Patents

Literature

165results about How to "Mobile impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

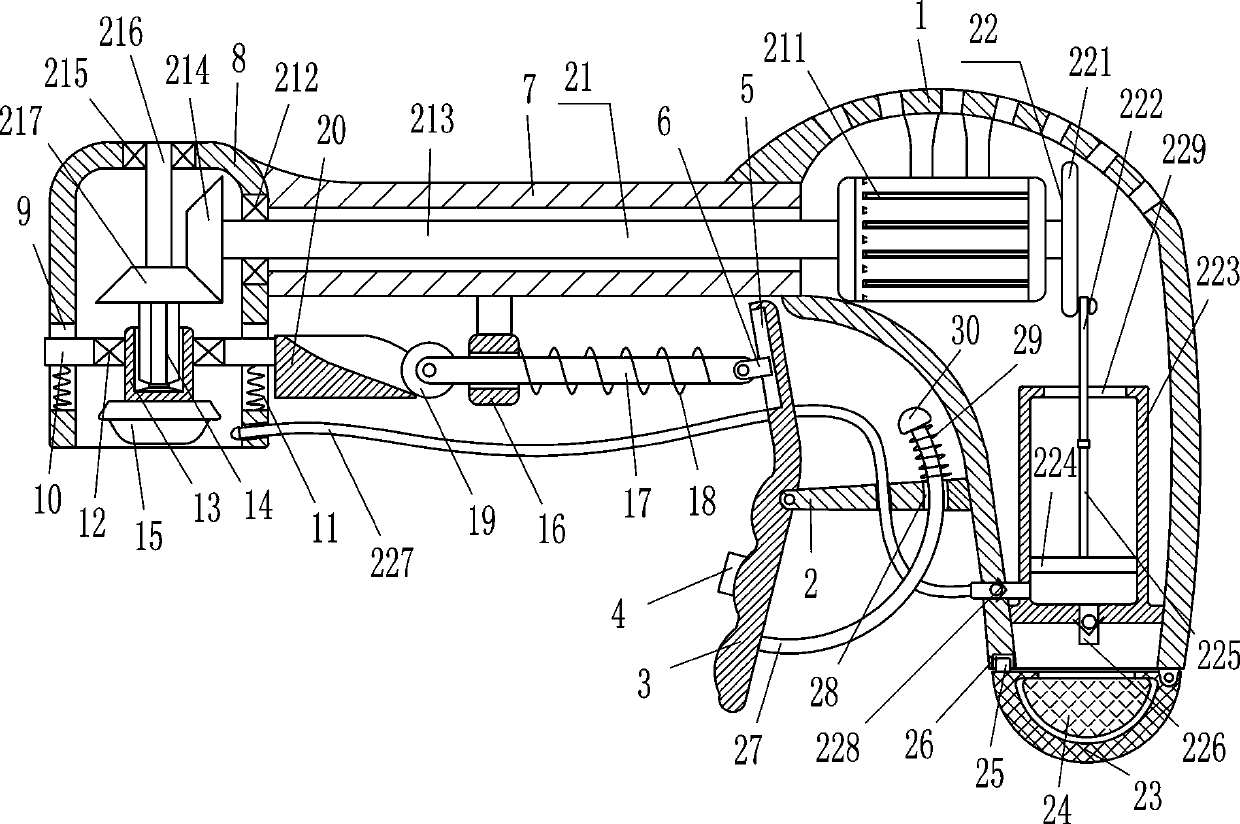

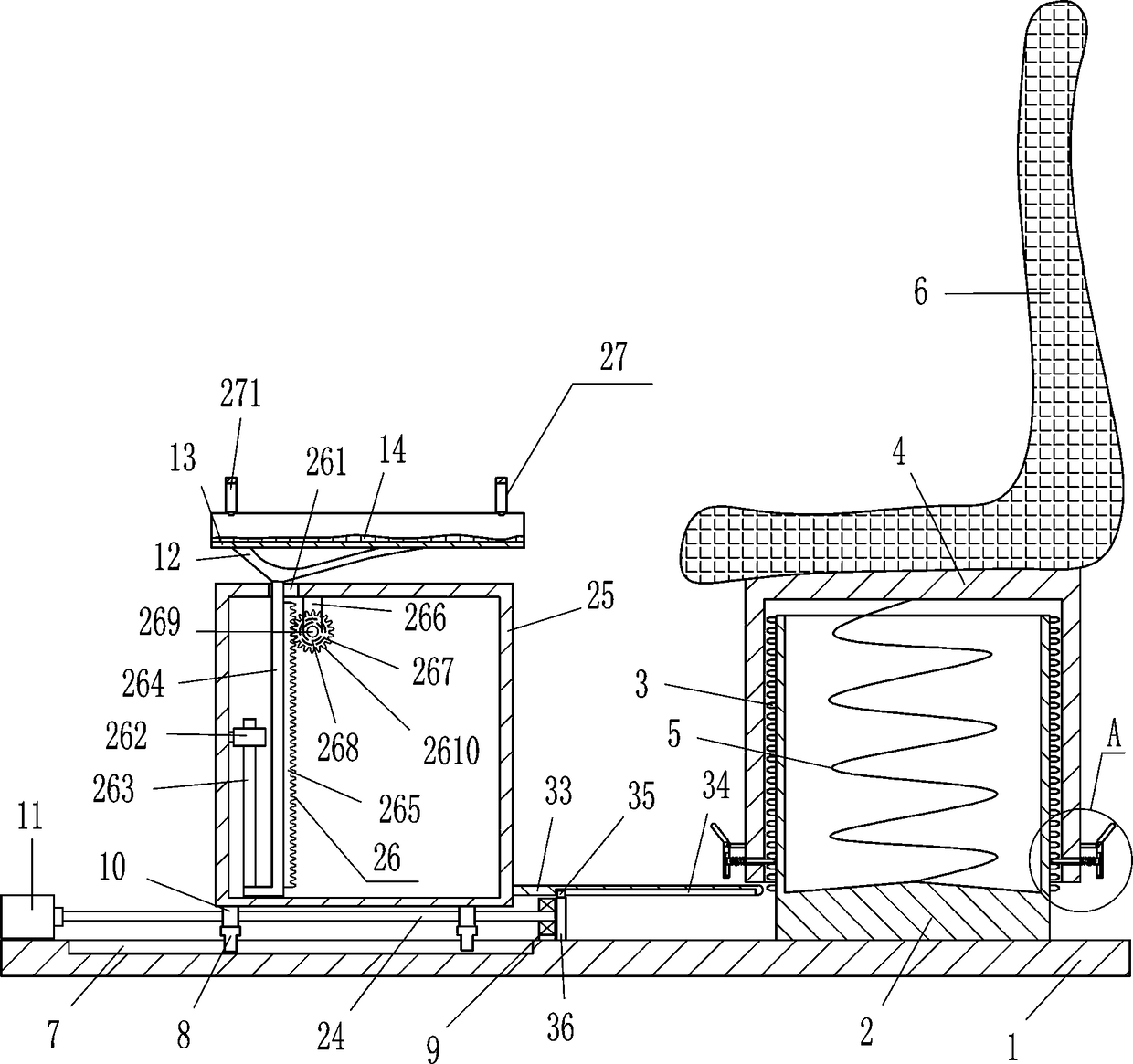

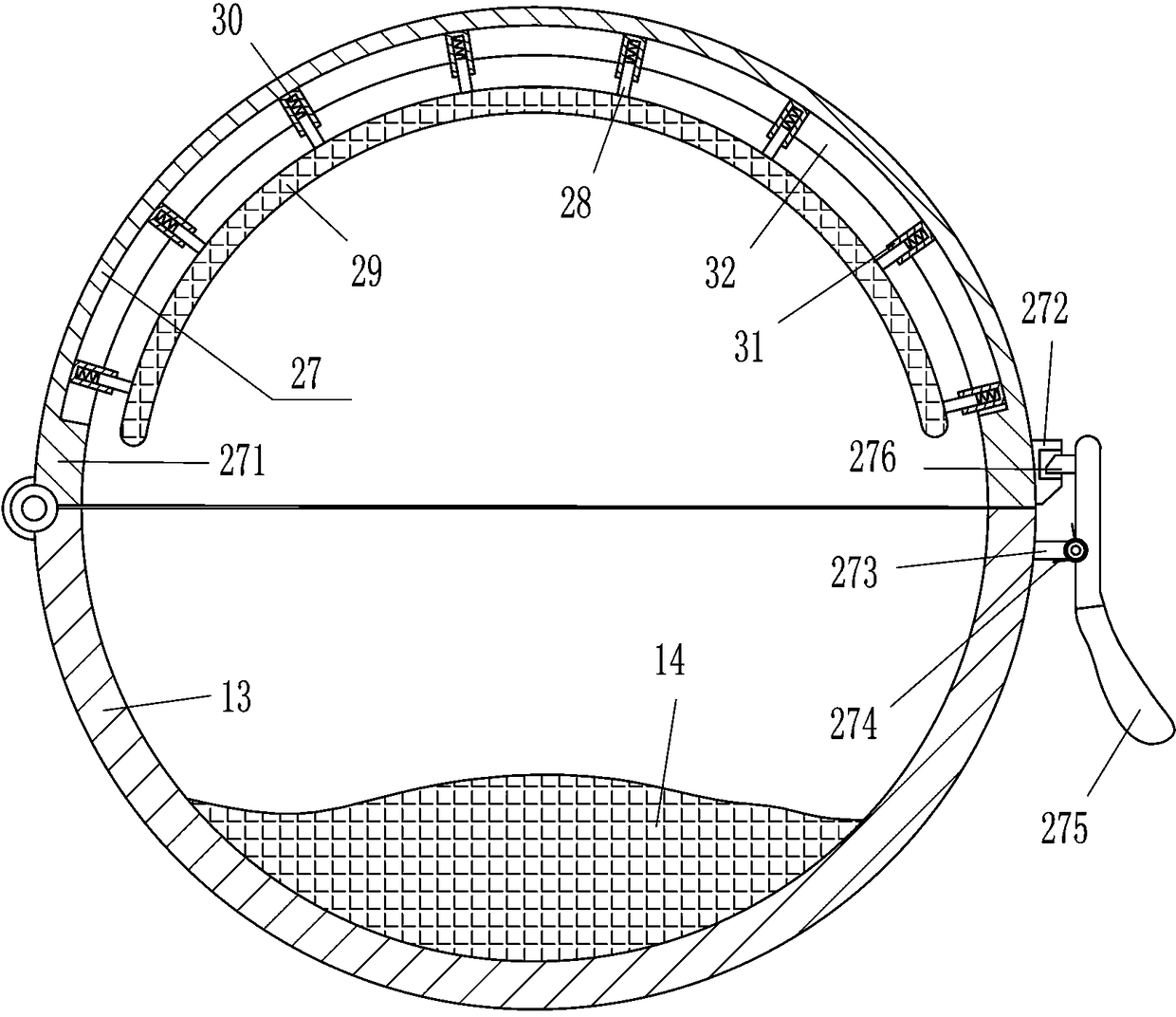

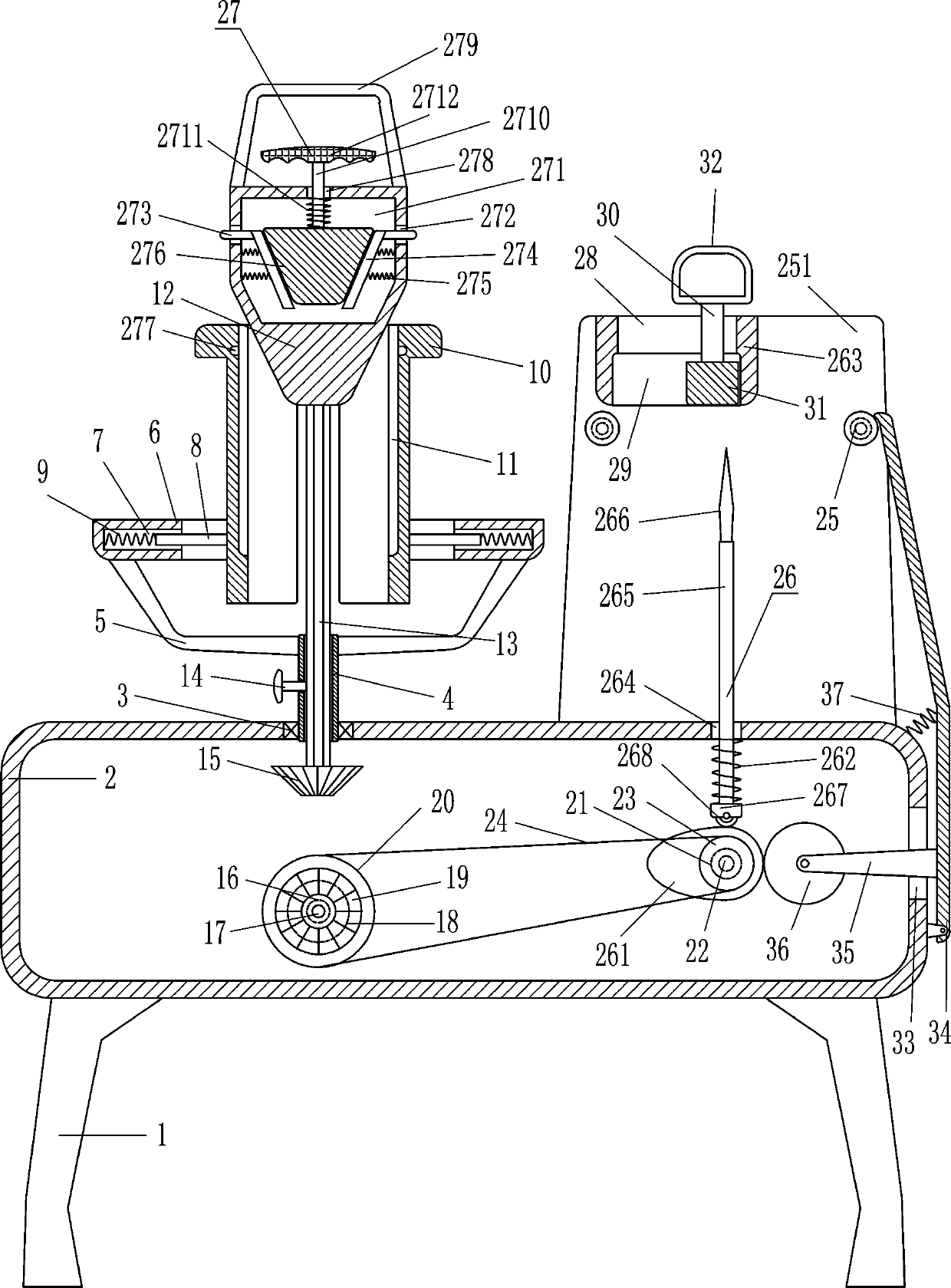

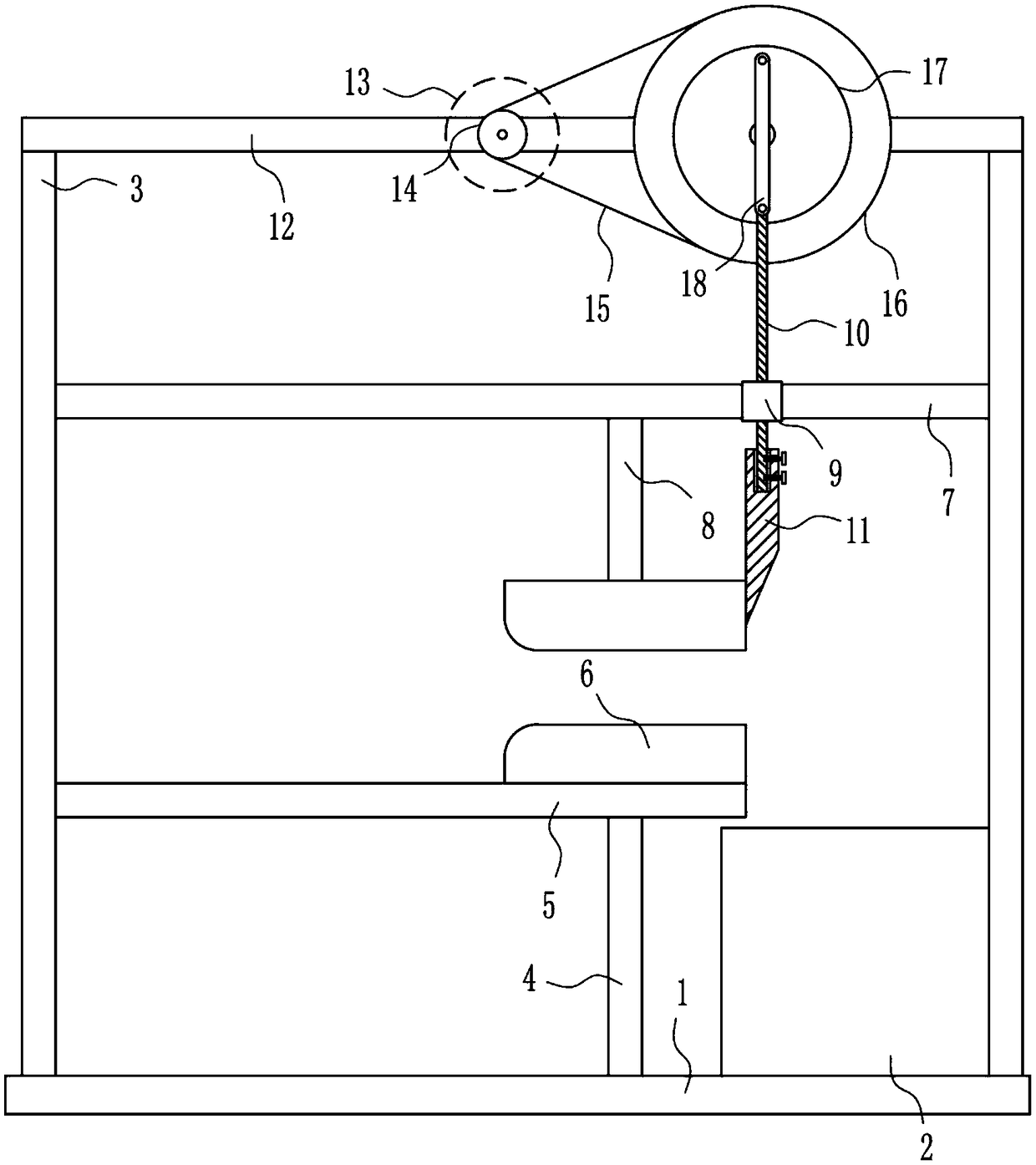

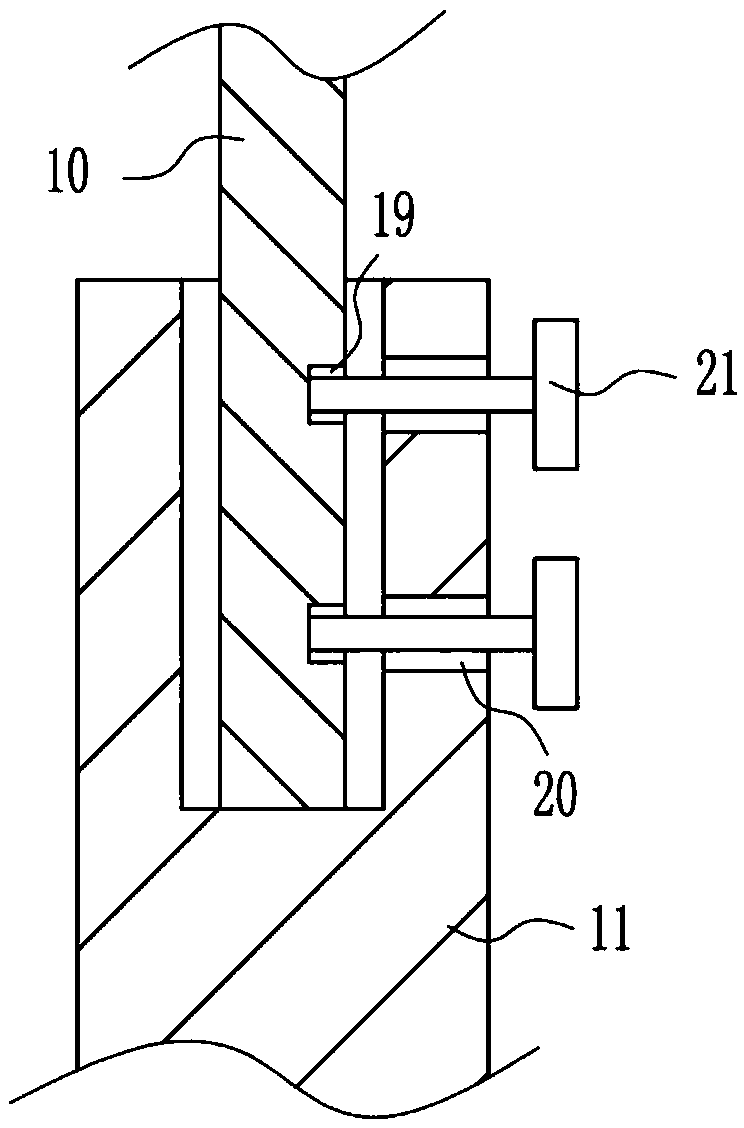

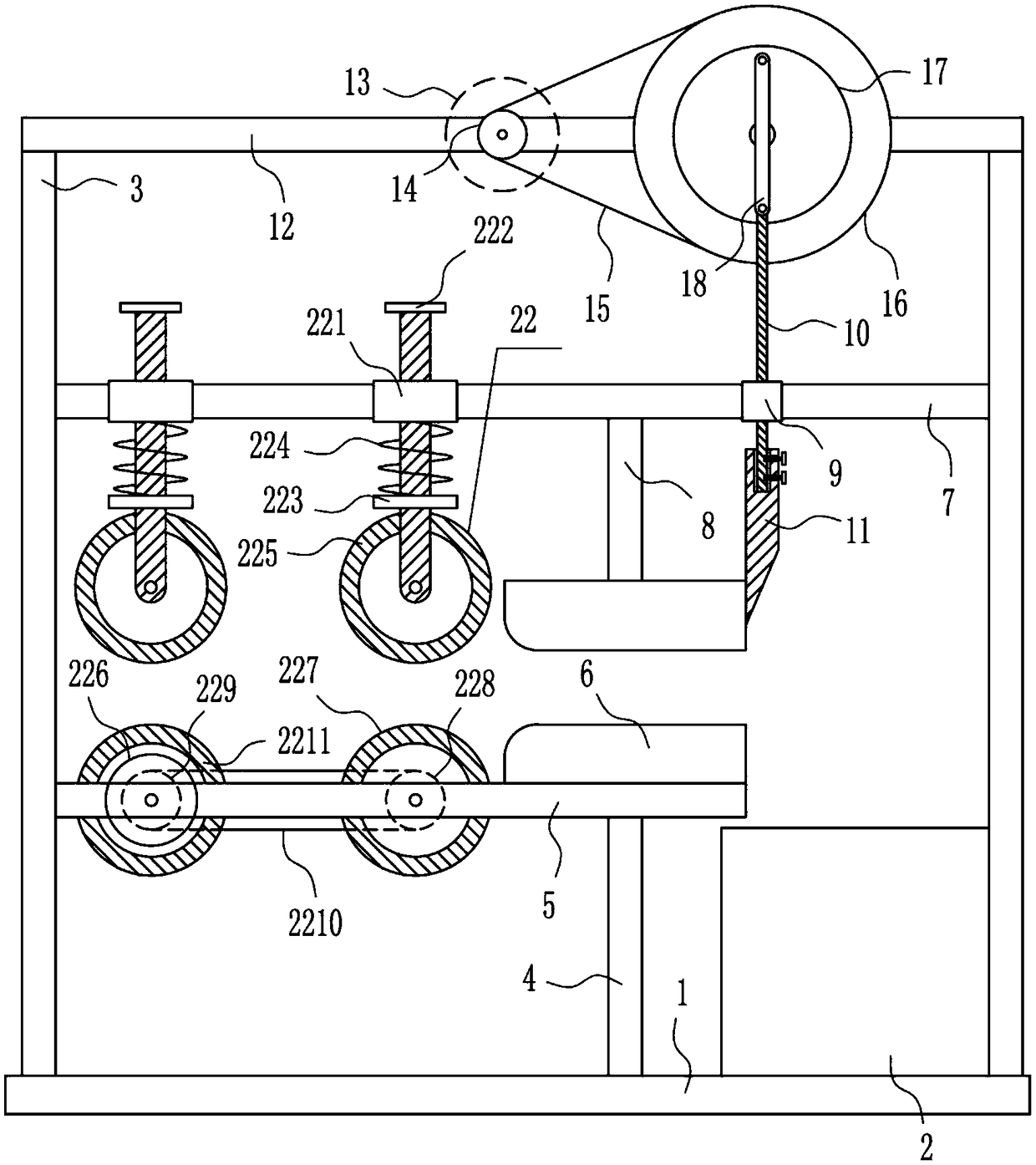

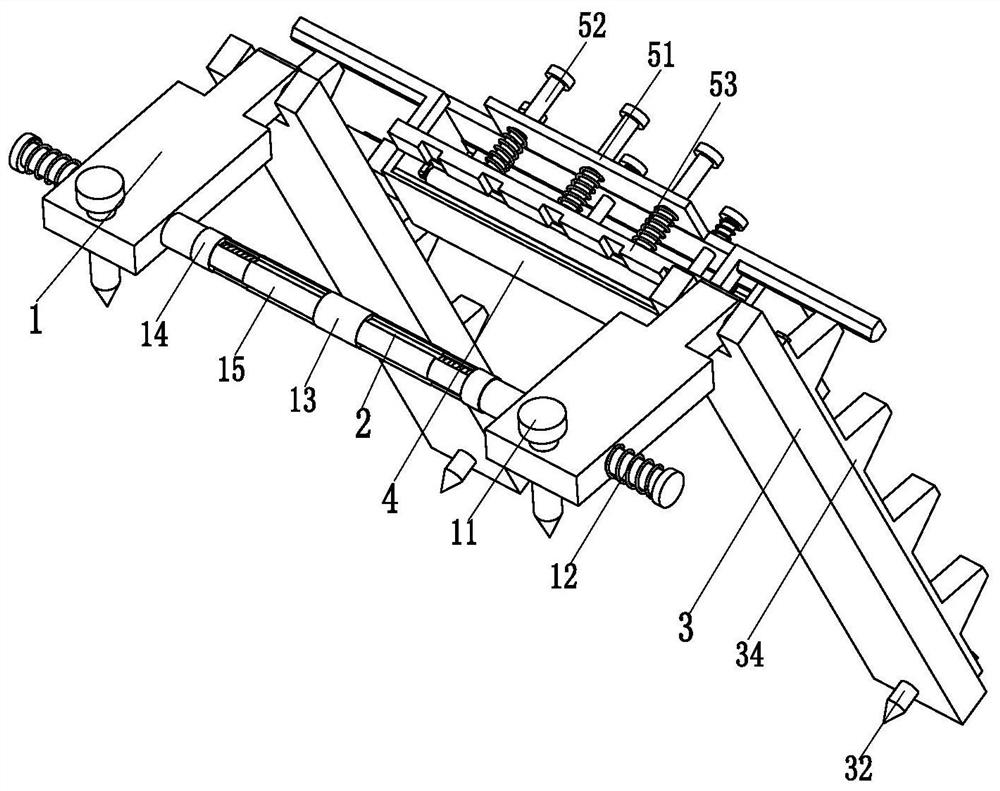

Burr grinding machine after part drilling

ActiveCN109605163AMobile impactAvoid affecting work efficiencyEdge grinding machinesGrinding carriagesEngineeringMetal debris

The invention relates to a grinding machine, in particular to a burr grinding machine after part drilling. In order to solve the technical problems, the invention provide a burr grinding machine afterpart grinding, and the burr grinding machine can replace people to grind and clear burrs, avoids hand ache, is high in working efficiency, further can clear metal debris and does not affect grinding.According to the technical scheme adopted by the invention, the burr grinding machine after part drilling comprises a shell, a transverse plate, a swing plate, a button, a guide slide block, a sleeve, a frame body, a vertical slide block, a first spring and the like, wherein the lower part of the left side surface outside the shell is fixedly connected with the transverse plate; the left end of the transverse plate is hinged with the swing plate; and a guide slide slot is formed in the upper part of the left side surface of the swing plate. According to the burr grinding machine disclosed bythe invention, the swing plate is pulled for enabling a grinding block to move downwards, and the button is pressed for starting a double-axis motor to drive the grinding block to rotate. The device is moved, so that the grinding block is in contact with burrs for grinding and clearing the burrs, and a user does not need to use a file to clear the burrs, and therefore, the burr grinding machine ismore convenient, and the working effect is prevented from being affected by hand ache.

Owner:JIANGXI UNIV OF SCI & TECH

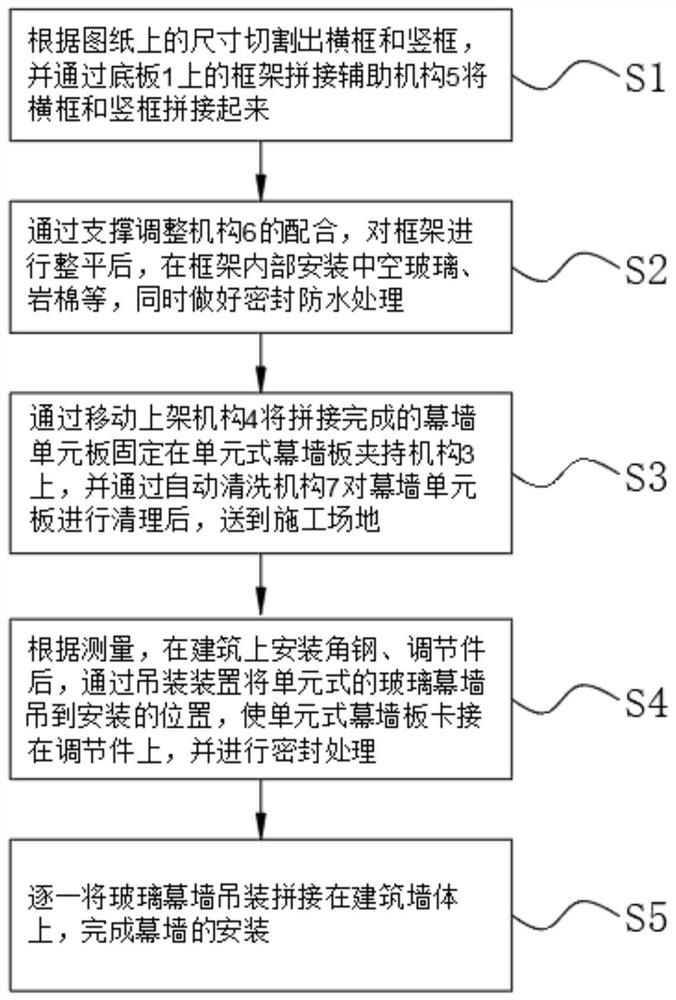

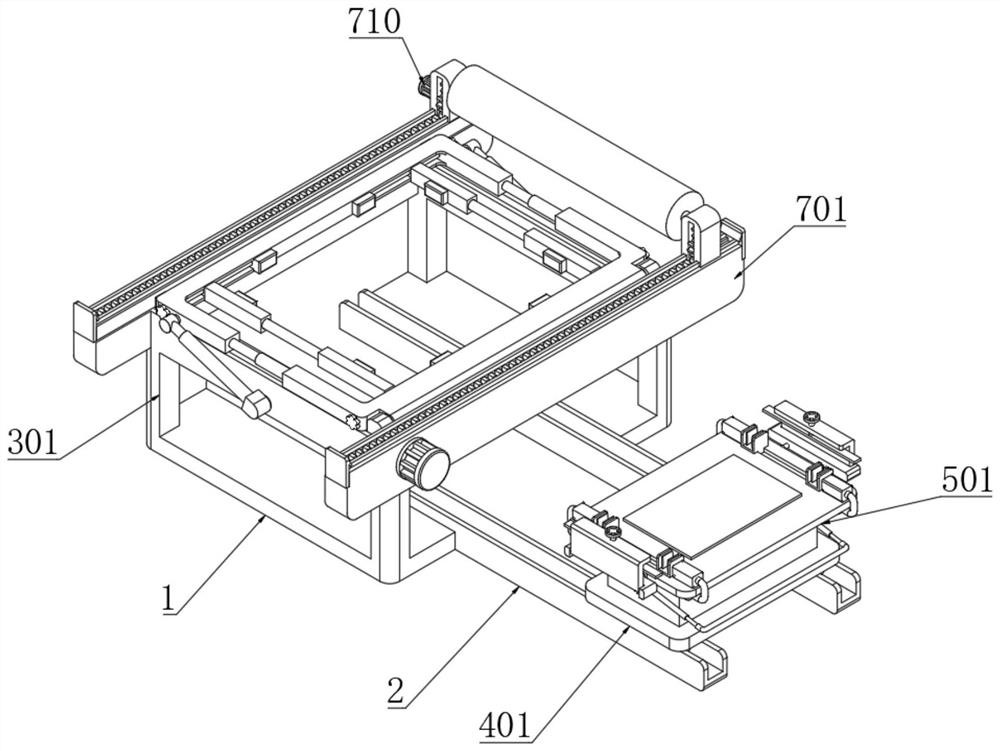

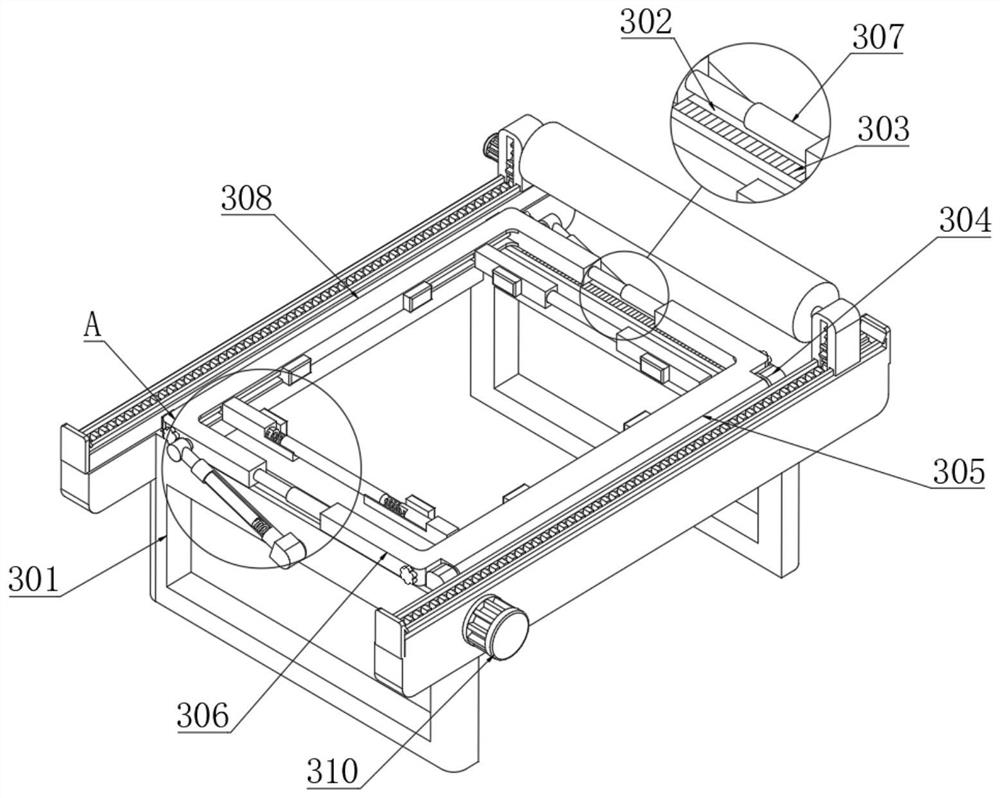

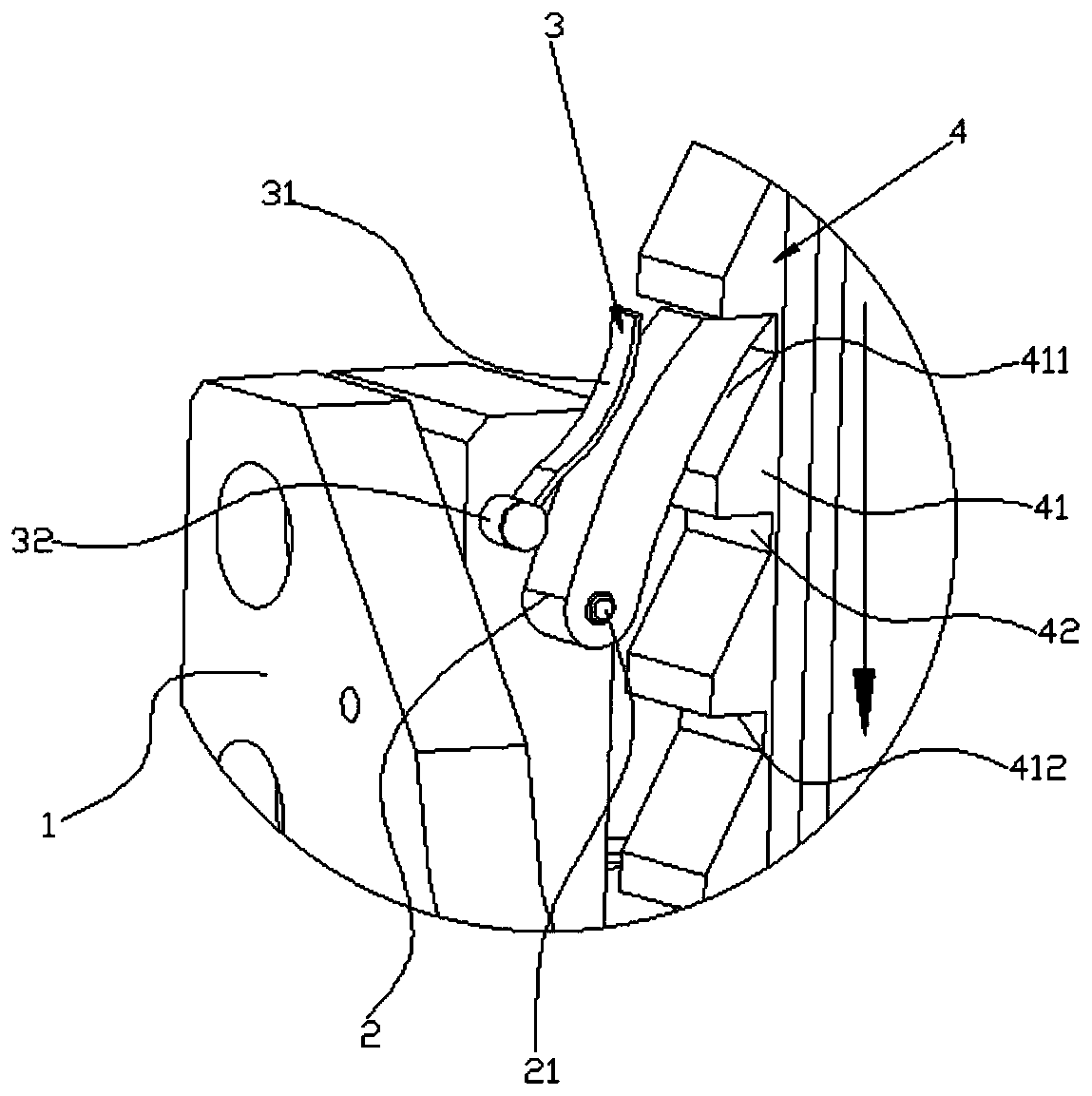

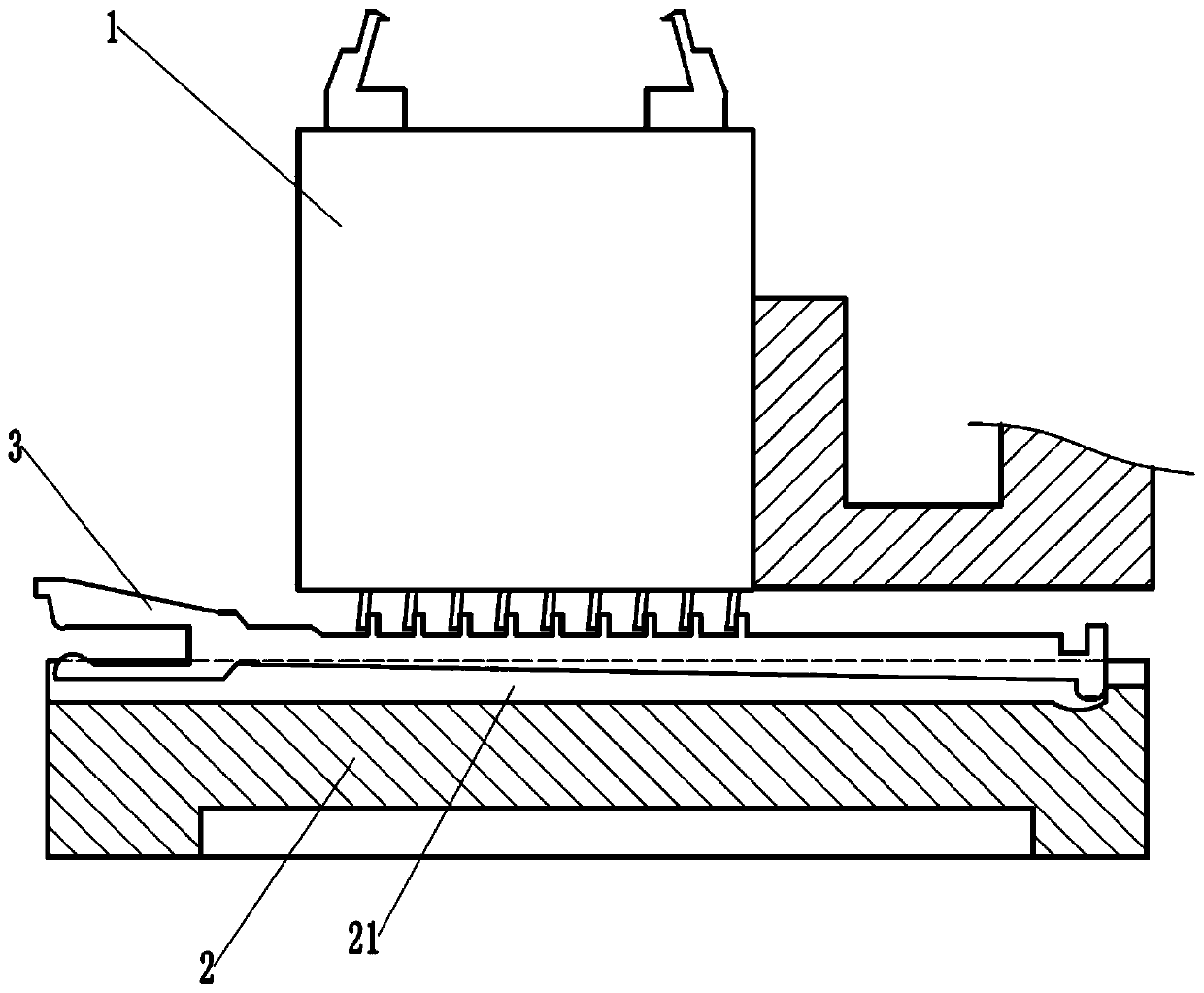

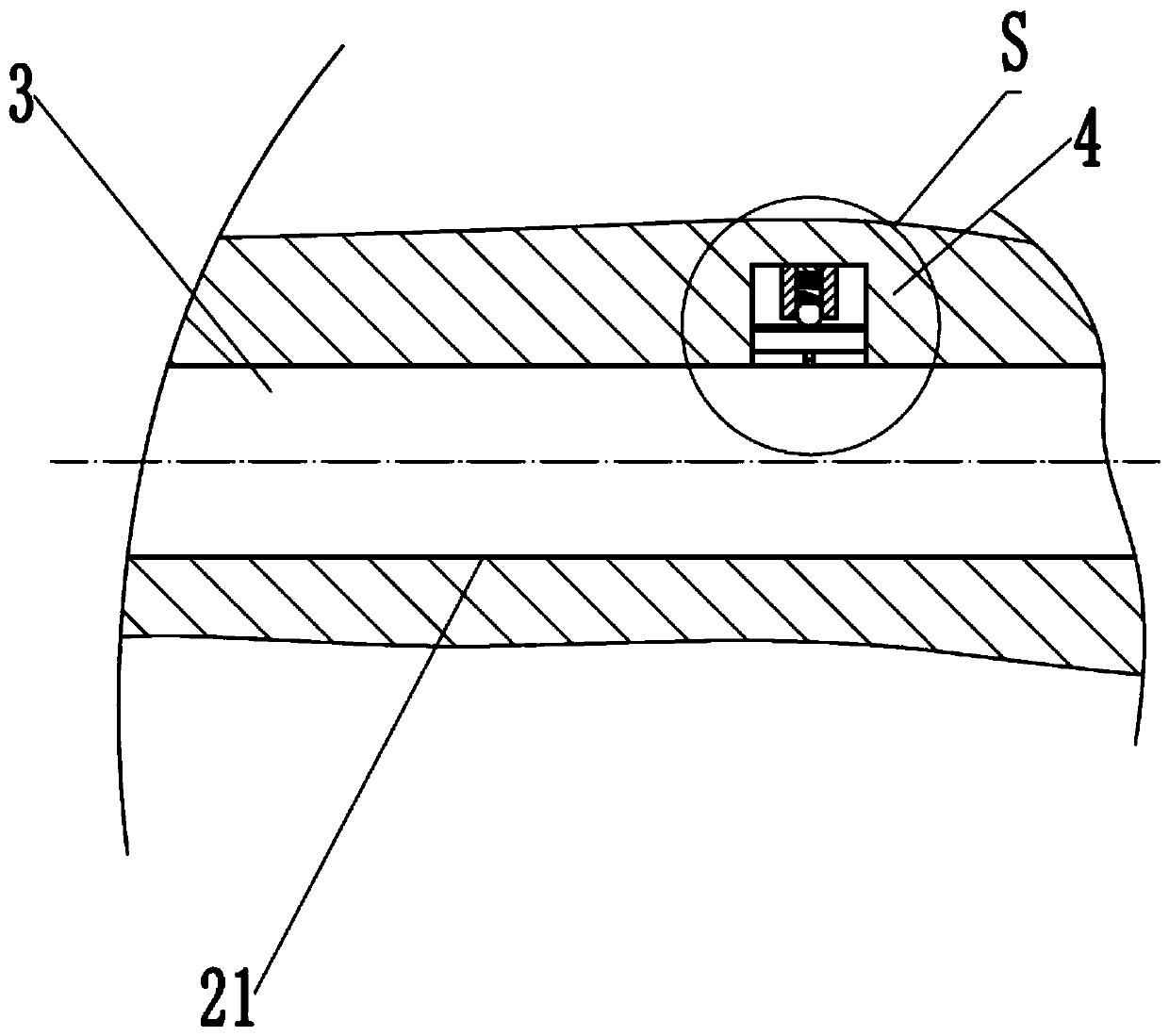

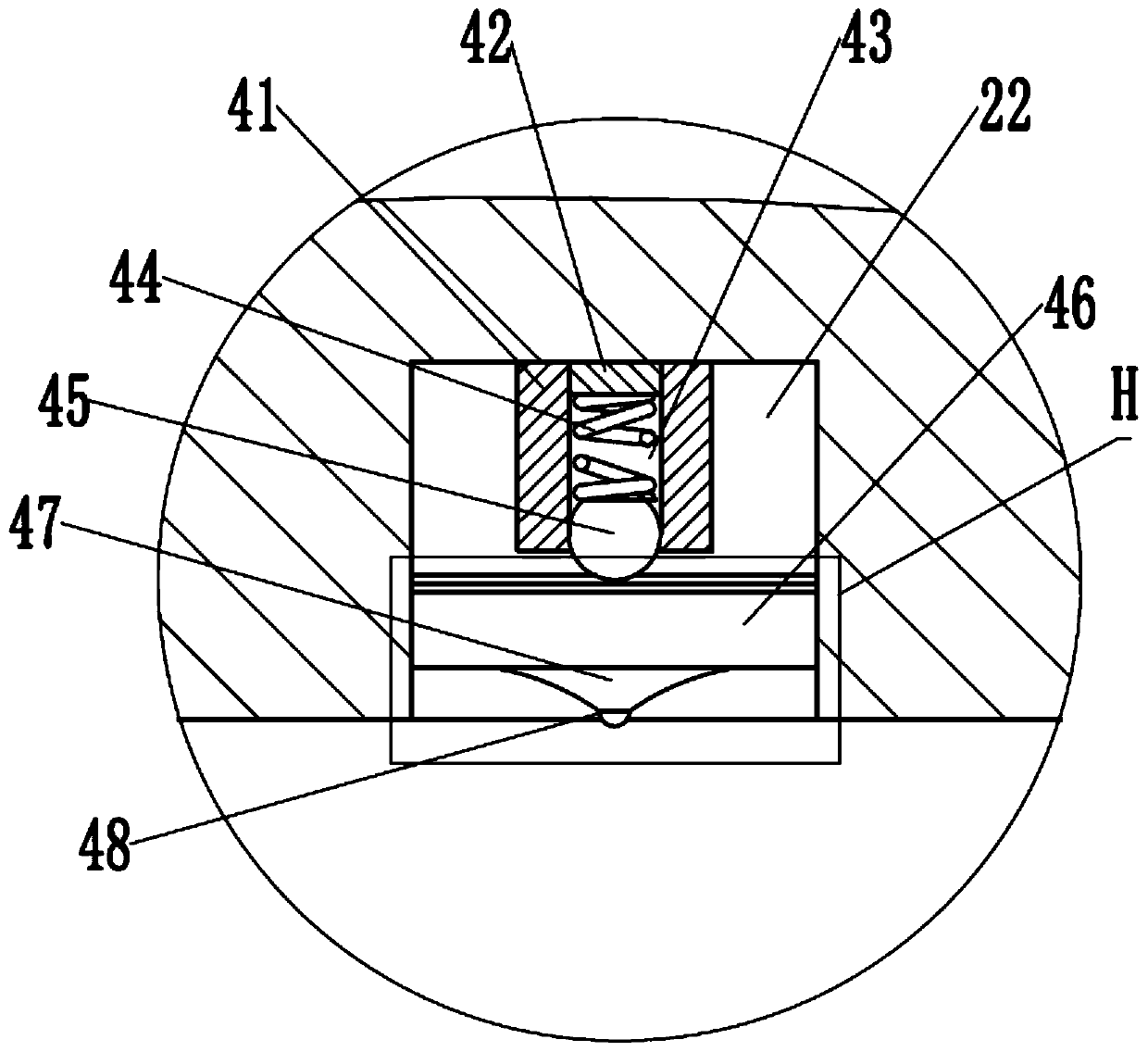

Installation method of spliced building curtain wall

InactiveCN112431336AScientific and reasonable structureEasy to useWallsWork holdersFixed frameEngineering

Owner:罗显容

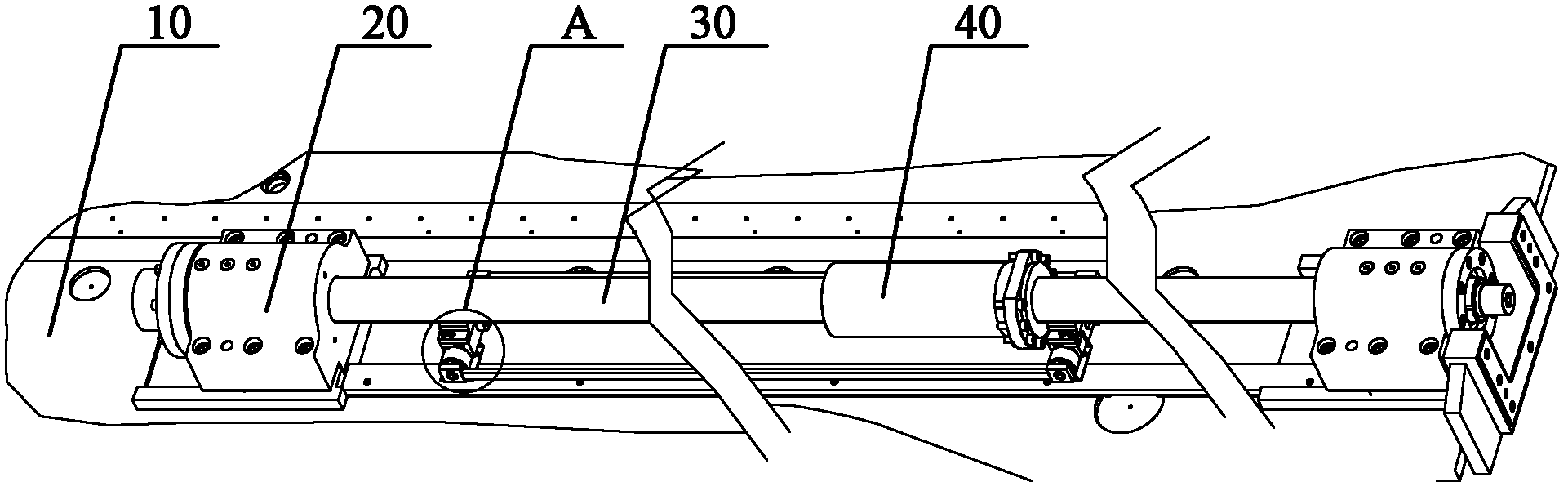

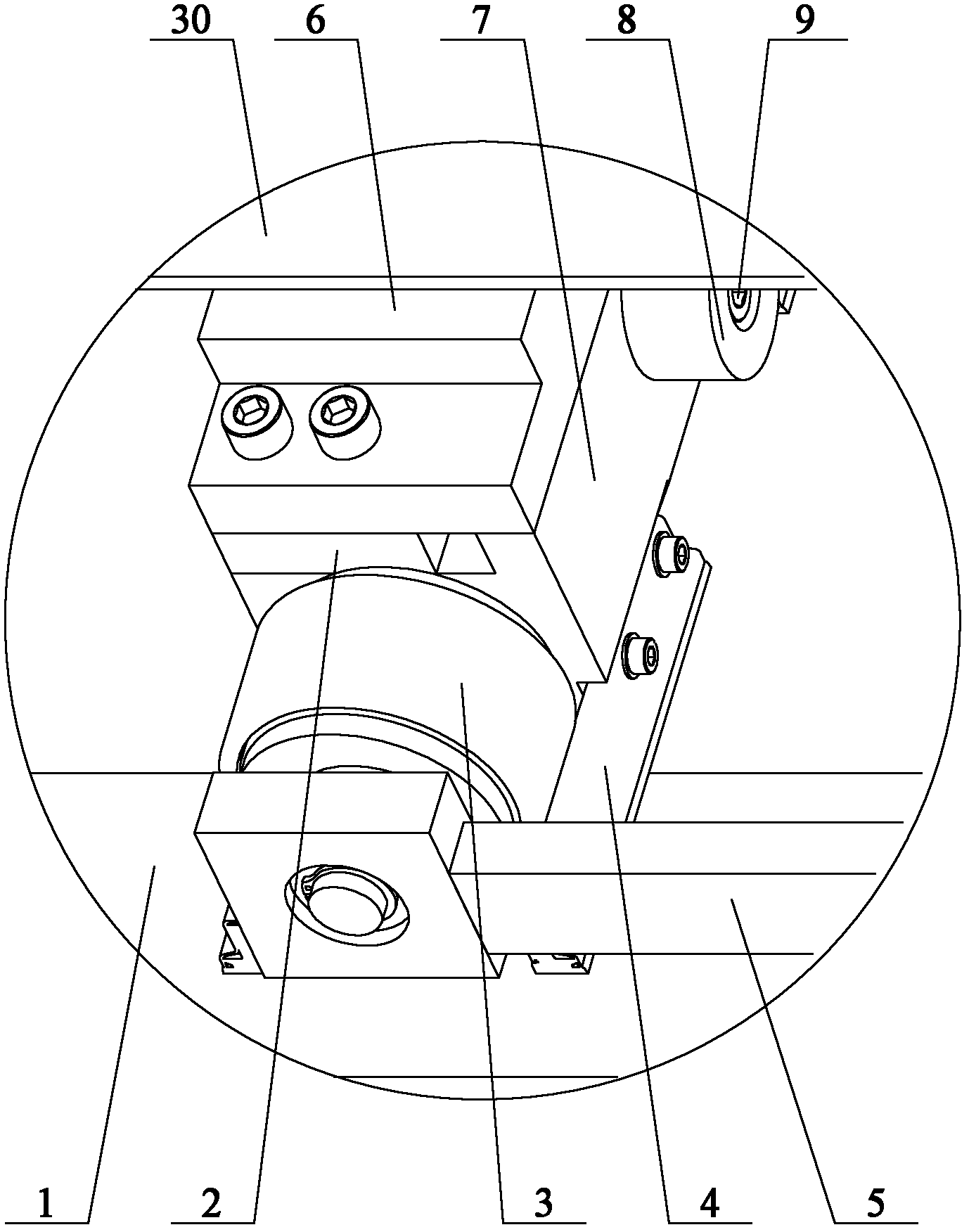

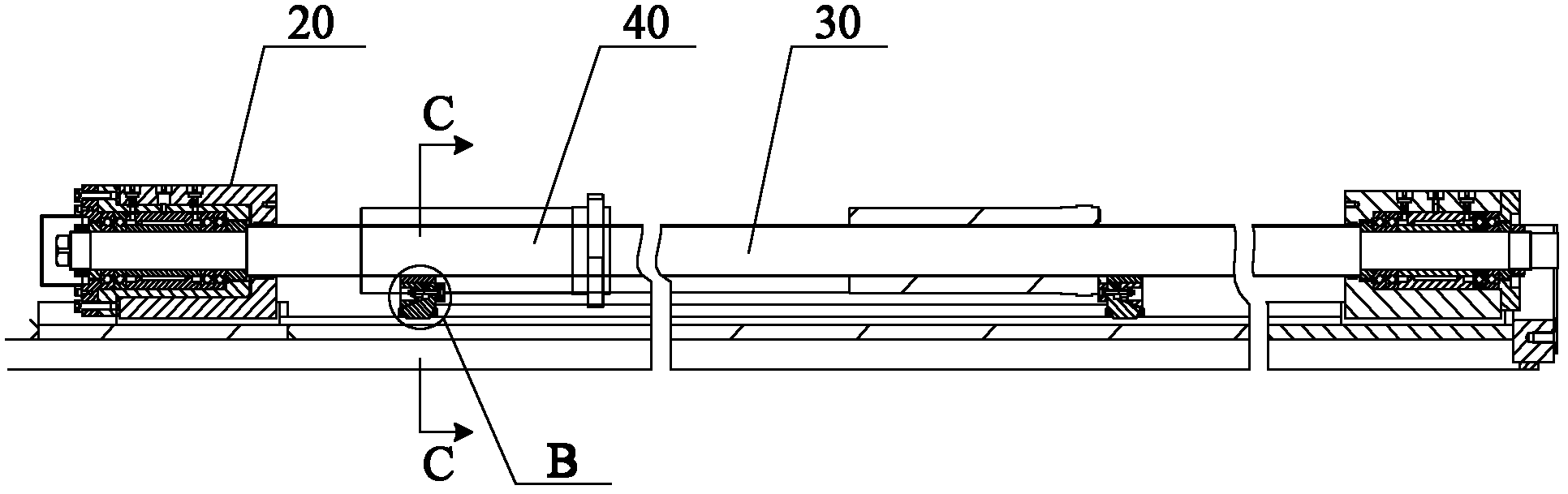

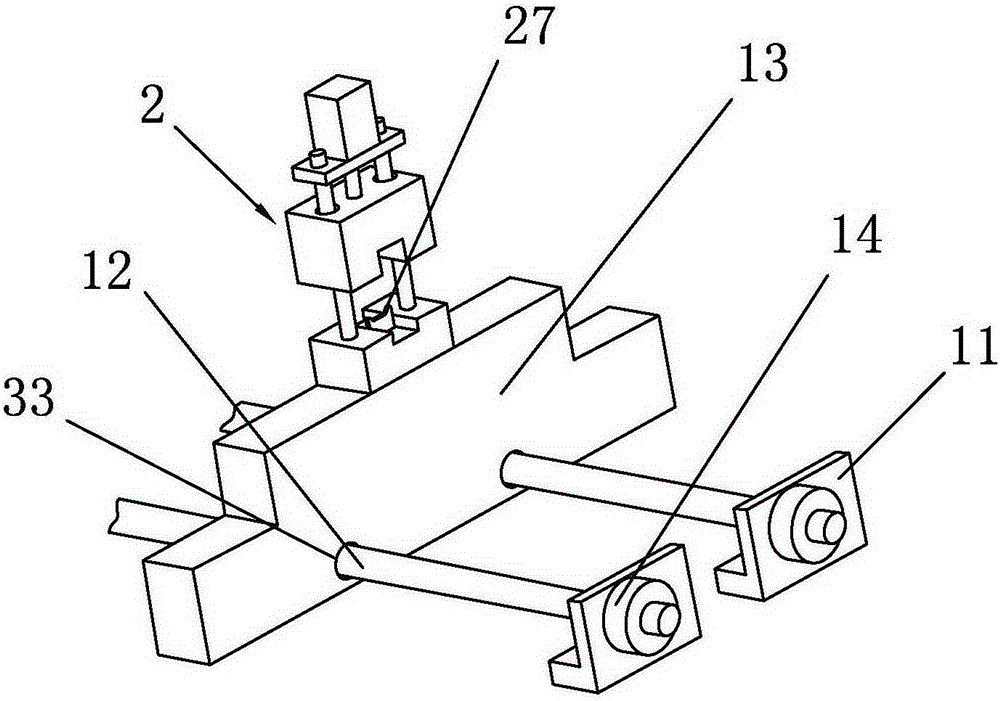

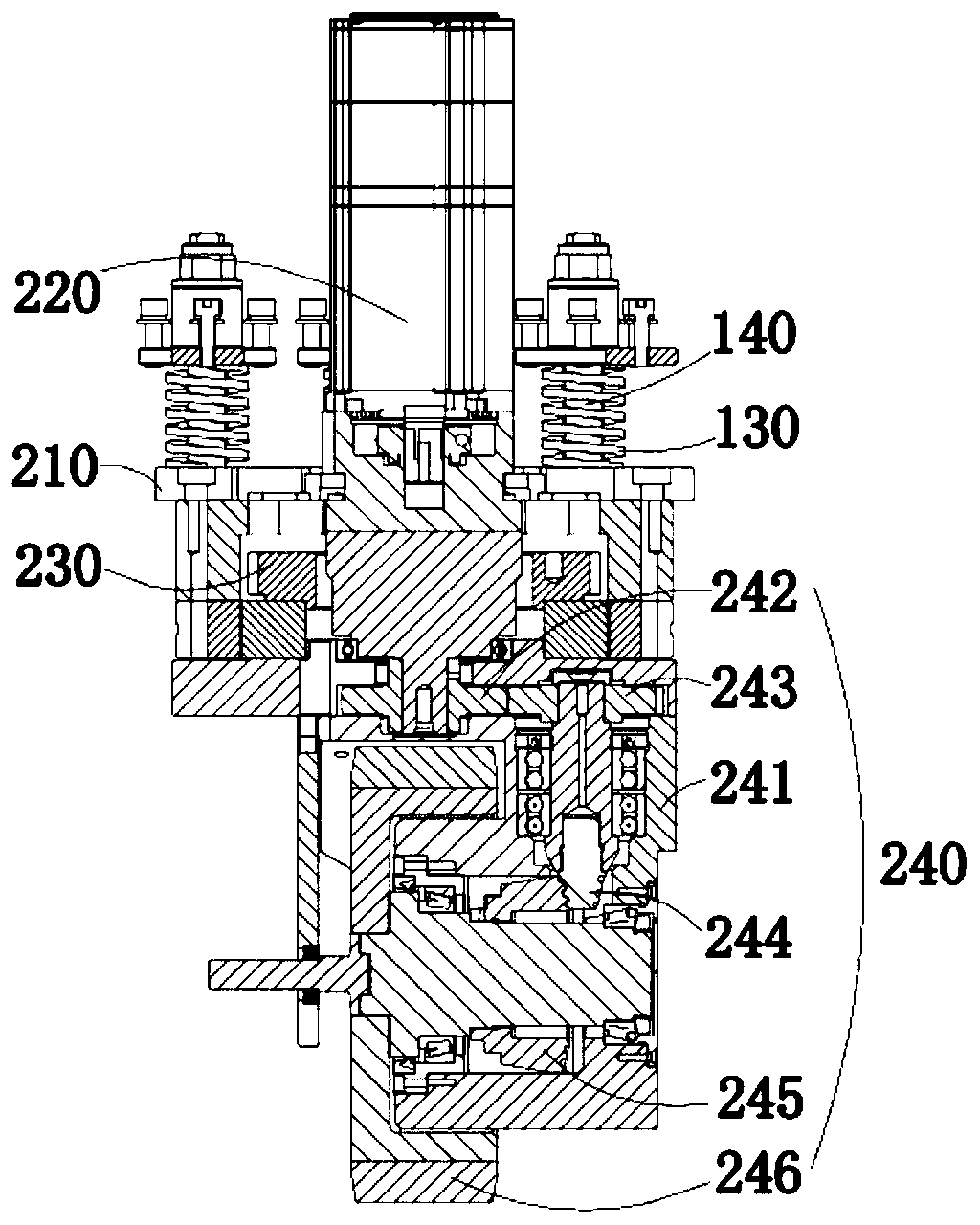

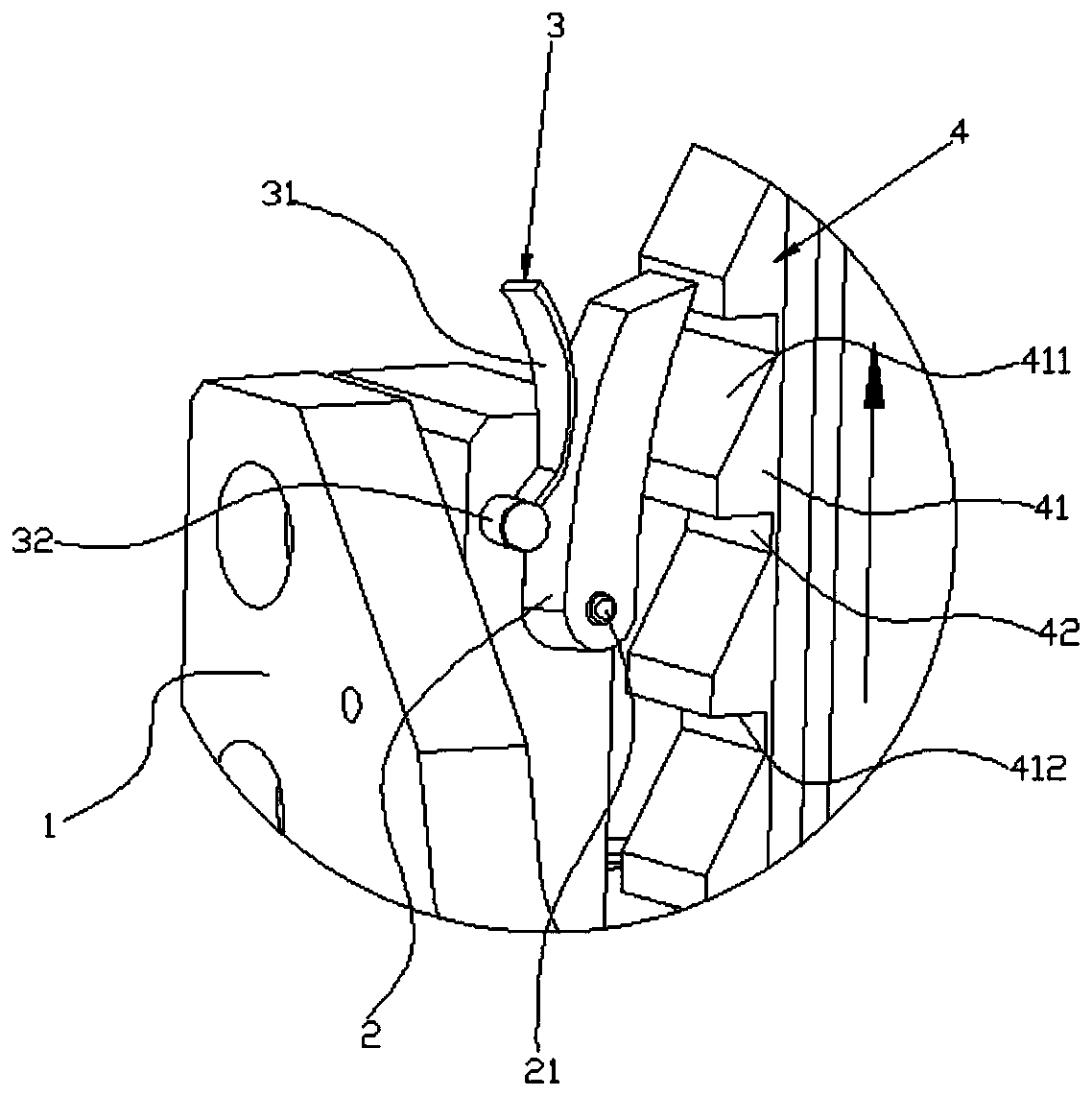

Auxiliary lead screw supporting device and processing center

The invention relates to the technical field of machine tools, and discloses an auxiliary lead screw supporting device and a processing center. The auxiliary lead screw supporting device comprises guide plates and a pair of auxiliary supporting components, the guide plates are parallel to a lead screw, the auxiliary supporting components are disposed on the guide plates on two sides of a nut and are connected by a connecting rod, each auxiliary lead screw supporting component consists of a supporting body and a supporting table, each supporting body can move along the corresponding guide plate, the bottom of each supporting table is connected with the corresponding supporting body, and the top of each supporting table is used for supporting the lead screw. In the auxiliary lead screw supporting device in an embodiment of the invention, the two auxiliary supporting components are respectively arranged below the lead screw on two sides of the nut, and are supported on the lower side of the lead screw via arc-shaped groove surfaces of the supporting tables, the hardness of each supporting table is slightly smaller than that of the lead screw, accordingly, the lead screw is supported while influences on the surface of the lead screw are reduced, and problems that the transmission precision is reduced and the service life is shortened due to the fact that the lead screw droops and vibrates are avoided.

Owner:SANY GRP

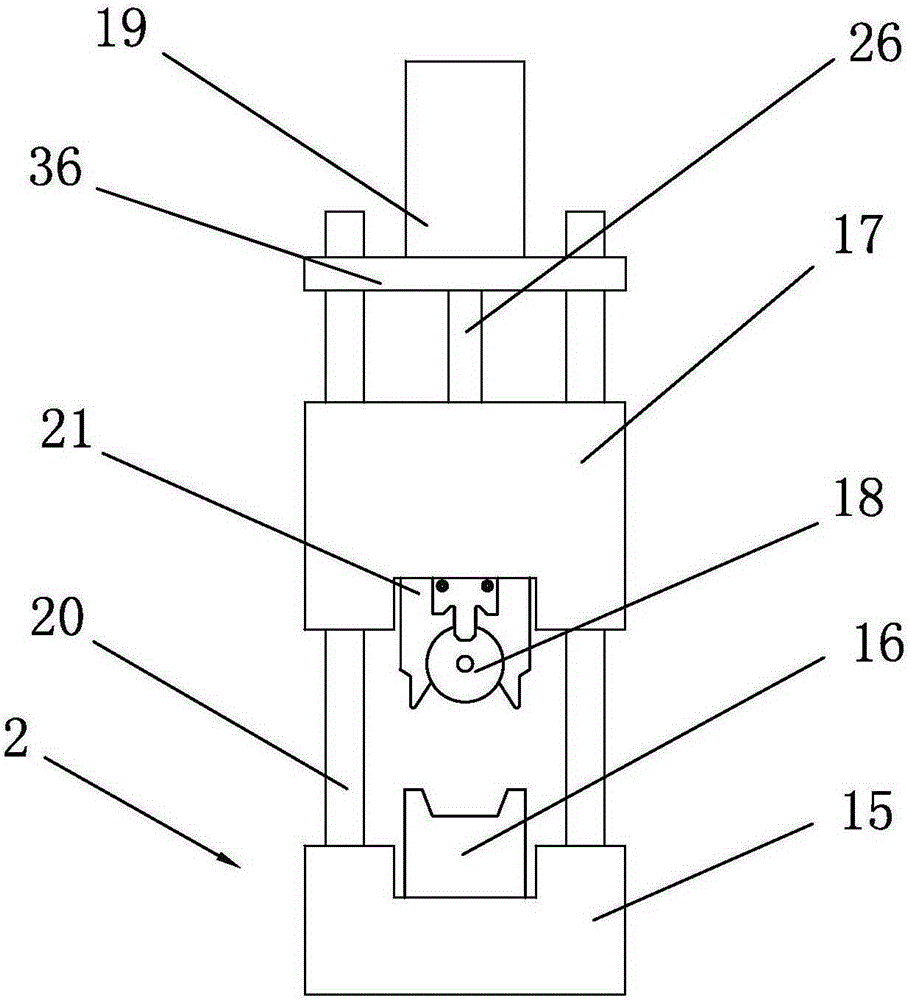

Cutting device applied to production and processing of tubular glass

InactiveCN105271686AEasy to installEasy to fixGlass severing apparatusMechanical engineeringEngineering

The invention discloses a cutting device applied to production and processing of tubular glass. The cutting device comprises a workbench, a clamping device, a sliding component and a cutting component, wherein the workbench comprises a first workbench and a second workbench; the clamping device comprises clamping blocks and clamping air cylinders; the sliding component comprises a support frame, a sliding bar and a sliding block; and the cutting component comprises a fixing block, a bracket, a moving block, a cutting knife and a telescopic air cylinder. The cutting device is simple in structure and strong in practicability; with the design of the clamping device, the tubular glass is more convenient and simpler to fix and clamp; the cutting stability of the tubular glass is improved; a cut surface after cutting is smoother; then, with the design of the sliding block component and the cutting component, the tubular glass is cut more automatically; furthermore, the position of the cutting knife can be adjusted by the sliding block component and the cutting component, so that the cutting device is applicable to cutting the tubular glass with different diameters; the application scope of the cutting device is enlarged; and the comprehensive utilization efficiency is improved.

Owner:SHENGZHOU HUANDING GLASS TECH CO LTD

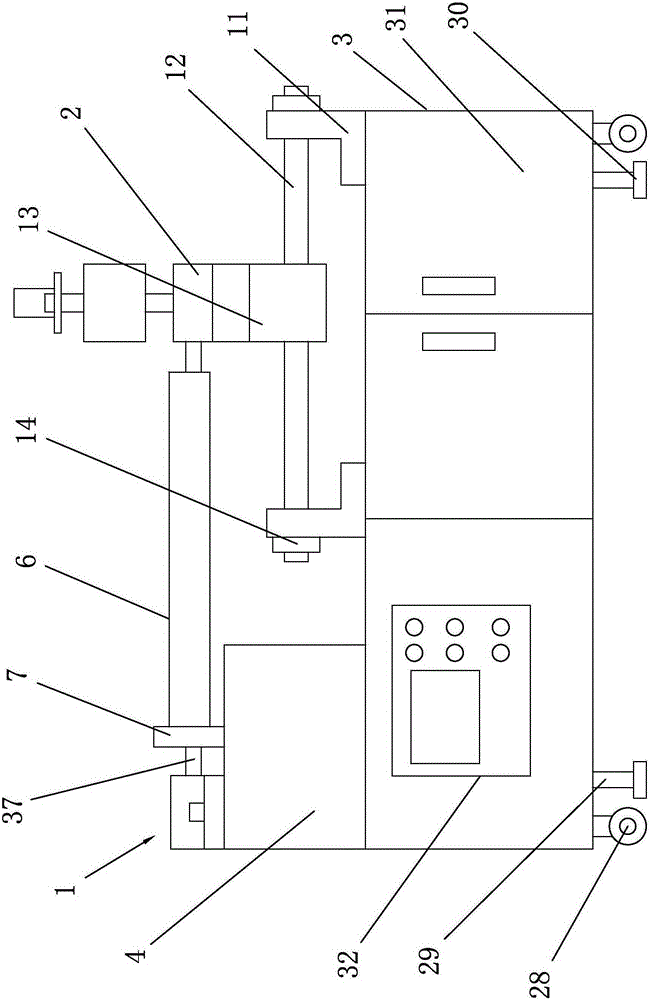

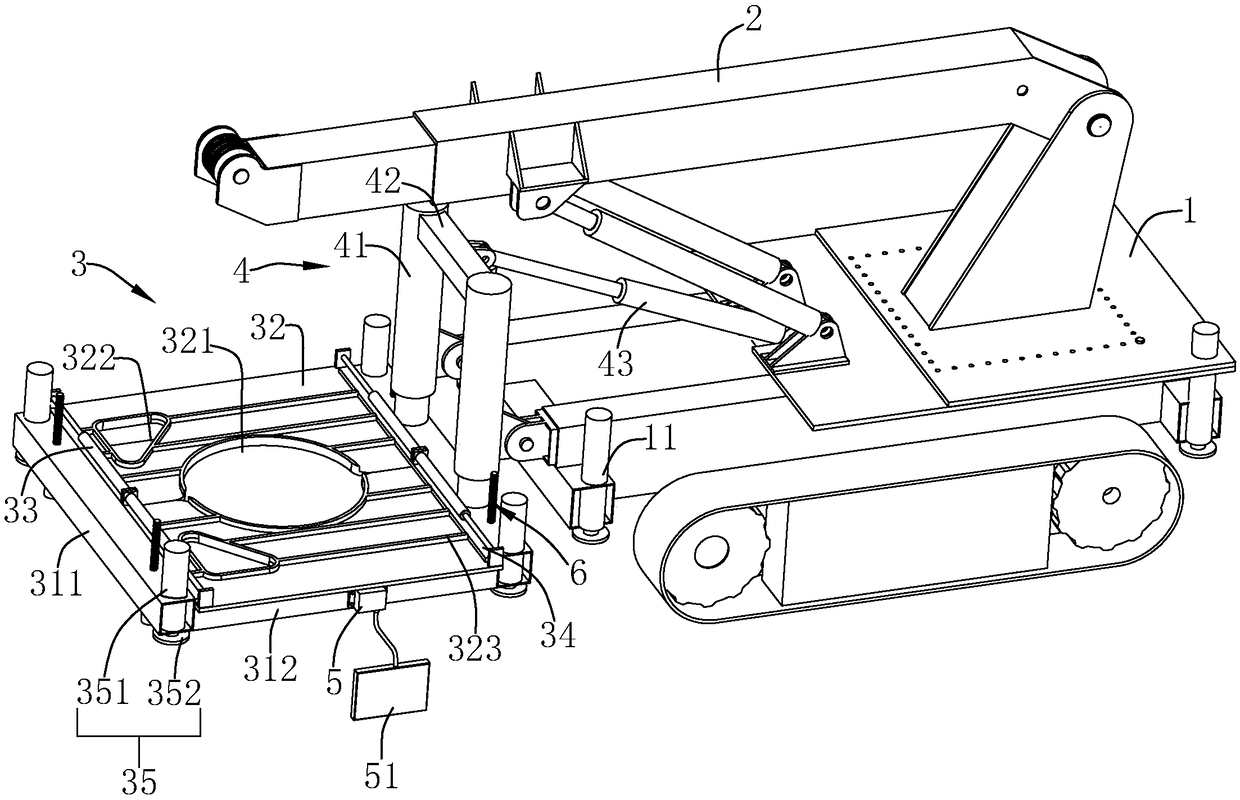

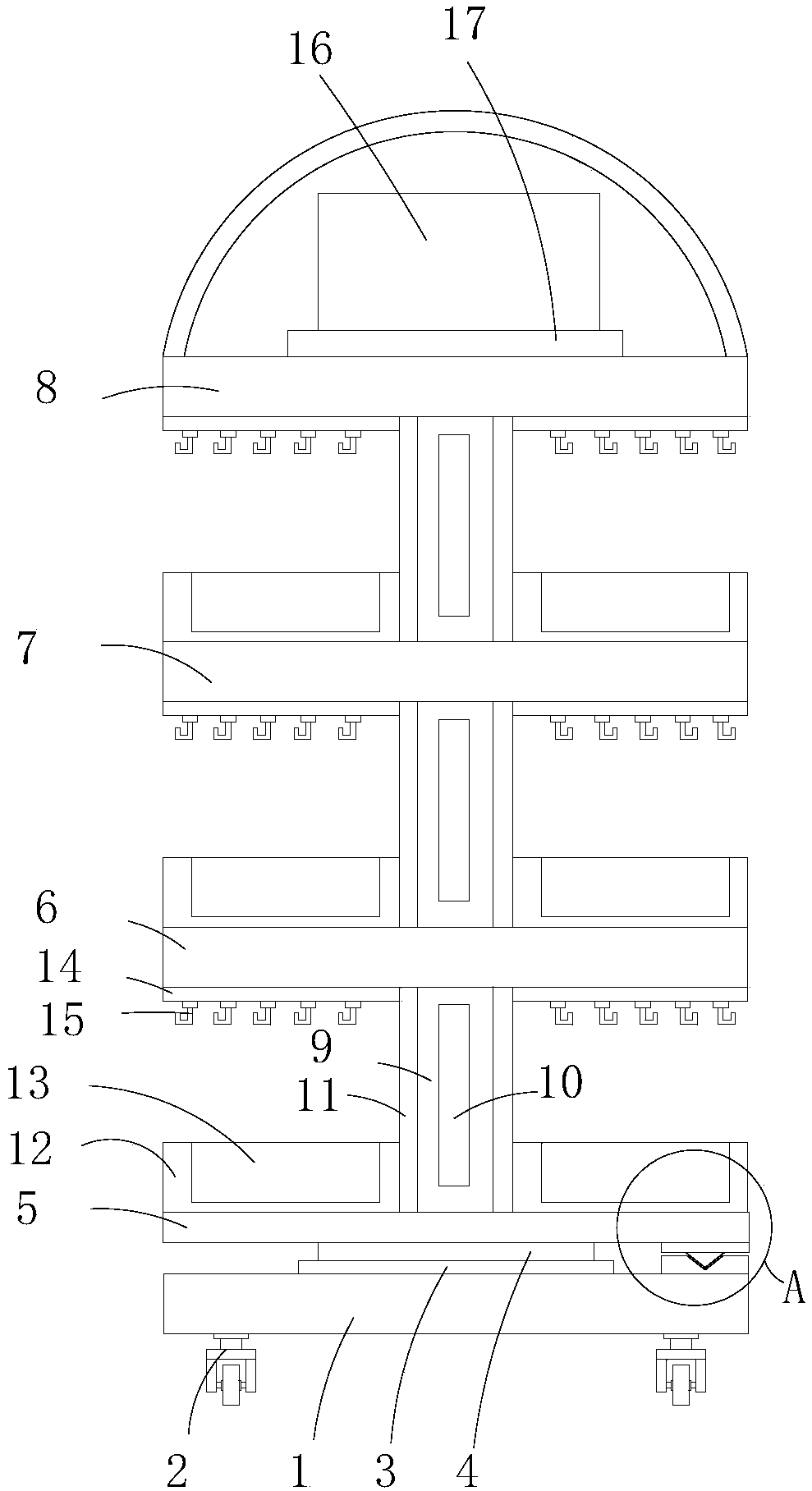

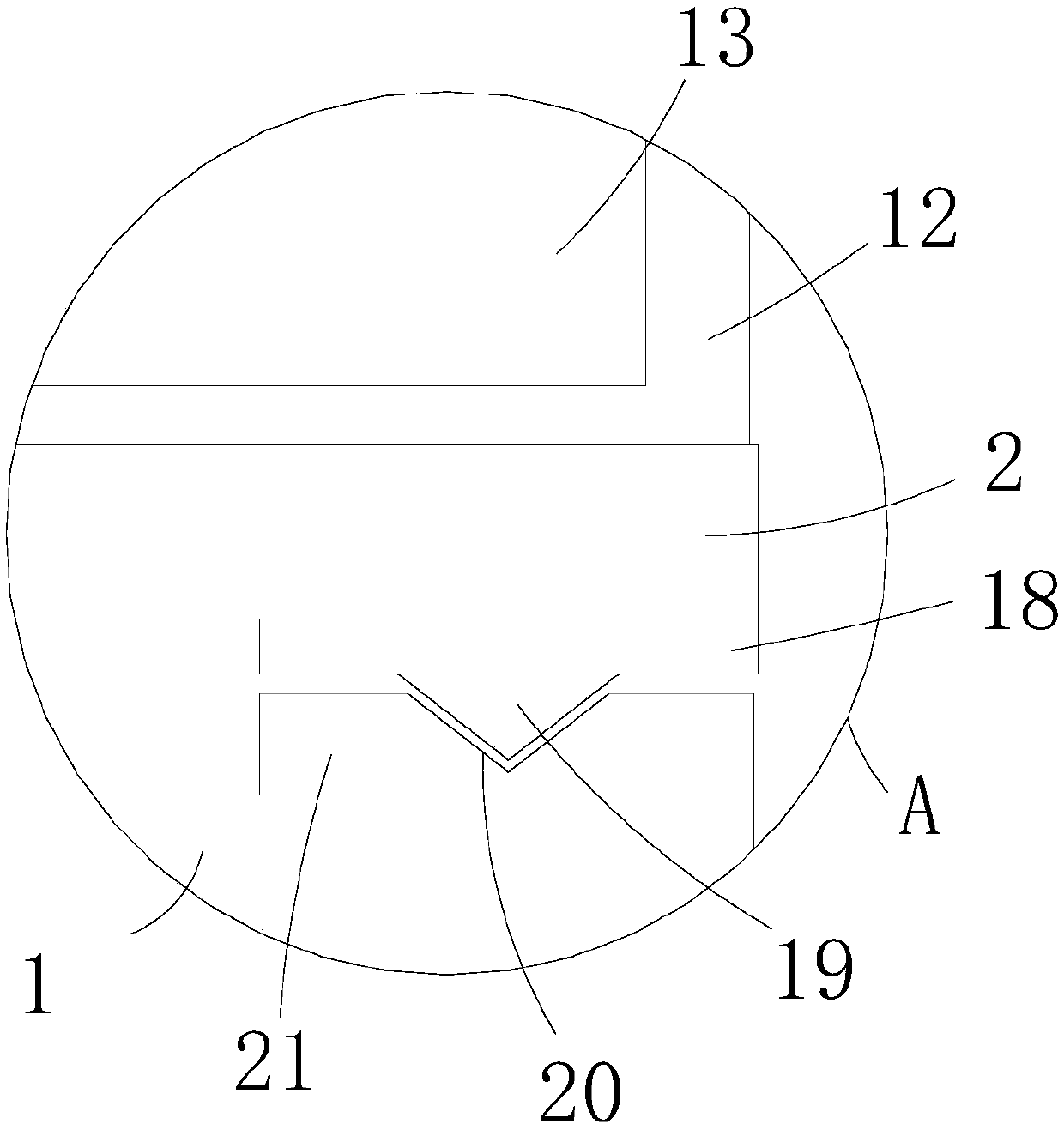

Multifunctional steel pipe column verticality adjusting machine for pile and column integral construction

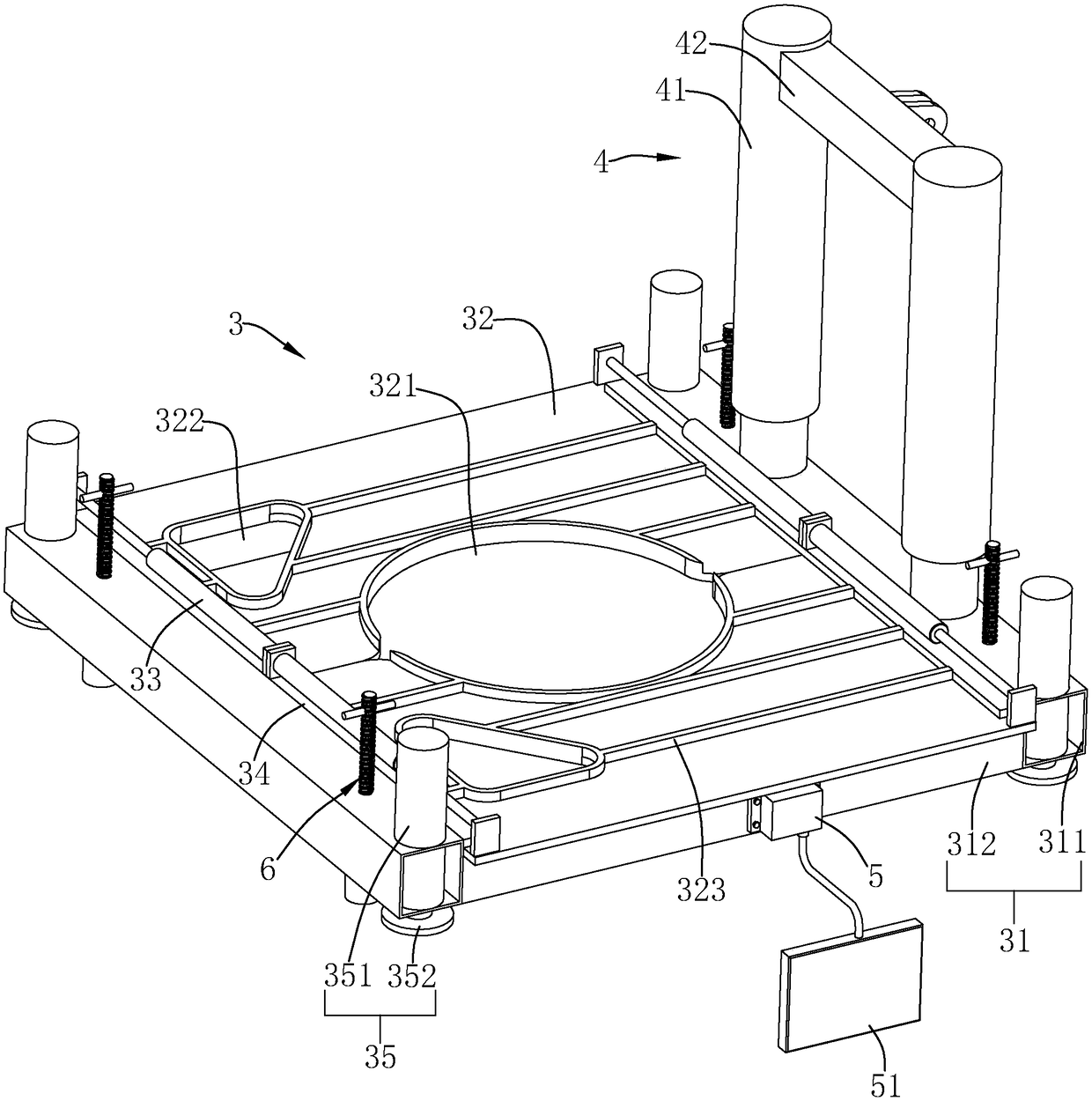

ActiveCN108867647AHigh precisionShorten the construction periodBulkheads/pilesMechanical engineeringBuilding construction

The invention discloses a multifunctional steel pipe column verticality adjusting machine for pile and column integral construction. The machine comprises a verticality adjusting machine body; a suspension device, extending to one side, is arranged above the verticality adjusting machine body; a clamping device is arranged on one side of the verticality adjusting machine body and positioned underthe extension end of the suspension device; the clamping device comprises a rectangular bracket horizontally arranged on one side of the verticality adjusting machine body and positioned under the extension end of the suspension device, clamping plates symmetrically and slidingly arranged on the rectangular bracket, and driving pieces arranged on the rectangular bracket and capable of driving theclamping plates to horizontally slide in an approaching or leaving direction to clamp or loosen lifted steel pipe columns; and the clamping device further comprises adjusting modules for leveling thebracket at four corners of the bracket. The machine has the following advantages: after the verticality adjusting machine body is leveled, the verticality of steel pipe columns is singly adjusted, sothat the verticality adjusting precision is improved, and meanwhile, the construction period is reduced.

Owner:BEIJING G&M ENG CONSTR CO LTD +1

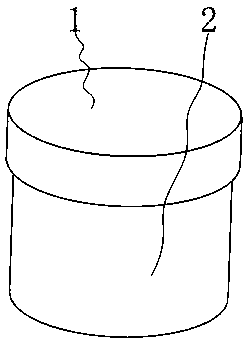

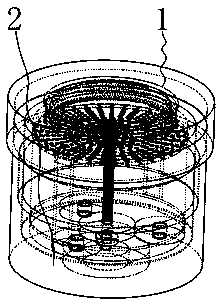

Powder box used for cosmetics package

ActiveCN109051365AMobile impactAvoid using influenceCapsPowdered material dispensingEngineeringCosmetics

The invention belongs to the technical field of cosmetics boxes, and particularly relates to a powder box used for a cosmetics package. The powder box comprises a box cover, a bottom box, a filter plate and a drive rod, and the box cover is arranged on the bottom box through cooperation of an inner thread on the box cover and an outer thread on the bottom box. The filter plate is arranged in the bottom box. In the powder box usage process, the filter plate is made to downwards move relative to the bottom box through rotation of a drive disc. Foundation make-up, located on the lower side of thefilter plate, in the bottom box seeps to the upper side of the filter plate through filter holes in the filter plate; accordingly, usage is conducted, and after usage is finished, the bottom box is reversely buckled down; at the time, the foundation make-up, located on the filter plate, in the bottom box can be poured out; the situation that when the foundation make-up is used by other people next time, infection is caused to other people through the foundation make-up left on the upper side of the filter plate is avoided; according to the designed powder box, the seepage amount of the foundation make-up in the bottom box can be increased through rotation and vibration of the filter plate; and the situation that due to the insufficient seepage amount, usage is influenced is avoided.

Owner:诸暨市金凯隆袜业有限公司

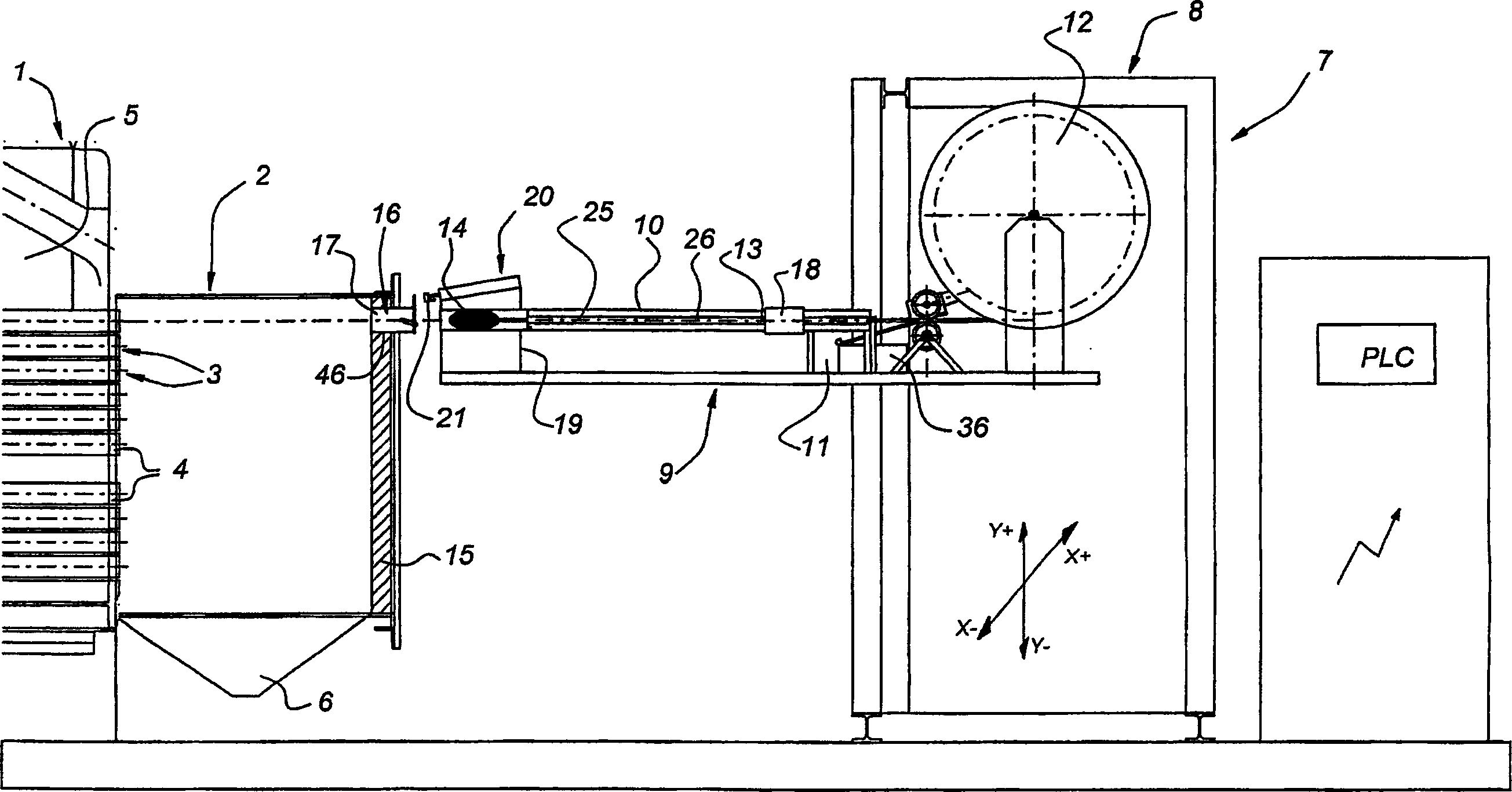

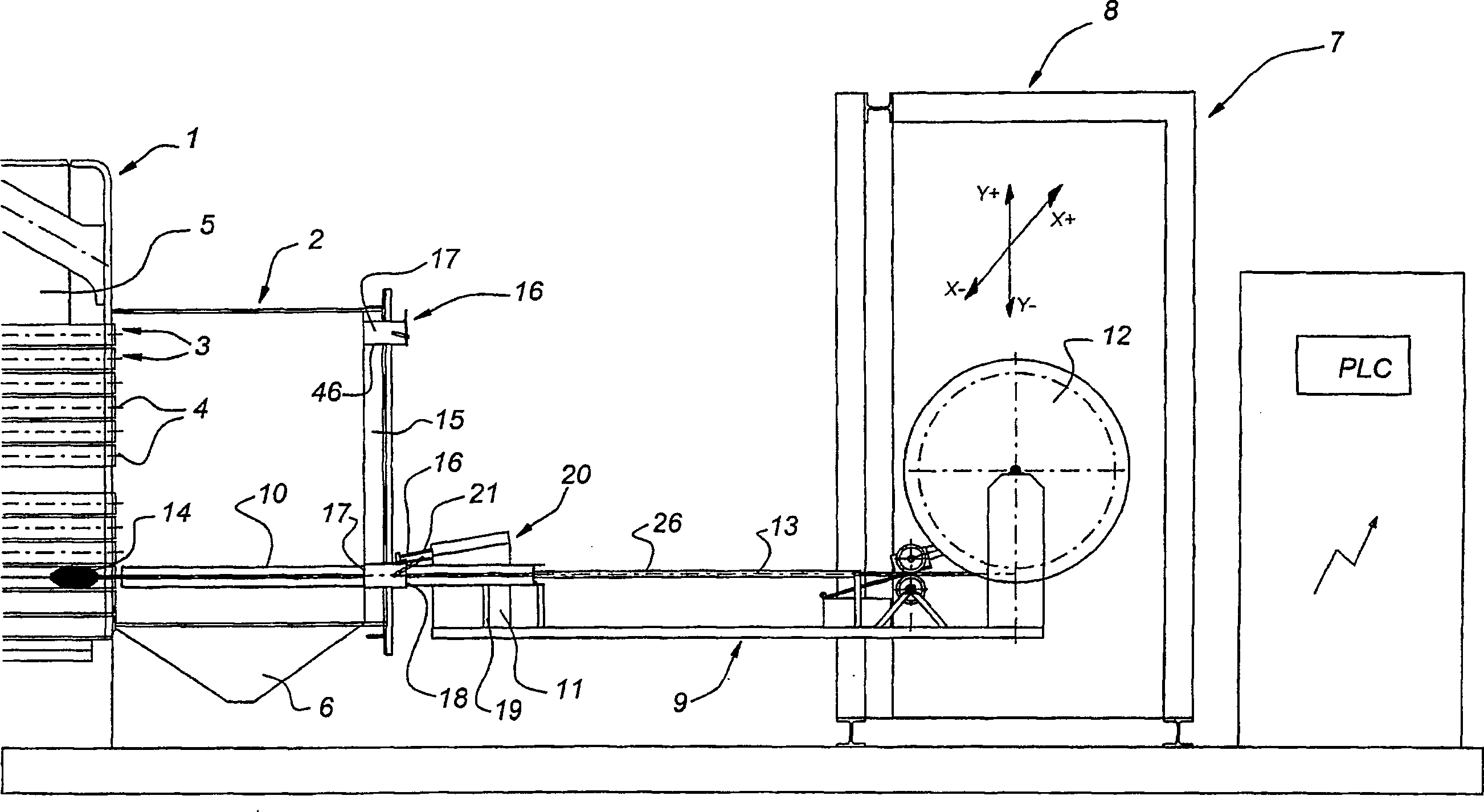

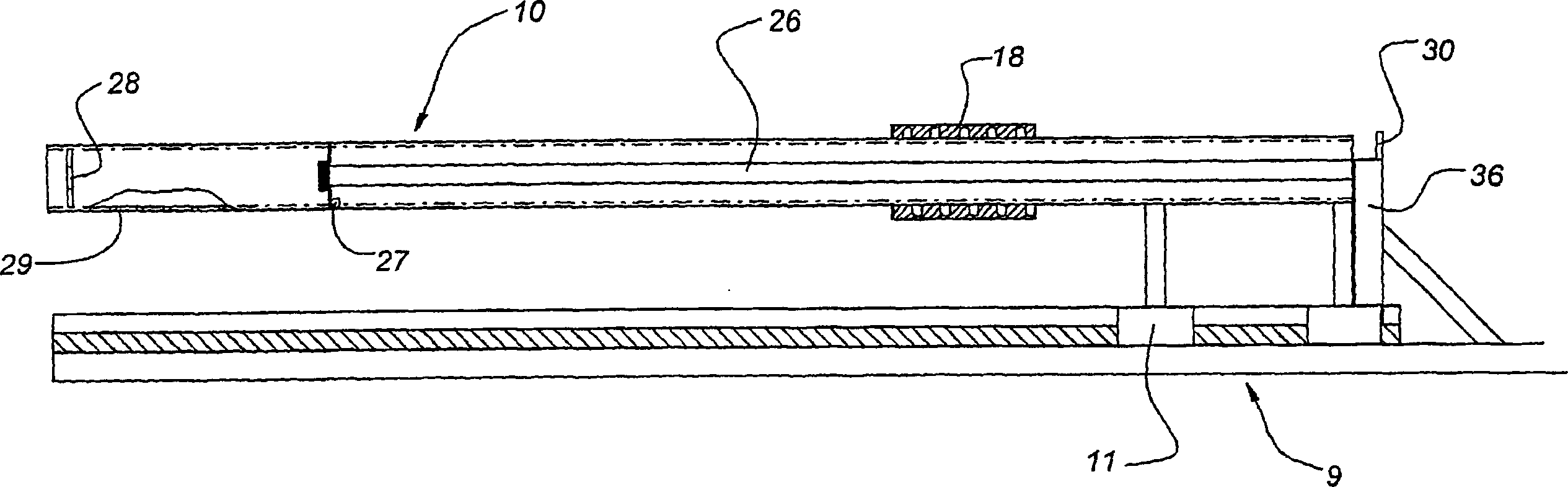

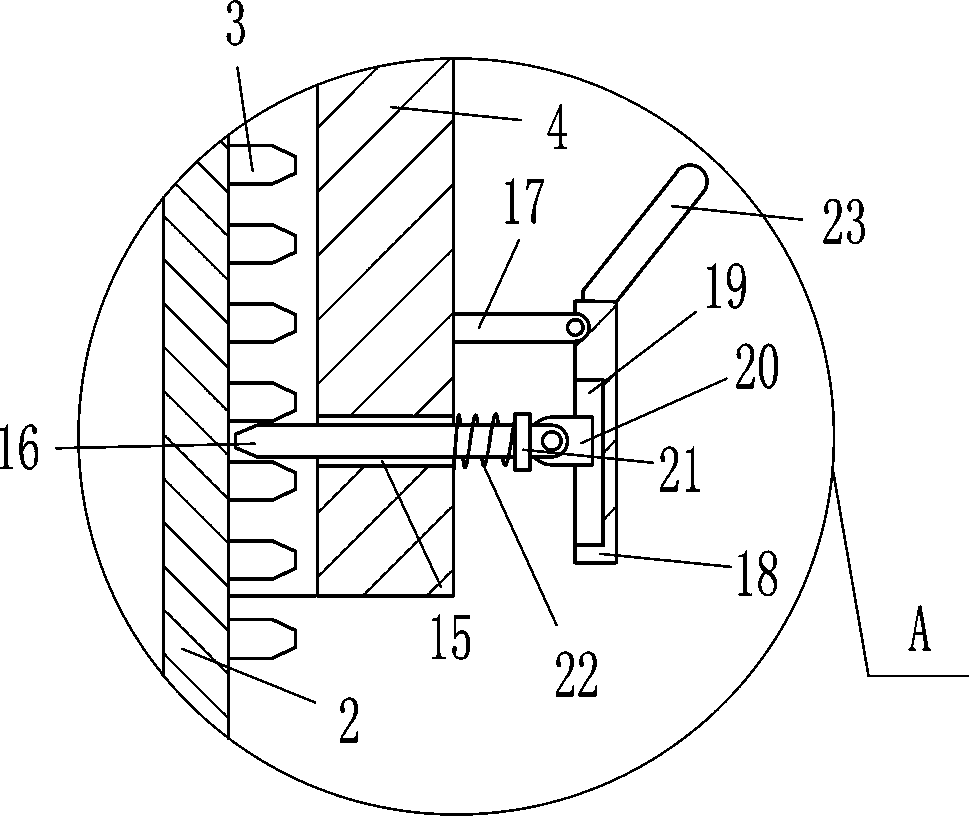

Device for cleaning the fire tubes in a boiler

ActiveCN1809723AMobile impactAutomated cleaningSolid removalNon-rotary device cleaningEngineeringMechanical engineering

Owner:OPTIMUM ENVIRONMENTAL & ENERGY TECH BV

Leg support frame for surgical leg injury patient

InactiveCN108969260AEasy to take medicineDrug effectNursing accommodationDrive motorPhysical therapy

The invention relates to a leg support frame, in particular to a leg support frame for a surgical leg injury patient. The technical problem is to provide the leg support frame which is convenient inapplying medicine to the leg of the patient and can fix the leg of the patient so as to avoid leg disorder of the patient, which may influence the medicine application. According to the technical scheme: the leg support frame for the surgical leg injury patient comprises a bottom plate, a frame body, fixing blocks, an n-shaped frame, a first spring, a seat, a first slide block and the like; the topof the bottom plate is provided with the frame body, and the fixing blocksare evenly arranged at the upper part of the left side and right side of the frame body at intervals. By pressing a swing rod,the height of the seat is adjusted, and the position of an arc-shaped placing plate can be adjusted through the action of a driving motor and a speed-reducing motor, so that the patient can more convenientlyplace the leg for applying the medicine, the leg of the patient can be fixed through the fixing device, and the medicine application is not affected by the disorder of the leg caused by pain.

Owner:吕文浩

Iron wire cutting machine for building

The invention relates to a cutting machine, in particular to an iron wire cutting machine for a building. The technical problem is to provide an iron wire cutting machine for a building which can replace the manual work to cut the iron wire, save labor and cut the iron wire into a uniform length. The technical scheme provided by the invention is as follows: an iron wire cutting machine for a building comprises legs, a frame body, a first bearing seat, a hexagonal hole rod, a strut, a disc, a first guide rod, a first spring, an arc-shaped movable plate, and the like; the left and right sides ofthe outer bottom of the frame body are provided with the legs, the first bearing seat is arranged at the left side of the top of the frame body, and the hexagonal hole rod is arranged on the first bearing seat. The iron wire cutting machine provided by the invention can engage a first bevel gear with a second bevel gear by sleeving the iron wire on the arc-shaped movable plate and pushing the arc-shaped movable plate; and then the head end of the iron wire is pulled to move between a guide wheel and a fixing block; and a servo motor is started, namely, the iron wire can be cut by a cutter; and the iron wire can be cut into the wires with consistent length; the iron wire is not needed to be cut by a wire cutter artificially, which is more labor-saving.

Owner:繁峙县同兴宇金属制品有限公司

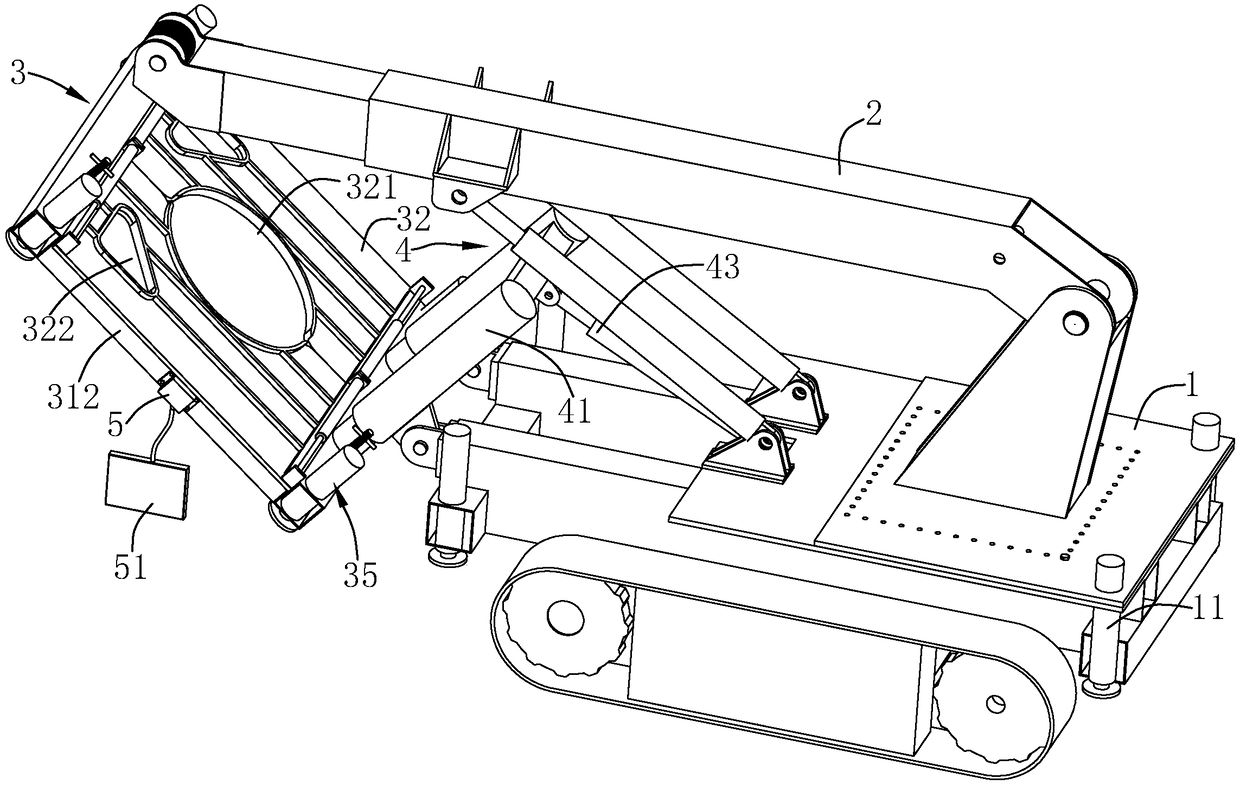

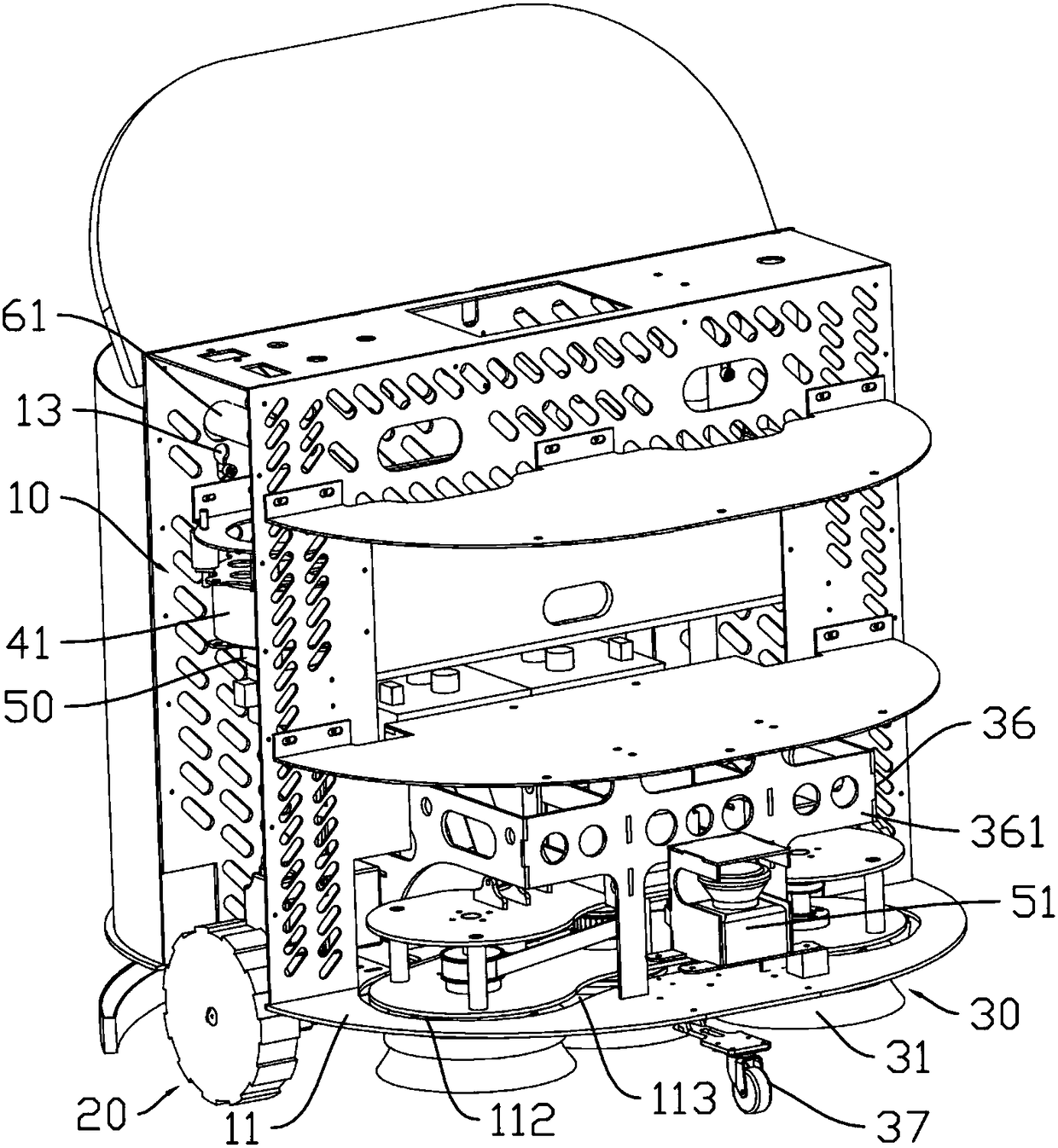

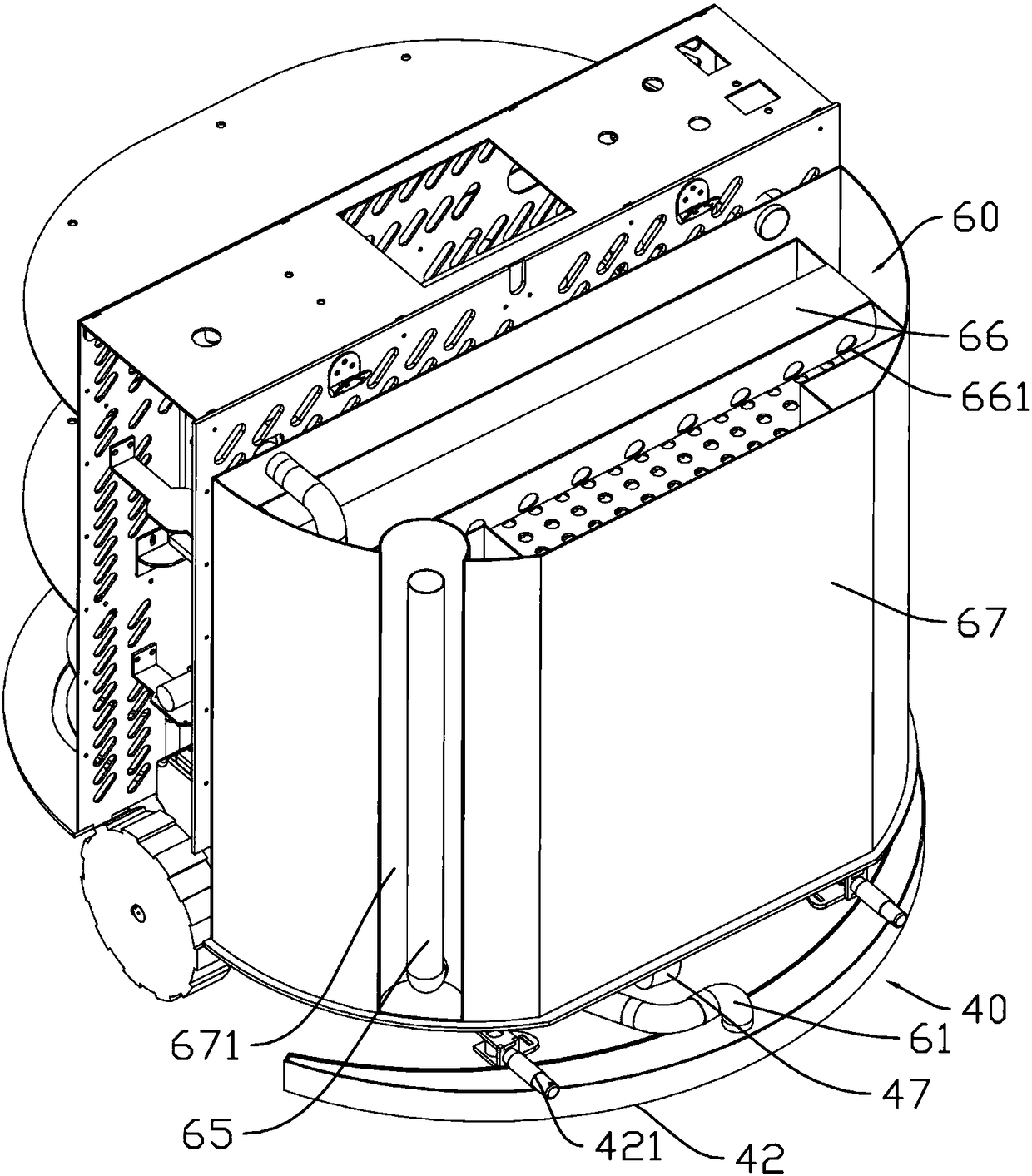

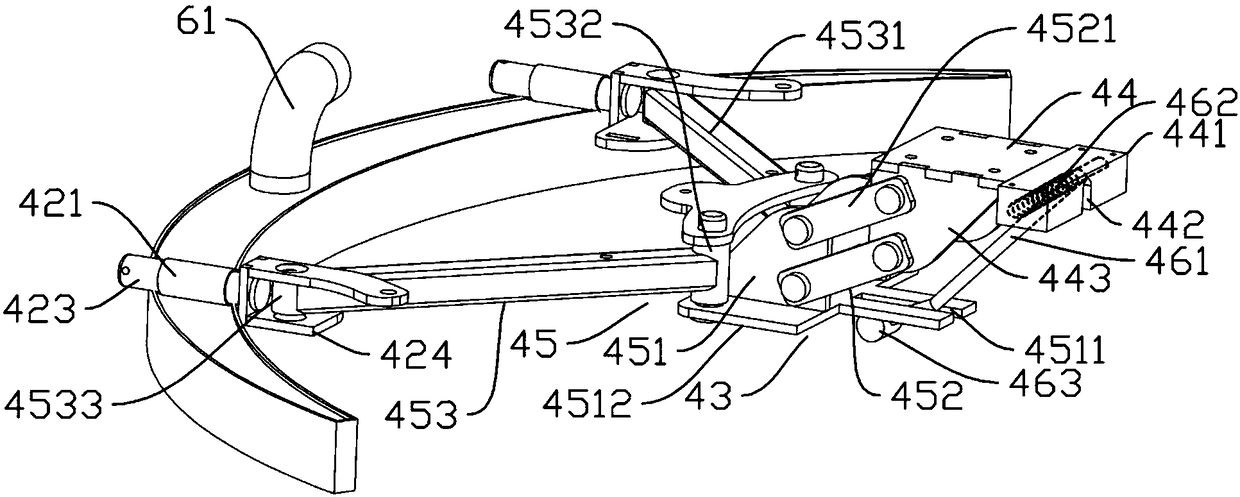

Intelligent floor cleaning robot

PendingCN108403027AAvoid damageSimple structureAutomatic obstacle detectionTravelling automatic controlStopped workControl system

The invention discloses an intelligent floor cleaning robot. The intelligent floor cleaning robot comprises a bottom plate, a driving system, a brushing system, a water wiping system, a control system, a water circulation system and a main frame used for mounting components, the water wiping system comprises a vacuum water absorption machine, a water absorption rake body and a water absorption rake lifting device, the water absorption rake lifting device comprises a mounting seat, the mounting seat is connected with the bottom plate, the mounting seat is connected with the water absorption rake body through a connecting rod mechanism, a return mechanism is arranged between the mounting seat and the connecting rod mechanism, the water absorption rake body is provided with a sewage pipe communicated with the vacuum water absorption machine, the water absorption rake body has a first state of being adsorbed on the ground under the action of the vacuum water absorption machine and a secondstate of breaking away from the ground under the action of the return mechanism after the vacuum water absorption machine stops working, the return mechanism comprises a return rod movably connectedwith the connecting rod mechanism and an elastic part driving the rotation of the return rod. The intelligent floor cleaning robot has the advantage that the quick decline and ascent of a water absorption rake can be achieved.

Owner:杭州吉迈机器人有限公司

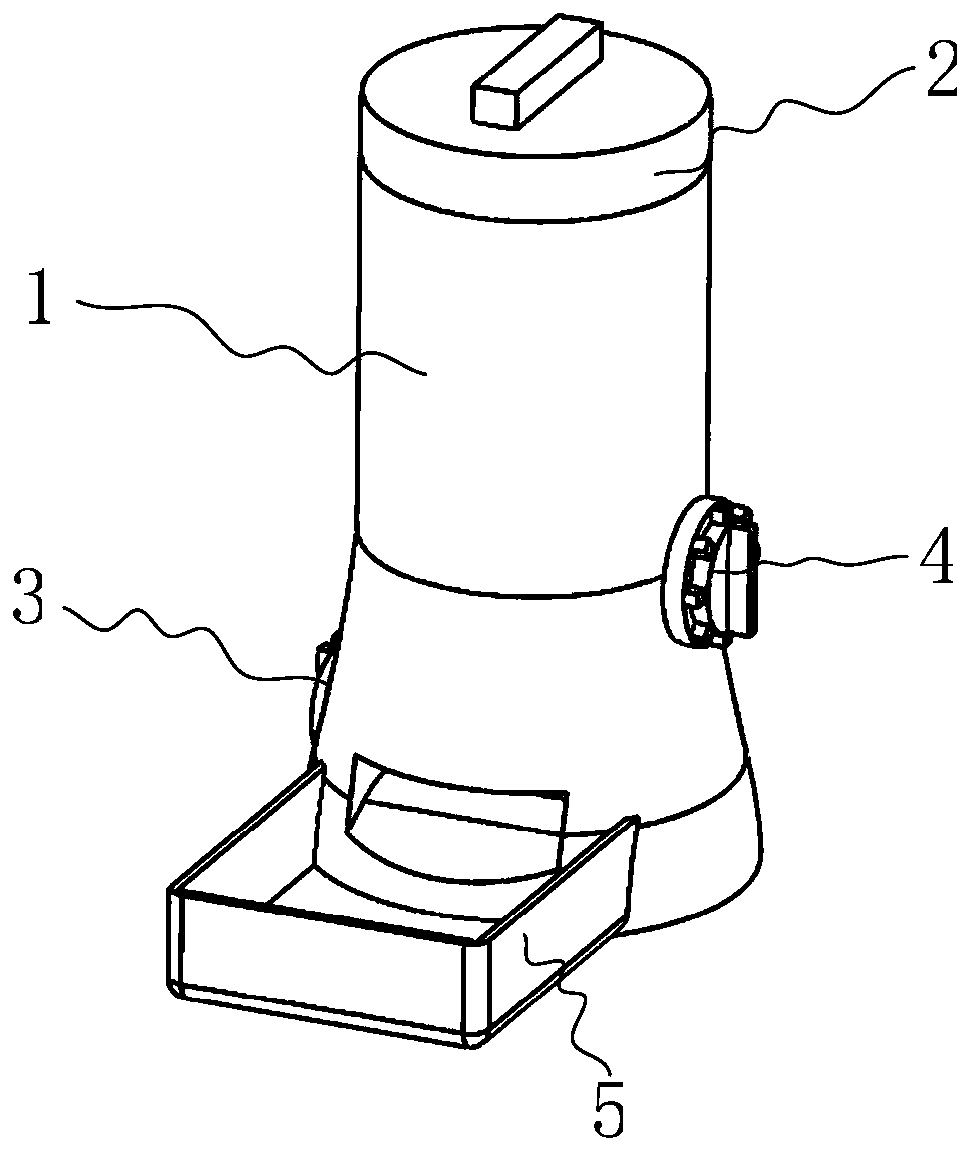

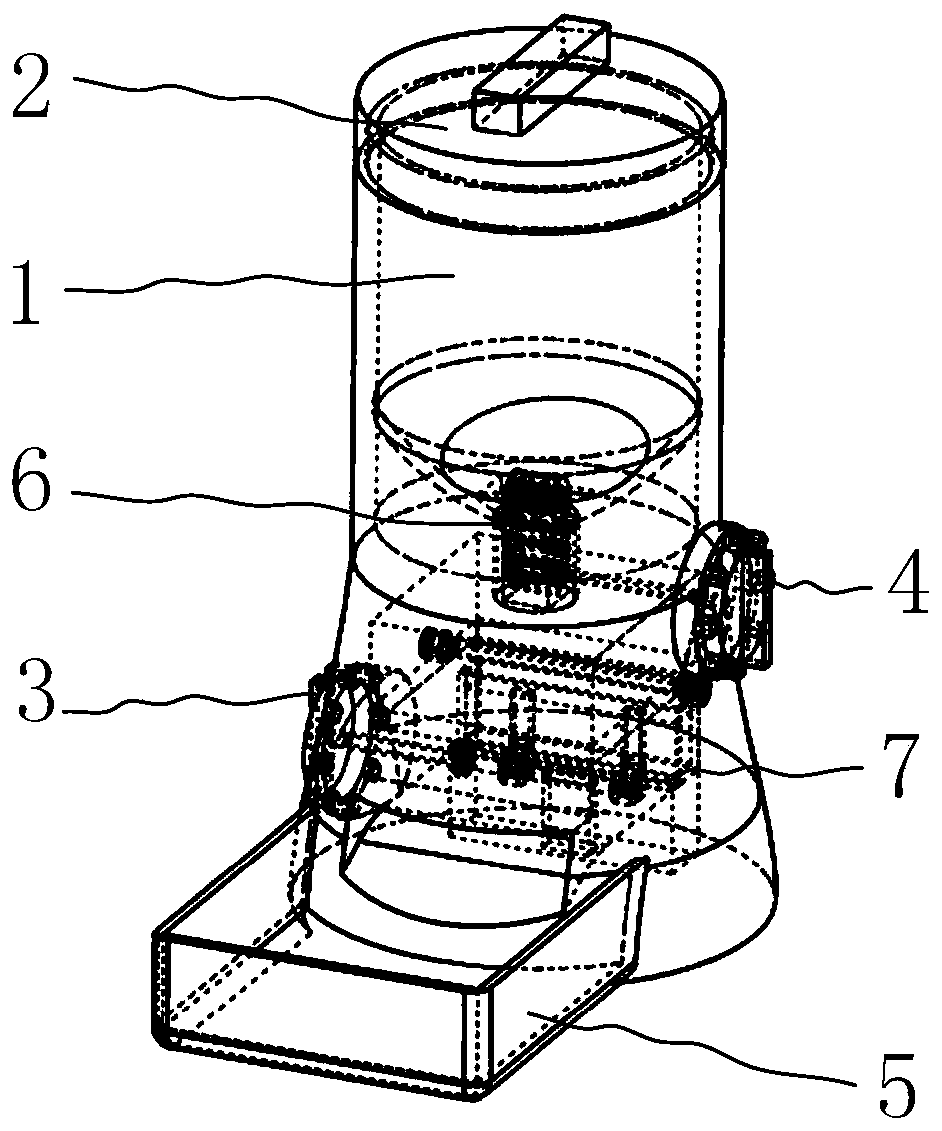

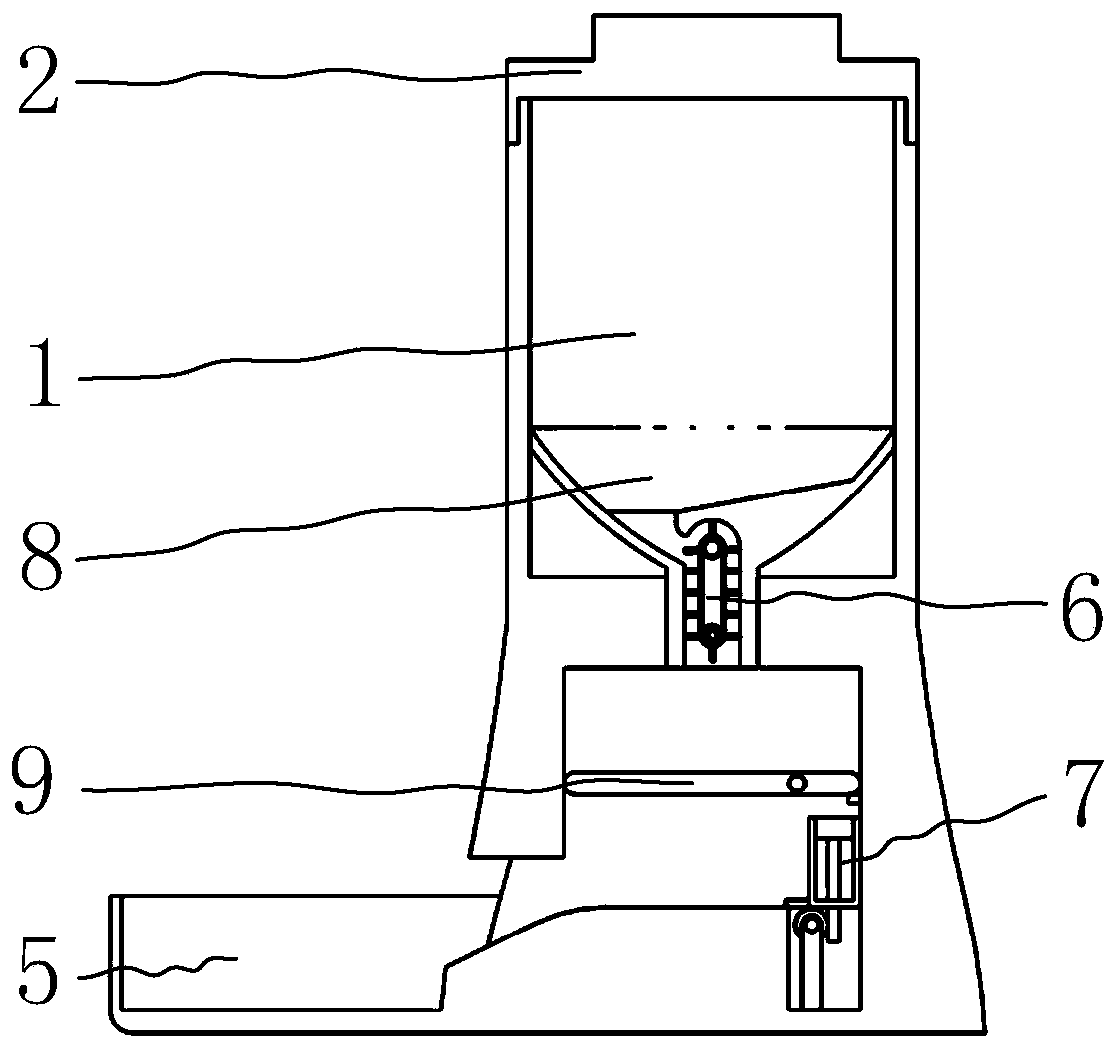

Automatic feeding machine

InactiveCN110301368ASimple structureLow costAnimal feeding devicesControl engineeringMechanical drive

The invention belongs to the technical field of feeding machines, in particular to an automatic feeding machine, which comprises a shell body, a transmission mechanism, an adjusting mechanism, a diversion bucket and a swinging plate. The feeding machine adopts mechanical transmission to realize automatic feeding, has simple structure and low cost, and does not need to be electrified, so that the feeding machine is prevented from being invalid and affecting the feeding of pets due to sudden power failure; on the other hand, pets can be prevented from biting off electric wires to cause short circuit and injuring the pets, and at the same time, fire and potential safety hazards can further be prevented. According to the automatic feeding machine, when a belt drives the transmission plate mechanism to move and transmit food, if the lower side of the transmission plate mechanism clamps the food entering through a food inlet opened on the diversion bucket at a food inlet, a sliding plate inthe transmission plate mechanism provides a frictional pulling force to the stuck food, so that the stuck food slides down, and the food stuck at the food inlet is prevented from influencing the movement of the transmission plate mechanism.

Owner:沈宇杰

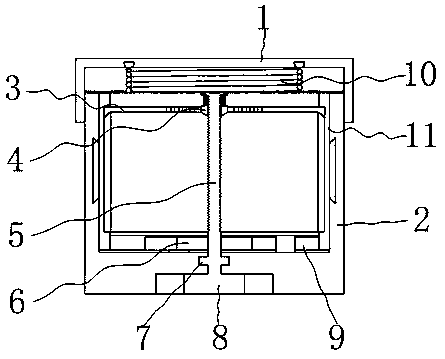

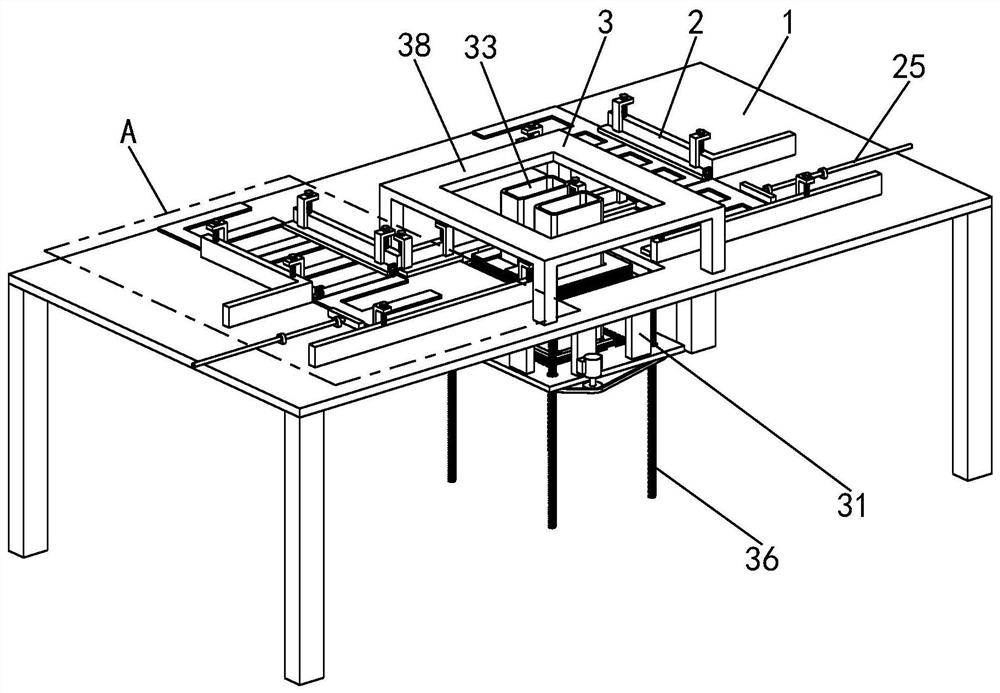

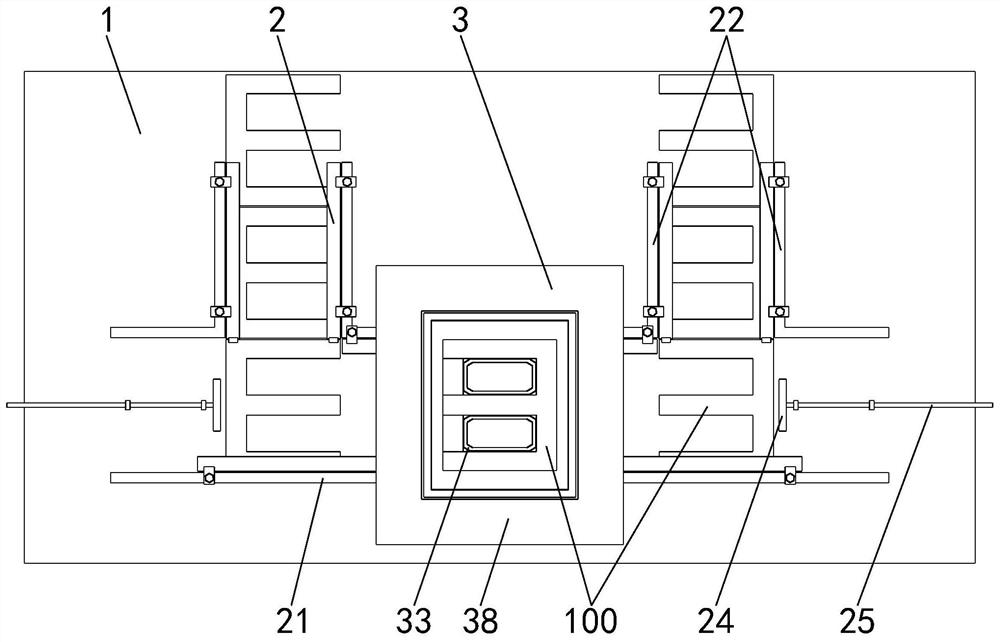

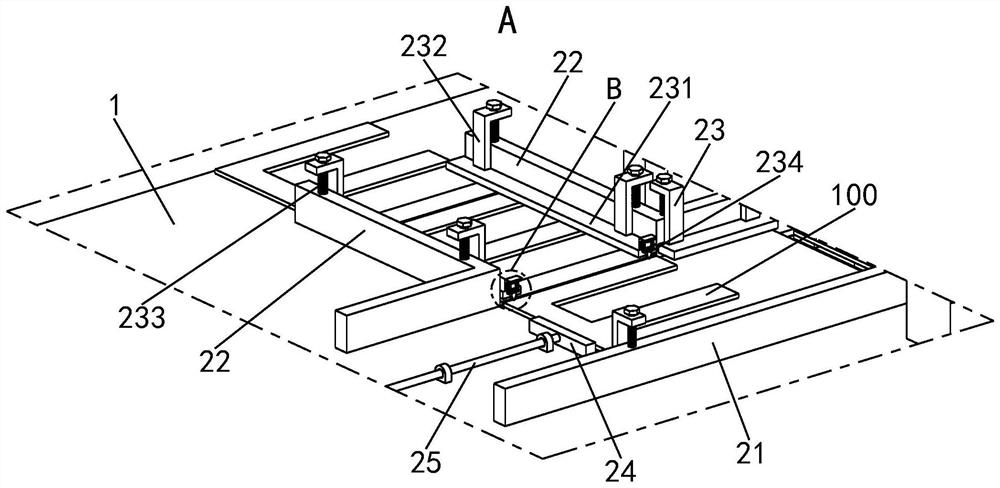

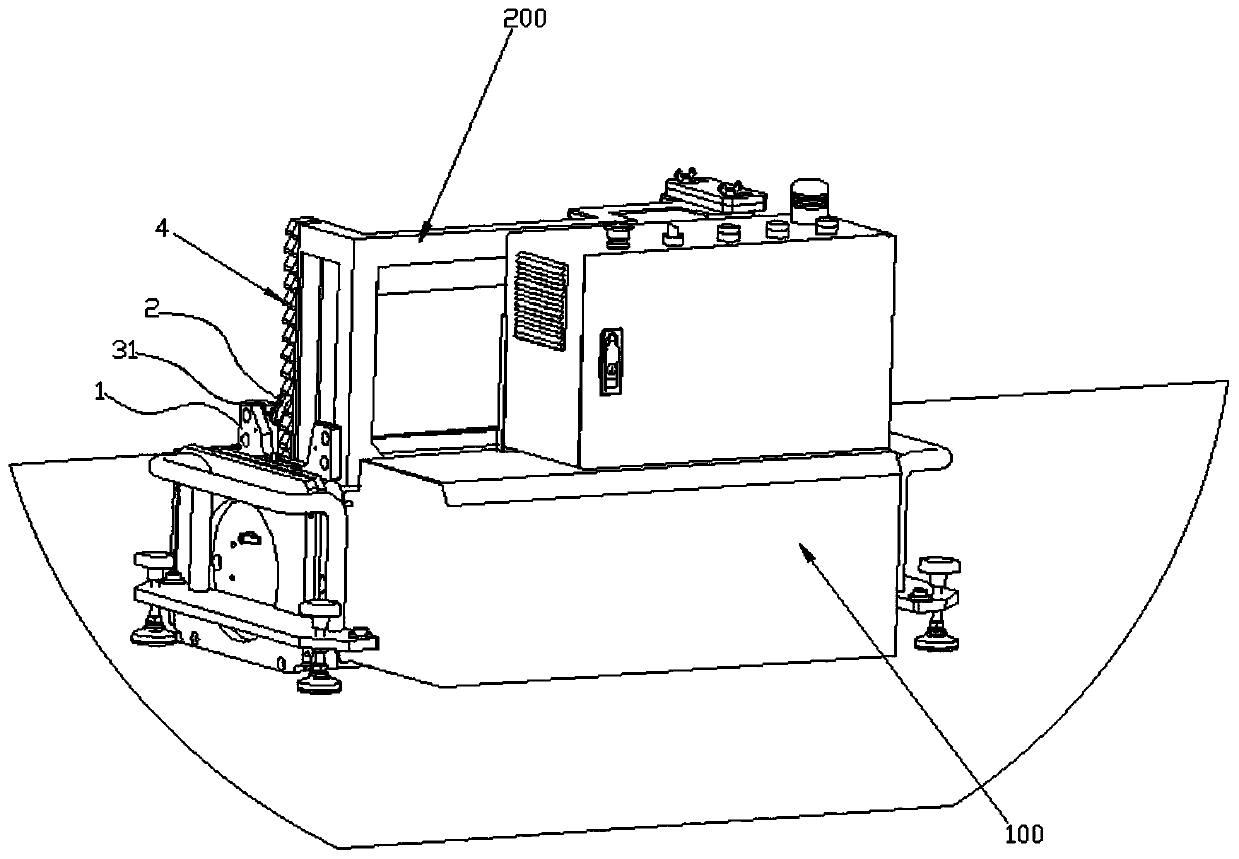

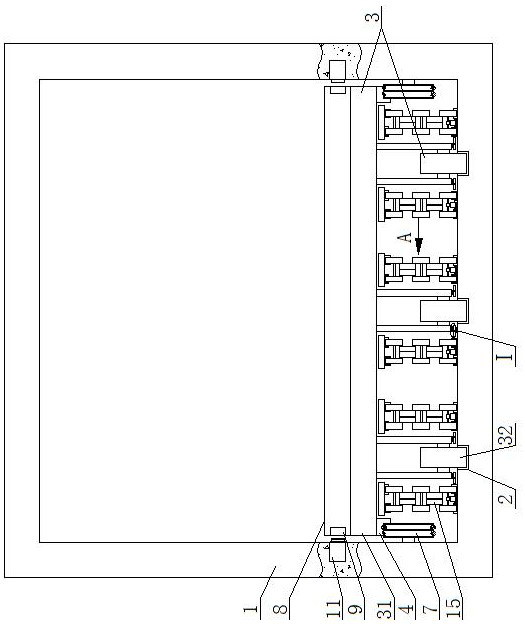

Automatic iron core stacking production line for marine transformer manufacturing

ActiveCN113921262AImprove stacking efficiencyAccurate number of stacksInductances/transformers/magnets manufactureProduction lineStructural engineering

The invention relates to the technical field of marine transformer manufacturing and processing, in particular to an automatic iron core stacking production line for marine transformer manufacturing. The production line comprises a stacking table, two guide devices and a stacking device, the two guide device which are symmetrical left and right are arranged in the upper end of the stacking table, and the stacking device is arranged in the middle of the stacking table and located between the two guiding devices. According to the iron core stacking device, the function of stacking silicon steel sheets of iron cores of the same shape and different specifications can be achieved by replacing placing plates and stacking frames of different specifications, meanwhile, the silicon steel sheets can be alternately stacked left and right through the two guiding devices, and therefore the iron core stacking efficiency can be improved; and scale strips are arranged on connecting plates, so that the descending height of the concentric-square-shaped frame during stacking of the silicon steel sheets can be observed conveniently, the height difference is the stacking thickness of the iron core, and whether the stacking number of the silicon steel sheets is accurate or not can be determined.

Owner:JIANGSU HAICHUAN ELECTRICAL MFG CO LTD

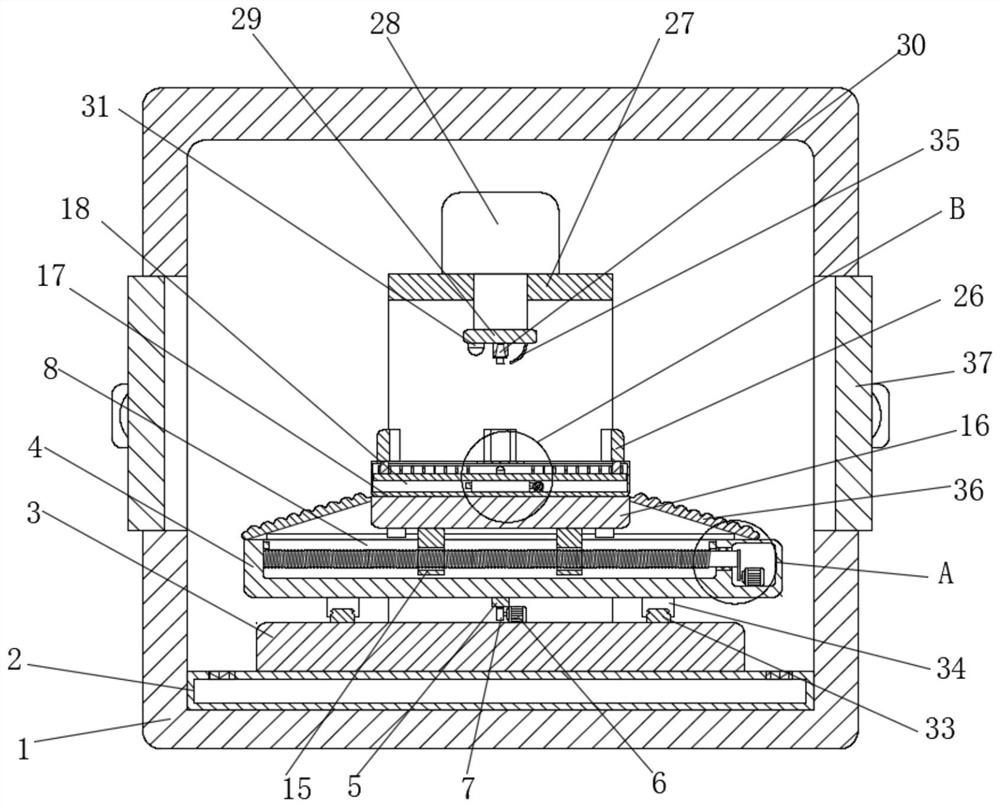

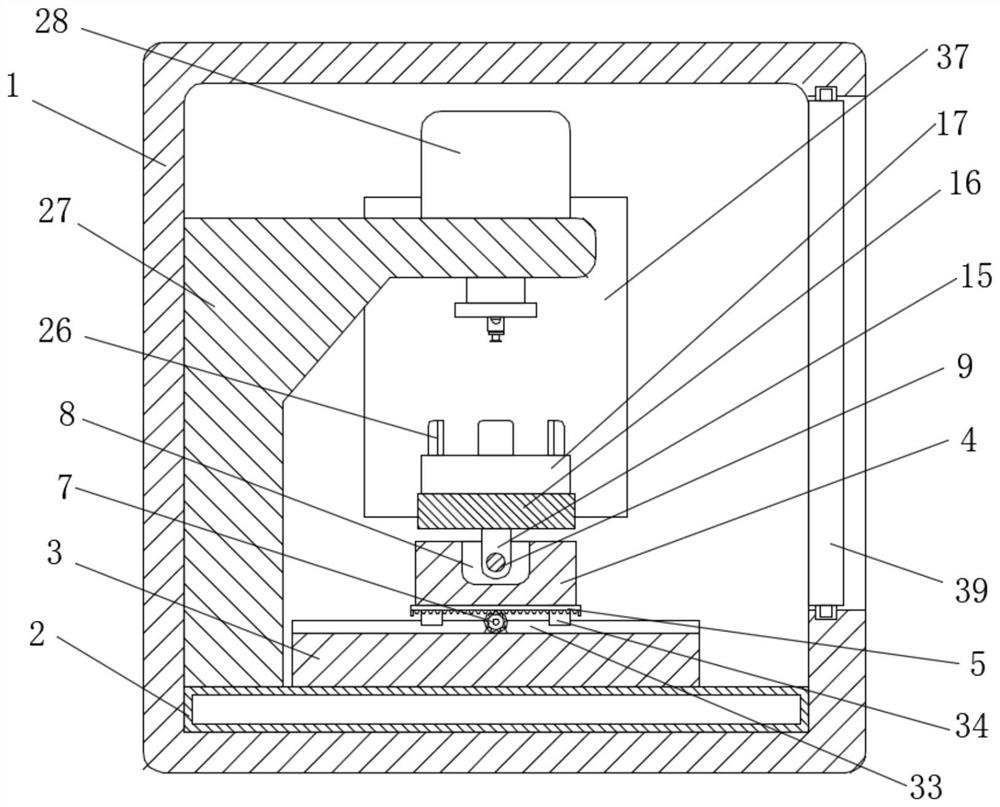

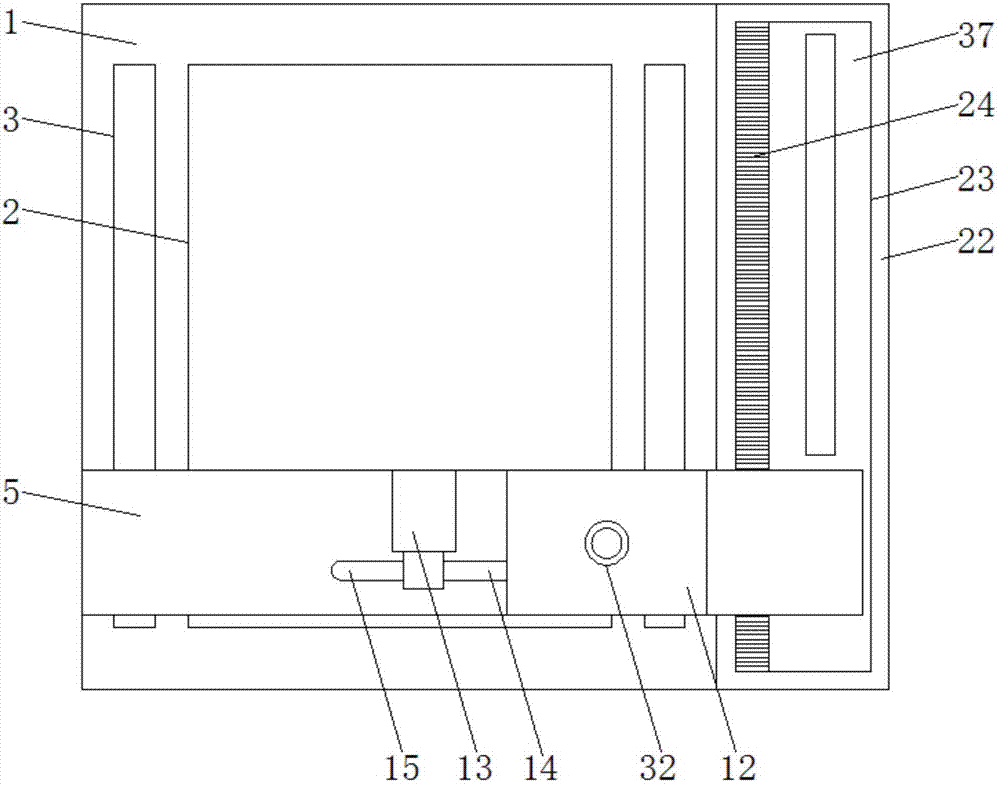

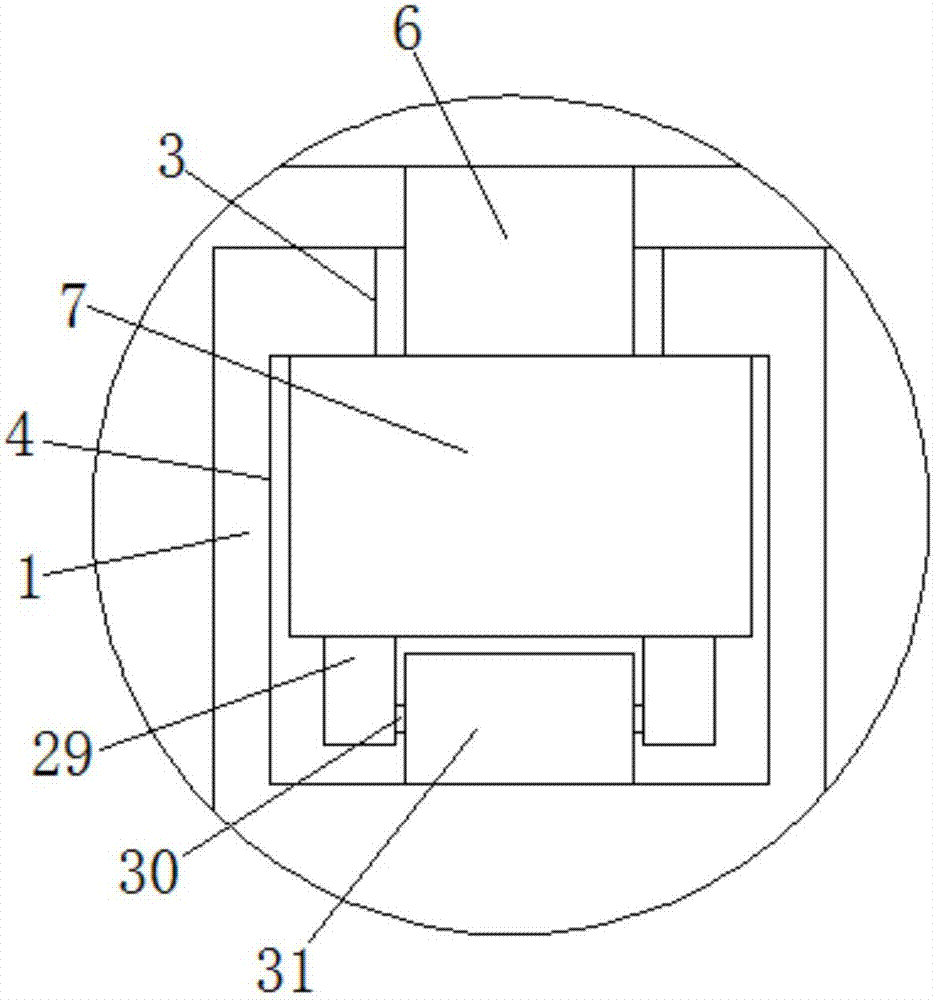

Numerically-controlled machine tool provided with automatic positioning and clamping device

PendingCN112548134ANo human intervention requiredAvoid failureMeasurement/indication equipmentsFeeding apparatusNumerical controlDetent

The invention belongs to the field of numerically-controlled machine tool equipment, particularly relates to a numerically-controlled machine tool provided with an automatic positioning and clamping device, and provides the following scheme for solving the existing problems. The numerically-controlled machine tool comprises a shell; a cooling liquid collecting box is fixedly connected to the innerwall of the bottom of the shell; a fixing table is fixedly connected to the top of the cooling liquid collecting box; a sliding table is glidingly connected to the upper side of the fixing table; a sliding assembly used for driving the sliding table to slide is arranged at the top of the fixing table; and a sliding plate is glidingly connected to the top of the sliding table. The machine tool iseasy to operate, position information is transmitted into a control panel through a positioner, so that automatic positioning can be conducted, positioning is accurate in the positioning and machiningprocess, and the machining efficiency is improved; clamping blocks can move through rotation of disc-shaped annular threads, and then a workpiece can be clamped, so that the automation degree is high, the working intensity is reduced, and the working efficiency is improved.

Owner:张红丽

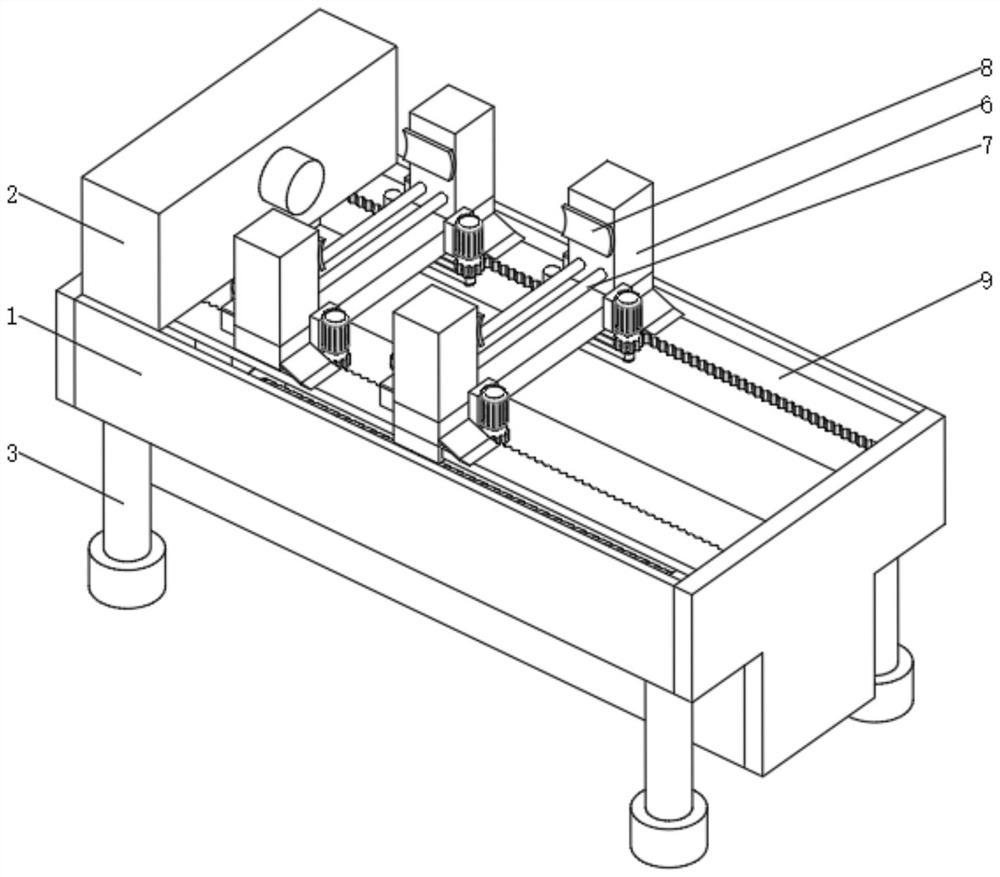

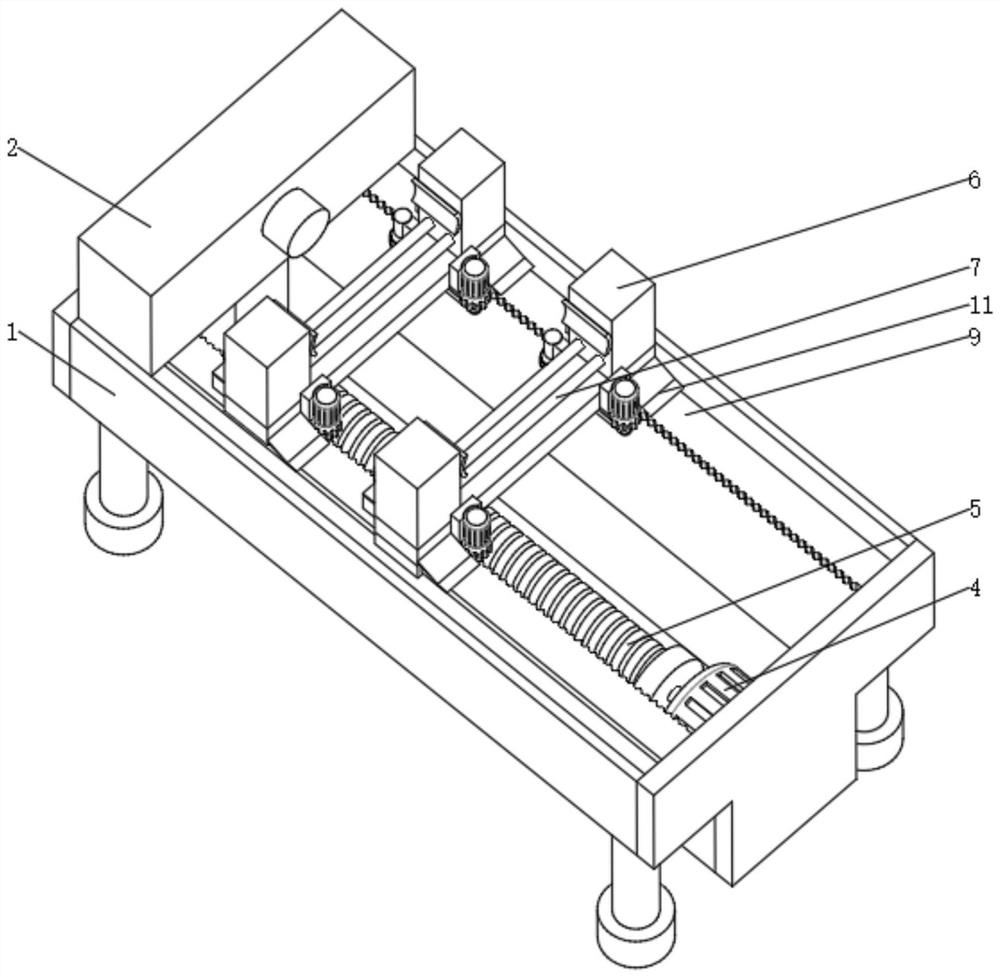

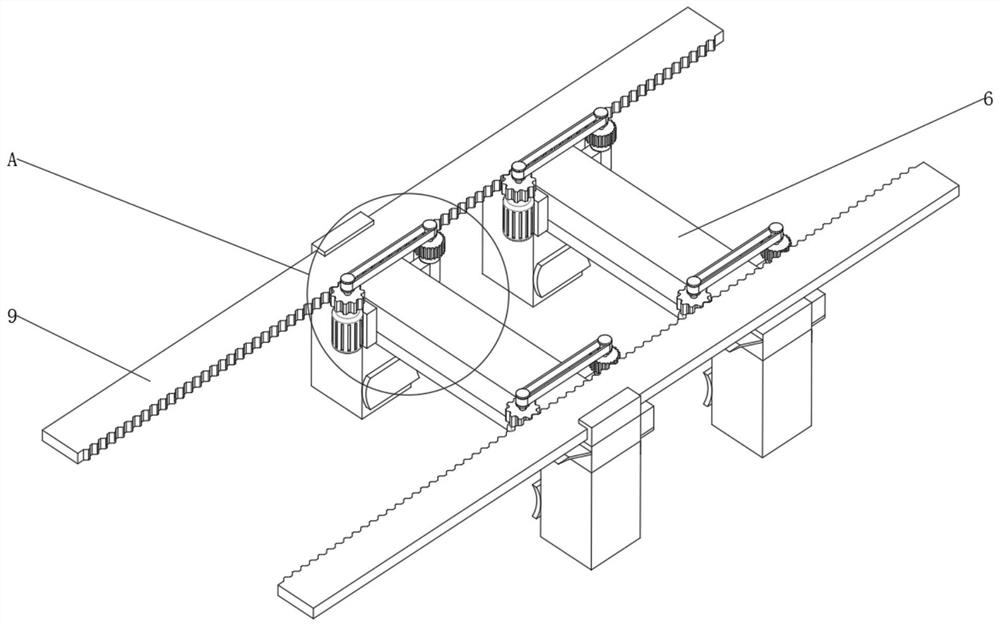

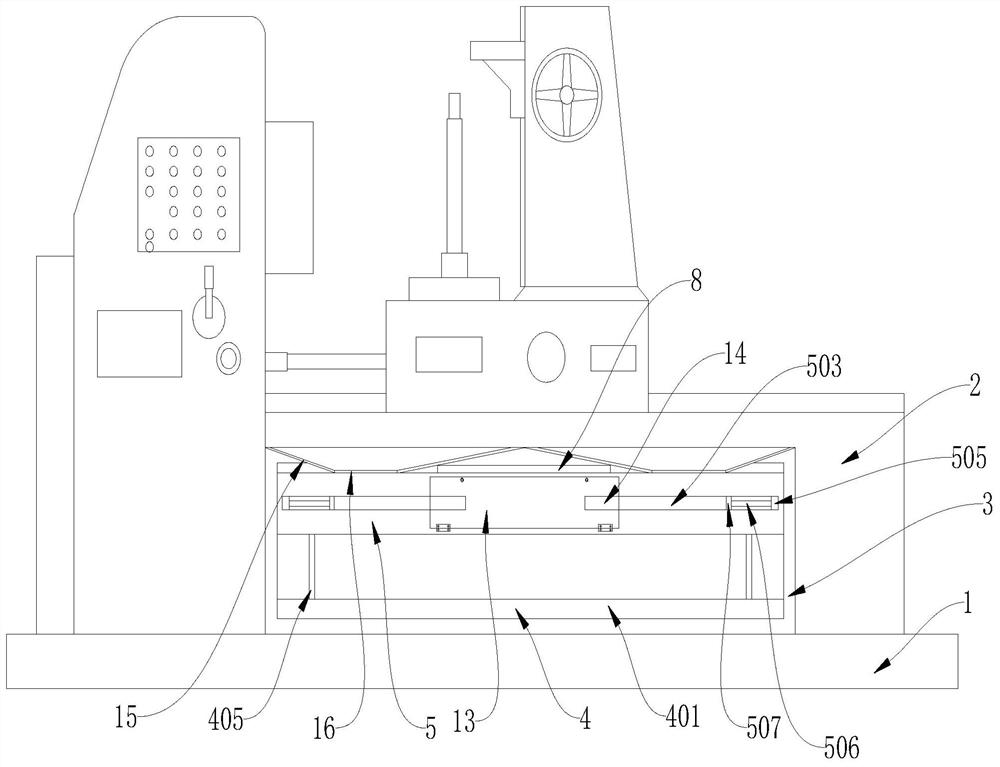

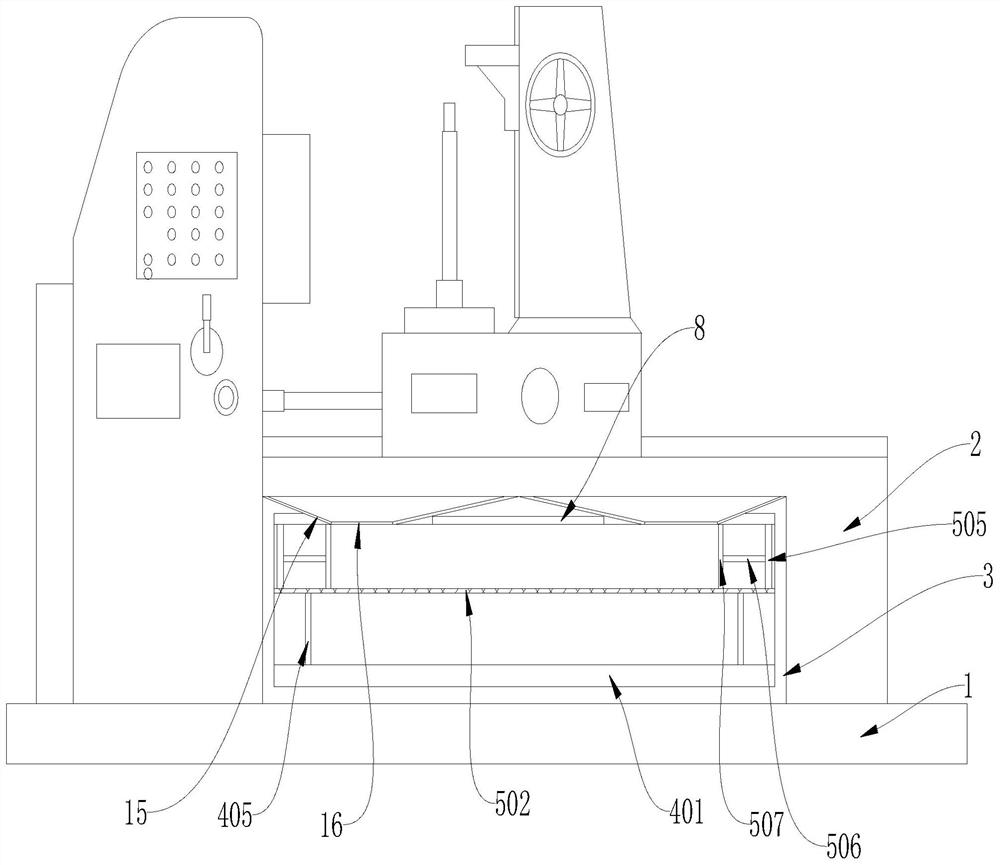

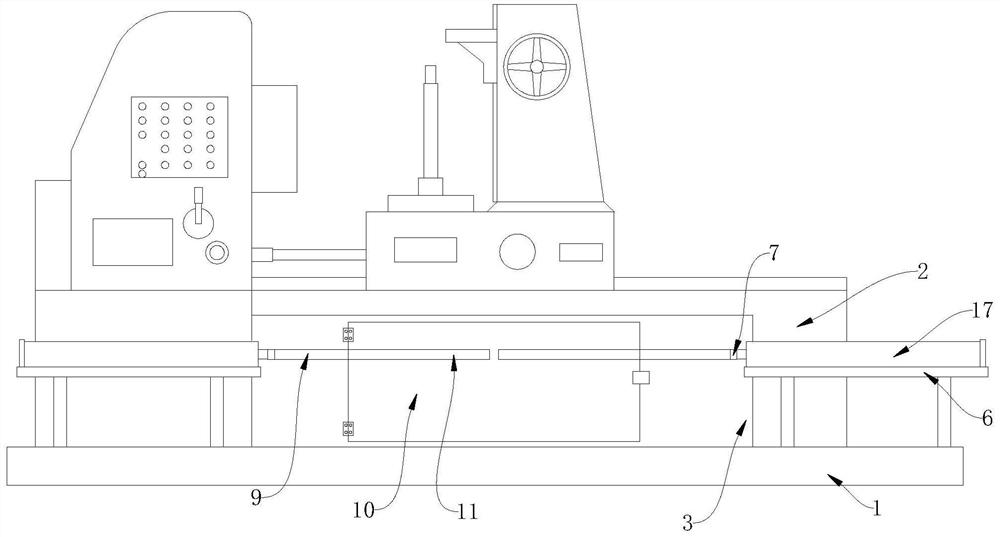

Supporting plate feeding system of numerical-control scraping rolling machine

InactiveCN112476011AAssisted movementReduce the impact of movementFeeding apparatusMaintainance and safety accessoriesServoRack and pinion

The invention relates to the technical field of oil cylinder machining, and discloses a supporting plate feeding system of a numerical-control scraping rolling machine. The supporting plate feeding system comprises a rack, wherein guide rails are fixedly mounted on the left side and the right side of the top end of the rack, fixed frames are movably mounted at the top ends of the guide rails, andracks are fixedly mounted at the ends, close to each other, of the two guide rails; and fixed seats are fixedly mounted on sides of the back surfaces of the fixed frames. According to the supporting plate feeding system of the numerical-control scraping rolling machine disclosed by the invention, the bottom ends of the output shafts of servo motors are fixedly sleeved with the gears, the racks arearranged on the side surfaces of the guide rails and connected to the gears in a meshed mode; and when the fixed frames need to be moved, the gears at the bottom ends of the servo motors can be driven to rotate at the moment by starting the servo motors; the gears can be driven by the racks to move relative to the guide rails and drive the fixed frames to move relative to the guide rails, so thatthe influence of sliding friction on movement of the fixed frames is reduced, and therefore, the advantage of assisting movement of the fixed frames is achieved.

Owner:娄底鼎力液压科技有限公司

Solar waste photovoltaic power generation plate crushing equipment

The invention relates to crushing equipment, in particular to solar waste photovoltaic power generation plate crushing equipment and aims to achieve the technical purpose of providing the solar wastephotovoltaic power generation plate crushing equipment which is large in crushing speed and can prevent shattered fragments from hurting surrounding people. According to the technical scheme, the solar waste photovoltaic power generation plate crushing equipment comprises a bottom plate, a collection frame, support plates, a fulcrum rod, a supporting plate, a cushion block, a transverse plate, a vertical rod, a first guide sleeve, a movable rod, a cutter and the like. The right side of the top of the bottom plate is provided with the collection frame. The left side and the right side of the top of the bottom plate are symmetrically provided with the support plates, and the support plate on the right side is located on the right side of the collection frame. According to the solar waste photovoltaic power generation plate crushing equipment, by means of a transmission mechanism, a waste photovoltaic power generation plate can be driven to rightwards move to be completely crushed, by means of a connecting plate and a rubber plate, the shattered fragments can be blocked and prevented from hurting the surrounding people, and the effects that the crushing speed is high and during crushing, the shattered fragments can be prevented from hurting the surrounding people are achieved.

Owner:谭令华

Economical energy-saving transportation box for logistics distribution

ActiveCN111532555AAvoid stacking each otherAvoid damageClosure with auxillary devicesNon-removalbe lids/coversLogistics managementMechanical engineering

The invention discloses an economical energy-saving transportation box for logistics distribution. The economical energy-saving transportation box comprises a box body, a telescopic rod, a first box door, a second box door and moving wheels, wherein the telescopic rod is embedded in one side of the top end of the box body, the first box door is installed on one side of the box body, the second boxdoor is installed on the other side of the box body, and the moving wheels are installed at two ends of the bottom end of the side, close to telescopic rod, of the box body. The economical energy-saving transportation box is scientific and reasonable, and is safe and convenient to use; the first box door and the second box door are arranged so that logistics products can be put into the box bodythrough the two sides of the box body, the logistics products are prevented from being stacked due to the fact that the logistics products are put in from one end, and then damage to the logistics products is avoided; and meanwhile, any logistics product can be conveniently taken out to be distributed, an extrusion air bag can be pressurized through rotation of the moving wheels by means of a pressurizing assembly, and convenience and rapidness are achieved.

Owner:SHENS ZEHAN SUPPLY CHAIN MANAGEMENT (CHONGQING) CO LTD

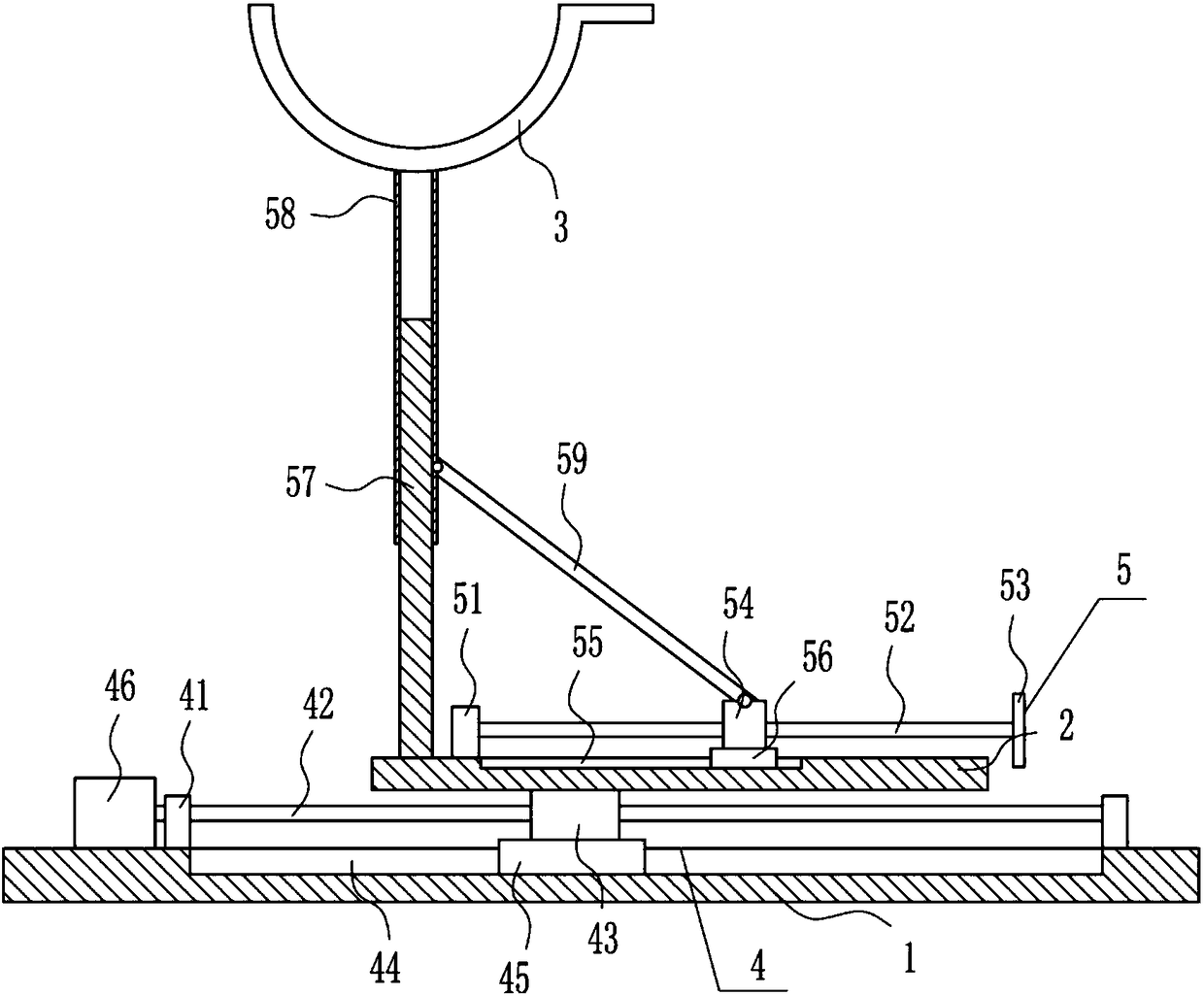

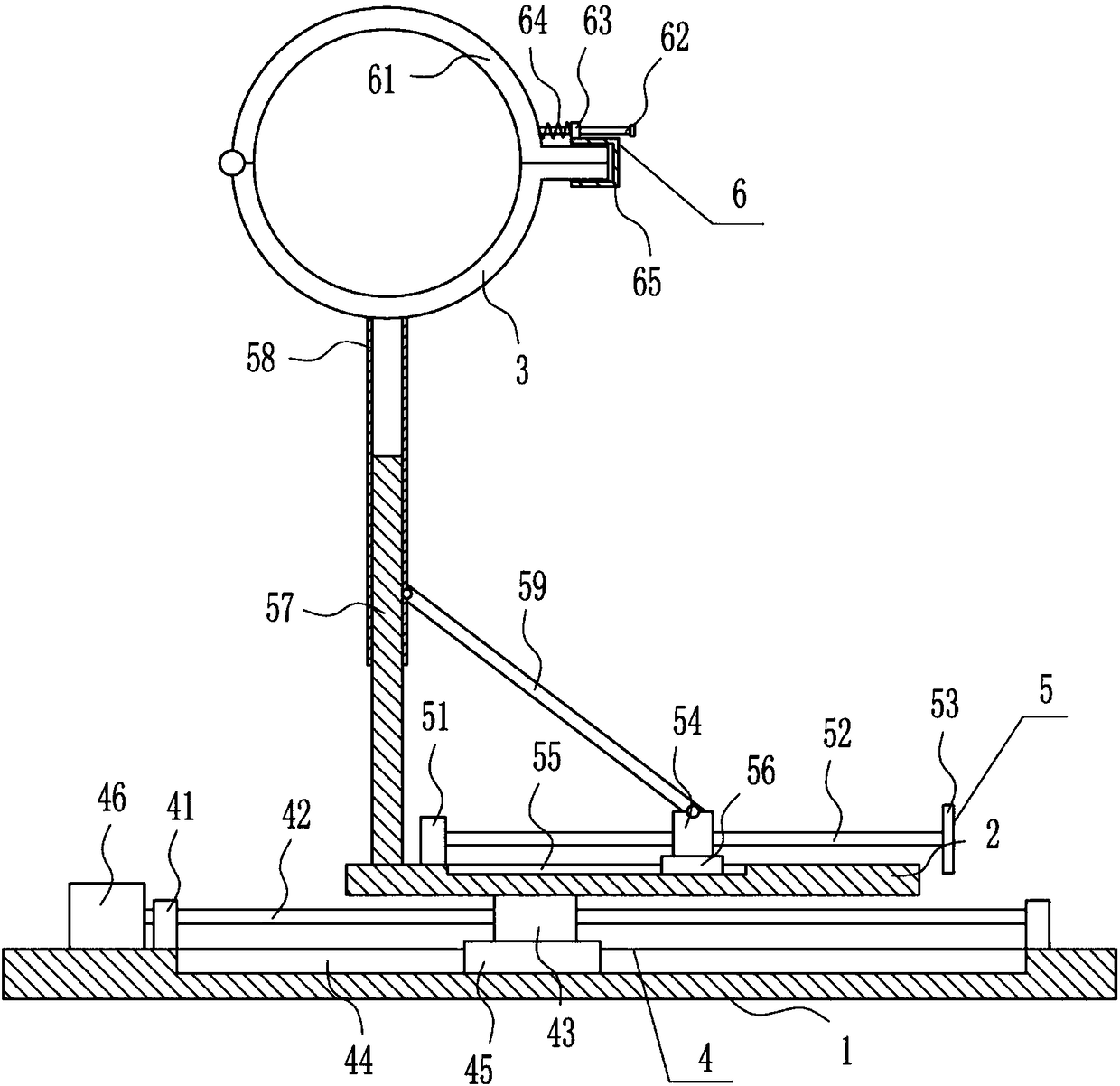

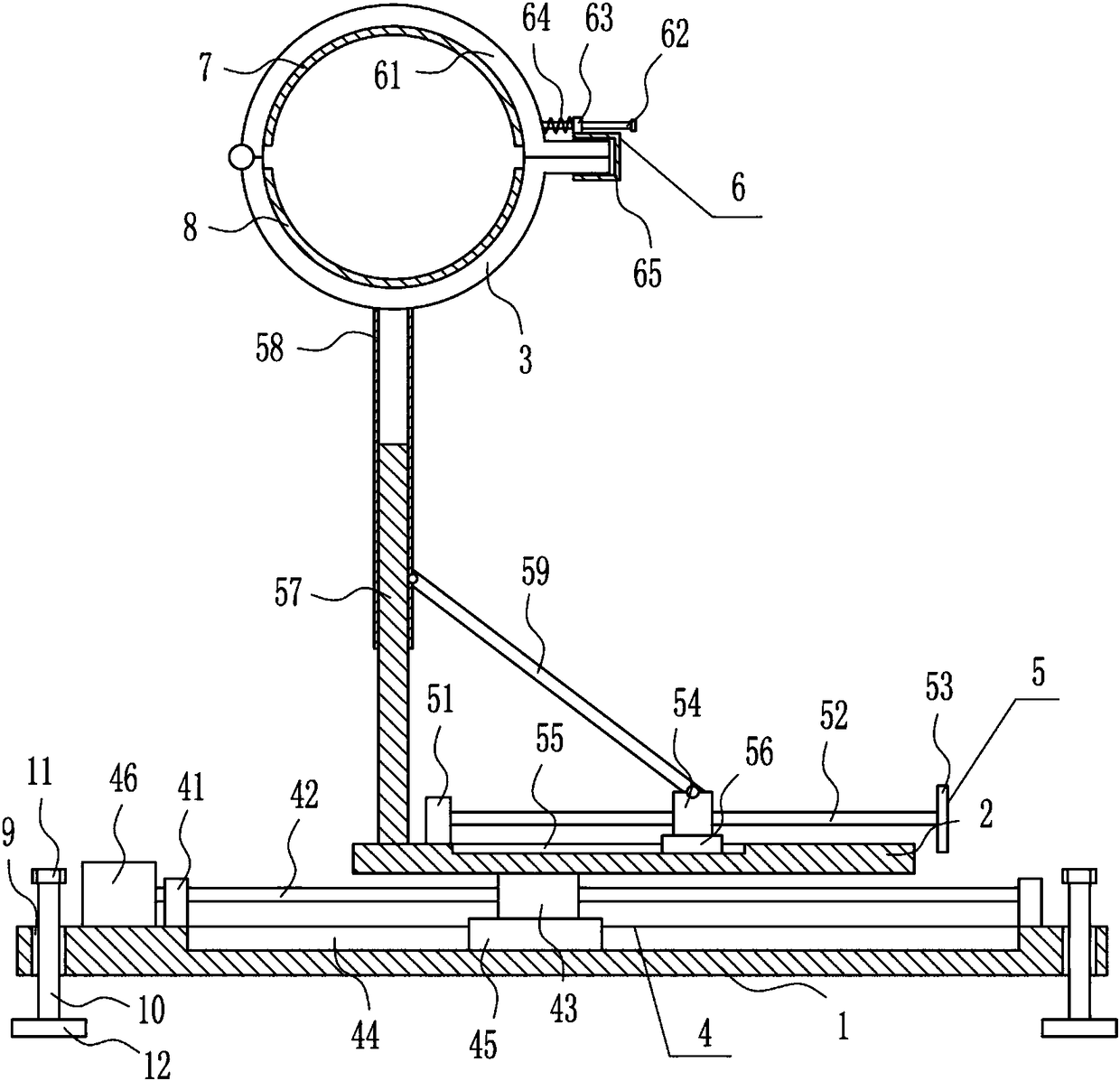

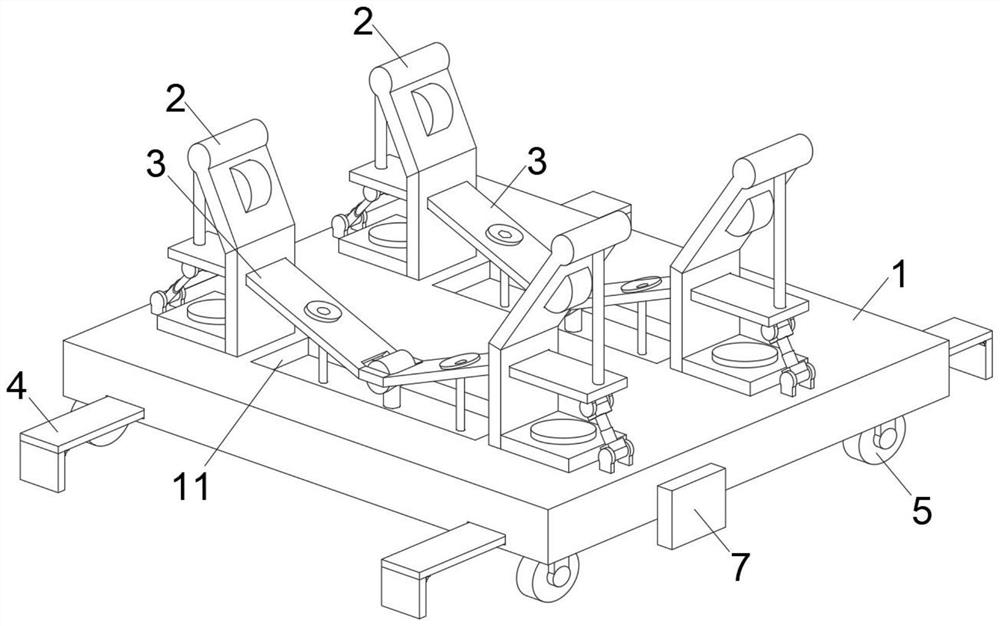

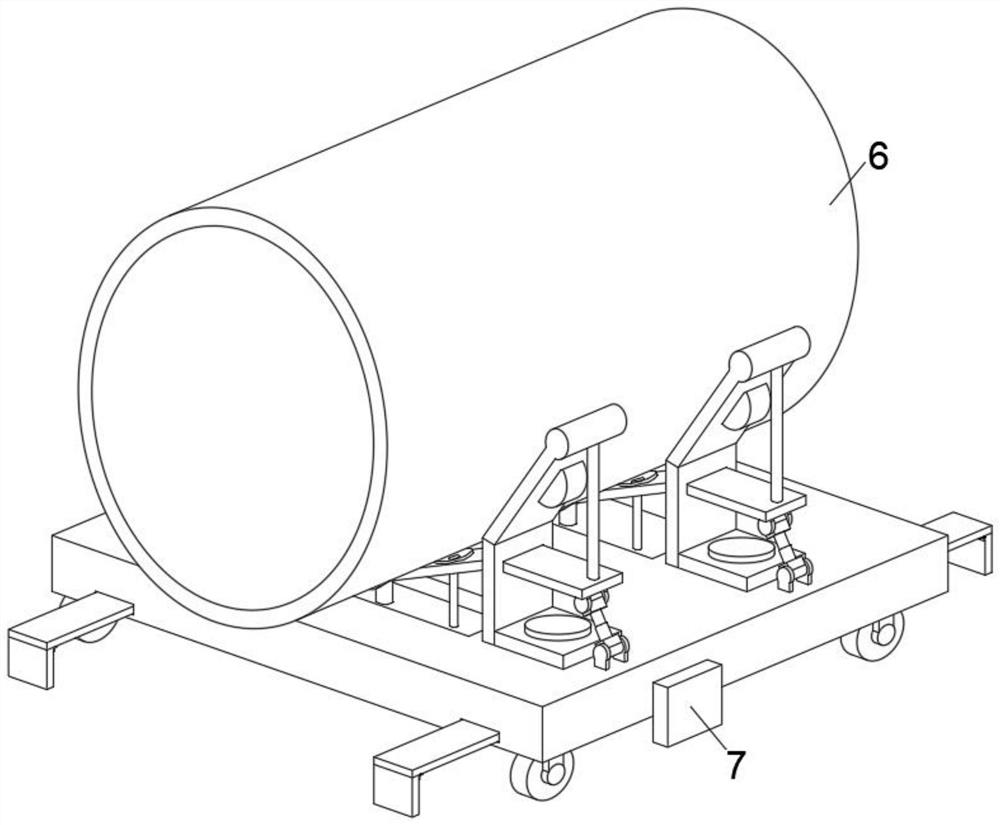

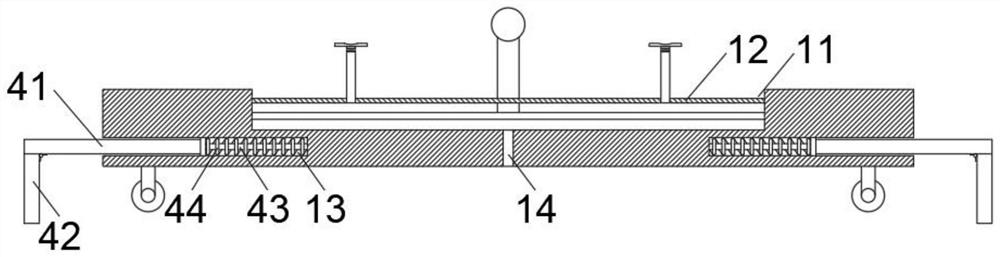

Supporting frame convenient to adjust and used for petroleum pipeline installation

ActiveCN108581358AProtects against welding effectsEasy to fixWelding/cutting auxillary devicesAuxillary welding devicesPetroleumPetroleum engineering

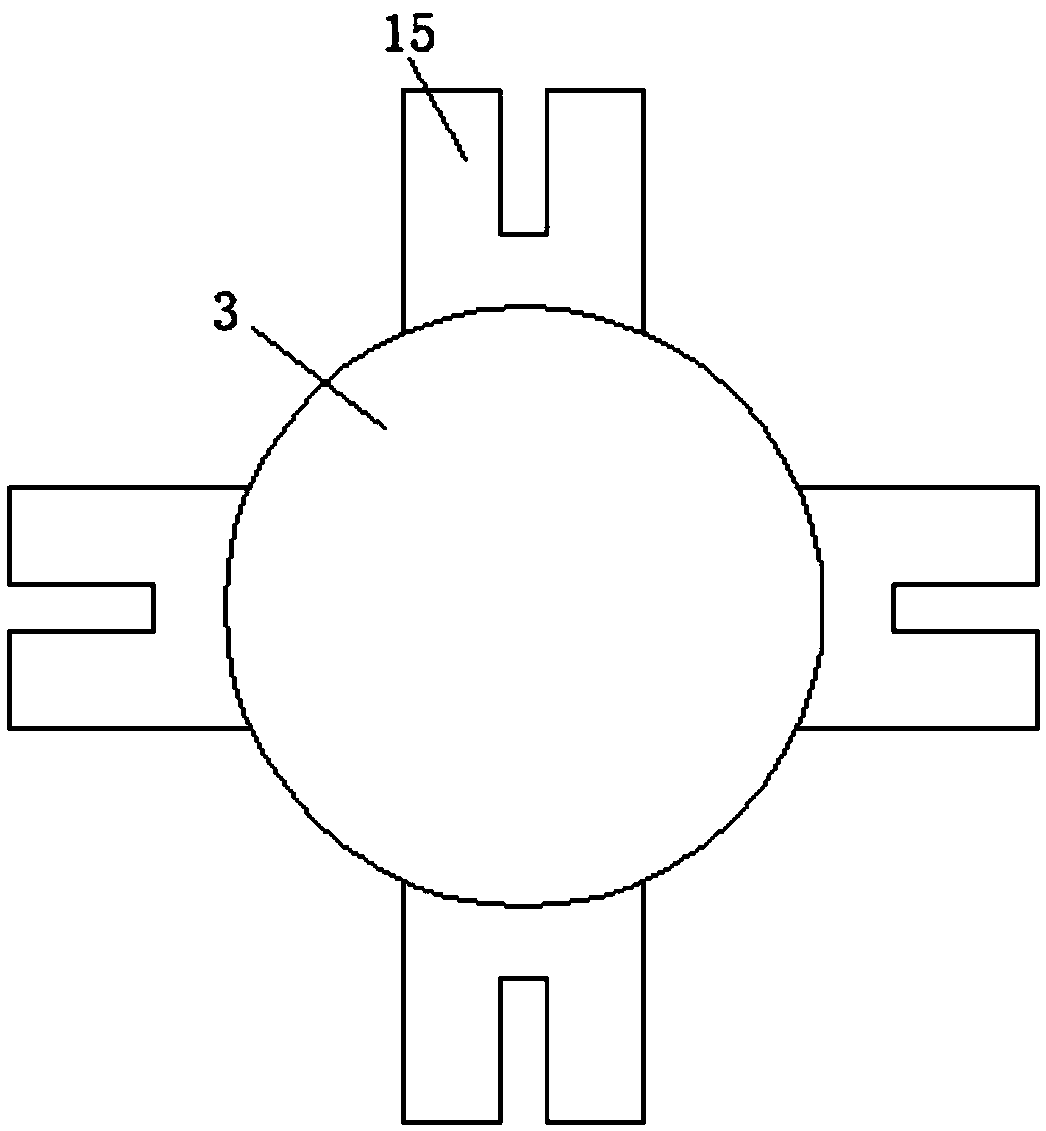

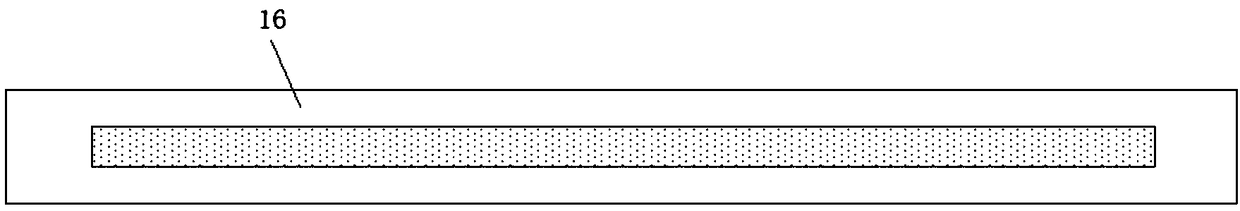

The invention relates to a supporting frame, in particular to a supporting frame convenient to adjust and used for petroleum pipeline installation. According to the technical purposes, the supportingframe convenient to adjust and used for petroleum pipeline installation can play a supporting role, and can also adjust a petroleum pipeline, so that welding is facilitated, the petroleum pipeline isnot likely to move during welding, and welding is not affected. According to the technical scheme, the supporting frame convenient to adjust and used for petroleum pipeline installation comprises a bottom plate and the like; a moving device is arranged on the top of the bottom plate, and a cross plate is connected to the moving device; the top of the cross plate is provided with an adjusting device; and an arc-shaped plate is connected to the adjusting device. According to the supporting frame convenient to adjust and used for petroleum pipeline installation, due to the moving device and the adjusting device, the position of the petroleum pipeline can be adjusted, so that welding is facilitated; due to a fixed device, the petroleum pipeline can be fixed, so that it is prevented that because of moving of the petroleum pipeline, welding is affected, and the effects that the supporting role is played, the petroleum pipeline can also be adjusted, so that welding is facilitated, the petroleum pipelines is not likely to move during welding, and welding is not affected are achieved

Owner:东营睿港投资服务有限责任公司

Tile comprehensive displaying device for industrial design

ActiveCN108836036AImprove utilizationRaise awarenessShow shelvesShow hangersEngineeringDisplay device

The invention relates to the technical field of industrial design displaying, in particular to a tile comprehensive displaying device for industrial design. The device comprises a base, a fixed rod isfixedly connected to the top of the base, and the top of the fixed rod penetrates through and is movably connected with a hollow rotating column; the top of the hollow rotating column successively penetrates through and is fixedly connected with a first installing plate, a second installing plate and a third installing plate, a first locating frame is fixedly connected to the side surface of thetop of the first installing plate, and a tile body is clamped in a locating groove formed in the top of the first locating frame; the top of the tile body is clamped in a locating groove formed in thebottom of the second locating frame, and the top of the second locating frame is fixedly connected to the bottom of the second installing plate through a telescopic locating rod. Compared with a placement mode that the tile is placed flatwise, through the comprehensive displaying mode, customers can visually observe the front and back surfaces of the tile and conveniently know the material and style of the tile, tiles of different materials and styles can be placed on a selling frame, and the customers can conveniently observe different tiles.

Owner:芜湖文青机械设备设计有限公司

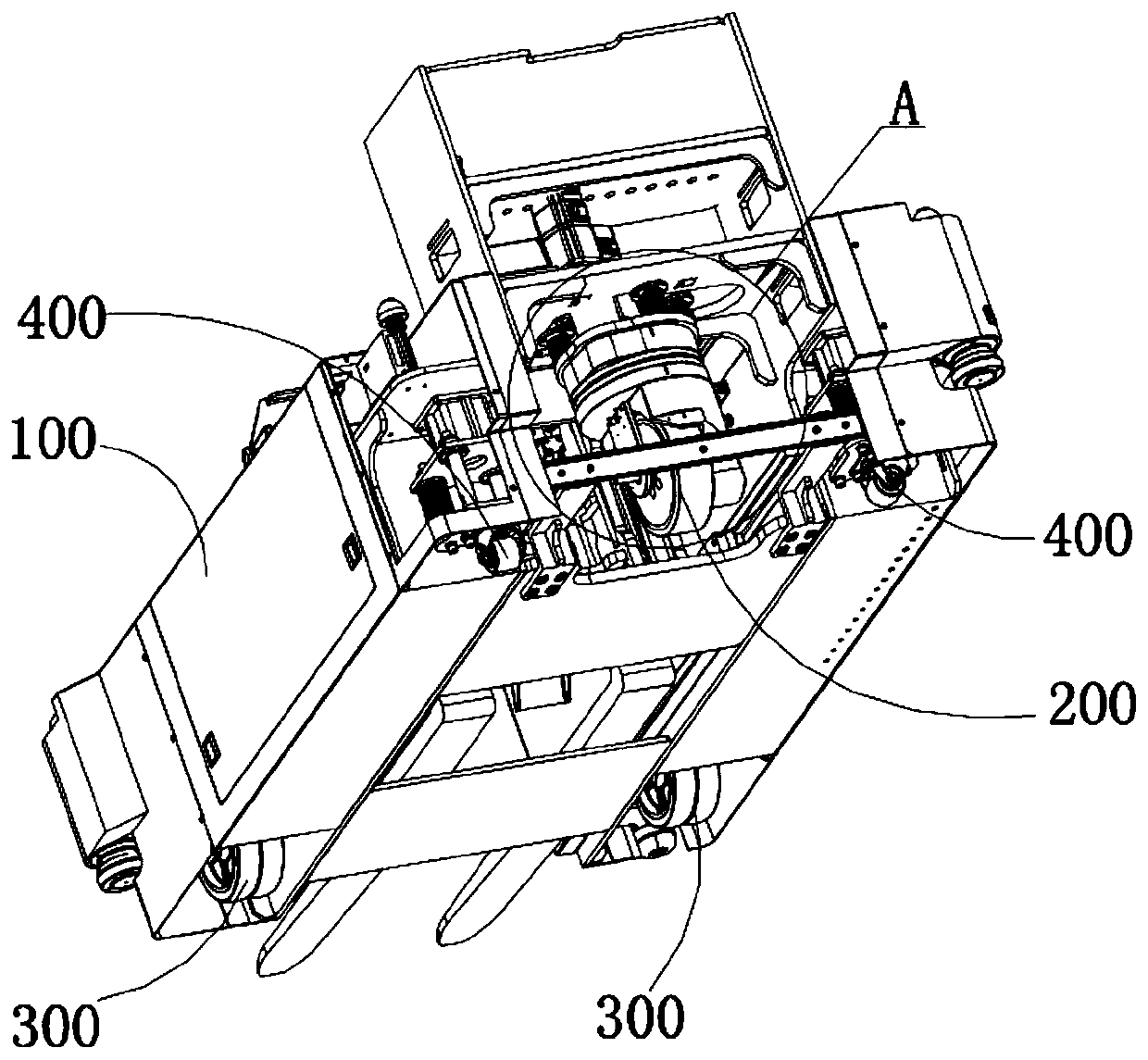

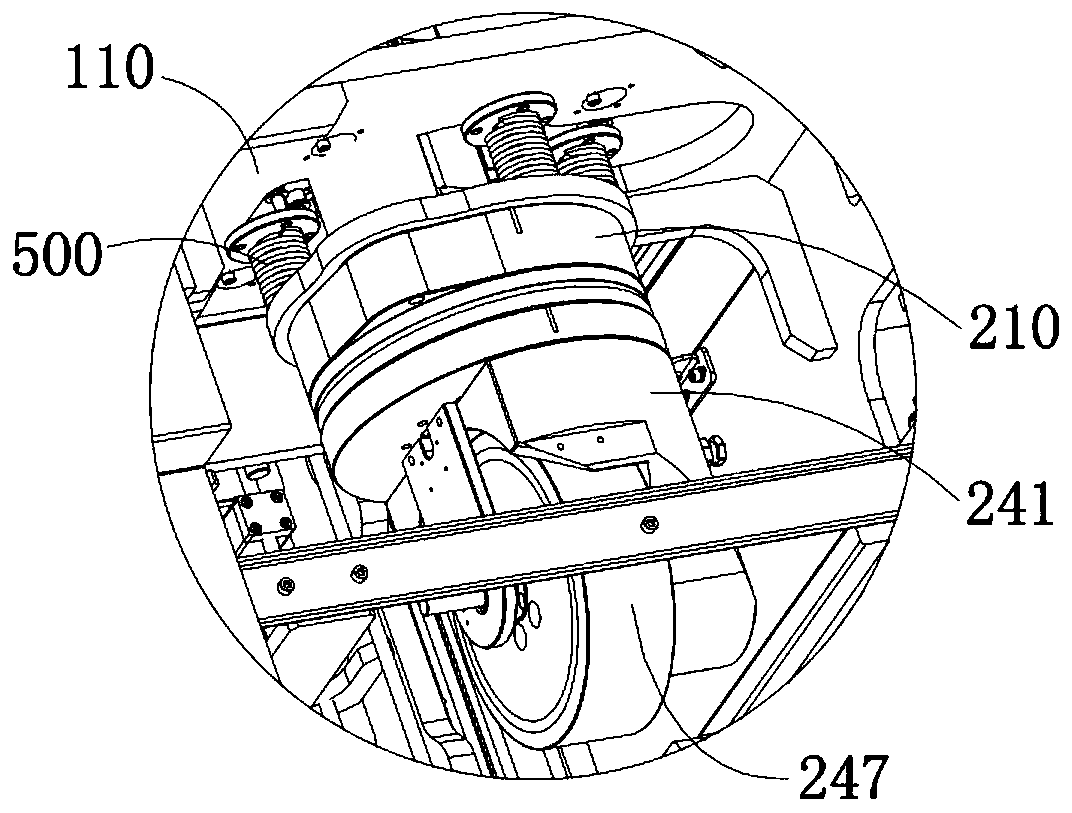

Chassis based on combination of steering wheel and active universal wheels in omnidirectional forklift AGV (automatic guided vehicle)

PendingCN110040195AMobile impactEasy to adjustLifting devicesElectrical steeringSteering wheelControl theory

The invention provides a chassis based on a combination of a steering wheel and active universal wheels in an omnidirectional forklift AGV (automatic guided vehicle), and relates to the technical field of AGVs. The chassis based on the combination of the steering wheel and the active universal wheels in the omnidirectional forklift AGV comprises a chassis, a steering wheel, and two active universal wheels, the steering wheel is mounted at the rear end of the chassis, the two active universal wheels are mounted at the front end of the chassis, and the steering wheel and the two active universalwheels are distributed in an isosceles triangle mode. The technical problem that aforklift in the prior art cannot travelin a stableandstraight mode due to the fact that the traveling speeds of the two steering wheels cannot be ensured to be completely identical is alleviated.

Owner:BLUESWORD INTELLIGENT TECH CO LTD

Car part classifying storage frame

InactiveCN109623761AEasy to placeEasy to hangLighting elementsWork tools storageOperations management

The invention discloses a car part classifying storage frame, and relates to the technical field of car parts. The car part classifying storage frame comprises a base, a rotating rod, a first supporting plate, a second supporting plate, a third supporting plate, a fourth supporting plate and a fixed pipe; universal wheels are movably connected to the bottom of the base, the middle of the top of the base is movably connected with the bottom of the rotating rod through a bearing, the top of the rotating rod is fixedly connected with the middle of the bottom of the first supporting plate, the middle of the top of the first supporting plate is fixedly connected with the bottom of the fixed pipe, and the first supporting plate, the second supporting plate, the third supporting plate and the fourth supporting plate are fixedly connected to the outer surface of the fixed pipe at equal distances from bottom to top. Through different placing frames, different car parts are placed, the rotatingrod rotates on the base, a user can conveniently take the car parts on the different positions, the structure is simple, and the occupied size is small.

Owner:邵清清

Off-line rubberizing machine

PendingCN113979182AImprove work efficiencyAccurate locationElectrode manufacturing processesRegistering devicesEngineeringPole piece

The invention relates to an off-line rubberizing machine. The off-line rubberizing machine comprises a box body, box doors, a shell and the like. The box doors are rotationally connected to the left side and the right side of the front side face of the box body, the box doors are in contact fit with the box body, and the box doors are used for sealing the interior of the box body. Square holes are formed in the middles of the left side and the right side of the box body, and the shell is fixedly connected to the upper portion of the right side face outside the box body. A pole piece is put into the box body from the left side, and the pole piece makes contact with a conveying mechanism. When the position, needing adhesive tape pasting, of the pole piece moves to correspond to an adhesive tape pasting mechanism, a driving mechanism is started, the driving mechanism can drive an adhesive tape pulling mechanism, and the adhesive tape pasting mechanism and an auxiliary mechanism to move inwards. When the auxiliary mechanism moves inwards, the adhesive tape pasting mechanism pastes a cut adhesive tape to the pole piece. When the driving mechanism moves outwards, the driving mechanism drives the conveying mechanism to operate, and the conveying mechanism drives the pole piece to move rightwards to the next position to be pasted with the adhesive tape. The adhesive tape does not need to be pasted on the pole piece manually, the working efficiency is high, and the pasting position of the adhesive tape is accurate and consistent.

Owner:GUANGZHOU EHOLLY MACHINERY CO LTD

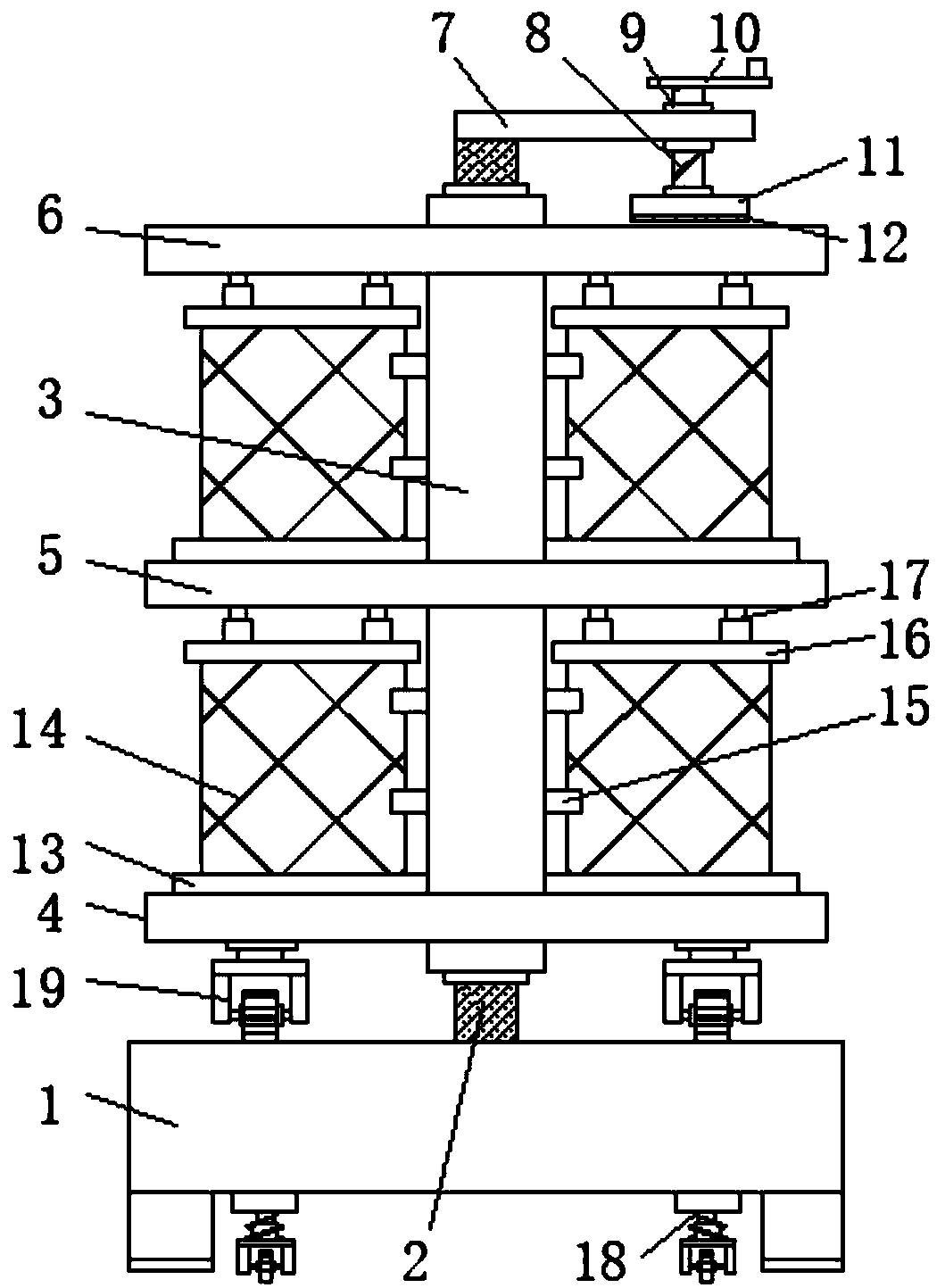

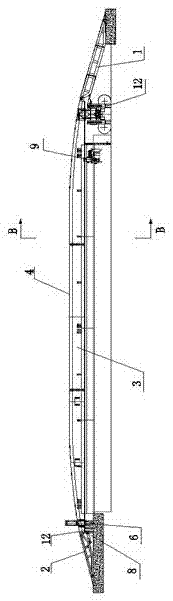

Self-propelled tunnel ultra-long inverted arch movable template steel box girder trestle

PendingCN107143351AImprove stabilityAvoid warpingUnderground chambersTravelling bridgesFront and back endsSteel box girder

The invention discloses a tunnel construction device and concretely relates to a self-propelled tunnel ultra-long inverted arch movable template steel box girder trestle comprising a front approach bridge, a back approach bridge and a main bridge and further comprising a walking device arranged under the main bridge and moving the trestle and a supporting device bearing trestle work weight. The walking device comprises a walking driving device arranged in front of the main bridge and a walking driven device arranged behind the main axle; the supporting device is arranged on the front and back ends of the main bridge; and the walking device and the supporting device are directly mounted on the main bridge. A problem of poor walking efficiency due to repeated operations to a bottom rack and track movements and repeated operation to the main bridge is overcome and a problem of trestle cocking and overturning upon great spanning of the front approach bridge can be solved; the self-propelled tunnel ultra-long inverted arch movable template steel box girder trestle has great walking efficiency, great spanning and cannot cock and overturn.

Owner:CHINA RAILWAY ERJU 4TH ENG +1

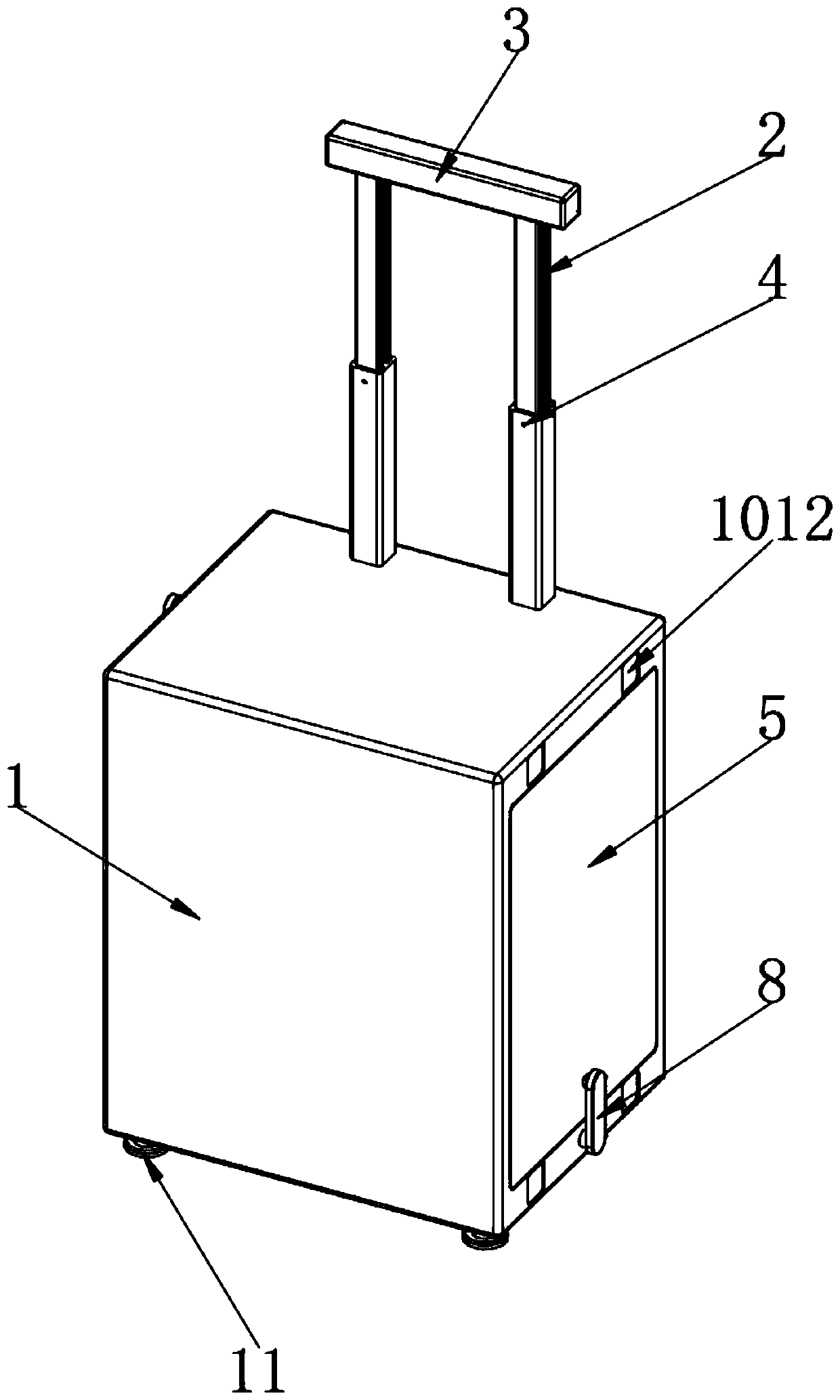

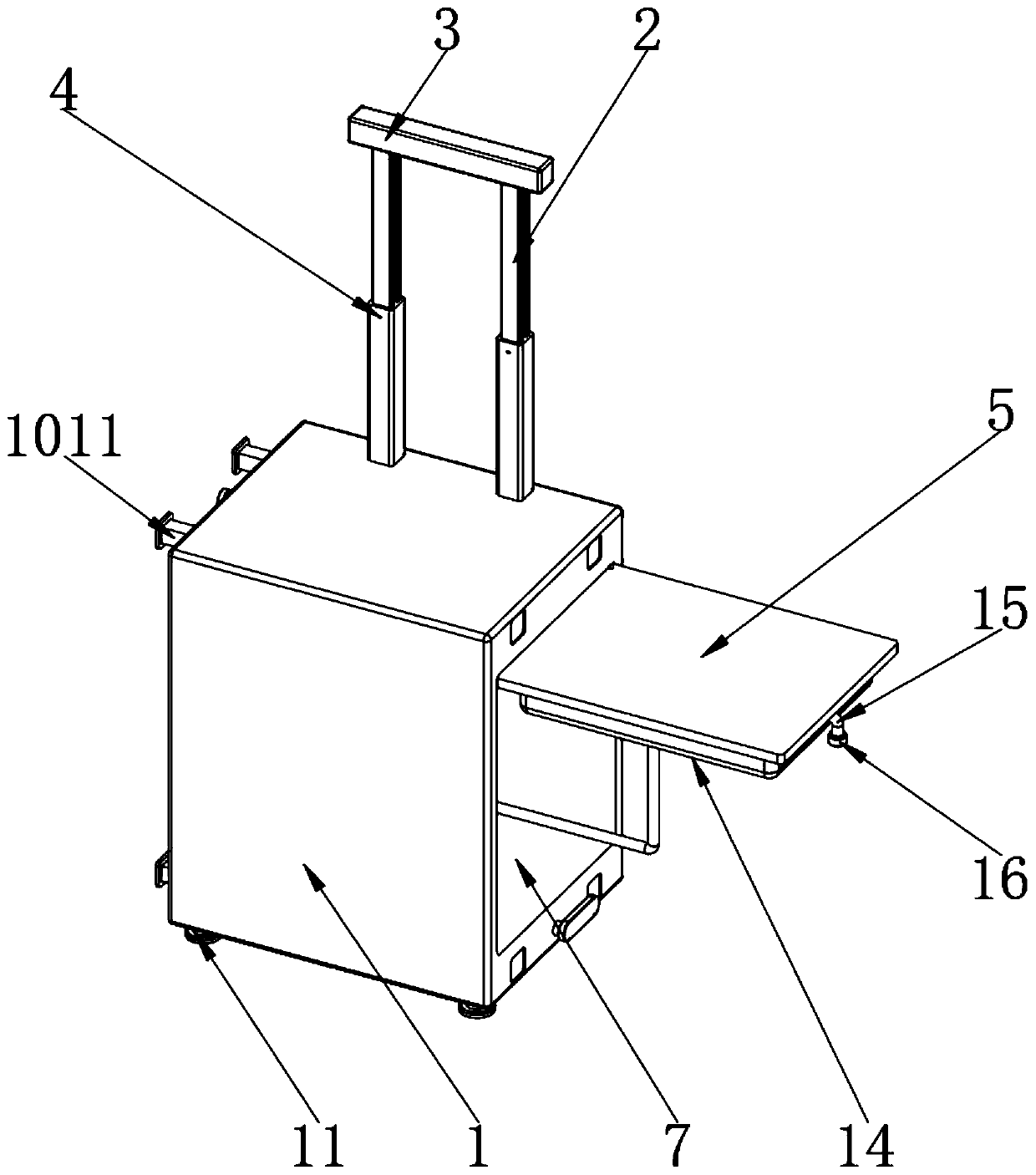

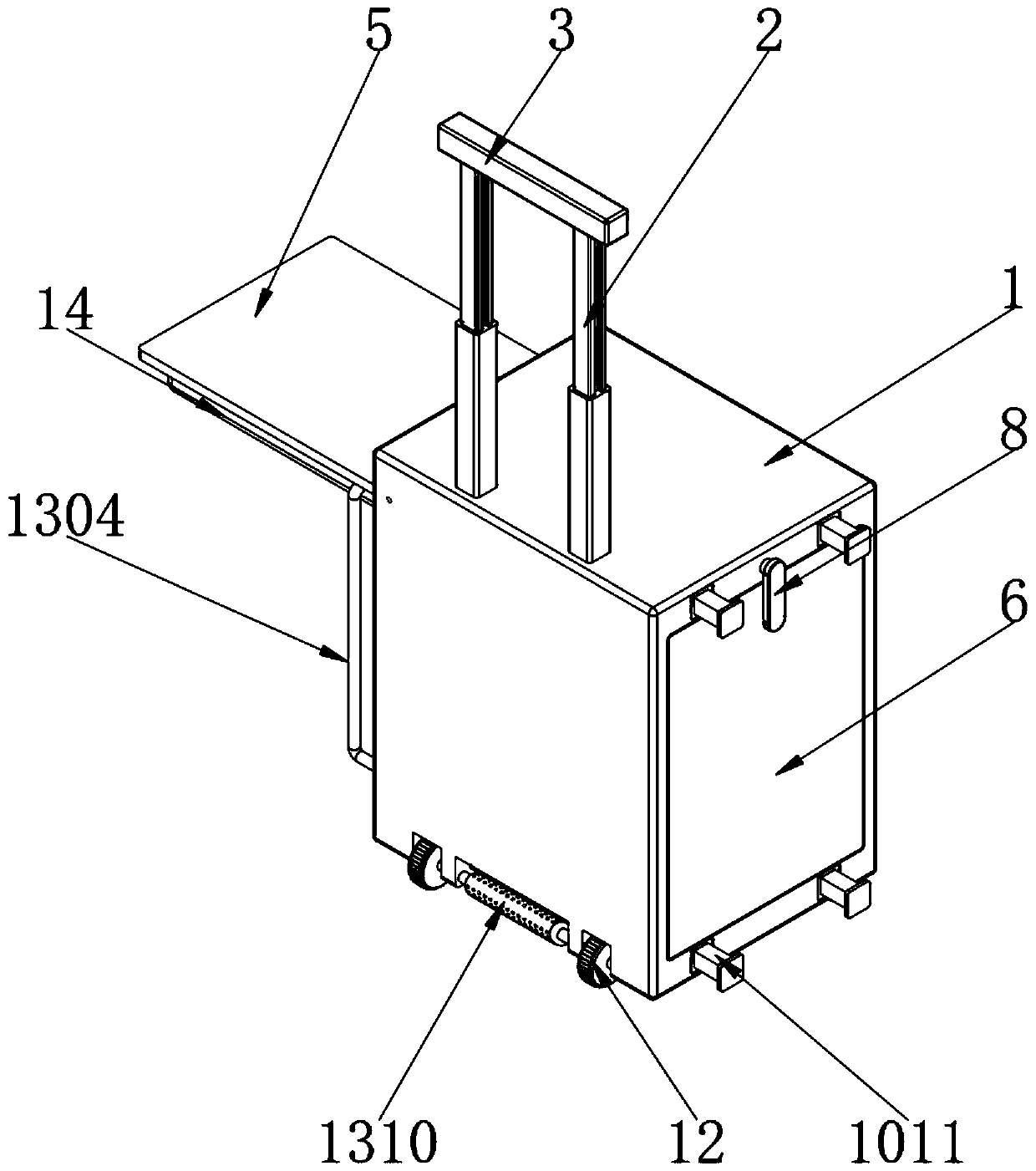

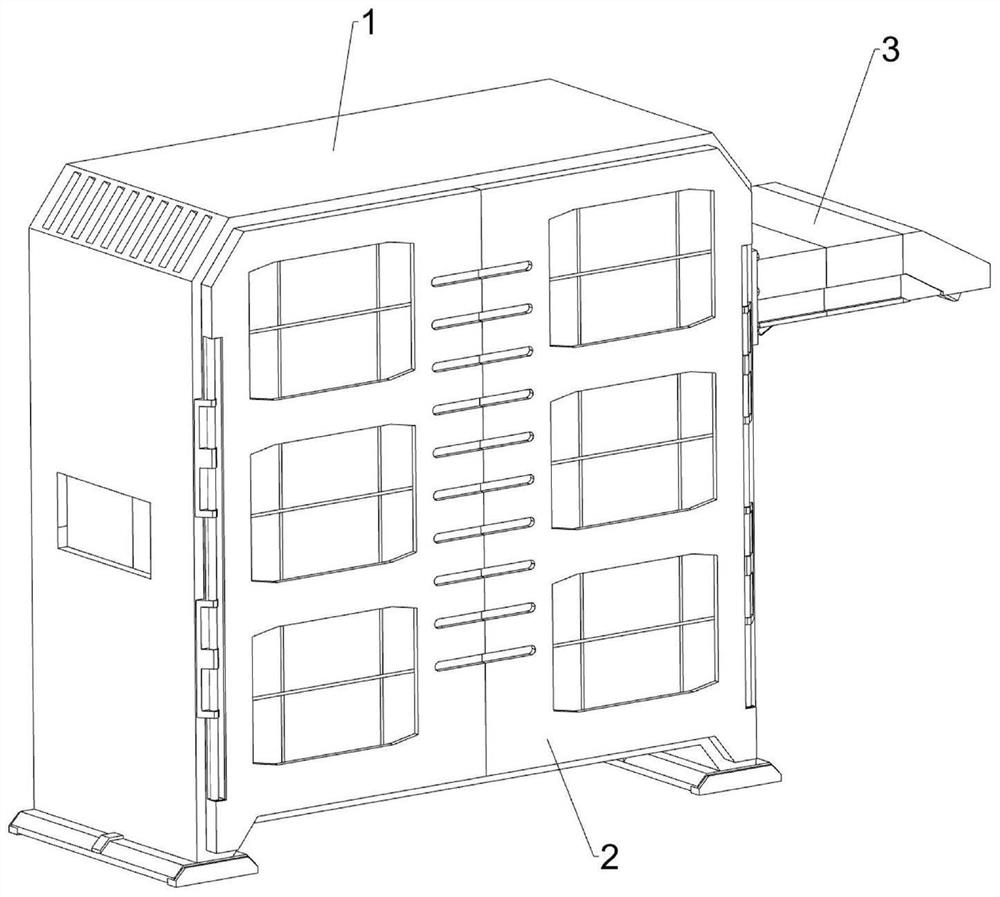

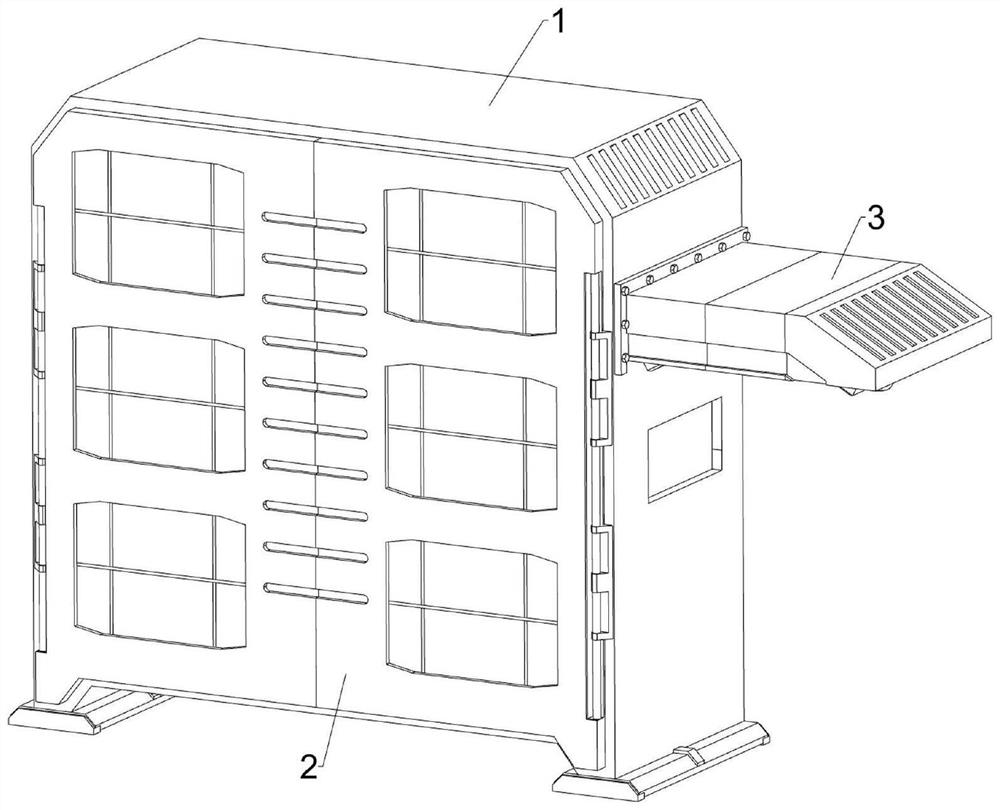

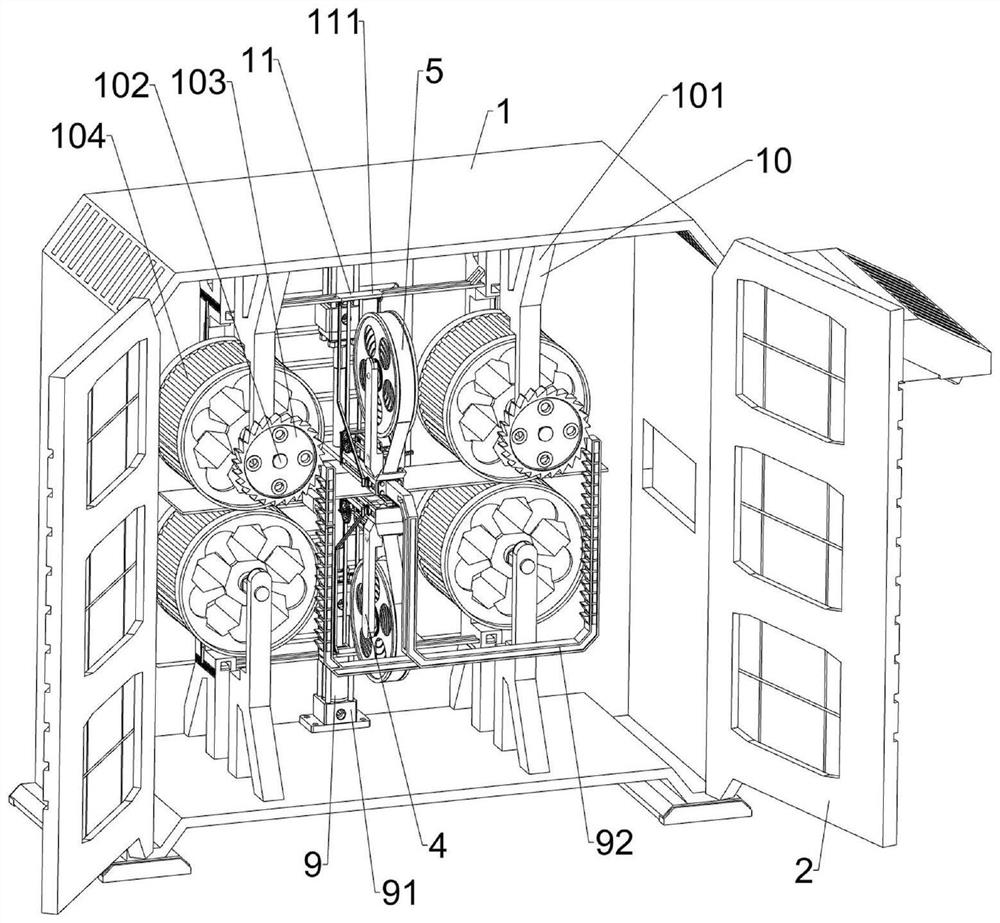

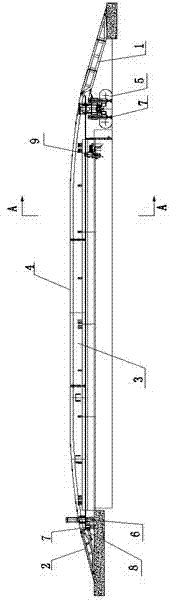

Aluminum template vertical conveyor

InactiveCN110668357AMobile impactFall arrestSafety devices for lifting equipmentsLifting framesStructural engineeringMachine

The invention discloses an aluminum template vertical conveyor. A main machine body, a driver and a material conveying box are included. The material conveying box and the main machine body are in sliding fit. The driver is arranged on the main machine body and used for driving the material conveying box to move. An anti-falling mechanism is further included and comprises a fixing base, a clamp block, an elastic piece and a rack, wherein the fixing base is arranged on the main machine body, the clamp block is arranged on the fixing base, and the elastic piece is arranged on the fixing base andused for tightly abutting against the clamp block so that the clamp block can be movably clamped in a tooth groove in the rack. The rack is arranged on the material conveying box, and teeth on the rack are provided with extrusion faces and locking faces, wherein when the material conveying box does the ascending movement, the extrusion faces are in sliding fit with the clamp block and are used for extruding the clamp block out of the tooth groove, and when the material conveying box does the descending movement, the locking faces abut against the clamp block in a locking manner. When the material conveying box falls due to the conveyor electronic self-lock failure situation, the clamp block can be in mechanical locking fit with the rack, accordingly, falling of the material conveying boxis stopped, and aluminum template transportation safety is improved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

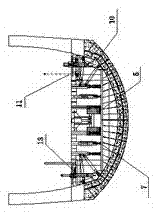

Anti-disorder needle withdrawing device of double-sided jacquard machine

The invention provides an anti-disorder needle withdrawing device of a double-sided jacquard machine. The anti-disorder needle withdrawing device comprises a needle dial, a pattern bit, a needle selector and a damper, wherein the pattern bit is placed in a needle groove, the damper exerts force on the side wall of the pattern bit, so that the pattern bit has no moving relative to the needle grooveunder the condition that the pattern bit is not driven by the needle selector, then a knitting needle connected with the pattern bit is static, the damper comprises a barrel body, the barrel body isinstalled in a placement hole in the inner wall of the needle groove, a plug is installed at the top of the barrel body, the plug enables the barrel body to form a counter bore, a first spring is placed in the counter bore, a first steel ball is placed at an opening of the counter bore, a piston is movably arranged in the placement hole, the upper end of the piston abuts against the first steel ball, a polyurethane body is arranged at the lower end of the piston, and the lower end of the polyurethane body extends out of the placement hole, enters the needle groove and abuts against the side wall of the pattern bit. According to the anti-disorder needle withdrawing device, the phenomenon of disordered needle withdrawing caused by external vibration can be avoided.

Owner:泉州市鼎丰针织机械有限公司

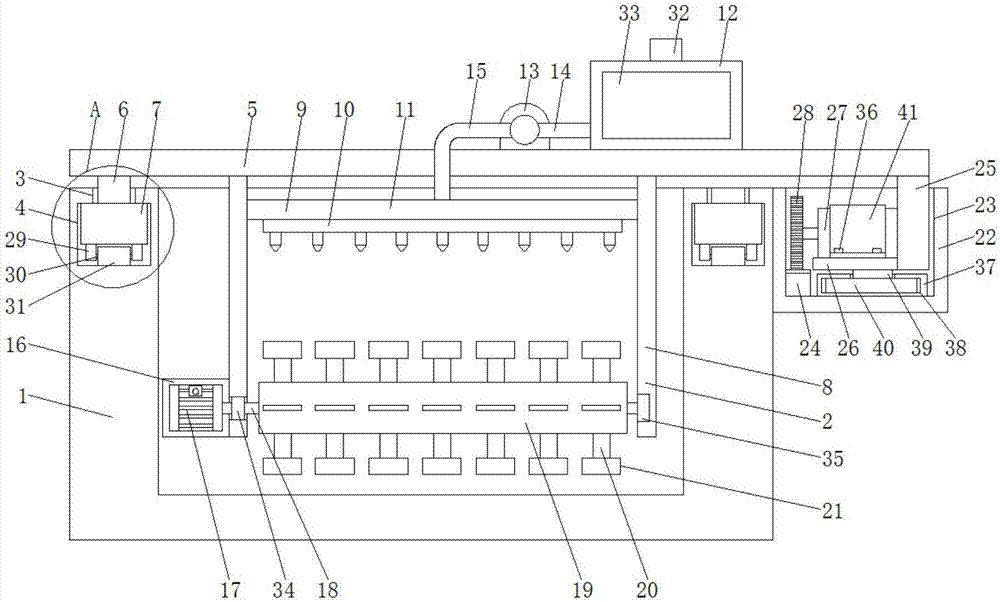

Automatic trough cleaning device for precise gear hobbing machine and cleaning method of automatic trough cleaning device

ActiveCN113334134AAvoid churnEasy to clean upHollow article cleaningGear-cutting machinesHobbingProcess engineering

The invention discloses an automatic trough cleaning device for a precise gear hobbing machine and a cleaning method of the automatic trough cleaning device, relates to the technical field of gear hobbing machines, and aims to solve the problems that when chippings in a trough of a precise gear hobbing machine in the prior art need to be cleaned, the chippings in the trough can only be manually scraped through a tool and then taken out for cleaning, and the problems that due to the fact that the trough is too large and the position of the trough is inconvenient for manual operation, manual operation is inconvenient during material scraping, a large amount of cutting fluid is mixed with cutting chippings, and therefore when the chippings are cleaned, a large amount of cutting fluid is lost, and recycling of the cutting fluid is not facilitated are solved. The automatic trough cleaning device comprises a base, a gear hobbing machine body is fixedly installed above the base, a waste box is installed on the portion, below a guide rail workbench, of one side of the gear hobbing machine body, a recycling mechanism is arranged on the lower portion in the waste box, a classified cleaning mechanism is arranged above the recycling mechanism, and mounting frames are fixedly arranged at the front ends and the rear ends of the two sides of the upper end surface of the base correspondingly; and the number of the mounting frames is four.

Owner:江苏马步崎电机制造有限公司

Printing and dyeing sewage processing equipment having good filtering effect

InactiveCN107381735ASimple structureEasy to useShaking/oscillating/vibrating mixersFlow mixersDyeingMotor drive

The invention discloses a printing and dyeing sewage processing equipment having good filtering effect, which relates to the field of printing and dyeing equipment. The printing and dyeing sewage processing equipment comprises a sewage processing pool, a sewage processing groove is arranged at the top of the sewage processing pool, and the bar-shaped grooves are arranged at the two sides of the sewage processing and at the top of the sewage processing pool. The printing and dyeing sewage processing equipment has the advantages of simple structure and convenient usage, a first motor drives a rotation rod to rotate a mixing drum, the cooperation of a stirring plate and a stirring blade is used for stirring and mixing sewage and an antiseptic solution, a second motor drives a gear to rotate, thrust is generated with a teeth plate to drive a movable plate to move, reciprocating movement is realized for stirring and mixing, the sewage and the antiseptic solution are uniformly mixed, the sewage filtering effect is increased, and the environment pollution status due to poor mixing effect in the prior art can be avoided.

Owner:姚飞

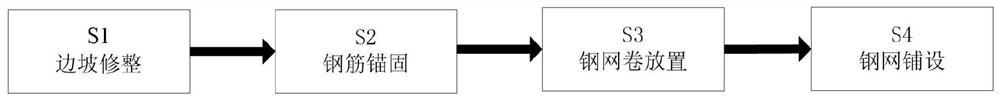

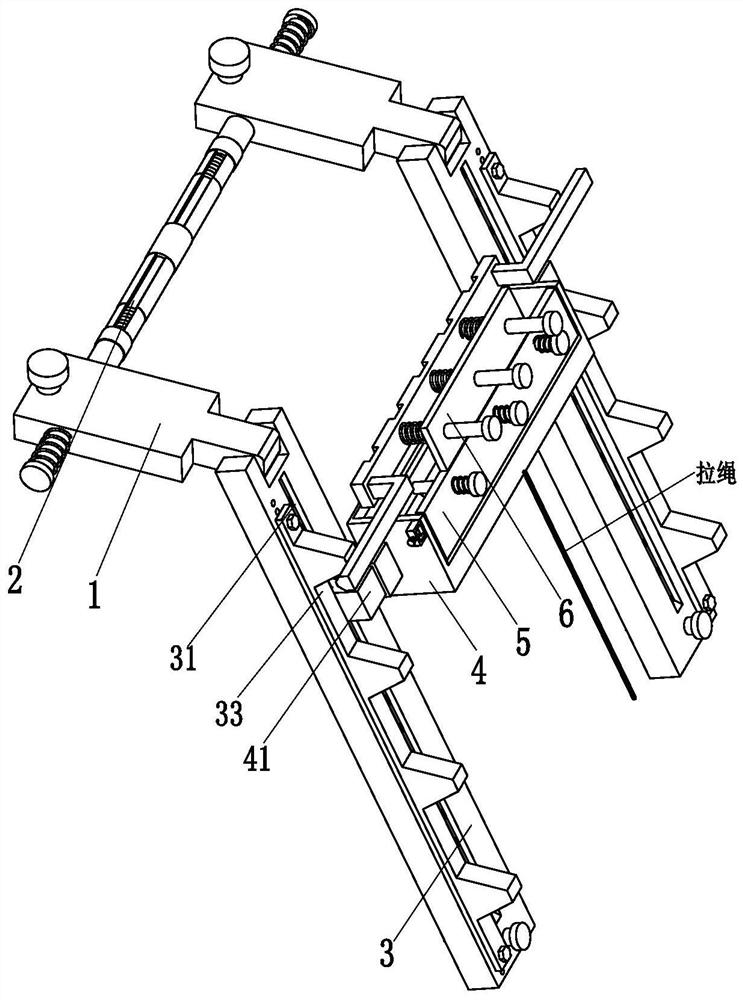

Deep foundation pit supporting and reinforcing construction method

ActiveCN113186938AImprove laying effectWrinkles and bends will not occurExcavationsArchitectural engineeringRebar

Owner:九江市辉浩建设工程有限公司

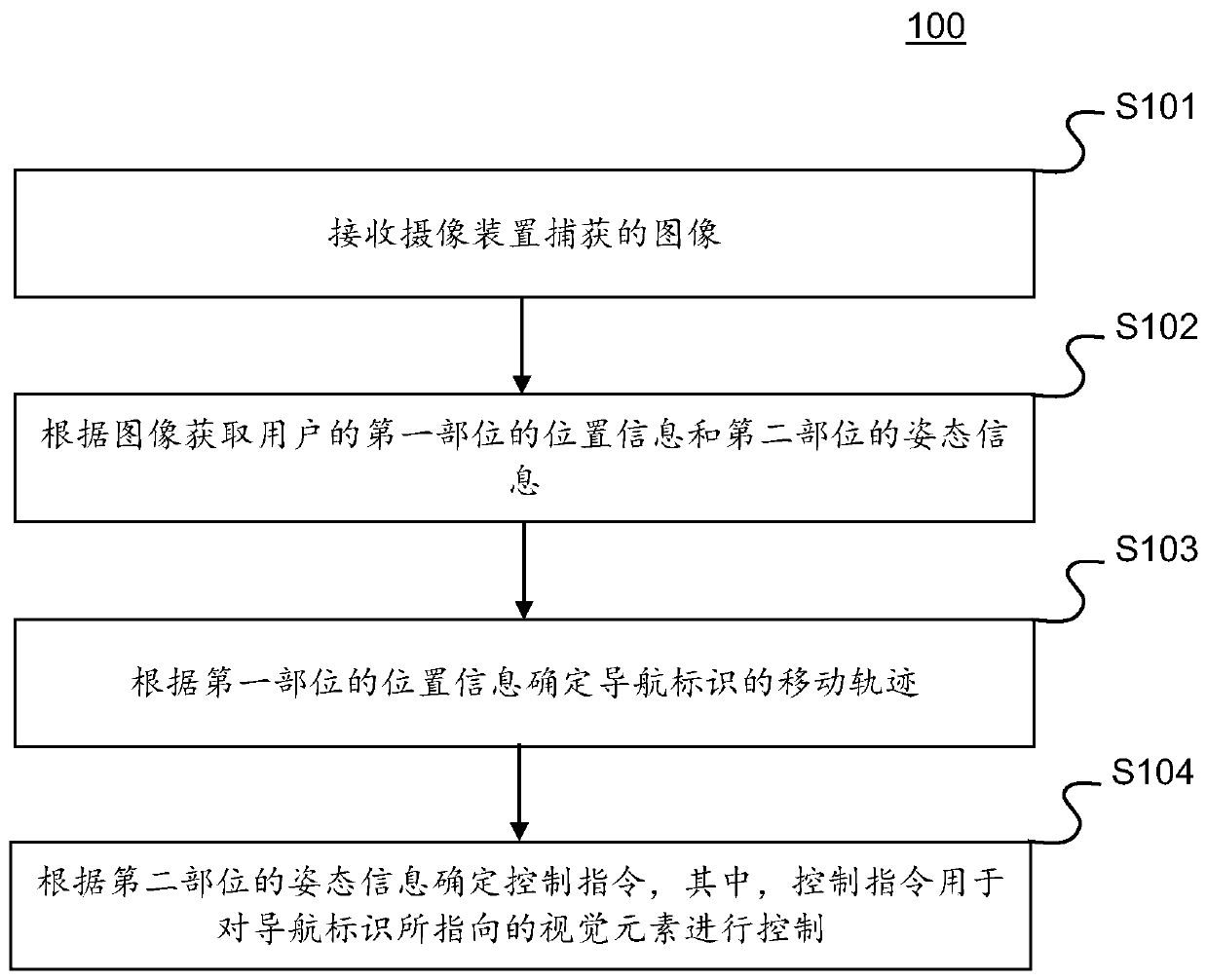

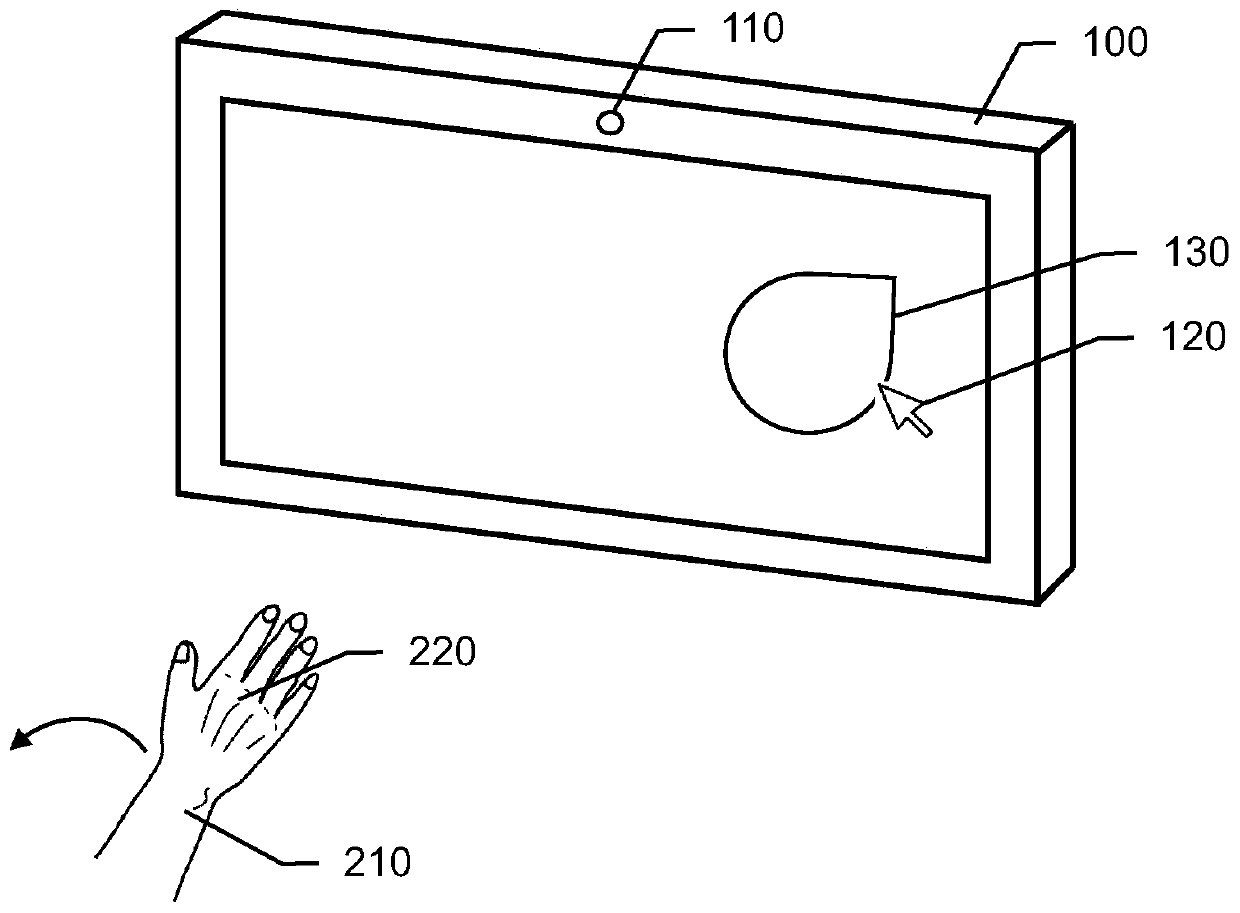

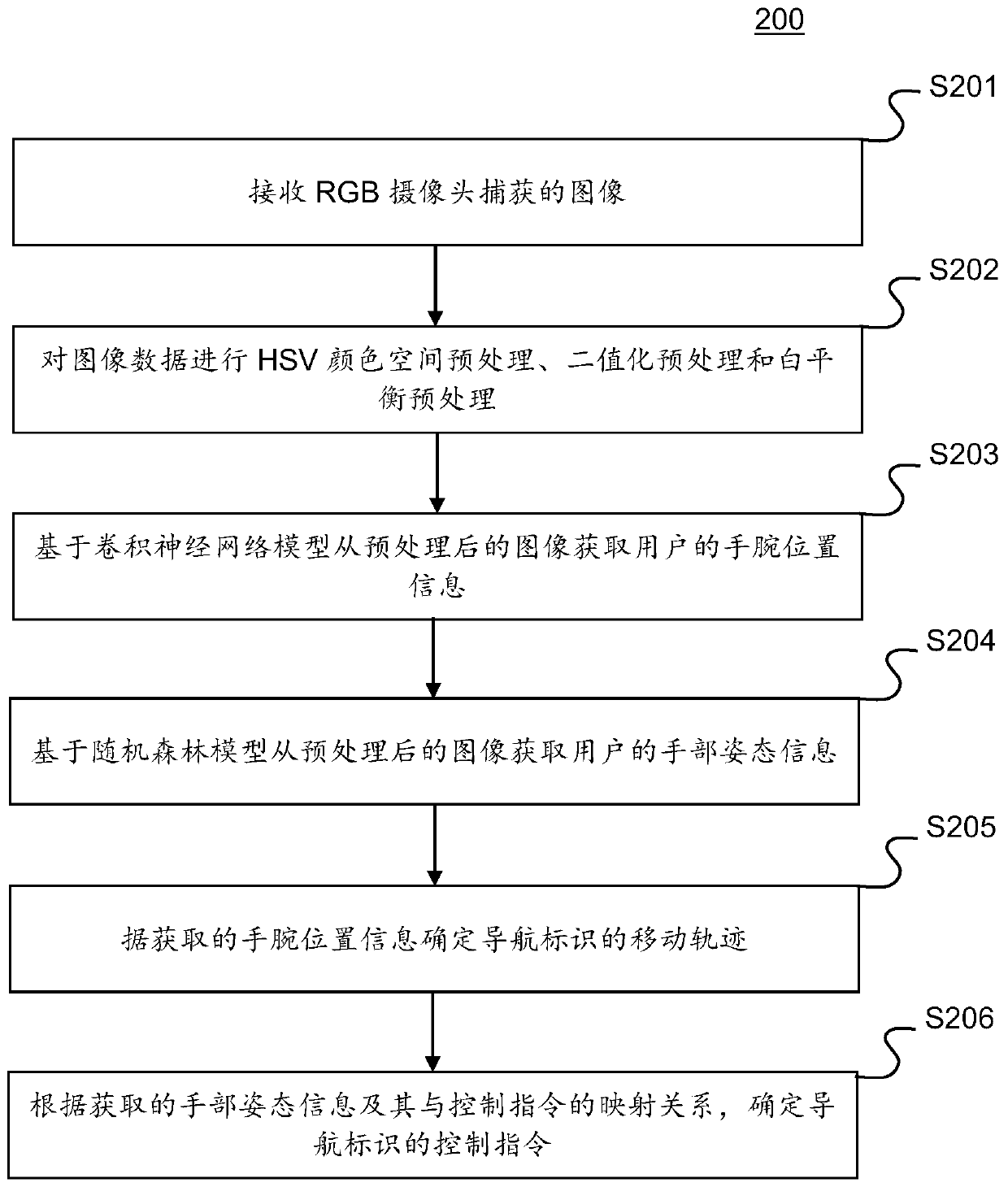

Control method and device, terminal and storage medium

ActiveCN111601129AMobile impactImprove recognition accuracyInput/output for user-computer interactionSelective content distributionEngineeringImage capture

Owner:BEIJING BYTEDANCE NETWORK TECH CO LTD

Hydraulic pipe clamp

InactiveCN114378748AHave a stable effectEasy to placeWork holdersWork benchesEngineeringStructural engineering

The invention relates to the technical field of pipe machining, and discloses a hydraulic pipe clamp which comprises a stable base, side clamping mechanisms are installed on the stable base, and a bottom clamping mechanism is inserted between the two side clamping mechanisms in a penetrating mode. The bottom clamping mechanism comprises an inclined bottom plate arranged between the two side clamping mechanisms and an adjusting push plate fixedly installed on the outer side of the inclined bottom plate, a connecting supporting rod is installed on the adjusting push plate, a telescopic hydraulic rod is movably installed at the lower end of the adjusting push plate, and the telescopic hydraulic rod is movably installed on a stable base. When the telescopic hydraulic rods extend, the adjusting push plates are driven to move upwards, the center parts of the inclined bottom plates move downwards, then the distance between the two sets of inclined bottom plates is shortened, pipe bodies with small diameters can be conveniently placed, and on the contrary, when the telescopic hydraulic rods are shortened, the distance between the two sets of inclined bottom plates can be increased. And a pipe body with a large diameter can be conveniently clamped, and the clamping effect is good.

Owner:XUZHOU COLLEGE OF INDAL TECH

Rapid conveying device for building materials

InactiveCN114671204AMobile impactFree from loading and unloading workMechanical conveyorsArchitectural engineeringFire brick

A rapid conveying device for building materials comprises a hole body and a plurality of rails arranged at the bottom of the hole body, a plate trailer for going in and out of the hole body is arranged on the rails, the plate trailer is composed of a comb plate and a plurality of rows of moving wheels at the bottom of the comb plate, a plurality of protruding blocks are installed at the bottom of the comb plate, and the front face and the rear face of each protruding block are connected with one end of a steel cable. The other ends of the two steel cables connected with each protruding block are connected with the corresponding wire stranding wheels, the wire stranding wheels are connected with a power device, a supporting plate is movably installed on the top of the comb plate, switch valves are arranged on the first pipeline, the second pipeline and the third pipeline, wedge-shaped blocks are arranged at the movable ends of the fourth oil cylinders, and the wedge-shaped blocks face the directions of the adjacent rails. A second strip-shaped plate is installed at the top of the second shear fork rod, one-way swing pieces are arranged on the two sides of the moving wheel correspondingly, and the one-way swing pieces can be in sliding contact fit with the wedge-shaped blocks. The conveying device is used for conveying building materials such as fired bricks, at least half of loading and unloading work can be omitted, and the working efficiency is doubled.

Owner:URUMQI VOCATIONAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com