Efficient numerical-control saw cutting machining machine tool for aluminum metal plates

A technology for processing machine tools and aluminum metal, which is applied in the field of high-efficiency CNC sawing machine tools for aluminum metal sheets, and can solve problems such as inability to remove built-up edge, low degree of automation, and restrictions on enterprise development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

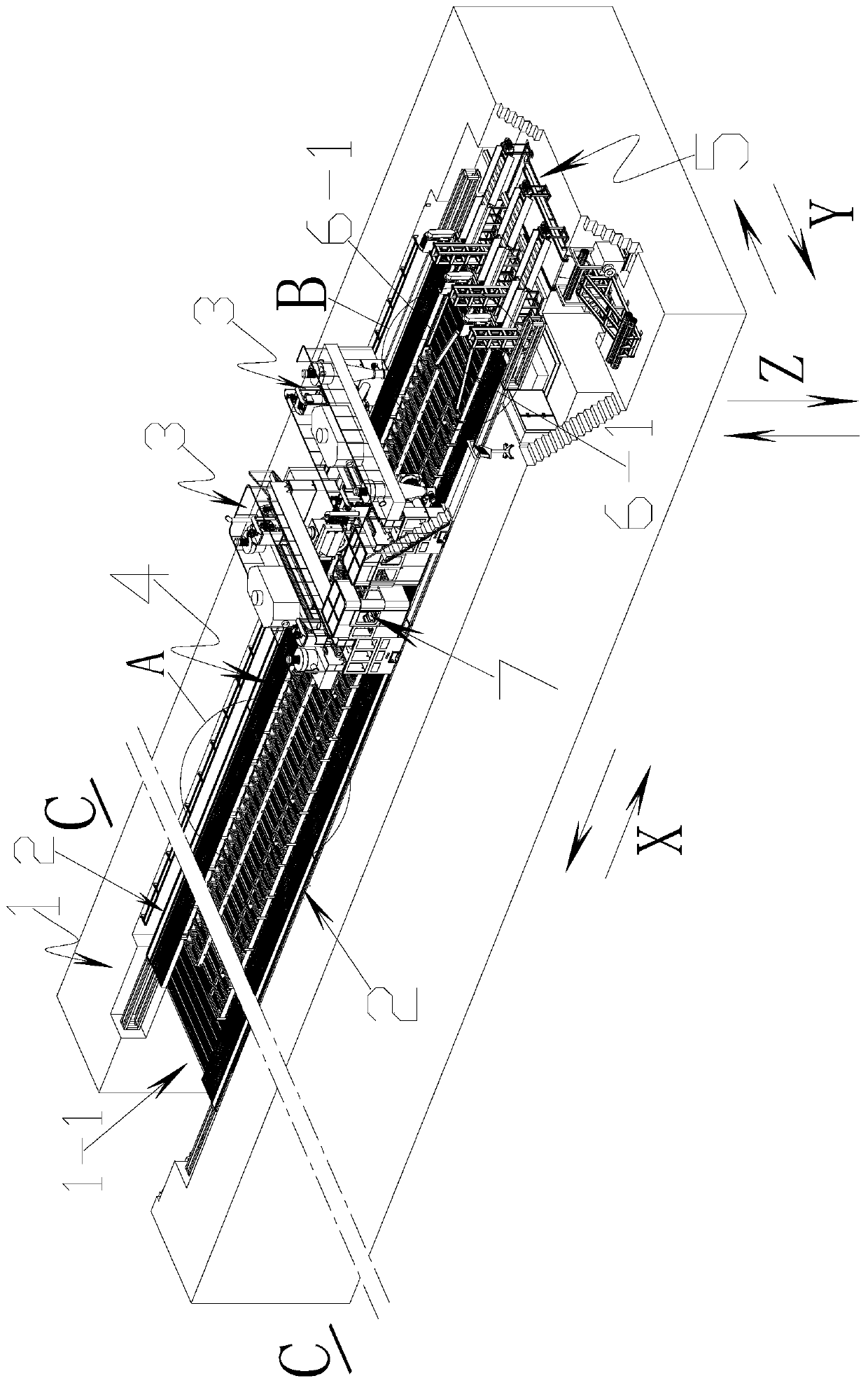

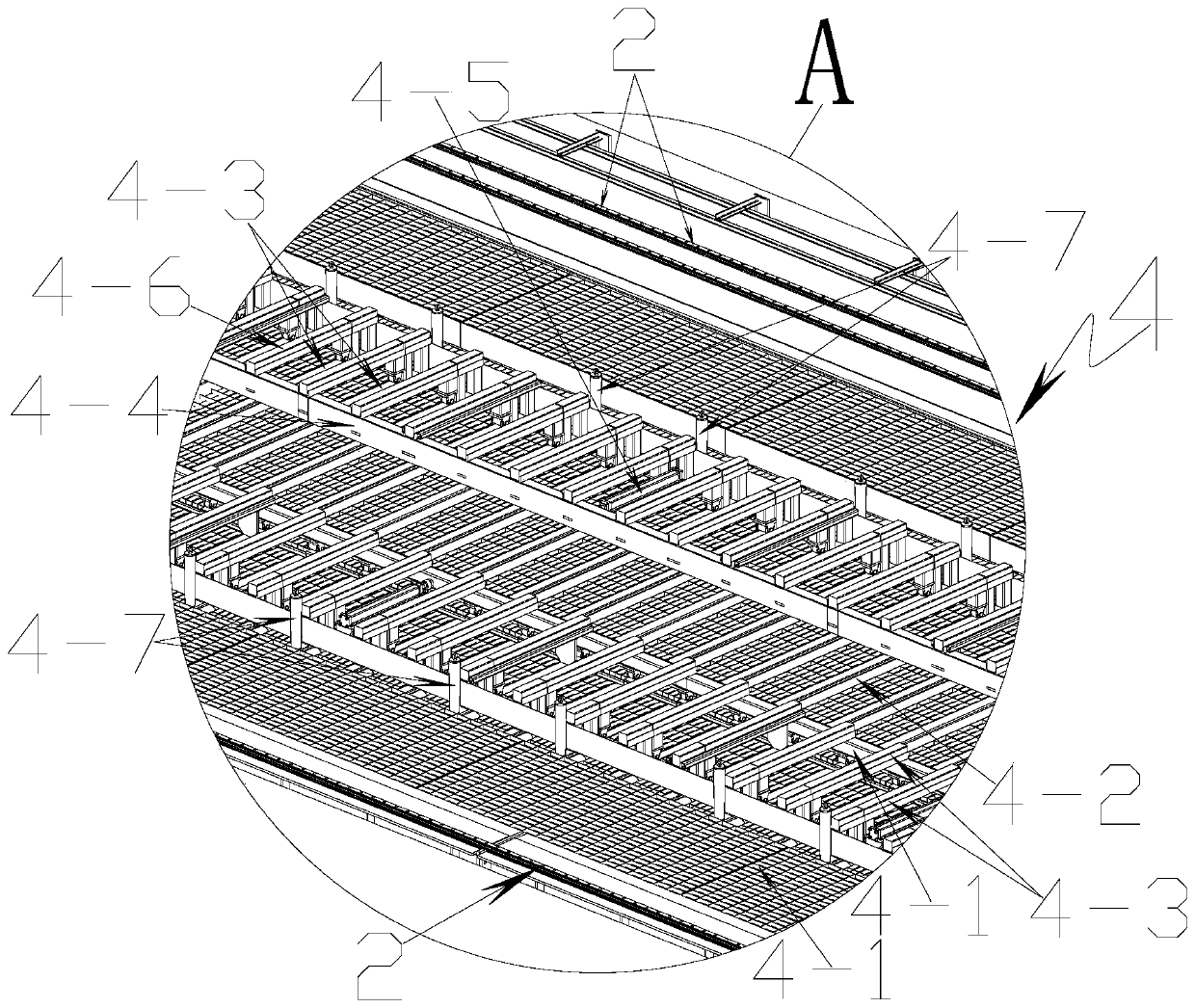

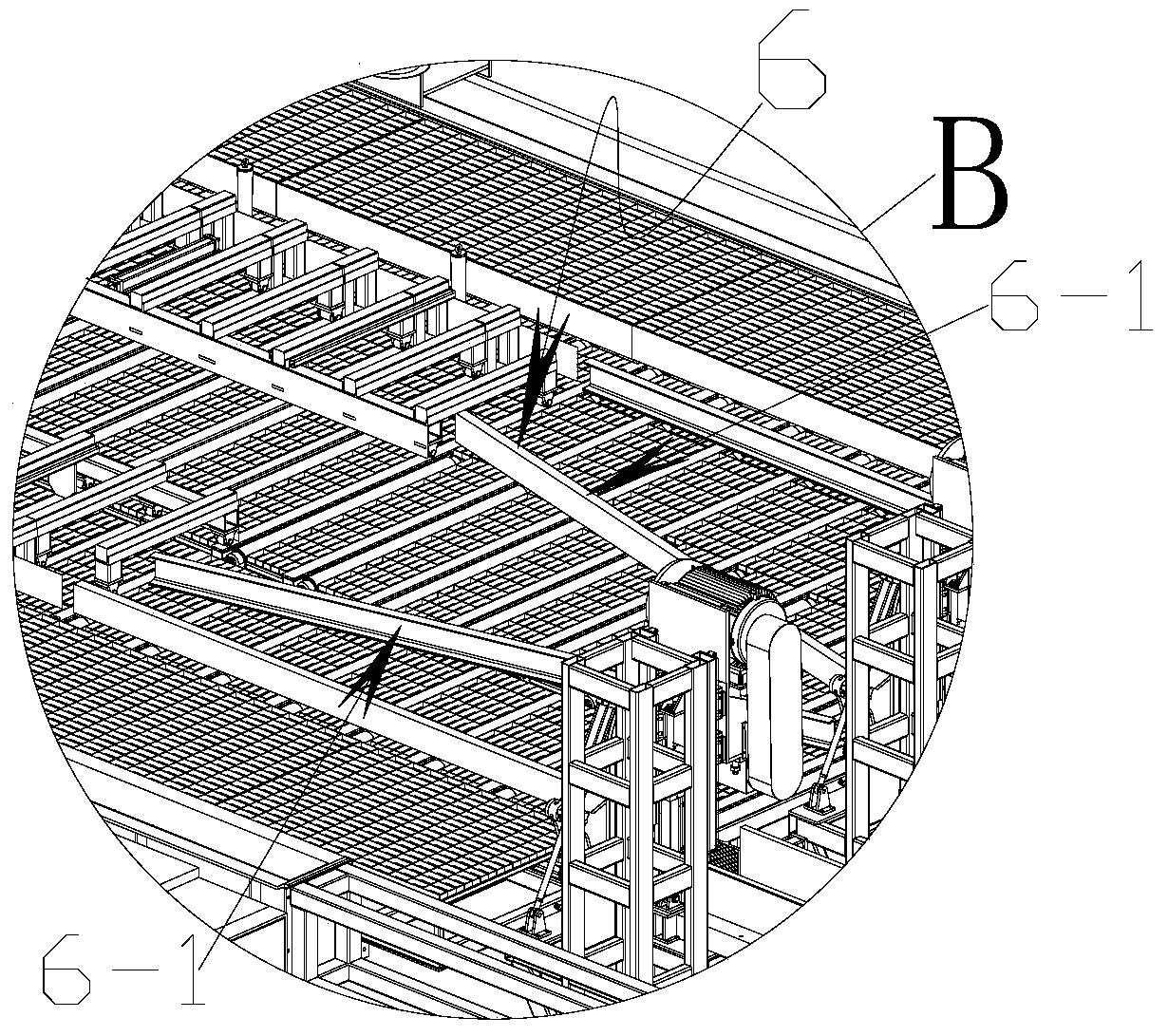

[0044] The present invention will be further described below in conjunction with accompanying drawing:

[0045]Referring to the accompanying drawings: This high-efficiency CNC sawing machine tool for aluminum metal plates includes a base 1, a foundation pit 1-1 is opened inside the base 1, slide rails 2 are fixed on both sides of the foundation pit 1-1, and on the base 1 There is a pair of aluminum plate gantry sawing device 3, the aluminum plate raw material placement and waste edge conveying device 4 is installed at the foundation pit 1-1, and the aluminum plate raw material placement and waste edge conveying device 4 is equipped with an aluminum plate installed at the base 1 Waste side length fixing and sawing and bundling device 5; aluminum plate gantry sawing device 3 includes a gantry body 3-1 that is slidably connected to the slide rail 2 and driven by a deceleration servo motor, and a pair of gantry body 3-1 is provided with The screw lifting and gear rotating power he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com