Patents

Literature

222results about How to "Reduce exception" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

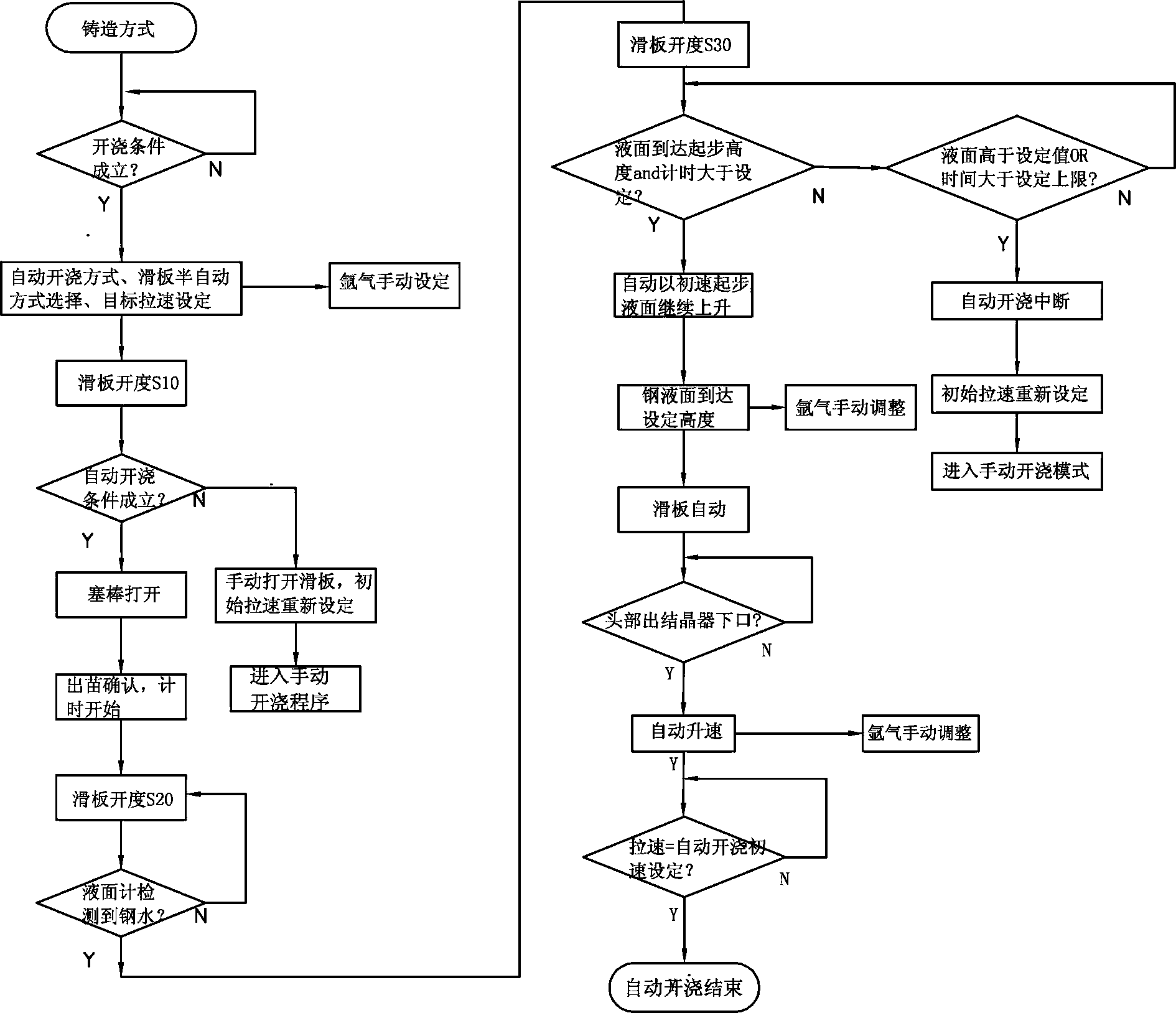

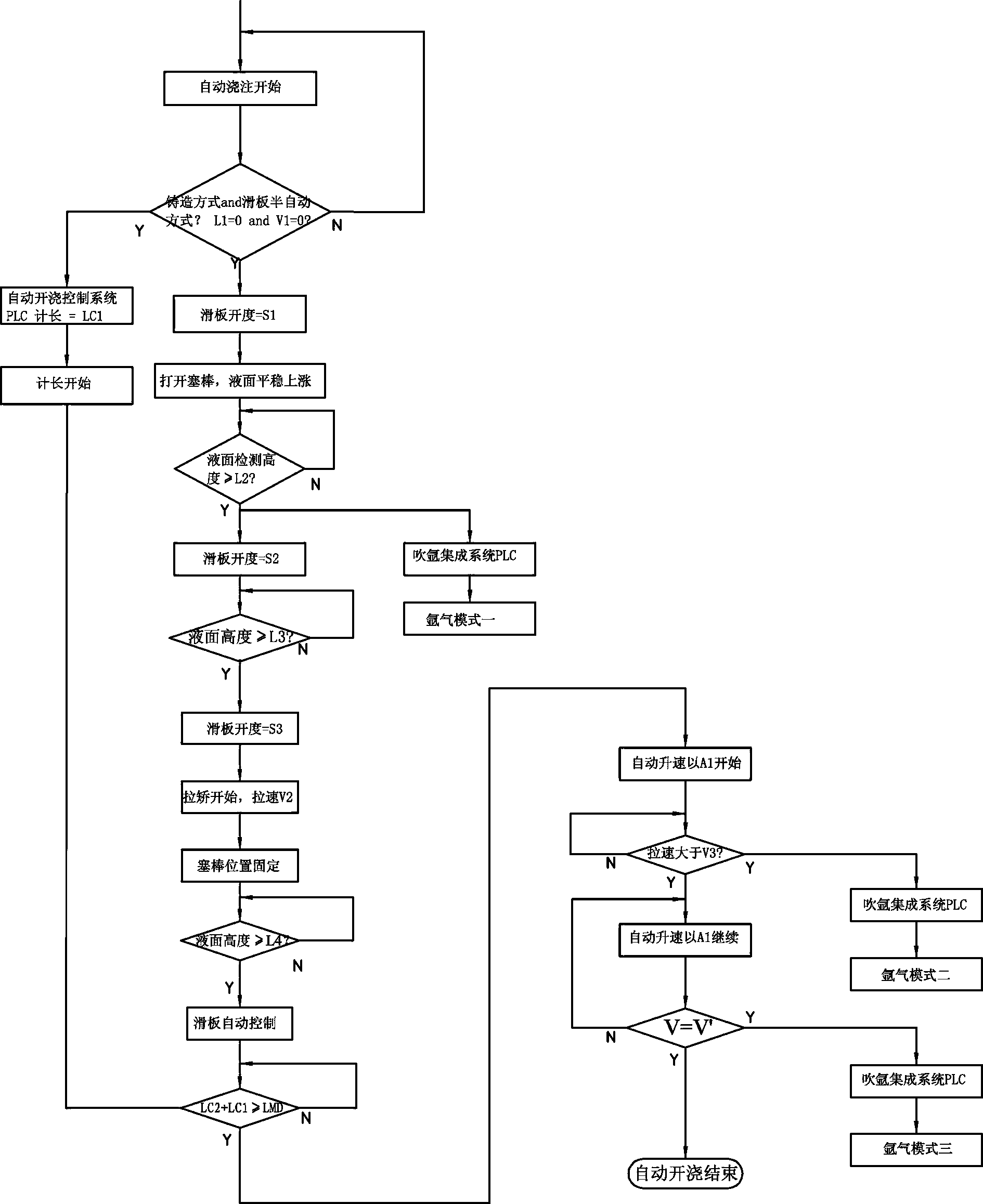

Control method for automatic casting of plug-in continuous casting machine

ActiveCN103878334AEliminate quality defects and abnormal accidentsLarge openingTundishIntegrated systems

The invention discloses a control method for automatic casting of a plug-in continuous casting machine. The control method includes that firstly, an automatic-casting control system judges conditions of automatic casting; if the conditions are met simultaneously, a fixed value is automatically given by a plate blank casting length counter in the automatic-casting control system; an initial casting speed is set; when molten steel in a tundish reaches a normal height, manual judgment is performed and a stopper is opened, casting is started, an operator controls the height of the stopper according to steel flow conditions and center-control countdown time to enable the molten steel in a crystallizer to smoothly rise; according to different heights detected based on liquid level of the crystallizer, the automatic-casting control system gives different openings to a sliding plate of a liquid level control system, and simultaneously sends instructions to an argon-blowing integrated system to invoke three argon modes. Argon control in each step of the casting process is performed in a linkage manner, and casting success rate and stability in casting control are guaranteed, so that quality of casting blanks during casting is improved, and various casting accidents are avoided.

Owner:BAOSHAN IRON & STEEL CO LTD

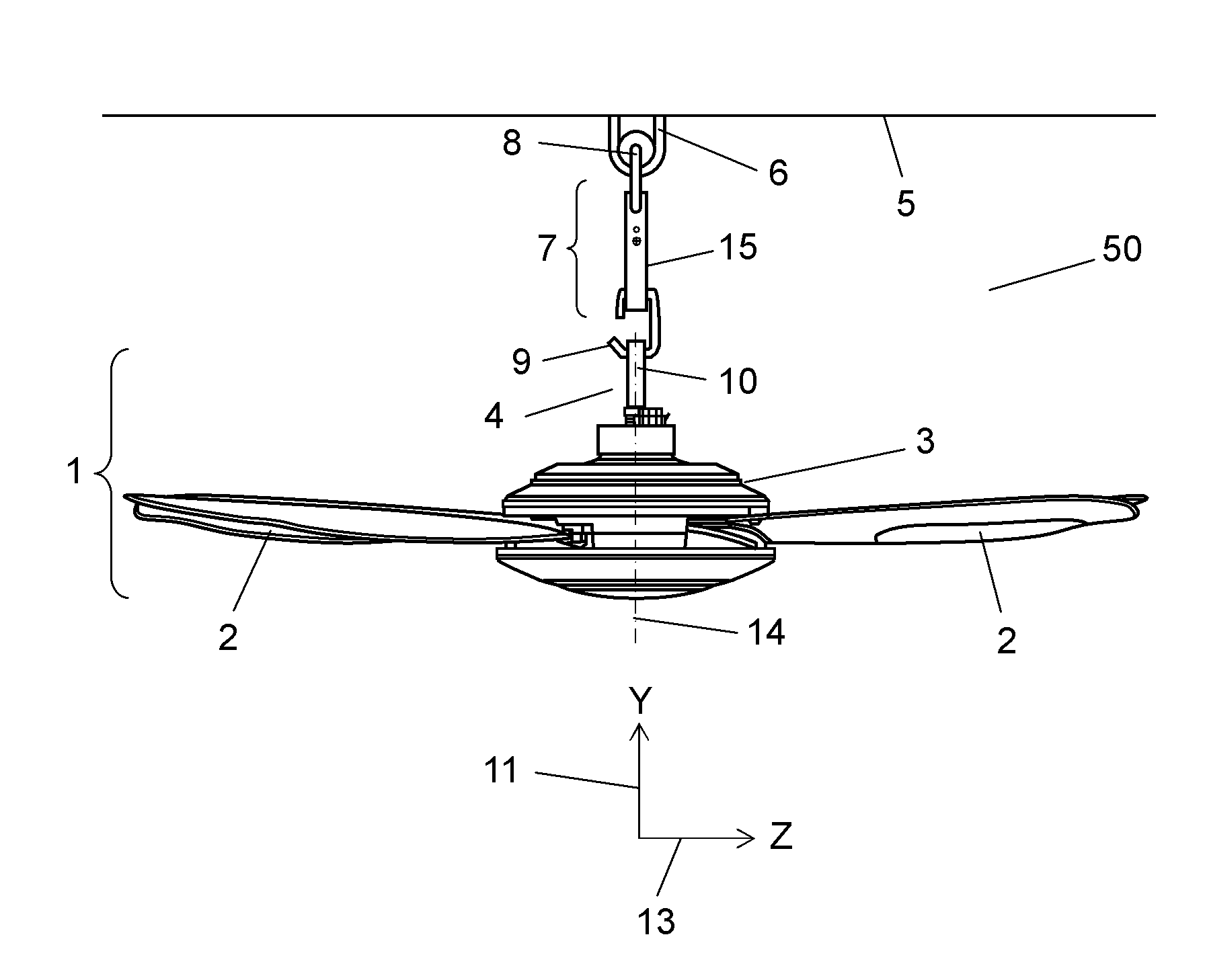

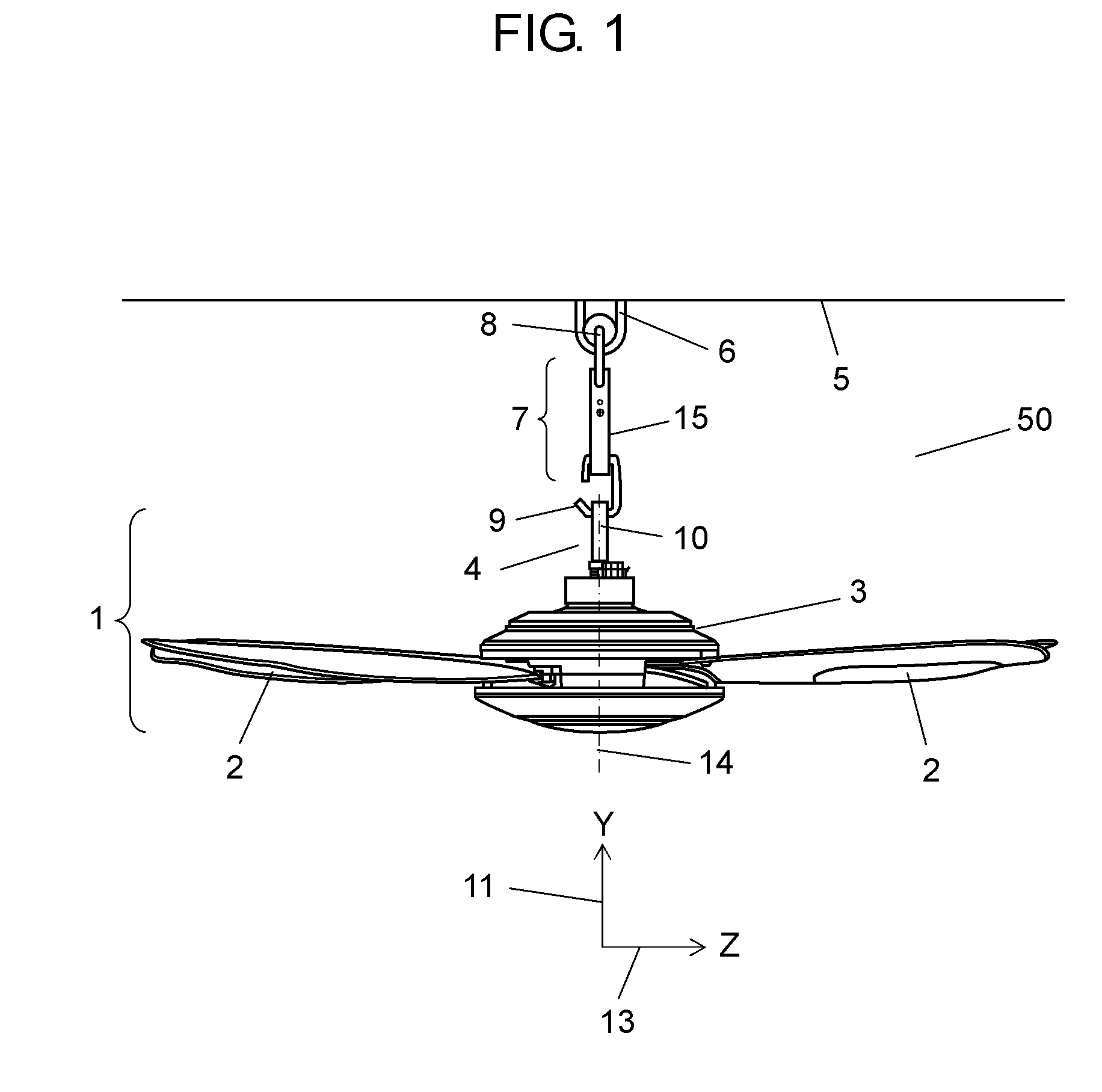

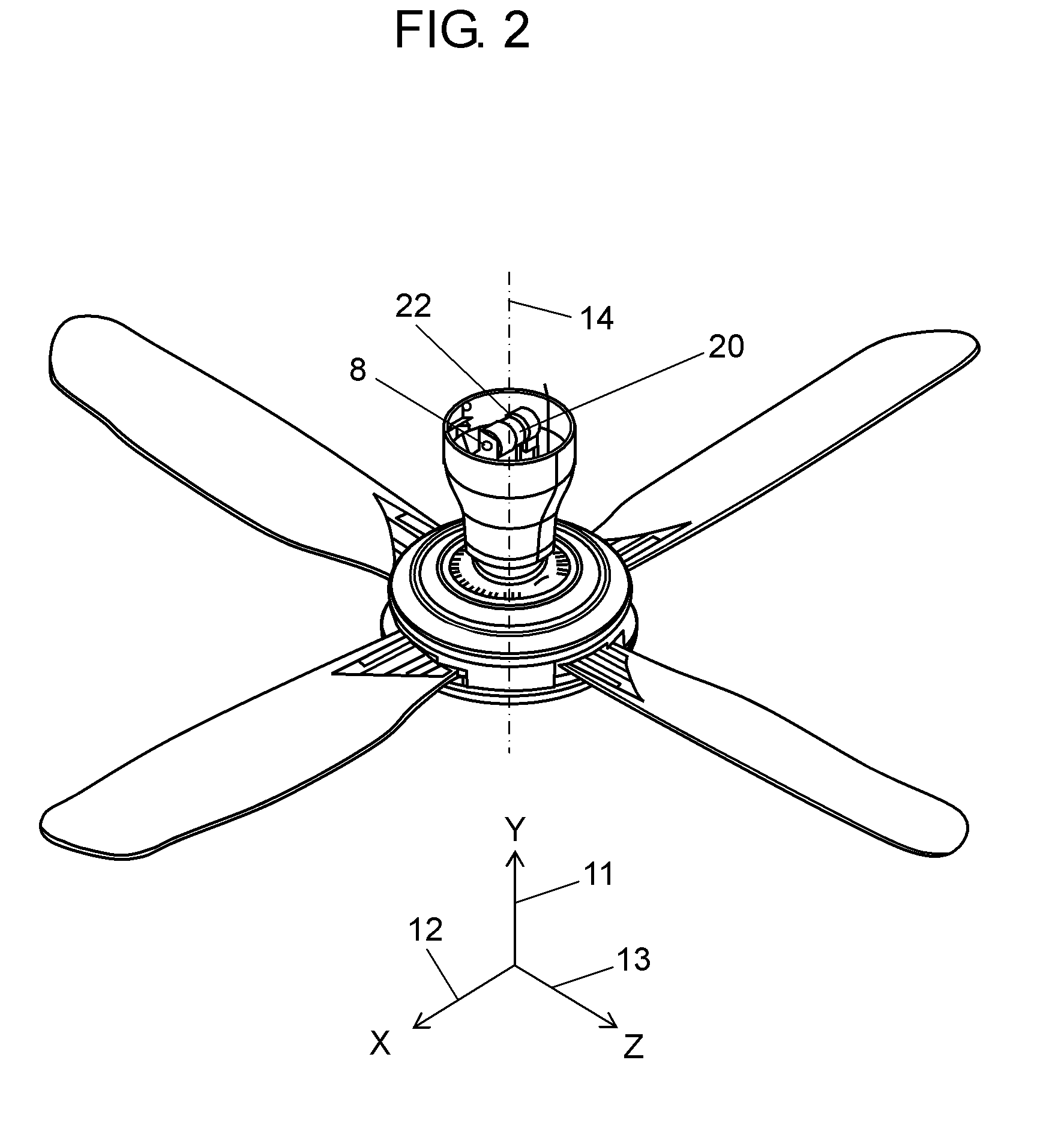

Ceiling fan

InactiveUS20110052411A1Reduce occurrence of abnormalityReduce operationPump componentsReaction enginesCeiling fanEngineering

A ceiling fan including a connecting fitting fixed to a ceiling, and a ceiling fan main body suspended from the connecting fitting via a suspension device. The ceiling fan main body includes a motor for rotating a plurality of blades attached in a horizontal direction, a shaft protruding to an upper part of the motor, and a joint portion fixed on an upper part of the shaft. The suspension device includes a first connecting portion capable of being movably mounted on the connecting fitting, and a second connecting portion located in a lower part of the first connecting portion. The joint portion is movably mounted on the second connecting portion.

Owner:PANASONIC CORP

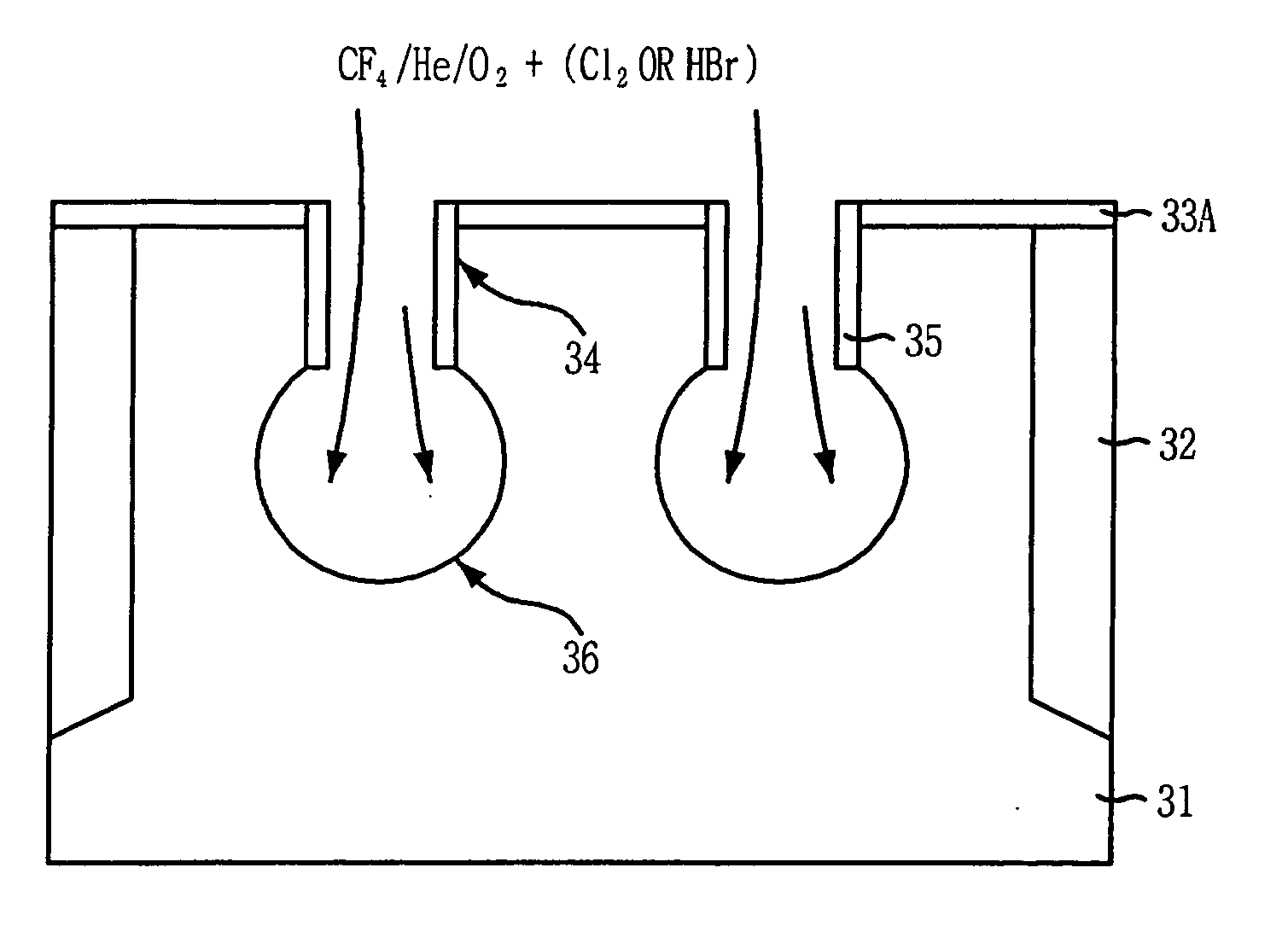

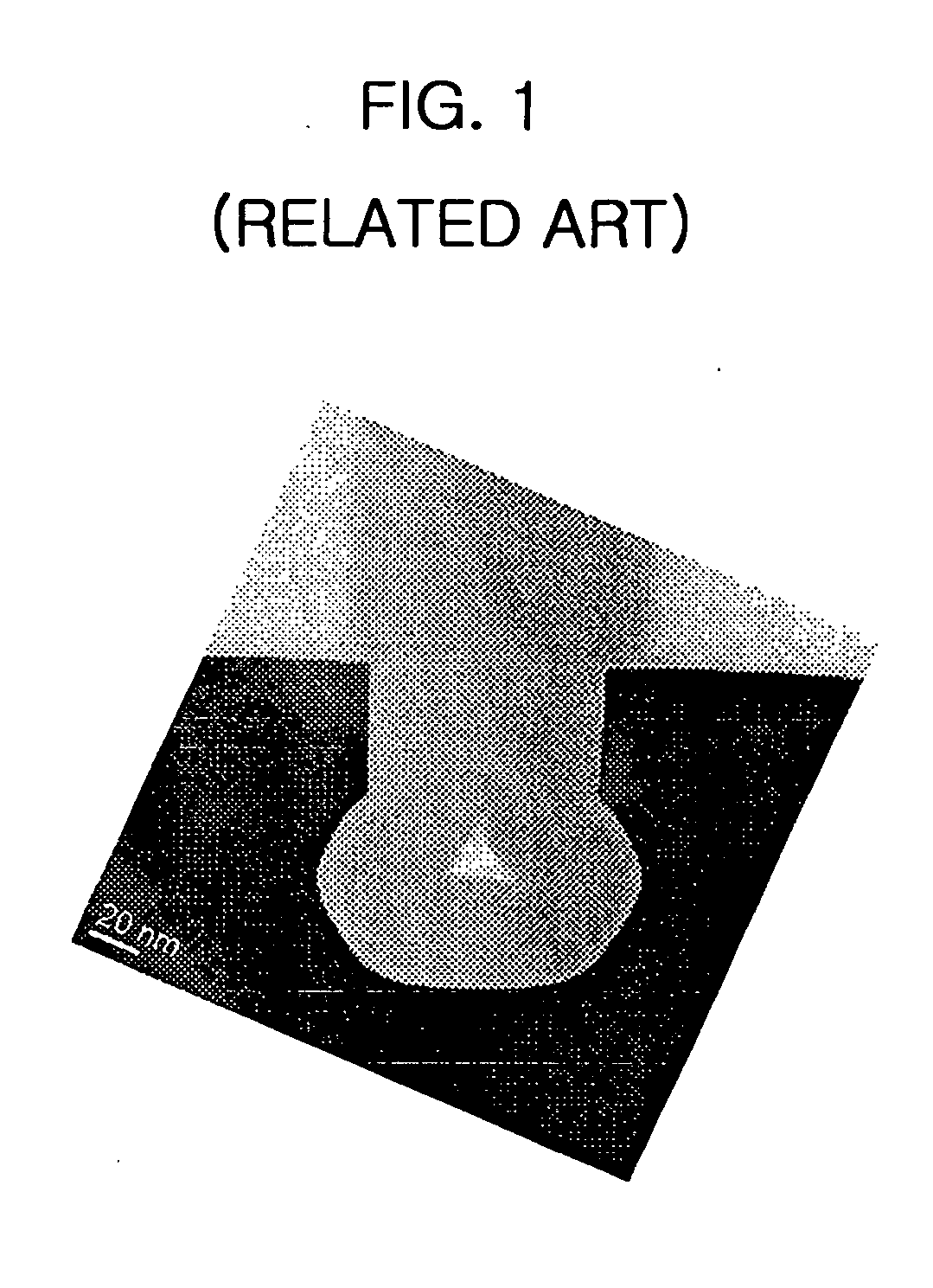

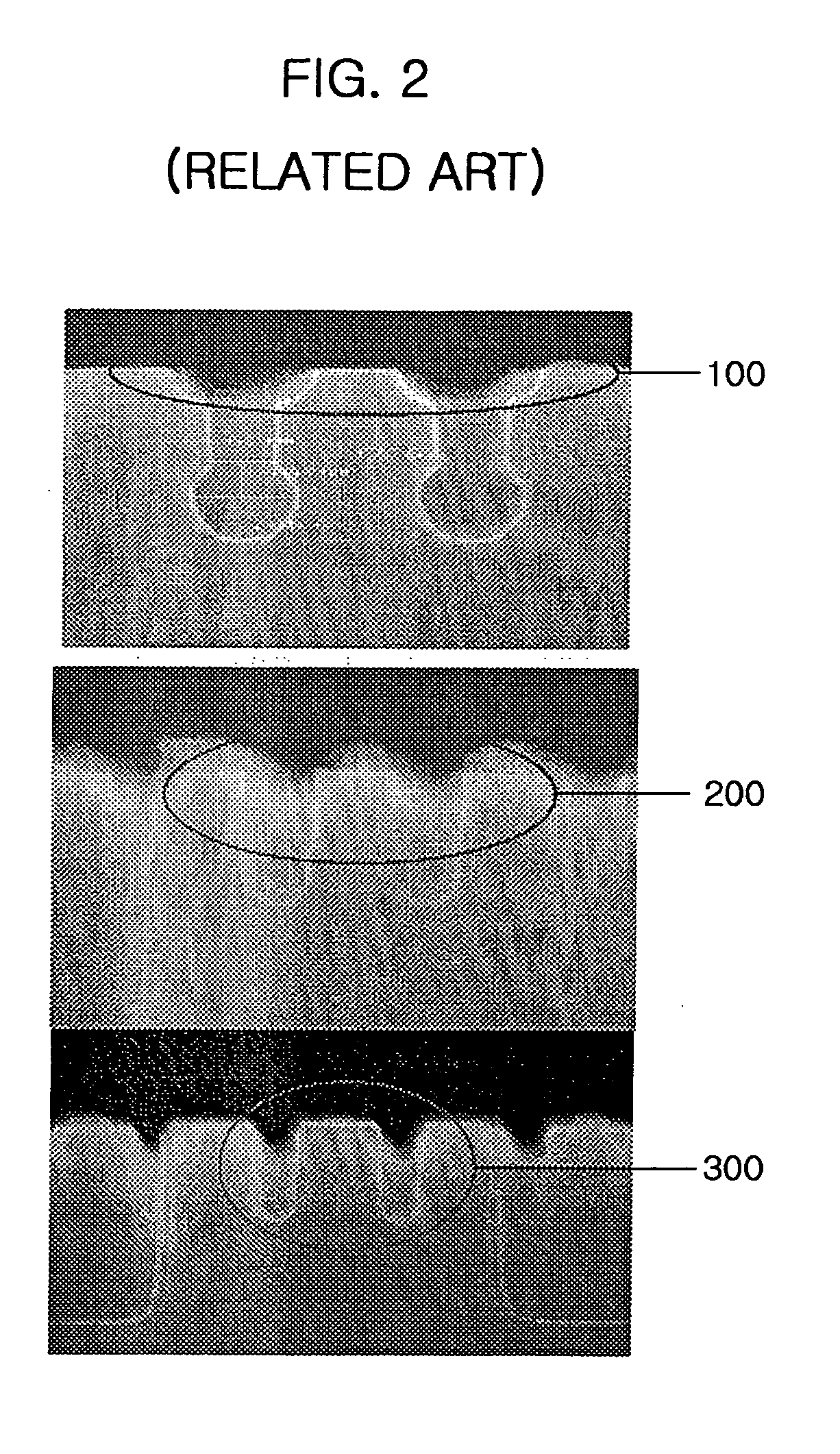

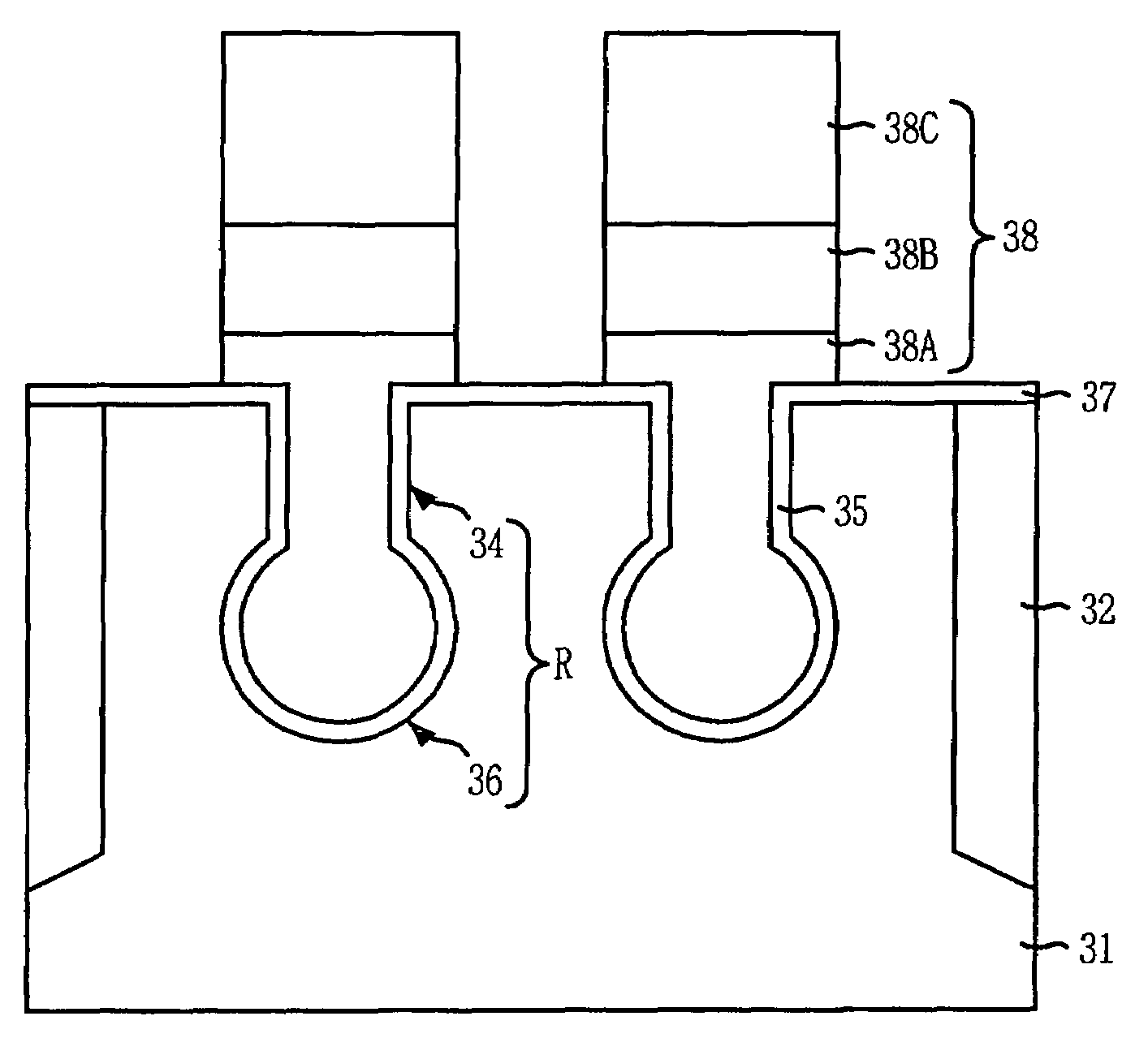

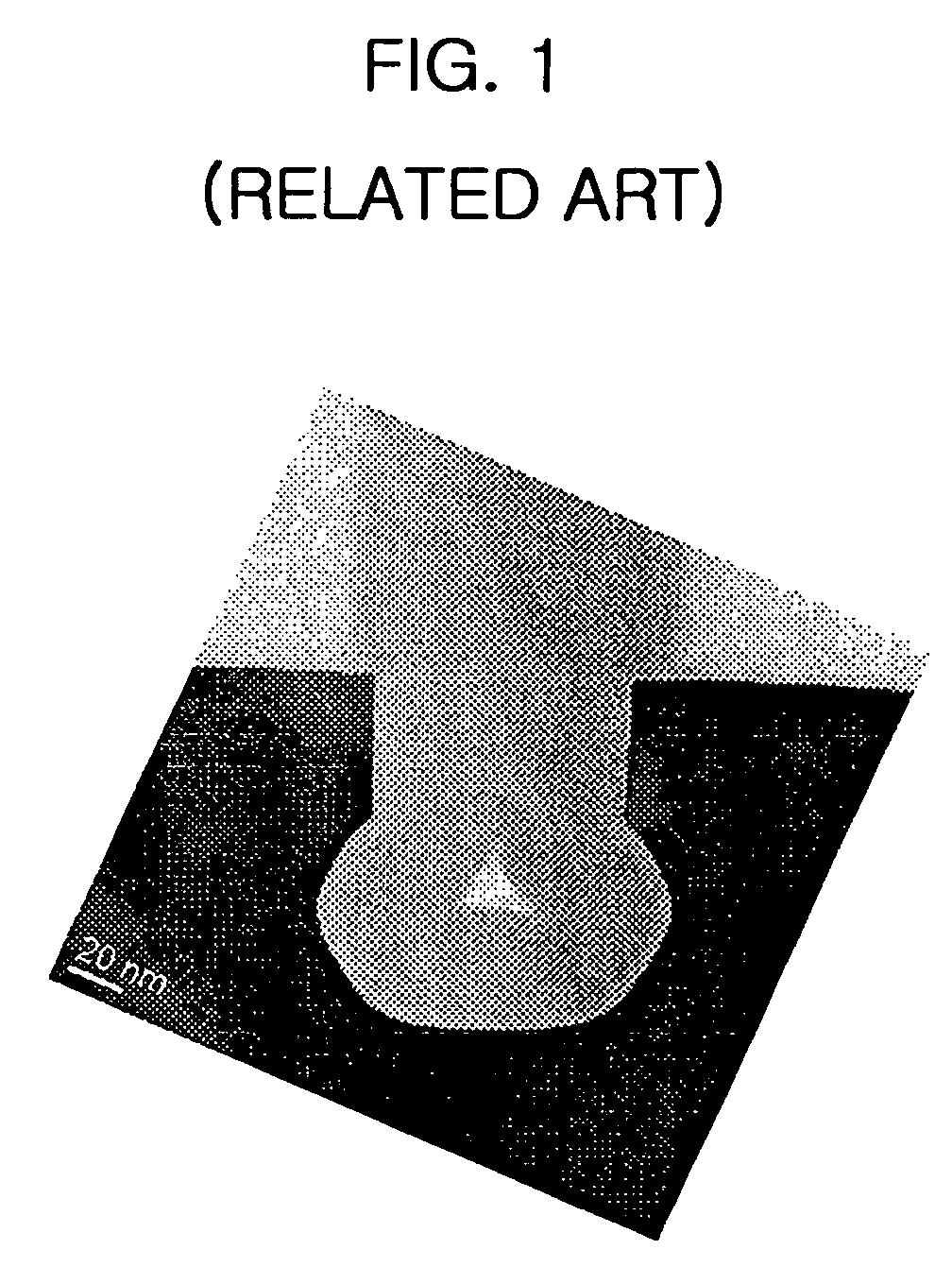

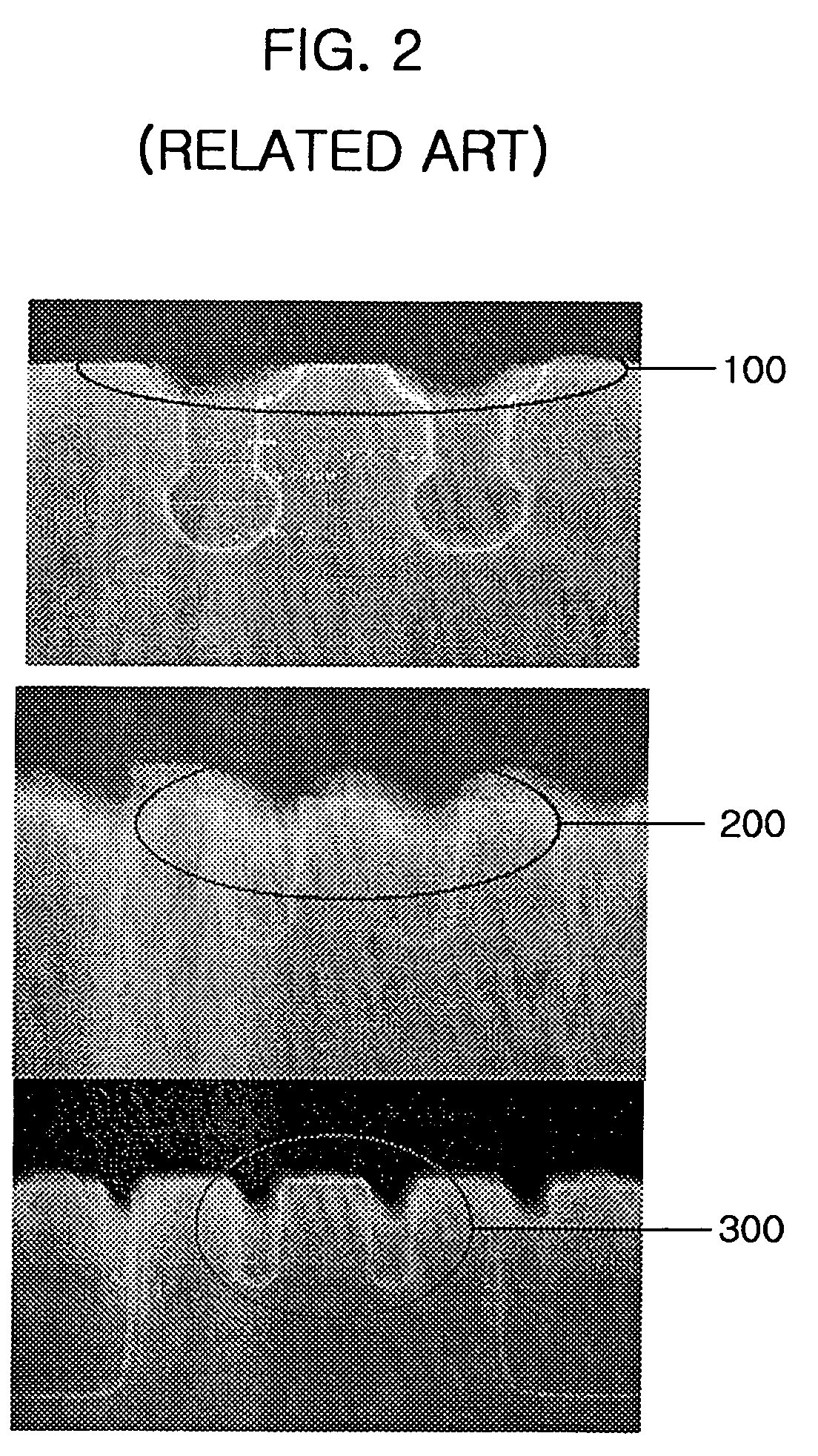

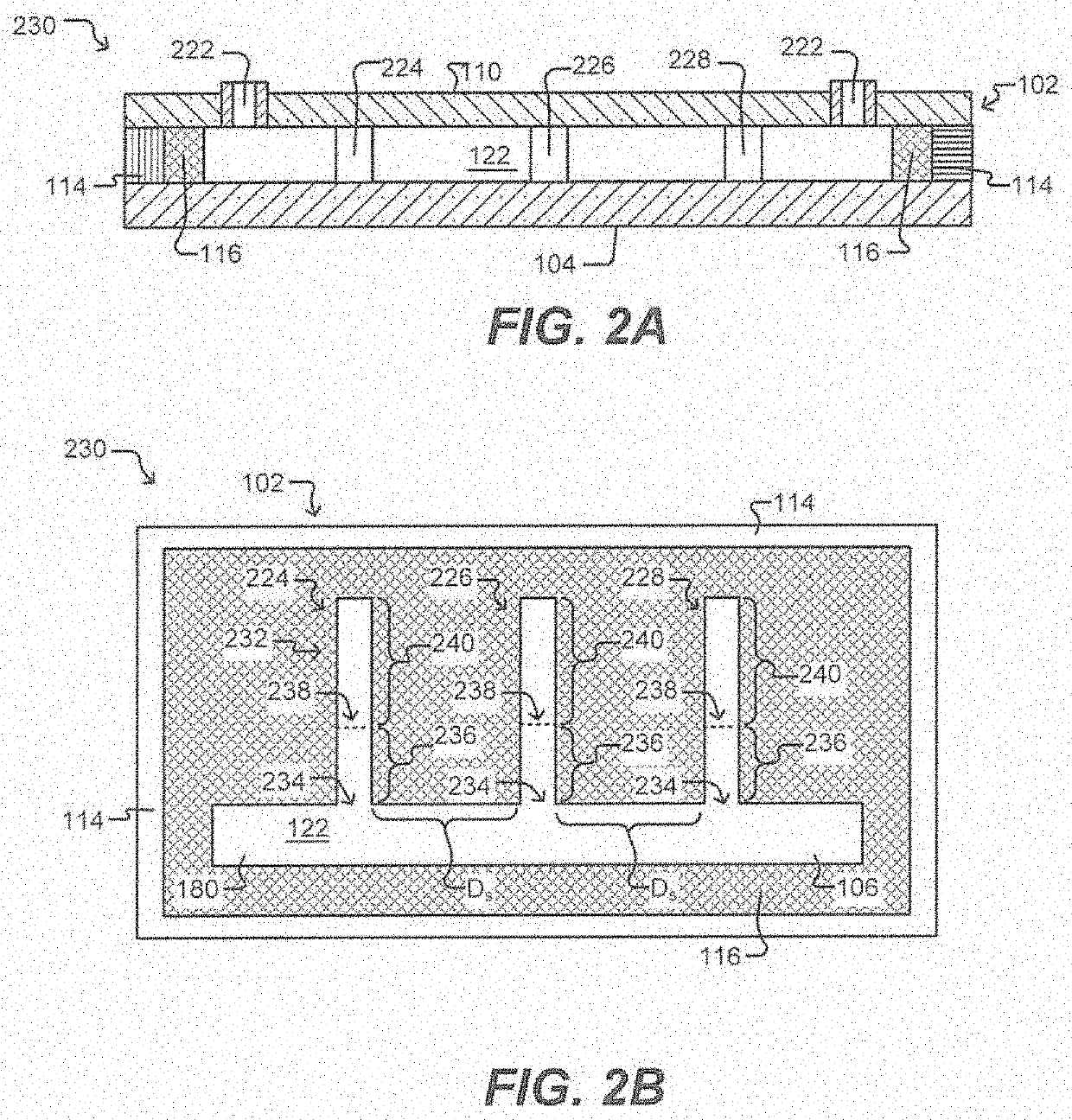

Method for fabricating semiconductor device with bulb shaped recess gate pattern

ActiveUS20070148934A1Reduce harmImprove etch selectivitySemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialSemiconductor

A method for fabricating a semiconductor device with a bulb shaped recess gate pattern includes selectively etching a first portion of a substrate to form a first recess; forming a spacer on sidewalls of the first recess; performing an isotropic etching process on a second portion of the substrate beneath the first recess to form a second recess, the second recess being wider and more rounded than the first recess; removing the spacer; and forming a gate pattern having a first portion buried into the first and second recesses and a second portion projecting over the substrate.

Owner:SK HYNIX INC

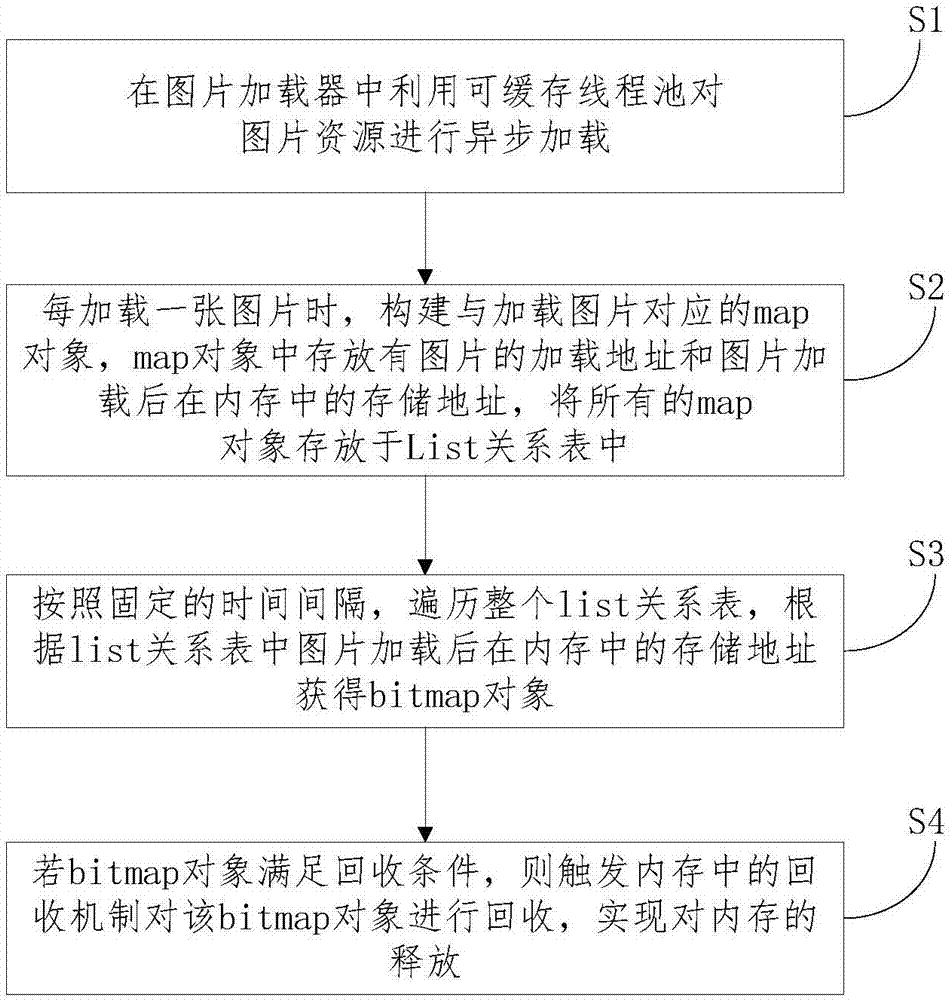

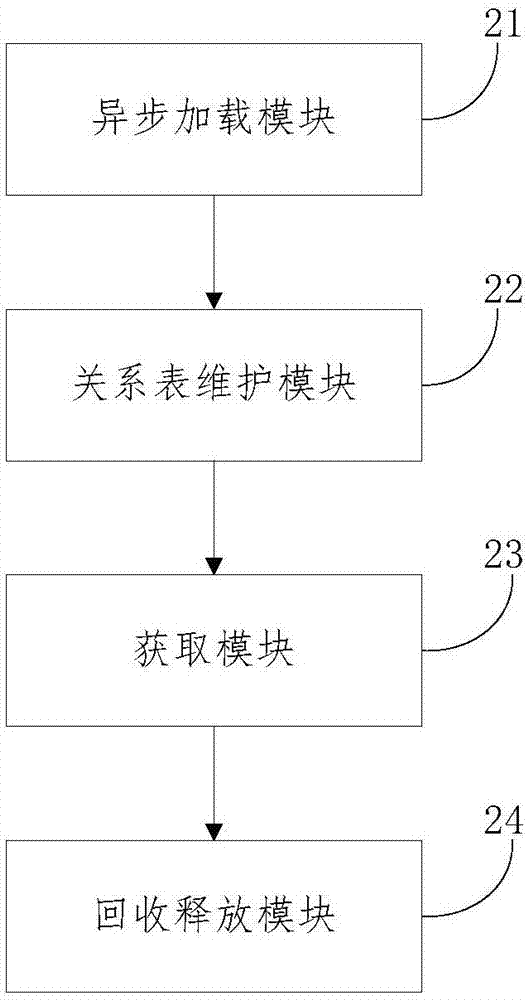

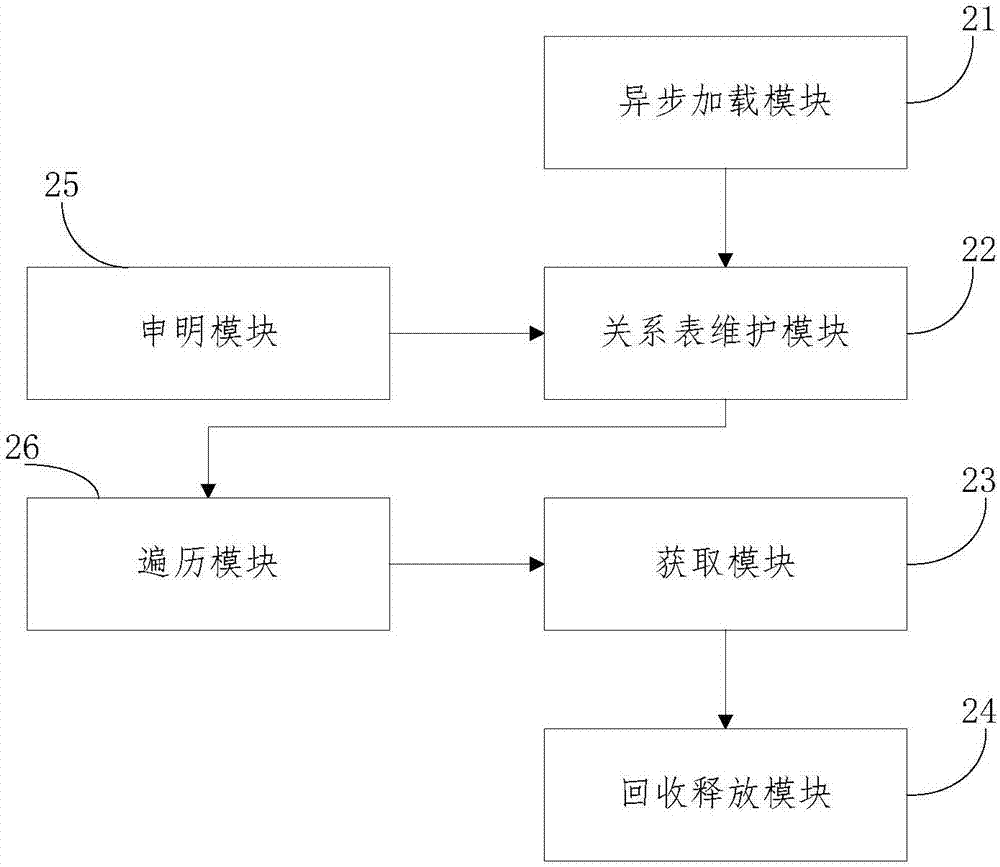

Automatic memory release method and system based on picture resources

ActiveCN107357650AImprove development efficiencyTo achieve the purpose of automatically releasing memoryResource allocationBitmapThread pool

The invention provides an automatic memory release method and system based on picture resources. The method comprises following steps: performing asynchronous loading on picture resources by means of a cacheable thread pool; building a map object corresponding to a loaded picture each time as the picture is loaded; storing all the map objects in a list relation table; traversing the whole list relation table according to a preset time interval and obtaining a bitmap bitmap object according to a storage address of the loaded picture in the map object; if the bitmap object satisfies a recovery condition, then the recovery mechanism in the memory is triggered for recovering the bitmap object. According to the method of the invention, a thread pool with cache function is selected to load pictures asynchronously, effectively solving the problem that large pictures lead to ANR problems and regularly cleaning bitmap objects in the memory to automatically release memory; when the system resource is limited, system memory abnormity is avoided; the development efficiency of developers is increased and the possibility of abnormal programs is reduced.

Owner:WUHAN DOUYU NETWORK TECH CO LTD

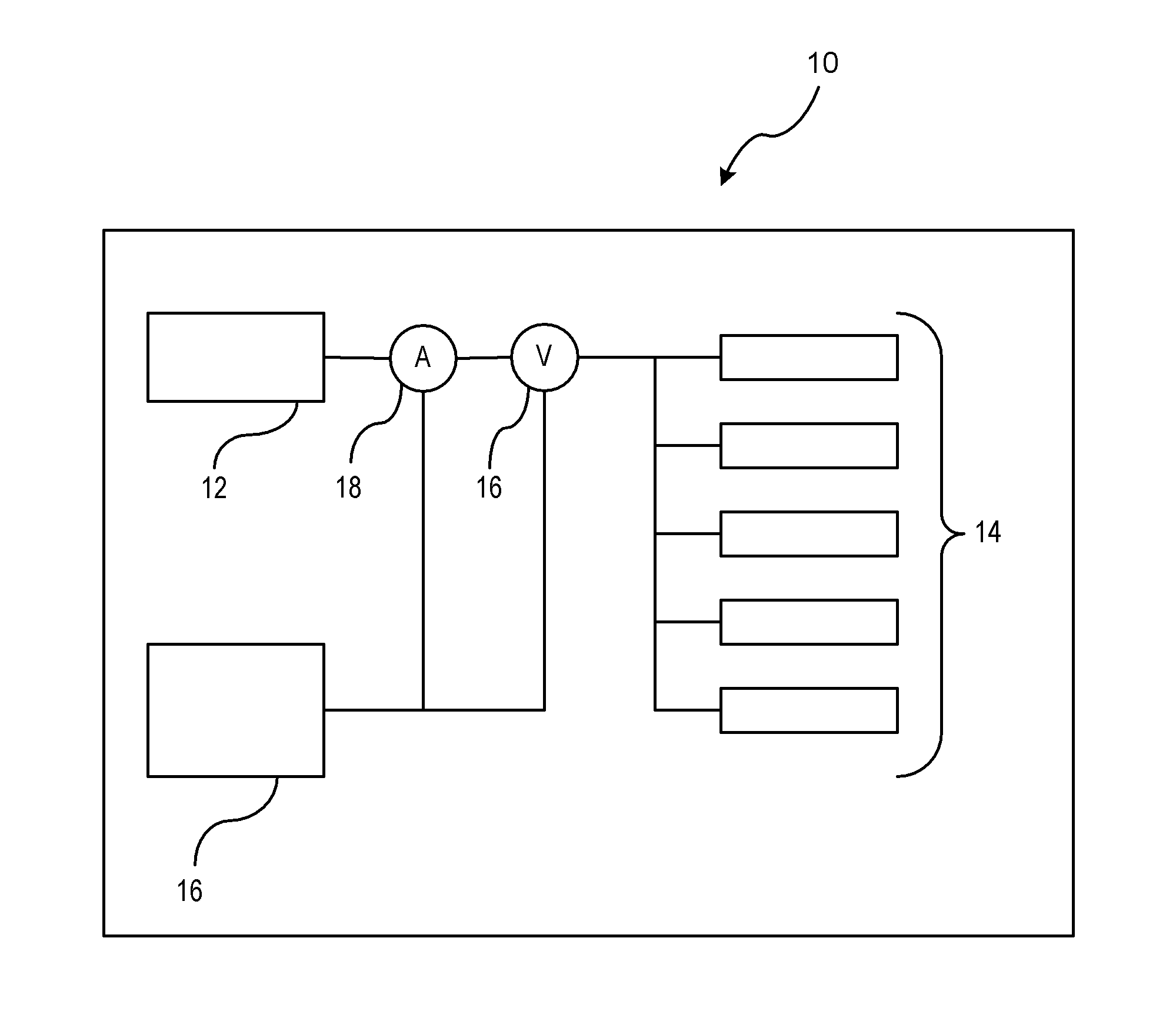

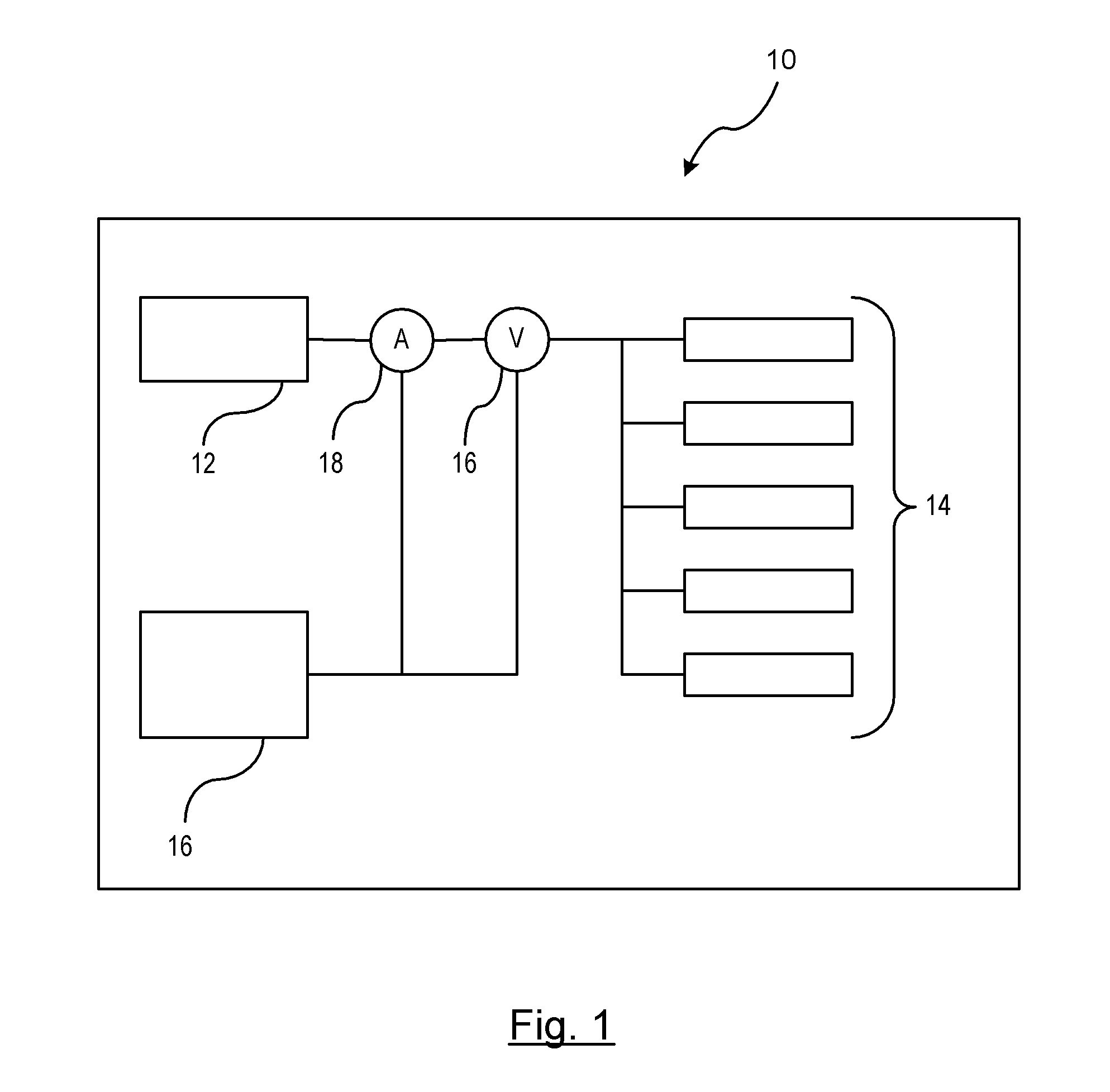

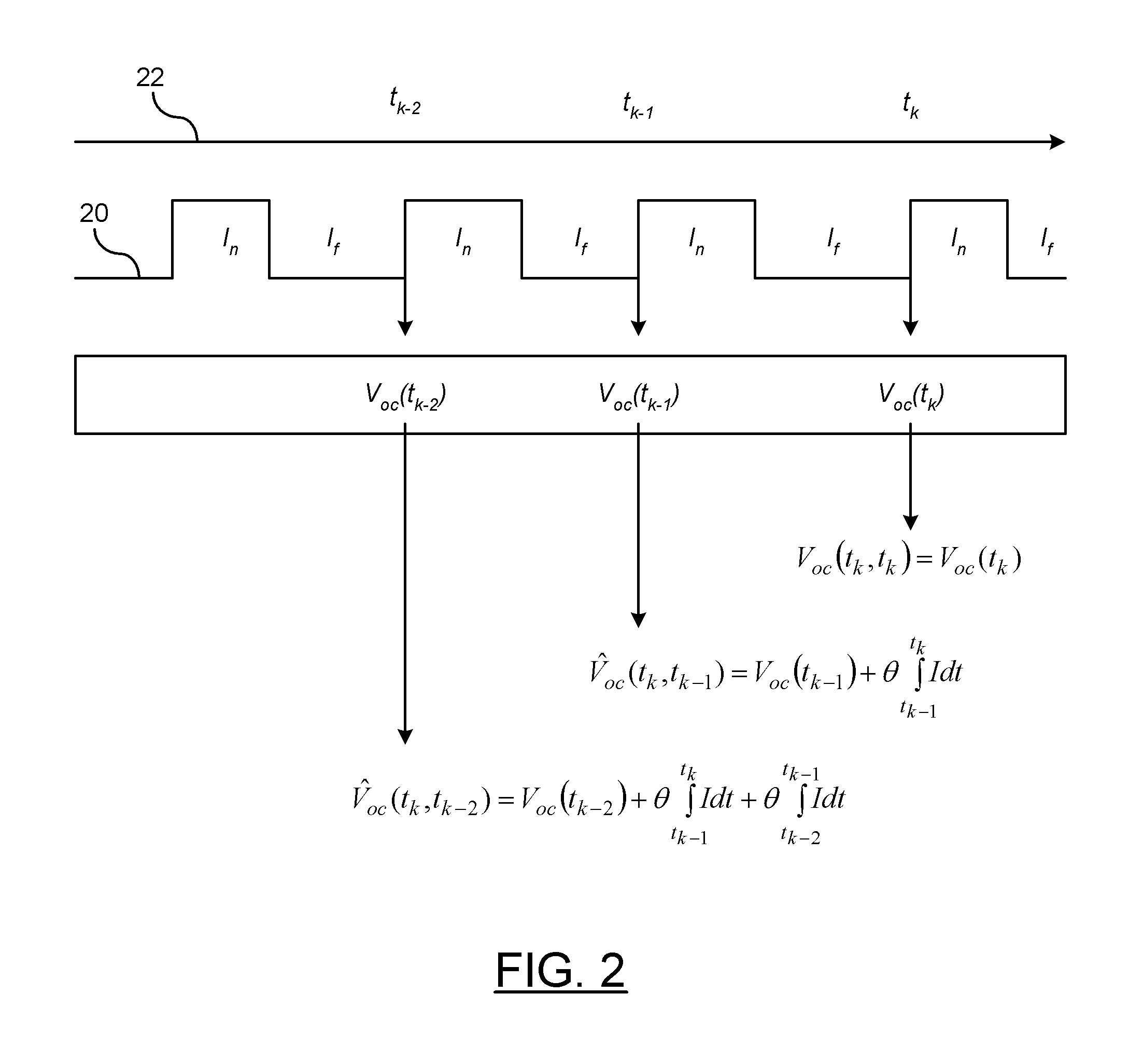

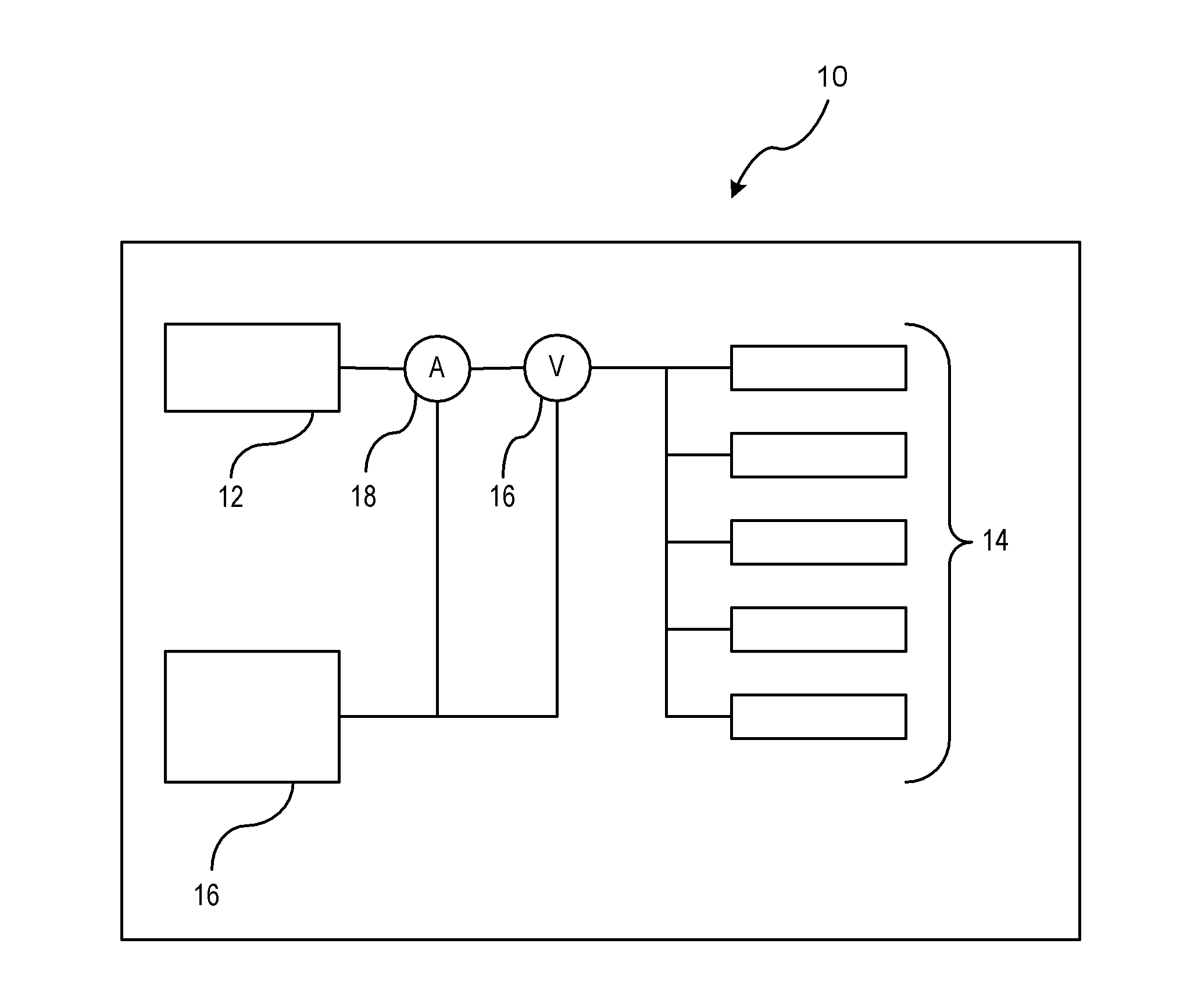

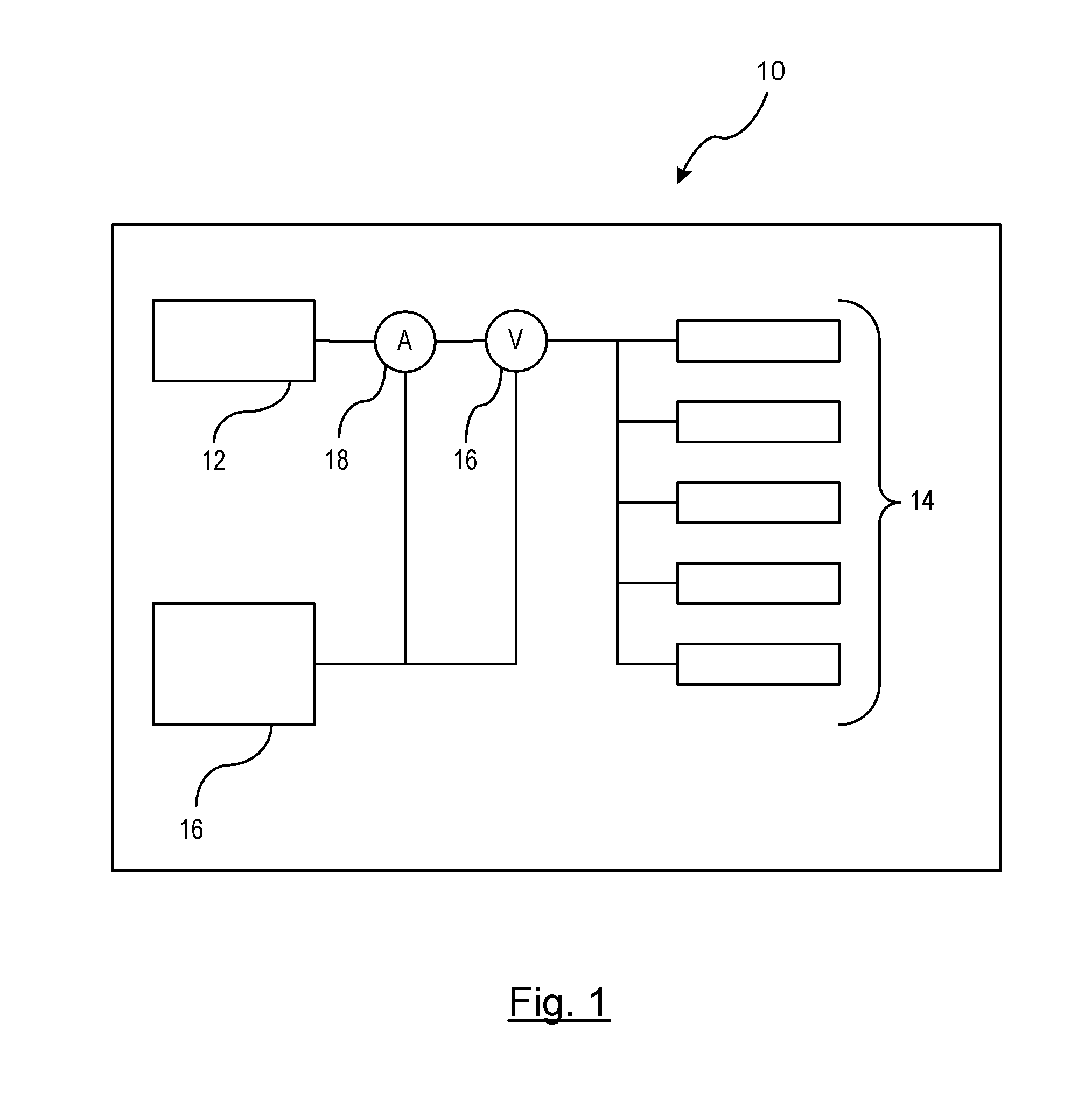

Method and Apparatus for Estimating Battery Capacity of a Battery

ActiveUS20120072145A1Reduce exceptionReduce capacityCurrent/voltage measurementResistance/reactance/impedencePower flowElectrical battery

A method is provided for determining a battery capacity for a vehicle battery. Open circuit voltages of a vehicle battery are measured during ignition startups. A battery parameter is estimated for the vehicle battery that is a function of a present open circuit voltage measurement for a present ignition startup, a function of at least one open circuit voltage observation of a previous ignition startup, a function of a current draw integration over a time period from a previous ignition startup event to a present ignition startup event, and a function of an adjustment factor. A battery parameter is determined based on a new battery. The battery capacity is calculated as function of the battery parameter for the vehicle battery and the battery parameter for the new battery.

Owner:GM GLOBAL TECH OPERATIONS LLC

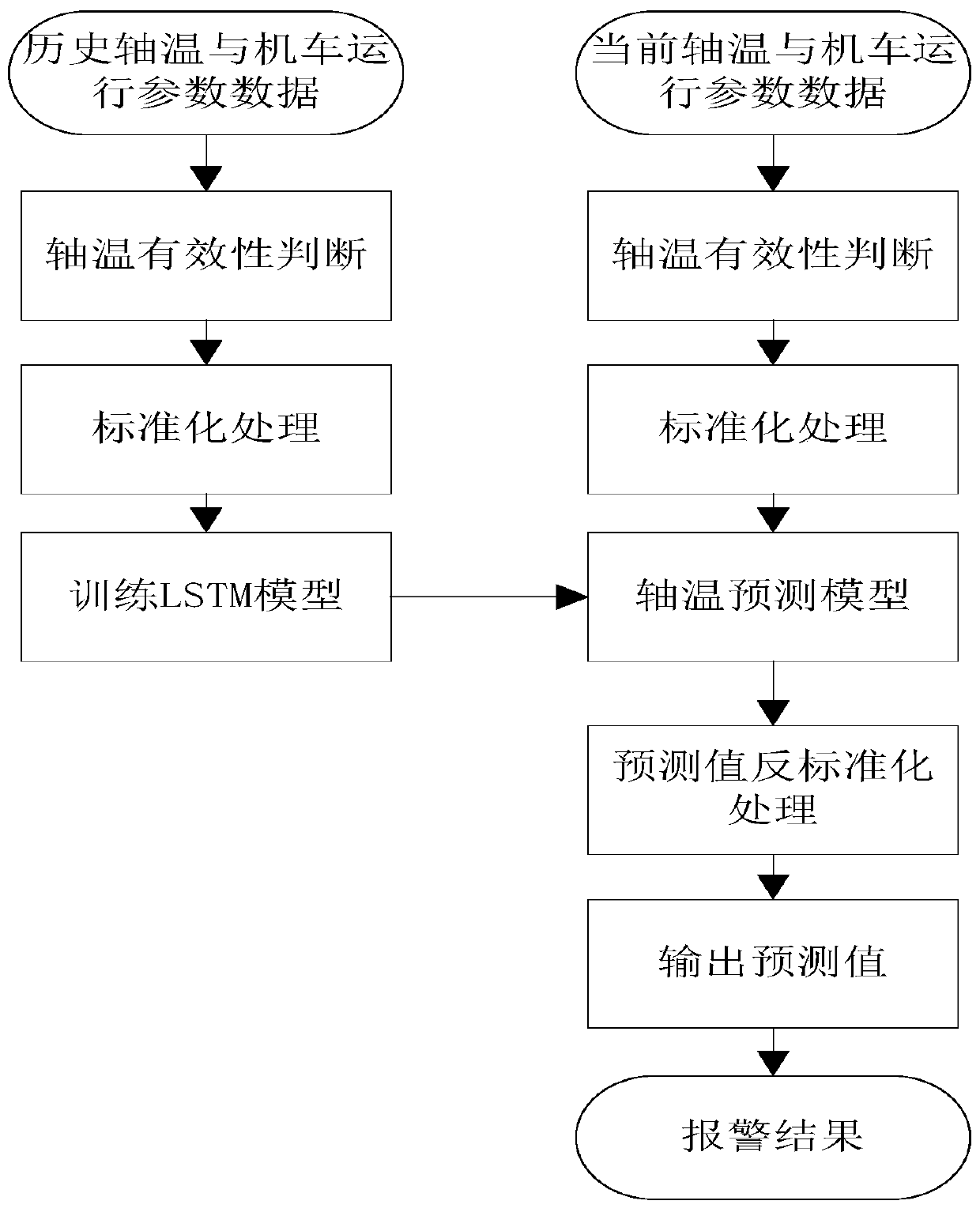

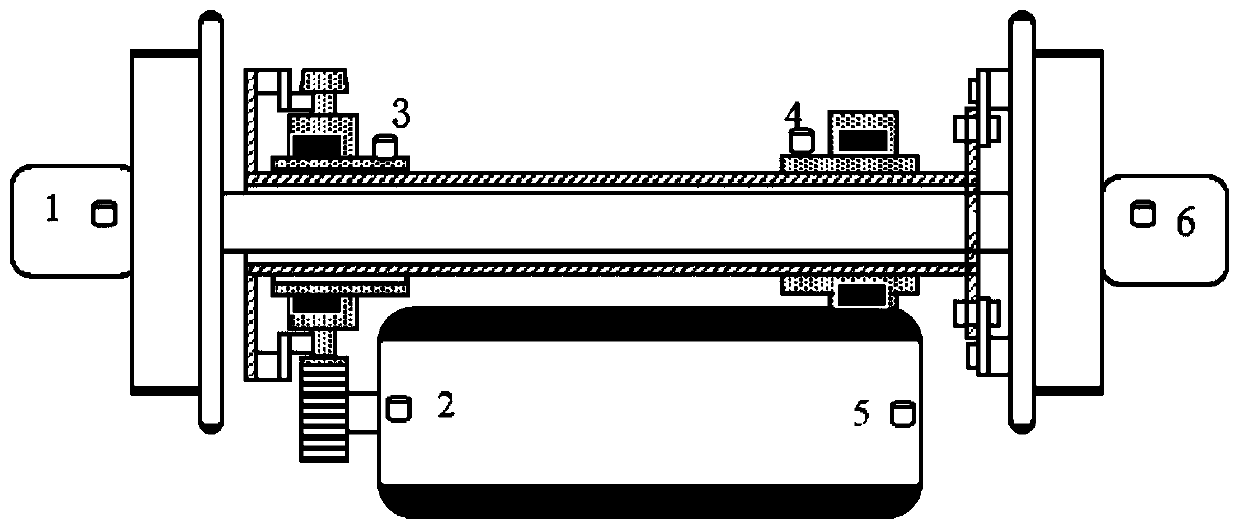

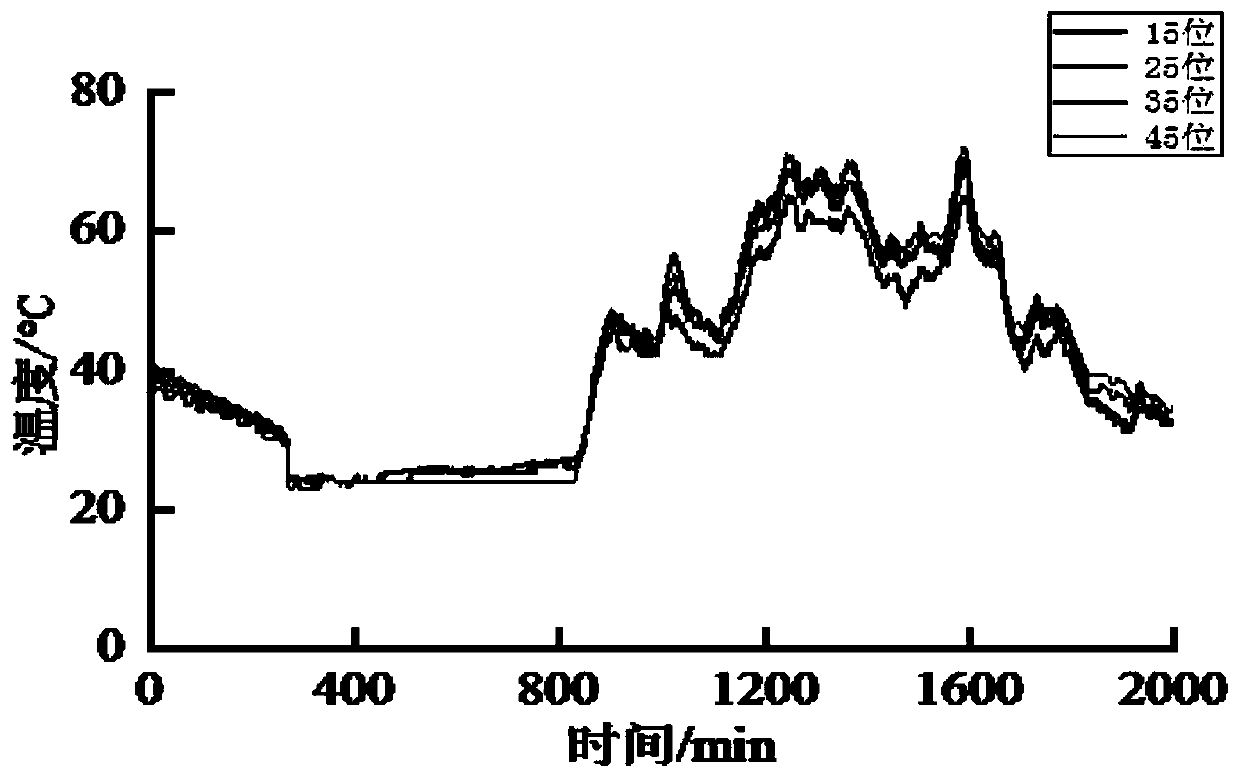

Bearing temperature prediction and alarm diagnosis method based on LSTM model

ActiveCN111351664AImprove accuracyAvoid failureMachine bearings testingMonitoring temperatureTerm memory

The invention discloses a bearing temperature prediction and alarm diagnosis method based on an LSTM model. Firstly, a bearing temperature prediction model is generated, model input data is obtained according to the real-time monitoring temperature, and then target shaft position temperature data is predicted; and finally, the running state of the bearing is judged according to a temperature alarmmechanism and an alarm result is output. According to the invention, temperature prediction of the target shaft position is carried out through the auxiliary shaft position temperature value; a long-short-term memory network model is adopted; the bearing fault alarm system based on the temperature sensor is prevented from being disturbed by temperature jump and temperature keeping unchanged in the using process, false alarm and missing alarm are avoided, the incidence relation in the time sequence can be analyzed, the trend of time sequence data is predicted, and meanwhile the defect that other neural networks cannot be predicted for a long time is overcome. And temperature alarm can be carried out more accurately.

Owner:CHENGDU YUNDA TECH CO LTD

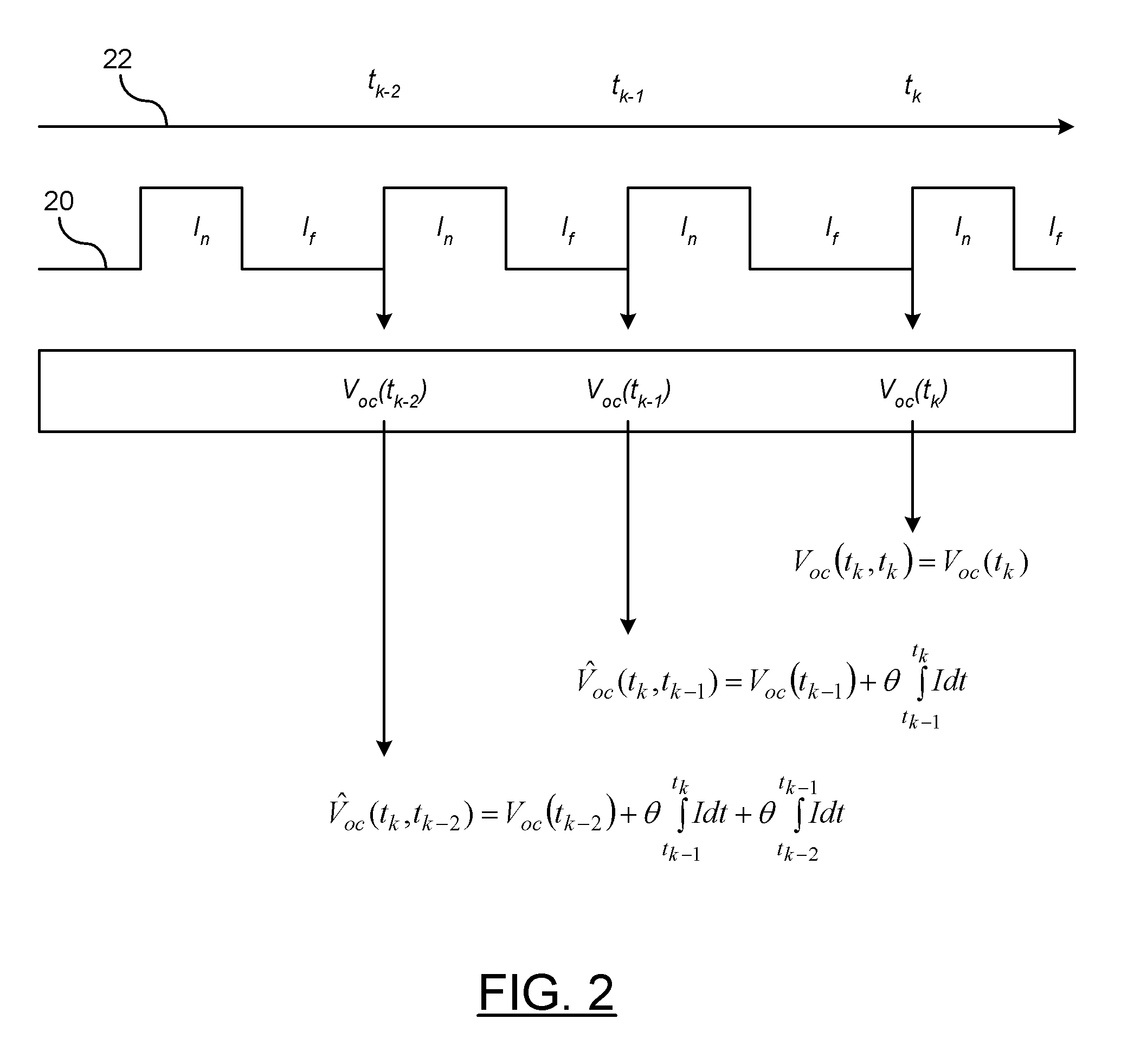

Method and apparatus for estimating soc of a battery

ActiveUS20120072144A1Reduce anomalyReduce exceptionCircuit monitoring/indicationDifferent batteries chargingState of chargeEngineering

A method of determining a state-of-charge for a battery is provided. A startup state-of-charge of the battery is determined as a function of a present open circuit voltage measurement for a present ignition startup, at least one open circuit voltage observation of a previous ignition startup, and a current draw integration over a time period from a previous ignition startup event to a present ignition startup event. A run state-of-charge change of the battery is determined for an ignition key-on operation. The run state-of-charge change comprises a difference between the present open circuit voltage measurement and the at least one previous open circuit voltage observation, and is determined in response to of a current draw integration over a respective period of time. The state-of-charge of the battery is calculated based on a function of the startup state-of-charge and the run state-of-charge change of the battery.

Owner:GM GLOBAL TECH OPERATIONS LLC

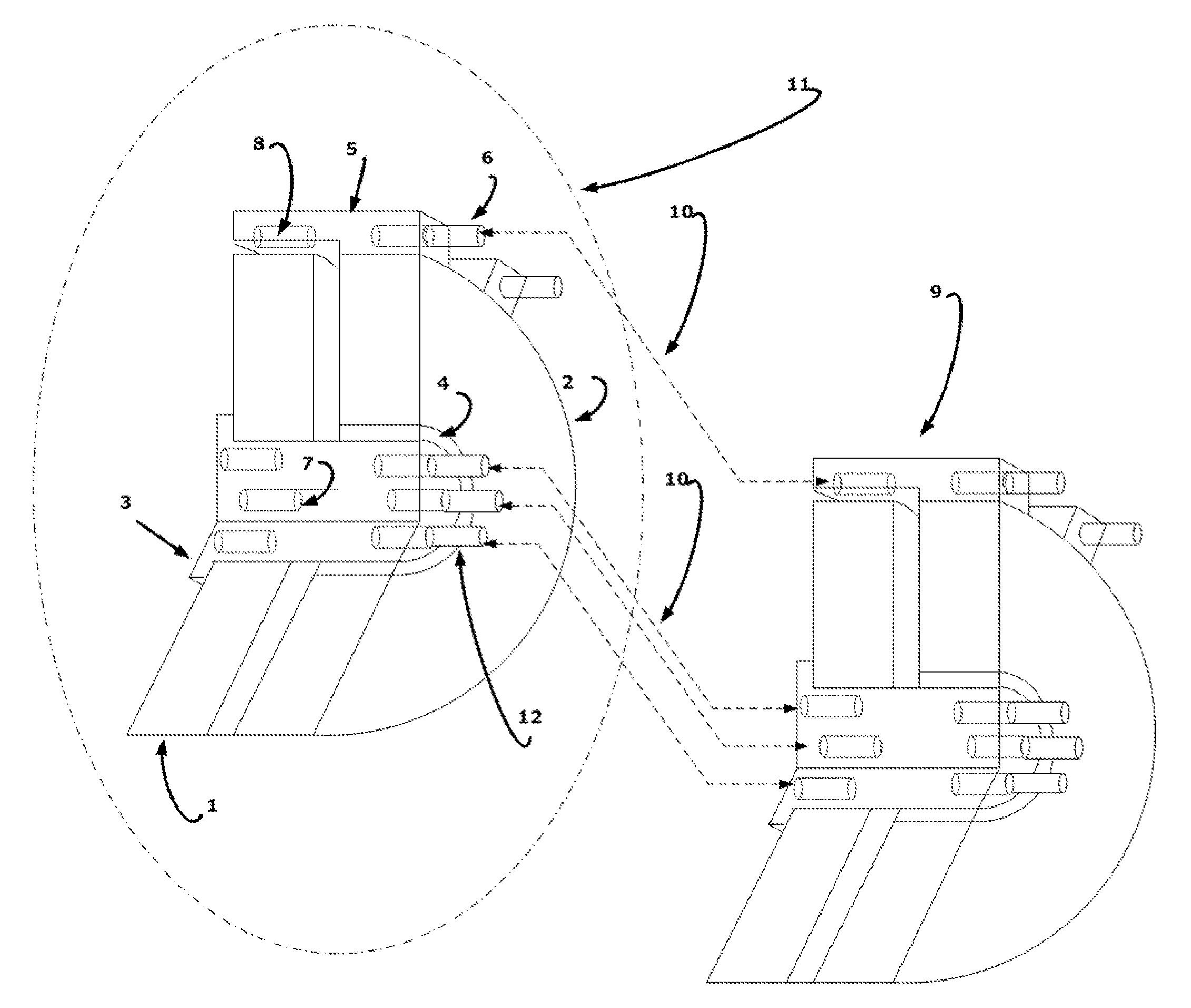

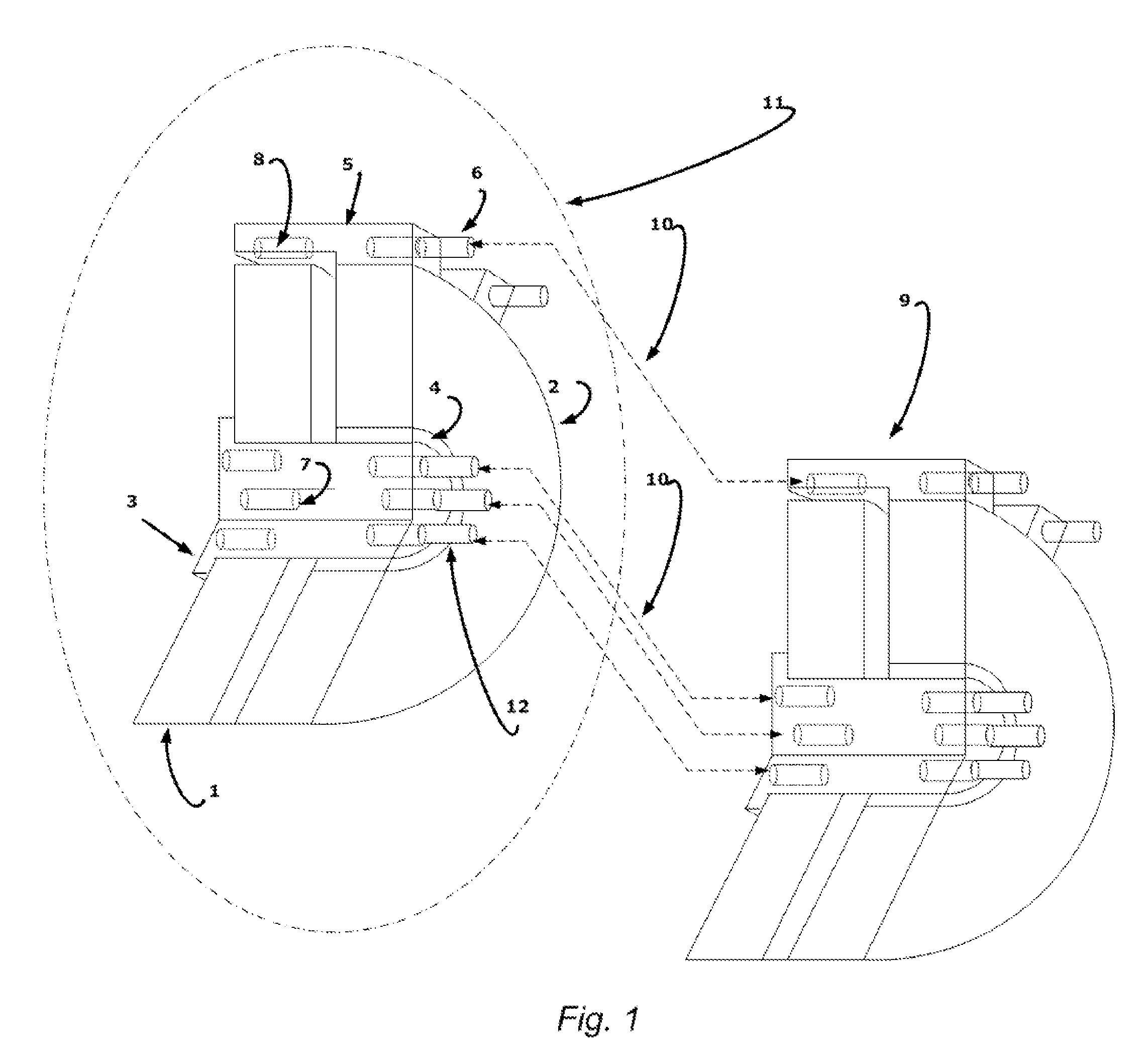

Stacking Method For Electric Machines

InactiveUS20100072835A1Increase areaSimplify shipping and assembly logisticsMagnetic circuit rotating partsMagnetic circuit stationary partsMechanical integrityEngineering

Stacking more than one electric machine module (i.e., electromagnetic electric motor or generator system) with all stator bodies commonly attached and all moving bodies commonly attached increases the overall power of the stack according to the sum of power rating of each module in the stack. A keying object means comprises complementary keys on the stator and rotor bodies that allow easy mating alignment of at least two autonomous electric machine modules in the stack and preserve the mechanical integrity so all modules in the stack move or act as one large electric machine. Furthermore as an integral component in the manufacturing process of the electric machine module, the keying object means serves as an alignment mechanism for precision manufacture of the module chassis without precision methods, such as precision machining, or precision materials, or precision pieces, such as castings.

Owner:KLATT FREDERICK WILLIAM

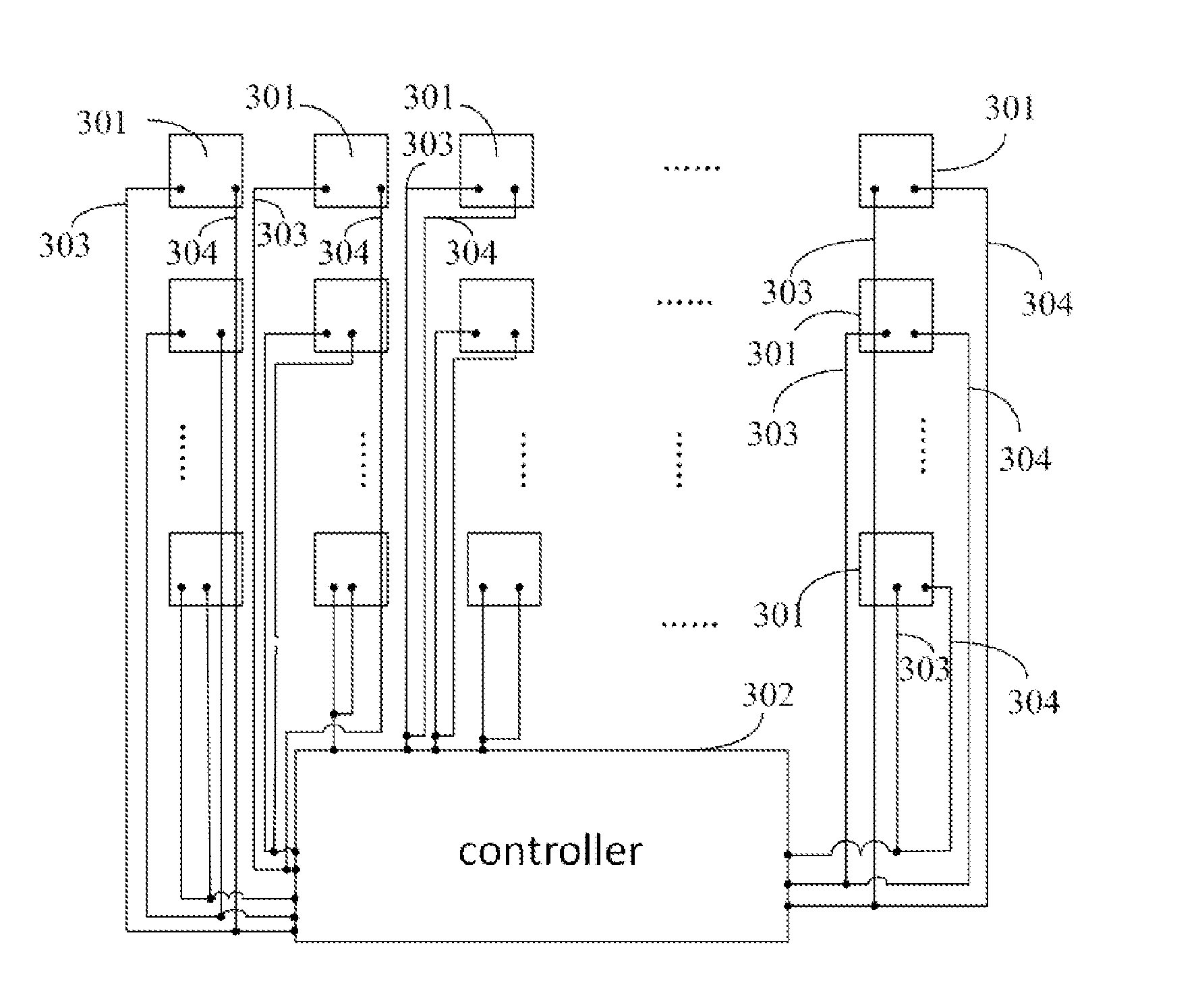

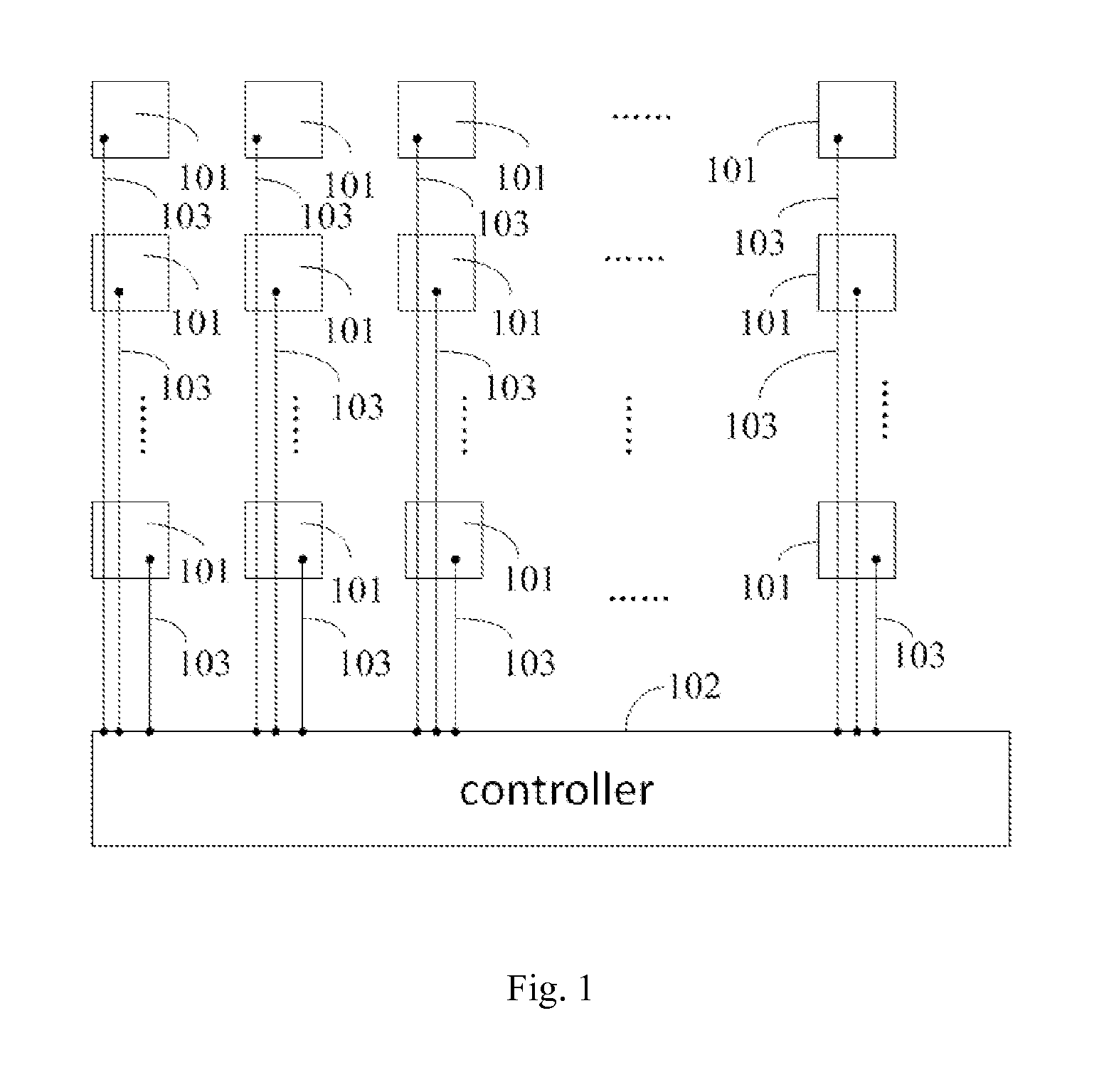

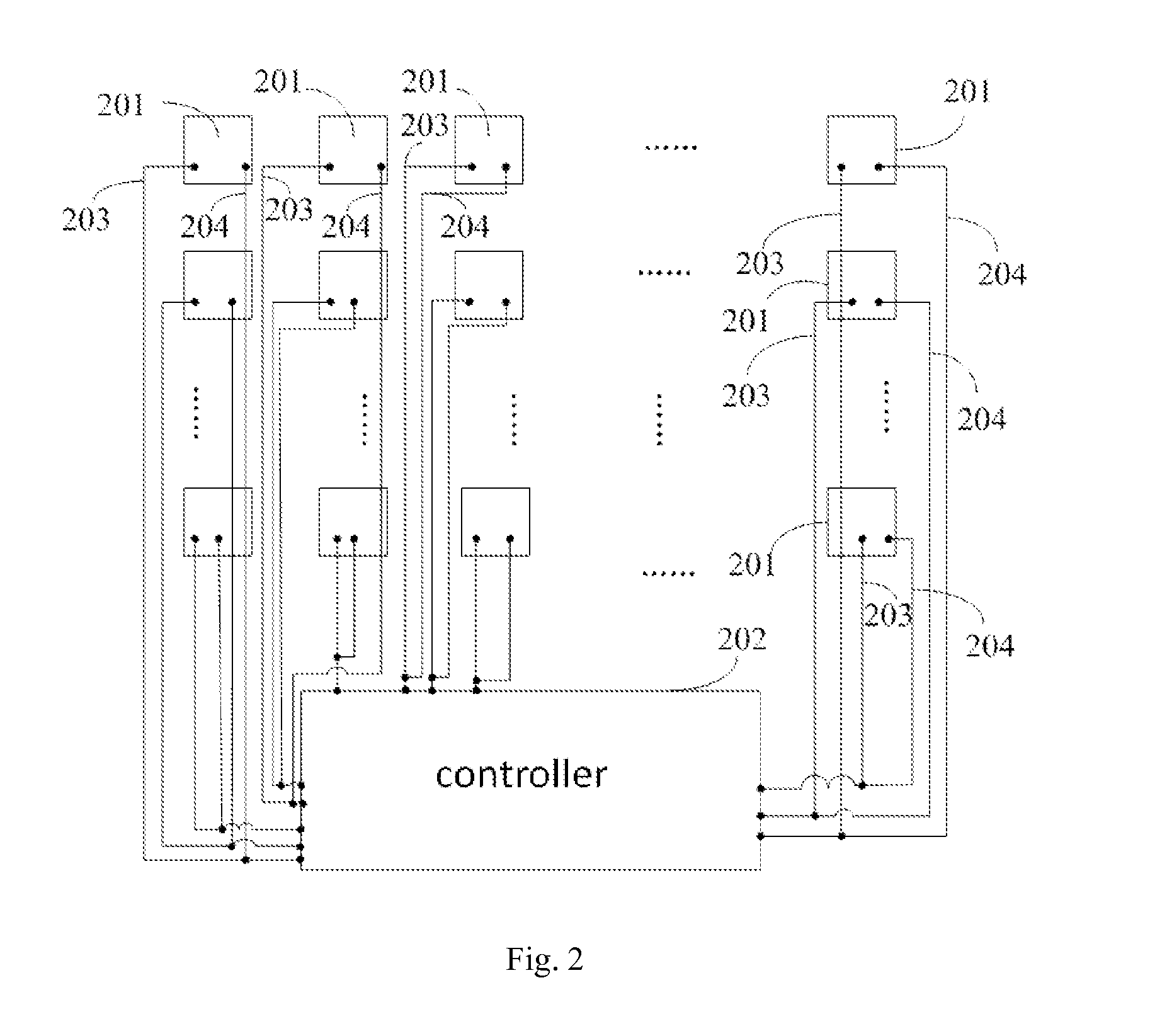

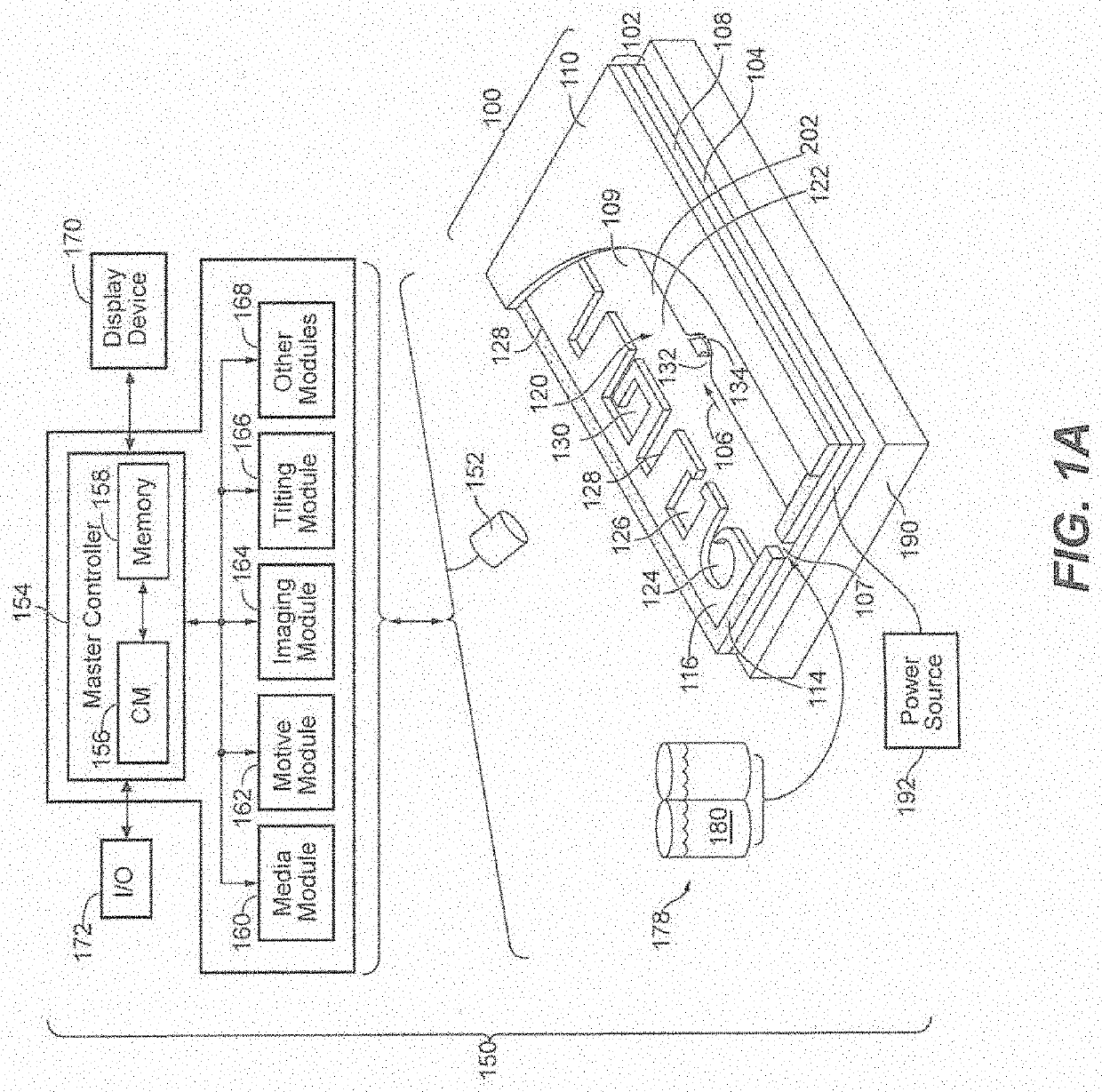

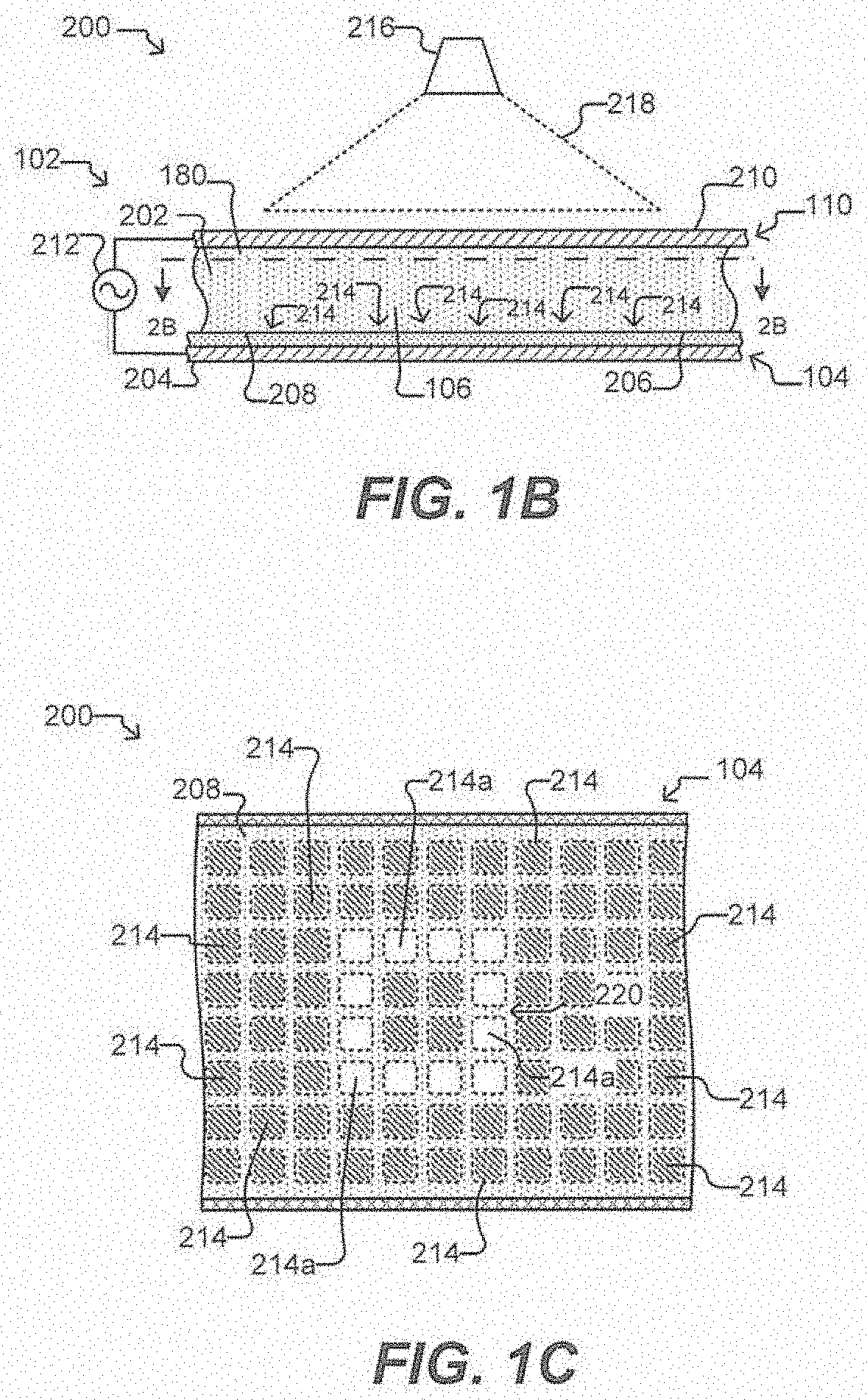

Touch panel and touch display device

InactiveUS20160349895A1Extended service lifeReduce defective rateNon-linear opticsInput/output processes for data processingDisplay deviceEngineering

A touch panel and a touch display device are disclosed. The touch panel comprises a controller and a plurality of the touch electrodes arranged in a matrix, and each of the touch electrodes connects to a pin of the controller by using at least two wires. Through the above mentioned way, the present invention solves the open circuit issue between the touch electrode and the controller, reduces the defective rate and improves the life time of the touch panel.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

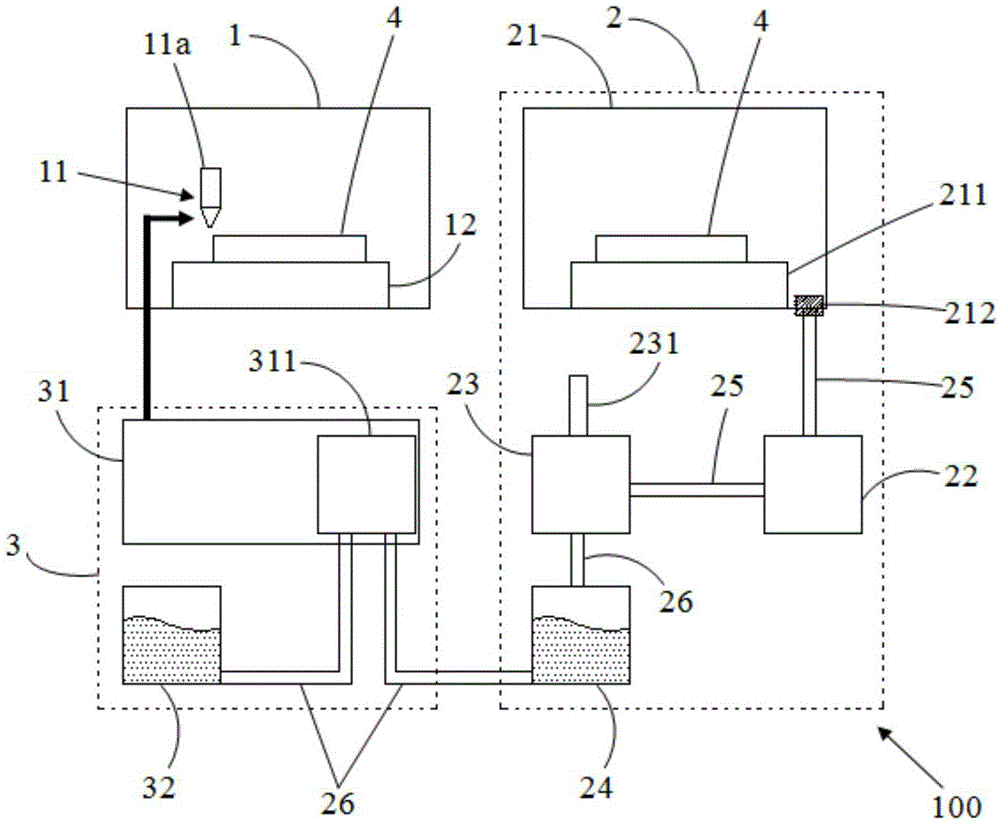

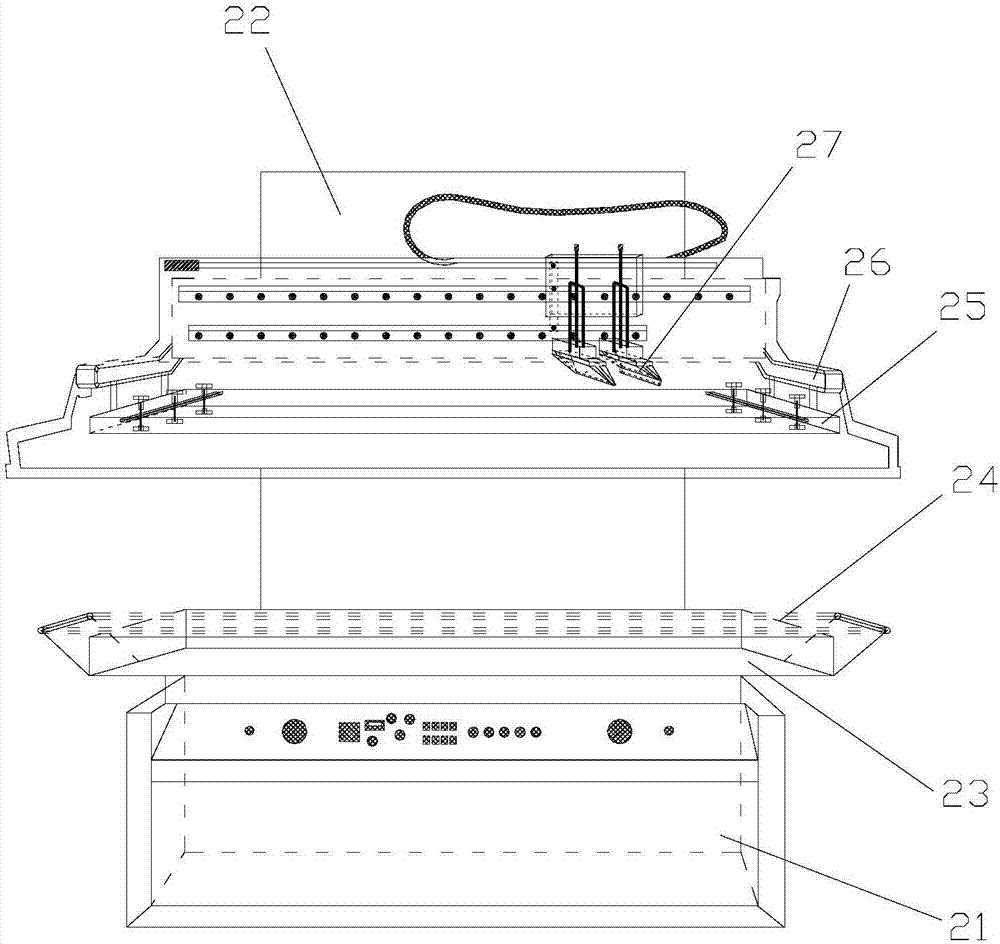

Photoresist coating device and lithography equipment

InactiveCN105242494AImprove protectionReduce exceptionPhotomechanical coating apparatusPhotomechanical exposure apparatusLithographic artistEvaporation

The invention discloses a photoresist coating device, comprising a coating unit, a drying unit and a cleaning unit. The coating unit comprises a spraying mechanism; the spraying mechanism is for spraying a photoresist material on a glass substrate; the drying unit comprises a drying chamber for evaporation and vaporization of a solvent in the photoresist material on the glass substrate; a vacuum pump is connected with the drying chamber and for discharging the vaporized solvent; a condenser is connected with the vacuum pump, and is used for condensing the liquefying gaseous solvent; a recycling container is connected with the condenser, and is for the storage of the liquefied solvent; the cleaning unit is connected between the recycling container and the coating unit; and solvent is obtained from the recycling container, and the solvent is used for cleaning the spraying mechanism. The invention also discloses lithography equipment containing the above photoresist coating device.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

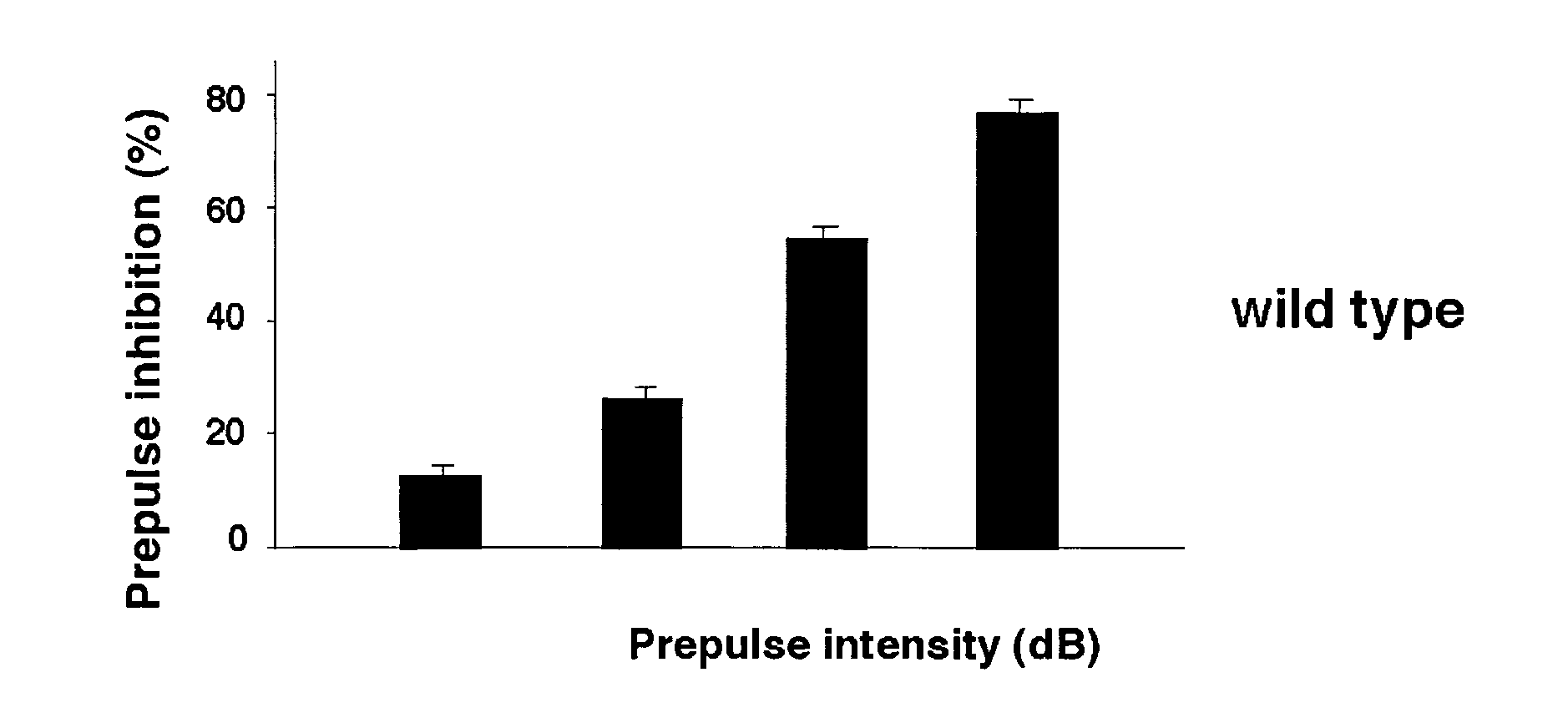

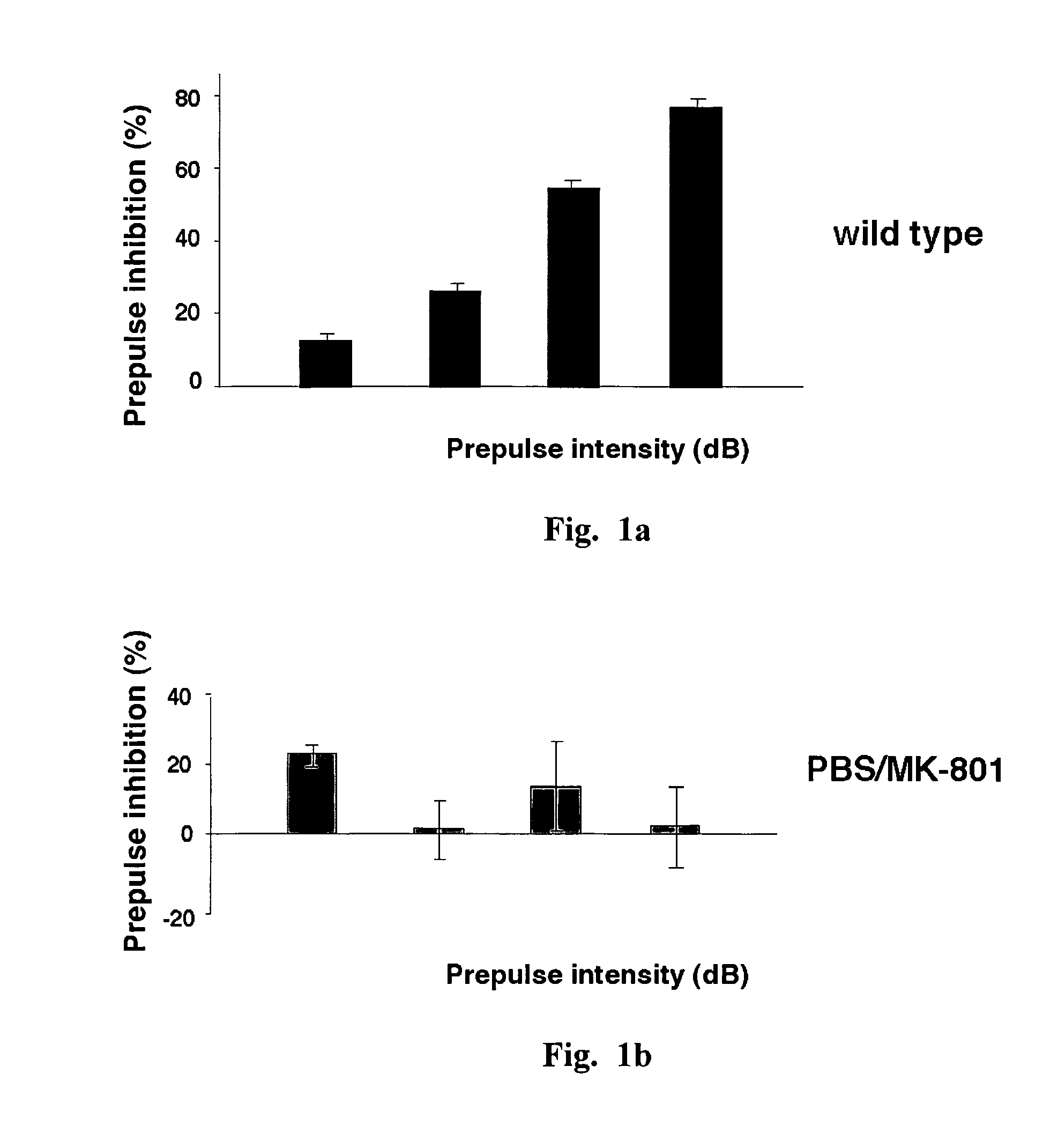

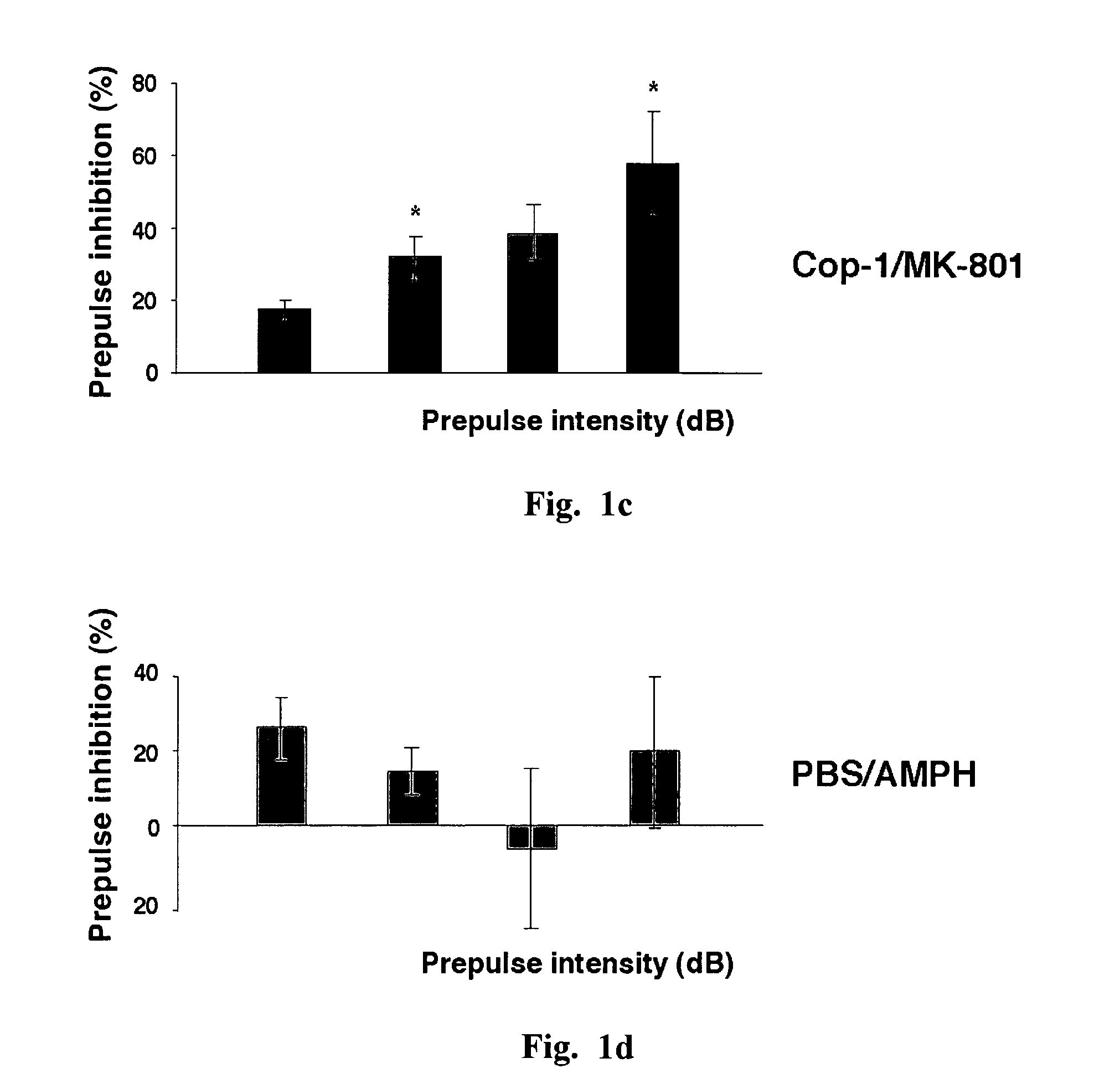

Method and vaccine comprising copolymer 1 for treatment of psychiatric disorders

InactiveUS20110117115A1Reduce exceptionImprove cognitive functionOrganic active ingredientsFungiDiseaseClinical psychology

Owner:EISENBACH SCHWARTZ MICHAL +1

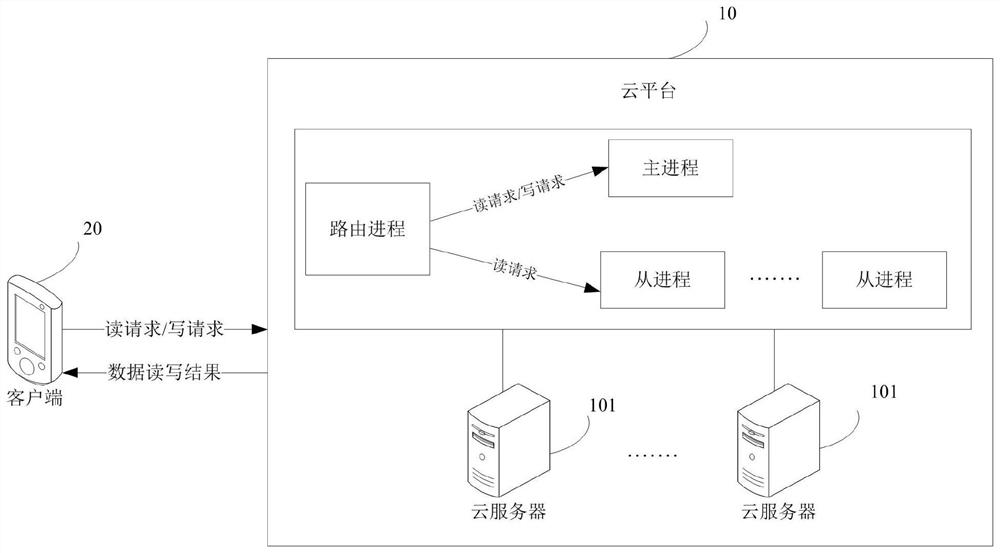

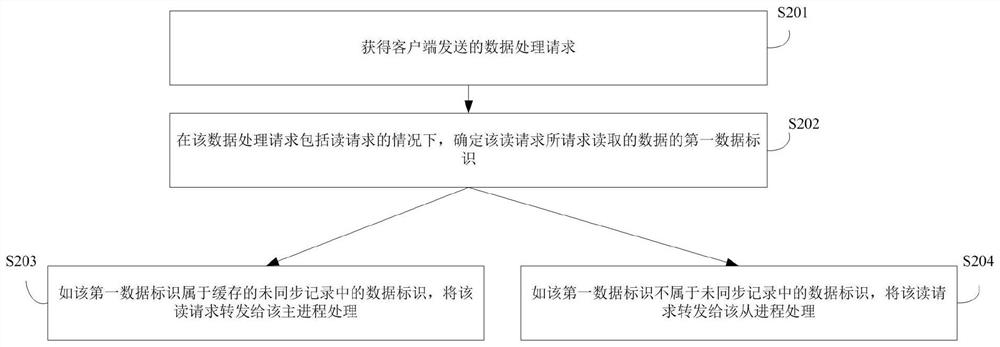

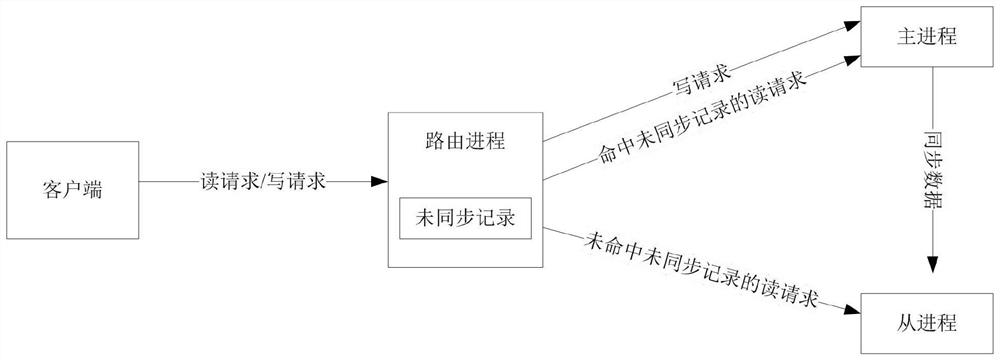

Data processing method and device, server and storage medium

PendingCN111813550AReduce read errorsReduce exceptionDigital data information retrievalResource allocationEngineeringData request

The invention discloses a data processing method and device, a server and a storage medium, the scheme of the invention is applied to a business service platform, the business service platform runs amaster process and at least one slave process. The method comprises the following steps: obtaining a data processing request sent by a client; under the condition that the data processing request comprises a reading request, determining a first data identifier of data requested to be read by the reading request; if the first data identifier belongs to a data identifier in a cached non-synchronousrecord, forwarding the read request to the master process for processing, the non-synchronous record recording a data identifier corresponding to data which is not synchronized from the master processto the slave process; and if the first data identifier does not belong to the data identifier in the non-synchronous record, forwarding the read request to the slave process for processing. Accordingto the scheme, the data request processing efficiency can be improved, Meanwhile, the situation of data reading errors or abnormalities caused by inconsistency of the master process data and the slave process data can be reduced.

Owner:深圳市腾讯网域计算机网络有限公司

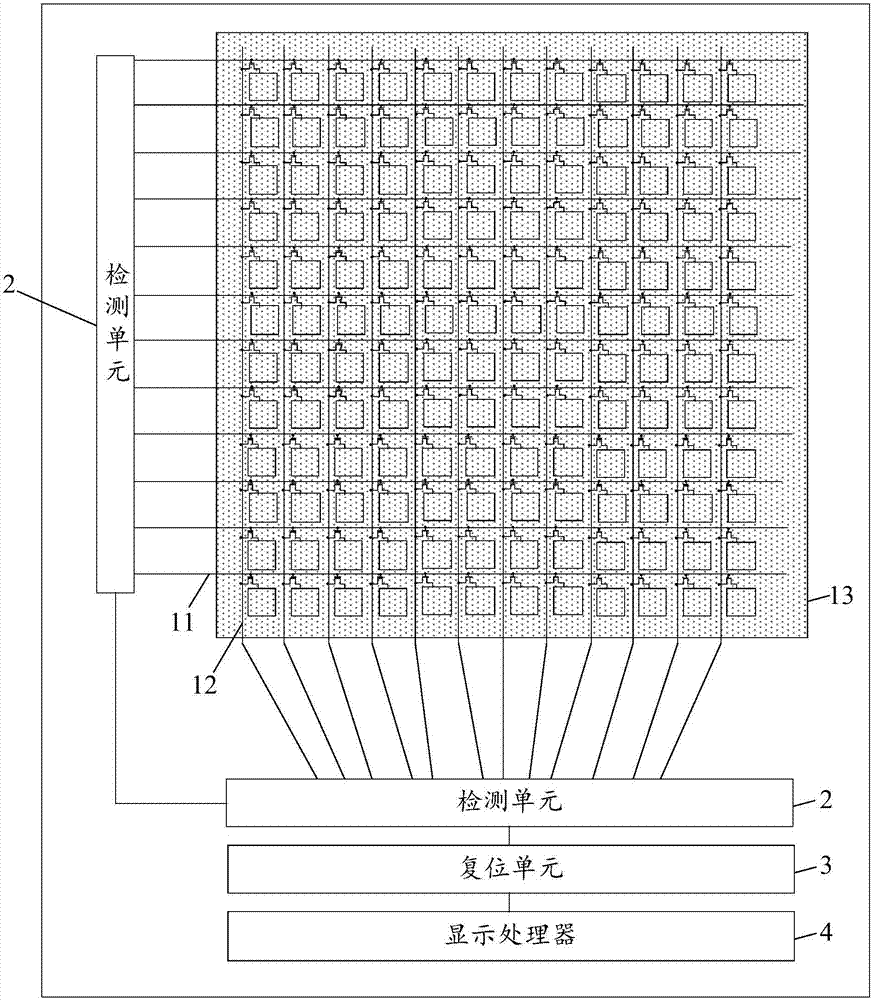

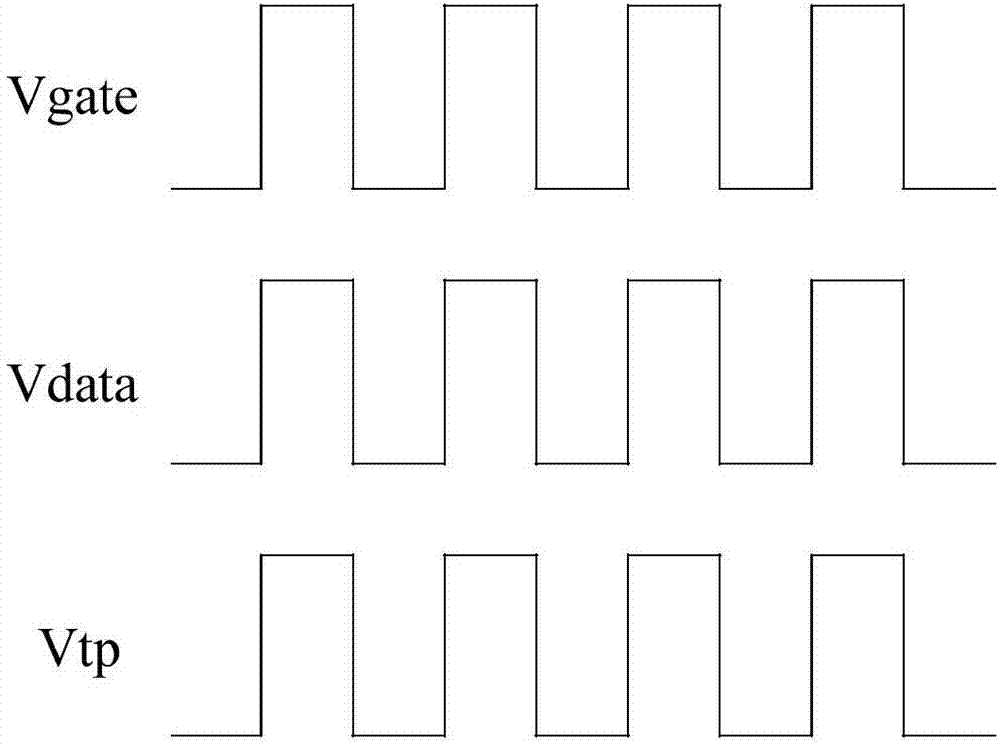

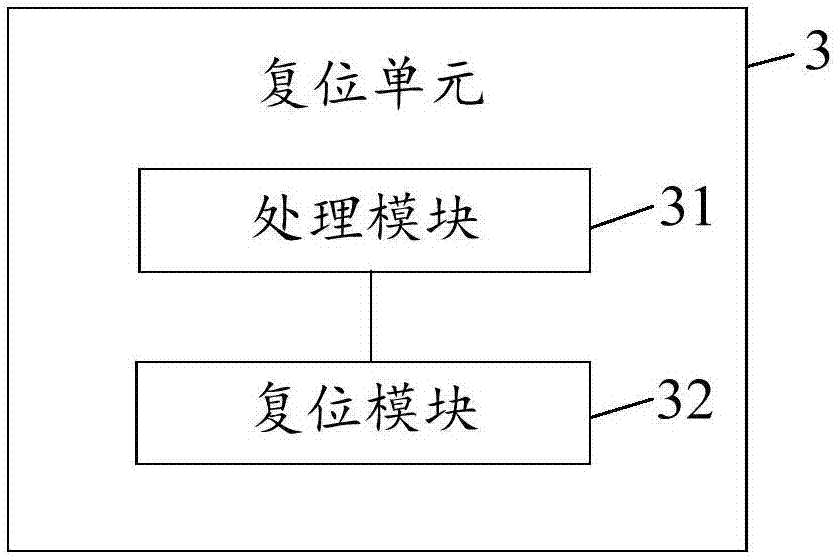

Touch display panel, touch display device and abnormal display processing method

ActiveCN106910447AReduce the probability of abnormalReduce exceptionStatic indicating devicesSolid-state devicesSignal onDisplay processing

The embodiment of the invention provides a touch display panel, a touch display device and an abnormal display processing method, and relates to the technical field of touch display. Through the touch display panel, the touch display device and the abnormal display processing method, the probability that image display is abnormal caused by static shock can be reduced. The touch display panel comprises a scanning line, a touch signal line and a data line. The touch signal line is further used as a common electrode line. The touch display panel further comprises a detection unit and a reset unit, wherein the detection unit is used for outputting the same preset pulse signal to the scanning line, the touch signal line and the data line during the testing period; the reset unit is used for receiving a feedback signal on the touch signal line during the testing period, and outputting reset information when the feedback signal meets a preset condition. The touch display panel, the touch display device and the abnormal display processing method are mainly used for processing abnormal display caused by static shock.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

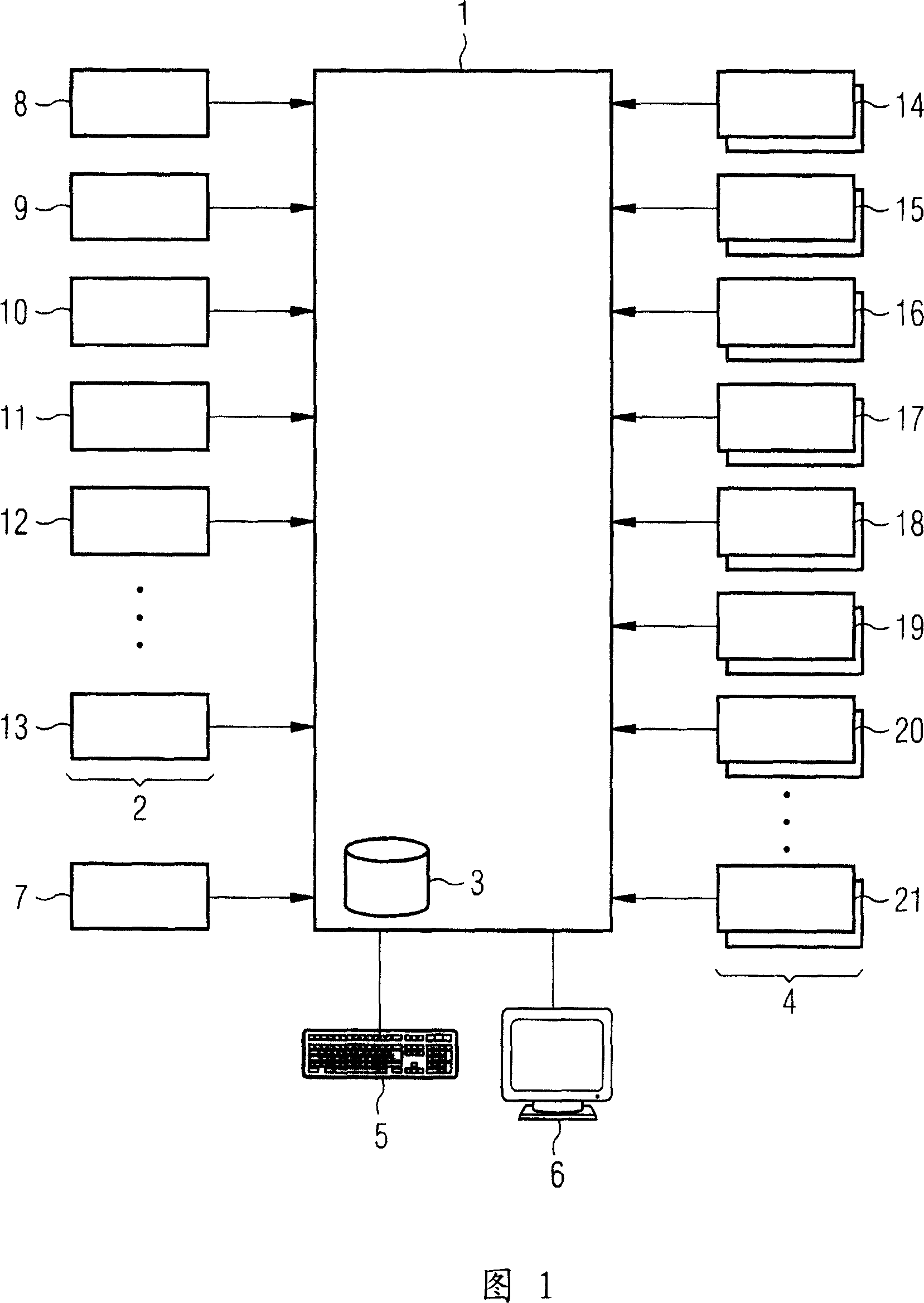

Apparatus for automatically detecting salient features in medical image data

An apparatus is disclosed for automatically detecting salient features in medical image data. The apparatus includes a memory device for storing the image data, at least one determination module for determining one or more anatomical regions which are acquired by the image data, a number of different examination modules that respectively include an application for automatically detecting specific salient features in a specific anatomical region, an input unit via which a primary application can be started, a control unit that on the basis of the anatomical regions determined by the determination module automatically selects and executes in the background further applications, as well as an output unit on which the result of the primary application is displayed together with an item of information relating to additional salient features that have been detected automatically with the aid of the applications executed in the background. The apparatus improves the diagnostic evaluation of medical image data.

Owner:SIEMENS HEALTHCARE GMBH

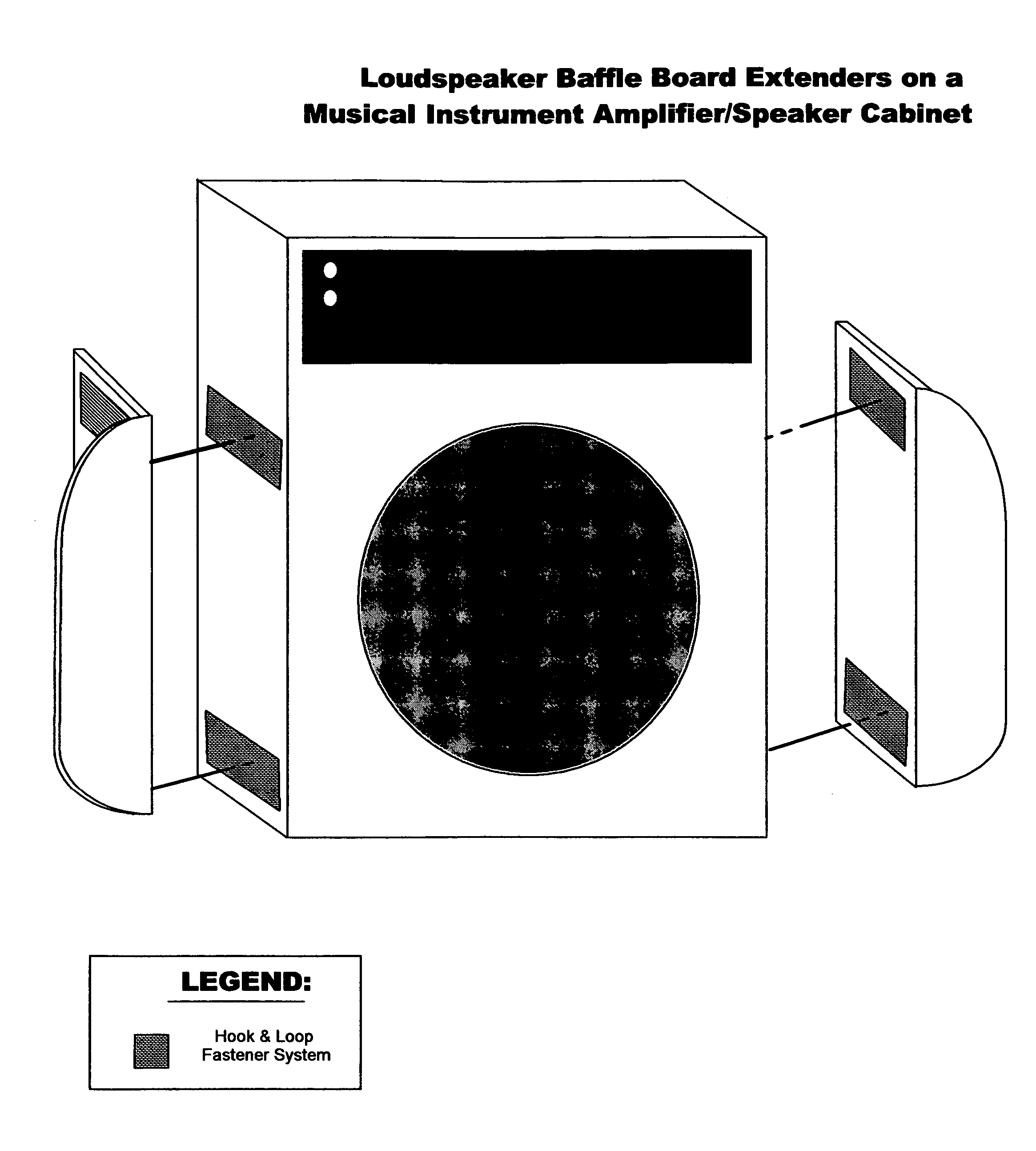

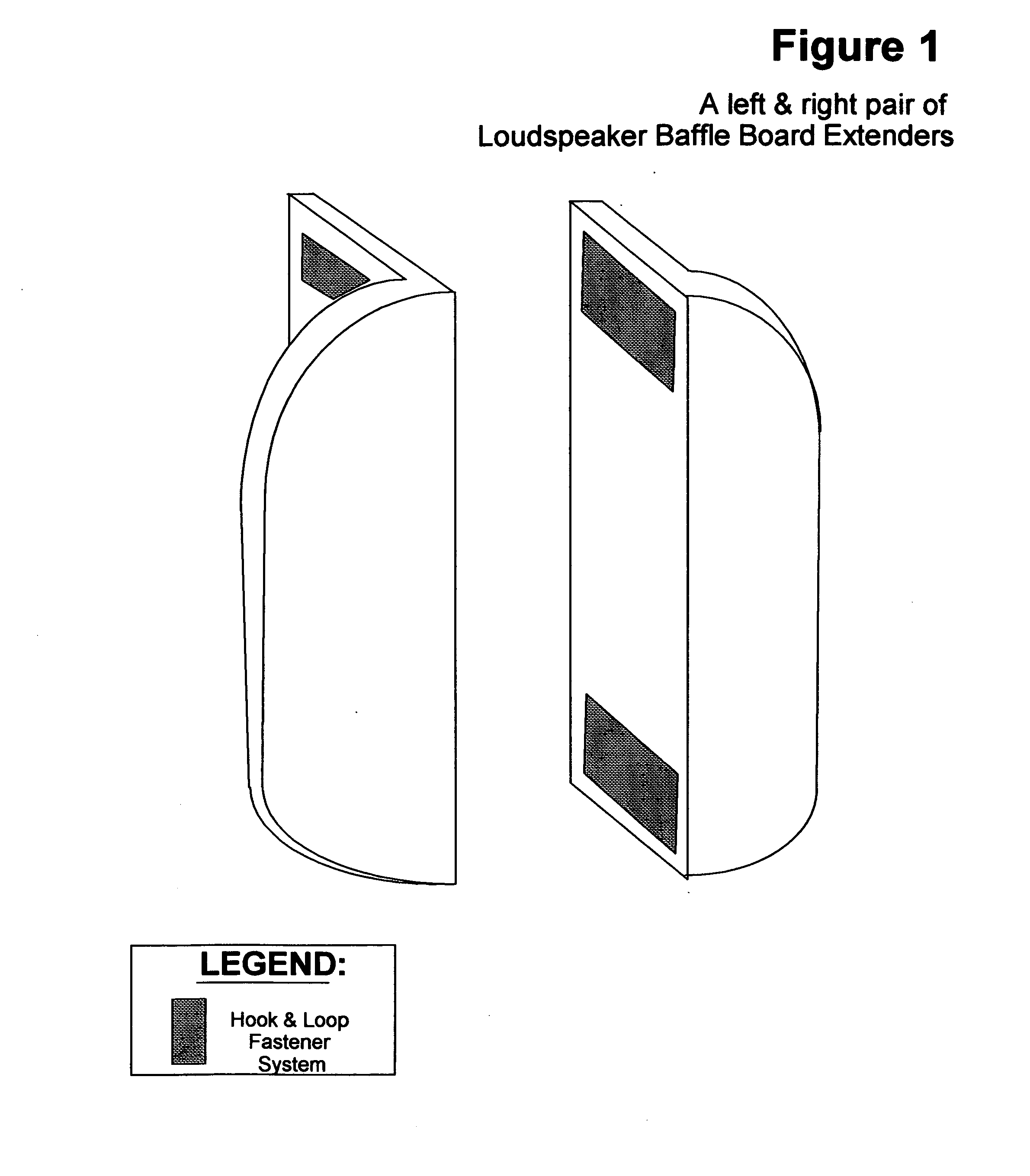

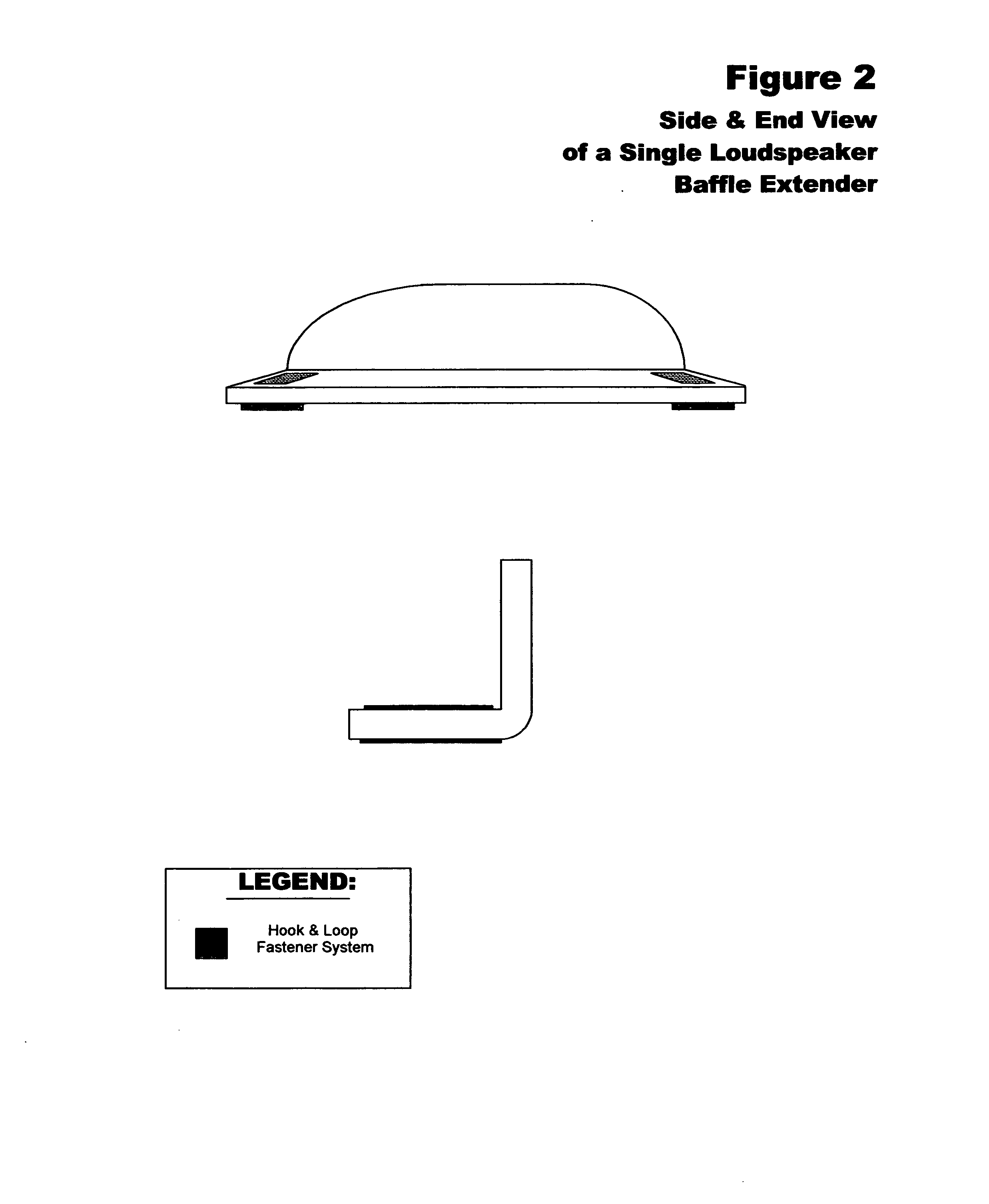

Loudspeaker baffle board extender

InactiveUS20070056796A1Improve sound qualityEasy to demonstrateCabinetsLoudspeaker spatial/constructional arrangementsEngineeringLoudspeaker

A Loudspeaker Baffle Board Extender that functionally improves the sound quality of cabinet-type loudspeaker systems. The Extenders are located one to each side of a loudspeaker cabinet and may be built into the cabinet for pull-out / push-in, hinged for folding open or closed or an L-shaped structurally stiff material attached to the loudspeaker cabinet in a manner that enables easy installation and removal or opening or closing.

Owner:MARLOWE STEPHEN GLEN

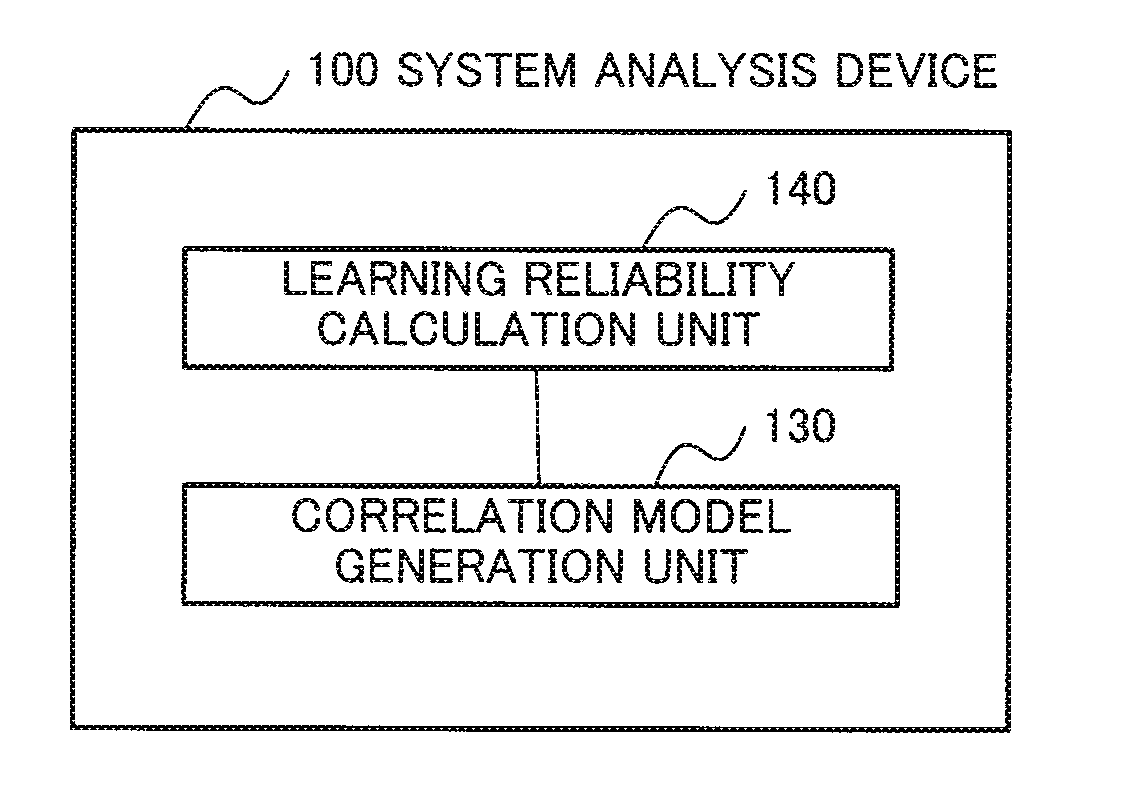

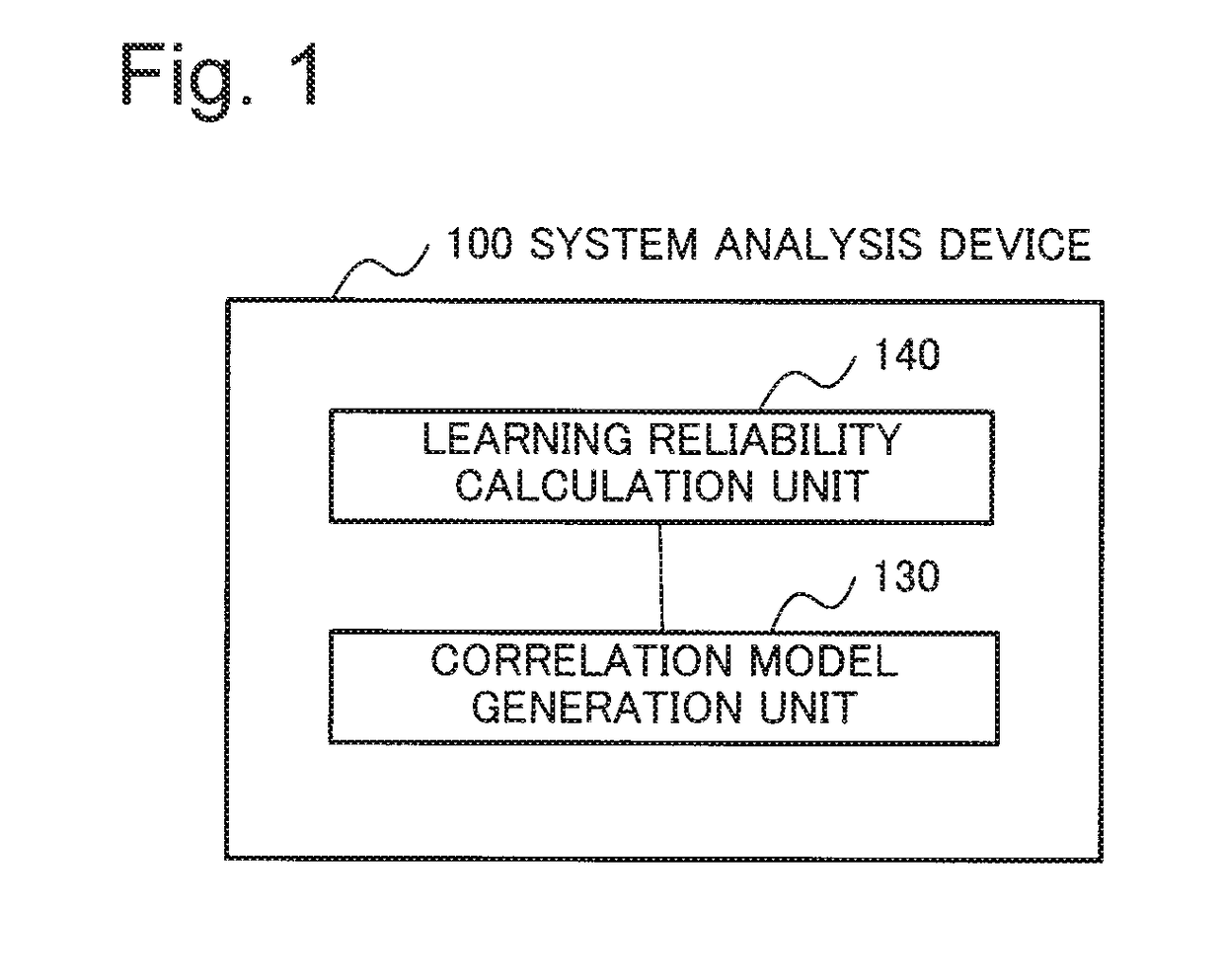

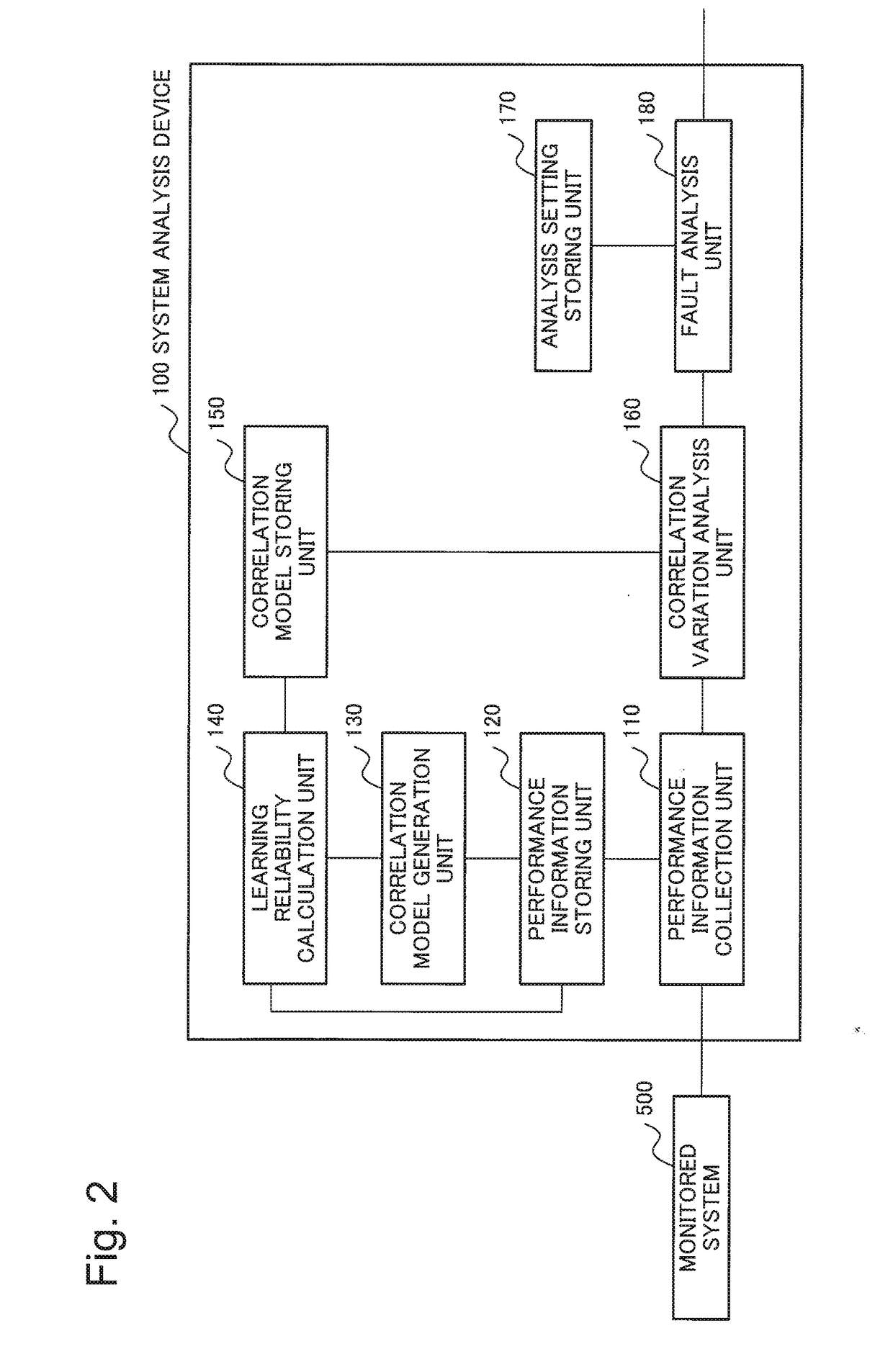

Information processing device, analysis method, and recording medium

ActiveUS20170139794A1Improve abilitiesReducing erroneous abnormality reportMachine learningDetecting faulty hardware using expert systemsInformation processingPattern recognition

In an invariant relation analysis, a capability to detect abnormalities is improved and erroneous abnormality reports are reduced. A system analysis device (100) includes a correlation model generation unit (130) and a learning reliability calculation unit (140). The correlation model generation unit (130) generates, based on time series of a plurality of metrics in a system in a learning period, a correlation model that includes a correlation between metrics. The learning reliability calculation unit (140) calculates learning reliability of the correlation, based on a behavior of a time series of each of metrics relevant to the correlation included in the correlation model, in the learning period.

Owner:NEC CORP

Method for fabricating semiconductor device with bulb shaped recess gate pattern

ActiveUS7507651B2Improve etch selectivityReduce harmSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringSemiconductor

Owner:SK HYNIX INC

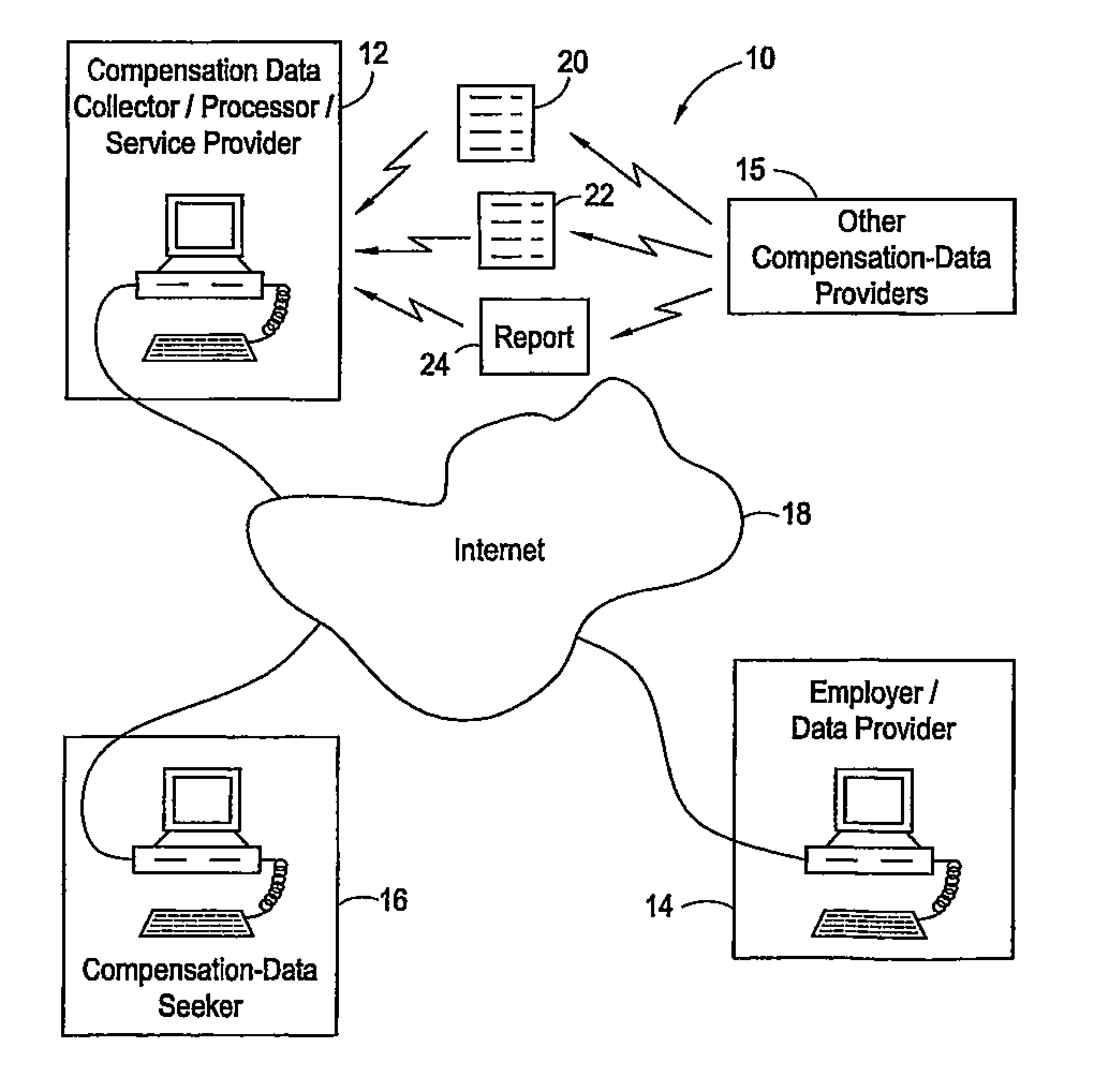

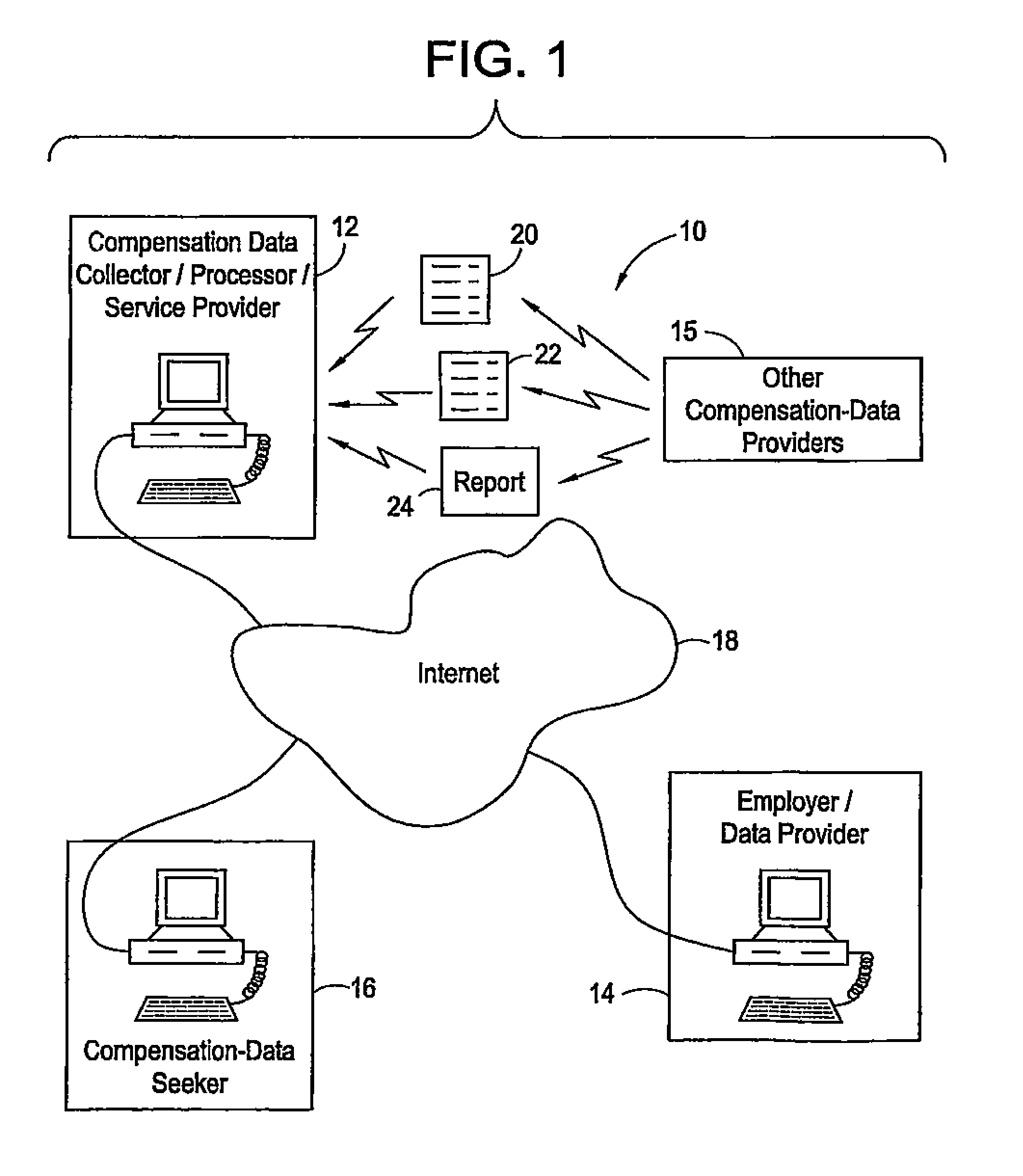

Compensation data prediction

InactiveUS7805354B2Quick turnaround timeReduce exceptionMarket predictionsFinanceOperandData prediction

Owner:SCMC ACQUISITION LLC

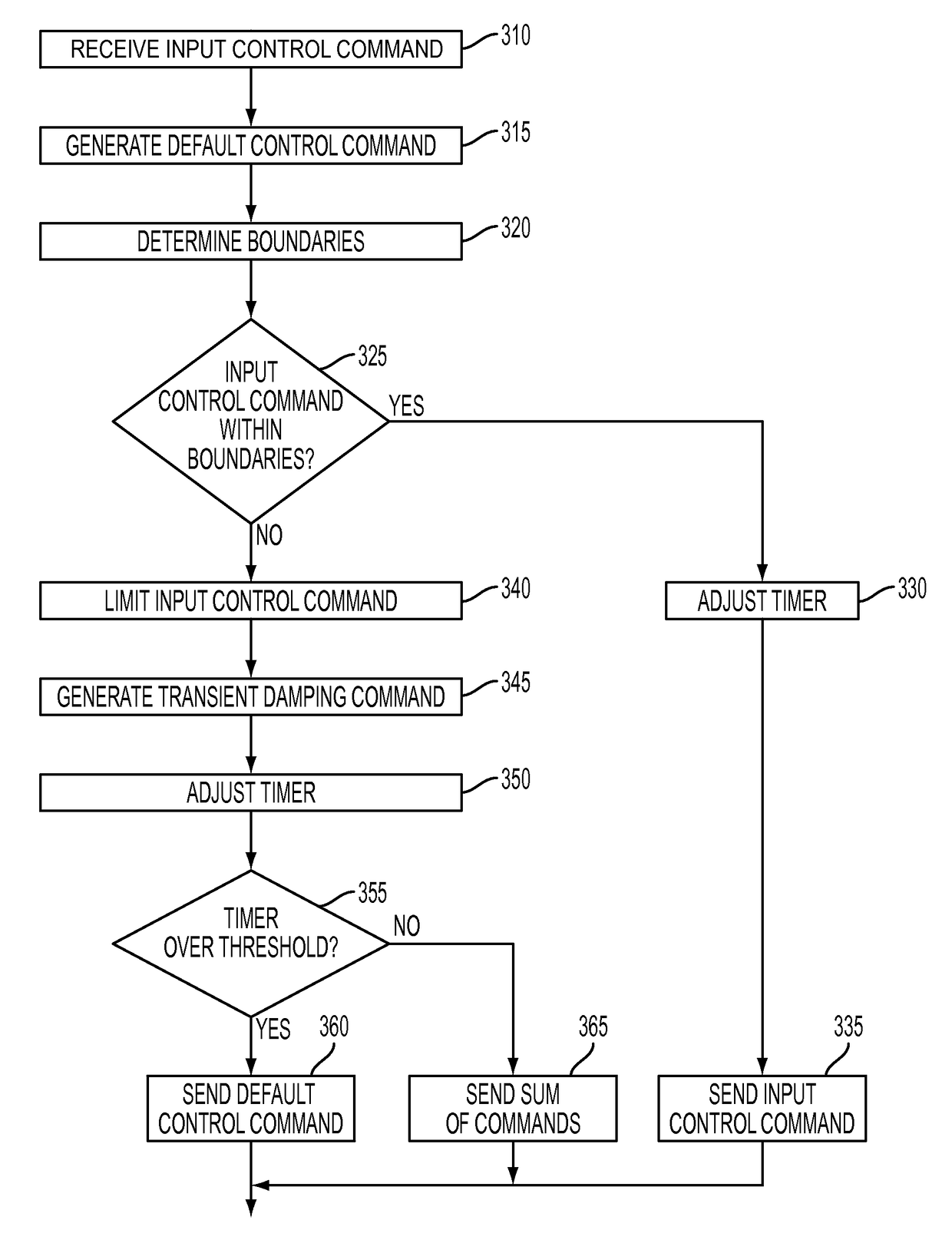

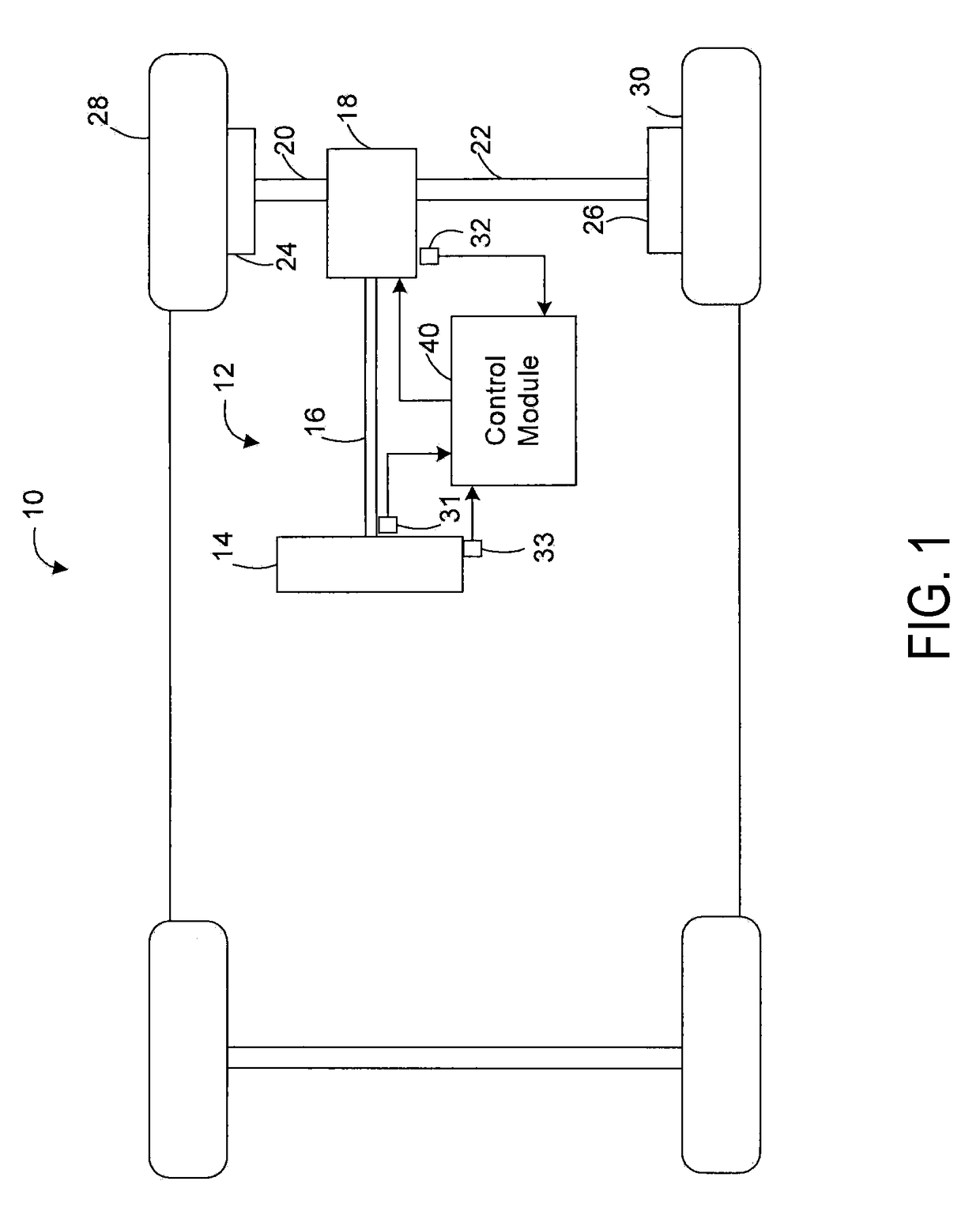

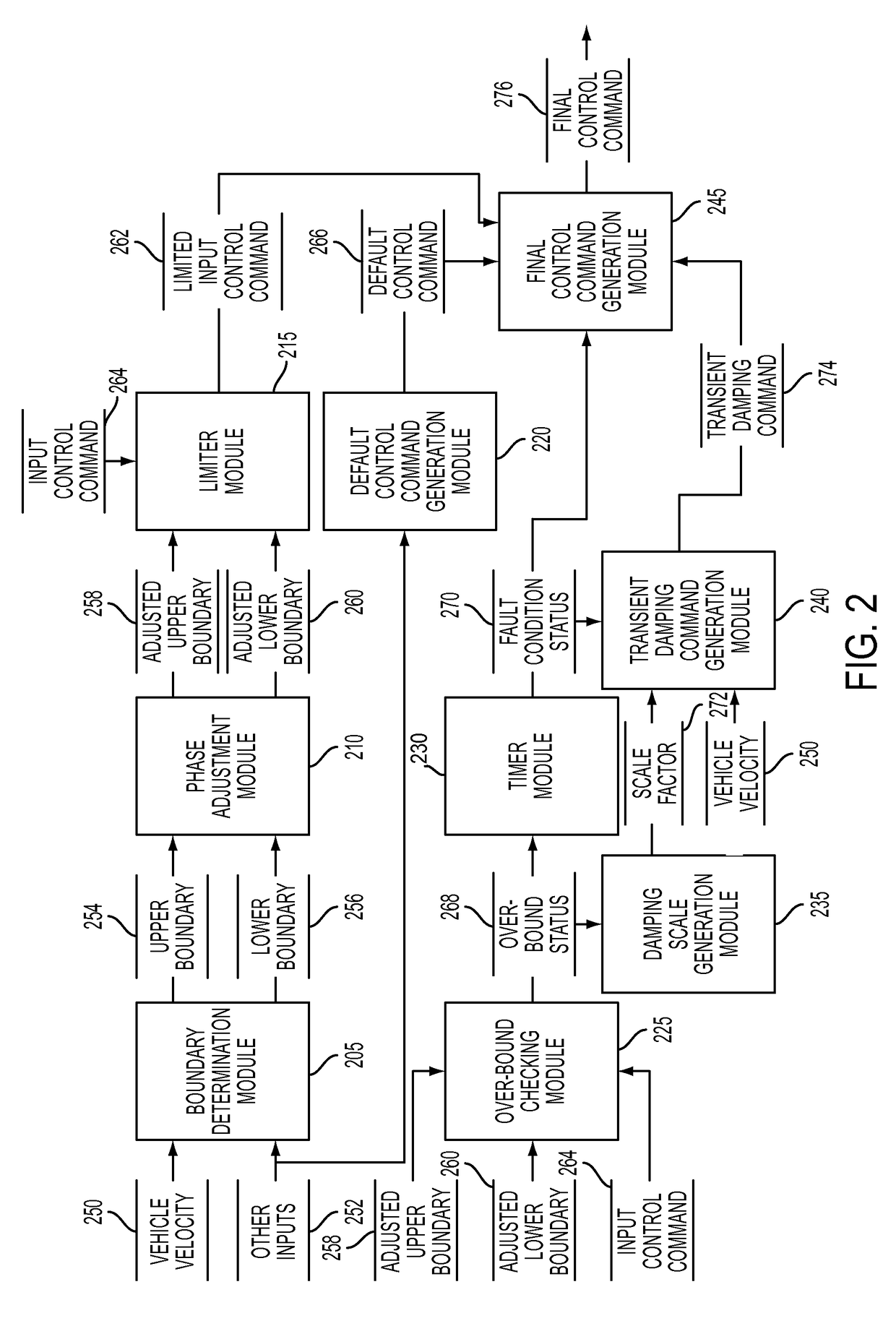

Systematic abnormality detection in control commands for controlling power steering system

A method of mitigating abnormalities in a first control command for controlling a power steering system is provided. The method generates a range signal indicative of a range of command values based on a plurality of input signals. The method determines whether the first control command is out of the range for longer than a predetermined duration of time. The method limits the first control command to the range and sends the limited first control command to the power steering system in response to determining that the first control command is out of the range for shorter than or equal to the duration of time.

Owner:STEERING SOLUTIONS IP HLDG +1

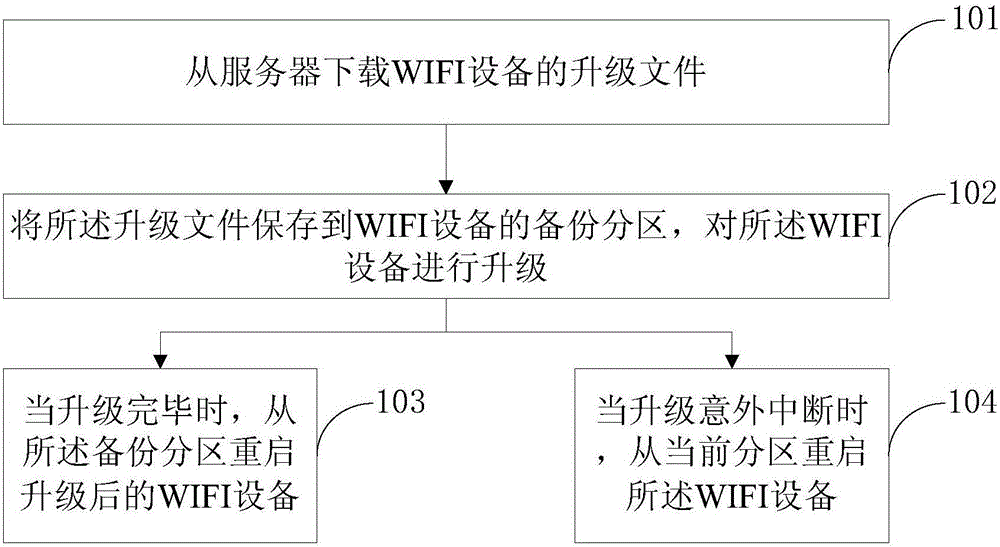

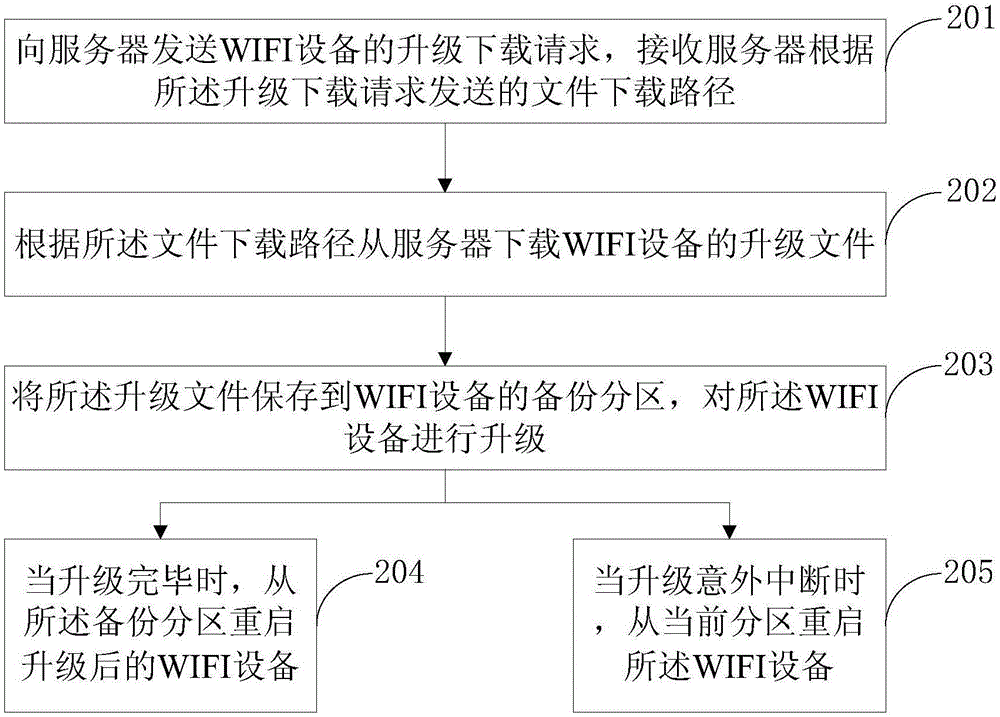

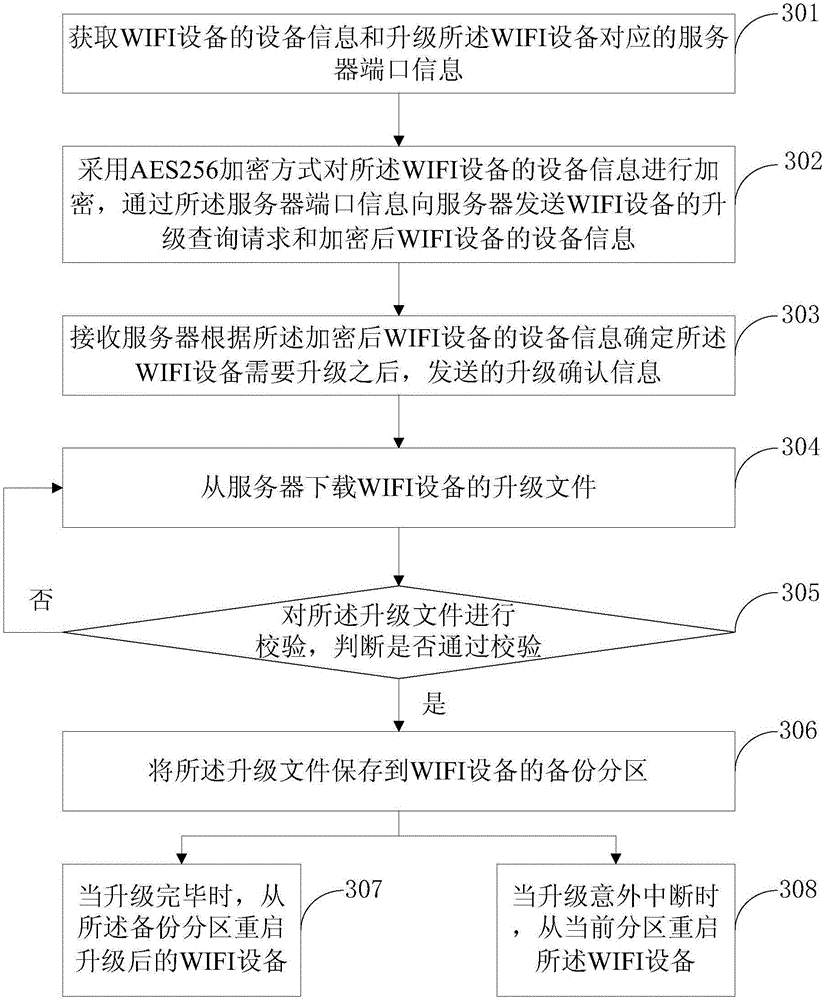

Method and system for upgrading WIFI equipment

InactiveCN106130808AAvoid issues that no longer workRealize unified automatic upgradeNetwork topologiesData switching networksSoftware engineeringNetwork topology

The invention discloses a method and a system for upgrading WIFI equipment. The method comprises the steps of: downloading an upgrade file of the WIFI equipment from a server; storing the upgrade file into a backup partition of the WIFI equipment, and upgrading the WIFI equipment; after completing upgrading, restarting the upgraded WIFI equipment from the backup partition; and when upgrading is interrupted by accident, restarting the WIFI equipment from a current partition. In the upgrading process of the WIFI equipment, if an accident occurs, the WIFI equipment is restarted from the current partition, so that the risk caused by abnormity in the upgrading process is reduced; the WIFI equipment directly downloads the upgrade file from the server without pushing the upgrade file of the WIFI equipment by a set top box, a network topology of a WIFI system is more reasonable and various WIFI product forms can be met; uniform and automatic upgrading of the WIFI equipment is implemented, and the method and the system are not limited to the set top box and are beneficial to development of WIFI software; and the upgrading process does not influence a user to use a network, so that user experience is improved.

Owner:SHENZHEN SKYWORTH DIGITAL TECH CO LTD

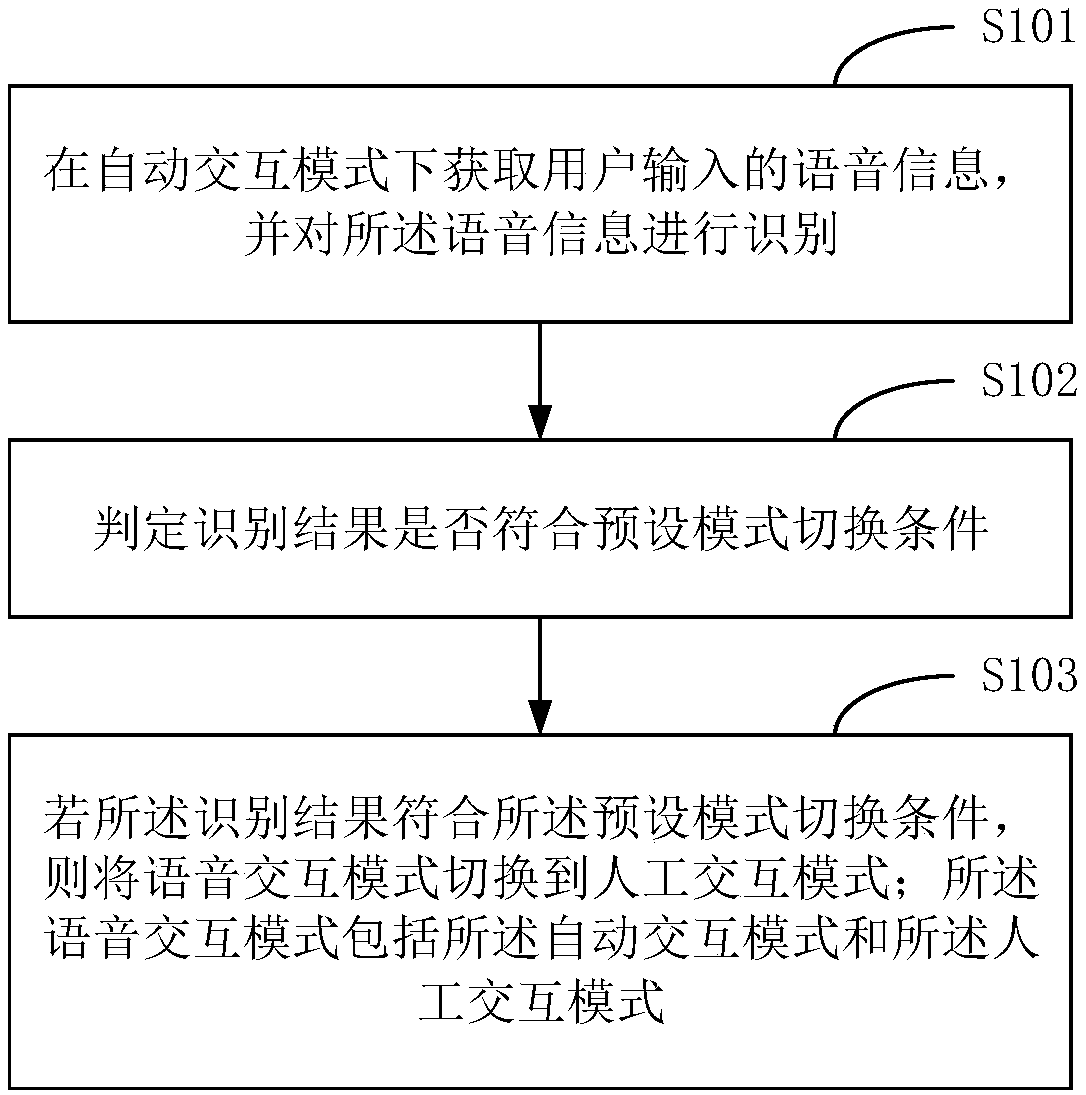

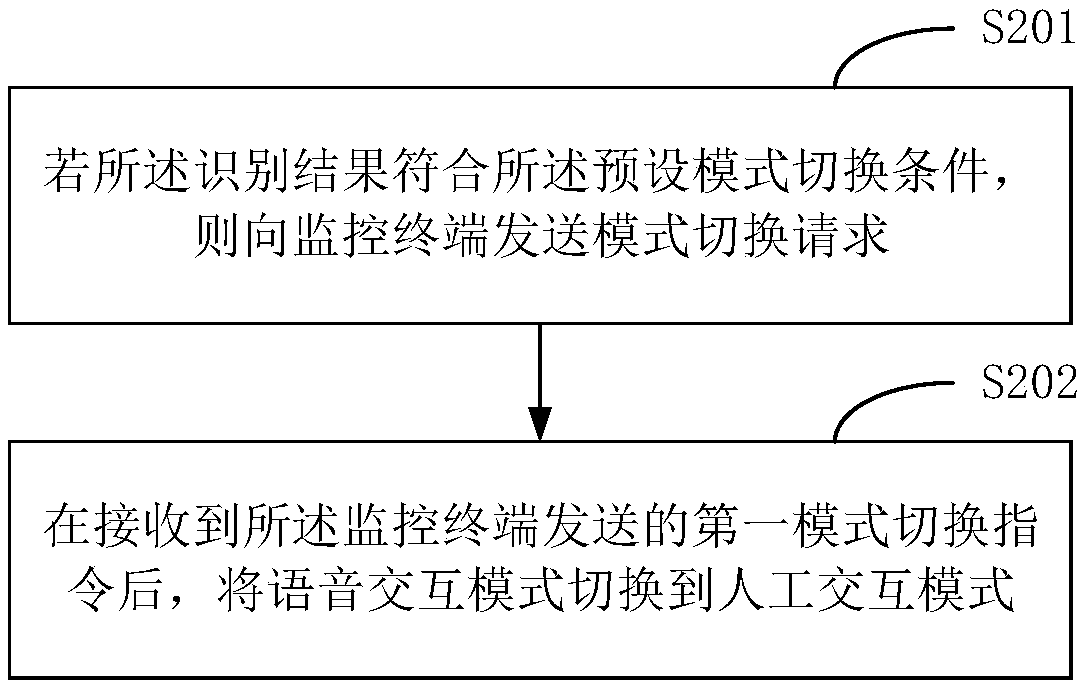

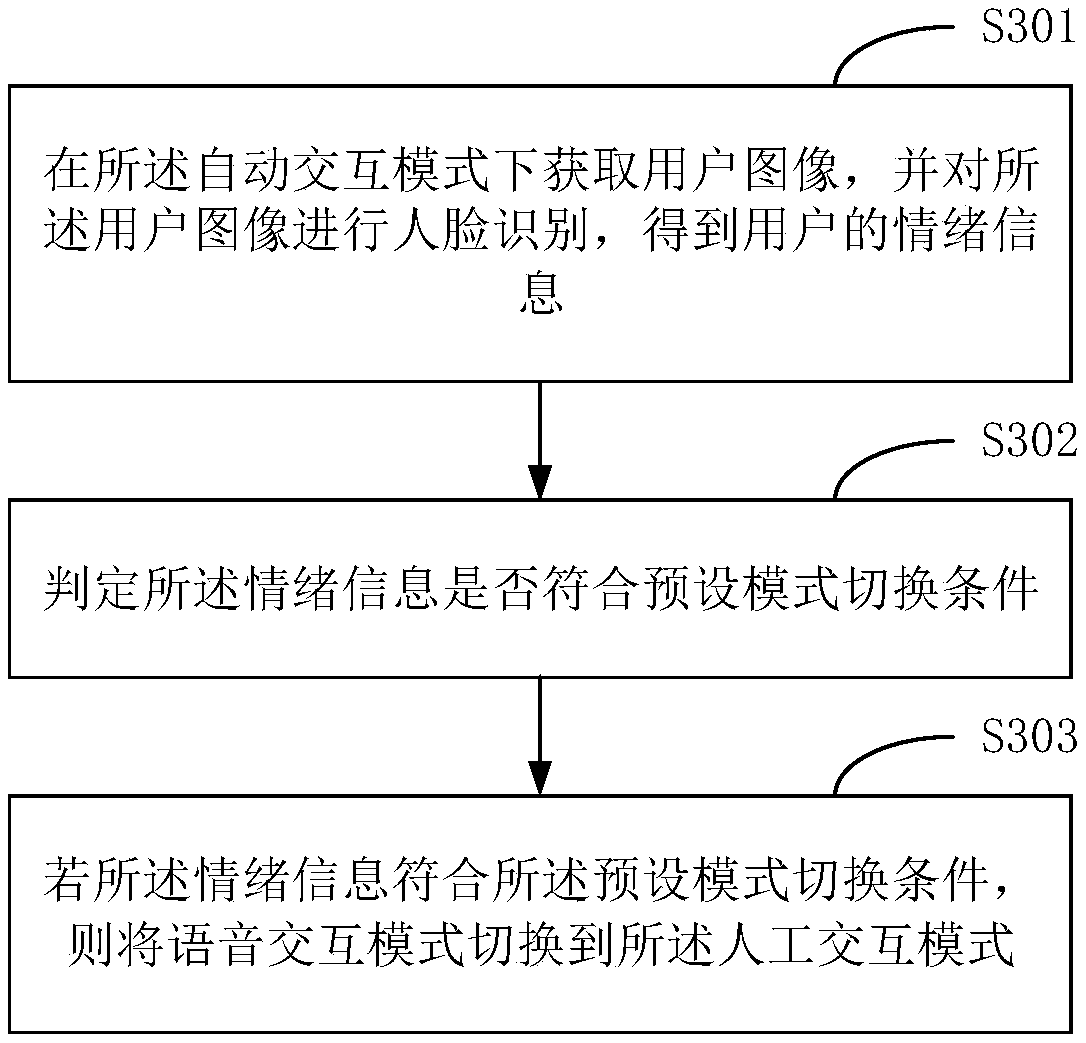

Voice interaction method and terminal equipment

InactiveCN109036413AImprove experienceImprove accuracySpeech recognitionTerminal equipmentSpeech sound

The invention relates to the computer technical field, and provides voice interaction method and terminal equipment; the method comprises the following steps: obtaining voice information inputted by auser under an automatic interaction mode, and identifying the voice information; determining whether the identification result complies with a preset mode switching condition or not; if yes, switching the voice interactive mode into an artificial interaction mode, wherein the voice interaction modes comprise an automatic interaction mode and the artificial interaction mode. When interaction abnormity happens in the automatic interaction mode, the method can timely switch to the artificial interaction mode; the method uses the artificial interaction mode to improve the user voice intention analysis accuracy, thus reducing the voice interaction process abnormity, and improving the user experiences.

Owner:UBTECH ROBOTICS CORP LTD

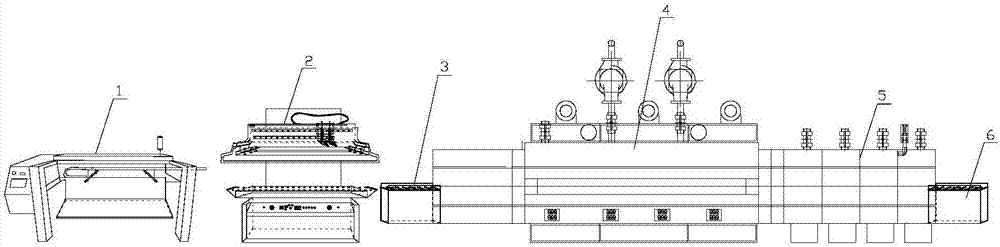

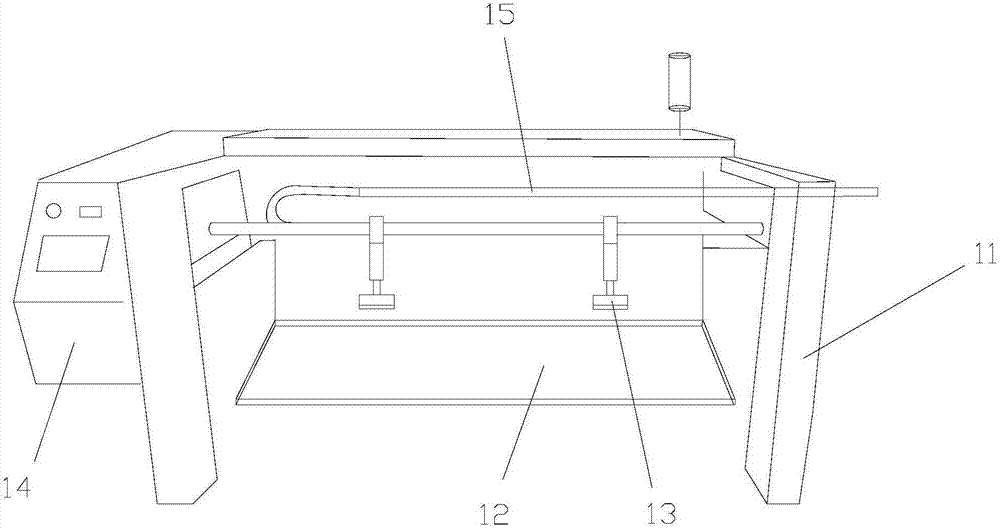

Fast and automatic production system and method for procedures of screen printing and baking of circuit board

ActiveCN107454755AImprove the level of intelligenceHigh degree of automationPrinted circuit dryingScreen printingAtmospheric pressure

The invention discloses a fast and automatic production system and method for procedures of screen printing and backing of a circuit board, and relates to the technical field of circuit board production. The fast and automatic production system comprises an electric pneumatic manipulator, a screen printing machine, an inspection conveyer belt, a tunnel furnace, a cooling device and a movable board collecting platform, and is characterized in that the screen printing machine is arranged at the rear side of the electric pneumatic manipulator, the inspection conveyor belt is arranged at the rear side of the screen printing machine, the tunnel furnace is arranged at the rear side of the inspection conveyor belt, the cooling device is arranged at the rear side of the tunnel furnace, and the movable board collecting platform is arranged at the rear side of the cooling device. The fast and automatic production system is high in production speed, high in efficiency and low in labor cost. The actions such as board taking, board sleeving, printing and conveying are all completed by the machinery, and even the baking and curing time is reduced from 1 hour in a vertical oven to 5 minutes in the tunnel furnace. Abnormities brought about by handling are reduced, and the quality is improved. The fast and automatic production system can avoid abnormities caused by scratching or wiping off the character ink and can avoid abnormities such as board falling in the transportation process, the quality is improved, and the yield is more guaranteed.

Owner:厦门利德宝电子科技股份有限公司

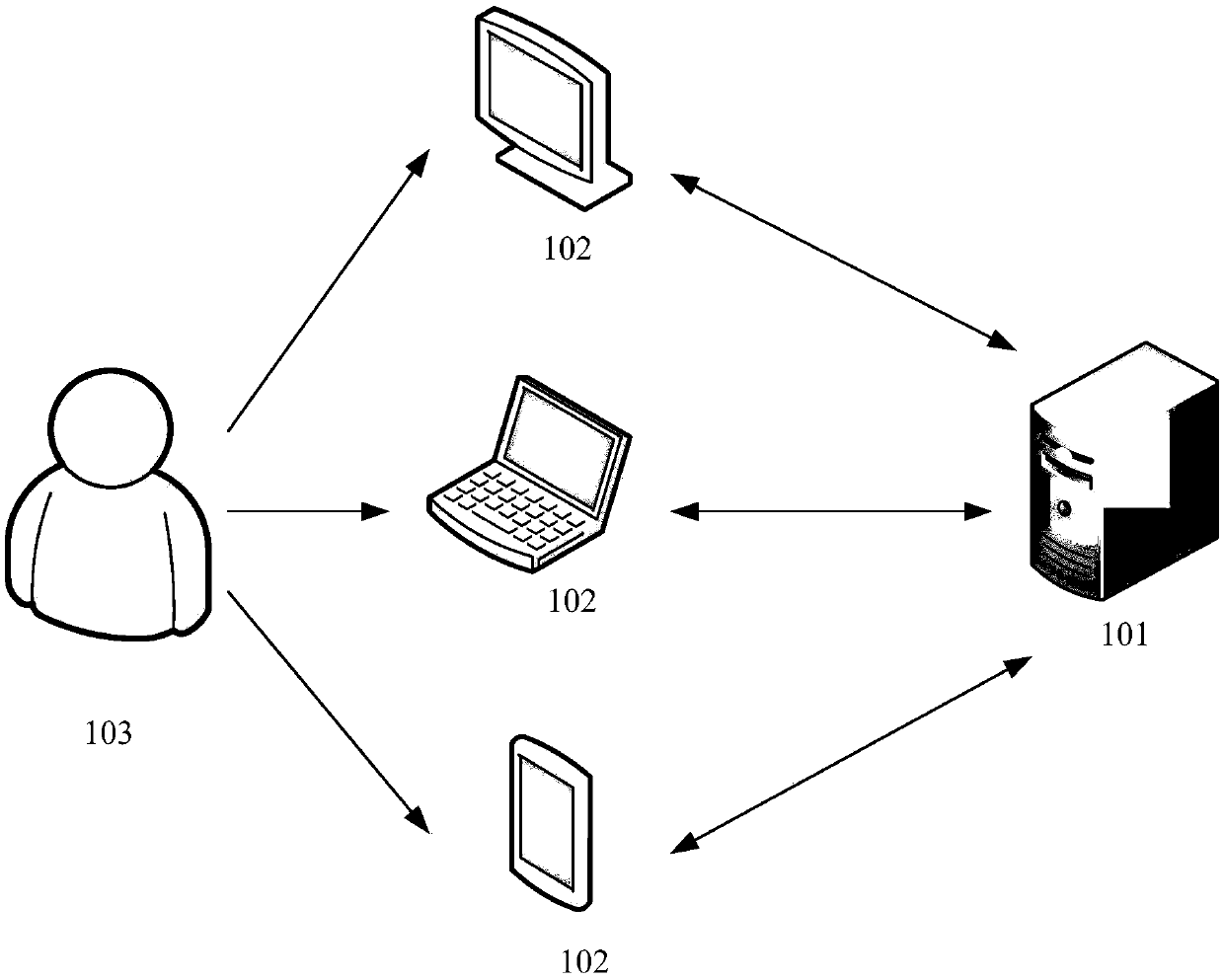

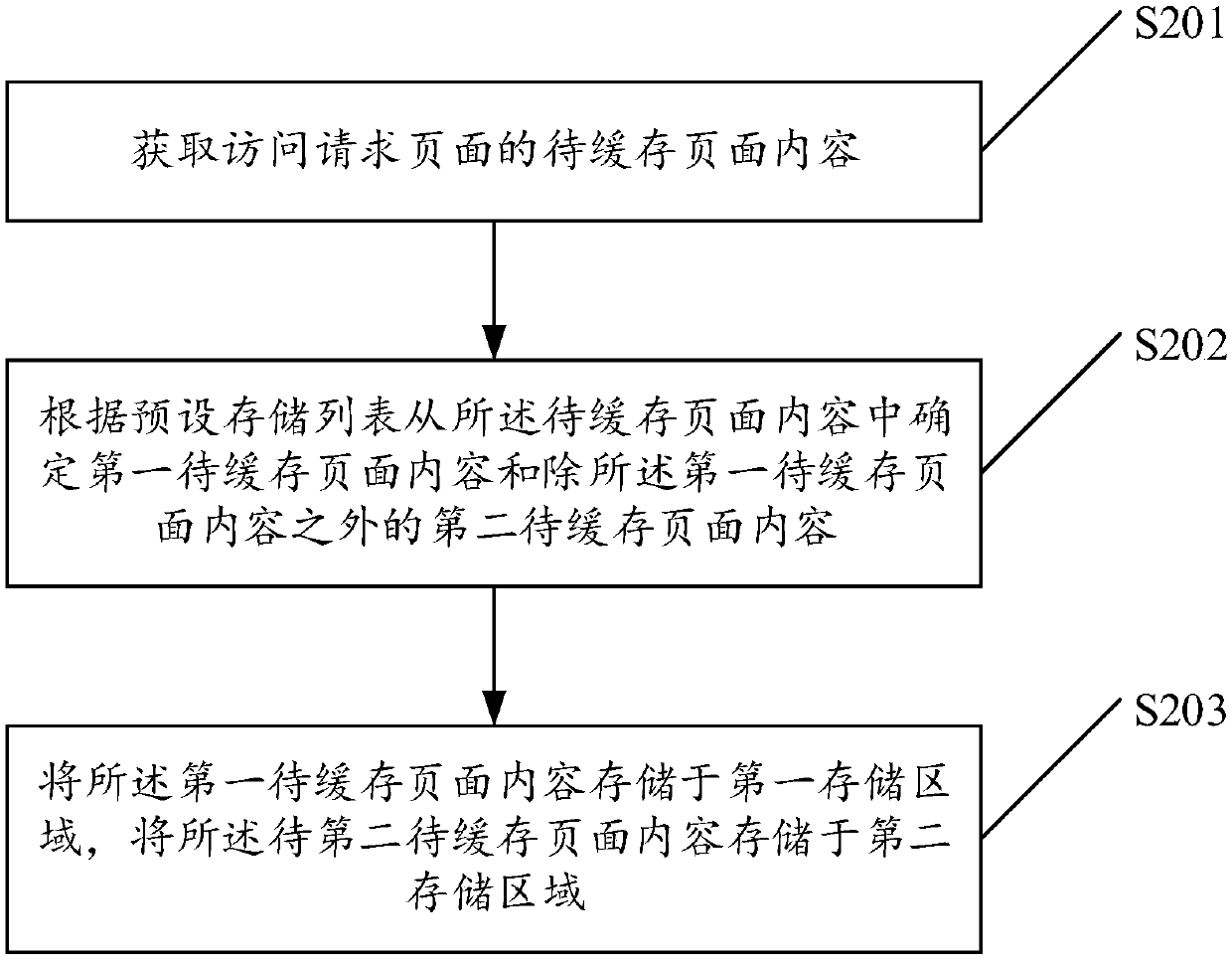

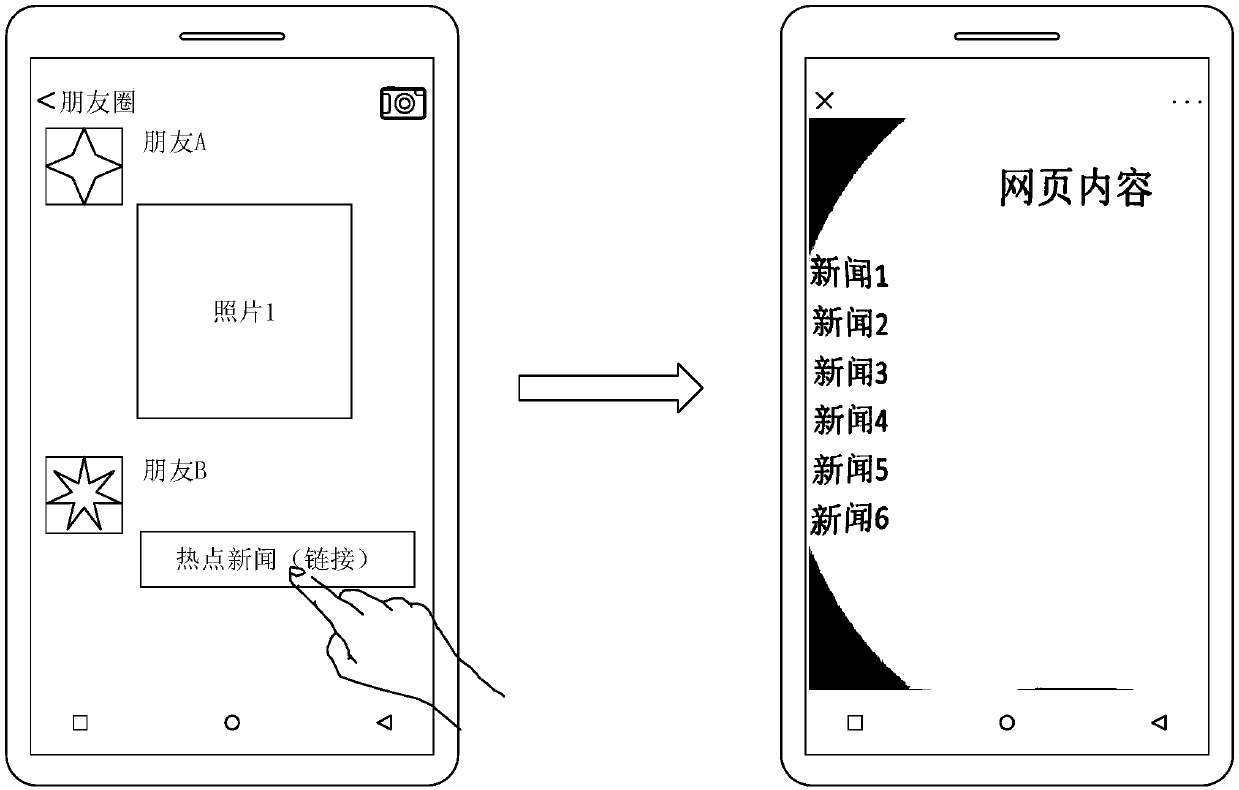

Page content management method and device

ActiveCN109522501AImprove performanceReduce exceptionWeb data browsing optimisationCache pageContent management

The embodiment of the invention provides a page content management method and device. The method comprises the following steps: obtaining to-be-cached page content of an access request page; Determining first to-be-cached page contents and second to-be-cached page contents except the first to-be-cached page contents from the to-be-cached page contents according to a preset storage list; And storing the first to-be-cached page content in a first storage area, and storing the to-be-cached page content in a second storage area. By adopting the embodiment of the invention, not only can cookie abuse be avoided, but also the state can be prevented from being oversaturated, so that the page performance can be improved, the loss of user bandwidth can be reduced, and the probability of page abnormity can be reduced.

Owner:TENCENT TECH (SHENZHEN) CO LTD

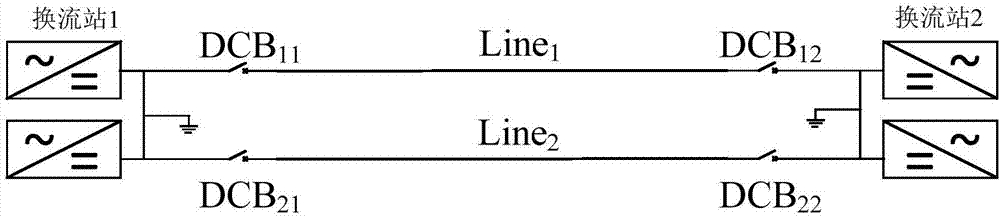

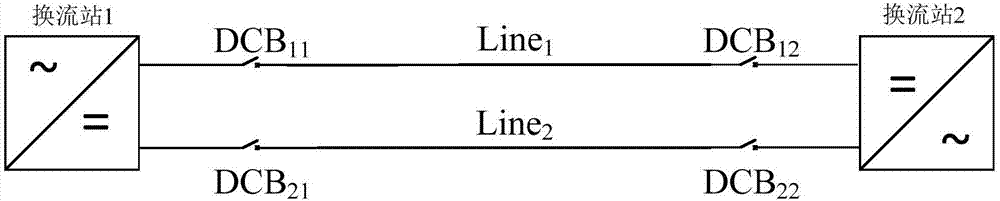

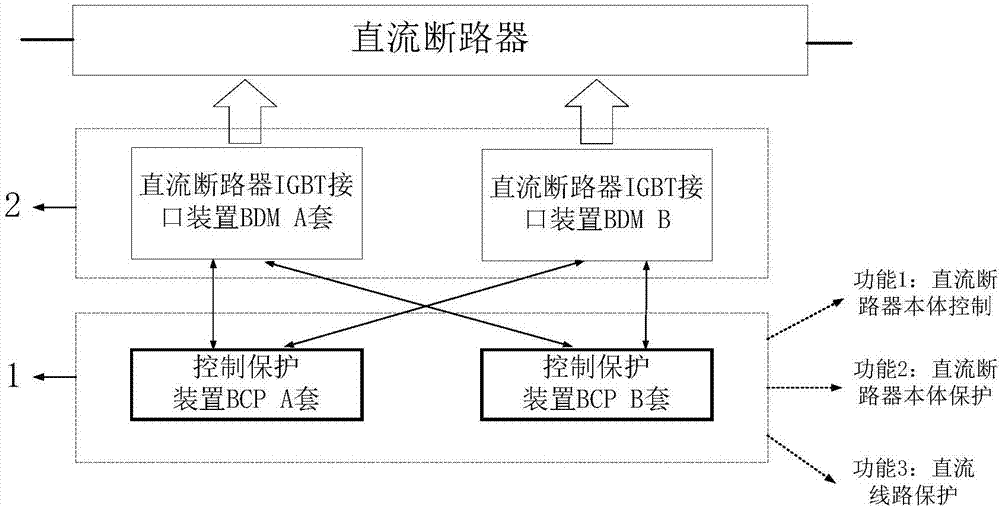

Control protection system of hybrid topology direct current circuit breaker

ActiveCN107294073ALower latencyImprove reliabilityEmergency protective circuit arrangementsDc circuit breakerPower grid

The invention provides a control protection system of a hybrid topology direct current circuit breaker, and is applied to a direct current power grid or a multi-terminal direct current power transmission system containing the hybrid direct current circuit breaker. The system has a direct current circuit breaker body control function, a circuit breaker body protection function, and a direct current line protection function, through the configuration of the system, the structure is compact, the quantity of secondary devices can be reduced, the direct current line fault clearing time can be reduced, and the requirement of operation reliability of the direct current system can be satisfied.

Owner:NR ELECTRIC CO LTD +1

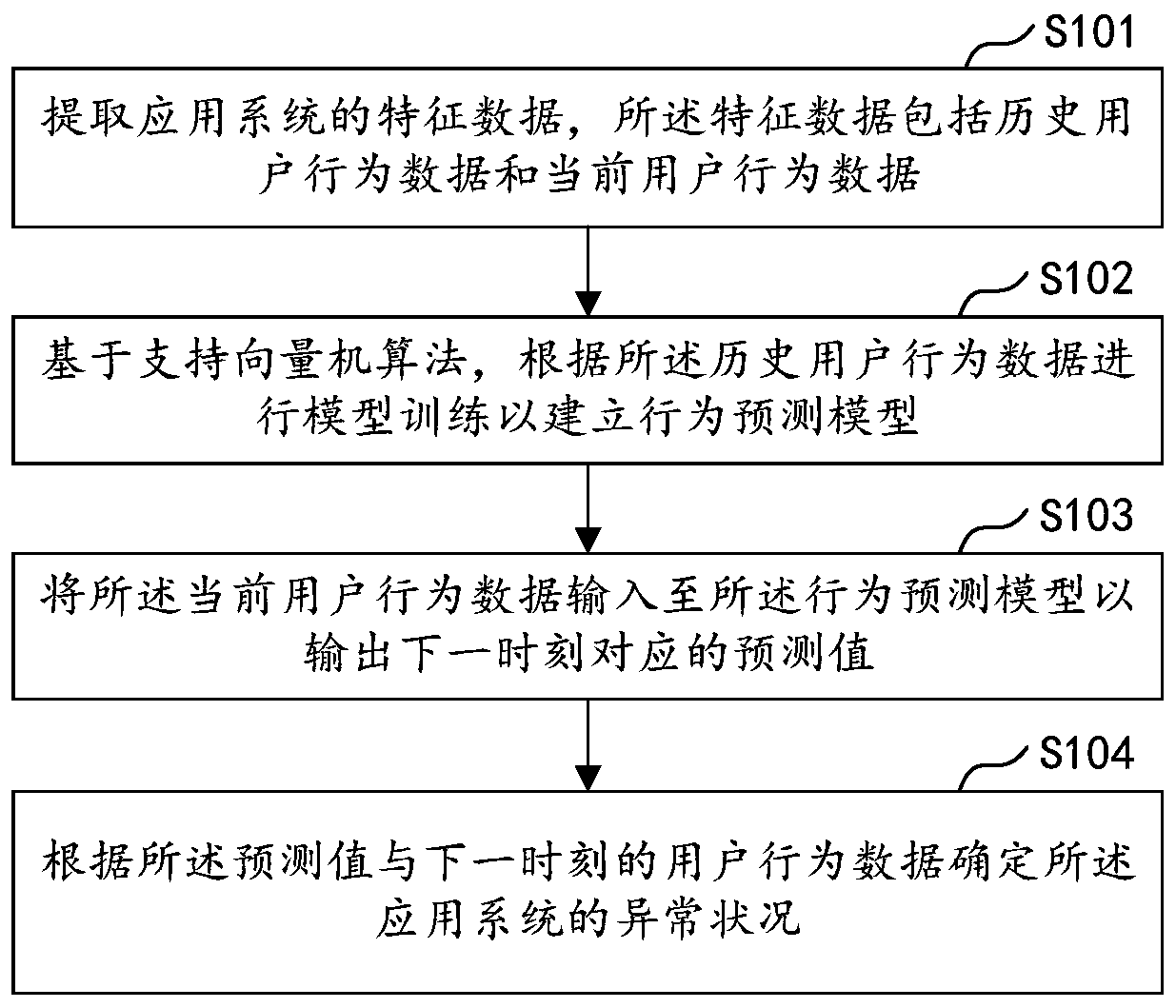

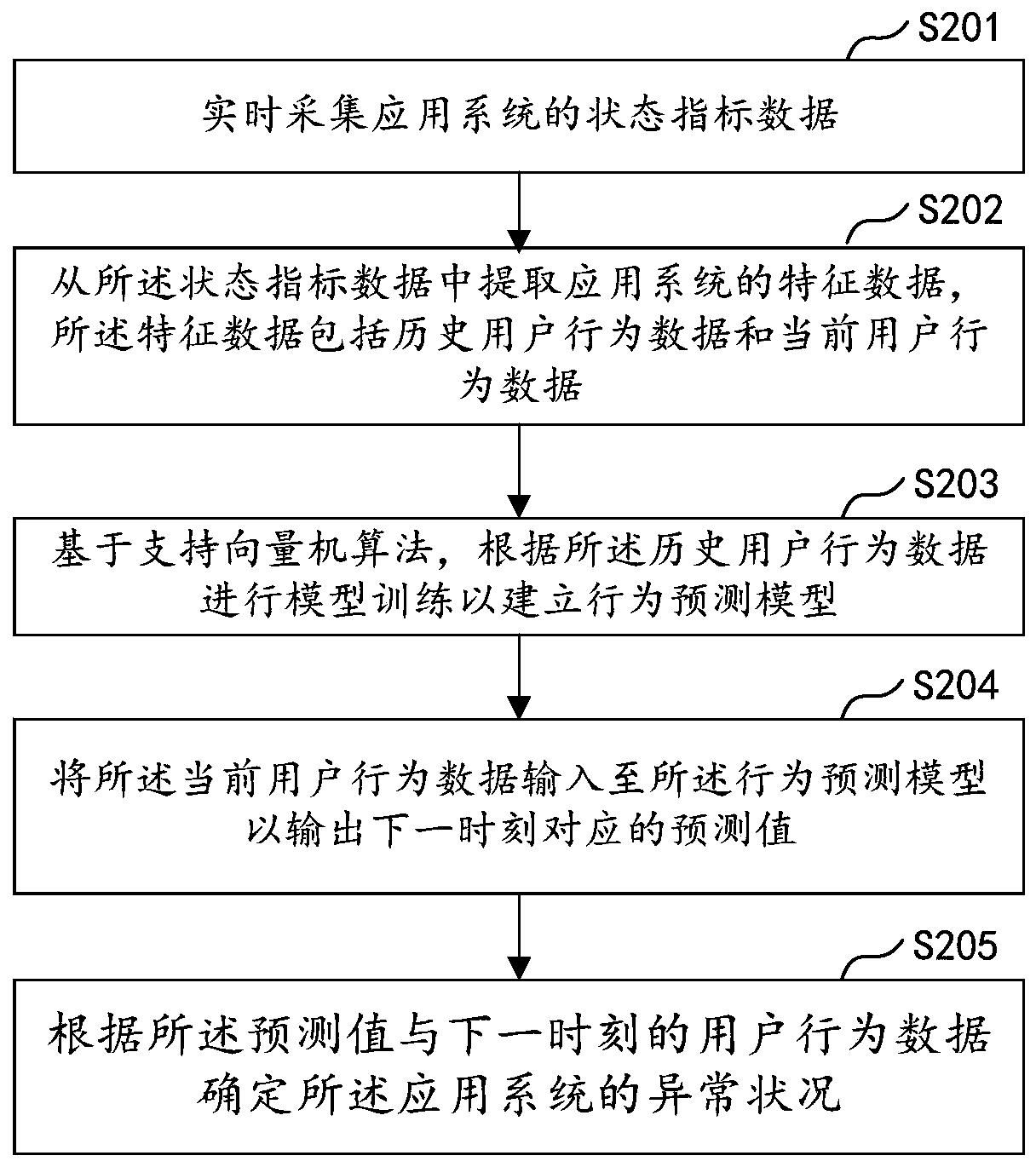

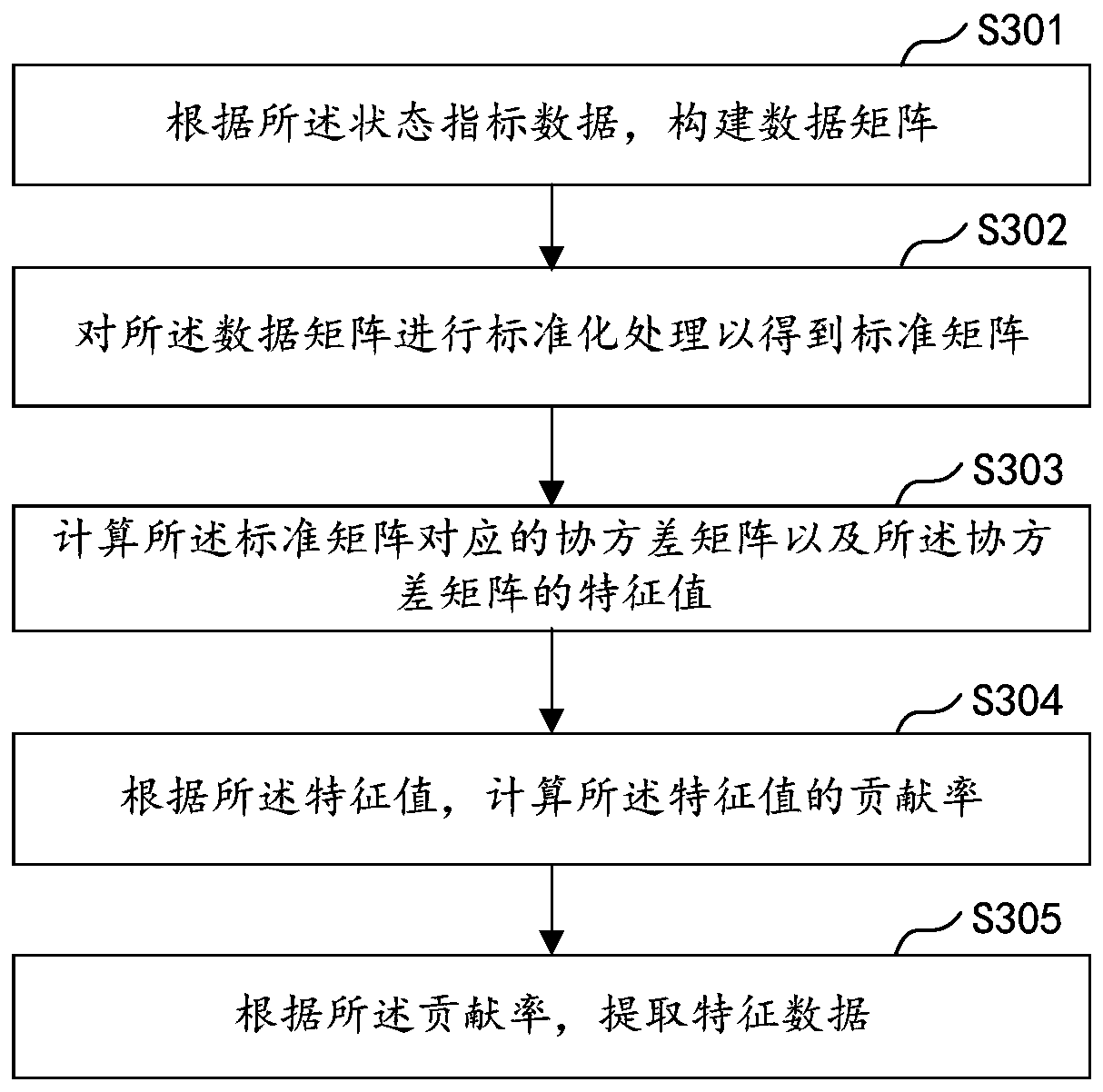

Monitoring method and device of application system, equipment and storage medium

ActiveCN109992473AReduce exceptionFinanceHardware monitoringSupport vector machine algorithmFeature data

The invention relates to the field of cloud monitoring, in particular to abnormal monitoring achieved by monitoring user behaviors, and discloses a monitoring method and device of an application system, equipment and a storage medium, the method comprises the steps of extracting feature data of the application system, wherein the feature data comprise historical user behavior data and current userbehavior data; based on a support vector machine algorithm, performing model training according to the historical user behavior data to establish a behavior prediction model; inputting the current user behavior data into the behavior prediction model to output a prediction value corresponding to the next moment; and determining the abnormal condition of the application system according to the predicted value and the user behavior data at the next moment. Therefore, the problem of the application system can be timely discovered, so that the application system can be timely improved by the subsequent technicians according to the abnormal condition, and the abnormal condition is reduced.

Owner:PING AN TECH (SHENZHEN) CO LTD

Automated detection and characterization of micro-objects in microfluidic devices

Methods are provided for the automated detection, characterization, and selection of micro-objects in a microfluidic device. In addition, methods are provided for grouping detected micro-objects into subgroups that share the same characteristics and, optionally, repositioning micro-objects in a selected sub-population within the microfluidic device. For example, micro-objects in a selected sub-population can be moved into sequestration pens. The methods also provide for visual displays of the micro-object characteristics, such as two- or three-dimensional graphs, and for user-based definition and / or selection of sub-populations of the detected micro-objects. In addition, non-transitory computer-readable medium in which a program is stored and systems for carrying out any of the disclosed methods are provided.

Owner:BERKELEY LIGHTS

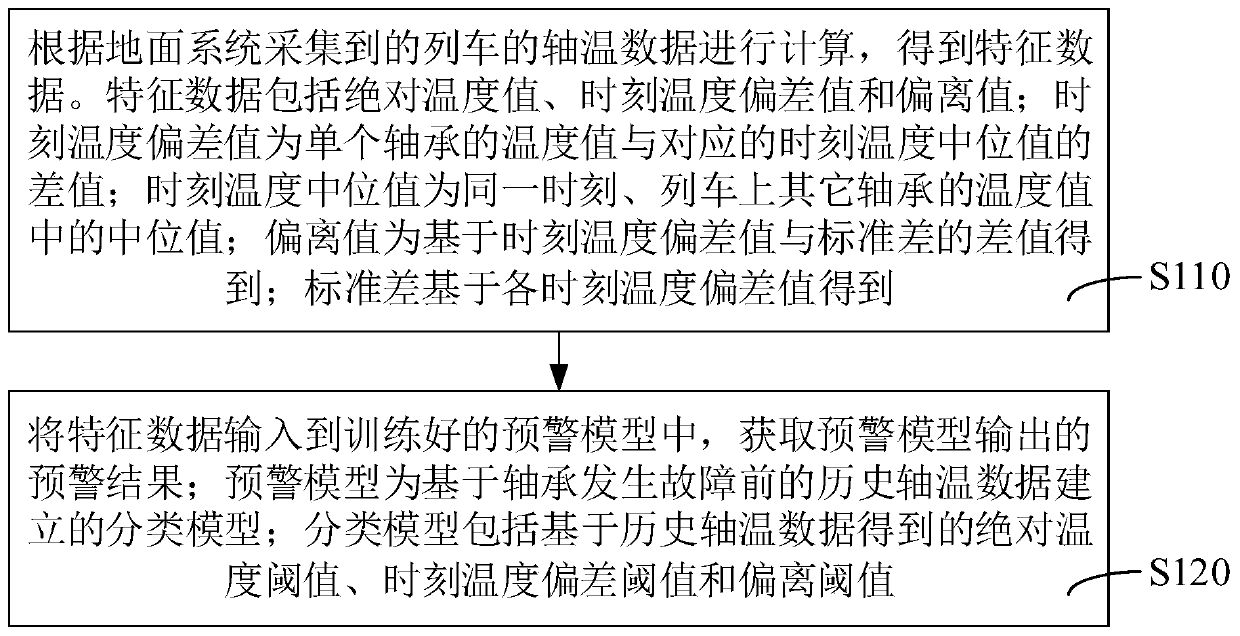

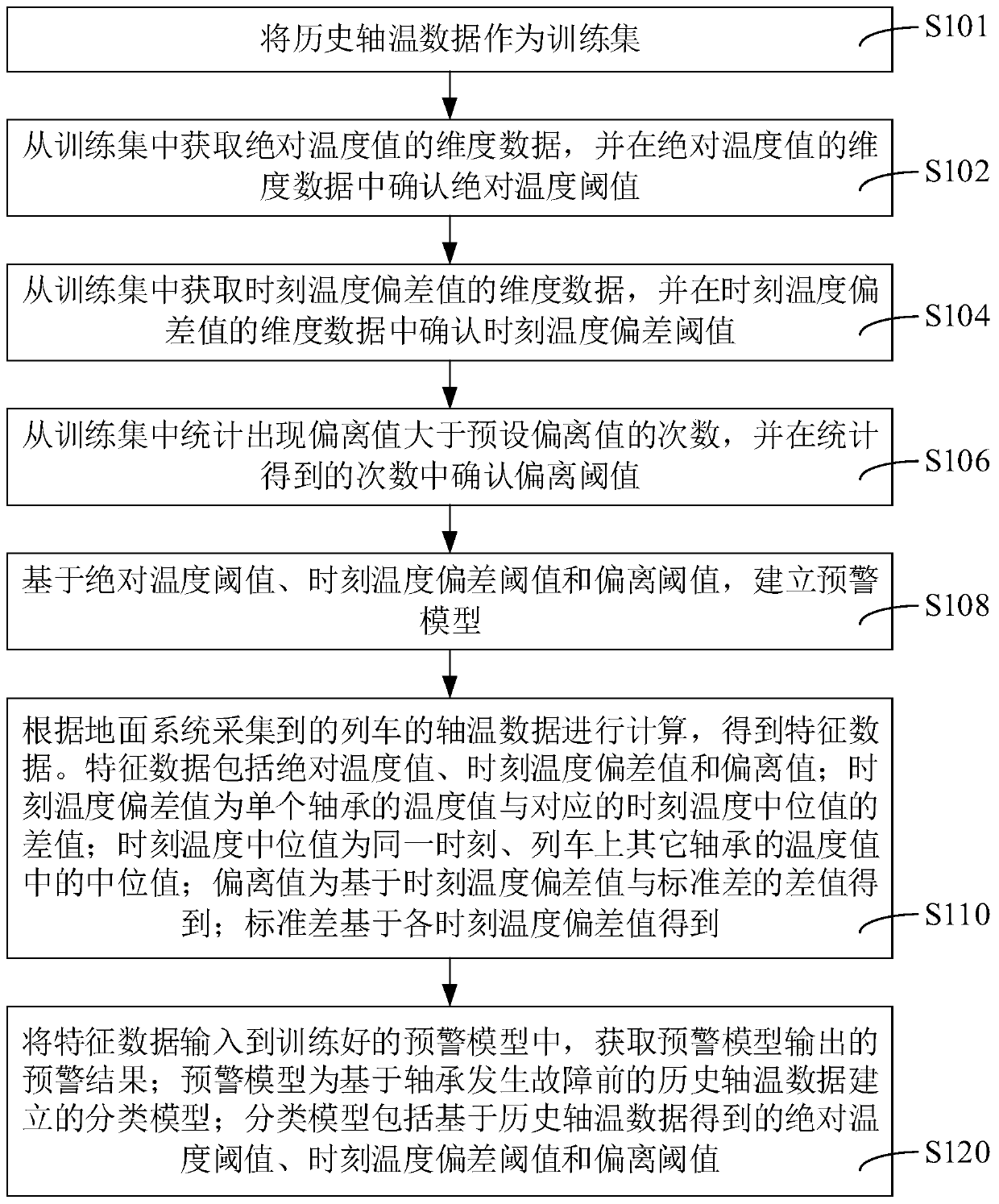

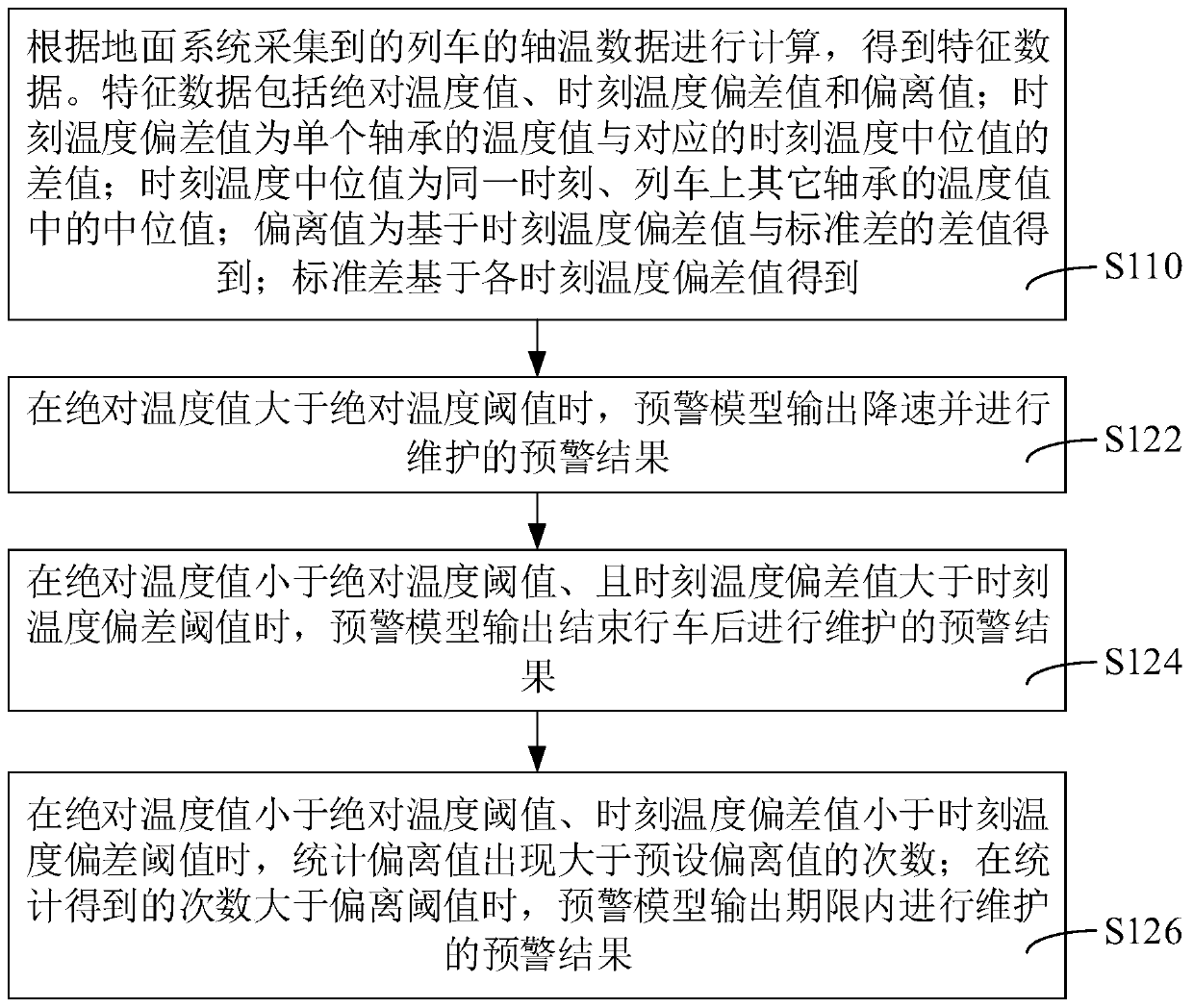

Train bearing fault early warning method, device and system and storage medium

ActiveCN110501160APrevent bearing failureGuarantee status is normalMachine bearings testingRailway vehicle testingData entryFault grading

The application relates to a train bearing fault early warning method, device and system and a storage medium. According to the train bearing fault early warning method, axle temperature data, collected by a ground system, of a train are calculated; calculated characteristic data are inputted into an early warning model to obtain an early warning result, wherein the early warning model is a grading model that is established by selecting data of a period of time before the bearing fault occurrence moment and based on historical shaft temperature data; and the feature data are compared with eachthreshold in the early warning model to obtain a corresponding early warning result. On the basis of the bearing fault grading early warning mode, the historical axle temperature data of a train canbe effectively utilized; and early warning is carried out at the early stage of bearing abnormity to discover the abnormity and process the abnormity early, so that the occurrence of the bearing faultis prevented. Meanwhile, the normal state of the bearing is ensured; the abnormal occurrence in the driving process can be reduced; the normal driving is ensured; and the line congestion caused by accidents caused by vehicle bearings is reduced.

Owner:CHINA SHENHUA ENERGY CO LTD

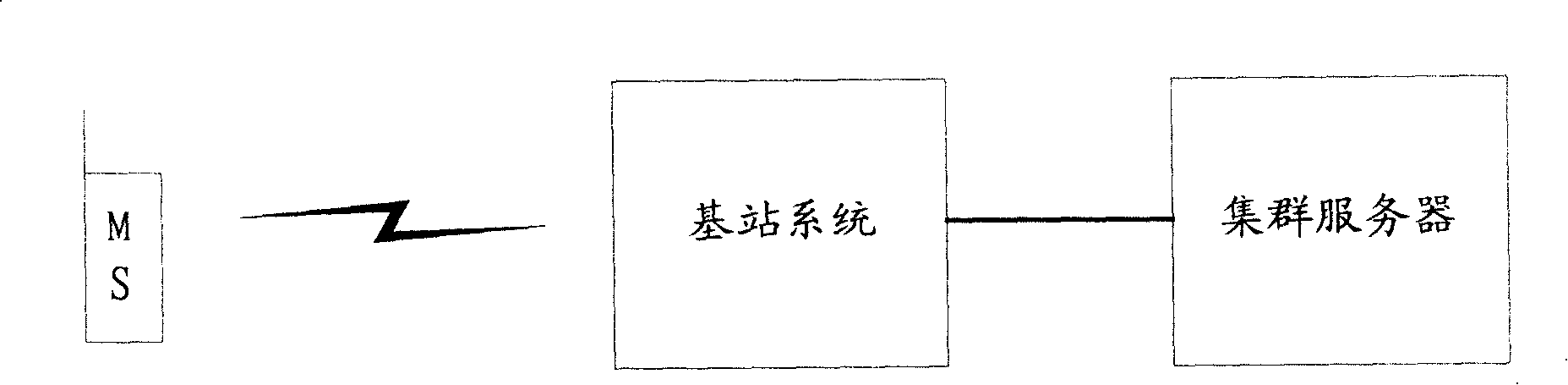

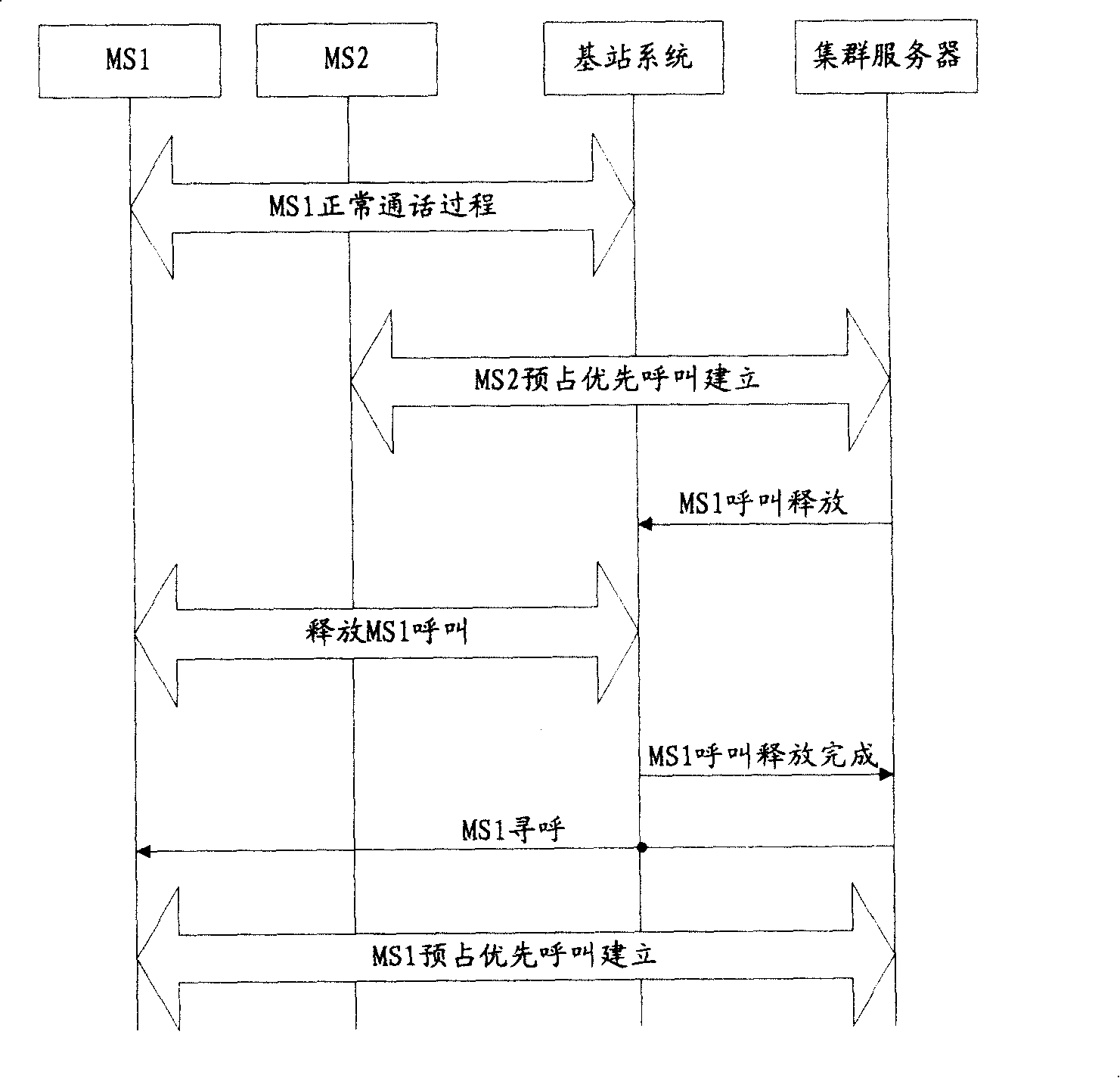

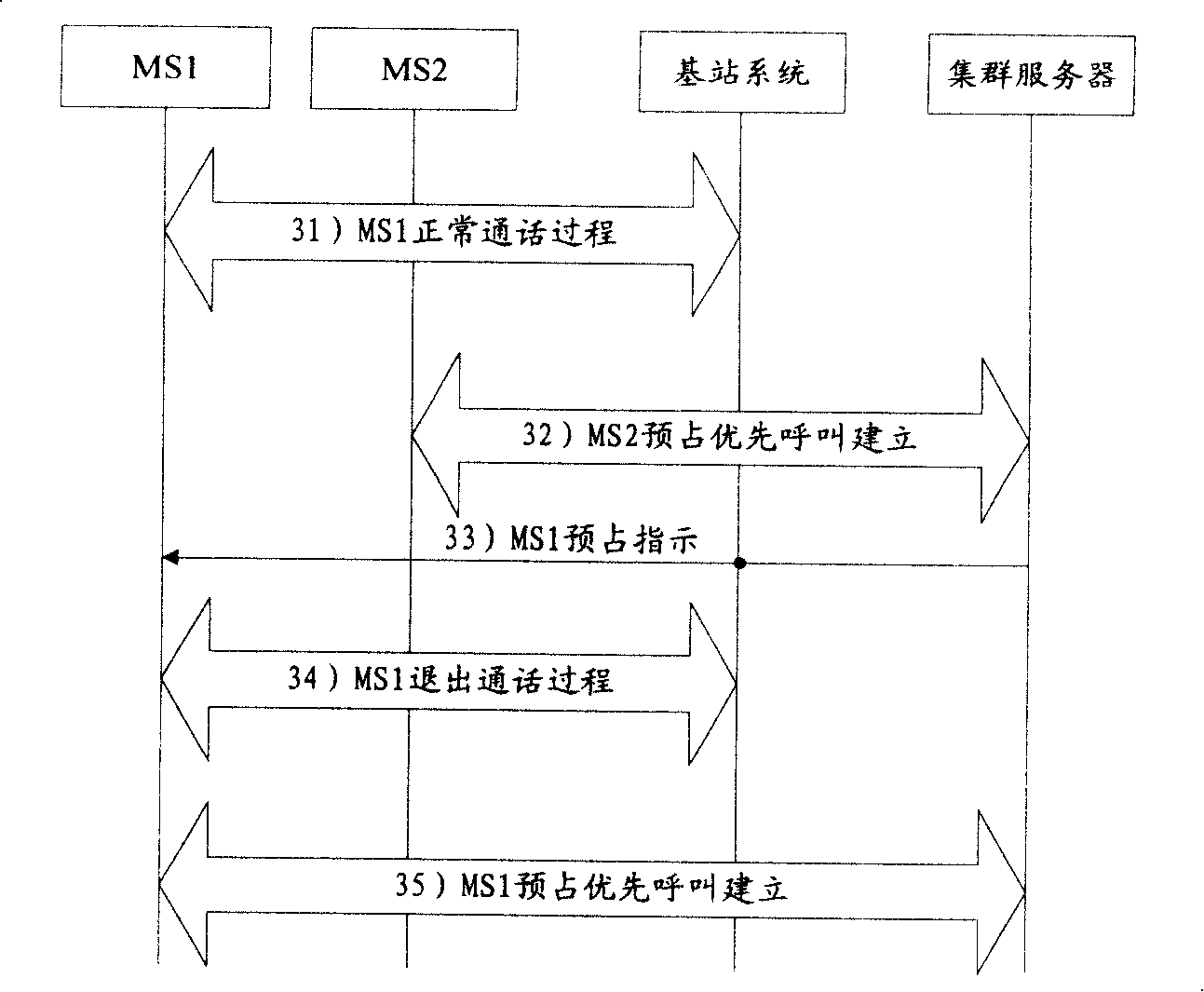

Method, cluster server, and terminal for implementing mobile cluster pre-occupied priority call

ActiveCN101212724AImprove reliabilityEasy to handleRadio/inductive link selection arrangementsEmergency/hazardous communication servicePriority callStandardization

The invention relates to a method for realizing camp-on preference call of a mobile cluster, a cluster server and a terminal thereof. In an embodiment of the invention, conversation being in progress is confirmed in a camp-on preference group while the terminal sponsoring the camp-on preference call belongs to the camp-on preference group after the cluster server receives the camp-on preference call, and the call priority of the conversation is lower than the call priority of the camp-on preference terminal on the camp-on preference call priority and sends camp-on preference indicating information to the terminal, and the camp-on preference call between the terminal receiving the camp-on preference indication information and the terminal sponsoring the camp-on preference call is established by the cluster server, thus overcoming the disadvantages of the prior art, improving the reliability and timeliness of the camp-on preference call so as to simplify and standardize the treatment process of the camp-on preference call, reduce calling capacity and abnormality occurrence, simplify the treatment of a base-station system and realize interface standardization.

Owner:HUAWEI TECH CO LTD

Method for cutting silicon wafer through low-particle electroplating gold wire

ActiveCN104441282AImprove cutting effectImprove pass rateFine working devicesVibration amplitudeEconomic benefits

The invention discloses a method for cutting a silicon wafer through a low-particle electroplating gold wire. The method includes the first step of bar adhesion, the second step of wire cutting, the third step of glue disengaging, the fourth step of wafer inserting, the fifth step of cleaning and the sixth step of verifying. According to the method, the silicon wafer is cut through the low-particle electroplating gold wire with a particle height of 6 microns to 12 microns; meanwhile, an existing production process is improved, the linear speed in the wire cutting step is increased, the steel wire feed and return distance is increased, the cooling temperature of cooling liquid is lowered; by means of the method, the abnormity, caused by the particle vibration amplitude generated by electroplating gold wire swinging, of the surface of the silicon wafer can be reduced, the cutting capacity of the low-particle electroplating gold wire can be reduced, it is ensured that the yield of the silicon wafer cut by the low-particle electroplating gold wire and the yield of the silicon wafer cut by an intermediate-particle electroplating gold wire are located at the same level, and the aims of increasing the silicon wafer yield, ensuring the high production efficiency and increasing the economic benefits are achieved.

Owner:INNER MONGOLIA ZHONGHUAN SOLAR MATERIAL

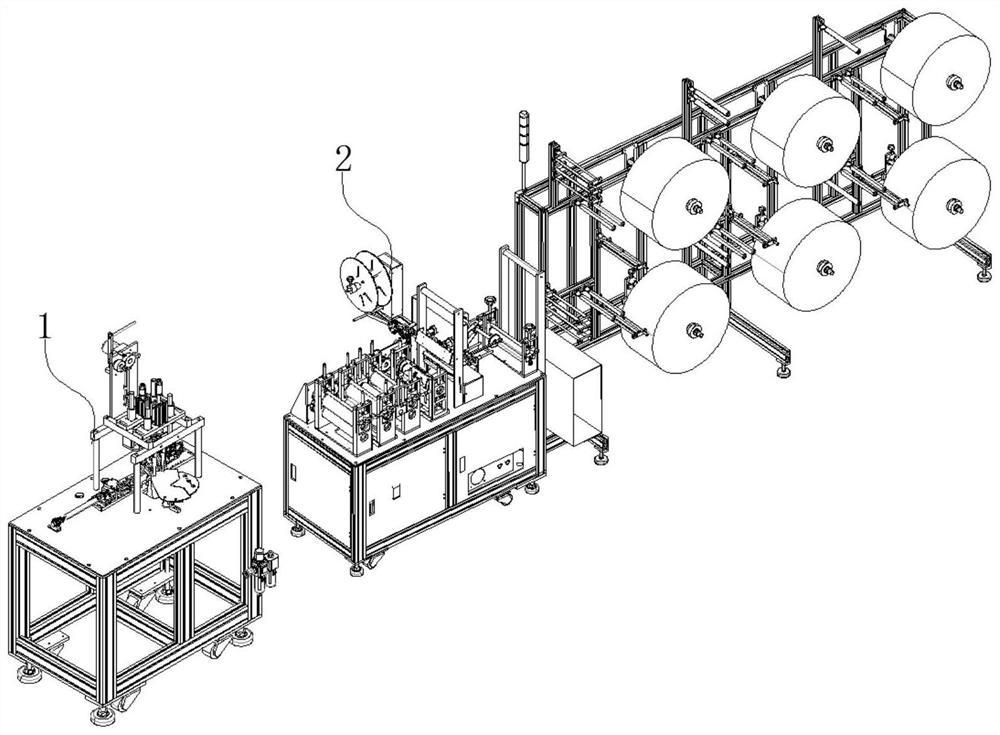

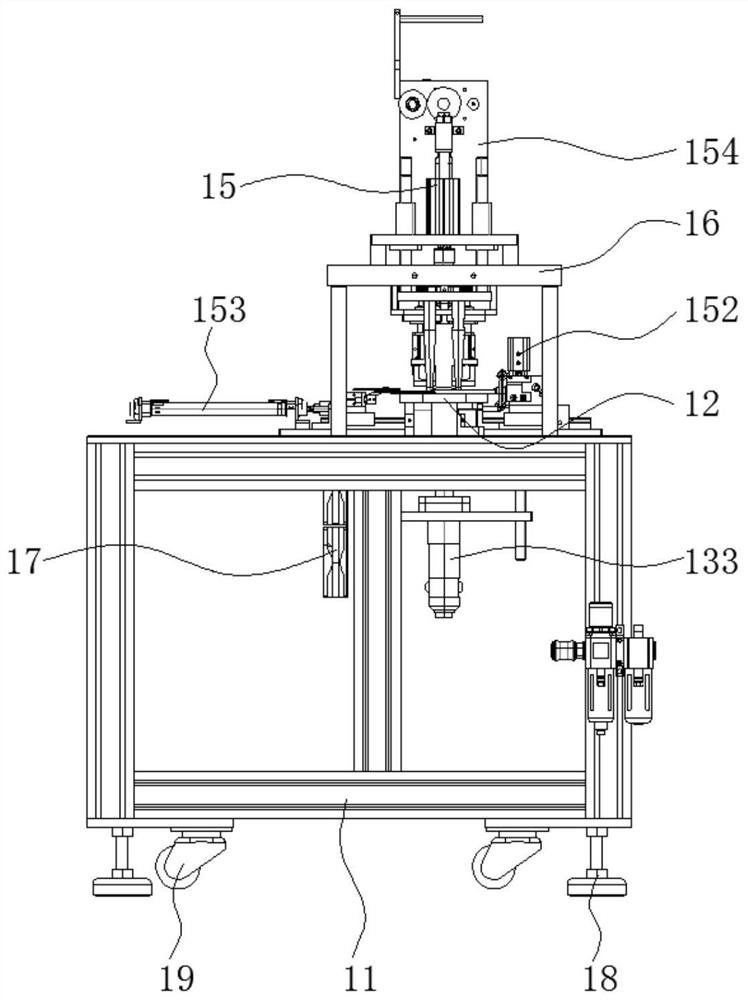

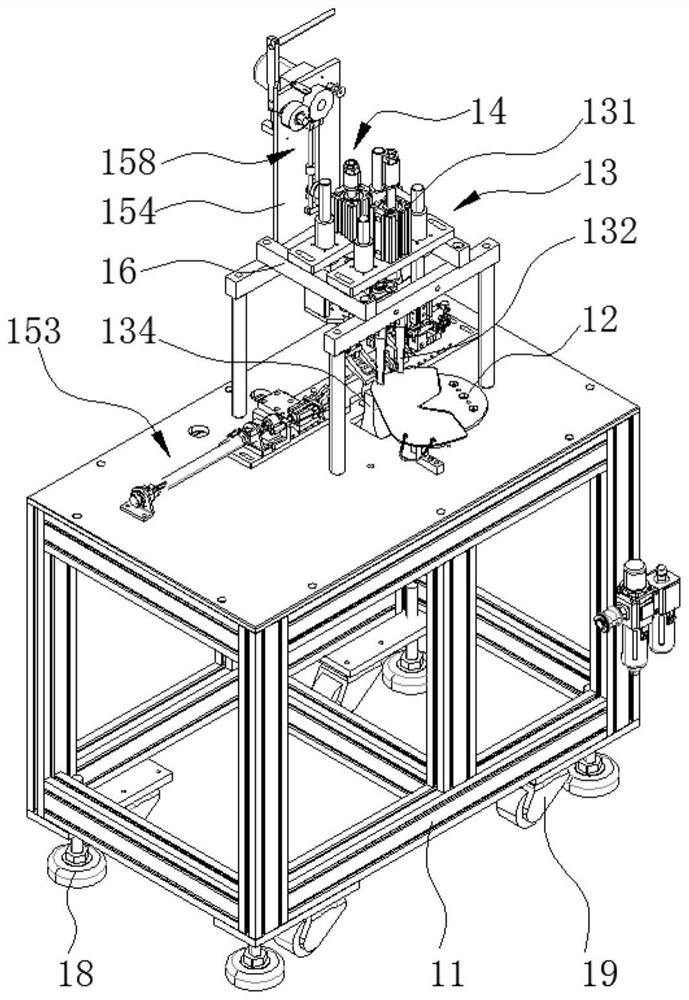

Semi-automatic N95 mask production line

InactiveCN111761825AReduce the difficulty of debuggingReduce exceptionMetal working apparatusProtective garmentProduction lineSemi automatic

The invention relates to the technical field of mask production equipment, and discloses a semi-automatic N95 mask production line. The production line comprises a filming machine and a mask earband welding machine that are arranged separately, wherein the filming machine comprises a discharging device and a filming machine main body; the mask earband welding machine comprises a first frame, a welding station, a welding assembly, an earband clamping assembly, an earband conveying and cutting mechanism arranged on the first frame, and a first support frame; the welding station can be rotatablyarranged on one side of the earband conveying and cutting mechanism, the welding assembly is arranged on the first support frame corresponding to the welding station, and the earband clamping assemblycan be lifted corresponding to the earband conveying and cutting mechanism and can be rotatably arranged on the first support frame. The semi-automatic N95 mask production line provided by the invention can reduce the difficulty of debugging, reduce abnormalities during production, facilitate the handling of abnormalities, accurately control the length of the earband, ensure product quality, andimprove production efficiency.

Owner:GREATOO INTELLIGENT EQUIP INC +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com