Sintering machine slide sliding plate and manufacturing method thereof

A manufacturing method and technology of sintering machine, which are applied in the direction of engine lubrication, mechanical equipment, engine components, etc., can solve the problems of high processing cost, waste of metal scrap resources, affecting the sealing effect, etc. The effect of the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

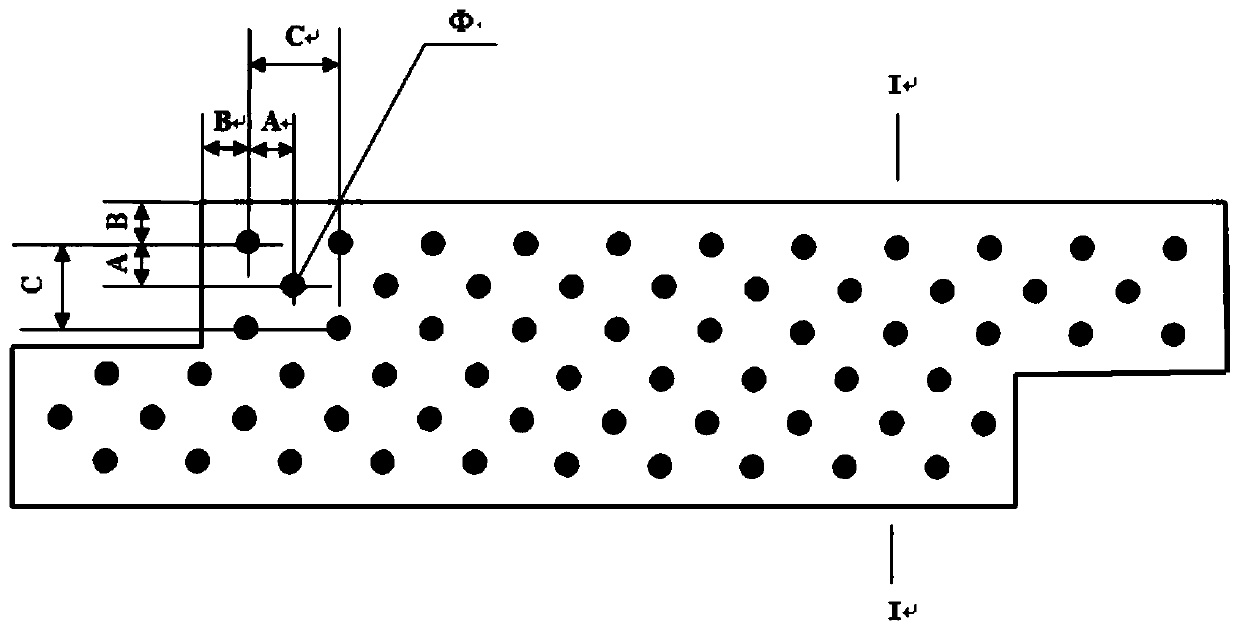

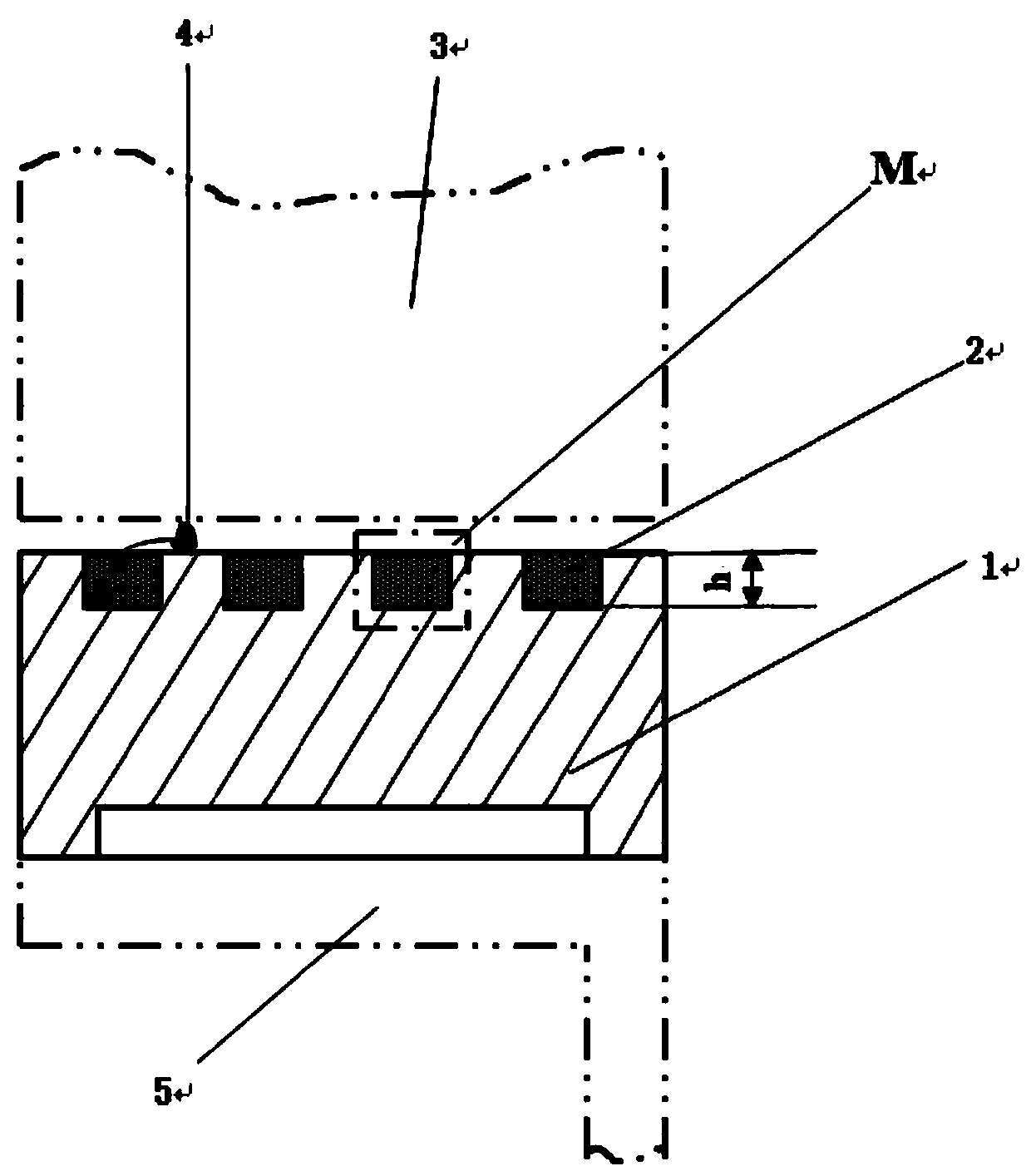

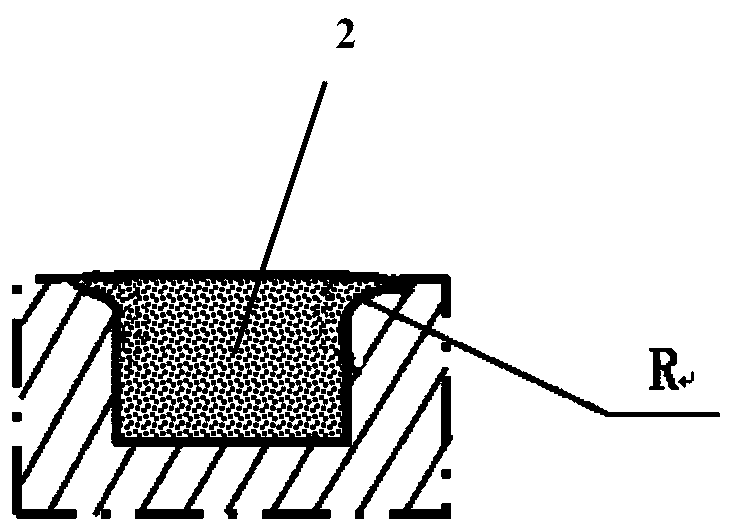

[0010] Attached below figure 1 , figure 2 , image 3 Specific embodiments of the present invention will be described.

[0011] A sintering machine slideway slide plate and its manufacturing method, comprising a sintering machine slideway slide plate 1 with lubricating holes, made of nodular cast iron; and a solid lubricant 2, which is a high-temperature-resistant and wear-resistant solid lubricating material. Such as figure 1 , figure 2 , image 3 As shown, the sliding plate of the sintering machine is made of nodular cast iron. When casting the sliding plate, lubricating holes arranged in a diamond shape are cast on the surface of the sliding plate at the same time. Rounded corners, when the swimming plate and the sliding plate move relatively, the rounded corner structure is more conducive to the lubricant being brought out, improving the sealing effect, and the rounded corner structure is also more conducive to the falling carbon particles falling into the lubricatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com