after the heavy oil is lifted to the ground, the performance is basically unchanged after washing and drying treatment, the magnetic molybdenum disulfide can be recycled, and the cost of doping the high-thermal-conductivity nano fluid to achieve viscosity reduction of the heavy oil is reduced.

Owner:CHANGZHOU UNIV

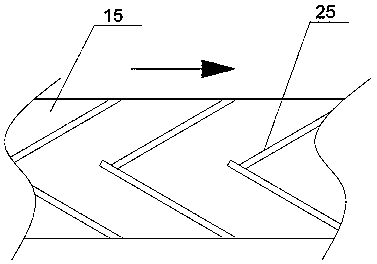

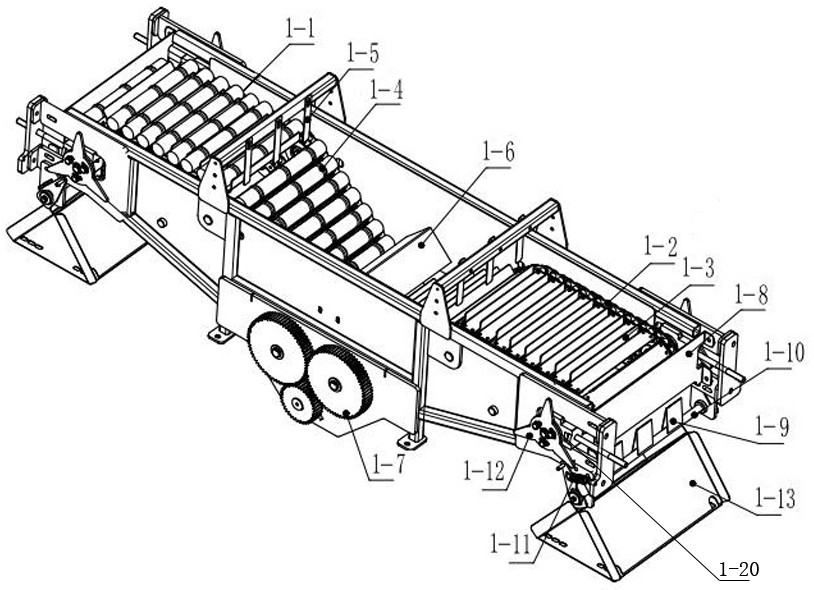

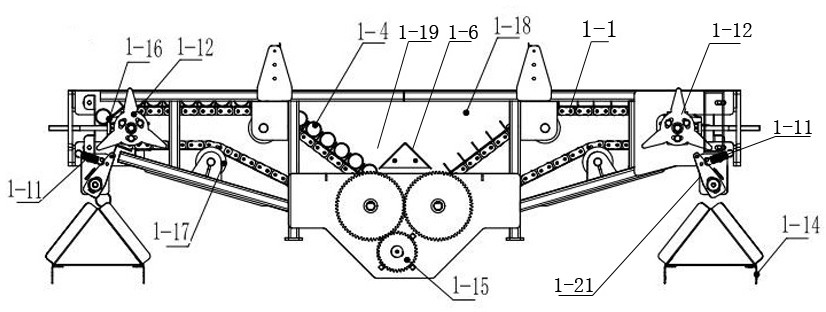

Sugarcane seed stem seeding device and sugarcane planter

ActiveCN114342618AUniform and stable deliveryConducive to fall intoPlantingAgricultural scienceAgricultural engineering

The sugarcane seed stem seeding device comprises two groups of conveying belts with opposite conveying directions, one ends of the two groups of conveying belts are close to each other, and the other ends of the two groups of conveying belts extend away from each other; inclined sections which are bent and extend downwards are formed at the ends, close to each other, of the two conveying belts, the bottom ends of the inclined sections of the two conveying belts oppositely define a seed stem groove for containing sugarcane seed stems, two inclined baffles are arranged in the middle of the seed stem groove, the tops of the two inclined baffles are opposite, and the lower portions of the two inclined baffles obliquely extend towards the two conveying belts respectively; seed conveying grooves extending in the width direction of the conveying belts are distributed in the conveying belts, and the ends, deviating from each other, of the two conveying belts are discharging ends extending to the position above the ditching device. Sugarcane seed stems can be automatically extracted, conveyed and fed, and the manual workload is reduced. And the two groups of conveying belts for reverse conveying increase the seeding area, so that multi-row seeding can be realized at the same time. Sugarcane seed stems can be stably and uniformly conveyed, uniform sowing is achieved, the phenomenon of material blocking is avoided in the sugarcane conveying process, and the sowing reliability and efficiency are guaranteed.

Owner:LUOYANG CHENHAN AGRI EQUIP TECH CO LTD

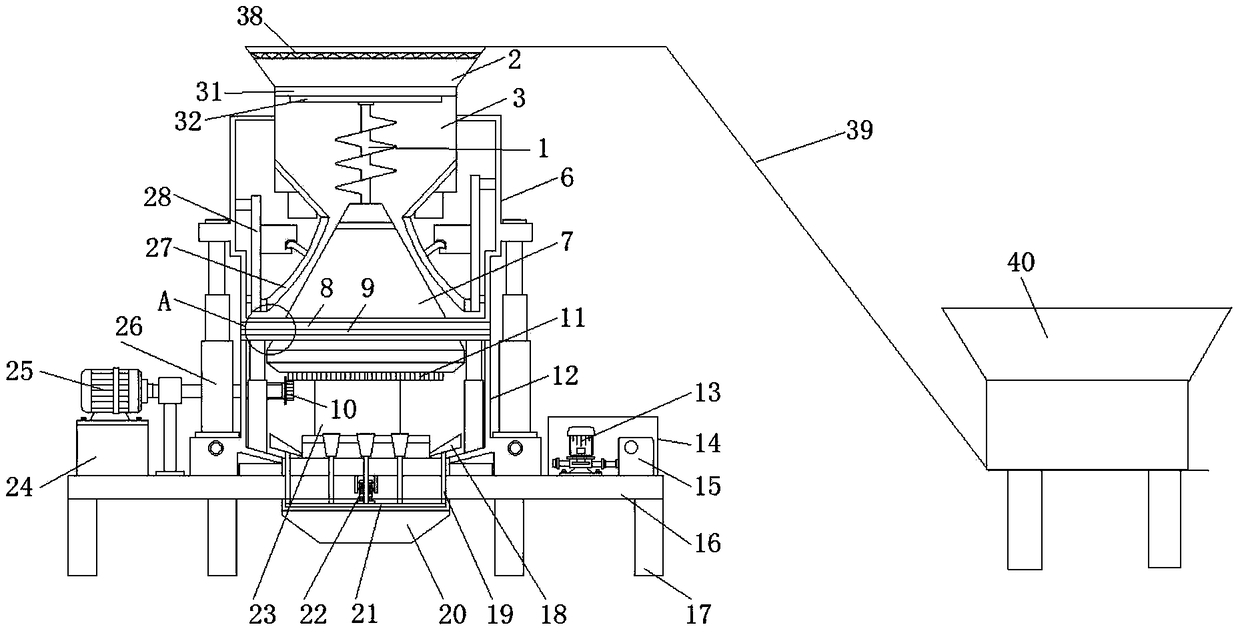

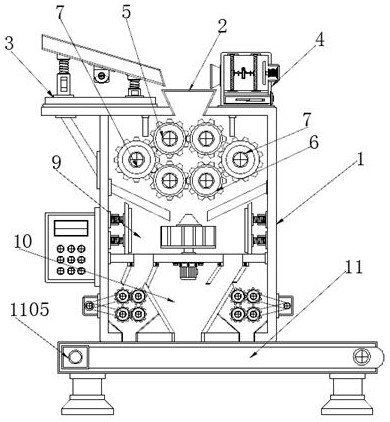

Novel high-quality aggregate shaping machine

PendingCN114392797AUniform and stable deliveryFast deliveryCleaning using gasesGrain treatmentsProcess engineeringMachine

The novel high-quality aggregate shaping machine comprises a shaping machine body, a feeding mechanism, a dust collection mechanism, a material throwing mechanism and a fine grinding discharging mechanism, and the material throwing mechanism and the fine grinding discharging mechanism are sequentially arranged in the shaping machine body from top to bottom. According to the novel high-quality aggregate shaping machine, through the arrangement of the feeding mechanism, the first crushing roller set, the second crushing roller set, the material throwing mechanism and the feeding mechanism, the overall automation degree of the device is greatly improved, the overall working efficiency is improved, meanwhile, raw materials can be preliminarily crushed through rotary crushing of the first crushing roller set and the second crushing roller set, and the crushing efficiency is improved. And then, the material throwing mechanism is used for carrying out collision and crushing again to remove edges and corners, a multi-layer crushing mode is adopted, so that the overall processing effect is better, meanwhile, through a vibration type feeding mode of the feeding mechanism, the raw materials are more uniform and stable during conveying, the possibility of blockage is reduced, and the overall working efficiency is improved.

Owner:山东华锴重工机械有限公司

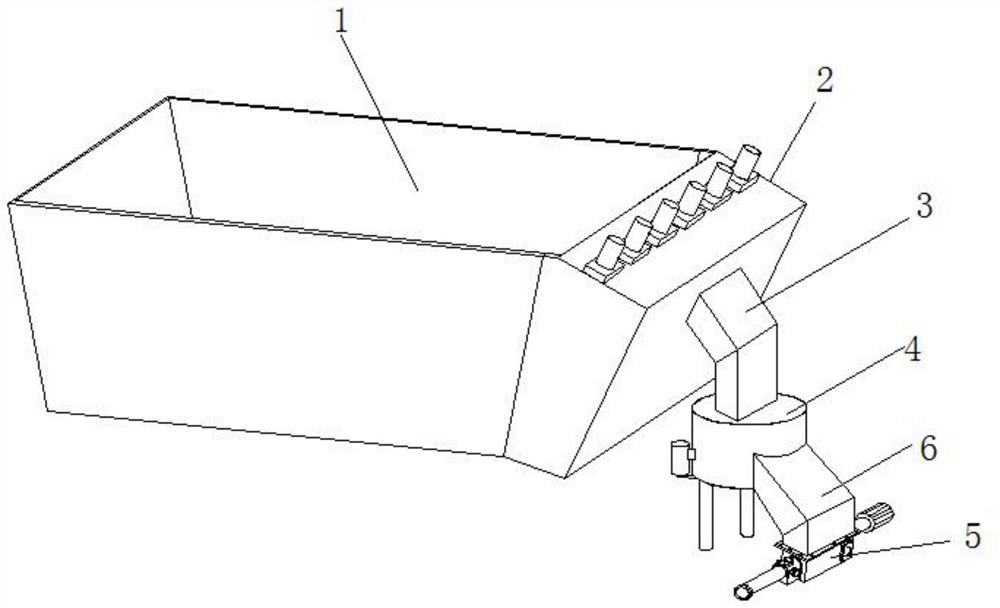

Feeding system for biomass biogas fermentation

PendingCN111876311AUniform and stable deliveryNo cloggingGas production bioreactorsEnzymology/microbiology apparatusMicroorganismFiber

The invention relates to a feeding system for biomass biogas fermentation. The feeding system comprises a biomass storage tank, wherein an auger lifting device is arranged on one side of the biomass storage tank, and an outlet in the side wall of the upper part of the auger lifting device communicates with a smashing device through a first pipeline; and an outlet of the smashing device communicates with a solid-liquid mixing feeding pump through a second pipeline. According to the invention, long fibers and materials with non-uniform structures are smashed, a larger surface area is formed after the materials are smashed, the degradation of microorganisms is greatly promoted, the smashed biomass and water or biogas are conveyed into a fermentation system together, the material conveying isstable and uniform, and blockage or accumulation is avoided.

Owner:定州四方诚信畜牧科技有限公司

A pressure regulating mixer

ActiveCN111097299BLittle resistance lossAvoid accumulationFlow mixersTransportation and packagingEngineeringPressure regulator

The invention discloses a pressure-regulating mixer, which comprises a powder inlet and a mixer main body, the powder inlet is arranged on the side wall of the mixer main body, and a blanking chamber is arranged inside the mixer main body facing the powder inlet. A nozzle is arranged in the blanking chamber, and the pressure regulating mixer also includes a pressure regulating assembly and a pressure equalizing chamber, and the pressure regulating assembly includes a negative pressure regulating mechanism. In the pressure regulating mixer disclosed by the present invention, the negative pressure regulating mechanism enters into the interior of the mixer main body to block the spraying of the nozzle, and adjusts the negative pressure in the mixer main body by adjusting the size of the spraying range of the nozzle, thereby reducing the resistance loss of the mixer; The pressure equalizing chamber and its pressure measuring hole prevent powder from accumulating in the blanking chamber; online adjustment of negative pressure can be easily realized, ensuring uniform and stable powder delivery.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com