Anti-disorder needle withdrawing device of double-sided jacquard machine

A double-sided jacquard and jacquard sheet technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of many product quality problems, high maintenance costs, wrong jacquard flowers, etc., to avoid the phenomenon of random needles, Lower maintenance costs and better manufacturing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

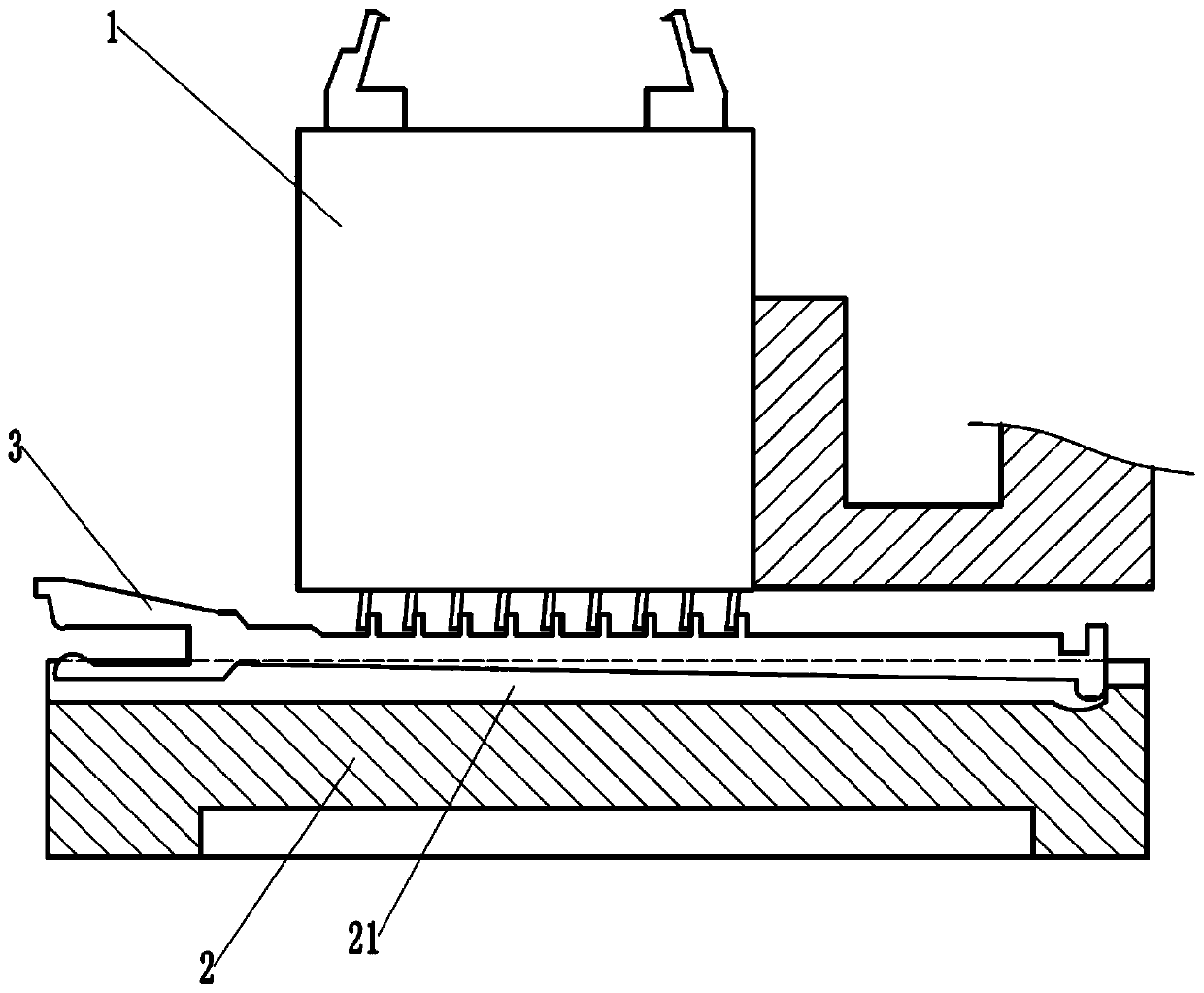

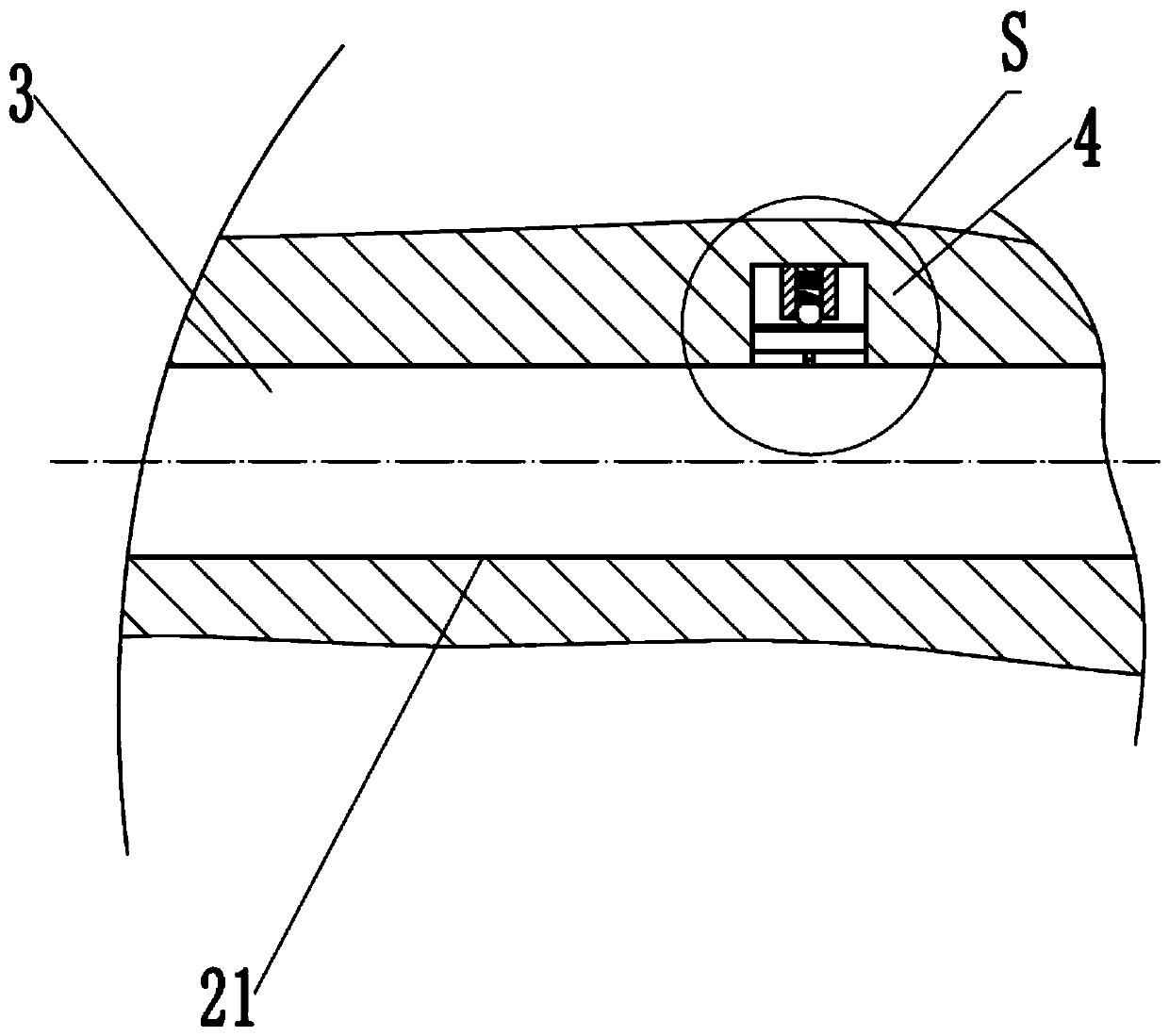

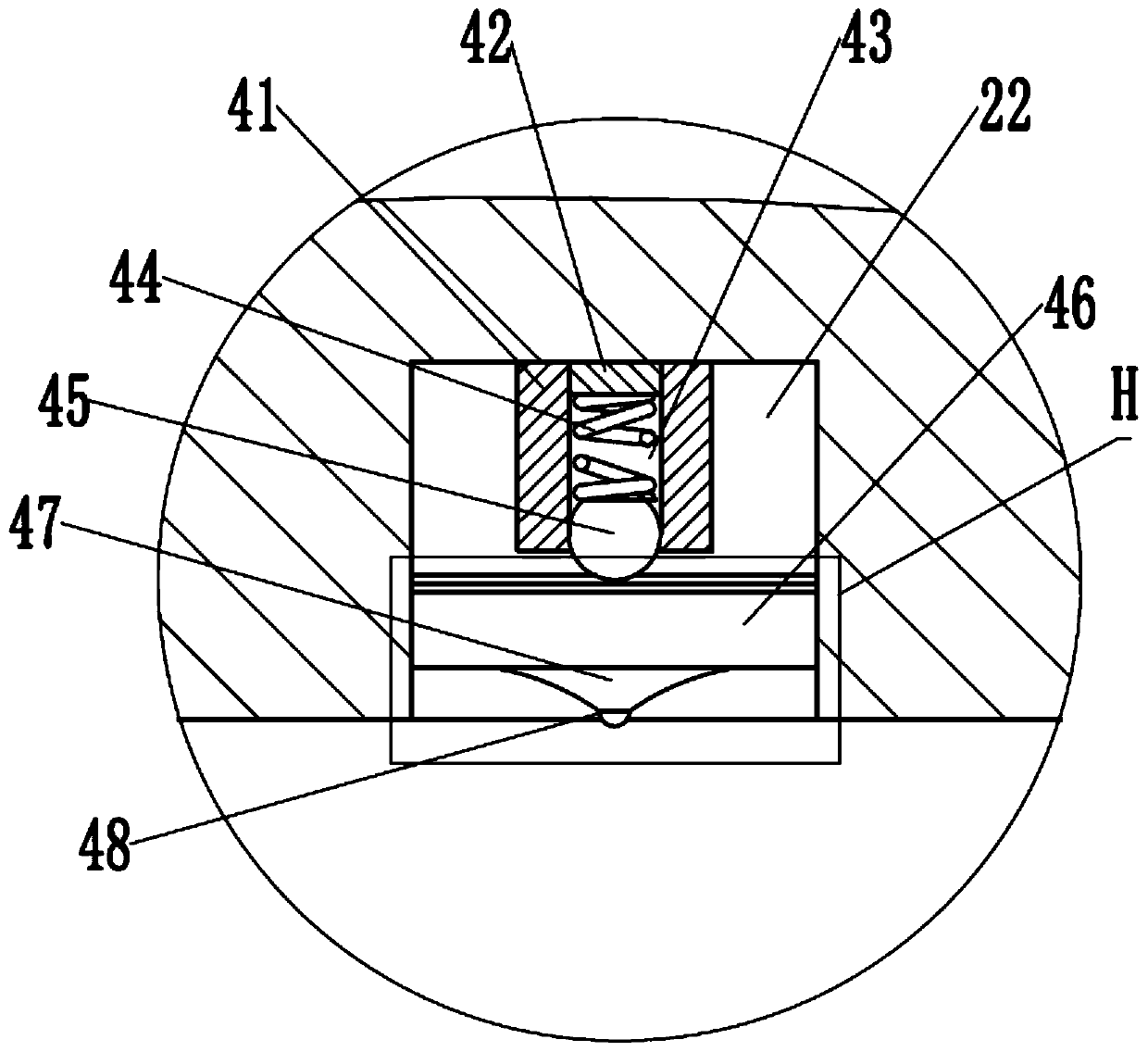

[0030] See attached Figure 1 to Figure 6 ,like figure 1 , figure 2 , image 3 The anti-chaos needle ejection device of a double-sided jacquard machine shown includes a dial 2, a jacquard sheet 3, a needle selector 1 and a damper 4, and a needle groove 21 is provided on the dial 2, and the jacquard sheet 3 is placed in the needle slot 21, the needle selector 1 is set above the dial 2 to select the jacquard piece 3, and the damper 4 is installed on the side of the needle slot 21. On the inner wall, the damper 4 exerts a force on the side wall of the jacquard piece 3, so that the jacquard piece 3 is opposite to the needle groove when the jacquard piece 3 is not driven by the needle selector 1. 21 does not move, thereby making the knitting needles connected to the jacquard sheet 3 stationary, wherein the damper 4 includes a cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com