Mold framework and liquid crystal display device

A frame and outer frame technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as reduced service life, SR layer shedding of COF film, short circuit of data lines, etc., to improve life, reduce friction, and avoid shedding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Mold frame embodiment one

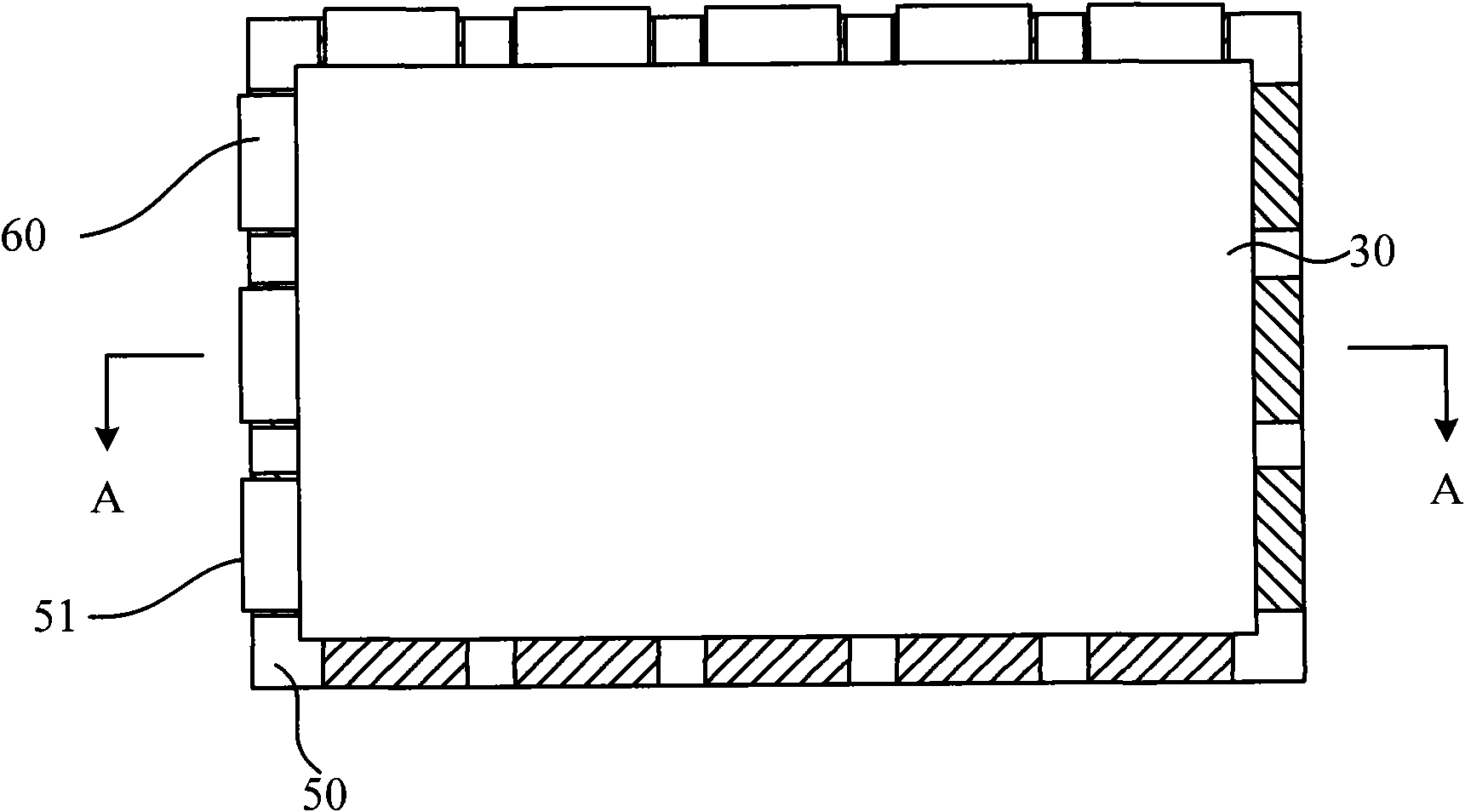

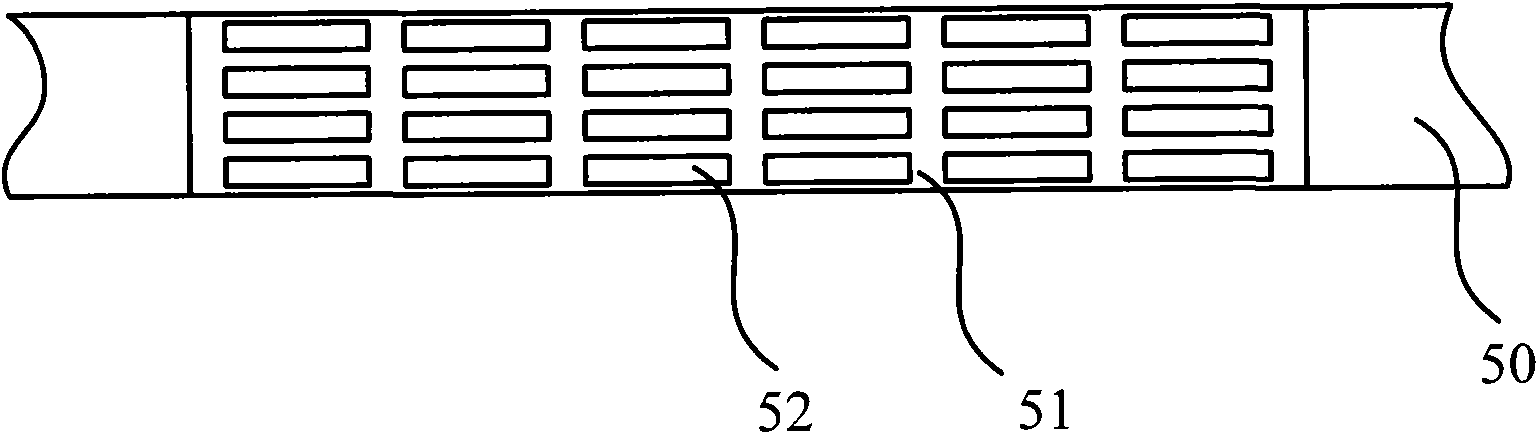

[0022] Such as image 3 Shown is a partial top view structure schematic diagram of a specific embodiment 1 of the mold frame of the present invention, and the mold frame 50 can be specifically applied to a liquid crystal display device to play a role of support and protection. The mold frame 50 is a rectangular frame, on which several notches 51 for accommodating the driving circuit of the liquid crystal display device are provided at intervals, and each notch 51 is provided with grooves 52 arranged in a matrix form, image 3 It is an enlarged schematic view of the structure of one of the notches 51 , and the cross-sectional shape of the notch 52 is a rectangle.

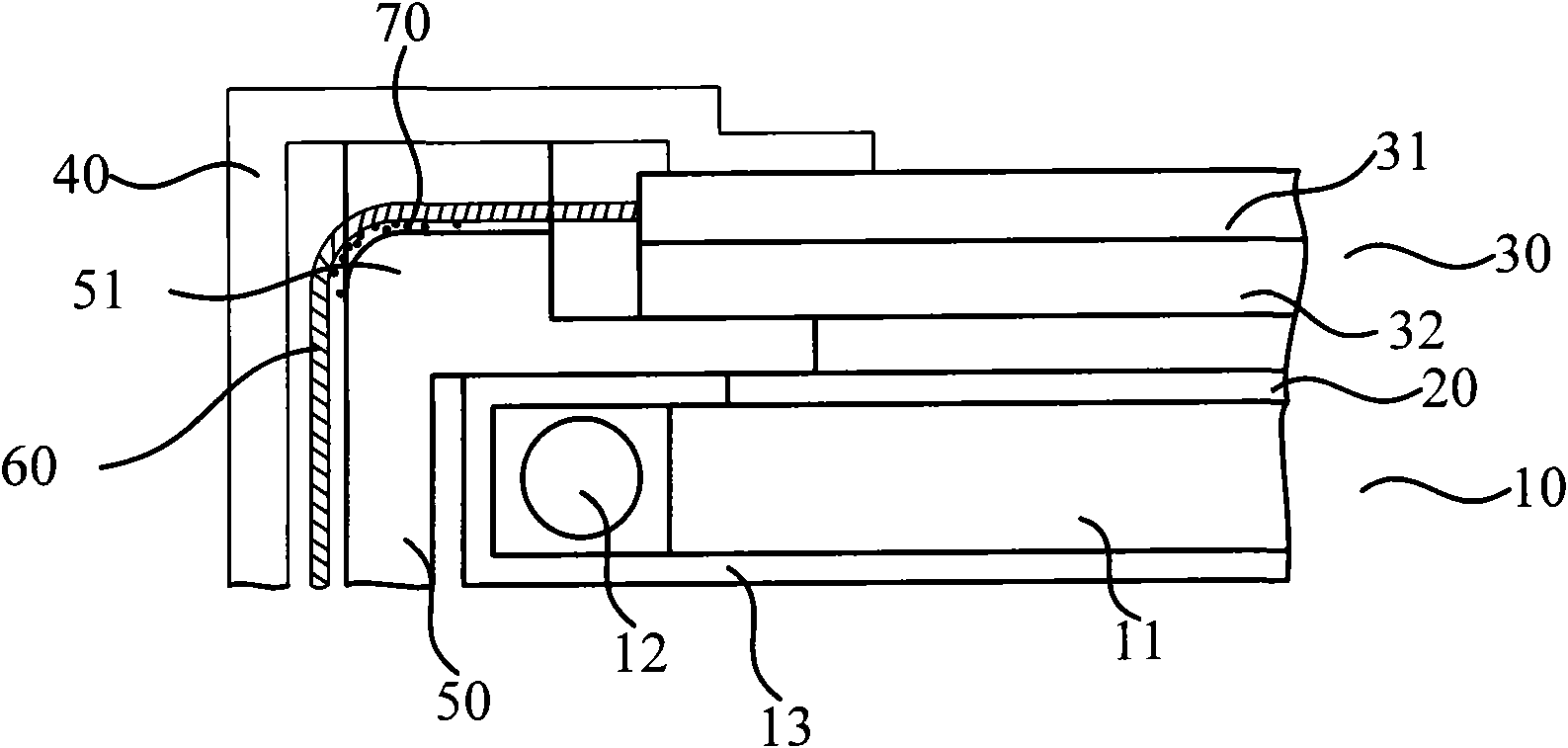

[0023] After the mold frame of this embodiment is placed into the liquid crystal display device, such as Figure 4 As shown, on the one hand, since the notch 51 is provided with a groove 52, the contact area between the data drive chip and the data line connection part (COF) and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com