Feeding system for biomass biogas fermentation

A biogas fermentation and biomass technology, applied in the field of biomass biogas fermentation feeding system, can solve the problems of not being able to supply normally and stably, and the feeding machine is easy to be blocked, and achieve the effect of stable and uniform material transportation and promotion of degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

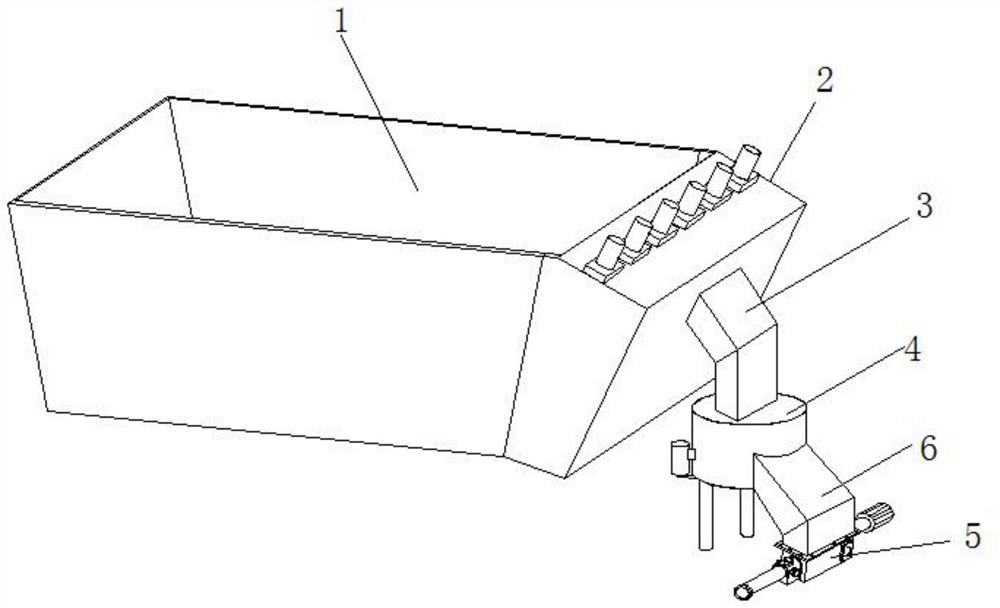

[0028] Such as figure 1 As shown, a feeding system for biomass biogas fermentation is disclosed in this embodiment, including a biomass storage tank 1, an auger lifting device 2 is arranged on one side of the biomass storage tank 1, and the auger lifts The outlet of the upper side wall of the device 2 communicates with the pulverizing device 4 through the first pipeline 3 , and the outlet of the pulverizing device 4 communicates with the solid-liquid mixing feeding pump 5 through the second pipeline 6 . It should be noted that the biomass storage tank 1 stores green or yellow corn stalks, preliminarily crushed rice straws, fertilizers or discarded fruits.

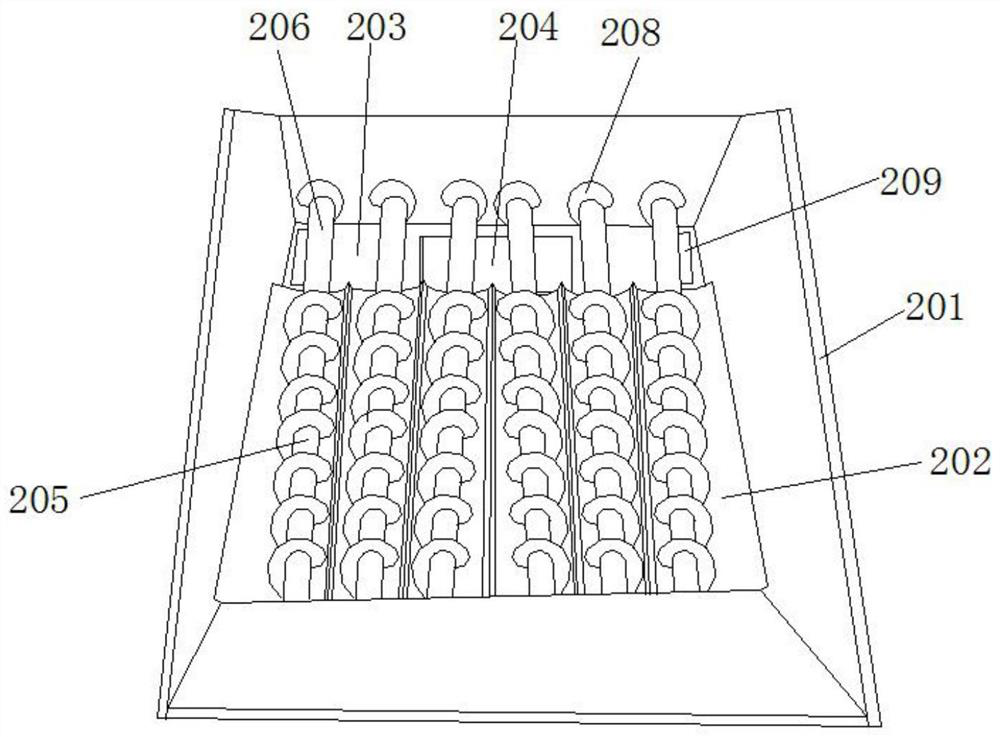

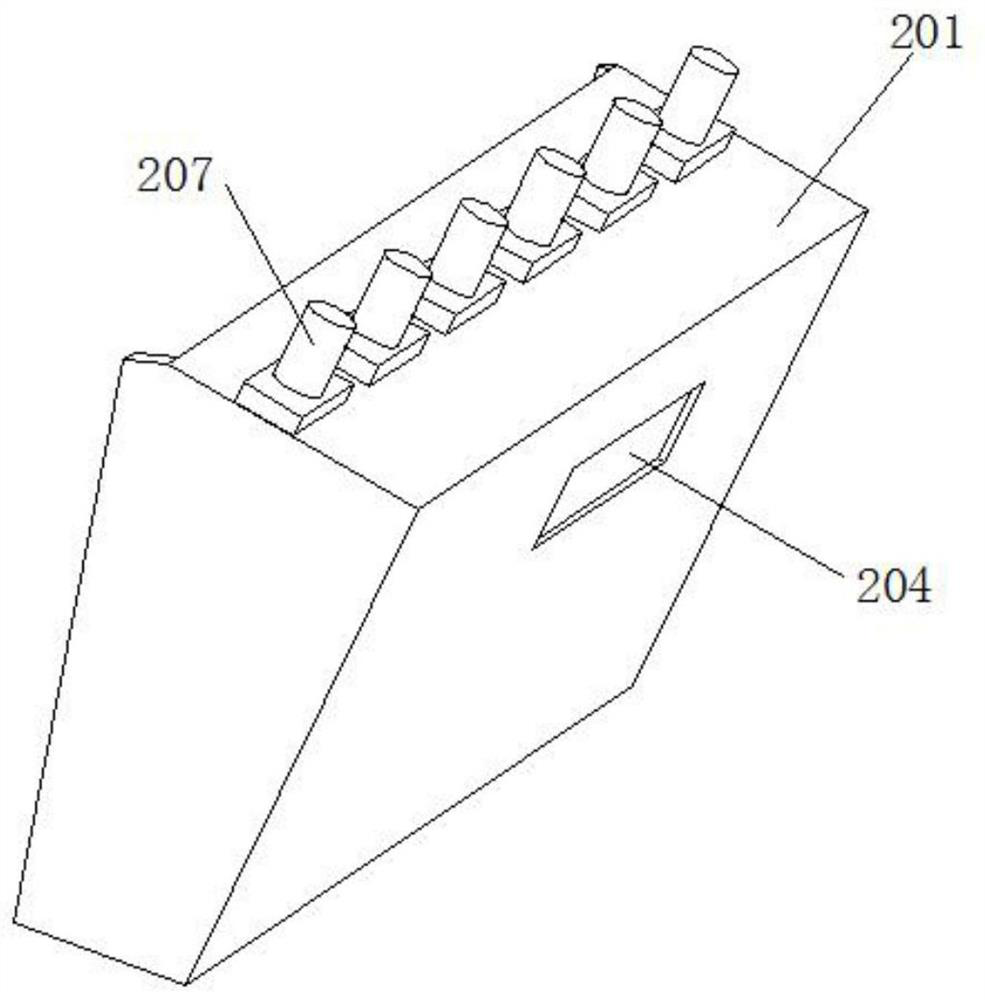

[0029] Such as figure 2 with 3 As shown, the auger lifting de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com