Full-automatic metal working machine

A metal processing, fully automatic technology, applied in metal processing, metal processing mechanical parts, metal processing equipment and other directions, can solve the problems of easily affecting the environment, low processing accuracy, troublesome operation, etc., to improve the operating environment, high processing accuracy, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

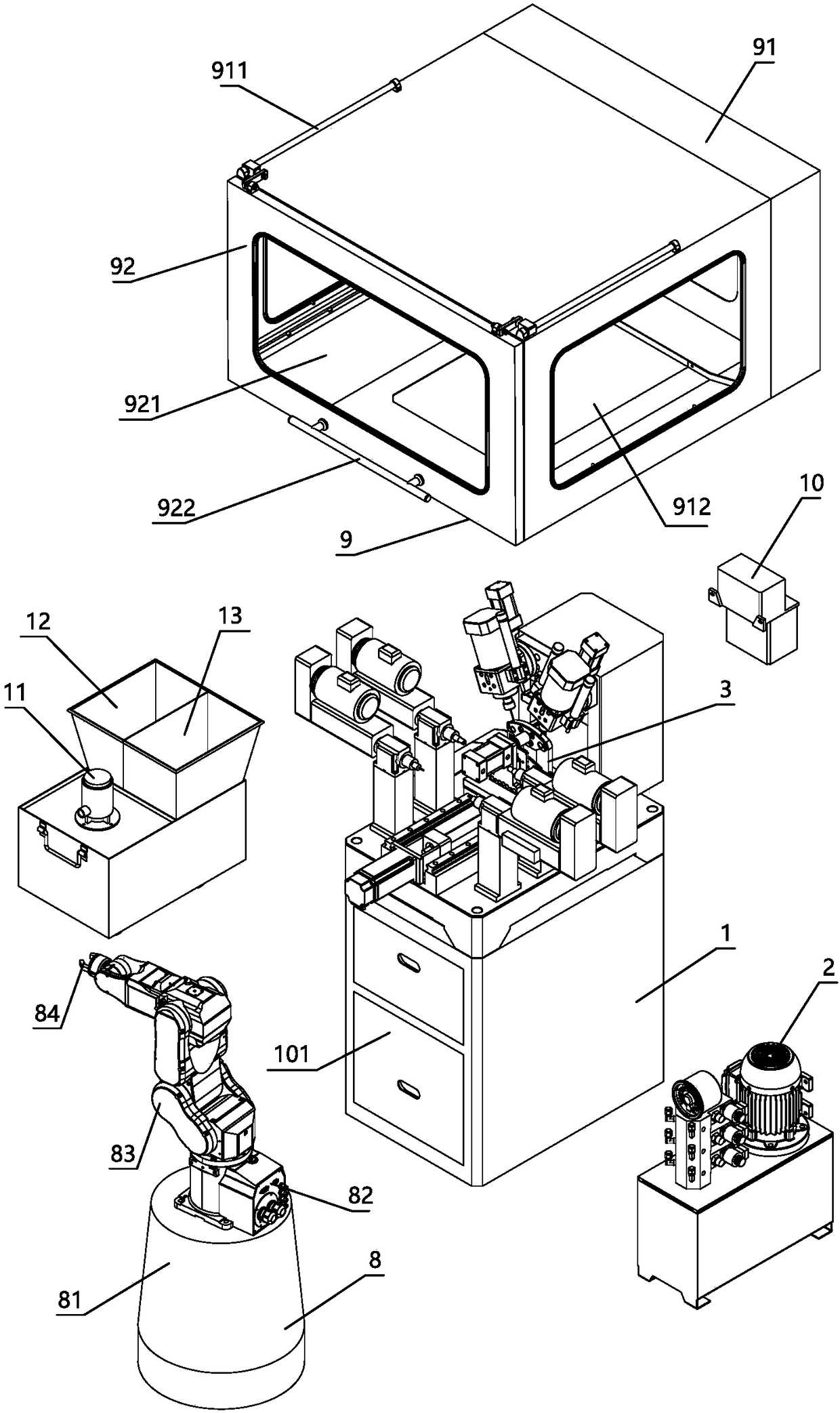

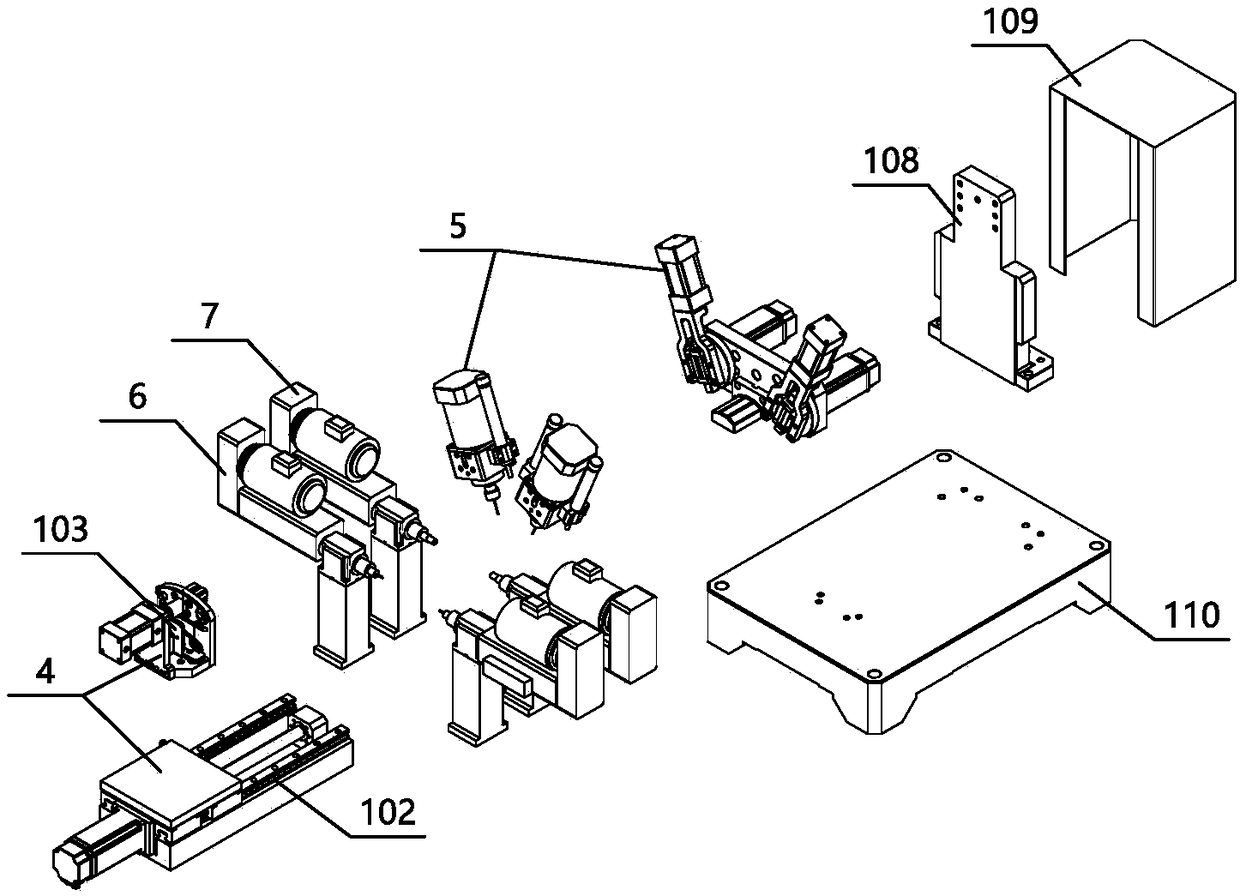

[0033] Attached below Figure 1-12 The present invention is further described.

[0034] Such as Figure 1-12 The shown fully automatic metal processing machine tool includes a frame 1, a shield device 9, a hydraulic device 2, a controller, a lubricating device 10, a cooling device 11, a processing device 3, a processing debris recovery device 15 and a manipulator device 8, processing The device 3, the processing debris recovery device 15 and the shield device 9 are installed on the frame 1, and the shield device 9 covers the processing device in it, and the hydraulic device 2, the cooling device 11, the processing device 3, the processing device are controlled by the controller. The debris recovery device 15 and the manipulator device 8 operate.

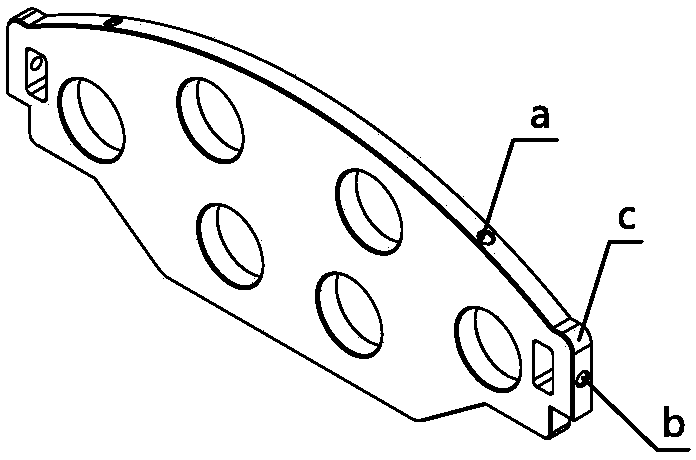

[0035] The processing device 3 includes a clamp mechanism 4 , a drilling mechanism 5 , a tapping mechanism 6 and a chamfering mechanism 7 . Frame 1 comprises frame main body 1011 and mounting plate 1012, and mounting plate 1012 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com