Elevator guide rail structure

A technology for elevator guide rails and elevators, which is applied to springs/shock absorbers, elevators, vibration suppression adjustment, etc., can solve the problems of falling off of the support plate, affecting the work efficiency of the staff, and poor fixing effect of the support plate, and achieves the effect of easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

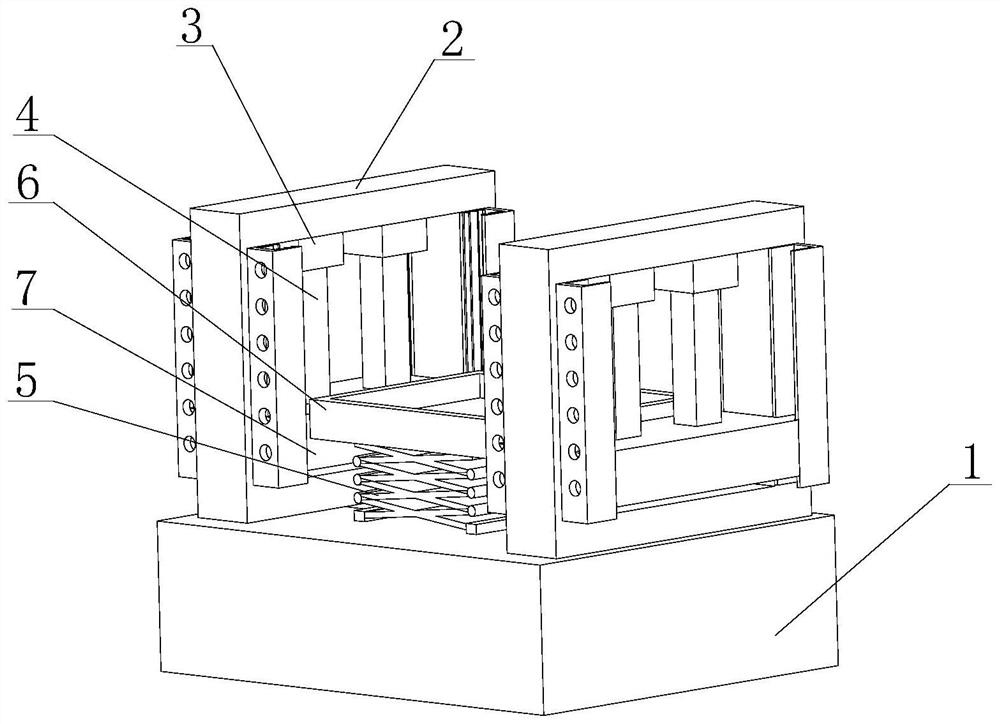

[0035] like Figure 1-6 As shown, the present invention provides an elevator guide rail structure, comprising a guide rail base 1, the upper end of the guide rail base 1 is fixedly connected with an elevator support 2, the lower end of the elevator support 2 is fixedly connected with a hydraulic cylinder 3, and the lower end of the hydraulic cylinder 3 is provided with a telescopic The lower end of the rod 4 and the telescopic rod 4 is fixedly connected with a support slide 7 .

[0036] The elevator bracket 2 , the hydraulic cylinder 3 , the telescopic rod 4 and the support slide plate 7 are arranged to facilitate the pulling of the support plate 6 , so as to make the elevator move and facilitate the operation of the staff.

[0037] The upper end of the guide rail base 1 is provided with a telescopic assembly 5, and the setting of the telescopic assembly 5 can support the lower end of the support plate 6, so as to avoid the large gravity of the upper end, causing the support s...

Embodiment 2

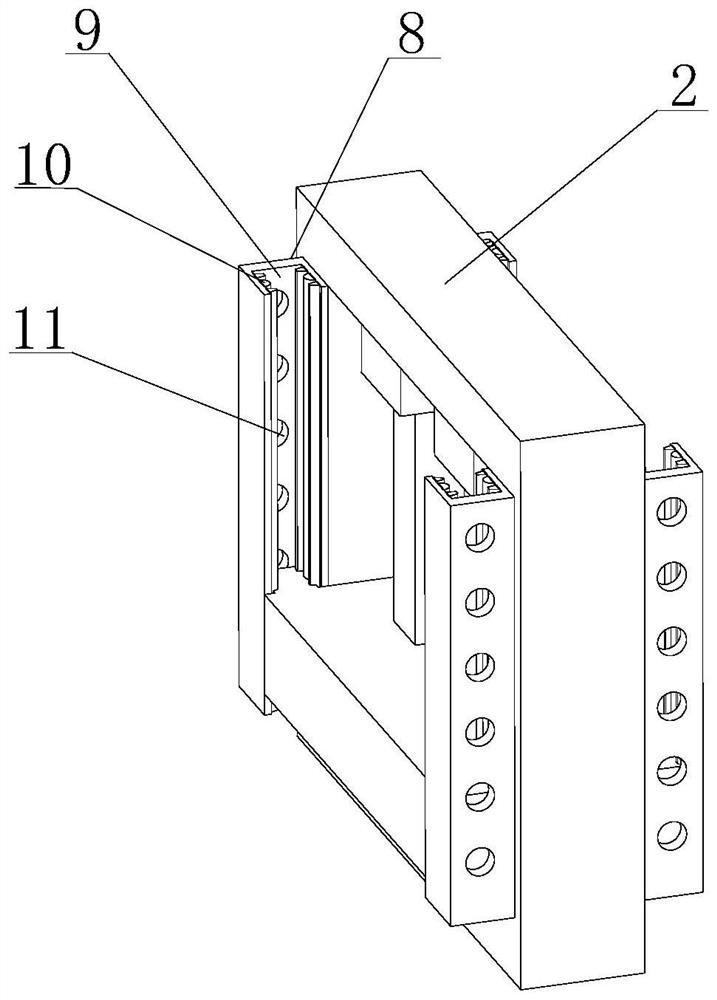

[0041] like Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, a card slot block 8 is fixedly connected to the left end of the elevator bracket 2, and a card slot 9 is opened inside the card slot block 8, and the card slot The inner side of 9 is fixedly connected to the limit card block 10, the lower end of the card slot block 8 is provided with a through positioning hole 11, and the end of the support slide 7 close to the card slot block 8 is adapted to the inner side of the set card slot 9, and the card slot block 8 The setting of the card slot 9, the limit block 10 and the through positioning hole 11 can limit the position of the support slide 7 during the movement of the support slide 7, so as to avoid the phenomenon of deviation during the movement. Cause damage to the device, thereby seriously affecting the service life of the device, the support slide 7 is slidably connected along the inner side of the se...

Embodiment 3

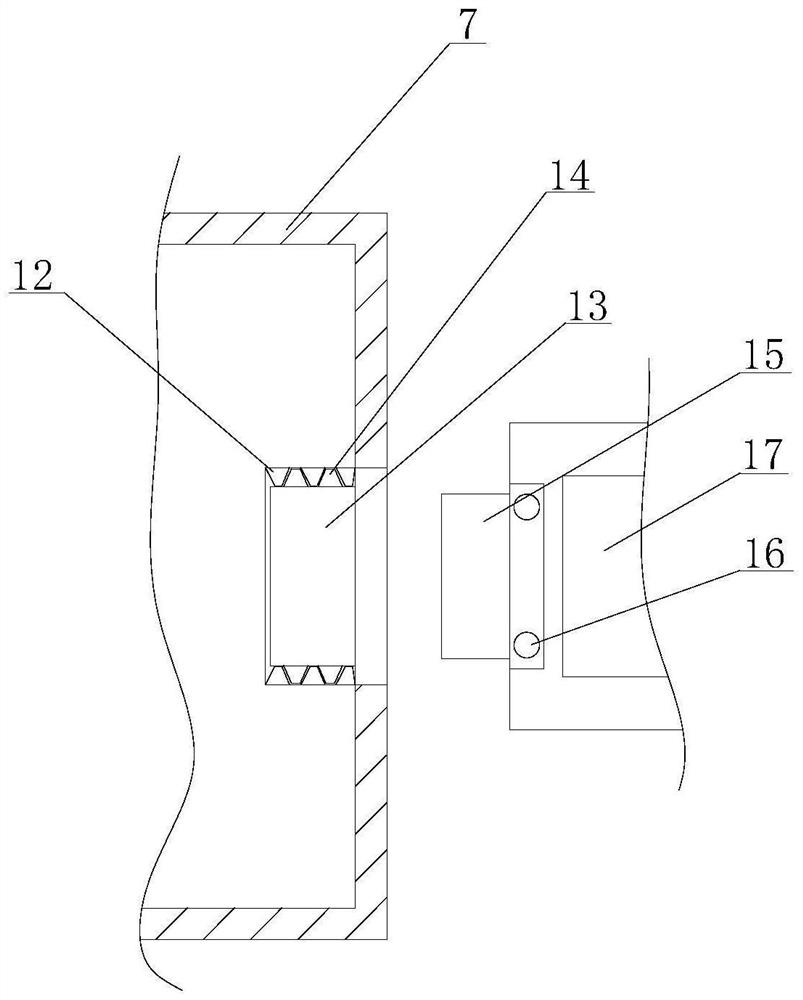

[0043] like Figure 1-6 As shown, on the basis of Embodiments 1 and 2, the present invention provides a technical solution: preferably, the left end of the support plate 6 is fixedly connected with a mounting block 15, and the upper end of the mounting block 15 is movably installed with a limit bolt 16, and the support plate 6 is provided with a groove 17 inside, the right end of the support slide 7 is provided with a mounting groove, and the interior of the mounting groove is provided with an extrusion block 13, the upper end of the extrusion block 13 is fixedly connected with a second trapezoidal friction block 14, The inner side is fixedly connected with a first trapezoidal friction block 12 .

[0044] The arrangement of the first trapezoidal friction block 12 , the extrusion block 13 , the second trapezoidal friction block 14 , the mounting block 15 and the limit bolt 16 allows the support plate 6 and the support slide plate 7 to be installed and clamped together, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com