Off-line rubberizing machine

A technology of gluing machine and gluing mechanism, which is applied in pile separation, thin material processing, winding strips, etc. It can solve problems such as low work efficiency, affecting the subsequent use of pole pieces, and people are prone to fatigue, and achieves accurate and consistent positions. , high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

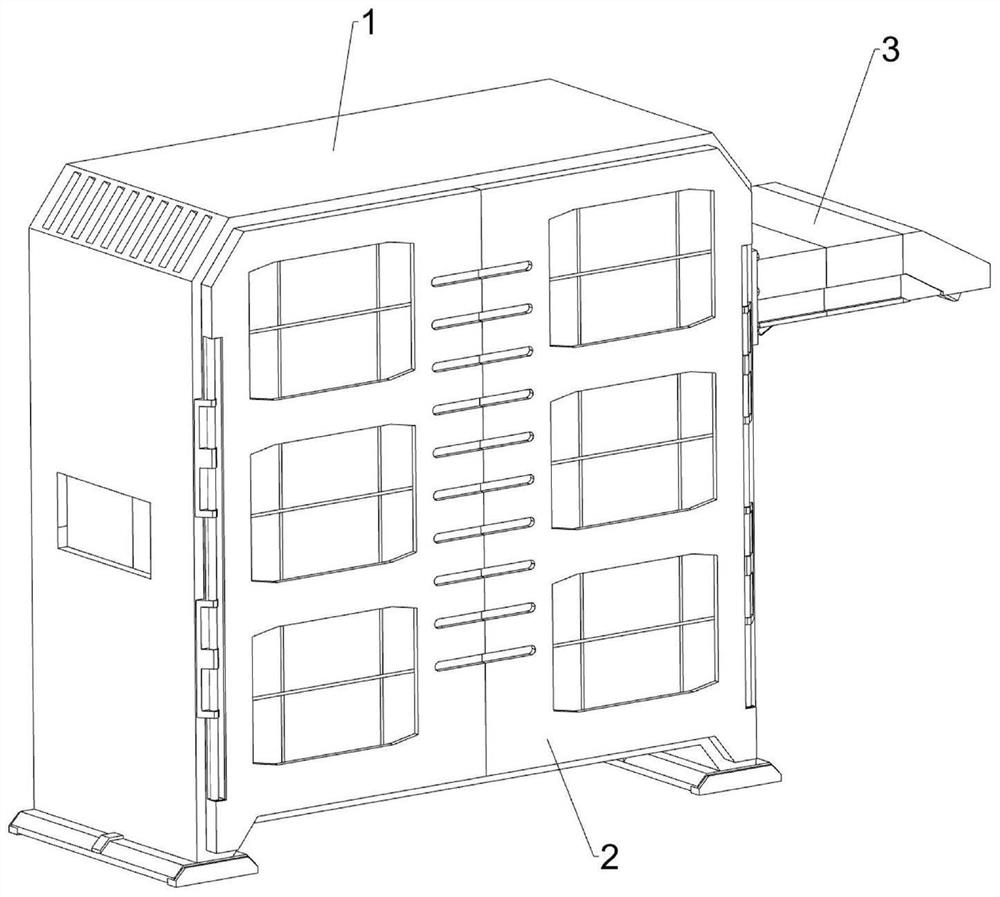

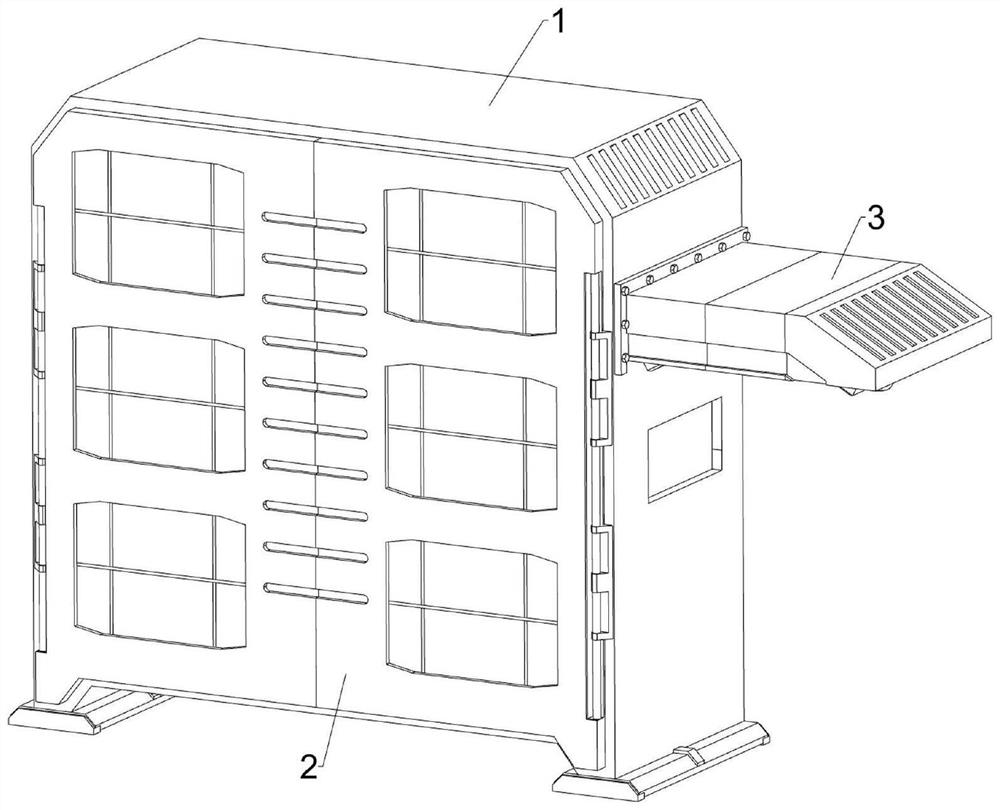

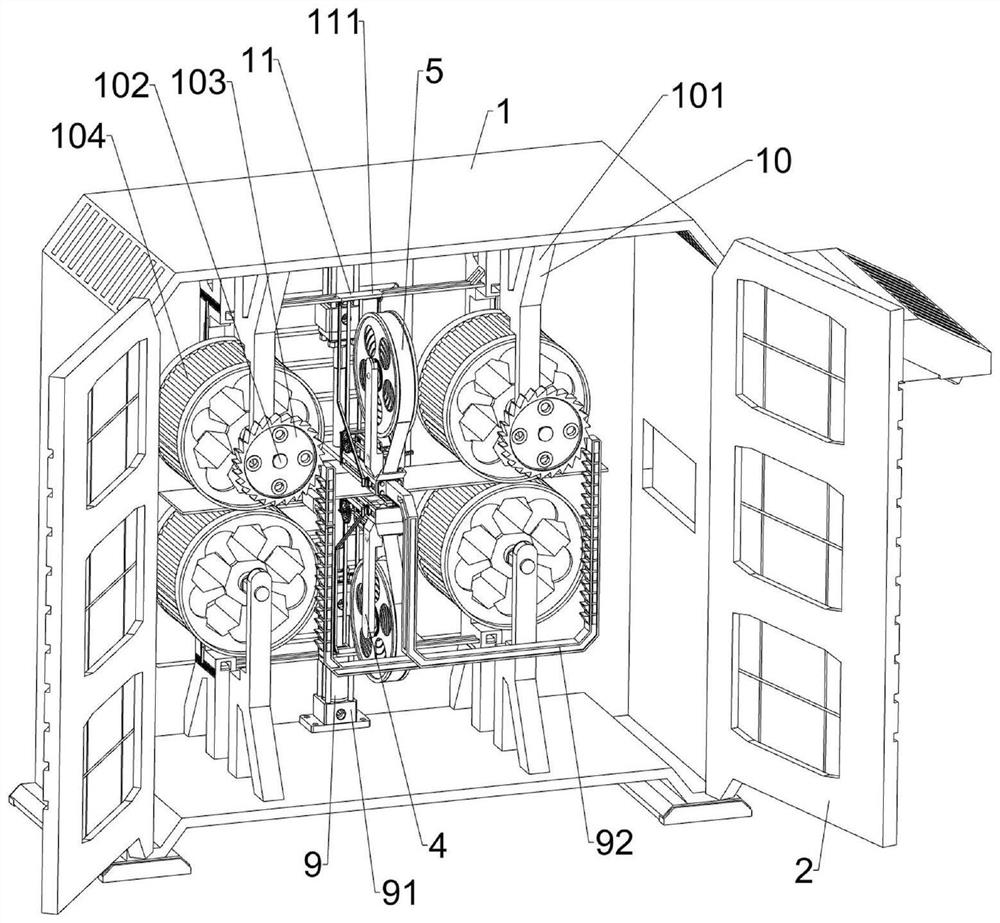

[0039] Embodiment: a kind of off-line gluing machine.

[0040] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 and Figure 17 As shown, it includes a box body 1, a box door 2, a casing 3, an illumination lamp 31, a camera 32, a movable plate with a groove 4, a rubber strip roll 5, a T-shaped block 6, a first spring 7, a hollow rod 8, a drive Mechanism 9, conveying mechanism 10, glue pulling mechanism 11, glue sticking mechanism 12, auxiliary mechanism 13 and cutting mechanism 14, the left and right sides of the front side of the box body 1 are all rotatably connected with the box door 2, the box door 2 and the box body 1 Contact fit, the box door 2 is used to close the box body 1, square holes are opened in the middle of the left and right sides of the box body 1, the outer right side of the box body 1 is fixed on the upper part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com