Sugarcane seed stem seeding device and sugarcane planter

The technology of a seeding device and a planting machine is applied in the field of sugarcane planting machinery, which can solve the problems of easy material jamming, uneven seeding of seeding equipment, high labor intensity of manual seeding, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings and specific embodiments. The specific content listed in the following embodiments is not limited to the technical features necessary for the technical problem to be solved by the technical solution described in the claims. Meanwhile, the enumeration is only a part of the present invention, not all of the embodiments.

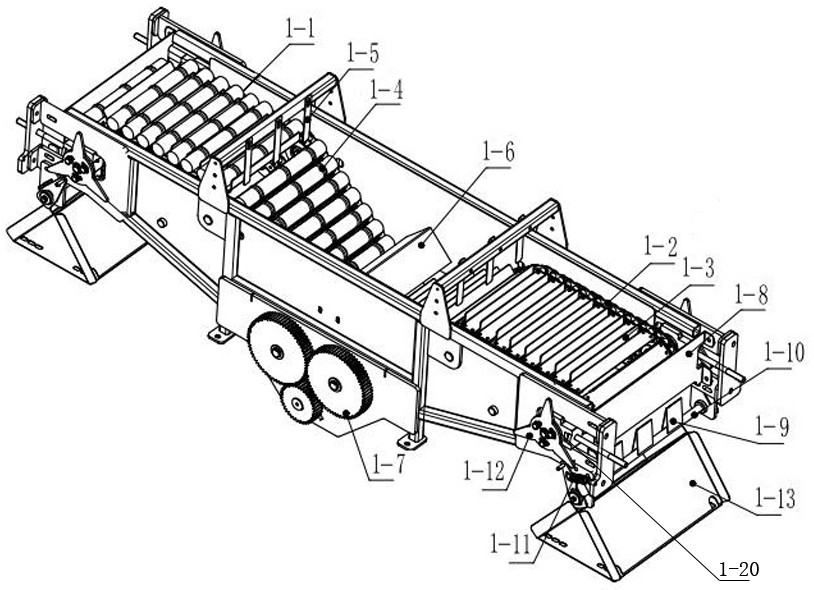

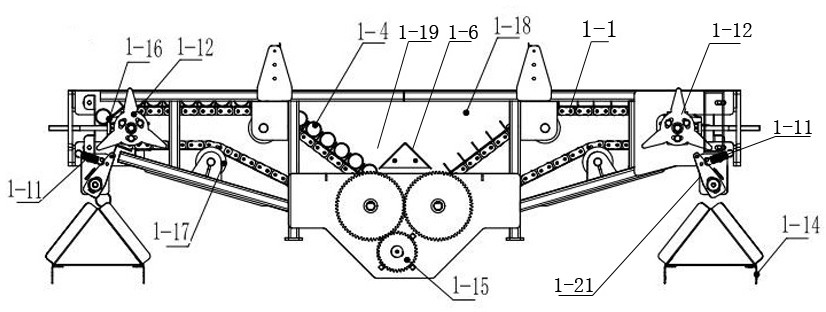

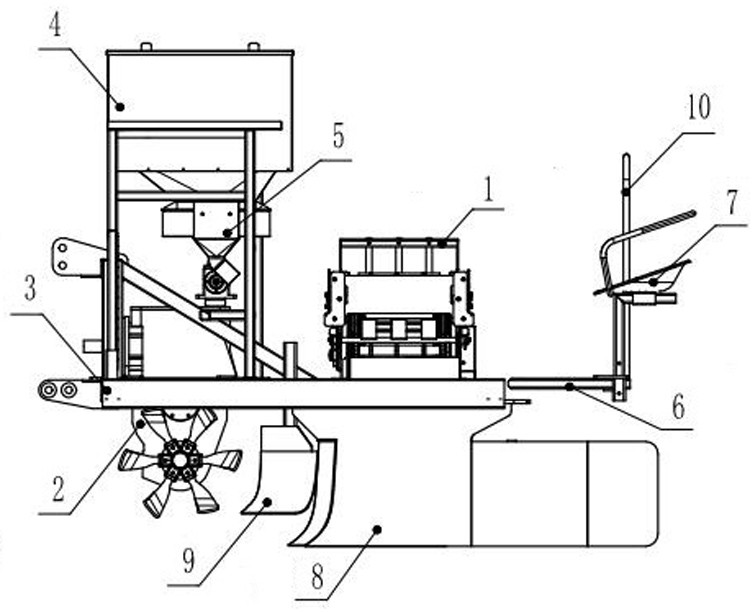

[0022] Such as figure 1 and 2 As shown, the sugarcane stem sowing device includes two groups of conveyor belts 1-1, one end of the two groups of conveyor belts 1-1 is opposite and close to each other, and the other end extends away from each other. Both sets of conveyor belts 1-1 have a curved section, so that the sides far away from each other are roughly horizontal, while the sides close to each other are bent downwards and extend. The part that bends down and extends is defined as an inclined segment. In ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com