Hydraulic pipe clamp

A hydraulic and pipe technology, which is applied in the direction of manufacturing tools, workpiece clamping devices, workbenches, etc., can solve the problems of inconvenient use and cumbersome operation, and achieve the effect of easy clamping, simple operation, and not easy to slip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

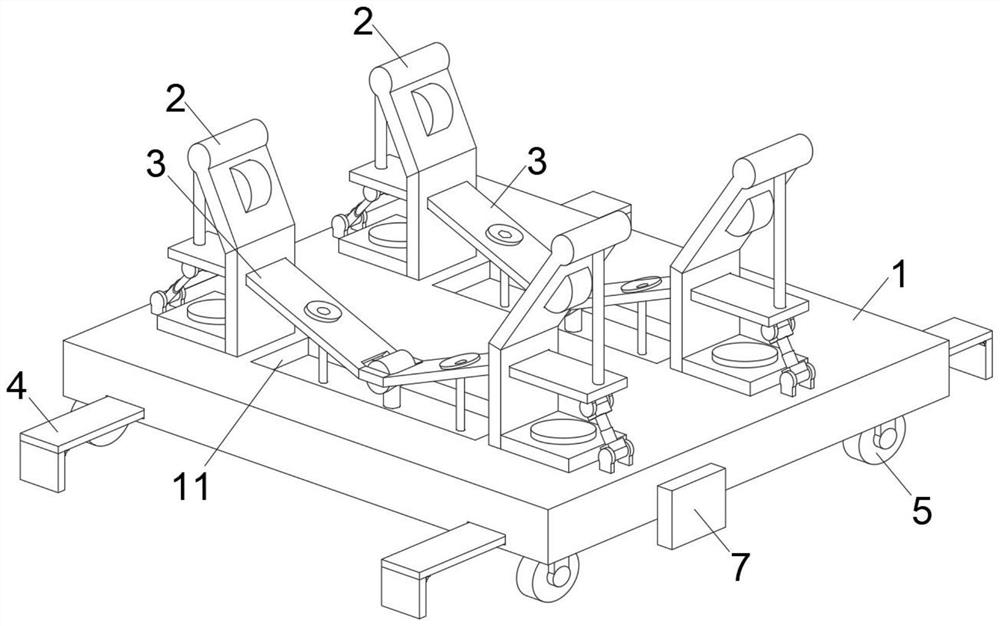

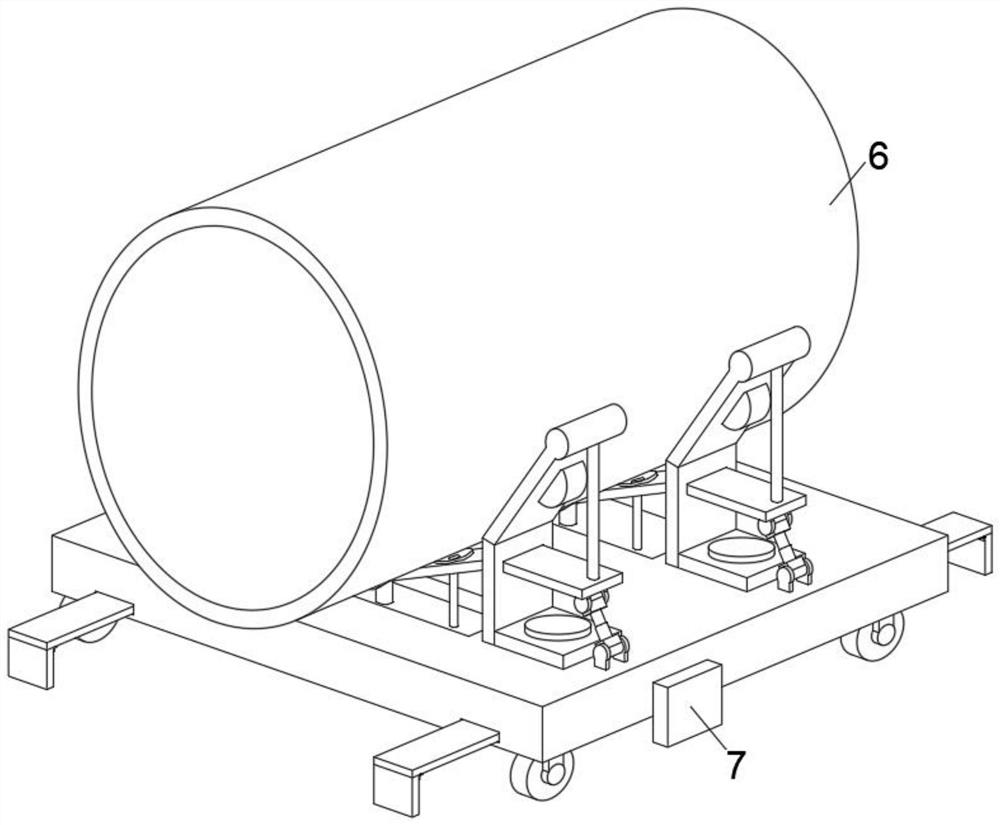

[0029] This embodiment is intended to promote the solution to the problem of how to clamp the pipe body 6, please refer to Figure 1-5 , a hydraulic clamp for pipes, comprising a stable base 1, a universal sliding wheel 5 is installed on the lower end of the stable base 1, by installing the universal sliding wheel 5, it is convenient to drag the stable base 1 to move around, and one end of the stable base 1 is fixed A control panel 7 is installed, and the operation of the whole device can be controlled through the control panel 7. The side clamping mechanism 2 is installed on the stable base 1, and the side clamping mechanism 2 is provided with two groups. On both sides of the base 1, a bottom clamping mechanism 3 is interspersed between the two groups of side clamping mechanisms 2, and the bottom clamping mechanism 3 is arranged on the inclined bottom plate 31 between the two groups of side clamping mechanisms 2 and is fixedly installed on the inclined bottom plate. 31 outsid...

Embodiment 2

[0040] This embodiment is intended to help solve the problem of how to clamp pipe bodies 6 of different diameters. This embodiment is an improvement made on the basis of Embodiment 1. For details, please refer to Figure 4-6 , the side clamping mechanism 2 includes a stable bottom plate 21 fixedly mounted on the stable base 1 and an elastic vertical plate 22 fixedly mounted on the stable bottom plate 21, the stable bottom plate 21 is interspersed with bolts 8, and the bolts 8 are threadedly connected with the stable base 1 , to facilitate the fixing of the stable base plate 21, the elastic vertical plate 22 is equipped with an elastic inclined plate 23, and the elastic vertical plate 22 is provided with an opening groove 25, and the opening groove 25 is inserted and connected with the adjustment push plate 32.

[0041] The angle between the inclined bottom plate 31 and the adjustment push plate 32 is fixed, so the opening slot 25 can be used as a fulcrum to swing up and down, s...

Embodiment 3

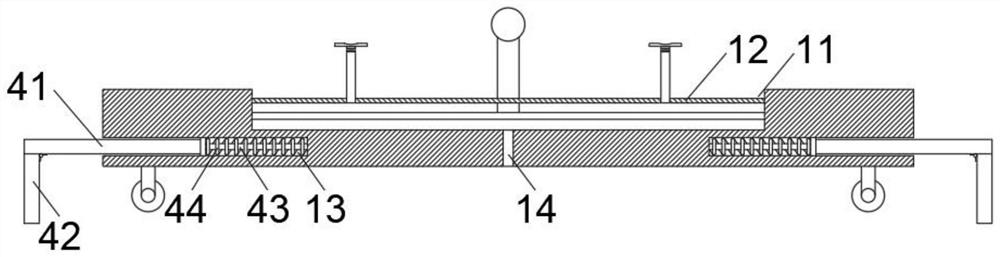

[0046] This embodiment is intended to promote the solution of how to securely fix the device on operating platforms of different lengths. This embodiment is an improvement made on the basis of Embodiment 1. For details, please refer to Figure 1-3 , a mounting mechanism 4 is installed on the stable base 1, and the mounting mechanism 4 includes a transverse connecting plate 41 inserted in the built-in hole 13 and a vertical limit plate 42 hinged at the lower end of the transverse connecting plate 41 through a damping shaft. A slide bar 43 is interspersed and connected, and the slide bar 43 is fixedly installed in the built-in hole 13 .

[0047] The installation mechanism 4 is provided with four groups, and the four groups of installation mechanisms 4 are installed on the two ends of the stable base 1 correspondingly. The horizontal connecting plate 41 fits together to avoid the movement of the vertical limiting plate 42 when the stable base 1 is moving. After the installation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com