Patents

Literature

53results about How to "Conducive to fall into" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

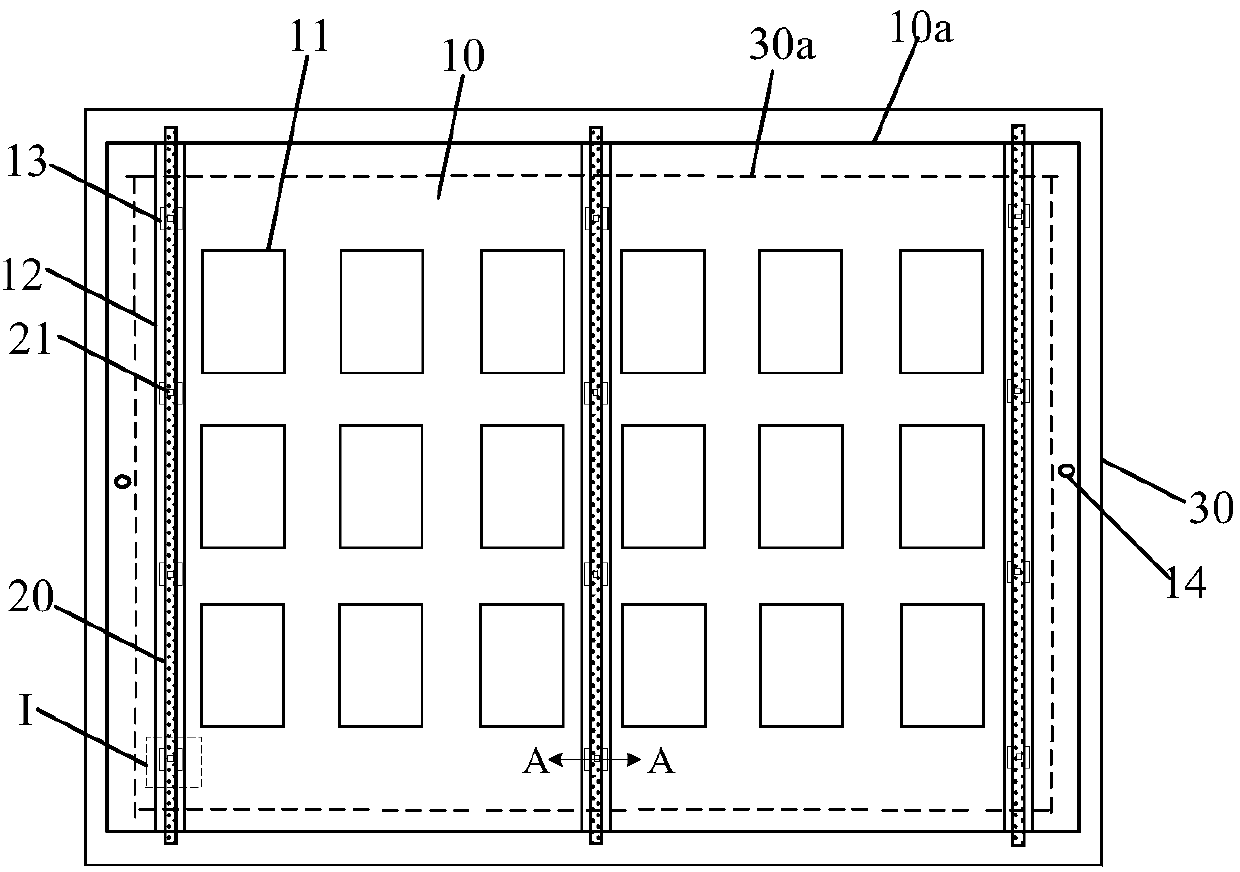

Mask plate and manufacturing method and evaporation method thereof

ActiveCN107653436AReduce thicknessImprove manufacturing precisionVacuum evaporation coatingSputtering coatingMechanical engineeringMaterials science

The invention provides a mask plate. The mask plate comprises a mask plate body provided with a mask pattern. The mask plate body comprises a first surface and a second surface which are opposite. Thefirst surface is provided with a groove, the groove is located in the area outside the mask pattern, and a first through hole penetrating the mask plate body is formed in the bottom of the groove. Correspondingly, the invention further provides a manufacturing method and an evaporation method of the mask plate. By means of the mask plate and the manufacturing method and the evaporation method ofthe mask plate, the mask plate alignment precision during evaporation can be improved, and accordingly the evaporation effect is improved.

Owner:BOE TECH GRP CO LTD

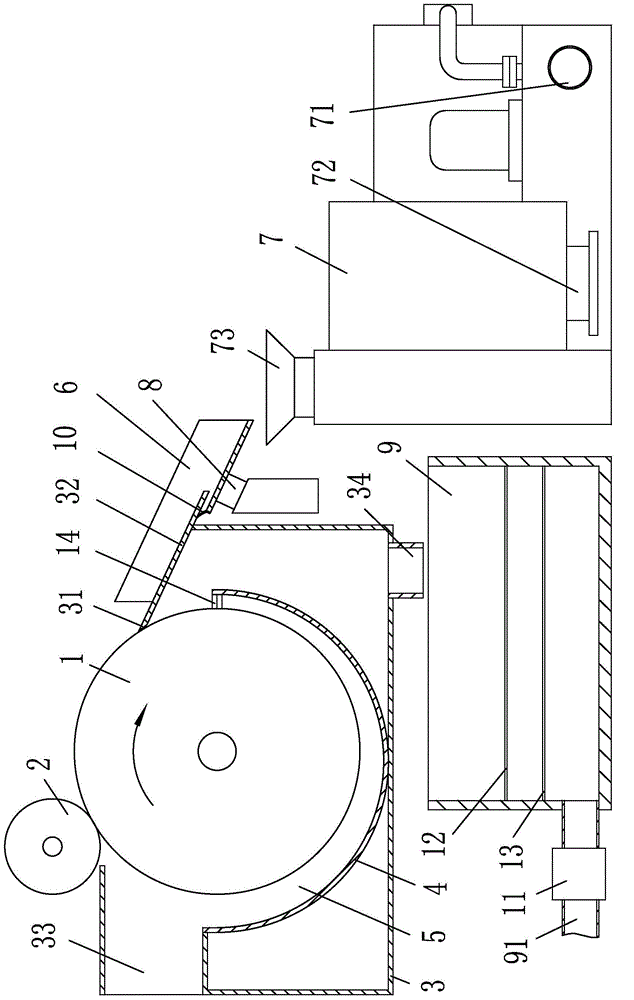

Cutting fluid recovering device for grinding machine

InactiveCN104972401AImprove recycling qualityEasy to separateMagnetic separationFiltration circuitsEngineeringCooling fluid

The invention relates to the field of recovery of cooling liquid of machine tools and provides a cutting fluid recovering device for a grinding machine. The cutting fluid recovering device for the grinding machine comprises a shell, a magnetic roller, a soft roller, an arc-shaped supporting plate, a scrap iron cutting fluid separation device and a cutting fluid filtering device, wherein both the magnetic roller and the soft roller are connected with the shell in a pivoted mode; the arc-shaped supporting plate is located under the magnetic roller, and the two ends of the arc-shaped supporting plate are connected with the shell. The shell is provided with an oblique scrap scraping plate, a fluid inlet and a fluid outlet, wherein the scrap scraping end of the oblique scrap scraping plate is located at the high end, the fluid inlet is located in the back side of the upper portion of the magnetic roller, and the fluid outlet is located in the bottom. A cutting fluid channel is formed between the magnetic roller and the arc-shaped supporting plate, and one end of the cutting fluid channel is communicated with the fluid inlet. The scrap scraping end is located above the other end of the cutting fluid channel. The soft roller is located between the scrap scraping end and the fluid inlet. The cutting fluid recovering device for the grinding machine is good in cutting fluid recovering quality and high in cutting fluid recovering rate.

Owner:宁波神丰汽车部件有限公司

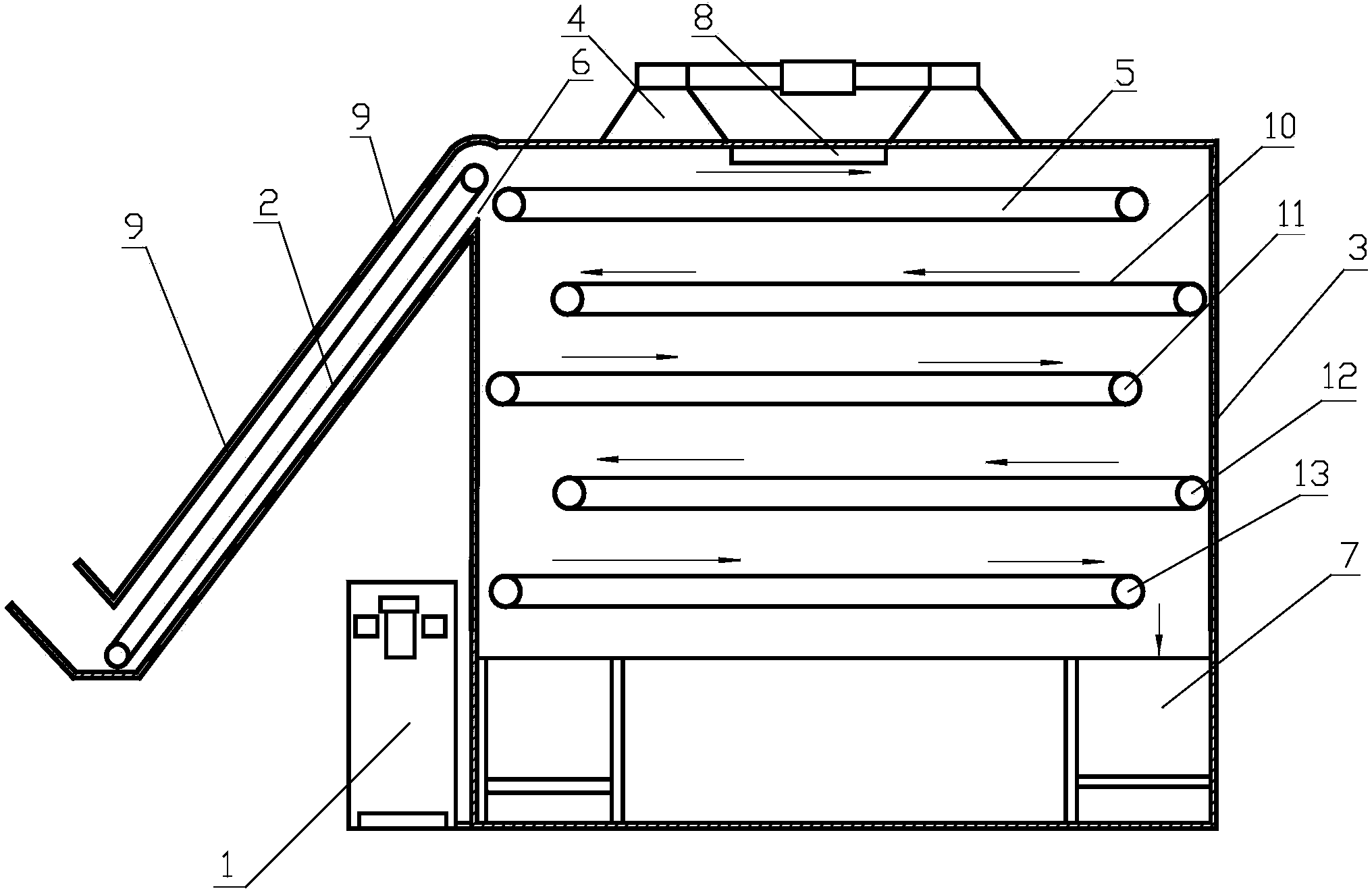

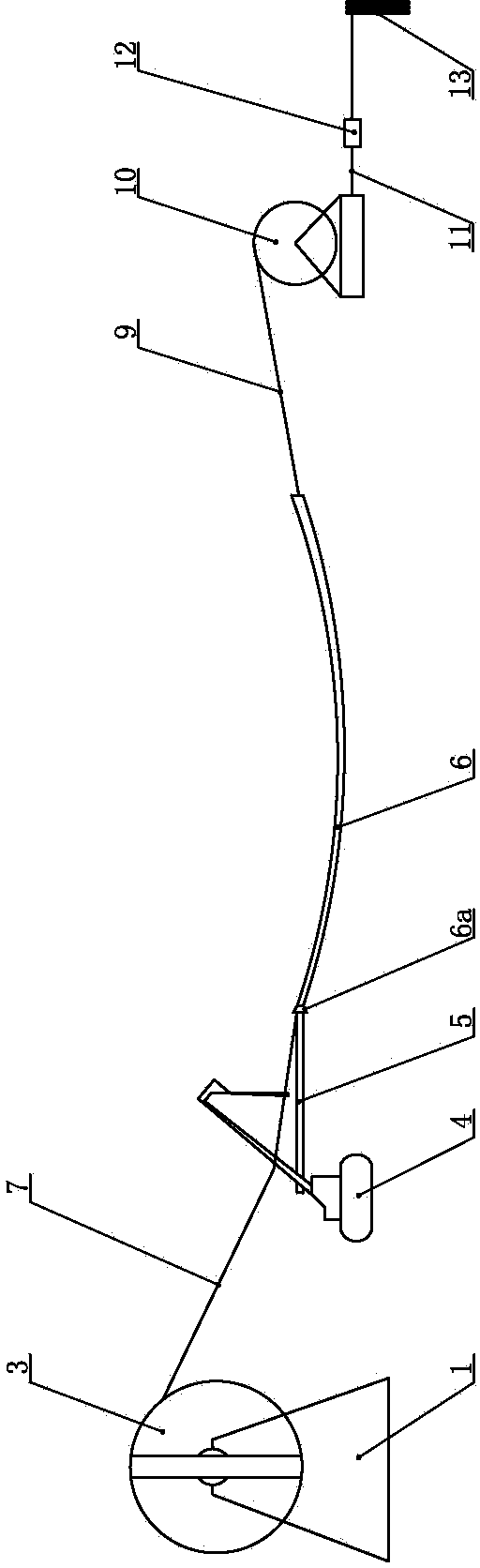

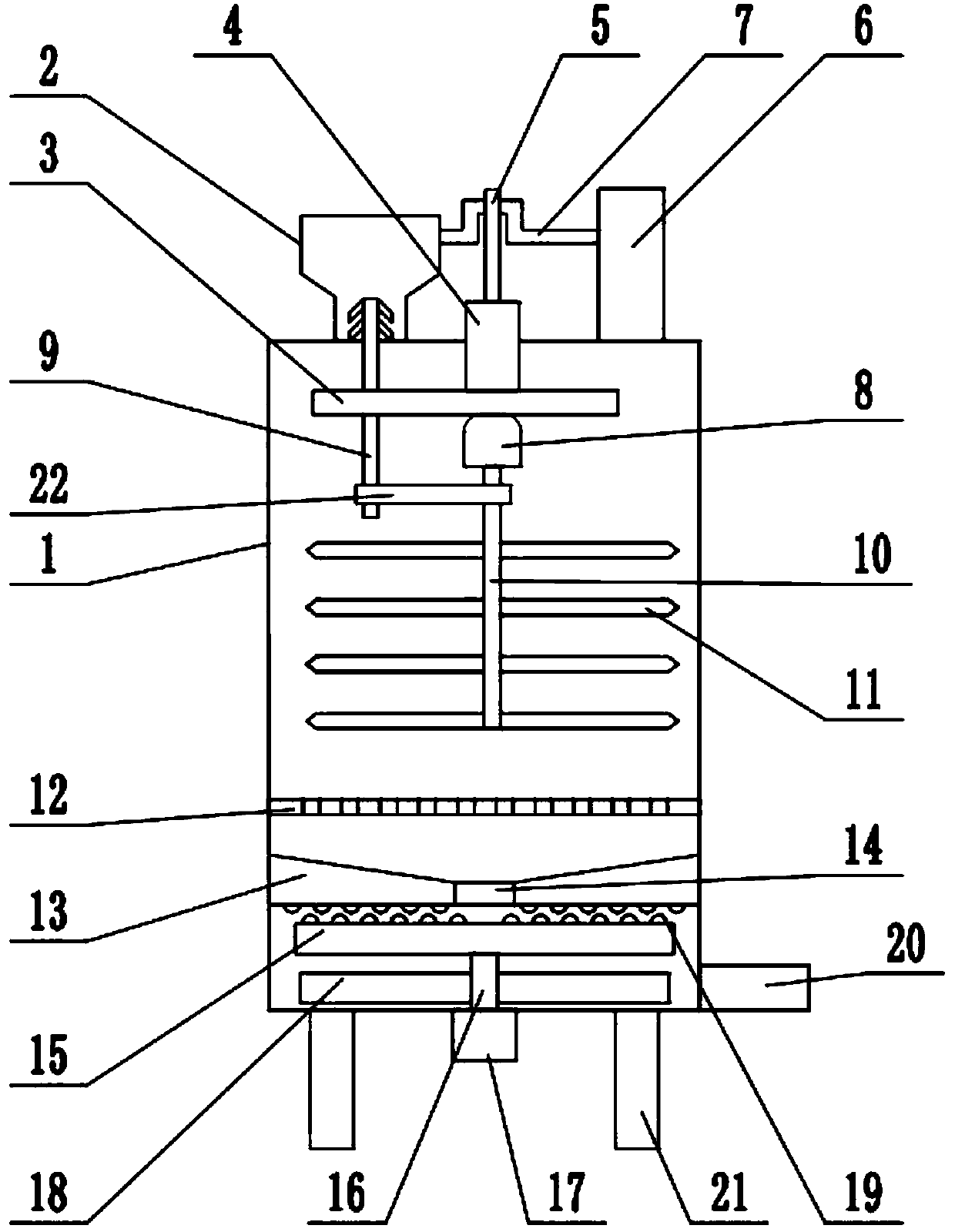

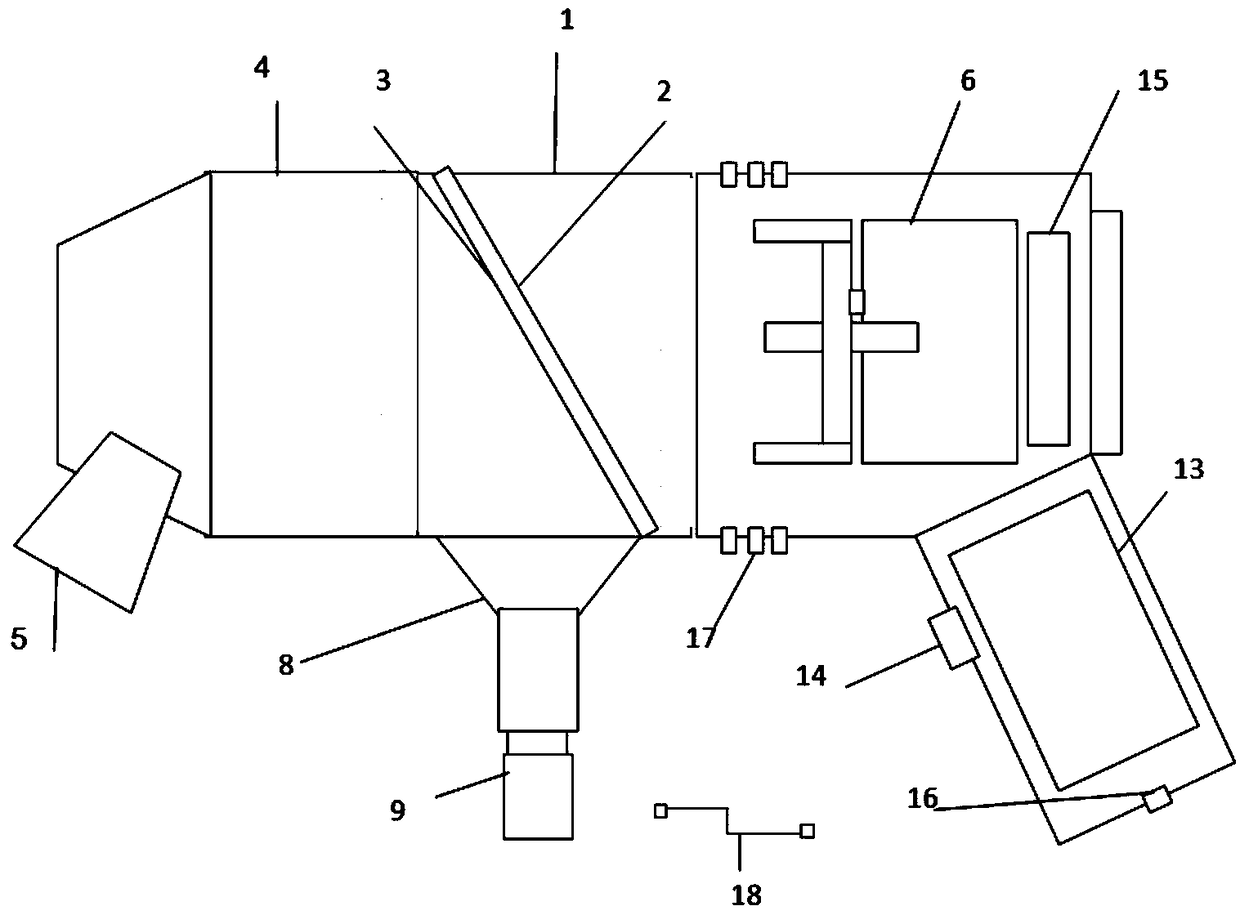

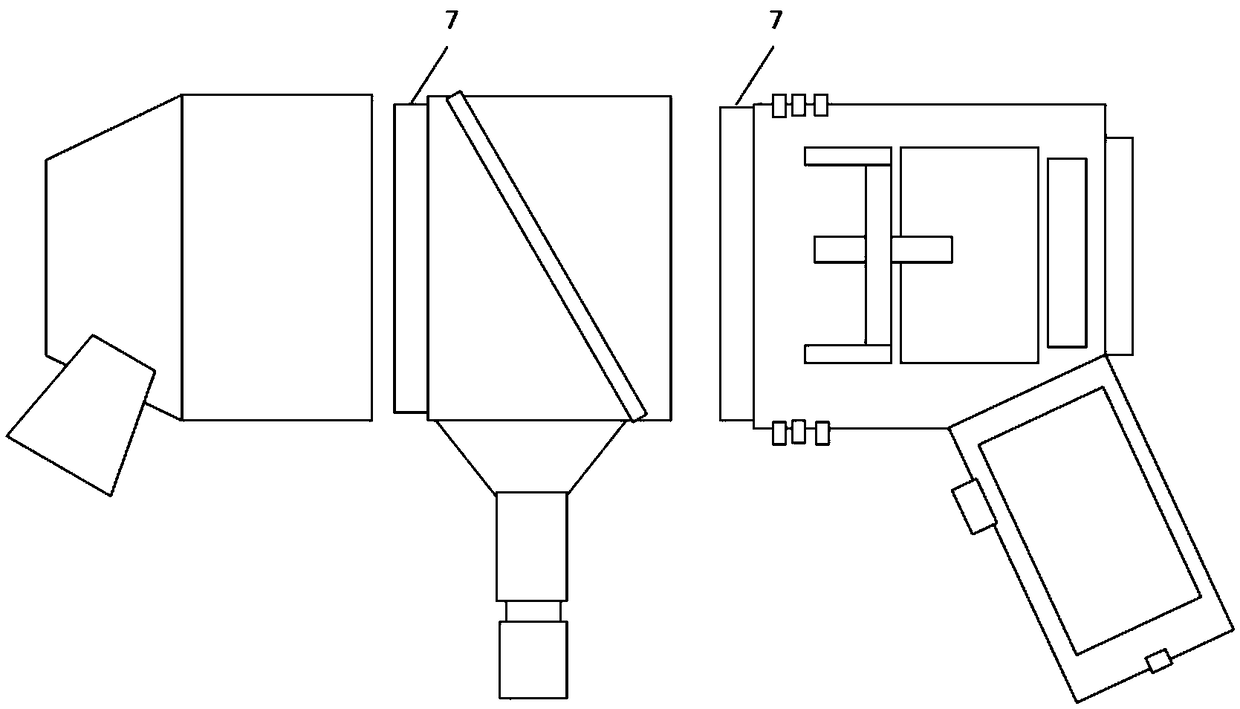

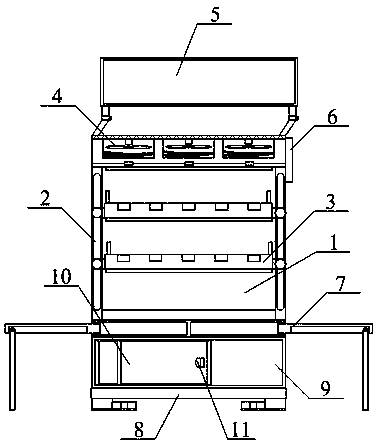

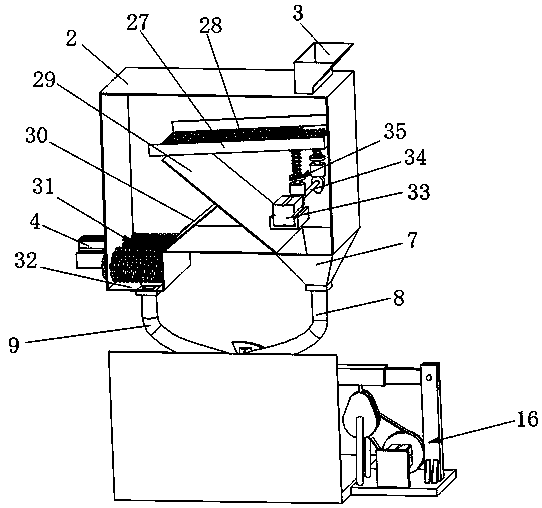

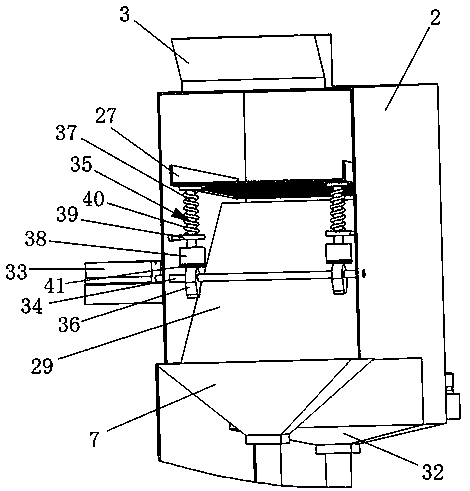

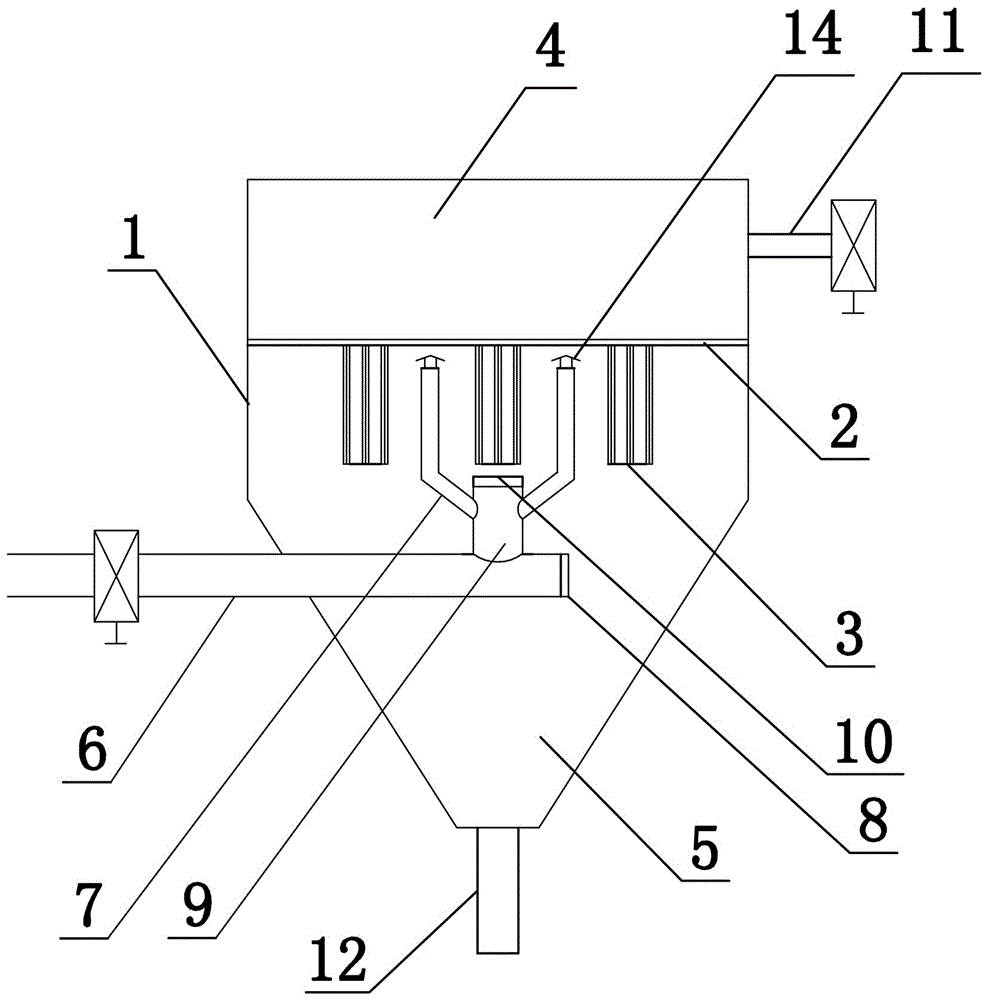

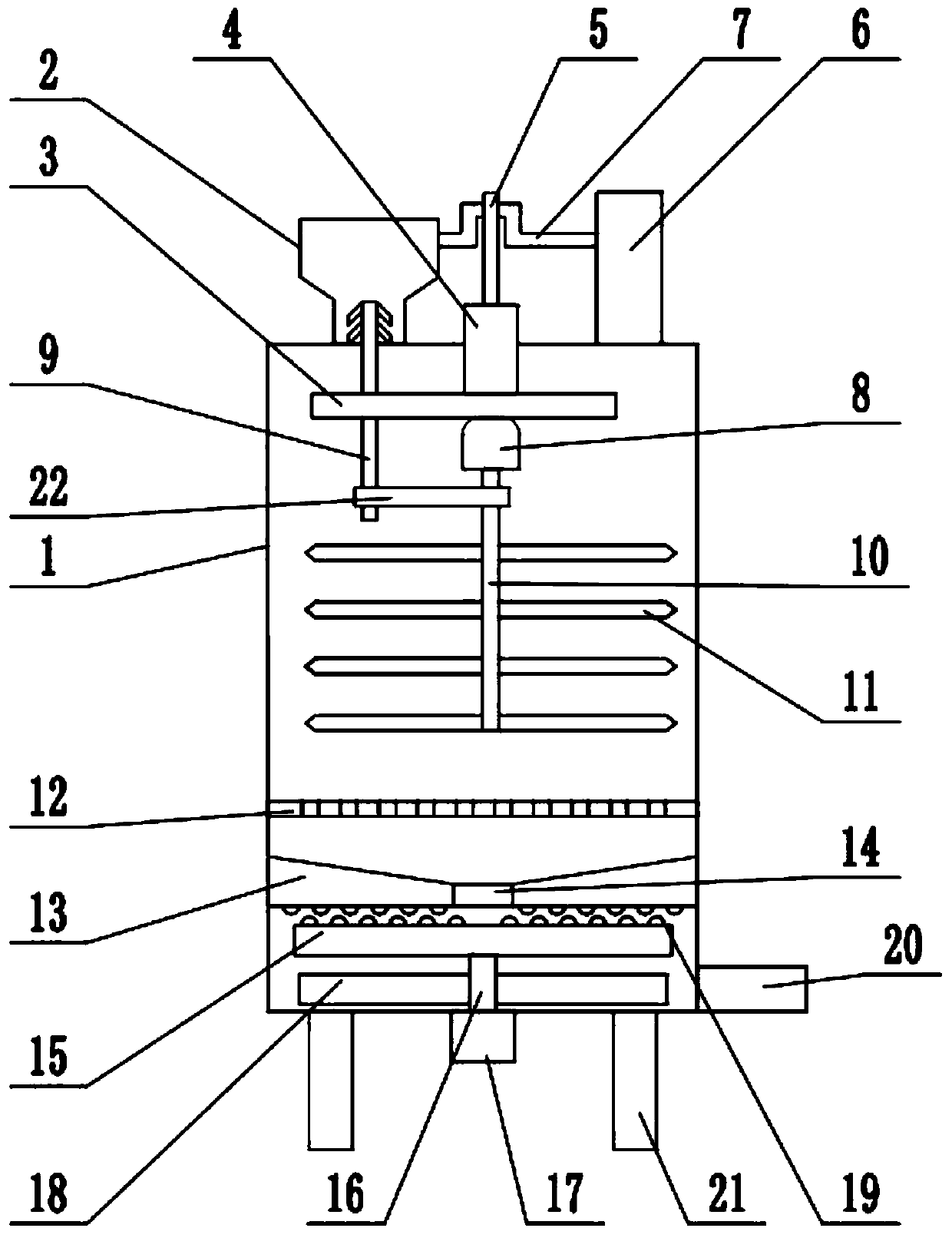

Multi-layer mesh belt type drying device

InactiveCN103851889AConducive to fall intoWon't come outDrying machines with progressive movementsDrying solid materialsEngineeringFar infrared

The invention relates to a drying device of Chinese herbal pieces, in particular to a multi-layer mesh belt type drying device which is simple in structure, uniform in heating, fast in drying speed, high in production efficiency and high in heat utilization rate. The multi-layer mesh belt type drying device comprises a drying box (3), a material feeding inlet (6), material discharging outlets (7), a first conveyor belt (5), a second conveyor belt (10), a third conveyor belt (11), a fourth conveyor belt (12), a fifth conveyor belt (13) and humidity outlets (4), wherein the material feeding inlet (6) is arranged at one side of the drying box (3), the material discharging outlets (7) are arranged at the lower part of the drying box (3), the first conveyor belt (5), the second conveyor belt (10), the third conveyor belt (11), the fourth conveyor belt (12) and the fifth conveyor belt (13) are arranged in the drying box (3), and the humidity outlets (4) are connected to the upper part of the drying box (3); the inner wall of the drying box (3) is provided with a far-infrared heating device (8), the material feeding inlet (6) is connected with a protection cover (9), and the inner part of the protection cover (9) is provided with a conveying device (2); the lower side of the protection cover (9) and the outer side of the drying box (3) are connected with an electric control cabinet (1). The multi-layer mesh belt type drying device disclosed by the invention has the beneficial effects that the structure is simple, the heating is uniform, the drying speed is fast, the production efficiency is high, and the heat utilization rate is high.

Owner:刘良贵

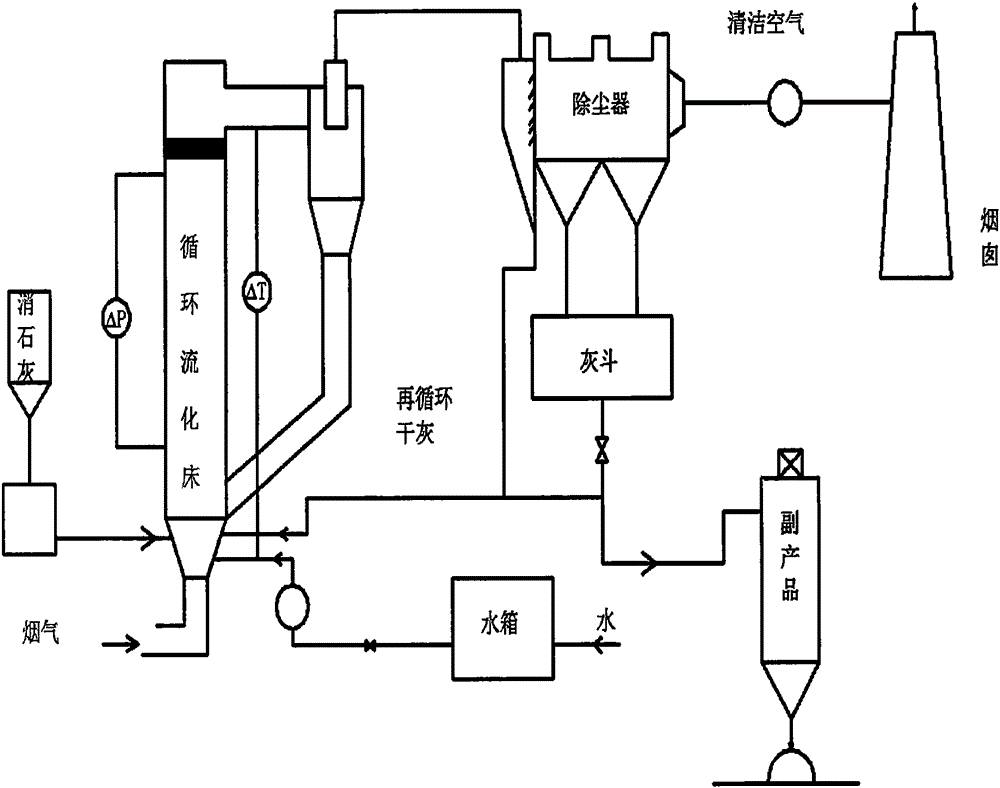

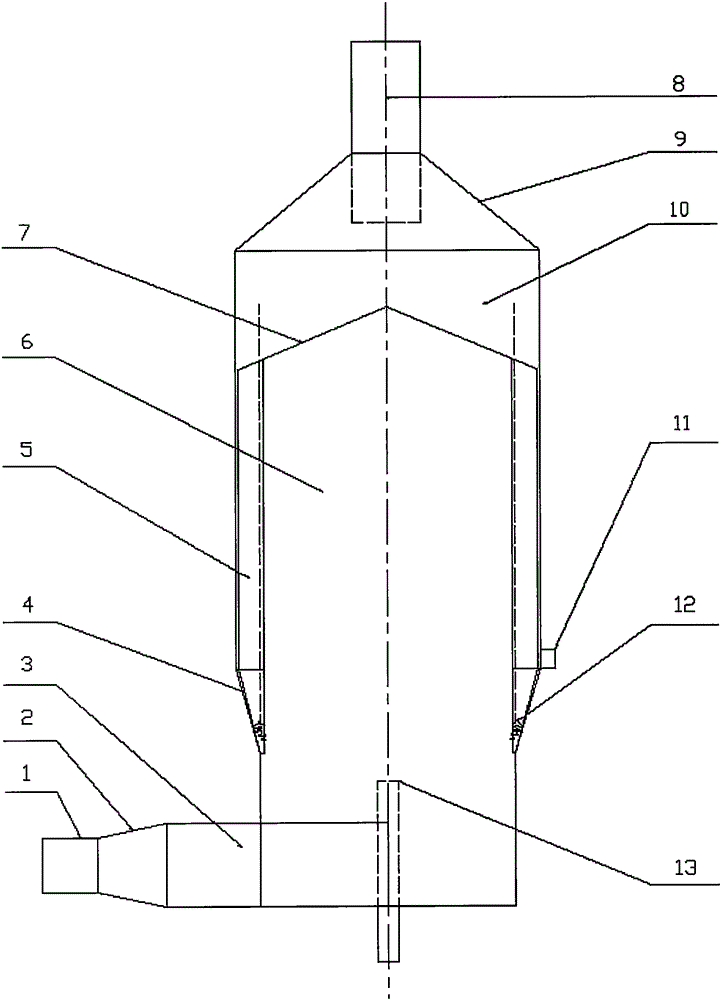

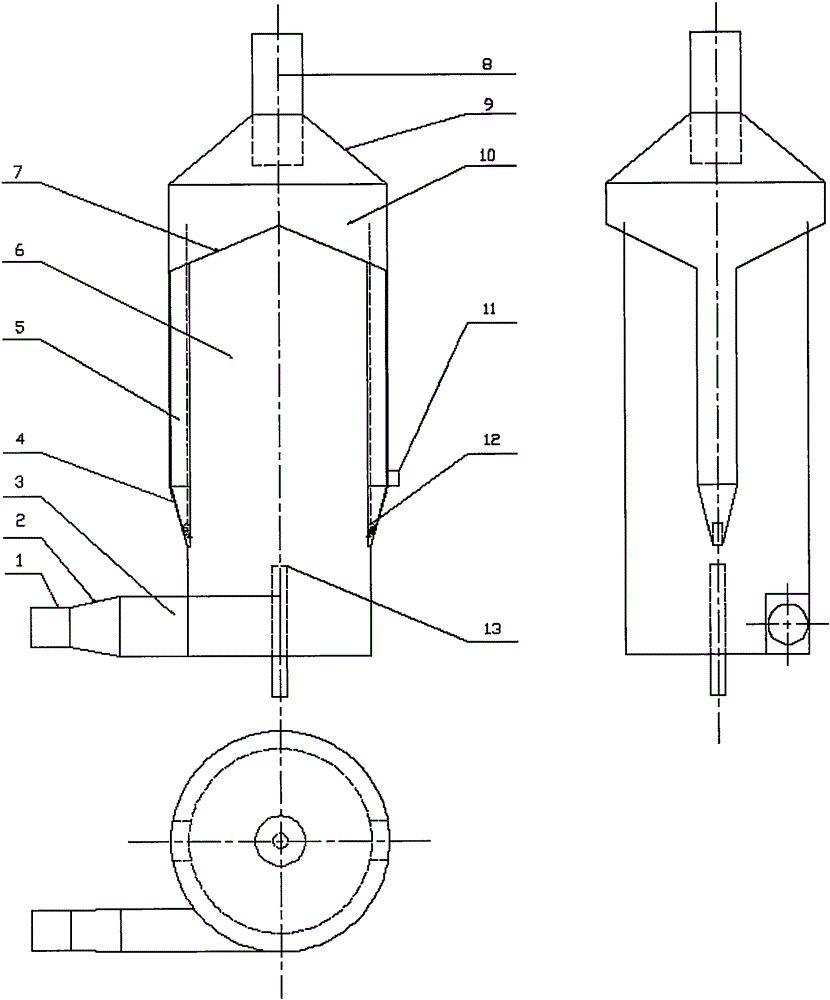

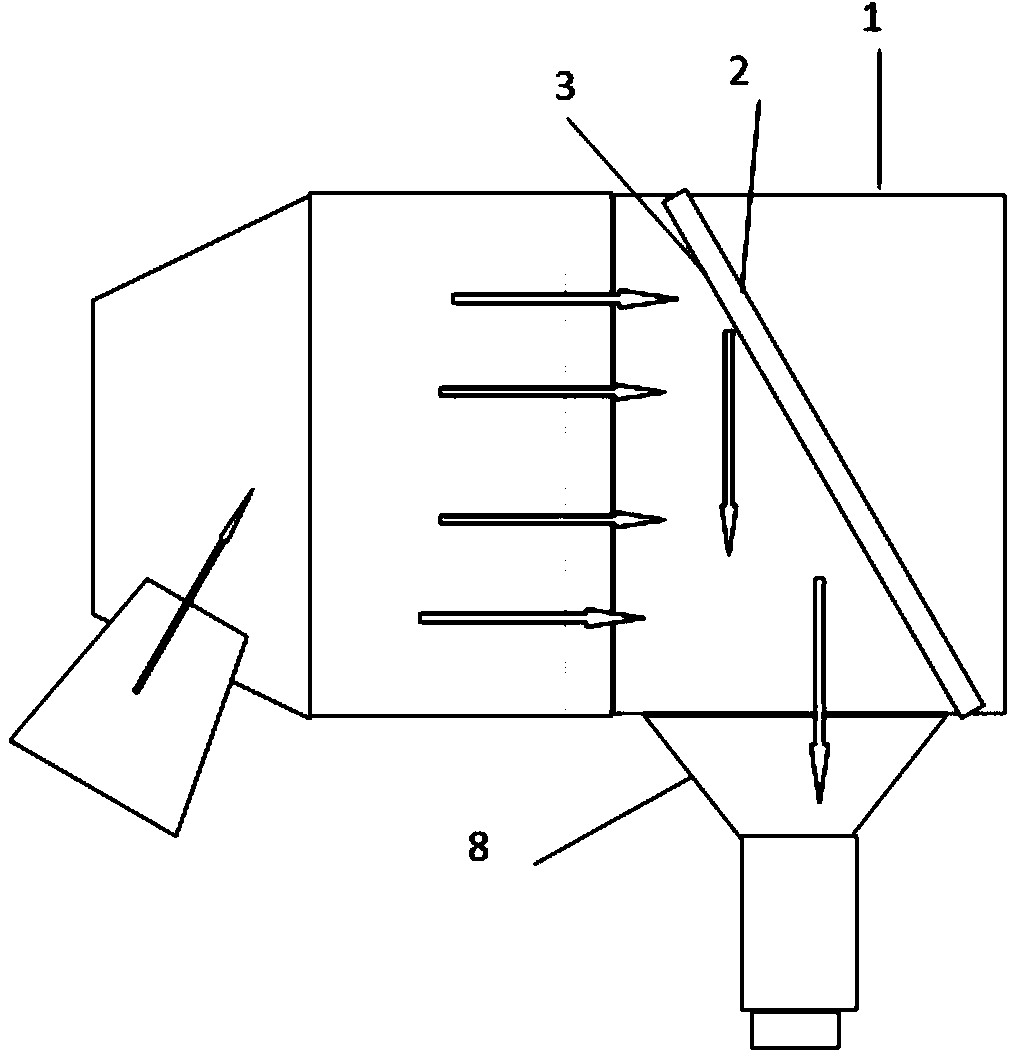

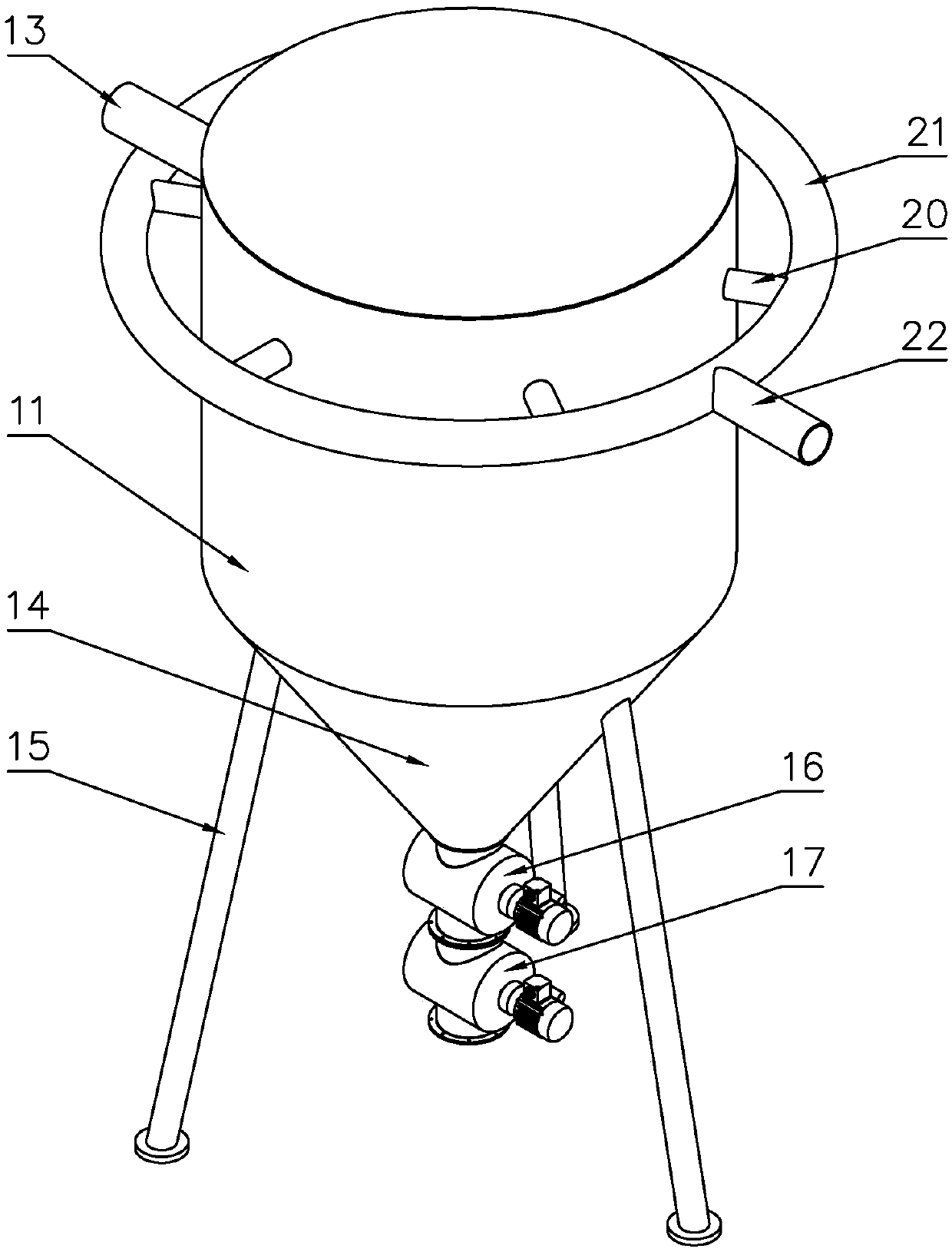

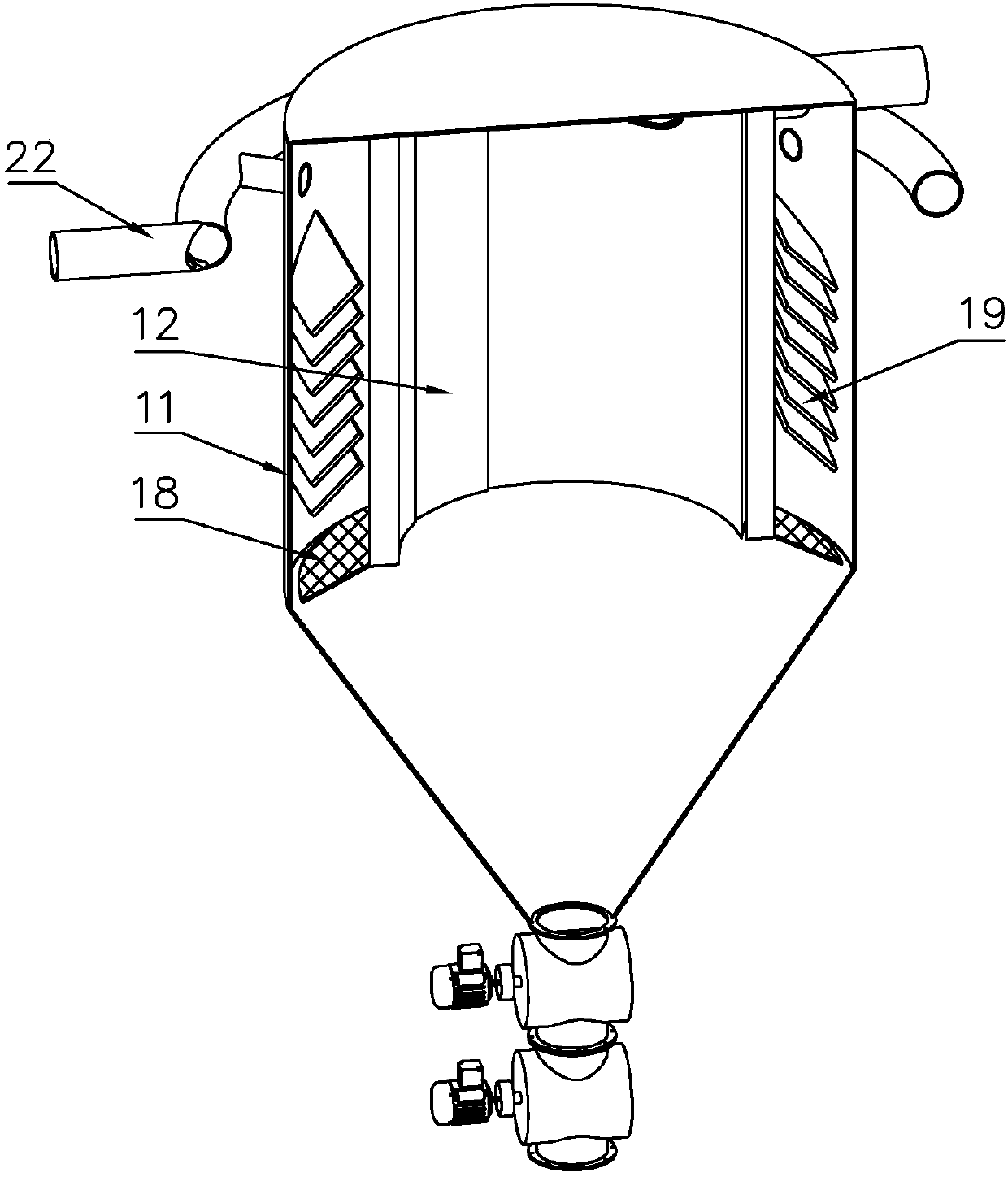

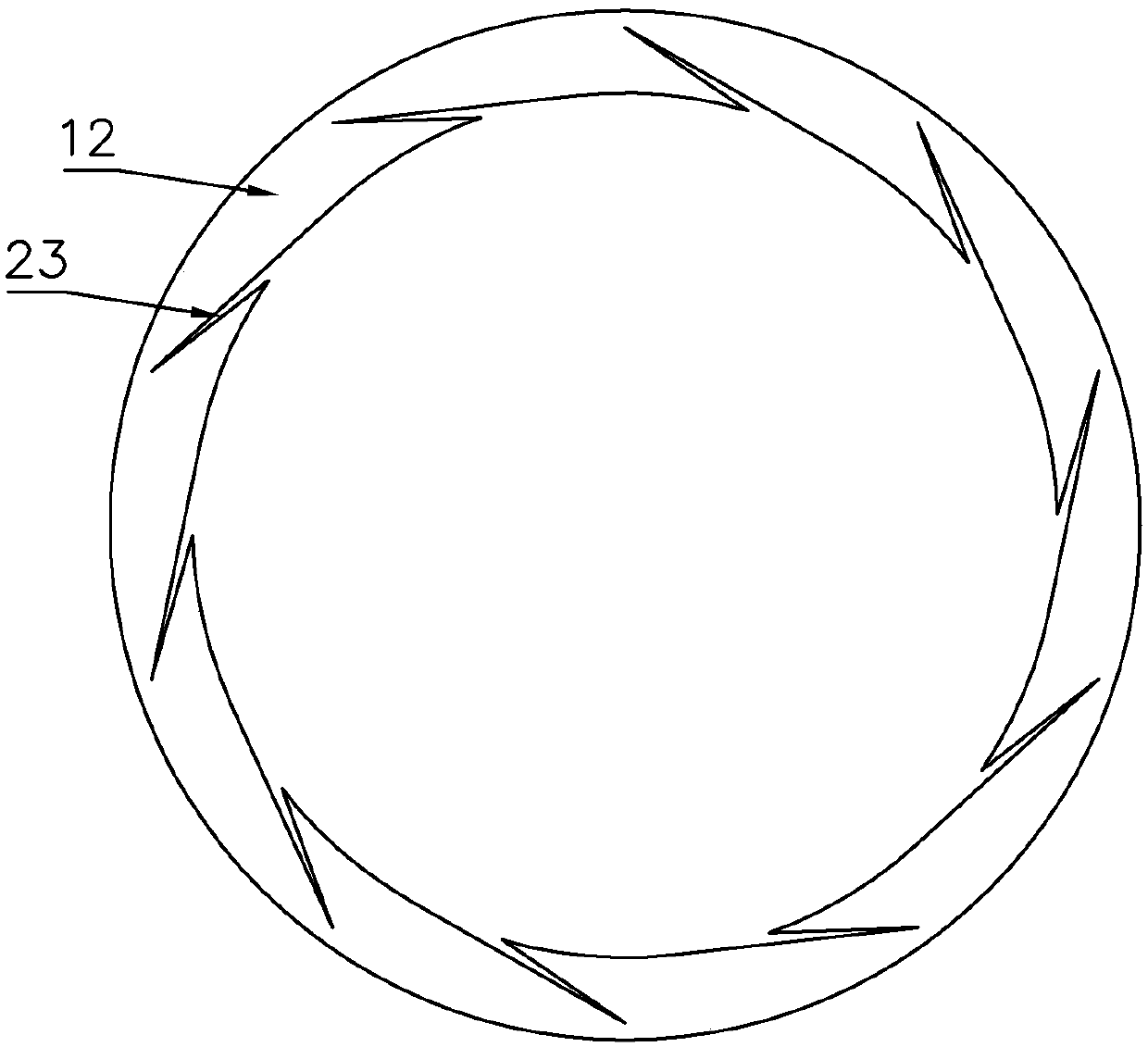

Desulphurization dedusting integrated half-dry type swirl desulfurization tower

InactiveCN105126460AConducive to fall intoIncrease the number of cyclesDispersed particle separationFlue gasEngineering

A desulphurization dedusting integrated half-dry type swirl desulfurization tower is disclosed. By arranging a tangential-direction air inlet structure, the flue gas in the desulfurization tower forms a rotating flow, the turbulent flow strength is enhanced, the sulfur-containing dust-containing flue gas is fully contacted with a desulphurization agent particle, bumping and friction among particles and between the particle and the tower wall are enhanced, desulphurization efficiency is improved, and wall adhesion and fouling phenomena are avoided. By employing the desulphurization dedusting integrated design, arranging a canopy structure and utilizing the tower wall to separate a desulphurization reaction chamber, an annular gas-solid separation chamber and a circulation ash feedback channel, the occupied space of a routine desulphurization tower and externally-arranged cyclone separator and feedback device, and the disclosed desulphurization tower is compact in structure and convenient to install.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

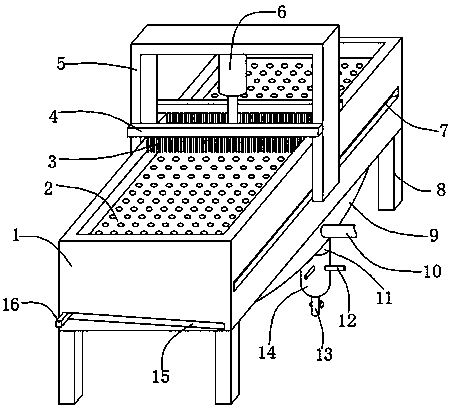

Whole gantry type water cutting platform

ActiveCN108372333AAvoid scratchesConducive to fall intoMaintainance and safety accessoriesWater dischargeWater flow

The invention discloses a whole gantry type water cutting platform. The whole gantry type water cutting platform comprises a bracket, a gantry frame and a high-pressure water-jet knife, wherein a carrying platform is arranged in the bracket; the gantry frame is arranged on side plates at the two sides of the bracket; the high-pressure water-jet knife is arranged at the bottom part of a cross rod of the gantry frame; a plurality of fine brushes are arranged at the two sides of the gantry frame; a water tank is arranged under the carrying platform; a water discharging port is formed in the bottom part of the water tank; a first filtering net is arranged on the water discharging port which is connected with a first water discharging pipe; a connecting port is arranged under the water discharging port and is connected with a collecting box; an electromagnet is arranged at the bottom part of the water tank. The whole gantry type water cutting platform disclosed by the invention has the beneficial effects that the fine brushes move along with the gantry frame and brush off iron scraps on a workpiece, the iron scraps fall into the water tank along with the water flow, so that the iron scraps can be removed in time when the workpiece is machined; after falling into the water tank, the iron scraps flow towards the water discharging port along with the water flow, and are blocked at theconnecting port by the first filtering net, and water is discharged by the first water discharging pipe; when the workpiece is completely machined, the collecting box is disassembled, and after the iron scraps in the collecting box are poured out, the collecting box is installed onto the connecting port, so that the purpose of collecting the iron scraps is achieved.

Owner:ANHUI AOYU CNC TECH

Construction method for enabling cable to pass through barrier

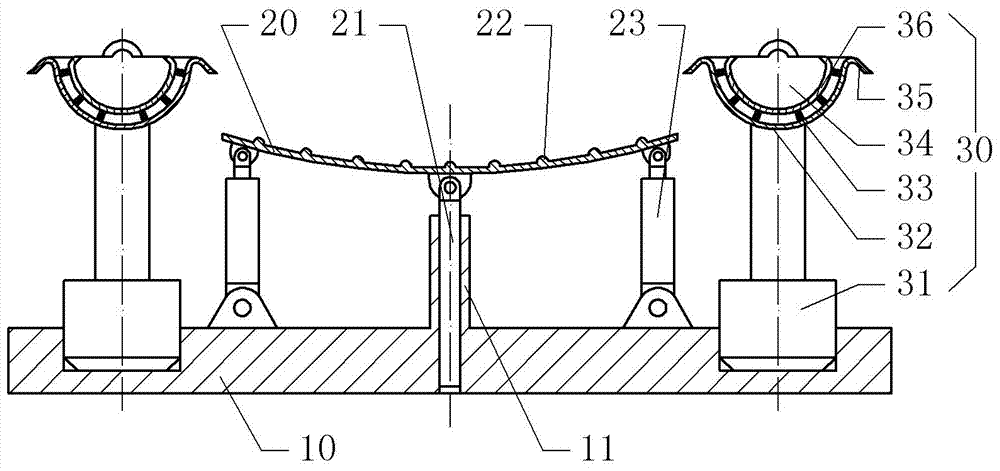

ActiveCN104332903AReduce tensionGuaranteed to be scientificApparatus for laying cablesPull forceRolling resistance

The invention relates to a construction method for enabling a cable to pass through a barrier. The construction method for enabling the cable to pass through the barrier sequentially includes following steps: firstly, confirming a pipe hole path so as to obtain the total length and the specification of a cable sleeve, prefabricating the cable sleeve by sections, threading a steel wire lead rope through the cable sleeve in advance, clearing the inner wall of the cable sleeve section by section, and performing anticorrosion and mouth repairing on the cable sleeve after a qualified pressure test on the cable sleeve is completed; then, performing a simulation experiment, obtaining a slide friction coefficient of the cable sleeve, figuring out the maximum slide traction resistance, judging whether the maximum slide traction resistance is larger than permissive pull force of the cable, and if yes, installing idler wheel hoops for a second experiment so as to obtain a rolling friction coefficient of the cable sleeve, figuring out the maximum rolling traction resistance during the cable passing process, and confirming specifications of traction facilities of a main steel wire rope and the like; finally, drilling pipe holes, enabling the cable to pass through the cable sleeve, using a winching to tow the cable, using an excavator to assist in cable feeding, feeding the cable in the cable sleeve for a section after installing each batch of the idler wheel hoops until the whole cable completely passes through the cable sleeve, and performing a performance test on the cable which passes through the cable sleeve after two end mouths of the cable sleeve are blocked. The construction method for enabling the cable to pass through the barrier can substantially reduce passing resistance of the cable, and is safe and reliable.

Owner:CHINA PETROLEUM & CHEM CORP +1

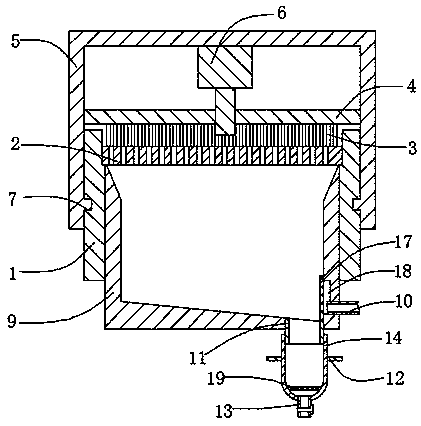

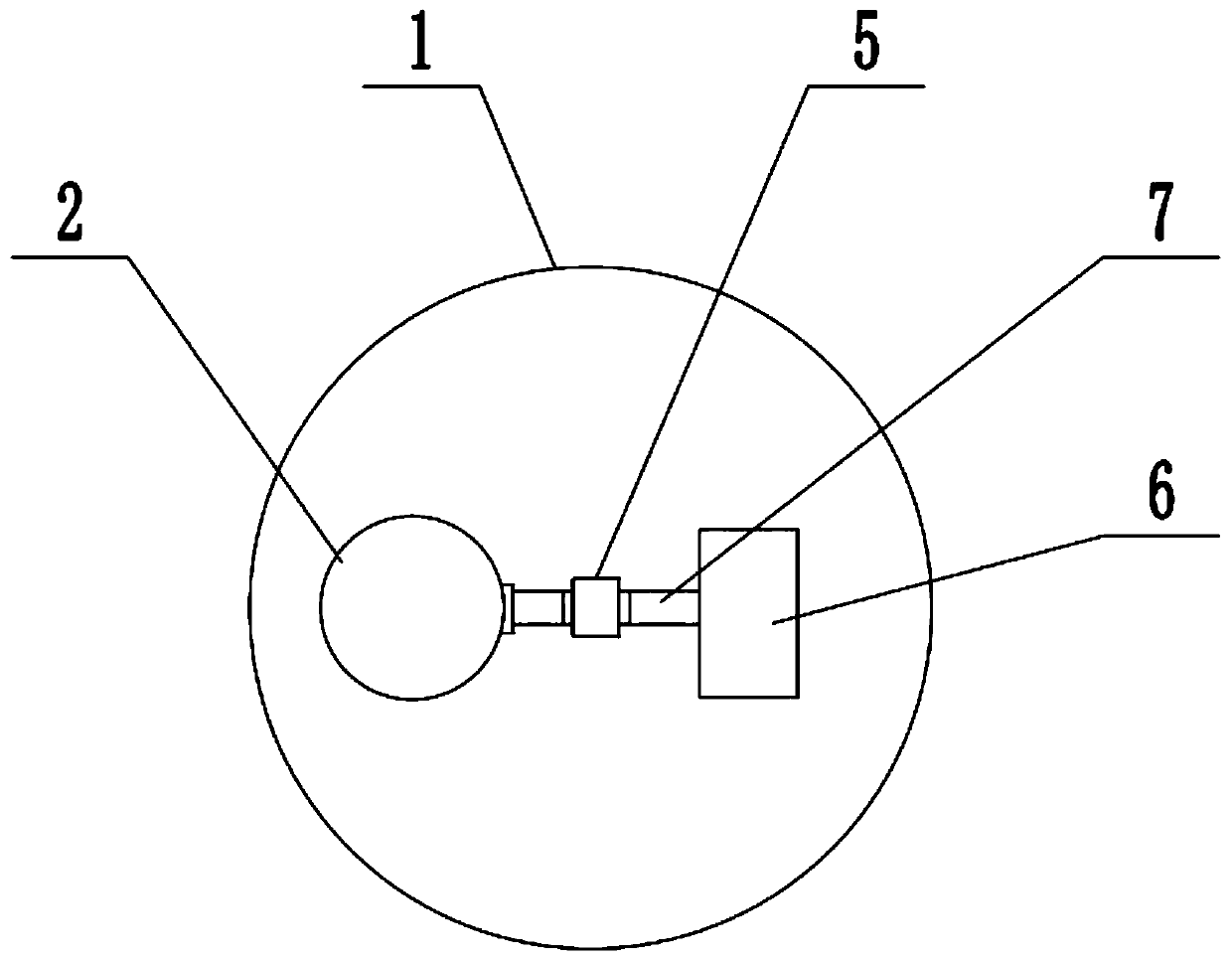

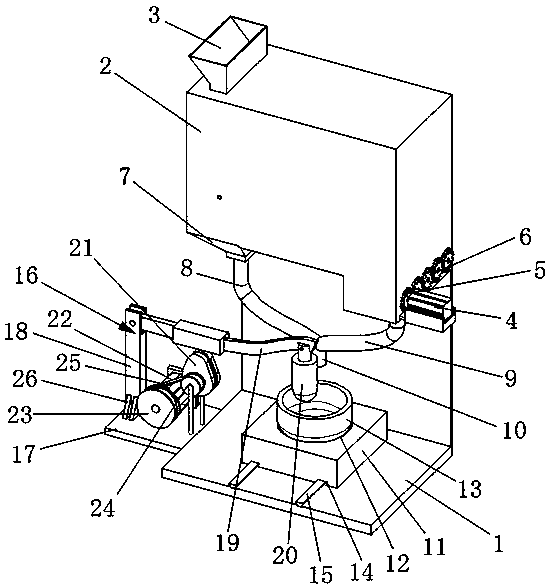

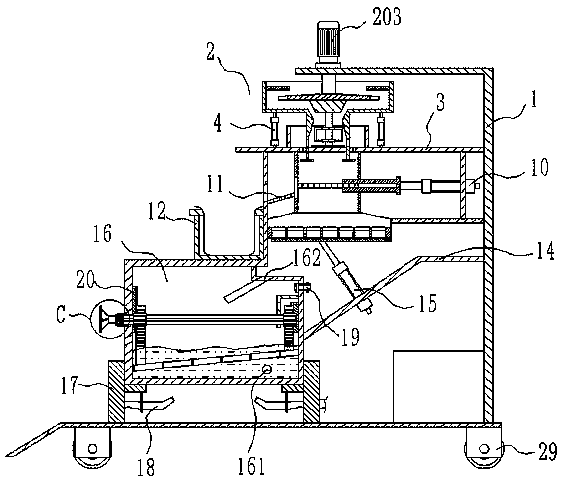

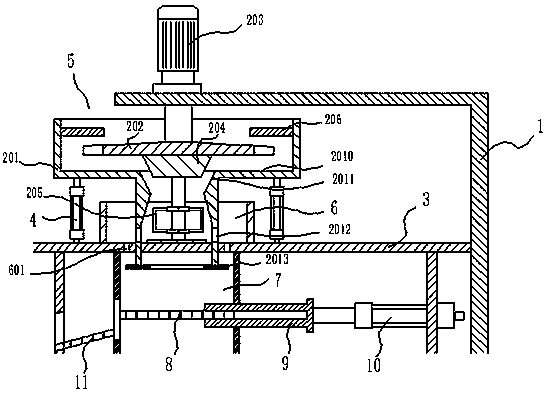

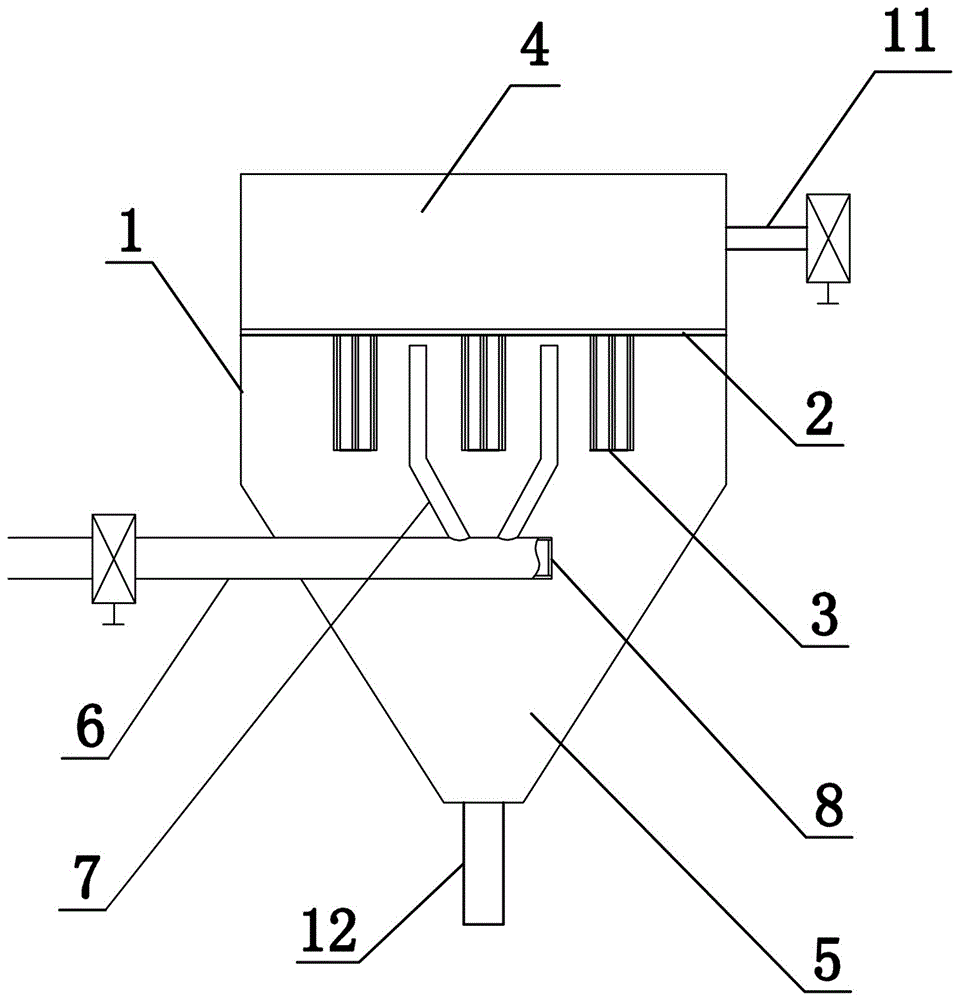

Traditional Chinese medicine crushing and grinding integrated machine capable of conveniently feeding

ActiveCN108672051AExpand the crushing rangeImprove crushing effectCocoaGrain treatmentsEngineeringTraditional Chinese medicine

The invention discloses a traditional Chinese medicine crushing and grinding integrated machine capable of conveniently feeding. The traditional Chinese medicine crushing and grinding integrated machine comprises an outer shell, a material inlet, a crushing shaft, a sieve plate, a material discharge port and supporting legs, wherein the top portion of the outer shell is fixedly connected to the material inlet, an installation plate is arranged inside the outer shell, the upper surface of the installation plate is fixedly connected to a movable column, the upper surface of the outer shell is fixedly connected to a vibration motor, the lower surface of the installation plate is fixedly connected to a crushing motor, the shaft extending end of the crushing motor is fixedly connected to the crushing shaft, crushing blades are distributed on the crushing shaft, the sieve plate is arranged below the crushing shaft, an upper grinding disc is arranged below the sieve plate, and a lower grinding disc is arranged on the lower surface of the upper grinding disc. According to the present invention, the traditional Chinese medicine is crushed by the crushing blades, and the vibration motor drives the crushing blades to move up and down so as to expand the crushing range and improve the crushing effect; the material feeding rotation and the moving up and down are simultaneously performed, such that the clogging of the material inlet by the traditional Chinese medicine can be prevented; and the crushed traditional Chinese medicine particles fall onto the lower grinding disc, and the traditional Chinese medicine is grinded by the grinding disc.

Owner:BOZHOU HUQIAO PHARMA

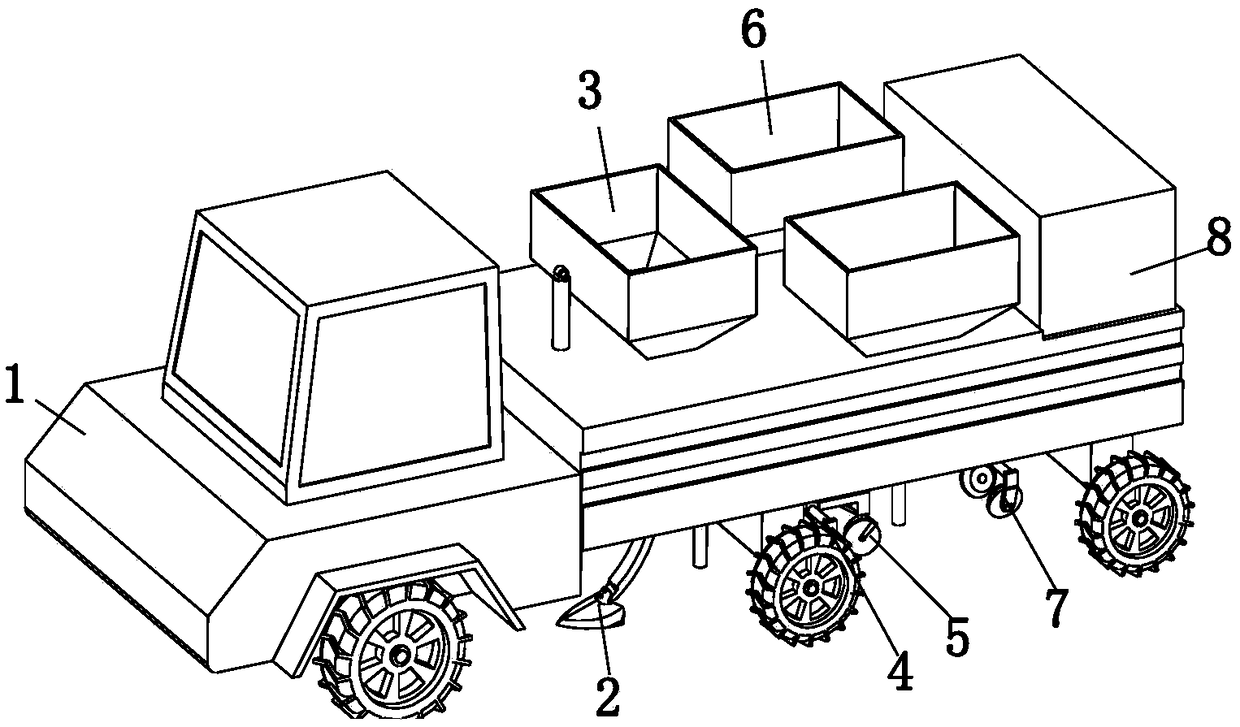

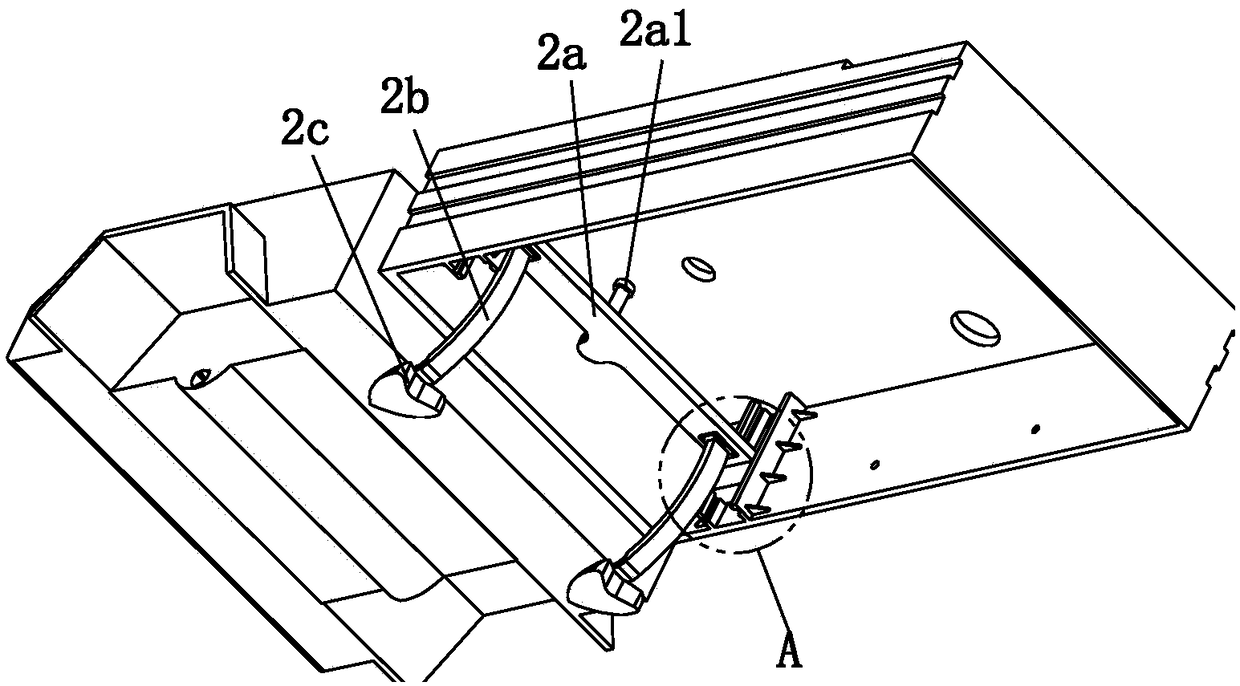

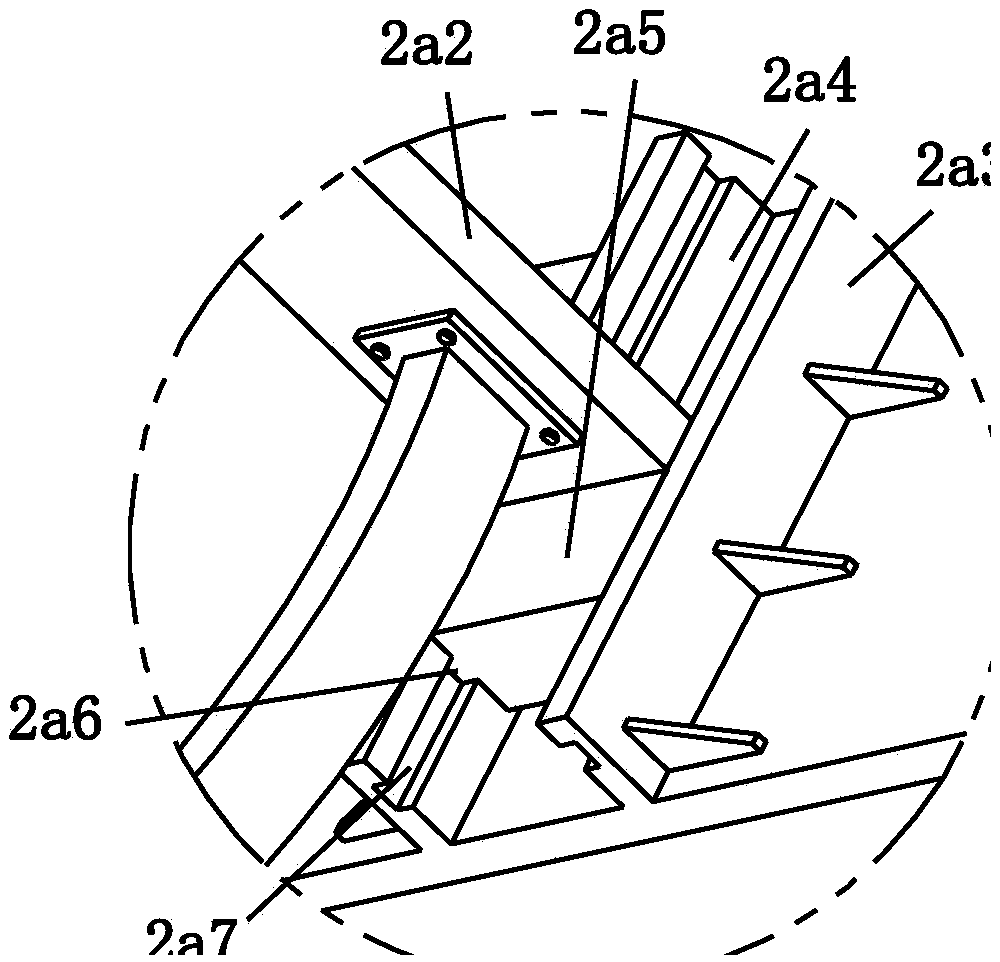

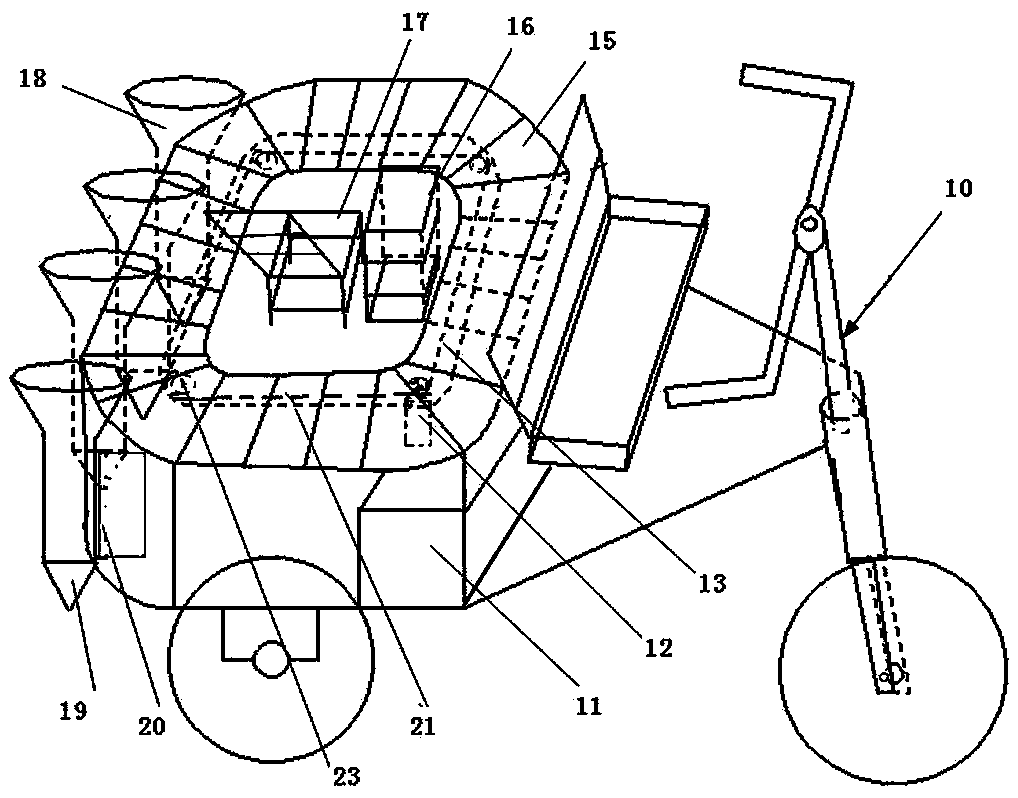

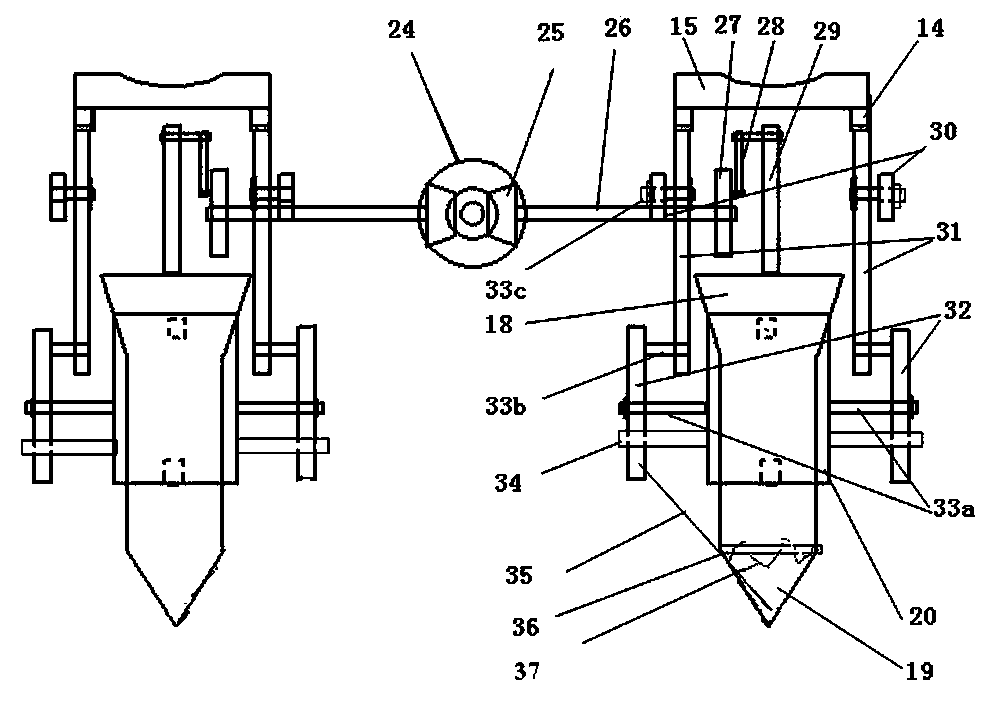

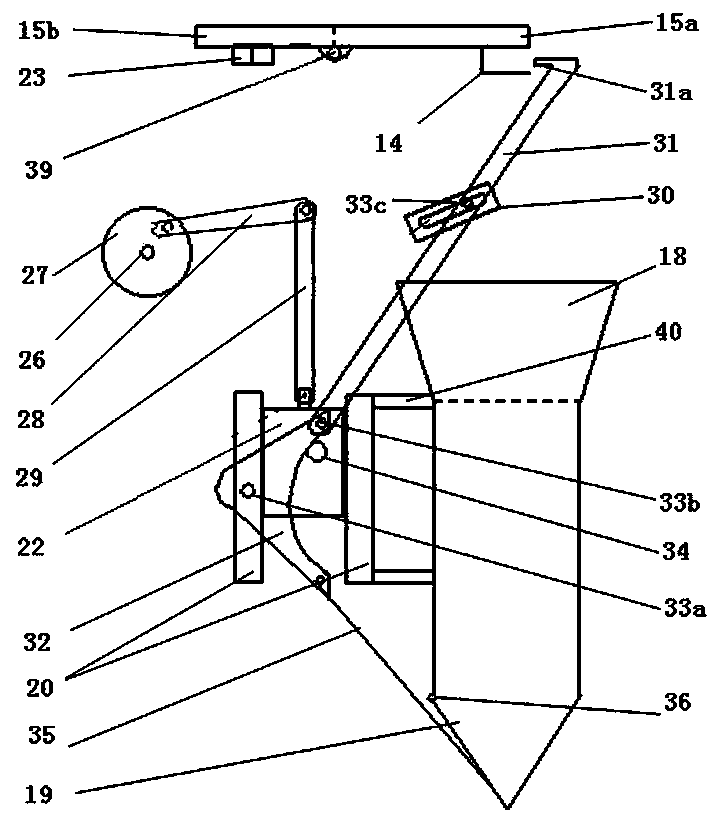

Seeding machine for corn seed breeding

PendingCN109121591AReduce manual laborAvoid Seed BurningPlantingWatering devicesFertilizerSeed drill

The invention provides a seeding machine for corn seed breeding, and belongs to the technical field of the agricultural machinery. The seeding machine for core seed breeding comprises a car body, a first ditching mechanism, a fertilization mechanism, a first earthing mechanism, a second ditching mechanism, a seeding mechanism, a second earthing mechanism and a watering mechanism; the first ditching mechanism, the fertilization mechanism, the first earthing mechanism, the second ditching mechanism, the seeding mechanism, the second earthing mechanism and the watering mechanism are orderly arranged on the car body; the second earthing mechanism and the first earthing mechanism have the same structure; the second ditching mechanism is arranged on a side of the first earthing mechanism. By arranging the first ditching mechanism, the fertilization mechanism, the first earthing mechanism, the second ditching mechanism, the seeding mechanism, the second earthing mechanism and the watering mechanism, the automatic corn seeding is realized, the hand labor is reduced, the seeds and the fertilizer can be seeded at the same time, or the dual-row alternative seeding can be realized, the distance between the seed and the fertilizer can be precisely controlled, and the automatic irrigation is realized.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

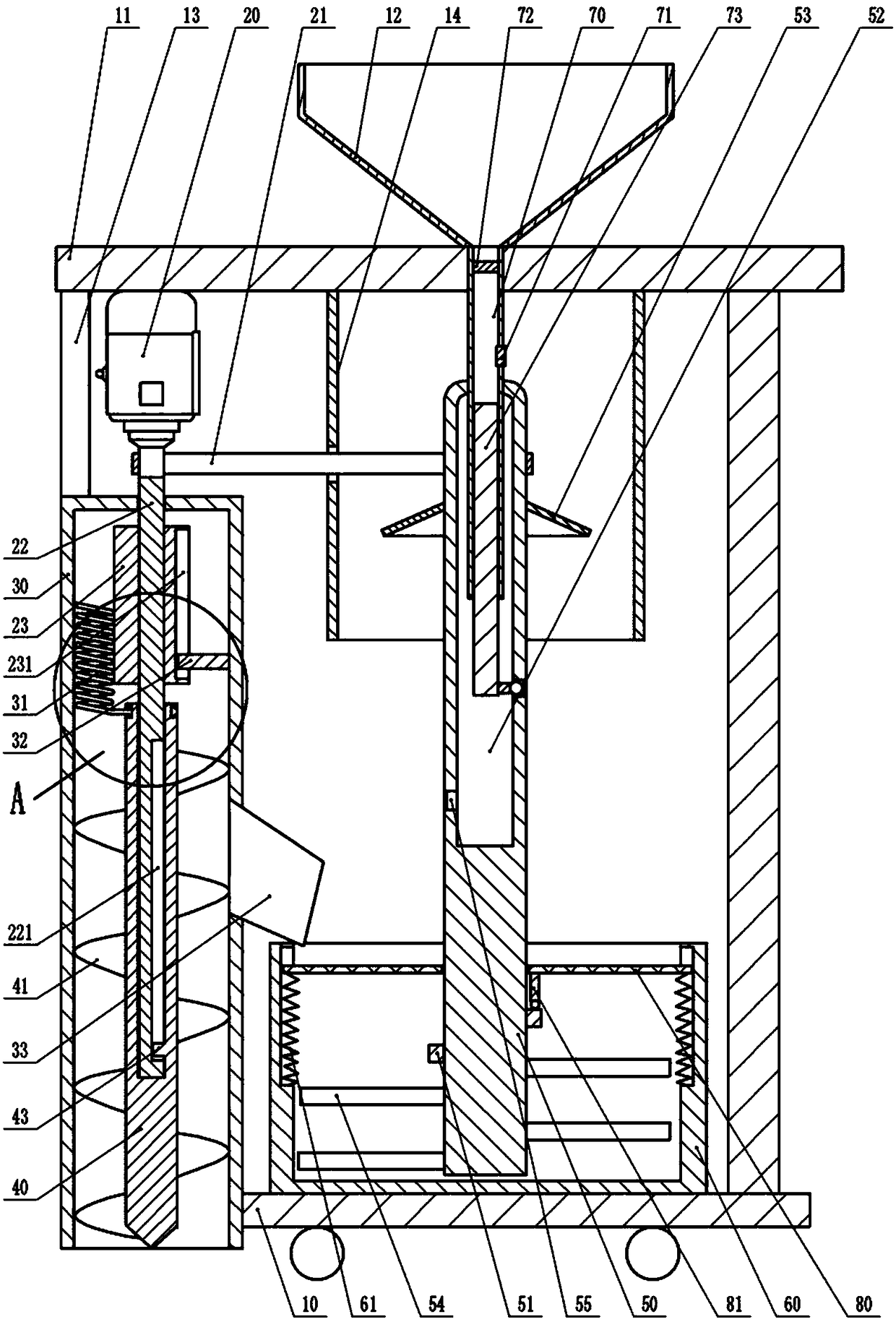

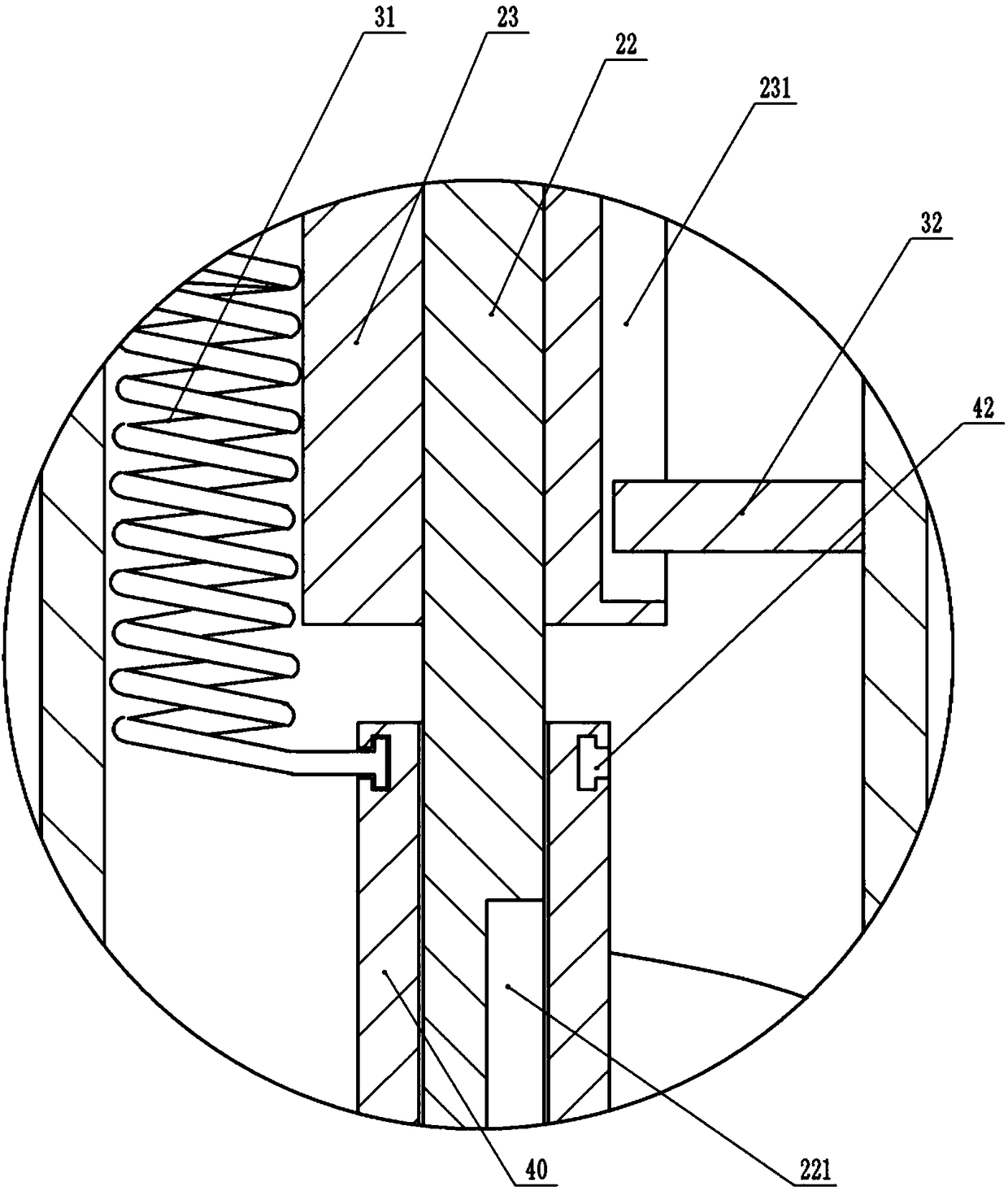

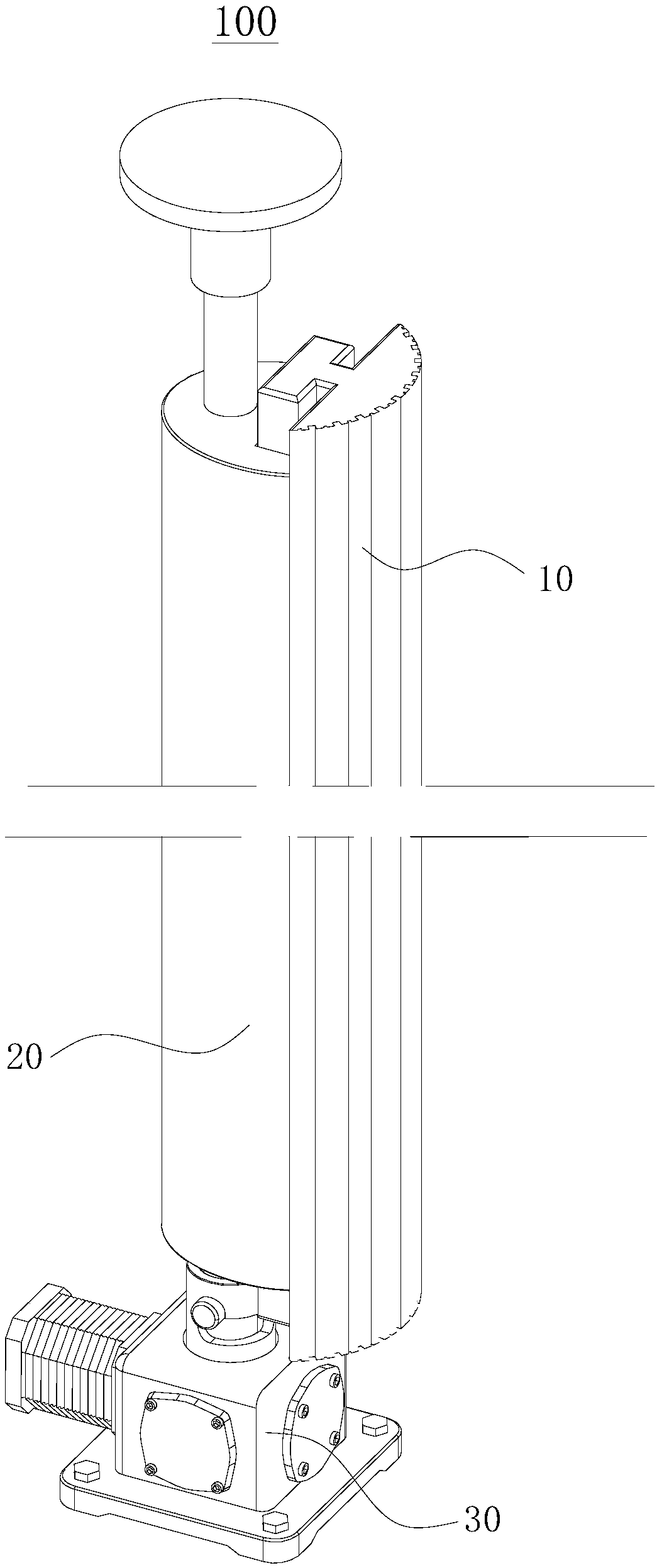

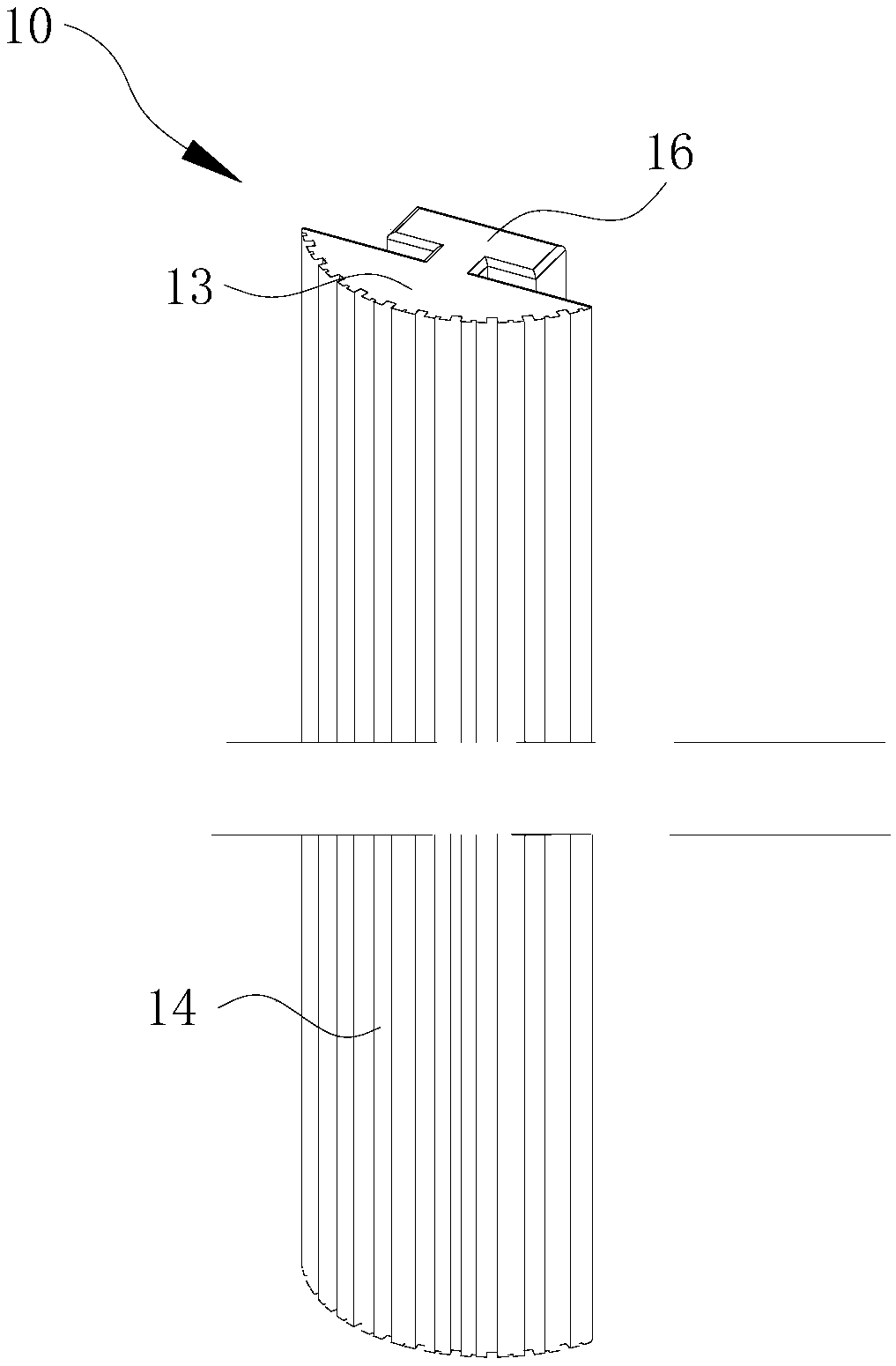

Pit digging machine for fruit tree planting

ActiveCN108496475ASimplify processing stepsEvenly distributedPlantingFertiliser distributersPistonFruit tree

The invention belongs to the technical field of digging machinery for sowing or planting and particularly discloses a pit digging machine for fruit tree planting. The pit digging machine comprises a digging unit, a mixing unit and a mobile trolley, wherein the digging unit comprises a motor, a cylinder and a screw-in rod, a concave cavity is formed in the upper part of the screw-in rod, a screw blade is arranged on the screw-in rod, an output shaft of the motor is connected with a rotating shaft, a push column is in threaded connection onto the rotating shaft, and a tension spring is connectedbetween the cylinder and the upper part of the screw-in rod; the mixing unit comprises a hopper, a piston barrel, a rotating column and a mixing barrel, the lower part of the piston barrel extends into a cavity of the rotating column, a drive mechanism is connected between the output shaft of the motor and the rotating column, a curved groove is formed in the inner wall of the rotating column, aplunger is glidingly connected in the piston barrel, a bulging strip is connected onto the plunger, a sieve plate is glidingly connected in the mixing barrel, a spring is connected between the sieve plate and the mixing barrel, and a stirring shaft located in the mixing barrel is arranged on the rotating column. By means of the pit digging machine, the following fertilization uniformity can be guaranteed while the pit digging efficiency is improved.

Owner:江苏世丰企业管理咨询有限公司

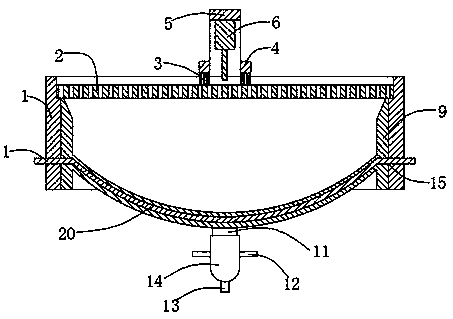

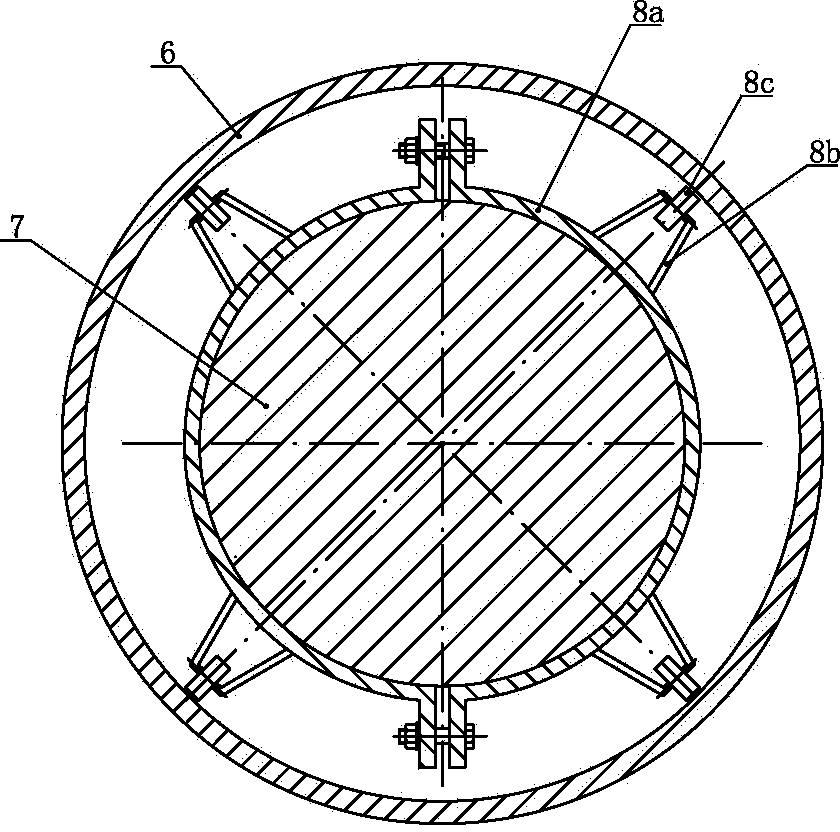

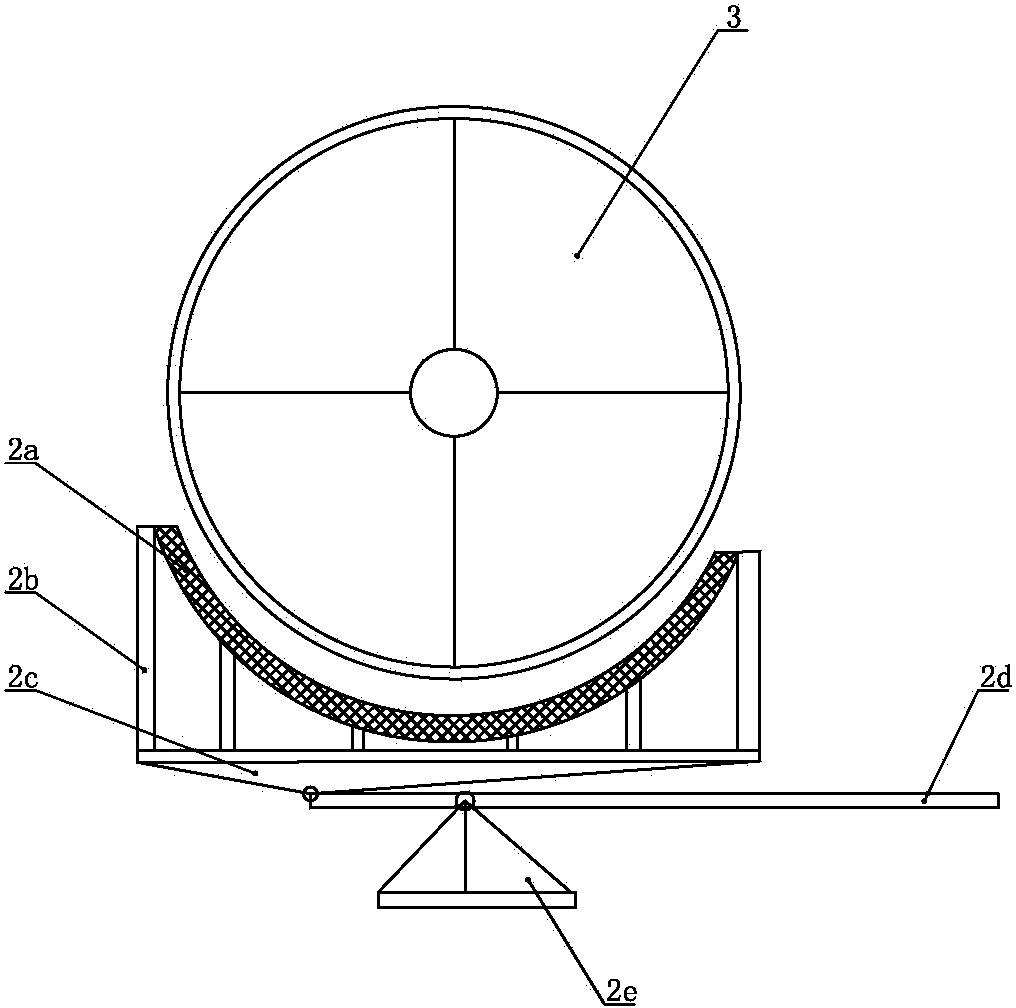

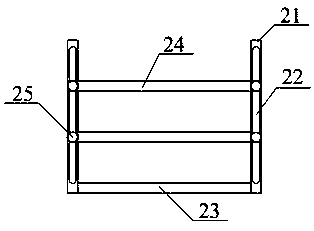

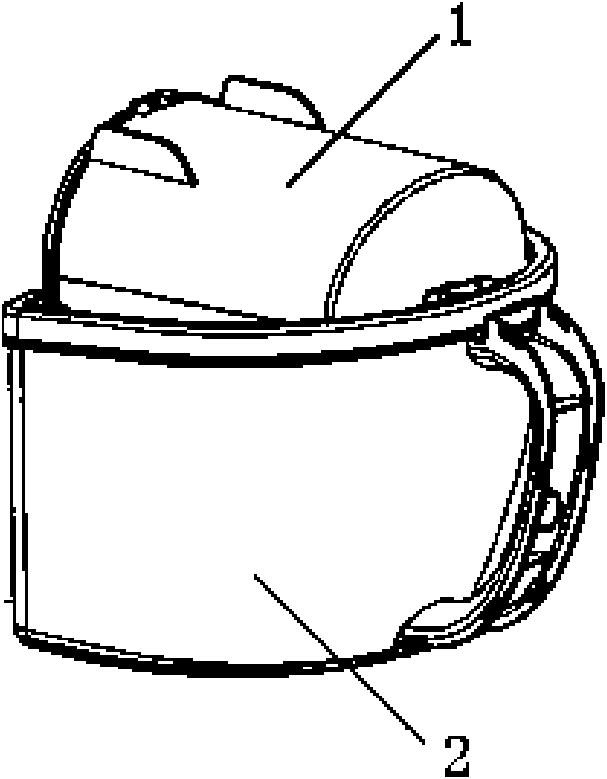

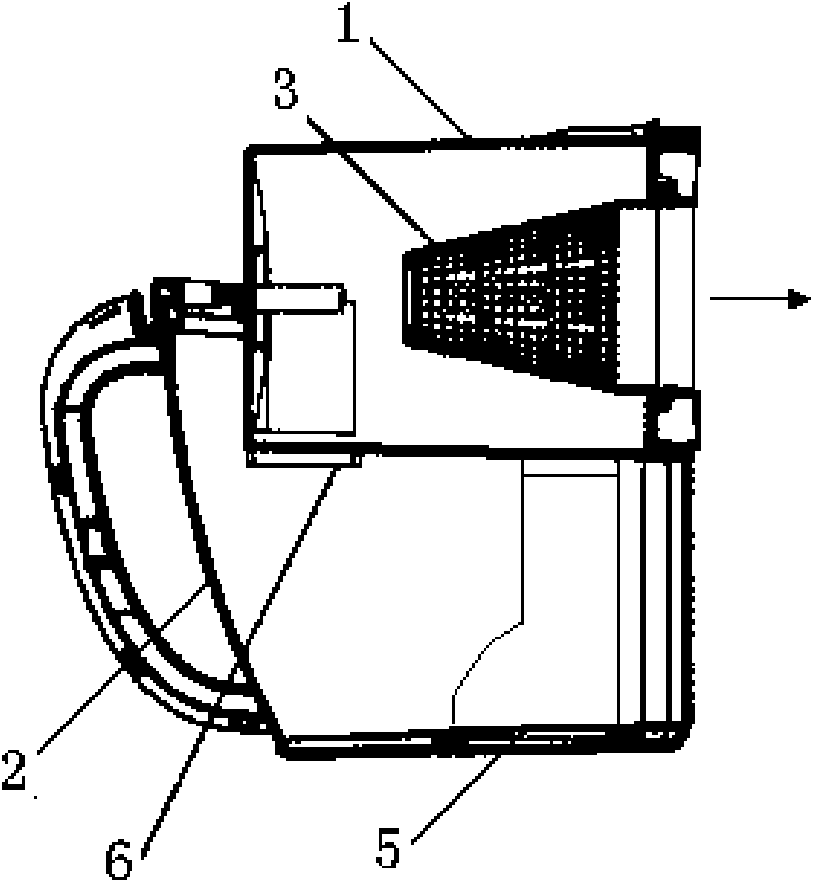

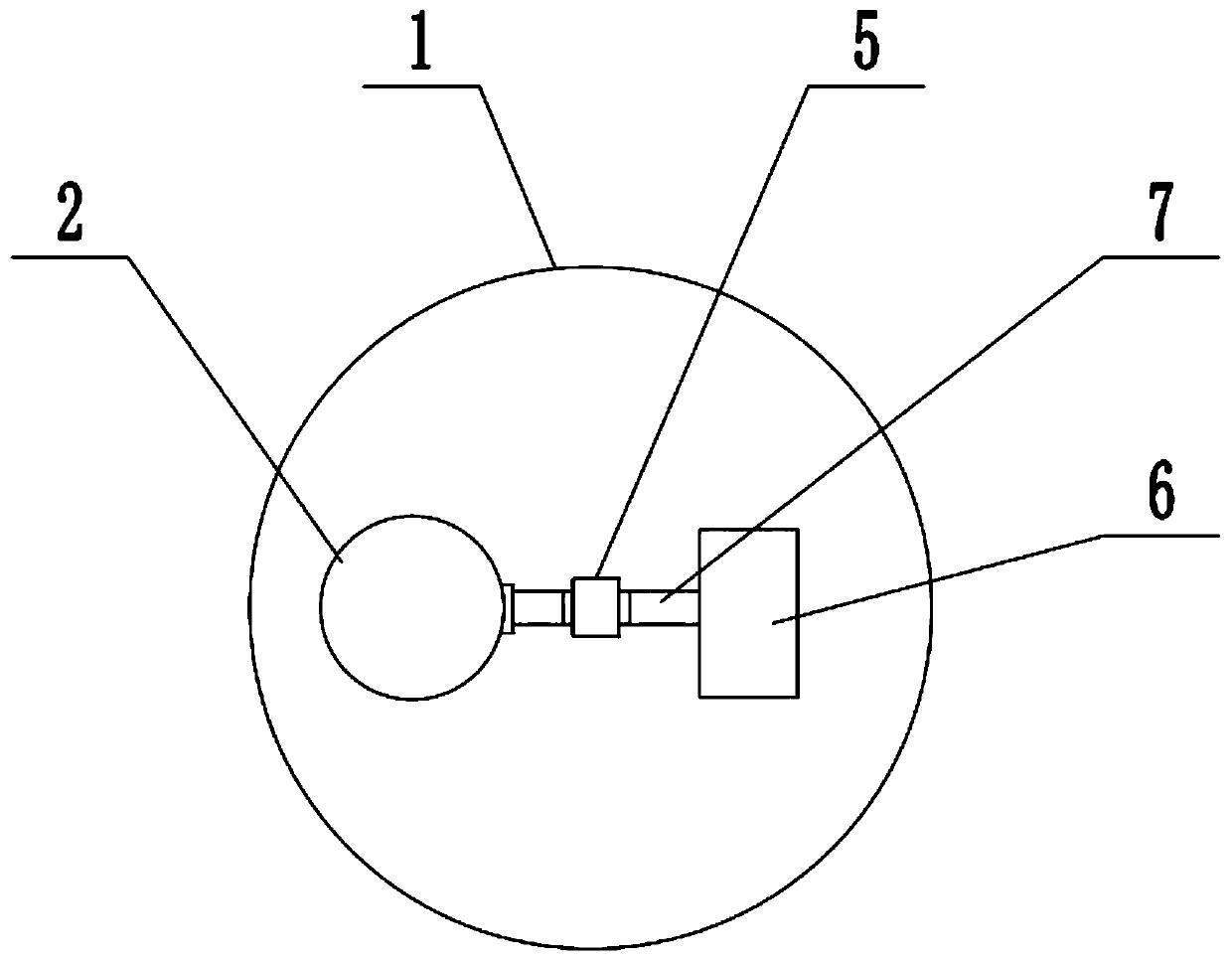

Combined pollen collector

PendingCN109452167AEasy to disassemble and clear powderConducive to fall intoPlant genotype modificationElectric power systemCollection system

The invention discloses a combined pollen collector. The combined pollen collector disclosed in the invention comprises a pollen collection system, a pollen collection system and an electric power system which are successively transversely connected; the pollen collection system comprises a hollow shell 1 with openings on three sides, and a pollen collector connected with the lower opening of thehollow shell 1 in a closing manner; the opening on the front end of the hollow shell 1 is detachably connected with the pollen collection system in a closing manner; the opening on the rear end of thehollow shell 1 is detachably connected with the electric power system in a closing manner; a ventilation filter net is arranged inside a shell of the pollen collection system; and the ventilation filter net consists of two-layer structure including a mesh plate 2 and a silk electric power woven fabric 3. The pollen collector not only can conveniently and effectively collect the pollen, but also can disassemble the structure to facilitate the pollen obtaining; and by adopting the ventilation filter assembly capable of effectively filtering the pollen, the pollen can be effectively prevented from entering the electric power system, and the net blockage can be prevented.

Owner:INST OF COTTON RES CHINESE ACAD OF AGRI SCI

Adjustable multifunctional showing shelf of self-service convenience store

InactiveCN108013666AAdjust position heightReduce sizeShow cabinetsShow shelvesEngineeringSelf-service

The invention provides an adjustable multifunctional showing shelf of a shelf-service convenience store. The showing shelf includes a showing shelf body, a goods shelf adjusting structure, a goods anti-drop device, a heating device, an adjustable showing shelf structure, a control device, a drawable seat structure, a fixing base structure, a back-up goods storage box, a sliding door and a handle;the goods shelf adjusting structure is installed on the front surface of the showing shelf body through bolts. Adjusting bolts penetrate through an adjusting sliding groove to be connected with a movable goods shelf, and more convenience is provided for adjusting the height of the movable goods shelf on an adjusting frame according to the size of goods; through cooperative arrangement of an infrared sensor, a draught fan and a heating strip, air heated by the heating strip can be conveniently blown downwards, and therefore a heat supply effect on the portion above customers is improved; a protective band is hung at the right side of a spring shaft through hooks, and the implementation of a protective effect on the goods on the movable goods shelf can be facilitated so that the goods on themovable goods shelf can be prevented from dropping.

Owner:张永军

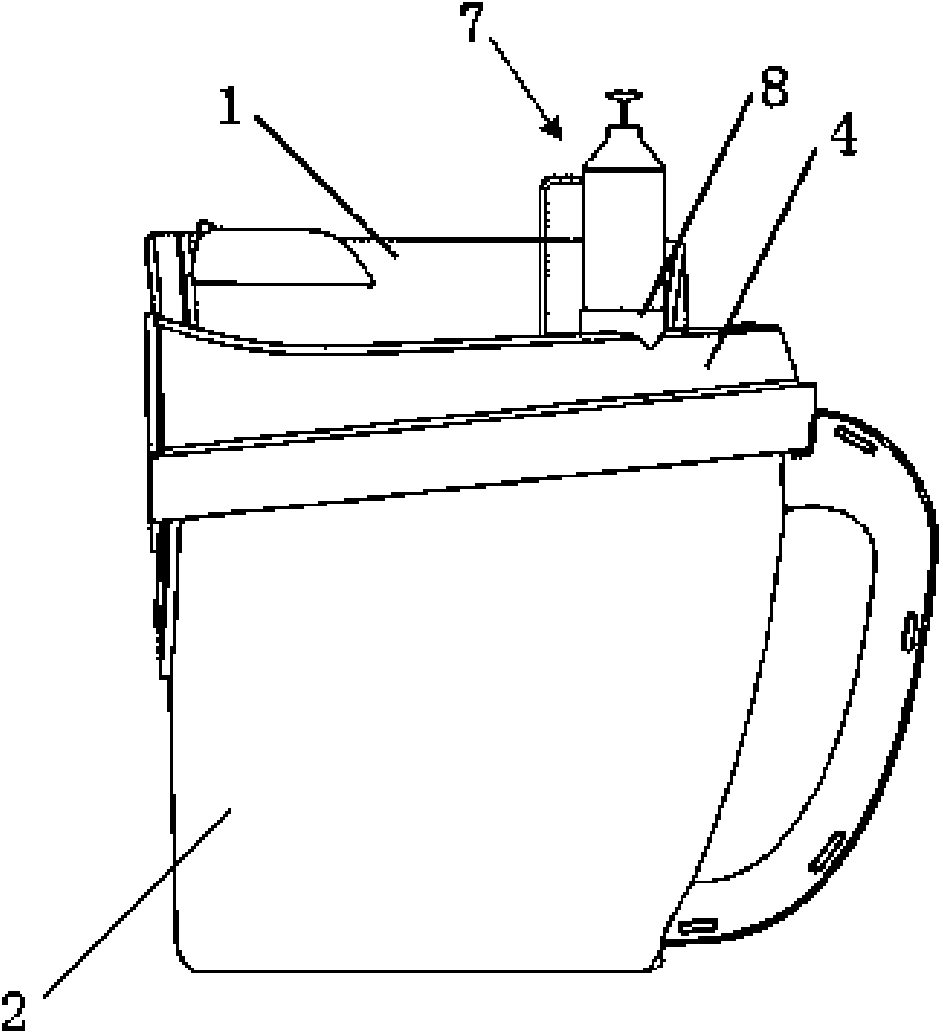

Dust collector dust-collecting device with water spray device

The invention discloses a dust collector dust-collecting device with a water spray device. The dust collector dust-collecting device with the water spray device comprises a dust-collecting barrel, a barrel cover of the dust-collecting barrel and a cyclone separator, wherein the water spray device which sprays liquid into the dust-collecting barrel is arranged on the dust-collecting barrel. The water spray device is arranged on the dust-collecting barrel and is used for spraying water into the dust-collecting barrel, so that humidity of the dust-collecting barrel is increased, mass of the dust is increased, dust can fall down into the bottom of the dust-collecting barrel conveniently, dust is prevented from being adsorbed on the wall of the dust-collecting barrel caused by electrostatic interaction, dust swirl is prevented when a customer dumps garbage, and the surrounding environment is not polluted. Water and bactericide or disinfectant can be put into the water spray device, so that the dust-collecting barrel can be sterilized timely and the cleanness of the dust-collecting barrel is improved.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

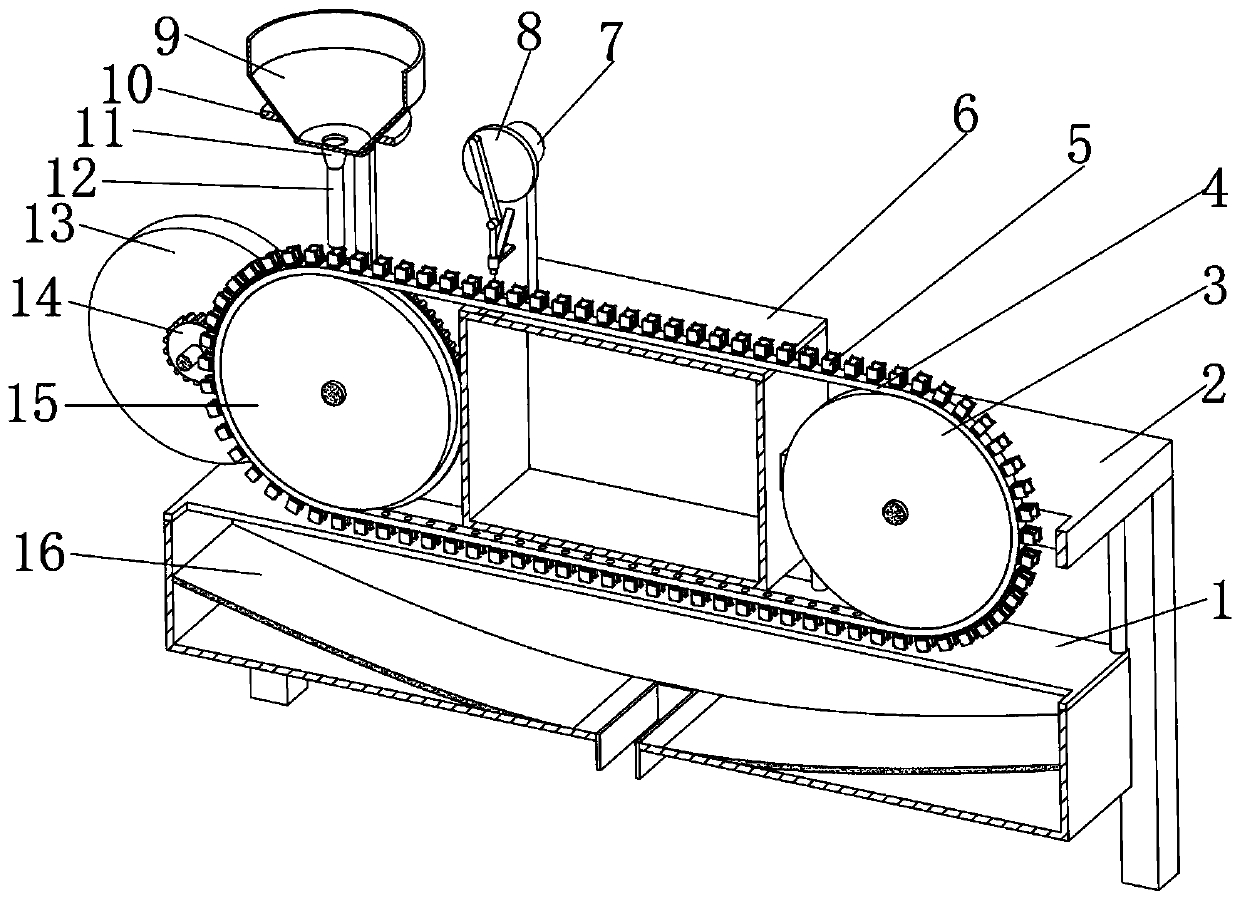

Red date denucleating device for agricultural production

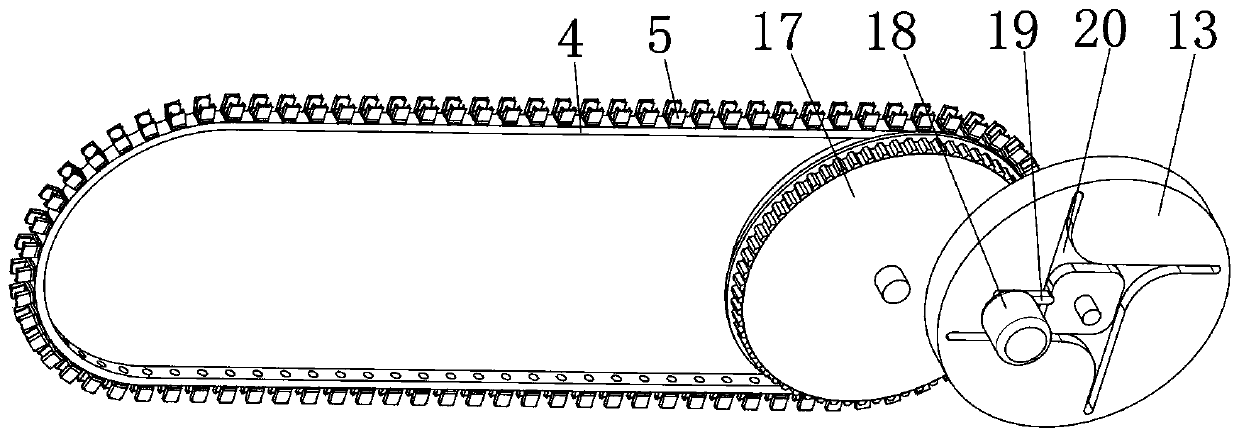

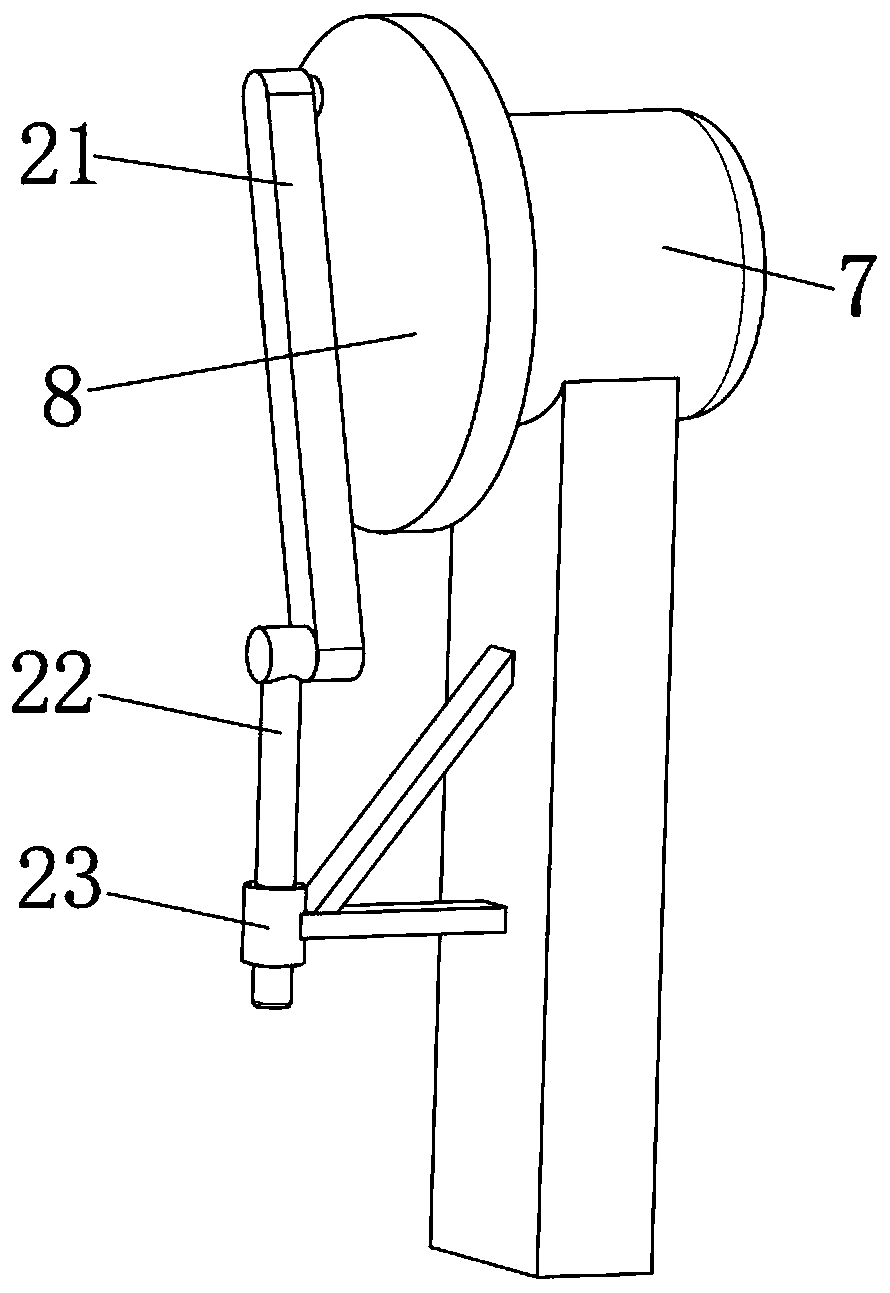

PendingCN111436620AConducive to fall intoNo manual operationFruit stoningAgricultural scienceDrive wheel

The invention belongs to the technical field of agricultural production, and particularly relates to a red date denucleating device for agricultural production; aiming to solve the problems that red dates need to be put into grooves one by one, a handle is pressed by a hand and denucleating is slow during red date denucleating, a scheme is proposed as follows: the red date denucleating device comprises a workbench, wherein a strip-shaped rectangular hole is formed in the outer wall of the top of the workbench; a second driven wheel and a first driven wheel are rotationally connected to the outer wall of the long edge of the strip-shaped rectangular hole through bearings respectively; the circumferential outer walls of the second driven wheel and the first driven wheel are sleeved with a belt, and denucleating columns which are evenly distributed are fixed to the outer wall of the belt; and a second gear concentric with the first driven wheel is fixed to the outer wall of one side of the first driven wheel. The output shaft of a first motor drives a rotating rod to rotate, a sliding rod on the rotating rod slides in a sliding groove, a driving wheel intermittently rotates to drive afirst gear and the second gear to rotate, and therefore a belt intermittently rotates, and red dates can fall into the denucleating columns and denucleating of the red dates is facilitated.

Owner:钟连慧

Machining device used for automatic partitioning

InactiveCN108499667AReduce manual operationsReduce contact timeCocoaCheese manufactureMachining processEngineering

The invention discloses a machining device used for automatic partitioning. The machining device comprises a rack and a braising box; the rack is provided with an upper bottom plate and a lower bottomplate, the upper bottom plate is provided with a grinding mechanism, a storing box and a parting bin, the grinding mechanism is composed of a grinding barrel and a grinding disc, a rubber baffle is connected to the lower end of the grinding barrel, a grinding stretchable air cylinder is connected to the grinding barrel, a through hole is formed in the lower end of the grinding barrel, and an unloading outlet is formed in the position, on the outer side of the grinding barrel, on the storing box; the grinding disc is divided into an upper grinding disc body and a lower grinding disc body, theupper grinding disc body, a cutter arranged on the grinding barrel bin and the upper end face of the grinding barrel form a long-strip grinding circuitous zone, and the upper grinding disc body and the lower grinding disc body are connected with a grinding motor; and a mould box is arranged at an opening in the lower end of the parting bin, and the braising box is provided with a steam connector.In order to solve the above problems, the machining device used for automatic partitioning is provided, integrated operation is achieved, the overall machining process is in an aseptic environment, and the working efficiency and the finished product quality are improved.

Owner:DONGGUAN UNIV OF TECH

Powder medicine mixing machine based on medicinal plant material sources

ActiveCN109771285AWell mixedImprove efficiencyPharmaceutical product form changeGrain treatmentsCrucibleEngineering

The invention discloses a powder medicine mixing machine based on medicinal plant material sources. The machine comprises a working panel, a material processing box is arranged above the working panel, a support table is arranged on the working panel, and a crucible is arranged on the support table; a medicine mixing mechanism is arranged on the working panel, the medicine mixing mechanism comprises a support bottom plate arranged on the working panel, the support bottom plate is provided with a support beam, the top of the support beam is hinged with a cantilever, the end of the cantilever isprovided with a medicine mixing column, and the bottom of the cantilever is provided with a T-shaped rod; a transmission cam is arranged below the cantilever, an annular T-shaped groove matched withthe T-shaped rod is formed in the transmission cam, and a driven pulley is arranged on one side of the transmission cam; a first stepping motor is arranged on the support bottom plate, a motor shaft of the first stepping motor is connected with a driving pulley, and the driving pulley and the driven pulley are covered with belts. The machine not only can effectively smash large quantities of medicines, but also can uniformly mix different medicinal material powder, has a high efficiency, and has a low labor cost.

Owner:WENZHOU UNIVERSITY

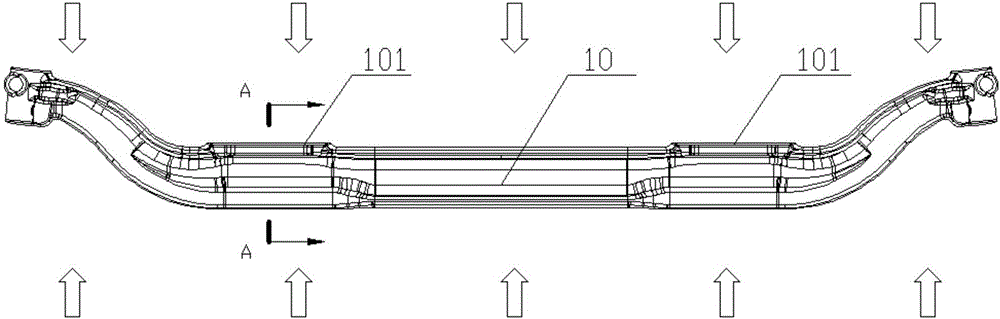

Multistage precipitating device for industrial sewage treatment

InactiveCN107737488AImprove precipitation effectImprove sedimentation efficiencyFiltration circuitsShort loopSewage

The invention discloses a multistage precipitating device for industrial sewage treatment. The device comprises an outer barrel, an inner barrel, a water inlet pipe, a sand collecting hopper, a plurality of supporting legs, a discharge valve I, a plurality of short joints, an annular pipe and a water outlet pipe, wherein the water inlet pipe is arranged on one side of the upper portion of the inner barrel and the water inlet pipe is tangentially connected to the inner barrel; the outer barrel is arranged on one side out of the inner barrel; the short joints which are uniformly distributed arearranged on one side of the upper portion of the outer barrel and are connected to the outer barrel in a through manner; and the short joints are connected to the annular pipe, the water outlet pipe is arranged on one side of the short joints, the sand collecting hopper which is funnel-shaped is arranged on one side of the lower portion of the outer barrel, the supporting legs are arranged on oneside of the outer side of the sand collecting hopper, and the discharge valve I is arranged on one side of the lower portion of the sand collecting hopper. The water inlet pipe is tangentially connected to the inner barrel, sand is removed by rotational flow in the inner barrel to remove most precipitates, and precipitation is performed in the outer barrel, so that the sewage precipitating effectis enhanced, and the sewage precipitating efficiency is improved.

Owner:张士伟

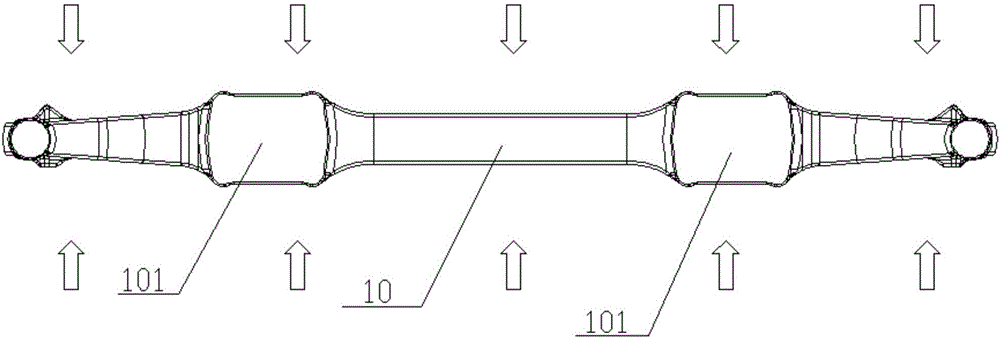

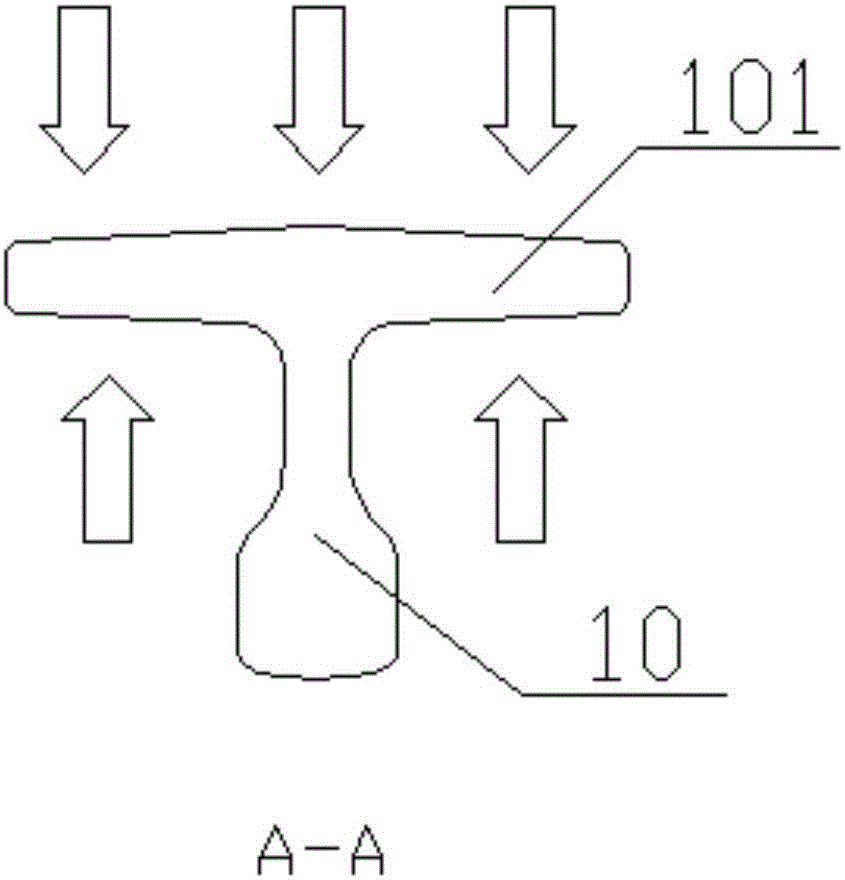

Trimming and thermal calibration tool for front shaft

ActiveCN106001348ASimple structureCompact layoutShaping toolsForging/hammering/pressing machinesProduction qualityAutomation

The invention relates to the field of trimming and thermal calibration tools for front shafts, in particular to a trimming and thermal calibration tool for post-forging of a front shaft. The tool comprises an upper die base and a lower die base and further comprises a trimming device and a calibration device. The trimming device is arranged between the upper die base and the lower die base. The calibration device is located on one side of the trimming device. The other side of the trimming device is further provided with a pushing device for pushing a workpiece to the calibration device through the trimming device. One side of the calibration device is provided with a reset device for pushing the calibration device to be closed and opened. During usage, the upper die base moves downwards to drive the trimming device to trim the workpiece, and the trimmed workpiece is pushed into the calibration device through the pushing device. The tool has the advantages that the structure is simple, the layout is compact, trimming, calibration and straightening of the front shaft can be achieved through one oil press, the equipment input is small, operation is easy and convenient, the automation degree is high, and the production quality and efficiency of products are improved.

Owner:QINGLING MOTORS GRP

Automatic block forming equipment having fishing function

InactiveCN108813470AEnsure the right amountAvoid contactRotary stirring mixersTransportation and packagingIntegrated operationsFishing

The invention discloses automatic block forming equipment having a fishing function. The automatic block forming equipment comprises a machine frame, wherein an upper bottom plate, a grinding mechanism, a material storing tank and a block forming and shaping bin are arranged on the machine frame; the grinding mechanism consists of a grinding cylinder and grinding disks; the lower end of the grinding cylinder is connected with a rubber baffle; a grinding telescopic air cylinder is connected to the grinding cylinder; a through hole is formed in the lower end of the grinding cylinder; a discharging outlet is formed in the material storing tank; an upper grinding disk and a lower grinding disk are connected with the grinding motor; a shaping tank box is arranged at the lower end of the block forming and shaping bin; a steam connector is formed in a braising tank; sliding seats are arranged on the braising tank; a rack plate is connected to each sliding seat; a lifting fishing disk is arranged at the lower end of the rack plate; a rotating shaft is arranged on the braising tank; a gear component is fixed to the rotating shaft; and a hand wheel is arranged at the tail end of the rotatingshaft. The invention aims to provide the automatic block forming equipment having a fishing function, in accordance with the above problems, so that integrated operation is realized; and the whole processing technical procedure is under an aseptic environment, so that the working efficiency and the quality of finished products are improved.

Owner:DONGGUAN UNIV OF TECH

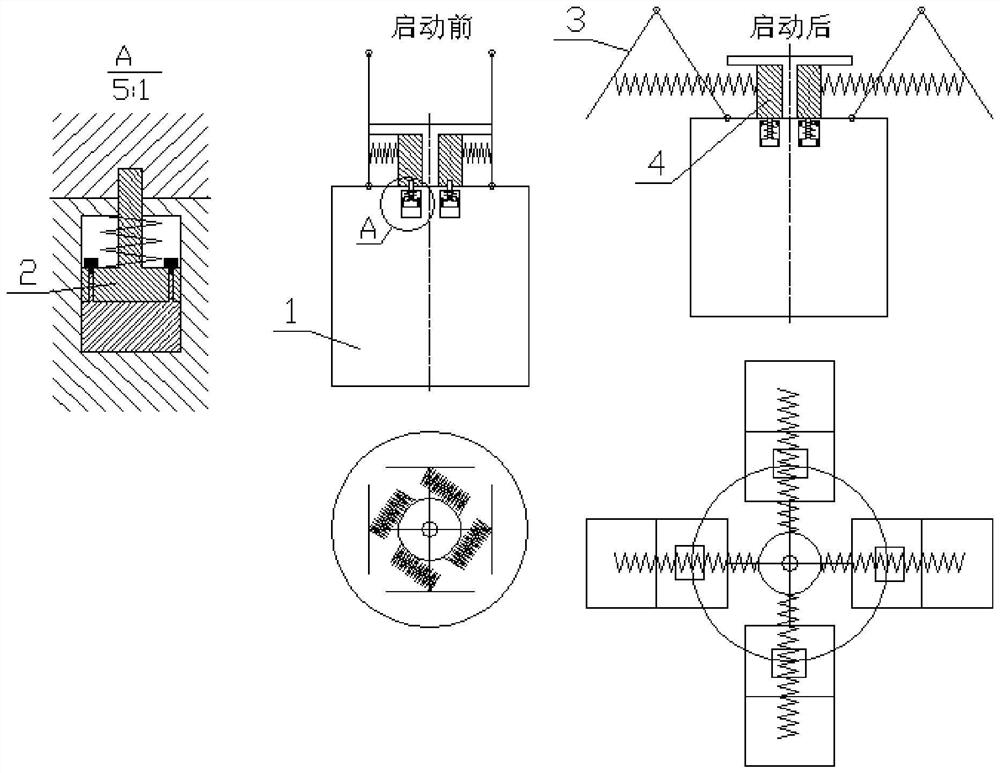

Fixed tail speed reduction device

ActiveCN113865443AReduce resistanceConducive to fall intoAmmunition projectilesProjectilesEngineeringMechanical engineering

The invention discloses a fixed tail speed reduction device. The fixed tail speed reduction device comprises a body detonation warhead shell body, a timing starting positioning pin, fixed tail speed brake parachutes and a rotary energy storage device, the upper end of a second cylindrical boss of the timing starting positioning pin is located in a fourth blind hole of the rotary energy storage device, the middle of the outer side face of a fourth cylinder of the rotary energy storage device is connected with four springs evenly distributed in the circumferential direction, the other ends of the four springs are connected with the centers of third rectangular plates, away from the axis of a rotary body of the body detonation warhead shell body, of the four fixed tail speed brake parachutes respectively, the windward areas of the fixed tail speed brake parachutes correspondingly change along with the speed of a body detonation warhead, when the speed of the body detonation warhead is high, the speed can be greatly reduced within a very short time, and when the speed of the body detonation warhead reaches 200 m / s, the resistance of the body detonation warhead is reduced to be the same as the gravity of the body detonation warhead, and the body detonation warhead moves at a constant speed. The high-energy fuel and the air are mixed to form an active cloud cluster form, so that affect subsequent body detonationis not affected, and it is guaranteed that the power of the body detonation warhead is exerted.

Owner:XIAN MODERN CHEM RES INST

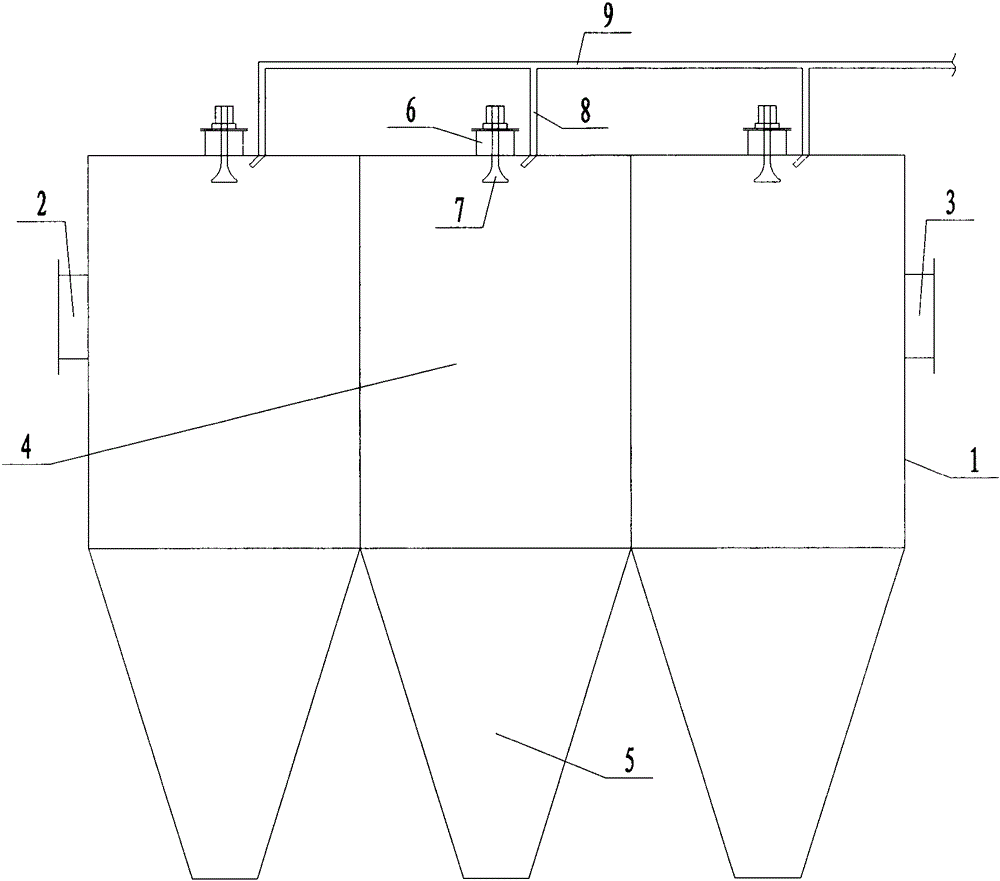

Bag-type dust collector auxiliary dust-cleaning device

InactiveCN105268259AExtended service lifeImprove dust removal effectDispersed particle filtrationBaghouseAcoustic wave

The invention discloses a bag-type dust collector auxiliary dust-cleaning device which is good in dust removing effect. The bag-type dust collector auxiliary dust-cleaning device comprises a bag-type dust collector body, an air inlet formed in one side of the bag-type dust collector body and an air outlet formed in the other side of the bag-type dust collector body; multiple cloth bags are evenly arranged in the bag-type dust collector body, a dust hopper matched with each cloth bag is arranged on the portion, located at the lower end of the corresponding cloth bag, of the bag-type dust collector body, a sound wave dust-cleaning device is arranged on the portion, located at the upper end of each cloth bag, of the bag-type dust collector body through a connecting flange, and the sound production end of each sound wave dust-cleaning device extends into the corresponding cloth bag; an air nozzle is arranged on the portion, located on one side of each sound wave dust-cleaning device, of the bag-type dust collector body, one end of each air nozzle extends into the corresponding cloth bag to be matched with the corresponding sound wave dust-cleaning device, and the other end of each air nozzle is connected with a compressed air connecting pipe.

Owner:JIANGSU SHENJIANG ENVIRONMENT TECH

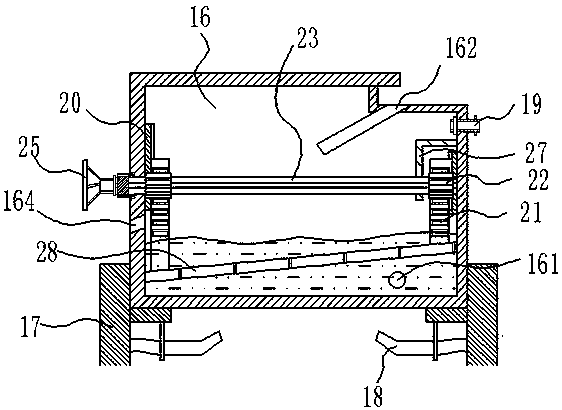

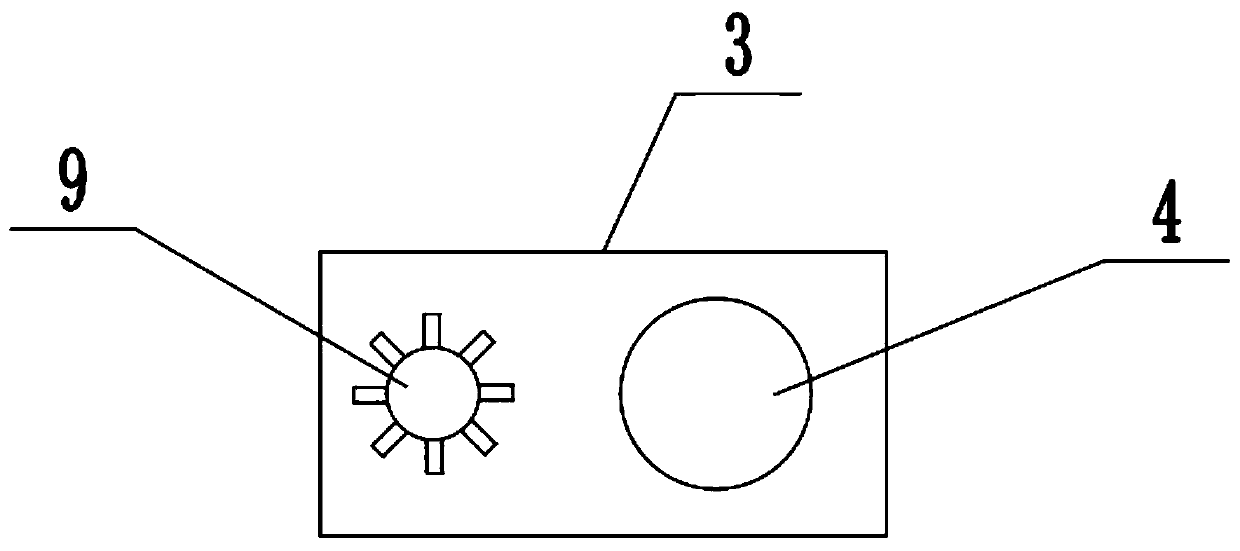

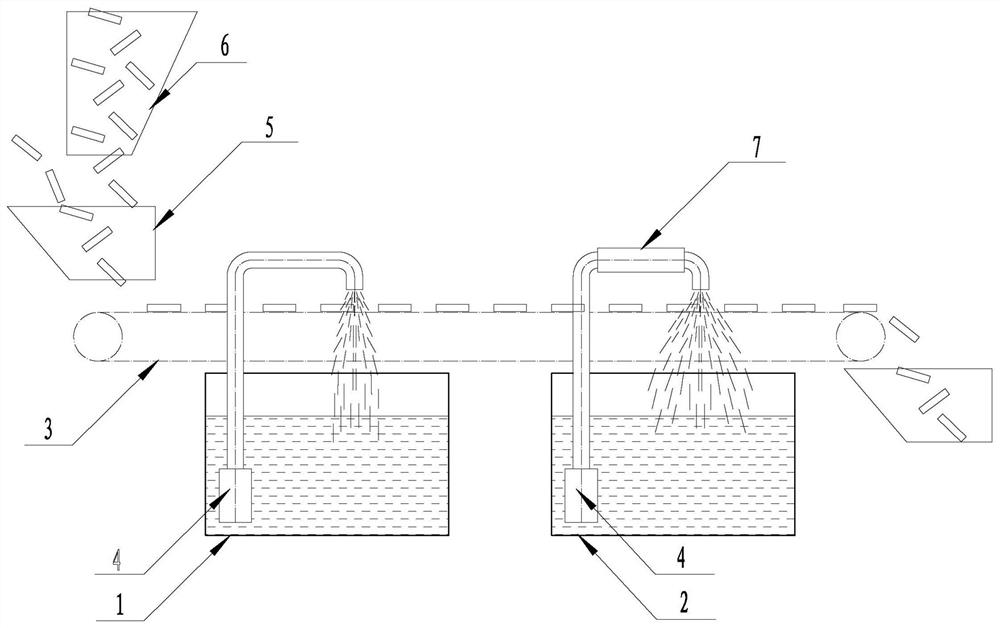

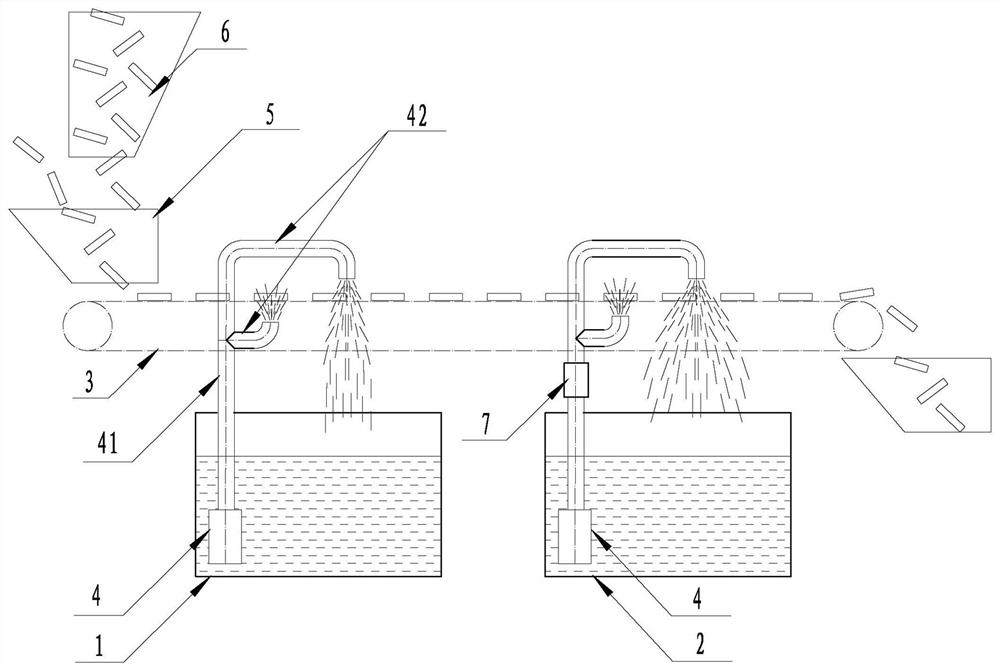

Online ultrasonic cleaning machine for furnace zone of sintering furnace

PendingCN108543769AReduce moistureSimple drying processElectrode thermal treatmentDrying gas arrangementsEngineeringAir knife

The invention discloses an online ultrasonic cleaning machine for a furnace zone of a sintering furnace. The online ultrasonic cleaning machine comprises a control cabinet and a cleaning machine, wherein the control cabinet comprises a cabinet body, an ultrasonic controller and a water pump; the ultrasonic controller is arranged at the upper part in front of the cabinet body, and the water pump isarranged at the lower part of the ultrasonic controller; and the cleaning machine is arranged in front of the cabinet body and comprises a water tank, a guide roller, a pressing wheel, a cleaning roller and an air knife. A first drying furnace is arranged on the right side of the cleaning machine and comprises a furnace body, supporting wheels, heating pipes and a guide roller. A plurality of supporting wheels are fixedly arranged at the upper part of the furnace body, a plurality of heating pipes are arranged in the middle of the furnace body along the left-right direction of the furnace body, and the guide roller is arranged at the upper part of the right side of the furnace body. A second drying furnace is arranged on the right side of the first drying furnace. The online ultrasonic cleaning machine has the advantages of online cleaning and improving the product quality.

Owner:平煤隆基新能源科技有限公司

Seedling cultivation machine

PendingCN109644637AReduce labor intensityRealize mechanized workTransplantingClimate change adaptationBiologyMotor drive

The invention relates to a seedling cultivation machine. The seedling cultivation machine comprises a motor rack, a seedling box, a seedling conveying track, a panel, a seedling inserting machine, a generator, a seedling conveying motor and a seedling inserting motor, wherein the seedling inserting motor comprises a seedling inserting barrel at the tail of the motor rack; a conical door is arranged at the lower end of the seedling inserting barrel; a lifting slider is connected to an eccentric wheel through a connecting rod; the eccentric wheel is connected with the seedling inserting motor; sliding tracks are arranged on two sides of the lifting slider; the seedling inserting barrel is fixed on one of the sliding tracks of the lifting slider; a rotating shifting block is arranged on the other sliding track; a panel hinge is arranged between an inner periphery panel and an outer periphery panel; a pushing portion is arranged at the lower end of the outer periphery panel; a hook is arranged at an end of a pushing rod; when the seedling inserting motor drives the lifting slider to descend through the eccentric wheel, the pushing rod hooks the pushing portion through the hook to pressdown the outer periphery panel, then seedlings which are placed on the outer periphery panel are conveyed into the seedling inserting barrel, and meanwhile, the rotating shifting block drives the conical door of the seedling inserting barrel to open; and mechanization of cultivation of the seedlings can be realized, the cultivation efficiency is improved, and the production cost is reduced.

Owner:DONGGUAN POLYTECHNIC

Pyrolysis gas dust remover-filter

ActiveCN106147880AFirmly connectedEven air distributionDispersed particle filtrationTransportation and packagingEngineeringExhaust pipe

The invention discloses a pyrolysis gas dust remover-filter, comprising a dust remover and a guide mechanism; a filter mechanism is disposed in the dust remover; the filter mechanism divides the dust remover into an upper exhaust chamber and a lower intake chamber; the guide mechanism comprises a main pipe and a branch pipe; the main pipe runs through the dust remover and extends into the intake chamber; the end of the main pipe extended into the intake chamber is a seal end, the branch pipe is arranged on the main pipe extended into the intake chamber, the upper end of the branch pipe is positioned below the filter mechanism, the lower end of the branch pipe is communicated with the main pipe, the upper end of the branch pipe is an open end, and the exhaust chamber is provided with an exhaust pipe. The main pipe and the branch pipe cooperate to enable the flow direction of high-temperature pyrolysis gas to be consistent with the return direction of dust, and thus the problems of reentrainment of dust and breakage of filter elements are prevented effectively.

Owner:HENAN DRAGON INTO COAL TECH CO LTD

Environment-friendly blackboard eraser and blackboard assembly using the environment-friendly blackboard eraser

InactiveCN106926621BSave precious timeImprove wiping efficiencyBoard cleaning devicesPush pullEngineering

The invention discloses an environment-friendly blackboard eraser and a blackboard assembly using the environment-friendly blackboard eraser, and relates to the field of teaching tools, in particular to the technical field of blackboards and blackboard erasers. An environment-friendly blackboard eraser is used in conjunction with a sliding blackboard or a push-pull blackboard, and includes a blackboard eraser body, a fixing piece and a fixing seat. The blackboard eraser body is detachably arranged on the fixing part, and the fixing part is connected with the fixing seat. The fixing seat can be fixedly arranged on the fixing plate of the sliding blackboard and can adjust the pressing force between the blackboard eraser body and the blackboard. The blackboard assembly includes at least two sliding blackboards with adjustable positions and the above-mentioned environment-friendly blackboard eraser. The sliding blackboard includes a top board and a bottom board, the environmentally friendly blackboard eraser is fixedly arranged between the top board and the bottom board and the blackboard eraser body can be set facing the sliding blackboard. The invention has reasonable design, simple structure, easy replacement and cleaning, high wiping efficiency, saves time, is not easy to raise dust, and reduces harm.

Owner:WUHAN POLYTECHNIC UNIVERSITY

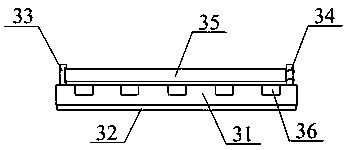

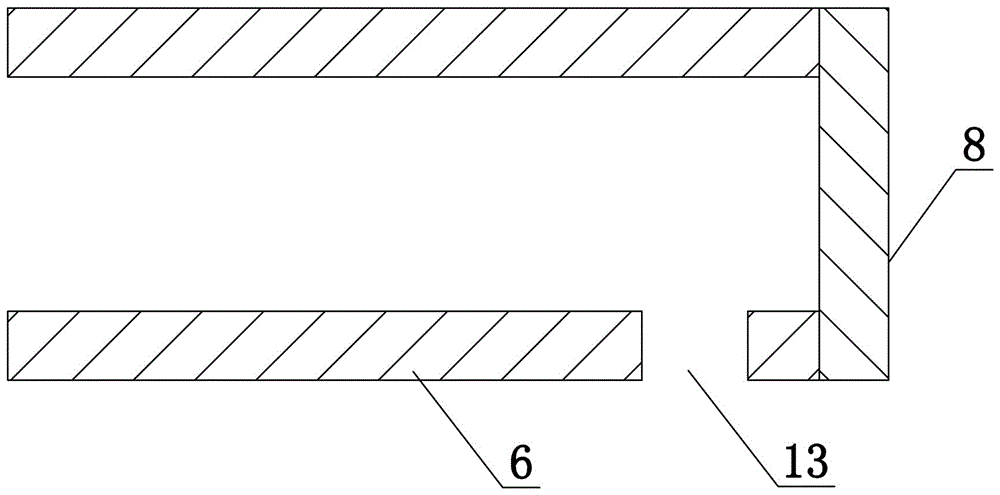

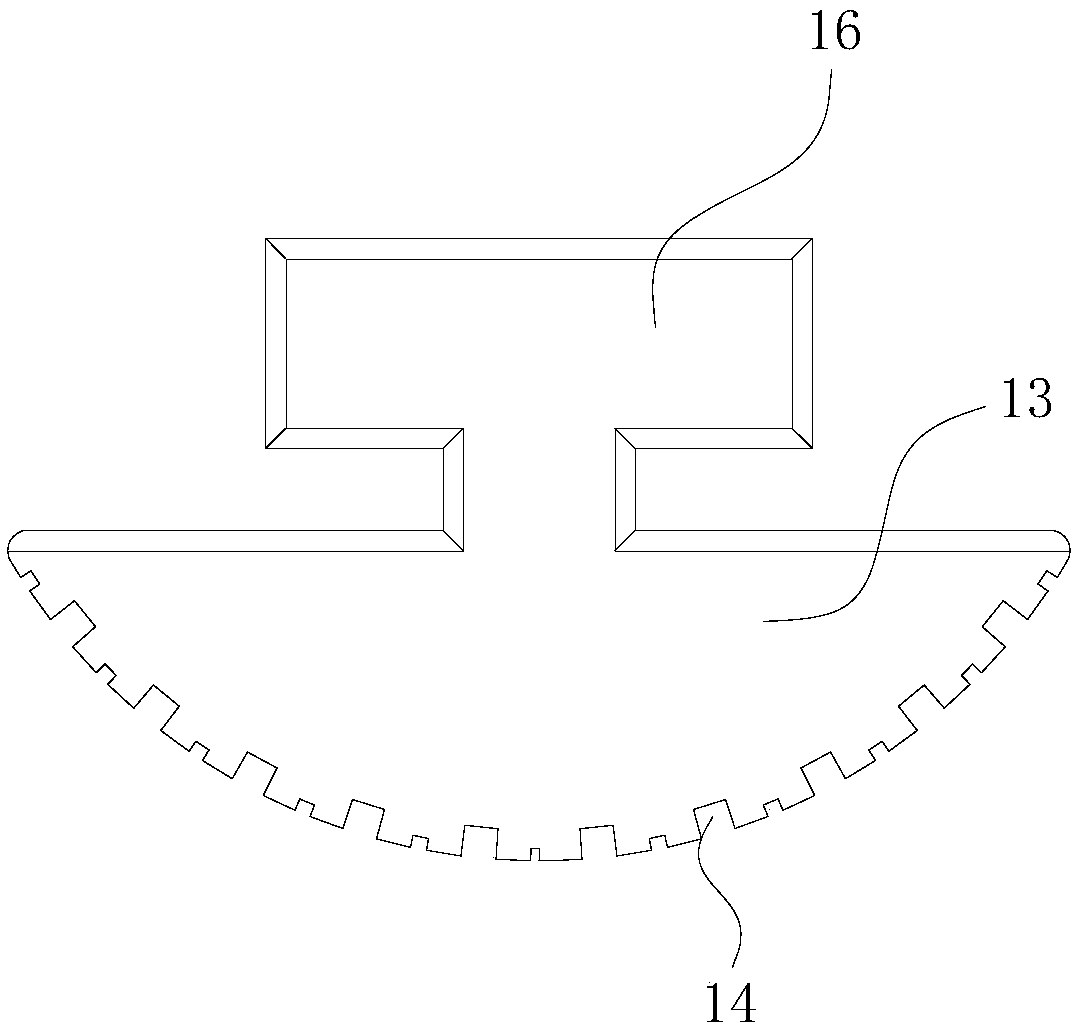

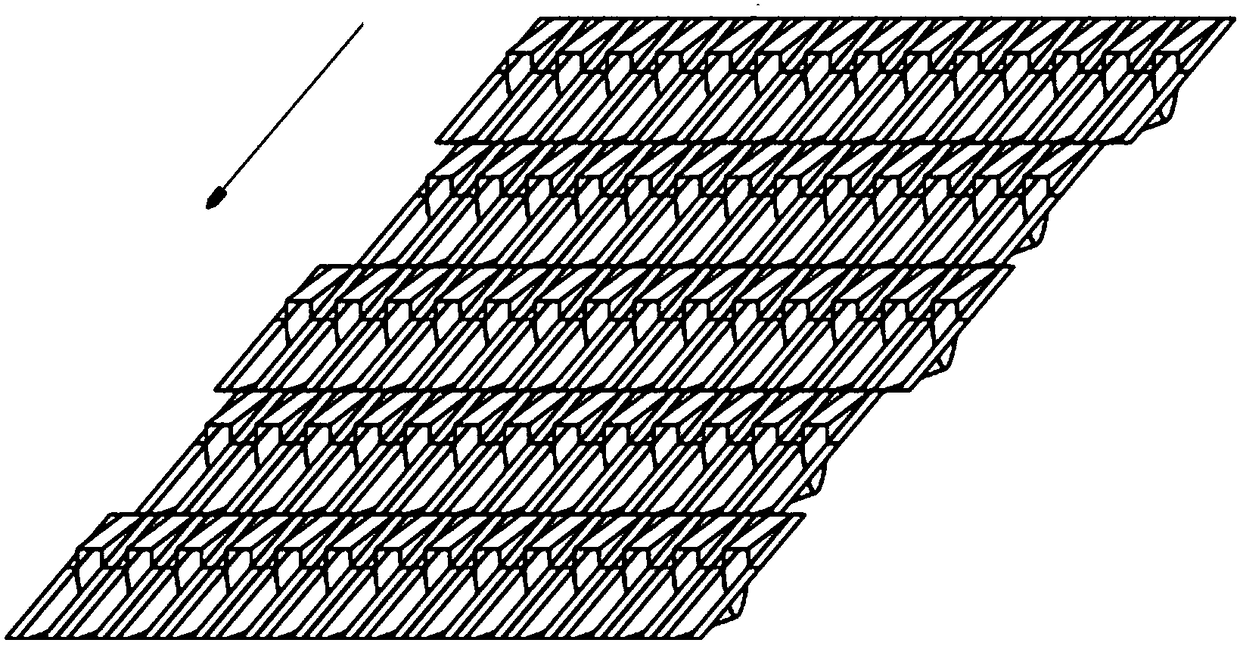

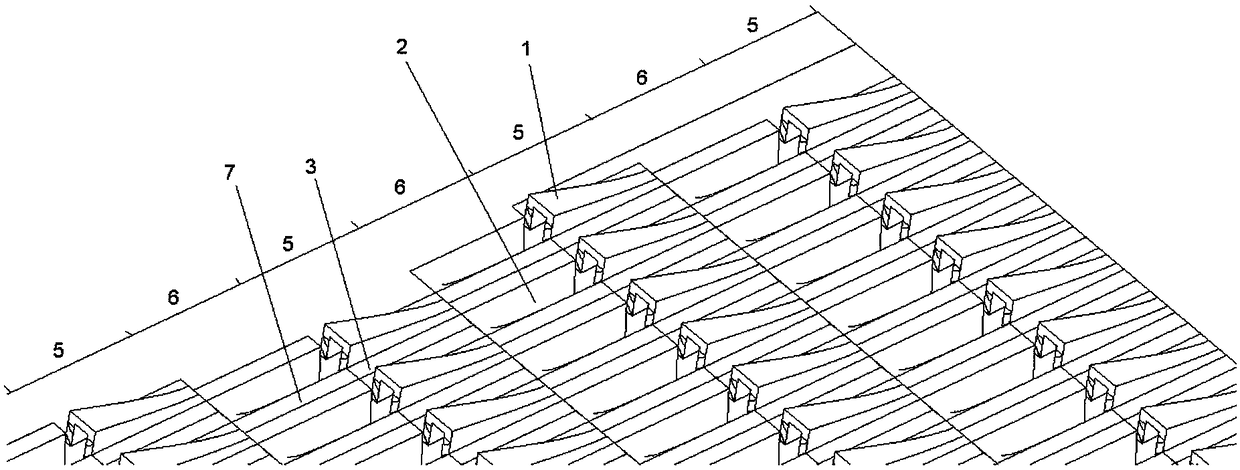

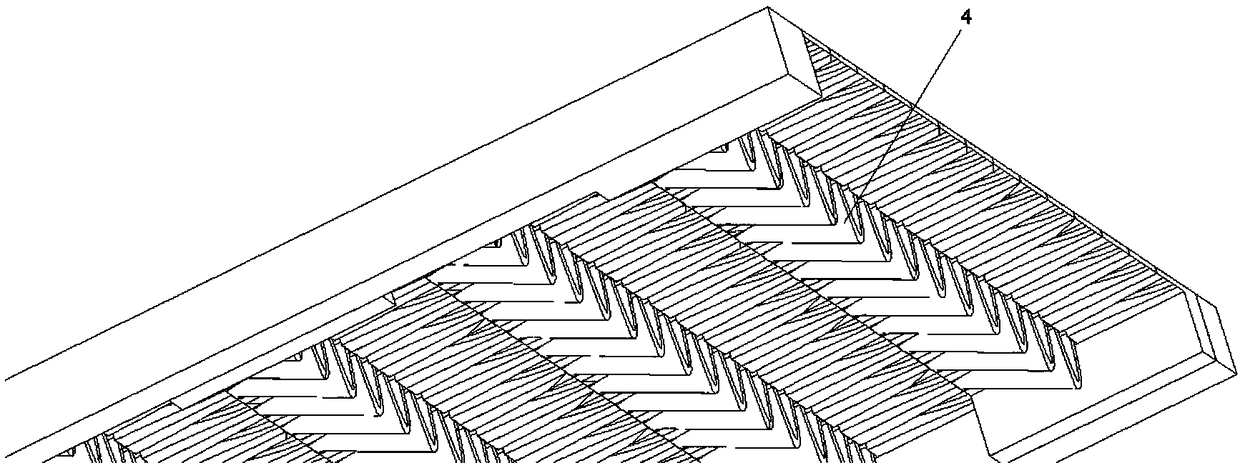

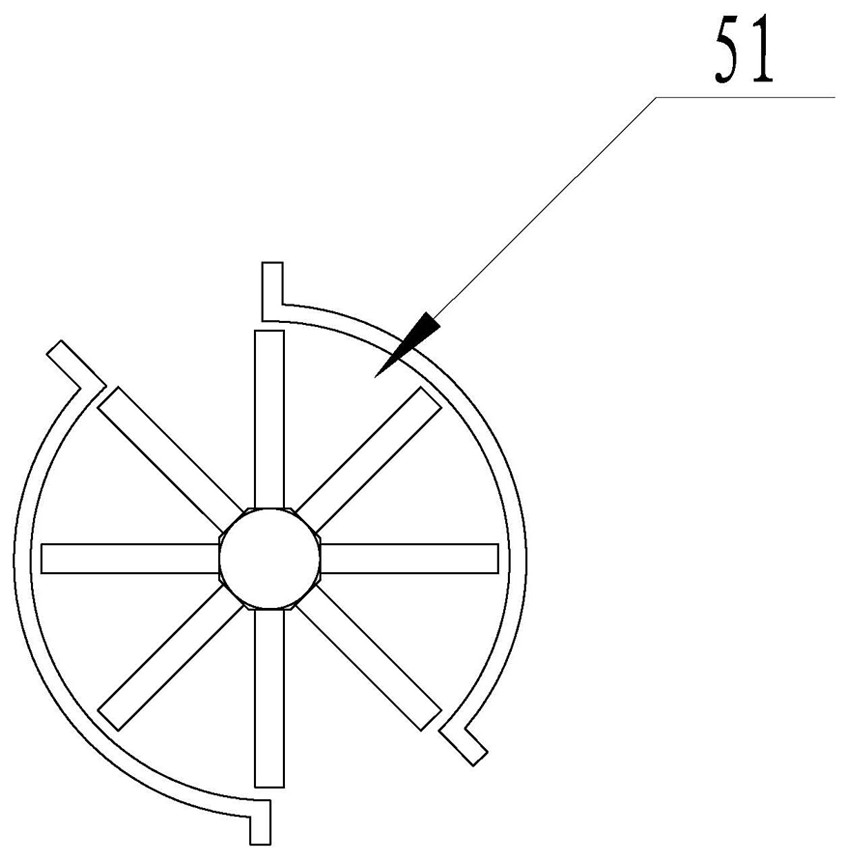

Special-shaped vibrating screen for separating silvers and tobacco shreds and screening method

PendingCN108523208AImprove separation efficiencyAchieve separationTobacco treatmentEngineeringScreening method

The invention discloses a special-shaped vibrating screen for separating silvers and tobacco shreds. The special-shaped vibrating screen is characterized by comprising multiple rows of diversion and organization zones (5) and screen hole zones (6) which are alternatively arranged in the front-back direction, wherein multiple rectangular screen holes (2) are distributed in the screen hole zones (6), a certain distance is reserved between every two adjacent rectangular screen holes (2) and a solid flat plate (7) is limited. Multiple forwards and upwards inclining diversion slope benches (1) aredistributed in the diversion and organization zones (5), a certain distance is reserved between every two adjacent diversion slope benches (1), and an organization groove channel (3) is limited. The special-shaped vibrating screen can solve the problem of silk hanging produced when a traditional screen window type vibrating screen screens a silver and tobacco shred mixture, long-time stable operation can be achieved, and the separating efficiency can be greatly improved.

Owner:CHINA TOBACCO YUNNAN IND

Tea leaf strip tidying device

InactiveCN106922867AGood for tightPromote loosePre-extraction tea treatmentAgricultural engineeringTea leaf

The invention discloses a tea leaf strip tidying device, and relates to a tea leaf processing device. The tea leaf strip tidying device comprises a machine frame, a driving mechanism, a heating mechanism, a strip tidying table arranged on the machine frame, and kneading and pressing mechanisms which correspond to two ends of the strip tidying table, wherein each kneading and pressing mechanism comprises a frame body, a kneading and pressing tank and a kneading and pressing shaft located above the corresponding kneading and pressing tank; each frame body is rotatably connected to the machine frame; each kneading and pressing tank is fixed to the corresponding frame body; each kneading and pressing shaft is rotatably connected to the corresponding frame body, arranged above the corresponding kneading and pressing tank, and corresponds to a groove of the corresponding kneading and pressing tank; a gap is formed between each kneading and pressing shaft and the groove of the corresponding kneading and pressing tank; brushes are arranged on each kneading and pressing shaft; a sliding rod is hinged to the middle part of the strip tidying table, and is in vertical slip connection with the machine frame; air cylinders corresponding to two ends of the strip tidying table are arranged on the machine frame; a cylinder body of each air cylinder is hinged to the machine frame; and a piston rod of each air cylinder is hinged to the end part of the strip tidying table. According to the tea leaf strip tidying device disclosed by the invention, through the rotation of the kneading and pressing tanks, the directions of tea leaves are adjusted, so that the situation that the tea leaves roll back on the strip tidying table cannot exist, and the winding up of the tea leaves is facilitated.

Owner:遵义茗香康源茶饮发展科技有限公司

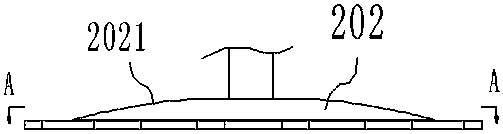

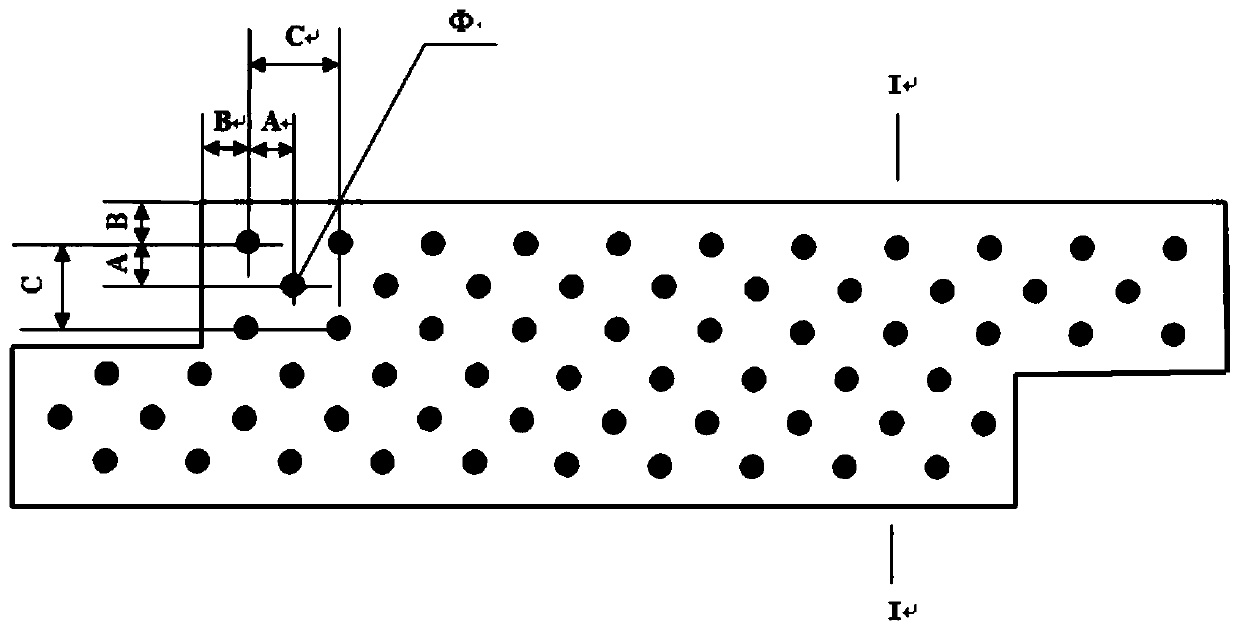

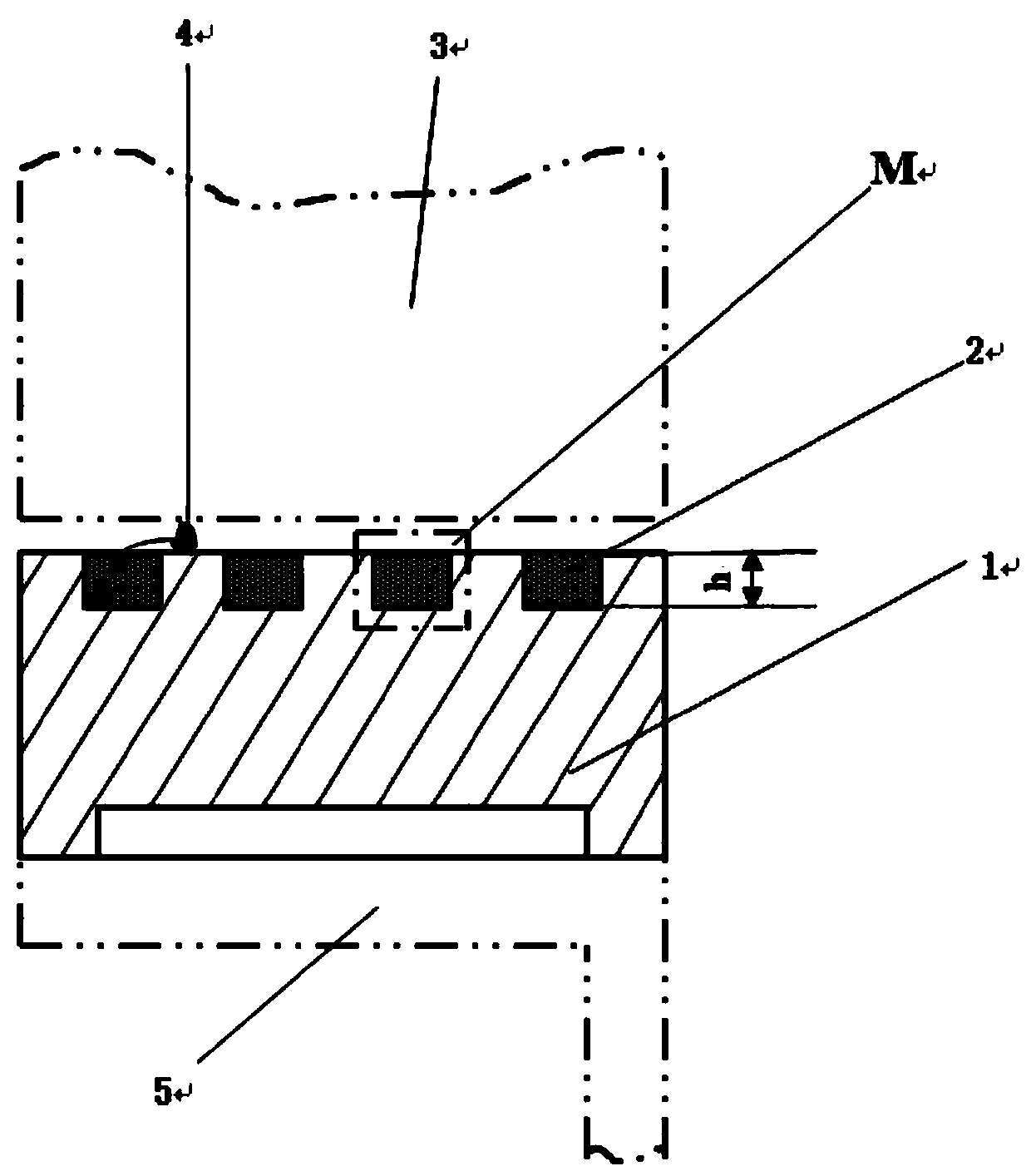

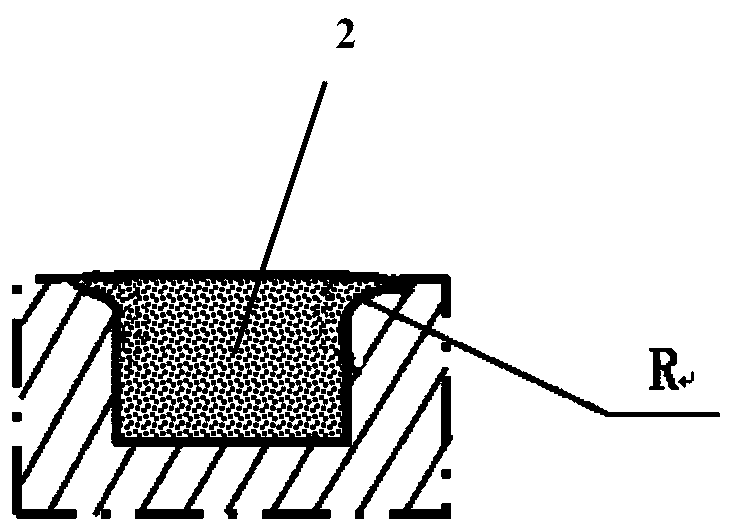

Sintering machine slide sliding plate and manufacturing method thereof

PendingCN110081710AAvoid wastingEasy to take outFurnace typesEngine lubricationRelative motionSlide plate

The invention relates to a sintering machine slide sliding plate and a manufacturing method thereof. The sintering machine slide sliding plate (1) with lubrication holes is included, and nodular castiron is used as a material; and a solid lubricant (2) is a high temperature and wear resistance solid lubricating material. As shown in a graph 1, a graph 2 and a graph 3, the sintering machine slidesliding plate (1) with the lubrication holes is cast from the nodular cast iron, and the lubrication holes arranged in a rhombus shape are simultaneously cast on the surface of the sliding plate whenthe slide sliding plate is cast, and the problem that metal material waste is caused by metal scrap generated by hole forming in the slide sliding plate is solved; the solid lubricant (2) is made of the high temperature and wear resistance solid lubricating material and is filled in the lubrication holes; cast circular beads are reserved between the hole walls of the lubrication holes and the surface of the slide sliding plate, the circular beads facilitate bringing-out of the lubricant during relative motion of a swimming plate and the sliding plate compared with straight corners, and the sealing effect is improved; the circular beads enable falling carbon particles to fall into the lubrication holes, and influences of the carbon particles on the sealing performance are reduced; and casting hole forming enables the hole walls of the lubrication holes to be rough, and the filled lubricant is not prone to falling during transportation and installation. The sintering machine slide sliding plate is simple in structure, low in processing cost, capable saving metal materials and capable of improving the sealing effect between the swimming plate and the sliding plate.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

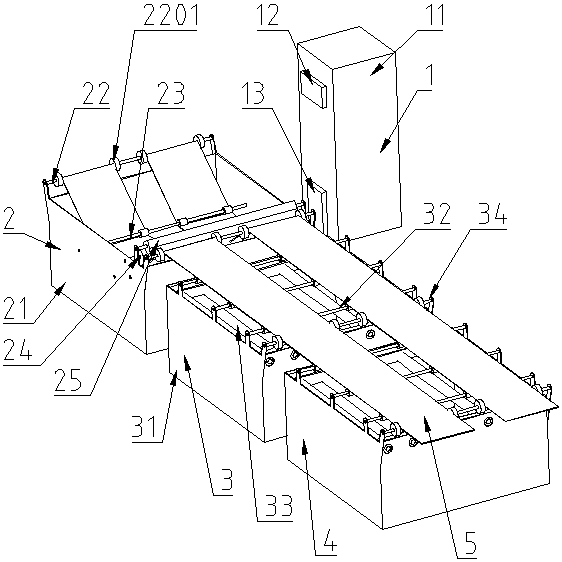

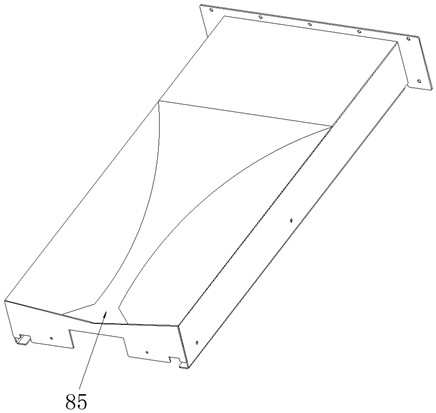

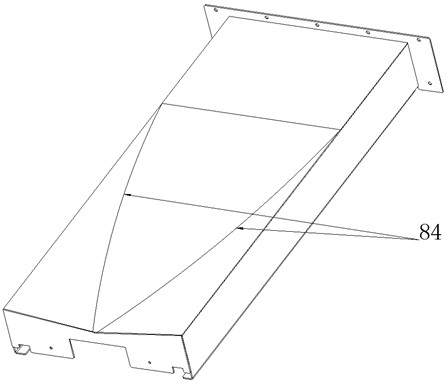

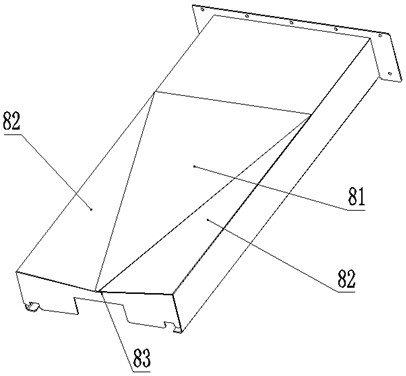

Slag-water separation and collection system for cutting cavity of cutting machine and dicing saw

ActiveCN114734544AAvoid stickingAvoid enteringWorking accessoriesFine working devicesCollection systemProcess engineering

The invention provides a cutting machine cutting cavity slag-water separation and collection system and a dicing saw, and relates to the technical field of cutting, the cutting machine cutting cavity slag-water separation and collection system comprises a cutting cavity part, and the cutting cavity part comprises a material receiving plate, the upstream end of the waterproof armor is connected with the downstream end of the material receiving plate, and the waterproof armor and the material receiving plate can move synchronously. The water tank is used for receiving cutting chip liquid falling from the downstream end of the waterproof armor, the downstream end of the water tank is communicated with an inlet of the filtering cavity part, and the waterproof armor is arranged on the water tank in a back-and-forth sliding mode; and the first brush body is arranged at the downstream end of the waterproof armor, is located in the water tank and is driven by the waterproof armor to sweep the cutting chip liquid at the upstream end of the water tank into the inlet of the filtering cavity part, so that the technical effect that the cutting chip liquid can be timely and thoroughly guided to the filtering cavity part to be filtered is achieved.

Owner:苏州和研精密科技有限公司

A traditional Chinese medicine crushing and grinding machine that is convenient for feeding

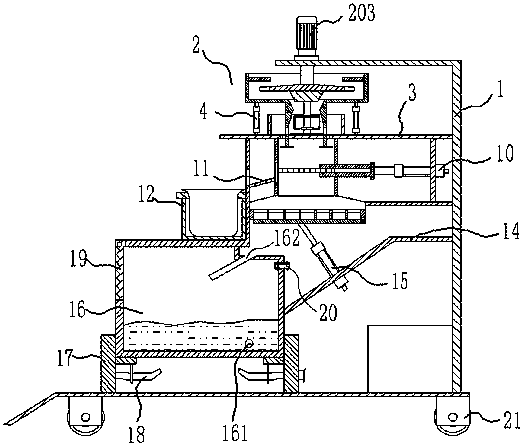

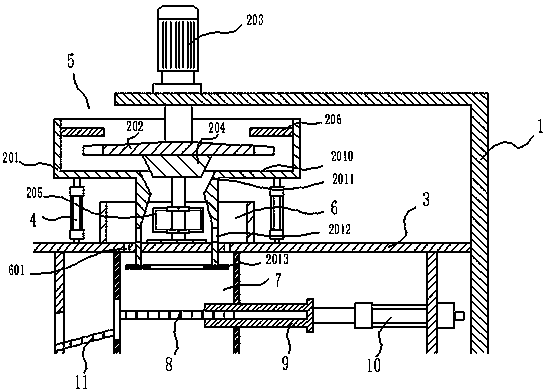

ActiveCN108672051BConducive to fall intoAvoid cloggingCocoaGrain treatmentsEngineeringMechanical engineering

The invention discloses a traditional Chinese medicine crushing and grinding integrated machine capable of conveniently feeding. The traditional Chinese medicine crushing and grinding integrated machine comprises an outer shell, a material inlet, a crushing shaft, a sieve plate, a material discharge port and supporting legs, wherein the top portion of the outer shell is fixedly connected to the material inlet, an installation plate is arranged inside the outer shell, the upper surface of the installation plate is fixedly connected to a movable column, the upper surface of the outer shell is fixedly connected to a vibration motor, the lower surface of the installation plate is fixedly connected to a crushing motor, the shaft extending end of the crushing motor is fixedly connected to the crushing shaft, crushing blades are distributed on the crushing shaft, the sieve plate is arranged below the crushing shaft, an upper grinding disc is arranged below the sieve plate, and a lower grinding disc is arranged on the lower surface of the upper grinding disc. According to the present invention, the traditional Chinese medicine is crushed by the crushing blades, and the vibration motor drives the crushing blades to move up and down so as to expand the crushing range and improve the crushing effect; the material feeding rotation and the moving up and down are simultaneously performed, such that the clogging of the material inlet by the traditional Chinese medicine can be prevented; and the crushed traditional Chinese medicine particles fall onto the lower grinding disc, and the traditional Chinese medicine is grinded by the grinding disc.

Owner:BOZHOU HUQIAO PHARMA

Food pretreatment equipment and automatic catering continuous cooking system

ActiveCN114259075AIncrease flexibilityStrong coordinationFood processingOil/fat bakingProcess engineeringFood material

The invention discloses food pretreatment equipment and an automatic catering continuous cooking system, and relates to the field of smart catering, and the food pretreatment equipment comprises a hot water storage unit, a paste storage unit and a hot oil storage unit which are sequentially arranged from the process upstream to the process downstream; a metal net conveying belt is erected over the hot water storage unit, the paste storage unit and the hot oil storage unit, and an extraction device is arranged in each storage unit and used for conveying hot water, paste and hot oil to designated positions of the upper-layer working face of the metal net conveying belt through conveying pipelines. The food materials on the metal net conveying belt are sequentially blanched, pasted and oiled, and all the storage units play a collecting role at the same time. The pretreatment equipment can automatically blanch, paste and oil food materials, and is compact, space-saving and low in cost; the automatic catering continuous cooking system manufactured on the basis of the equipment can realize full-automatic cooking of various dishes, is high in intelligent degree, and is beneficial to standardized and rapid meal delivery.

Owner:唐德顺

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com