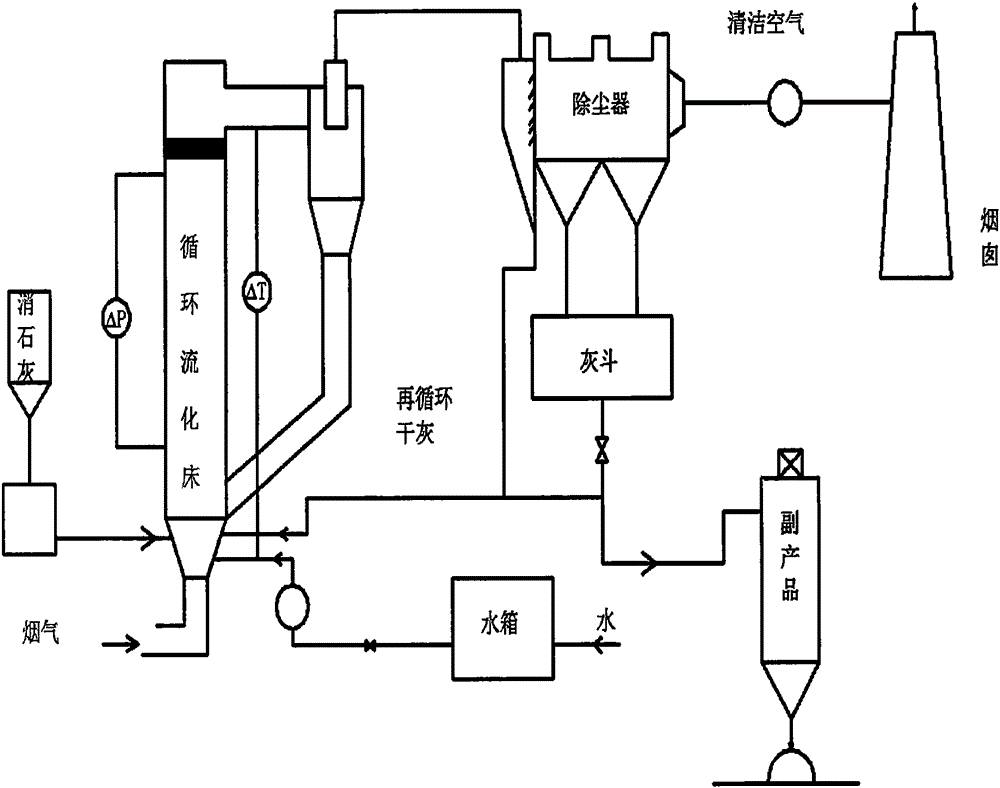

Desulphurization dedusting integrated half-dry type swirl desulfurization tower

A desulfurization and dust removal, semi-dry technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of low turbulence intensity and small shear force, and achieve the reduction of calcium-sulfur ratio, weakening deviation, The effect of increasing the number of cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

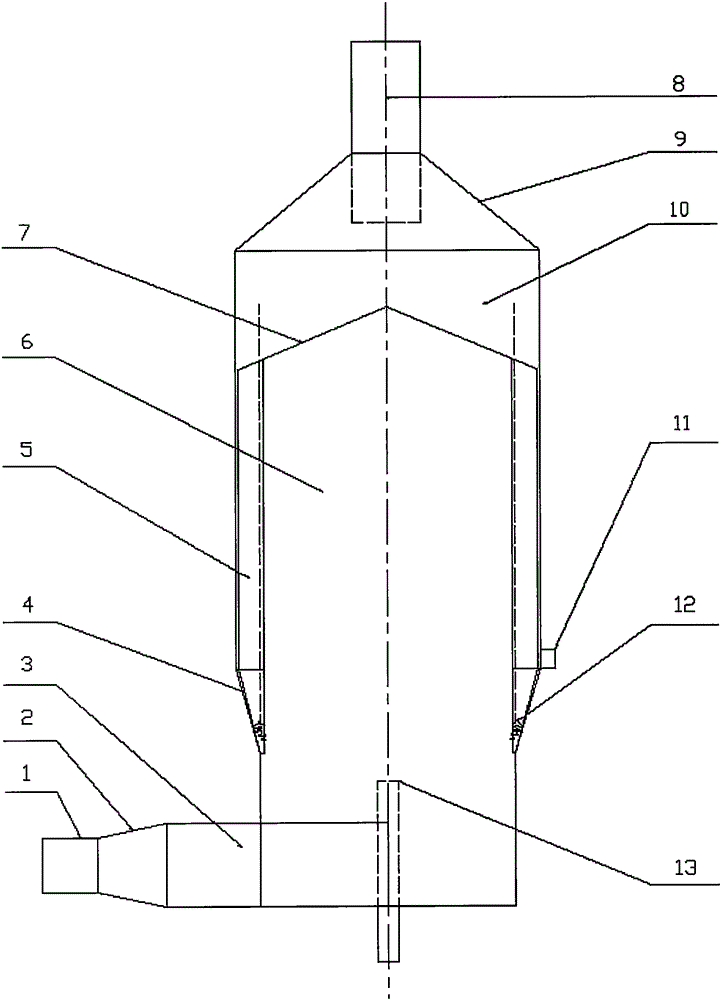

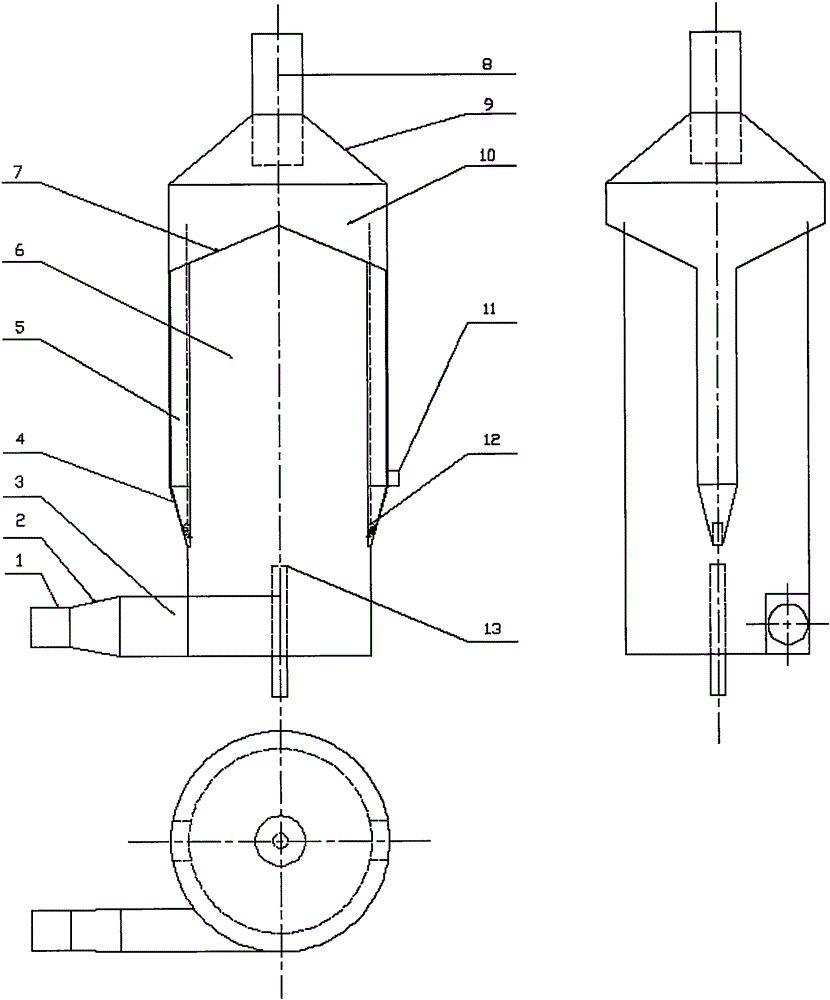

[0030] In order to overcome the problems of small airflow shear force in the conventional circulating fluidized bed flue gas desulfurization tower, low airflow turbulence intensity, insufficient mixing and contact between dusty and sulfur-containing flue gas and desulfurization absorbent, and low utilization rate of desulfurization agent, combined with attached figure 2 , by setting a tangential air intake structure (3) at the bottom of the desulfurization tower, a strong swirling flow is formed in the desulfurization reaction chamber (6). Under the action of swirling flow, the shear force and turbulence intensity of the airflow are significantly increased, and the full mixing and contact between the dust-laden and sulfur-laden flue gas and the desulfurization absorbent are strengthened. And under the effect of strong swirling flow, the gas flow field in the desulfurization reaction chamber (6) is turbulent strongly, and the desulfurizer particles entrained in the air flow co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com