Cutting processing machine and processing method for valve body casting pouring openings

A processing machine and sprue technology, which is applied in the valve body casting sprue cutting processing machinery and processing field, can solve the problems of sprue notch unevenness, unequal size, and unstable placement of the valve body, so as to avoid deformation and place smoothly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

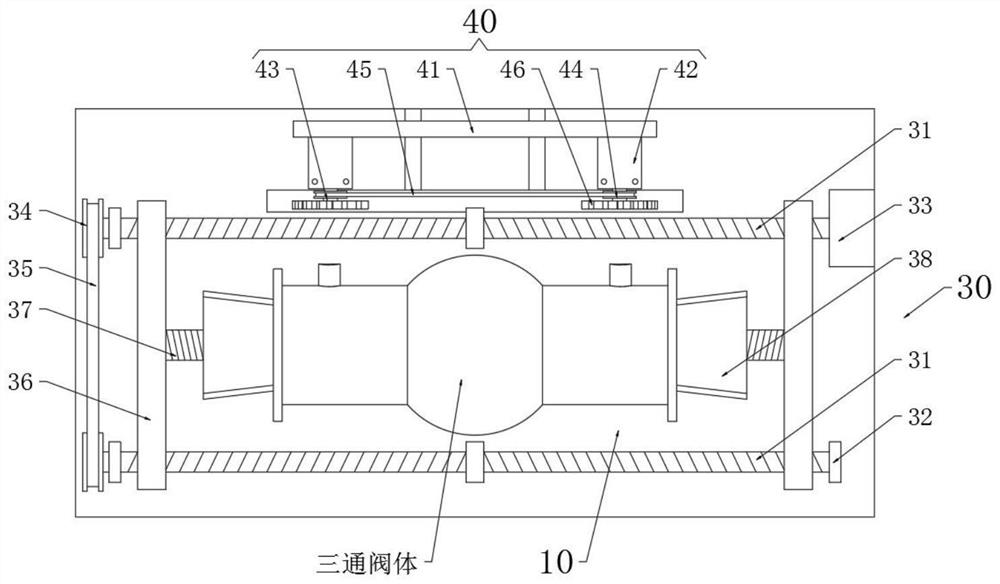

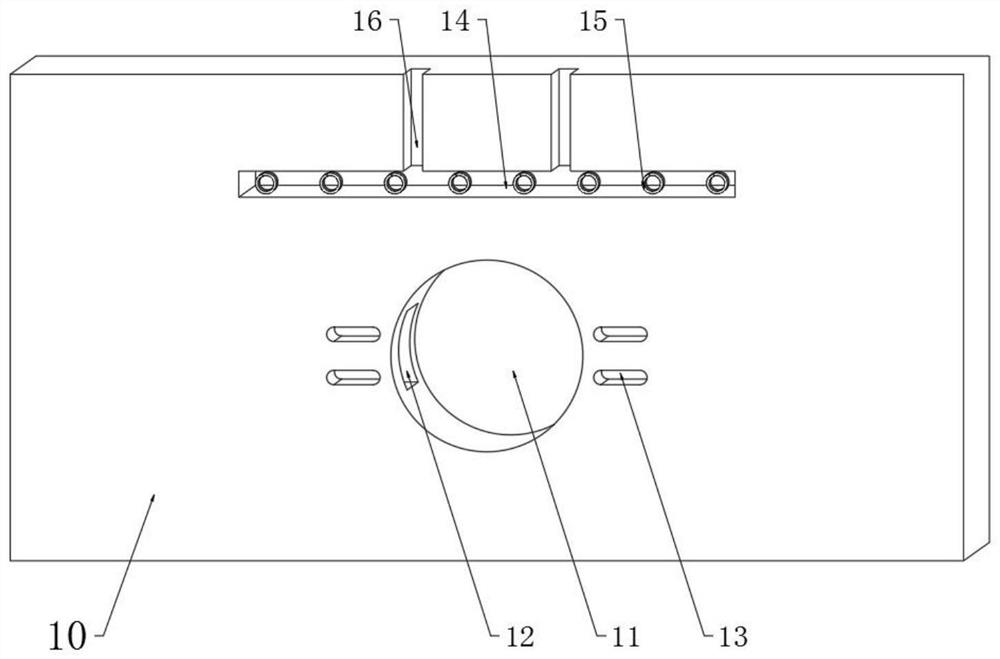

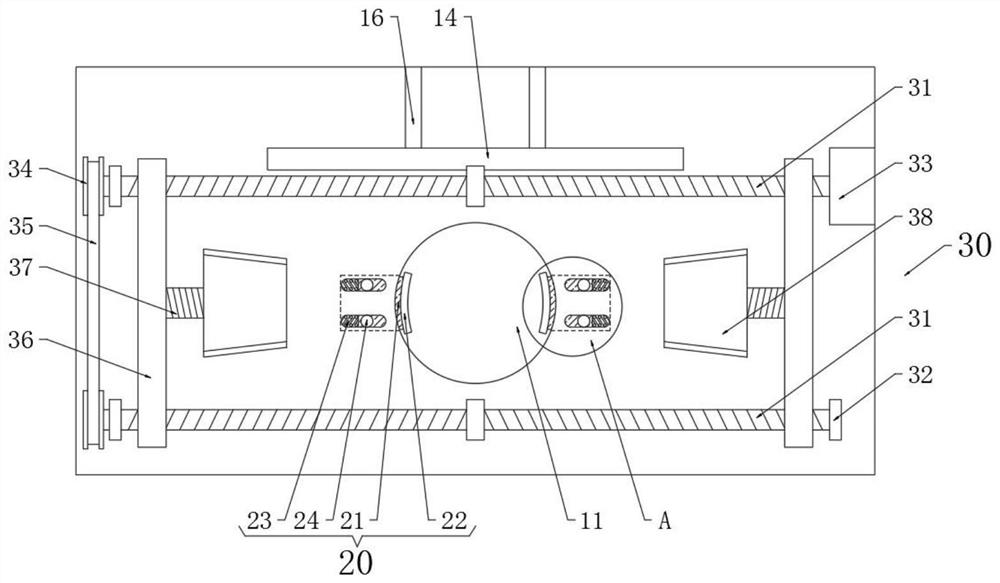

[0034] Such as Figure 1 to Figure 7 As shown, a valve valve body casting sprue cut-off processing machine includes a bottom plate 10 and a fixing device 30 arranged on the top of the bottom plate 10, a circular groove 11 is opened in the center of the top of the bottom plate 10, and the inner wall of the circular groove 11 is symmetrically opened on both sides. There is a telescopic groove 12, and an alignment device 20 is arranged symmetrically inside the circular groove 11, wherein the alignment device 20 includes a telescopic plate 21 slidingly butted in the telescopic groove 12, and one end of the telescopic plate 21 connects with the telescopic groove 12 through a second spring 23 The inner wall is fixedly connected, and the other end is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com