Patents

Literature

293 results about "Metal debris" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

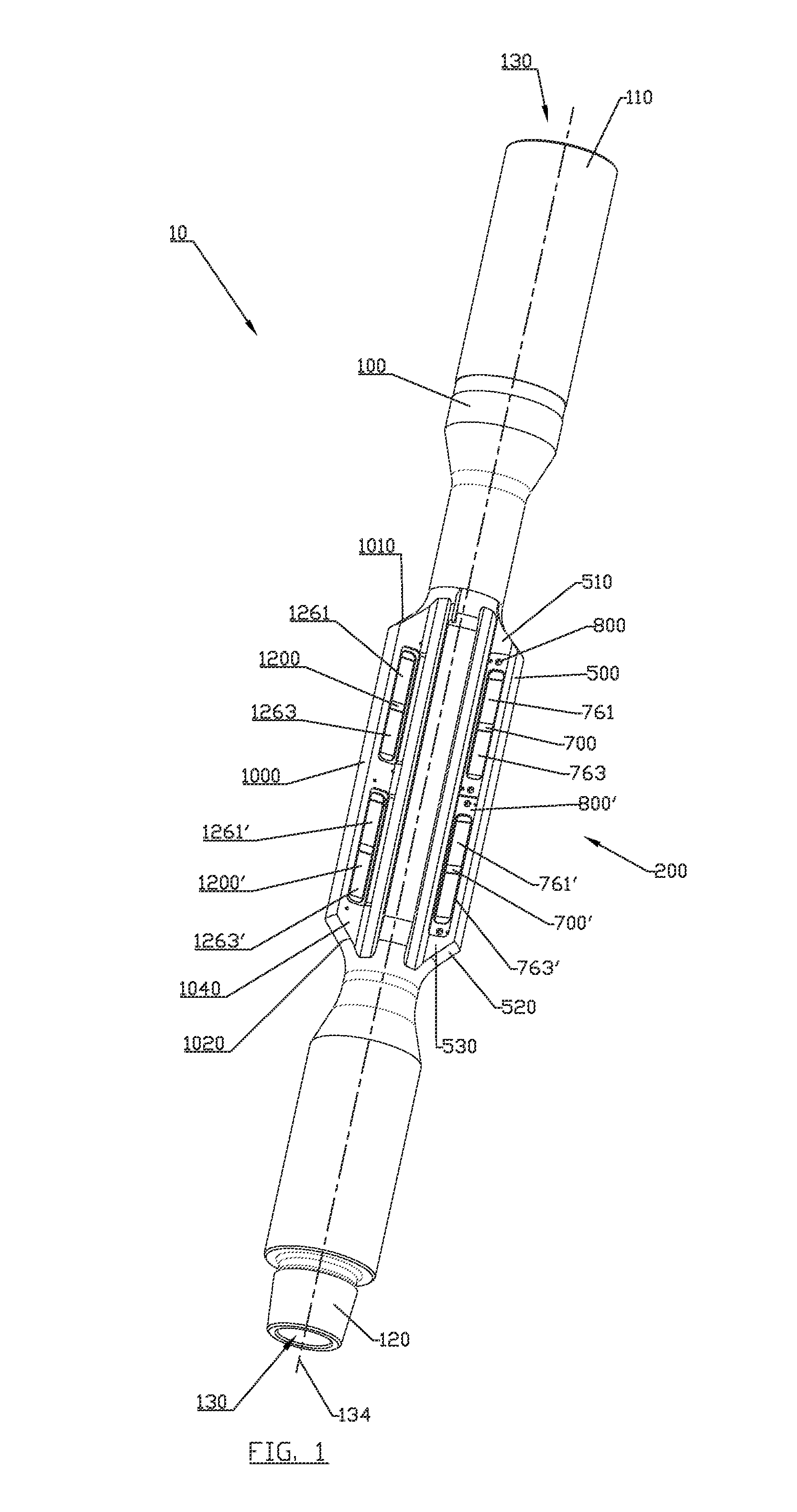

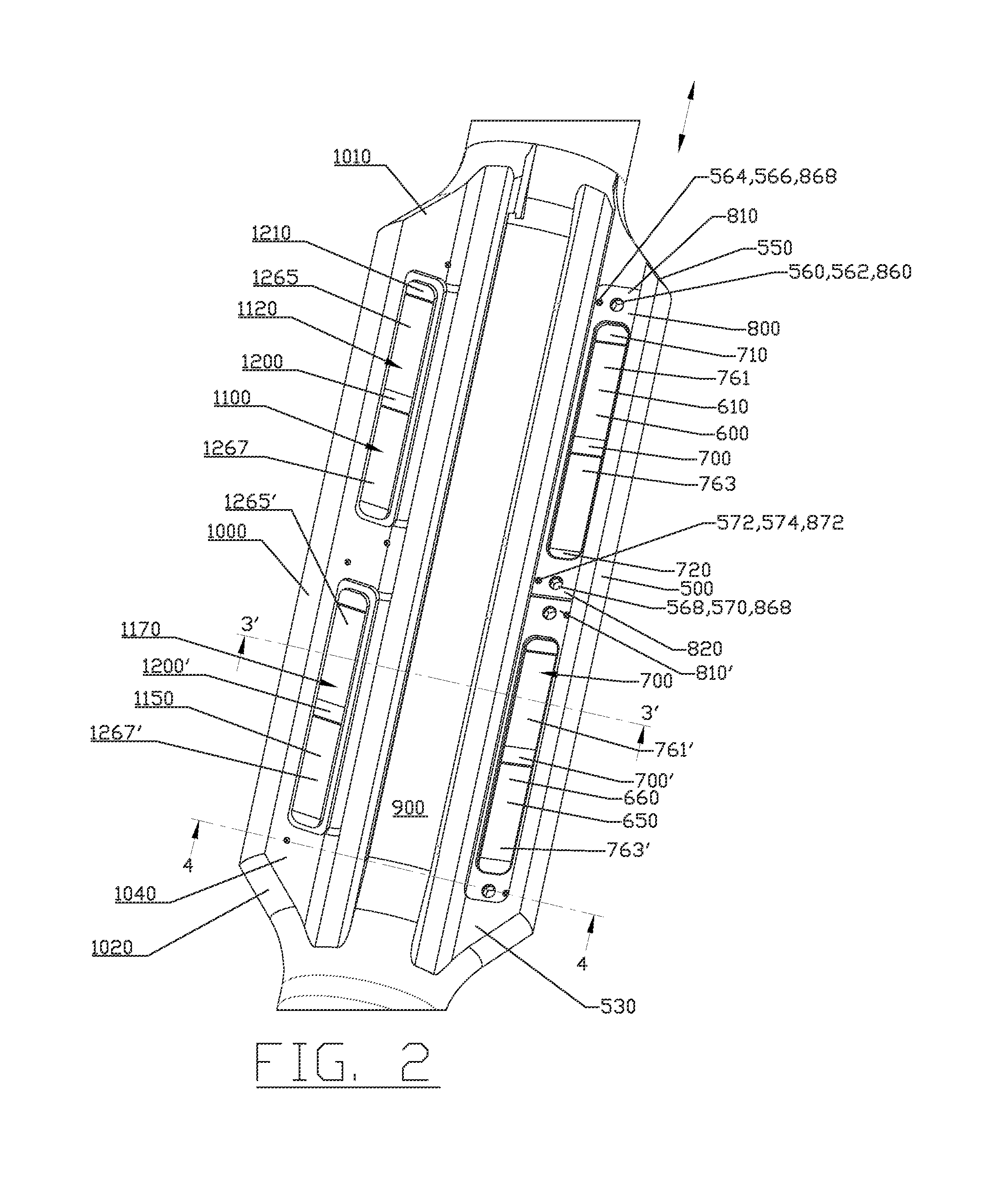

Downhole magnetic retrieval tool

ActiveUS7219724B2Reliable holdEasy to disassembleCleaning apparatusHollow article cleaningEngineeringMetal debris

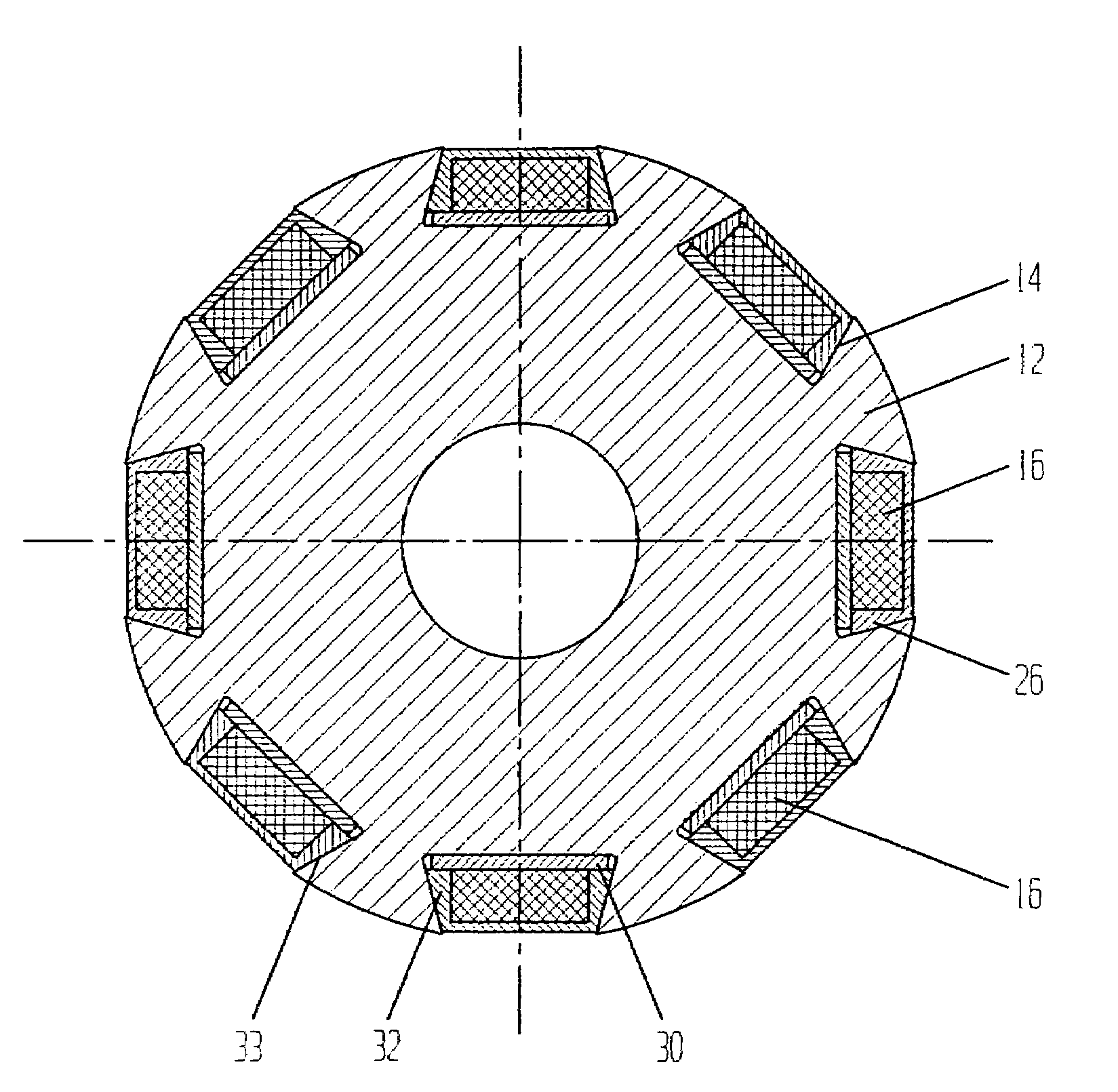

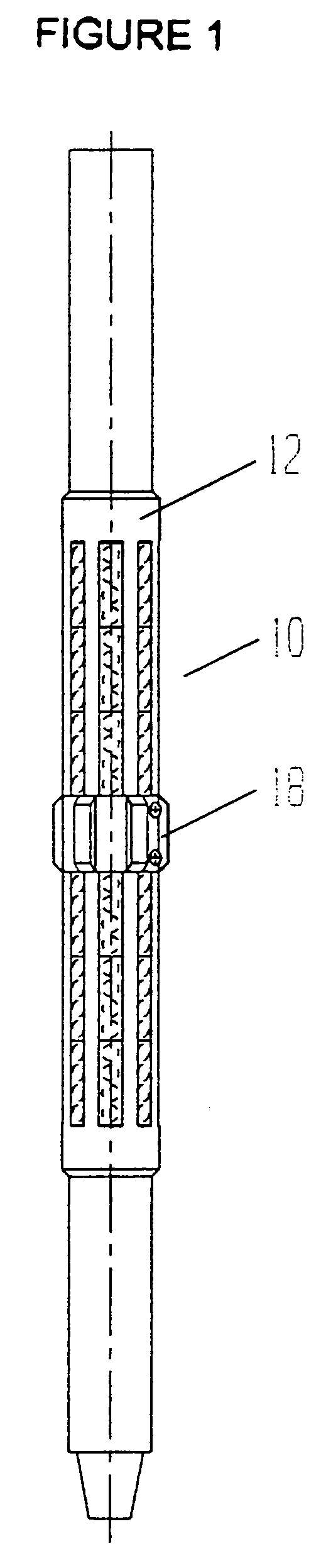

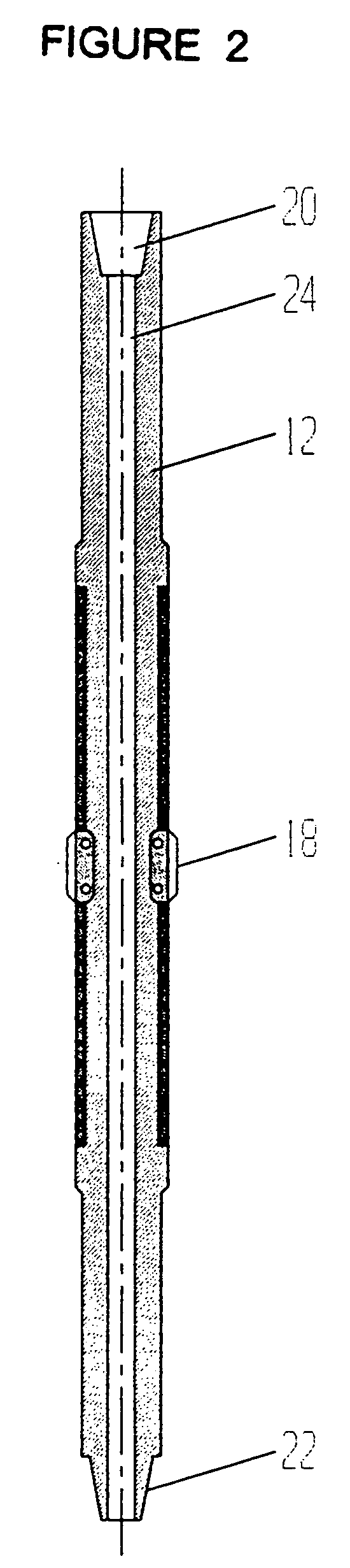

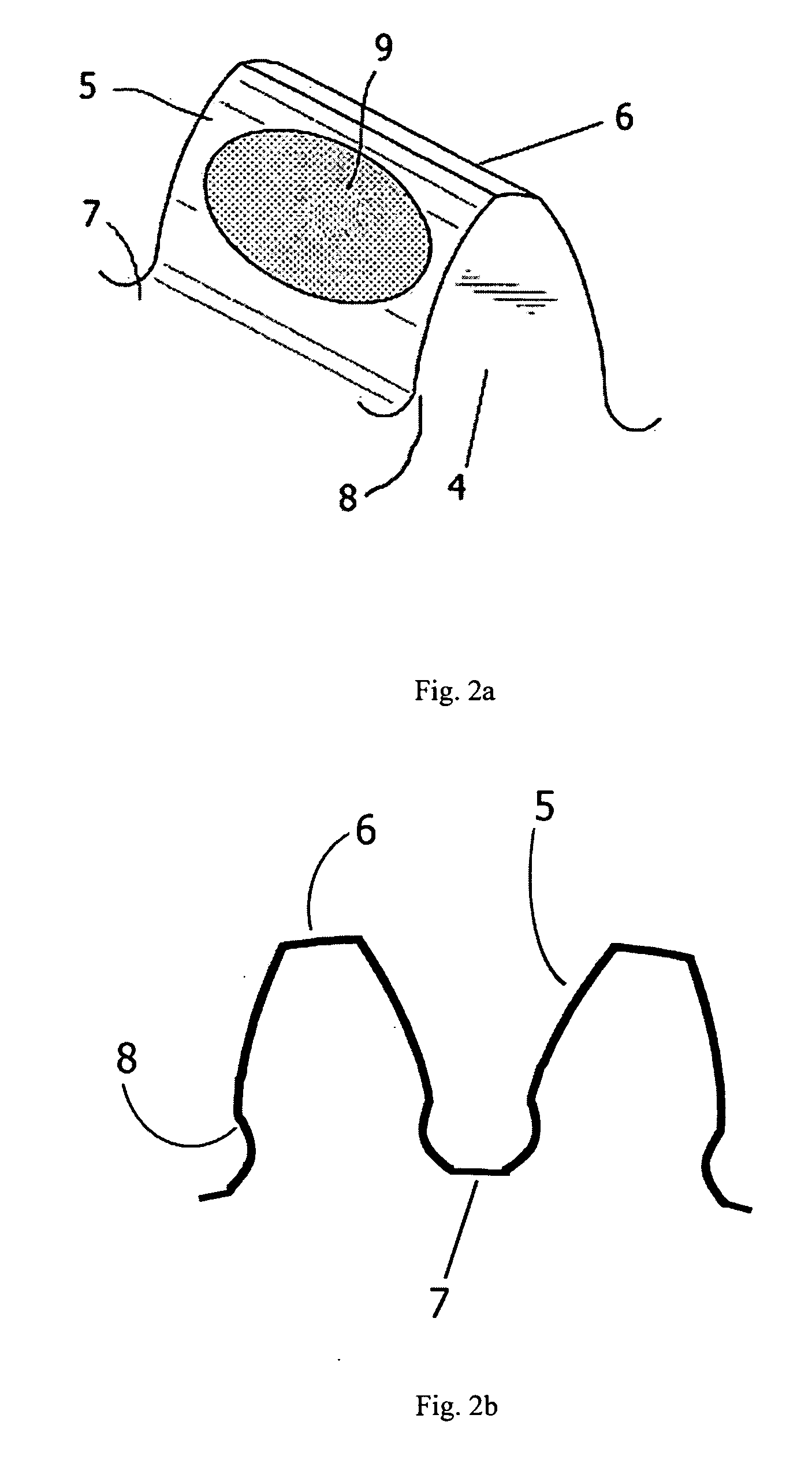

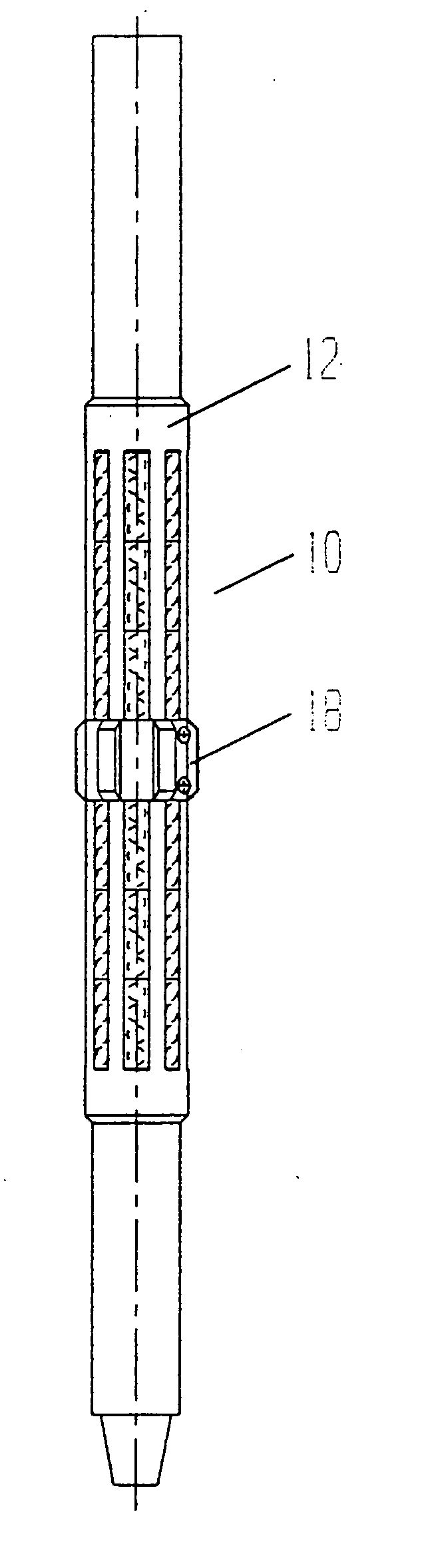

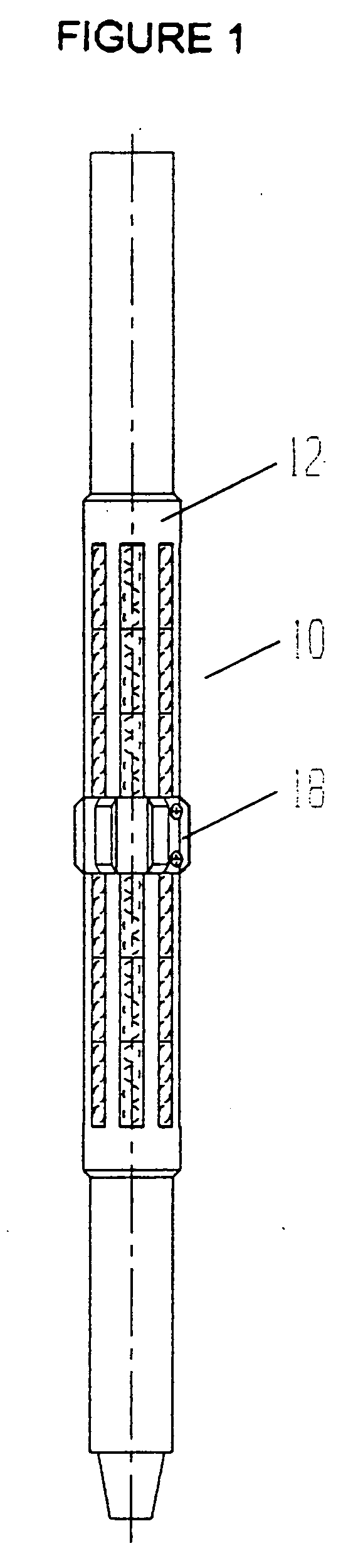

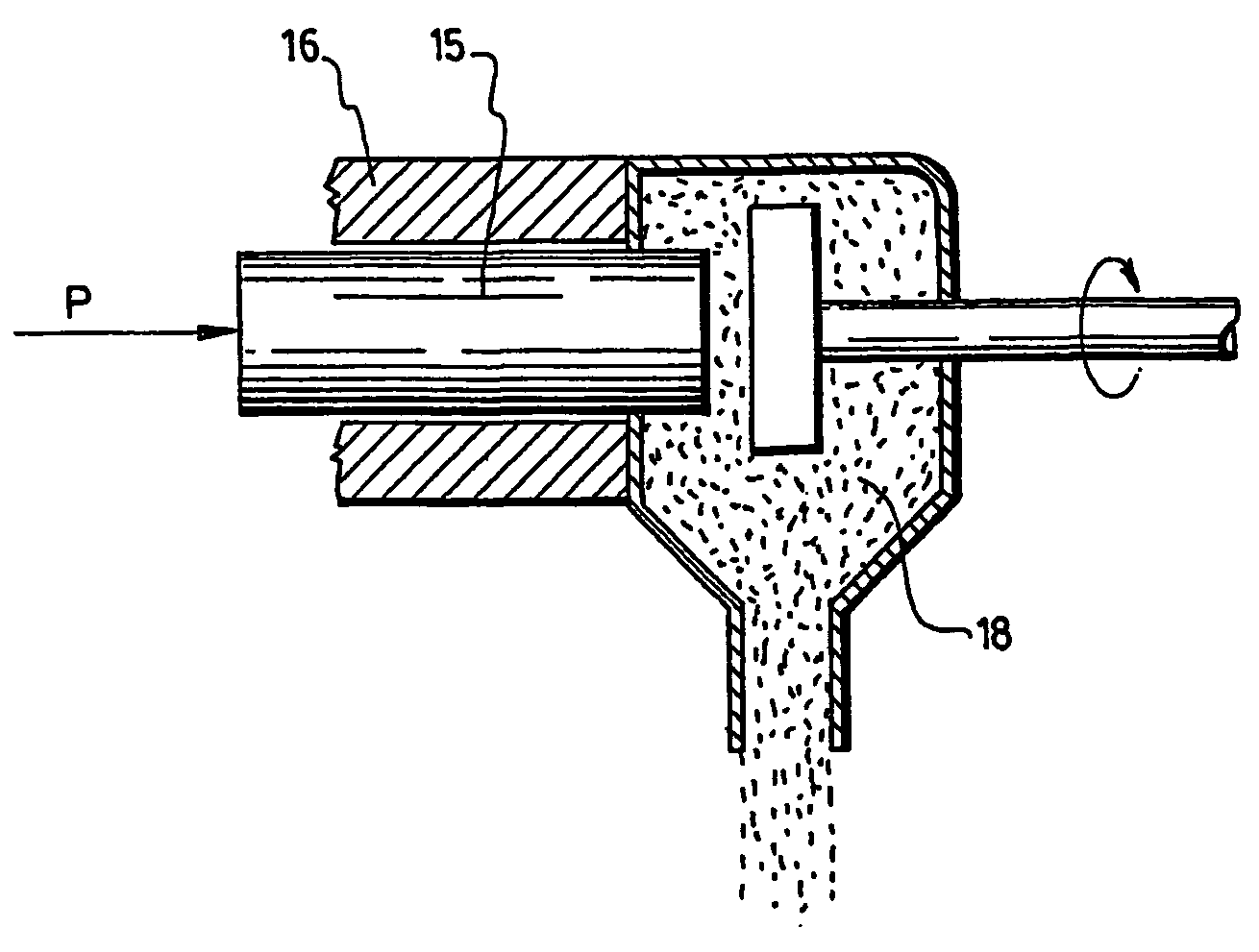

A tool 10 for suspending in a well retrieves various metal debris from the well, and includes an elongate tool body 12 within a plurality of circumferentially shaped slots 14. Each slot having a radially outward portion with a circumferential width less than a circumferential width of a radially inward portion. The plurality of magnets 16 are provided in each slot, and one or more stop rings 18 retain the plurality of magnets in the slots while allowing for removal of the magnets from the slots. Each of the plurality of magnets 16 may be substantially enclosed within a non-ferrous carrier 26 having an outer configuration for fitting within a respective of one of the plurality of slots. According to the method of invention, the magnets are postioned within the slots and are retained within the slots by the one or more stop rings, and the elongate tool body and the plurality of the magnets are suspended in a well.

Owner:BILCO TOOLS

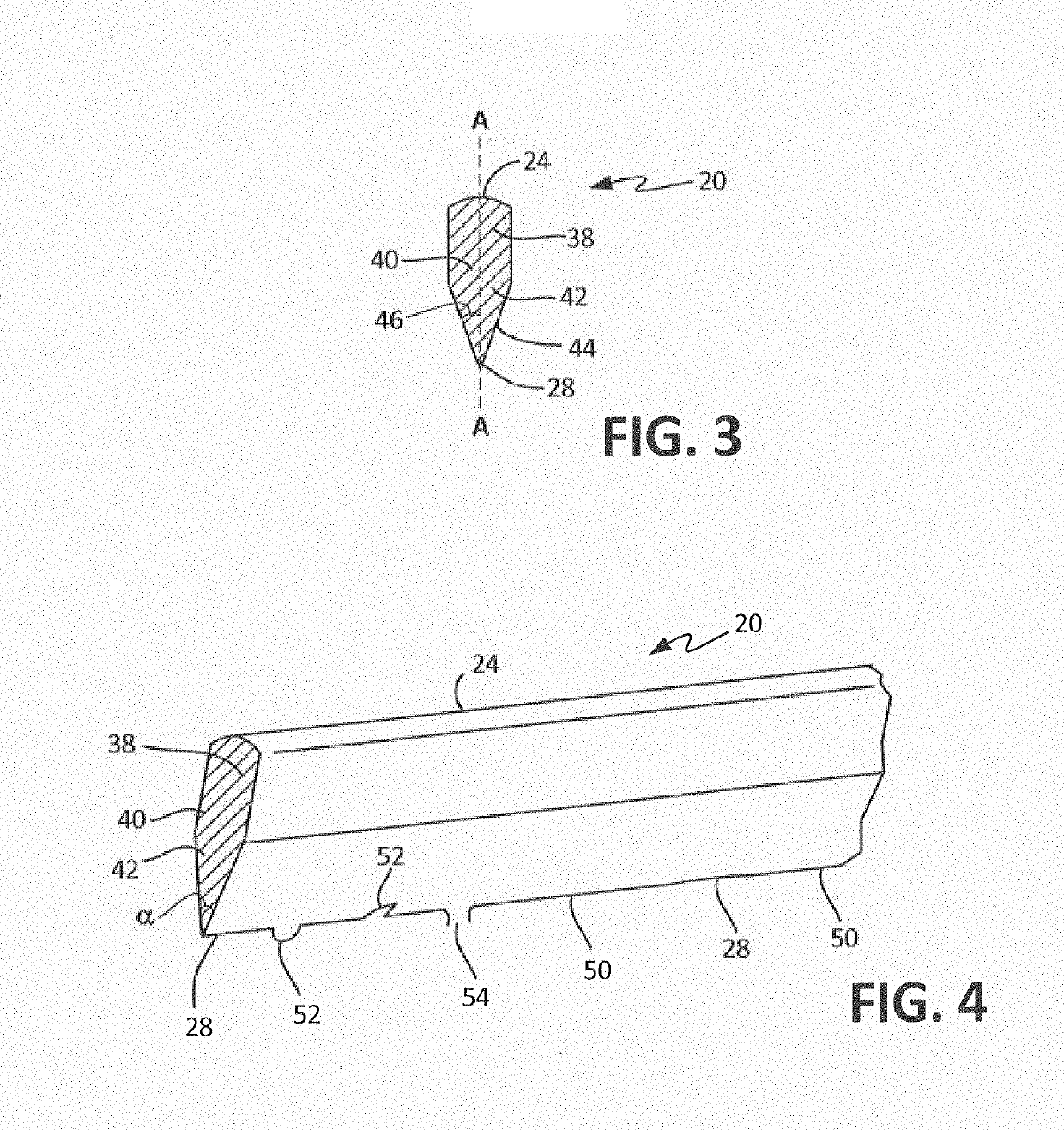

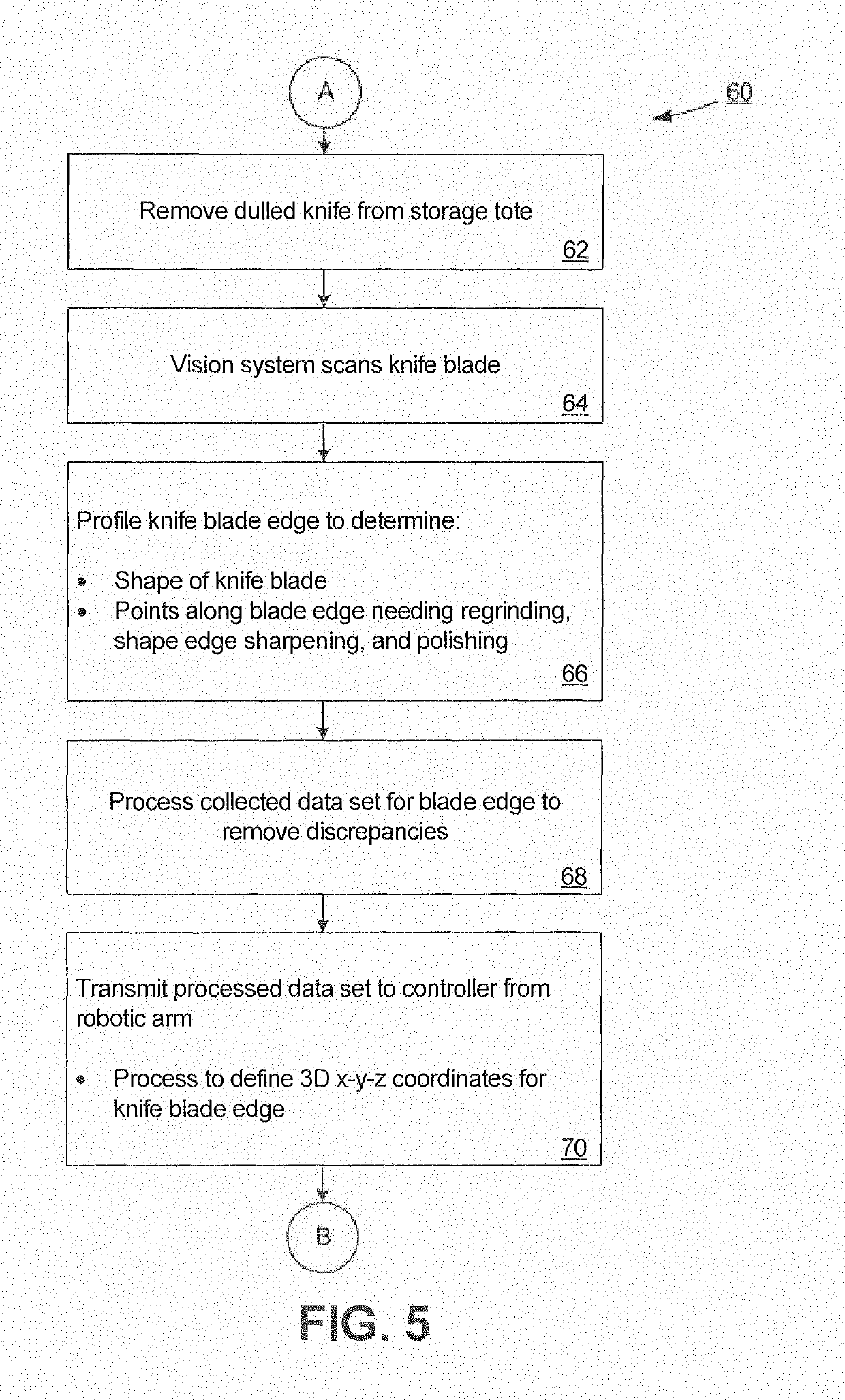

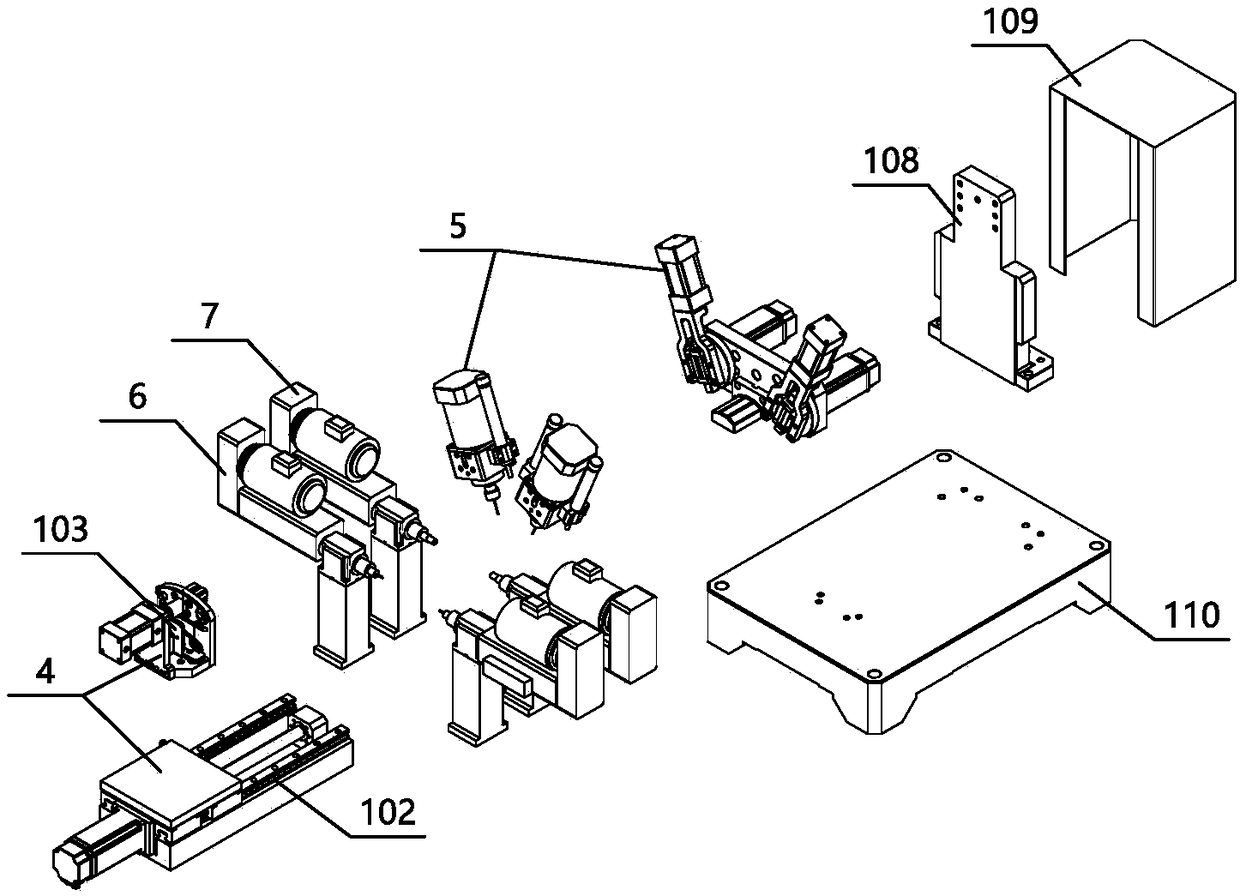

Robotic hand tool sharpening and cleaning apparatus

ActiveUS20190210177A1Improve throughputLess operator repetitive stressProgramme controlProgramme-controlled manipulatorCamera imageRobotic hand

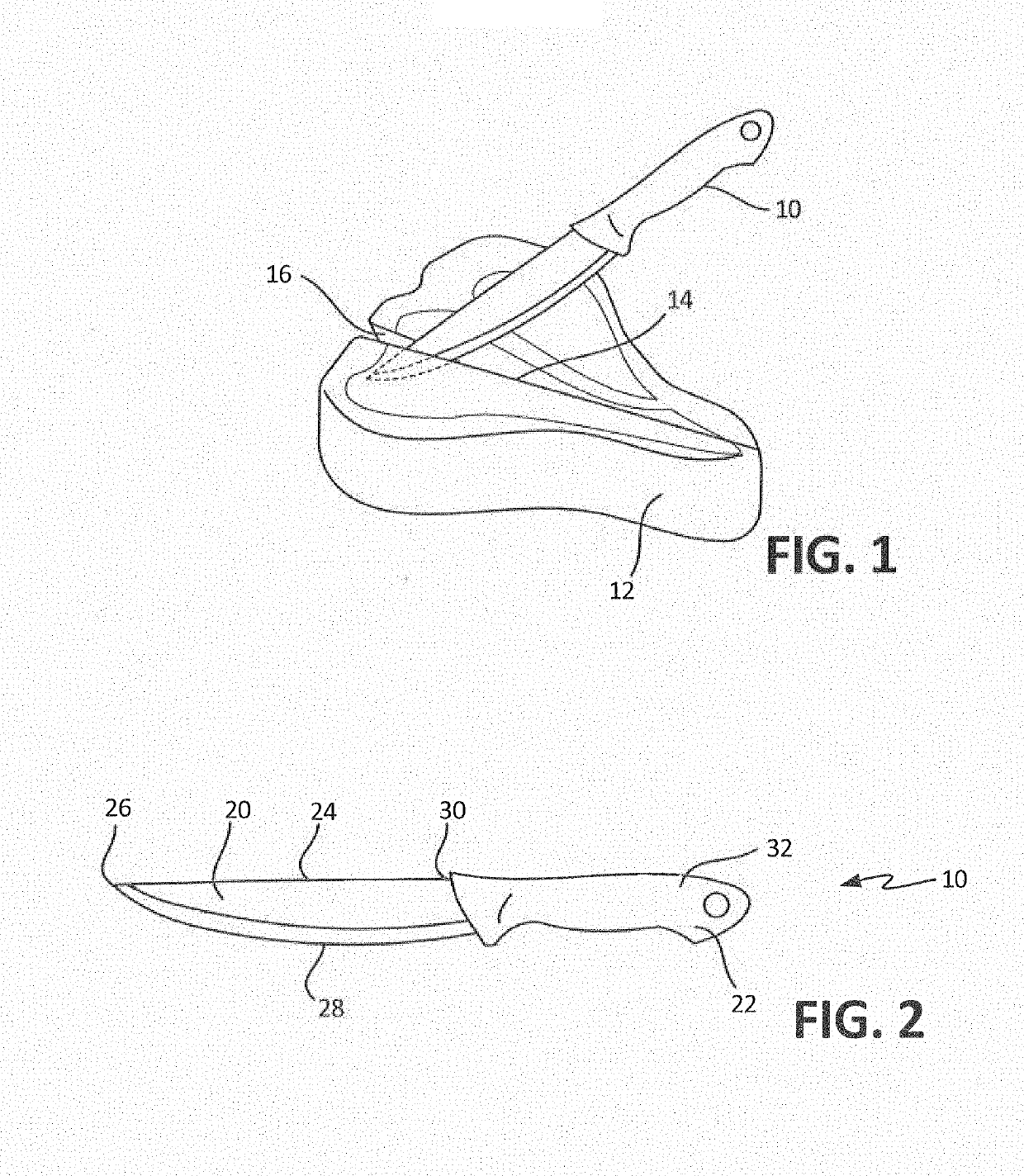

An automated hand tool sharpening and cleaning system for sharpening the two opposed cutting edges of domestic, industrial, sport, or hobby hand tool like a knife blade is provided by the invention. The apparatus comprises a six-axis robotic arm, a pneumatic gripper, a vision sensor camera for profiling the blade edges, a robotic controller, and sequentially-arranged grinding, coarse sharpening, fine sharpening, and buffing rotating wheel assemblies used to grind, sharpen, and buff or polish the cutting edges of the knife blade. The blade cutting edges are profiled by the camera image that is processed by associated software to define the blade by multiple points defined along its edge, followed by a set of algorithms that are used to clean up any discrepancies in the profile data. The resulting corrected profile data is then translated into a set of machine control commands fed to the robotic arm and pneumatic gripper via the robot controller for manipulating the knife blade edges via the robotic arm with respect to each of the grinding, coarse sharpening, fine sharpening, and buffing / polishing wheels and an associated wash station for remove bits of metal and other residue resulting from the sharpened knife blade.

Owner:RAZOR EDGE SYST

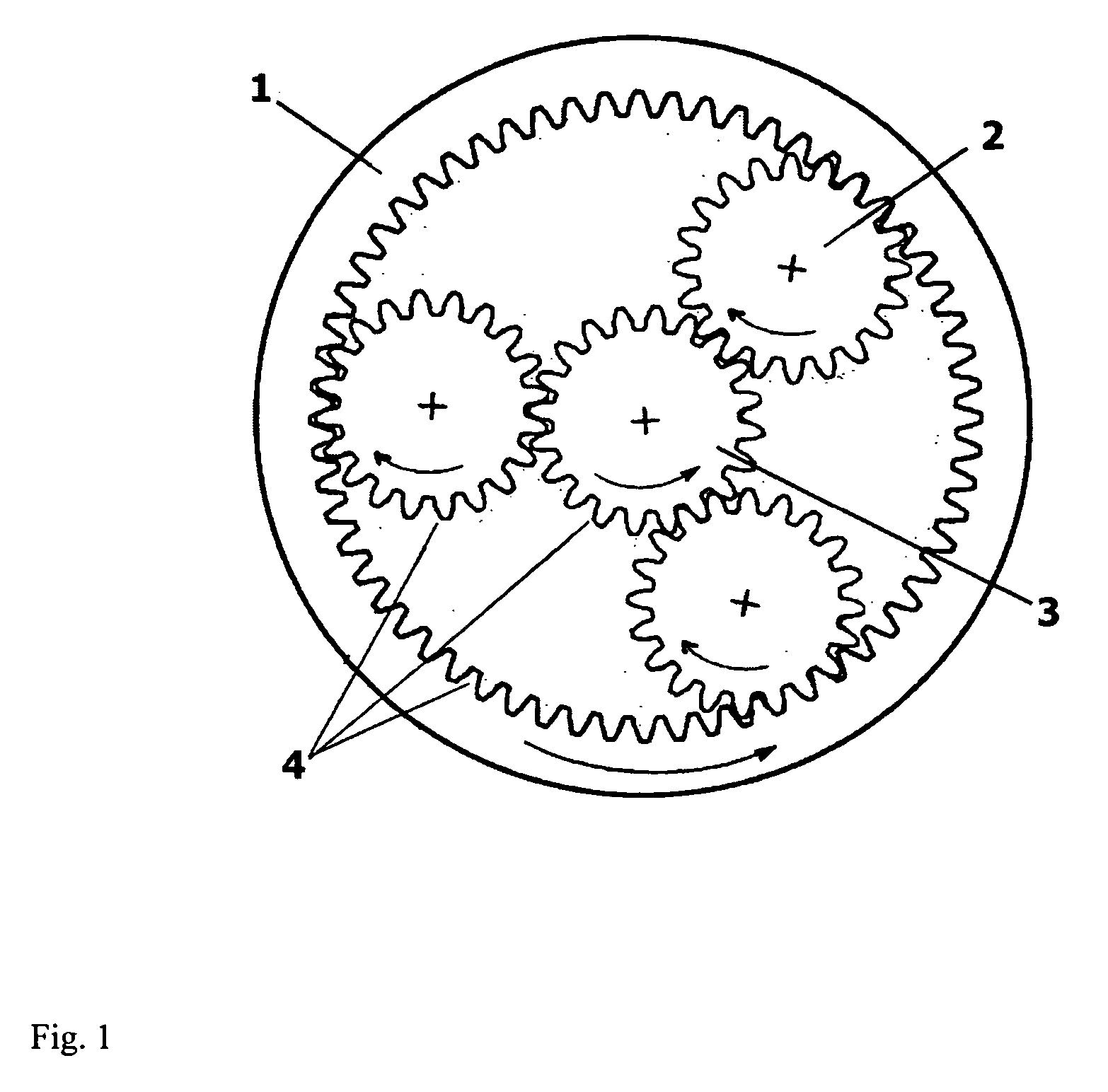

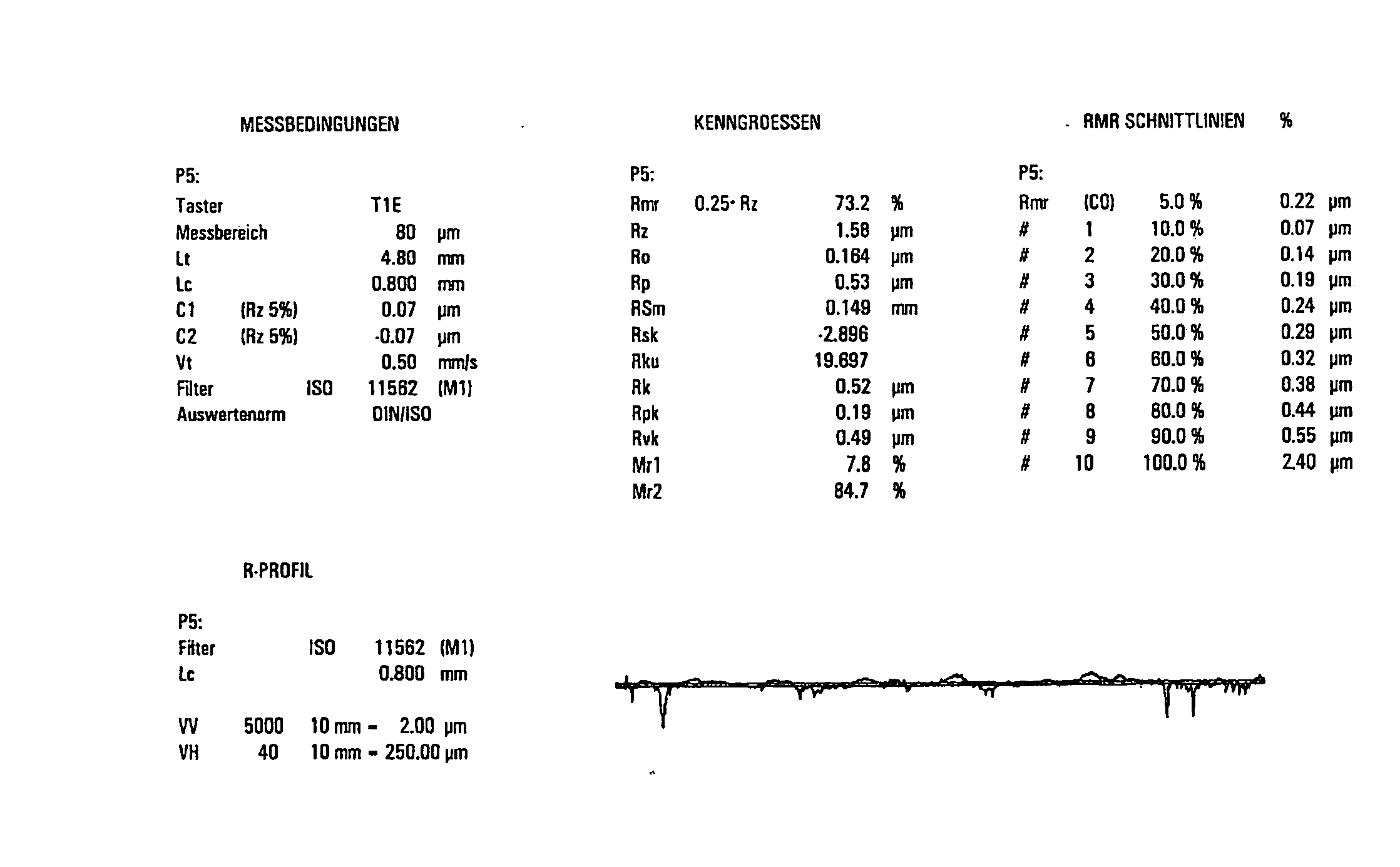

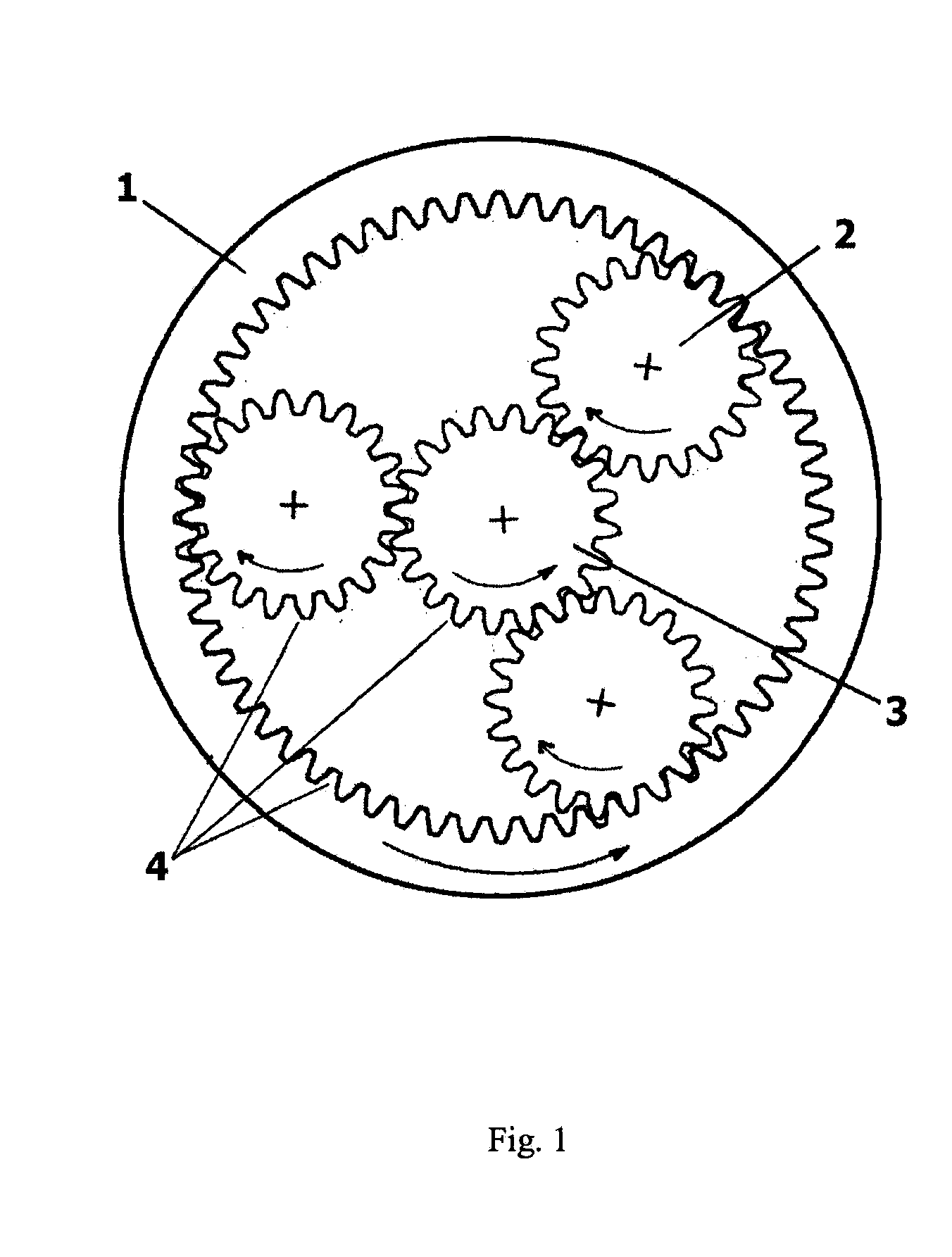

Superfinishing large planetary gear systems

ActiveUS20050014597A1Reduces and eliminates lubricant debrisAvoid damageEdge grinding machinesPolishing machinesGear wheelEngineering

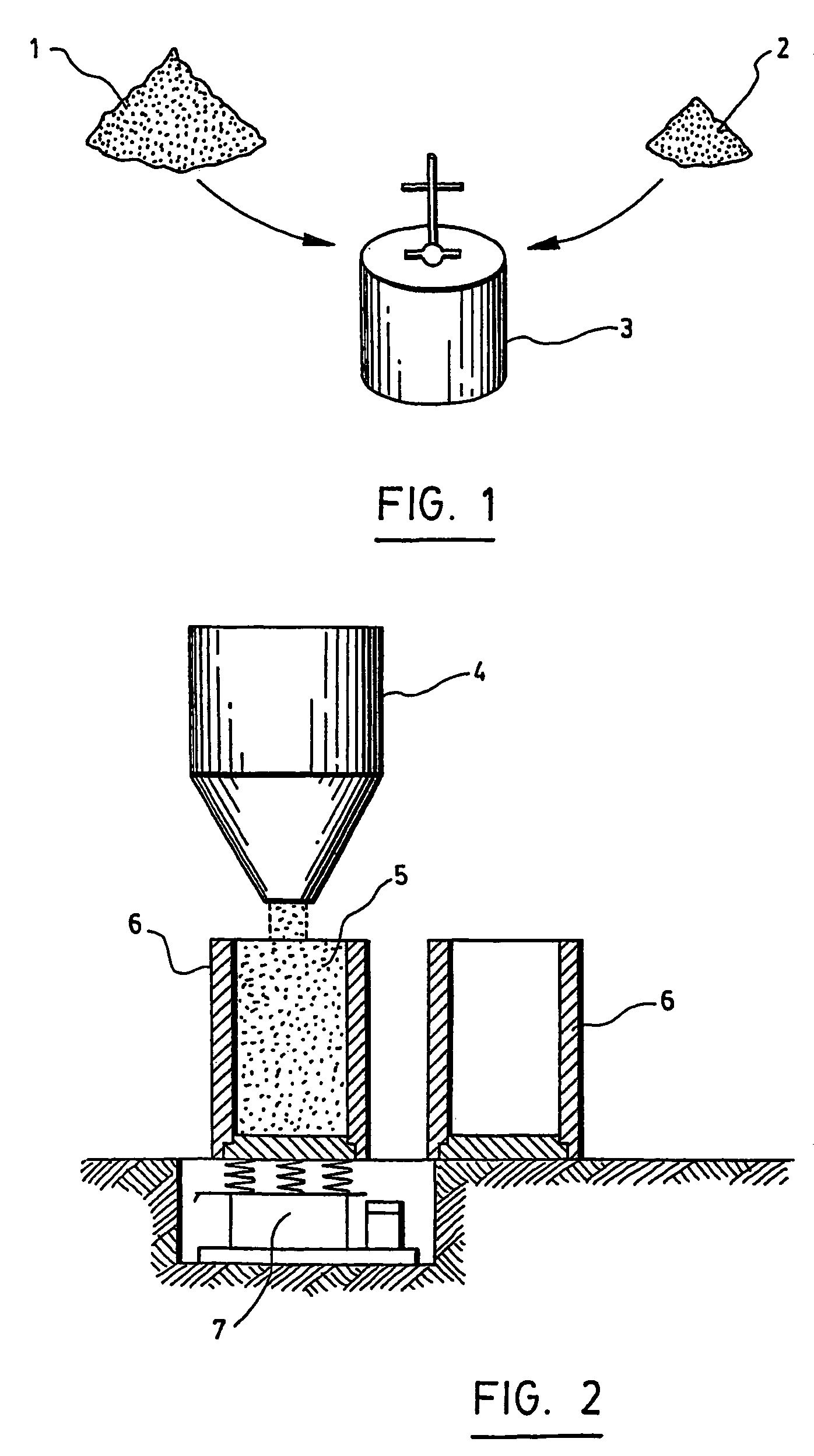

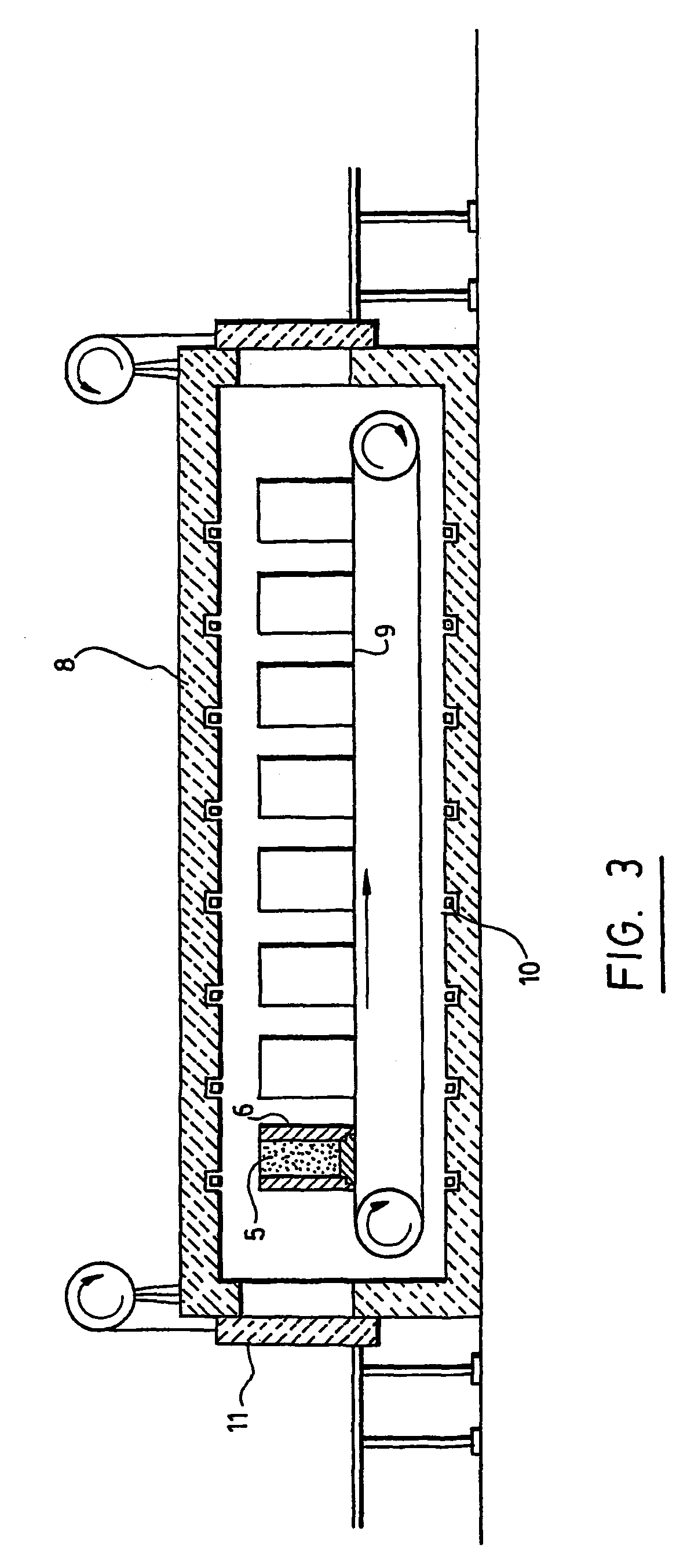

Disclosed herein is a new improved large planetary gear system used on the input stage of wind turbine power generators. This improved planetary gear system reduces or eliminates lubricant debris traditionally generated from the gear teeth, thereby eliminating an initiating source for bearing failure. To achieve these results, some and preferably all of the gear teeth within the planetary gear system are superfinished using chemically accelerated vibratory finishing to a surface roughness of approximately 0.25 micron or less. Several objects and advantages of the invention are to provide a gearbox with reduced metal debris, improved bearing life, reduced wear, reduced vibro-frictional noise, improved contact fatigue, improved fretting resistance, improved lubrication, to simplify the run-in process, and to enhance the durability and efficiency of the gearbox.

Owner:OSRO GMBH +1

Downhole magnetic retrieval tool

ActiveUS20060011346A1Easy to cleanPromote repairHollow article cleaningCleaning apparatusNonferrous metalEngineering

A tool 10 for suspending in a well retrieves various metal debris from the well, and includes an elongate tool body 12 within a plurality of circumferentially shaped slots 14. Each slot having a radially outward portion with a circumferential width less than a circumferential width of a radially inward portion. The plurality of magnets 16 are provided in each slot, and one or more stop rings 18 retain the plurality of magnets in the slots while allowing for removal of the magnets from the slots. Each of the plurality of magnets 16 may be substantially enclosed within a non-ferrous carrier 26 having an outer configuration for fitting within a respective of one of the plurality of slots. According to the method of invention, the magnets are postioned within the slots and are retained within the slots by the one or more stop rings, and the elongate tool body and the plurality of the magnets are suspended in a well.

Owner:BILCO TOOLS

1070 aluminum alloy explosion-proof foil and processing technology thereof

ActiveCN102912190ARaise room temperatureHigh temperature strengthLarge containersRheniumDehydrogenation

The present invention discloses a 1070 aluminum alloy explosion-proof foil and a processing technology thereof. The explosion-proof foil contains rhenium, iron, rare earth metals and aluminum. The processing technology includes preparing raw materials according to ratios, preparing the alloy, smelting, smelting in a holding furnace, grain refinement, online degassing and deslagging, filteration deslagging, continuous casting and rolling, cold rolling, finish rolling, cutting and packing. Due to the configuration of the material composition, deoxidation, desulfurization, dehydrogenation, denitrification and grain refinement abilities of the aluminum melt in the smelting process are improved, and the explosion-proof foil has characteristics of good corrosion resistance, high strength at a room temperature and a high temperature, good wear resistance, etc. By employing processing methods such as smelting, continuous casting and rolling, cold rolling, foil rolling, small feeding amount and multi-pass horizontal rolling, and natural aging, the strength and flexibility of the aluminum alloy foil are improved, with a short entire process and a low production cost. The aluminum foil mesh formed by slitting and expanding the explosion-proof foil has the advantages of good toughness, and being not easy to crack and shedding metal debris, so that the safety performance requirements of the aluminum alloy explosion-proof aluminum foil used in aerospace oil tank and fuel tank are satisfied in use.

Owner:新疆天展新材料科技有限公司

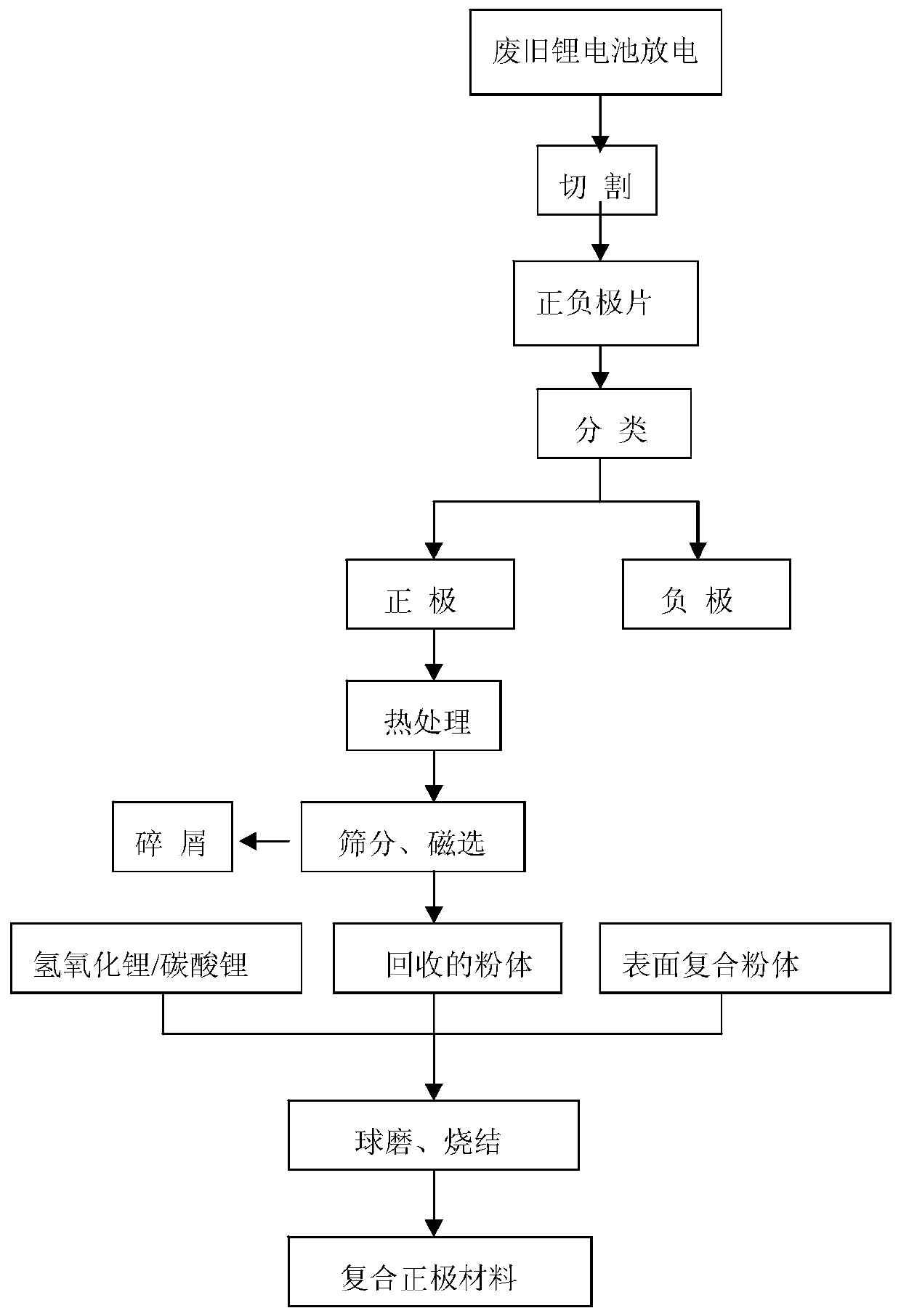

Method and system for recycling positive poles from waste lithium batteries and carrying out regeneration and repair

ActiveCN110165324AAdvanced stripping technologyEasy to separateWaste accumulators reclaimingBattery recyclingPole pieceHydrometallurgy

The invention discloses a method and system for recycling positive poles from waste lithium batteries and carrying out regeneration and repair. The method comprises the steps of recycling an electrolyte in a waste ternary lithium battery; removing a binder in the obtained positive and negative pole pieces, separating out the positive pole piece through cold quenching, magnetic separation and screening, then carrying out roasting treatment to obtain positive pole powder; and grinding and sintering a mixture containing the positive pole powder, lithium salt and a coating raw material to obtain arepaired composite cathode material. According to the invention, the components of the lithium battery are classified and recycled, priority is given to the recycling of the electrolyte, the anode and cathode materials are accurately disassembled and separated, the technological conditions are strictly screened, metal debris are enabled to be completely separated from the positive pole powder, and the method is combined with an advanced modification technology. The technological process is basically a dry recycling process, thereby avoiding the problems such as secondary pollution caused by acid-alkali leaching and extraction recycling in the traditional wet metallurgy recycling process. The recycled and repaired regenerated cathode material can be directly applied to the production of lithium batteries.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

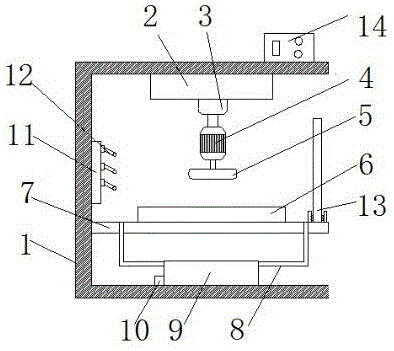

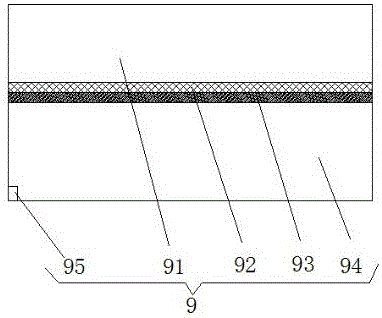

Polishing machine capable of recycling metal debris

InactiveCN106078498ASave resourcesReduce processing costsGrinding carriagesGrinding drivesWater storage tankWater flow

The invention discloses a polishing machine capable of recycling metal debris. The polishing machine comprises a machine base, wherein the top of the machine base is fixedly connected with a cross beam, a pneumatic telescopic rod is fixedly arranged at the bottom of the cross beam, a motor is arranged at the bottom of the pneumatic telescopic rod, an output shaft of the motor is fixedly connected with a polishing plate, one side of the machine base is fixedly connected with a polishing platform, a clamping base is arranged at the top of the polishing platform and below the polishing plate, and the two ends of the clamping base penetrate through a water flowing pipeline of the polishing platform to be fixedly connected with the top of a recycling device. The polishing machine capable of recycling the metal deris has the advantages that the metal deris produced in a polishing process is washed by spraying water by virtue of a high pressure water spraying head, and washing water is filtered by virtue of the recycling device, so that the metal deris is reserved; meanwhile, the filtered washing water flows into a water storage tank by virtue of a circulating water pump and can be utilized again. The device, namely the polishing machine capable of recycling the metal deris, can recycle the metal deris and can save resources, and treatment cost is reduced.

Owner:WUXI ZUNBAO ELECTRIC VEHICLE CO LTD

Method for production of metal foam or metal-composite bodies with improved impact, thermal and sound absorption properties

InactiveUS7105127B2Improve rigidityHigh strengthMetal-working apparatusRecycling and recovery technologiesSolidusFoaming agent

A method for the production of foamable or foamed metal pellets, parts and panels. The method comprises the steps of: i) providing a mixture of a metal alloy powder with a foaming agent powder, ii) pre-compacting the mixture of step i); iii) heating the pre-compacted mixture of step ii) to a temperature below a decomposition temperature of the foaming and at which permanent bonding of the particles occurs v) hot compacting the body for producing a compacted body made of a metal matrix embedding the foaming agent; and vi) reducing the compacted body into metal fragments and thereby obtaining dense foamable metal chips. A method for the production of a foam metal using a closed volume metal shell is also disclosed. The method comprises the steps of: a) providing metal pieces and reducing said metal pieces into smaller metal particles; b) mixing the metal particles with an additive having a decomposition temperature that is greater than a solidus temperature of said metal particles; c) pouring the mixture of step b) into a closed volume metal shell having a given thickness and providing the metal shell with at least one passage for gases to escape; d) reducing the thickness of the metal shell by applying pressure; e) heating the metal shell to a temperature above said solidus temperature of the metal particles and below said decomposition temperature of the additive, and immediately applying pressure on the metal shell sufficient to compress the metal particles and to create micro shear conditions between the metal particles so as to obtain a dense metal product.

Owner:VATCHIANTS SERGUEI MR

Downhole magnet, downhole magnetic jetting tool and method of attachment of magnet pieces to the tool body

ActiveUS20140096972A1Prevent removalSolve the real problemCleaning apparatusFluid removalMetal debrisLongitudinal ridges

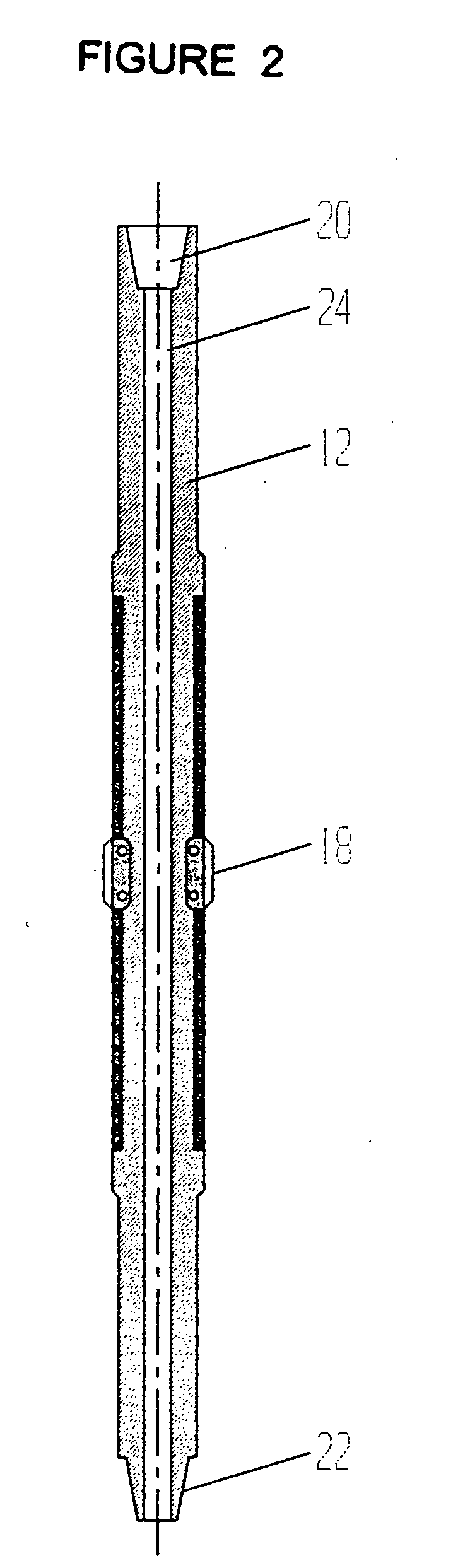

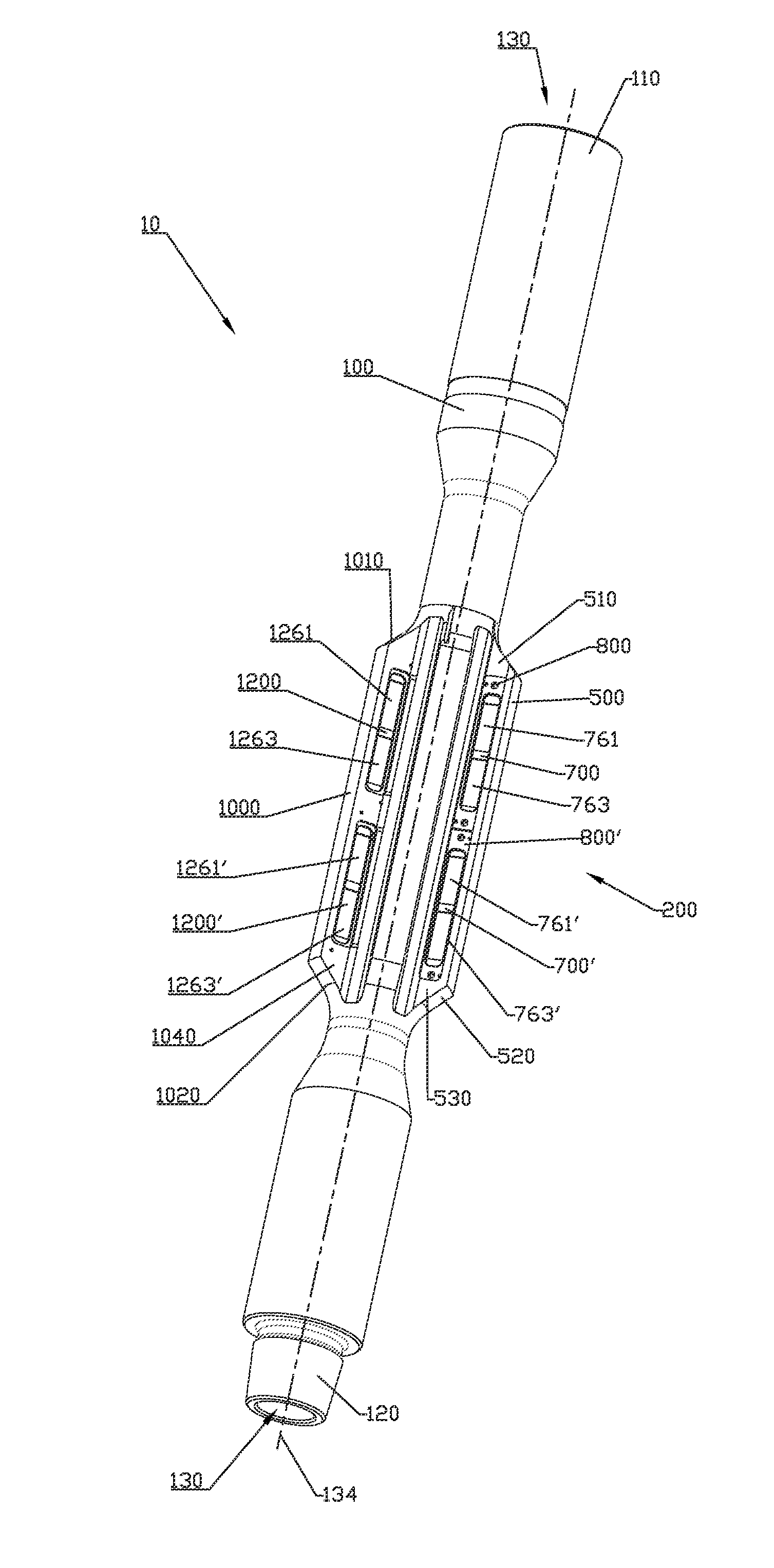

A tool for suspending in a well retrieves various metal debris from the well, and includes an elongated tool body with a plurality of magnets included in a plurality longitudinal ridges which are circumferentially spaced. In the method a plurality of magnets can be positioned within openings, recesses, or pockets in each ridge, and held in place by one or more retaining plates, the tool being connected to a drill string and lowered into a well.

Owner:ODFJELL WELL SERVICES NORWAY AS

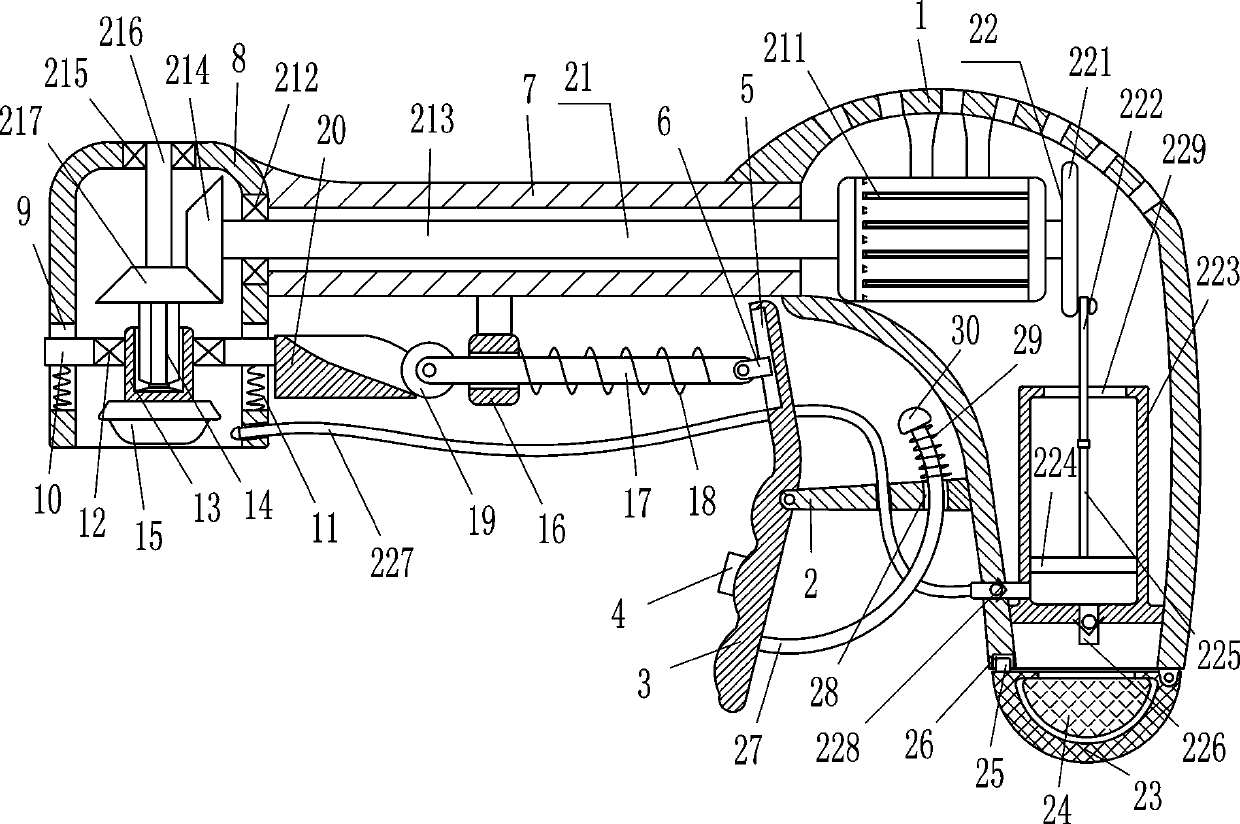

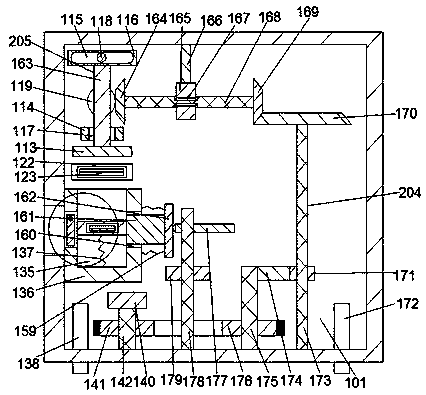

Burr grinding machine after part drilling

ActiveCN109605163AMobile impactAvoid affecting work efficiencyEdge grinding machinesGrinding carriagesEngineeringMetal debris

The invention relates to a grinding machine, in particular to a burr grinding machine after part drilling. In order to solve the technical problems, the invention provide a burr grinding machine afterpart grinding, and the burr grinding machine can replace people to grind and clear burrs, avoids hand ache, is high in working efficiency, further can clear metal debris and does not affect grinding.According to the technical scheme adopted by the invention, the burr grinding machine after part drilling comprises a shell, a transverse plate, a swing plate, a button, a guide slide block, a sleeve, a frame body, a vertical slide block, a first spring and the like, wherein the lower part of the left side surface outside the shell is fixedly connected with the transverse plate; the left end of the transverse plate is hinged with the swing plate; and a guide slide slot is formed in the upper part of the left side surface of the swing plate. According to the burr grinding machine disclosed bythe invention, the swing plate is pulled for enabling a grinding block to move downwards, and the button is pressed for starting a double-axis motor to drive the grinding block to rotate. The device is moved, so that the grinding block is in contact with burrs for grinding and clearing the burrs, and a user does not need to use a file to clear the burrs, and therefore, the burr grinding machine ismore convenient, and the working effect is prevented from being affected by hand ache.

Owner:JIANGXI UNIV OF SCI & TECH

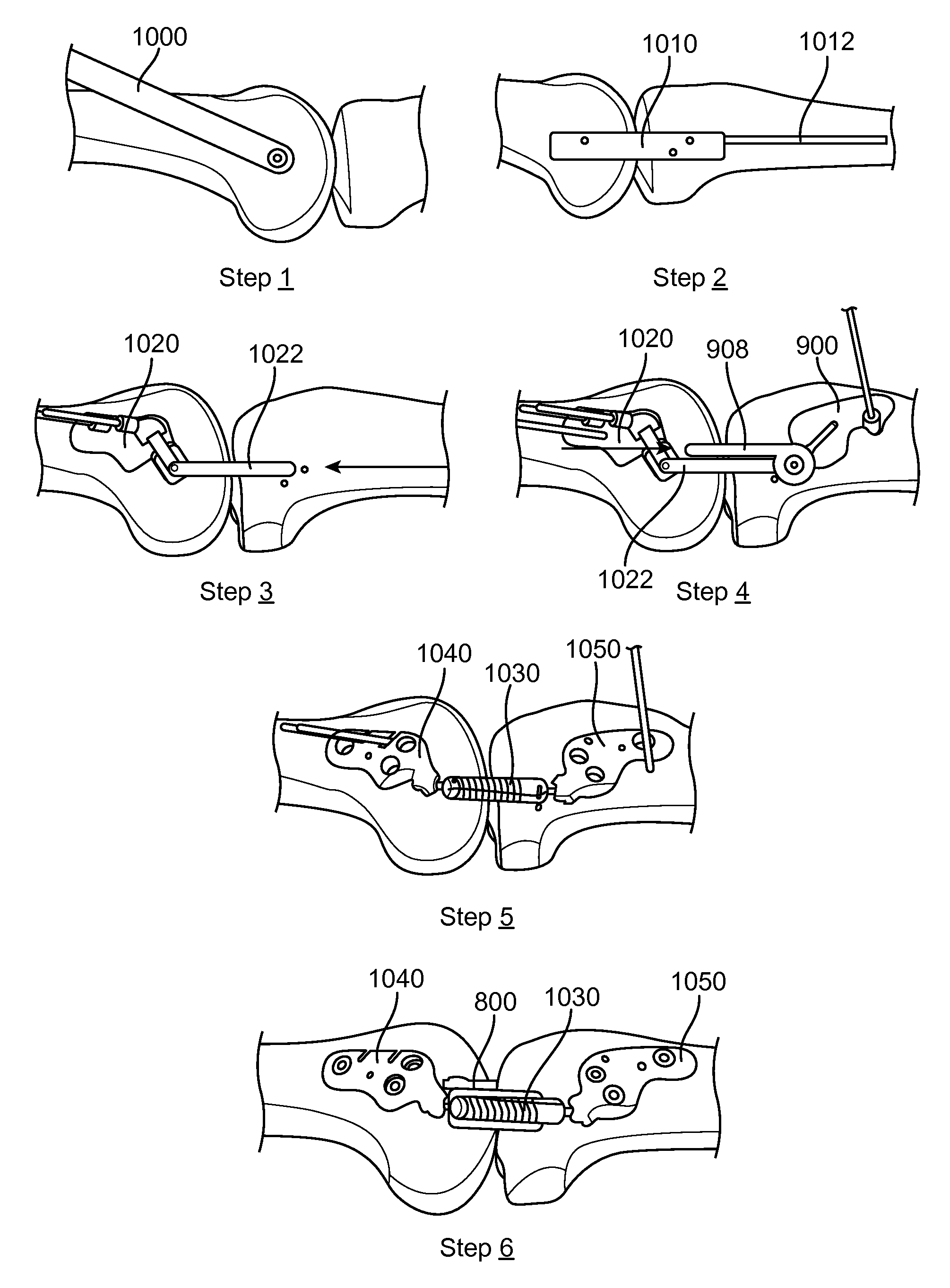

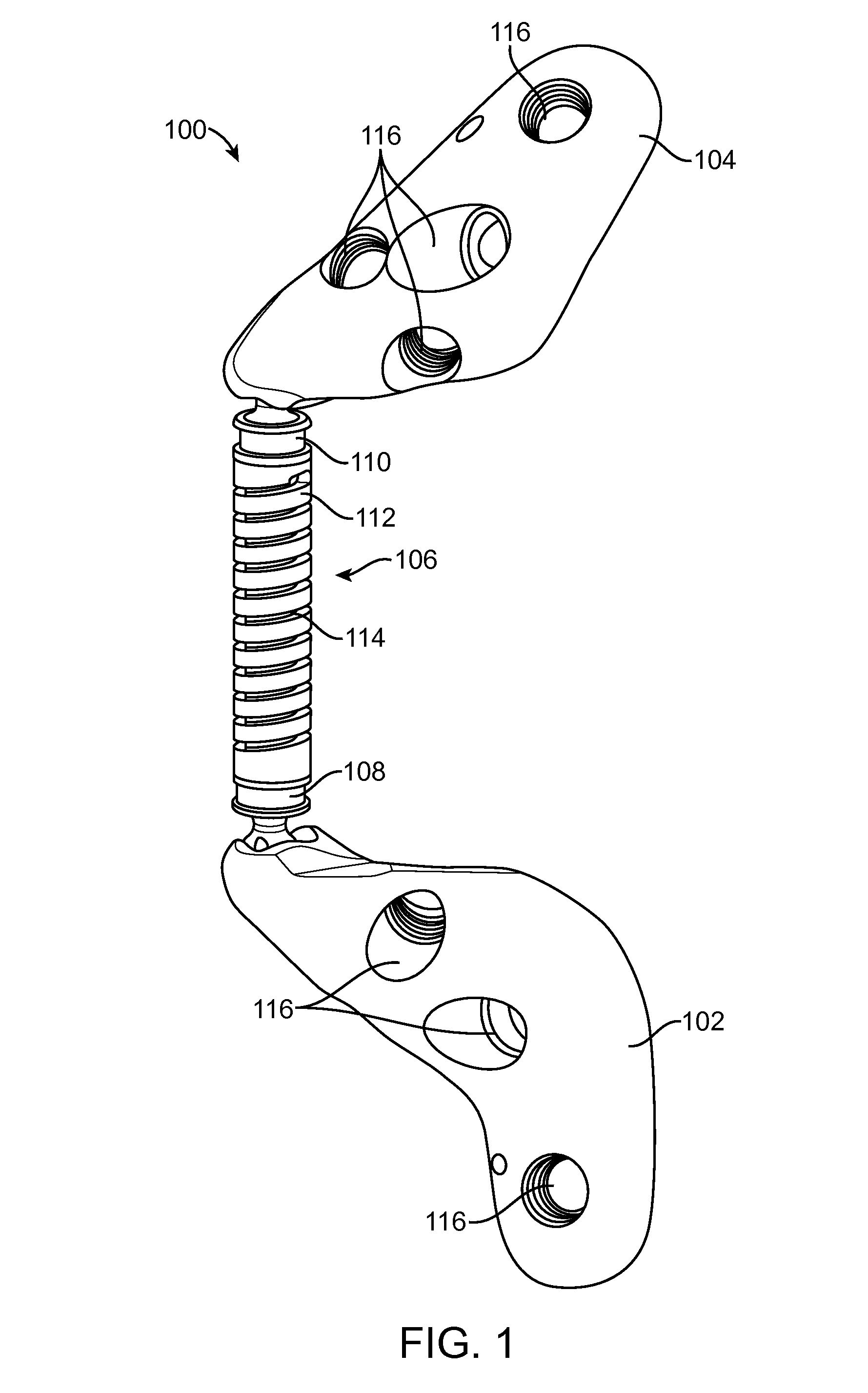

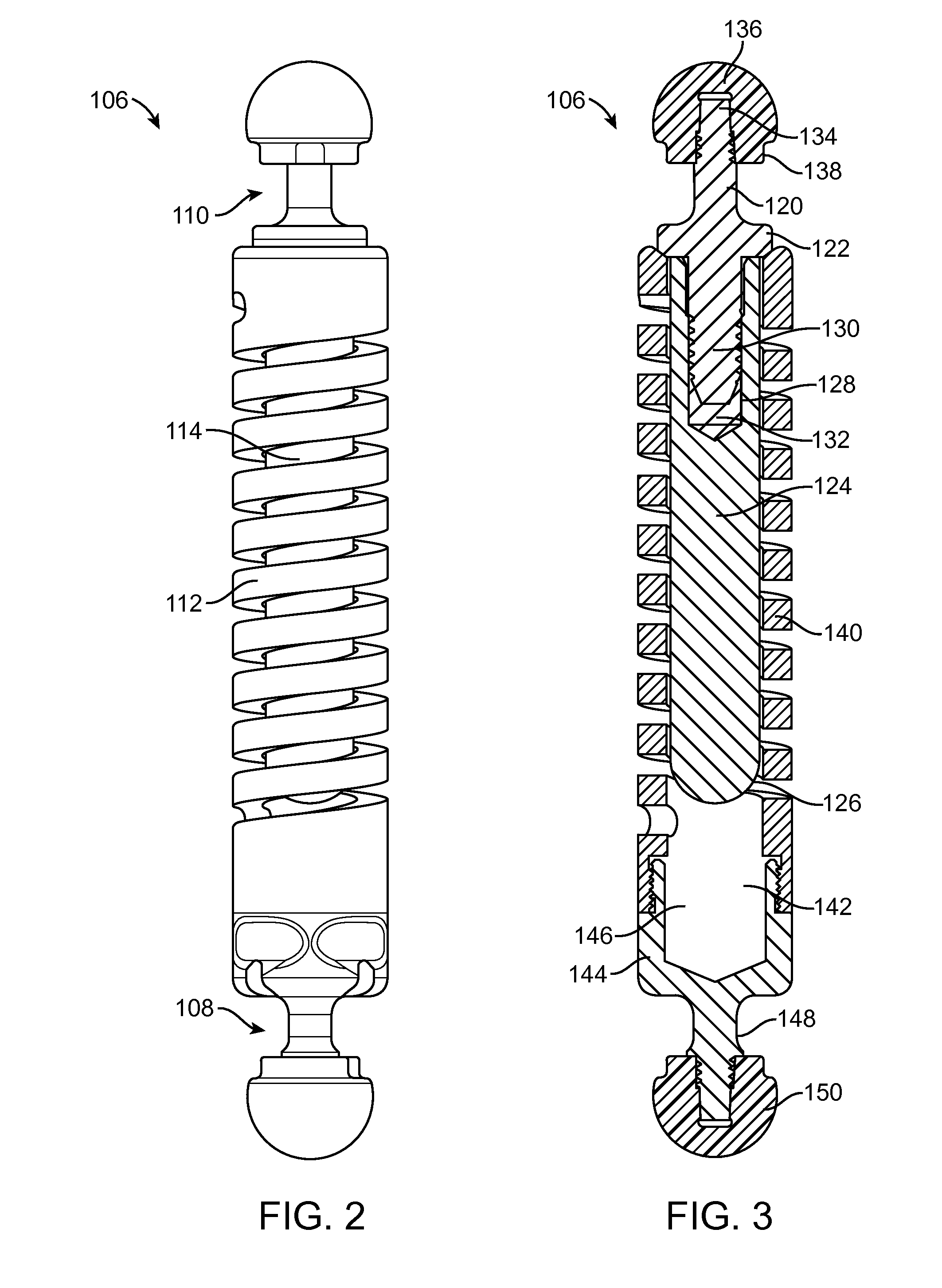

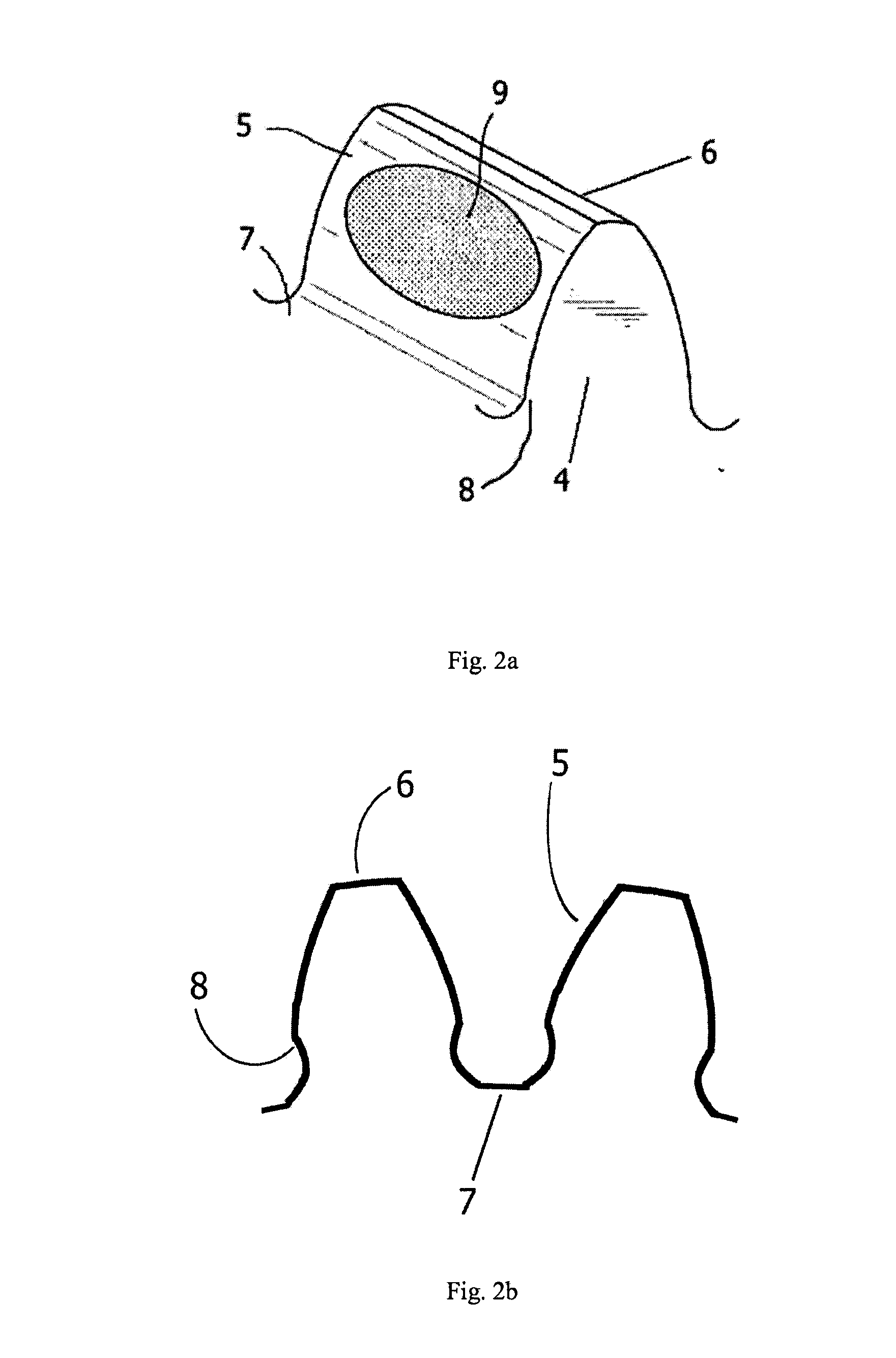

Joint Energy Absorbing System and Method of Use

An energy absorbing system, useful for attachment across a patient's joint, includes portions which are formed entirely or in part of a non-metallic material, e.g., PAEK, and thus reduces the possibility of the formation of metal debris in vivo. The system can include a flexibility-enhanced piston, retained within a spring, which reduces the possibility of tissue impingement with the system.

Owner:MOXIMED INC

Recovery processing technique of waste chip card and smart card

InactiveCN101259480AAchieve securityImplement resourcesDispersed particle filtrationElectrostatic separationSmart cardEddy current

The invention discloses a destroying and reclamation technique of waste chip cards and intelligent cards which is used for treating and destroying various waste chip cards and intelligent cards and recycling the metal and non-metal materials in the cards; the technique includes the following technique steps: (1) the cards are cracked into pieces of a certain size; (2) an eddy current sorting is carried out on the pieces to sort the pieces into metal pieces and non-metal pieces; (3) the metal pieces are grinded into powders by an eddy current mill; (4) a high voltage static separation is carried out on the powder to sort the powder into metal powders and non-metal powders; (5) the dust which is generated in the processes of grinding and high voltage static separation is collected by a pulse bag dust catcher. The technique of the invention realizes the complete information destroying of the chip cards and the intelligent cards as well as resource recycling and solves the difficulty that the current chip cards and the intelligent cards can not be treated in batch; the treatment process is safe and environment protective without secondary pollution and has the broad practicability.

Owner:SHANGHAI XINJINQIAO ENVIRONMENTAL PROTECTION

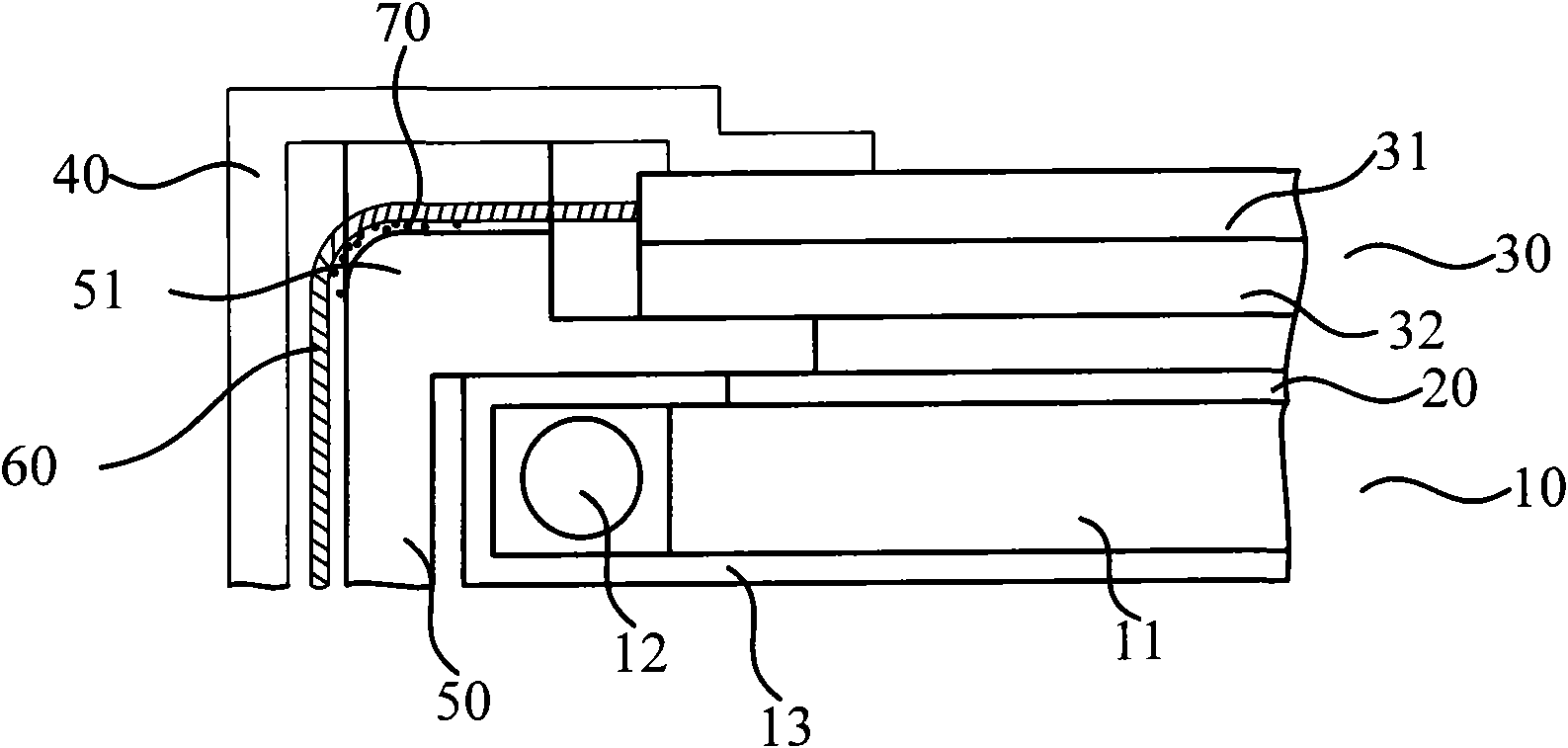

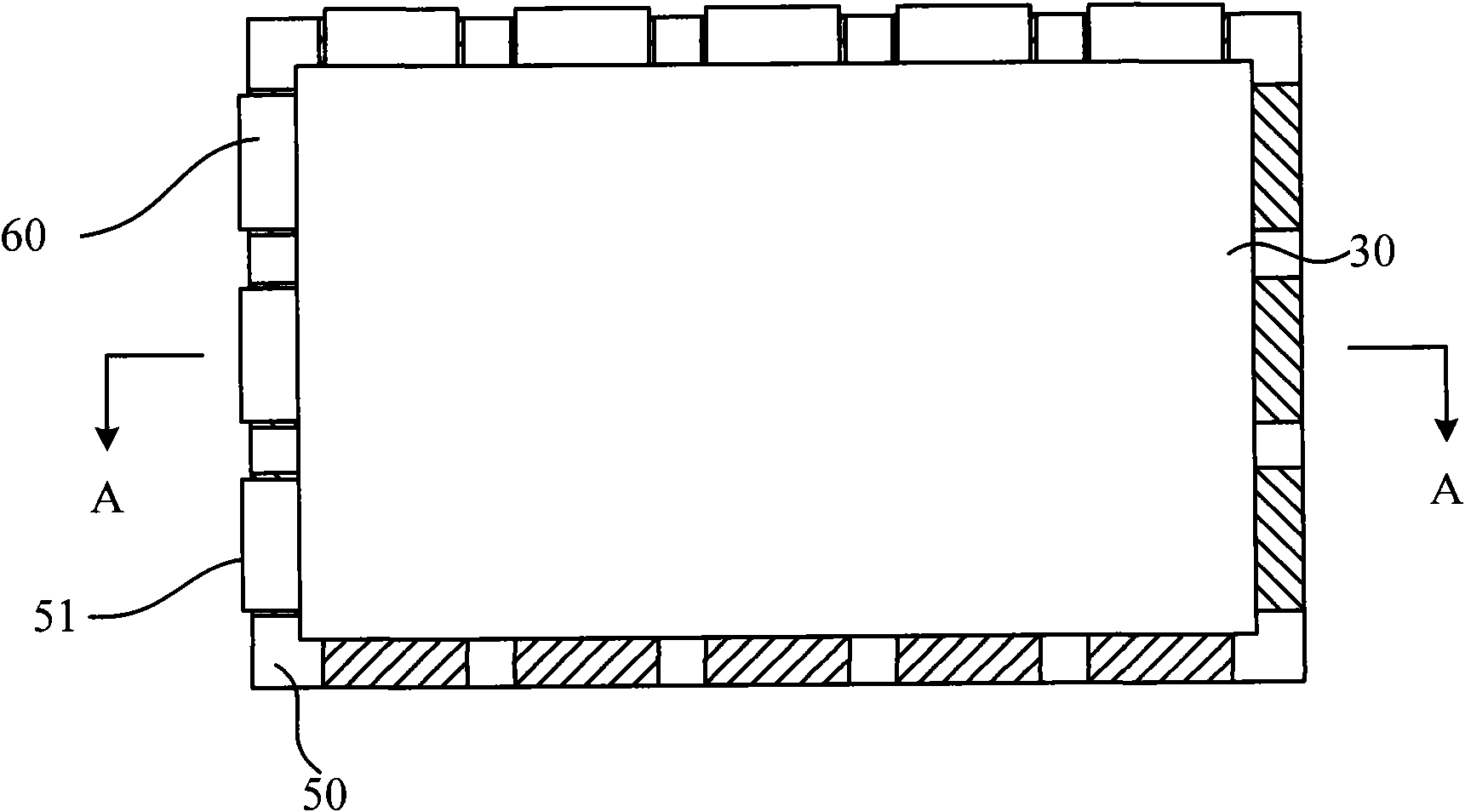

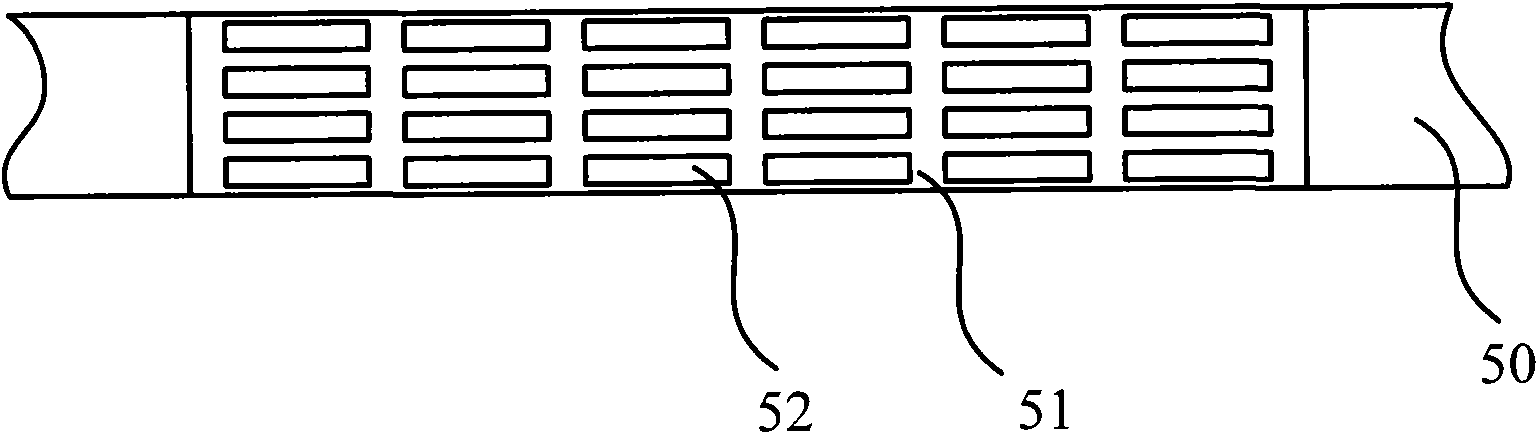

Mold framework and liquid crystal display device

ActiveCN101551539AReduce contact areaAvoid short circuitNon-linear opticsLiquid-crystal displayEngineering

The invention relates to a mold framework and a liquid crystal display device. A plurality of notches for containing and embedding driving lines are arranged on the mold framework at intervals, wherein a plurality of projections and / or grooves are arranged on each notch. The liquid crystal display device adopts the mold framework of the invention and further comprises: a backlight module, an optical film layer and a panel which are sequentially arranged from bottom to top, as well as an external framework which is surrounded at the outside of the backlight module, the optical film layer and the panel, wherein the mold framework is embedded between the external framework and the backlight module and between the optical film layer and the panel, and the driving lines connected on the panel are embedded in the notches of the mold framework. The invention reduces the contact area of the driving lines with the mold framework, reduces the friction occurred on the contact surface, avoids theshedding phenomenon of an SR layer, plays the role of collecting metal debris, further avoids the short-circuit phenomenon of a data cable caused by the adhesion of the metal debris on COF and can improve the service life of the liquid crystal display device.

Owner:BOE TECH GRP CO LTD +1

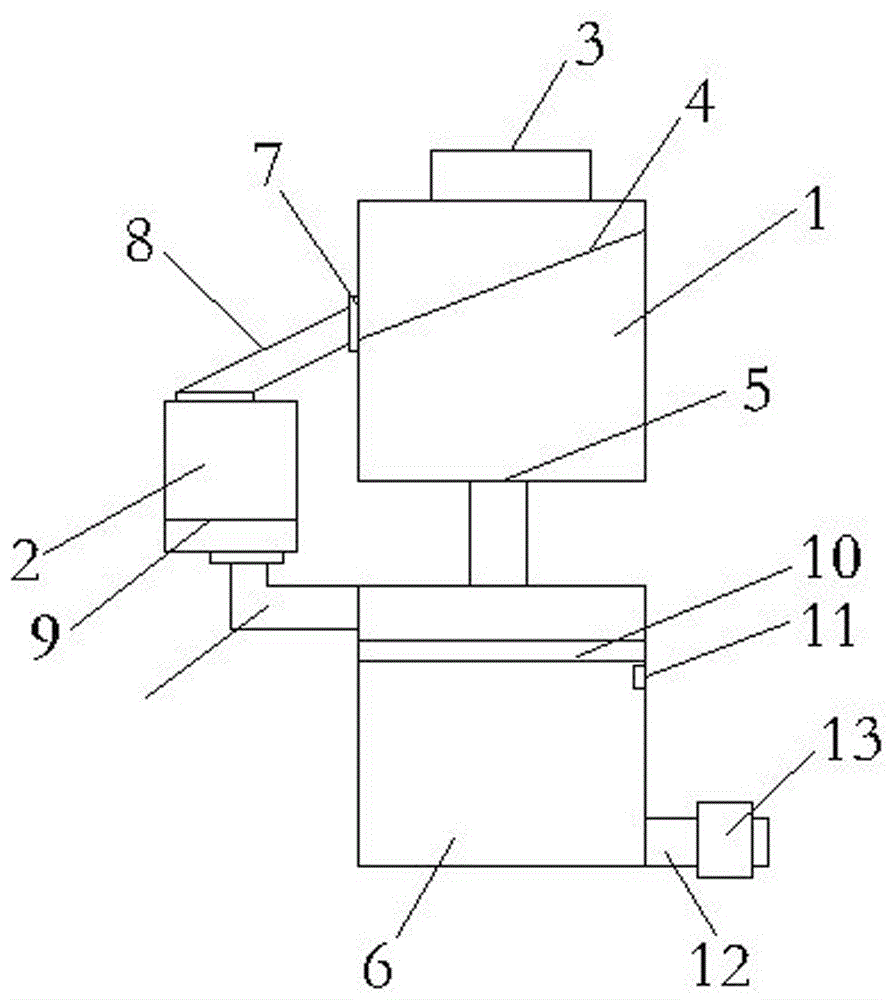

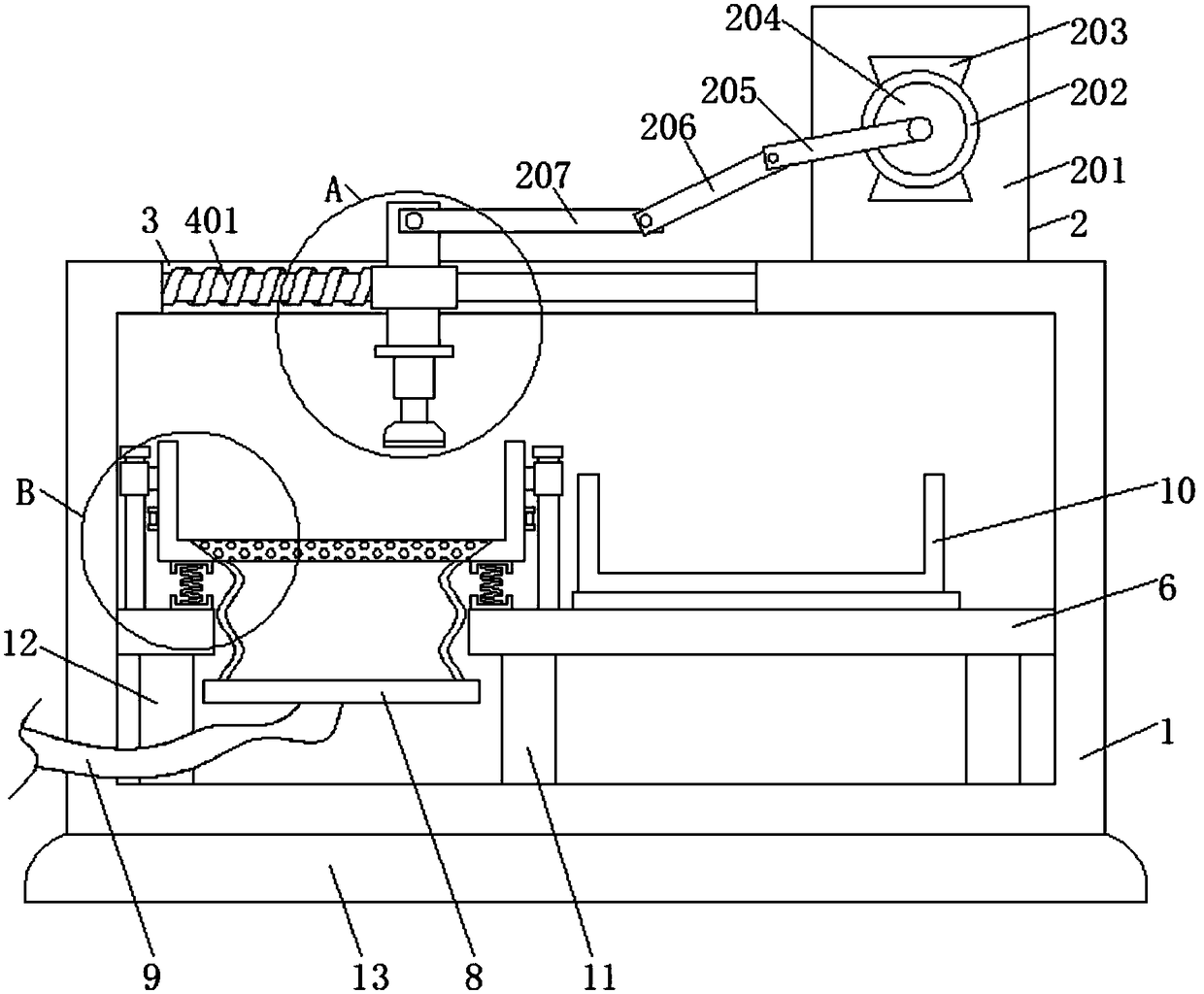

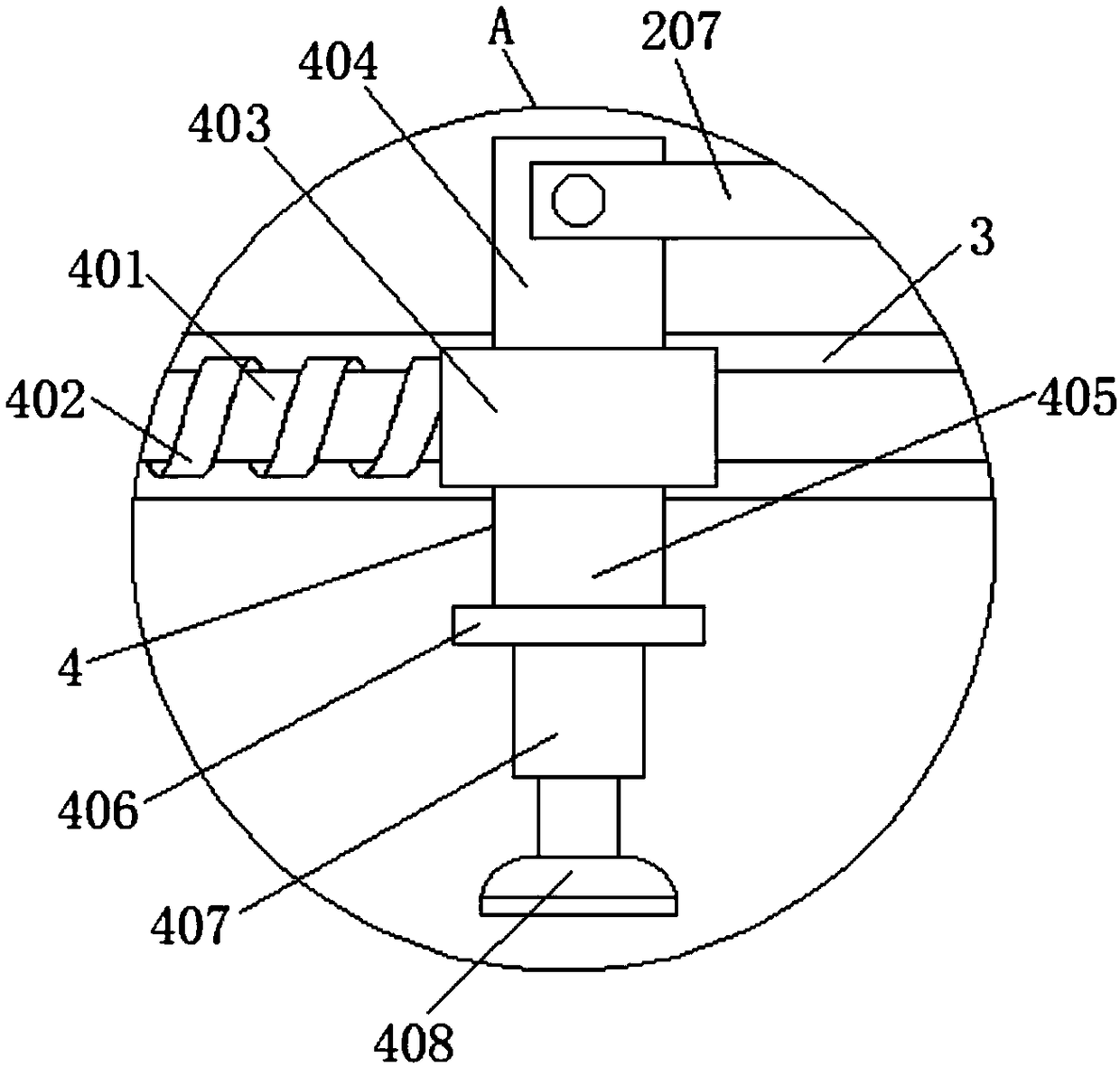

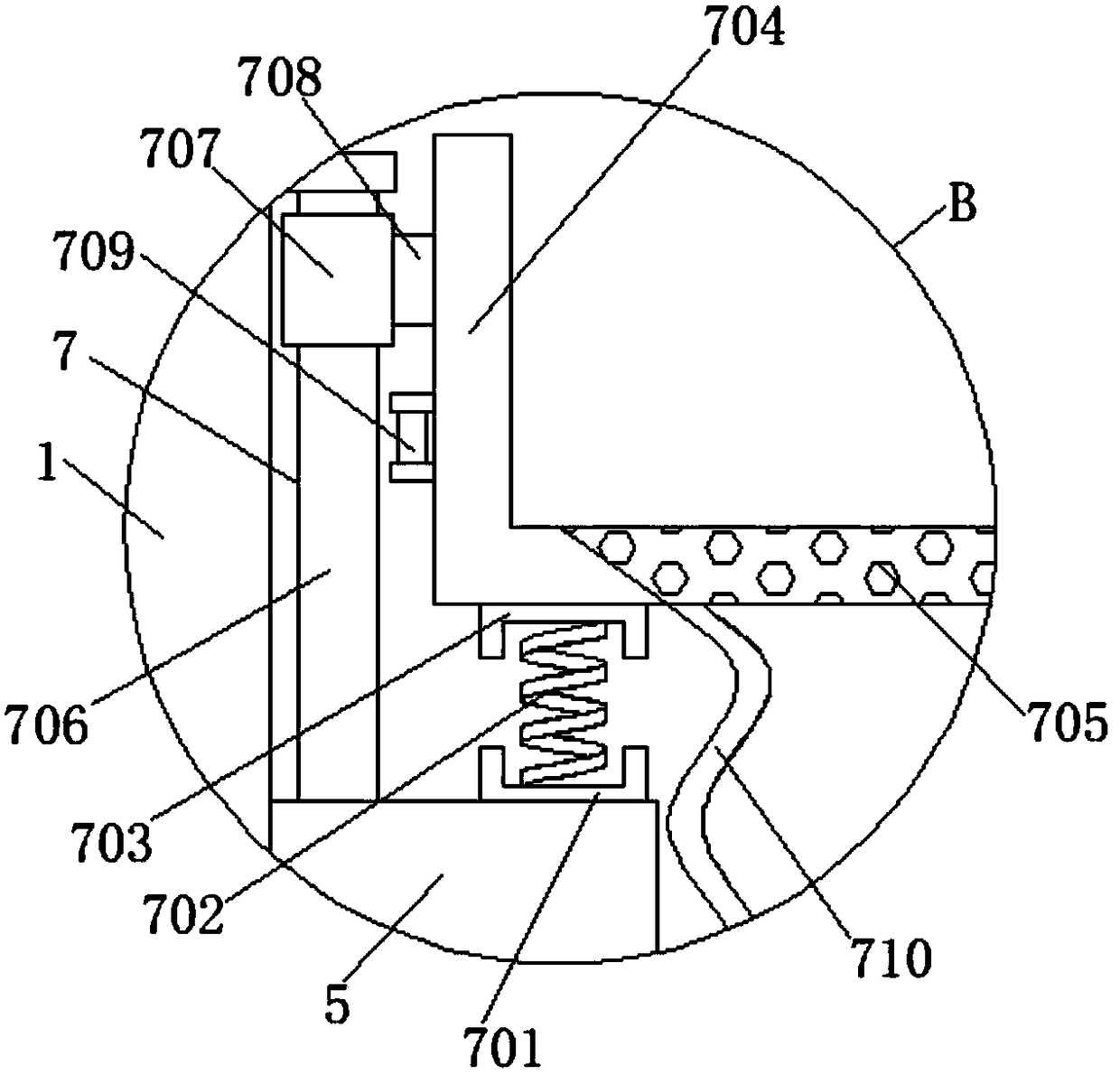

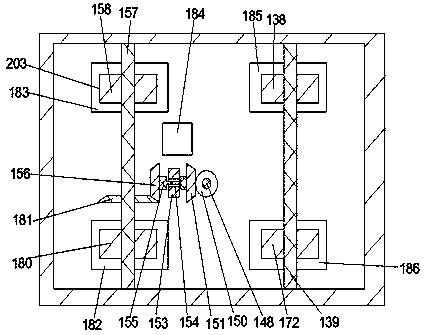

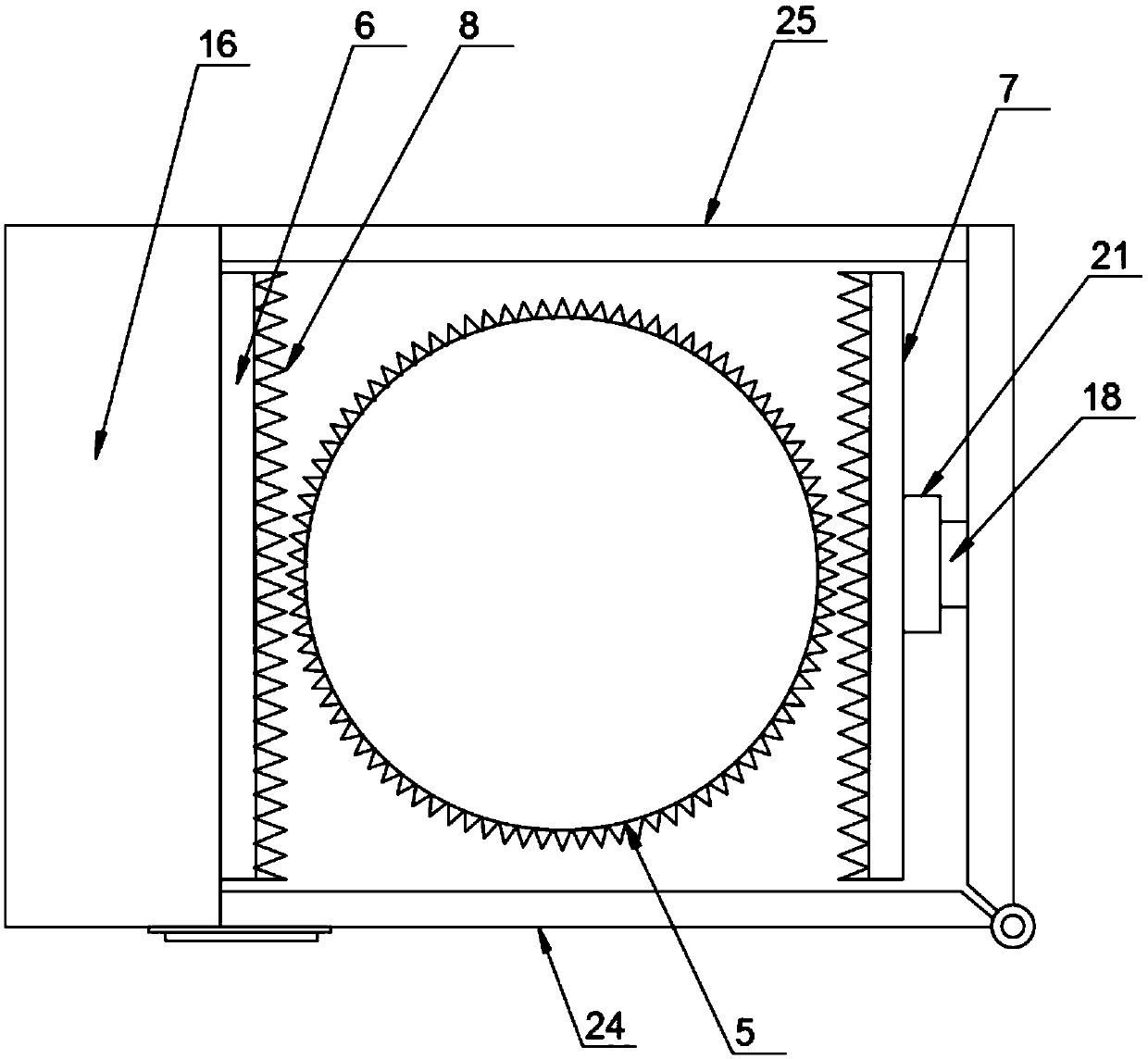

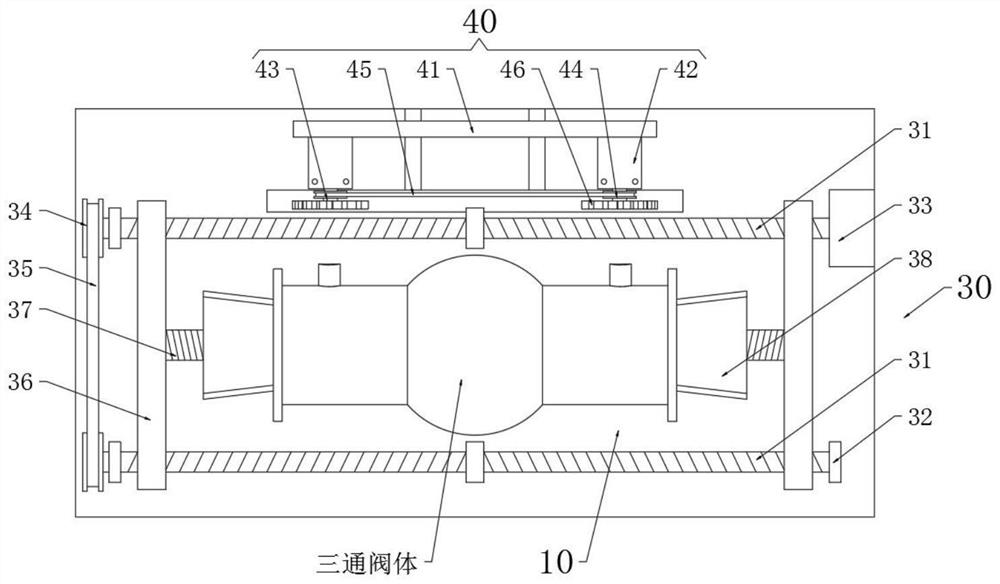

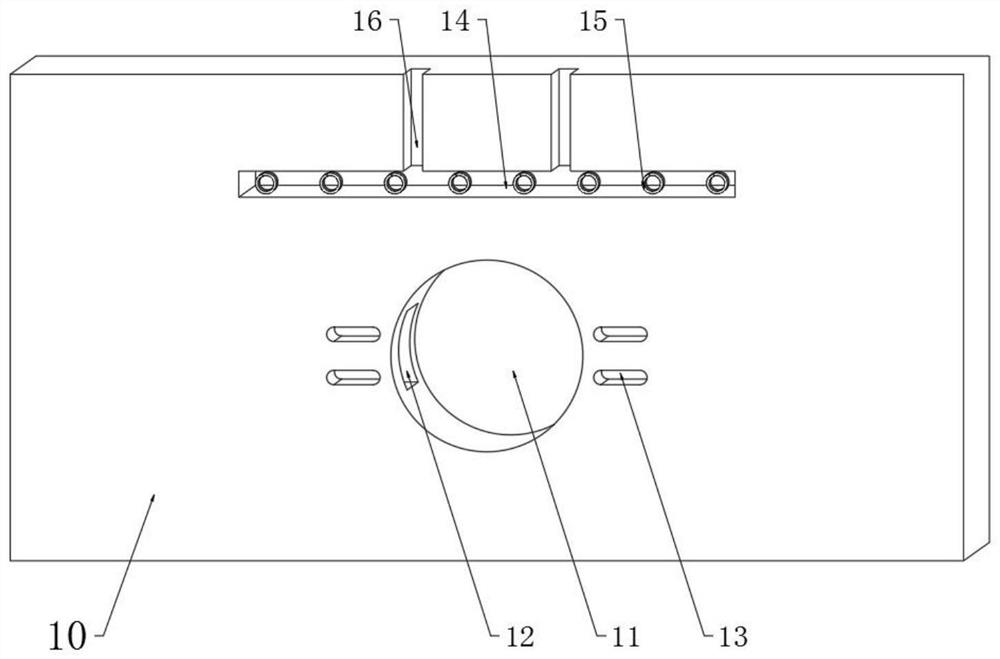

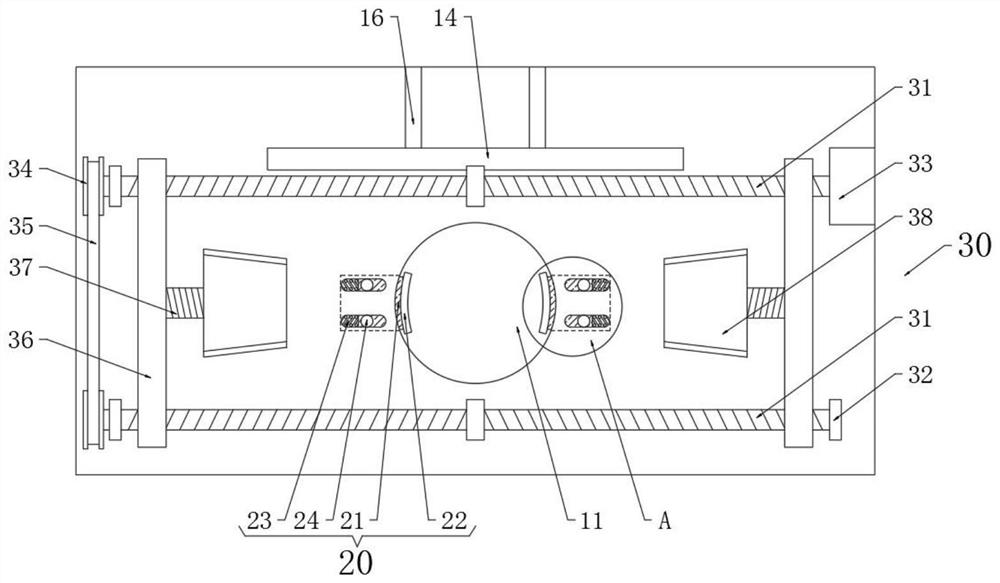

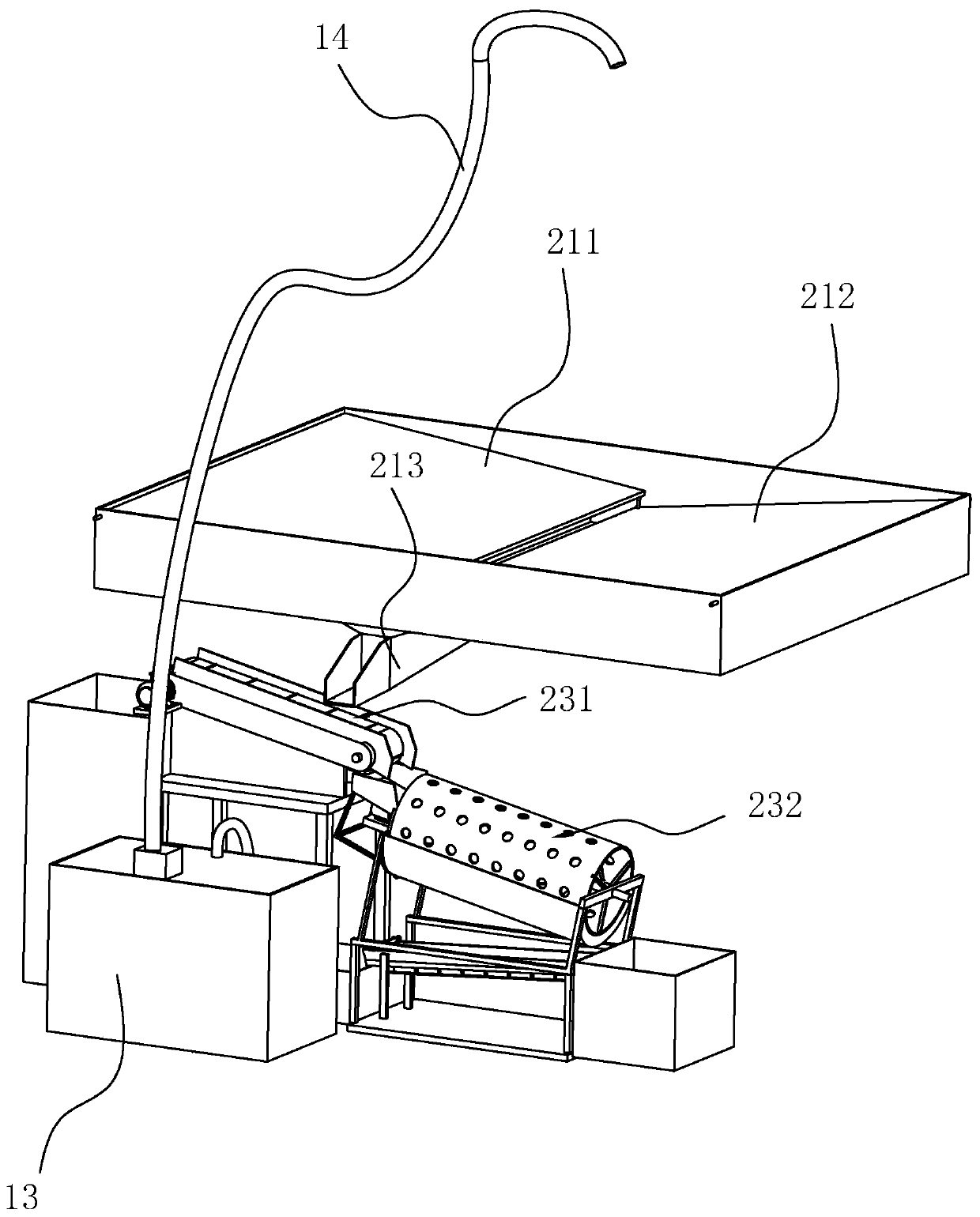

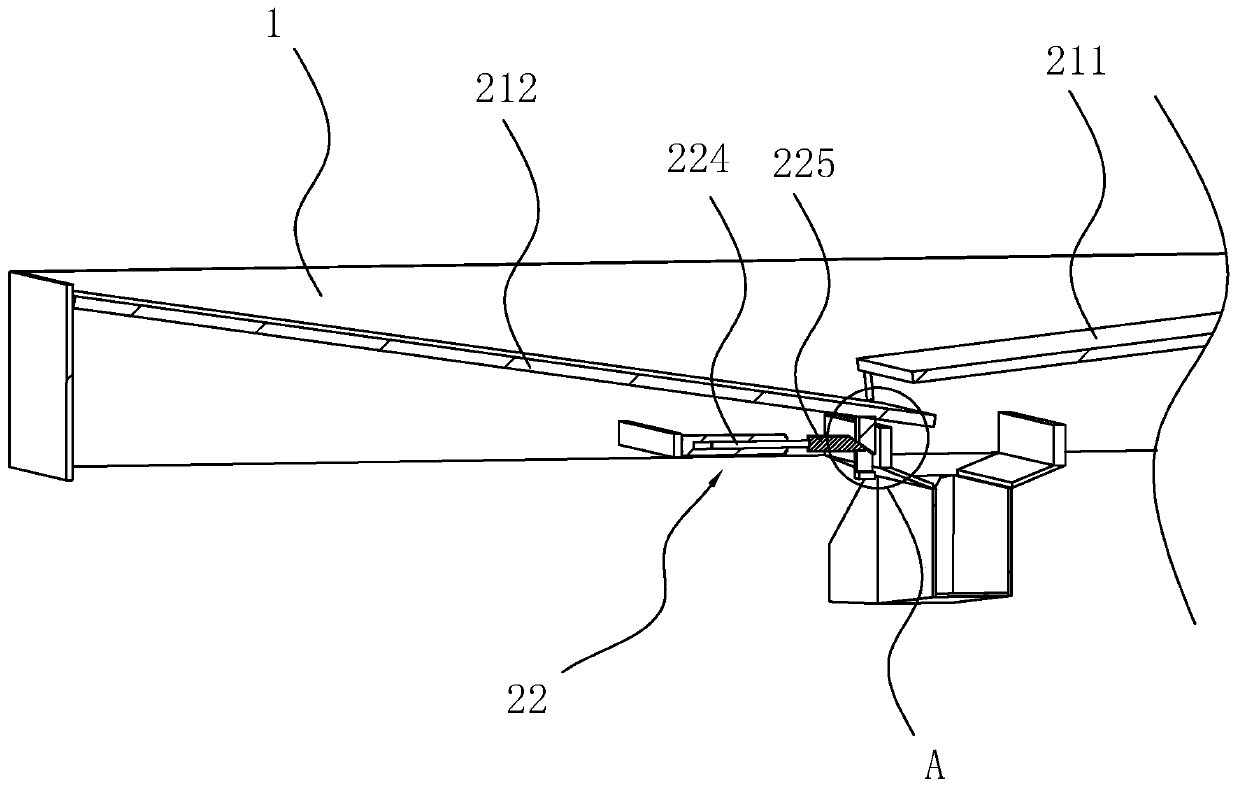

Metal debris collection device for milling machine machining milling head part

InactiveCN110712061AEasy to collectAvoid accumulationPositioning apparatusMaintainance and safety accessoriesMilling cutterGear wheel

The invention relates to the technical field of milling machines and discloses a metal debris collection device for a milling machine machining milling head part. The metal debris collection device comprises a bottom plate. A mounting plate is fixedly mounted on the top of the bottom plate. A rotating motor is fixedly mounted on the left side of the top of the mounting plate. A driving bevel gearis fixedly mounted at an output shaft of the rotating motor. A stabilizing bearing is fixedly mounted on the left side of the top of the inner side of the mounting plate. A main rotating rod with oneend penetrating and extending to the outer side of the mounting plate is fixedly mounted on the top of the stabilizing bearing. A driven bevel gear is fixedly mounted at the bottom of the outer surface of the main rotating shaft. According to the metal debris collection device for the milling machine machining milling head part, when the device is used for cutting, dust suction is carried out on amilling cutter and the top of a containing platform, so that the purpose of conveniently collecting the metal debris is achieved, the precision and efficiency during cutting are indirectly guaranteed, manual timing cleaning is not needed, use is convenient, and the device is suitable for various situations.

Owner:WENZHOU POLYTECHNIC

Metal debris filtering device

InactiveCN106239254ASpeed up filteringImprove filtration efficiencyMaintainance and safety accessoriesLiquid tankMetal debris

The invention relates to a metal debris filtering device comprising a base; the top of the base is provided with a first supporting column; one side of the first connecting column is provided with a second supporting column, and the other side of the first supporting column is provided with a cooling liquid tank; the top of the cooling liquid tank is connected with a cooling liquid spraying device through a guide pipe; one side of the second supporting column is provided with a third supporting column; one side of the third supporting column is provided with a metal debris collecting tank; the bottoms of both the first supporting column and the third supporting column are connected with a filtering device through springs; the other side of the filtering device is provided with a liquid storage tank; a belt is connected with the filtering device to ensure that the filtering device can vibrate to filter so that the filtering speed and efficiency are increased; the filtered cooling liquid is input to the spraying device through a delivery pump to ensure that the cooling liquid can be recycled, so that resources are saved; and an S-shaped filter screen is arranged and is enabled to filter all around, so that the filtering efficiency is increased. The metal debris filtering device is simple in structure and convenient to operate.

Owner:张家港市华扬冶金机械有限公司

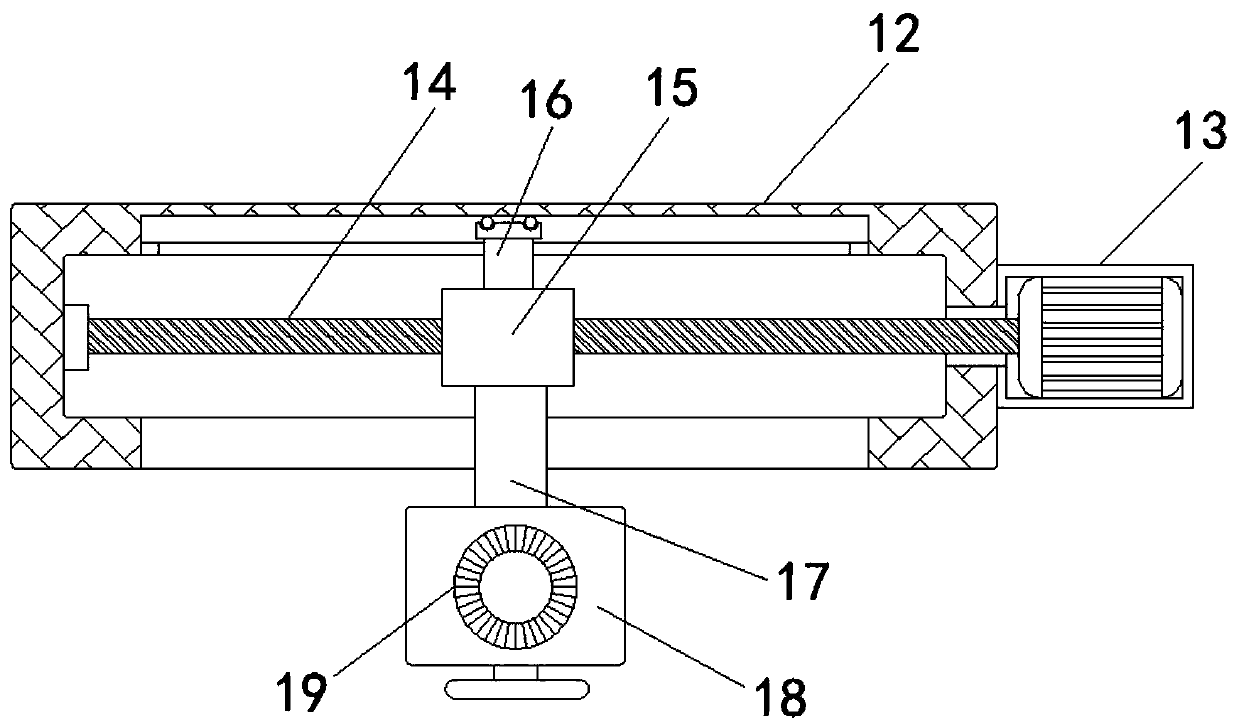

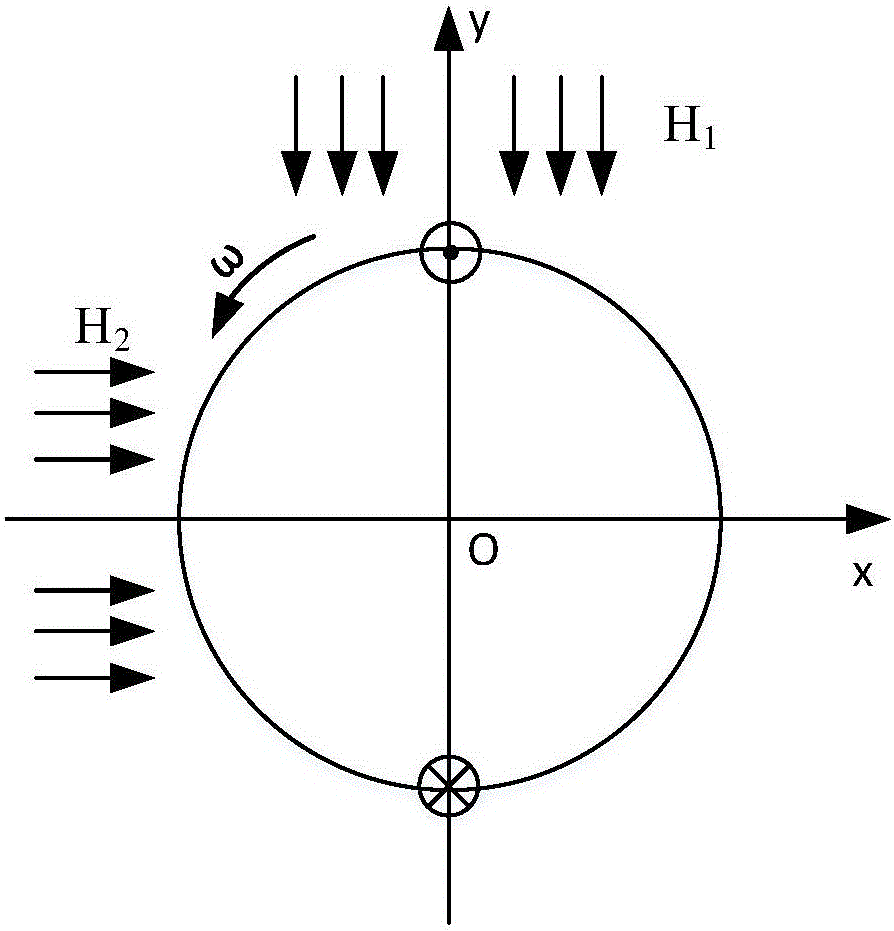

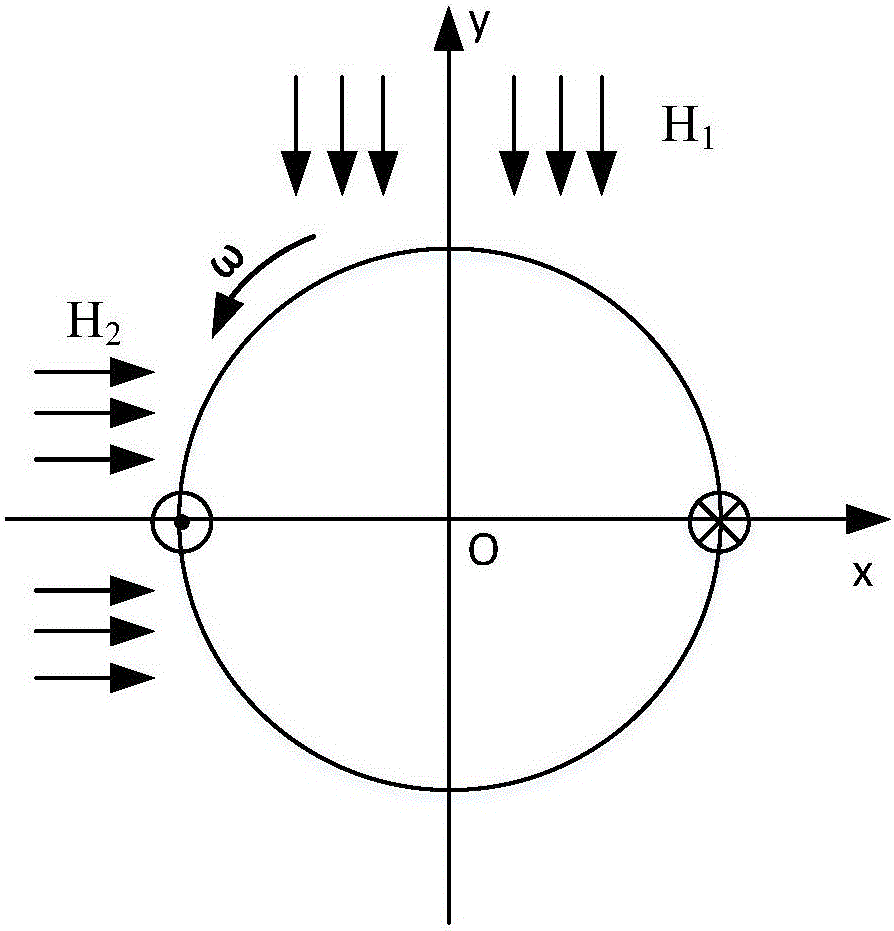

Method for setting alternating magnetic field for despinning spacial non-magnetized metal debris

ActiveCN105717976AImprove transfer efficiencyToolsMagnetic variable regulationEnergy transferRotational axis

The invention relates to a method for setting an alternating magnetic field for despinning spacial non-magnetized metal debris, i.e., a method for setting a torque despinning magnetic field formed by setting alternating magnetic fields which are mutually orthogonal in the space on a plane vertical to a rotating axis outside the rotated non-magnetized metal debris and utilizing an eddy current effect generated inside a metal conductor to act with external related magnetic fields. Compared with the prior art, the method provided by the invention has the advantages that on the basis of analyzing an eddy current torque generating substance, an eddy current torque generating way is changed, so that a single way that magnetic lines of force are cut by a moving conductor is transformed into a compound way that an eddy current torque is generated under the combined action of the moving conductor and the changed magnetic fields, the torque despinning magnetic field setting conditions are put forward, and the efficiency of energy transfer is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

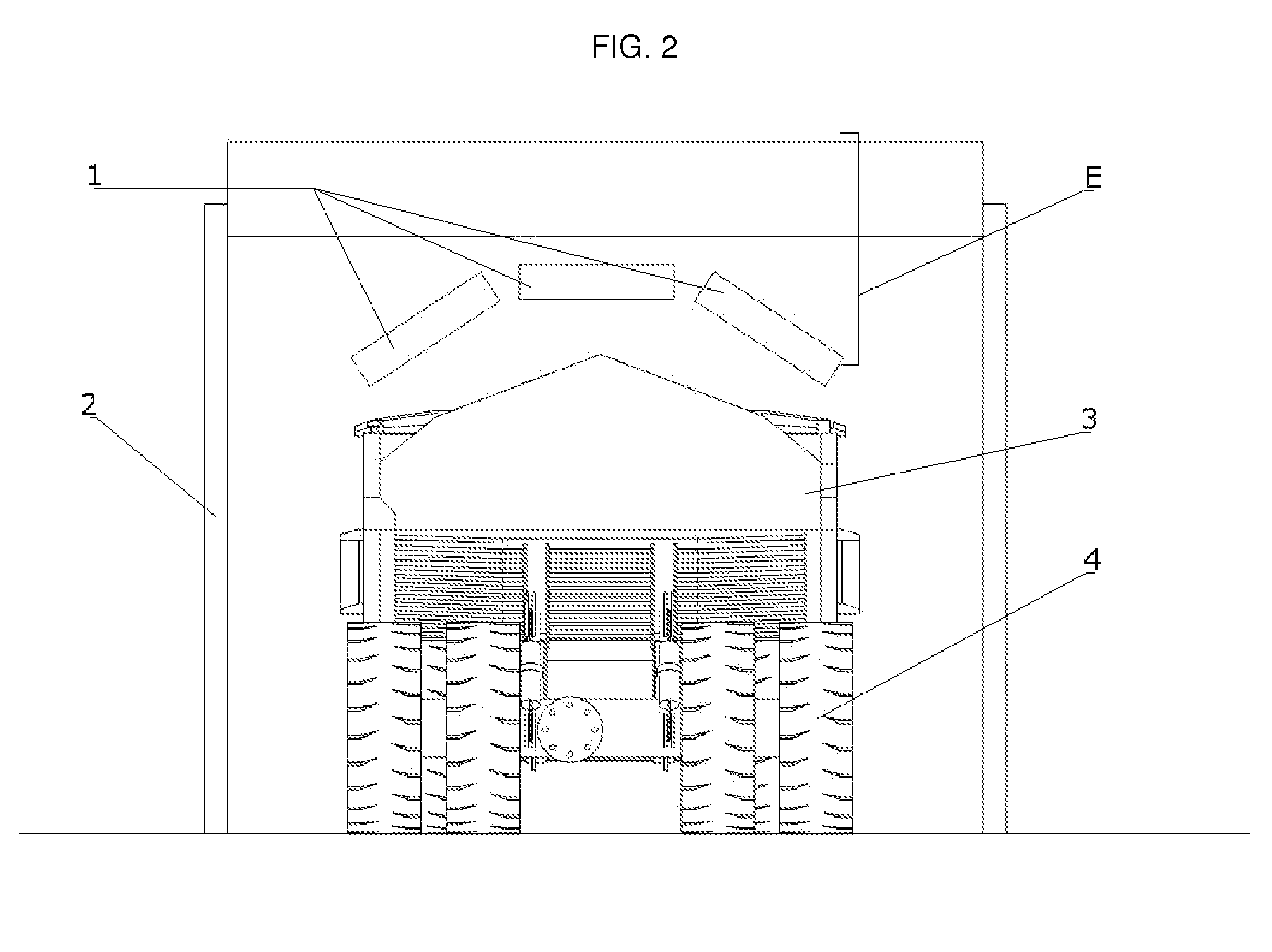

System and method of detection of uncrushable metallic pieces in mineral loads

InactiveUS20110074619A1Avoid problemsHigh yieldAlarmsRadio wave reradiation/reflectionRadarEngineering

A system and method to detect uncrushable metallic pieces hidden inside a mineral load directly inside a transport device to a primary crusher includes a directionally adjustable radar having at least one device with electromagnetic wave emitter / receiver antennas, a portal through which the transport device passes, a spectral generator / analyzer connected to the antenna devices that generates the electromagnetic waves and analyzes the echoes of the electromagnetic waves that interact with the mineral load, and a computational device that includes a digital signal processor connected to the spectral generator / analyzer.

Owner:TECHA INTEGRAL

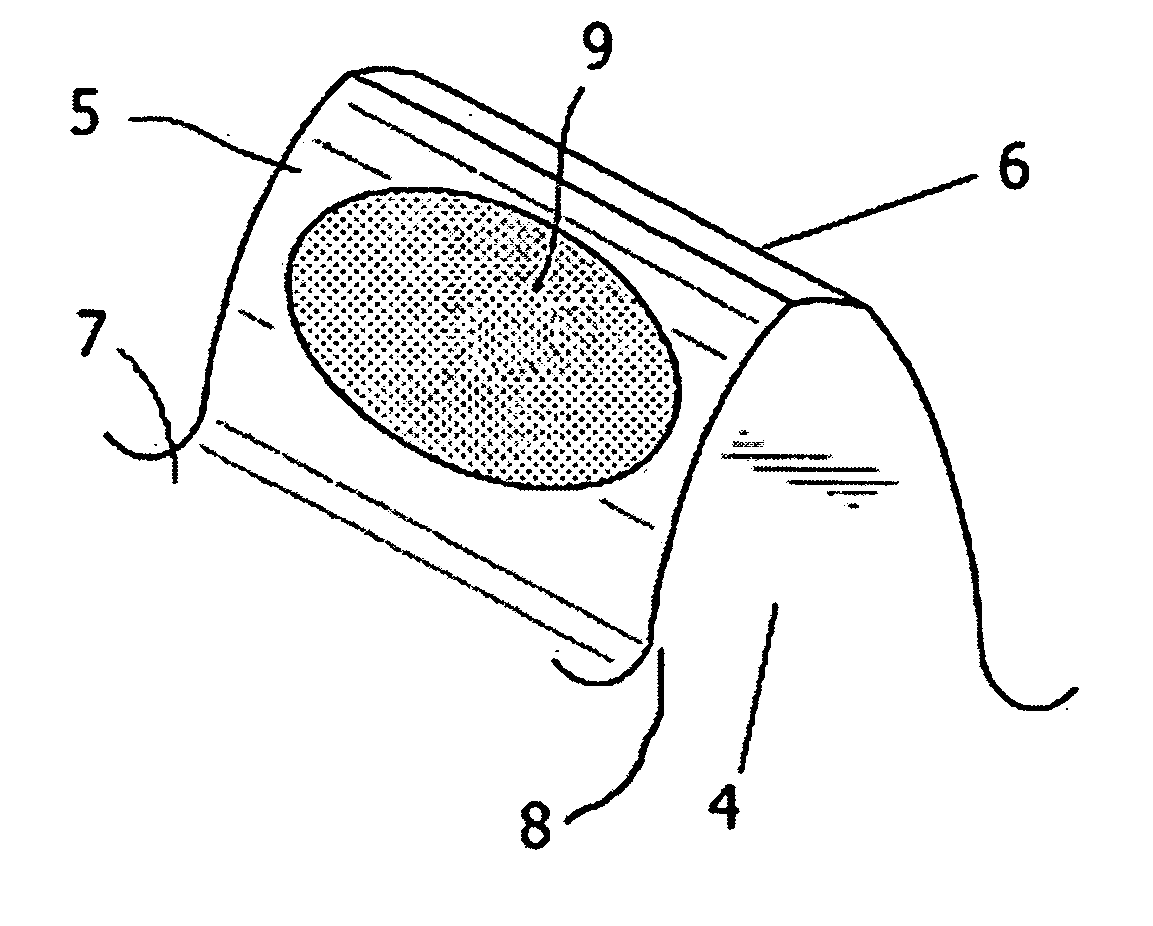

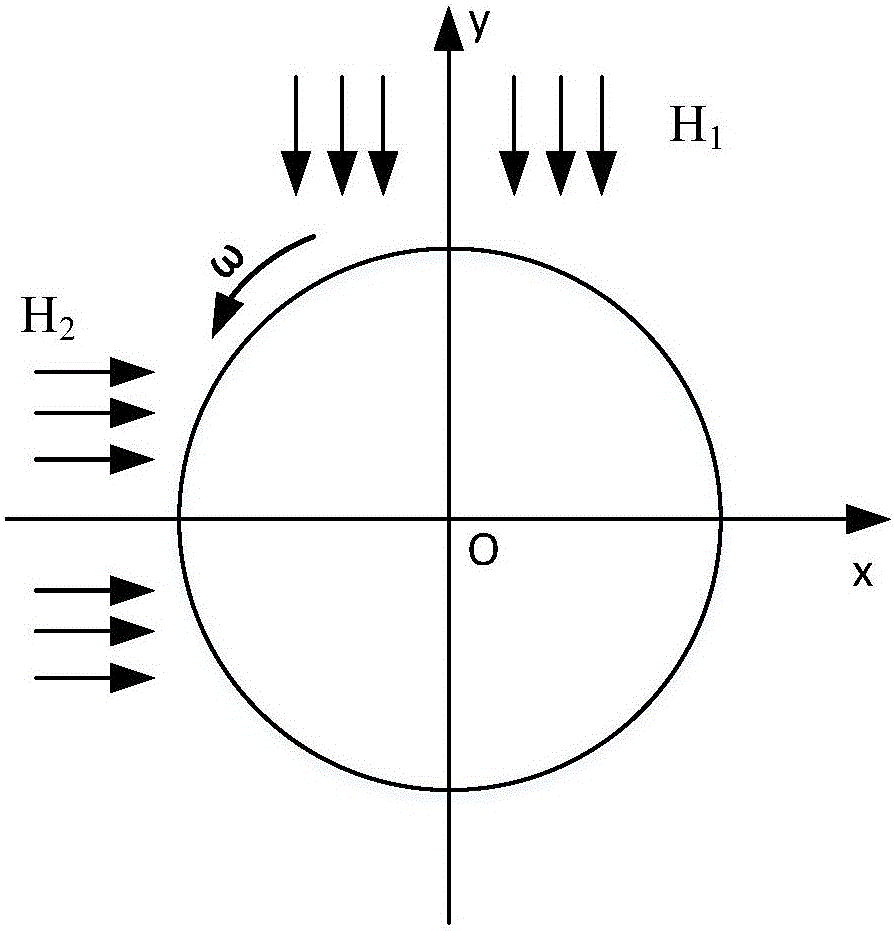

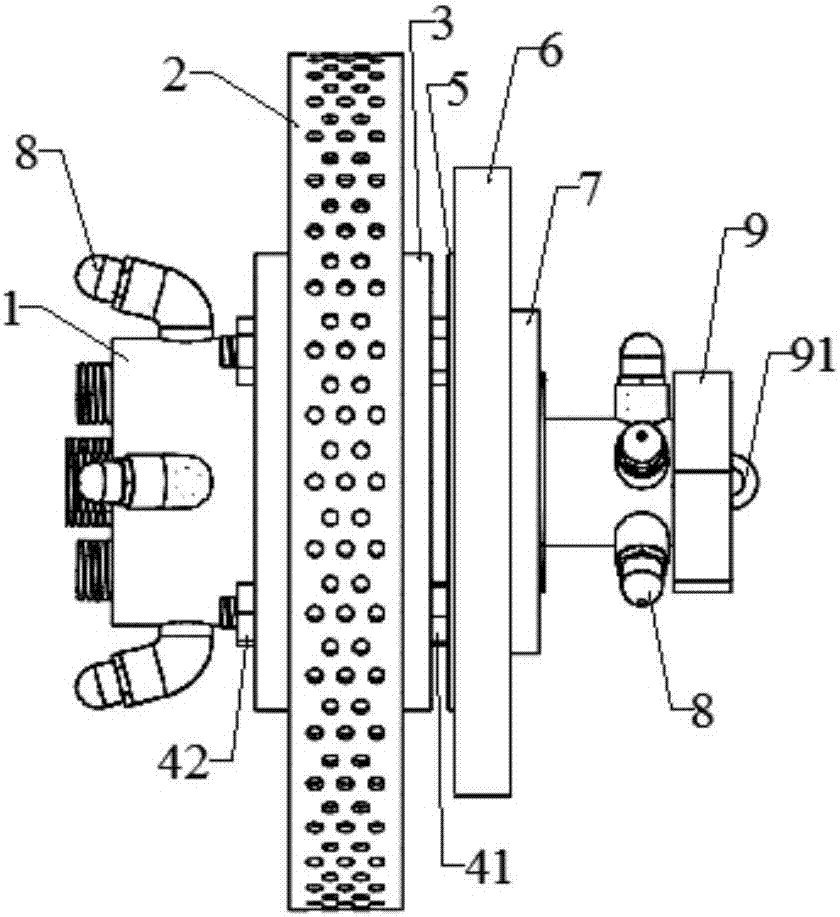

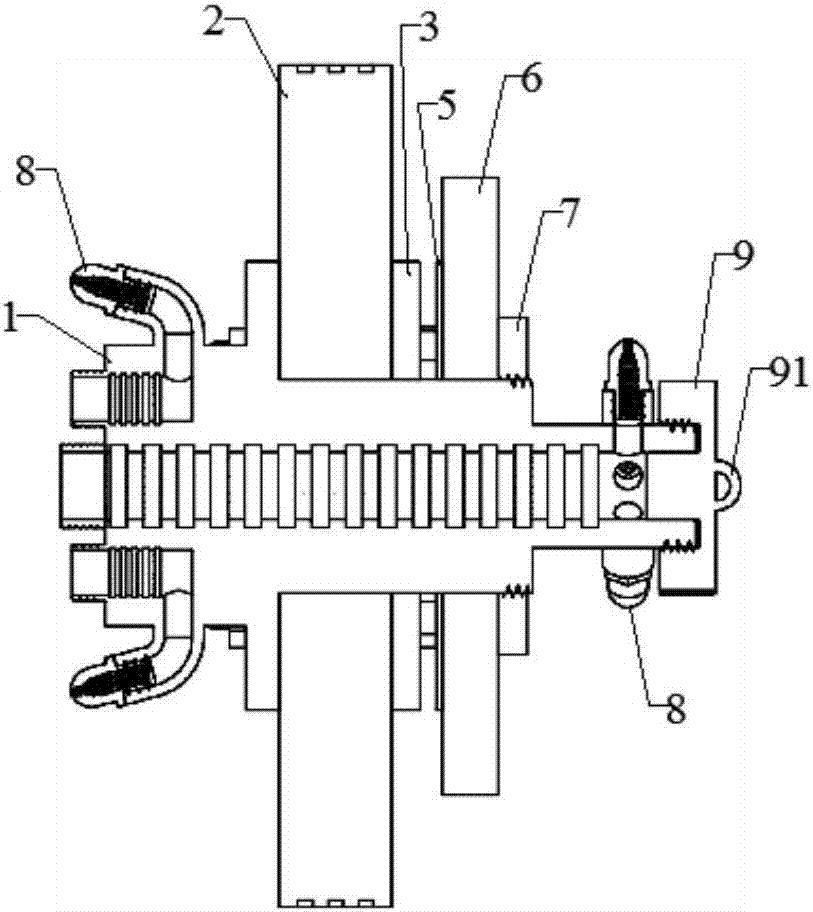

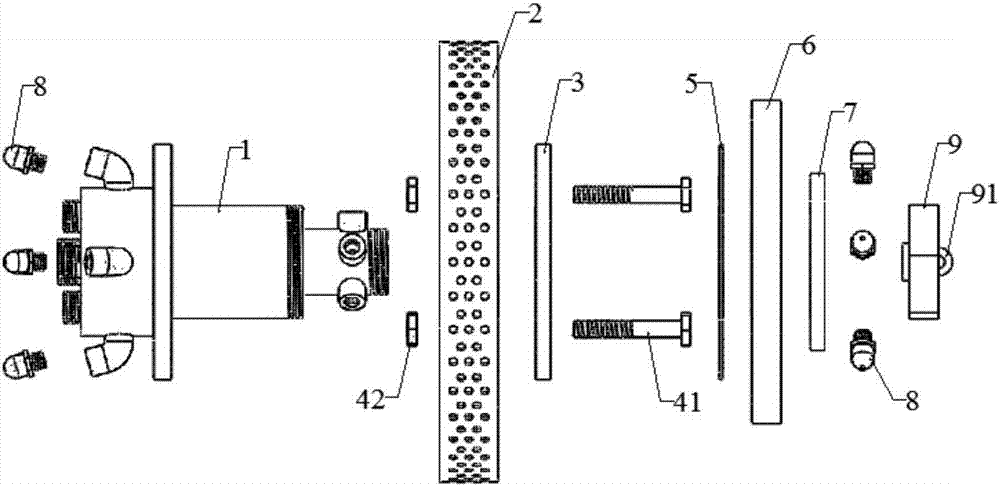

Multifunctional bionic tube cleaner and cleaning method thereof

ActiveCN106975641AWide range of applicationsIncrease flexibilityHollow article cleaningRubber ringStructural engineering

The invention relates to a multifunctional bionic tube cleaner and a cleaning method thereof. The bionic tube cleaner comprises a center shaft, a rubber ring, a rubber ring pressing plate, an annular magnet and a baffle plate, wherein the center shaft is sleeved with the rubber ring, the rubber ring pressing plate, the annular magnet and the baffle plate in order; the inner part of the center shaft is hollow, and a liquid flow channel is formed in the center shaft; a liquid inlet connecting port and a plurality of air inlet connecting ports are formed in the left end face of the center shaft, the liquid inlet connecting port is communicated with the liquid flow channel, and the air inlet connecting ports are communicated with nozzles through airflow channels in a mode of one to one correspondence; all nozzles positioned at the left end of the center shaft incline to the left; the right end of the center shaft is detachably provided with a plugging end cover in a sealing mode, and the right end of the center shaft is annularly provided with a plurality of nozzles communicated with the liquid flow channel. The inner wall of a tube is cleaned in a scraping mode through high-pressure liquid flow and the rubber ring, metal debris in the tube can be attracted through the annular magnet, and the whole device can move in the tube through high pressure air flow. The multifunctional bionic tube cleaner has the advantages of high efficiency, environmental protection, low consumption and strong flexibility and adaptability.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Metal debris filtering mechanism

InactiveCN106178637AEasy to installSimple structureStationary filtering element filtersMechanical equipmentEngineering

The invention relates to a metal debris filtering mechanism. The metal debris filtering mechanism comprises a coarse filter box and a scrap collecting box, wherein a material inlet is formed in the top of the coarse filter box; an inclined coarse filter screen is arranged inside an inner cavity of the coarse filter box; a liquid outlet is formed in the bottom of the coarse filter box; a liquid collecting box is connected to the bottom of the liquid outlet through a pipe; a movable connecting device is arranged on one side of the coarse filter box; movable connecting devices are arranged at both the top and the bottom of the scrap collecting box; the movable connecting device at the top of the scrap collecting box is connected with the inclined pipe; the other end of the inclined pipe is connected with the movable connecting device on the coarse filter box; a fine filter screen is arranged at the bottom of an inner cavity of the scrap collecting box; a fine filter screen layer is arranged inside an inner cavity of the liquid collecting box; a liquid level controller is arranged below the fine filter screen layer. The metal debris filtering mechanism which can be conveniently mounted inside mechanical equipment can separate metal debris from a cooling fluid, collect the metal debris and filter the cooling fluid, and can recycle the cooling fluid, thereby being energy-saving and environment-friendly.

Owner:张家港市华扬冶金机械有限公司

Cooling liquid treatment device for machining

The invention relates to the technical field of cooling liquid, in particular to a cooling liquid treatment device for machining. The cooling liquid treatment device aims to solve the technical problem that the cooling liquid filtering effect is influenced due to the fact that a filter screen is blocked by metal debris in cooling liquid. In order to solve the technical problem, the invention provides the cooling liquid treatment device for machining. The cooling liquid treatment device comprises a machine body, a driving device is fixedly connected to one side of the top of the machine body, astrip-shaped groove is formed in the other side of the top of the machine body, a moving device is arranged in the strip-shaped groove, the top of the moving device is movably connected to one end ofthe driving device, a first supporting plate is fixedly connected to one side of the inner wall of the machine body, a second supporting plate is fixedly connected to the other side of the inner wallof the machine body, and a filtering device is fixedly connected to the top of the first supporting plate and the top of the second supporting plate. According to the cooling liquid treatment device,the phenomenon that the filter screen is blocked by the excessive metal debris can be effectively avoided, and the filtering effect of the cooling liquid can be improved.

Owner:桂骏

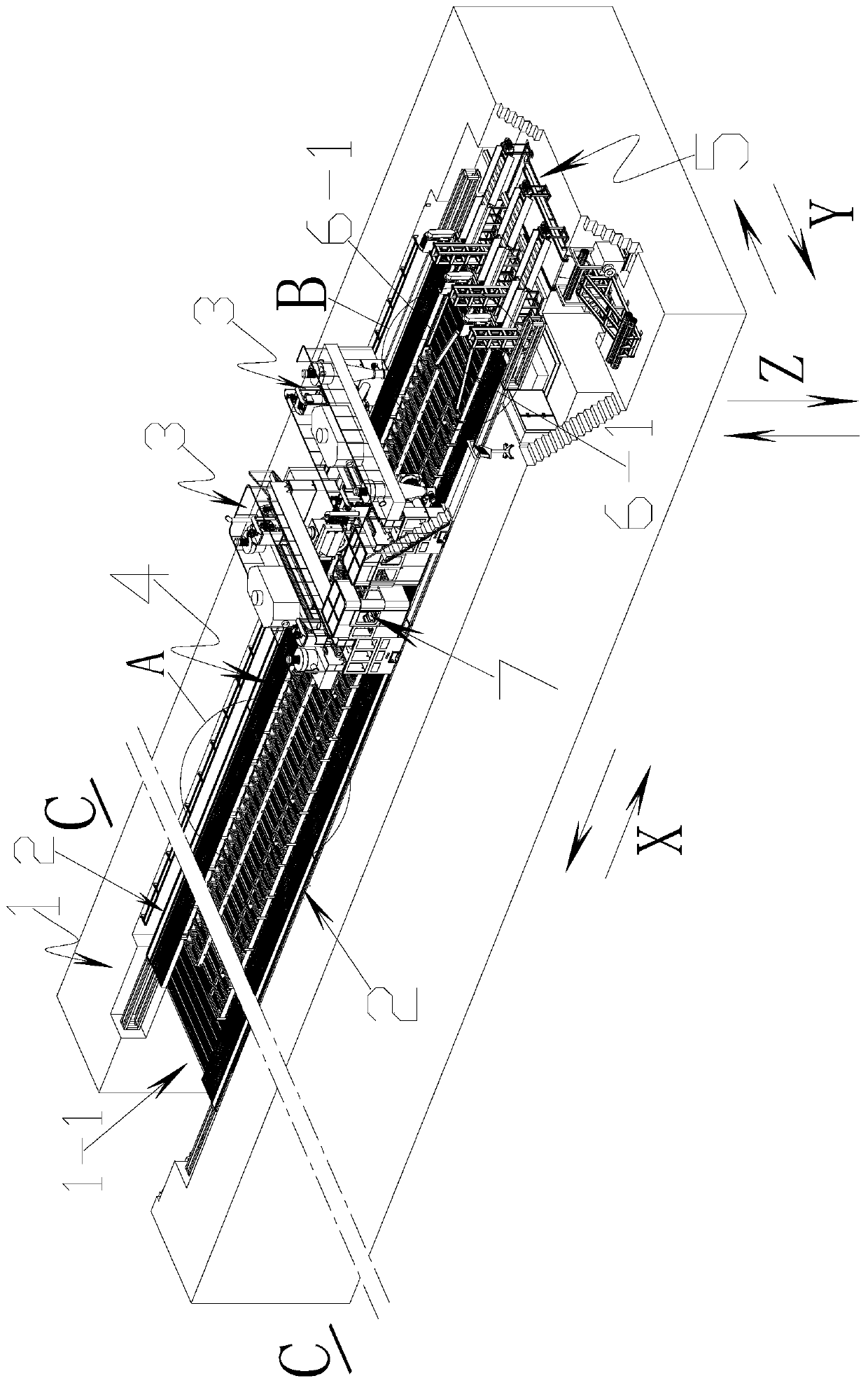

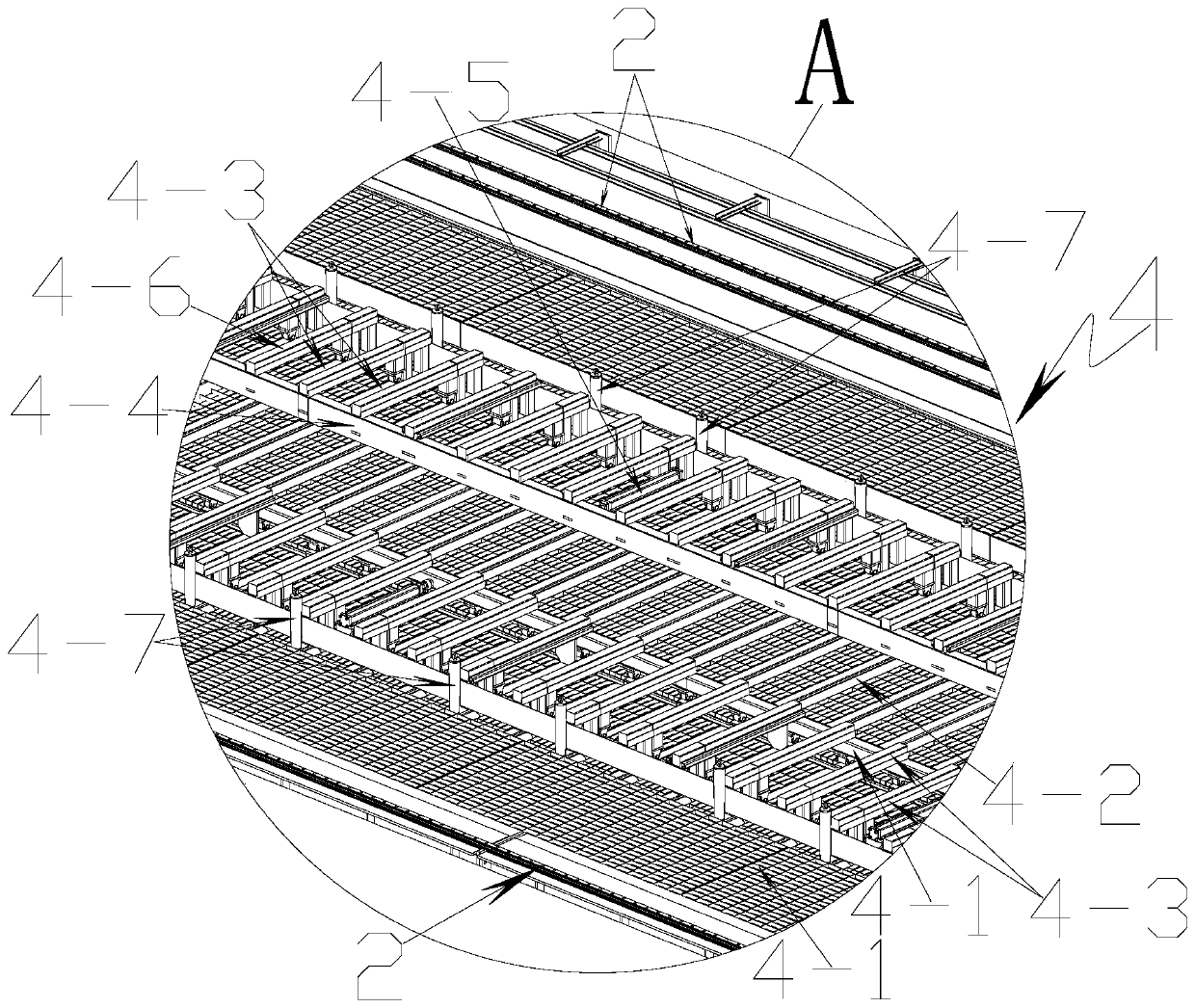

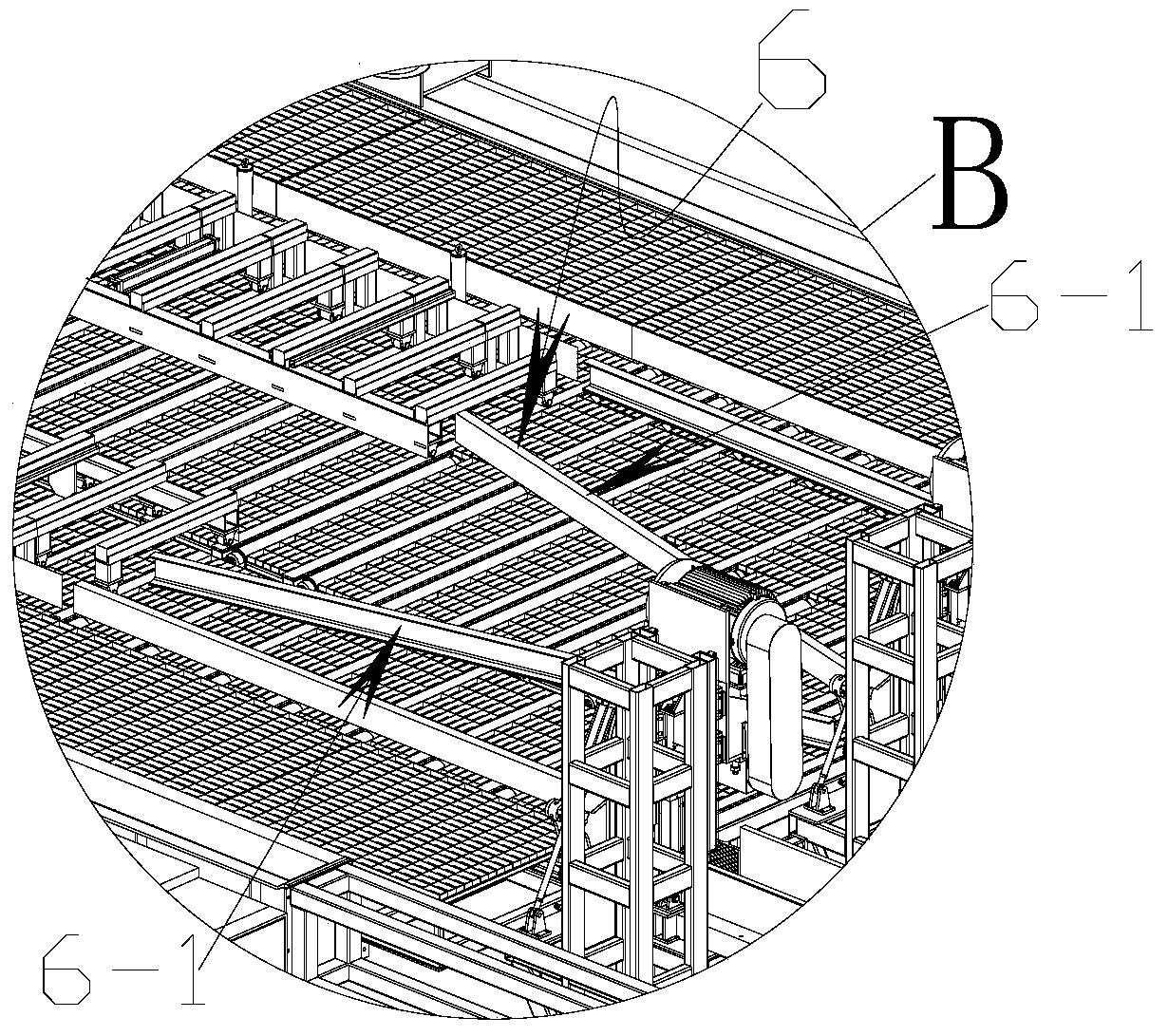

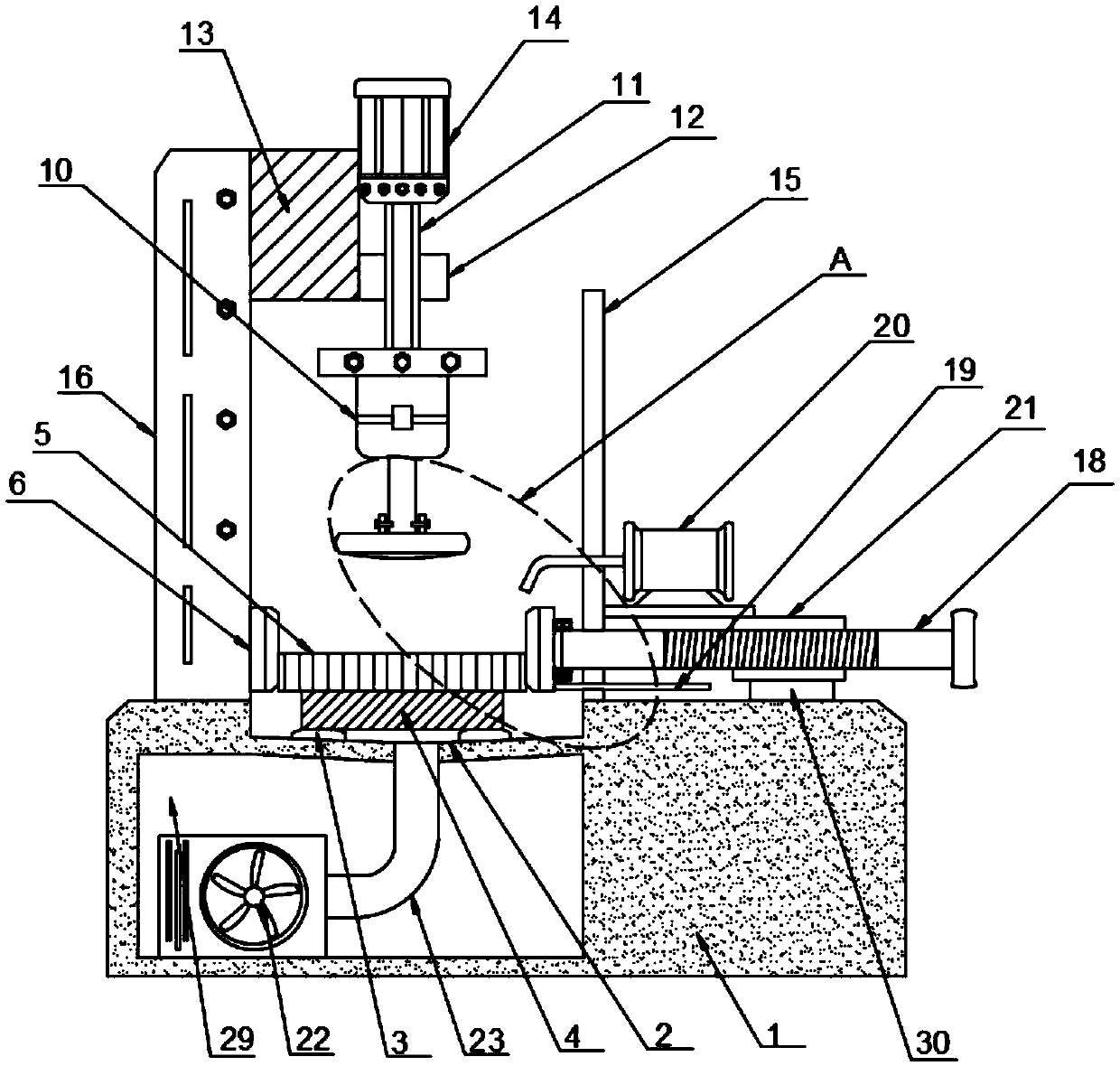

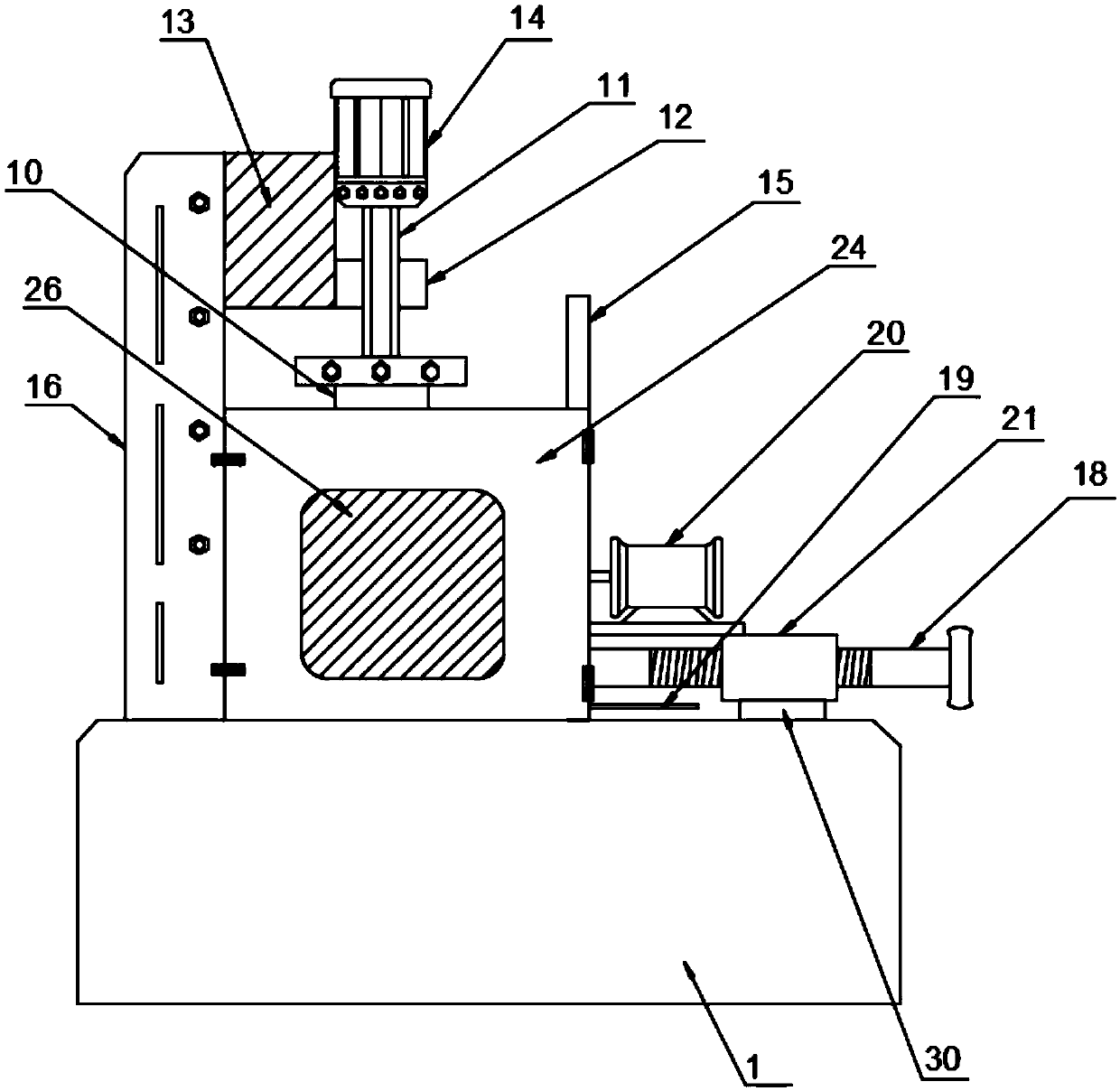

Efficient numerical-control saw cutting machining machine tool for aluminum metal plates

PendingCN110842283AIngenious structural designReasonable structural designMetal sawing devicesMetal sawing accessoriesEngineeringAluminum metal

The invention discloses an efficient numerical-control saw cutting machining machine tool for aluminum metal plates. The machine tool comprises a base, wherein a foundation pit is formed in the base,sliding rails are fixed to the two sides of the foundation pit, and a pair of aluminum plate gantry sawing devices are arranged on the base; an aluminum plate raw material placing and waste edge conveying device is mounted at the foundation pit, and an aluminum plate waste edge fixed length saw cutting and bundling device is arranged on the portion, at the side part of the aluminum plate raw material placing and waste edge conveying device, of the base; and position correction pieces are mounted on the portions, between the aluminum plate material placing and waste conveying device and the aluminum plate waste edge fixed length saw cutting and bundling device, of a supporting plate, and the position collation pieces are two guide rods with big-end-out openings. According to the machine tool, the aluminum metal plates can be subjected to size correction cutting, finished products of the aluminum metal plates are cut into small pieces of aluminum metal plate bodies, and the functions such as waste edge fixed length cutting, aluminum metal plate waste edge bundling, metal debris collection treatment, smoke collection treatment and cutting saw blade lubricating oil lubrication are integrated; and the efficiency is high, the precision is high, the automation degree is high, the labor is low, and the cost is low.

Owner:浙江锯力煌工业科技股份有限公司

Metal debris recycle device

InactiveCN109222773AEasy to collectReduce consumptionAutomatic obstacle detectionTravelling automatic controlWorking environmentEngineering

The invention discloses a metal debris recycle device, including an iron scrap collection car. A work space is arranged in the iron scrap collection car, A link mechanism is arranged in that work space, At that rear side of the link mechanism, an iron chip attracting mechanism is arranged, the iron chip attracting mechanism comprises a chain, the connecting mechanism is use for controlling the rotation of the chain, and at the front side of the connecting mechanism, a moving mechanism is arranged, and the connecting mechanism can drive the moving mechanism to move left and right while controlling the rotation of the chain; In operation of that device, through its own motion, in factories and workshops, The iron chips dropped on the ground are collected automatically, and the collected ironchips are quantitatively compressed and discharged, so as to facilitate the subsequent collection of workers, facilitate the subsequent recycling and processing, improve the working environment, andto a certain extent, the recycling and utilization of the iron chips also save the consumption of materials, which is conducive to environmental protection and economic maximization.

Owner:三门汇真环保科技有限公司

Gear machining device

InactiveCN109623545AImprove practicalityImprove removal efficiencyEdge grinding machinesGrinding drivesEngineeringHigh torque

The invention discloses a gear machining device. The gear machining device comprises a machine body, a machining groove is embedded into the top of the machine body, a cushion block is arranged at thebottom of an inner cavity of the machining groove, a base plate is arranged at the top of the cushion block, a gear is arranged at the top of the base plate, and a fixed clamping plate is arranged onone side of the gear and a movable clamping plate is arranged on the other side of the gear. Anastomotic teeth are arranged on the inner sides of the fixed clamping plate and the movable clamping plate, a grinding disc is arranged at the top of the gear, a high torque motor is arranged at the top of the grinding disc, telescopic rods are arranged at the top of the high torque motor, and a sleevesleeves the outer walls of the telescopic rods. According to the gear machining device, by arranging a relatively sealed environment, wind power generated by a pipeline draught fan is used for actingon the gear end surface for being ground through an air blowing pipe, metal debris after grinding is blown, suction generated by a dust collector collects the debris upfloated in the machining groovethrough a dust collecting pipe, and the efficiency and quality of removing burrs of the gear are improved.

Owner:ANHUI JISITE INTELLIGENT EQUIP CO LTD

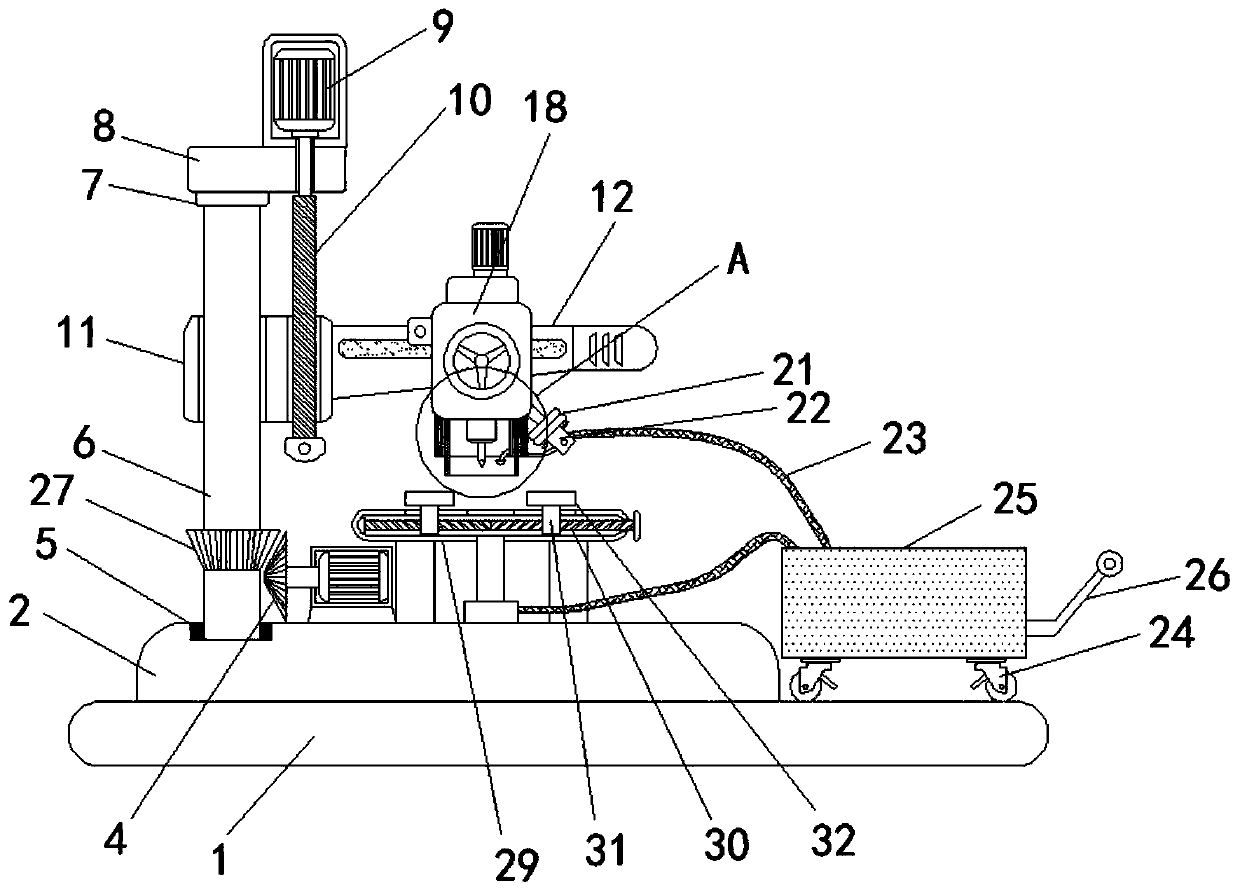

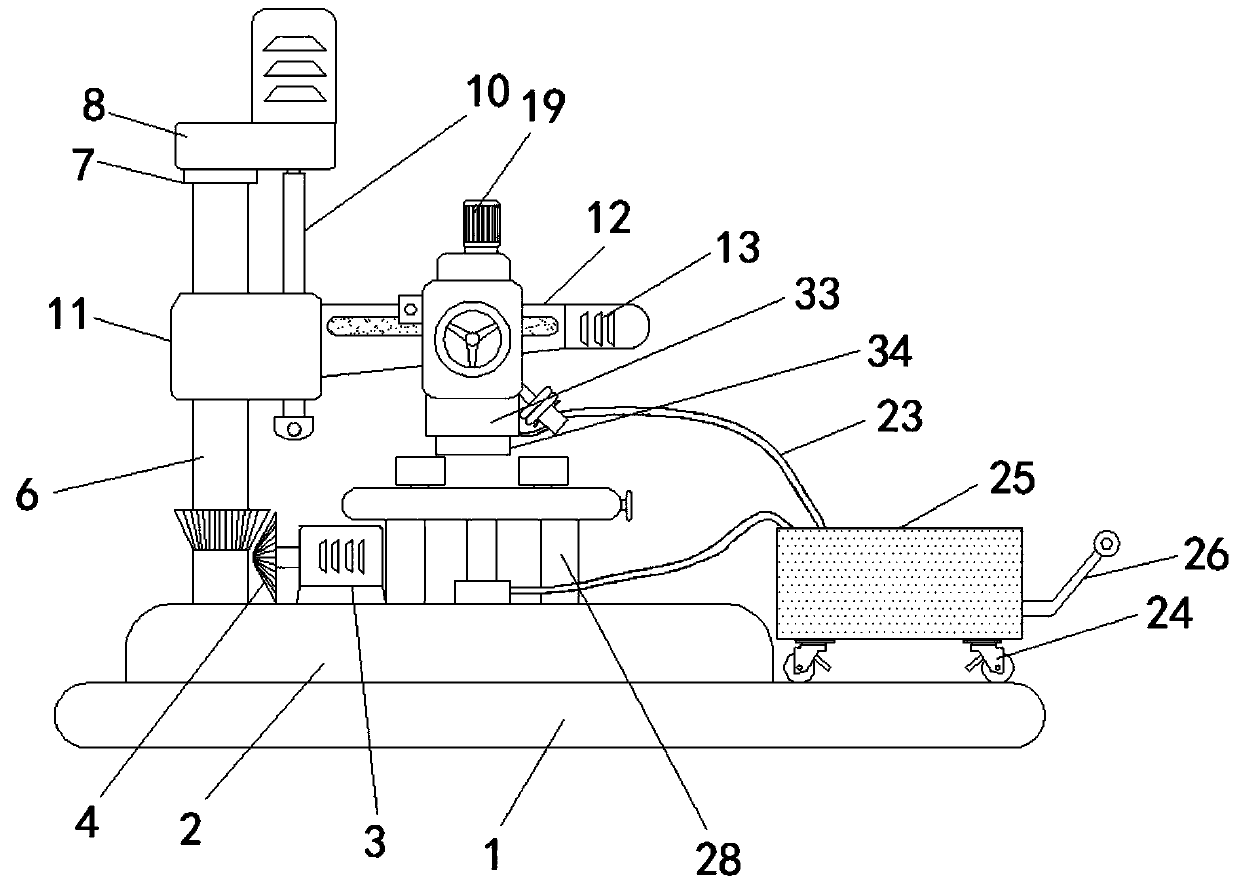

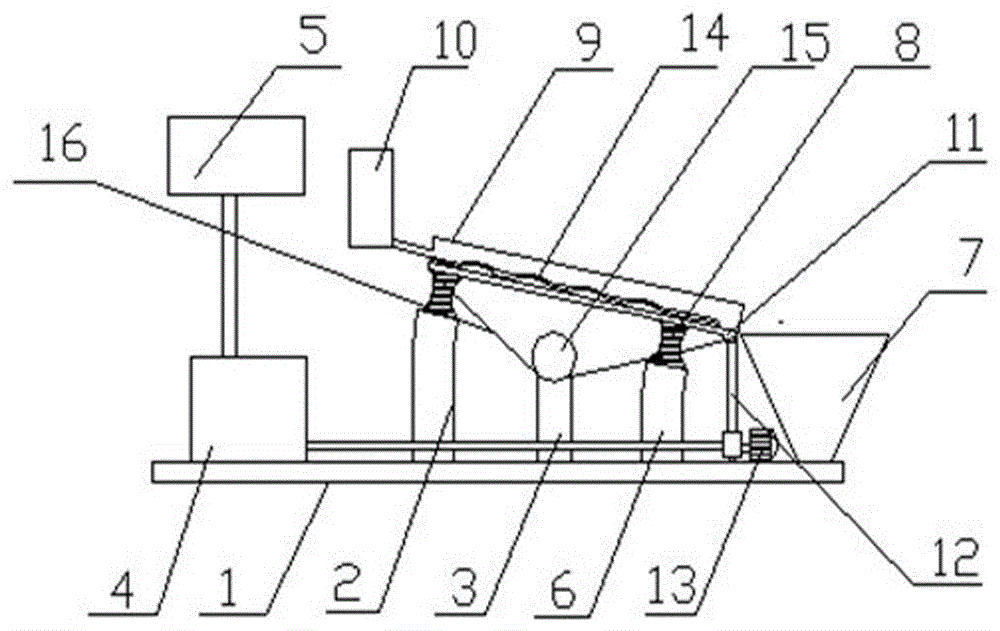

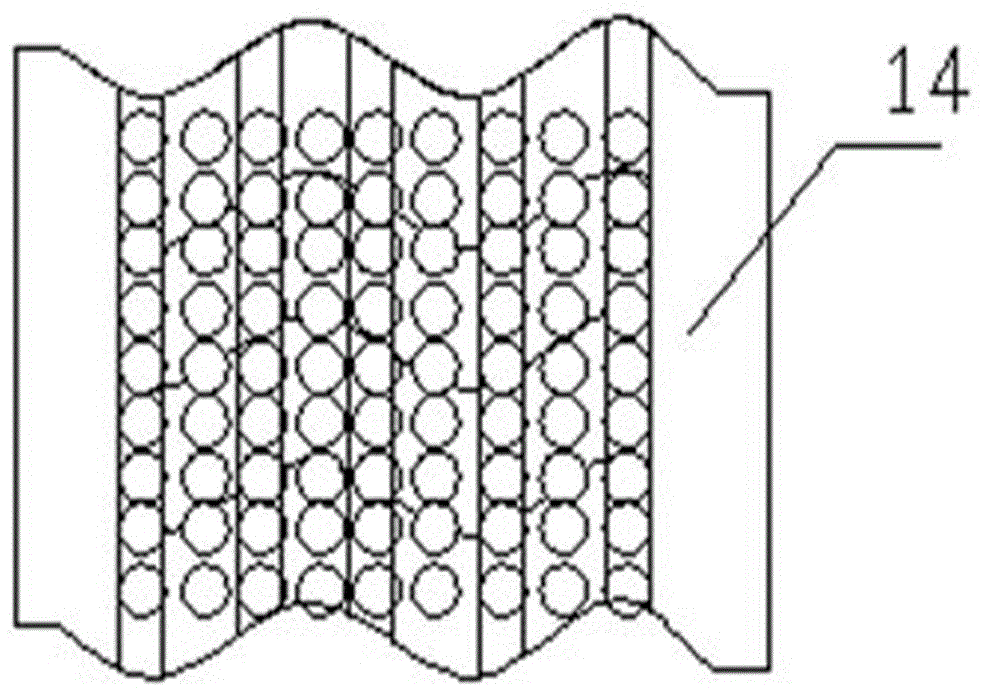

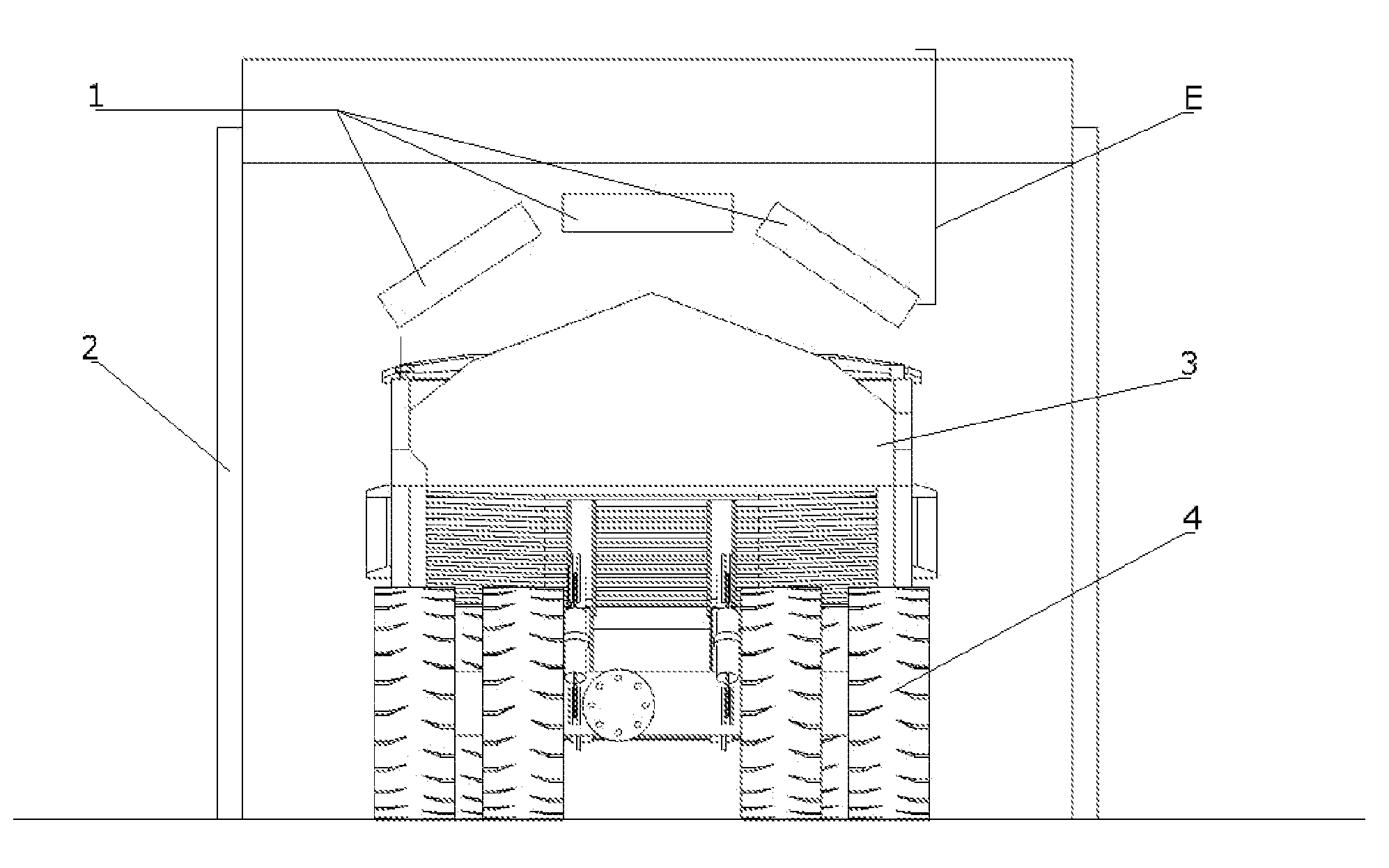

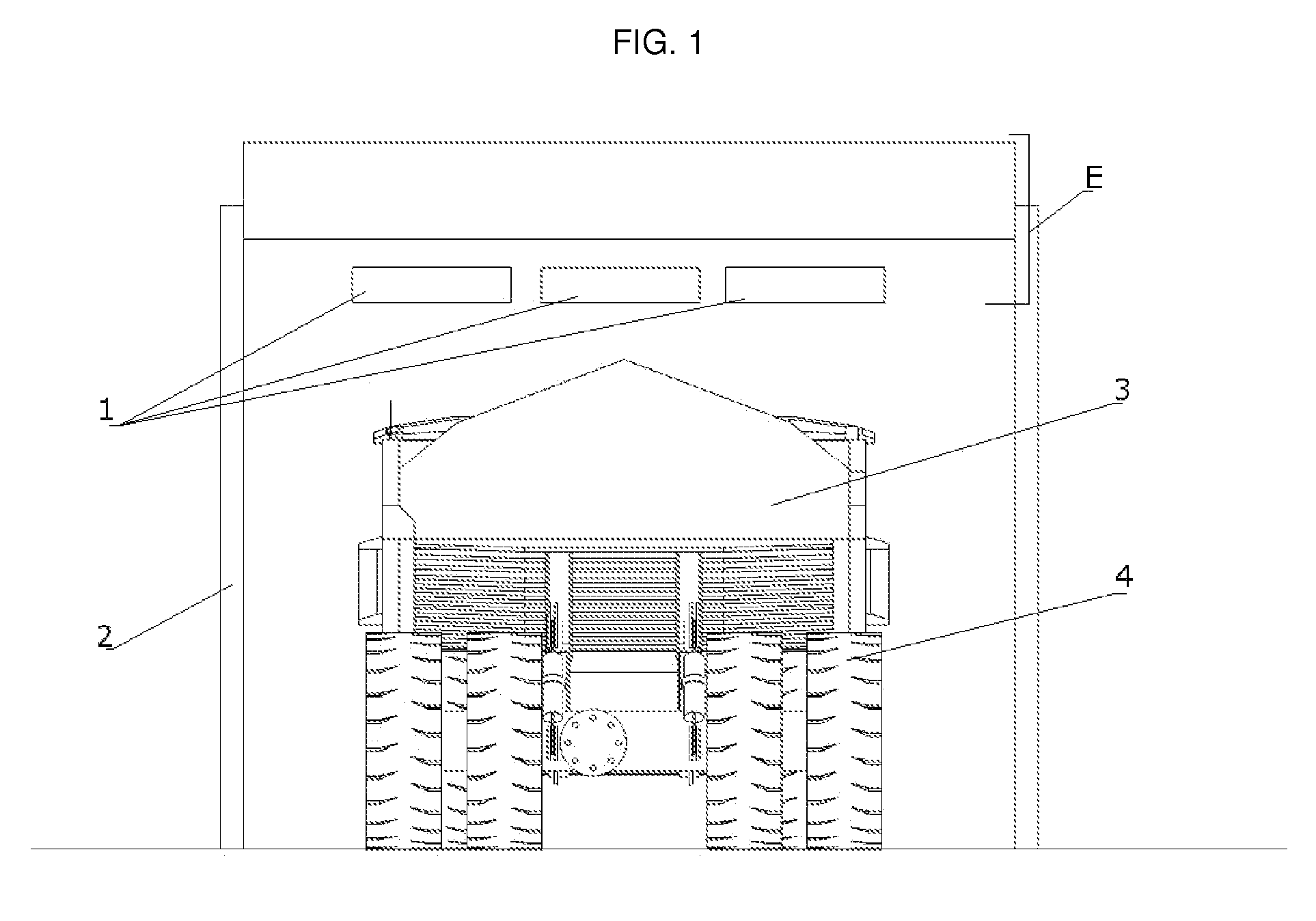

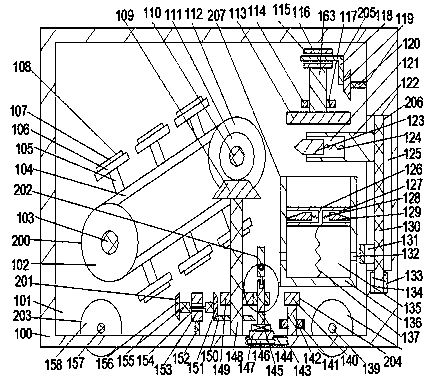

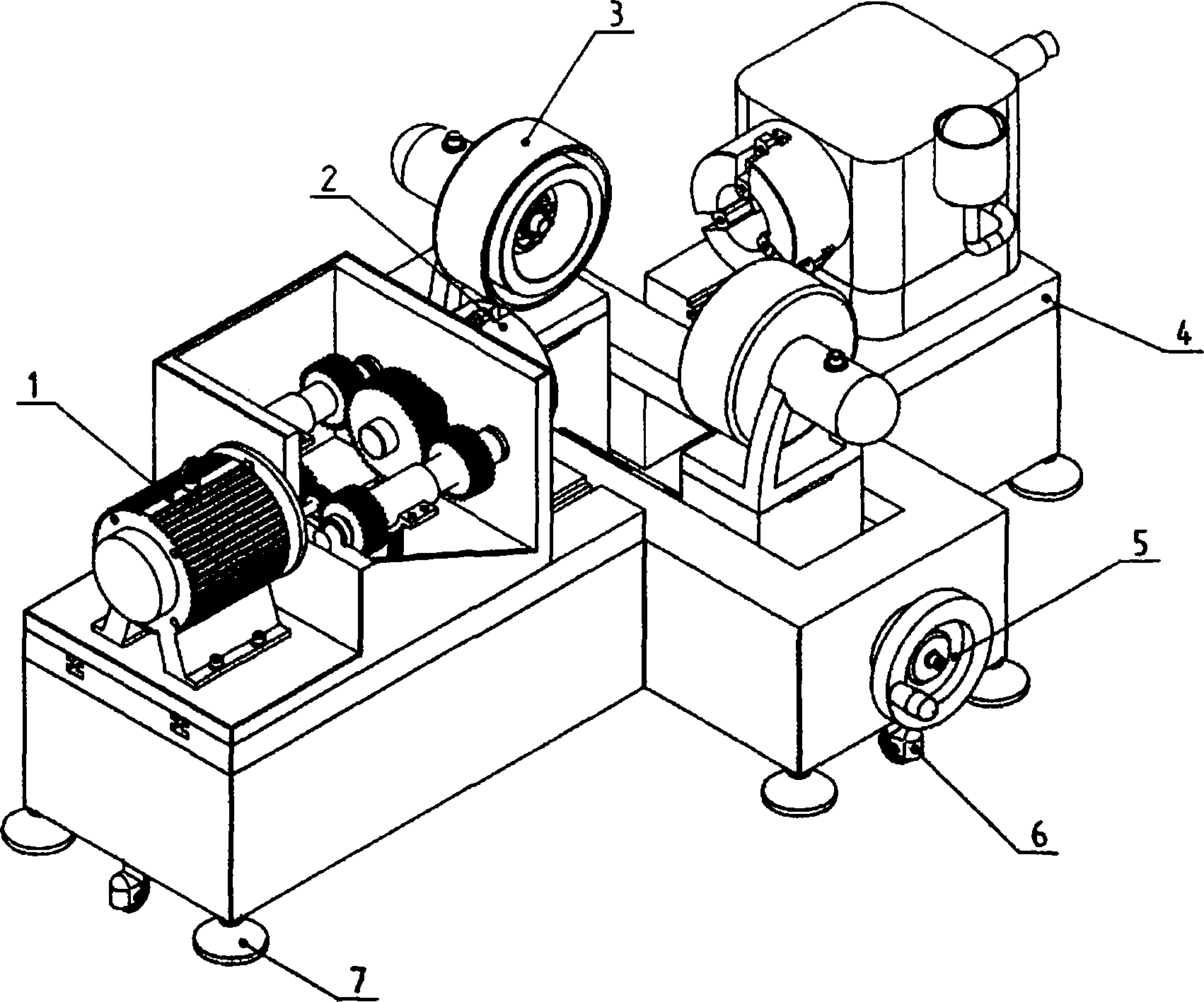

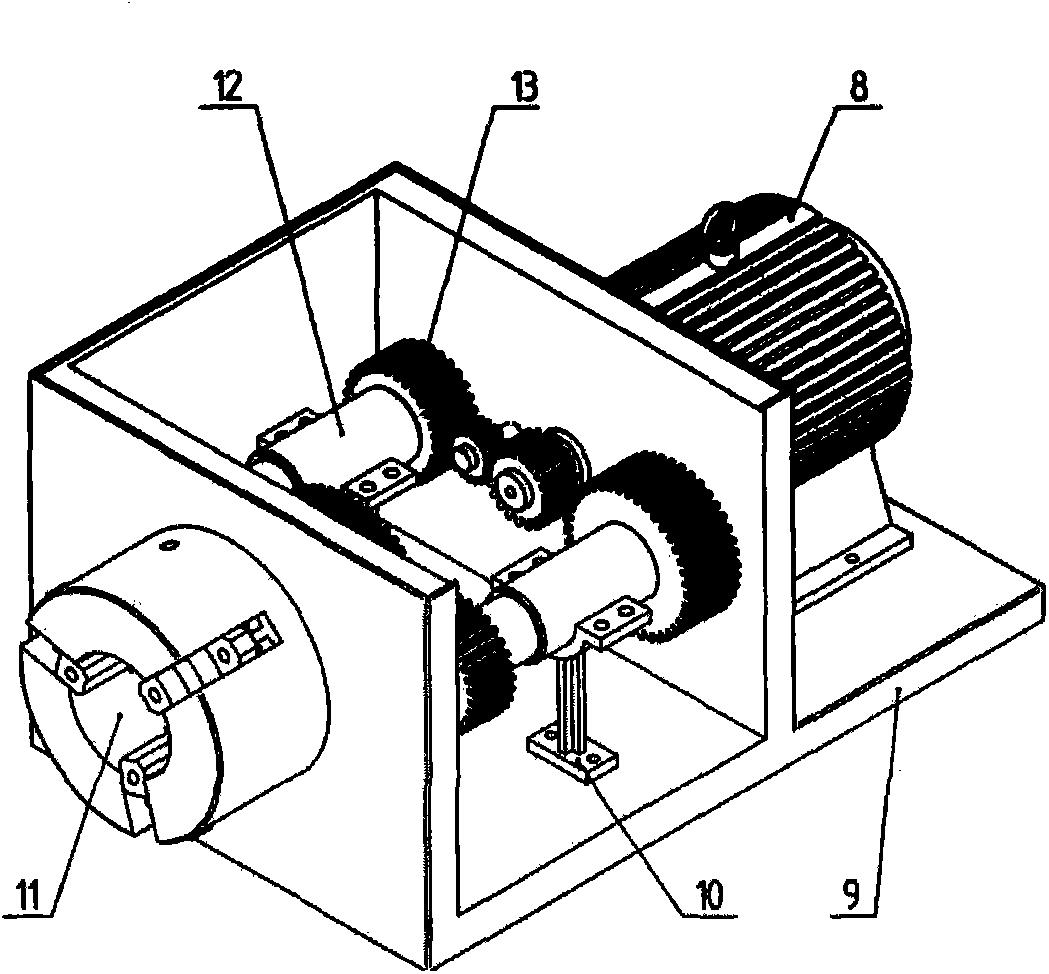

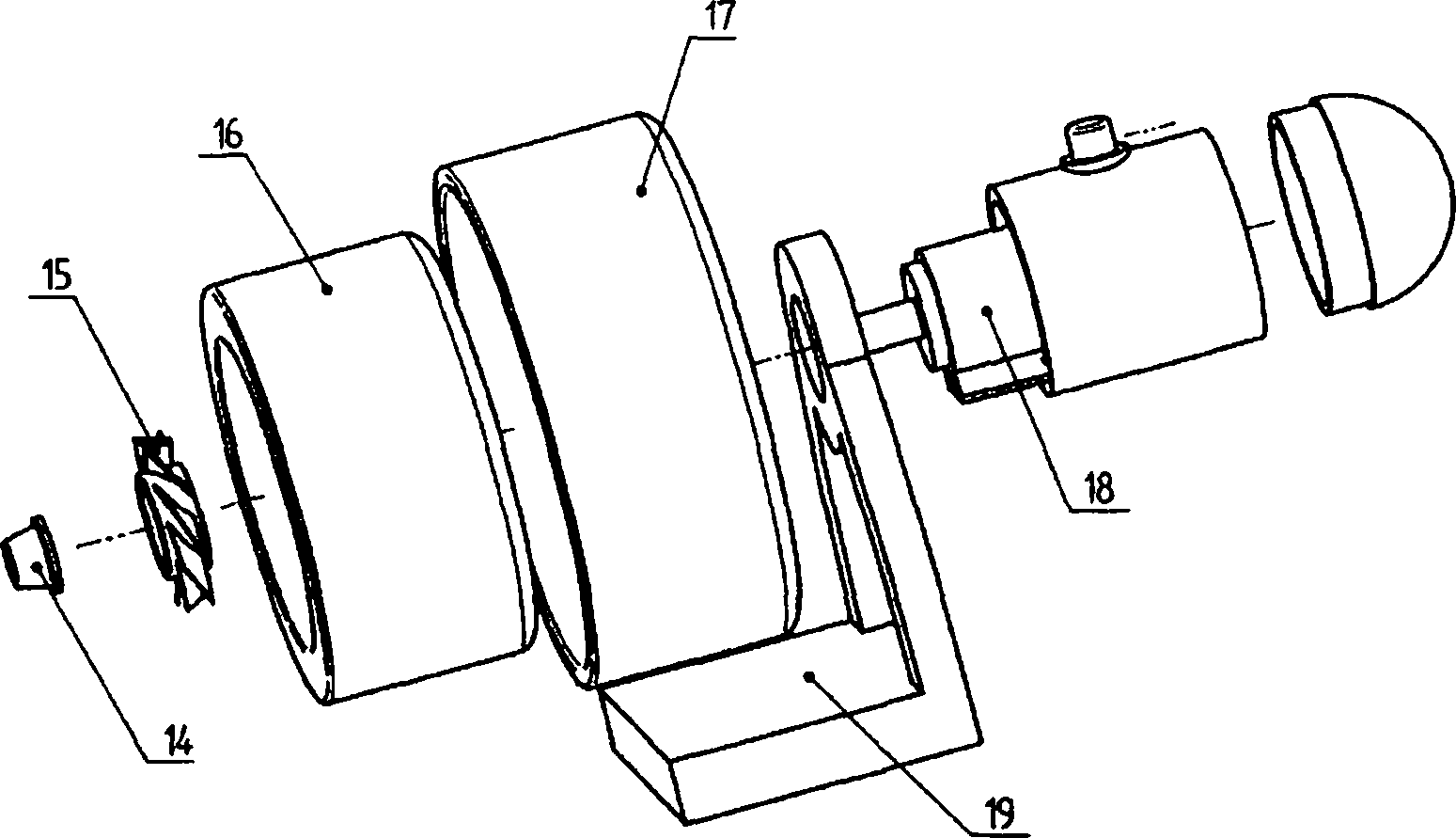

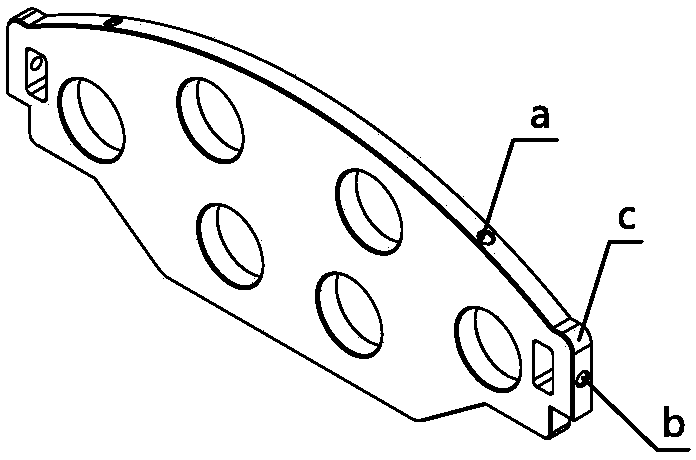

Large-diameter corn milling cutter grinding device

ActiveCN104029089AHigh precisionExtended service lifeMilling cuttersGrinding work supportsMilling cutterMetal debris

The invention provides a large-diameter corn milling cutter grinding device and belongs to the technical field of wood material cutting and processing. The device comprises a power mechanism, a clamping mechanism, a cutter grinding mechanism, an assistant guide mechanism, a distance adjusting mechanism, universal wheels and a fixed supporting mechanism. The total size of the device equals to 1600*10000*674mm, linear movement within two degrees of freedom in a plane can be implemented, the diameter Phi of adaptive cutters ranges from 50 to 500mm, and the length of the adaptive cutters ranges from 0 to 800mm. The cutter grinding device comprises two diamond coated grinding wheels, a magnetic motor is arrange in the cutter grinding device body, and the tail ends of blades are provided with hook-type collecting tanks to collect metal debris produced during cutting grinding. The device comprises three motors, one large motor is directly connected to a gearbox, and two small motors are directly connected to the grinding wheels. The assistant guide mechanism comprises a lighting device, a changeable independent drill bit and a clamping device. The fixed supporting mechanism allows the cutter grinding device body to be in movable and fixed states. The device is capable of implementing cutting grinding process of large-diameter corn milling cutters and has the advantages of wide adjustable range, low powder contamination and high efficiency.

Owner:BEIJING FORESTRY UNIVERSITY

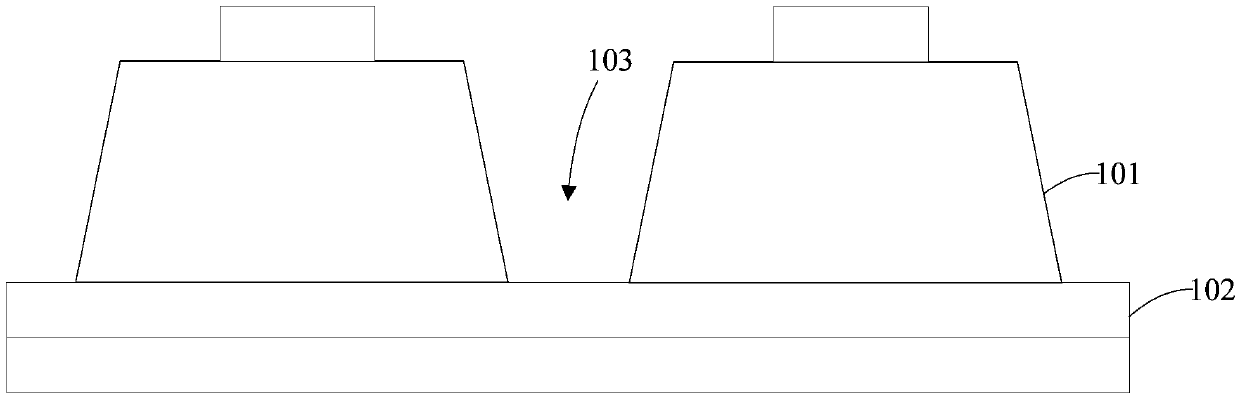

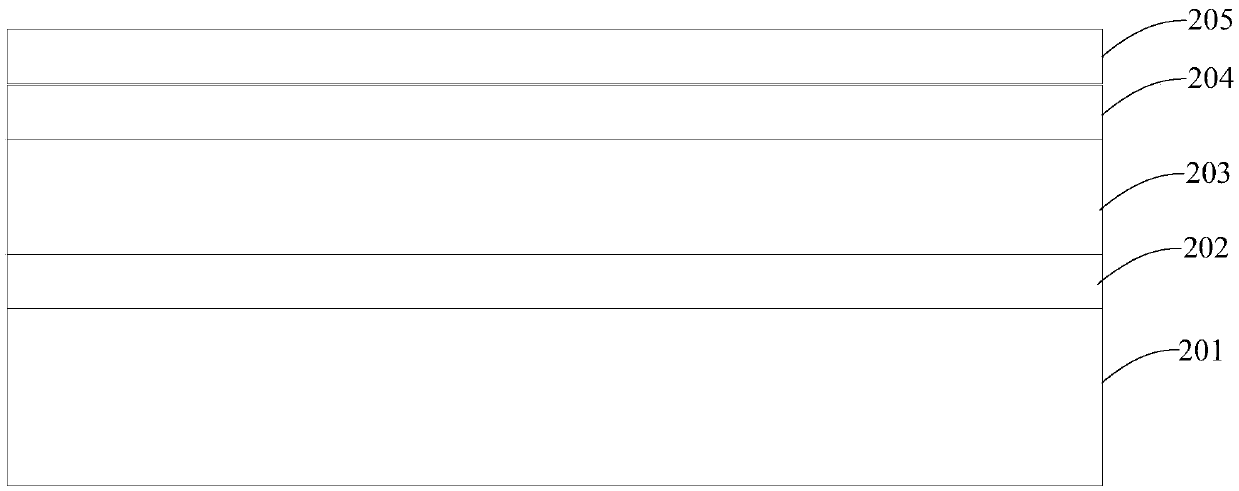

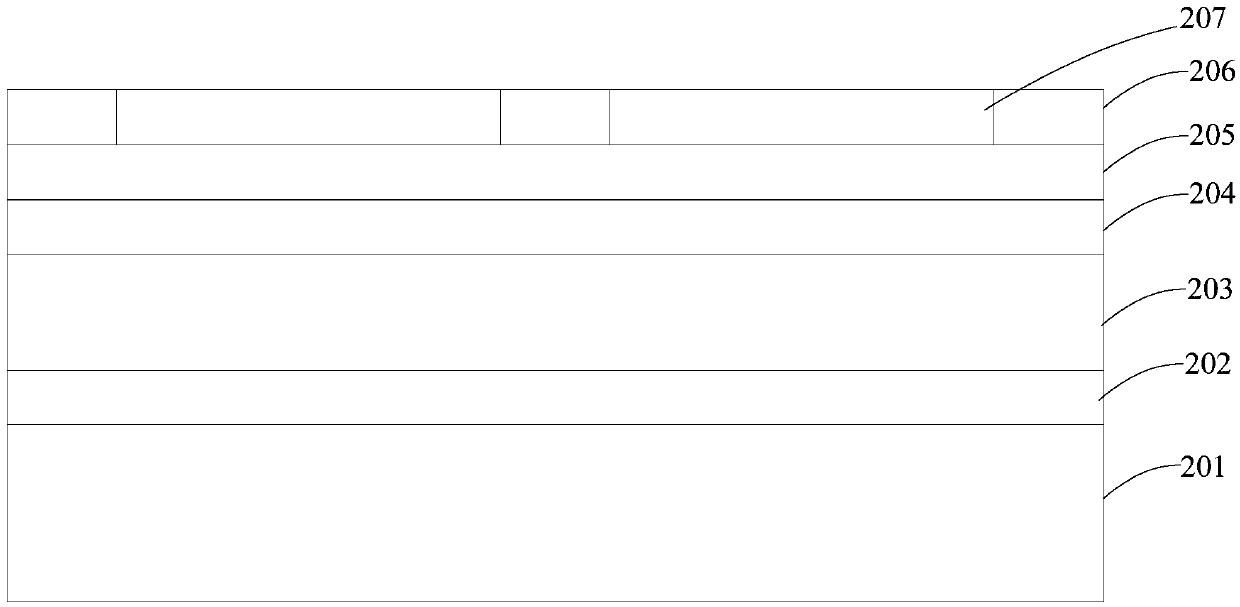

GaN-base LED vertical chip structure and manufacture method thereof

The invention provides a GaN-base LED vertical chip structure and a manufacture method thereof. This structure comprises a bonding substrate; an etching barrier layer connected to the surface of the bonding substrate in correspondence with a cutting channel area; a P electrode bonded to the bonding substrate; a luminescent epitaxial structure connected to the P electrode and comprising a P-GaN layer, a quantum well layer and an N-GaN layer stacked in succession, wherein the luminescent epitaxial structure is divided by the cutting channel area into luminescent epitaxial top structures; and an N electrode formed on the surface of the N-GaN layer. The invention discloses a device structure enabling an improvement in vertical chip reliability and a manufacture method thereof, a SiO2 etching barrier layer is grown on the cutting channel area, thereby solving the problem that when ICP deep etching is used on an MESA top after peeling, metal debris spatters from the cutting channel area to the sidewall of a chip, causing electric leakage. The device structure is finished just by photo-etching using a single negative photoresist, the manufacture process is simple, the cost is low, and the device structure is suitable for batch production.

Owner:ENRAYTEK OPTOELECTRONICS

Superfinishing Large Planetary Gear Systems

InactiveUS20080108470A1Reduces and eliminates lubricant debrisEdge grinding machinesPolishing machinesEngineeringSuperfinishing

Disclosed herein is a new improved large planetary gear system used on the input stage of wind turbine power generators. This improved planetary gear system reduces or eliminates lubricant debris traditionally generated from the gear teeth, thereby eliminating an initiating source for bearing failure. To achieve these results, some and preferably all of the gear teeth within the planetary gear system are superfinished using chemically accelerated vibratory finishing to a surface roughness of approximately 0.25 micron or less. Several objects and advantages of the invention are to provide a gearbox with reduced metal debris, improved bearing life, reduced wear, reduced vibro-frictional noise, improved contact fatigue, improved fretting resistance, improved lubrication, to simplify the run-in process, and to enhance the durability and efficiency of the gearbox.

Owner:REM TECHNOLOGY INC

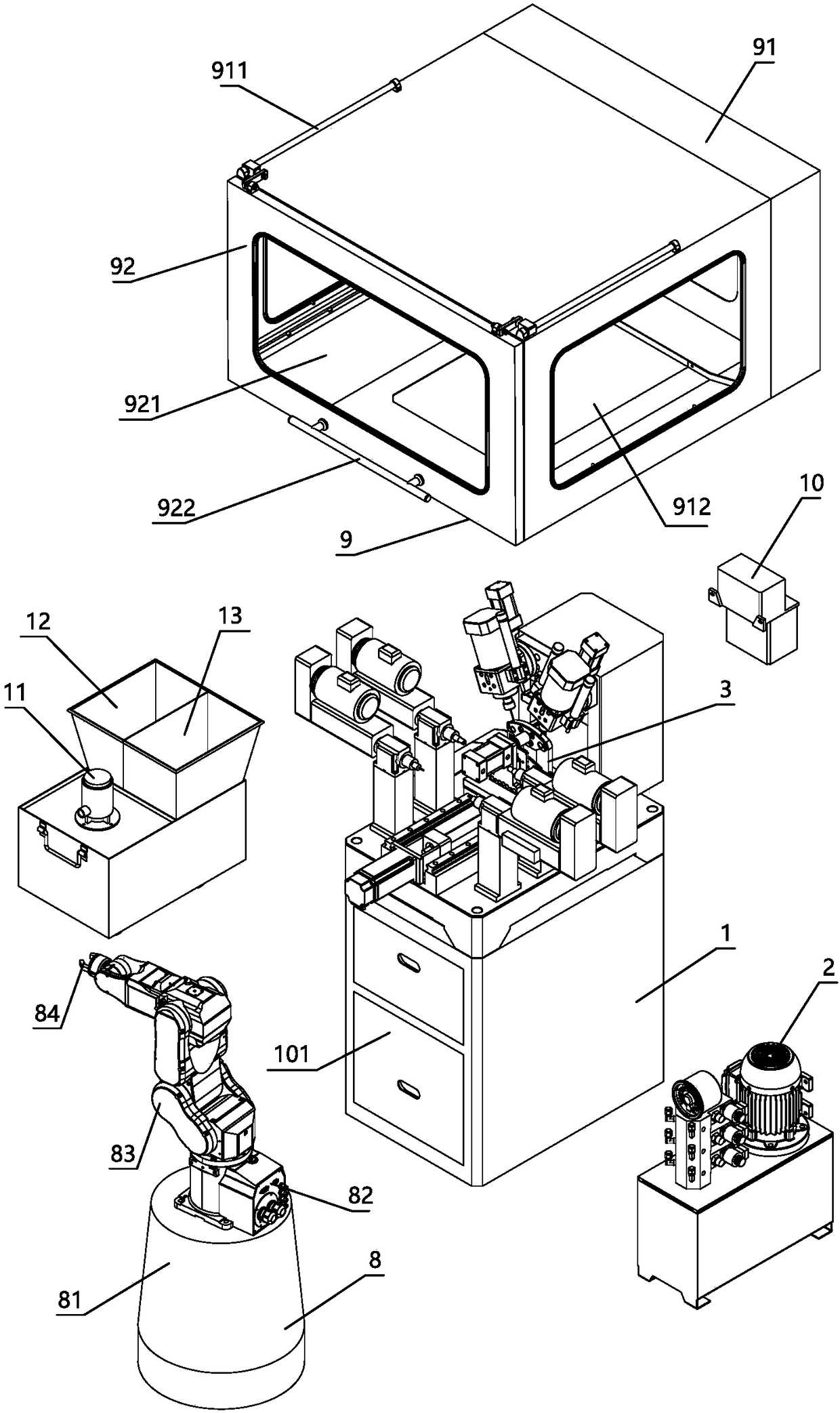

Full-automatic metal working machine

InactiveCN108381180AEasy to recyclePrevent flying outOther manufacturing equipments/toolsMetal working apparatusMechanical equipmentEngineering

The invention relates to the field of mechanical equipment. A full-automatic metal working machine comprises a machine frame, a protective cover device, a lubrication device, a hydraulic device, a controller, a cooling device, a working device, a machining debris recovery device and a manipulator device. The working device, the machining debris recovery device, the recovery device and the protective cover device are mounted on the machine frame. The working device is covered with the protective cover device. The controller controls the hydraulic device and the working device to act. The working device comprises a clamp mechanism, a drilling mechanism, a tapping mechanism and a chamfering mechanism. The full-automatic metal working machine has the advantages that feeding, discharging, double-hole drilling, double-hole tapping and double-edge chamfering of a workpiece can be automatically completed, the protective cover device can effectively prevent metal debris from flying out of equipment in the working process, and the machining debris recovery device can conveniently recover metal debris.

Owner:杭州显庆科技有限公司

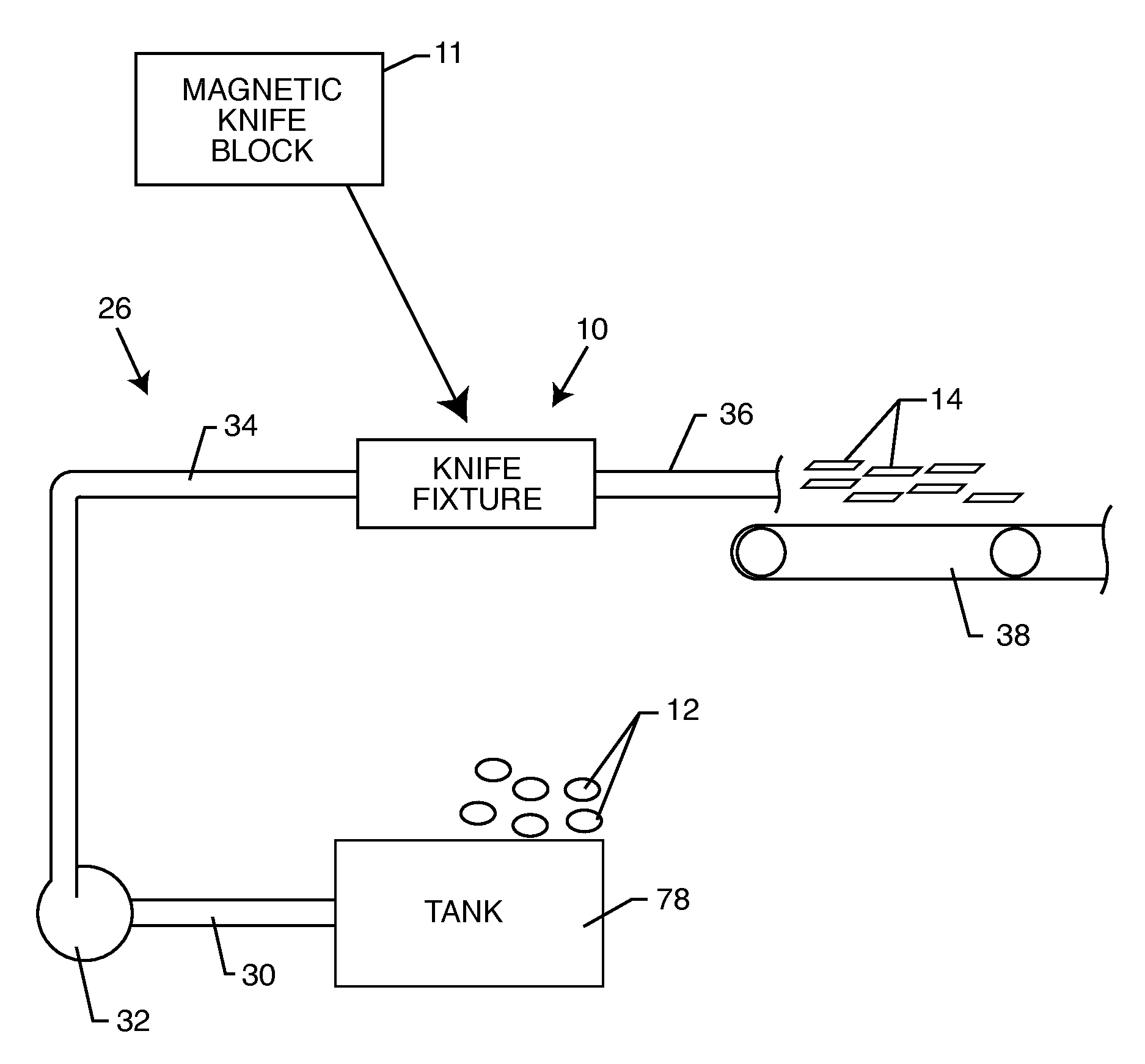

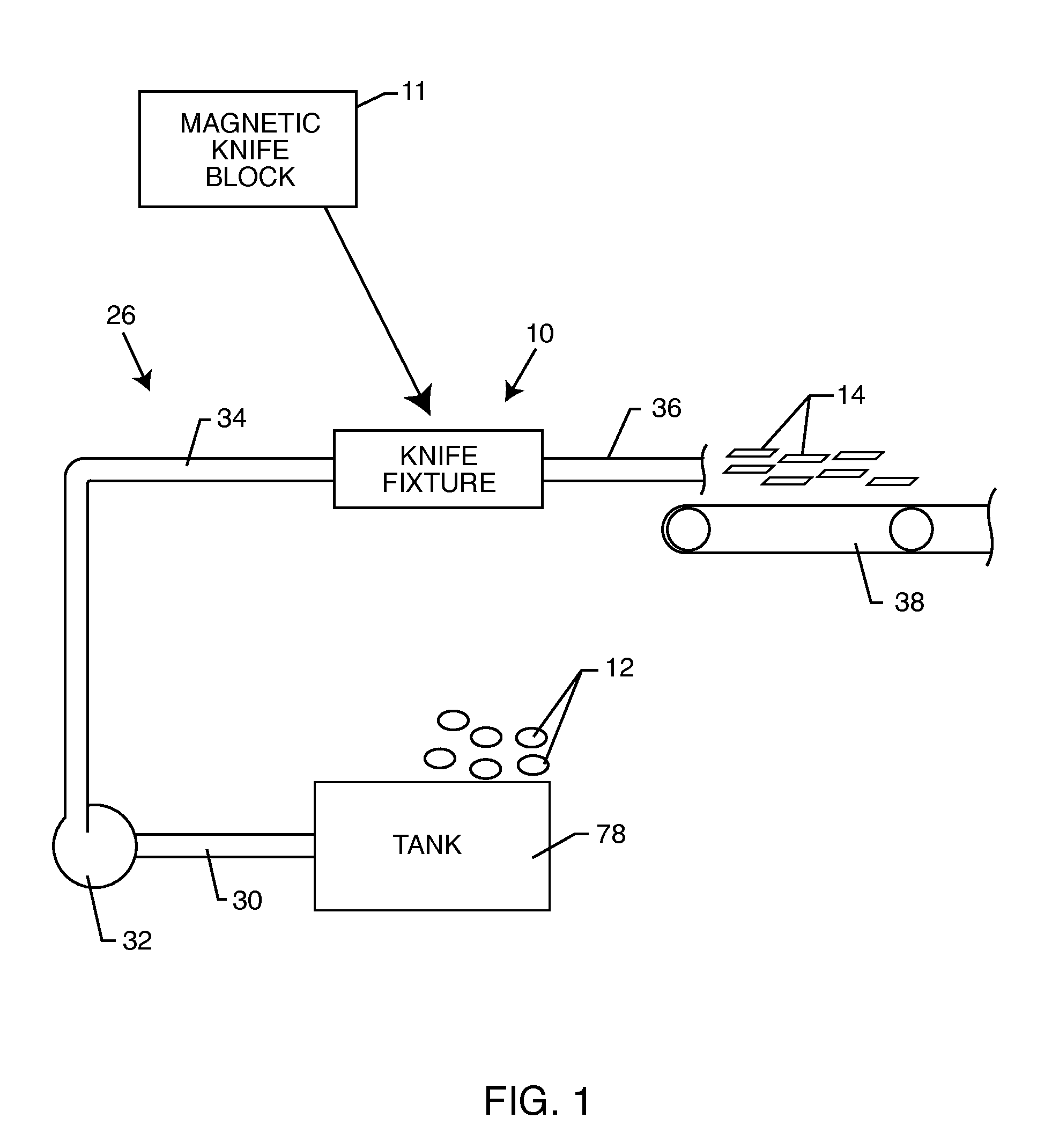

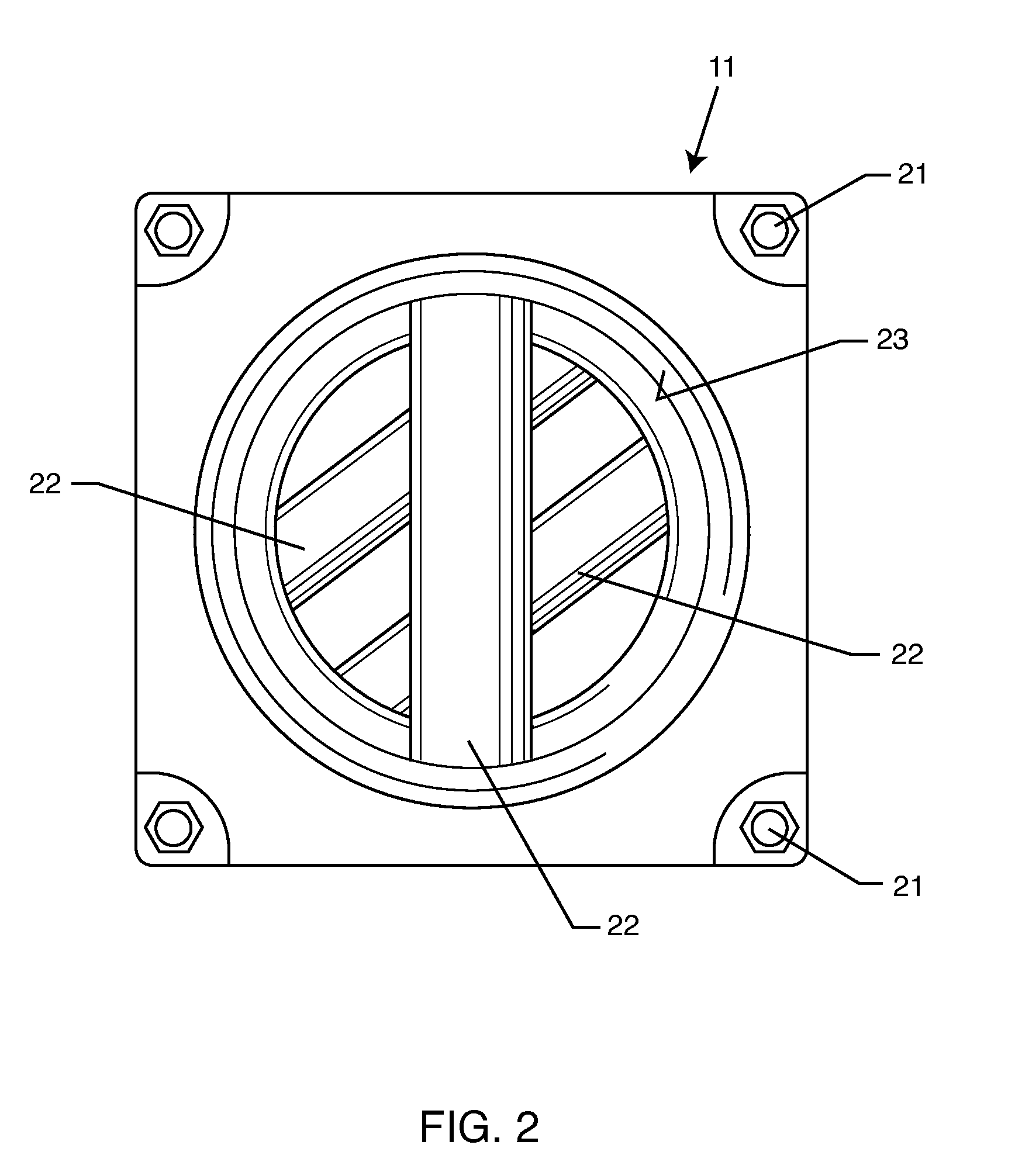

Magnetic block for a water knife

InactiveUS20110023729A1Quickly and easily removableFruit stoningWater/sewage treatment by magnetic/electric fieldsWater flowMetal debris

A magnetic knife block is provided for temporary installation along a hydraulic flow conduit of a cutting system, in lieu of a conventional hydraulic water knife fixture, for collecting metal debris attributable to construction and / or maintenance activity. The magnetic knife block includes at least one and preferably multiple magnets for collecting metal debris upon initial water flow through the cutting system. The magnetic water knife block is then removable from the hydraulic flow conduit and replaced by the conventional water knife fixture for normal cutting operation, such as cutting a succession of raw potatoes into elongated French fry strips.

Owner:J R SIMPLOT

Cutting processing machine and processing method for valve body casting pouring openings

The invention is a cutting processing machine and processing method for valve body casting pouring openings. The cutting processing machine comprises a bottom plate and a fixing device arranged on thetop of the bottom plate, wherein the center of the bottom plate is symmetrically provided with alignment devices, and the top of the bottom plate is also provided with a cutting device. The inventionuses the alignment devices to adjust the position of the valve body to make the valve body located at the center of the fixing device, and uses a bidirectional motor to drive a bidirectional screw tomake two sets of fixing plugs approach at the same time until the fixing plugs are inserted into the valve body, so that the valve body is fixed and stably placed, and the cutting incision is flat. The invention drives two sets of ring cutters through a set of motors at the same time to cut the two pouring openings at the same time to ensure that the remaining lengths of the pouring openings after the cutting are the same, provides a protective cover outside the ring cutters to prevent metal debris from splashing into the eyes of the operator, and provides a support plate on the top of the support rods to assist to support the valve body, thereby preventing the connecting rods from deforming due to excessive pressure when the pouring openings are cut from top to bottom.

Owner:湖南森革精密机械有限公司

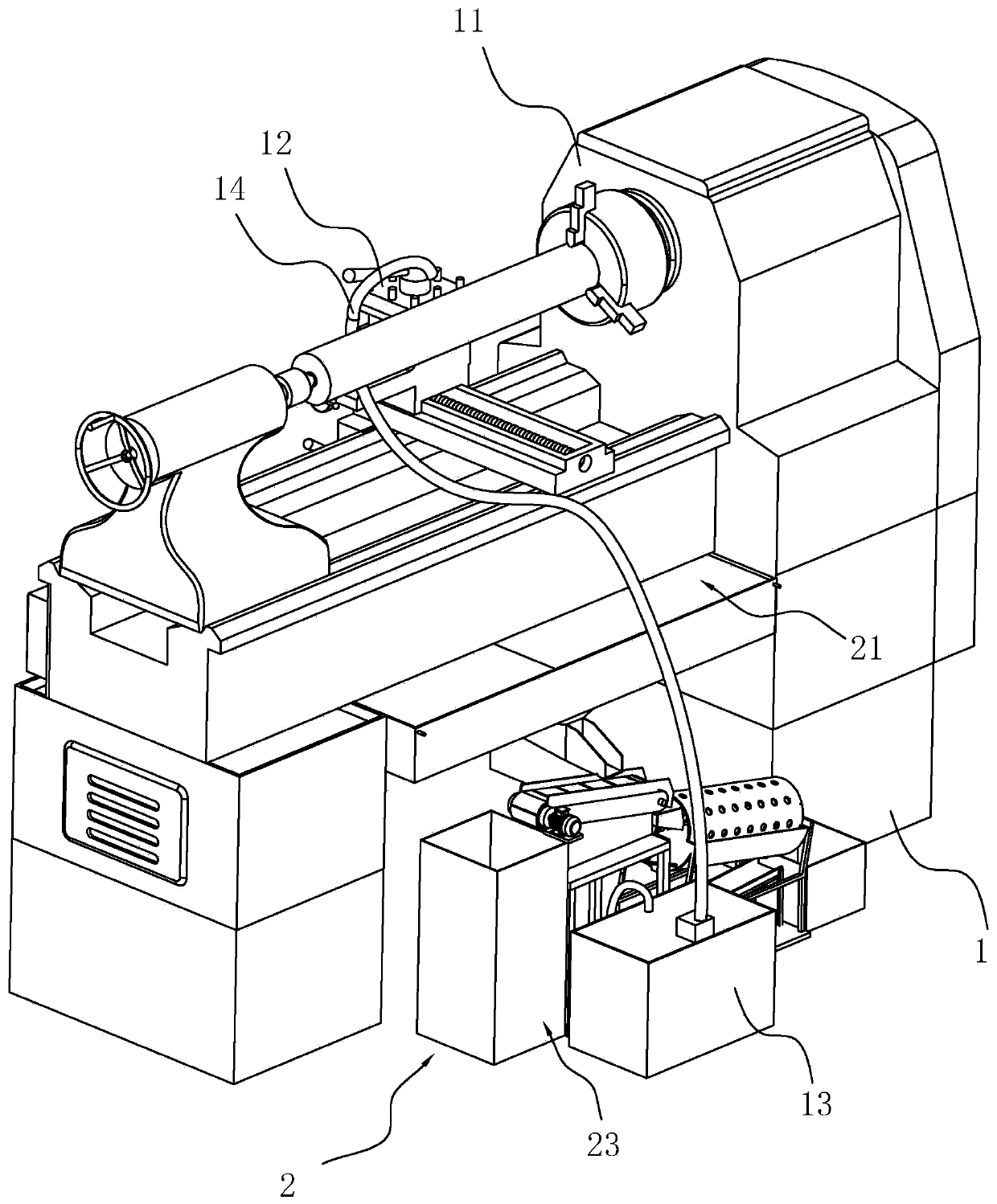

Lathe with coolant recovery device

ActiveCN110732690ADoes not affect the cooling effectAuxillary equipmentMaintainance and safety accessoriesCooling effectStructural engineering

The invention discloses a lathe with a coolant recovery device, and belongs to the technical field of lathes. The lathe includes a rack, and one side of the rack is provided with a recovery device forrecovery and reuse of a coolant; the recovery device includes a collection mechanism and a filtration mechanism located on one side of the rack; the collection mechanism includes two first guide plates and two second guide plates hinged to the bottom of the rack, the bottoms, located at the joints of the first guide plates and the second guide plates, of the rack are provided with collection grooves, and the bottoms, located on the second guide plates, of the rack are fixedly provided with power assemblies for driving the second guide plates to overturn around the hinge points between the rack and the second guide plates; and the filtration mechanism includes a primary filtration assembly and a secondary filtration assembly for respectively conducting primary filtration and secondary filtration on metal debris and the coolant in the coolant, a sedimentation basin is connected to the secondary filtration assembly, and the sedimentation basin is connected with an accommodating box. Thelathe has the effects of collecting, filtering and reusing the coolant without affecting the cooling effect of the coolant.

Owner:杭州铭锻机床有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com