Device for cleaning the fire tubes in a boiler

A technology for fire tubes and boilers, which is applied in the direction of cleaning heat transfer devices, removing solid residues, cleaning non-rotating equipment, etc., and can solve problems such as not being able to reapply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

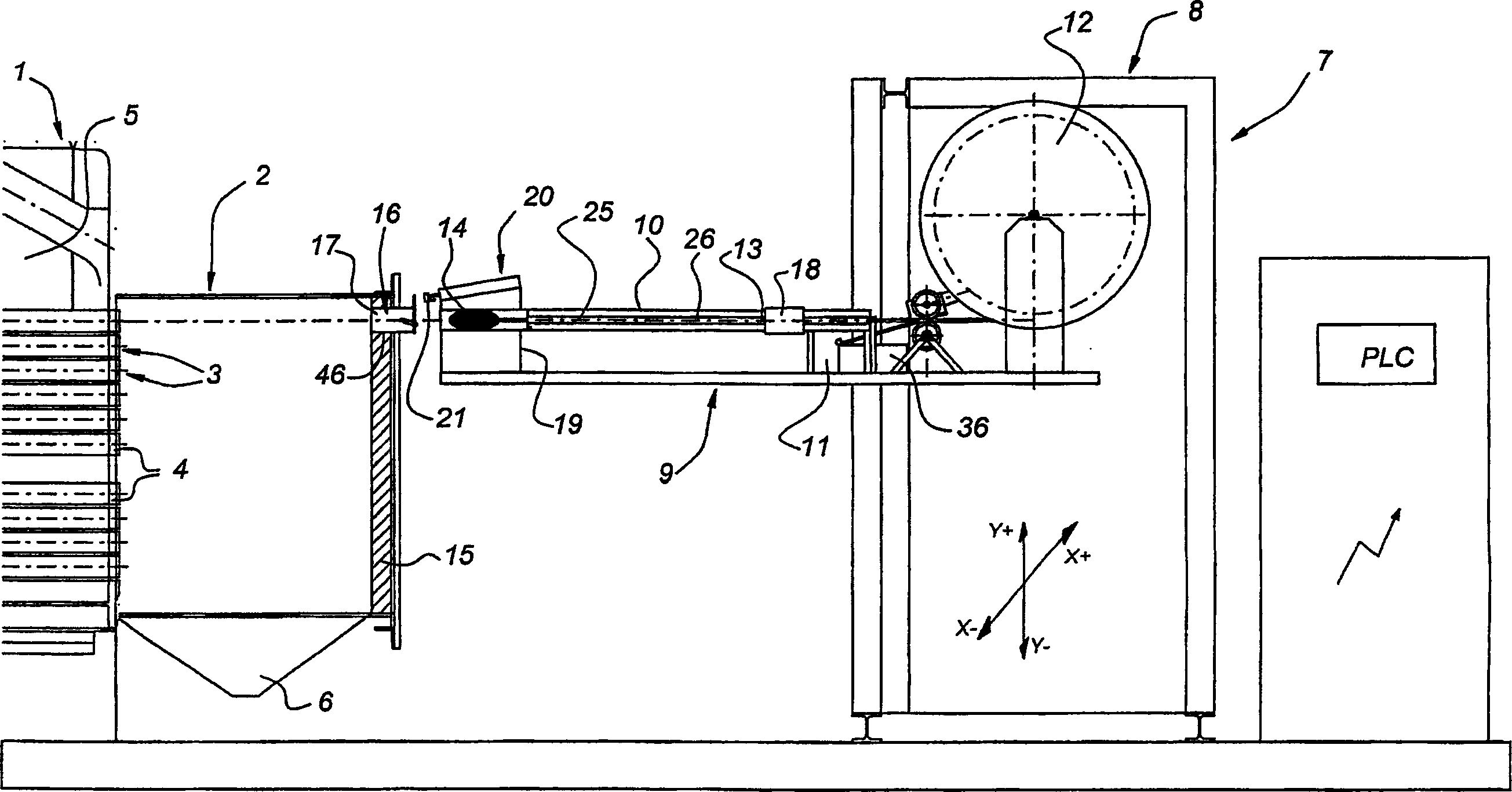

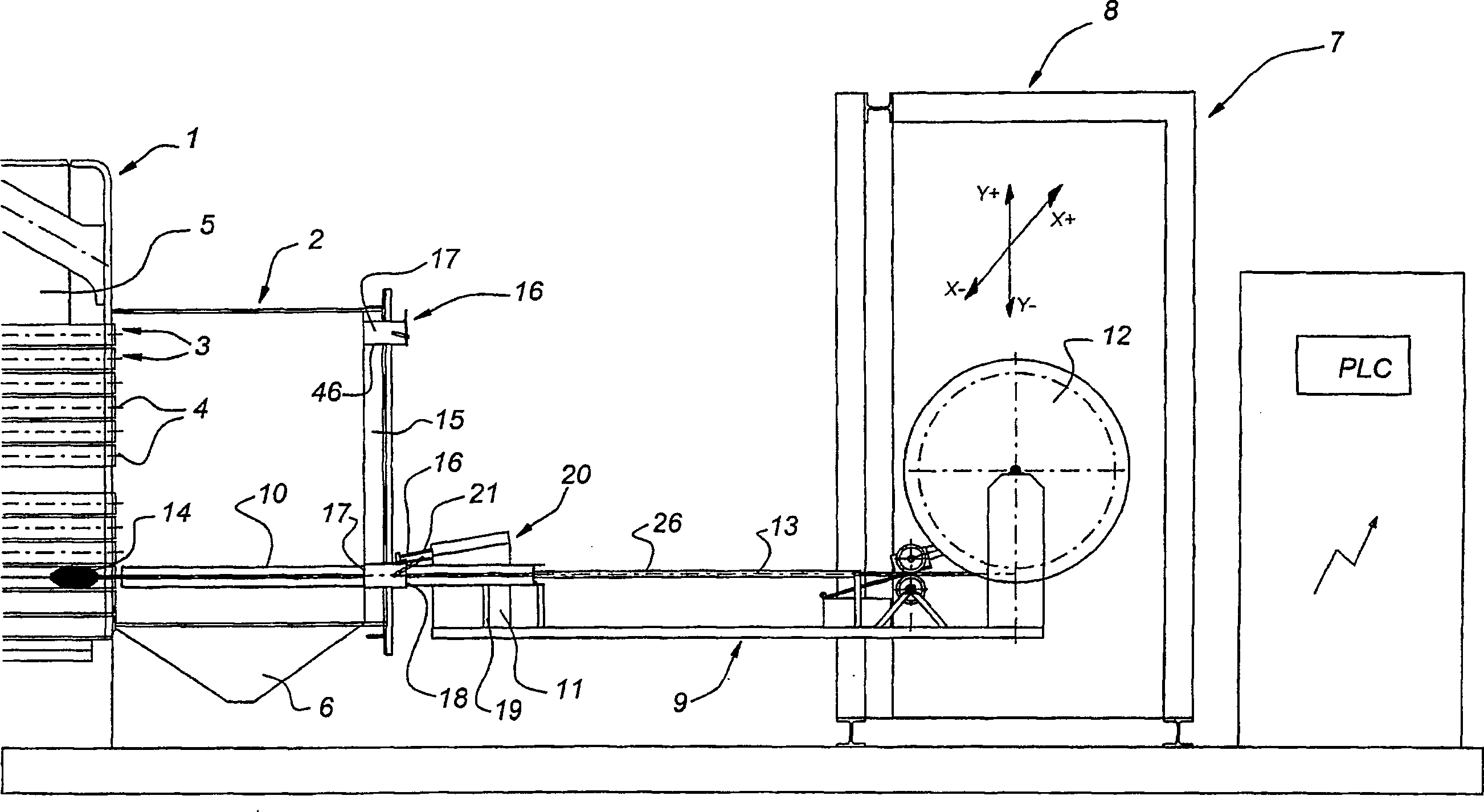

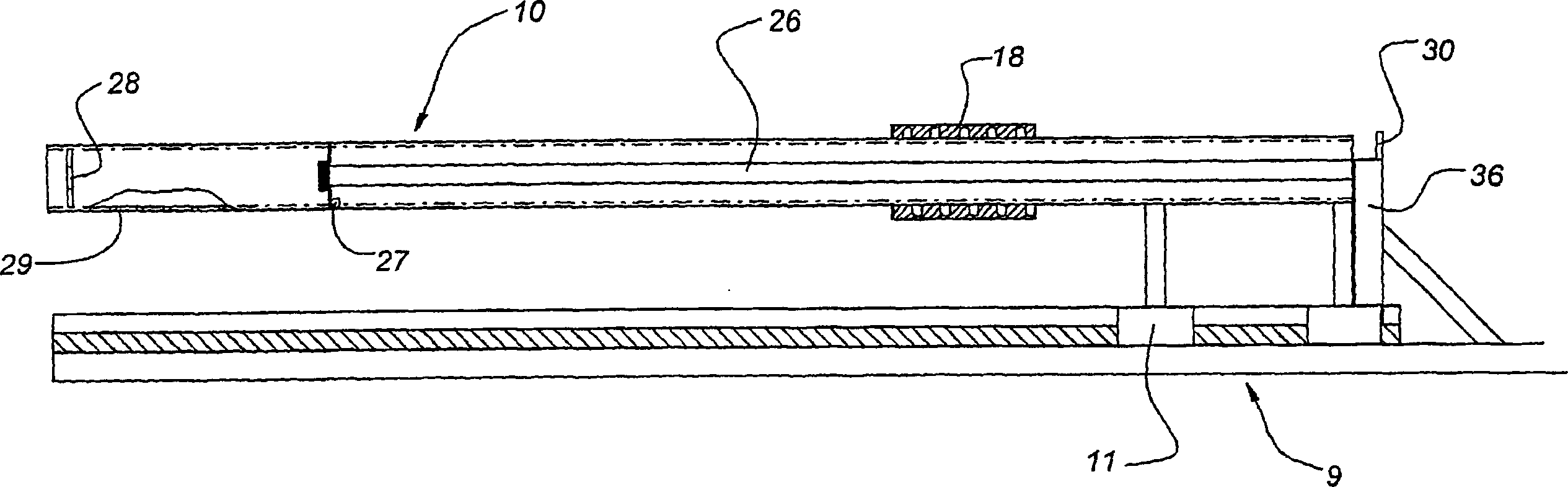

[0034] figure 1 with 2 The end of the boiler 1 is shown where the flue chamber 2 is arranged. In conventional manner, the boiler 1 has a number of fire tubes 3 , the ends 4 of which open into the flue chamber 2 as shown. At the other end, not shown, there is a burner which produces hot flue gases which flow through the fire tube 3 . The water outside the fire tubes 3 of the chamber 5 in the boiler 1 can be heated with these hot flue gases.

[0035]The flue gases that have flowed through the fire tube 3 can be collected in the flue chamber 2 . The flue chamber 2 is delimited at the bottom by a collection device 6 , in which wastes arising from the combustion process as well as wastes settled inside the fire tube 3 can be collected. These deposits are mainly dependent on the fuel used in the burner. Combustion of gases produces relatively little fouling; solid fuels, on the other hand, produce more fouling deposits in the fire tube.

[0036] Adjacent to the flue chamber 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com