A pressure regulating mixer

A mixer and negative pressure technology, applied in fluid mixers, mixers, chemical instruments and methods, etc., can solve the problems of difficult negative pressure adjustment, large resistance loss, powder accumulation in the blanking chamber, etc., and achieve convenient adjustment of negative pressure. pressure, ensure powder transportation, and reduce the effect of resistance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 provides a plate type pressure regulating mixer, and its structure will be described in detail below.

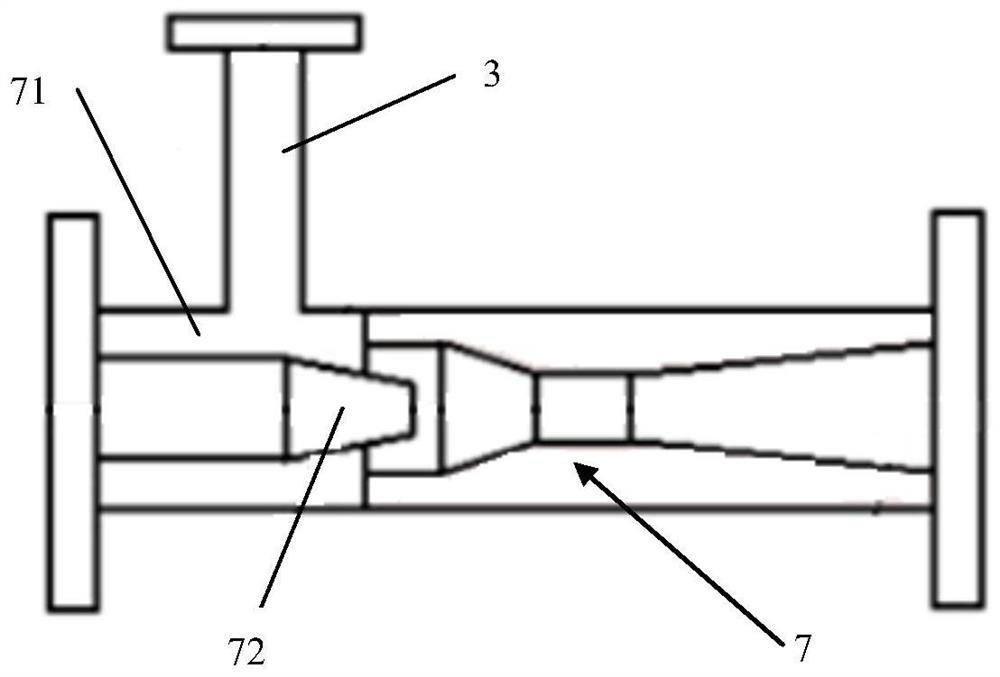

[0023] refer to figure 1 , the high-pressure Venturi mixer includes a powder inlet 3 and a mixer body 7, the mixer body 7 is an important place for mixing powder and carrier gas, the powder inlet 3 is arranged on the side wall of the mixer body 7, and the powder The material falls into the mixer main body 7 from the powder inlet 3, and a blanking chamber 71 is arranged in the mixer main body 7 facing the powder inlet 3, and a nozzle 72 is arranged in the blanking chamber 71, and the carrier gas flows from the nozzle 72 spray out.

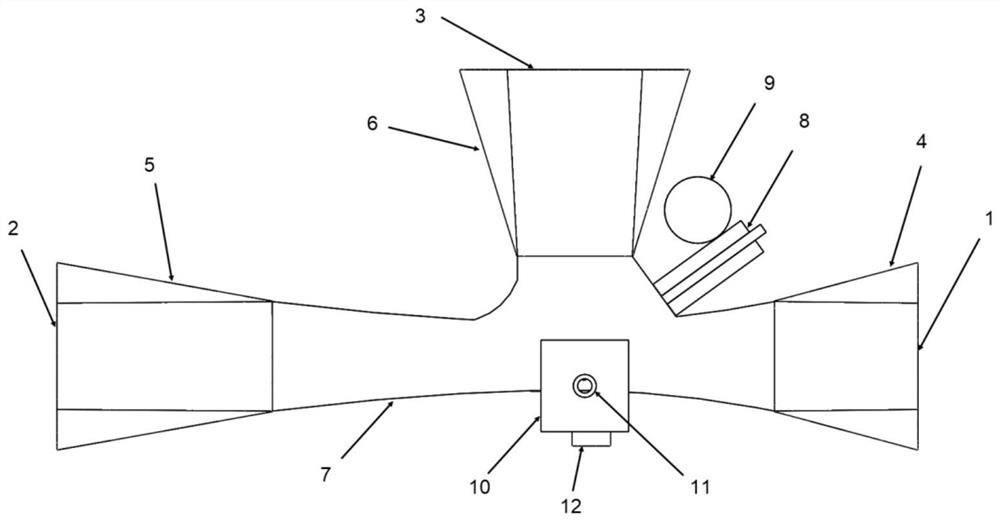

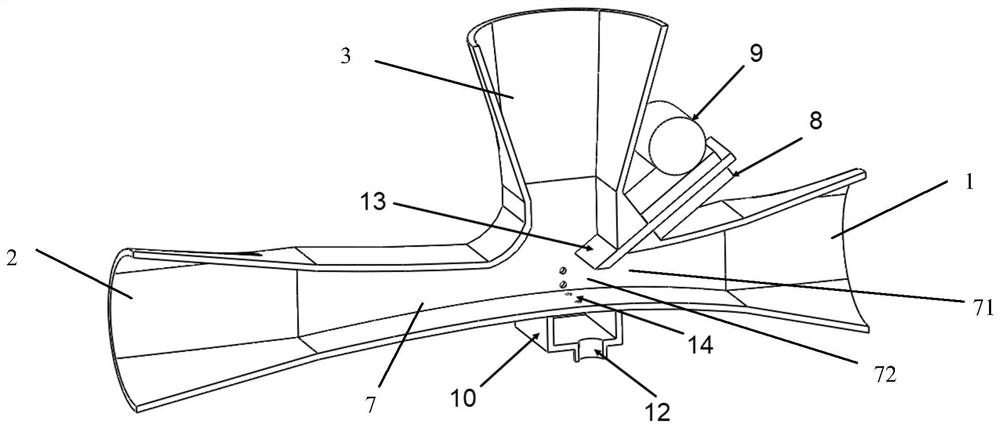

[0024] On the basis of the existing high-pressure Venturi mixer, the plate-type pressure-regulating mixer provided in Example 1 improves it. Specifically, the two ends of the mixer body 7 are respectively set as the carrier gas inlet 1 and the gas-solid two-phase outlet 2, refer to figure 2 , usually connected to a square p...

Embodiment 2

[0038] Embodiment 2 provides a knob-type pressure-regulating mixer. On the basis of Embodiment 1, the negative pressure regulating mechanism is improved, and the improvements will be described in detail below.

[0039] As another embodiment of the negative pressure adjusting mechanism, the negative pressure adjusting mechanism includes a negative pressure adjusting rotating plate 15 and a rotating shaft 16 .

[0040] refer to Figure 4 and Figure 5 The fixed end of the negative pressure adjusting rotating plate 15 is arranged on the inner wall of the connection between the powder inlet 3 and the mixer main body 7, and the movable end of the negative pressure adjusting rotating plate 15 extends into the blanking chamber inside the mixer main body 7 71,

[0041] The lower bottom surface of the negative pressure adjustment rotary plate 15 and the two sides of the adjacent mixer main body 7 and the bottom surface of the mixer main body 7 opposite to it form the nozzle 72, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com